Page 1

Display Attached Controller

@E.Terminal for MC

USER'S MANUAL

Hardware

FEH300b

Page 2

Preface

This hardware edition of the user’s manual describes system composition, specifications, and handling of the @E.Terminal.

In order to operate the hardware properly, please read this user’s manual carefully. When using modules or peripheral

devices, be sure to read the corresponding user’s manuals listed below.

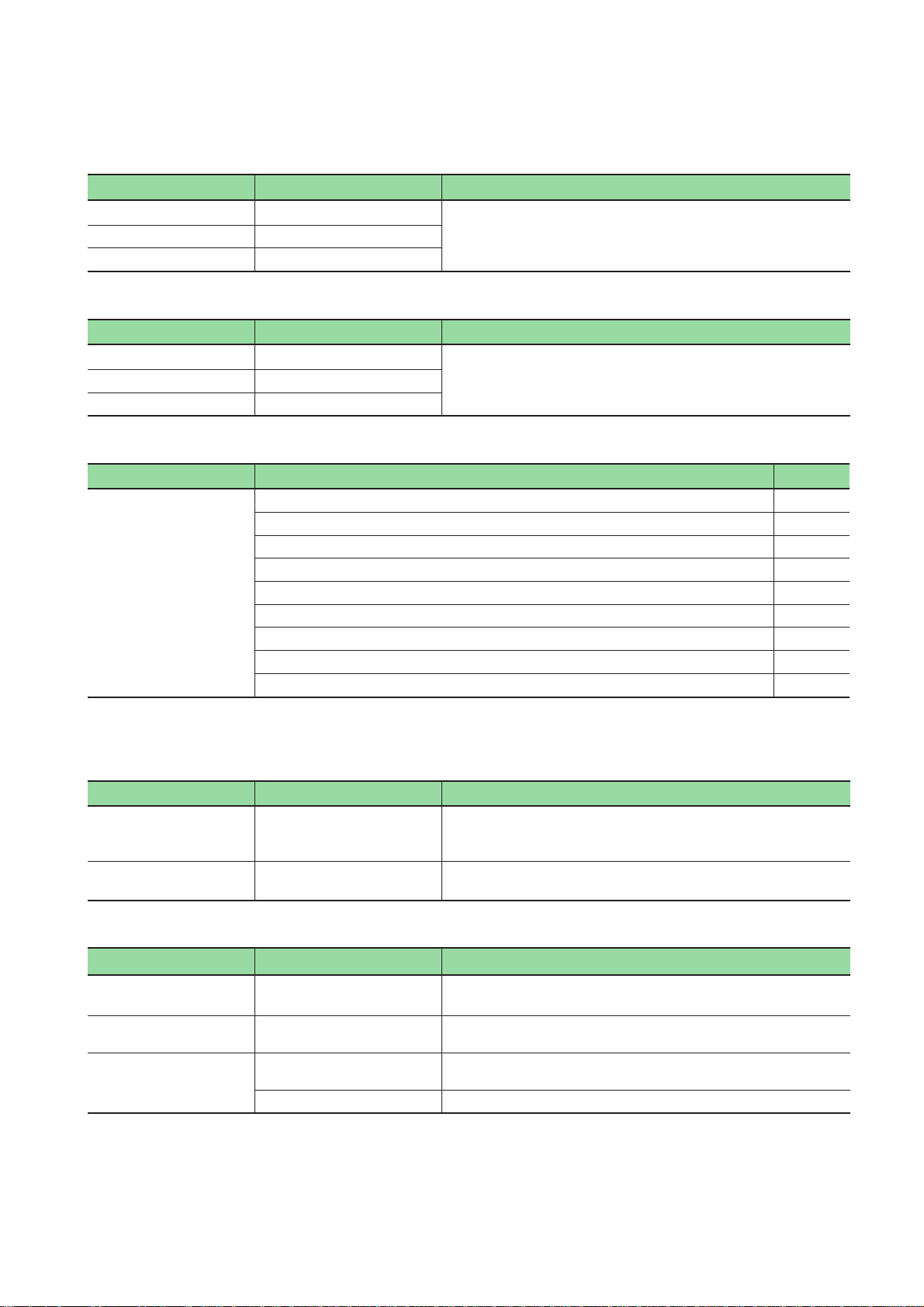

Title Manual No. Contents

@E.Terminal for MC

User's Manual <Function>

V8 series Hardware Specifications 2016NEx Hardware specifications and handling procedures of the

V8 series Reference Manual 1055NEx Describes functions and the usage of the MONITOUCH

V series Macro Reference 1056NEx Describes overview of the macro of the V-SFT version 5,

V8 series Introductory Manual 1057NEx Describes basic operation of the MONITOUCH V8 series.

V8 series Connection Manual 2201NEx The connection and communication parameters for the V8

User's Manual Hardware, MICREX-SX series

SPH

User's Manual Instruction (Standard Loader),

MICREX-SX series

User's Manual SX-Programmer Standard

<Reference>, MICREX-SX series

User's Manual Instruction (D300win),

MICREX-SX series

User's Manual D300win <Reference>,

MICREX-SX series

FALDIC α series User's Manual, RYS-V Type MHT258 (Eng) Describes the specifications and operations of FALDIC α

ALPHA 5 series User's Manual,

RYT-V Type

FEH301 Describes functions and the usage of motion control

content for @E.Terminal for MC.

MONITOUCH V8 series are explained.

V8 series.

the usage of the macro editor and contents of the macro

commands.

series and controllers are explained in detail.

FEH201 Describes the system configuration, the specifications and

operations of modules in the MICREX-SX series.

FEH588 Describes the memory, language and system definitions of

the MICREX-SX series.

FEH590 Describes the menu and icon of the SX-Programmer

Standard all of the operations of the SX-Programmer

Standard.

FEH200 Describes the memory, language and system definitions of

the MICREX-SX series.

FEH257 Describes the menu and icon of D300winV3 and all of the

operations of D300winV3.

series.

MEHT300 Describes the specifications and operations of ALPHA 5

series.

In addition to the above manuals, the following Fuji Electric Systems Co., Ltd. site offers var ious manuals and technical

documents associated with the @E.Terminal for MC.

URL http://www.fesys.co.jp/eng/

Notes

1. This manual may not be reproduced in whole or part in any form without prior written approval by the manufacturer.

2. The contents of this manual (including specifications) are subject to change without prior notice.

3. If you find any ambiguous or incorrect descriptions in this manual, please write them down (along with the manual

No. shown on the cover) and contact FUJI.

Page 3

Be sure to read the “Safety Precautions” thoroughly before using the module.

Warning

◊ Never use the output signal of @E.Terminal for operations that may threaten human life or damage the system, such

as signals used in case of emergency. Please design the system so that it can cope with the malfunctions of a touch

switch. A malfunction of a touch switch will result in machine accident or damage.

◊ Turn off the power supply when you set up the unit, connect new cables or perform maintenance or inspections.

Otherwise, electrical shock or damage may occur.

◊ Never touch any terminals while the power is on. Otherwise, electric shock may occur.

◊ You must put a cover on the terminals on the unit when you turn the power on and operate the unit. Otherwise,

electric shock may occur.

◊ The liquid crystal in the LCD panel is a hazardous substance. If the LCD panel is damaged, do not ingest the leaked

liquid crystal. If the liquid crystal spills on skin or clothing, use soap and wash off thoroughly.

◊ Never disassemble, recharge, deform by pressure, short-circuit, reverse the polarity of the lithium battery, nor dispose

of the lithium battery in fire. Failure to follow these conditions will lead to explosion or ignition.

◊ Never use a lithium battery that is deformed, leaks, or shows any other signs of abnormality. Failure to follow these

conditions will lead to explosion or ignition.

◊ The power lamp flashes when the backlight is at the end of life or is faulty. However, the switches on the screen are

operable at this time. Do not touch the screen when the screen becomes dark and the power lamp flashes.

Otherwise, a malfunction may occur and result in machine accident or damage.

Here, the safety precaution items are classified into “Warning” and “Caution.”

Safety Precautions

Warning

Caution

Even some items indicated by “Caution” may also result in a serious accident.

Both safety instruction categories provide important information. Be sure to strictly observe these instructions.

: Incorrect handling of the device may result in death or serious injury.

: Incorrect handling of the device may result in minor injury or physical damage.

Page 4

Safety Precautions

Caution

◊ Check the appearance of the unit when it is unpacked. Do not use the unit if any damage or deformation is found.

Failure to do so may lead to fire, damage or malfunction.

◊ For use in a facility or for a system related to nuclear energy, aerospace, medical, traffic equipment, or mobile

installations, please consult your local distributor.

◊ Operate (or store) @E.Terminal under the conditions indicated in this manual and related manuals. Failure to do so

could cause fire, malfunction, physical damage or deterioration.

◊ Understand the following environmental limits for use and storage of @E.Terminal. Otherwise, fire or damage to the

unit may result.

- Avoid locations where there is a possibility that water, corrosive gas, flammable gas, solvents, grinding fluids or

cutting oil can come into contact with the unit.

- Avoid high temperature, high humidity, and outside weather conditions, such as wind, rain or direct sunlight.

- Avoid locations where excessive dust, salt, and metallic particles are present.

- Avoid installing the unit in a location where vibration or physical shock may be transmitted.

◊ Equipment must be correctly mounted so that the main terminal of @E.Terminal will not be touched inadvertently.

Otherwise, an accident or electric shock may occur.

◊ Check periodically that terminal screws on the power supply terminal block and fixtures are firmly tightened. Loosened

screws may result in fire or malfunction.

◊ Tighten terminal screws on the power supply terminal block of display part equally to a torque of 0.8 N·m for the

NP5M0101-5H4/4H4, NP5N0011-5H4/4H4, or 1.2 N·m for the NP5M0101-3H4/NP5N-0011-3H4. And tighten terminal

screws on the power supply terminal block of the controller unit equally to a torque of 0.5 to 0.6 N·m. Improper

tightening of screws may result in fire, malfunction, or trouble.

◊ Tighten mounting screws on the unit equally to a torque of 0.5 to 0.7 N·m. Excessive tightening may distort the panel

surface. Loose tightening may cause @E.Terminal to come off, malfunction or be short-circuited.

◊ @E.Terminal has a glass screen. Do not drop or give physical shock to the unit. Otherwise, the screen may be

damaged.

◊ Connect the cables correctly to the terminals of @E.Terminal in accordance with the specified voltage and wattage.

Over-voltage, over-wattage, or incorrect cable connection could cause fire, malfunction or damage to the unit.

◊ Be sure to establish a ground of @E.Terminal. The FG terminal must be used exclusively for the unit with the level of

grounding resistance less than 100Ω. Otherwise, electric shock or a fire may occur.

◊ Prevent any conductive particles from entering into @E.Terminal. Failure to do so may lead to fire, damage, or

malfunction.

◊ After wiring is finished, remove the paper used as a dust cover before starting to operate @E.Terminal. Operation with

the cover attached may result in accident, fire, malfunction, or trouble.

◊ Do not attempt to repair @E.Terminal at your site. Ask us or the designated contractor for repair.

◊ Do not repair, disassemble or modify @E.Terminal. We are not responsible for any damages resulting from repair,

disassembly or modification of @E.Terminal that was performed by an unauthorized person.

◊ Do not use a sharp-pointed tool when pressing a touch switch. Doing so may damage the screen. Doing so may

damage the screen.

◊ Only experts are authorized to set up the unit, connect the cables or perform maintenance and inspection.

◊ Lithium batteries contain combustible material such as lithium or organic solvent. Mishandling may cause heat,

explosion or ignition resulting in fire or injury. Read related manuals carefully and handle the lithium battery correctly

as instructed.

◊ When using @E.Terminal that has analog switch resolution with resistance film, do not press two or more points on the

screen at the same time. If two or more positions are pressed at the same time, the switch located between the

pressed positions activates.

◊ Take safety precautions during such operations as setting change during running, forced output, start, and stop.

Any misoperation may cause unexpected machine motions, resulting in machine accident or damage.

◊ In facilities where a failure of @E.Terminal could lead to accident threatening human life or other serious damage, be

sure that the facilities are equipped with adequate safeguards.

◊ At the time of disposal, @E.Terminal must be treated as industrial waste.

◊ Before touching @E.Terminal, discharge static electricity from your body by touching grounded metal. Excessive static

electricity may cause malfunction or trouble.

◊ The LED lamp on the CF card interface cover illuminates in red when the power is supplied to the CF card.

Never remove the CF card or turn off the power of @E.Terminal while the LED lamp is lit. Doing so may destroy the

data on the CF card. Check that the LED lamp has gone off before removing the CF card or turning off the power of

@E.Terminal.

Page 5

Safety Precautions

[General Notes]

• Never bundle control cables nor input/output cables with high-voltage and large-current carrying cables such as

power supply cables. Keep these cables at least 200 mm away from the high-voltage and large-current carrying

cables. Otherwise, malfunction may occur due to noise.

• When using @E.Terminal in an environment where a source of high-frequency noise is present, it is recommended

that the FG shielded cable (communication cable) be grounded at its ends. However, the cable may be grounded

only at one end if this is necessary due to unstable communication conditions or for any other reason.

• Plug connectors or sockets of @E.Terminal in the correct or ientation. Failure to do so may lead to damage or

malfunction.

• If a LAN cable is inserted into the MJ1 or MJ2 connector on @E.Terminal, the counterpart device may be

damaged. Check the indication on the unit and insert a cable into the correct position.

• Do not use thinners for cleaning because they may discolor @E.Terminal surface. Use alcohol or benzine

commercially available.

• If a data receive error occurs when @E.Ter minal and the counterpart (PLC, temperature controller, etc.) are

started at the same time, read the manual for the counterpart unit and remove the error correctly.

• Avoid discharging static electricity on the mounting panel of @E.Terminal. Static charges can damage the unit and

cause malfunctions. Otherwise, malfunction may occur due to noise.

• Avoid prolonged display of any fixed pattern. Due to the characteristics of the liquid crystal display, an afterimage

may occur. If a prolonged display of a fixed pattern is expected, use the auto OFF function of the backlight.

[Notes on LCD]

Note that the following conditions may occur under normal circumstances.

• The response time, brightness and colors of @E.Terminal may be affected by the ambient temperature.

• Tiny spots (dark or luminescent) may appear on the display due to the liquid crystal characteristics.

• There are variations in brightness and colors on each unit.

• Cold cathode tubes are incorporated into the LCD display for backlights. Optical properties (brightness, irregular

colors, etc.) may change in a low-temperature environment or over time of operation.

Page 6

*Manual No. is shown on the cover.

Printed on *Manual No. Revision contents

Aug. 2008 FEH300 First edition

Nov. 2008 FEH300a • Display part is changed from UG40 series to V8 series.

• Accessory "Noise filter" is eliminated from controller hardware version "03" or later.

Dec. 2008 FEH300b @E.Terminal (No contents installed) was added.

Revisions

Page 7

Contents

Preface

Safety Precautions

Revisions

Contents

Page

Section 1 General ..........................................................................................1-1

1-1 Overview of @E.Terminal for MC.................................................................................................. 1-1

1-2 Appearance ..................................................................................................................................... 1-2

1-3 Types................................................................................................................................................ 1-3

1-4 System Composition...................................................................................................................... 1-5

Section 2 Specifications ...............................................................................2-1

2-1 Specifications ................................................................................................................................. 2-1

2-1-1 General specifications ........................................................................................................................... 2-1

2-1-2 Display unit specifications ..................................................................................................................... 2-2

2-1-3 Controller unit specifications ................................................................................................................. 2-6

2-2 Dimensions and Panel Cut-out ..................................................................................................... 2-8

2-2-1 External dimensions and panel cut-out dimensions for the NP5M0101-5H4/NP5N0011-5H4............ 2-8

2-2-2 External dimensions and panel cut-out dimensions for the NP5M0101-4H4/NP5N0011-4H4............ 2-9

2-2-3 External dimensions and panel cut-out dimensions for the NP5M0101-3H4/NP5N0011-3H4.......... 2-10

2-3 Names and Functions .................................................................................................................. 2-11

2-3-1 Display unit .......................................................................................................................................... 2-11

2-3-2 Controller unit ...................................................................................................................................... 2-14

2-4 Serial Connector........................................................................................................................... 2-16

2-5 Modular Jack (MJ1 / MJ2)............................................................................................................ 2-17

2-6 Dip Switches ................................................................................................................................. 2-18

Section 3 Installation ....................................................................................3-1

3-1 Mounting Procedure ...................................................................................................................... 3-1

3-2 Power Supply Cable Wiring ........................................................................................................... 3-2

Section 4 Inspection and Maintenance .......................................................4-1

4-1 Inspection and Maintenance ......................................................................................................... 4-1

4-1-1 Daily inspection ..................................................................................................................................... 4-1

4-1-2 Periodical inspection ............................................................................................................................. 4-1

4-2 Battery Replacement ..................................................................................................................... 4-2

4-3 Maintenance Services.................................................................................................................... 4-4

4-3-1 Ordering notes....................................................................................................................................... 4-4

4-3-2 Free-of-charge warranty period and scope of warranty........................................................................ 4-4

4-3-3 Service costs ......................................................................................................................................... 4-4

Appendix 1

About Project for @E.Terminal (No contents installed)

...

App.

1-1

Page 8

Section 1 General

Page

1-1 Overview of @E.Terminal for MC...............................................................................1-1

1-2 Appearance ................................................................................................................. 1-2

1-3 Types ............................................................................................................................1-3

1-4 System Composition ..................................................................................................1-5

Page 9

Section 1 General

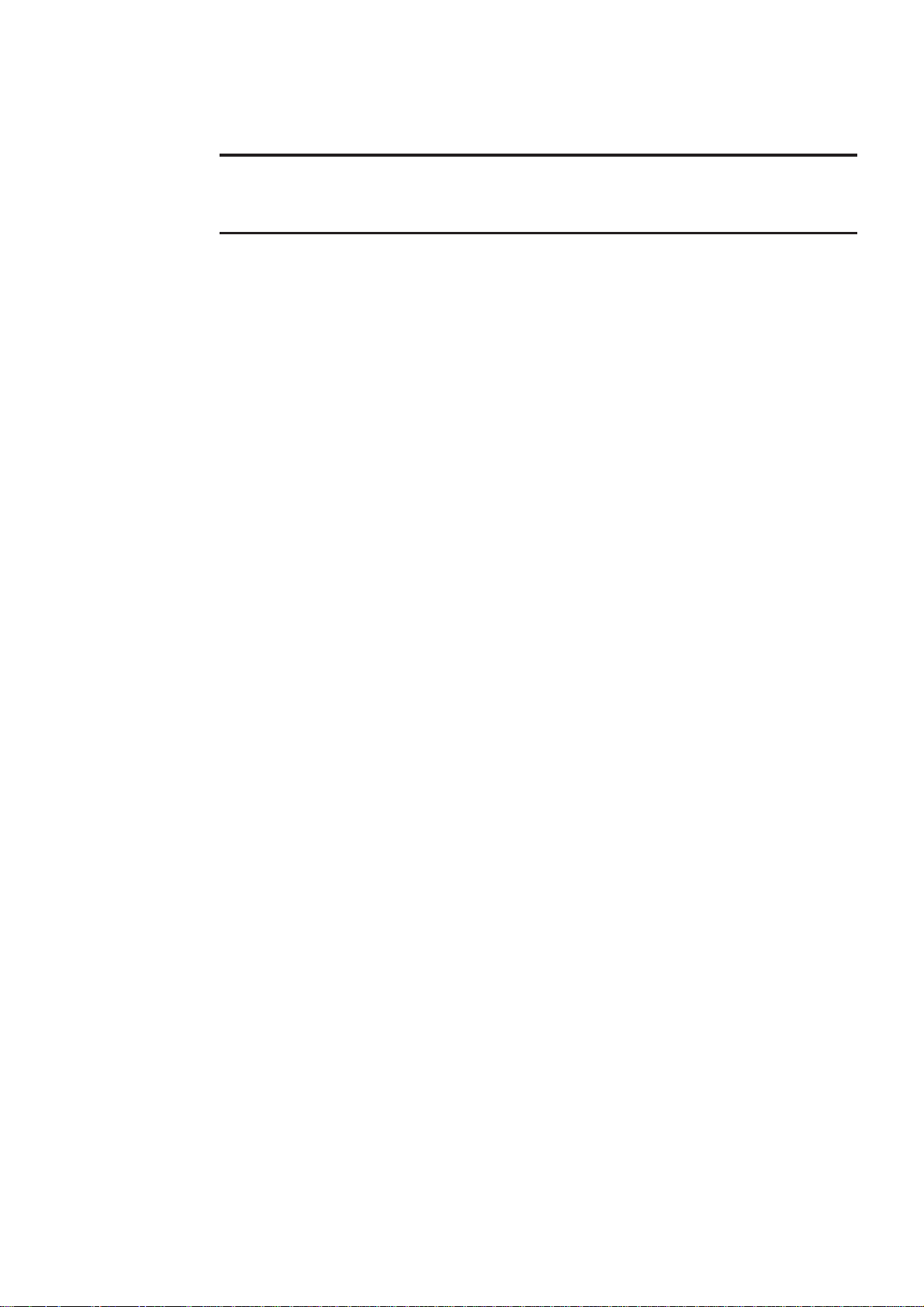

1-1 Overview of @E.Terminal for MC

The @E.Terminal for MC Display Attached Controller is an all-in-one programmable operation displa y and motion controller.

Features:

1) The guidance function of the display screen allows you to easily set up parameters and positioning data

previously set up by a dedicated machine.

Also, it enables easy equipment maintenance.

2) The SX bus allows one-touch connection of up to eight servo amplifiers (axes) (FALDIC-α and APLHA5 VS

type), minimizing the need for wires.

3) The upper level controller can be connected by Ethernet and the like.

4) The lineup includes three different display screen sizes. 8 inch, 10 inch and 12 inch models are available.

5) The content corresponding to motion is supplied in the standard package.

Content for PTP control and synchronous control (ratio synchronization, cycle synchronization, flying shear, and

rotary shear) are provided.

Ethernet, ctc.

@E.Terminal for MC

Contents for motion control

• Screen data

• Controller built-in software

Motion functions

(Setting/Display)

SX bus Note)

Note: The SX bus is a MICREX-SX series dedicated high-speed serial bus.

1-1

Page 10

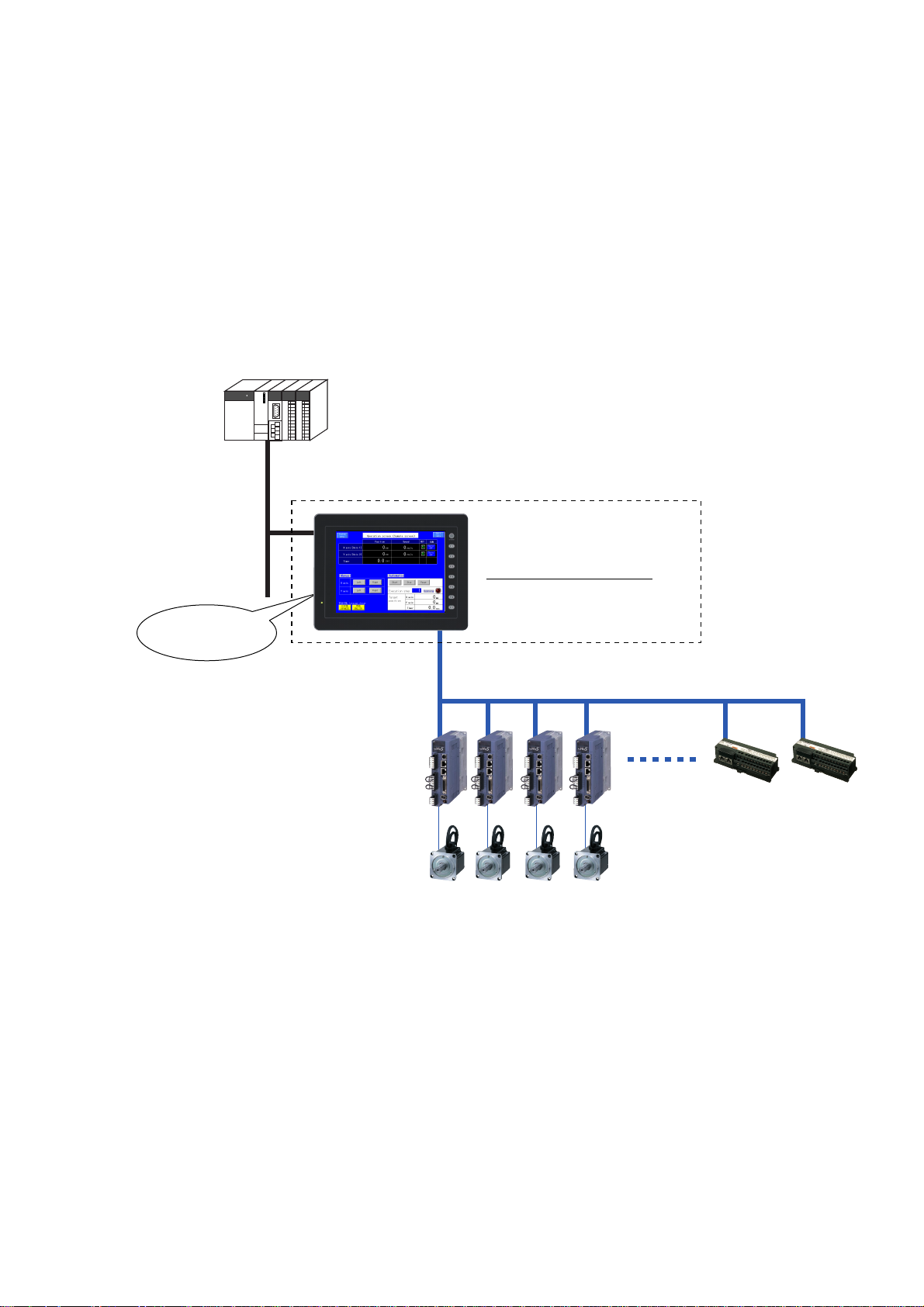

1-2 Appearance

@E.Terminal for MC is composed of a programmable operation display (the display unit) and a controller unit attached to

the back of the display unit.

The controller unit is attached with screws to the connector area of the communication unit at the back of the display unit,

similar to the way in which the communication unit is attached.

Type 12

Controller unit

Type 10

Type 8

Front

Display unit

SX-BUS

Side

Controller unit

CN5

ONL

ERR

UROM

RUN

IN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CPU

No.

OUT

+

24V DC

FG

MJ2

MJ1

USER ROM CARD

USB

LOADER

CN1

CN7

CF

LAN

U-AU-B

Back

1-2

Page 11

1-3 Types

• @E.Terminal for MC

Product types Display size Specifications

NP5M0101-5H4 12.1 inches

NP5M0101-4H4 10.4 inches

NP5M0101-3H4 8.4 inches

• @E.Terminal (No contents installed)

Product types Display size Specifications

NP5N0011-5H4 12.1 inches

NP5N0011-4H4 10.4 inches

NP5N0011-3H4 8.4 inches

• Accessories

Product types Names Quantity

NP5M0101-5H4

NP5M0101-4H4

NP5M0101-3H4

NP5N0011-5H4

NP5N0011-4H4

NP5N0011-3H4

Instruction Manual 1

Backup CD of the @E.Terminal for MC Note1) 1

SX bus terminating plug 2

Screw driver 1

Fixture 4

Binder for USB cable (Only NP5M0101-3H4/NP5N0011-3H4) 1

USB cable cramp for port A/B (Only NP5M0101-5H4/4H4, NP5N0011-5H4/4H4) 2

M3 x 8 screw for USB cable cramp (Only NP5M0101-5H4/4H4, NP5N0011-5H4/4H4) 2

Noise filter Note2) 1

• TFT color, 800 x 600 dots, DC power supply

• Controller unit

• Contents of the motion control

(Screen data, built in software in the controller)

• TFT color, 800 x 600 dots, DC power supply

• Controller unit

• No contents installed

Note 1: Backup CD is not attached to NP5N0011-5H4/4H4/3H4.

Note 2: Noise filter is not attached from controller unit hardware version “03” or later.

• Screen drawing tools

Names Types Specifications

Configuration software:

English version

Screen data transfer cable V-CP 3m, Used for connection between the V8 series and a personal

V-SFT-5 Screen editor:

Windows98SE/NT4.0/Me/2000/XP/XP64Edition/Vista32-bit

compatible

computer.

• Programming support tool for controller

Names Types Specifications

SX-Programmer Standard NP4H-SWN Programming support tool SX-Programmer Standard,

SX-Programmer Expert

(D300win)

Support tool cable NW0H-CNV RS-232C/RS-485 converter for the programming support tool for AT

NP4H-SEDBV3 IEC61131-3 based on Programming support tool D300winV3,

NW0H-CA3 Support tool connection cable (Used to combined the NW0H-CNV)

Standard expansion FB, Windows95/98/ME/2000/XP/NT4.0

Standard expansion FB, Windows2000/XP/NT4.0

compatible personal computer

1-3

Page 12

1-3 Types

• Auxiliaries and others

Names Types Specifications

Battery for display unit V7-BT Replacement lithium primary battery for the V8 series

Replacement backlight for

TFT

Battery for controller NP8P-BT Primary lithium battery for memory data backup for controller unit

SX bus terminating plug NP8B-BP For SX bus loop terminating (1 piece)

SX bus expansion cabl NP1C-P3 Cable length: 300mm

V812-FL Replacement backlight for V812 TFT

V810-FL Replacement backlight for V810S TFT

V808S-FL Replacement backlight for V808S TFT

NP1C-P6 Cable length: 600mm

NP1C-P8 Cable length: 800mm

NP1C-02 Cable length: 2000mm

NP1C-05 Cable length: 5000mm

NP1C-10 Cable length: 10000mm

NP1C-15 Cable length: 15000mm

NP1C-25 Cable length: 25000mm

* For information about peripheral accessories of the display unit not documented in this manual, please refer to “V8

series Hardware Specifications (2016NEx)”.

1-4

Page 13

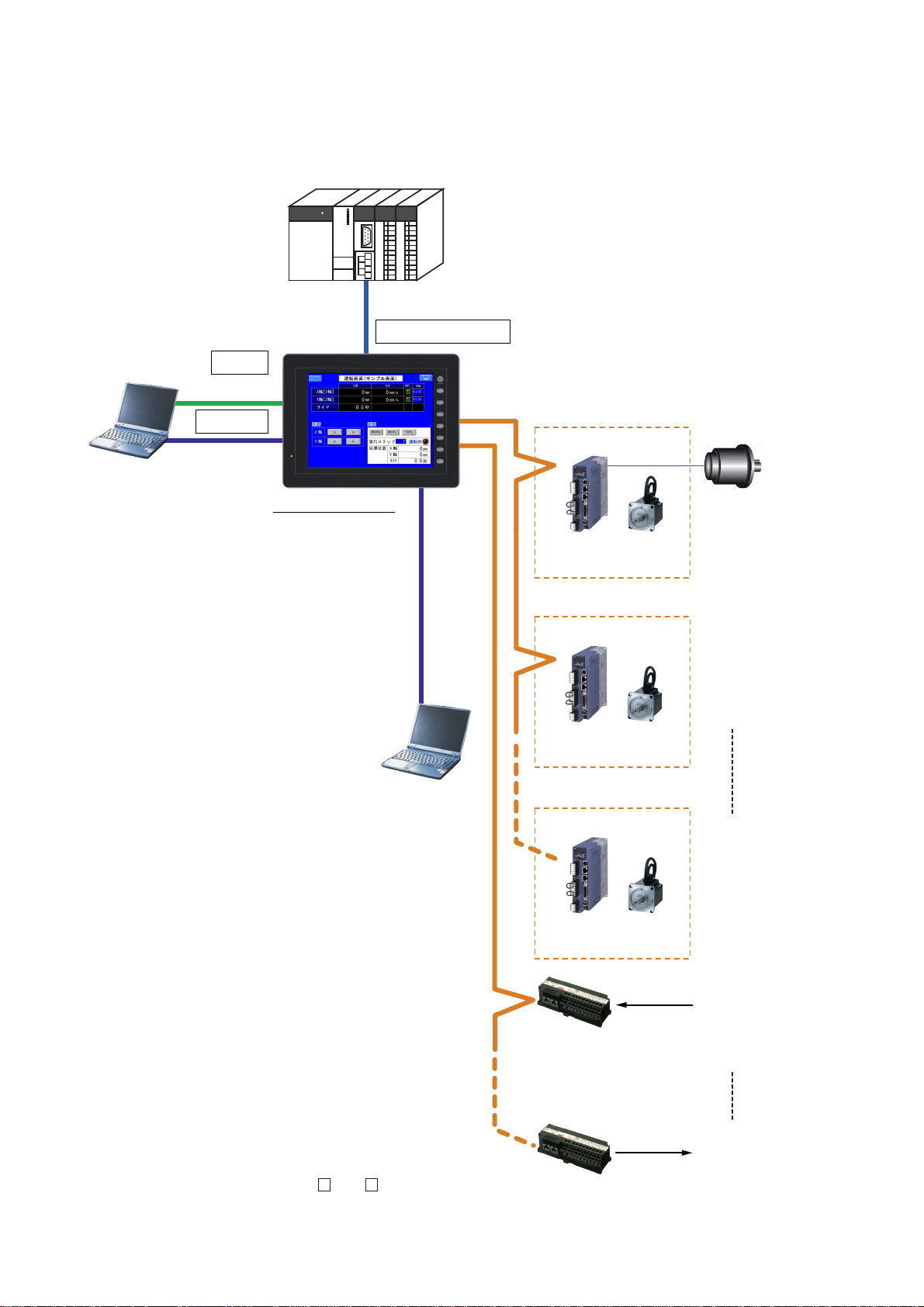

1-4 System Composition

@E.Terminal for MC

Screen editor

"V-SFT-5"

(V5.3.0.0 or later)

SX bus

Ethernet/RS-232C or RS-485

LAN/CN1/MJ1/MJ2

USB-B

MJ1/MJ2

External PG

(only No. 1 axis)

[No. 1 axis]

SX bus station No.: "201"

[No. 2 axis]

SX bus station No.: "202"

[No. 8 axis]

SX bus station No.: "208"

FALDIC ALPHA5

FALDIC - α

FALDIC ALPHA5

FALDIC - α

FALDIC ALPHA5

FALDIC - α

"V-CP"

Up to 8 servos and I/O terminals each

can be connected.

SX bus station No.: "221"

SX bus station No.: "228"

I/O terminal

Input 8 points/

Output 8 points

(NR1SW-16T65DT)

I/O terminal

Input 8 points/

Output 8 points

(NR1SW-16T65DT)

Starting up signal etc.

RDY etc.

Programming support tool

SX-Programmer Standard

"NP4H-SWN" (V2.3.5.1 or later)

SX-Programmer Expert (D300win)

"NP4H-SEDBV3" (V3.4.4.0 or later)

"NW0H-CNV + NW0H-CA3"

or

commercially available USB cable

PLC/general purpose

computer

The following illustration shows the system composition of @E.Terminal for MC.

Note) Connectable servo amplifier

FALDIC- α (RYS***S3-VSS, RYS***M3-VSK)

FALDIC ALPHA5 (RYT*** 5-VS )

1-5

Page 14

Section 2 Specifications

Page

2-1 Specifications.............................................................................................................. 2-1

2-1-1 General specifications........................................................................................................... 2-1

2-1-2 Display unit specifications..................................................................................................... 2-2

(1) Display unit specifications....................................................................................................................... 2-2

(2) Touch switch specifications .....................................................................................................................2-2

(3) Function switch specifications.................................................................................................................2-2

(4) Interface specifications ...........................................................................................................................2-3

(5) Clock and backup memory specifications............................................................................................... 2-3

(6) Drawing environment ..............................................................................................................................2-4

(7) Display function specifications ................................................................................................................2-4

(8) Function performance specifications ......................................................................................................2-5

2-1-3 Controller unit specifications ................................................................................................. 2-6

(1) Application performance specifications...................................................................................................2-6

(2) Specific system memory .........................................................................................................................2-7

2-2 Dimensions and Panel Cut-out..................................................................................2-8

2-2-1 External dimensions and panel cut-out dimensions for the

NP5M0101-5H4/NP5N0011-5H4.......................................................................................... 2-8

2-2-2 External dimensions and panel cut-out dimensions for the

NP5M0101-4H4/NP5N0011-4H4 .......................................................................................... 2-9

2-2-3 External dimensions and panel cut-out dimensions for the

NP5M0101-3H4/NP5N0011-3H4 ........................................................................................ 2-10

2-3 Names and Functions............................................................................................... 2-11

2-3-1 Display unit.......................................................................................................................... 2-11

(1) NP5M0101-5H4/NP5N0011-5H4.......................................................................................................... 2-11

(2) NP5M0101-4H4/NP5N0011-4H4.......................................................................................................... 2-11

(3) NP5M0101-3H4/NP5N0011-3H4.......................................................................................................... 2-12

2-3-2 Controller unit...................................................................................................................... 2-14

2-4 Serial Connector .......................................................................................................2-16

2-5 Modular Jack (MJ1 / MJ2)......................................................................................... 2-17

2-6 Dip Switches.............................................................................................................. 2-18

Page 15

Section 2 Specifications

2-1 Specifications

2-1-1 General specifications

Items

Physical

environmental

conditions

Mechanical

working

conditions

Electrical

working

conditions

Power supply Rated input voltage 24V DC (Note2)

Isolation resistance 500 V DC, 5 MΩ or more

Dimensions WxHxD(mm) 326.4 x 259.6 x 99.0 303.8 x 231.0 x 99.0 233.0 x 178.0 x 96.0

Mass Approx. 3.5 kg Approx. 3.1 kg Approx. 2.1 kg

Note 1) Pollution degree 2: This pollution does not conduct usually, but under certain circumstances temporary

Note 2) Use 24V DC power supply which comply to UL standard Class2 insulation.

Operational ambient

temperature

Storage ambient

temperature

Operational ambient

humidity

Operational altitude 2000 m or less above sea level (Transport condition: 70 kPa or more)

Operational atmosphere No corrosive gas, no excessive dust, no conductive dust contamination, and

Pollution degree 2 (Note1)

Vibration resistance Half-amplitude: 0.075 mm, acceleration: 9.8 m/s

Shock resistance Peak acceleration: 147 m/s

Noise resistance Rising time: 1 ns, pulse width: 1 µs, Noise voltage: 1.5 kVp-p

Static electricity

discharge resistance

Rated voltage (tolerance) 24V DC ±10%

Permissible momentary

power failure

power supply consumption

(Max. rated)

Rush current 170 A or less

Input terminal block

Display unit Terminal block screw: M3.5 - (Connection to the

Controller unit Terminal block screw: M3

Dielectric strength 500 V AC 1 minute (Between external terminals and frame ground)

conductivity occurs due to condensation.

Specifications

NP5M0101-5H4

NP5N0011-5H4

0to+50°C

-10 to +60 °C

85 % RH or less

(Without dew condensation, max. wet-bulb temperature: 39 °C or less)

not stained with organic solvents.

X, Y, Z: 3 directions for one hour

(Measured by using a noise simulator.)

Contact: ±4 kV, air: ±8 kV

1 ms or less

42 W or less 37 W or less 35 W or less

Tightening torque: 0.8 N·m

Tightening torque: 0.5 to 0.6 N·m

NP5M0101-4H4

NP5N0011-4H4

2

, X, Y, Z: 3 directions three times each

NP5M0101-3H4

NP5N0011-3H4

2

,

controller unit)

• Installation specifications

Item Specifications

Grounding Less than 100Ω, FG/SG separated

Protection structure Front panel (Note 1) Compliant with IP65 (When using waterproof gasket) (Note 2)

Cooling system Cooling naturally

Structure Inserted in a mounting panel

Appropriate mounting panel thickness 1.5 to 5 mm

Note: 1) Protection structure for the front when the @E.Terminal is mounted on the mounting panel.

Note: 2) It is recommended to use the mounting panel whose thickness (steel, stainless) is 3.0 mm or more to keep the

unit compliant with IP65. The strength differs depending on the material of the mounting panel. Check the

environment where the @E.Terminal is used.

2-1

Page 16

2-1 Specifications

2-1-2 Display unit specifications

(1) Display unit specifications

Item

Display device TFT color

Display size 12.1-inch 10.4-inch 8.4-inch

Colors 65,536 colors (without blinks) / 32,768 colors (with blinks)

Display resolution (W x H) 800 x 600 dots

Dot pitch (W x H) 0.3075 x 0.3075 mm 0.264 x 0.264 mm 0.2135 x 0.213 mm

Backlight Cold cathode tube

Backlight life

(average life of backlight only)

Backlight auto OFF function Always ON, random setting

Brightness adjustment Function switch: 3 levels / Macro: 128 levels

Surface sheet material Polycarbonate, 0.3 mm thick

POWER lamp ON: Normal (green)

NP5M0101-5H4

NP5N0011-5H4

Approx. 50,000 hours (at the normal temperature of 25° C)

Blink: Backlight error

NP5M0101-4H4

NP5N0011-4H4

NP5M0101-3H4

NP5N0011-3H4

(2) Touch switch specifications

Item Specifications

Method Analog resistance film type

Number of switches 1024 x 1024

Mechanical life One million activations or more

Surface treatment Hard-coated, anti-glare treatment 5 %

(3) Function switch specifications

Item Specifications

Number of function switches 8 pcs.

Method Matrix resistance film type

Mechanical life One million activations or more

2-2

Page 17

2-1 Specifications

(4) Interface specifications

Item Specifications

D-sub 9-pin (CN1) Applicable

Modular jack 8-pin

(MJ1/MJ2)

USB connector

(USB-A/B)

Ethernet port

100BASE-TX/

10BASE-T

(LAN)

CF card interface Compliant with CompactFlash

Extensional communication port

(CN5)

Optional unit port (CN7) RGB input/output, video, sound

Note) For details, refer to the User’s Manual <V8 Series Connection Manual> (2201NEx).

(5) Clock and backup memory specifications

Item Specifications

Battery specification Coin-type lithium primary cell

Backup memory SRAM 512 kbytes

Backup period Approx. 5 years (Ambient temperature at 25 °C)

Battery voltage drop detection Provided (Internal memory of $s167 allocated)

Calendar accuracy Monthly deviation ±90 s (Ambient temperature at 25 °C) (Note)

Note) Time loss is approximately 90 seconds a month in an ambient temperature of 25 °C in the non-energized state

(backup with battery). Depending on the ambient temperature, the calendar may lose 356 seconds or advance

189 seconds in a month at the maximum. Correct the clock periodically.

standards

Synchronization Asynchronous type

Data length 7- or 8-bit

Parity None, odd, even

Stop bit 1- or 2-bit

Baud rate 4800, 9600, 19200, 38400, 57600, 76800, 115.2kbps

Applications PLC, temperature controller, barcode reader, etc.

Applicable

standards

Applications Screen data transfer (MJ1), PLC, temperature controller, CREC, barcode reader,

Applicable

standards

Baud rate Low speed: 1.5 Mbps, full speed: 12 Mbps

USB-AUSB-B

Applications Printer (EPSON PM series), CF card reader/writer

Applicable

standards

Baud rate Low speed: 1.5 Mbps, full speed: 12 Mbps

Applications Screen data transfer, PictBridge-compatible printer

Applicable

standards

Baud rate 100 Mbps, 10 Mbps

Recommended

cable

Applications PLC connection, etc.

RS-232C, RS-422/485

(187500 bps for MPI connection (Note))

RS-232C, RS-485 (2-wire connection)

V-I/O, Multi-link 2, V-Link, etc.

Compliant with USB version 1.1

Compliant with USB version 1.1

Compliant with IEEE802.3u (100BASE-TX), IEEE802.3 (10BASE-T)

100 Ω UTP (unshielded twist-pair cable), category 5, max. 100 m long

TM

Controller unit connection

(The communication unit is not connectable.)

(The optional unit "GU-xx" is necessary.)

2-3

Page 18

2-1 Specifications

(6) Drawing environment

Item Specifications

Drawing method Exclusive configuration software

Drawing tool Name of exclusive configuration software: V-SFT-5

(7) Display function specifications

Item Specifications

Interface language (Note: 1) Japanese English/

Characters 1/4-size, 1-byte ANK code Latin 1 ASCII code ASCII code ASCII code

2-byte 16-dot JIS #1, 2 levels - Chinese

2-byte 32-dot JIS #1 level - - - -

Font Windows font

Character size 1/4-size 8 x 8 dots

1-byte 8 x 16 dots

2-byte 16 x 16 dots or 32 x 32 dots

Enlargement

factor

Number of

displayable

characters

Character properties Display properties: Normal, reverse, blink, bold, shadow, transparent

Graphics Lines: Line, continuous line, box, parallelogram, polygon

Graphic properties Line types: 6 (thin, thick, dot, chain, broken, two-dot chain)

Note: 1) In addition, the following fonts are available.

Gothic, English/Western Europe HK Gothic, English/Western Europe HK Times, Central Europe, Cyrillic, Greek,

Turkish. For more information, refer to the “V8 series Reference Manual.”

Note: 2) Applicable when Gothic font, Windows font or stroke font is used.

Display

resolution

1/4-size 100 characters x 75 lines

1-byte 100 characters x 37 lines

2-byte 57 characters x 37 lines

Personal computer: Pentium III 800 MHz or above

OS: Windows98SE/NT4.0/Me/2000/XP/XP64 Edition/Vista 32-bit

Capacity of hard disk required:

Display: Resolution 1024 x 800 or above

Stroke font (under development)

X: 1 to 8 times, Y: 1 to 8 times

Point (Note: 2) : 8, 9, 10, 11, 12, 14, 16, 18, 20, 22, 24, 26, 28, 36, 48, 72

800 x 600

Colors: 65,536 colors (without blinks) / 32,768 colors (with blinks)

Circles: Circle, arc, sector, ellipse, elliptical arc

Others: Tile patterns

Tile patterns: 16 (incl. user-definable 8 patterns)

Display properties: Normal, reverse, blink

Colors: 65,536 colors (without blinks) 32,768 colors (with blinks)

Color selection: Foreground, background, boundary (line)

(Pentium IV 2.0 GHz or above recommended)

Free space of approx. 850 Mbytes or more

Screen color: 16 bits or more

Western Europe

Chinese

(Traditional)

(traditional)

Chinese

(Simplified)

Chinese

(simplified)

Korean

Hangul

(without Kanji)

2-4

Page 19

2-1 Specifications

(8) Function performance specifications

Item Specifications

Screens Max. 1024

Screen memory Flash memory: Approx. 12.5 Mbytes (Varies depending on the font)

Switch 1024 per screen

Switch actions Set, reset, momentary, alternate, to light

Lamp Reverse, blink, exchange of graphics

Graph Pie, bar, panel meter and closed area graph:No limitation

Data

setting

Sampling Sampling display of buffer data

Graphic library Max. 2560

Overlap library Max. 1024

Data blocks Max. 1024

Messages Max. 32768 lines

Patterns Max. 1024

Macro blocks Max. 1024

Page blocks Max. 1024

Direct blocks Max. 1024

Screen blocks Max. 1024

Data sheets Max. 1024

Screen library Max. 1024

Comments Max. 32768

Device memory map Max. 32 x 8 (PLC1 to PLC8)

Time display Provided

Hard copy Provided

Buzzer Provided, 2 sounds (short beep, long beep)

Auto OFF function Always ON, random setting

Self-diagnostic function Switch self-test function

Note: 1) The number of setting memor y locations is limited to 1024 per screen.

Note: 2) Layer: 4 per screen (base + 3 overlap displays)

Numerical data display No limitation

Character display No limitation

Message display Display resolution: 800 x 600: Max. 100 characters (1-byte)

(Possible to press a function switch and a switch on the display at the same time)

1024 per screen

Statistics and trend graphs: Max. 256 per layer (Note: 2)

No limitation

(Constant sampling, bit synchronization, alarm logging, time order alarming, alarm

function)

Communication parameter setting check function

Communication check function

2-5

Page 20

2-1 Specifications

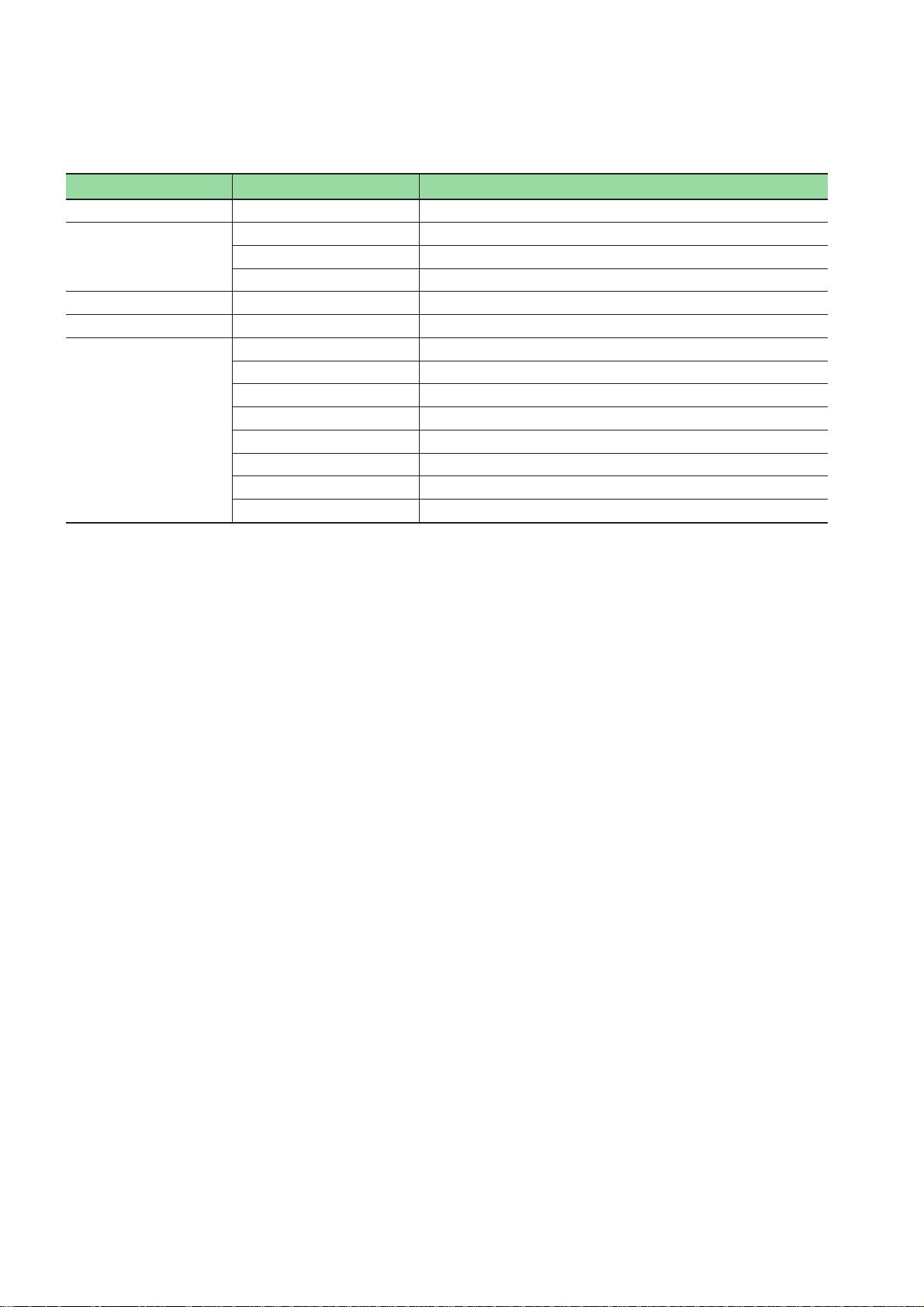

2-1-3 Controller unit specifications

(1) Application performance specifications

Item Specifications

Type NP5M0101-5H4/4H4/3H4 NP5N0011-5H4/4H4/3H4

Control system Stored program,

Input / Output connection method Direct input / output (SX bus)

I/O control system Via SX bus: Synchronous refresh with takt

CPU 32-bit RISC processor

Memory types Program memory, data memory, temporary memory

Programming language <When used the D300win> <When used the Standard Loader>

Program memory capacity 49152 steps

Memory I/O memory 512 words

General memory 65536 words

Retain memory 22528 words 8192 words

User FB instance memory 4096 words 8192 words

Memory for

System FB

System memory 512 words

No. of tasks Default tasks (Cyclic scanning): 1

No. of programs Max. 256 (Max. 128 for one task)

Diagnosis function Self diagnosis (memory checking, ROM sum checking), system configuration

Secret preserving function By password (set with the support tool)

Calendar Available up to 12/31/2069 23:59:59

Backup of application program Flash ROM built in CPU module

User ROM function Application programs, system definitions, zipped files and compressed projects

Backup of data

memory

Note: The application specifications of the controller unit are equivalent to those of the NP1PM-48R MICREX-SX series

CPU module. For more information on memory, language, and system definition, please refer to “User’s Manual

Instruction Edition, MICREX-SX series” as appropriate for your programming support tool.

• SX-Programmer Standard FEH588

• SX-Programmer Expert (D300win) FEH200

Timer

Integrating timer 64 points 128 points

Counter 128 points 256 points

Edge detection 512 points 1024 points

Others 2048 words 8192 words

Backup area Retain memory, retain attributed memory (e.g. current value of counter),

Battery Lithium primary cell, replacement time: 5 minutes or less (at 25 °C)

Backup period Approx. 5 years (at 25 °C)

Cyclic scanning system (default task), periodic task, event task

IL language (Instruction List) LD language

ST language (Structured Text) ST language

LD language (Ladder Diagram)

FBD language (Function Block Diagram)

SFC elements (Sequential Function Chart)

(Up to 256 words, useable I/O memory on the @E.Termina for MC.)

6144 words 16384 words

256 points 512 points

Periodic tasks: 4

Event tasks : 4 (Total of 4 tasks when periodic task is used)

monitoring, module fault monitoring

Precision: ± 27 s/month (at 25 °C, when active)

Backup area: Application program, system definition, ZIP file

can be stored in user ROM cards.

calendar IC memory, RAS area

2-6

Page 21

2-1 Specifications

(2) Specific system memory

The table below lists system memory specific to @E.Terminal controller unit.

[Expansion annunciator relay area]

Address Names Descriptions

SM1240

(%MX10.124.0)

[Cause of memory error]

Address Names Descriptions Level

SM84

(%MX10.8.4)

Display unit connection status

flag

Display unit DPRAM error Turns ON when an error occurs in DPRAM for

Represents whether a display unit is connected

(ON/OFF of display unit power supply).

1: Connected 0: None

Fatal fault

display unit I/F in controller unit.

2-7

Page 22

2-2 Dimensions and Panel Cut-out

2-2-1 External dimensions and panel cut-out dimensions for the NP5M0101-5H4/NP5N0011-5H4

(Unit: mm)

• Front view

259.6

• Rear view

245.2

+0.5

326.4

+0.5

-0

313.0

-0

Panel cut-out dimensions

246.2

F 2

F 1

SYSTEM

F 7F 6F 5F 4F 3

• Side view

312.0

CN5

ONL

SX-BUS

ERR

UROM

RUN

IN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CPU

No.

OUT

+

24V DC

FG

USER ROM CARD

LOADER

CN1

MJ1

MJ2

CN7

USB

LAN

CF

U-B U-A

(66)

Note)

99.0

7.0

• Bottom view

99.0

312.0

Note: Arrange SX bus expansion cable so that

radius of bend in the cable is at least 50mm.

Plug/unplug the SX bus expansion cable in

the perpendicular direction.

2-8

Page 23

2-2 Dimensions and Panel Cut-out

2-2-2 External dimensions and panel cut-out dimensions for the NP5M0101-4H4/NP5N0011-4H4

(Unit: mm)

• Front view

231.0

303.8

SYSTEM

F 1

F 2

F 3

F 4

F 5

F 6

F 7

-0

+0.5

216.2

Panel cut-out dimensions

289.0

+0.5

-0

• Rear view

215.2

• Bottom view

99.0

• Side view

288.0

CN5

ONL

SX-BUS

ERR

UROM

RUN

IN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CPU

No.

OUT

+

24V DC

FG

USER ROM CARD

LOADER

MJ2

CN1

MJ1

CN7

USB

LAN

CF

U-AU-B

(66)

Note)

288.0

99.0

7.0

Note: Arrange SX bus expansion cable so that

radius of bend in the cable is at least 50mm.

Plug/unplug the SX bus expansion cable in

the perpendicular direction.

2-9

Page 24

2-2 Dimensions and Panel Cut-out

2-2-3 External dimensions and panel cut-out dimensions for the NP5M0101-3H4/NP5N0011-3H4

(Unit: mm)

• Front view

178.0

233.0

-0

+0.5

Panel cut-out dimensions

165.5

220.5

+0.5

-0

• Rear view

SX-BUS

IN

CN5

165.0

OUT

+

FG

• Bottom view

96.0

• Side view

220.0

(66)

96.0

6.9

ONL

ERR

UROM

RUN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CPU

No.

24V DC

24VDC

FG

USB

USER ROM CARD

CN1

LOADER

CN7

LAN

MJ1

CF

Note)

U-B

U-A

MJ2

220.0

Note: Arrange SX bus expansion cable so that

radius of bend in the cable is at least 50mm.

Plug/unplug the SX bus expansion cable in

the perpendicular direction.

2-10

Page 25

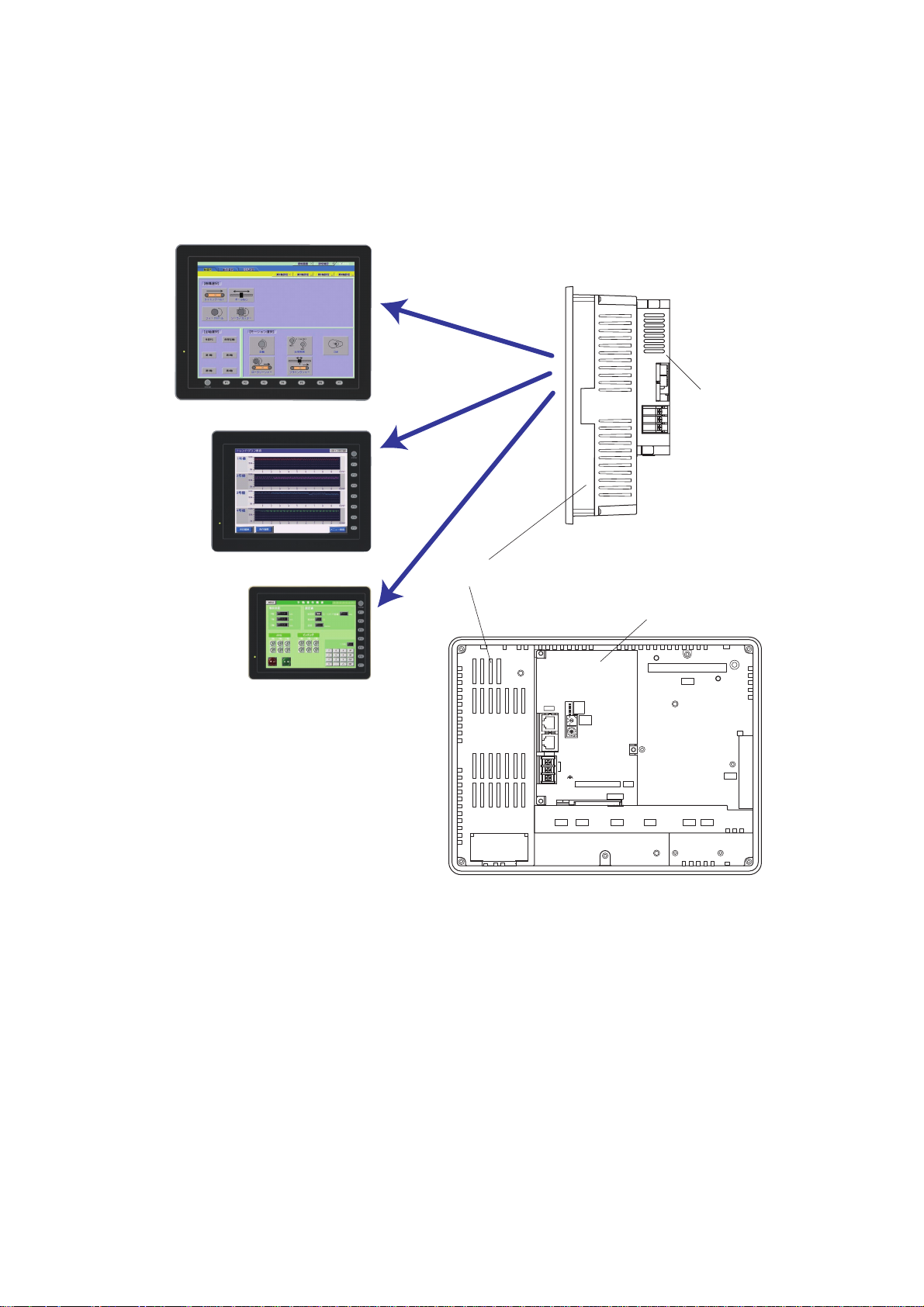

2-3-1 Display unit

(1) NP5M0101-5H4/NP5N0011-5H4

1)

2-3 Names and Functions

4)

6)

8)

5)

2)

F 2

F 1

SYSTEM

3)

(2) NP5M0101-4H4/NP5N0011-4H4

1)

CN5

CN1

MJ1

MJ2

F 7F 6F 5F 4F 3

CN7

7)

CF

U-B U-A

LAN

16)

15)14)13)12)11)10)9)

17)

4) 5)

6)

8)

2)

SYSTEM

F 1

F 2

F 3

F 4

F 5

F 6

F 7

3)

9) 10)

CN5

MJ2

CN1

MJ1

11) 12) 13) 14) 15)

CN7

CF

7)

LAN

U-AU-B

16)

17)

2-11

Page 26

2-3 Names and Functions

(3) NP5M0101-3H4/NP5N0011-3H4

1)

4)

6)

5)

CF

7)

3)

CN7

CN5

2)

24VDC

9)

FG

12)

LAN

U-B

MJ2

MJ1

14) 15)

U-A

CN1

13)

16)

8)

10) 11)

17)

1) Display

This is the display unit.

2) Power lamp (POWER)

Illuminates in green when the display unit is powered on, and is operating normally. Flashes when an error occurs to the

backlight (burned-out backlight, etc.).

3) Function keys

Used for RUN/STOP selection, brightness adjustment and backlight ON/OFF (setting on the V-SFT-5 editor required).

These switches can be used as user-defined switches in the RUN mode.

4) Communication interface unit connector (CN5)

Connects with the controller unit.

* Hidden by the controller unit.

5) Optional unit connector (CN7)

Used for mounting the optional unit “GU-xx” for video input, sound output, RGB input or RGB output.

6) Battery holder

Contains a backup battery for SRAM and clock.

When the battery voltage drops, replace the battery with a new one (V7-BT).

* Hidden by the controller unit. Replace battery by detaching the controller unit.

7) CF card connector (CF)

This is the connector where the CF card is inserted. Access to the CF card is enabled when the cover is closed.

8) Dip switch

8-bit Dip switch used for setting terminating resistance of the CN1 signal line and the MJ1/MJ2 RS-485 signal line.

* In NP5M0101-5H4/4H4, NP5N0011-5H4/4H4, the dip switch is hidden by the controller unit. Operate dip switch by

detaching the controller unit.

2-12

Page 27

2-3 Names and Functions

9) Power supply terminal block (display unit)

Supplies the power to the display unit (24 V DC).

10) Modular jack 1 (MJ1)

Used for screen data transfer and connection with PLCs or other peripheral devices.

11) Modular jack 2 (MJ2)

Used for connection with PLCs or other peripheral devices.

12) PLC communication connector (CN1)

Used for connection with a controller (PLC, temperature controller, inverter, etc.).

13) 100BASE-TX/10BASE-T connector (LAN)

Used for Ethernet connection.

14) USB-B (slave port)

Used for screen data transfer or connection with a PictBridge-compatible printer.

15) USB-A (master port)

This is the connector where a printer or a CF card reader/writer is connected.

16) USB cable clamp mounting hole

For NP5M0101-5H4/4H4, NP5N0011-5H4/4H4, this hole is used for attaching a USB cable clamp.

For NP5M0101-3H4/NP5N0011-3H4, this hole is used for attaching a USB cable binder.

17) Mounting holes

Used for inserting fixtures when securing the @E.Terminal to the mounting panel.

2-13

Page 28

2-3 Names and Functions

2-3-2 Controller unit

1) Status indication

LED

5) SX bus

connector

6) Power supply

terminal block

(3 poles)

Version No.

SX-BUS

IN

OUT

Name plate

+

24V DC

FG

ONL

ERR

UROM

RUN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CPU

No.

USER ROM CARD

Seal of the occasion of next

battery replacement

2) Key switch

3) CPU No. selection key switch

USB

LOADER

4) Data backup

battery

9) USB-miniB connector

card (CF card)

8) Loader connector 7) Connector for user ROM

2-14

Page 29

2-3 Names and Functions

1) Status indication LED (Controller unit)

Symbol Color Descriptions

ONL

ERR

UROM Green Lights on continuously when the CPU recognizes a user ROM card.

RUN

ALM

Green

Red

Green

Red

Status of the controller unit.

<Lights on pattern>

ONL ERR Status of controller unit

OFF OFF Power OFF, system resetting or initializing

Blinks - SX bus standing on

ON OFF Normally running

ON ON Nonfatal fault, at a running

OFF ON Fatal fault at a stop

Lights on continuously when a user ROM card (compact flash card) is correctly installed in the CPU

module and the key switch is set to "3" or "4".

Status of system of the conntroller unit.

(Note)

<Lights on pattern>

RUN ALM Status of system

OFF OFF Power OFF or application program at a stop

ON OFF Normally running

ON ON Nonfatal fault, at a running

OFF ON Fatal fault, at a stop

Blinks - While the CPU is accessing the user ROM

BAT Orange Turned on when data backup battery dropped or disconnected.

Note: The system includes the own CPU.

2) Key switch (Controller unit)

Selects the running mode of the controller unit.

1: STOP 2: TERM 3: U-TERM 4: RUN

* The shipment default is 3 (U-TERM).

3) CPU No. selection key switch

Sets the CPU number of the controller unit. Set the number to “0”.

4) Data backup battery (Controller unit)

The battery backs up the retain memory of the contoller uint.

5) SX bus connector (IN, OUT)

Be sure to connect cable from OUT to IN.

For the connection cable, use a dedicated SX bus extension cable.

6) Power supply terminal block (Controller unit)

Supplies the power to the display unit (24 V DC).

7) Connector for user ROM card (CF card) (Controller unit)

This is the connector where the User ROM card (CF card) is inserted.

8) Loader connector

For the personal computer loader, use a RS-232C port.

9) USB-miniB connector (Controller unit)

Connects to the USB port of a personal computer loader.

Please use a commercially sold USB cable (male A connector _ male miniB connector).

2-15

Page 30

2-4 Serial Connector

Communication (RS-232C, RS-422/485) with a controller is enabled via the serial connector (CN1).

• For NP5M0101-5H4/4H4

NP5N0011-5H4/4H4

Bottom view Bottom view

The serial connector pins correspond to signals as given below.

CN1 (D-sub 9-pin, female)

15

69

RS-232C (Note: 1) RS-422 / RS-485 (Note: 1)

Pin No.

Signal Contents Signal Contents

1

2

3

4

5

6

7

8

9

NC

RD

SD

NC

SG

NC

RTS

CTS

NC

Not used +RD Receive data (+)

Receive data -RD Receive data (-)

Send data -SD Send data (-)

Not used +SD Send data (+)

Signal ground SG Signal ground

Not used +RTS Request to send (+)

Request to send -RTS Request to send (-)

Clear to send NC Not used

Not used +5V Use prohibited (Note: 2)

• For NP5M0101-3H4

NP5N0011-3H4

Note: 1) The signal level can be changed between RS-232C and RS-422/485 on the configuration software.

When RS-232C is selected, set the dip switches 5 and 7 to the OFF position.

(For more information on the dip switch, refer to “Chapter 2-6”.)

Note: 2) When RS-422/485 is selected, +5V is output from pin No. 9.

+5V is used as the power supply for the external terminating resistance for RS-422/485 communication.

It cannot be used as an external power supply.

Recommended connector

The following connector is recommended for a self-made cable.

Recommended

connector

DDK's 17JE-23090-02 (D8C) -CG D-sub 9-pin / male / inch screw thread (#4-40UNC) type /

with hood / lead- and cadmium-free

2-16

Page 31

2-5 Modular Jack (MJ1 / MJ2)

A screen data transfer cable (MJ1 only), temperature controller, barcode reader, CREC, or V-I/O can be connected to the

modular jack (MJ1 or MJ2).

• For NP5M0101-5H4/4H4

NP5N0011-5H4/4H4

Bottom view Bottom view

Pins of MJ1 and MJ2 correspond to signals as given below.

MJ1/2 Pin No. Signal Contents

1 +SD/RD RS-485 + data

2 -SD/RD RS-485 - data

3 +5V

4 +5V

5 SG Signal ground

12345678

Note: 1) Allowable current for the external power supply +5V at MJ1/MJ2/USB-A of the @E.Terminal.

• For MJ1 and MJ2, the maximum allowable current is 150 mA in total.

• When connecting an optional unit or communication unit, be careful not to exceed the total allowable current

(650 mA) for USB-A, MJ1 and MJ2.

6SG

7 RD RS-232C receive data

8 SD RS-232C send data

• For NP5M0101-3H4

NP5N0011-3H4

Externally supplied +5 V

(Note: 1)

2-17

Page 32

2-6 Dip Switches

In NP5M0101-5H4/4H4, NP5N0011-5H4/4H4, the dip switch is hidden by the controller unit.

Operate the dip switch by detaching the controller unit.

The @E.Terminal is equipped with eight (1 to 8) dip switches. When setting the dip switch, turn the power off.

Upon delivery, all the dip switches are set to OFF.

• For NP5M0101-5H4/4H4

NP5N0011-5H4/4H4

• For NP5M0101-3H4

NP5N0011-3H4

Rear view Rear view

CN5

MJ2

CN1

MJ1

CN7

CN5

CF

LAN

U-AU-B

24VDC

FG

Dip switch

ON

12345678

CF auto-uploading

CF card interface cover

access control

Not used

CN1 +SD/-SD terminating resistor at pins 3 and 4

MJ2 (modular jack 2) terminating resistor

CN1 +RD/-RD terminating resistor at pins 1 and 2

MJ1 (modular jack 1) terminating resistor

CN7

LAN

CN1

U-B

MJ1

CF

U-A

MJ2

Dip switch number 1 (Note: ) (CF Auto-uploading)

Set the dip switch number 1 to the ON position when auto-uploading a screen data file saved on a CF card.

Procedure

1. Have a CF card

Have a CF card to which the screen data is loaded using the V-SFT-5 editor. (For the loading procedure, refer to

the “V8 series Reference Manual.” )

2. Insert a CF card

Turn the power of the display unit off, and set the dip switch number 1 to the ON position. Open the CF card

interface cover, and insert a CF card.

3. Auto-uploading starts

Turn the power of the display unit on. The screen data is automatically loaded into the FLASH memory of the unit.

Note: Be sure to set the dip switch number 1 to the OFF position if you do not use CF auto-uploading function.

2-18

Page 33

Dip switch number 2 (CF Card interface cover access control)

When the dip switch number 2 is set to the ON position, access to the CF card is possible

Caution

whether the cover is opened or not. In case access to the CF card is disabled because of

damage of the CF card interface cover, set the dip switch number 2 to the ON position.

Normally keep it in the OFF position.

With the dip switch number 2, the LED status when the CF card interface cover is opened can be set.

Dip switch number 2 LED Contents

Access to the CF card is not performed.

CF card can be removed.

Accessing the CF card.

After the access is finished, the LED goes off.

OFF

ON

Not lit

Lights up in red

Lights up in red Access to the CF card is possible at all times.

Dip switch number 3, 4 (Not used)

Set the dip switch number 3 and 4 to OFF.

Dip switch number 5, 6, 7, 8 (Terminating resistor setting)

2-6 Dip Switches

Caution

When connecting a controller at CN1 via RS-232C, set the dip switch number 5 and 7 to the

OFF position.

• When connecting a controller at CN1 via RS-422/485 (2-wire connection), set the dip switch number 7 to the ON

position.

• When connecting a controller at CN1 via RS-422/485 (4-wire connection), set the dip switch number 5 and 7 to the

ON position.

• For the following connections at modular jack 1 or 2, set the dip switch number 6 or 8 to the ON position.

• Master station for multi-link 2 connection

• Connection with a controller (PLC, temperature controller, etc.) via RS-485

• Connection with the card recorder “CREC” (optional)

• Connection with the serial extension I/O “V-I/O” (optional)

• Connection to the @E.Ter minal at the termination of V-Link connection via RS-485

* Detaching controller unit

To operate the dip switch in NP5M0101-5H4/4H4, NP5N0011-5H4/4H4, remove the controller unit.

Remove mounting screws at three places to remove the controller unit from the display unit.

Be careful not to drop or lose the mounting screws.

CN7

CF

LAN

U-AU-B

Mounting screws at three places

M3 screws thread,

Tightening torque:

0.5 to 0.7N·m

SX-BUS

CN5

ONL

ERR

UROM

RUN

IN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CPU

No.

OUT

+

24V DC

-

FG

MJ2

MJ1

USER ROM CARD

USB

LOADER

CN1

2-19

Page 34

Section 3 Installation

Page

3-1 Mounting Procedure ................................................................................................... 3-1

(1) Mounting procedure ................................................................................................................................3-1

(2) Mounting angle .......................................................................................................................................3-1

3-2 Power Supply Cable Wiring ........................................................................................ 3-2

(1) Power supply cable wiring....................................................................................................................... 3-2

(2) Grounding ............................................................................................................................................... 3-4

Page 35

(1) Mounting procedure

1) Insert the @E.Terminal unit into the mounting panel (max. thick: 5 mm).

Section 3 Installation

3-1 Mounting Procedure

Panel cut-out dimensions

X

Y

Types

NP5M0101-5H4/NP5N0011-5H4

NP5M0101-4H4/NP5N0011-4H4

NP5M0101-3H4/NP5N0011-3H4

X

Unit: mm

X

313.0

289.0

220.5

+0.5

-0

+0.5

-0

+0.5

-0

246.2

216.2

165.5

+0.5

-0

+0.5

-0

+0.5

-0

Y

Y

2) Insert four fixtures attached to the @E.Terminal unit into the mounting holes, and tighten them with the

tightening screws.

Tightening torque: 0.5 to 0.7 N·m

Fixture dimensions

(Unit: mm)

7

N

C

F

B

S

U

D

R

A

C

M

O

R

R

E

R

E

D

A

O

L

1

N

C

C

T

E

S

E

R

A

-

U

B

-

U

N

A

L

18.0

17.8

10.5

5

N

C

L

N

O

R

R

E

M

O

R

U

S

U

B

-

N

X

U

R

S

M

L

A

T

A

B

N

I

N

U

R

:

4

M

R

E

T

-

U

:

3

M

R

E

T

:

2

P

O

T

S

:

1

U

P

C

.

o

N

T

U

O

V

4

2

C

D

V

0

G

F

S

U

2

J

M

1

J

M

* When the @E.Terminal unit is attached to the mounting panel, the fixtures and frame grounds (FG) are connected.

To prevent static electricity, be sure to connect the mounting panel to the frame ground.

3) Mount the gasket so that it will be sandwiched securely between the @E.Terminal unit and the mounting panel.

(2) Mounting angle

Install the unit within the angle of 15° to 135° as shown on the right.

90°

135°

Display

3-1

Display

15°

0°

Page 36

3-2 P ower Supply Cable Wiring

Warning

Electric shock hazard.

Shut the power off before wiring the power supply cable.

(1) Power supply cable wiring

Power supply terminal blocks of the display unit and the controller unit are connected with each other with a cable by

default. Use one power supply terminal block to connect the power supply cable.

• For NP5M0101-5H4/4H4

NP5N0011-5H4/4H4

Connect the power supply cable to the power

supply terminal block of the display unit.

CN5

ONL

SX-BUS

ERR

UROM

RUN

IN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CPU

No.

OUT

+

24V DC

-

FG

USER ROM CARD

LOADER

MJ2

CN1

MJ1

CN7

USB

LAN

CF

U-AU-B

• For NP5M0101-3H4

NP5N0011-3H4

Connect the power supply cable to the power

supply terminal block of the controller unit.

ONL

SX-BUS

ERR

UROM

RUN

IN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CN5

CPU

No.

OUT

+

24V DC

-

24VDC

FG

FG

USER ROM CARD

LOADER

USB

CN1

CN7

LAN

MJ1

CF

U-B

U-A

MJ2

+

24V DC

FG

24V DC

+

Power

supply

FG

Grounding

Power supply

Grounding

• Attaching noise filter

Attach accompanying noise filter to the power supply cable between the DC power supply and the power supply terminal

block.

Keep the distance between the DC power supply

and the power supply module as short as possible,

and the cable must be twisted densely.

@E.terminal side

DC power

supply

Noise filter

(accessory)

+

24V DC

-

FG

Do not bundle up and do not close.

* Noise filter is not required for controller unit hardware version “03” or later.

Noise filter is not attached as accessory with above version.

3-2

Page 37

3-2 P o wer Supply Cable Wiring

φ 3.7mm

8mm

or less

3.7mm

8mm

or less

3.7mm

7.1mm

or less

φ 3.7mm

7.1mm

or less

• Tighten terminal screws on the power supply terminal block of the display unit with the following torque.

Use a power supply cable within the range shown below.

Tterminal screw

Types

NP5M0101-5H4

NP5M0101-4H4

NP5N0011-5H4

NP5N0011-4H4

Screw

size

Tightening

torque

Crimp-style terminal

M3.5 0.8N·m AWG18 - 16

Power

Cable

NP5M0101-3H4

NP5N0011-3H4

M3.5 1.2N·m AWG16 - 14

• The power supply terminal block of the controller unit uses M3 terminal screws. Their tightening torque should be

0.5 to 0.6 N·m.

Select the appropriate cable, and crimp terminals to be used. Applicable cable sizes and crimp terminals are as

follows:

Maker Form Types

Cable size

AWG mm

2

36467

AMP

Round

terminals

34104

22 to 18 0.3 to 0.8 mm

2

34105

Nichifu

Round

terminals

0.3-3

0.3-3N

24 to 20 0.2 to 0.5 mm

1.25-3

1.25-3N

1.25-3S

22 to 16 0.3 to 1.3 mm

1.25-3.5N

1.25-3.5S

2-3N 16 to 14 1.3 to 2.0 mm

0.3Y-3 24 to 20 0.2 to 0.5 mm

2

2

2

2

6

Terminal dimensions

7.6

1.25Y-3

JST

NTK

Angle edge

terminals

Round

terminals

Round

terminals

Angle edge

terminals

1.25Y-3N

1.25Y-3S

22 to 16 0.3 to 1.3 mm

1.25Y-3.5

2Y-3

2Y-3.5S

16 to 14 1.3 to 2.0 mm

AT1-10 22 to 16 0.3 to 1.3 mm

AT2-10 16 to 14 1.3 to 2.0 mm

SRA-20-3.2

SRA-20T-3.2

22 to 18 0.3 to 0.8 mm

0.4-3 26 to 22 0.2 to 0.3 mm

1.25-3

VR1.25-3

22 to 16 0.3 to 1.3 mm

VD1.25-3

VD2-3S 16 to 14 1.3 to 2.0 mm

2

2

2

2

2

2

2

2

3-3

Page 38

3-2 P ower Supply Cable Wiring

(2) Grounding

Caution

Be sure to establish a ground of the @E.Terminal.

(The level of grounding resistance should be less than 100Ω.)

• An independent earth pole must be used for the @E.Terminal.

• Use a cable which has a nominal cross section of more than 2 mm2 for grounding.

• Set the grounding point near the @E.Terminal to shorten the distance of grounding cables.

@E.Terminal

equipment

@E.TerminalOther

equipment

@E.TerminalOther

Other

equipment

* When the @E.Terminal unit is attached to the mounting panel, the fixtures and frame grounds (FG) are connected.

To detach the FG terminal from the ground, attach the insulating sheet to the fixtures and the mounting panel for

insulation.

3-4

Page 39

Section 4 Inspection and Maintenance

Page

4-1 Inspection and Maintenance......................................................................................4-1

4-1-1 Daily inspection..................................................................................................................... 4-1

4-1-2 Periodical inspection ............................................................................................................. 4-1

4-2 Battery Replacement .................................................................................................. 4-2

(1) Battery specification................................................................................................................................ 4-2

(2) Precautions .............................................................................................................................................4-2

(3) How to replacement battery ....................................................................................................................4-2

4-3 Maintenance Services ................................................................................................ 4-4

4-3-1 Ordering notes ...................................................................................................................... 4-4

4-3-2 Free-of-charge warranty period and scope of warranty ........................................................ 4-4

4-3-3 Service costs......................................................................................................................... 4-4

Page 40

Section 4 Inspection and Maintenance

4-1 Inspection and Maintenance

Warning

Be sure to turn off the power before conducting inspection or maintenance.

Failure to do so could cause an electric shock or damage to the unit.

4-1-1 Daily inspection

• Check that the screws on the @E.Terminal are tightened firmly.

• Check that the connectors and terminal screws used for connection with other devices are tightened firmly.

• If the display surface or frame is dirty, wipe it with a soft cloth soaked in alcohol (commercially available).

• Conduct periodical inspection once or twice a year. The number of inspections may be increased as necessary if

facilities are relocated or modified, or the environment is hot, humid, or dusty.

4-1-2 Periodical inspection

Inspect the following points periodically.

• Are the ambient temperature and humidity appropriate?

0 to +50 °C, 85 % RH or less

• Are the environmental conditions appropriate?

No excessive dust, no conductive dust contamination, and not stained with organic solvents.

• Does the atmosphere contain no corrosive gas?

• Is the source voltage in the allowable range?

With DC power supply: 24 V DC ± 10 %

• Are the @E.Terminal mounting screws tightened firmly?

• Are the connectors and terminal screws used for connection with other devices tightened firmly?

• Is the lithium primary battery within the expiry date?

About 5 years from the date of your purchase

4-1

Page 41

4-2 Battery Replacement

When the time comes to replacement the battery, replace it for a new one even if battery error is not displayed.

Also, when low battery voltage of the display unit and the controller unit is discovered, replace the battery for a new one

immediately.

Replacement the batteries of the display unit and the controller unit at the same time.

(1) Battery specification

• Controller unit

Items Specifications

Battery specification Lithium primary cell

Backup time Approx. 5 years (Ambient temperature at 25 °C)

Battery boltage drop

detection funnction

Battery for replacement Type: NP8P-BT

Required time in the

battery replacement

• Display unit

Items Specifications

Battery specification Coin-type lithium primary cell

Backup time Approx. 5 years (Ambient temperature at 25 °C)

Battery boltage drop

detection funnction

Battery for replacement Type: V7-BT

Required time in the

battery replacement

Provided (Status indication LED: BAT)

5 minutes or less

Provided (Internal memory of $s167 allocated)

3 minutes or less

Battery replacement

(2) Precautions

• Do not short across the batter y.

• Do not discard in a fire.

• Do not attempt to recharge the battery.

• Do not disassemble the battery.

• Observe local and governmental regulations when disposing of waste batteries.

(3) How to replacement battery

• Battery replacement of controller unit

1) Turn off power supply of the @E.Terminal.

2) Remove battery holder cover at top of controller unit. Remove battery connector and then remove battery from

battery holder.

3) Attach a new battery connector, mount battery into the battery holder, and attach the cover.

Perform the exchange quickly (within five minutes). When battery is detached for a long time, the data retained

during power outage may become erased.

4) Enter the battery guarantee period on a seal to be used on the occasion of the next battery replacement, and

affix seal to the controller unit.

4-2

Page 42

Battery replacement

4-2 Battery Replacement

• Battery replacement of display unit

1) Remove the controller unit from @E.Terminal.

Remove mounting screws at three places to remove the controller unit from the display unit.

Be careful not to drop or lose the mounting screws.

CN7

CF

LAN

U-AU-B

Mounting screws at three places

M3 screws thread,

Tightening torque:

0.5 to 0.7N·m

SX-BUS

CN5

ONL

ERR

UROM

RUN

IN

ALM

BAT

4:RUN

3:U-TERM

2:TERM

1:STOP

CPU

No.

OUT

+

24V DC

-

FG

MJ2

MJ1

USER ROM CARD

USB

LOADER

CN1

2) Open the battery holder cover of the display unit in the direction of the arrow as shown in the left illustration below.

CN5

MJ2

MJ1

CN1

CN7

CF

LAN

RESET

U-AU-B

3) Remove battery connector, and slide battery to remove it from its socket, as shown in

the right figure.

4) Insert a new battery into the socket so that the red cable side of the new battery faces

the board and the cable is on the left side. Next, slide battery from the arrow key

direction shown in the right figure.

5) Connect the battery connector, and close the battery holder cover.

6) Attach the controller unit to the display unit and fix it with mounting screws at

three places.

Socket

Note: Replace the display unit battery “UG30P-BT” within three minutes after

the unit is turned off. If it is not possible to replace within three minutes,

make a backup copy of data in the SRAM.

4-3

Battery holder

Printed

circuit

board

Battery

connector

Page 43

4-3 Maintenance Services

Maintenance services

4-3-1 Ordering notes

When ordering electrical and control equipment (or requesting price estimates), the following general notes are to be

observed, unless otherwise specified in the estimation paper, contract paper, catalogs, or specifications.

When the product is delivered, check the contents of the package as soon as possible. Even before inspection, use

caution on storing and using the product safely.

4-3-2 Free-of-charge warranty period and scope of warranty

[Free-of-charge warranty period]