Epson EPL-5700 Service Manual

6(59,&(0$18$/

3DJH3ULQWHU

EPSON EPL-5700

®

4009173

NOTICE

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective

owners. EPSON disclaims any and all rights in those marks.

Copyright © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIER WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. W HEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POW ER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LI STED ON T HE SERIAL NUMBER/RATING PLAT E. IF

THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POW ER SOURCE, DO NOT CONNECT IT TO THE POW ER

SOURCE.

3. ALWAYS VERIFY THAT T HE EPSO N PRODUCT HAS BEEN DI SCONNECT ED FRO M THE POWER SOURCE BEFORE REMOVING OR REPLACING

PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maint enance and repair procedures of EPL - 5700. T he instr uctions and

procedures included herein are intended for t he experienced repair technicians, and at tention should be g iven to the precaution s on the preceding page. T he

chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

REVISION STATUS

Rev. Date Page(s) Contents

A 1998/05/06 All First release

TABLE OF CONTENTS

PRODUCT DESCRIPTION

1.1 FEATURES.................................................................................................................................................................1-1

1.2 PAPER SPECIFICATION ...........................................................................................................................................1-6

1.3 PANEL OPERATION..................................................................................................................................................1-8

1.3.1 Power Switch .................................................................................................................................................................................. 1-8

1.3.2 Control Panel .................................................................................................................................................................................. 1-8

1.3.2.1 Switches................................................................................................................................................................................ 1-8

1.3.2.2 Lights..................................................................................................................................................................................... 1-8

1.3.3 List of Panel Setting ....................................................................................................................................................................... 1-9

1.3.4 Special(alternative) Operation..................................................................................................................................................... 1-13

1.3.4.1 Operation at Power On........................................................................................................................................................ 1-13

1.3.4.2 Up-dating ROM Program..................................................................................................................................................... 1-14

1.4 OPTIONS AND CONSUMABLE...............................................................................................................................1-15

OPERATING PRINCIPLES

2.1 OPERATING PRINCIPLES OF MECHANISM............................................................................................................2-1

2.1.1 Overview.......................................................................................................................................................................................... 2-1

2.1.2 Paper Path....................................................................................................................................................................................... 2-2

2.1.3 Paper Feed Mechanism.................................................................................................................................................................. 2-3

2.1.3.1 Paper Feed Operation........................................................................................................................................................... 2-3

2.1.3.2 Paper Empty Sensor................................................................................................................................................................2-4

2.1.4 Second Paper Feed Unit(Option)......................................................................................................................................................2-4

2.1.4.1 Mechanism...............................................................................................................................................................................2-4

2.1.4.2 Paper Empty Sensor................................................................................................................................................................2-5

2.1.4.3 Cassette Type Sensor..............................................................................................................................................................2-5

2.1.5 Laser Exposure..................................................................................................................................................................................2-6

2.1.5.1 Sub Scanning Direction(Vertical scanning direction)................................................................................................................2-6

2.1.5.2 Main Scanning Direction(Horizontal scanning direction)..........................................................................................................2-7

2.1.5.3 Printable Area ..........................................................................................................................................................................2-7

2.1.6 Charging Process..............................................................................................................................................................................2-7

2.1.6.1 Overview (Refer to Figure2-9 on the next page)......................................................................................................................2-7

2.1.6.2 Cleaning OPC drum.................................................................................................................................................................2-8

2.1.7 Developing .........................................................................................................................................................................................2-9

2.1.7.1 Overview ..................................................................................................................................................................................2-9

2.1.7.2 Function of each parts in the development part.......................................................................................................................2-9

2.1.8 Transfer Process .............................................................................................................................................................................2-10

2.1.8.1 Overview ................................................................................................................................................................................2-10

2.1.9 Fusing Process................................................................................................................................................................................2-11

2.1.9.1 Overview ................................................................................................................................................................................2-11

2.1.9.2 Fusing Temperature Control Circuit.......................................................................................................................................2-11

2.1.9.3 Prevention of paper bent from the fusing...............................................................................................................................2-12

2.1.10 Paper Eject.....................................................................................................................................................................................2-13

2.1.10.1 Face up/Face down disengage mechanism.........................................................................................................................2-13

2.2 ELECTRIC CIRCUIT...................................................................................................................................................2-14

2.3 CONTROLLER OPERATING PRINCIPLES...............................................................................................................2-16

TROUBLESHOOTING

3.1 OVERVIEW...................................................................................................................................................................3-1

3.2 ELECTRIC CHECK POINT...........................................................................................................................................3-1

3.2.1 Rating of Power Fuse F1...................................................................................................................................................................3-1

3.2.2 Coil Resistance of Main Motor..........................................................................................................................................................3-1

3.2.3 Checking Sensors .............................................................................................................................................................................3-2

3.3 PRINTER CONDITION .................................................................................................................................................3-3

3.3.1 Indication............................................................................................................................................................................................3-3

3.3.1.1 “Status” Conditions...................................................................................................................................................................3-3

3.3.1.2 “Error” Conditions.....................................................................................................................................................................3-4

3.3.1.3 “Warning” Conditions ...............................................................................................................................................................3-6

3.3.1.4 Service Req. Error....................................................................................................................................................................3-7

3.3.2 Paper Jam Sensor .............................................................................................................................................................................3-9

3.3.2.1 Overview ..................................................................................................................................................................................3-9

3.3.2.2 Paper Jam Sensor Conditions..................................................................................................................................................3-9

3.3.2.3 Resetting the Paper Jam..........................................................................................................................................................3-9

3.4 TROUBLESHOOTING................................................................................................................................................3-10

3.4.1 Handling Paper Jam ........................................................................................................................................................................3-10

3.4.1.1 Paper Jam at power on..........................................................................................................................................................3-10

3.4.1.2 Paper Jam at Paper Feed and Transporting..........................................................................................................................3-10

3.4.2 Troubleshooting for Abnormal Operations ...................................................................................................................................3-11

3.4.2.1 Abnormal Laser......................................................................................................................................................................3-11

3.4.2.2 Abnormal Polygon Motor........................................................................................................................................................3-11

3.4.2.3 Abnormal Fusing....................................................................................................................................................................3-11

3.4.2.4 Power can not be turned on...................................................................................................................................................3-11

3.4.3 Troubleshooting Print Quality Problems.......................................................................................................................................3-12

3.4.4 Horizontal Lines...............................................................................................................................................................................3-14

DISASSEMBLY AND ASSEMBLY

4.1 OVERVIEW...................................................................................................................................................................4-1

4.1.1 Precaution for Disassembly and Assembly.....................................................................................................................................4-1

4.1.2 Recommended Tools ........................................................................................................................................................................4-2

4.1.3 Specification for Screws...................................................................................................................................................................4-2

4.1.4 Work Completion Check ...................................................................................................................................................................4-2

4.2 DISASSEMBLY PROCEDURE.....................................................................................................................................4-3

4.2.1 Preparation Before Disassembly......................................................................................................................................................4-4

4.2.2 Right Cover Removal.........................................................................................................................................................................4-5

4.2.3 Paper Feed Roller Removal ..............................................................................................................................................................4-6

4.2.4 Paper Empty Sensor Removal(PE1).................................................................................................................................................4-6

4.2.5 ROM(C215PROG-B) Exchange.........................................................................................................................................................4-7

4.2.6 Control Panel Removal......................................................................................................................................................................4-8

4.2.7 Front Cover Removal.........................................................................................................................................................................4-9

4.2.8 Interlock Switch Removal ...............................................................................................................................................................4-10

4.2.9 Main Control Board Removal..........................................................................................................................................................4-11

4.2.10 Left Cover Removal.......................................................................................................................................................................4-12

4.2.11 Print Head Unit Removal...............................................................................................................................................................4-13

4.2.12 Paper Feed Roller Unit Removal ..................................................................................................................................................4-14

4.2.13 Paper Feed Solenoid Removal .....................................................................................................................................................4-15

4.2.14 Top Cover Removal.......................................................................................................................................................................4-16

4.2.15 Rear Cover Removal......................................................................................................................................................................4-17

4.2.16 Fusing Unit Removal.....................................................................................................................................................................4-18

4.2.17 Disassembling the Fusing Unit ....................................................................................................................................................4-19

4.2.17.1 Heater Lamp Removal ......................................................................................................................................................... 4-19

4.2.17.2 Thermister, Thermostat Removal.........................................................................................................................................4-21

4.2.17.3 Paper Eject Sensor(PS3).....................................................................................................................................................4-22

4.2.18 Transfer Roller Exchange .............................................................................................................................................................4-23

4.2.19 Power Board Removal................................................................................................................................................................... 4-24

4.2.20 High Voltage Board Removal........................................................................................................................................................4-26

4.2.21 Paper Sensor(PS1) Removal.........................................................................................................................................................4-27

4.2.22 Main Motor Removal......................................................................................................................................................................4-27

4.2.23 Driving Unit Removal.....................................................................................................................................................................4-28

4.3 DISASSEMBLY AND ASSEMBLY FOR OPTIONAL SECOND PAPER FEED UNIT.................................................4-29

4.3.1 Second Paper Feed Roller Exchange ............................................................................................................................................4-29

ADJUSTMENT

5.1 ADJUSTMENT..............................................................................................................................................................5-1

5.1.1 Interlock Switch Position Adjustment..............................................................................................................................................5-1

MAINTENANCE

6.1 MINTENANCE..............................................................................................................................................................6-1

6.1.1 User Maintenance..............................................................................................................................................................................6-1

6.1.2 Service Maintenance .........................................................................................................................................................................6-1

APPENDIX

7.1 CONECTOR PIN ASSIGMENTS ..................................................................................................................................7-1

7.2 CIRCUIT BOARD COMPONENT LAYOUT..................................................................................................................7-6

7.3 EXPLODED DIAGRAM.................................................................................................................................................7-7

7.4 CIRCUIT DIAGRAM....................................................................................................................................................7-17

PRODUCT DESCRIPTION

&+$37(5

EPL-5700 Chapter1 Product Description

1.1 FEATURES

EPL-5700 is a small and compact A4 size page printer that semiconductor

laser beam scanning is applied for. Following shows features.

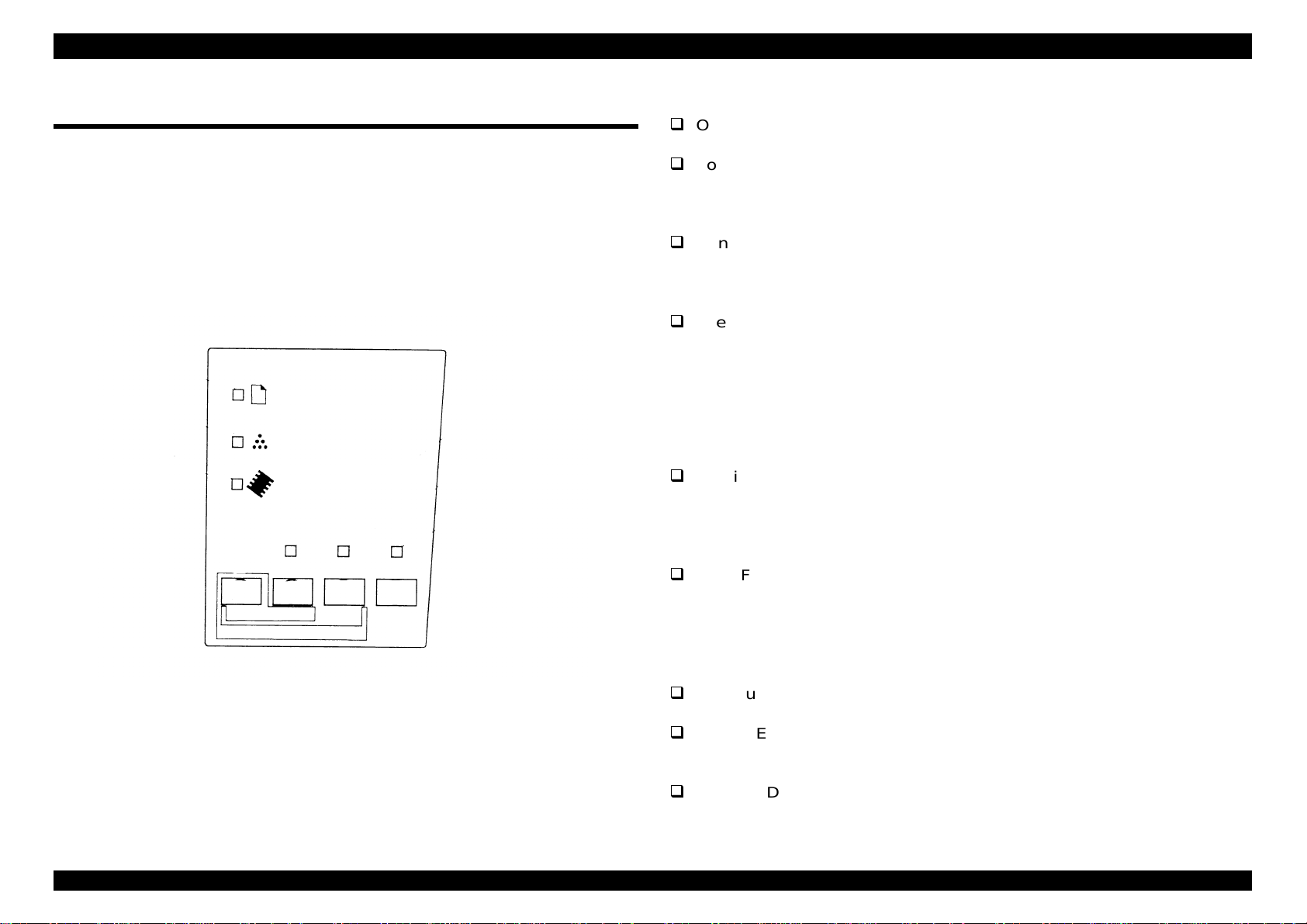

Figure 1-1. Exterior View

PROCESS SPECIFICATION

Method: Dry mono-component xerographic method

Light source: Semiconductor laser

Photoelectric unit: OPC drum(organic photoconductor)

Charge: Rotating brush charging type

Developer: Exposed section developer system

Toner: Mono-component nonmagnetic toner

Transfer method: Roller transfer

Fixing: Heat roller system

Density regulator: Developer bias variation system(user can regulate)

*2:Regarding printing with custom size(non-standard

size)paper, the printing speed will become faster

because cleaning takes place automatically.

First print: 19 seconds(A4/LTR), 18.2 seconds(B5)

17.3 seconds(A5), 20.2 seconds(legal)

Warm-up time: 20 seconds or less (at 23 degree Celsius, standard

voltage)

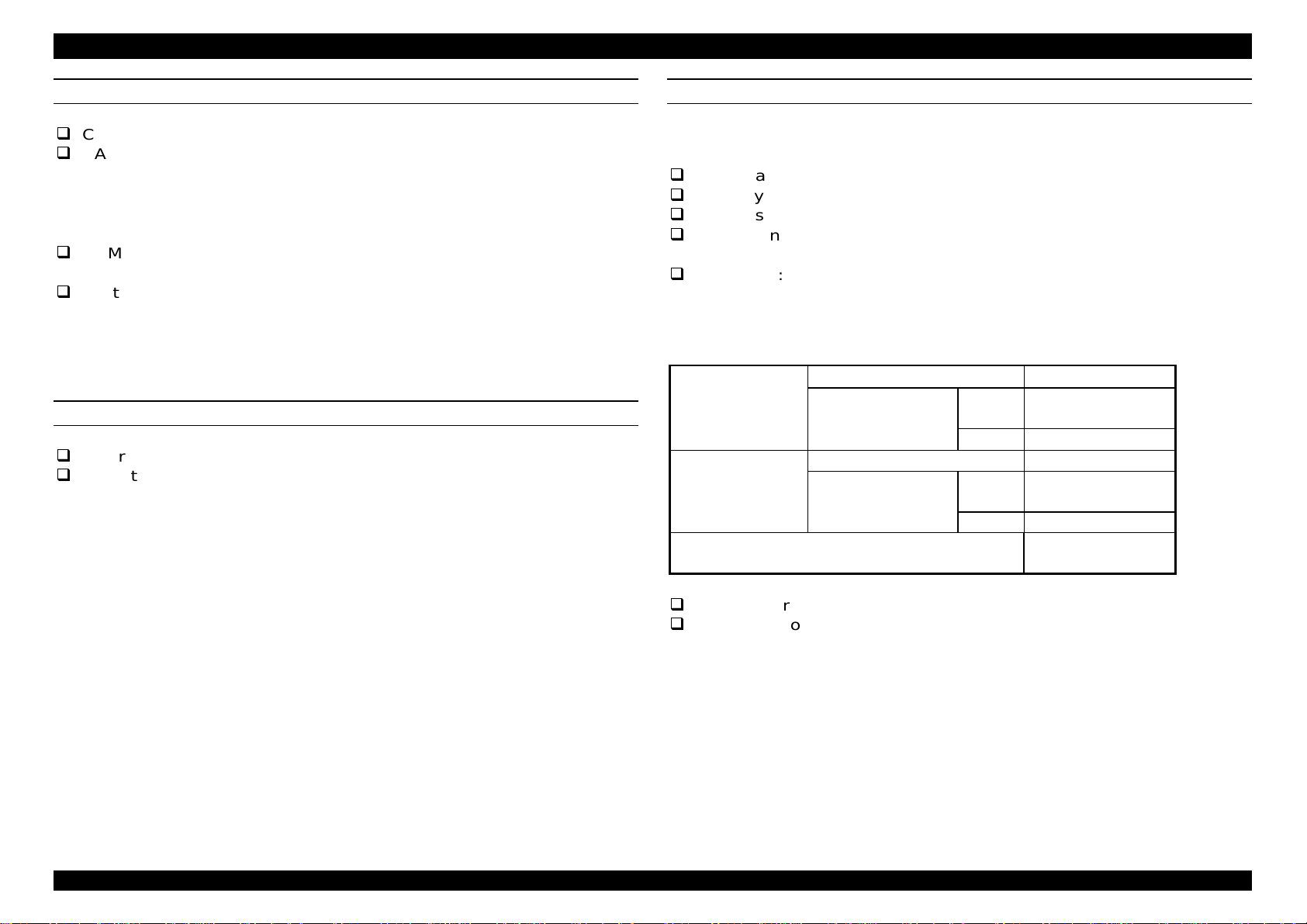

PRINTABLE AREA

Print area Area within margins of 4mm from each side.

(Refer to Figure 1-2)

Note)

The printable area may change depending on

the print mode.

4mm

4mm

4mm

Printable Area

PRINT SPEED

Resolution: 600 dpi

Print Speed: 8ppm(A4/LTR/B5/A5),

6.9ppm(legal)

*1:Same with optional cassette

Rev. A

4mm

Figure 1-2. Printable Area

1-1

EPL-5700 Chapter1 Product Description

2

PAPER HANDLING

Paper supply

method

Multipurpose tray 150

Note)

*1 For 20lb(75g/m2) paper.

*2 When printing on the back file of the paper using manual printing,

since the paper may curl, a maximum of 20 pages can be set.

Table 1-1. Paper Handling

Capacity Supplied paper size Permissible

paper thickness

sheets*1

Standard paper types

are those that fall

within the range of

Normal paper 60

to 90g/m2 (16 to

24lb)

those usable sizes

given below.

76.2 x 127∼ 215.9

x355.6 mm

(A4, JIS-B5,A5,

Letter, Government

letter, Executive,

Legal, Government

Legal, F4, Half

Letter) or Custom

size (optional size

that falls within the

range of standard

paper sizes)

50sheets

20sheets

Japanese official

post card*2

Japanese official

Special paper

190g/m

2

post card*2

(when printing on

back)

10

sheets

Envelopes

Monarch, C10, DL,

C5,C6

International-B5

Labels/OHP/thick

pages

Normal paper 60

to 90g/m2(16 to

24lb)

Thick paper 90 to

157 g/m

2

Special paper

(labels, OHP)

Table 1-2. Paper Handling (Cont.)

Paper supply

method

Manual Feed slot*4 1 sheet Standard or

Capacity Supplied paper

size

Custom paper

sizes that fall

within the range of

usable sizes given

below.

Permissible

paper thickness

Normal paper 60 to

90g/m2(16 to 24lb)

Thick paper 90 to

157g/m

2

Special paper

(labels, OHP)

100x148∼215.9x

355.6 mm

Lower cassette

*1,*5

500

sheets*1

A4, LG, LT Normal paper

60 to 90g/m

2

(16 to 24lb)

Note)

*1: For 20lb(75g/m2) paper.

*4: Manually fed papers are inserted one page at a time above the

cover of the paper tray.

*5: Cassette trays can be used for each of the standard paper sizes.

The maximum size of the paper supply including the paper tray is

650 sheets.

CONSUMABLES

Name: Developer and Toner cartridge

Organic Photoconductor Unit

Life1* Developer equipment

(Black colored mono component nonmagnetic toner:

Average 6000 sheets.)

OPC drum(organic photo conductor unit):20000

sheets.

Note 1*)

These number represent the number of printed pages that can be

printed assuming continuous printing on an A4 page with print duty of 5%.

The life will change based on the print duty and method of printing

(continuous printing, intermittent printing, printing density, toner

economizing)

Rev. A

1-

EPL-5700 Chapter1 Product Description

3

CONTROLLER SPECIFICATION

CPU RISC VR4300 100MHz

RAM Standard 4MB(EDO type)

SIMM option: 1

32MB, 16MB, 8MB, 4MB (EDO type, 1 slot)

Maximum 36MB(4MB(standard) + 32MB(expansion

SIMM slot)

ROM Font: 2Mbytes(mounted on main board)

Program: 4Mbytes (mounted on ROM DIMM board)

Host interface Standard, Centronics, Bi-direnctional parallel

IEEE-1284 nibble

ECP

RS232C Serial

Type-B I/F: 1 slot

SOFT SPECIFICATION

Control Code Bi-direction EJL

Emulation ESC/Page mode

PCL5E mode

GL/2 mode

FX mode

ESC/P2 mode

I239x

Post Script level 2(Option)

ENVIRONMENTAL CONDITION

[Usage conditions including expendable parts]

Temperature: 10 to 35 °C

Humidity: 15% to 85% without condensation

Air pressure(altitude): 760hPa or more(2500 meters or less)

Surface angle: 1 degree incline or less (for both front

to rear and side to side)

Luminosity: 3000 lux or less(not exposed to direct

sunlight)

[Environmental conditions for storage and transportation]

Normal

Temperature Extremes

(1/3 of total

holding period) Low

Normal 30 to 85%

Humidity Extremes

(1/3 of total

holding period) Low 10 to 30%

Holding Period 18 months after

Shipping Air Pressure: 460 to 760 hPa

Resistance to shock: For JIS Z0200 1987 Level 1 with no

abnormalities.

Dropping direction: 1 corner, 6 sides, 3 edges

High

High 85 to 95%

0 to 35 °C

35 to 40 °C

-20 to 0 °C

manufacture

Rev. A

1-

EPL-5700 Chapter1 Product Description

4

ELECTRICAL SPECIFICATION

Power supply:

120 model

120V +/- 10%, 50-60Hz +/-3Hz

200V model

220 to 240V +/- 10%, 50-60Hz +/- 3Hz

Electrical characteristic

1) AC line noise:

Pulse width: 50 to 1000 ns

Pulse polarity: ±

Repeat: non-simultaneous

Modes: common/normal

Voltage: 1kv

However, the parts can withstand up to 2kv without damage.

2) Instant cutoff: DIP 100%(for standard voltage-10%) for one

cycle with normal print quality.

3) Electrostatic durability:

up to ± 10kv: no hardware errors

no unrecoverable software errors for the operator

up to ± 15kv: without damage to components

4) Rush current: 1/2 cycle, 50A or less

5) Insulation resistance: 10 M Ω or less

6) Dielectric strength: Assuming the following voltages are input for

one minute with no breakdowns.

120V model: AC 1000V(duration of one

surge)

200V model: AC1500V(duration of one

surge)

7) Leakage current: 3.5mA or less (120V model)

3.5mA or less (200V model)

DIMENSIONS

Dimensions: Main unit 397(W)mm x 463(L)mm x251(H) mm

Weight: Approximately 7.5Kg(not including expendable or

optional parts)

RELIABILITY AND DURABILITY

Product life Approximately 180000 printed pages or five years,

whichever comes first.

MPBF: 25000 sheets or more

Note)

This is the average number of sheets before a breakdown will

occur that either requires the change of parts or for which the user is

unable to resolve.

MTBF: 3000 hrs(10 months) or more

Paper Feed Reliability(for recommended paper or normal paper)

Jam rate: 1/2000 or less(not including multiple pages)

Misfeed: 1/2000 or less

Multiple page feed rate: 1/500 or less

Paper wrinkling: 1/1000 or less

Paper leading edge folds: 1C or more, 1/1000 or less

Instances of only 1C excluded*1

Note)

*1: 1C signifies a corner folded

1mm.

Rev. A

1-

EPL-5700 Chapter1 Product Description

5

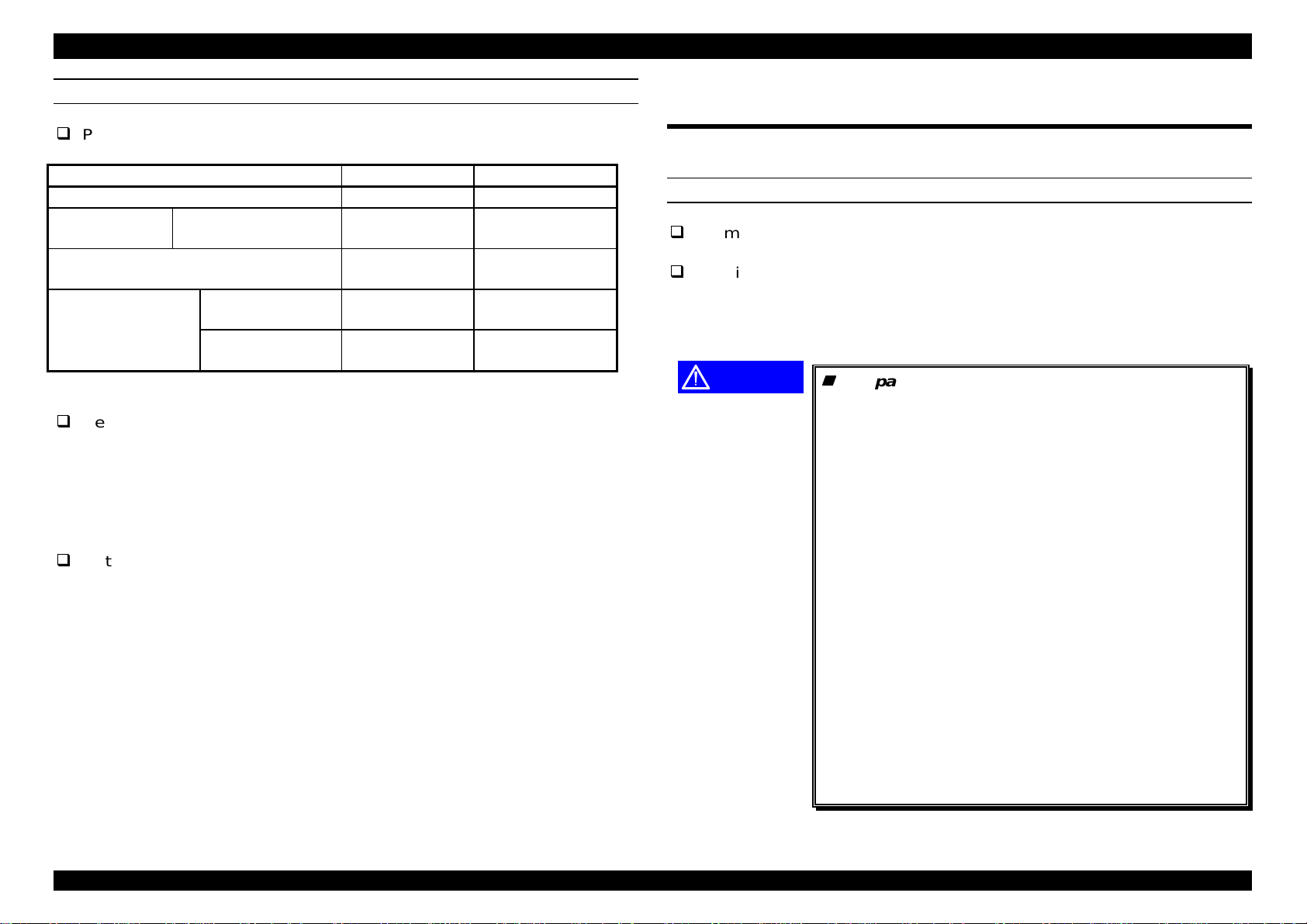

APPLICABLE CERTIFICATION STANDARDS AND REGULATIONS

The specification of this engine meet the certification standards and

regulations below. There are cases in which the standards and regulations

that apply differently to products, including the controller, depending on their

destination.

[Safety Standards]

Table 1-3. Safety Standards

Model Name Applicable certification

120V model UL 1950

CSA 22.2 No.950

200V model TÜV-GS(EN60950)

NEMKO(EN60950)

[Safety Regulations]

Table 1-4. Safety Regulations

Model Name Applicable certification

120V model FDA(NCDRH) Class 1

200V model TÜV-GS(EN60825)

NEMKO(EN60825)

[EMC]

Table 1-5. EMC

Model Name Applicable certification

100V model CNS 13438

CISPR22(Taiwan)

FCC Part15 Subpart B Class B/CSA

C108.8 Class B

200V model EC EMC Directive 89/336/PEC

EN55022 Class B

EN61000-3-2

EN61000-3-3

EN50082-1

AS 3548(Australia)

Power consumption: In compliance with international Energy

Star standards.

Others:

Toner: Do not effect on human body(in

accordance with OSHA, TSCA,

EINECS and CSCL)

OPC: Does not effect human body(in

accordance with OSHA)

Ozone emissions: Conforms to UL 478, 5th version.

Materials: Conforms to Swiss environmental

protection laws(does not include CdS)

Ozone: 0.02 ppm or less.

Potential toxicity: OPC, toner, and plastic parts are

nontoxic.

Noise: Stand-by 30 dB(A) or less.

In operation, 47.0 dB(A) or less.

Rev. A

1-

EPL-5700 Chapter1 Product Description

6

POWER CONSUMPTION

Power consumption

120V model 220-240V model

Standard Maximum current 5.3A 3.0A

Power

consumption

Average during continuous printing Less than

Standby mode

(average)

Note)

*1 Energy star compliment.

Resistance to vibration: Vibration frequency, 5 to 100Hz, 100 to 5 Hz.

Maximum(during

warming up)

heater on Less than

heater off*1 Less than

580W 580W

Less than

200W

210W

Less than

40W

40W

Less than

15W

15W

Acceleration:1G

Cleaning time:10 minutes(one way)

Added vibration direction: 3 directions

Added vibration time: 60 minutes in each

direction X,Y, and Z, for 180 minutes total.

Output paper: Face-down-maximum 100 sheets (for 20lb. (75g/

2

m

)paper)

Face up-maximum 20 sheets(for 20lb. (75g/m

when using the optional face up tray)

Use the lever on the right side of the printer to switch

the front and rear sides of the paper when changing

the face up orientation.

2

) paper,

1.2 PAPER SPECIFICATION

Useable paper types are mentioned below.

PAPER TYPES

Normal Paper 60g/m

Copy, bond, and recycled paper in general use.

Special Paper Labels, Japanese official post cards, OHP film, Color

paper, thick paper(90 to 157 g/ m

paper, letterhead.

Note)

Ibs:ream weight= ib./500 pages/17x22 g/m2:1g/m2=0.2659763 lbs.

CAUTION

The paper type listed below can not be used with

• • Carbon paper, non-carbon paper, thermal

• • Paper that has gone through a thermal transfer

• • Paper that is too thick or too thin.

• • Wet(damp) paper.

• • Paper to which a special coating has been

• • Paper that has been lubricated(too smooth or

• • Paper with holes for binders or perforations.

• • Folder, curled, or damaged paper.

• • Paper of irregular shape or not cut with right

• • Paper with labels that come off and stick easily.

• • Paper with glue, staples, or paper clips attached.

2

to 90g/ m2 (16 lbs. to 24 lbs.)

2

), special DTP

this printer. They will result in bad printouts,

paper jams, and can damage the printer.

transfer paper, impact paper, acidic paper.

or ink-jet printer.

applied, or colored paper that has gone through

surface process.

slippery), too rough, or whose texture is

different on the front and back.

angles.

Rev. A

1-

EPL-5700 Chapter1 Product Description

7

CAUTION

• • Special ink-jet paper(surface fine paper, glossy

paper, glossy film, etc).

PAPER CLASSIFICATIONS

Table 1-6.Paper Classification

Paper

supply

Paper

Tray

Lower

Cassette**

Note)

1* OHP

2* Government postcards.

3* Labels.

4*Thick paper(90 to 157g/m2)

5* Envelopes(MON, C10, DL, C5, C6, International-B5)

O: Can guarantee paper feed reliability and image quality.

♦: Can guarantee paper feed reliability and image quality. However,

this is limited to those paper types used generally.

♠: Can print characters. However, this is limited to those paper types

used generally.

X: Can not feed.

**:Option.

Standard

paper

O

O

Normal

Paper

(60 to 90

g/m2)

1* 2* 3* 4* 5*

♦ ♠ ♠ ♠ ♠ ♠

♦

X X X X X

Special Paper

PAPER SIZE

Table 1-7.Paper Size and Paper Feeding

Paper

Type

Normal Half Letter (5.5)x(8.5) O O

Paper Legal (8.5)x(14) O O O*

Note)

Special Monarch(MO) 98.43x190.5 O O

Paper C10 104.78x241.3 O O

O: O.K

*: Depends on destinations.

Paper

Type

Paper Size Paper

Tray

A4 210x297 O O O*

A5 148x210 O O

JIS-B5 182x257 O O

Letter (8.5)x(11) O O O*

EXE (7.25)x(10.5) O O

Government

Legal

Government

Legal

F4 210x330 O O

3x5” 3x5”

Table 1-8. Paper Size and Paper Feeding(Cont.)

Paper Paper Size

Post Card 100x148 O O

DL 110x220 O O

C5 162x229 O O

C6 114x162 O O

International-

B5

16MO 198x275 O O

(8.5)x(13) O O

(8)x(10.5) O O

O

(76.2x127)

Paper Tray Manual Feed

(mm/inch)

176x250 O O

Manual

Feed

Slot

Optional

Lower

Cassette

Slot

Rev. A

1-

EPL-5700 Chapter1 Product Description

8

1.3 PANEL OPERATION

1.3.1 Power Switch

Power switch is located left rear side of the printer. It controls power On/Off.

1.3.2 Control Panel

The control panel of EPL-5700 is located right edge of the front printer.

There are six LED lights and four non lock type switches.

Paper

Toner

Memory

Alt

Continue

Reset

Status Sheet

Figure 1-3. Control Panel

Form Feed On Line

1.3.2.1 Switches

On line switch: Switches the printer between on line and off line

status.

Form feed switch: When the printer is off line and data remains in the

printer’s memory, prints out the data and clears the

buffer. If used in combination with the Alt button, a

status sheet is printed.

Continuous switch:Enables the printer to resume printing after certain

maintenance-required conditions or errors have been

cleared. If used in combination with the Alt button, the

printer is reset.

Alternate switch: Use this button in combination with the Continue

button in order to stop printing and reset (Warm boot).

In the reset condition, if both Alt switch and Continue

switch are pressed more than 5 seconds, the printer

goes to “Reset All” condition.

1.3.2.2 Lights

On Line LED(green): Displays a non-flashing light when the printer

is on line, indicating the printer can receive

print data. When the printer is off line, this light

is off. The light flashes as the system switches

between on-line and off-line status.

Form Feed LED(yellow): Comes on when data is received and stored in

the printer’s buffer prior to printing. Flashing

indicates the printer is processing data. When

no data remains in the printer buffer(the

section of memory reserved for receiving

data), this light is off.

Continue LED(red): Flashes when an error is detected or a

maintenance procedure must be performed.

Paper LED(yellow): Displays a non-flashing light when a general

paper error, or “Printer Open” error has

occurred.

Toner LED(yellow): Displays a non-flashing light when it is time to

change the developer cartridge (toner).

Flashes to indicate the toner is low.

Rev. A

1-

EPL-5700 Chapter1 Product Description

9

Memory LED(yellow): Displays a non-flashing light when either a

Print Overrun or Mem Overflow error has

1.3.3 List of Panel Setting

occurred. Flashes when the resolution is

reduced from 600 to 300 dpi, because of lack

of memory size.

This printer has no LCD display in the control panel, so it is not possible to

make function settings from the control panel, excluding toner left quantity

reset and OPC drum life reset by the special operation and status sheet.

Refer to Chapter 3 for error conditions.

Function settings can be performed using “RCP”(remote control panel).

In the Table below, note that the bold and italic value in the “Value” column

CAUTION

This printer has EEPROM to maintain the function

setting. Data-writing to EEPROM can not be

guaranteed, if the power is turned off during

writing. Therefore, sometimes service error call

occurs or the panel setting returns to the initial

setting by all reset or at the next power on. In

order to prevent this, do not turn off the printer at

the following conditions, since data-writing to

EEPROM is performed.

•• From the power is turned on until the On Line

light stays on.

••When On-line light is flashing.

indicates the factory default setting.

Table 1-9. Function Setting for Control Panel

Menu Item Value

Test Menu

• Status sheet

• ESC/Page Font

Sample.

• LJ4 Font Sample.

• ESCP2 Font

Sample.

• FX Front Sample

• 1239X Front

Emulation

Menu

Printing

Menu

Sample.

• PS Status Sheet

• PS Font Sample

• PS Fact Sheet

• Parallel

• Serial

• AUX

*2

• Paper Source

• Page Size

• Wide A4

• Orientation

• Copies

• Manual Feed

• Resolution

• Skip Blank Page

*1

*1

*1

LJ4

, ESCP2, I239X, PS*1, GL2,

AUTO

•

Auto

*10

•

A4

LGL, GLT, GLG, EXE, F4,

MON, C10, DL, C5, C6, IB5,

CTM.

Off,

Port

-999

1

Off,

600,

Off

ON

On

, On

•

•

•

•

•

•

, MP, LC1*3.

, A5, B5,

, Land

300

*14

LT

*17

, HLT,

Rev. A

1-

EPL-5700 Chapter1 Product Description

0

Table 1-10. Function Setting for the Control Panel(Cont.)

Menu Item Value

Tray Size

Menu

• MP Tray Size

*16

•

A4

HLT, LGL, GLT, GLG,

EXE, F4, MON, C10,

DL, C5, C6, IB5.

, LT, LGL.

•

A4

•

On

•

Off

4, 5, 1, 2

•

3,

• -9.0, -

Config Menu

• LC1 Size

*3

• RITech

• Toner Save

• Density

• Top Offset, Left Offset

0.5mm.

• Size Ignore

• Auto Cont

• Page Protect

• Image Optimum

• Paper Type

*5

•

Off,

•

Off,

•

Auto

•

Auto

•

Normal

Transprnc.

Setup Menu

• Interface

• Time Out

• Standby

• Language

•

Auto

AUX*2.

• 0, 5-

•

Enable

•

English

Deutsch, ITALIANO,

ESPANOL, SVENSKA,

Dansk, Dederl., SUOMI,

Portugues.

• Toner

• Page Count

• 0∼100

• 0∼999999999

• SelecType Init

Parallel Menu

• Speed

• Bi-D

• Buffer Size

•

Fast,

•

Nibble

•

Normal

Minimum.

, A5, B5,

LT

, Off.

, On.

, -99.0 mm step

0.0

On

On

, On

, Off, On

, Thin*5, Thick,

, Parallel, Serial,

-300

60

, Disable

, Francais,

Normal

, ECP, Off

, Maximum,

*17

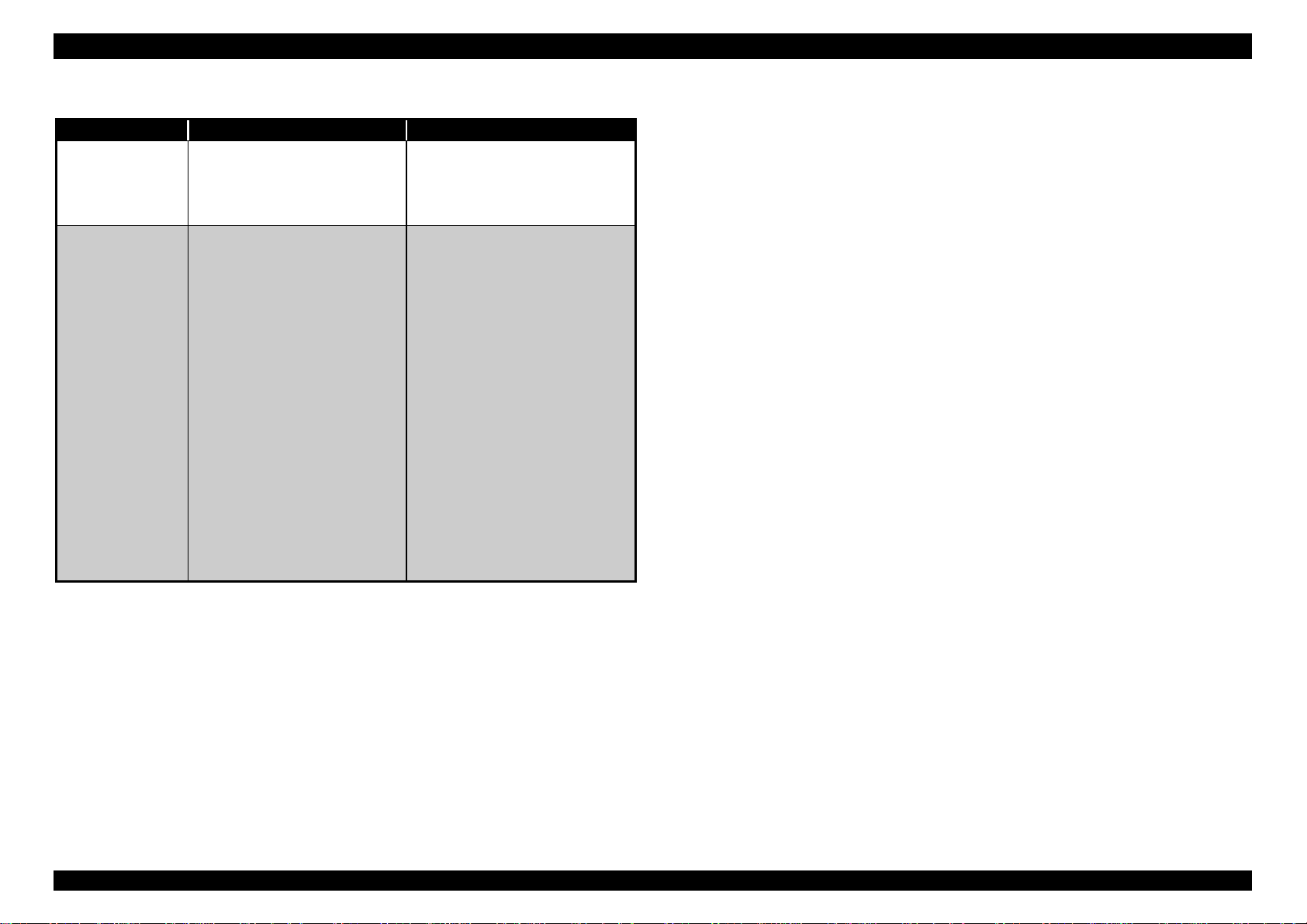

Table 1-11. Function Setting for the Control Panel(Cont.)

Menu Item Value

,

Serial Menu

• Word Length

• Baud Rate

•

•

, 7

8

, 19200, 38400, 57600, 300,

9600

600, 1200, 2400, 4800

Even, odd

, 2

, Off

Off, Robust

, Maximum, Minimum.

Maximum, Minimum.

, Off

Off

CR+LF

LF

, FF

Space

, On

DIMM, Download.

∼ available(Max 65535)

∼99.99 cpi step 0.01

10.00

∼999.75pt step 0.25 pt

12.00

, Roman-8, ECM94-1,

AUX Menu

ESC/Page

*4

Menu

LJ4 Menu

• Parity

• Stop Bit

• DTR

• Xon/Xoff

• Buffer Size

*2

• Buffer Size

• Auto CR

• Auto FF

• CR Function

• LF Function

• FF Function

• Error Code

• Avoid Error

• Font Source

• Font Number

•

Pitch

•

Height

• SymSet

*15

*15

•

None,

•

1

•

On

•

On,

•

Normal

Normal,

•

On

•

On,

•

CR,

•

LF+CR,

•

FF+CR

•

Ignore,

•

Off

•

Resident,

•

0

• 0.44∼

cpi

• 4.00∼

•

*7

IBM-US

8859-2 ISO, 8859-9 ISO, IBM-DN,

PcMuktiling, PcE. Europe,

PcTk437, WiAnsi, WiE.Europe,

WiTurkish, DeskTop, PsText,

VeInternati, VeUS, MsPublishin,

Math-8, PsMath, PiFont, Legal,

UK, ANSI ASCII, Swedis2,

Intalian, Spanish,

German,Norweg1, Fench2,

Windows.

*17

• Form

• Source SymSet

*7

• 5∼

• 0∼

60

277

*16

∼

64

∼3199

∼128 Lines.

Rev. A

1-1

EPL-5700 Chapter1 Product Description

Table 1-12. Function Setting for the Control Panel(Cont.)

Menu Item Value

LJ4 Menu Dest Symset

GL2 Menu

• GL-Mode

• Scale

• Origin

• Pen

• End

• Join

• Pen0

• Pen1

• Pen2

• Pen3

• Pen4

• Pen5

• Pen6

*6

*6

*6

*6

*6

PS Menu

• Error Sheet

• Protect Level

• MicroGray

0∼

277

∼3199

• GLlike,

•

•

•

, A0, A1, A2, A3

Off

Corner,

Pen0

Pen4*6, Pen5*6, Pen6

•

Butt,

Round.

•

Mitered

Triangular, Round, Beveled,

None.

• 0.05∼

0.05mm.

• 0.05∼

0.05mm.

• 0.05∼

0.05mm.

• 0.05∼

0.05mm.

• 0.05∼

0.05mm.

• 0.05∼

0.05mm.

• 0.05∼

0.05mm.

Off

, On

•

• 1∼5

, Off

•

On

LJ4GL2

Center

, Pen1, Pen2*6, Pen3*6,

*6

Square, Triangular,

, Miteredbeveled.

∼5.00mm step

0.35

∼5.00mm step

0.35

∼5.00mm step

0.35

∼5.00mm step

0.35

∼5.00mm step

0.35

∼5.00mm step

0.35

∼5.00mm step

0.35

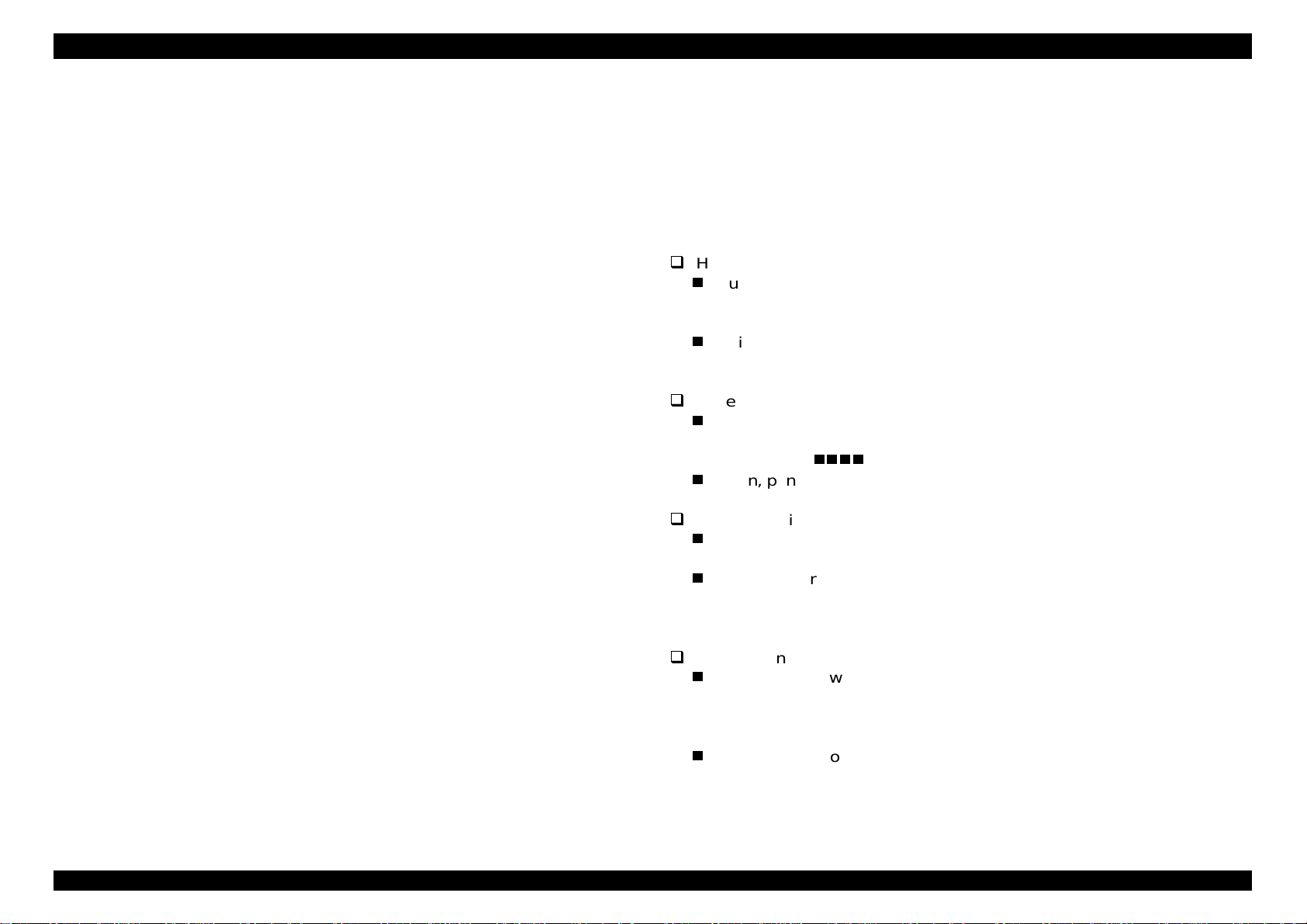

Table 1-13. Function Setting for the Control Panel(Cont.)

Menu Item Value

ESCP2 Menu

FX Menu

• Font

• Pitch

• Condensed

• T. Margin

• Text

• CGTable

*7

• Country

• Auto CR

• Auto LF

• Bit Image

• ZeroChar

• Font

• Pitch

• Condensed

• T.Margin

• Text

• CGTable

• Country

•

Courier,

serif, Roman T, Orator S, Sans H,

Script, OCR A, OCR B.

•

10cpi

•

Off,

• 0.40∼

• 1∼

62

•

PcUSA

PcCanFrenc, PcNordic, PcTurkish2,

PcE. Europe, BpBRASCII,

BpAbicomp

•

USA,

Denmark, Sweden, Italy, Spain1,

Japan, Norway, Denmark2, Spain2,

LatinAmeric, Korea, Legal.

•

On,

•

Off,

•

Dark

, φ

•

0

•

Courier

Script, Orator S, OCR A, OCR B

•

10cpi

•

Off,

• 0.40∼

• 1∼

62

•

PcUSA

PcCanFrenc, PcNordic, PcTurkish2,

PcE. Europe, BpBRASCII,

BpAbicomp

•

USA,

Denmark, Sweden, Italy, Spain1,

Prestige, Roman, Sans,

, 12cpi, 15cpi, Prop.

On

∼1.50 inch step 0.05 inch

0.50

*17

*16

66

, Italic, PcMultiln, PcPortugue,

France, Germany, UK,

Off

On

, Light, BarCode

, Prestige, Roman, Sans serif,

, 12cpi, 15cpi, Prop.

On

∼1.50 inch step 0.05 inch

0.50

*17

*16

66

, Italic, PcMultiln, PcPortugue,

France, Germany, UK,

Japan, Norway, Denmark2, Spain2,

LatinAmeric

∼available (Max 81) Lines

∼available (Max 81) Lines

Rev. A

1-11

EPL-5700 Chapter1 Product Description

2

Table 1-14. Function Setting for the Control Panel(Cont.)

Menu Item Value

FX Menu

1239X Menu

• Auto CR

• Auto LF

• Bit Image

• ZeroChar

• Font

• Pitch

• Code Page

• Text

• Auto CR

• Auto LF

• Alt.Graphic

• Bit Image

• ZeroChar

• CharacterSet

•

On,

•

Off,

•

Dark

, φ

•

0

•

Courier

Roman, Sans serif,

Script, Orator S, OCR A,

OCR B

•

10cpi

17cpi, 20cpi, 24cpi,Prop.

•

437,

• 0.30∼

step 0.05 inch

• 1∼

63

(Max111)Lines

•

Off,

•

Off,

•

Off,

•

Dark

, φ

•

0

• 1,

Off

On

, Light, BarCode

, Prestige,

, 12cpi, 15cpi,

850, 860, 863, 865

∼1.50 inch

0.40

*17

*16

∼

∼available

67

On

On

On

, Light, BarCode

2

Note)

*1: Can only be selected when Parrot-V option.

*2: Can only be selected when Type-BI/F option is installed.

*3: Can only be selected when optional lower cassette is installed.

*4: These item will not be displayed on the panel and can not select or

change from the RCP etc. And these items will not be printed on

status sheet. Also these items will be hidden to the users.

*5: Normal Select when using normal paper.

Thin Invalid for EPL-5700. This setting is only possible to

change by EJL command, but if printer receive this

command, internal setting will force to set to Normal

setting.

Thick Select when using narrow media such as envelopes,

postcards, etc.

*6 Can only be selected in GLlike mode.

*7 When the NLSP font DIMM is added, the selectable SymSet and

CGTable for RCP for DOS are added. Following symbol set will be

added.

For LJ4 mode:

Pclcelandic*

PcEt850*

PcNordic*

WiEstonian*

BpBRASCII*

PcGk869*

PcCy855*

WiCyrillic*

8859-8ISO*

PcAr864*

For ESCP2 mode:

PcSI437*

Mazowia*

8859-7ISO*

PcUkr866*

*8 Indicated only when NLSP Bitmap3 Font ROM for Turkey*

*9 Indicated only when NLSP EDG OEM Scalable Font ROM for

Turkey*

13

.

8

, PCLt774*8, PcTurk1*8*9, PcPortugues*8,

8

, PcTurk2*8*9, PcCanFrench*8, PcSI437*8,

8

, 8859-3ISO*8, 8859-4ISO*8,WiBaltic*8,

8

, WiLantvian*8 Mazowia*8*12, CodeMJK*8*12,

8

, BPAbicomp*8, PcGk437*

8*10

, 8859-7ISO*8*10, WiGreek*8, Europe3*8,

8*11

, PcCy866*8*11, PcLt866*8, 8859-5ISO*8,

8

, Bulgarian*8*11, PcUkr866*8, Hebrew7*8,

8

, Bebrew8*8, PcHe862*8, Arabic8*8,

8

,8859-6ISO*8, OCR A*8, OCR B*

8

, PCTurkish1*8, Pclceiandic*8, 8859-ISO*8,

8

,CodeMJK*8, PcGk437*8, PcGk851*8, PcGk869*8,

8

,PcCy855*8, PcCy866*8, Bulgarian*8,

8

, Hebrew7*8,Hebrew8*8, PcAr864*8, PcHe862*8.

8*10

, PcGk851*8,

8

13

.

Rev. A

1-1

EPL-5700 Chapter1 Product Description

3

*10 Indicated only when NLSP EDG OEM Scalable Font ROM for

Greek*

*11 Indicated only when NLSP EDG OEM Scalable Font ROM for

Cyrillic*

*12 Indicated only when NLSP EDG OEM Scalable Font ROM for

Latin*

13

.

13

.

13

.

*13 When changing the “SymSet” to this value, “Font Source” and “Front

Number” is set to “Resident” and “0”. So it is necessary to change

“Font Source” and “Front Number” to the font which supports this

symbol set.

*14 Only applied to LJ4 and ESC/Page mode.

*15 Either pitch or height will be displayed.(decided by selected font)

*16 Factory setting for Europe and Pacific.

*17 Factory setting for North America.

1.3.4 Special(alternative) Operation

1.3.4.1 Operation at Power On

After turning the power on while pressing a particular button, and keep

pressing the switch until the paper feed lamp, toner lamp and memory lamp

are turned on, following function will start.

Hexadecimal Damp

Turn on the power while pressing the Form Feed switch, then the

printer will enter damp mode. The received data is converted by

hexadecimal ASCII and printed out.

This function is canceled by Warm Boot(see page 1-8) or turning

power again.

Toner Reset

Turn on the power while pressing On Line switch and Form Feed

switch, the left toner quantity is reset and becomes toner full

condition. (E

Then, printer returns to the normal condition.

OPC Drum life reset

Turn on the power while pressing On-line switch and Continue switch.

The printer sets OPC drum life 100%.

Then, printer returns to the normal condition.

F)

Rev. A

Following is not opened to the users.

Initialization of EEPROM

Turn on the power while pressing On-line switch, Continue Switch and

Alt switch. Then, EEPROM setting returns to the original settings,

which were set at the factory. All setting including the total print count

is cleared.

Then, printer goes to Warm Boot and returns to the normal condition.

1-1

EPL-5700 Chapter1 Product Description

4

Initialization of Panel Setting Values

Turn on the power while pressing Continue switch, then the printer

resets panel setting values to the original setting which were set at the

factory.

Then, printer goes to Warm Boot and returns to the normal condition.

1.3.4.2 Up-dating ROM Program

Since the ROM programs, which were produced during the initial massproduction, are using Flash-ROM, they can be up-dated through the parallel

interface from the host computer, when it becomes necessary to up-date.

Procedure for up-dating

1. Connect the printer and host computer by parallel interface cable.

2. Turn the power of the printer on, while pressing On-line, Form Feed and

Continue switches.

3. Stop pressing switches after Paper, Toner and Memory lights turn on.

Continue light and From Feed light turns off 3 seconds after other lights turn

on with flashing On-line light. The printer is ready to receive the program

data from the host computer.

4. Transfer the program data by COPY command of DOS from the host

computer, as it is shown below.

>COPY_/B_File Name_LPT1 press Return key.

Note)

”_” above means to take one space.

CHECK POINT

9

The printer indicates that old program is being erased, turning the Toner,

Memory and Form Feed lights on and blinking the on-line light.

Then, the printer indicates that new program is being written, turning the

Memory and Form Feed lights on and blinking On-line light.

5. On-line light blinks and other lights turns off after up-date process is

completed normally.

6. Press On-line switch and re-boot the printer.

Printer should be receiving condition before the

data is sent from the host computer.

CAUTION

If you fail to up-date the program ROM correctly,

Service Req. Error appears and the printer will not

be able to start.

Solution when error occurs.

If up-dating RON fails, error is indicated and goes to Check SUM error

(service req. error) without appropriate operations.

Write Error

Because of defective device of Flash-ROM or defective confection

with DIMM slot, Paper, Continue and Form Feed lights turn on while

writing or erasing program , then On-line light blinks and light error is

indicated. Operation is canceled by pressing Alt switch. In this case,

old program still remains and transferred data is red but abandoned.

Up-date is proceeded by pressing On-line switch, but the printer does

not operate well.

Data Error

Data error is indicated by turning Toner, Continue and Form Feed

lights on and blinking On-line light.

Operation is canceled by pressing Alt switch. In this case, old

program still remains and transferred data is red but abandoned.

Up-date is proceeded by pressing On-line switch, but the printer does

not operate well.

Address Error

This error occurs when writing address to program ROM is done out

of range. Address error is indicated by turning Toner, Continue and

Form Feed lights on and blinking On-line light. Operation is canceled

by pressing Alt switch. In this case, old program still remains and

transferred data is red but abandoned. Up-date is proceeded by

pressing On-line switch, but the printer does not operate well.

Check SUM Error of Program ROM

When up-dating ROM fails, Check SUM error appears. Memory and

Continue lights turn on and On-line light blinks to indicate Check SUM

error. Press On-line switch and re-boot the printer.

Rev. A

1-1

EPL-5700 Chapter1 Product Description

5

1.4 OPTIONS AND CONSUMABLE

Following shows options and consumable for EPL-5700.

Table 1-15. Printer Options

Name Code

500 Sheet Lower Paper Cassette C81287*

Face Up Tray C81286*

Operational memory module Refer to Reference

Guide

EPSON Script Level 2 module C83229*

Optional Interface Cards;

• Optional Ethernet Card

• 32KB Serial Interface Card

• 32KB Parallel Interface Card

• Coax Interface Card

• Twinax Interface Card

• AppleTalk Interface Card

• GPIB Interface Card

Note)*

The asterisk(*) is a substitute for the last digit of the product number,

which varies by country.

• C82357*/C82362*

• C82307*

• C82310*

• C82314*

• C82315*

• C82312*

• C82313*

Rev. A

1-1

Loading...

Loading...