Page 1

EPSON

EPSON TERMINAL PRINTER

FX-870/1170

SERVICE MANUAL

4001461

REV.-A

Page 2

.-.

. .

&

{’”’

-.. ,

NOTICE

“ All rights reserved. Reproduction of any part of this manual in any from

whatsoever without SEIKO EPSON’s express written permission is forbidden.

“ The contents of this manual are subject to change without notice.

“ All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

“ The above notwithstanding SEIKO EPSON can assume no responsibility for any

errors in this manual or the consequences thereof.

@

Copyright 1992 by SEIKO EPSON CORPORATION

Nagano, Japan

-i-

Page 3

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1 ) personal injury, and 2) damage

to equipment:

DANGER

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER headings.

DANGER

1

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND THE

HOST COMPUTER BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

2,

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

3

<

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1.

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY-AC RATING DIFFERENT FROM THE AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

3.

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

/.LP

IN ORDER TO PROTECT SENSITIVE

4.

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENDED BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE

ICS OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND

VOID ANY APPLICABLE EPSON WARRANTY.

CHIPS AND CIRCUITRY, USE STATIC

– ii -

Page 4

PREFACE

This manual describes functions, theory of electrical and mechanical

operations, maintenance, and repair of the

The instructions and procedures included herein are intended for the

experienced repair technician,

precautions on the preceding page. The chapters are organized as follows:

and attention should be given to the

FX-870/l

170.

REV.-A

Chapter 1 -

Chapter 2 -

Chapter 3 -

Chapter 4 -

Chapter 5 -

Chapter 6 -

● The contents of this manual are subject to change without notice.

Provides a general product overview, lists specifications,

and illustrates the main components of the printer.

Describes the theory of printer operation.

Includes a step-by-step guide for product disassembly and

assembly.

Includes a step-by-step guide for adjustment.

Provides Epson-approved techniques for troubleshooting.

Describes preventive maintenance techniques.

-

iv -

Page 5

REVISION SHEET

.7,,

.

,. :;::

\

f

. .

REVISON

A

DATE ISSUED

June 15, 1992

CHANGE DOCUMENT

1st issue

-v–

(“

*

‘?:

Page 6

TABLE OF CONTENTS

REV.-A

CHAPTER 1.

CHAPTER 2.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENTS

CHAPTER 5.

CHAPTER

APPENDIX

6,

GENERAL DESCRIPTION

OPERATING PRINCIPLES

TROUBLESHOOTING

MAINTENANCE

–

vi -

Page 7

CHAPTER 1

GENERAL DESCRIPTION

REV.-A

1.1

Scope

1.2 Specifications

1.3 Interface

1.4 Control Panel

1.5 Functions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Features

1.1.2 Options

1.2.1 Hardware Specifications

1.2.1.1 Printing Method

1.2.1.2 Paper Handling

1.2.1.3 Paper Specifications

1.2.1.4 Printable Area

1.2.1.5 Ribbon

1.2.1.6 Electrical Specifications

1.2.1.7 Environmental Conditions

1.2.1.8 Reliability

1.2.1.9 Safety Approvals

1.2.2 Firmware Specifications

1.2.2.1 Print Control

1.2.2.2 Input Data Buffer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Parallel Interface

1.3.2 Optional Interface

1.4.1 Components

1.4.2 Buttons

1.4.3 Indicators

1.5.1 Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Power On Default Settings

1.5.3 Buffer-full Printing

1.5.4 Hexadecimal Dump

1.5.5 Self Test

1.5.6 Paper-out Detection

1.5.7 Auto Tear-off

1.5.8 Thermal Protection

1.5.9 High Duty Printing

1.5.10 Sheet Loading and Sheet Ejection

1.5.11 Adjust Lever Operation

1.5.12 Printer Initialization

1.5.13 Buzzer ................. o.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

1-1

1-1

.

1-3

1-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

., . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cattridge

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4

1-4

1-4

1-6

1-9

1-11

1-12

1-12

1-13

1-13

1-13

1-13

1-14

1-15

1-15

1-17

1-17

1-17

1-18

1-19

1-20

. 1-20

1-23

1-23

1-23

1-24

1-24

1-24

1-24

1-24

1-25

1-25

1-26

. 1-27

l-i

Page 8

REV.-A

1.6 Main Components

1.6.1 BOARDASSEMBLY,C094MAlN(Main ControlCircuitBoard) ............1-29

1.6.2

BOARDASSEMBLY,C094PNL(Control Pand~HtiWd) .....-.l-3O

1.6.3 BOARD ASSEMBLY,

1.6.4 Printer Mechanism

1.6.5 Housing Assembly

~~ti...m-.--.--...--.-.m.m..-.mm.

C076PSBFSE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........................................1-28

(Power

SuPPIY

circuit Board) ......1 -30

1-31

1-32

LIST OF FIGURES

Figure 1-1. External View of

Figure 1-2. Pin Configuration

Figure 1-3. Printable Area for Cut Sheets

Figure 1-4. Printable Area for Continuous Paper

Figure 1-5. Printable Area for Roll Paper

Figure 1-6. Data Transmission Timing

figure 1-7. Control Panel

Figure 1-8. Hexadecimal Dump Printout

Figure 1-9. Self Test Printout

Figure 1-10. Lever Positions

Figure 1-11. Main Components

Figure 1-12. BOARD ASSEMBLY,

Figure 1-13. BOARD ASSEMBLY, C094 PNL (Control Panel

Figure 1-14. BOARD

Figure 1-15. Printer Mechanism

Figure 1-16. Housing Assembly

ASSEMBLY, C076

FX-870/1170

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C094MAIN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Main Control

PSB/PSE

(Power Supply Circuit Board) .....1 -30

circuit

Board) ...........1 -29

Cimuit

Board) .............1 -30

1-2

1-4

1-9

1-1o

1-11

1-15

1-17

1-23

1-24

1-26

1-28

1-31

1-32

Iii

. . .

Page 9

LIST OF TABLES

REV.-A

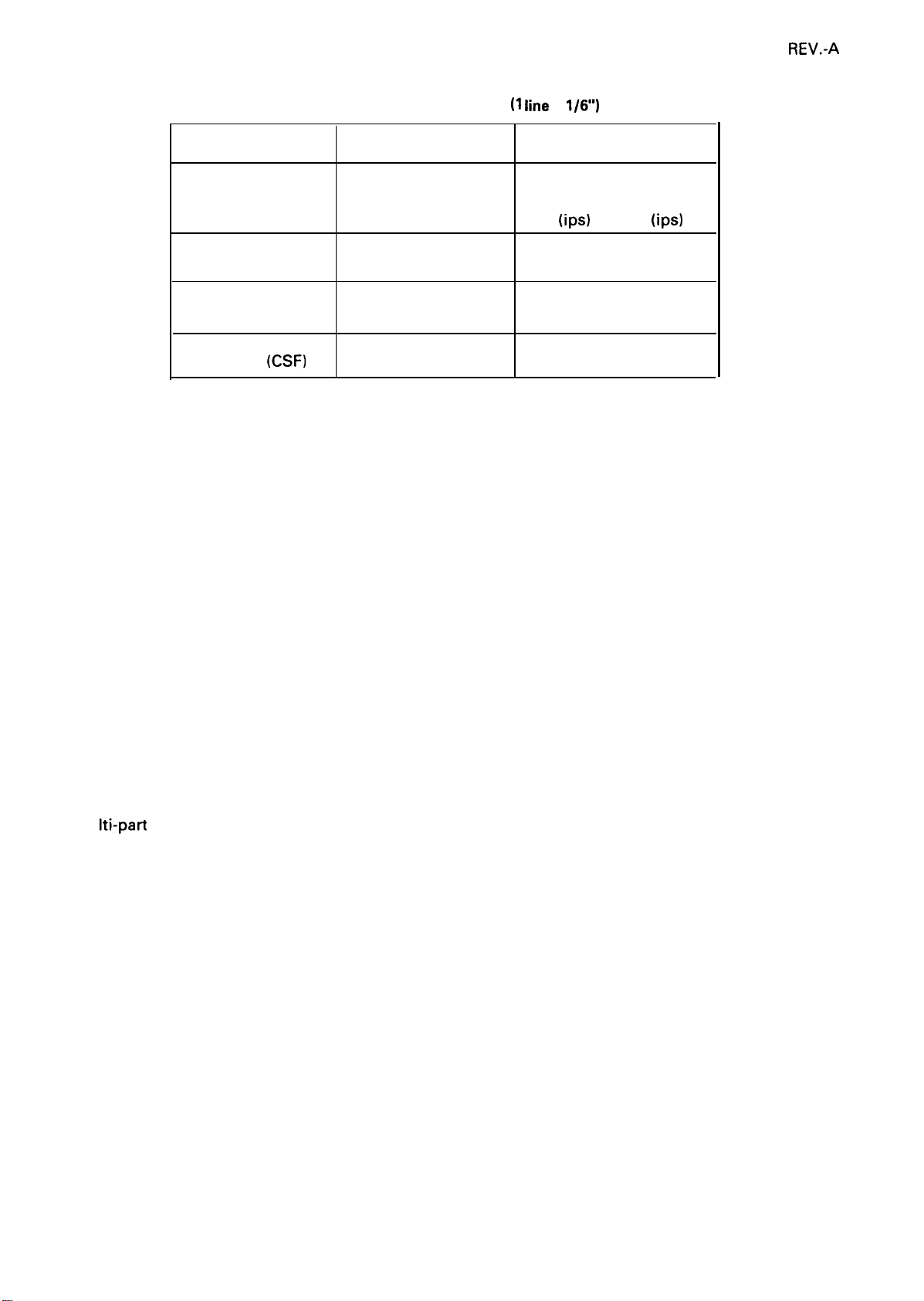

Table 1-1. Line Feed Speed (1 line= 1/6”)

Table 1-2. Specifications for Cut

Table 1-3. Specifications for

Table 1-4. Specifications for Continuous Paper

Table 1-5. Specifications for Envelopes

Table 1-6. Specifications for Labels

Table 1-7. Specifications for Roll Paper

Table 1-8. Electrical Specifications for 120V Model

Table 1-9. Electrical Specifications for

Table 1-10. Environmental Conditions

Table 1-11. Character Size and Pitch

Table 1-12. Printable Columns

Table 1-13. Print Speed

Table 1-14. Connector Pin Assignments and Signal Functions . . . . . . . . . . . . . . . . . . . . . 1-15

Table 1-15. Optional Interface

Table 1-16. Group 1 Features

Table 1-17. Group 2 Features

Table 1-18. Group 2 Features (IBM Mode)

Table 1-19. Group 3 Features (Power-on Settings)

Table 1-20. Lever Positions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sheets (plain paPer)

Cut She*s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(ESC/P

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(carbonless Dwli-tim

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

220/240V Model

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

paPer) ...”.s 1-7

1-5

1-6

1-7

1-7

1-8

1-8

1-12

1-12

1-12

1-14

1-14

1-14

1-17

1-21

1-22

1-22

1-23

1-25

l-iii

Page 10

1.1

Scope

REV.-A

These specifications apply to the

EPSON

FX-87WI 170 dot matrix Printer.

1.1.1 Features

● Upward compatibility with the FX-850(+)/1050(+), FX-800/1000, FX-86e/286e

● 380

cps

(high-speed draft for both 80 and 136-column models)

● 285

cps

(draft pica), 342

● Advanced paper handling

CPS

(draft elite)

Continuous paper

-3 paths for insertion (front/bottom/rear)

- Dual paper park and auto load (front/rear)

- The standard tractor unit can be set to 3 positions (2 push and 1 pull)

- Continuous paper can be used without removing the cut-sheet feeder

(CSF)

Cut sheets

-2 paths for insertion (top/optional front)

- Auto loading

● 24K byte input buffer

● 16 character tables are supported for European model.

(Italic, pC437,

● 6 character tables are supported for Non-European model.

(Italic, pC437,

● Default setting mode replaces DIP switches.

● Type B optional l/F boards can be installed.

850,860,863,865, 437 Greek, 851,869,852,853,857, 855,866, GOST, 861)

850,860,863, 865)

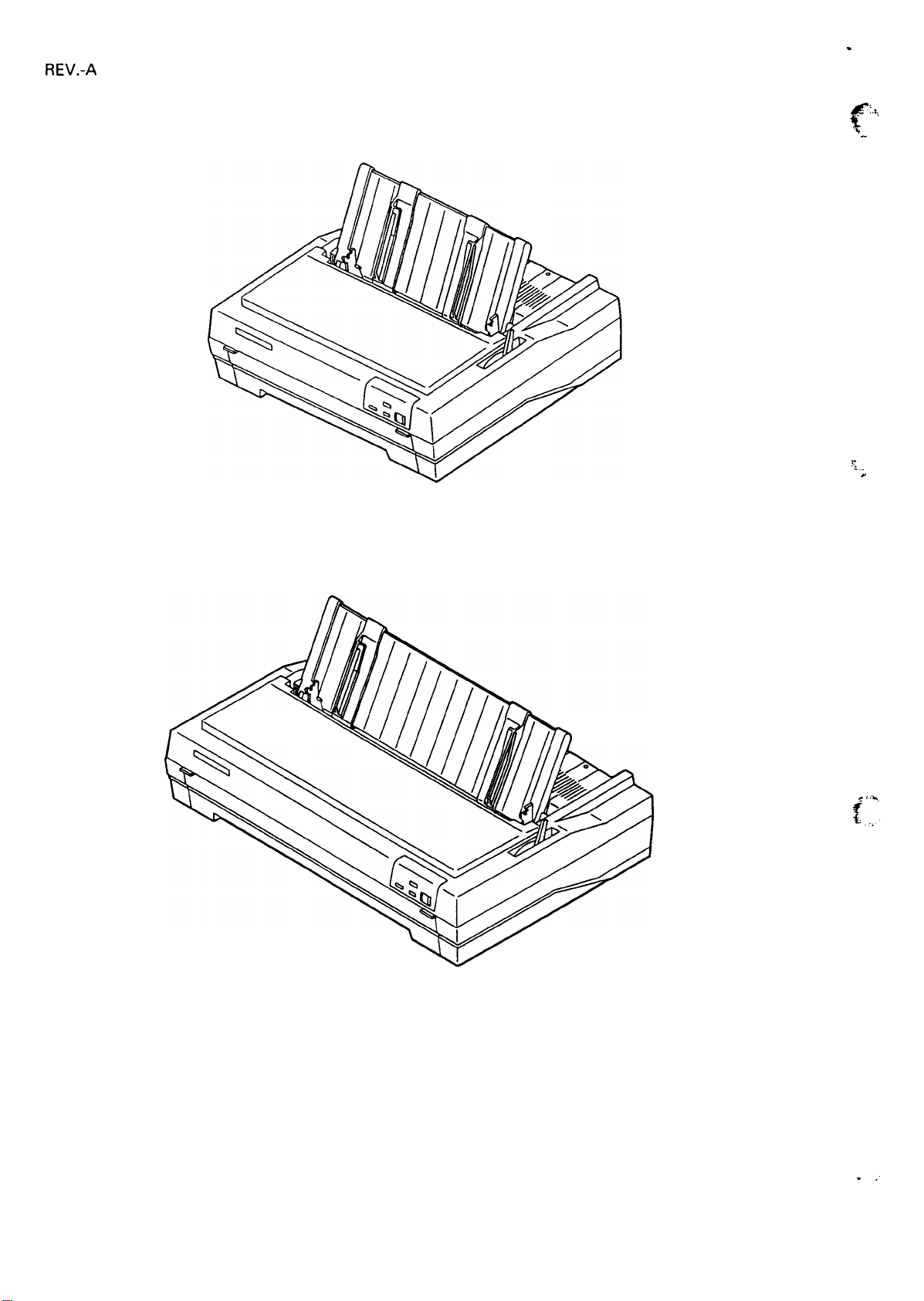

Figure 1-1 shows an exterior view of the

FX-870/l 170.

1-1

Page 11

REV.-A

.

4%

~

r~..

.-

. . .

“

80-column model

136-column model

Figure 1-1. External View of the FX-870/1170

1-2

. ,.

Page 12

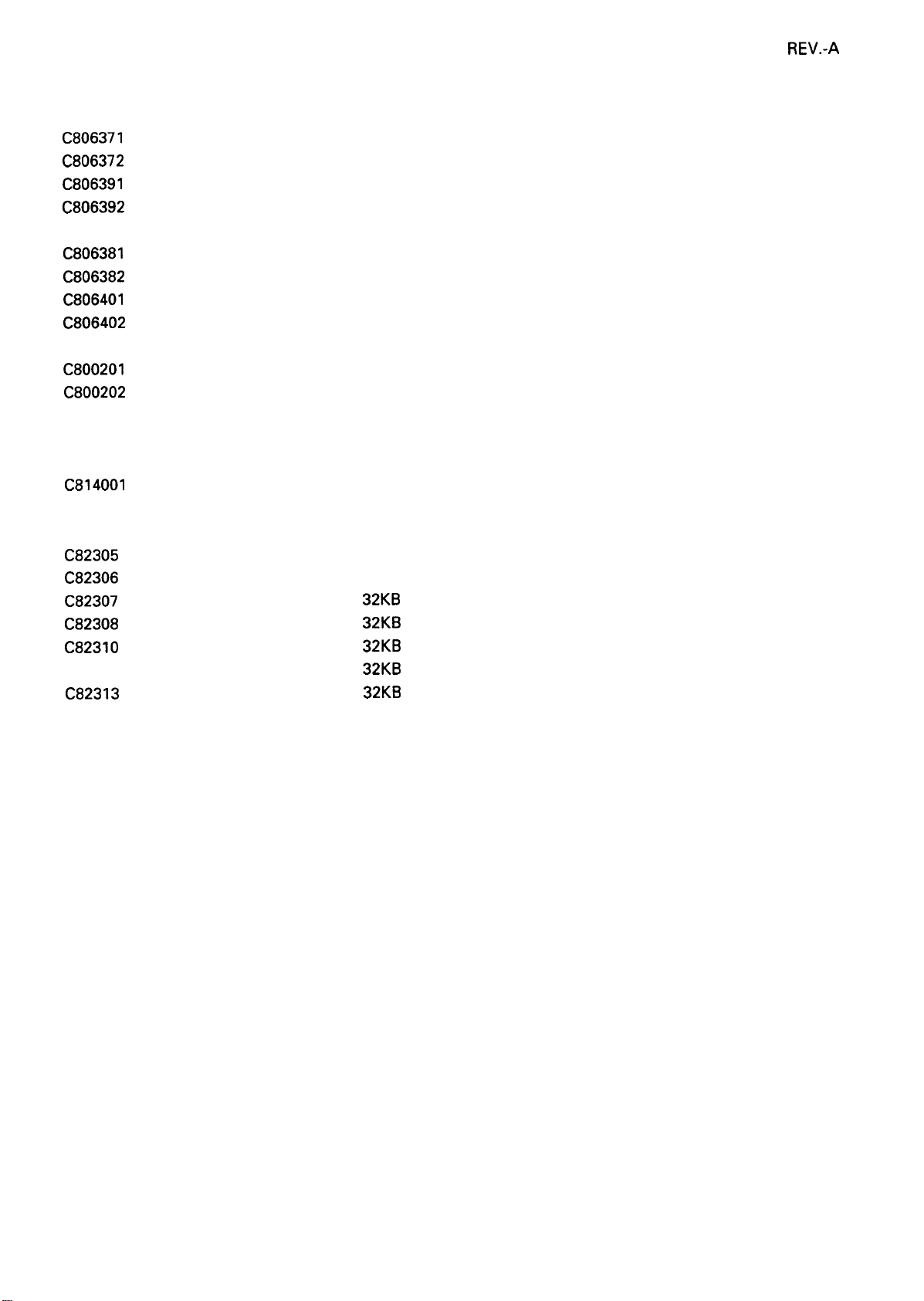

1.1.2 Options

REV.-A

C806371

C806372

C806391

C806392

C806381

C806382

C806401

C806402

C800201

C800202

C800211 (U.S. version)

C800212 (other)

C814001

C814011

C82305

C82306

C82307

C82308

C8231O

C82311 (mm screw)

C82313

(U.S. version)

(other)

(U.S. version)

(other)

(U.S. version)

(other)

(U.S. version)

(other)

(U.S. version)

(other)

(inch screw)

(mm screw)

(inch screw)

(mm screw)

(inch screw)

Plain cut sheet feeder ( 80-column)

Plain cut sheet feeder ( 80-column)

Plain cut sheet feeder (136-column)

Plain cut sheet feeder (136-column)

Cut sheet feeder ( 80-column)

Cut sheet feeder ( 80-column)

Cut sheet feeder (136-column)

Cut sheet feeder (136-column)

Tractor unit ( 80-column)

Tractor unit ( 80-column)

Tractor unit (136-column)

Tractor unit (136-column)

Front sheet guide ( 80-column)

Front sheet guide (136-column)

Serial l/F card

Serial l/F card

32KB

intelligent serial l/F card

32KB

intelligent serial l/F card

32KB

intelligent parallel l/F card

32KB

intelligent parallel l/F card

32KB

IEEE-488 l/F card

#8750

#8755(M)

#8758

#8310

Fabric ribbon cartridge ( 80-column)

Fabric ribbon cartridge (136-column)

Fabric ribbon sub cartridge

Roll paper holder (only for 80-column model)

1-3

Page 13

REV.-A

1.2 Specifications

1.2.1 Hardware Specifications

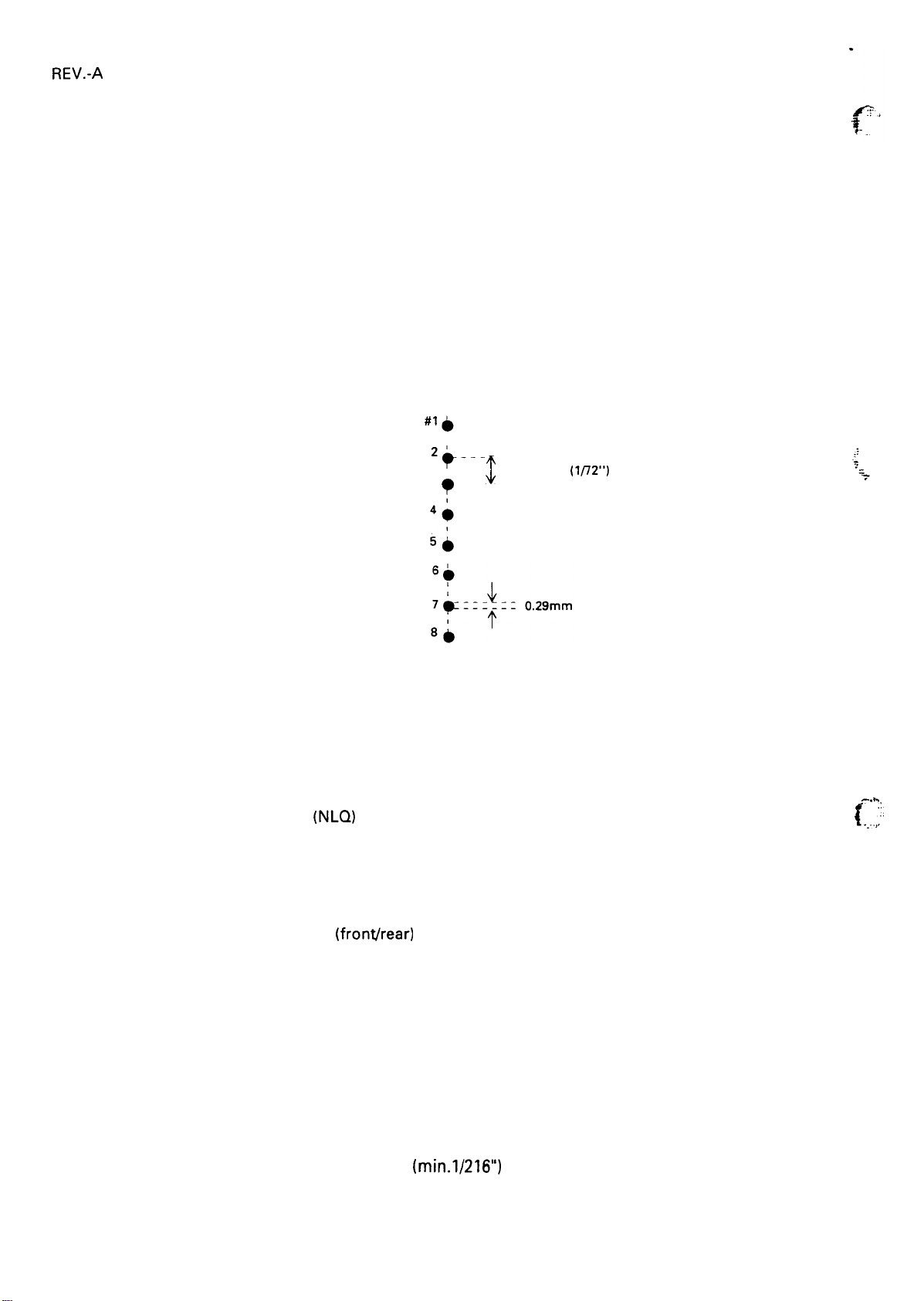

1.2.1.1 Printing Method

Printing method:

Pin configuration: 9 wires

Impact dot matrix

(diameter 0.29 mm)

wire

2+---

3 ‘ -------

--

$

9

9&

0.35mm (lf12”)

Dot matrix:

1.2.1.2 Paper Handling

Feeding method:

Fanfold:

Cut sheet:

Envelope:

Label:

Roll:

Line spacing:

9 x 7 matrix (high-speed draft)

9 x 9 matrix (draft)

18x 23 matrix

Friction feed (front/top)

Push tractor feed

Pull tractor feed (front./rear/bottom)

Push-pull tractor feed (front/rear)

Tractor feed

Friction feed

Friction feed

Tractor feed

Friction feed

1/6”, 1/8”, or programmable (min.1/216”)

Figure 1-2. Pin Configuration

(NLQ)

(frontfrear)

.=.

!..,

{....;’

1-4

Page 14

REV.-A

* Thin:

Thick:

Table 1-1. Line Feed Speed (1

Intermittent feed

Type of paper

Fanfold paper

Cut sheet (manual)

Cut sheet

(CSF)

Thin

ms

77

69

71

Thick

ms

85

77

77

Thickness is less than or equal to 0.18 mm.

Thickness is more than 0.18 mm.

iine

=

1/6”)

Continuous feed

Thin

ms

(ips)

Thick

ms

55 (3.0) 66 (2.5)

45 (3.7) 55 (3.0)

48 (3.5) 55 (3.0)

(ips)

***** precautions for Handling Paper *****

1 ) Friction feed

● Set the release lever to the FRICTION position.

● Load the paper from the front or top entrance.

● Do not use continuous paper.

● Do not perform any reverse paper feeds within the top 8.5 m m area and bottom 22 mm area.

● Do not perform reverse feeds greater than 1/6” after the paper end has been detected.

● Use the paper-tension unit.

● Insert the multi-part cut sheet forms only from the front.

2) Push tractor feed

● Set the release lever to the REAR PUSH/FRONT PUSH position.

● Load the paper from the rear or front entrance.

● Release the friction feed mechanism.

●

M u Iti-part paper must be carbonless.

● Use the paper-tension unit.

● Do not perform reverse feeds greater than 1/6”.

● Do not perform reverse feeding after the paper end has been detected, because accuracy of paper feed

cannot be assured.

1-5

Page 15

REV.-A

“-

3) Pull tractor feed

● Set the release lever to the PULL position.

● Load the paper from the front, rear, or bottom entrance.

(The front or bottom entrance is recommended for thick paper or

● Release the friction feed mechanism.

● Remove the paper-tension unit and attach the pull tractor unit.

● Insert the paper from either front or bottom.

● Multi-part paper must be carbonless.

● Do not perform reverse feeds.

labels.)

4) Push-pull tractor feed

● Set the release lever to the REAR PUSH/FRONT PUSH position.

● Load the paper from the front or rear entrance.

● Release the friction feed mechanism.

● Remove the paper-tension unit and attach the pull tractor unit.

c

Remove any slack in the paper between the platen and the pull tractor.

s

Precisely adjust the horizontal position of the pull tractor and push tractor.

● Multi-part paper must be carbonless.

● Do not perform reverse feeds greater than 1/6”.

● Do not perform reverse feeds after the paper end has been detected.

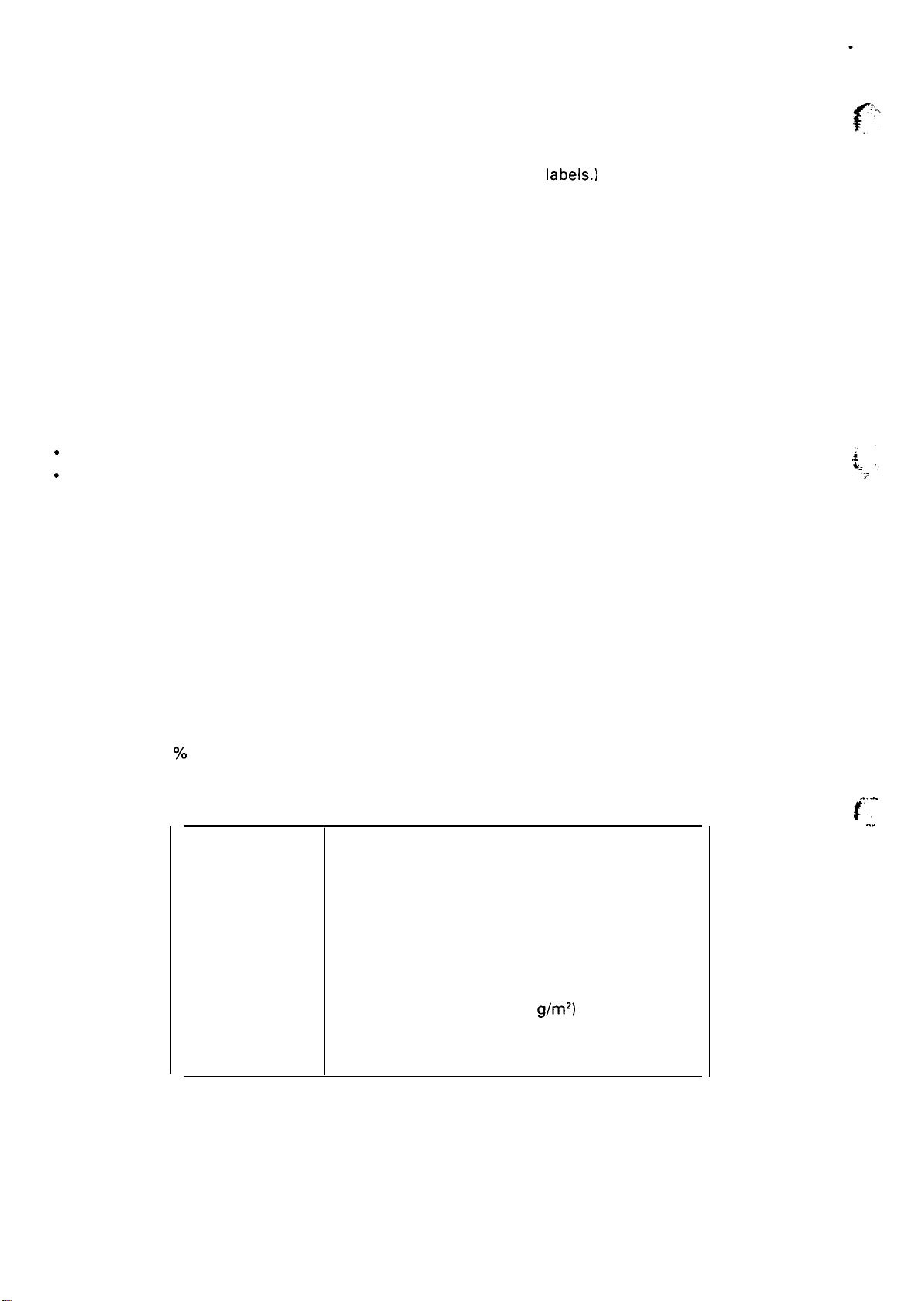

1.2.1.3 Paper Specifications

See Tables 1-2, 1-3, 1-4, 1-5, 1-6, and 1-7.

Recycled paper, envelopes, and labels require the following environmental conditions.

Normal environment

Temperature: 15-25 deg. C (59-68 deg. F)

?!.

Humidity: 30-60

RH

Table 1-2. Specifications for Cut Sheets (Plain Paper)

Width

top insertion

148-257 mm (5.8-10.1”)

148-420 mm (5.8-16.5”)

front insertion 182-257 mm (7.2-10.1”)

182-364 mm (7.2-14.3”)

364

Length

Thickness

Weight

Quality

Up to

0.065-0.14 mm

14-24 lb (45-78 Kg) (52.3-90

Plain paper

mm (14.3”)

(0.0025-0.0055”)

g/m2)

80-column

136-column

80-column

136-column

Recycled paper (in normal environment)

~.

●

... -

1-6

Page 16

- . .

- . - .,. . .

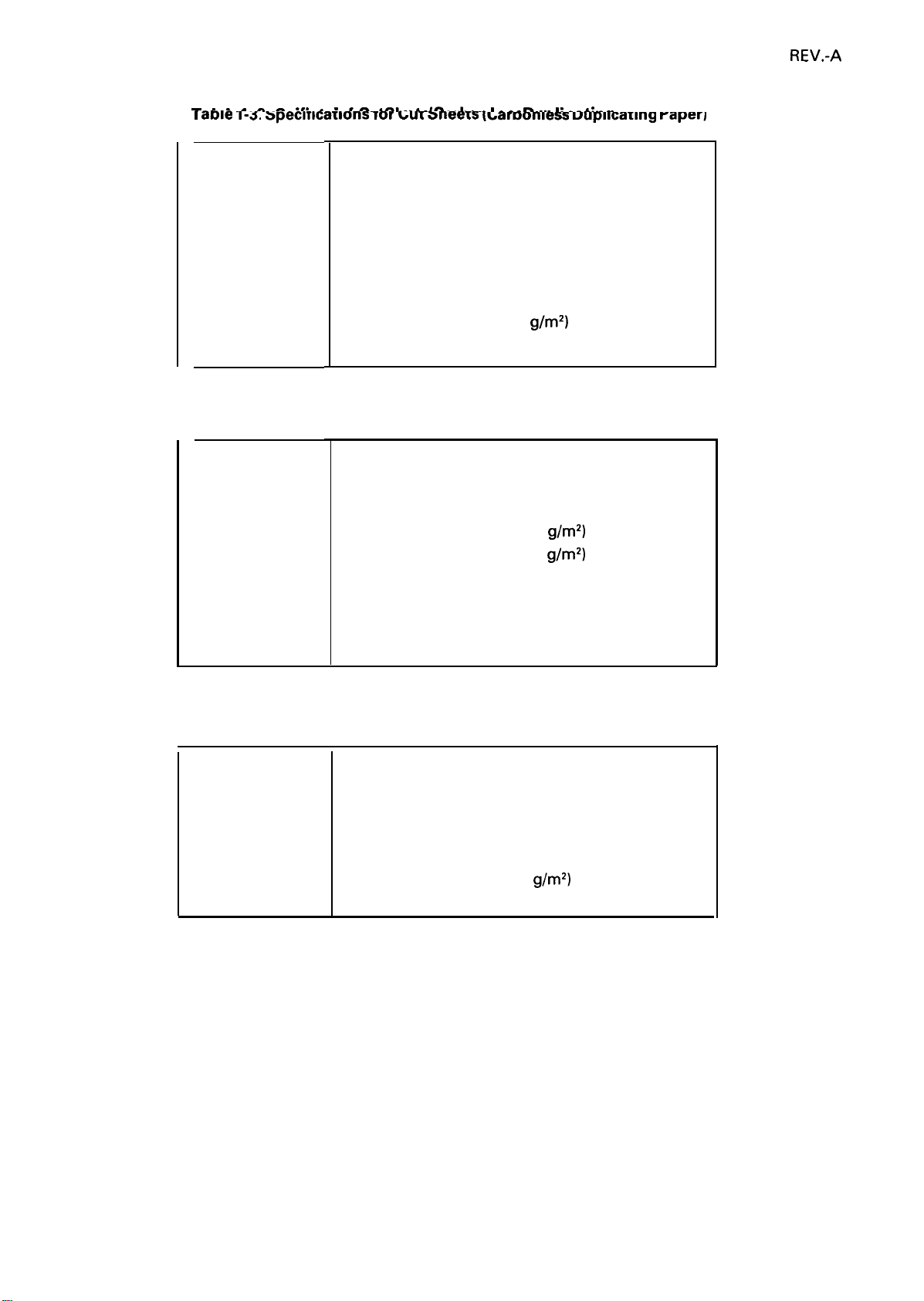

1 ame 1-s. specmcawons lor uu~ mee~s [eamomess uupncamng raper]

,

n-

-A

-,- - —A— ,-—

..L . -.

m .

——

R-

--–

m,

-—

A,.-

— m- —--i

Width

front insertion

Length

Quality

Thickness

Weight

Copies

182-257 mm (7.2-10.1”)

182-364 mm

(7.2-14.3”)

Up to 297 mm (1 1.7”)

Up to 364 mm (14.3”)

Carbonless duplicating paper

0.12-0.22 mm (0.0047-0.0086”)

12-15 lb (34-50 kg) (40-58

g/m2)

4 sheets (1 original + 3 copies) maximum

80-column

136-column

80-column

136-column

- each

Table 1-4. Specifications for Continuous Paper

REV.-A

Width

101-254 mm (4-10”)

101-406 mm (4-16”)

Thickness

Weight

Quality

0.065-0.32 mm (0.0025-0.012”)

14-22 lb (45-70 kg) (52.3-82

12-15 lb (34-50 kg) (40-58.2

g/m2)

g/m2)

Plain or carbonless duplicating paper

Recycled paper (in normal environment)

(with push tractor and optional pull tractor)

Copies

4 sheets (1 original + 3 copies) maximum

Table 1-5. Specifications for Envelopes

Size

No.

6

166 mm x 92 mm

No. 10 240 mm x 104 mm

Thickness

0.16-0.52 mm (0.0063-0.0197”)

* Differences in thickness within the printing area

must be less than 0.25 mm (0.0098”).

Weight 12-24 lb (39-78 kg) (45-91

g/m2)

Quality Bond paper, plain paper, airmail

80-column

136-column

- single sheet

- each

Notes: 1) Envelopes must be inserted from the top.

2) Keep the longer side of the envelope horizontal during insertion.

3) Set the left edge of a No. 6 envelope at the sheet guide setting mark.

4) Do not feed envelopes with the cut sheet feeder.

1-7

Page 17

REV.-A

Table 1-6. Specifications for Labels

.

“:%

t.

C.

Size

Thickness

Quality

Notes: 1) Labels must be fanfold.

2) Example of labels

3) Labels should be used with the pull tractor (front, bottom), or with the front push tractor.

4) Do not perform reverse feed at any time. (including by

5) Remove labels from the paper path when not in use.

Size

Thickness

Weight

Quality

2 1/2” X 15/16”

X

15/16”

4“

4“ X 17/16”

0.07-0.09 mm (0.0028-0.0031”) - base paper

0.16-0.19 mm

Plain paper

AVERY CONTINUOUS FORM

AVERY MINI-LINE LABELS

Table 1-7. Specifications for Roll Paper

216

+/-

3 mm (8.5

0.07-0.09 mm

14-22

Plain paper

(0.0063-0.0075”) -

IABELS

+/-

0.12”)

(0.0028-0.0035”)

lb (45-70 Kg) (52.3-82

total

hand).

g/m2)

z

i

.3.,

Note: Roll paper isavailable only forthe 80-column model optionally, and itsdiameter must notexceed 127

mm (5”).

.%,

,.,

[“

,: ,.,

1-8

. . ,.

Page 18

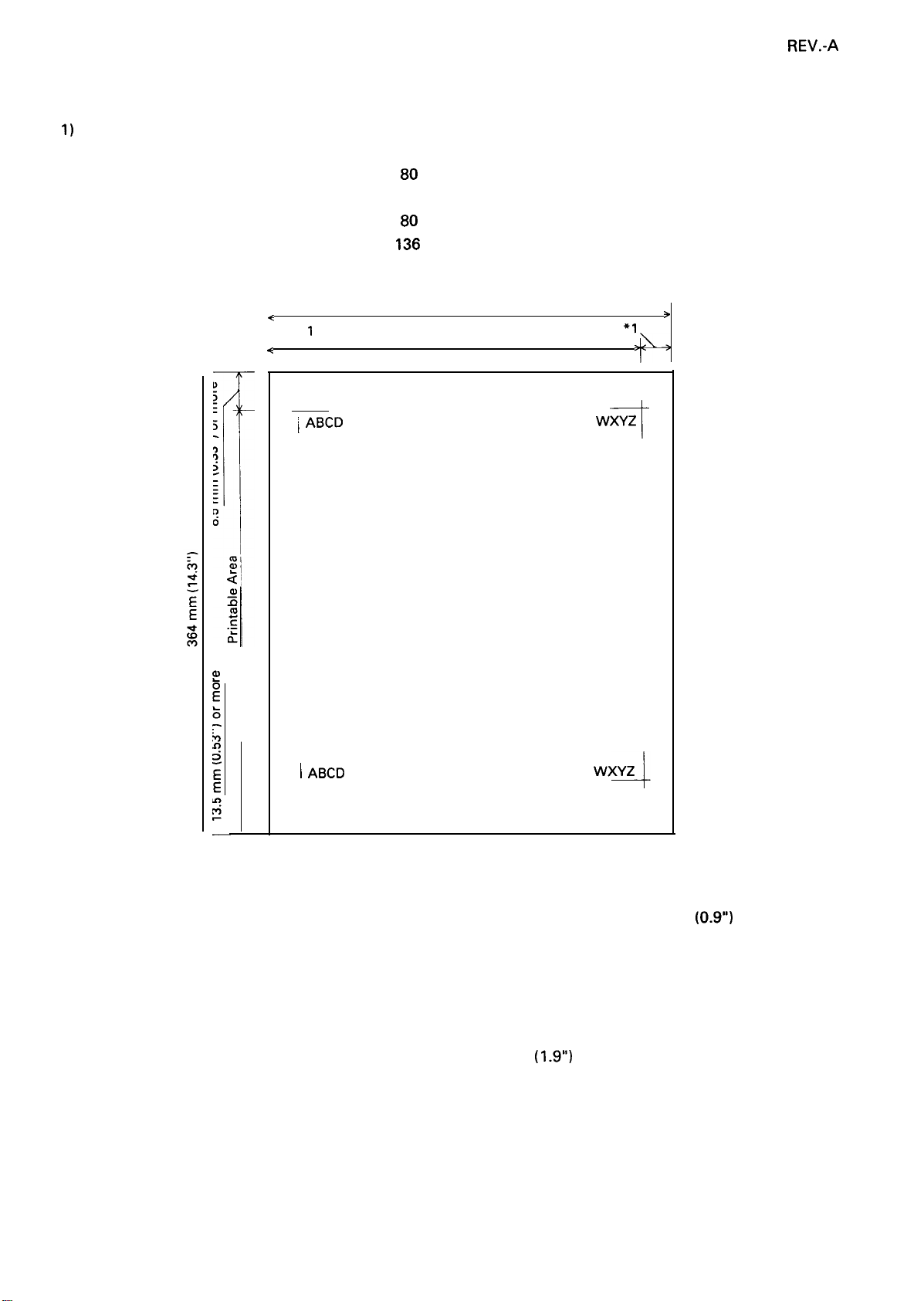

1.2.1.4 Printable Area

1)

Cut sheets

top insertion

front insertion

148-257 mm (5.8-10.1”):

148-420 mm (5.8-16.5”) : 136 columns

182-257 mm (7.2-10.1”):

182-364 mm (7.2-14.3”):

80

columns

80

columns

136

columns

REV.-A

<

<

●

1

L

~ ABCD

Printable Area

>

*1

1.

T“

WXYZ

I_

I ABCD

Figure 1-3. Printable Area for Cut Sheets

* 1 3.0 mm (0.1 2“) or more when the paper width is less than 364 mm (14.3”). 25 mm

the paper width is 420 mm (16.5”).

3.0 mm (0.12”) or more.

Note:

Paper feed accuracy cannot be assured within 24 mm (0.94”) from the bottom edge of the paper.

Paper feed accuracy cannot be assured within 48.5 mm

paper.

1-9

(1.9”)

WXYZ

-1-

from the bottom edge of the

(0.9”)

or more when

(136-column)

( 80-column)

(top insertion)

(front insertion)

Page 19

REV.-A

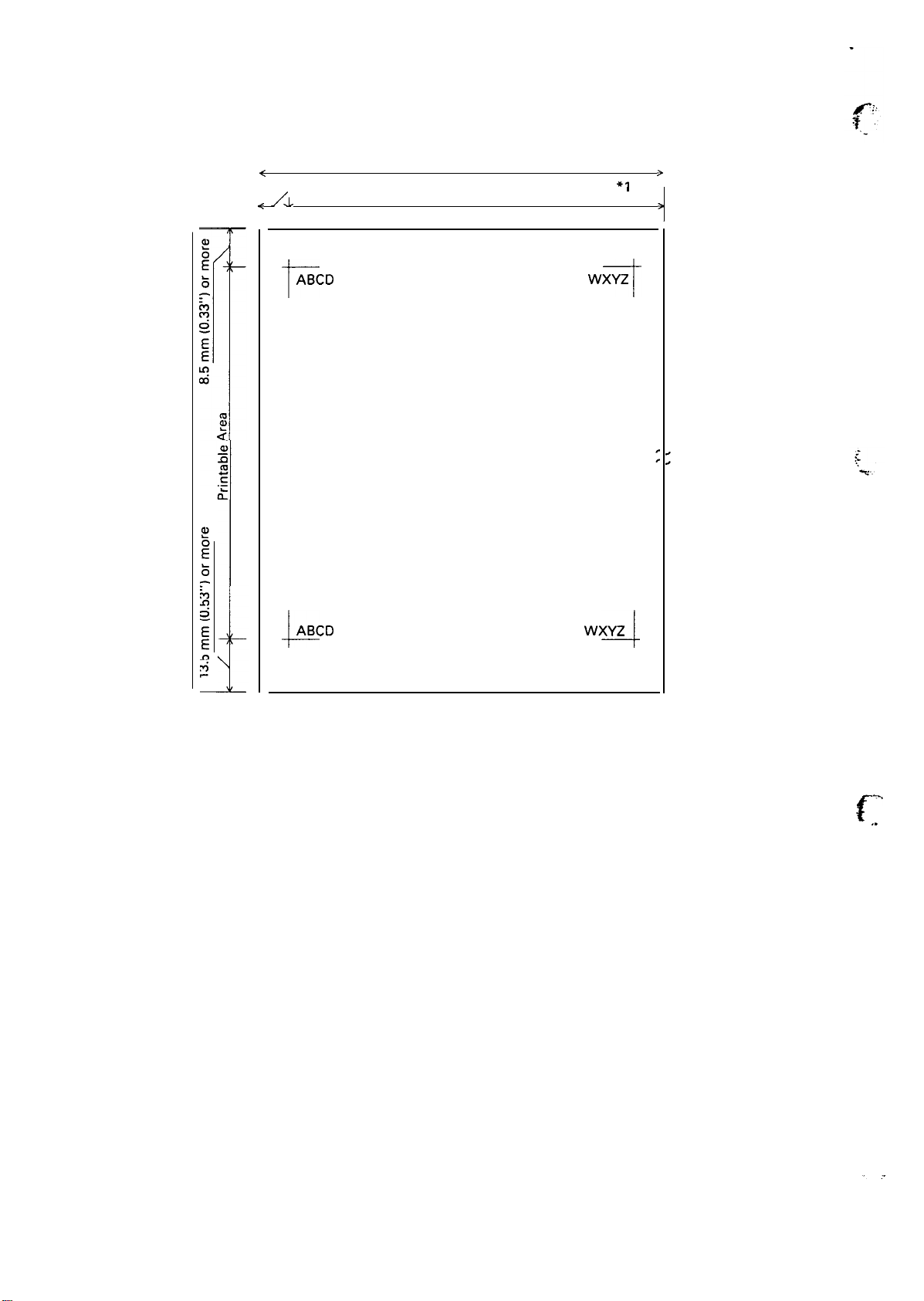

2) Continuous paper

<

*1

A.

<

ABCD

t

Printable Area

WXYZ

I_

*1

>

,

L\

i

ABCD

4--

Figure 1-4. Printable Area for Continuous Paper

*1 13 mm (0.51”) or more when the paper width is 101 mm to 241 mm (4” to 9.5”). 25 mm (1.0”) or more

when the paper width is 254 mm (10”).

13 mm (0.51”) or more when the paper width is 101 mm to 377.8 mm (4” to 14.87”). 25 mm or more

when the paper width is 381 mm to 406 mm (15” to 16”).

WXYZ

4

( 80 columns) . .

(136 columns)

~~.

1

.

1-1o

Page 20

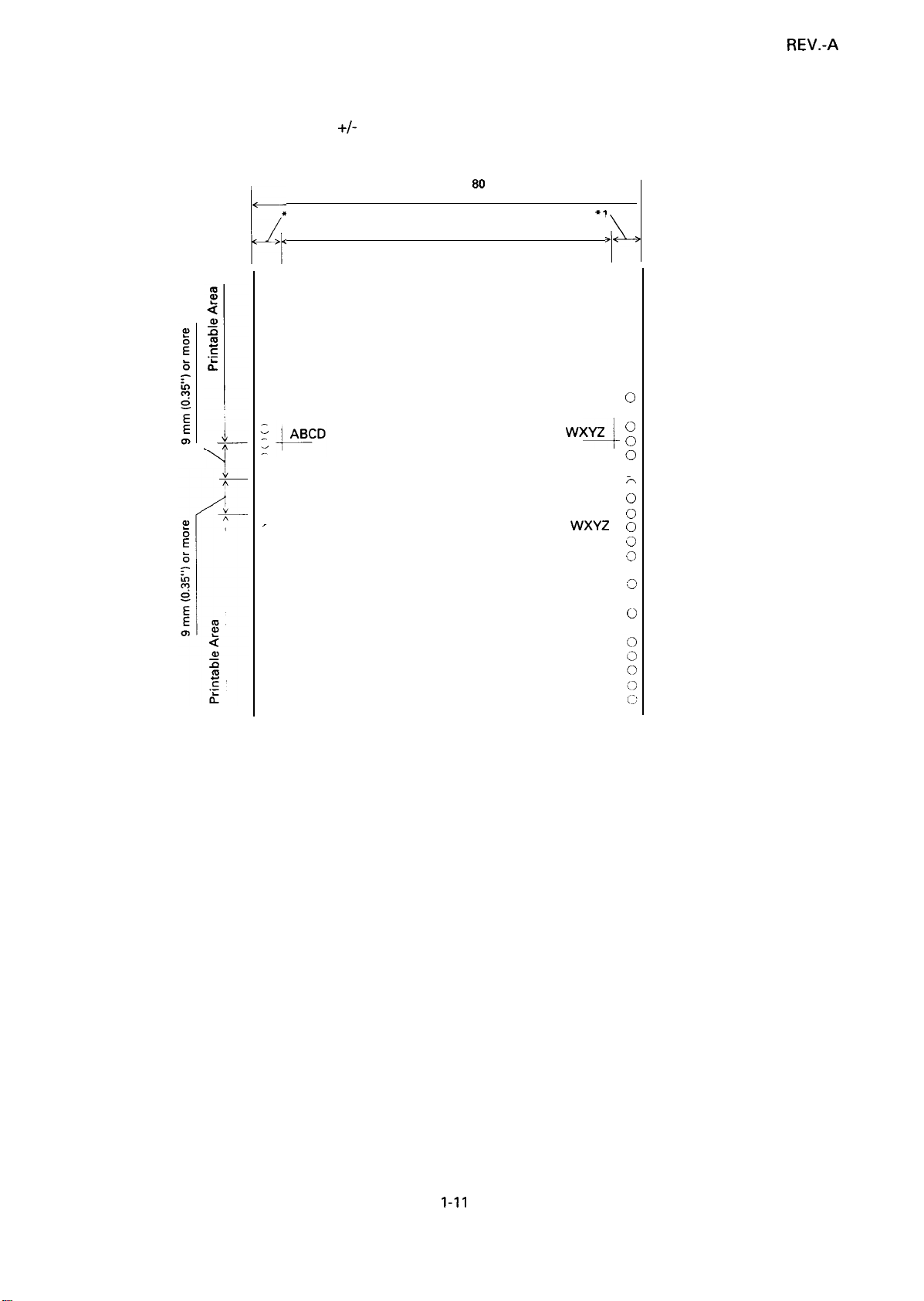

3) Roll paper (80-column model only)

top insertion

216 +/- 3 mm (8.5

●

1

k

.

ABCD

. .

+/-

0.12”)

101-254 mm (4-10”): 80 columns

101-406

mm

(4-16”): 136 columns

Printable Area

+1

WXYZ

4

WXYZ

+

o

0

,0

.--0.

0

0

0

0

0

0

0

o

0

0

%

u

o

0

0

0

0

0

0

0

0

0

REV.-A

>

*1 3.0

Note:

1.2.1.5

Ribbon

Color

Life of ribbon

mm (0.1 2“) or more

Paper feed accuracy cannot be assured within 24 mm (0.94”) from the bottom edge of the paper.

Ribbon Cartridge

Figure 1-5. Printable Area for Roll Paper

Cartridge type (same as FX series)

# 8750

# 8755(M)

# 8758- Subcartridge

Black

3 x 106 characters (at

14 dots/character)

(top insertion only)

- 80-column model

- 136-column model

1-11

Page 21

REV.-A

.

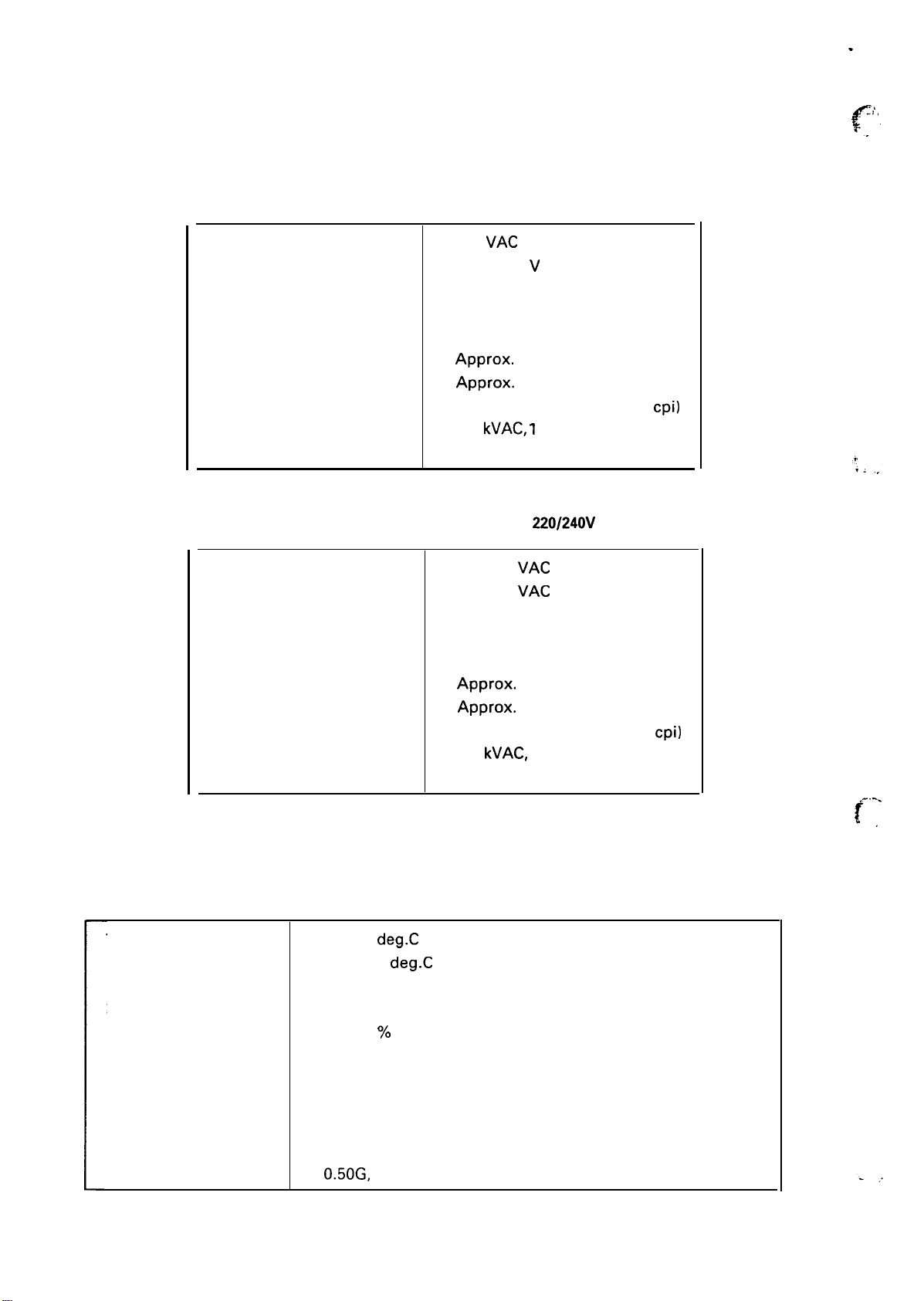

1.2.1.6 Electrical Specifications

See Table 1-8 and 1-9.

Table 1-8. Electrical Specifications for 120V Model

Rated voltage

Input voltage range

Rated frequency range

Input frequency range

Rated current

Power consumption

Dielectric strength

Table 1-9. Electrical Specifications for

120

VAC

103.5-132 V AC

50-60 Hz

49.5-60.5 Hz

1.8 A

Approx.

Approx. 45 W (136 columns)

(Self test in draft mode, 10

1.0

(Between AC line and chassis)

45 W ( 80 columns)

kVAC, 1

second

220/240V

cpi)

Model

. .

. . . . .

.,

c-

Rated voltage

Input voltage range

Rated frequency range

Input frequency range

Rated current

Power consumption

Dielectric strength

1.2.1.7 Environmental Conditions

Table 1-10. Environmental Conditions

Temperature

Humidity 10 to 80

5 to 35

-30 to 60

5 to 85

deg.C

Y.

220-240

198-264 VAC

50-60 Hz

49.5-60.5 Hz

0.9 A

Approx. 45 W ( 80 columns)

Approx. 45 W (136 columns)

(Self test in draft mode, 10

1.5

(Between AC line and chassis)

(41 to 95 deg. F) — operating

deg.C

(-22 to 140 deg. F) — in shipment container

‘Y. RH — operating

RH — non-operating

kVAC,

VAC

1 second

cpi)

f“-

.,

Resistance to shock

Resistance to vibration

IG, within 1 ms — operating

2G, within 1 ms — non-operating

0.25G, 55 Hz max. — operating

0.50G,

55 Hz max. — non-operating

1-12

Page 22

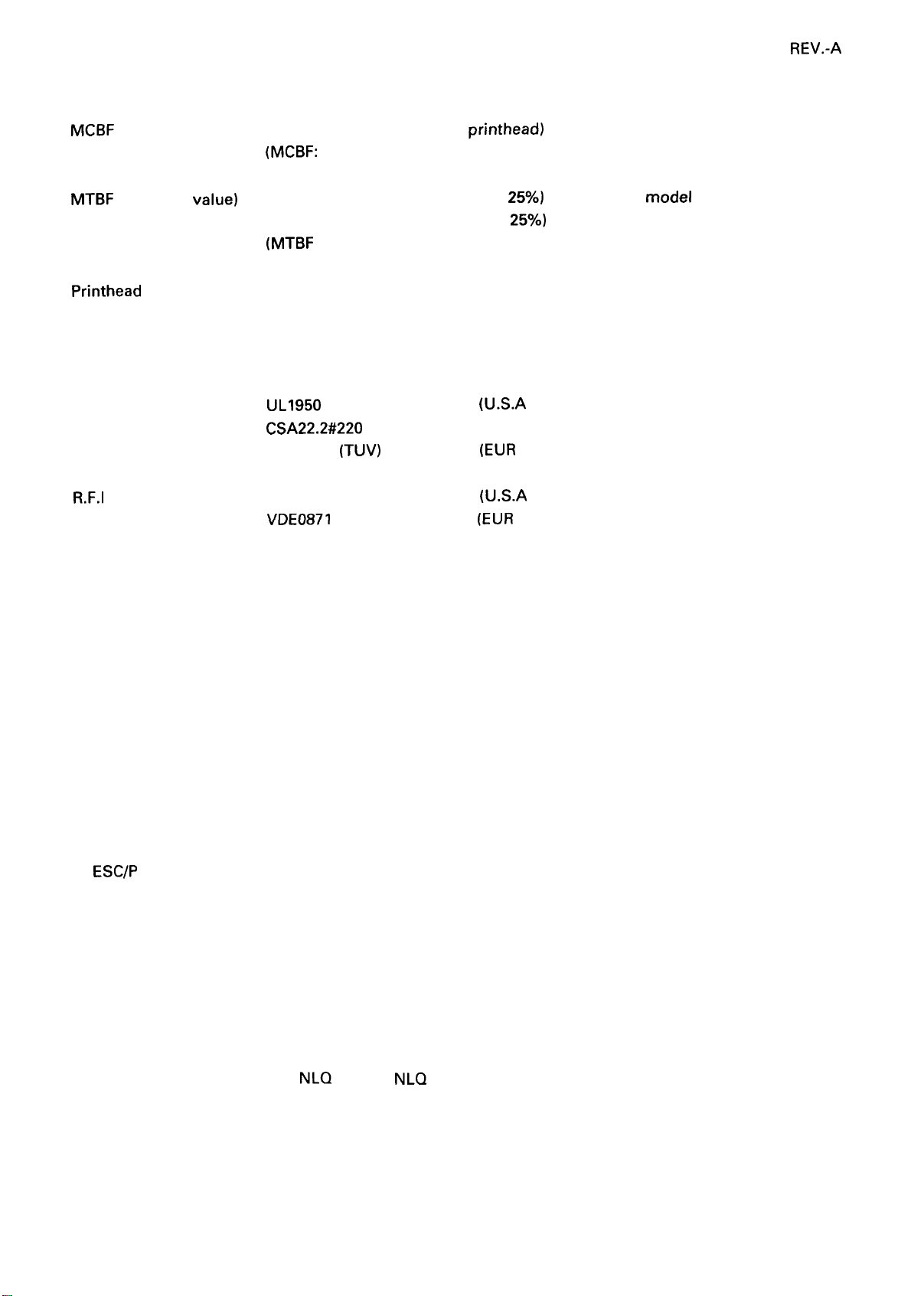

1.2.1.8 Reliability

REV.-A

MCBF

MTBF

(expected value)

5 million lines (excluding a printhead)

(MCBF:

Mean Cycles Between Failures)

4000 power on hours (duty cycle

6000 power on hours (duty cycle

Printhead

(MTBF

Life

: Mean Time Between Failures)

100 million characters (14 dots/character)

1.2.1.9 Safety Approvals

Safety standards

UL1950

CSA22.2#220

EN 60950

R.F.I

FCC class B

VDE0871

1.2.2 Firmware Specifications

with D3

(TUV)

(Self certification)

25Yo)

— 80-column model

25Yo)

—136-column model

(U.S.A model)

(EUR

model)

(U.S.A model)

(EUR

model)

1.2.2.1 Print Control

Printing direction

Text mode Bidirectional printing with logic seeking.

(Unidirectional printing can be specified by software.)

Bit image mode Unidirectional printing

Character sets

—

ESC/P

mode —

ASCII characters

International characters (13 countries) and their italics

PC 437,850,860,863,865, 437 Greek, 851,869,852,853,857, 855,866, GOST, 861 (European

model)

PC 437,850,860,863,865 (Non-European model)

— IBM mode —

PC 473,865

(PC = Personal Computer character table )

Fonts: Draft,

NLQ

Roman,

NLQ

Saris serif

1-13

Page 23

REV.-A

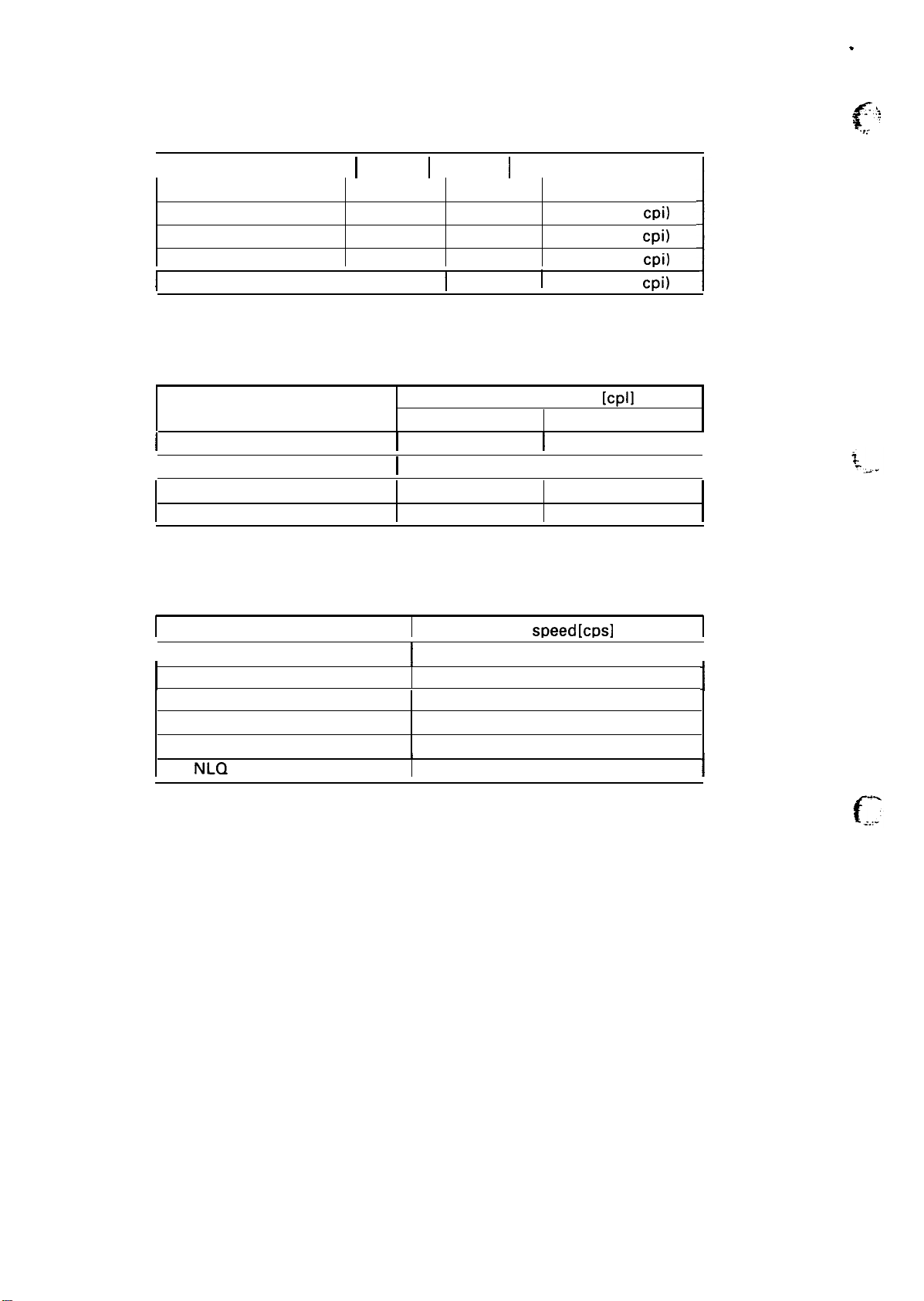

Table 1-11. Character Size and Pitch

Type of letters I Width I Height I Character pitch

I

[mm]

Pica

Condensed

Elite

I

Condensed elite \ 0.85

Table 1-12. Printable Columns

2.1

1.05

1.7 3.1

[mm]

3.1

3.1

I

3.1

I

[mm]

2.54 (10

1.48 (17

2.11 (12

1.27 (20

cpi)

cpi)

cpi)

cpi)

.

f’

:.

.,.-

.,’;:

Notes: 1)

Type of letters Printable columns

80-column model 136-column model

I

I

I

The printing speed for high speed draft is reduced to the value in “( )“ with thick paper (over 0.18

mm).

2)

The printing speed for high speed draft is reduced to the value of “draft pica” when any graphic

character is in the line.

3)

The printing speed for draft is reduced to the value in “[ ]“ when any italic character is in the

line.

4)

The speed for high duty printing is reduced to approximately half of each speed, except for the

printing speed in “[ l“.

Pica

Condensed

Elite 96 163

Condensed elite

Table 1-13. Print Speed

Type of letters

High-speed draft

Draft pica

Draft elite

Condensed draft pica

Emphasized draft pica

NLQ

normal pica

I

I

I

t

I

80

137

160

380

285

342

243

142

57

speed

Print

(320) [1421

[142]

[170]

[122]

[ 711

I

I

[cm]

[cpl]

136

233

272

I

I

I

1

I

1.2.2.2 Input Data Buffer

24K

or OK bytes (selectable with power on default settings; see Section 1.5.2. )

1-14

Page 24

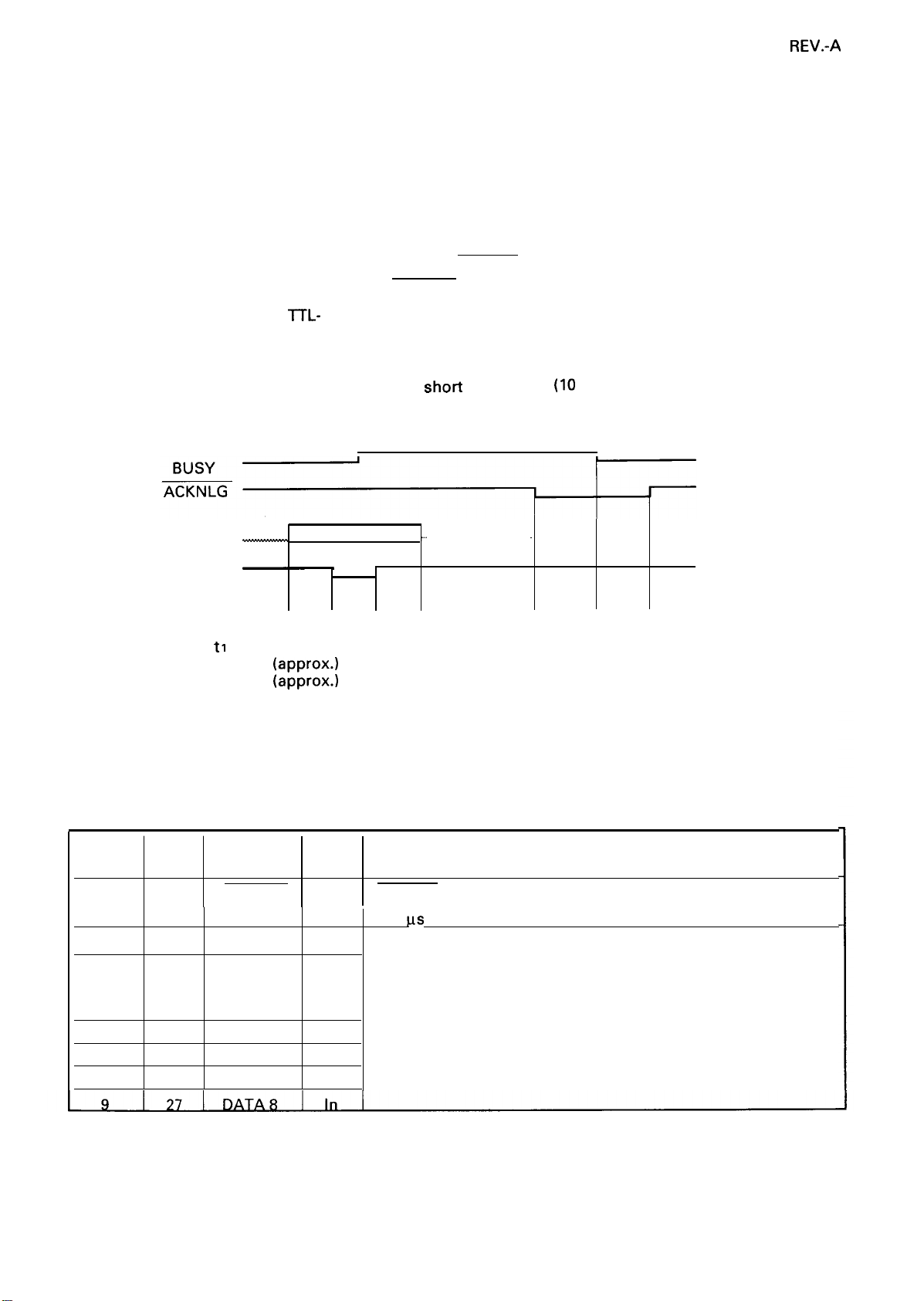

, 1.3 Interface

This printer has a built-in, 8-bit centronics parallel interface.

1.3.1 Parallel Interface

REV.-A

Data transmission mode

Synchronization

Handshaking

Logic level

Connector plug

It is recommended that the interface cable be as

DATA

STROBE

tl

: 0.5 us (min.)

t2: 7 us

t3: 5 us

8-bit parallel

Controlled by external STROBE pulse.

Controlled by ACKNLG and BUSY signals.

ITL-

compatible

57-30360 (Amphenol) or equivalent

tl tl tl

(approx.)

(approx.)

short

as possible

:...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(10

feet maximum).

.

t2

t3

Signal

Pin No. Pin No.

Return

1

2

3

4

5

6

7

8 26

19

20 DATA 1

21

22

23

24

25

Figure 1-6. Data Transmission Timing

Table 1-14. Connector Pin Assignments and Signal Functions

Signal

Name

STROBE

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

Dir.

In

In

In

In

In

In

In

In

STROBE pulse to read data in. Pulse width must be more than

0.5 Bs at receiving terminal.

These signals represent the 1st to 8th bits of parallel data,

respectively. Each signal is HIGH when data is a logical 1 and

LOW when a logical O.

Description

1-15

Page 25

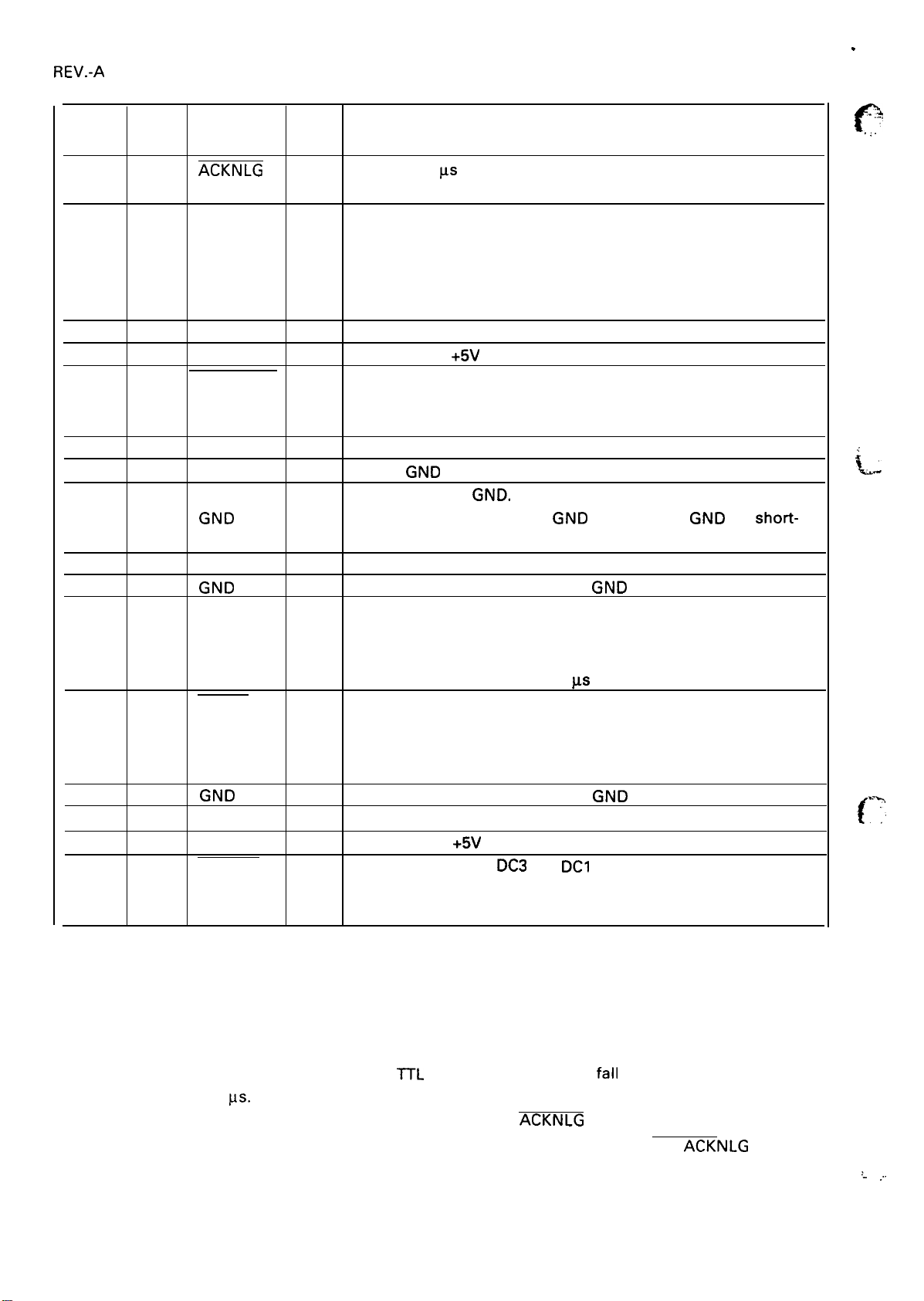

.

REV.-A

Signal

Pin No.

10

11

12

13

14

15

16

17

18

9 to 30 —

31

32

33

34

35

36 —

Return

Pin No.

28

29

30

—

—

—

—

—

—

—

—

—

—

—

Signal

Name

ACKNLG

BUSY

PE

—

AUTO FEED

XT

NC

Ov

CHASSIS

GND

NC

GND

INIT

ERROR

GND

NC

— —

SLCT IN

Dir.

out

out

out

—

In

—

—

—

—

—

In

out

—

—

In

(Continued)

Description

Approx.12

received and that the printer is ready to accept more data.

A HIGH signal indicates that the printer cannot receive more

data. The signal becomes HIGH in the following cases:

1. During data entry

2. During input buffer full

3. During printer error status

A HIGH signal indicates that the printer is out of paper.

Pulled up to +5V through a 3.3 K-ohm resistor.

When this signal is LOW, paper is automatically fed one line

upon receipt of a CR code.

(The signal level can be set LOW by default.)

Not used.

Logic GND level.

Printer chassis GND.

In the printer, the chassis

circuited.

Not used.

TWISTED-PAIR RETURN signal

When the level of this signal becomes LOW, the printer

controller is reset to its initial state and the print buffer is

cleared. This signal is normally atthe HIGH level, and its pulse

width must be more than 50 ps at the receiving terminal.

The level of this signal becomes LOW when the printer is

in —

1. Paper-out status

2. Error status

TWISTED-PAIR RETURN signal GND level.

Not used.

Pulled up to

The data between

is HIGH.

(The level of this signal is factory set to LOW.)

us

pulse. LOW indicates that data has been

GND and the logic GND are

GND level.

+5V

through a 3.3 K-ohm resistor.

DC3

and DCI is invalid when this signal

short-

.- ...,

e

. . .

.

.

~~

-=

{.

‘

.

.

Notes: 1 ) Direction of signal flow is as viewed from the printer.

2) Return means TWISTED PAIR RETURN and is to be connected at signal ground level.

3) Be sure to use a twisted-pair cable for each signal and always complete connection on the return

side. To prevent noise effectively, these cables should be shielded and connected to the chassis

of the host computer and the printer, respectively.

4) All interface conditions are based on

less than 0.2

5) Data transfer must not be carried out by ignoring the

(Data transfer to this printer can be carried out only after confirming the

the level of the BUSY signal is LOW.)

VS.

ITL

level. Both the rise and

1-16

ACKNLG

fall

times of each signal must be

or BUSY signal.

ACKNLG

signal or when .

.

:_

.,.

Page 26

, 1.3.2 Optional Interface

The following interface cards can be used for this printer.

Table 1-15. Optional Interface

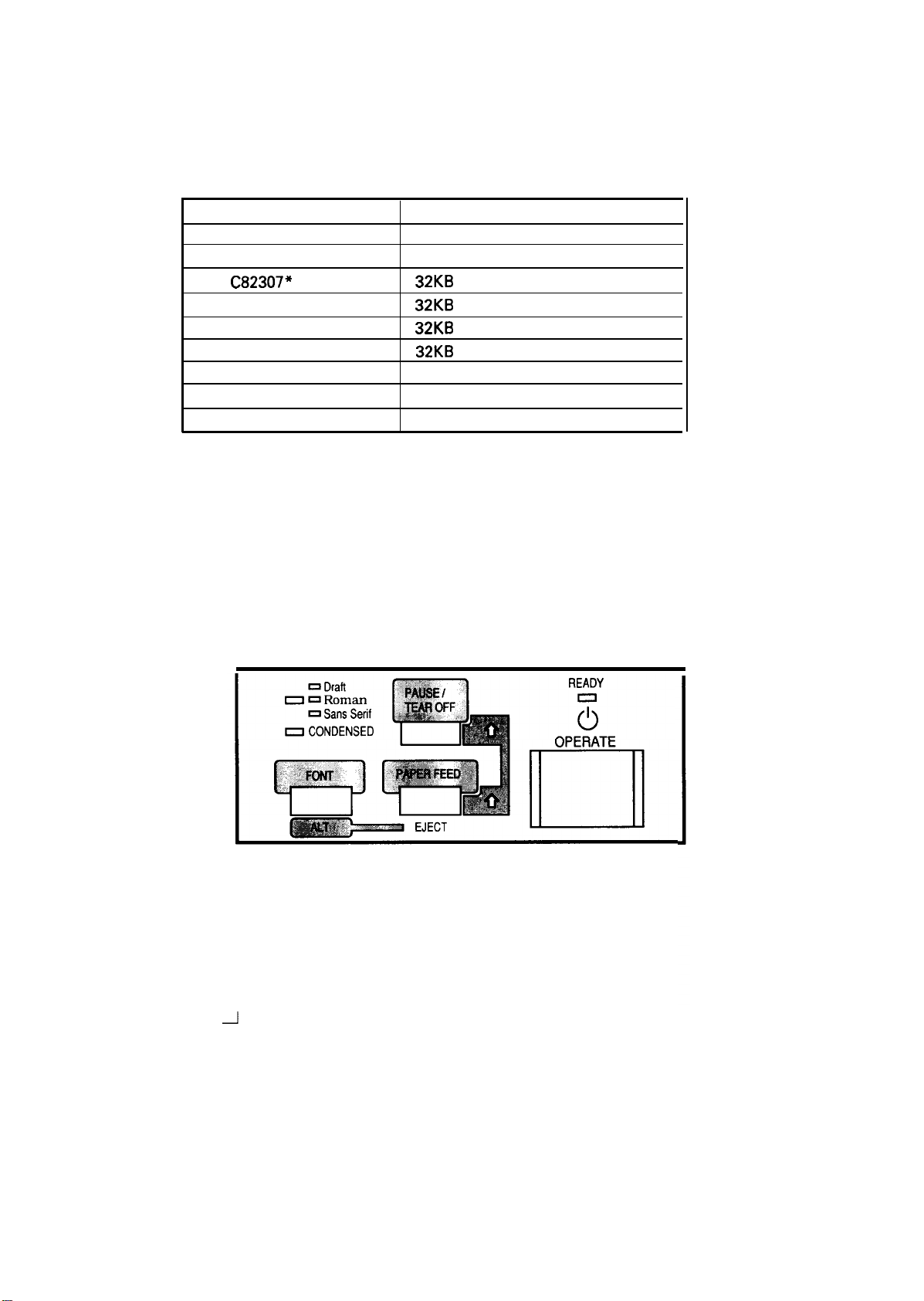

Catalog #

C82305* (inch screw)

C82306* (inch screw)

C82307* (inch screw)

C82308* (inch screw)

C8231O* (inch screw)

C82312* (inch screw)

C82313* (inch screw)

C82314* (inch screw)

C82315* (inch screw) Twinax l/F card

Note: The last digit of catalog # “*” varies depending on the country.

Serial I/F card

Serial l/F card

32KB

intelligent serial l/F card

32KB

intelligent serial l/F card

32KB

intelligent parallel l/F card

32KB

intelligent parallel l/F card

Local Talk l/F card card

Coax l/F card

Type

REV.-A

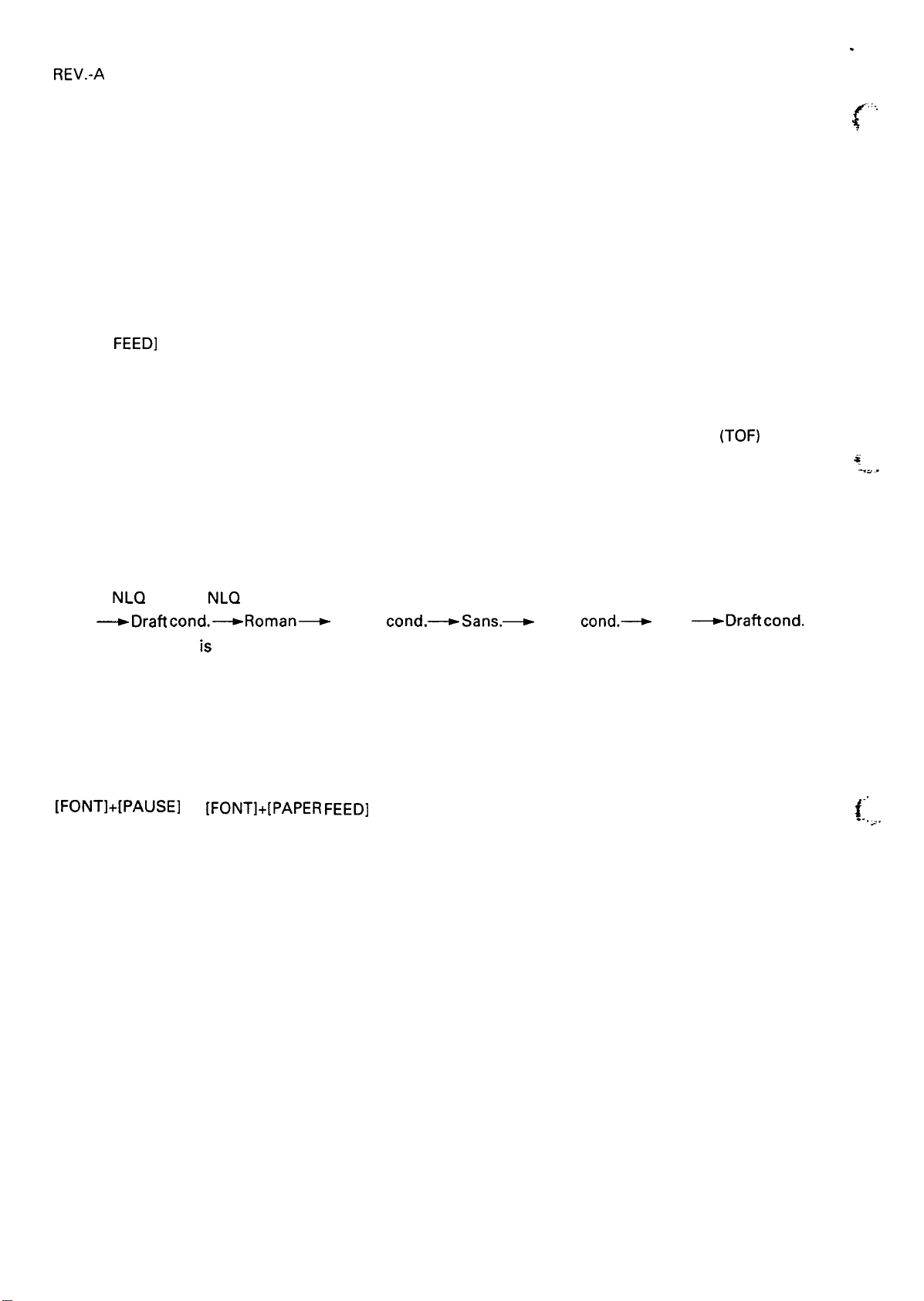

1.4 Control Panel

1.4.1 Components

Buttons

OPERATE

PAUSE/TEAR OFF

PAPER FEED

FONT

l--

J

Figure 1-7. Control Panel

1

lock type button

(non-lock Push type buttons)

Indicators

READY — (green)

FONT (Draft, Roman, Saris

CONDENSED — (green)

3 LEDs

serif) — (green)

1-17

Page 27

REV.-A

1.4.2 Buttons

[PAUSEI

Selects printing or pause alternately when there is some data to print in the input buffer.

Advances continuous paper to tear-off position when the printer has printed all received data and is ready

to receive more print data.

.

(-

,:.,

.

[PAPER

Advances the paper line by line using the current line spacing setting while the printer is ready to print or

paused by PAUSE button.

Holding down the button for about 1 second, it advances the paper to the next top-of-form

Loads continuous paper inserted in the push tractor or cut sheets in the CSF when the printer has detected

a paper out.

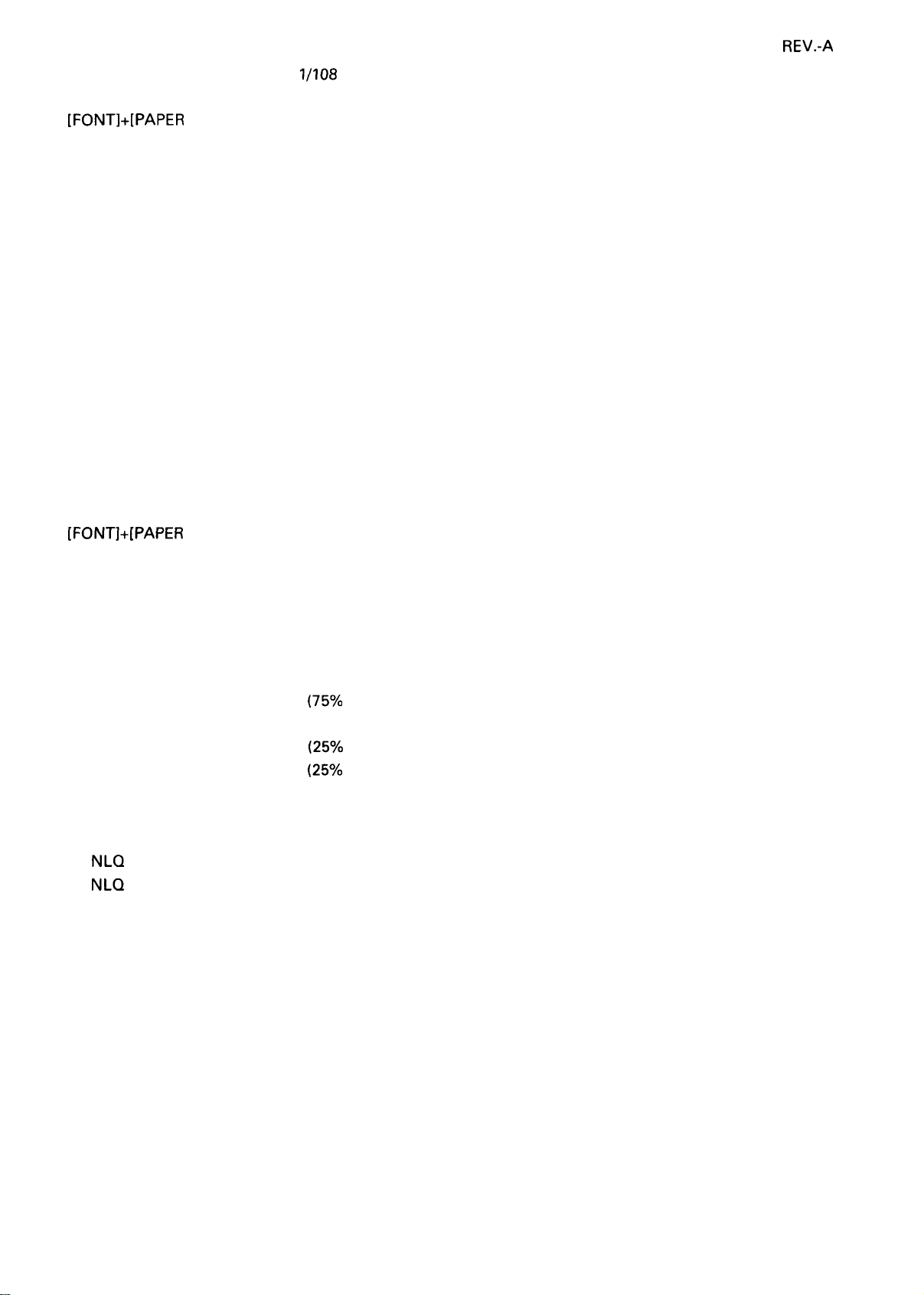

[FONT]

Selects

(Draft

(The factory setting k the Draft, uncondensed font)

The selection is executed when the button is released.

The selection is stored in non-volatile memory.

Enables the micro feed function when pressed along the PAUSE or PAPER FEED button. The micro

feed function is described below.

FEEDI

NLQ

Roman,

~Draft cond.~

NLQ

Saris serif, Draft, and condensed of those 3 fonts in rotation:

Roman~

Roman

cond.~

Sans.~

Saris.

cond.~

Draft

~Draft cond.

(TOF)

position.

....)

*

‘“’

FONTI+[PAUSEI

Activates the function.

as described below:

[FONT]+ [PAUSE]

or

IFONTI+[PAPER FEEDI

The PAUSE and PAPER FEED buttons micro-adjust the paper position up or down,

1-18

~.

: . .

. . . .

.

. .

Page 28

REV.-A

Advances the paper forward by

1/108

inch per step.

IFONTl+[pApER FEEDI

Moves the paper backward by 1/108 inch per step.

Pressing FONT along with PAUSE or PAPER FEED lets you micro-adjust the following positions:

● the loading position, immediately after paper is loaded in the printer.

● the tear-off position, when paper has been advanced for tear off.

● the current print position.

The adjusted loading and tear-off positions will be stored in non-volatile memory (except for the loading

position of cut sheets by manual insertion).

You can end micro feed (or micro adjust) mode by pressing the FONT button again. The printer exits this mode

automatically in several seconds if no operation is performed.

Pressing FONT+ PAUSE or FONT+ PAPER FEED switches bins when a double-bin CSF is installed, there is no

paper in the paper path, and friction feed is selected.

IFONTl+[pApER

FEED]

Ejects a cut sheet forward or feeds continuous paper backward to the paper park position.

1.4.3 Indicators

<READY>

Ready to print :

Tear-off :

Pause :

Paper error :

Head hot :

<FONT>

Draft :

NLQ

Roman :

NLQ

Saris serif:

<CONDENSED>

Normal pitch :

Condensed pitch : ON

ON

Blinking

(ls~o

duty)

Blinking (50% duty)

Blinking

Blinking

(25’Yo

(25Y0

duty)

duty)

OFF

ON

Blinking

OFF

When an error occurs, the READY, FONT, and CONDENSED LEDs will be used in combination to identify the

error.

All indicators blink simultaneously: Fatal error

All indicators blink sequentially in the clockwise direction: Voltage error

1-19

Page 29

REV.-A

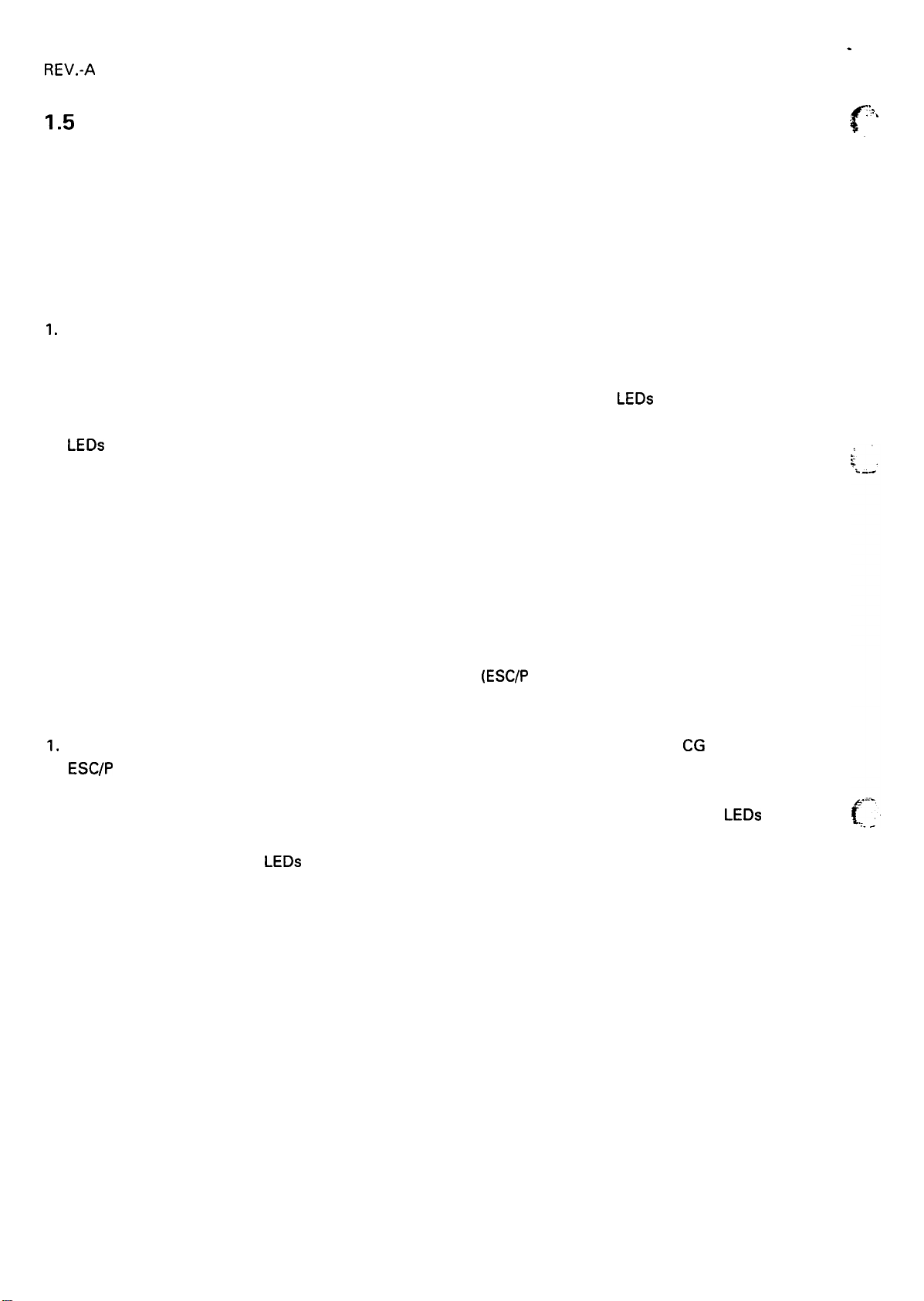

1.5 Functions

1.5.1 Default Settings

Users can set certain default parameters, which will be used at printer initialization.

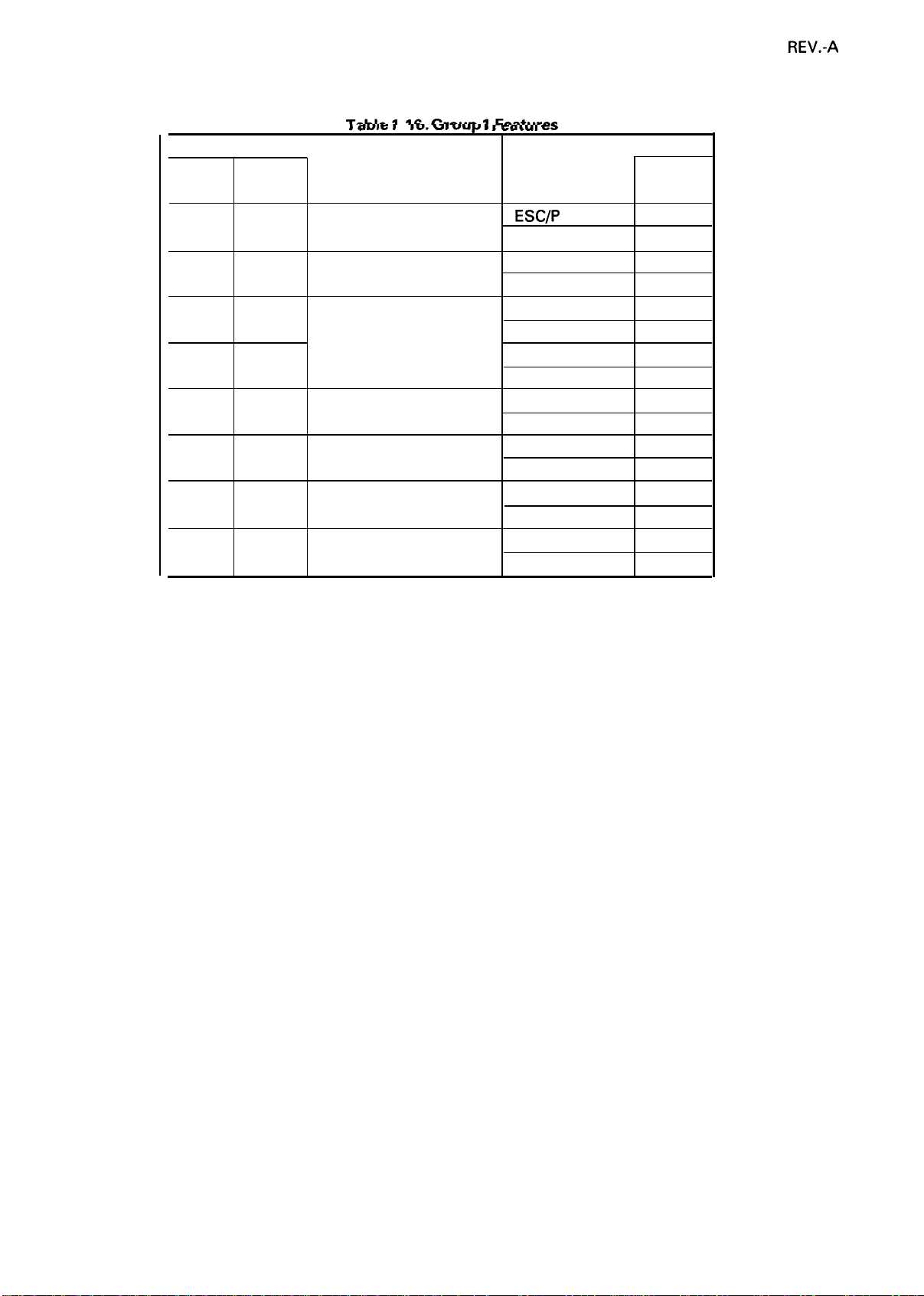

To change the parameters shown in Table 1-16, Group 1 Features, follow the steps below.

1.

Turn on the printer while pressing the FONT button. Then, the current default settings will be printed on

the paper loaded in the paper path.

LEDs

Press the FONT button to select a parameter. The FONT and CONDENSED

2.

show the current parameter selected. Press the FONT button as many times as necessary to make the

LEDs

indicate the setting you want. (See Table 1-16.)

Press the PAUSE button to change the setting. The READY LED shows your selection.

3.

turn on, off, or blink to

c

.!.

,,. ,

4.

Repeat this procedure for any Group 1 feature you want to change. (After you have set the feature at the

bottom of Table 1-16, the printer returns to the first feature in Table 1-16.)

When all the settings are as you want them, turn off the printer. The settings will be stored in non-volatile

5.

memory.

To change the settings shown in Table 1-17, Group 2 Features

(IBM mode), follow the steps below.

1.

Turn on the printer while pressing the FONT and PAUSE buttons. Then, the current CG table for either

ESC/P

or IBM mode will be printed on the paper loaded in the paper path.

Press the FONT button to select the character table. The FONT, CONDENSED, and READY

2.

off, or blink to show your selection. Press the FONT button as many times as necessary until the FONT,

LEDs

CONDENSED, and READY

Turn off the printer. The settings will be stored in non-volatile memory.

3.

indicate the character set you want.

(ESC/P

mode), or in Table 1-18, Group 2 Features

LEDs

turn on,

1-20

Page 30

I ault$

I -

Iu. -g uup m rcacul ca

REV.-A

FONT

LED

OFF

COND.

LED

ON

Feature

Emulation

Setting

ESC/P

IBM Proprinter

OFF BLINKS

Character pitch

Pica OFF

Elite ON

ON

OFF

Page length 11 inch

12 inch ON

ON

ON

8.5 inch

70/6 inch (A4)

ON

BLINKS

Skip over perforation

No skip

Skip 1 inch ON

BLINKS OFF

Zero face

o

0

BLINKS ON

BLINKS BLINKS

Note: The factory setting is that the READY LED is OFF for all features.

Auto tear-off Valid

Invalid

Auto LF with CR Depends on l/F

Valid

READY

LED

OFF

ON

OFF

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

ON

1-21

Page 31

REV.-A

,.

Table 1

FONT

LED

I

I

OFF I ON

OFF

OFF

OFF

OFF

OFF

ON

ON OFF

ON

ON ON

ON

ON

I

ON

ON

I

BLINKS I OFF

I

BLINKS I OFF

t

BLINKS I OFF

BLINKS

BLINKS

BLINKS

COND.

LED

I

ON

ON

BLINKS

BLINKS

BLINKS

OFF

OFF

ON

BLINKS OFF

BLINKS

BLINKS

ON

ON

ON

7. Group 2 Features

READY

LED

ON

BLINKS

OFF

ON

BLINKS

OFF

ON

BLINKS

OFF

ON

BLINKS

OFF

ON

BLINKS

ON

BLINKS

OFF

ON

BLINKS

OFF

ON

BLINKS

Italic

I

I

Character table

I

I

I

I

(ESC/P

Mode)

CG

table

U. S. A.(std. setting)

France

Germany

U.K.

Denmark

Sweden

Italy

Spain

PC437

PC850

PC860

PC863

PC865

PC437

Greek

PC851

PC869

PC852

PC853

PC857

PC855

PC866

GOST

PC861

+

..

.

Note: The CG tables between ‘PC437 Greek’ and

CG table of PC

ESC tl

Then

Notes: 1) For table 1, codes

For table 2, codes

2) The CG tables

memory.

XXX is selected, the table is assigned as the table selected by the

and

ESC

6 are set as defaults. (Codes

Table 1-18. Group 2 Features (IBM Mode)

FONT

LED

OFF OFF

OFF

OFF

OFF ON

COND.

LED

OFF

ON

80-9FH

80-9FH

for ESC/P mode and IBM mode are saved independently in non-volatile

are control codes.

READY

LED

ON

BLINKS

OFF

ON

are printable characters.

‘PC861’

are available only for European models. When the

80-9FH

Character table

(ESC

1-22

are printable characters.)

CG table

PC437

(table 1) (std.)

PC437

(table 2)

PC865

(table 1)

PC865

(table 2)

7 is set.)

(ESC

6 is set. )

ESC

tl command.

Page 32

REV.-A

1.5.2 Power On Default Settings

The printer also lets you change some of its power on parameters. To change the settings shown in Table 1-

19, Group 3 Features (Power on settings), follow the steps below.

1. Turn on the printer while pressing the PAUSE, PAPER FEED, and FONT buttons.

2. Press the button indicated in Table 1-19 for a few seconds to change parameters.

Table 1-19. Group 3 Features (Power-on Settings)

Button

[PAUSE]

[PAPER FEEDI

[FONT]

Notes: 1) Auto CR moves the next print position to the left margin when LF or ESC J code is sent.

2) ‘*’ is one beep, and ‘**’ is two beeps.

If no operation is executed within a few seconds, the printer exits the power on selection mode with

five beeps (*****).

The selected value is stored in non-volatile memory.

* The printer automatically becomes ready to print after the selection.

1.5.3

1.5.4

Buffer-full Printing

Hexadecimal Dump

Feature

Input buffer

Draft printing speed

Auto CR

valid (**) or invalid (*)

high (**) or normal (*)

valid (**) or invalid (*)

standard setting

Setting

Press the PAUSE button while turning on the printer to put the printer in hexadecimal dump mode. In this

mode, received data is printed out in hexadecimal format, along with the corresponding ASCII characters.

This function is useful to check received data from the host. If a received code is not a printable

the printer prints a period (.) in the ASCII column.

Figure 1-8. Hexadecimal Dump Printout

1-23

ASCll

character,

Page 33

REV.-A

1.5.5 Self Test

Press the PAPER FEED button while turning on the printer to put the printer in self-test mode. To stop the self

test, turn off the printer. (The control panel is still operational in self-test mode for paper handling and font

CSF,

selection. ) When pages are printed from the

the maximum number of printable lines is printed in the bottom line of the sheet and saved in non-volatile

memory as the default page length. Page lengths are saved individually when a dual bin

The self test prints out the following:

(a) Maximum printable lines (only on cut sheets from the

(b) Firmware version

(c) Current default settings

(d) Short help messages for control panel operation

(e) A Pattern of characters, as shown

below.

the first sheet is used for scaling the sheet length. Then,

CSF

is in use.

CSF)

Figure 1-9. Self Test Printout

1.5.6 Paper-out Detection

When the paper-out sensor detects a paper out, the printer enters the pause condition automatically after

feeding or printing several lines. When a paper-out is detected, load new paper properly and set the printer

ready to print by pressing

Auto Tear-off

1.5.7

When the release lever is set to one of the tractor positions, the paper advances to the tear-off position

automatically if the input data buffer is empty and the paper is at the top-of-form position (If the printer

receives no additional data after it has received a form feed). If subsequent data is sent to the printer, the paper

reverse feeds to the original position automatically and the printing starts. This function can be turned off in

the default setting mode.

1.5.8 Thermal Protection

When the printhead temperature exceeds 82 deg. C, the printer stops printing to protect the printer from

overheating.

the PAUSE button.

a.,

{ “

>,.,

..-”

1.5.9 High Duty Printing

the

The printer stops printing when

printer continues printing the rest at half speed.

printing duty is

too heavy

1-24

for the

printer’s power

supply. If it occurs, the

:“

.

Page 34

, 1.5.10 Sheet Loading and Sheet Ejection

The release lever engages or disengages the push-tractor unit drive mechanism. The lever’s operation

provides with improved paper-handling functions:

(a) Automatic cut sheet loading without the cut sheet feeder

REV.-A

Move the release

A few seconds later, the sheet is automatically loaded to the top-of-form position, and the printer becomes

ready to print.

(b) Automatic cut sheet loading and ejection with the cut sheet feeder

Move the release lever to the FRICTION position and load a stack of paper into the hopper of the cut sheet

feeder. Pressing the PAPER FEED button loads the sheet to the top-of-form position. If a paper-out is detected

before printing starts, the sheet is automatically loaded to the top-of-form position, without the PAPER FEED

button being pressed.

(c)

Continuous paper loading and ejection (paper park)

Move the release lever to REAR PUSH/FRONT PUSH position and load the paper into the tractor unit. Press

the PAPER FEED button to load the paper automatically to the top-of-form position. If a paper-out is detected

before printing starts, the paper is automatically loaded to the top-of-form position, without the PAPER FEED

button being pressed.

If the FONT+ PAPER FEED buttons are pressed when the continuous paper is loaded, the paper is ejected

backward to the paper park position. To feed several pages backward, repeat this operation several times.

Ievertothe

FRICTION position and load a sheet using the paper guide (top or optional front).

1.5.11 Adjust Lever Operation

The platen gap adjust lever must be set to the proper position (from the 8 step available) for the paper

thickness.lf this lever is set to the position 2 (4th step) or higher, printing speed and paper feeding speed will

be reduced.

Table 1-20. Lever Positions

Lever position Paper thickness

O (2nd step)

1 (3rd step)

I

I

Note: If printing density becomes lighter, move the platen gap adjust lever position one step closer.

2 (4th step)

3 (5th step)

I

I

0.06-0.12 mm

0.13-0.17 mm

0.18-0.25 mm

0.26-0.32 mm

1-25

Page 35

REV.-A

$

\

-=.

Position 1 (3rd step)

\

. .

r’

Platen Gap Adjust Lever

&’”

Q

Figure 1-10. Lever Positions

1.5.12 Printer Initialization

The printer is initialized in the following cases.

(1) When the printer is turned on.

(2) When the

When the printer is initialized, it performs the following functions:

● The printhead returns to the leftmost position (carriage home).

● The READY LED lights.

● The printer clears the print buffer and input data buffer.

● The line spacing is set to 1/6 inch.

● The page length and skip over perforation settings are returned to their default values.

● All vertical tab positions are cleared.

● The horizontal tab positions are set to every 8 columns.

● The print mode is set to the default value set from the control paneI and stored in non-volatile memory.

INIT

signal

or

CMREQ

(optional l/F ) is input.

4.-

TOF position will be reset in the following cases.

(1) Power on

(2)

INIT

signal or CMREQ (optional I/F)

(3) Sofiware reSet command

(4) Page length command

NOTE: The

CMREQ

system.

signal goes

(ESC @)

(ESC

C)

Low

when the command request is sent from the

1-26

optional card to

the main

Page 36

REV.-A

1.5.13 Buzzer

The buzzer beeps for 0.1 second at a time. These beep sounds a recombined in various ways, as shown below,

to indicate different meanings.

In the following table, each “*” stands for one beep.

Table 1-21. Buzzer Functions

Status

BEL

code

Carriage trouble

Voltage error

Fatal error

Incorrect memory

Paper error

Illegal paper

release/u nrelease

Recognition of

operation

Sound and Description

*

BEL

Sounds when a

code has been input.

*** ***

An error has occurred with the carriage position.

No beeps.

(Shown by indicators blinking sequentially in the clockwise direction.)

No beeps.

(Shown by indicators blinking simultaneously.)

** ** ** **

**

** ** ** **

**** **** **** ****

— RAM

2

PROM

— E

****

Continuous paper has run out.

CSF

Cut sheet paper from the

has run out.

No paper was present at the start of a self test.

A sheet could not be ejected from the

CSF.

***

Other paper detection error have occurred.

With single sheet feed selected, no paper is present.

Continuous paper can’t be loaded.

Paper

runs out after the PAPER FEED button has been

messed.

***** ***** *****... (continuously till corrected)

The release lever has been changed while there was paper in the paper

path.

Change the lever again or remove the paper in the path to stop the sound.

*

Power-on operation (self test, hex dump, default setting, power-on

selection)

CSF

bin-1 selected.

**

Micro feed

CSF

bin-2 selected.

*

The adjusted value set using micro feed is the same as the factory setting

value (loading position or tear-off position).

***** ***** *****... (continuously until button is released)

The micro feed value has reached its upper or lower limit.

1-27

Page 37

REV.-A

.

1.6 Main Components

The components of the

and repair.

The main components are:

BOARD ASSEMBLY,

(1)

BOARD ASSEMBLY,

(2)

BOARD ASSEMBLY, C076

(3)

Printer Mechanism

(4)

Housing Assembly

(5)

The following figure shows the main components of the FX-870/l 170.

Platen

FX-870/l 170 are

C094

MAIN

C094

PNL

PSB/PSE

Ga

designed for easy

removal

and replacement during maintenance

.::,

.

\

f’

Pril

f-::

-..

PSB/PSE

y,

C094

M

AIN

7

Figure 1-11. Main Components

1-28

”

1

Page 38

REV.-A

q.6.I BOARD ASSEMBLY,

Basically, the same board layout is used in both the 136-column model and the 80-column model. The CPU

on this board controls all the main functions of the printer.

E05A55YA gate array, an

CR MOTOR

~~~f~4M

HEAD DRIVE

TRANSISTOR . .

\\

4

C094

E2PROM,

PF MOTOR

DRIVER

LPAI 476H

~

0

o

MAIN (Main Control Circuit Board)

It consists of a

a PSRAM, a MASK ROM, motor drivers, and head drive transistors.

~>

n

,,,,,

Q=

CPU

TM

P90C041F

\’

Ill

1

— —

Cl”lp

——

CENTRONICS l/F

7

“

~—

q

E

/ I +7

~

TMP90C041F 8-bit CPU, an

o

E2PROM

“

*PS

RAM

”MASK

‘

OM

;~-

I

CN2

o

0

for OPTION

IF

T/ “

<136-column model>

PF MOTOR

DRIVER

pPA1476H

CR MOTOR

g;!f;24M

\

?r-

HEAD DRIVE

TRANSISTOR

r~;--o’”

00

,(0

0:

n:

0’

o

~

r

CPU

TM P90C041F

ml

0

~~

GATE ARRAY

E05A66YA

\//

r

–y

‘~

GATE ARRAY

E05A66YA

CENTRONICS l/F

-

qE2pR0M

,PS

E

I

0

“

‘

RAM

MASK ROM

CN2

for OPTION

-

l/F

c80-column model>

Figure 1-12. BOARD ASSEMBLY,

C094

MAIN (Main Control

1-29

Circuit

B-d

Page 39

REV.-A

.

1.6.2 BOARD ASSEMBLY, C094

This board functions as the control panel of the

switches, and three indicator LEDs.

Figure 1-13. BOARD ASSEMBLY,

PNL

(Control Panel Circuit Board)

FX-870/l

C094 PNL

170, and consists of a power switch, three function

(Control Panel Circuit Board)

K’.

*“

1.6.3 BOARD ASSEMBLY,

This board is composed of an input filter circuit, a transforming circuit, a switching regulator circuit, a

rectifying circuit, a smoothing circuit, and various protecting circuits.

C076 PSB/PSE

(Power Supply Circuit Board)

,.~..

f..;

Figure 1-14. BOARD ASSEMBLY,

C076 PSB/PSE

(Power Supply Circuit Board)

1-30

Page 40

REV.-A

1.6.4 Printer Mechanism

The printer mechanism consists of a 9-pin impact dot head, a carriage mechanism, a carriage motor, a paPer

feed mechanism, a paper feed motor, a ribbon feed mechanism, and various sensors.

<136-column

<80-column model>

Figure 1-15. Printer Mechanism

1-31

Page 41

REV.-A

1.6.5 Housing Assembly

The printer mechanism and all the boards are contained in a housing assembly that consists of the uppercase

and the lower case.

Printe

Upper

.

L

Lower

Front Co

Figure 1-16. Housing Assembly

.-,. .

{’

:..:;

,..

1-32

Page 42

CHAPTER 2

OPERATION PRINCIPLES

REV.-A

2.1 Printer

2.2 Power

2.3

Control Circuit Operation

Mechanism Operation

Printhead

2.1.1

Carriage Mechanism

2.1.2

Platen Gap Adjustment

2.1.3

Paper Handling Mechanisms

2.1.4

2.1.4.1 Paper Feed Mechanisms

2.1.4.2 Paper Advance Mechanisms

2.1.4.3 Paper Paths

Ribbon Advance Mechanism

2.1.4

Supply Operation

Power Supply Overview

2.2.1

Power Supply Circuit Operation

2.2.2

Control Circuit Operation Overview

2.3.1

Reset Circuit

2.3.2

Sensor Circuits

2.3.3

Carriage Motor Drive Circuit

2.3.4

Paper Feed Motor Drive Circuit

2.3.5

Printhead

2.3.6

Parallel Interface Circuit

2.3.7

E2pRoM Control circuit

2.3.8

Mechanism

Drive Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-1

2-3

2-4

2-5

2-5

2-6

2-13

2-18

2-19

2-19

2-20

2-22

2-22

2-25

2-26

2-27

2-28

2-23

2-29

2-30

Z.i

Page 43

REV.-A

.

LIST OF FIGURES

Figure 2-l. Howthe

Figure 2-2. Carriage Operation . . . . . . . . . . . . . . . . . . .

Figure 2-3. Platen Gap Adjust Lever

Figure 2-4. Friction Advance Operation UsingtheTop Paper Entrance ...........2-6

Figure 2-5. Push Tractor Operation Using the Rear Paper Entrance .................2-7

Figure 2-6. Push Tractor Operation Using the Front Paper Entrance ................2-8

Figure 2-7. Pull Tractor Operation Using the Bottom Paper Entrance ..............2-9

Figure 2-8. Push-Pull Tractor Operation Using the Rear Paper Entrance

Figure 2-9. Push-pull Tractor Operation Using the Front Paper Entrance ......2-11

Figure 2-10. Release Lever

Figure 2-11. Release Lever Setting Function

Figure 2-12. Paper Path for Friction Feeding Using the Top Entrance ............2-13

Figure 2-13. Paper Path for Push Tractor Feeding

Ftgure

2-14. Paper Path for Pull Tractor Feeding Using the Rear Entrance ....2-14

figure

2-15. Paper Path for push-pull Tractor Feeding Using the Rear Entrance .....2-15

Figure 2-16. Paper Path for Pull Tractor Feeding Using the Bottom Entrance .........2-15

Figure 2-17. Paper Path for Friction Feeding Using the Front Entrance

Figure 2-18. Paper Path for Push Tractor

figure

2-19. Paper Path for Pull Tractor Feeding Using the Front Entrance ...2-17

Figure 2-20. Paper Path for Push-pull Tractor Feeding Using the Front

Figure 2-21. Ribbon Advance Mechanism

Figure 2-22. Power Supply Circuit Block Diagram

Figure 2-23. Control Circuit Block Diagram

figure

2-24. Data flow

figure

2-25. Power On Reset Circuit

figure

2-26. Sensor Circuit Block Diagram

Figure 2-27. Carriage Motor Drive Circuit

Figure 2-28. Paper Feed Motor Drive Circuit

Figure 2-29.

Figure 2-30. Parallel Interface Circuit

Figure 2-31. E2PROM Control Circuit

Printhead

Printhead

Drive Circuit

Works

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.~.--........-..-..

.

--~...f~~.~~..~.~~.-.----~~..-

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Uskg

l%eding Ueingthe

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................2-2

2-3

2-4

........2-lO

2-12

2-12

the Rear

Front

EntTence............2-l4

..........2-l6

En&ance

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

..........2-16

Entrence....2-l7

2-18

2-21

2-22

2-23

2-25

2-26

2-27

2-28

2-29

2-29

2-30

.’%

c’

.

.

%

...4

LIST OF TABLES

Table 2-1. Paper Feed Methods and Paper Entrances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-2. Ribbon Advance Gear Linkage

Table 2-3. Power Supply Input Voltages and Fuse Ratings

Table 2-4. Power Supply Output Voltages and Applications ...........................2-19

Table 2-5. Functions of Main Components of C094 MAIN

Table 2-6. Carriage Motor Drive Modes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

................................2-24

.............................................................2.27

Z.ii

.

2-5

2-18

2-19

Page 44

2.1 Printer Mechanism Operation

REV.-A

This section describes the printer mechanism of the

FX-870/l

The

parts: 1) the

4) the ribbon advance mechanism. Each of these is described below.

170 printer mechanism features a 9-pin impact dot printhead for

printhead mechanism, 2) the carriage movement mechanism, 3) the paper feed mechanism, and

FX-870/l

170 printer and explains how the printer works.

seriaI

Printin9. It has four main

2.1.1 Printhead Mechanism

The

printhead

a column of 9 wires. Each of these wires has a drive coil which causes the wire to move in and out of the

printhead to print each dot. The four steps below describe how these driving wires work.

(1) The control

voltage, and current flows through the corresponding

generates a magnetic force.

Thisinducedforce causesthe plate toapproach the coil rod andtheassociated dotwire is rapidly ejected

(2)

to impact on the platen.

(3) The dot wire presses the ink ribbon up against the paper as it hits the platen and in this way prints a dot

on the paper.

mechanism consists of the

circuit

outputs drive signals to the printhead drive circuit. This changes the printhead drive

printhead

itself, the ink ribbon, and the platen. The printhead contains

printhead

coil. The coil acts as a solenoid and

(4 As

soon as the current through the coil is switched off, the force induced in the coil rod stops. The plate

then returns to its original position (the position assumed before the coil was energized) through the

action of the plate spring. After the dot wire hits the platen, the rebounding force of hitting the platen works

with the wire resetting spring to pull the wire back to its original position.

2-1

Page 45