Page 1

MF1224-01

CMOS 4-BIT SINGLE CHIP MICROCOMPUTER E0C6011

D

EVELOPMENT TOOL

M

ANUAL

Page 2

NOTICE

No part of this material may be reproduced or duplicated in any form or by any means without the written

permission of Seiko Epson. Seiko Epson reserves the right to make changes to this material without notice.

Seiko Epson does not assume any liability of any kind arising out of any inaccuracies contained in this material

or due to its application or use in any product or circuit and, further, there is no representation that this material

is applicable to products requiring high level reliability, such as medical products. Moreover, no license to any

intellectual property rights is granted by implication or otherwise, and there is no representation or warranty that

anything made in accordance with this material will be free from any patent or copyright infringement of a third

party. This material or portions thereof may contain technology or the subject relating to strategic products under

the control of the Foreign Exchange and Foreign Trade Control Law of Japan and may require an export license

from the Ministry of International Trade and Industry or other approval from another government agency.

MS-DOS and EDLIN are registered trademarks of Microsoft Corporation, U.S.A.

PC-DOS, PC/AT, PS/2, VGA, EGA and IBM are registered trademarks of International Business Machines Corporation, U.S.A.

NEC PC-9801 Series and NEC are registered trademarks of NEC Corporation.

All other product names mentioned herein are trademarks and/or registered trademarks of their respective owners.

© SEIKO EPSON CORPORATION 1999 All rights reserved.

Page 3

CONTENTS

E0C6011 DEVELOPMENT TOOL MANUAL EPSON i

E0C6011 Development Tool Manual

PREFACE

This manual mainly explains the outline of the development support tool for the 4-bit Single Chip Microcomputer E0C6011.

Refer to the "E0C62 Family Development Tool Reference Manual" for the details (common to all models) of

each development support tool. Manuals for hardware development tools are separate, so you should also

refer to the below manuals.

Development tools

☞ E0C62 Family Development Tool Reference Manual

EVA6011 Manual

ICE62R (ICE6200) Hardware Manual

Development procedure ☞ E0C62 Family Technical Guide

Device (E0C6011)

☞ E0C6011 Technical Manual

Instructions ☞ E0C6200/6200A Core CPU Manual

CONTENTS

1 COMPOSITION OF DEVELOPMENT SUPPORT TOOL _____________ 1

1.1 Configuration of DEV6011 ...................................................................................... 1

1.2 Developmental Environment ....................................................................................1

1.3 Development Flow....................................................................................................2

1.4 Production of Execution Disk...................................................................................3

2 CROSS ASSEMBLER ASM6011 __________________________________ 4

2.1 ASM6011 Outline ..................................................................................................... 4

2.2 E0C6011 Restrictions...............................................................................................4

2.3 ASM6011 Quick Reference....................................................................................... 5

3 FUNCTION OPTION GENERATOR FOG6011______________________ 7

3.1 FOG6011 Outline .....................................................................................................7

3.2 E0C6011 Option List................................................................................................ 7

3.3 Option Specifications and Selection Message.......................................................... 9

3.4 FOG6011 Quick Reference ..................................................................................... 16

3.5 Sample File.............................................................................................................. 18

4 SEGMENT OPTION GENERATOR SOG6011_______________________ 20

4.1 SOG6011 Outline .................................................................................................... 20

4.2 Option List ............................................................................................................... 21

4.3 Segment Ports Output Specifications ...................................................................... 22

4.4 SOG6011 Quick Reference...................................................................................... 23

4.5 Sample Files ............................................................................................................ 25

5 ICE CONTROL SOFTWARE ICS6011 _____________________________ 27

5.1 ICS6011 Outline ...................................................................................................... 27

5.2 ICS6011 Restrictions ............................................................................................... 27

5.3 ICS6011 Quick Reference ....................................................................................... 29

Page 4

CONTENTS

ii EPSON E0C6011 DEVELOPMENT TOOL MANUAL

White

6 MASK DATA CHECKER MDC6011 _______________________________ 32

6.1 MDC6011 Outline ...................................................................................................32

6.2 MDC6011 Quick Reference..................................................................................... 32

APPENDIX A. E0C6011 INSTRUCTION SET ________________________ 35

B. E0C6011 RAM MAP ________________________________ 39

C. E0C6011 I/O MEMORY MAP_________________________ 40

D. TROUBLESHOOTING ______________________________ 41

Page 5

1 COMPOSITION OF DEVELOPMENT SUPPORT TOOL

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 1

1 COMPOSITION OF

DEVELOPMENT SUPPORT TOOL

Here we will explain the composition of the software for the development support tools, develop-

mental envilonment and how to generate the execution disk.

1.1 Configuration of DEV6011

The below software are included in the product of the E0C6011 development support tool DEV6011.

1. Cross Assembler ASM6011 .......................................... Cross assembler for program preparation

2. Function Option Generator FOG6011 ........................... Function option data preparation program

3. Segment Option Generator SOG6011 .......................... Segment option data preparation program

4. ICE Control Software ICS6011...................................... ICE control program

5. Mask Data Checker MDC6011...................................... Mask data preparation program

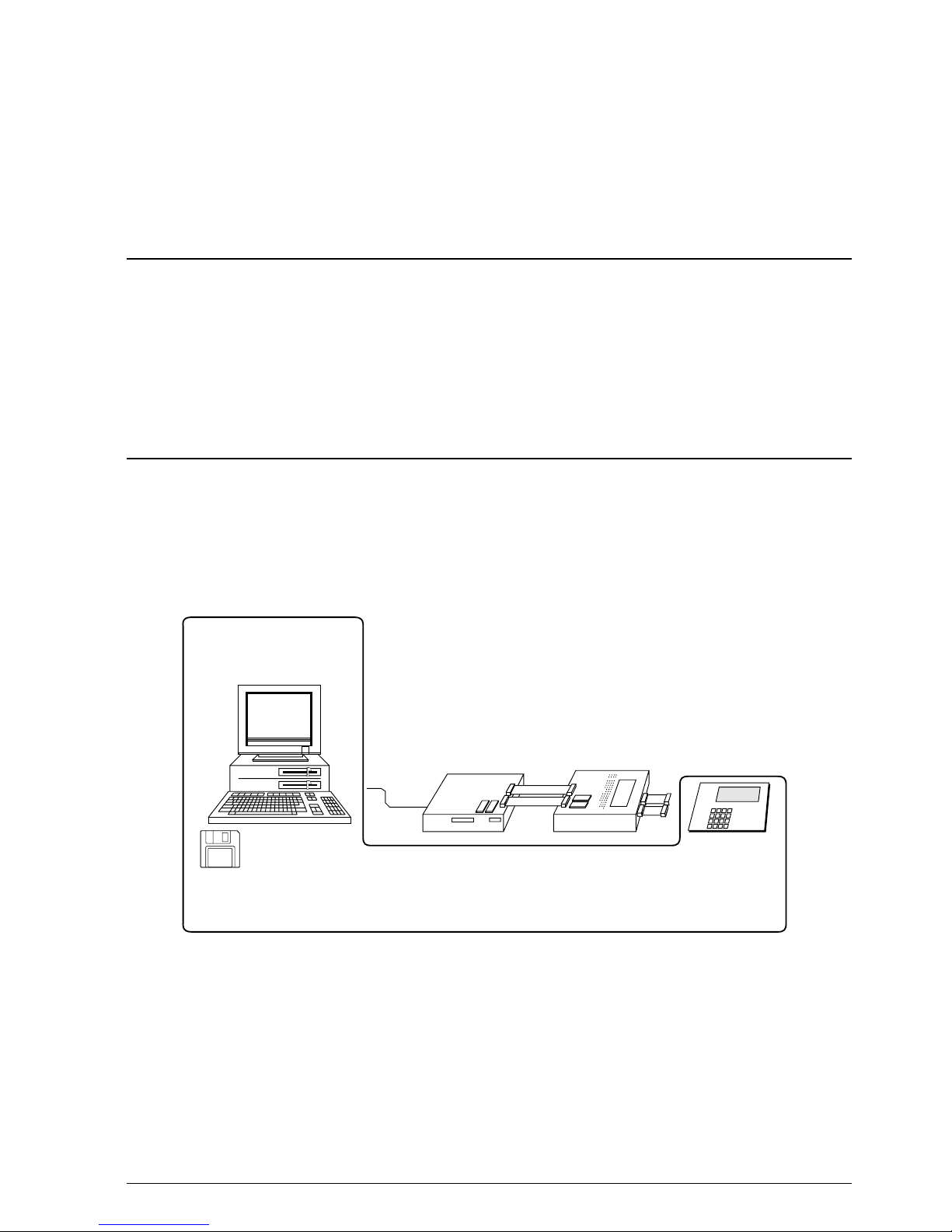

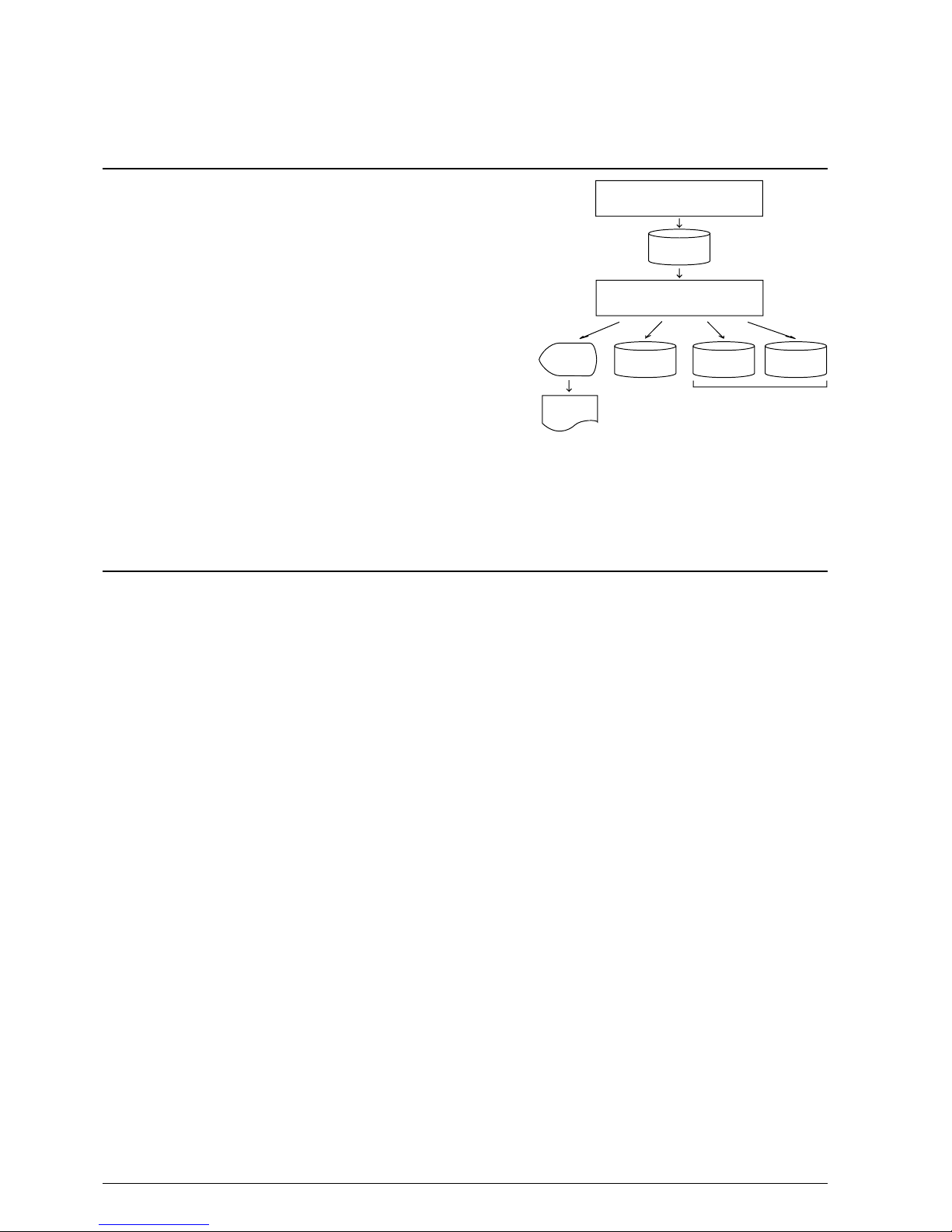

1.2 Developmental Environment

The software product of the development support tool DEV6011 operates on the following host systems:

• IBM PC/AT (at least PC-DOS Ver. 2.0)

• NEC PC-9801 Series (at least MS-DOS Ver. 3.1)

When developing the E0C6011, the above-mentioned host computer, editor, P-ROM writer, printer, etc.

must be prepared by the user in addition to the development tool which is normally supported by Seiko

Epson.

Fig. 1.2.1 System configuration

Note The DEV6011 system requires a host computer with a RAM capacity of about 140K bytes.

Since the ICE62R (ICE6200) is connected to the host computer with a RS-232C serial interface,

adapter board for asynchronous communication will be required depending on the host computer

used.

Host computer

PC-9801 Series

IBM PC/AT

[ ]

Target board

MS-DOS/PC-DOS

Editor

• P-ROM writer

• Printer

To be prepared by the user

E0C6011 Series Development Tool

EVA6011

ICE62R (ICE6200)

RS-232C

ICE6200

Page 6

1 COMPOSITION OF DEVELOPMENT SUPPORT TOOL

2 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

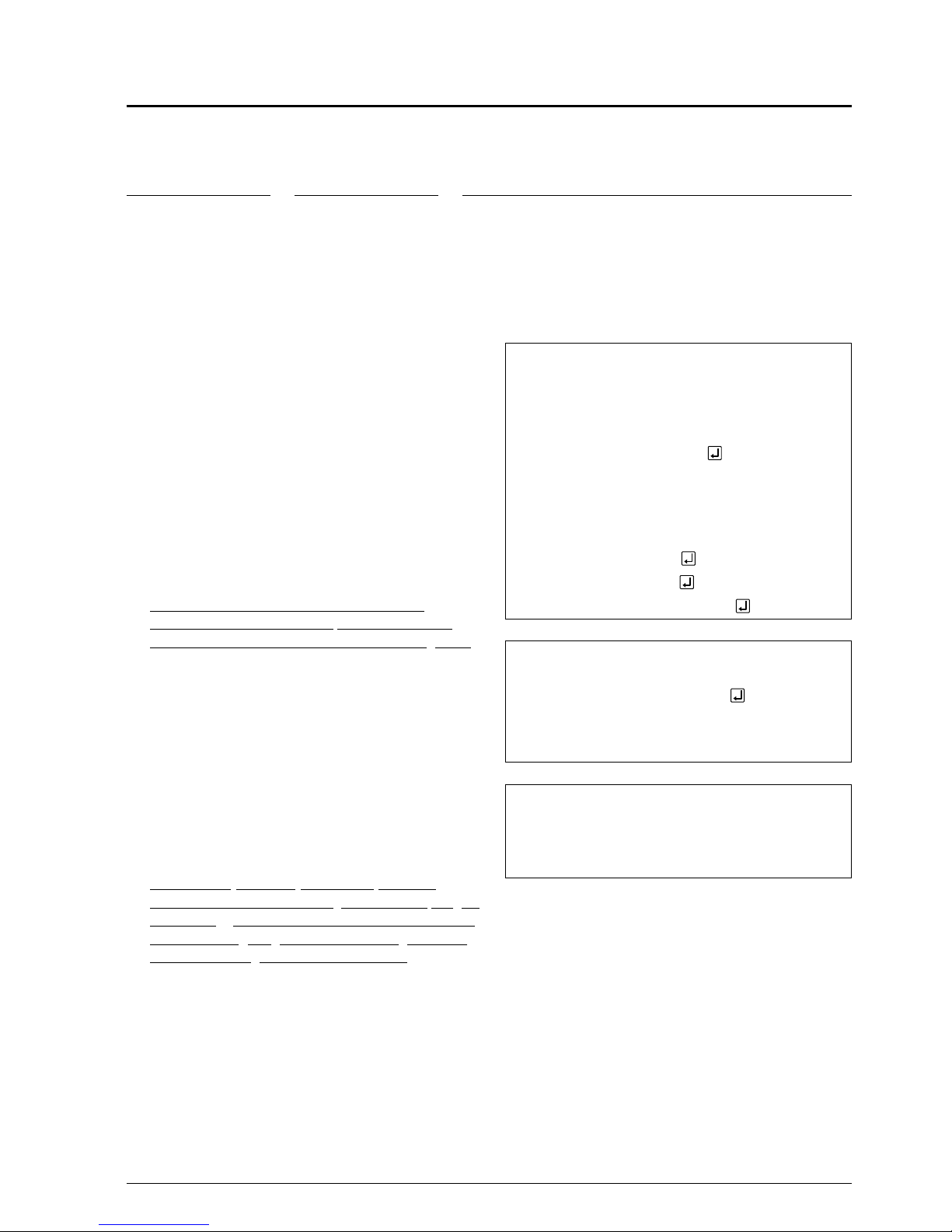

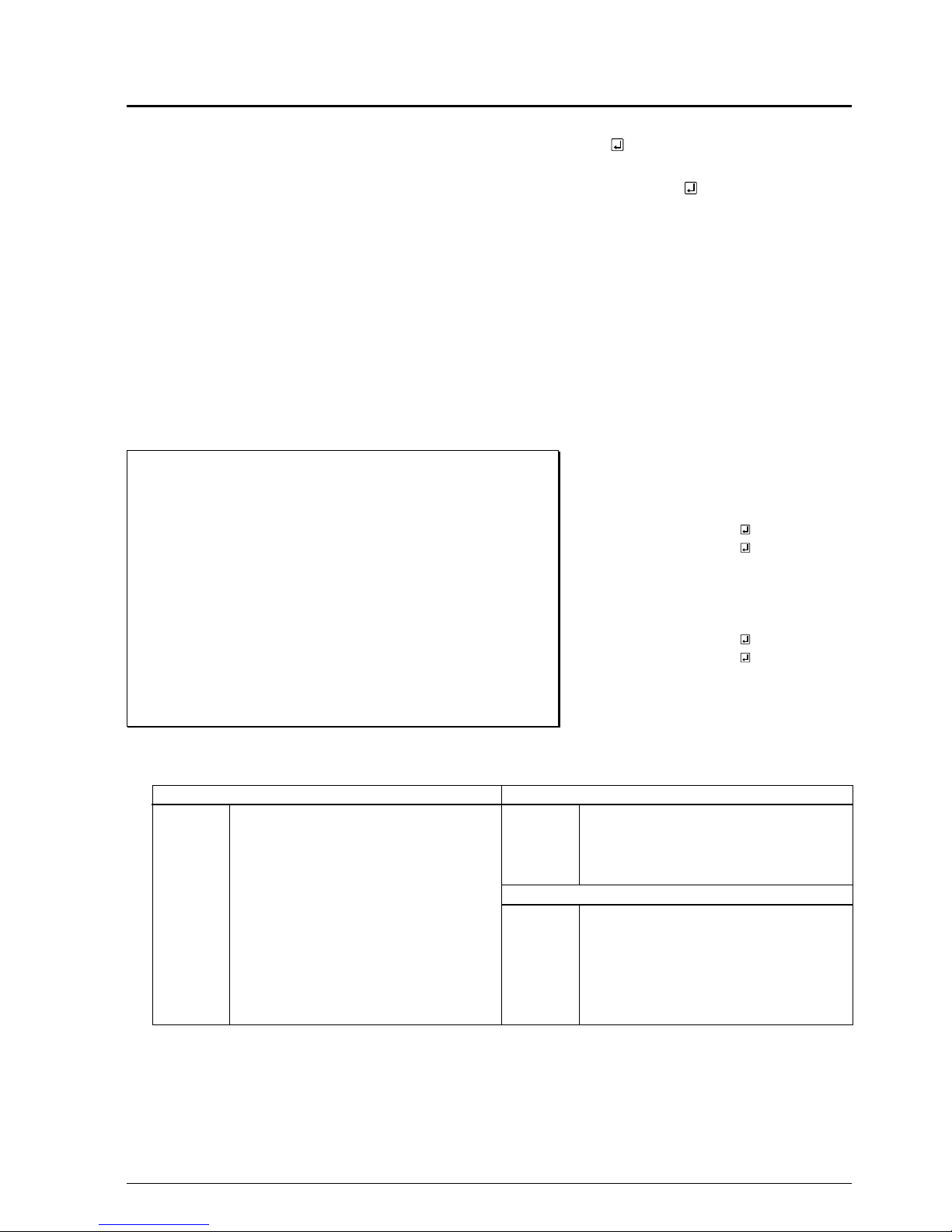

1.3 Development Flo w

Figure 1.3.1 shows the development flow through the DEV6011.

Fig. 1.3.1 DEV6011 development flow

Concerning file names

All the input-output file name for the each development support tool commonly use "C011XXX". In principle

each file should be produced in this manner. Seiko Epson will designate the "XXX" for each customer.

☞ Reference Manual

*1 E0C6011 Technical Hardware Manual *4 E0C6011 Development Tool Manual (this manual)

*2 E0C6200/6200A Core CPU Manual *5 EVA6011 Manual

*3 E0C62 Family Development Tool Reference Manual *6 ICE62R (ICE6200) Hardware Manual

C011XXXH

.HEX

Function option list

generation

Segment option list

generation

Function Option Generator

FOG6011 execution

Segment Option Generator

SOG6011 execution

Determination of

software specifications

Cross Assembler

ASM6011 execution

Source file generation

by using editor

Function

option

list

Segment

option

list

C011XXX

.DAT

Program

source file

Coding

sheet

Flow chart generation

and coding

Source file generation

by using editor

C011XXX

.SEG

Segment option

source file

C011XXXL

.HEX

Object file

C011XXXF

.HEX

Function

option

HEX file

Determination of

hardware specifications

EVA6011

Target board

Segment

option ROM

(one)

Function

option ROM

(one)

C011XXXS

.DOC

C011XXXF

.DOC

Segment option

document file

Function option

document file

C011XXX

.PRN

Assembly

list

Mask Data Checker

MDC6011 execution

C6011XXX

.PAn

File for

submission

SEIKO EPSON

*1 *1

*2, *3 *3, *4 *3, *4 *1, *5

*3, *4 *3, *4*3, *4

*3, *4

*3, *4

*3, *6 *5

C011XXXS

.HEX

Segment

option

HEX file

Creation of

target board

Debugging with

ICE Control Software

ICS6011

Debugging

completion

ICE62R (ICE6200)

ICE6200

Page 7

1 COMPOSITION OF DEVELOPMENT SUPPORT TOOL

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 3

1.4 Production of Execution Disk

Execution files for each software development support tool and batch and parameter files for the ICE62R

(ICE6200) are recorded in the DEV6011 floppy disk.

The content of the files contained in the DEV6011 floppy disk are shown below.

PC-DOS version

ASM6011.EXE

FOG6011.EXE

ICS6011B.BAT

ICS6011W.EXE

ICS6011P.PAR

MDC6011.EXE

SOG6011.EXE

MS-DOS version

ASM6011.EXE

FOG6011.EXE

ICS6011.BAT

ICS6011J.EXE

ICS6011P.PAR

MDC6011.EXE

SOG6011.EXE

Contents

Cross Assembler execution file

Function Option Generator execution file

ICE Control Software batch file

ICE Control SoftzÀre execution file

ICE Control Software parameter file

Mask Data Checker execution file

Segment Option Generator execution file

■ First copy the entire content of this disk using

commands such as DISKCOPY then make the

execution disk. Carefully conserve the original

floppy disk for storage purposes.

When copying into a hard disk, make a subdirectory with an appropriate name (DEV6011,

etc.) then copy the content of the floppy disk into

that subdirectory using the COPY command.

Example:

Copying into a floppy disk

Insert the original disk into the A drive and

the formatted disk to be copied into B drive,

then execute the DISKCOPY command.

A>DISKCOPY A: B:

Copying into a hard disk (C drive)

Make a subdirectory (DEV6011), then insert

the original disk into the A drive and execute

the COPY command.

C\>MD DEV6011

C\>CD DEV6011

C\DEV6011\>COPY A:*.*

Example:

Setting of FILES (CONFIG.SYS)

C\>TYPE CONFIG.SYS

:

FILES=20

:

■ In "ICS6011(B).BAT" the batch process is

indicated such that the ICS6011J(W).EXE is

executed after the execution of the command for

the setting of the RS-232C communication

parameters.

The SPEED (MS-DOS) or MODE (PC-DOS)

command is used for setting the RS-232C, so you

should copy these commands into the disk to be

executed or specify a disk or directory with the

command using the PATH command.

■ Next make a CONFIG.SYS file using Editor or

the like.

When a CONFIG.SYS has previously been made

using a hard disk system, check the setting of

the FILES within it. (If there is none add it.)

Set the number of files to be described in

CONFIG.SYS at 10 or more, so that the Mask

Data Checker MDC6011 will handle many files.

Note The driver for the RS-232C must be included

in CONFIG.SYS by the host computer.

RS-232C Setting (PC-DOS version)

MODE COM1: 9600, n, 8, 1, p

RS-232C Setting (MS-DOS version)

SPEED R0 9600 B8 PN S1

Page 8

2 CROSS ASSEMBLER ASM6011

4 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

2 CR OSS ASSEMBLER ASM6011

2.1 ASM6011 Outline

The ASM6011 cross assembler is an assembler program

for generating the machine code used by the E0C6011 4bit, single-chip microcomputers. The Cross Assembler

ASM6011 will assemble the program source files which

have been input by the user's editor and will generate

an object file in Intel-Hex format and assembly list file.

In this assembler, program modularization has been

made possible through macro definition functions and

programming independent of the ROM page structure

has been made possible through the auto page set

function. In addition, consideration has also been given

to precise error checks for program capacity (ROM

capacity) overflows, undefined codes and the like, and

for debugging of such things as label tables for assembly

list files and cross reference table supplements.

2.2 E0C6011 Restrictions

Note the following when generating a program by the E0C6011:

Fig. 2.1.1 ASM6011 execution flow

☞

The format of the source file and its operating method are same as for the E0C62 Family. Refer to the

"E0C62 Family Development Tool Reference Manual" for details.

■ ROM area

The capacity of the E0C6011

ROM is 1,536 steps (0000H to

05FFH).

Therefore, the specification

range of the memory setting

pseudo-instructions and PSET

instruction is restricted.

Memory configuration:

Bank: Only bank 0, Page: 6 pages (0 to 5H), each 256 steps

Significant specification range:

ORG pseudo-instruction: 0000H to 05FFH

PAGE pseudo-instruction: 00H to 05H

BANK pseudo-instruction: Only 0H

PSET instruction: 00H to 05H

A>EDLIN C011XXX.DAT

Create the source file

A>ASM6011 C011XXX

Execute the cross assembler

C011XXX

.DAT

C011XXX

.PRN

C011XXXL

.HEX

C011XXXH

.HEX

Error

message

Error

message

Assembly

listing file

Object file

■ RAM area

The capacity of the E0C6011 RAM

is 144 words (000H to 06FH, 080H

to 09FH, 4 bits/word). Memory

access is invalid when the unused

area of the index register is

specified.

Example: LD X,0A0H A0H is loaded into the IX register, but an

unused area has been specified so that the

memory accessible with the IX register

(MX) is invalid.

LD Y,0B7H B7H is loaded into the IY register, but an

unused area has been specified so that the

memory accessible with the IY register

(MY) is invalid.

■ Undefined codes

The following instructions have not

been defined in the E0C6011

instruction sets.

PUSH XP PUSH YP

POP XP POP YP

LD XP,r LD YP,r

LD r,XP LD r,YP

Page 9

2 CROSS ASSEMBLER ASM6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 5

2.3 ASM6011 Quick Reference

■ Starting command and input/output files

Execution file: ASM6011.EXE

Starting command: ASM6011_ [drive-name:] source-file-name [.shp]_ [-N]

Option: .shp Specifies the file I/O drives.

s Specifies the drive from which the source file is to be input. (A–P, @)

h Specifies the drive to which the object file is to be output. (A–P, @, Z)

p Specifies the drive to which the assembly listing file is to be output. (A–P, @, Z)

@: Current drive, Z: File is not generated

-N The code (FFH) in the undefined area of program memory is not created.

Input file: C011XXX.DAT (Source file)

Output file: C011XXXL.HEX (Object file, low-order)

C011XXXH.HEX (Object file, high-order)

C011XXX.PRN (Assembly listing file)

■ Display example

_ indicates a blank.

indicates the Return key.

A parameter enclosed by [ ] can be omitted.

*** E0C6011 CROSS ASSEMBLER. --- Ver 1.00 ***

EEEEEEEEEE PPPPPPPP SSSSSSS OOOOOOOO NNN NNN

EEEEEEEEEE PPPPPPPPPP SSS SSSS OOO OOO NNNN NNN

EEE PPP PPP SSS SSS OOO OOO NNNNN NNN

EEE PPP PPP SSS OOO OOO NNNNNN NNN

EEEEEEEEEE PPPPPPPPPP SSSSSS OOO OOO NNN NNN NNN

EEEEEEEEEE PPPPPPPP SSSS OOO OOO NNN NNNNNN

EEE PPP SSS OOO OOO NNN NNNNN

EEE PPP SSS SSS OOO OOO NNN NNNN

EEEEEEEEEE PPP SSSS SSS OOO OOO NNN NNN

EEEEEEEEEE PPP SSSSSSS OOOOOOOO NNN NN

(C) COPYRIGHT 1999 SEIKO EPSON CORP.

SOURCE FILE NAME IS " C011XXX.DAT "

THIS SOFTWARE MAKES NEXT FILES.

C011XXXH.HEX ... HIGH BYTE OBJECT FILE.

C011XXXL.HEX ... LOW BYTE OBJECT FILE.

C011XXX .PRN ... ASSEMBLY LIST FILE.

DO YOU NEED AUTO PAGE SET? (Y/N) Y . . . (1)

DO YOU NEED CROSS REFERENCE TABLE? (Y/N) Y . . . (2)

When ASM6011 is started, the start-up

message is displayed.

At (1), select whether or not the auto-pageset function will be used.

Use........................ Y

Not use ................. N

If the assembly listing file output is

specified, message (2) is displayed. At this

stage, cross-reference table generation may

be selected.

Generating ............ Y

Not generating ...... N

When the above operation is completed,

ASM6011 assembles the source file.

To suspend execution, press the "CTRL"

and "C" keys together at stage (1) or (2).

Arithmetic operators

+a

-a

a+b

a-b

a*b

a/b

a_MOD_b

a_SHL_b

a_SHR_b

HIGH_a

LOW_a

Monadic positive

Monadic negative

Addition

Subtraction

Multiplication

Division

Remainder of a/b

Shifts a b bits to the left

Shifts a b bits to the right

Separates the high-order eight bits from a

Separates the low-order eight bits from a

Logical operators

a_AND_b

a_OR_b

a_XOR_b

NOT_a

Relational operators

a_EQ_b

a_NE_b

a_LT_b

a_LE_b

a_GT_b

a_GE_b

Logical product

Logical sum

Exclusive logical sum

Logical negation

True when a is equal to b

True when a is not equal to b

True when a is less than b

True when a is less than or equal to b

True when a is greater than b

True when a is greater than or equal to b

■ Operators

Page 10

2 CROSS ASSEMBLER ASM6011

6 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

EQU

SET

DW

ORG

PAGE

SECTION

END

MACRO

LOCAL

ENDM

To allocate data to label

To allocate data to label

(data can be changed)

To define ROM data

To define location counter

To define boundary of page

Pseudo-instruction

(Equation)

(Set)

(Define Word)

(Origin)

(Page)

(Section)

(End)

(Macro)

(Local)

(End Macro)

To define boundary of section

To terminate assembly

To define macro

To make local specification of label

during macro definition

To end macro definition

Meaning Example of Use

ABC EQU 9

BCD EQU ABC+1

ABC SET 0001H

ABC SET 0002H

ABC DW 'AB'

BCD DW 0FFBH

ORG 100H

ORG 256

PAGE 1H

PAGE 3

SECTION

END

CHECK MACRO DATA

LOCAL LOOP

LOOP CP MX,DATA

JP NZ,LOOP

ENDM

CHECK 1

S

U

M

O

P

R

!

FILE NAME ERROR

FILE NOT PRESENT

DIRECTORY FULL

FATAL DISK WRITE ERROR

LABEL TABLE OVERFLOW

CROSS REFERENCE TABLE OVERFLOW

An unrecoverable syntax error was encountered.

The label or symbol of the operand has not been defined.

The label field has been omitted.

A syntax error was encountered in the operand, or the operand could

not be evaluated.

Error message

(Syntax Error)

(Undefined Error)

(Missing Label)

(Operand Error)

(Phase Error)

(Range Error)

(Warning)

Explanation

The same label or symbol was defined more than once.

•

•

•

The source file name was longer than 8 characters.

The specified source file was not found.

No space was left in the directory of the specified disk.

The file could not be written to the disk.

The number of defined labels and symbols exceeded the label table

capacity (4000).

The label/symbol reference count exceeded the cross-reference table

capacity (only when the cross-reference table is generated).

The location counter value exceeded the upper limit of the program

memory, or a location exceeding the upper limit was specified.

A value greater than that which the number of significant digits of the

operand will accommodate was specified.

Memory areas overlapped because of a "PAGE" or "ORG" pseudoinstruction or both.

■ Pseudo-instructions

■ Error messages

Page 11

3 FUNCTION OPTION GENERATOR FOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 7

3 FUNCTION OPTION GENERA T OR FOG6011

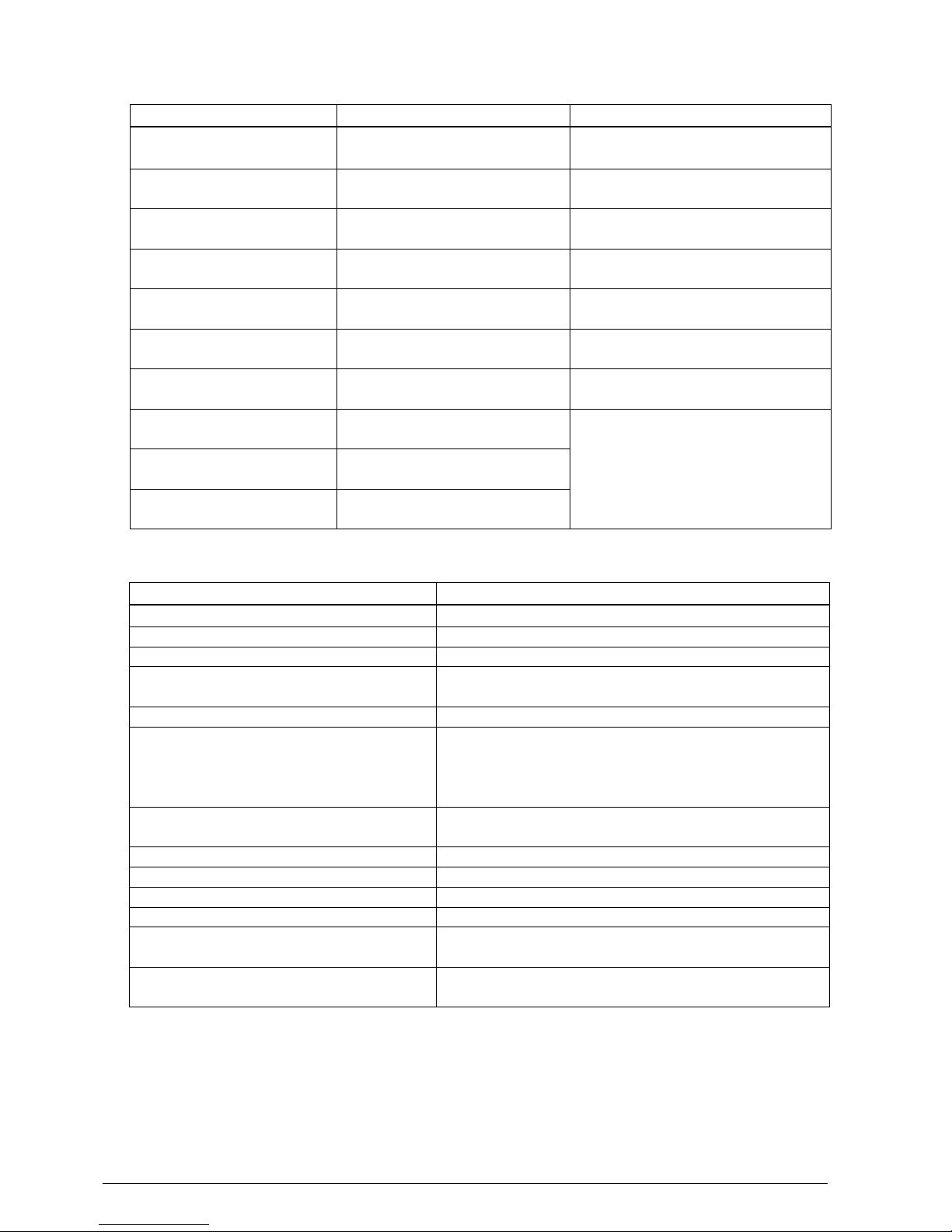

3.1 FOG6011 Outline

Seiko Epson

EVA6011

C011XXXF

.HEX

C011XXXF

.DOC

Set function

option

Start FOG6011

Floppy disk

EPROM

Option list

generation

☞

The operating method is same as for the E0C62

Family. Refer to the "E0C62 Family Development

Tool Reference Manual" for details.

With the 4-bit single-chip E0C6011 microcomputers, the

customer may select 12 hardware options. By modifying

the mask patterns of the E0C6011 according to the

selected options, the system can be customized to meet

the specifications of the target system.

The Function Option Generator FOG6011 is a software

tool for generating data files used to generate mask

patterns. It enables the customer to interactively select

and specify pertinent items for each hardware option.

From the data file created with FOG6011, the E0C6011

mask pattern is automatically generated by a general

purpose computer.

The HEX file for the evaluation board (EVA6011)

hardware option ROM is simultaneously generated with

the data file.

Fig. 3.1.1 FOG6011 execution flow

3.2 E0C6011 Option List

Multiple specifications are available in each option item as indicated in the Option List. Using "3.3 Option

Specifications and Selection Message" as reference, select the specifications that meet the target system. Be

sure to record the specifications for unused ports too, according to the instructions provided.

1. DEVICE TYPE

■■ 1. E0C6011 LCD 3 V

■■ 2. E0C6011 LCD 4.5 V

2. OSC1 SYSTEM CLOCK SELECT

■■ 1. Internal Resistor OSC1 = 65 kHz

■■ 2. Internal Resistor OSC1 = 130 kHz

■■ 3. Internal Resistor OSC1 = 195 kHz

■■ 4. Internal Resistor OSC1 = 260 kHz

3. INTERRUPT NOISE REJECTOR K00–K03

■■ 1. Use ■■ 2. Not Use

4. INPUT PORT PULL DOWN RESISTOR

• K00 ......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K01 ......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K02 ......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• K03 ......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

5. R00 SPECIFICATION

• R00 OUTPUT SPECIFICATION ........ ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• R00 OUTPUT TYPE ............................. ■■ 1. DC Output ■■ 2. Buzzer Output

6. R01 SPECIFICATION

• R01 OUTPUT SPECIFICATION ........ ■■ 1. Complementary ■■ 2. Pch-OpenDrain

Page 12

3 FUNCTION OPTION GENERATOR FOG6011

8 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

7. R02 SPECIFICATION

• R02 OUTPUT SPECIFICATION ........ ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• R02 OUTPUT TYPE ............................. ■■ 1. DC Output

■■ 2. FOSC/2

■■ 3. FOSC/4

■■ 4. FOSC/8

■■ 5. FOSC/16

■■ 6. FOSC/32

■■ 7. FOSC/64

■■ 8. FOSC/128

■■ 9. FOSC/256

8. R03 SPECIFICATION

• R03 OUTPUT SPECIFICATION ........ ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• R03 OUTPUT TYPE ............................. ■■ 1. DC Output

■■ 2. Buzzer Output (R00 control)

■■ 3. Buzzer Output (R03 control)

9. I/O PORT SPECIFICATION

• P00 .......................................................... ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• P01 .......................................................... ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• P02 .......................................................... ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• P03 .......................................................... ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• P10 .......................................................... ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• P11 .......................................................... ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• P12 .......................................................... ■■ 1. Complementary ■■ 2. Pch-OpenDrain

• P13 .......................................................... ■■ 1. Complementary ■■ 2. Pch-OpenDrain

10. I/O PORT PULL DOWN RESISTOR

• P00 .......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P01 .......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P02 .......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P03 .......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P10 .......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P11 .......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P12 .......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

• P13 .......................................................... ■■ 1. With Resistor ■■ 2. Gate Direct

11. LCD COMMON DUTY AND BIAS

■■ 1. 1/4 Duty, 1/3 Bias or 1/4 Duty, 1/2 Bias

■■ 2. 1/3 Duty, 1/3 Bias or 1/3 Duty, 1/2 Bias

■■ 3. 1/2 Duty, 1/3 Bias or 1/2 Duty, 1/2 Bias

12. SEGMENT MEMORY ADDRESS

■■ 1. 40H–6FH ■■ 2. C0H–EFH

Page 13

3 FUNCTION OPTION GENERATOR FOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 9

*** OPTION NO.1 ***

--- << DEVICE TYPE & LCD POWER VREG >> ---

1. E0C6011 LCD 3V

2. E0C6011 LCD 4.5V

PLEASE SELECT NO.(1) ? 1

1. E0C6011 LCD 3V SELECTED

1 Device type and LCD voltage

Select the chip specification.

There are two models: 3-V LCD type and 4.5-V

LCD type.

*** OPTION NO.2 ***

--- << OSC1 SYSTEM CLOCK SELECT >> ---

1. INTERNAL RESISTOR OSC1=65KHZ

2. INTERNAL RESISTOR OSC1=130KHZ

3. INTERNAL RESISTOR OSC1=195KHZ

4. INTERNAL RESISTOR OSC1=260KHZ

PLEASE SELECT NO.(1) ? 1

1. INTERNAL RESISTOR OSC1=65KHZ SELECTED

2 OSC1 system clock

The E0C6011 has a CR oscillation circuit with

resistor and capacitor built-in. Four frequencies are

available.

3.3 Option Specifications and Selection Message

Screen that can be selected as function options set on the E0C6011 are shown below, and their specifications

are also described.

*** OPTION NO.3 ***

--- << INTERRUPT NOISE REJECTOR K00-K03 >> ---

1. USE

2. NOT USE

PLEASE SELECT NO.(1) ? 1

1. USE SELECTED

Select whether noise rejector will be supplemented to

the input interruptor of K00–K03.

When "Use" is selected, the entry signal will pass the

noise rejector, and occurrence of interrupt errors due

to noise or chattering can be avoided. Note, however,

that because the noise rejector performs entry signal

sampling at 4 kHz, "Not Use" should be selected

when high speed response is required.

3 Interrupt noise rejector

Page 14

3 FUNCTION OPTION GENERATOR FOG6011

10 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

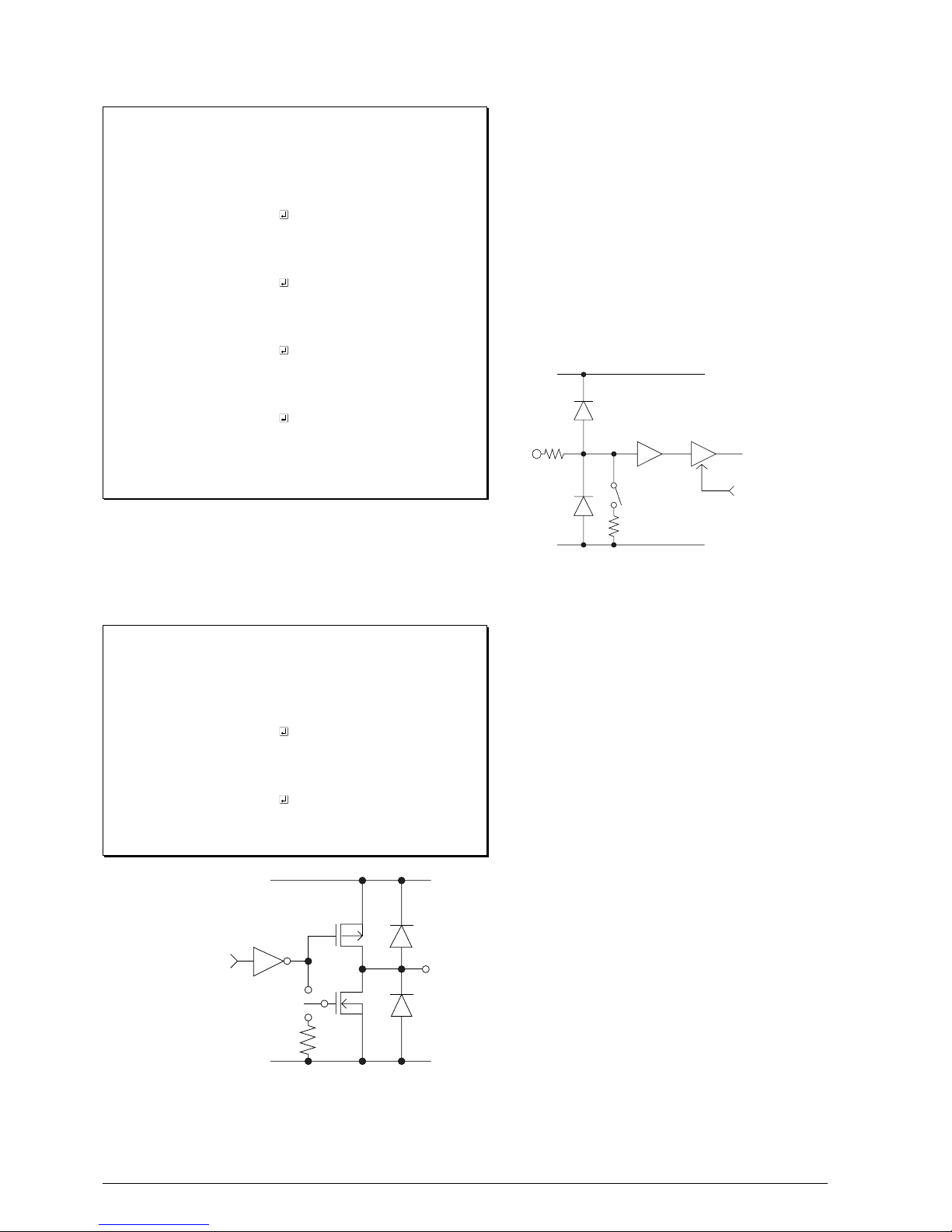

5 R00 specification

Select the output specification and the output type

for the R00 terminal.

• Output specification

Either complementary output or Pch open drain

output may be selected.

The output circuit configuration is shown in Figure

3.3.2.

*** OPTION NO.5 ***

--- << R00 SPECIFICATION >> ---

R00 OUTPUT SPECIFICATION 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

R00 OUTPUT TYPE 1. DC

2. BZ OUTPUT

PLEASE SELECT NO.(1) ? 1

R00 OUTPUT SPECIFICATION 1. COMPLEMENTARY SELECTED

R00 OUTPUT TYPE 1. DC SELECTED

Output

register

V

DD

R

Complementary

Pch open drain

V

SS

*** OPTION NO.4 ***

--- << INPUT PORT PULL DOWN RESISTOR >> ---

K00 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 2

K01 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 2

K02 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 2

K03 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 2

K00 2. GATE DIRECT SELECTED

K01 2. GATE DIRECT SELECTED

K02 2. GATE DIRECT SELECTED

K03 2. GATE DIRECT SELECTED

Select whether input ports (K00–K03) will each be

supplemented with pull down resistors or not. When

"Gate Direct" is selected, see to it that entry floating

state does not occur. Select "With Resistor" for

unused ports.

Moreover, the input port status is changed from high

level (VDD) to low (VSS) with pull down resistors, a

delay of approximately 1 msec in waveform rise time

will occur depending on the pull down resistor and

entry load time constant. Because of this, when input

reading is to be conducted, ensure the appropriate

wait time with the program.

The configuration of the pull down resistor circuit is

shown in Figure 3.3.1.

4 Input port pull down resistor

Fig. 3.3.1 Configuration of pull down resistor

V

DD

K

Data bus

Read signal

V

SS

• Output type

When DC output is selected, R00 becomes a

regular output port. When buzzer output is

selected, by writing "1" to the R00 register, buzzer

drive signal is output from the R00 terminal.

∗ When DC output is selected, the R03 terminal

output type (see Option 8, "R03 specification")

selection is limited to DC output only.

Refer to Figure 3.3.5 for buzzer output waveform.

Fig. 3.3.2 Configuration of output circuit

Page 15

3 FUNCTION OPTION GENERATOR FOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 11

Select the output specification for the R01 terminal.

Either complementary output or Pch open drain

output may be selected.

The circuit configuration is the same as that of the

output port R00 (Figure 3.3.2).

6 R01 specification

*** OPTION NO.6 ***

--- << R01 SPECIFICATION >> ---

R01 OUTPUT SPECIFICATION 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

R01 OUTPUT SPECIFICATION 1. COMPLEMENTARY SELECTED

7 R02 specification

*** OPTION NO.7 ***

--- << R02 SPECIFICATION >> ---

R02 OUTPUT SPECIFICATION 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

R02 OUTPUT TYPE 1. DC

2. FOSC/2

3. FOSC/4

4. FOSC/8

5. FOSC/16

6. FOSC/32

7. FOSC/64

8. FOSC/128

9. FOSC/256

PLEASE SELECT NO.(1) ? 1

R02 OUTPUT SPECIFICATION 1. COMPLEMENTARY SELECTED

R02 OUTPUT TYPE 1. DC SELECTED

Select the output specification and the output type

for the R02 terminal.

• Output specification

Either complementary output or Pch open drain

output may be selected.

The circuit configuration is the same as that of the

output port R00 (Figure 3.3.2).

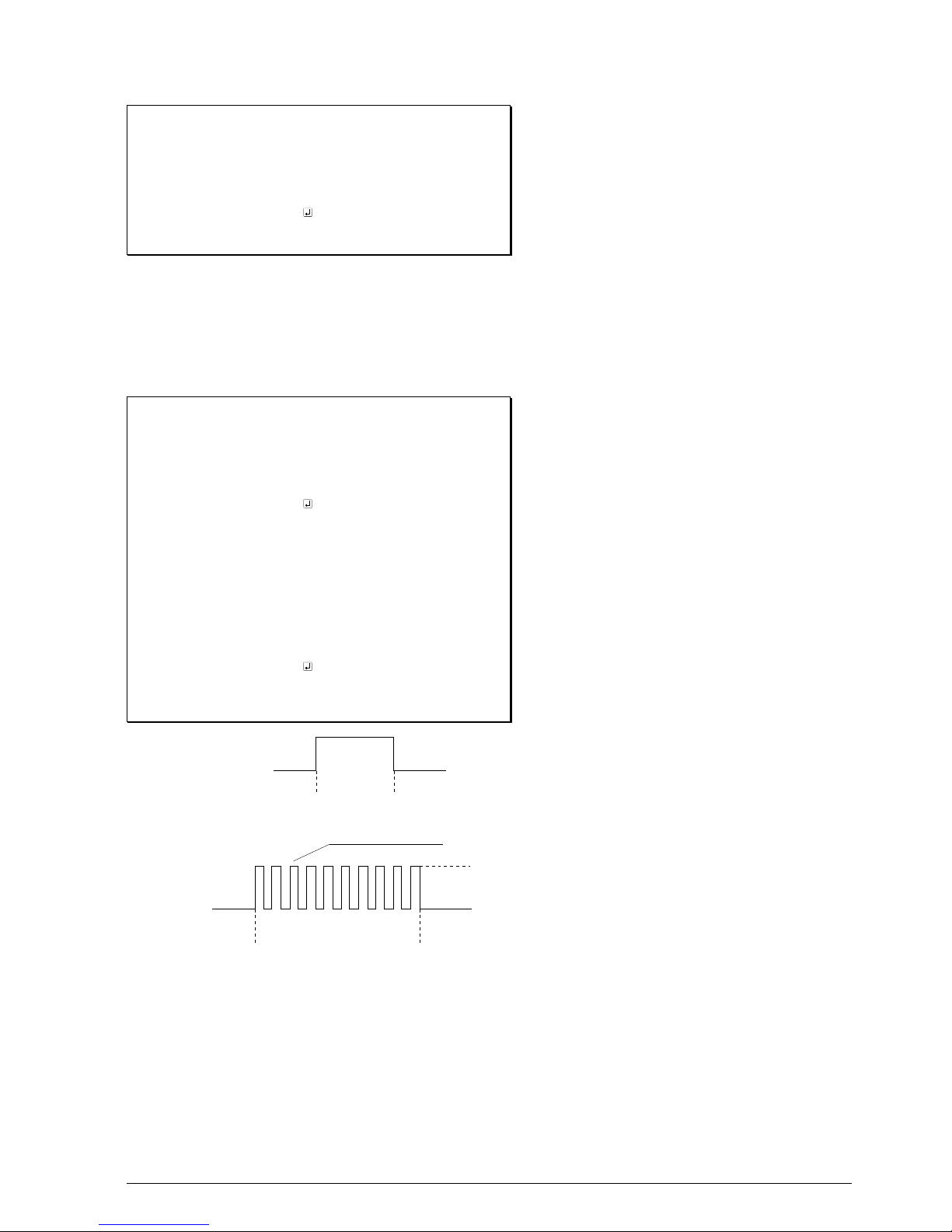

• Output type

Either DC output or FOUT output may be

selected.

When DC output is selected, R02 becomes a

regular output port.

When the R02 register is set to "1", the R02

terminal output goes high (VDD), and goes low

(VSS) when set to "0".

The output waveform is shown in Figure 3.3.3.

When FOUT is selected, a clock with a set

frequency can be output from the R02 terminal.

When the FOUT bit (R02 register) is set to "1",

50% duty and VDD–VSS amplitude square wave is

generated at the specified frequency. When set to

"0", the FOUT terminal goes low (VSS). A FOUT

frequency may be selected from among 8 types,

ranging from fOSC/256 to fOSC/2.

The FOUT output is normally utilized to provide

clock to other devices but since hazard occurs at

the square wave breaks, great caution must be

observed when using it.

The output waveform is shown in Figure 3.3.4.

Fig. 3.3.3 Output waveform at R02 DC output selection

V

DD

V

SS

010

R02 register

R02 output

Fig. 3.3.4 Output waveform at R02 FOUT output selection

R02 output

R02 register 0 1 0

Specified frequency

VDD

VSS

Page 16

3 FUNCTION OPTION GENERATOR FOG6011

12 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

Select the output specification to be used during I/O

ports (P00–P03 and P10–P13) output mode selection.

Either complementary output or Pch open drain

output may be selected.

The circuit configuration of the output driver is the

same as that of output ports (Figure 3.3.2).

Select complementary output for unused ports.

The I/O ports can control the input/output direction

according to the IOC bit (07EH•D0 and 0FEH•D0);

at "1" and "0" settings, it is set to output port and

input port, respectively.

The pull down resistor of this port is turned on by the

read signal and is normally turned off to minimize

leak current.

Because of this, when the port is set for input, take

care that a floating state does not occur in the

terminal.

The I/O port circuit configuration is shown in Figure

3.3.6.

Select the output specification and the output type

for the R03 terminal.

• Output specification

Either complementary output or Pch open drain

output may be selected.

The circuit configuration is the same as that of the

output port R00 (Figure 3.3.2).

• Output type

Either DC output or buzzer output (buzzer inverted

output) may be selected.

When DC output is selected, R03 becomes a

regular output port.

When buzzer output is selected, inverted waveform of R00 buzzer output is generated from the

R03 terminal. When "BZ OUTPUT (R03)" is

selected, the R03 outputs the buzzer inverted

signal when "1" is written to the R03 register.

When "BZ OUTPUT (R00)" is selected, the R03

buzzer output can be controlled by the R00

register as well as the R00 buzzer output.

∗ The buzzer output for R03 may not be selected

when the output type of the R00 terminal (see

Option 5, "R00 specification") is not set to

buzzer output. Moreover, at this point, when the

R00 output type is reselected after selecting

buzzer output, the R00 output type is fixed at

buzzer output.

The buzzer output waveform is shown in Figure

3.3.5.

8 R03 specification

100

R00/R03 register

R00 buzzer output

R03 buzzer inverted output

Fig. 3.3.5 Buzzer output waveform

*** OPTION NO.8 ***

--- << R03 SPECIFICATION >> ---

R03 OUTPUT SPECIFICATION 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

R03 OUTPUT TYPE 1. DC

2. BZ OUTPUT(R00)

3. BZ OUTPUT(R03)

PLEASE SELECT NO.(1) ? 1

R03 OUTPUT SPECIFICATION 1. COMPLEMENTARY SELECTED

R03 OUTPUT TYPE 1. DC SELECTED

*** OPTION NO.9 ***

--- << I/O PORT SPECIFICATION >> ---

P00 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

P01 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

P02 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

P03 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

P10 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

P11 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

9 I/O port specification

Page 17

3 FUNCTION OPTION GENERATOR FOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 13

P12 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

P13 1. COMPLEMENTARY

2. PCH-OPENDRAIN

PLEASE SELECT NO.(1) ? 1

P00 1. COMPLEMENTARY SELECTED

P01 1. COMPLEMENTARY SELECTED

P02 1. COMPLEMENTARY SELECTED

P03 1. COMPLEMENTARY SELECTED

P10 1. COMPLEMENTARY SELECTED

P11 1. COMPLEMENTARY SELECTED

P12 1. COMPLEMENTARY SELECTED

P13 1. COMPLEMENTARY SELECTED

Fig. 3.3.6 Circuit configuration of I/O port

Data bus

Read signal

Register

I/O control

register

P

V

SS

10 I/O port pull down resistor

Select whether I/O ports (P00–P03, P10–P13) will

each be supplemented with pull down resistors or

not. When "Gate Direct" is selected, see to it that

entry floating state does not occur. Select "With

Resistor" for unused ports.

Moreover, when the I/O port is set to the input mode

and a low-level voltage (VSS) is input, an erroneous

input results if the time constant of the capacitive

load of the input line and the built-in pull-down

resistor load is greater than the read-out time. When

the input data is being read, the time that the input

line is pulled down is equivalent to 0.5 cycles of the

CPU system clock. Hence, the electric potential of

the terminals must settle within 0.5 cycles. If this

condition cannot be met, some measure must be

devised, such as arranging a pull-down resistor

externally, or performing multiple read-outs.

*** OPTION NO.10 ***

--- << I/O PORT PULL DOWN RESISTOR >> ---

P00 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 1

P01 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 1

P02 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 1

P03 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 1

P10 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 1

P11 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 1

P12 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 1

P13 1. WITH RESISTOR

2. GATE DIRECT

PLEASE SELECT NO.(1) ? 1

P00 1. WITH RESISTOR SELECTED

P01 1. WITH RESISTOR SELECTED

P02 1. WITH RESISTOR SELECTED

P03 1. WITH RESISTOR SELECTED

P10 1. WITH RESISTOR SELECTED

P11 1. WITH RESISTOR SELECTED

P12 1. WITH RESISTOR SELECTED

P13 1. WITH RESISTOR SELECTED

Page 18

3 FUNCTION OPTION GENERATOR FOG6011

14 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

11 LCD specification

Table 3.3.1 Common duty selection standard

Number of segments Common duty

1–76 1/2

77–114 1/3

115–152 1/4

Fig. 3.3.8 Drive waveform from COM terminals (1/2 bias)

Fig. 3.3.7 Drive waveform from COM terminals (1/3 bias)

COM0

COM1

COM2

COM3

1/3 duty drive waveform1/4 duty drive waveform

V

DD

V

L1

V

L2

V

L3

COM0

COM1

COM2

COM3

V

DD

V

L1

V

L2

V

L3

COM0

COM1

COM2

COM3

1/2 duty drive waveform

V

DD

V

L1

V

L2

V

L3

COM0

COM1

COM2

COM3

1/3 duty drive waveform1/4 duty drive waveform

V

DD

VL1, V

L2

V

L3

COM0

COM1

COM2

COM3

V

DD

VL1, V

L2

V

L3

COM0

COM1

COM2

COM3

1/2 duty drive waveform

V

DD

VL1, V

L2

V

L3

*** OPTION NO.11 ***

--- << LCD COMMON DUTY AND BIAS >> ---

1. 1/4 DUTY,1/2 BIAS

2. 1/3 DUTY,1/2 BIAS

3. 1/2 DUTY,1/2 BIAS

PLEASE SELECT NO.(1) ? 1

1. 1/4 DUTY,1/2 BIAS SELECTE

Select the specification (drive duty) for the LCD drive

circuit.

• Drive duty

Select a drive duty.

When 1/2 duty is selected, up to 76 segments of LCD

panel can be driven with 2 COM terminals and 38

SEG terminals. When 1/3 duty is selected, up to 114

segments can be driven with 3 COM terminals, and

when 1/4 duty is selected, up to 152 segments with 4

COM terminals.

When 1/2 duty is selected, the COM0 and COM1

terminals are effective for COM output and the COM2

and COM3 terminals always output an off signal.

When 1/3 duty is selected, the COM0 to COM2

terminals are effective and the COM3 terminal always

outputs an off signal. Refer to Table 3.3.1 for common

duty selection.

Figures 3.3.7 and 3.3.8 show the drive waveforms of

1/3 bias driving and 1/2 bias driving, respectively.

(for 3-V LCD model)

Page 19

3 FUNCTION OPTION GENERATOR FOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 15

The LCD drive bias is decided according to the LCD

voltage selection of Option 1.

When 4.5 V LCD is selected, the LCD drive bias is

set to 1/3 (drives LCD with 4 levels, VDD, VL1, VL2

and VL3). When 3 V LCD is selected, the LCD drive

bias is set to 1/2 (drives LCD with 3 levels, VDD, VL1

= VL2 and VL3).

Figure 3.3.9 shows the external element configuration

for the LCD voltage selected by Option 1.

The LCDON register (0FFH•D0) is used for turning

the LCD display ON and OFF.

12 Segment memory address

Select the segment memory area.

When "40H–6FH" is selected for the segment

memory area, it is possible to read and write from/to

this area because a RAM is assigned to this area.

When "C0H–EFH" is selected, this segment memory

area becomes a write-only area.

*** OPTION NO.12 ***

--- << SEGMENT MEMORY ADDRESS SELECT >> ---

1. 40H-6FH

2. C0H-EFH

PLEASE SELECT NO.(1) ? 2

2. C0H-EFH SELECTED

V

DD

V

L1

V

L2

V

L3

CA

CB

V

SS

1.5 V

C2

C3

C1

0.1µF

0.1µF

0.1µF

V

DD

VL1=V

SS

VL2=2V

L1

VL3=3V

L1

V

SS

4.5 V LCD Panel

1/4, 1/3 or 1/2 duty, 1/3 bias

V

L1

and VSS are shorted internally.Note:

LCD

voltage

circuit

V

DD

V

L1

V

L2

V

L3

CA

CB

V

SS

1.5 V

C2C10.1µF

0.1µF

V

DD

VL1=V

SS

VL2=V

SS

VL3=2V

L1

V

SS

3 V LCD Panel

1/4, 1/3 or 1/2 duty, 1/2 bias

V

L1

and VSS are shorted internally.Note:

LCD

voltage

circuit

Fig. 3.3.9 External elements for LCD power supply circuit

Page 20

3 FUNCTION OPTION GENERATOR FOG6011

16 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

3.4 FOG6011 Quick Reference

■ Starting command and input/output files

Execution file: FOG6011.EXE

Starting command: FOG6011

Input file: C011XXXF.DOC (Function option document file, when modifying)

Output file: C011XXXF.DOC (Function option document file)

C011XXXF.HEX (Function option HEX file)

■ Display example

*** E0C6011 FUNCTION OPTION GENERATOR. --- Ver 2.00 ***

EEEEEEEEEE PPPPPPPP SSSSSSS OOOOOOOO NNN NNN

EEEEEEEEEE PPPPPPPPPP SSS SSSS OOO OOO NNNN NNN

EEE PPP PPP SSS SSS OOO OOO NNNNN NNN

EEE PPP PPP SSS OOO OOO NNNNNN NNN

EEEEEEEEEE PPPPPPPPPP SSSSSS OOO OOO NNN NNN NNN

EEEEEEEEEE PPPPPPPP SSSS OOO OOO NNN NNNNNN

EEE PPP SSS OOO OOO NNN NNNNN

EEE PPP SSS SSS OOO OOO NNN NNNN

EEEEEEEEEE PPP SSSS SSS OOO OOO NNN NNN

EEEEEEEEEE PPP SSSSSSS OOOOOOOO NNN NN

(C) COPYRIGHT 1994 SEIKO EPSON CORP.

THIS SOFTWARE MAKES NEXT FILES.

C011XXXF.HEX ... FUNCTION OPTION HEX FILE.

C011XXXF.DOC ... FUNCTION OPTION DOCUMENT FILE.

STRIKE ANY KEY.

indicates the Return key.

Start-up message

When FOG6011 is started, the start-up

message is displayed.

For "STRIKE ANY KEY.", press any key

to advance the program execution.

To suspend execution, press the "CTRL"

and "C" keys together: the sequence returns

to the DOS command level.

Setting new function options

Select "1" on the operation selection menu.

(1) Enter the file name.

(2) Enter the customer's company name.

(3) Enter any comment.

(Within 50 characters x 10 lines)

Next, start function option setting from

option No. 1.

In case a function option document file with

the same name as the file name specified in

the current drive exists, the user is asked

whether overwriting is desired. Enter "Y" or

"N" accordingly.

Date input

Enter the 2-digit year, month, and day of the

month by delimiting them with a slash ("/").

When not modifying the date, press the

RETURN key "

" to continue.

Operation selection menu

Enter a number from 1 to 3 to select a

subsequent operation.

1. To set new function options.

2. To modify the document file.

3. To terminate FOG6011.

*** OPERATION SELECT MENU ***

1. INPUT NEW FILE

2. EDIT FILE

3. RETURN TO DOS

PLEASE SELECT NO.?

*** E0C6011 USER'S OPTION SETTING. --- Ver 2.00 ***

CURRENT DATE IS 99/01/22

PLEASE INPUT NEW DATE :

*** OPERATION SELECT MENU ***

1. INPUT NEW FILE

2. EDIT FILE

3. RETURN TO DOS

PLEASE SELECT NO.? 1

PLEASE INPUT FILE NAME? C0110A0 . . (1)

PLEASE INPUT USER'S NAME? SEIKO EPSON CORP. . . (2)

PLEASE INPUT ANY COMMENT

(ONE LINE IS 50 CHR)? FUJIMI PLANT . . (3)

? 281 FUJIMI SUWA-GUN NAGANO-KEN 399-0293 JAPAN

? TEL 0266-61-1211

? FAX 0266-61-1273

?

PLEASE INPUT FILE NAME? C0110A0

EXISTS OVERWRITE(Y/N)? N

PLEASE INPUT FILE NAME? C0110B0

PLEASE INPUT USER'S NAME?

Page 21

3 FUNCTION OPTION GENERATOR FOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 17

*** OPERATION SELECT MENU ***

1. INPUT NEW FILE

2. EDIT FILE

3. RETURN TO DOS

PLEASE SELECT NO.? 2

*** SOURCE FILE(S) ***

C0110A0 C0110B0 C0110C0 . . (1)

PLEASE INPUT FILE NAME? C0110A0 . . (2)

PLEASE INPUT USER'S NAME? . . (3)

PLEASE INPUT ANY COMMENT

(ONE LINE IS 50 CHR)? . . (4)

PLEASE INPUT EDIT NO.? 4 . . (5)

:

(Modifying function option settings)

:

PLEASE INPUT EDIT NO.? E

Modifying function option settings

Select "2" on the operation selection menu.

(1) Will display the files on the current drive.

(2) Enter the file name.

(3) Enter the customer's company name.

(4) Enter any comment.

Previously entered data can be used by pressing

the RETURN key "

" at (3) and (4).

(5) Enter the number of the function option to be

modified. When selection of one option is

complete, the system prompts entry of another

function option number. Repeat selection until

all options to be modified are selected.

Enter "E

" to end option setting. Then, move

to the confirmation procedure for HEX file

generation.

In step (1), if no modifiable source exists, the following message is

displayed and the sequence returns to the operation selection menu.

*** SOURCE FILE(S) ***

FUNCTION OPTION DOCUMENT FILE IS NOT FOUND.

PLEASE INPUT FILE NAME? C0110N0

FUNCTION OPTION DOCUMENT FILE IS NOT FOUND.

PLEASE INPUT FILE NAME?

In step (2), if the function option document file is not in the current drive,

the following message is displayed, prompting entry of other file name.

END OF OPTION SETTING.

DO YOU MAKE HEX FILE (Y/N) ? Y . . (1)

*** OPTION EPROM SELECT MENU ***

1. 27C64

2. 27C128

3. 27C256

4. 27C512

PLEASE SELECT NO.? 2 . . (2)

2. 27C128 SELECTED

MAKING FILE(S) IS COMPLETED.

*** OPERATION SELECT MENU ***

1. INPUT NEW FILE

2. EDIT FILE

3. RETURN TO DOS

PLEASE SELECT NO.?

*** OPTION NO.3 ***

--- << INTERRUPT NOISE REJECTOR K00-K03 >> ---

1. USE

2. NOT USE

PLEASE SELECT NO.(1) ? 2

2. USE SELECTED

EPROM selection

When setting function options setting is completed,

the following message is output to ask the operator

whether to generate the HEX file.

(1) When debugging the program with EVA6011,

HEX file is needed, so enter "Y

". If "N " is

entered, no HEX file is generated and only

document file is generated.

(2) For the option ROM selection menu displayed

when "Y

" is entered in Step (1), select the

EPROM to be used for setting EVA6011

options.

When a series of operations are complete, the

sequence returns to the operation selection menu.

Option selection

The selections for each option correspond one to

one to the option list. Enter the selection number.

The value in parentheses ( ) indicates the default

value, and is set when only the RETURN key "

"

is pressed.

In return, the confirmation is displayed.

When you wish to modify previously set function

options in the new setting process, enter "B

" to

return 1 step back to the previous function option

setting operation.

Page 22

3 FUNCTION OPTION GENERATOR FOG6011

18 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

3.5 Sample File

■ Example of function option document file

* E0C6011 FUNCTION OPTION DOCUMENT V 2.00

*

* FILE NAME C0110A0F.DOC

* USER’S NAME SEIKO EPSON CORP.

* INPUT DATE 1999/01/22

*

*

*

* OPTION NO.1

* < << DEVICE TYPE & LCD POWER VREG >> >

* E0C6011 LCD 3V ----------- SELECTED

OPT0101 01

*

* OPTION NO.2

* < << OSC1 SYSTEM CLOCK SELECT >> >

* INTERNAL RESISTOR OSC1=65KHZ SELECTED

OPT0201 01

*

* OPTION NO.3

* < << INTERRUPT NOISE REJECTOR K00-K03 >> >

* USE ----------------------- SELECTED

OPT0301 01

*

* OPTION NO.4

* < << INPUT PORT PULL DOWN RESISTOR >> >

* K00 WITH RESISTOR ------------- SELECTED

* K01 WITH RESISTOR ------------- SELECTED

* K02 WITH RESISTOR ------------- SELECTED

* K03 WITH RESISTOR ------------- SELECTED

OPT0401 01

OPT0402 01

OPT0403 01

OPT0404 01

*

* OPTION NO.5

* < << R00 SPECIFICATION >> >

* R00 OUTPUT SPECIFICATION COMPLEMENTARY ------------- SELECTED

* R00 OUTPUT TYPE DC ------------------------ SELECTED

OPT0501 01

OPT0502 01

*

* OPTION NO.6

* < << R01 SPECIFICATION >> >

* R01 OUTPUT SPECIFICATION COMPLEMENTARY ------------- SELECTED

OPT0601 01

*

* OPTION NO.7

* < << R02 SPECIFICATION >> >

* R02 OUTPUT SPECIFICATION COMPLEMENTARY ------------- SELECTED

* R02 OUTPUT TYPE DC ------------------------ SELECTED

OPT0701 01

OPT0702 01

*

* OPTION NO.8

* < << R03 SPECIFICATION >> >

* R03 OUTPUT SPECIFICATION COMPLEMENTARY ------------- SELECTED

* R03 OUTPUT TYPE DC ------------------------ SELECTED

OPT0801 01

OPT0802 01

*

Page 23

3 FUNCTION OPTION GENERATOR FOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 19

* OPTION NO.9

* < << I/O PORT SPECIFICATION >> >

* P00 COMPLEMENTARY ------------- SELECTED

* P01 COMPLEMENTARY ------------- SELECTED

* P02 COMPLEMENTARY ------------- SELECTED

* P03 COMPLEMENTARY ------------- SELECTED

* P10 COMPLEMENTARY ------------- SELECTED

* P11 COMPLEMENTARY ------------- SELECTED

* P12 COMPLEMENTARY ------------- SELECTED

* P13 COMPLEMENTARY ------------- SELECTED

OPT0901 01

OPT0902 01

OPT0903 01

OPT0904 01

OPT0905 01

OPT0906 01

OPT0907 01

OPT0908 01

*

* OPTION NO.10

* < << I/O PORT PULL DOWN RESISTOR >> >

* P00 WITH RESISTOR ------------- SELECTED

* P01 WITH RESISTOR ------------- SELECTED

* P02 WITH RESISTOR ------------- SELECTED

* P03 WITH RESISTOR ------------- SELECTED

* P10 WITH RESISTOR ------------- SELECTED

* P11 WITH RESISTOR ------------- SELECTED

* P12 WITH RESISTOR ------------- SELECTED

* P13 WITH RESISTOR ------------- SELECTED

OPT1001 01

OPT1002 01

OPT1003 01

OPT1004 01

OPT1005 01

OPT1006 01

OPT1007 01

OPT1008 01

*

* OPTION NO.11

* < << LCD COMMON DUTY AND BIAS >> >

* 1/4 DUTY,1/2 BIAS --------- SELECTED

OPT1101 01

*

* OPTION NO.12

* < << SEGMENT MEMORY ADDRESS SELECT >> >

* C0H-EFH ------------------- SELECTED

OPT1201 02

*

*

*

* SEIKO EPSON’S AREA

*

*

*

* OPTION NO.13

OPT1301 01

*

* OPTION NO.14

OPT1401 01

\\END

Note End mark "¥¥END" may be used instead of "\\END" depending on

the PC used. (The code of \ and ¥ is 5CH.)

Page 24

4 SEGMENT OPTION GENERATOR SOG6011

20 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

4 SEGMENT OPTION GENERATOR SOG6011

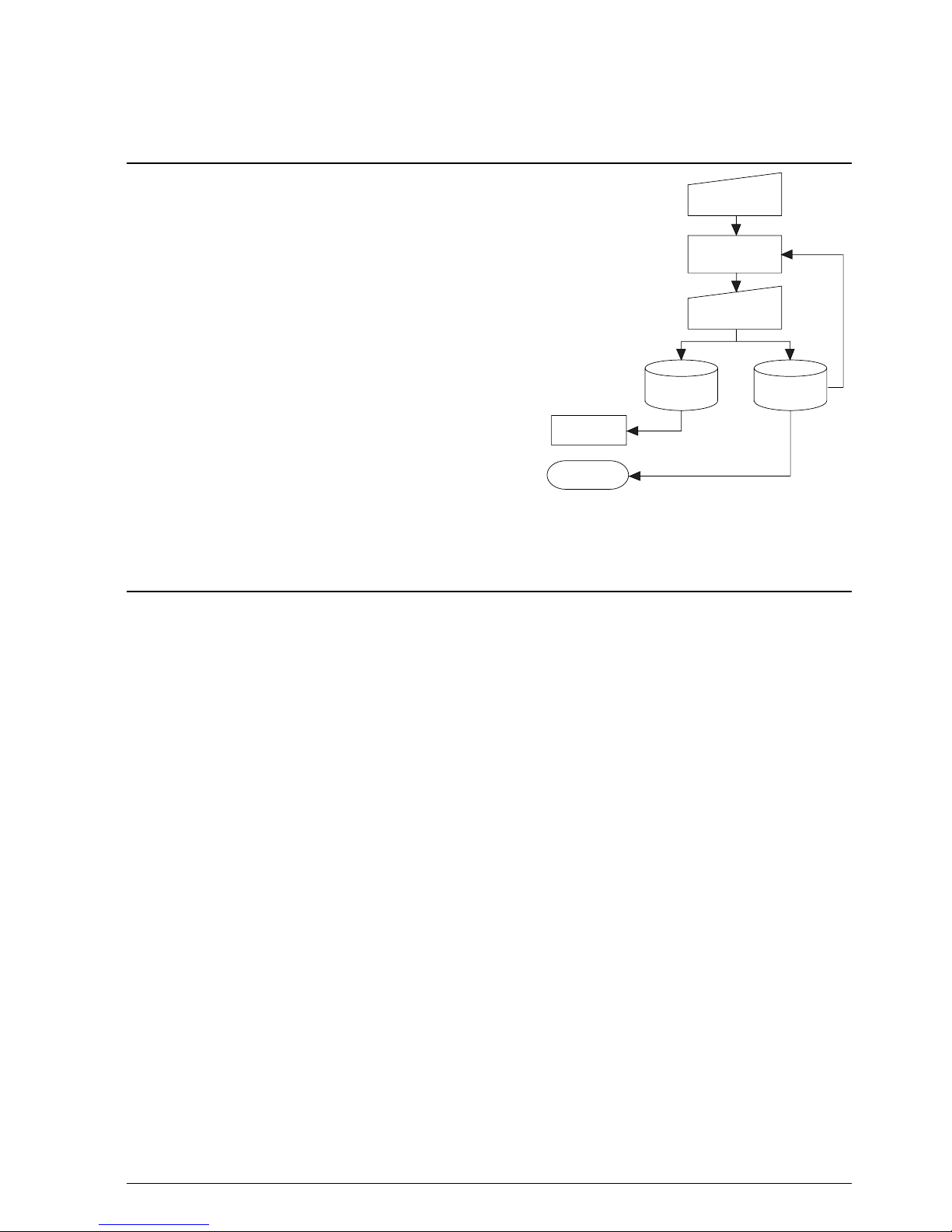

4.1 SOG6011 Outline

With the 4-bit single-chip E0C6011 microcomputers,

the customer may select the LCD segment options.

By modifying the mask patterns of the E0C6011

according to the selected options, the system can be

customized to meet the specifications of the target

system.

The Segment Option Generator SOG6011 is a

software tool for generating data file used to

generate mask patterns. From the data file created

with SOG6011, the E0C6011 mask pattern is automatically generated by a general purpose computer.

The HEX file for the evaluation board (EVA6011)

segment option ROM is simultaneously generated

with the data file.

Fig. 4.1.1 SOG6011 execution flow

A>EDLIN C011XXX.SEG

Segment source file generation

A>SOG6011

Execute the segment option generator

C011XXX

.SEG

Error

message

Error

message

for EVA6011 use

C011XXXS

.DOC

Segment option

HEX file

Segment option

document file

C011XXXS

.HEX

☞

The operating method is same as for the E0C62 Family. Refer to the "E0C62 Family Development

Tool Reference Manual" for details.

Page 25

4 SEGMENT OPTION GENERATOR SOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 21

4.2 Option List

Note: 1. Even if there are unused areas, set "---" (hyphens) such that there are no blank columns.

2. When DC output is selected, the display memory of the COM0 column becomes effective.

OUTPUT SPECIFICATIONCOM0 COM1 COM2 COM3

ADDRESS

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

SEG36

SEG37

LHDLHDLHDLHD

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

SEG output

DC output

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

Legend: <ADDRESS>

H: High order address, L: Low order address

D: Data bit

<OUTPUT SPECIFICATION>

C: Complementary output

P: Pch open drain output

TERMINAL

NAME

Page 26

4 SEGMENT OPTION GENERATOR SOG6011

22 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

4.3 Segment Ports Output Specifications

For the output specification of the segment output ports SEG0–SEG37, segment output and DC output can

be selected in units of two terminals. When used for liquid crystal panel drives, select segment output;

when used as regular output port, select DC output. When DC output is selected, either complementary

output or Pch open drain output may further be selected.

However, for segment output ports that will not be used, select segment output.

Refer to the "E0C62 Family Development Tool Reference Manual" for the segment option source file

creation.

■ When segment output is selected

The segment output port has a segment decoder built-in, and the data bit of the optional address in the

segment memory area (040H–06FH or 0C0H–0EFH) can be allocated to the optional segment. With this,

up to 152 segments (114 segments when 1/3 duty is selected or 76 segments when 1/2 duty is selected)

of liquid crystal panel could be driven.

The segment memory may be allocated only one segment and multiple setting is not possible.

The allocated segment displays when the bit for this segment memory is set to "1", and goes out when

bit is set to "0".

Segment allocation is set to H for high address (4–6 or C–E), to L for low address (0–F), and to D for

data bit (0–3) and are recorded in their respective column in the option list. For segment ports that will

not be used, write "---" (hyphen) in the H, L, and D columns of COM0–COM3.

Examples

• When 1/4 duty is selected

0 C00 C01 C02 C03 S

1 C10 C11 C12 C13 S

• When 1/3 duty is selected

0 C00 C01 C02 --- S

1 C10 C11 C12 --- S

• When 1/2 duty is selected

0 C00 C01 --- --- S

1 C10 C11 --- --- S

■ When DC output is selected

The DC output can be selected in units of two terminals and up to 38 terminals may be allocated for DC

output. Also, either complementary output or Pch open drain output is likewise selected in units of two

terminals. When the bit for the selected segment memory is set to "1", the segment output port goes

high (VDD), and goes low (VSS) when set to "0". Segment allocation is the same as when segment output

is selected but for the while the segment memory allocated to COM1–COM3 becomes ineffective. Write

three hyphens ("---") in the COM1–COM3 columns in the option list.

Example

• When complementary output is set to SEG34 and SEG35, and Pch open drain output is set to SEG36 and SEG37.

34 E00 --- --- --- C

35 E10 --- --- --- C

36 E20 --- --- --- P

37 E30 --- --- --- P

Page 27

4 SEGMENT OPTION GENERATOR SOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 23

4.4 SOG6011 Quick Reference

■ Starting command and input/output files

Execution file: SOG6011.EXE

Starting command: SOG6011_ [-H]

Option: -H:Specifies the segment option document file for input file of SOG6011.

Input file: C011XXX.SEG (Segment option source file)

C011XXXS.DOC (Segment option document file, when -H option use)

Output file: C011XXXS.DOC (Segment option document file)

C011XXXS.HEX (Segment option HEX file)

■ Display example

_ indicates a blank.

indicates the Return key.

A parameter enclosed by [ ] can be omitted.

*** E0C6011 SEGMENT OPTION GENERATOR. --- Ver 2.00 ***

EEEEEEEEEE PPPPPPPP SSSSSSS OOOOOOOO NNN NNN

EEEEEEEEEE PPPPPPPPPP SSS SSSS OOO OOO NNNN NNN

EEE PPP PPP SSS SSS OOO OOO NNNNN NNN

EEE PPP PPP SSS OOO OOO NNNNNN NNN

EEEEEEEEEE PPPPPPPPPP SSSSSS OOO OOO NNN NNN NNN

EEEEEEEEEE PPPPPPPP SSSS OOO OOO NNN NNNNNN

EEE PPP SSS OOO OOO NNN NNNNN

EEE PPP SSS SSS OOO OOO NNN NNNN

EEEEEEEEEE PPP SSSS SSS OOO OOO NNN NNN

EEEEEEEEEE PPP SSSSSSS OOOOOOOO NNN NN

(C) COPYRIGHT 1999 SEIKO EPSON CORP.

SEGMENT OPTION SOURCE FILE NAME IS " C011XXX.SEG "

THIS SOFTWARE MAKES NEXT FILES.

C011XXXS.HEX ... SEGMENT OPTION HEX FILE.

C011XXXS.DOC ... SEGMENT OPTION DOCUMENT FILE.

STRIKE ANY KEY.

*** E0C6011 USER'S OPTION SETTING. --- Ver 2.00 ***

CURRENT DATE IS 99/01/14

PLEASE INPUT NEW DATE :

*** SOURCE FILE(S) ***

C0110A0 C0110B0 C0110C0 . . (1)

PLEASE INPUT SEGMENT OPTION FILE NAME? C0110A0 . . (2)

PLEASE INPUT USER'S NAME? SEIKO EPSON CORP. . . (3)

PLEASE INPUT ANY COMMENT

(ONE LINE IS 50 CHR)? FUJIMI PLANT . . (4)

? 281 FUJIMI SUWA-GUN NAGANO-KEN 399-0293 JAPAN

? TEL 0266-61-1211

? FAX 0266-61-1273

?

PLEASE INPUT SEGMENT OPTION SOURCE FILE NAME? C0110N0

SEGMENT OPTION SOURCE FILE IS NOT FOUND. . . (7) -H option not use

PLEASE INPUT SEGMENT OPTION DOCUMENT FILE NAME? C0110N0

SEGMENT OPTION DOCUMENT FILE IS NOT FOUND. . . (8) -H option use

*** SOURCE FILE(S) ***

SEGMENT OPTION SOURCE FILE IS NOT FOUND. . . (5) -H option not use

*** SOURCE FILE(S) ***

SEGMENT OPTION DOCUMENT FILE IS NOT FOUND. . . (6) -H option use

Start-up message

When SOG6011 is started, the start-up

message is displayed.

For "STRIKE ANY KEY.", press any key

to advance the program execution.

To suspend execution, press the "CTRL"

and "C" keys together: the sequence returns

to the DOS command level.

Date input

Enter the 2-digit year, month, and day of the

month by delimiting them with a slash ("/").

When not modifying the date, press the

RETURN key "

" to continue.

Input file selection

(1)

Will display the files on the current drive.

(2) Enter the file name.

(3) Enter the customer's company name.

(4) Enter any comment.

(Within 50 characters x 10 lines)

Then, move to the confirmation procedure

for HEX file generation.

In step (1), if no modifiable source exists,

an error message (5) or (6) will be displayed and the program will be terminated.

In step (2), if the specified file name is not

found in the current drive, an error message

(7) or (8) is displayed, prompting entry of

other file name.

Page 28

4 SEGMENT OPTION GENERATOR SOG6011

24 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

EPROM selection

When selecting file is completed, the following

message is output to ask the operator whether to

generate the HEX file.

(1) When debugging the program with EVA6011,

HEX file is needed, so enter "Y

". If "N " is

entered, no HEX file is generated and only

document file is generated.

(2) For the option ROM selection menu displayed

when "Y

" is entered in Step (1), select the

EPROM to be used for setting EVA6011

options.

When a series of operations are complete, the

SOG6011 generates files. If no error is committed

while setting segment options, "MAKING FILE IS

COMPLETED" will be displayed and the

SOG6011 program will be terminated.

END OF OPTION SETTING.

DO YOU MAKE HEX FILE (Y/N) ? Y . . (1)

*** OPTION EPROM SELECT MENU ***

1. 27C64

2. 27C128

3. 27C256

4. 27C512

PLEASE SELECT NO.? 2 . . (2)

2. 27C128 SELECTED

MAKING FILE IS COMPLETED.

■ Error messages

S

N

R

D

Out Port Set Error

The data was written in an invalid format.

The segment number outside the specificable range was specified.

The segment memory address or data bit outside the specificable range was specified.

Error message

(Syntax Error)

(Segment No. Select Error)

(RAM Address Select Error)

(Duprication Error)

Explanation

The same data (SEG port No., segment memory address, or data bit) was specified

more then once.

The output specifications were not set in units of two ports.

Page 29

4 SEGMENT OPTION GENERATOR SOG6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 25

4.5 Sample Files

■ Example of segment option source file

; C0110A0.SEG, VER.2.00

; EVA6011 LCD SEGMENT DECODE TABLE

0 C00 C01 C02 C03 S

1 C10 C11 C12 C13 S

2 C20 C21 C22 C23 S

3 C30 C31 C32 C33 S

4 C40 C41 C42 C43 S

5 C50 C51 C52 C53 S

6 C60 C61 C62 C63 S

7 C70 C71 C72 C73 S

8 C80 C81 C82 C83 S

9 C90 C91 C92 C93 S

10 CA0 CA1 CA2 CA3 S

11 CB0 CB1 CB2 CB3 S

12 CC0 CC1 CC2 CC3 S

13 CD0 CD1 CD2 CD3 S

14 CE0 CE1 CE2 CE3 S

15 CF0 CF1 CF2 CF3 S

16 D00 D01 D02 D03 S

17 D10 D11 D12 D13 S

18 D20 D21 D22 D23 S

19 D30 D31 D32 D33 S

20 D40 D41 D42 D43 S

21 D50 D51 D52 D53 S

22 D60 D61 D62 D63 S

23 D70 D71 D72 D73 S

24 D80 D81 D82 D83 S

25 D90 D91 D92 D93 S

26 DA0 DA1 DA2 DA3 S

27 DB0 DB1 DB2 DB3 S

28 DC0 DC1 DC2 DC3 S

29 DD0 DD1 DD2 DD3 S

30 DE0 DE1 DE2 DE3 S

31 DF0 DF1 DF2 DF3 S

32 E00 E01 E02 E03 S

33 E10 E11 E12 E13 S

34 E20 E21 E22 E23 S

35 E30 E31 E32 E33 S

36 E40 --- --- --- C

37 E50 --- --- --- C

Page 30

4 SEGMENT OPTION GENERATOR SOG6011

26 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

■ Example of segment option document file

* E0C6011 SEGMENT OPTION DOCUMENT V 2.00

*

* FILE NAME C0110A0S.DOC

* USER’S NAME SEIKO EPSON CORP.

* INPUT DATE 99/01/14

*

*

* OPTION NO.13

*

* < LCD SEGMENT DECODE TABLE >

*

* SEG COM0 COM1 COM2 COM3 SPEC

*

0 C00 C01 C02 C03 S

1 C10 C11 C12 C13 S

2 C20 C21 C22 C23 S

3 C30 C31 C32 C33 S

4 C40 C41 C42 C43 S

5 C50 C51 C52 C53 S

6 C60 C61 C62 C63 S

7 C70 C71 C72 C73 S

8 C80 C81 C82 C83 S

9 C90 C91 C92 C93 S

10 CA0 CA1 CA2 CA3 S

11 CB0 CB1 CB2 CB3 S

12 CC0 CC1 CC2 CC3 S

13 CD0 CD1 CD2 CD3 S

14 CE0 CE1 CE2 CE3 S

15 CF0 CF1 CF2 CF3 S

16 D00 D01 D02 D03 S

17 D10 D11 D12 D13 S

18 D20 D21 D22 D23 S

19 D30 D31 D32 D33 S

20 D40 D41 D42 D43 S

21 D50 D51 D52 D53 S

22 D60 D61 D62 D63 S

23 D70 D71 D72 D73 S

24 D80 D81 D82 D83 S

25 D90 D91 D92 D93 S

26 DA0 DA1 DA2 DA3 S

27 DB0 DB1 DB2 DB3 S

28 DC0 DC1 DC2 DC3 S

29 DD0 DD1 DD2 DD3 S

30 DE0 DE1 DE2 DE3 S

31 DF0 DF1 DF2 DF3 S

32 E00 E01 E02 E03 S

33 E10 E11 E12 E13 S

34 E20 E21 E22 E23 S

35 E30 E31 E32 E33 S

36 E40 E41 E42 E43 C

37 E50 E51 E52 E53 C

\\END

Note End mark "¥¥END" may be used instead of "\\END" depending on

the PC used. (The code of \ and ¥ is 5CH.)

Page 31

5 ICE CONTROL SOFTWARE ICS6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 27

5 ICE CONTROL SOFTWARE ICS6011

5.1 ICS6011 Outline

The In-circuit Emulator ICE62R (ICE6200) connects the target board produced by the user via the EVA6011

and performs real time target system evaluation and debugging by passing through the RS-232C from the

host computer and controlling it. The operation on the host computer side and ICE62R (ICE6200) control is

done through the ICE Control Software ICS6011.

The ICS6011 has a set of numerous and highly functional emulation commands which provide sophisticated break function, on-the-fly data display, history display, etc., and so perform a higher level of debugging.

Host computer

PC-9801 Series

IBM PC/AT

[ ]

RS-232C

EVA6011

Target boardICE62R (ICE6200)

ICE6200

Fig. 5.1.1 Debugging system using ICE62R (ICE6200)

☞

The functions of the ICE62R (ICE6200) and commands are same as for the E0C62 Family. Refer to

the "E0C62 Family Development Tool Reference Manual" for details.

5.2 ICS6011 Restrictions

Take the following precautions when using the ICS6011.

■ ROM Area

The ROM area is limited to a maximum address of 5FFH. Assigning data above the 5FFH address

causes an error.

■ RAM Area

The RAM area is limited to a maximum address of 0FFH. Assigning data above the 0FFH address

causes an error. Furthermore, as the following addresses are in the unused area, designation of this area

with the ICE commands produces an error.

Unused area: 0A0H to 0EFH (When segment memory is assigned from 040H to 06FH)

0A0H to 0BFH (When segment memory is assigned from 0C0H to 0EFH)

071H, 072H, 074H, 076H, 077H, 07BH, 07FH, 0F0H to 0F5H, 0F7H to 0FCH

Refer to the "E0C6011 Technical Manual" for details.

■ Undefined Code

The instructions below are not specified for the E0C6011 and so cannot be used.

PUSH XP POP XP LD XP,r LD r,XP

PUSH YP POP YP LD YP,r LD r,YP

■ OPTLD Command

In the ICS6011, OPTLD command can be used.

This command is used to load HEX files (function option data and segment option data for LCD) in the

EVA6011 memory with the ICE62R (ICE6200).

Load of function option data: #OPTLD,1,C011XXX

Load of segment option data: #OPTLD,2,C011XXX

Page 32

5 ICE CONTROL SOFTWARE ICS6011

28 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

OPTLD READ HEXA DATA FILE

Format

#OPTLD,1,<file name> ...(1)

#OPTLD,2,<file name> ...(2)

(1) Load function option HEX file in the EVA6011 function option data memory.

It is HEX file output by the function option generator and has intel HEX format.

(2) Load segment option HEX file in the EVA6011 segment option data memory.

It is HEX file output by the segment option generator and has intel HEX format.

Function

Examples

#OPTLD,1,C011XXX ..... C011XXXF.HEX file is loaded in the function option data memory.

#OPTLD,2,C011XXX

..... C011XXXS.HEX file is loaded in the segment option data memory.

Page 33

5 ICE CONTROL SOFTWARE ICS6011

E0C6011 DEVELOPMENT TOOL MANUAL EPSON 29

5.3 ICS6011 Quick Reference

■ Starting command and input/output files

Execution file: ICS6011.BAT (ICS6011J.EXE) . . . for MS-DOS

ICS6011B.BAT (ICS6011W.EXE) . . . for PC-DOS

Starting command: ICS6011 (ICS6011J) . . . for MS-DOS

ICS6011B (ICS6011W)

. . . for PC-DOS

Input file: C011XXXL.HEX (Object file, low-order)

C011XXXH.HEX (Object file, high-order)

C011XXXD.HEX (Data RAM file)

C011XXXC.HEX (Control file)

Output file: C011XXXL.HEX (Object file, low-order)

C011XXXH.HEX (Object file, high-order)

C011XXXD.HEX (Data RAM file)

C011XXXC.HEX (Control file)

■ Display example

indicates the Return key.

*** E0C6011 ICE CONTROL SOFTWARE. --- Ver 3.01 ***

EEEEEEEEEE PPPPPPPP SSSSSSS OOOOOOOO NNN NNN

EEEEEEEEEE PPPPPPPPPP SSS SSSS OOO OOO NNNN NNN

EEE PPP PPP SSS SSS OOO OOO NNNNN NNN

EEE PPP PPP SSS OOO OOO NNNNNN NNN

EEEEEEEEEE PPPPPPPPPP SSSSSS OOO OOO NNN NNN NNN

EEEEEEEEEE PPPPPPPP SSSS OOO OOO NNN NNNNNN

EEE PPP SSS OOO OOO NNN NNNNN

EEE PPP SSS SSS OOO OOO NNN NNNN

EEEEEEEEEE PPP SSSS SSS OOO OOO NNN NNN

EEEEEEEEEE PPP SSSSSSS OOOOOOOO NNN NN

(C) COPYRIGHT 1991 SEIKO EPSON CORP.

* ICE POWER ON RESET *

* DIAGNOSTIC TEST OK *

#

Start-up message

When ICS6011 is started, the start-up

message is displayed, and a self-test is

automatically performed. ICS6011

commands are awaited when the program

is properly loaded and the # mark is

displayed.

Debugging can be done by entering

command after the # mark.

The ICS6011 program is terminated by

entering the Q (Quit) command.

Note Confirm that the cables con-

nected properly, then operate

the ICS6011.

■ Error messages

Error message Meaning

* COMMUNICATION ERROR

OR ICE NOT READY *

* TARGET DOWN (1) *

* TARGET DOWN (2) *

* UNDEFINED PROGRAM

CODE EXIST *

* COMMAND ERROR *

(No response after power on)

ICE62R (ICE6200) is disconnected

or power is OFF.

Evaluation board is disconnected.

(Check at power ON)

Evaluation board is disconnected.

(Check at command execution)

Undefined code is detected in the

program loaded from ROM or FD.

A miss occurs by command input.

The ICE-to-HOST cable is

disconnected on the host side.

Switch OFF the host power supply, connect cable, and

reapply power. Or switch ON power to ICE62R (ICE6200).

Switch OFF power to ICE, and connect the evaluation

board. Then, apply power to ICE62R (ICE6200).

Switch OFF power to ICE, and connect the evaluation

board. Then, apply power to ICE62R (ICE6200).

Convert ROM and FD data with the cross assembler,

then restart the ICE62R (ICE6200).

Reenter the proper command.

Switch OFF the host power supply, connect cable,

and reapply power.

Recover procedure

Page 34

5 ICE CONTROL SOFTWARE ICS6011

30 EPSON E0C6011 DEVELOPMENT TOOL MANUAL

■ Command list

1

2

3

4

5

6

7

8

9

10

Assemble

Disassemble

Dump

Fill

Set

Run Mode

Trace

Break

Move

Data Set

Change CPU

Internal

Registers

#A,a

#L,a1,a2

#DP,a1,a2

#DD,a1,a2

#FP,a1,a2,d

#FD,a1,a2,d

#G,a

#TIM

#OTF

#T,a,n

#U,a,n

#BA,a

#BAR,a

#BD

#BDR

#BR

#BRR

#BM

#BMR

#BRES

#BC

#BE

#BSYN

#BT

#BRKSEL,REM

#MP,a1,a2,a3

#MD,a1,a2,a3

#SP,a

#SD,a

#DR

#SR

#I

#DXY

#SXY

Assemble command mnemonic code and store at address "a"

Contents of addresses a1 to a2 are disassembled and displayed

Contents of program area a1 to a2 are displayed

Content of data area a1 to a2 are displayed

Data d is set in addresses a1 to a2 (program area)

Data d is set in addresses a1 to a2 (data area)

Program is executed from the "a" address

Execution time and step counter selection

On-the-fly display selection