Page 1

Developer’s Guide

*Includes information on OT-BU30.

00139800 EN

M

Rev.A

Page 2

Cautions

No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation.

The contents of this document are subject to change without notice. Please contact us for the latest

information.

While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes

no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties

for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product,

or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and maintenance

instructions.

Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options

or any consumable products other than those designated as Original Epson Products or Epson Approved

Products by Seiko Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/POS are registered trademarks or trademarks of Seiko Epson Corporation.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and/or other

countries.

Android TM is a trademark of Google LLC.

All other trademarks are the property of their respective owners and used for identification purpose only.

ESC/POS® Command System

Epson ESC/POS is a proprietary POS printer command system that includes patented or patent-pending

commands. ESC/POS is compatible with most Epson POS printers and displays.

ESC/POS is designed to reduce the processing load on the host computer in POS environments. It comprises a set

of highly functional and efficient commands and also offers the flexibility to easily make future upgrades.

©Seiko Epson Corporation 2021.

(1)

Page 3

Important Safety Information

This document presents important information intended to ensure safe and effective use of this product. Read

this section carefully and store it in an accessible location.

Safety Precautions

WA R NI N G : Handling the product improperly by ignoring this symbol can lead to death or serious injury.

In the following cases, immediately turn off the power and contact qualified service personnel.

Continued use may lead to fire or electric shock.

If the product emits smoke, a strange odor, or unusual noise.

If water or other liquid spills into the product.

If the product is too hot to touch or the case is deformed.

Note the following points to avoid accidents such as fire, electric shock, or burn.

Do not use this product where flammable fumes from gasoline, benzine, thinner, or other flammable liquids

may be in the air.

Do not use aerosol sprayers containing flammable gas inside or around the product.

Do not cover the product with cloth, or place the product in locations subject to high levels of humidity or dust.

Do not allow foreign objects or flammable objects to fall into the equipment.

Do not touch the inside of the product except where mentioned in the manual.

Do not use the product with any voltage and current other than the ones specified.

Do not connect cables in ways other than those mentioned in the manual.

Never disassemble or modify the product.

CAU T ION: Handling the product improperly by ignoring this symbol can lead to injury and property

damage.

Note the following points to avoid injury or malfunction.

Setup the product on a firm, stable, horizontal surface.

Do not place heavy objects on top of the product. Never stand or lean on the product.

Do not press your hands or fingers against the cutter when removing printed paper or loading/replacing roll

paper.

Do not put your hands between the cover and the body of the product when opening/closing the cover.

Never attempt to repair the product yourself.

Do not connect a telephone line to the drawer kick connector (Model for specified customer only).

For safety, turn off the power if the product will not be used for a long period.

(2)

Page 4

Caution Labels

The caution labels on the product indicate the following precautions.

CAU T ION: Do not touch the thermal head and the frame on its side because it can be very hot after

printing.

CAU T ION: The sharp edge can cut your fingers.

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as transportation devices related to

aviation, rail, marine, automotive, etc.; disaster prevention devices; various safety devices, etc.; or

functional/precision devices, etc., you should use this product only after giving consideration to including failsafes

and redundancies into your design to maintain safety and total system reliability. Because this product was not

intended for use in applications requiring extremely high reliability/safety, such as aerospace equipment, main

communication equipment, nuclear power control equipment, or medical equipment related to direct medical care,

etc., please make your own judgment on this product's suitability after a full evaluation.

(3)

Page 5

Product Overview

This chapter describes features of the product.

Features

This product (printer unit) is intended to be integrated into a self-service terminal.

For details on how to integrate it into a self-service terminal, refer to the following:

Appendix M PRINTER INSTALLATION DESIGN GUIDE

Appendix N INSTALLING THE POWER SWITCH AND POWER/FEED SWITCH COVER

Appendix O REPLACEMENT FOR SMALL COVER OPEN LEVER

Appendix P BEZEL OPTION (OT-BU30)

Appendix Q RECOMMENDED POWER SUPPLY

Appendix R PRINTER UNIT HANDLING

(4)

Page 6

Product Configurations

Models

Standard model

Models for specified customers

Accessories

Included

Main unit

Roll paper (φ 35 mm)

Switch cover

For power switch

For power/feed switch

Small cover open lever, including 1 spare screw

Roll paper guides for 58 mm {2.28"} paper: 2

Equipment mounting brackets: 2

Product fixing brackets, including 2 screws + 1 spare (total of 3 screws)

Options

Bezel option (Model: OT-BU30)

AC Adapter (Model: PS-180)

Optional external buzzer (Model: OT-BZ20) (Model for specified customer only)

(5)

Page 7

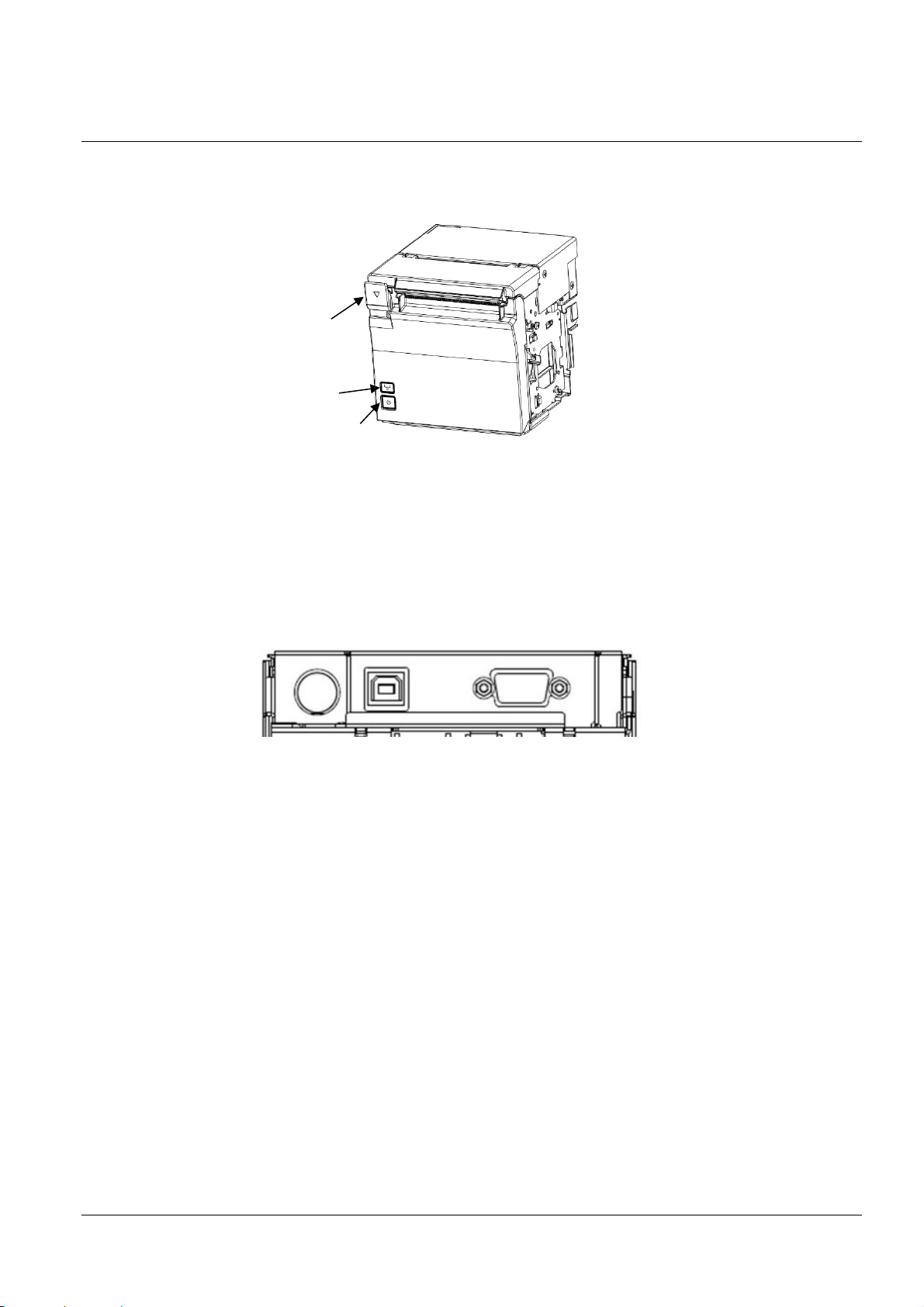

Part Names and Function

1

2

3

1 2 3

4

5

Front

1 Cover open lever Operate this lever to open the roll paper cover.

2 Feed button

3 Power switch Turns the printer on or off.

4 Roll paper cover Open this cover when loading or replacing roll paper.

5 Panel LED For details on LED, see "Panel LED" on page 16.

NOTE

When turning off the printer without using the power switch, it is recommended to send a power-

off command to the printer. If you use the power-off sequence, the latest maintenance counter

values are saved. (Maintenance counter values are usually saved every two minutes.)

For information about ESC/POS commands, see the ESC/POS Command Reference.

Pressing this button once feeds roll paper for one line. Hold down this

button to continue feeding roll paper.

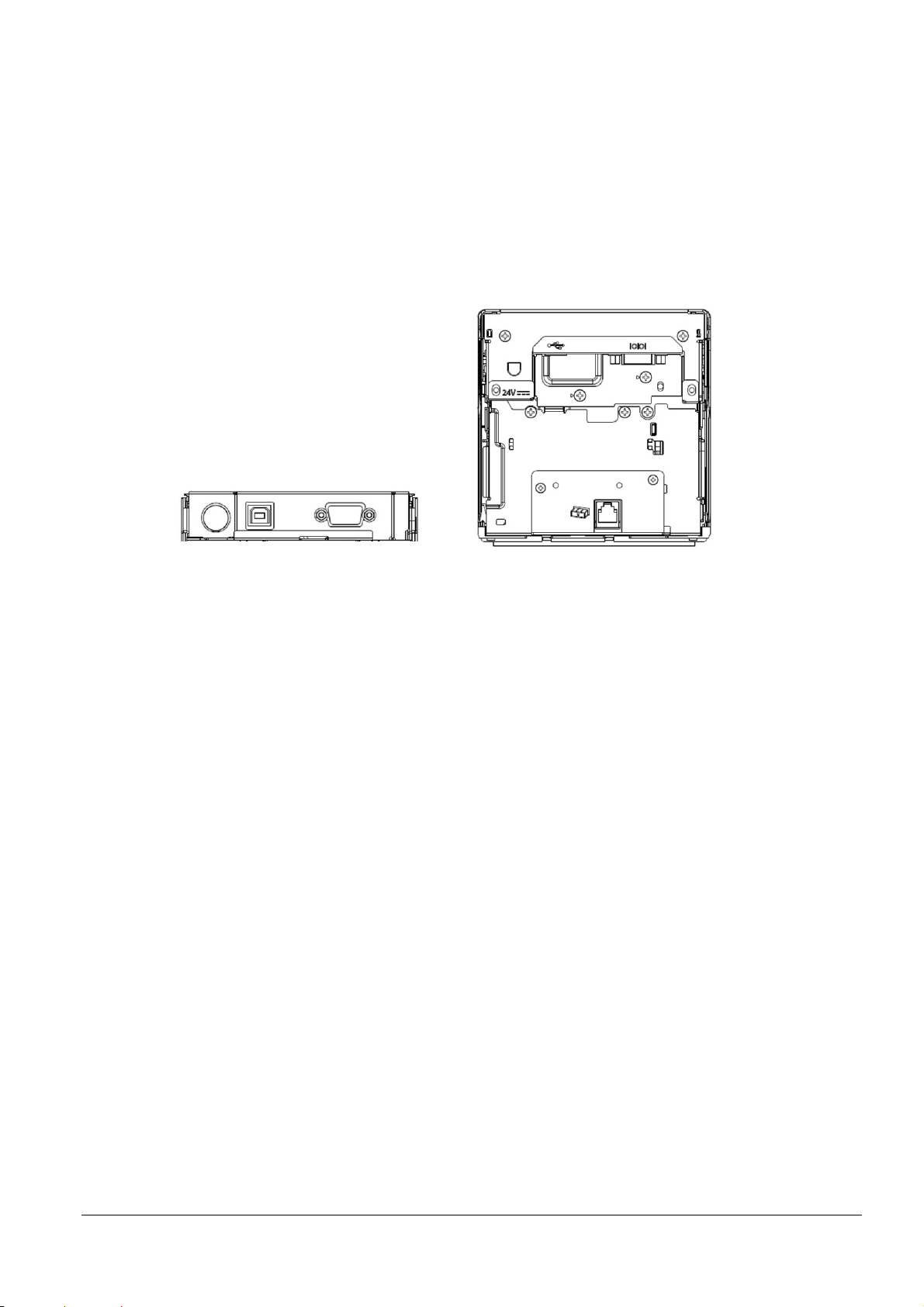

Connectors

4

1 Power supply connector Connect the AC adapter.

2 USB connector (Type-B) Connects the USB cable for connecting to a computer.

3 Serial connecter Connects the serial cable for connecting to a computer.

4 Drawer kick connector

(Model for specified customer only)

Connects the cash drawer or the optional external buzzer.

(6)

Page 8

Storage humidity

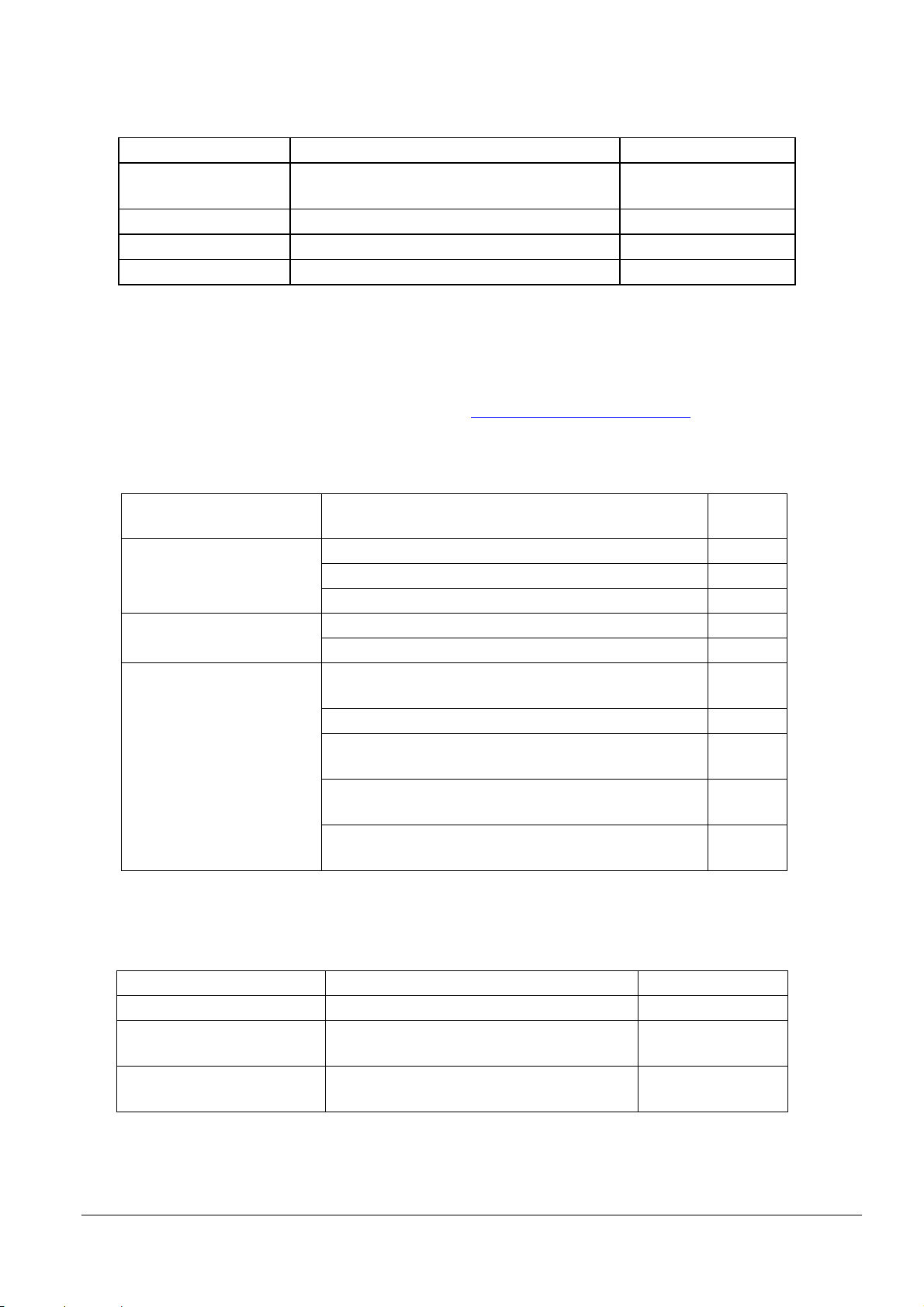

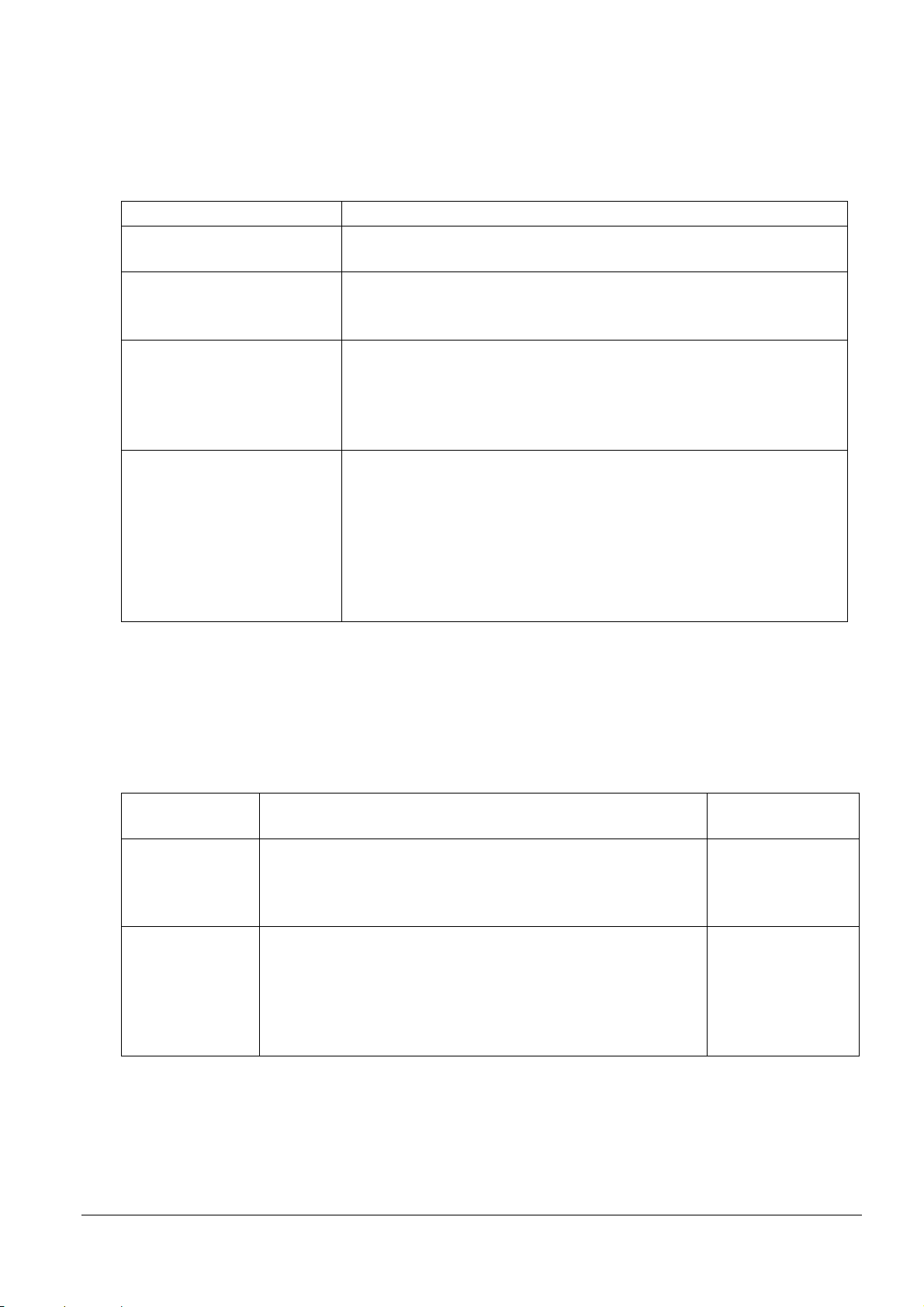

(1) Scope of this document

This document applies to the EU-m30 and bezel option OT-BU30.

(2) Product safety precautions

1) Do not allow a voltage that exceeds the absolute maximum rating to be applied to the power connector.

If the applied voltage exceeds the absolute maximum rating, excess current may flow, causing thermal damage

to components.

OUTLINE

Absolute maximum rating

Circuit input power supply voltage 26.4 V

Storage temperature See 1.13 Environmental Conditions (2)

2) Use the product within the range of operating conditions shown in the table below.

Operating conditions

Articles Min. Typ. Max. Units

Printer power supply voltage 22.3 24.0 25.7 V

Operating temperature See 1.13 Environmental Conditions (1) Guaranteed

Operating humidity

3) Do not create short circuits between connector terminals in the printer unit.

Do not create short circuits between power connector terminals.

A short circuit to a low-impedance power supply can create excess current, causing thermal damage to

components.

4) During transport and storage, properly protect printer unit exterior (exposed) circuit boards and electronic

components with conductive sponges, aluminum foil, and such.

5) Do not drop clips and other conductive materials onto the printer unit's circuit board.

Short circuits between component connectors (terminals) can create excess current, causing thermal damage

to components.

6) Use only the cables indicated in this document. Also, use only the wiring indicated in this document.

Wiring done incorrectly can lead to a failure, fire, explosion, or other accident.

7) Do not disassemble or modify. Such actions can lead to injury or electric shock.

8) During operation, do not directly touch gears or other moving parts. You can get cut or otherwise injured.

9) Do not install in an unstable location (such as on an unsteady pedestal or sloping area). The product can

fall and you can get injured.

10) Do not install in a damp or dusty location. Also, ensure that the product is not exposed to water droplets.

Failure to do so may result in product failure, fire, or electric shock.

11) If the product will not be used for a long period, be sure to turn off the power to the printer unit for safety.

12) The symbols shown below are used in order to ensure safety and proper use of this product.

Read and thoroughly understand the meaning of each symbol before using the product.

Articles Rating Units

Storage environment.

operating environment.

1

Page 9

Caution

Caution: Hot Surface (See Appendix B.)

Caution: Sharp Edges (See Appendix P.)

2

Page 10

TABLE OF CONTENTS

OUTLINE .............................................................................................................................................................................. 1

(1) Scope of this document ............................................................................................................................................ 1

(2) Product safety precautions ...................................................................................................................................... 1

TABLE OF CONTENTS ........................................................................................................................................................... 3

1 GENERAL SPECIFICATIONS ....................................................................................................................... 6

1.1 Print Specifications ................................................................................................................................................... 6

1.2 Character Specifications ........................................................................................................................................... 6

1.3 Autocutter .................................................................................................................................................................. 6

1.4 Paper Sensor .............................................................................................................................................................. 7

1.5 Roll Paper Supply Device ......................................................................................................................................... 7

1.6 Paper Specifications .................................................................................................................................................. 7

1.7 Print Area ................................................................................................................................................................... 8

1.8 Printing and Cutting Positions ............................................................................................................................... 8

1.9 Internal Memory ..................................................................................................................................................... 10

1.10 Electrical Characteristics ........................................................................................................................................ 10

1.11 EMI and Safety Standards Applied ....................................................................................................................... 12

1.12 Reliability ................................................................................................................................................................. 13

1.13 Environmental Conditions .................................................................................................................................... 13

1.14 Installation ............................................................................................................................................................... 15

1.15 Interface .................................................................................................................................................................... 15

1.15.1 Interfaces equipped ........................................................................................................................................ 15

1.15.2 USB interface .................................................................................................................................................. 16

1.15.3 RS-232 serial interface ................................................................................................................................... 18

1.16 Connectors ............................................................................................................................................................... 21

1.16.1 Interface connector ........................................................................................................................................ 21

1.16.2 Power supply connector ................................................................................................................................ 21

1.16.3 Drawer kick connector (modular connector) *For specified customer only ........................................ 22

1.16.4 Allowable interface/power supply cable dimensions ................................................................................ 24

2 Structure ............................................................................................................................................................ 25

2.1 EU-m30, Standard model ...................................................................................................................................... 25

2.2 For specified customer ........................................................................................................................................... 26

3 Function ............................................................................................................................................................ 27

3.1 Control Commands ................................................................................................................................................ 27

3.2 Character Code Tables ........................................................................................................................................... 27

3.3 Switches .................................................................................................................................................................... 27

3.3.1 Power switch ................................................................................................................................................... 27

3.3.2 Feed button ..................................................................................................................................................... 27

3.4 Indicators ................................................................................................................................................................. 28

3.4.1 Displayed color and icon ............................................................................................................................... 28

3.4.2 Displayed patterns .......................................................................................................................................... 28

3.5 Printer Setting .......................................................................................................................................................... 29

3.5.1 DIP switch settings ......................................................................................................................................... 29

3.5.2 Software setting .............................................................................................................................................. 29

3.6 Self-test ..................................................................................................................................................................... 34

3.6.1 Self-test function ............................................................................................................................................ 34

3.6.2 Running self-test ............................................................................................................................................ 34

3.7 Hexadecimal Dumping .......................................................................................................................................... 34

3.7.1 Hexadecimal dumping function .................................................................................................................. 34

3.7.2 Running hexadecimal dumping ................................................................................................................... 34

3.8 Information Print Modes and Setting Modes ..................................................................................................... 35

3

Page 11

3.8.1 NV graphics information print mode ......................................................................................................... 35

3.8.2 R/E (receipt enhancement) information print mode ................................................................................ 36

3.8.3 Software setting mode ................................................................................................................................... 36

3.8.4 Initial setting restoration mode .................................................................................................................... 37

3.9 Error Processing ...................................................................................................................................................... 37

3.9.1 Errors that recover automatically ................................................................................................................ 37

3.9.2 Recoverable errors .......................................................................................................................................... 38

3.9.3 Unrecoverable errors ..................................................................................................................................... 38

3.10 Open Cover .............................................................................................................................................................. 38

3.11 Print Buffer-full Printing ....................................................................................................................................... 39

3.12 Optional external buzzer *For specified customer only .................................................................................... 39

3.13 Printing Using Multiple Interfaces ....................................................................................................................... 40

3.14 Updating Firmware ................................................................................................................................................ 40

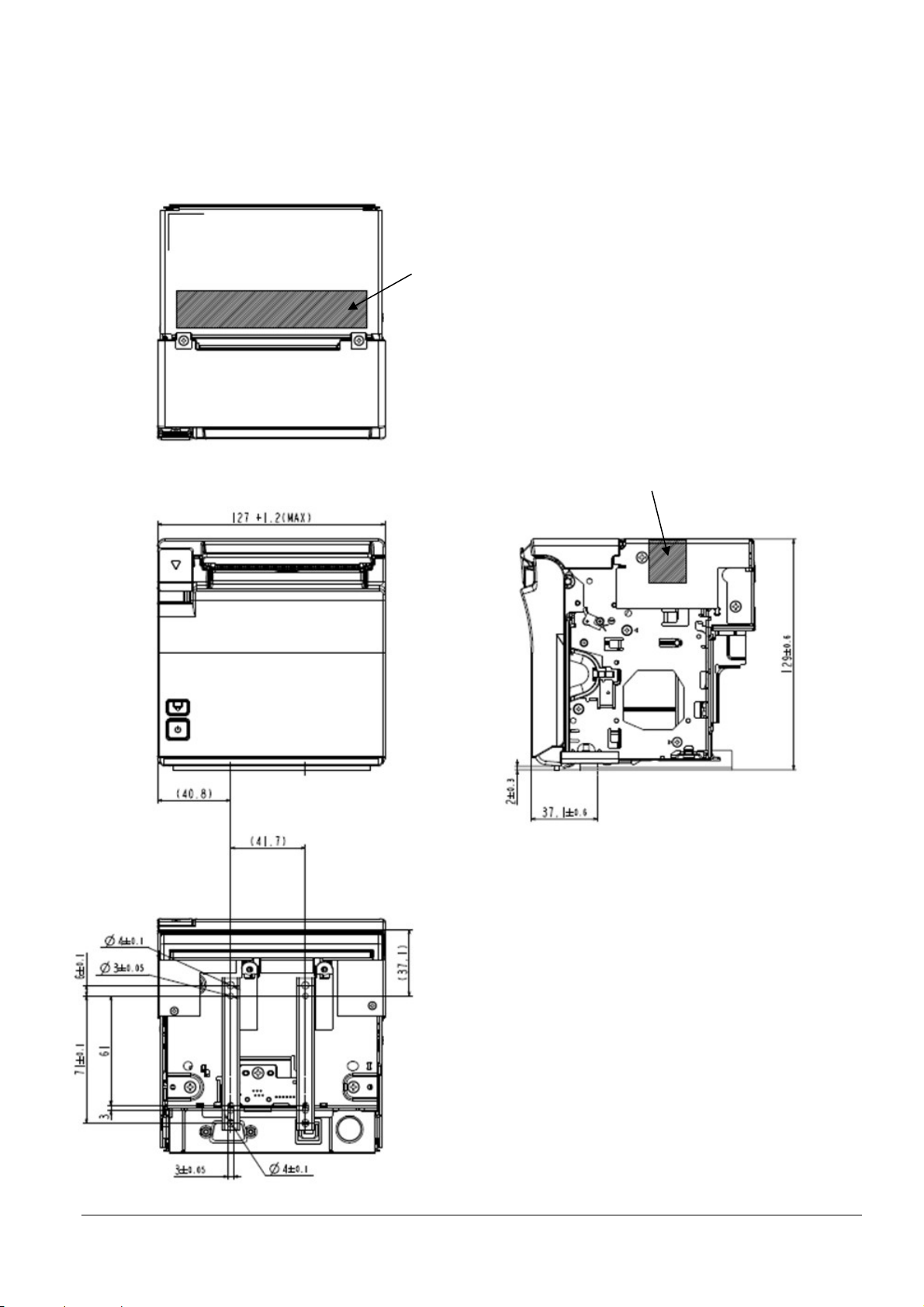

4 Case Specifications .......................................................................................................................................... 42

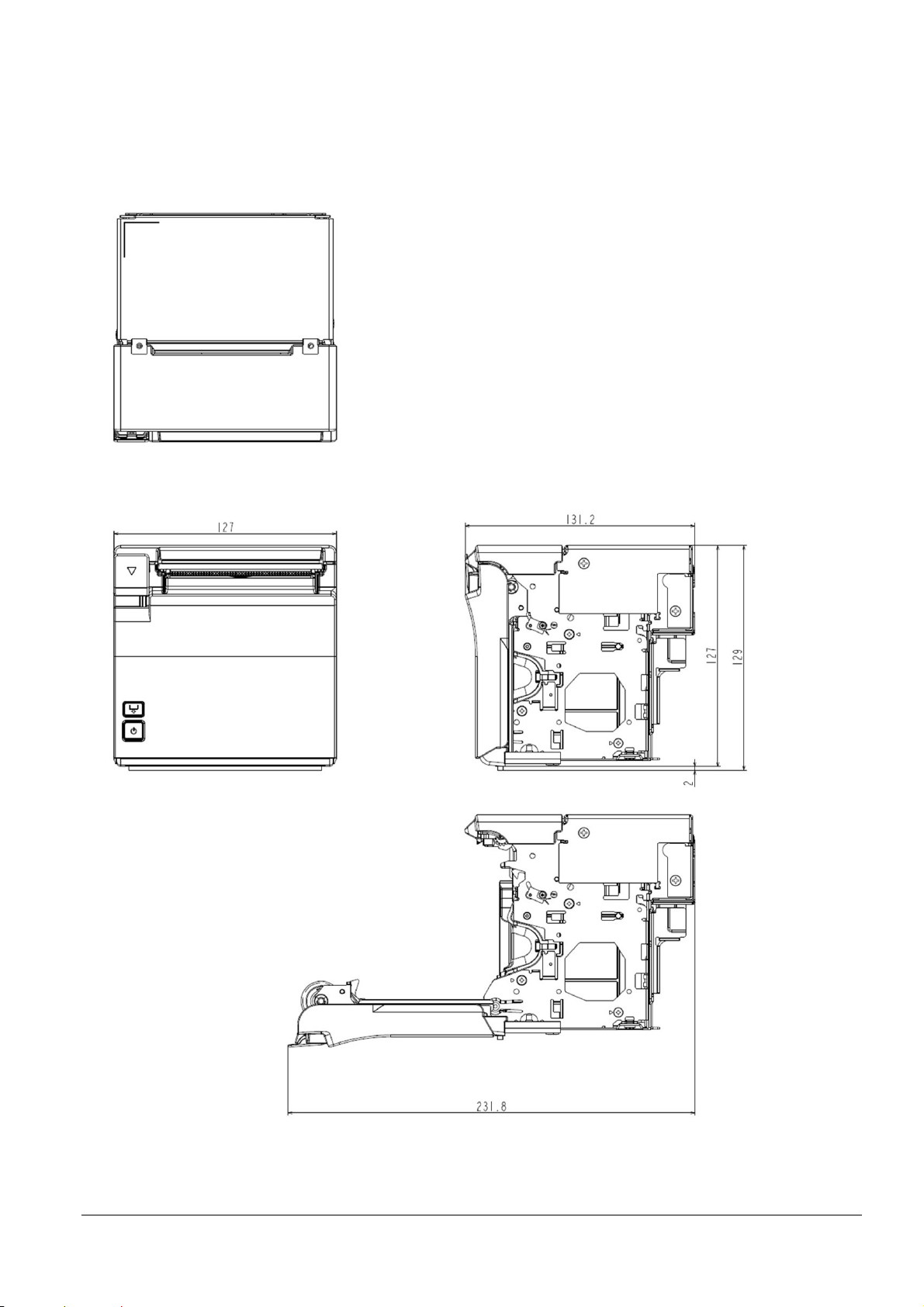

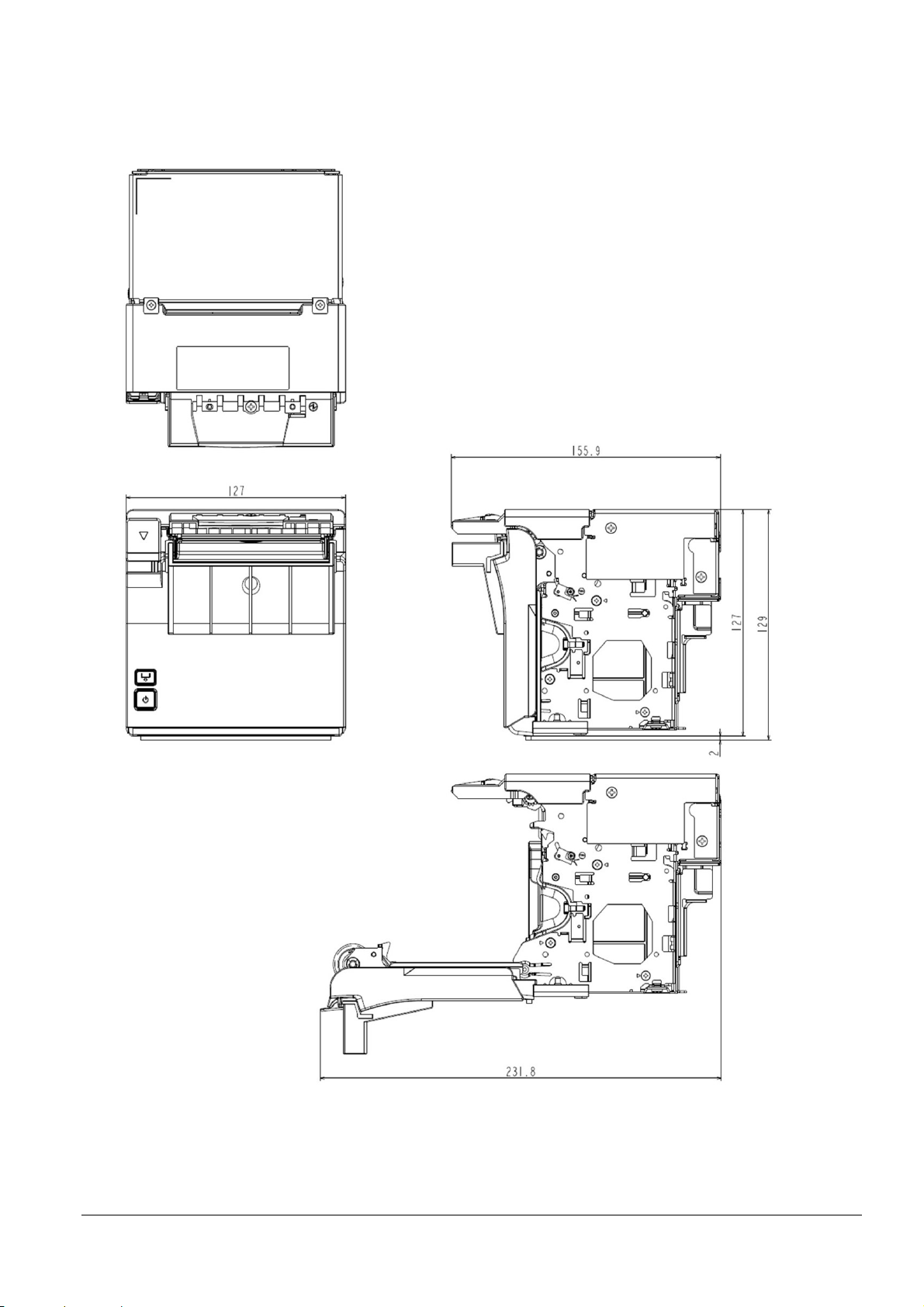

4.1 External Dimensions and Mass ............................................................................................................................ 42

4.1.1 Bezel Option Not Equipped .......................................................................................................................... 42

4.1.2 Bezel Option Equipped.................................................................................................................................. 42

4.2 Color ......................................................................................................................................................................... 42

4.3 External Dimensions .............................................................................................................................................. 43

4.3.1 Bezel Option Not Equipped .......................................................................................................................... 43

4.3.2 Bezel option equipped ................................................................................................................................. 44

4.4 Dimensions for Installing to Customer Device .................................................................................................. 45

Appendix A RECOVERY FROM AN AUTOCUTTER ERROR .................................................................................... 46

A.1 If You Can Open the Roll Paper Cover................................................................................................................ 46

A.2 If You Cannot Open the Roll Paper Cover .......................................................................................................... 46

Appendix B PRINT HEAD AND PLATEN ROLLER CLEANING ............................................................................... 47

B.1 Thermal Head .......................................................................................................................................................... 47

B.2 Platen Roller............................................................................................................................................................. 47

Appendix C NOTES ON USING THE DRAWER KICK CONNECTOR *For specified customer only ................. 48

C.1 Conditions for Using the Drawer Kick Connector ............................................................................................ 48

C.2 Notes on the pulse generating command (ESC p) ............................................................................................. 48

C.3 Using a drawer that does not meet the conditions in C.2 (ESC p, DLE DC4) ............................................... 49

Appendix D NOTES ON UPDATING THE MAINTENANCE COUNTER AND TURNING THE PRINTER'S

POWER OFF ............................................................................................................................................................................ 51

D.1 About Updating the Maintenance Counter ........................................................................................................ 51

D.2 Printer Power-off Procedures ............................................................................................................................... 51

Appendix E NOTES ON PRINTING BAR CODES AND 2-DIMENSIONAL SYMBOLS ........................................ 52

Appendix F NOTES ON SCANNING THE PRINT RESULT ON THE RECEIPT .................................................... 53

Appendix G NOTES ON USING THE ASB STATUS ..................................................................................................... 54

Appendix H NOTES ON ARP (AUTOMATIC REDUCTION OF PAPER) AND AUTOMATIC LOGO

PRINTING FUNCTION ......................................................................................................................................................... 55

H.1 ARP: Reduction of Excessive Top Margin, Reduction of Excessive Bottom Margin, Reduction of Line

Spacing, and Reduction of Line Spacing Where Extra Line Feeds Are Included ....................................................... 55

H.2 ARP: Reduction of Bar Code Height .................................................................................................................... 55

H.3 Automatic Logo Printing Function ...................................................................................................................... 55

Appendix I SETTING PAPER WIDTH ............................................................................................................................ 56

I.1 Notes ......................................................................................................................................................................... 56

I.2 Method for Installing 58 mm {2.28"} Roll Paper Guides ................................................................................... 56

Appendix J NOTES ON PRINTING AND BACKFEED ................................................................................................ 58

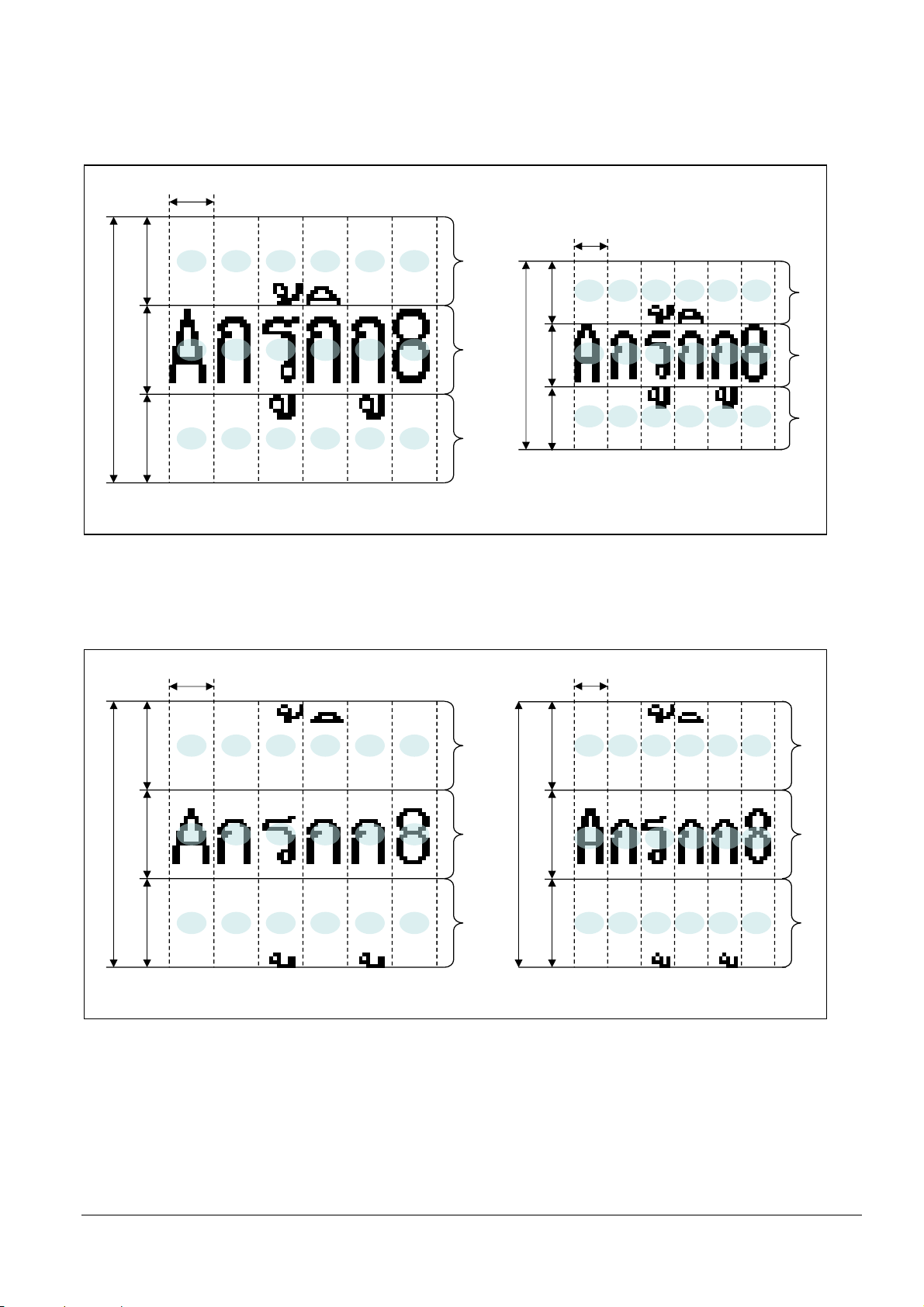

Appendix K THAI CHARACTER PRINTING ................................................................................................................. 59

K.1 Character Size for Printing Thai Characters ....................................................................................................... 59

K.2 Character Structure for Thai Character 1-pass Print Mode ............................................................................. 60

4

Page 12

K.3 Character Structure for Thai Character 3-pass Print Mode ............................................................................. 61

Appendix L USING A POWER SUPPLY OTHER THAN THE PS-180 ...................................................................... 62

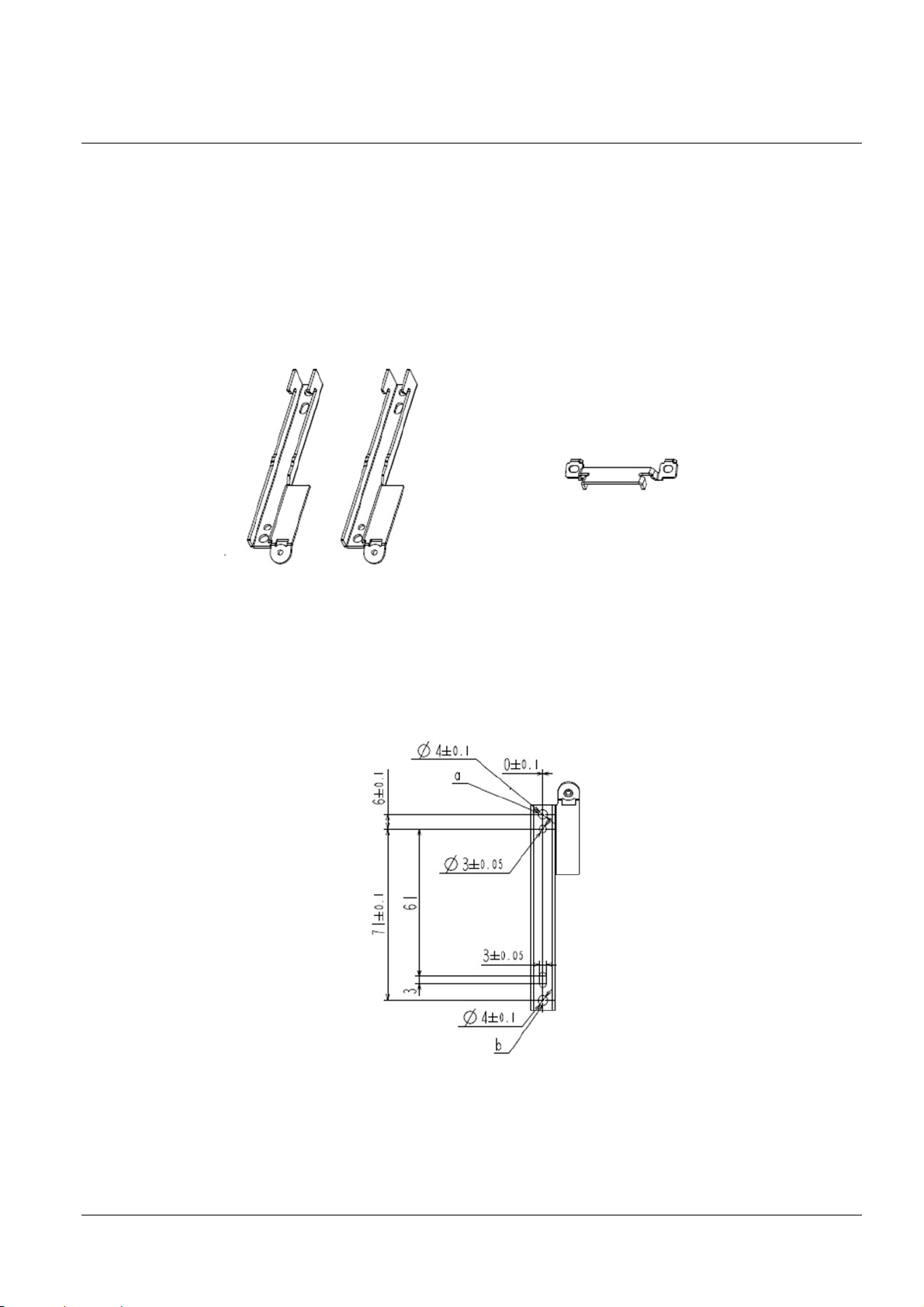

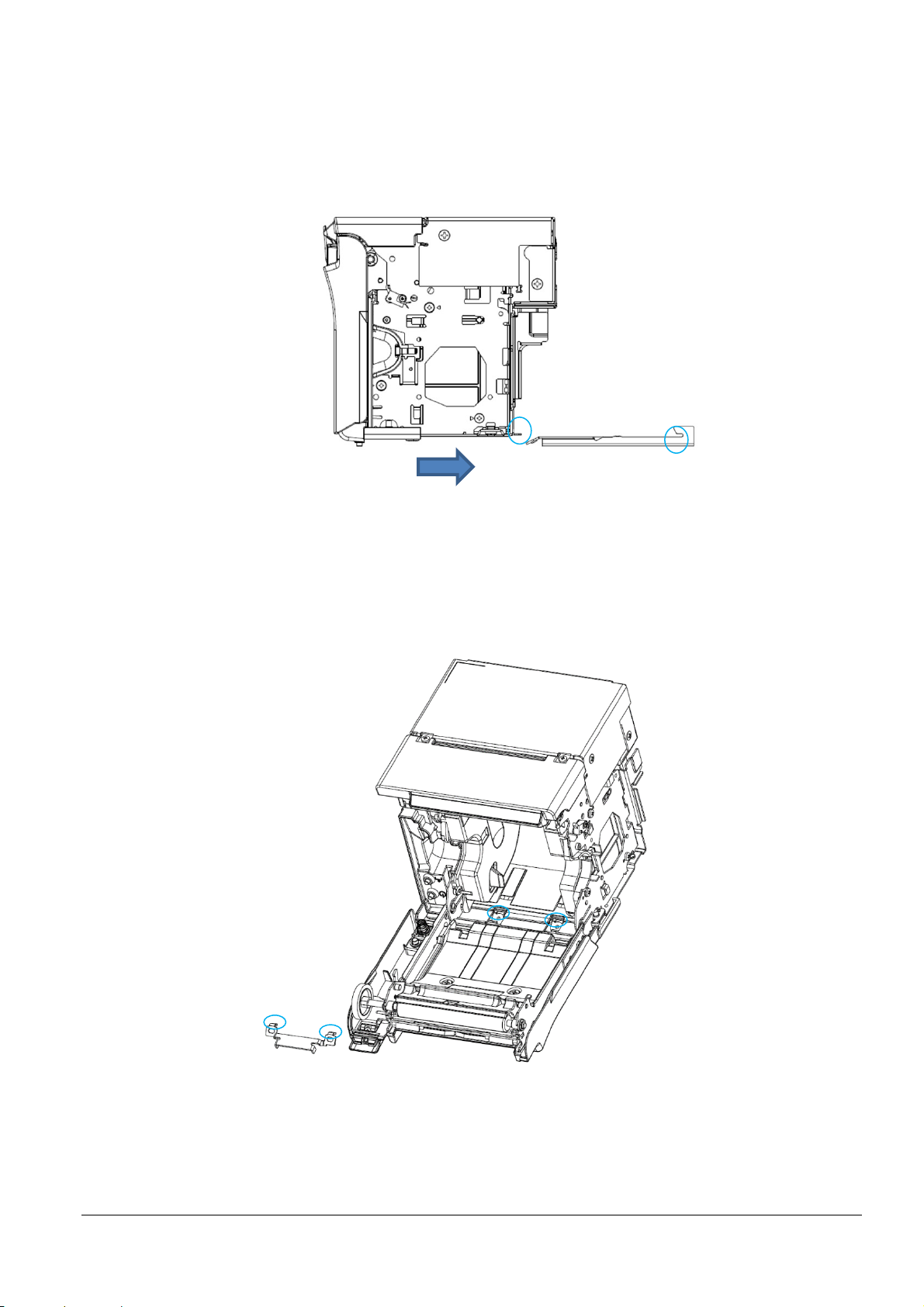

Appendix M PRINTER INSTALLATION DESIGN GUIDE ........................................................................................... 63

M.1 Notes on Printer Installation ................................................................................................................................. 63

M.2 Bezel Option Not Equipped .................................................................................................................................. 65

M.3 Bezel Option Equipped .......................................................................................................................................... 67

Appendix N INSTALLING THE POWER SWITCH AND POWER/FEED SWITCH COVER ............................... 69

N.1 Installing the Switch Cover .................................................................................................................................... 69

Appendix O REPLACEMENT FOR SMALL COVER OPEN LEVER ........................................................................... 70

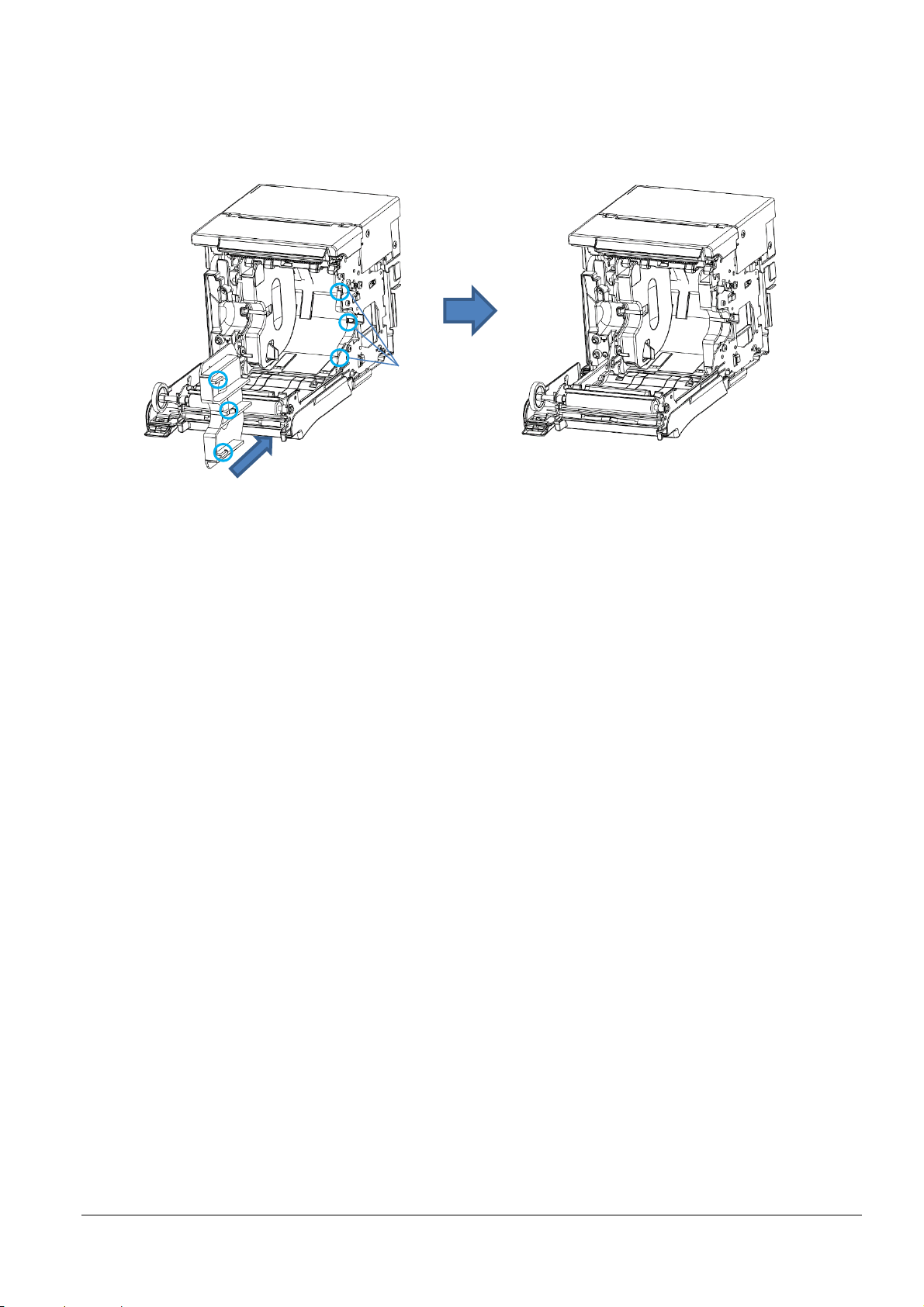

O.1 Replacement for Small Cover Open Lever .......................................................................................................... 70

Appendix P BEZEL OPTION (OT-BU30) ........................................................................................................................ 71

P.1 Notes on Using the Bezel Option (OT-BU30) .................................................................................................... 71

P.2 Installing the Bezel Option (OT-BU30) ............................................................................................................... 71

Appendix Q RECOMMENDED POWER SUPPLY ......................................................................................................... 73

Appendix R PRINTER UNIT HANDLING ...................................................................................................................... 74

R.1 When purchasing this product ............................................................................................................................. 74

R.2 Notes on use ............................................................................................................................................................. 74

R.3 Prohibitions ............................................................................................................................................................. 74

R.4 When not using for a long period ........................................................................................................................ 74

R.5 When using at low temperature ............................................................................................................................ 74

R.6 When using at high temperature .......................................................................................................................... 74

Appendix S Application Development Information ........................................................................................................ 75

S.1 Controlling the Printer ........................................................................................................................................... 75

S.1.1 ESC/POS .......................................................................................................................................................... 75

S.2 Controlling the Cash Drawer (Model for specified customer only) ................................................................ 75

S.2.1 ESC/POS Commands .................................................................................................................................... 75

S.2.2 For Windows Printer Drivers (APD) .......................................................................................................... 75

S.2.3 OPOS (OCX Driver) ...................................................................................................................................... 75

S.2.4 OPOS for .NET ............................................................................................................................................... 75

S.2.5 Epson ePOS SDK for Android ..................................................................................................................... 76

S.3 Controlling the Optional External Buzzer (Model for specified customer only) .......................................... 76

S.3.1 ESC/POS Command ...................................................................................................................................... 76

S.3.2 For Windows Printer Drivers (APD) .......................................................................................................... 76

S.3.3 OPOS (OCX Driver) ...................................................................................................................................... 76

S.3.4 OPOS for .NET ............................................................................................................................................... 76

S.3.5 Epson ePOS SDK for Android ..................................................................................................................... 76

S.4 Software .................................................................................................................................................................... 77

S.4.1 Development Kit ............................................................................................................................................ 77

S.4.2 Drivers ............................................................................................................................................................. 77

S.4.3 Utilities............................................................................................................................................................. 78

S.4.4 Download ........................................................................................................................................................ 78

5

Page 13

1 GENERAL SPECIFICATIONS

1.1 Print Specifications

(1) Print speed

The maximum is 100 mm/s {3.94"/s} when printing ladder bar codes, 2-dimensional symbols, or multi-tone

graphics.

The print speed changes automatically depending on the voltage applied to the printer and the condition of the

head temperature.

Maximum print speed may not be achieved depending on the data transmission conditions and the combination

of commands.

If the print speed fluctuates or intermittent printing occurs due to the data transmission conditions, printing

may be shaded or white lines may occur.

(2) Multi-tone graphics printing and limitations

Multi-tone graphics printing is possible (up to 16 tones when using our specified paper).

Multi-tone printing is not supported in Page mode.

Voids (white spaces) may appear depending on the paper type (uneven application of chromogenic coating).

It may not be possible to recreate an original image because a certain density level cannot be achieved due to th

following causes:

Environmental temperature, power supply and voltage

Paper type (chromogenic characteristics)

Paper variations, such as variations among manufacturing lots

Printing pattern (effect of heat accumulation of the print head or of voltage drop/speed change due to high

duty)

For multi-tone printing, the preservative quality of materials printed using multi-tone printing decreases in

direct relationship with the lighter the printing. Accordingly, do not use multi-tone printing when preservative

quality is required.

Reading quality of bar codes/2-dimensional symbols in multi-tone graphics printing is not guaranteed.

e

1.2 Character Specifications

Can be changed via the software settings.

For details, see 3.8.3 Software setting mode.

1.3 Autocutter

The cut paper may be pulled at the cut edge when it is removed, causing reduced printing pitch for the first line

o

f the next receipt.

To prevent dot displacement, after cutting, feed the paper approximately 1 mm {16/406"} or more before the firs

l

ine of printing. This operation can be enabled by enabling the pre-feed before next print, or by setting the top

margin specification via backfeed to 8.5 to 2 mm.

For the setting method, see 3.5.2. Software setting.

When issuing paper whose vertical length is short, ensure at least 20 mm.

t

6

Page 14

1.4 Paper Sensor

(1) Function

Detects whether paper is present in the paper path.

(2) Method

Microswitch

1.5 Roll Paper Supply Device

Use roll paper that is not deformed, and ensure there is no slack when setting.

(1) Function

Supplies paper with a width of 80 mm {3.15"} or 58 mm {2.28"}

(2) Method

Drop-in roll paper

1.6 Paper Specifications

(1) Paper specifications

Paper types Specified thermal paper

Form Roll paper, Chromogenic side: Outside

Size Roll paper diameter 83 mm {3.27"} maximum

Roll paper core

Roll width when taken up 58 + 0.5/-1.0 mm

Paper width 57.5 ± 0.5 mm {2.26 ± 0.02"} 79.5 ± 0.5 mm {3.13 ± 0.02"}

Paper thickness Maximum of 80 μm, minimum of 48 μm

Table 1.6.1 Paper Specifications

Paper width 58 mm Paper width 80 mm

Outside diameter: 18 + 0.5/-0.1 mm {0.71 + 0.02/-0.004"}

Inner diameter: 12 + 0.5/-0.1 mm {0.47 + 0.02/-0.004"}

Width: Same as the roll paper width, or smaller than the

paper width by 1 mm {0.04"} or less.

*Paper must not be pasted to the roll paper core

80 + 0.5/-1.0 mm

{2.28 + 0.02/-0.04"}

{3.15 + 0.02/-0.04"}

) Specified original paper

(2

Use the following specified original papers to ensure print quality and reliability.

Table 1.6.2 Specified Original Paper

Specified original paper Manufacturer

TF50KS-EY, TF60KS-E NIPPON Paper Industries Co., Ltd.

PD160R, PD190R Oji Imaging Media Co., Ltd.

P220AGB-1 Mitsubishi Paper Mills Limited.

AP45KS-ND, AP50KS-ND Jujo Thermal Oy

F5047(55), F5047(48) Mitsubishi HiTec Paper Europe GmbH

KT55FA, KT48FA, KT55PF, KT48PF Papierfabrik August Koehler SE

7

Page 15

(3) Print density adjustment depending on the specified original paper

In order to ensure optimal print quality and reliability, we recommend using the print density settings in the

table below.

The initial setting is 100% print density.

The print density can be changed using customized values.

When the print density setting is too dark, the print speed tends to drop.

When the print density setting is too dark, paper dust sticks to the print head surface, often resulting in faded

print.

Table 1.6.3 Specified Original Paper and Recommended Print Density Setting

Specified original paper Print density Print speed

TF50KS-EY, TF60KS-E, PD160R,

PD190R, P220AGB-1, AP45KS-ND,

AP50KS-ND, KT55PF

KT48FA, KT55FA, KT48PF, P5047(55) 110% 250 mm/s {9.84"/s}

(4) Notes on preprinting

Preprinted thermal paper may cause faulty printing and decreased print density due to the thermal head sticking

to the recording surface. Therefore, it is preferable to avoid using preprinted thermal paper.

If using preprinted thermal paper, make sure in advance that the conditions recommended by the original paper

manufacturing company (type of ink, print conditions, etc.) are met, and that there is no faulty printing or

decreased print density in the actual usage environment.

100% 250 mm/s {9.84"/s}

1.7 Print Area

(1) When paper width is set to 80 mm {3.15"}

(a) Maximum print area

72 ± 0.2 mm {2.84 ± 0.0079"} (576 dots)

(b) Left margin

Approx. 3.75mm {0.15"} for a paper width of 79.5 ± 0.5 mm {3.13 ± 0.02"}

(c) Right margin

Approx. 3.75 mm {0.15"} for a paper width of 79.5 ± 0.5 mm {3.13 ± 0.02"}

(2) When paper width is set to 58 mm {2.28"}

(a) Maximum print area

52.5 ± 0.2 mm {2 ± 0.00787"} (420 dots)

(b) Left margin

Approx. 2.5 mm {0.098"} for a paper width of 57.5 ± 0.5 mm {2.26 ± 0.02"}

(c) Right margin

Approx. 2.5 mm {0.098"} for a paper width of 57.5 ± 0.5 mm {2.26 ± 0.02"}

1.8 Printing and Cutting Positions

(1) Autocut

Approx. 9.5 mm {0.37"} from the print position

(2) Emergency cutting

Approx. 19.5 mm {0.77"} from the print position

8

Page 16

Approx. 9.5 mm

Paper feed direction

Approx. 19.5 mm

{0.77"}

Emergency cutting position

Autocut position

Print position

{0.37"}

Figure 1.8.1 Printing and Cutting Positions

These values are the design center values for the position of the structures, and vary from the top margin values.

When setting the cut position, take into account that values may vary as a result of paper slack or variations in

the paper.

9

Page 17

1.9 Internal Memory

(1) Receive buffer

4 KB or 45 bytes (Select using software settings)

(2) Downloaded character area

12 KB (Shared with the downloaded bit image area)

(3) Macro area

2 KB

(4) NV graphics area

384 KB

(5) Downloaded graphics area

208 KB

(6) NV user memory area

1 KB

1.10 Electrical Characteristics

(1) Supply voltage

+24 VDC ± 7%

*Safety Information

Be sure to use a safety-standards-applied power source that meets the following specifications.

Rated output: 24V/2.1A - 10.0A, Maximum output: 240VA or less

(2) DC current consumption (at 24 VDC, 25°C {77°F}, normal print density)

Operating: See Table 1.10.1 to 1.10.2.

Standby: Average current 0.1 A

10

Page 18

(a) When paper width is set to 80mm {3.15"}

52.5 mm {2.07"}

72 mm {2.84"}

EU-m30: 35 columns

EU-m30: 48 columns

52.5 mm {2.07"}

ABCDE

6789

67890

BCDE

ABCDE

6789

67890

BCDE

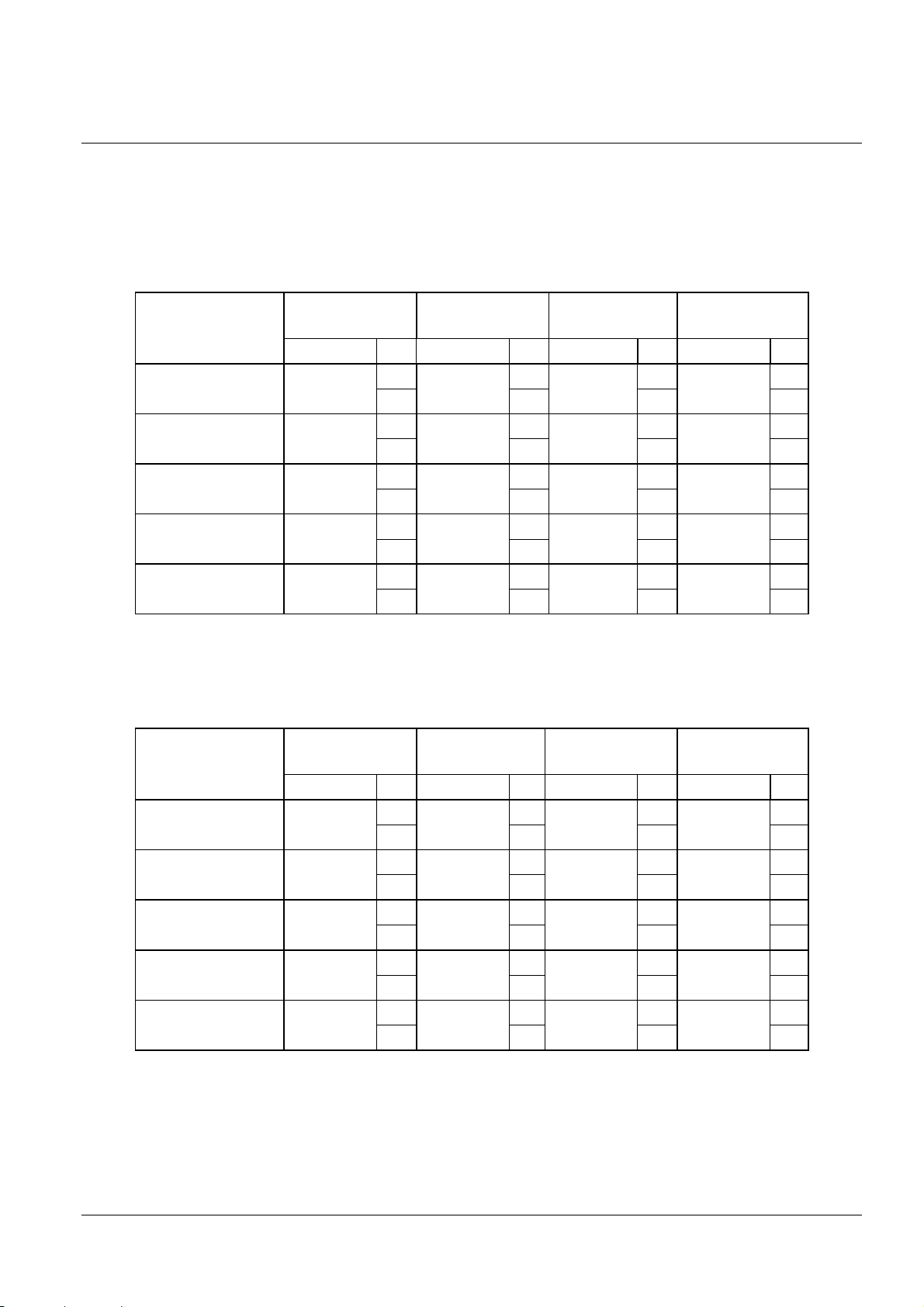

Table 1.10.1 Current Consumption (Operating) (when paper width is set to 80 mm {3.15"})

Print ratio Approximately 18% (with

the print pattern below)

Font A, ANK rolling

pattern for 30 lines + paper

feeing of 5 lines +

autocutting

(Repeats 20h to 7Fh)

Print

example

50%

(Printing length: 20 mm

{0.79"})

100%

(Printing length: 20 mm

{0.79"})

72 mm {2.84"}

EU-m30 Mean: Approximately 1.5 A Mean: Approximately 3.5 A Mean: Approximately 4.6 A

(b) When paper width is set to 58 mm {2.28"}

Table 1.10.2 Current Consumption (Operating)

Print ratio Approximately 18% (with

the print pattern below)

Font A, ANK rolling pattern

50%

(Printing length: 20 mm

{0.79"})

100%

(Printing length: 20 mm

{0.79"})

for 30 lines + paper feeing of

5 lines + autocutting

(Repeats 20h to 7Fh)

Print

example

EU-m30 Mean: Approximately 1.5 A Mean: Approximately 3.1 A Mean: Approximately 4.0 A

11

Page 19

Front

Rear

Figure 1.11.1 Scope of Static Electricity Evaluation

Note:

Printing with this product is assumed to be receipts or the equivalent. If printing is continuously performed

with a high print ratio, the overcurrent limitation may be operated. Therefore, the printing length must not

exceed 20mm {0.79"} when printing with 100% print ratio.

(3) AC power consumption (AC100 to 230 V / 50 to 60 Hz)

EU-m30

Operating: Approx. 24.2 W

Standby: Approx. 0.8 W

*Average power under operating conditions. Depends on use conditions and model.

1.11 EMI and Safety Standards Applied

(1) Safety standards

Certified as part (component) installed and used in product: Recognized component product

*Not certified as final product: Not final product

CB (IEC60950-1/IEC62368-1)

TUV Bauart (EN62368-1)

UL cULus UL62368-1/CAN/CSA No62368-1

(2) EMC

Europe EMC Directive (EN55032/24) EMC Class A

Oceania RCM AS/NZS CISPR32 Class A

North America FCC Class A, ICES-003 Class A

Scope of static electricity evaluation is shown below.

(3) Model for specified customer

In addition to aforementioned (1) safety standards and (2) EMC, acquire the following:

CQC GB4943/GB9254 Class A

*Product has no CQC mark displayed.

12

Page 20

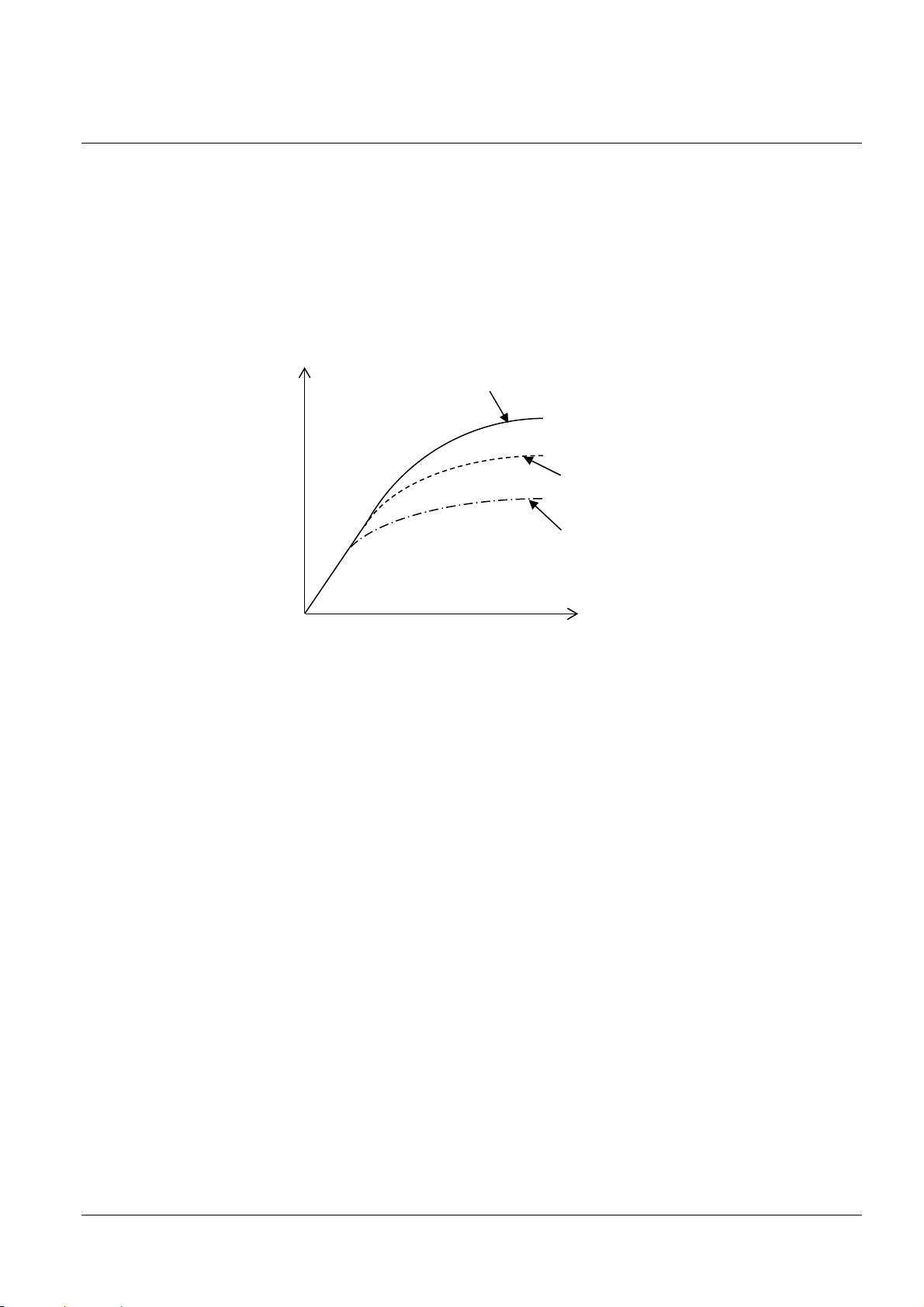

1.12 Reliability

Relative

humidity

Ambient temperature

[%RH]

[°C]

10

20

40

60

80

90

0

0

10

20

30

40

50

Guaranteed operating

environment

40°C {104°F} 65%

34°C {93°F} 90%

45°C {113°F} 50%

5°C {41°F} 90%

5°C {41°F} 10%

45°C {

113°F} 10%

(1) Life

Printer mechanism: 17 million lines (Repeating 10 line-printing + 5 line-paper feeding)

Print head 150 km

Autocutter 1,500,000 cuts

(At room temperature and normal humidity with specified original paper type no. being TF50KS-EY,

PD160R, KT55FA)

Note: End of life is defined as the point at which the component reaches the beginning of the wearout period.

(2) MTBF

360,000 hours

Note: Failure is defined as a random failure occurring at the time of the random failure period.

(3) MCBF

65,000,000 lines printed

Note: This is an average failure interval based on failures relating to wear-out and random failures

up to the service life.

1.13 Environmental Conditions

(1) Guaranteed operating environment (Temperature and humidity)

Figure 1.13.1 Guaranteed Operating Environment (Temperature and Humidity)

(2) Storage environment

-20 to 60°C {-4 to 140°F}, 10 to 90% RH

13

Page 21

(3) Vibration resistance

(a) When packed

Vibration conditions

Frequency: 5 to 55 Hz

Acceleration: Approximately 19.6 m/s² {2 G}

Sweep: 10 minutes (half cycle)

Duration: 1 hour

Directions: x, y, and z

Test method

After applying vibration under the above conditions, visually inspect the interior and exterior and check

operation.

Test result

No visible exterior or interior damage, and no abnormal operation.

(4) Impact resistance

(a) When packed

Drop conditions

Packing method: Epson standard package

Height: 60 cm {23.62"}

Directions: 1 corner, 3 edges, and 6 surfaces

Test method

After dropping under the above conditions, visually inspect the interior and exterior and check

operation.

Test result

No visible exterior or interior damage, and no abnormal operation.

(b) When unpacked

Drop conditions

Height: 5 cm {1.97"}

Directions: Lift one edge and release it (for all 4 edges)

Test method

After dropping under the above conditions, visually inspect the interior and exterior and check

operation.

Test result

No visible exterior or interior damage, and no abnormal operation.

14

Page 22

(c) When using included mounting brackets (impact resistance test specifications)

Z direction

Y direction

X direction

Impact acceleration: Approximately 147 m/s² {15 G}

Operation time: 11 ms

Direction, count: 1 time each in Y, Z directions

Point of impact: Unit installation point

Note: See Appendix M if impact may possibly be applied in X direction.

Figure 1.13.2 Direction of Impact

(5) Acoustic noise

(a) Operation noise

Test conditions: Epson standard

Test method: Epson standard

Measuring result: Approx. 60 dB (Bystander position)

Note: Measured value fluctuates depending on the paper used and the print conditions (print pattern, print

speed, print density, etc.).

(6) Altitude

3000m or less

1.14 Installation

Install in a level place.

See Appendix M for details.

1.15 Interface

1.15.1 Interfaces equipped

Note: For details about printing on models equipped with multiple interfaces, see 3.13 Printing Using Multiple

Interfaces.

Standard, for specified customer

USB interface

RS-232 serial interface

15

Page 23

1.15.2 USB interface

Pin number

Signal name

1

VBUS

2

D-

3

D+ 4 GND

Shell

Shield

Bit

Field

Description

Reserved

Reserved

0: Paper Not Empty

1: Paper Empty

4

Select

1: Select (Fixed)

0: Error

1: Not Error

2, 1, 0

Reserved

Reserved

2 1 4 3 2 1 4

3

(1) USB connector

Type USB upstream port connector (USB type-B connector)

Pin assignments

(2) USB communication specifications

(a) USB functions

Overall specifications: Complies with USB 2.0

Communication speed: Full-Speed (12 Mbps)

Communication method: USB bulk transmission method

Power supply specifications: USB self power supply function

Current consumed by USB bus: 2 mA (provided entirely from the main unit)

USB packet size

With full-speed connection

USB bulk OUT: 64 bytes

USB bulk IN: 64 bytes

USB device class

USB vendor-defined class and USB printer class

Switching of the class can be set by the software settings on startup.

(For the setting method, see 3.5.2.)

(b) Receiving the status from the printer

The status of the printer is sent to the host computer via the USB bulk transmission method.

The USB bulk transmission method is a host-controlled transmission method. Unlike RS-232 transmission,

it cannot spontaneously interrupt data transmission to the host computer.

The printer has a 128-byte status data buffer. Statuses that exceed the buffer capacity are canceled. In

order to avoid lack of status data, it is necessary to periodically retrieve status data at the host computer.

(c) USB Device Requests of USB printer class

GET PORT STATUS

If this USB device request is requested, the printer returns the following statuses.

5 Paper Empty

3 Not Error

16

Page 24

GET DEVICE ID

If this USB Device Request is requested, the printer returns the following character string.

[00H][XXH] *1

MFG:EPSON;

CMD:ESC/POS;

MDL:EU-m30; *2

CLS:PRINTER;

DES:EPSON[SP]EU-m30; *2

CID:EpsonTM00001021; *2

*1: DeviceID character string size

*2: The character string depends on the language model and mode.

SOFT RESET

The host computer uses this USB Device Request when initializing the printer input buffer.

(3) Notes

Use a cable that complies with the USB 2.0 standard.

17

Page 25

1.15.3 RS-232 serial interface

Pin number

Function

1 – 2

RXD

3

TXD

4

DTR

5

SG 6 DSR

7

RTS

8

–

9 – Shell

Shield

(1) Connectors

Type D-SUB9 (Male)

Pin assignments

(2) Specifications (Complies with RS-232)

Data transmission method: Serial

Synchronization: Asynchronous

Handshaking: DTR/DSR or XON/XOFF control

Signal levels: MARK = -3 to -15 V: Logic "1"/ OFF

SPACE = +3 to +15 V: Logic "0"/ ON

Transmission speeds: 2400, 4800, 9600, 19200, 38400, 57600, 115200 bps

[bps: bits per second]

Bit length: 7 and 8-bit

Parity settings: None, even, odd

Stop bits: 1 or more

Connector: D-SUB9 (Male)

Notes:

Handshaking, bit length, transmission speed and parity settings are the same as the setting of the

communication conditions of the serial interface (3.5.2).

The stop bit for data transfer from the printer is fixed at 1 bit.

(3) Online/Offline switching

This printer does not have an online/offline switch. This printer goes offline under the following conditions:

During the period from when the power is turned on until the printer is ready to receive data after

mechanism initialization

During a self-test

When the cover is open

Feeding paper via Feed switch

When the printer stops printing due to a paper-end (when a paper-end is detected by the roll paper-end

sensor)

When waiting for a switch to be pressed during macro execution

When an error has occurred

18

Page 26

Offline

(4) Interface connector terminal assignments and signal functions

Table 1.15.1 Signal Layout and Functions

Pin

number

Signal

name

Signal

direction

Function

2 RXD Input Data reception

3 TXD Output Data transmission

4 DTR Output When DTR/DSR control is selected:

This signal indicates whether the printer is busy.

SPACE indicates that the printer is ready to receive data, and MARK

indicates that the printer is busy.

The printer becomes busy (MARK) under the following conditions:

Printer status

(1) During the period from when the

power is turned on until the printer

is ready to receive data after

mechanism initialization

(2) During a self-test

(3) When the cover is open

(4) Feeding paper via Feed switch

(5) When the printer stops printing

due to a paper-end

(6) When waiting for a switch to be

pressed during macro execution

(7) When an error has occurred

(8) When the receive buffer is full (*1) BUSY BUSY

When XON/XOFF control is selected:

The signal indicates whether the printer is correctly connected and is

ready to receive data from the host computer.

SPACE indicates that the printer is correctly connected and is ready to

receive data from the host computer. The signal is always SPACE

except in the following cases:

• During the period from when the power is turned on until the

printer is ready to receive data after mechanism initialization

• During a self-test

5 SG – Signal ground

6 DSR Input This signal indicates whether the host computer can receive data.

SPACE indicates that the host computer can receive data, and MARK

indicates that the host computer cannot receive data. When DTR/DSR

control is selected, the printer transmits data after confirming this signal

(except when transmitting data by DLE EOT or GS a).

When XON/XOFF control is selected, the printer does not check this

signal.

7 RTS Output Same as DTR

Memory switch

1-3 status

ON OFF

BUSY

BUSY

----

----

----

----

----

BUSY

BUSY

BUSY

BUSY

BUSY

BUSY

BUSY

*1: Definition of “receive buffer full”

1) When the receive buffer capacity is specified as 4 KB (Memory switch 1-2 is off ):

19

Page 27

(1) If Memory switch 5-2 is OFF:

The printer status becomes "buffer full" from when the remaining space in the receive buffer drops to 128

bytes until such time that the remaining space in the receive buffer increases to 256 bytes.

(2) If Memory switch 5-2 is ON:

The printer status becomes "buffer full" from when the remaining space in the receive buffer drops to 128

bytes until such time that the remaining space in the receive buffer increases to 138 bytes.

2) When the receive buffer capacity is specified as 45 bytes (Memory switch 1-2 is ON):

The printer status becomes "buffer full" from when the remaining space in the receive buffer drops to 16 bytes

until such time that the remaining space in the receive buffer increases to 26 bytes regardless of the Memory

switch 5-2 status.

The printer ignores the data received when the remaining space in the receive buffer is 0 byte.

(5) XON/XOFF transmission timing

When XON/XOFF control is selected, the printer transmits an XON or XOFF signal at the timing shown below.

The transmission timing differs depending on the Memory switch 1-3 setting.

Printer status

Memory switch 1-3

status

ON OFF

XON

transmission

(9) First time the printer goes online after turning the power on

(10) When the receive buffer full status is cleared

(11) When the printer status changes from offline to online

(12) When the printer recovers from a recoverable error by use of

Tran smit

Tran smit

––

––

Tran smit

Tran smit

Tran smit

Tran smit

a command

XOFF

transmission

(13) When the receive buffer becomes full

(14) When the printer status changes from online to offline

Tran smit

––

Tran smit

Tran smit

Notes:

The XON code is <11>H and the XOFF code is <13>H.

XON is not transmitted when the receive buffer is full even in case (3) above.

XOFF is not transmitted when the receive buffer is full even in case (6) above.

(6) RS-232 connection example

Host computer side Printer side

TXD ------------------------------------ RXD

DSR ------------------------------------ DTR

CTS ------------------------------------ RTS

RXD ------------------------------------ TXD

DTR ------------------------------------ DSR

F.G. ------------------------------------ F.G.

S.G. ------------------------------------ S.G.

Notes:

Be careful that the status is not handshaking if connected to a DCE (data is discharged). (DCE: Data Circuit

Terminating Equipment)

Transmit data to this printer after turning on the power and initializing the printer.

(7) Notes on setting Memory switch 1-3 to ON

1) Print operation stops but the status does not become busy when an error has occurred, the cover is open,

printing stops due to a paper-end, or paper is fed by using the Feed switch.

20

Page 28

2) When setting Memory switch 1-3 to ON to enable handshaking with the printer, be sure to check the printer

1 2 3

status using the GS a command and the automatic status back function of the data dependent on that

command.

In this setting, the default value of n for GS a is 2. The printer automatically transmits the printer status

when the online/offline status changes.

3) Be sure that the receive buffer does not become full when using DLE EOT, DLE ENQ, or DLE DC4.

Notes on using a host computer that cannot transmit data when the printer is busy:

DLE EOT, DLE ENQ, and DLE DC4 cannot be used if an error occurs when the printer is busy due to a

receive buffer-full status.

Notes on using a host computer that can transmit data when the printer is busy:

A DLE EOT, DLE ENQ, or DLE DC4 command used while transmitting bit-image data is processed as

bit-image data if the receive buffer becomes full while transmitting bit-image data.

Data transmitted when the receive buffer is full may be lost.

Example:

Check the printer status using GS r after transmitting each line of data with a 4-KB receive buffer. The

amount of data for one line must not make the receive buffer become full.

(8) Notes on setting Memory switch 1-7 to ON

1) When using #6 pin (DSR) to reset, turn memory switch 1-7 ON.

2) When memory switch 1-7 is turned ON, the printer enters reset status when MARK level is input to #6 pin

(DSR) or connector (terminal) is open.

1.16 Connectors

1.16.1 Interface connector

(1) See Section 1.15. Interfaces.

1.16.2 Power supply connector

(1) Function

This is the connector for the external power supply.

Using PS connector, it is possible to connect optional power supply PS-180, etc.

(2) Pin assignments

Pin number Function

1 +24 V

2 GND

3 N.C

SHELL F. G

(3) Model

Printer side: Hosiden TCS7960-532010 or equivalent

User side: Hosiden TCP8927-631167 or equivalent

21

Page 29

1.16.3 Drawer kick connector (modular connector) *For specified customer only

Frame GND

Drawer kick drive signal 1

Drawer kick open/close signal

+24 V

Drawer kick drive signal 2

Signal GND

ON

OFF

t1×2 ms

t2×2 ms

6 1 6

1

(1) Function

Connect to the drawer or the optional external buzzer.

The pulse specified by the ESC p or DLE DC4 command is output to this connector.

The host computer can confirm the status of the input signal by using the DLE EOT, GS a, or GS r command.

(2) Pin assignments

Pin number Signal name Direction

1

2

3

4

5

6

Note: +24 V is output through pin 4 when the power is turned on. However, pin 4 must be used only for the

drawer or the optional external buzzer.

(3) Connector model

Printer side: MOLEX 52065-6615 or the equivalent

User side: 6-position 6-contact (RJ12 telephone jack)

–

Output

Input

–

Output

–

(4) Drawer kick drive signal

Output voltage: Approximately 24 V

Output current: 1 A or less

The drawer kick solenoid must have a resistance value of 24 Ω or higher.

Do not use one that is less than 24 Ω, as it will result in an overcurrent.

Figure 1.17.1 shows the ON/OFF signal of the drawer kick solenoid.

t1 (ON time) and t2 (OFF time) are specified by ESC p or DLE DC4.

Figure 1.16.1 Drawer Kick Drive Signal

22

Page 30

(5) Drawer open/close signal

A

B

F. G

P-GND +24V

1

2

3

4

5

6

P-GND

Control device

Drawer-kick connector

Shielded

Drawer-kick solenoid

Drawer open/close switch

User side (Drawer side)

Printer side

Figure 1.16.2 Drawer Kick Connection Diagram

Use a shielded cable for the drawer connector cable.

Two driver transistors cannot be energized simultaneously.

The drawer drive duty should be designed by the user so as to use the following ratio.

ON time

(ON time + OFF time)

≤ 0.2

Be sure to use the printer power supply (connector pin 4) for the drawer power source.

The resistance of the drawer kick solenoid must not be less than specified. Otherwise, an overcurrent could

damage the solenoid.

Do not connect a telecommunication network to the drawer kick connector.

Do not insert the USB connector ("B" Plugs of the series B connectors) into the drawer kick connector. Doing

so may damage the connector, printer, or the host computer system.

(6) Connection of the optional external buzzer

The optional external buzzer can be connected to the drawer kick connector.

When the optional external buzzer is connected, be sure to set the optional external buzzer to Enable with the

software setting. (See 3.5.2 for how to change the setting.)

When the optional external buzzer is used, a drawer cannot be used. It is prohibited that both the optional

external buzzer and the drawer are connected at the same time by using a branched connector.

23

Page 31

1.16.4 Allowable interface/power supply cable dimensions

12

11

13

13

Note: User must confirm that the connector plug and cable fit in the storage space.

<USB cabel>

(Type-B Plug)

<Power supply cable>

<Serial cable>

24

Page 32

2 Structure

1

3

2

1

2

3

2.1 EU-m30, Standard model

(1) Exterior

1: Cover open lever 2: Feed button 3: Power switch

(2) Interfaces equipped

USB and serial (RS-232, D-Sub 9 pin)

(3) Connector layout

1: Power supply connector 2: USB connector (Type-B) 3: Serial connector

(4) Accessories

Roll paper (φ 35 mm)

Switch cover

For power switch

For power/feed switch

Small cover open lever, including 1 spare screw

Roll paper guides for 58 mm {2.28"} paper: 2

Equipment mounting brackets: 2

Product fixing brackets, including 2 screws + 1 spare (total of 3 screws)

(5) Options

Bezel option: Model: OT-BU30

Power supply adapter: Model: PS-180

25

Page 33

2.2 For specified customer

1 2 3

4

(1) Exterior

Same as EU-m30 (See 2.1.(1).)

(2) Interfaces equipped

USB and serial (RS-232, D-Sub 9 pin)

(3) Connector layout

1: Power supply connector 2: USB connector (Type-B) 3: Serial connector 4: DK connector

(4) Accessories

Roll paper (φ 35 mm)

Switch cover

For power switch

For power/feed switch

Small cover open lever, including 1 spare screw

Roll paper guides for 58 mm {2.28"} paper: 2

Equipment mounting brackets: 2

Product fixing brackets, including 2 screws + 1 spare (total of 3 screws)

(5) Options

Bezel option: Model: OT-BU30

Power supply adapter: Model: PS-180

Optional external buzzer: Model: OT-BZ20

26

Page 34

3 Function

3.1 Control Commands

See "ESC/POS Command Reference" (www.epson-biz.com/pos/reference/).

3.2 Character Code Tables

See "Character Code Tables for TM Printers"(www.epson-biz.com/pos/reference/).

3.3 Switches

3.3.1 Power switch

(1) Type

Locking push switch

(2) Function

(a) Turn the power on or off.

Notes:

Operate the power switch with the power connector connected.

If turning on the power after turning the power off, first check that the panel LED has turned off before doing

so.

If turning off the power without using the power switch, or if you do not execute the DLE DC4 (fn = 2)

command, the maintenance counter value may not be updated properly. For the proper usage of the

maintenance counter, see Appendix D.

3.3.2 Feed button

(1) Type

Non-locking push switch

(2) Function

1) Executes paper feeding. Press once to feed paper based on the line spacing set by the ESC 2 and ESC 3

commands, or press and hold to continue feeding paper.

Note: Paper feeding cannot be performed under the following conditions.

When the paper is at the end

When the roll paper cover is open

While printing is in progress

When set to disabled by ESC c 5.

2) If you push this button when the printer is in the macro execution standby state, the defined macro is

executed.

3) When executing a self-test, use the button to temporarily stop or restart the test.

4) Starts printing/setting mode for each type of information, selects the menu, and executes it.

27

Page 35

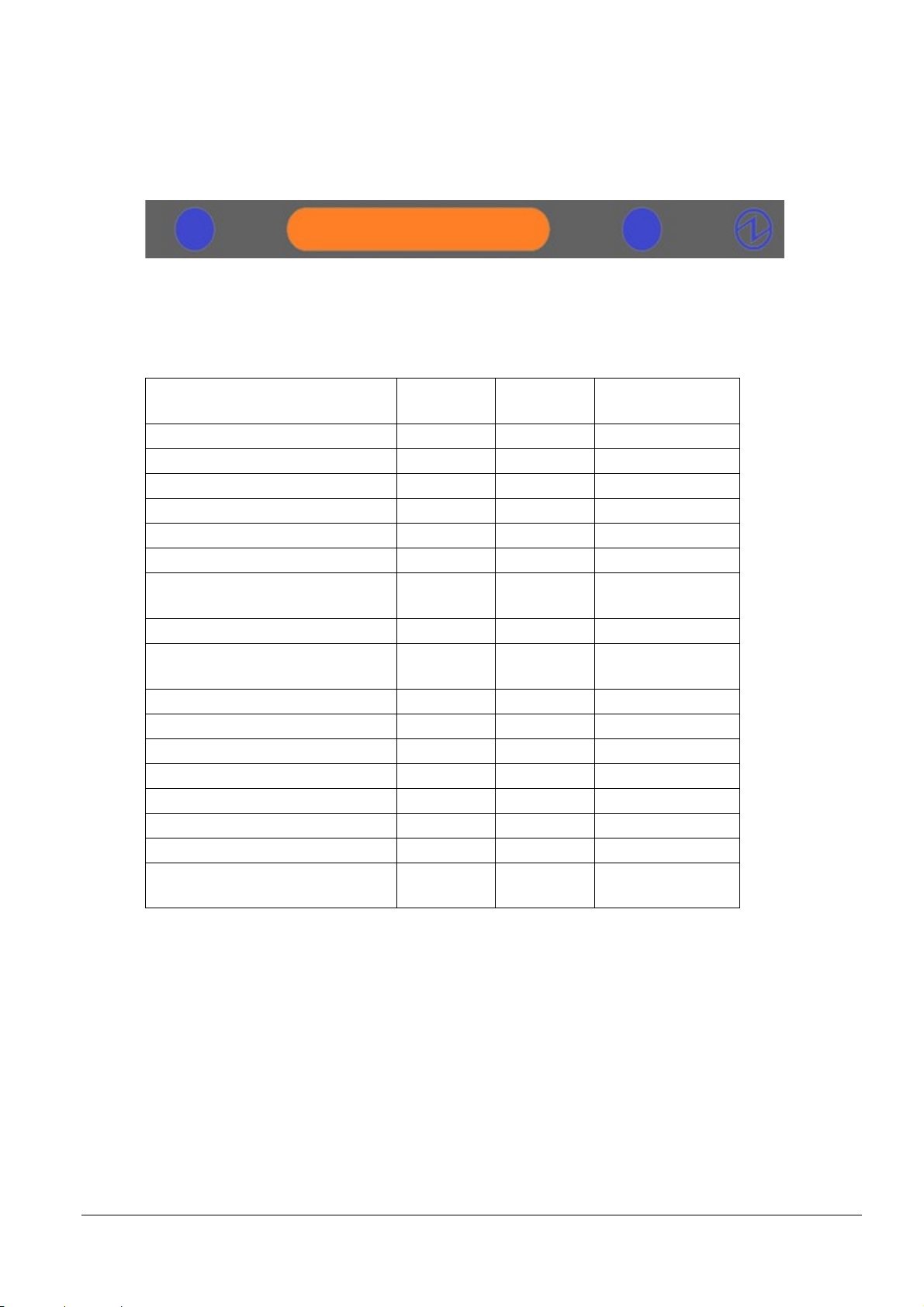

3.4 Indicators

3 3 2

1

3.4.1 Displayed color and icon

1: POWER LED (Blue) 2: ERROR LED (Orange) 3: Flashing LED (Blue)

3.4.2 Displayed patterns

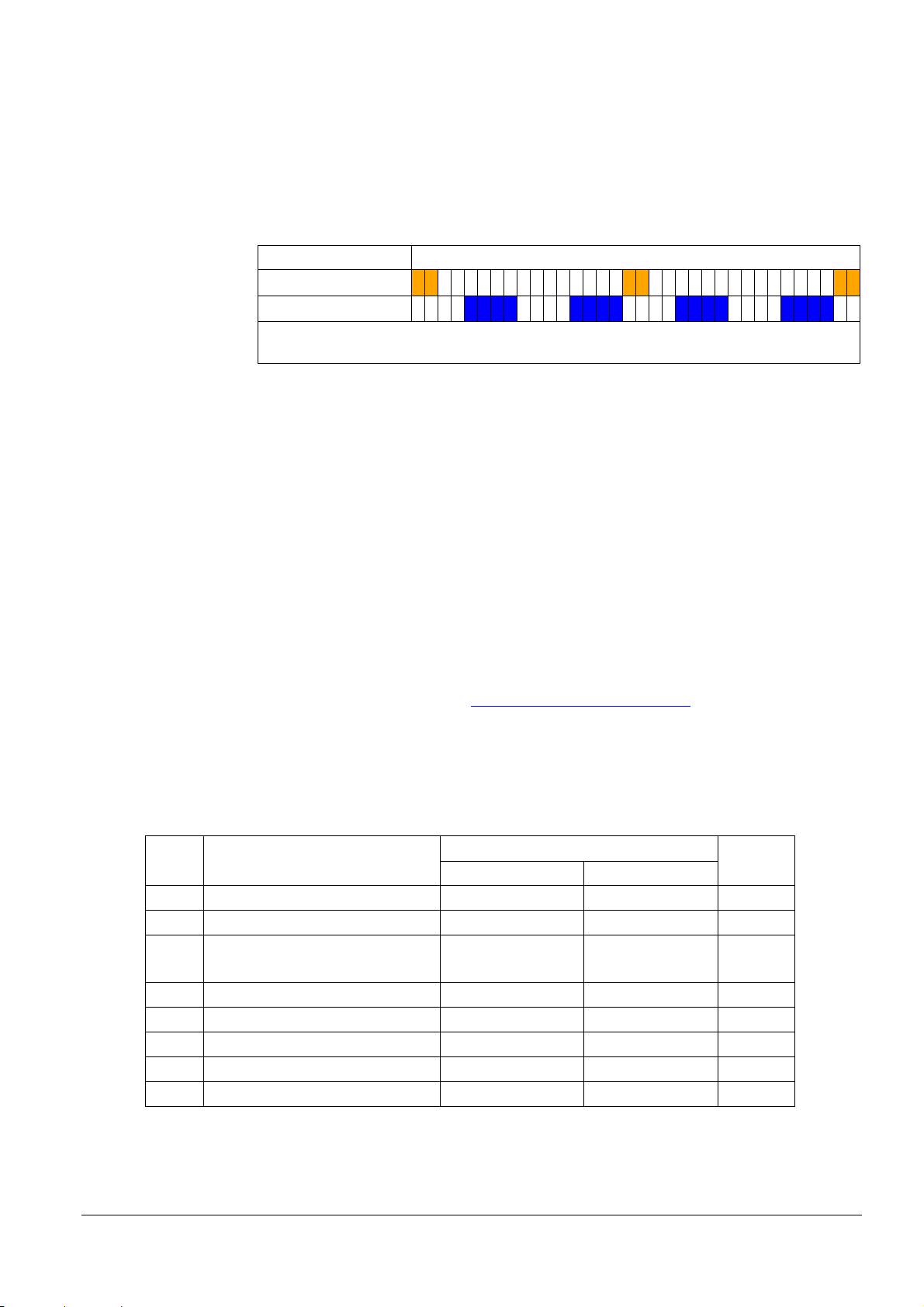

(1) Printer status icon

POWER

Normal status On Off On or [Off]*3

Initializing after power-on On On On

Executing self-test On *1 Off

Continued self-test standby On Flashing - (1) Off

Paper is being fed by the Feed button On *1 Off

Macro execution standby On Flashing - (1) Off

Roll paper cover open when not

printing

Paper-end On On Off

Near-end On Flashing - (3)

Errors that recover automatically On On Off

Recoverable errors On On Off

Unrecoverable errors On Flashing - (4) Off

Updating firmware Flashing - (1) Off Off

In firmware forced update mode On On On

Power OFF in process Flashing - (1) On Off

Power OFF standby *2 Flashing - (2) Off Off

Printing completed flashing

(Attention flashing)

ERROR

LED

On On Off

On *1 [Flashing - (5) *4 *5]

LED

*5

Flashing

LED

According to normal

status above

or Off *3

Flashing - (1): Repeats between on for 320 ms then off for 320 ms.

Flashing - (2): Repeats between on for 160 ms then off for 2,400 ms.

Flashing - (3): Repeats between on for 320 ms then off for 2240 ms.

Flashing - (4): Repeats between on for 480 ms then off for 160 ms.

Flashing - (5): Repeats between on for 640 ms then off for 640 ms.

*1 Depends on the paper sensor status. It is Off if there is paper, and On if there is no paper. Furthermore,

when a near-end is detected (if equipped with near-end sensor), the light is Flashing - (4), and when a nearend is not detected, it depends on the paper sensor status.

*2 See Appendix D.2.

*3 Can select with the EU-m30 Utility. [ ]: Set when shipped.

*4 Flashing starts when print job is completed. Can select the flashing duration with the EU-m30 Utility.

When the flashing duration ends, the light turns Off.

If, however, a new print job is received during the preset duration and printing starts, the flashing stops at

28

Page 36

that time.

ERROR LED

Also, if the time from the completion of a print job (end of operation) to the start of the next print job is less

than 640 ms, the next print job will start without flashing.

For details, see 3.5.2 Software setting.

*5 A Near-End Error (orange) LED and Printing Completed (blue/attention) LED will not flash at the same

time.

3.5 Printer Setting

3.5.1 DIP switch settings

This printer is not equipped with DIP switches.

3.5.2 Software setting

(1) Memory switches

Can be changed using one of the following methods.

1 segment: 160 ms Elapsed time

Flashing LED

640 ms

640 ms

(a) User setup commands: GS ( E

Step 1: Moves to the user setting mode with GS ( E <Function 1>

Step 2: Change settings with GS ( E <Function 3>.

Step 3: End the user setting mode with GS ( E <Function 2>.

For details, see "ESC/POS Command Reference" (www.epson-biz.com/pos/reference/

(b) Software setting mode (except some functions)

For details, see 3.8.3 Software setting mode.

(c) EU-m30 Utility

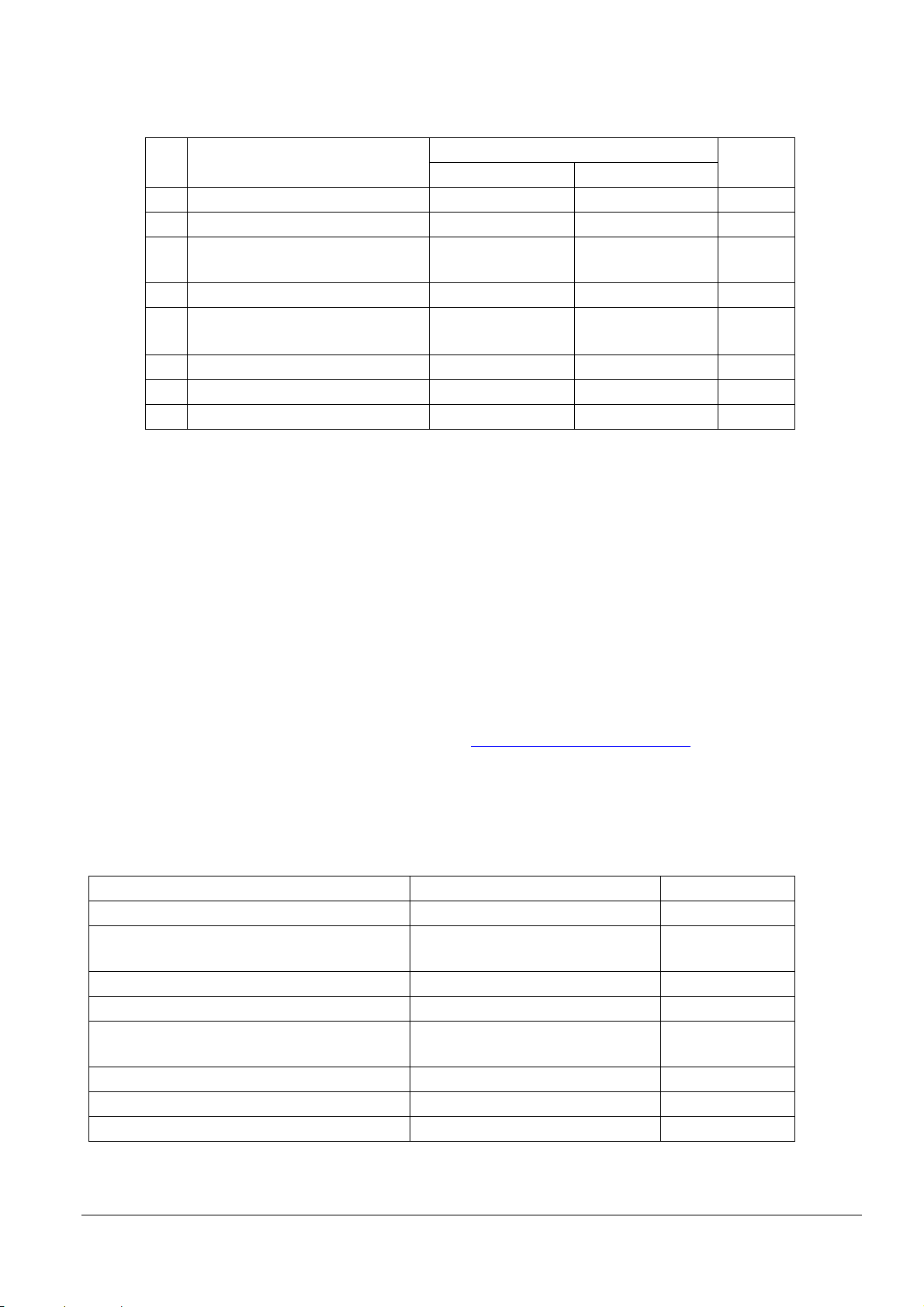

Table 3.5.1 Memory Switch 1 (Msw1)

Msw Function Setting value Factory

1-1 (Reserved) - - 48 (OFF)

1-2 Receive buffer capacity 4 KB 45 bytes 48 (OFF)

1-3 Condition for BUSY Receive buffer full

1-4 Data processing with reception error Replace with "?" Ignored 48 (OFF)

1-5 Automatic line feed Always disabled Always enabled 48 (OFF)

1-6 (Reserved) - - 48 (OFF)

1-7 Pin 6: Reset signal selection Not used Used 48 (OFF)

1-8 (Reserved) - - 48 (OFF)

48 (OFF) 49 (ON)

Receive buffer full 48 (OFF)

and offline

).

setting

29

Page 37

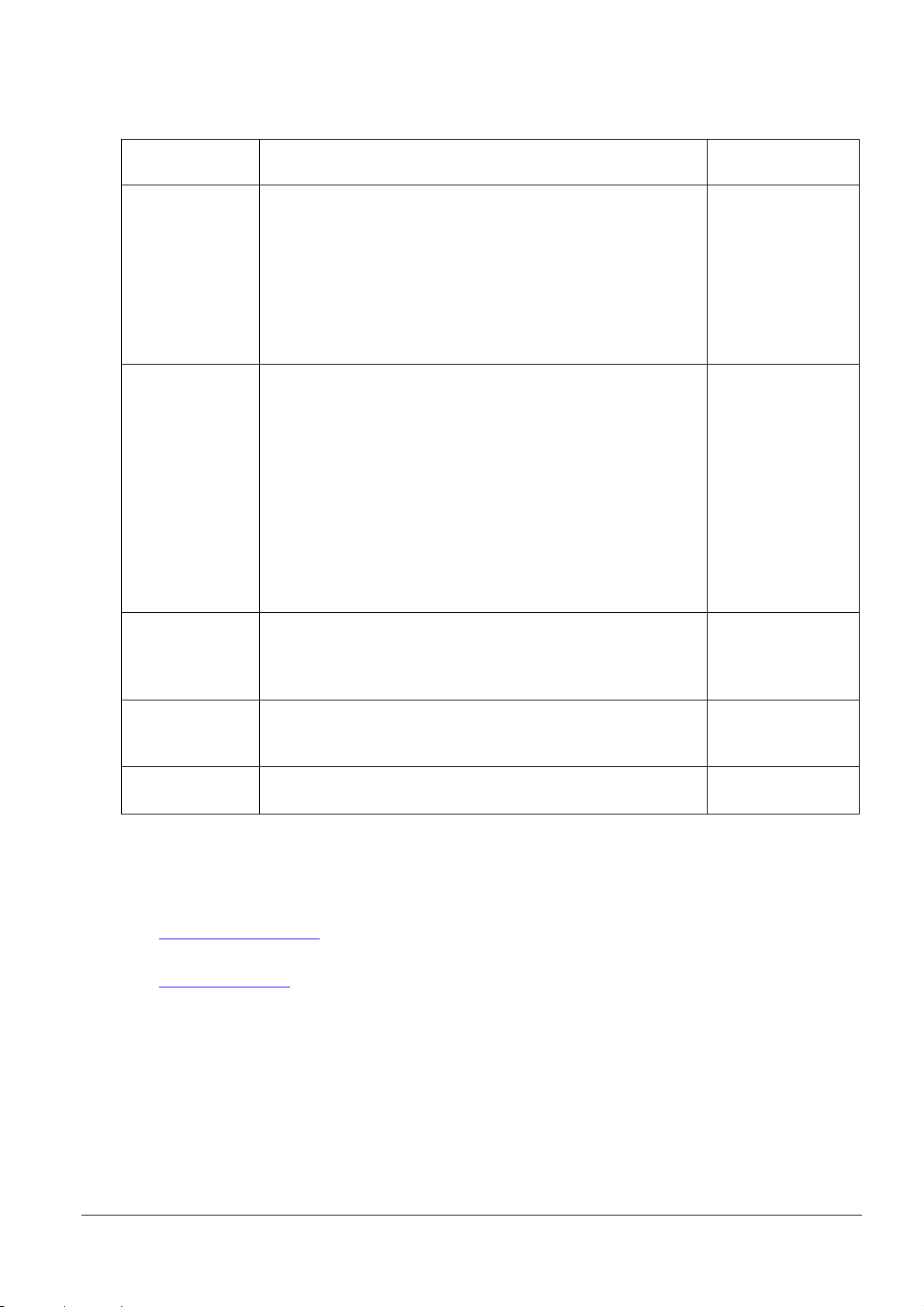

Table 3.5.2 Memory Switch 5 (Msw5)

48 (OFF)

49 (ON)

5-2

(Reserved)

– – 48 (OFF)

Msw Function Setting value Factory

setting

5-1 USB power-saving function *1 Enabled Disabled 48 (OFF)

5-3 Paper sensors to output paper end

signal

Roll paper end, nearend sensor enabled

Disabled 48 (OFF)

5-4 Error signal output Enabled Disabled 48 (OFF)

5-5 Pre-feed before next print

*2

Disabled Enabled 48 (OFF)

*3

5-6 Roll paper near-end sensor Disabled Enabled 49 (ON)

5-7 (Reserved) – – 48 (OFF)

5-8 (Undefined) – – 48 (OFF)

*1: Valid only when the USB interface communication condition is set to the vendor-defined class and the

system configuration is set so that the USB driver can support the USB power-saving function.

*2: When a customized value (specification for the top margin by backfeed) is set and back feed occurs, this

setting is disabled.

*3: Japanese model only, default setting 49 (ON).

(2

) Customized value setting

Can be changed using one of the following methods.

(a) User setup commands: GS ( E

Step 1: Moves to the user setting mode with GS ( E <Function 1>

Step 2: Change the setting with GS ( E <Function 5>.

Step 3: End the user setting mode with GS ( E <Function 2>.

For details, see "ESC/POS Command Reference" (www.epson-biz.com/pos/reference/

).

(b) Software setting mode (except some functions)

For details, see 3.8.3 Software setting mode.

(c) EU-m30 Utility (except some functions)

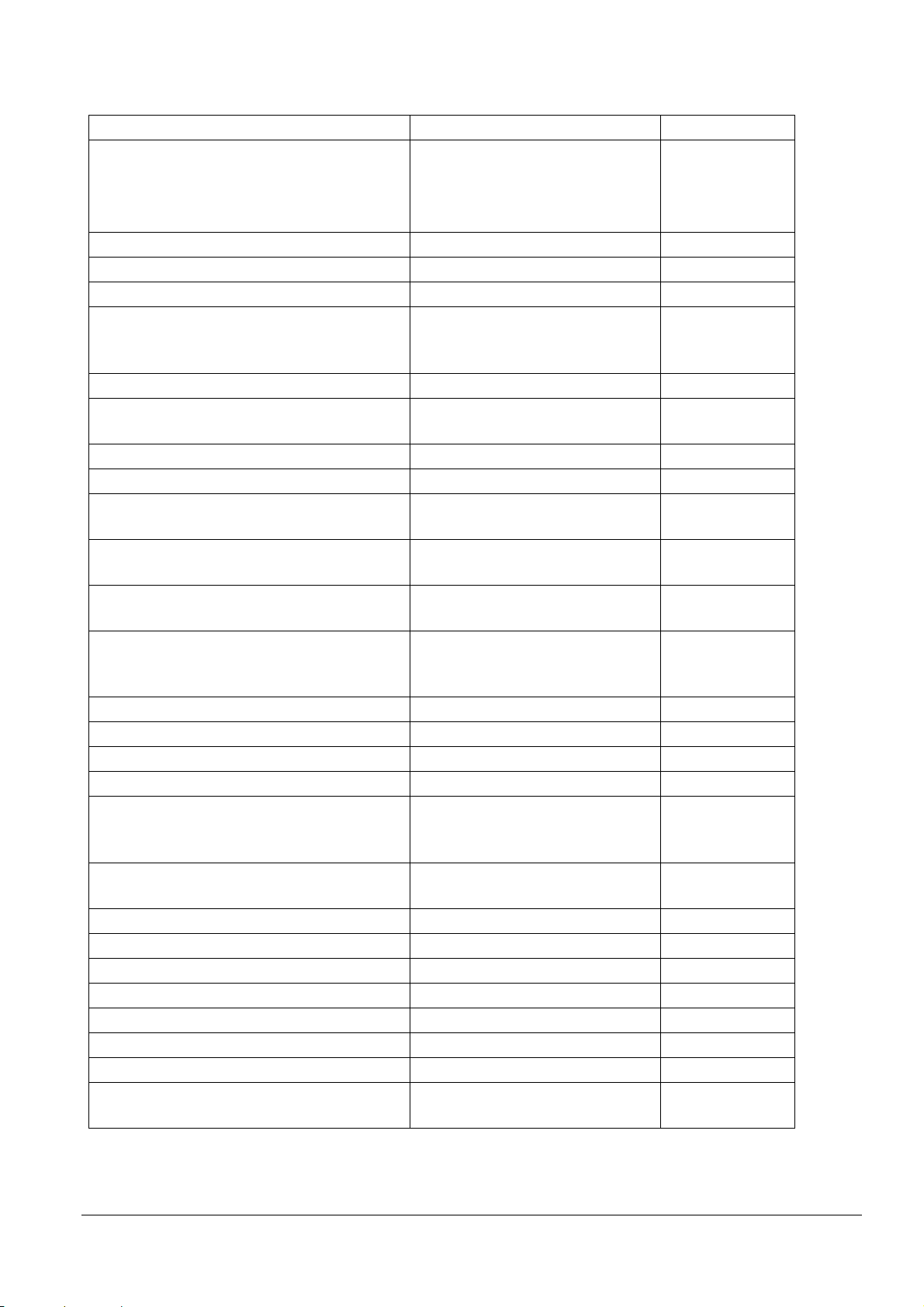

Table 3.5.3 Types of Customized Values

Function Selectable values Factory setting

NV user memory capacity 1 KB, 64 KB, 128 KB, 192 KB 1 KB

NV graphics memory capacity None, 64 KB, 128 KB, 192 KB, 256 KB,

384 KB

320 KB, 384KB

Roll paper width *2 80 mm {3.15"}, 58 mm {2.28"} 80 mm {3.15"}

Print density 70 to 130% (In 5% units) 100%

Print speed Level 1 to 13 (Low speed to high

Level 13

speed)

Thai character print mode Thai 1 pass / Thai 3 pass Thai 1 pass

Default character code table 43 pages selectable with ESC t 0

Default international character 18 types selectable with ESC R 0

30

Page 38

Function Selectable values Factory setting

Selection of the interface Fixed to serial interface

Fixed to built-in USB

All interfaces

enabled

Serial/USB automatic switching

All interfaces enabled

Command execution (offline) Enabled/Disabled Enabled

Specification for the top margin by backfeed *3 9.5 to 2 mm (in 0.5 mm units) 9.5 mm {0.37"}

Switchover time for a valid interface 1 to 10 seconds (1 second units) 1 second

Selection of primary connection interface Auto (Interface where data was first

Auto

received)/Serial/USB/No primary

connection

Power supply capacity *5 Power supply capacity level 1 to 3 Capacity: High

Autocutting of roll paper when the roll paper

Does not cut/cuts Cuts

cover is closed

(ARP) Reduction of excessive top margin Does not reduce/reduces Does not reduce

(ARP) Reduction of excessive bottom margin Does not reduce/reduces Does not reduce

(ARP) Reduction ratio of line spacing Does not reduce/reduces 25%/

Does not reduce

reduces 50%/reduces 75%

(ARP) Reduction ratio of line spacing where extra

line feeds are included

(ARP) Reduction ratio of bar code height Does not reduce/reduces 25%/

Does not reduce/reduces 25%/

reduces 50%/reduces 75%

Does not reduce

Does not reduce

reduces 50%/reduces 75%

(ARP) Reduction ratio of character height Does not reduce/reduces 25%/reduces

Does not reduce

50%/reduces 75%/reduces 75% and

shortens character height

Font A auto replacement Does not replace/Font B/Font C Does not replace

Font B auto replacement Does not replace/Font A/Font C Does not replace

Font C auto replacement Does not replace/Font A/Font B Does not replace

Print density during multi-tone printing 70 to 130% (In 5% units) 100%

Buzzer function: Optional external buzzer

Enabled/Disabled Disabled

enabled/disabled

*For specified customer only

Buzzer function: Buzzer frequency (Error) *1 Does not sound/sounds 1 time/

Sounds continuously

Sounds

continuously

Buzzer function: Sound pattern (Autocut) *1 Patterns A to E Pattern A

Buzzer function: Buzzer frequency (Autocut) *1 Does not sound/sounds 1 time Sounds 1 time

Buzzer function: Sound pattern (Pulse 1) *1 Patterns A to E Pattern A

Buzzer function: Buzzer frequency (Pulse 1) *1 Does not sound/sounds 1 time Sounds 1 time

Buzzer function: Sound pattern (Pulse 2) *1 Patterns A to E Pattern B

Buzzer function: Buzzer frequency (Pulse 2) *1 Does not sound/sounds 1 time Sounds 1 time

Command-compatible mode EU-m30/TM-m30/TM-m30II EU-m30

Selection of batch print enabled/disabled and

print direction

Disabled/enabled (forward)/enabled

(reverse)

Disabled

*1: The functions are enabled for the optional external buzzer. *For specified customer only

*2: For the method for changing the paper width, see Appendix I.

*3: For notes on using the backfeed, see Appendix J.

31

Page 39

(3) Set the customized values of model-specific

Can be changed using one of the following methods.

(a) User setup commands: GS ( E

Step 1: Moves to the user setting mode with GS ( E <Function 1>

Step 2: Change settings with GS ( E <Function 97>.

Step 3: End the user setting mode with GS ( E <Function 2>.

For details, see "ESC/POS Command Reference" (www.epson-biz.com/pos/reference/

).

(b) Software setting mode (except some functions)

For details, see 3.8.3 Software setting mode.

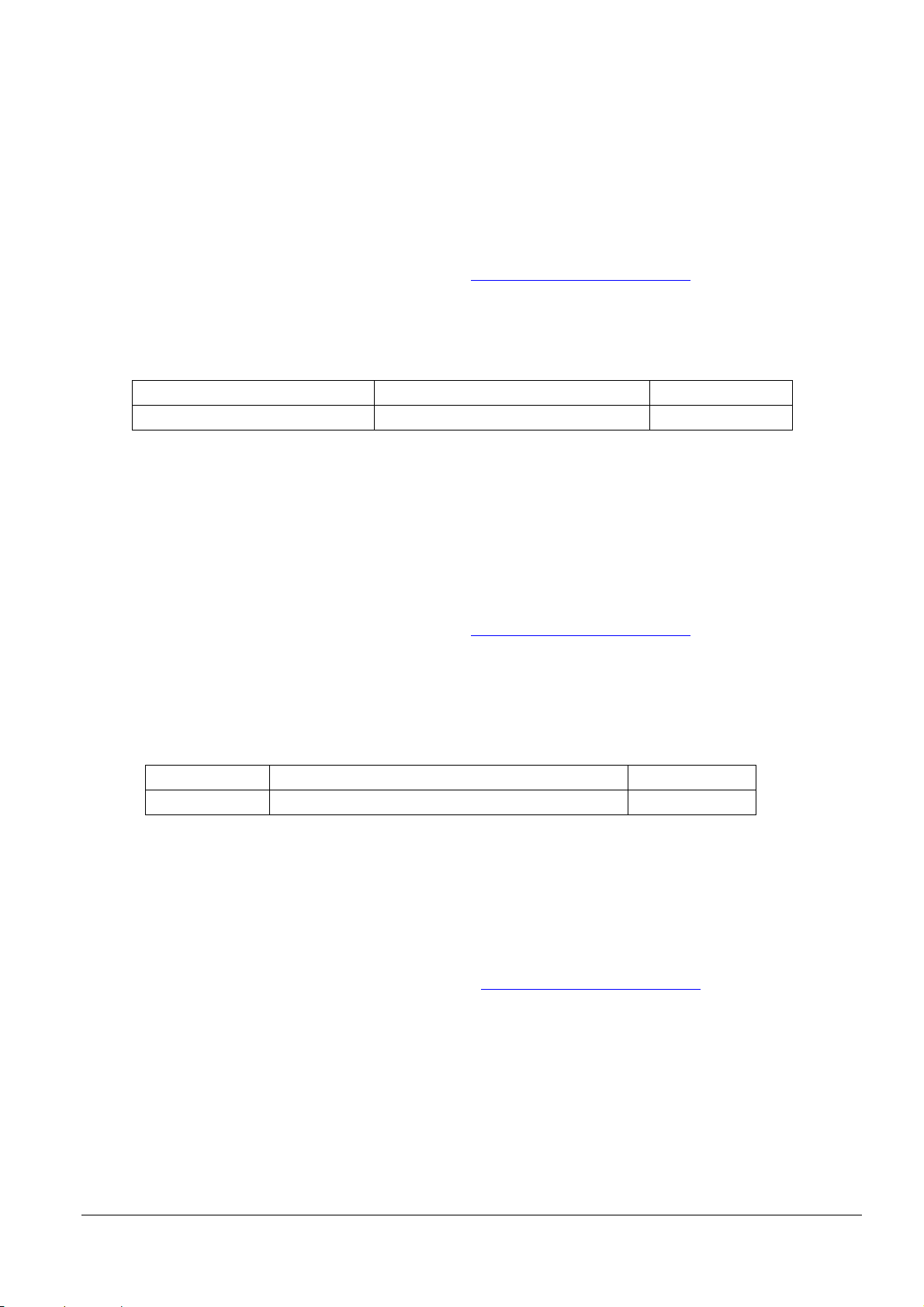

Table 3.5.4 Model-specific Customized Values

Function Selectable values Factory setting

Selection of built-in character types South Asia languages / Simplified Chinese South Asia languages

(4) USB interface communication condition setting

Can be changed using one of the following methods.

(a) User setup commands: GS ( E

Step 1: Moves to the user setting mode with GS ( E <Function 1>

Step 2: Change settings with GS ( E <Function 15>.

Step 3: End the user setting mode with GS ( E <Function 2>.

For details, see "ESC/POS Command Reference" (www.epson-biz.com/pos/reference/

).

(b) Software setting mode (except some functions)

For details, see 3.8.3 Software setting mode.

(c) EU-m30 Utility (except some functions)

Table 3.5.5 USB Interface Communication Condition

Function Selectable values Factory setting

Class Vend o r-defined class/Printer class Printer class

(5) Serial interface communication condition setting