Page 1

1

Page 2

DE

WALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in U.S.A. (SEP02-CD-5) Form No. 392261-00

DW7464 Copyright © 2002

Page 3

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW7464

52" Rail System

Système de rails 52 po (132,08 cm)

Sistema de rieles de 52” (1.32 m)

A utiliser seulement avec les scies à table DEWALT DW746

For Use Only With D

EWALT DW746 Table Saw

Para uso sólo con la Sierra de Mesa D

EWALT DW746

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTIA. ADVERTENCIA: LEASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO. SI TIENE DUDAS, POR FAVOR LLAME.

Before returning this

product call

1-800-4-DEWALT

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PURCHASE,

CALL 1-800-4 DEWALT.

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF DEWALT'S QUAL-

ITY IMPROVEMENT PROGRAM.

See our catalog on the World Wide Web. www.dewalt.com

Page 4

English

DE

WALT… GUARANTEED TOUGH

D

EWALT high performance industrial tools are made for America’s

toughest industrial and construction applications. The design of

every tool in the line – from drills to sanders to table saws – is the

result of rigorous use on job sites and throughout industry. Each

tool is produced with painstaking precision using advanced manufacturing systems and intense quality control. Every tool is

checked before it leaves the factory to make sure that it meets your

standards for durability, reliability and power.

D

EWALT Built Job site Tough…WE GUARANTEE IT.

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING SAW • ALWAYS WEAR EYE PROTECTION • DO NOT WEAR

GLOVES, NECKTIES, JEWELRY OR LOOSE CLOTHING • CONTAIN LONG HAIR • KEEP HANDS AND FINGERS OUT OF THE SAW BLADE PATH — USE EXTRA

CAUTION WHEN BEVELING • ALWAYS USE BLADE GUARD AND SPREADER FOR EVERY OPERATION FOR WHICH IT CAN BE USED, INCLUDING THROUGH

SAWING • USE A “PUSH STICK” WHEN REQUIRED • KNOW HOW TO AVOID KICKBACKS — SEE MANUAL • ALWAYS SUPPORT WORK WITH TABLE AND

FENCE OR MITER GAUGE • NEVER USE FENCE AND MITER GAUGE TOGETHER • NEVER REACH AROUND OR OVER SAW BLADE • SECURELY MOUNT

SAW BLADE BEFORE OPERATING • NEVER REMOVE JAMMED OR CUT-OFF PIECES UNTIL POWER IS OFF AND BLADE HAS STOPPED • DO NOT EXPOSE

TO RAIN OR USE IN DAMP LOCATIONS • DO NOT OPERATE THIS MACHINE WHILE UNDER THE INFLUENCE OF ALCOHOL OR DRUGS • FAILURE TO COMPLY WITH THESE WARNINGS MAY RESULT IN SERIOUS PERSONAL INJURY.

WARNING: USE OF THIS TOOL CAN GENERATE DUST CONTAINING CHEMICALS

KNOWN TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

USE APPROPRIATE RESPIRATORY PROTECTION.

Page 5

English

1

Items Included

Box #1

• (1) 52" rail system table sub-assembly

• (1) Support pan

• (1) Support bracket

• (2) Lower support rail

• (3) Rear brackets

Box #2 (Rail Carton)

• (1) Front rail sub-assembly

• (1) Rear rail

• (2) Legs

• (2) Feet

• (1) Hardware bag

Tools Included

• 6mm hex wrench

• Torx T40 wrench

• Torx T50 wrench

Tools Needed

• 17 mm open end wrench

• (2) 16mm or 5/8" open end wrench

• 13mm or 1/2" open end wrench

• Ruler

• Soft hammer or regular hammer and block of wood

• Small flat blade screwdriver

To speed assembly, the following would be helpful:

• 16mm or 5/8" socket wrench

• 13mm or 1/2" socket wrench

• T25 Torx driver

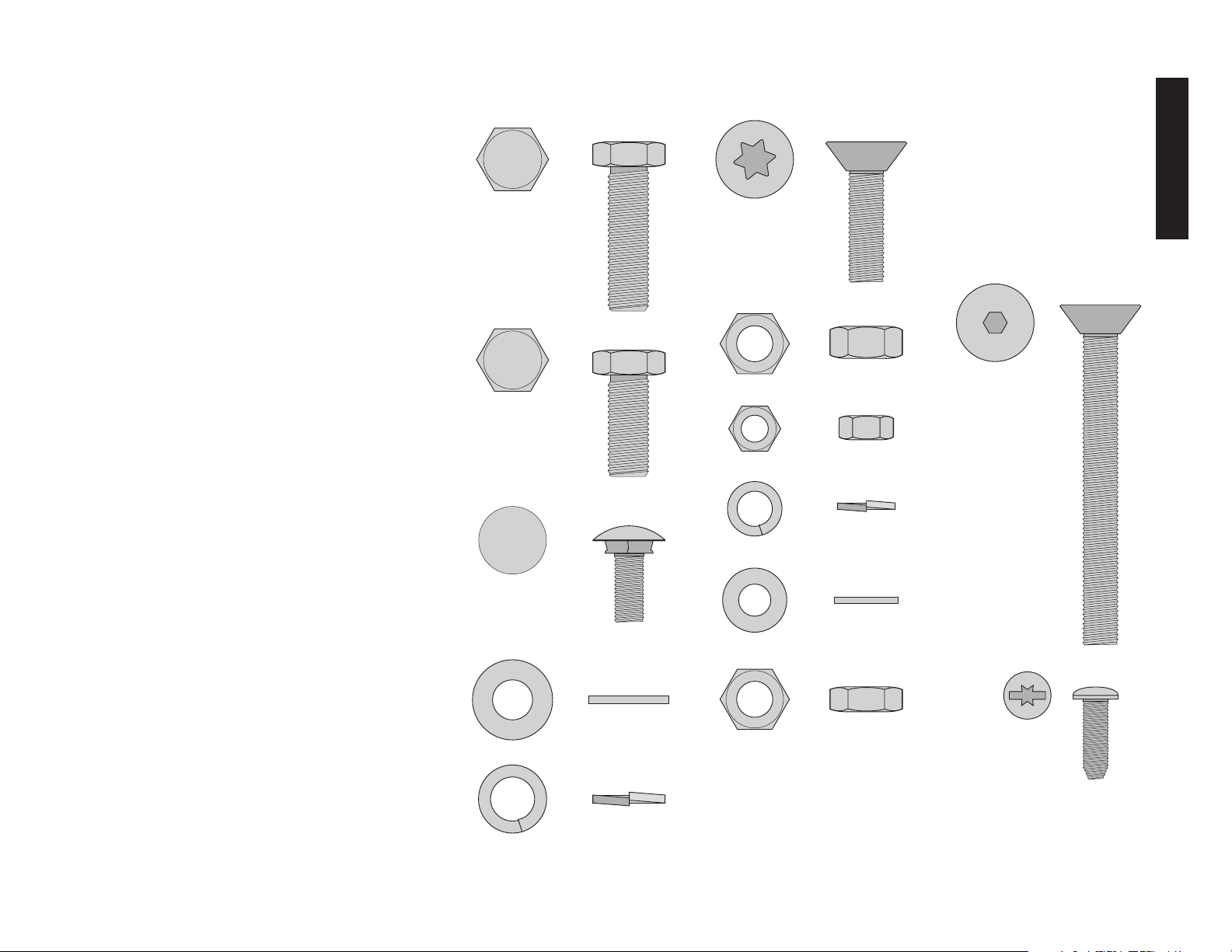

Necessary Hardware

The included hardware bags contains all the necessary

nuts, bolts, and washers to assemble the components

included with the DW7464 52" Rail System and to attach

it to the DW746 Woodworker’s Table Saw. (When

attaching as an add-on accessory use new hardware in

place of removed hardware).

To make assembly of your saw/accessory easier, match

the nuts, bolts, and washers with the hardware chart.

Before each step, check your hardware against the chart

and identify the pieces you need. Additional pieces may be

included in the hardware bags.

M 10 JAM NUT 17 mm HEX

(6 PIECES)

BOLT

10 mm x 25 mm

(5 PIECES)

BOLT

10 mm x 35 mm

(8 PIECES)

T50 TORX

FLAT HEAD SCREW

10mm X 30mm

(6 PIECES)

CARRIAGE BOLT

8 mm x 20 mm

(11 PIECES)

CAP HEAD SCREW

8mm x 20 mm

(15 PIECES)

10MM FLAT WASHER

(22 PIECES)

10 MM LOCK WASHER

(20 PIECES)

8 MM LOCK WASHER

(25 PIECES)

M 8 NUT 13 mm HEX

(25 PIECES)

M 10 NUT 16 mm HEX

(13 PIECES)

6 MM HEX SOCKET

FLAT HEAD SCREW

10mm X 80mm

(2 PIECES)

Hardware Included with the DW7464 52" Rail System

8MM FLAT WASHER

(19 PIECES)

Page 6

2

English

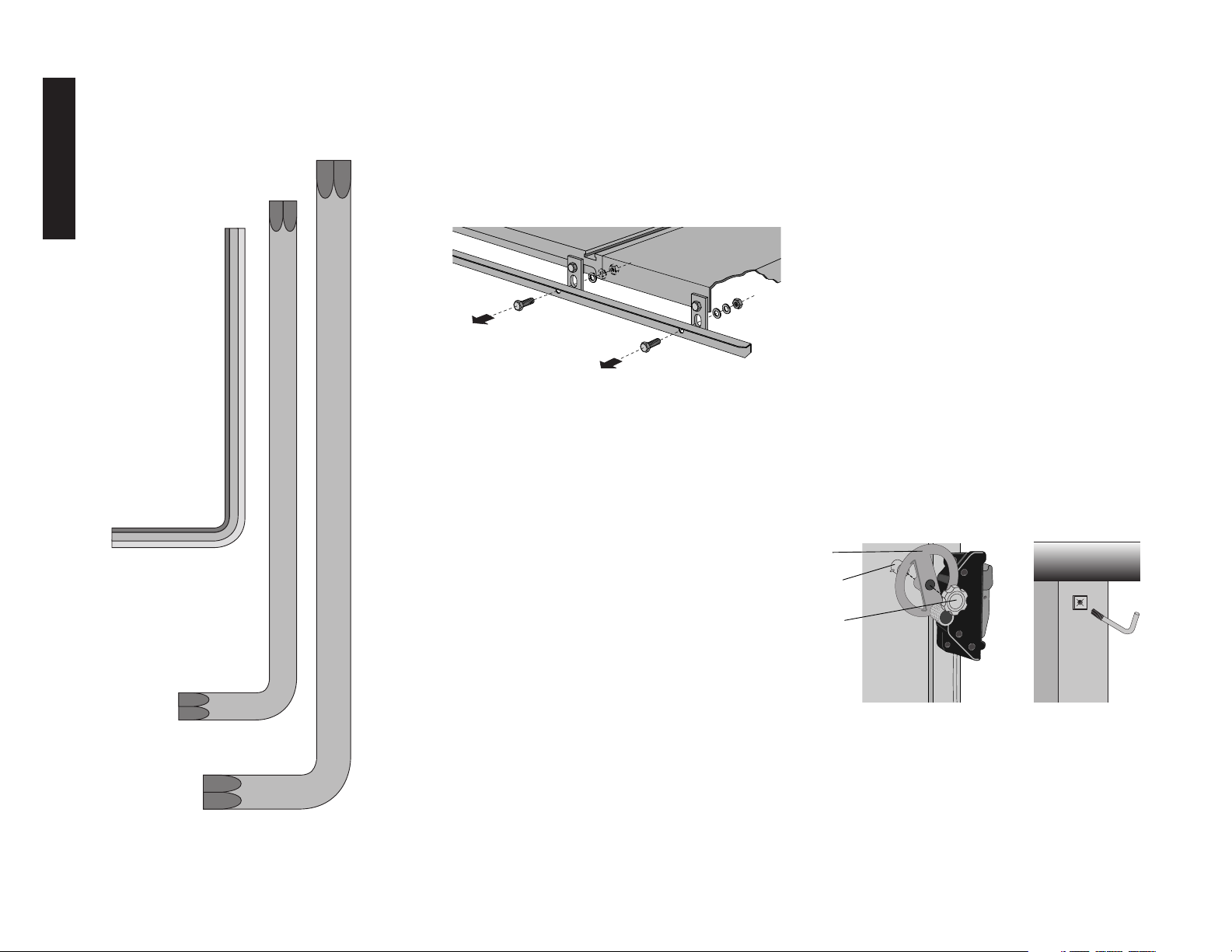

T40 TORX

WRENCH (1)

T50 TORX

WRENCH (1)

6 MM HEX

WRENCH (1)

Table saw Preparation: If you purchased the 52" Rail

System as an add-on accessory, start with this section.

If you purchased your 52" Rail System with your DW746

Woodworker’s Table Saw, skip to the assembly section.

• Remove rear rail and associated hardware. If your

saw has an Outfeed Table, remove the rail and any rear

support brackets, but leave the hanger brackets in

place (Fig. 1).

Assembly

If you have other accessories (Slide Table and/or Outfeed

Table) completely assemble the 52" Rail system first,

except for attaching the rear rail. Outfeed Table should be

assembled last.

PLEASE READ ENTIRE ASSEMBLY SECTION

BEFORE PROCEEDING.

STEP 1. Remove parts box, motor cover, fence beam, and

side tables from saw packaging.

STEP 2.Turn the saw right side up.You will need help. The

combined weight of the table top and motor is approximately 200 lbs.

STEP 3. Cut and remove plastic strap holding the motor.

STEP 4. Using front hand crank, lower the motor some

and remove the foam packing material between the

motor and the mechanism.

STEP 5. Install bevel crank.(Fig. 2) To do this, first install

the crank handle (A) over the shaft (B), rotate slightly to

fully engage the shaft pin. Screw the lock knob (C) into

place until it is fully seated, then back it off 1/4 to 1/2

turn.

STEP 6. Using height crank, raise mechanism up as high

as it will go.

STEP 7. Install wrench hook. (Fig. 3) On the front right

leg, near the top is a plastic threaded insert. Thread

the "L" shaped wrench hook in until only a few threads are

visible.

• Remove front rail by removing the four M10 x 25 flat

head bolts from the top of each front rail bracket.

If your saw has a Sliding Table accessory it will be

necessary to remove M8 x 20 carriage bolts from the

front rail brackets also.

• Remove front rail brackets from the front rail. Loosen

the M8 nuts until only a few threads are holding them in

place. Slide carriage bolt out of keyslot in rail and

remove hardware from brackets. Retain the front rail

brackets for assembly of your 52" Rail System.

• Remove the motor cover by removing the two screws

and washers from the top of the cover at the top of the

two side legs. Pull the top of the cover away from the

saw and disengage bottom tabs from the slots in the

right crossmember. Re-install the screws and washers

for later use.

• Remove right side support table. Loosen the three

M10 bolts holding the support table to the table saw.

You can now lift the support table up and off. Finish

removing the hardware. (If you are also adding a Slide

Table accessory, the left side support table can be

removed at this time.)

• Continue with Assembly, starting at Step 8.

REMOVE

REMOVE

FIG. 1

A

B

C

FIG. 2

FIG. 3

Page 7

English

3

STEP 8. Unpack rail carton and 52" Rail System table

sub-assembly carton.

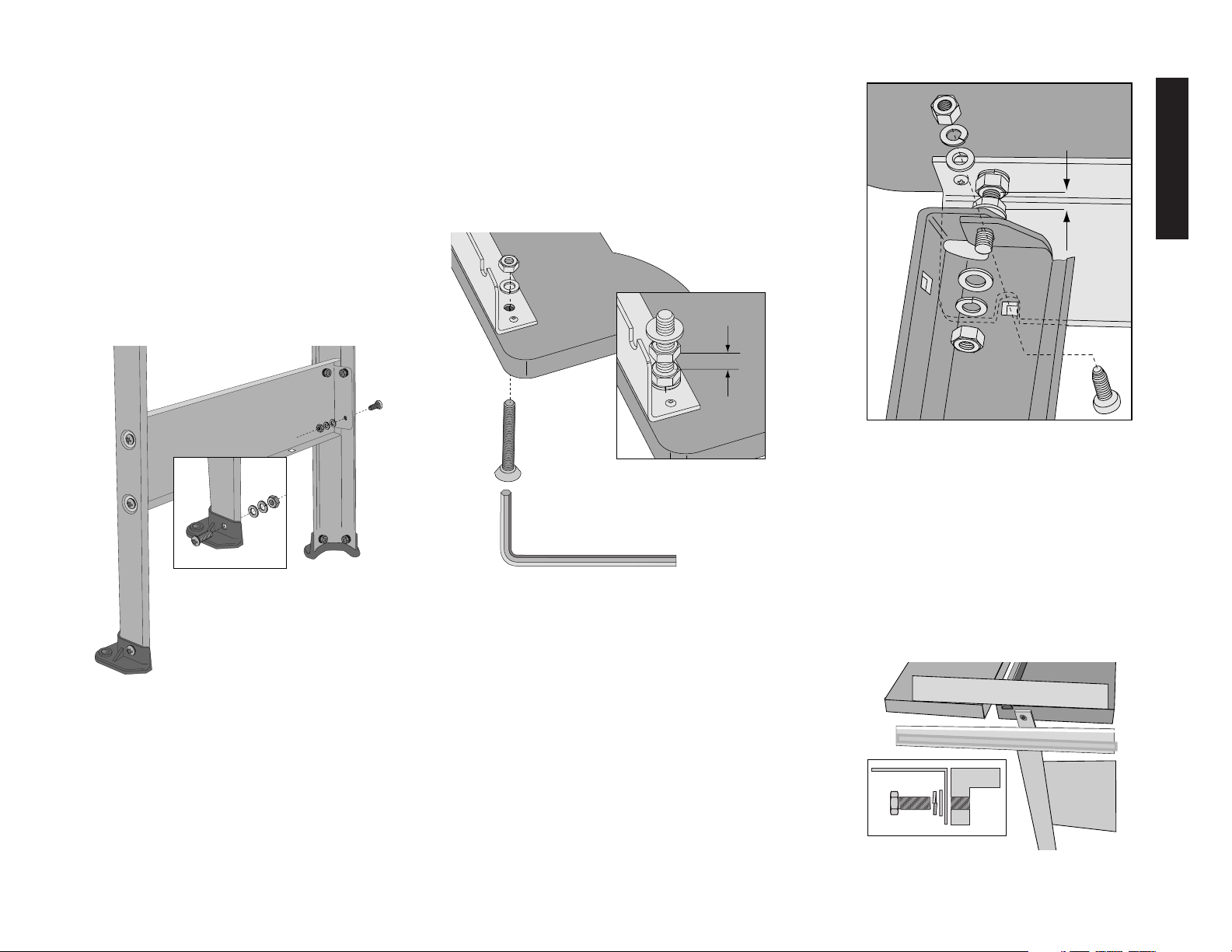

STEP 9. Assemble feet to legs.

You will need: 4 - 8mm cap head screws

4 - 8mm flat washers

4 - 8mm lock washers

4 - 8mm nuts

Place a foot over leg end as shown (Fig. 4) and secure

with hardware, keeping washers and nut to the inside.

If you are installing the 52" Rail System on a saw with

the Mobile Base, adjust the foot all the way down per

Figure 19. If you are not using a Mobile Base, insure

the foot is in the full up position and tighten hardware.

Repeat for remaining leg.

STEP 13. Attach support table to left side (Fig. 7).

(If you have a Slide Table skip this step.)

You will need: 3 - 10 x 25mm hex head bolts

3 - 10mm flat washers

3 - 10mm lock washers

Without the support table in place, install the 3 bolts to

the left side with washers as shown keeping 1/4" gap.

Rest a support table on the bolts, fitting into the notches. Using the extruded fence face as a straightedge,

flush the support table to the saw table edge and snug

the front bolt. Repeat this process for the rear bolt and

the center bolt. Tighten hardware.

STEP 11. Assemble leveling hardware to table (Fig. 5).

You will need: 2 - 10 x 80mm flat head bolts

2 - 10mm lock washers

2 - 10mm jam nuts

Place flat head bolts through table from the top side.

Secure each bolt with a lock washer and nut.

Tighten hardware, be careful not to damage the board

by over-tightening.

STEP

10.

Assemble leg set.

You will need: 8 - 8mm cap head screws

8 - 8mm flat washers

8 - 8mm lock washers

8 - 8mm nuts

Assemble legs to support pan (Fig. 4) using eight M8

cap head screws. Insure that the square holes in the

support pan are oriented closest to the feet end of the

legs. Secure each bolt with a flat washer, lock washer,

and nut, keeping the washers and nuts to the inside.

Tighten hardware.

STEP 12.Attach leg set to table sub-assembly.

You will need: 2 - 8mm cap head screws

2 - 8mm flat washers

2 - 8mm lock washers

2 - 8mm nuts

4 - 10mm flat washers

2 - 10mm lock washers

4 - 10mm jam nuts

Place the table on the floor, flat side down. Add an M10

jam nut and a flat washer to each leveling bolt (Fig. 5)

and run nuts to within 6.4mm (or 1/4") of previously

added jam nut. Place leg set, facing outward, over leveling bolts. Leg set is not yet secure, steady it while

you add a flat washer, lock washer, and a jam nut to

each bolt and tighten, snug only. Add an M8 cap head

screw through the open ended slot in each side rail and

the square hole in the legs. Secure each bolt with a

flat washer, lock washer, and nut, keeping the washers

and nut to the inside of the leg (Fig. 6). Finger tighten.

FIG. 4

FIG. 5

FIG. 6

FIG. 7

6.4 MM

1/4”

6.4 MM

1/4”

Page 8

4

English

STEP 17.Attach 52" front rail with brackets to the table

top (Fig. 12).

You will need: 2 - 10 x 30mm flat head screws

2 - 10mm flat washers

2 - 10mm lock washers

2 - 10mm nuts

Secure each screw through the upper hole in the rail

support brackets, as shown, keeping the flat washer,

lock washer and nut to the inside of the table. Tighten

snug but not very tight. Tighten the rail brackets 8mm

nuts, leaving the outer ones finger tight.

STEP 15. Attach support bracket (Fig. 9).

You will need: 3 - 10mm x 30 flat head screws

Attach to the right side of the table saw using the

included T50 torx wrench. Screw directly into the table,

no washers or nuts needed.

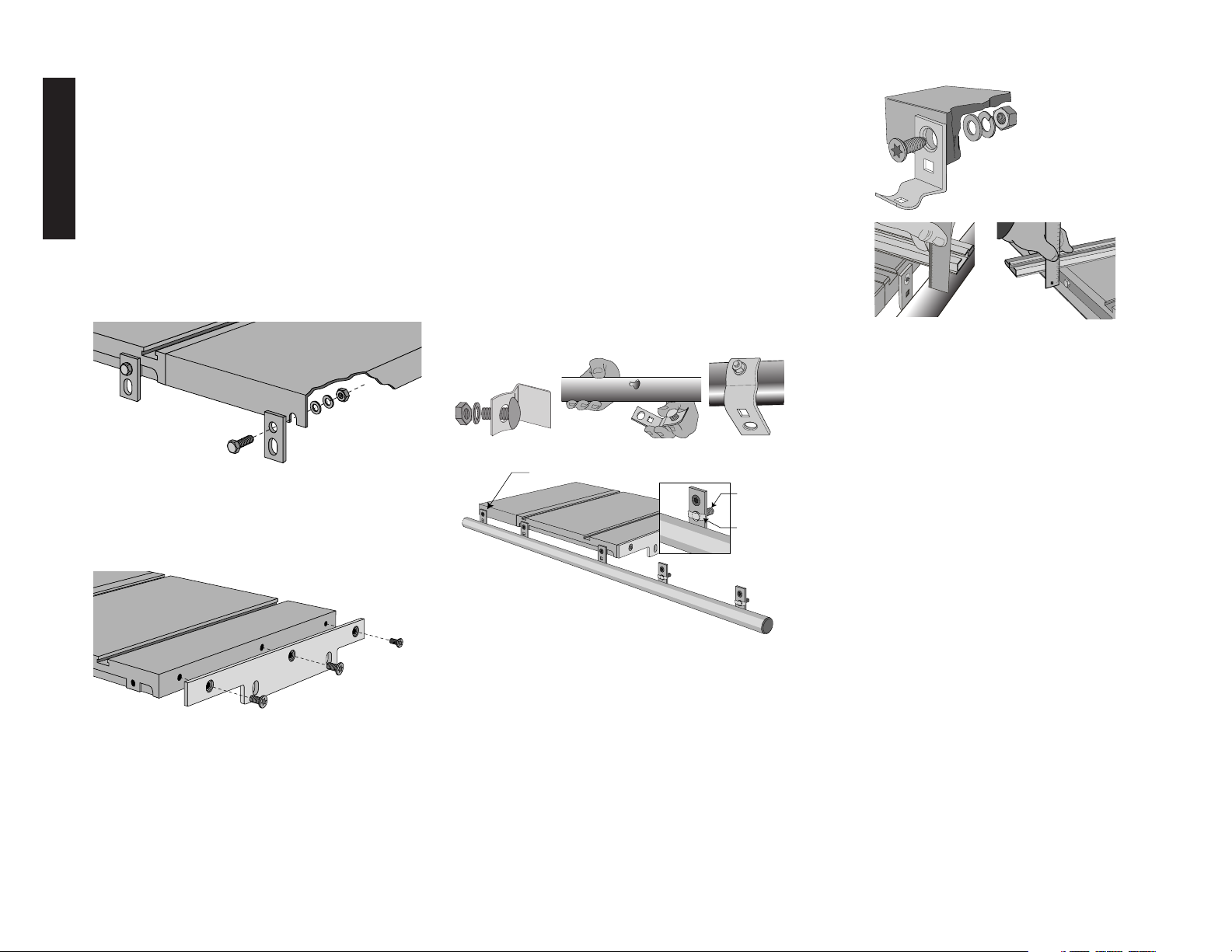

STEP 16. Assemble 52" front rail and brackets (Fig. 10).

You will need: 7 - *8mm carriage bolts

(8 if adding Slide Table)

5 - 8mm lock washers

5 - 8mm nuts

5 - front rail brackets

STEP 18. Parallel the front rail to the saw table

(Fig. 13). Using your fence face or a straightedge to

extend the table surface over the rail, make sure the

distance from the saw table top to the rail top is the

same at both the left and right side of the table. If the

rail is not aligned correctly, loosen the mounting screws

slightly and tap on the rail with a soft hammer or a regular hammer and a block of wood until the distances

are the same. Tighten the hardware securely.

STEP 19. Attach front rail bracket to support table (Fig. 12).

(If you have a Slide Table skip this step)

You will need: 1 - 10 x 30mm flat head screw

1 - 10mm flat washer

1 - 10mm lock washer

1 - 10mm nut

Attach the support table to the outer front rail support

bracket, keeping the washers and nut on the inside of

the table. Using the fence face as a straight edge, make

sure the front outer corner of the support table is level

with the inner edge and main table surface. Tighten

hardware, including the 8mm rail support bracket nut.

STEP 20. Carefully move table into position (Fig. 14).

You will need: 2 - 10 x 25mm hex head bolts

4 - 10mm flat washers

2 - 10mm lock washers

2 - 10mm nuts

2 - 8mm lock washers

2 - 8mm nuts

Allow table to rest against the support bracket and over

the M8 x 20 carriage bolts previously installed through

the front rail brackets.

FIG. 9

FIG. 10

NOT NEEDED WITH SLIDING TABLE

TAPE

M8 x 20

FIG. 11

FIG. 12

FIG. 13

STEP 14.Attach three rear support brackets (Fig. 8) to

the support table and the back of the saw table.

You will need: 3 - 10 x 35mm hex head bolts

3 - 10mm flat washers

3 - 10mm lock washers

3 - 10mm nuts

Secure a bolt through the round hole in each bracket

with a flat washer, lock washer, and a nut, keeping the

washers and nut to the inside. When tightening nuts,

keep the brackets positioned square to the table. (The

Sliding Table accessory will take the place of one rear

support bracket, the rear rail will attach directly to this

accessory. If you are adding an Outfeed Table, use the

Outfeed Table hanger brackets in place of the two rear

support brackets on the saw table).

FIG. 8

(4 previously removed from rail + 1 from hardware bag)

Assemble carriage bolts, washers and nuts to front rail

brackets (just a few threads). Put the head of the

carriage bolts into the keyhole slots in the front rail and

slide to engage the square part of the bolt. Run nut

until it is finger tight, repeat for other four brackets(If

you are also adding a Slide Table accessory, the left

most front rail bracket is not needed). When attaching

brackets to the rail, the rail must be positioned so that

the rip scale is right side-up. Also all 5 brackets should

face the same direction.

*Two of the front rail brackets will attach to the 52" Rail

System table and will need an M8 x 20 carriage bolt

through the square hole (Fig. 11). (If you are also

adding a Slide Table accessory, add M8 carriage bolts

to front rail brackets that attach to the Saw Table.)

It may be helpful to hold the carriage bolts in place with

a piece of tape.

Page 9

English

5

STEP 24. Parallel the rear rail to the saw table top (Fig.

13). Using your fence face or a straightedge to extend

the table surface over the rail, make sure the distance

from the saw table top to the rail top is the same at both

the left and right side of the saw table. If the rail is not

aligned correctly, loosen the mounting screws slightly

and tap on the rail with a soft hammer or a regular

hammer and a block of wood until the distances are the

same. Tighten the hardware securely. Repeat for the

three remaining attachment points checking the

distance along the full length of the rail.

STEP 25. Install motor cover (Fig. 18). Remove the two

screws and washers from the top of the two side legs

with a small flat blade screwdriver (or T25 Torx driver).

Snap the two bottom tabs of the cover into the slots in

the right crossmember. Lower support rails are very

close to the crossmember slots, it may be necessary to

slightly loosen carriage bolts holding the rails to

engage tabs. Place the cover in position and re-install

the screws and washers.

STEP 26. See DW746 manual for Table Saw operating

instruction and adjustments.

Secure the side of the 52" rail table to the front rail

brackets using the two M8 x 20 carriage bolts, 10mm flat

washers, 8mm lock washers and nuts. Finger tighten.

Attach 52" rail table to the support bracket (Fig. 15)

using the M10 x 25 bolts. Secure each bolt with a flat

washer, lock washer, and nut. Tighten snug only.

STEP 21. Attach lower support rails.

You will need: 4 - 8mm carriage bolts

4 - 8mm flat washers

4 - 8mm lock washers

4 - 8mm nuts

Attach lower support rails between the bottom of the

support pan and the right cross member (Fig. 16) with

four M8 x 20 carriage bolts. Secure each bolt with a flat

washer, lock washer, and nut. Tighten securely.

NOTE: If you are installing the 52" Fence System with

a Mobile Base, insure the adjustable rubber feet are

adjusted all the way up into the Mobile Base, and

insure the cast iron feet on the table saw legs are seated against the legs.

STEP 22. Parallel 52" rail table to the saw table top.

Table should be level with the table saw top. For the

edge closest to the saw table use your fence face or a

straightedge to extend the saw table surface over the

rail table. To align the tables tap on the rail table with a

soft hammer or a regular hammer and a block of wood

until they are even. Tighten the M10 hardware through

the support bracket (Fig. 15) securely. Using the

adjusting hardware at the top of the leg set (Fig. 5)

STEP 23. Attach 52" rear rail (Fig. 17).

You will need: 5 - 10 x 35mm hex head screws

5 - 10mm flat washers

5 - 10mm lock washers

5 - 10mm nuts

Attach through the slotted holes in the rear support

brackets and the side of the 52" rail table using the M10

bolts. Secure each bolt with a flat washer, lock

washer, and nut, keeping the washers and nuts to the

inside. Tighten snug the hardware that attaches to the

saw table, leaving the remaining finger tight. (If you are

also adding a Slide Table accessory, assemble it before

attaching the rear rail. If adding an Outfeed Table

accessory, check that you have Outfeed Table hanger

brackets attached to the saw table instead of the rear

support brackets and continue.)

FIG. 14

FIG. 15

FIG. 16

FIG. 16

FIG. 18

FIG. 19

M10 WASHER

adjust the rail table, along its length, gauging against

the front rail (Fig. 13). Once level, front and back,

tighten the adjusting hardware, the M8 cap head

screws in the top of the legs, and the M8 x 20 carriage

bolts through the front rail brackets securely.

NOTE: If you are installing the extension table with a

Mobile Base, the M8 cap head screws in the top of the

legs, shown in Figure 6, may extend below the slot in

the table.These two screws are used for assembly and

are not necessary once the cross members are in

place.

Page 10

6

English

Additional Information

Adjustment:

• If you add a Mobile Base to your saw it will be

necessary to adjust the height of the legs on your 52"

Rail System:

• Place the Mobile Base under your saw as described

in the mobile base instruction manual.

• Move the saw to the location you will most likely use

it and disengage base.

• Loosen the M8 cap head screw through the open

ended slot in each side rail and the square hole in the

legs (Fig. 6). Use the adjusting hardware through the

top of the legs to adjust the leg set all the way down or

until the M8 screws are at the bottom of the open

ended slots..

• Re-tighten the M8 hardware.

• For each leg (Fig. 19): Loosen the two screws that

hold the foot to the leg. Let the foot fall to the floor surface. Re-tighten the screws holding the foot to the leg.

Adjust the rear fence glide

If necessary, adjust the rear glide to locate it correctly

against the rear rail by loosening the two screws which

secure it to the fence beam. The plastic retaining clip

should be deflected somewhat when the glide is positioned correctly. This adjustment should only be necessary

if the rear rail has been relocated by the addition of an

optional accessory.

Cleaning:

• The table board of your 52" Rail System is a

composite material, excessive moisture can cause

deterioration. Cleaning with a damp cloth or a mild

solvent on the top surface is acceptable, but the

edges of the board should not be wetted.

Page 11

Français

7

DeWalt… GARANTI SOLIDE

Les outils industriels de haute performance DeWalt sont fabriqués pour les

applications en construction et industrielles les plus rudes. La conception

de chaque outil dans la gamme – des perceuses aux ponceuses et aux

scies à table – est le résultat d’un emploi dans des conditions rigoureuses

sur le tas dans tous les secteurs d’activité. Chaque outil est fabriqué avec

une précision méticuleuse au moyen de systèmes de fabrication sophistiqués et d’un contrôle intensif de la qualité. Chaque outil est contrôlé avant

qu’il ne quitte l’usine afin de vérifier qu’il satisfait à nos normes de durabilité, fiabilité et puissance.

DeWALT Fabriqué pour les travaux durs...NOUS LE GARANTISSONS.

AVERTISSEMENT : POUR VOTRE PROPRE SÉCURITÉ, LISEZ LE GUIDE D’UTILISATION AVANT D’UTILISER LA SCIE • PORTEZ TOUJOURS DES LUNETTES DE PROTECTION DES YEUX • NE

PORTEZ PAS DE GANTS, DE CRAVATE, DE BIJOUX OU DE VÊTEMENTS AMPLES • ATTACHEZ VOS CHEVEUX S’ILS SONT LONGS • GARDEZ VOS MAINS ET VOS DOIGTS HORS DU TRAJET DE

LA LAME — FAITES EXTRÊMEMENT ATTENTION SI VOUS BISEAUTEZ • UTILISEZ TOUJOURS LE PROTECTEUR DE LA LAME ET L’ÉCARTEUR POUR TOUTE OPÉRATION POUR LAQUELLE IL PEUT

ÊTRE UTILISÉ Y COMPRIS SCIER • UTILISEZ UN « POUSSOIR » AU BESOIN • SACHEZ ÉVITER LES REBONDS — VOIR LE GUIDE • SOUTENEZ TOUJOURS VOTRE TRAVAIL AVEC LA TABLE ET

LE GUIDE OU LE CALIBRE À ONGLETS • N’UTILISEZ JAMAIS LE GUIDE ET LE CALIBRE À ONGLETS ENSEMBLE • NE PASSEZ JAMAIS LA MAIN AUTOUR OU AU DESSUS DE LA LAME • MONTEZ

BIEN LA LAME AVANT DE L’UTILISER • NE RETIREZ JAMAIS DES MORCEAUX COINCÉS OU COUPÉS TANT QUE L’ALIMENTATION N’EST PAS ÉTEINTE ET QUE LA LAME N’EST PAS ARRÊTÉE •

N’EXPOSEZ PAS CET OUTIL À LA PLUIE ET NE L’UTILISEZ PAS DANS DES LIEUX HUMIDES • NE LE FAITES PAS FONCTIONNER EN CAS D’ÉTAT D’ÉBRIÉTÉ OU D’ÉTAT D R O GU É • MANQUER DE

RESPECTER CES CONSIGNES PEUT RÉSULTER DANS DES BLESSURES GRAVES.

AVERTISSEMENT : L’UTILISATION DE CET OUTIL PEUT GÉNÉRER DES POUSSIÈRES

CONTENANT DES PRODUITS CHIMIQUES CONNUS POUR ÊTRE À L’ORIGINE DE CANCERS,

DE MALFORMATIONS CONGÉNITALES OU AUTRES ENDOMMAGEMENTS DU SYSTÈME

REPRODUCTIF. UTILISEZ UN APPAREIL RESPIRATOIRE APPROPRIÉ.

Page 12

Français

8

Articles inclus

Boîte no.1

• (1) table à système de rails 52 po (132,08 cm)

• (1) plaque de support

• (1) fixation de support

• (2) rail de support inférieur

• (3) support arriére

Boîte no.2 (carton des rails)

• (1) rail frontal

• (1) rail dorsal

• (2) jambes

• (2) pieds

• (1) sac de quincaillerie

Outils inclus

• clé hexagonale de 6 mm

• clé Torx T40

• clé Torx T50

Outils requis

• clés 17 mm à extrémités ouvertes

• (2) clés 16 mm ou 5/8 po à extrémités ouvertes

• clé 13 mm ou 1/2 po à extrémités ouvertes

• mètre

• marteau mou ou régulier et un bloc de bois

• petit tournevis à lame plate

Pour accélérer le montage, les outils suivants seraient les bien-

venus :

• clé à douilles 16 mm ou 5/8 po

• clé à douilles 13 mm ou 1/2 po

• tournevis Torx T25

Quincaillerie requise

Le sac de quincaillerie inclus contient tous les articles,

écrous, boulons et rondelles nécessaires au montage des

composants du système de rails DW7464 52 po (132,08

cm) et à sa fixation sur la scie à table pour travail du bois

DW746. (Lors du montage en tant qu’accessoire supplé-

mentaire, utilisez les articles de quincaillerie neufs à la

place des articles démontés).

Pour faciliter le montage de votre scie/accessoire,

appariez les écrous, boulons et rondelles avec le tableau

des articles de quincaillerie. Avant chaque étape, consultez le tableau et identifiez les articles dont vous avez

besoin. Des pièces supplémentaires pourront être incluses dans les sacs de matériel.

CONTRE-ÉCROU

HEXAGONAL M 10 17 mm

(6 PIÈCES)

BOULON

10 mm x 25 mm

(5 PIÈCES)

BOULON

10 mm x 35 mm

(8 PIÈCES)

VIS TÊTE PLATE

TORX T50

10 mm x 30 mm

(6 PIÈCES)

BOULON DE

CARROSSERIE

8 mm x 20 mm

(11 PIÈCES)

VIS PORTE PASTILLE

8 mm x 20 mm

(15 PIÈCES)

RONDELLE PLATE

10 MM

(22 PIÈCES)

RONDELLE D’ARRÊT

10 MM

(20 PIÈCES)

RONDELLE D’ARRÊT

8 MM

(19 PIÈCES)

RONDELLE D’ARRÊT

8 MM

(25 PIÈCES)

ÉCROU HEXAGONAL

M 8 13 mm

(25 PIÈCES)

ÉCROU HEXAGONAL

M 10 16 mm

(13 PIÈCES)

VIS TÊTE PLATE

10 mm x 80 mm

(2 PIÈCES)

Articles de quincaillerie compris avec le système de rails

DW7464 52 po (132,08cm)

Page 13

Français

9

CLÉ TORX

T40 (1)

CLÉ TORX

T50 (1)

CLÉ HEXAGONALE

6 MM (1)

Préparation de la scie à table : Si vous avez acheté le système

de rails 52 po (132,08 cm) comme un accessoire rajouté, commencez par cette section. Si vous avez acheté le système de rails

52 po (132,08 cm) avec la scie à table pour travail du bois

DW746, passez à la section montage.

• Retirez le rail dorsal et la quincaillerie associée. Si votre scie

dispose d’une table de sortie, retirez le rail et toute fixation de

support dorsal, mais laissez les fixations pour suspendre en

place (Fig. 1).

Montage

Si vous avez d’autres accessoires (table coulissante et/ou table

de sortie) montez d’abord complètement le système de rails 52

po (132,08 cm), en attachant toutefois aussi le rail dorsal. La

table de sortie doit être montée en dernier.

VEUILLEZ LIRE COMPLÈTEMENT LA SECTION

MONTAGE AVANT DE PROCÉDER.

ÉTAPE 1. Retirez la boîte des composants, le panneau couvrant

le moteur, le montant du guide et les tables latérales hors de

l’emballage de la scie.

ÉTAPE 2. Retournez la scie pour mettre le côté droit en haut.

Vous aurez besoin d’aide. Le poids combiné du dessus de

table et du moteur est d’environ 200 lb.

ÉTAPE 3. Coupez et retirez les lanières en plastique qui retien-

nent le moteur.

ÉTAPE 4. Au moyen de la manivelle frontale, abaissez un peu le

moteur et retirez la mousse d’emballage entre le moteur et le

mécanisme.

ÉTAPE 5. Installer la manivelle à biseau. (Fig. 2). Pour cela,

installez d’abord la poignée de la manivelle (A) sur le manche

(B) puis tournez légèrement pour enclencher complètement

l’ergot du manche. Vissez le bouton de verrouillage (C) en

place jusqu’à ce qu’il soit complètement enfoncé, puis dévissez-le de 1/4 à 1/2 tour.

ÉTAPE 6. Au moyen de la manivelle de réglage de la hauteur

soulevez le mécanisme jusqu’au niveau le plus haut possible.

ÉTAPE 7. Installer le crochet-clé. (Fig. 3). Sur la jambe frontale

droite, presque tout en haut se trouve un insert en plastique

fileté. Vissez le crochet-clé en forme de « L » jusqu’à ce que

seulement quelques pas de vis soient visibles.

• Retirez le rail frontal en ôtant les quatre boulons à tête plate

M10 x 25 du haut de chaque fixation du rail frontal.

Si votre scie dispose d’une table coulissante, il sera néces-

saire de retirer aussi les boulons de carrosserie M8 x 20 des

fixations du rail frontal.

• Retirez les fixations du rail frontal. Desserrez les écrous de

carrosserie M8 jusqu’à ce qu’ils soient retenus par seulement

quelques pas de vis. Faites glisser les écrous de carrosserie

hors des fentes du rail et retirez-les des fixations. Conservez

les fixations du rail frontal pour le montage du système de rails

52 po (132,08 cm).

• Retirez le panneau couvrant le moteur en ôtant les deux vis

et les deux rondelles du dessus du panneau en haut des deux

jambes latérales. Tirez le panneau loin de la scie et libérez les

deux onglets du bas des fentes dans la traverse droite.

Réinstallez les vis et les rondelles pour utilisation ultérieure.

• Retirez la table de support du côté droit. Desserrez les

trois écrous M10 attachant la table de support à la scie à

table. Il vous est possible de soulever maintenant la table de

support et de la retirer. Finissez de retirer tous les articles de

quincaillerie. (Si vous ajoutez aussi comme accessoire la

table coulissante, vous pouvez retirer la table de support du

côté gauche maintenant.)

• Continuez avec le montage en commençant à l’étape 8.

REMOVE

REMOVE

FIG. 1

A

B

C

FIG. 2

FIG. 3

Page 14

Français

10

ÉTAPE 8. Déballez le carton des rails et celui de la table du sys-

tème de rails 52 po (132,08 cm).

ÉTAPE 9. Monter les pieds sur les jambes.

Vous aurez besoin de :

4 – vis porte pastille 8 mm

4 – rondelles plates 8 mm

4 – rondelles d’arrêt 8 mm

4 – écrous 8 mm

Enfilez un pied par dessus la jambe comme montré (Fig. 4) et

fixez avec les articles de quincaillerie, en positionnant les rondelles et l’écrou à l’intérieur. Assurez-vous que le pied est en

position complètement levée et serrez les articles de quincaillerie. Répétez pour la jambe restante.

ÉTAPE 13. Attacher la table de support au côté gauche (Fig. 7).

(Si vous disposez d’une table coulissante, sautez cette étape.)

Vous aurez besoin de :

3 – boulons à tête hexagonale 10 x 25 mm

3 – rondelles plates 10 mm

3 – rondelles d’arrêt 10 mm

La table de support n’étant pas en place, installez les 3 écrous

sur le côté gauche avec des rondelles comme montré en

maintenant un espace de 1/4 po (6,36 mm). Faites reposer la

table de support sur les écrous, en l’encastrant dans les

encoches. En utilisant le guide comme une règle de vérification, faites araser la table de support avec le bord de la table

de la scie et ajustez le boulon frontal. Répétez ce procédé

pour le boulon dorsal et le boulon central. Serrez tous les articles de quincaillerie.

ÉTAPE 11. Monter le niveau sur la table (Fig. 5).

Vous aurez besoin de :

2 – boulons à tête plate 10 x 80 mm

2 – rondelles d’arrêt 10 mm

2 – contre-écrous 10 mm

Introduisez les boulons à tête plate à travers la table à partir

du côté supérieur. Fixez chaque boulon avec une rondelle

d’arrêt et un écrou..

Serrez en faisant attention de ne pas endommager le plateau

en serrant de trop.

ÉTAPE 10. Monter le jeu de jambes.

Vous aurez besoin de :

8 – vis porte pastille 8 mm

8 – rondelles plates 8 mm

8 – rondelles d’arrêt 8 mm

8 – écrous 8 mm

Montez les jambes sur la plaque de support (Fig. 4) en utilisant les 8 vis porte pastille M8. Assurez-vous que les trous

carrés dans la plaque de support sont orientés de façon à être

les plus près du pied des jambes. Fixez chaque boulon avec

une rondelle plate, une rondelle d’arrêt et un écrou en positionnant les rondelles et les écrous à l’intérieur. Serrez tous

les articles de quincaillerie.

ÉTAPE 12. Attacher le jeu de jambes à la table.

Vous aurez besoin de :

2 – vis porte pastille 8 mm

2 – rondelles à tête plate 8 mm

2 – rondelles d’arrêt 8 mm

2 – écrous 8 mm

4 – rondelles à tête plate 10 mm

2 – rondelles d’arrêt 10 mm

4 – contre-écrous 10 mm

Posez la table par terre, le côté plat contre le sol. Ajoutez un

écrou M10 et une rondelle plate à chaque boulon du niveau

(Fig. 5) en espaçant l’contre-écrous à moins de 6,4 mm (ou

1/4 po) de l’écrou ajouté précédemment. Mettez en place le

jeu de jambes, orienté vers le haut, par dessus les contreécrous du niveau. Le jeu de jambes n’est pas encore bien

fixé, consolidez-le en ajoutant une rondelle à tête plate, une

rondelle d’arrêt et un écrou à chaque boulon et serrez pour

ajuster seulement. Ajoutez une vis porte pastille M8 à travers

la fente ouverte dans chaque rail latéral et chaque trou carré

de la jambe. Fixez chaque boulon avec une rondelle plate,

une rondelle d’arrêt et un contre-écrous en positionnant les

rondelles et l’écrou à l’intérieur de la jambe (Fig. 6). Serrez

avec les doigts.

FIG. 4

FIG. 5

FIG. 6

FIG. 7

6.4 MM

(1/4 PO)

6.4 MM

(1/4 PO)

Page 15

Français

11

ÉTAPE 17. Attacher le rail frontal 52 po (132,08 cm) avec des

fixations au dessus de la table (Fig. 12).

Vous aurez besoin de :

2 – vis à tête plate 10 x 30 mm

2 – rondelles plates 10 mm

2 – rondelles d’arrêt 10 mm

2 – écrous 10 mm

Fixez chaque vis à travers le trou supérieur dans les fixations

de support du rail comme montré en positionnant la rondelle

plate, la rondelle d’arrêt et l’écrou sut le côté interne de la

table. Serrez pour ajuster mais pas trop. Serrez les écrous de

8 mm des fixations du rail, en conservant le seul serrage

manuel pour les plus extérieurs.

ÉTAPE 15. Attacher la fixation de support (Fig. 9).

Vous aurez besoin de :

3 – vis à tête plate 10 mm x 30

Fixez-les au côté droit de la scie à table au moyen de la clé

Torx T50 fournie. Vissez directement dans la table, pas besoin

de rondelles ou d’écrous.

ÉTAPE 16. Monter le rail frontal 52 po (132,08 cm) et les fixa-

tions (Fig. 10).

Vous aurez besoin de :

7 – boulons de carrosserie *8 mm

(8 si vous ajoutez la table coulissante)

5 – rondelles d’arrêt 8 mm

5 – écrous 8 mm

5 – fixations du rail frontal

ÉTAPE 18. Disposer le rail frontal parallèlement à la table de

la scie (Fig. 13). En utilisant le devant du guide ou une règle

de vérification pour prolonger la surface de la table par dessus

le rail, assurez-vous que la distance du dessus de la table de

la scie au haut du rail est la même du côté droit et du côté

gauche de la table. Si le rail n’est pas aligné correctement,

dévissez les vis de montage légèrement et tapotez sur le rail

avec un marteau doux ou un marteau régulier et un bloc de

bois jusqu’à ce que les distances soient identiques. Serrez à

fond les articles de quincaillerie.

ÉTAPE 19. Attacher la fixation du rail frontal à la table de sup-

port (Fig. 12). (Si vous disposez d’une table coulissante,

sautez cette étape)

Vous aurez besoin de :

1 – vis à tête plate 10 x 30 mm

1 – rondelle plate 10 mm

1 – rondelle d’arrêt 10 mm

1 – écrou 10 mm

Attachez la table de support à la fixation extérieure de support du rail frontal en positionnant les rondelles et l’écrou sur

le côté interne de la table. En utilisant le devant du guide

comme une règle de vérification, assurez-vous que le coin

extérieur frontal de la table de support est de niveau avec le

coin interne et la surface principale de la table. Serrez tous les

articles de quincaillerie, y compris l’écrou de la fixation de

support du rail 8 mm.

ÉTAPE 20. Positionner la table avec précaution (Fig. 14).

Vous aurez besoin de :

2 – boulons à tête hexagonale 10 x 25 mm

4 – rondelles plates 10 mm

2 – rondelles d’arrêt 10 mm

2 – écrous 10 mm

2 - rondelles d’arrêt 8 mm

2 – écrous 8 mm

Laissez la table reposer contre les fixations de support et par

dessus les boulons de carrosserie M8 x 20 précédemment

installés à travers les fixations du rail frontal.

FIG. 9

FIG. 10

NOT NEEDED WITH SLIDING TABLE

TAPE

M8 x 20

FIG. 11

FIG. 12

FIG. 13

ÉTAPE 14. Attacher les trois fixations de support dorsal (Fig. 8)

à la table de support et au dos de la table de la scie.

Vous aurez besoin de :

3 – boulons à tête hexagonale 10 x 35 mm

3 – rondelles plates 10 mm

3 – rondelles d’arrêt 10 mm

3 – écrous 10 mm

Fixez un boulon à travers le trou rond dans chaque fixation

avec pour chacun une rondelle plate, une rondelle d’arrêt et

un écrou en positionnant les rondelles et l’écrou à l’intérieur.

Pendant le serrage des écrous, maintenez les fixations à l’é-

querre avec la table. (La table coulissante prendra la place

d’une des fixations de support dorsal, le rail dorsal lui étant

directement attaché. Si vous ajoutez une table de sortie, utilisez

les fixations pour suspendre de la table de sortie à la place des

deux fixations de support dorsal sur la table de la scie).

FIG. 8

(4 précédemment retirées du rail + 1 sortie du sac de quincaillerie)

Montez les boulons de carrosserie, les rondelles et les écrous

sur les fixations du rail frontal (juste quelques pas de vis).

Mettez la tête des boulons de carrosserie dans les fentes

dans le rail frontal et faites glisser pour enclencher la partie

carrée du boulon . Vissez manuellement l’écrou et répétez la

procédure pour les quatre autres fixations (si vous ajoutez

aussi une table coulissante, la fixation à l’extrême gauche du

rail frontal est inutile). Pendant la fixation des fixations sur le

rail, le rail doit être positionné de manière que l’échelle longitudinale ait le côté droit vers le haut. Les 5 fixations doivent

aussi regarder dans la même direction.

*Deux des fixations du rail frontal seront attachées à la table

du système de rails 52 po (132,08 cm) et requerront un boulon

de carrosserie M8 x 20 à travers le trou carré (Fig. 11). (Si

vous ajoutez aussi une table coulissante, ajoutez des boulons

de carrosserie M8 aux fixations du rail frontal attachant à la

table de la scie.) Il peut s’avérer utile de maintenir en place les

boulons de carrosserie avec du ruban adhésif.

Page 16

Français

12

ÉTAPE 24 Placer le rail dorsal 52 po (132,08 cm) parallèle-

ment au dessus de la table de la scie (Fig. 13). En vous

servant du devant du guide ou d’une règle de vérification pour

prolonger la surface de la table par dessus le rail, assurezvous que la distance du dessus de la table de la scie au haut

du rail est la même sur le côté droit et sur le côté gauche de

la table de la scie. Si le rail n’est pas correctement aligné,

desserrez légèrement les vis de montage et tapotez sur le rail

avec un marteau mou ou un marteau régulier et un bloc en

bois jusqu’à ce que les distances soient identiques. Serrez à

fond les articles de quincaillerie. Répétez la procédure pour

les trois points d’attache restants en vérifiant la distance sur

toute la longueur du rail.

ÉTAPE 25. Installer le panneau couvrant le moteur (Fig. 18).

Retirez les deux vis et rondelles du haut des deux jambes

latérales avec un petit tournevis à lame plate (ou un tournevis

Torx T25). Enclencher les deux onglets inférieurs du panneau

dans les fentes de la traverse droite. Les rails de support

inférieur sont très proches des fentes de la traverse et il peut

s’avérer nécessaire de desserrer légèrement les boulons de

carrosserie retenant les rails pour pouvoir enclencher les

onglets. Mettez en place le panneau couvrant et réinstallez

les vis et les rondelles.

ÉTAPE 26. Voir le guide DW746 pour le mode d’emploi et le

réglage de la scie à table.

Fixez le côté de la table du rail 52 po (132,08 cm) aux fixations

du rail frontal en utilisant les deux boulons de carrosserie M8 x

20, les rondelles plates de 10 mm, les rondelles d’arrêt de 8 mm

et les écrous. Serrez avec les doigts. Attachez la table du rail

52 po (132,08 cm) à la fixation de support (Fig. 15) au moyen

des boulons M10 x 25. Fixez chaque boulon avec une rondelle

plate, une rondelle d’arrêt et un écrou. Serrez pour ajuster.

ÉTAPE 21. Attacher les rails de support inférieur.

Vous aurez besoin de :

4 – boulons de carrosserie 8 mm

4 – rondelles plates 8 mm

4 – rondelles d’arrêt 8 mm

4 – écrous 8 mm

Attachez les rails de support inférieur entre le socle de la

plaque de support et la traverse droite (Fig. 16) avec quatre

boulons de carrosserie M8 x 20. Fixez chaque boulon avec une

rondelle plate, une rondelle d’arrêt et un écrou. Serrez à fond.

ÉTAPE 22. Placer la table du rail 52 po (132,08 cm) parallèle-

ment au dessus de la table de la scie. La table devrait être

de niveau avec le dessus de la scie à table. Pour le bord le

plus proche de la table de la scie, servez-vous du devant du

guide ou d’une règle de vérification pour prolonger la surface de

la table de la scie par dessus la table du rail. Pour aligner les

tables, tapotez sur la table du rail avec un marteau mou ou un

marteau régulier et un bloc de bois jusqu’à ce qu’elles soient

au même niveau. Serrez à fond les articles M10 à travers la

fixation de support (Fig. 15). En utilisant l’article d’ajustement

en haut du jeu de jambes (Fig. 5) ajustez la table du rail, sur

toute sa longueur en calibrant par rapport au rail frontal (Fig.

13). Une fois le devant et le derrière de niveau, serrez à fond

les articles d’ajustement, les vis porte pastille M8 en haut des

jambes et les boulons de carrosserie M8 x 20 à travers les fixations du rail frontal.

ÉTAPE 23. Attacher le rail dorsal 52 po (132,08 cm) (Fig. 17).

Vous aurez besoin de :

5 – vis à tête hexagonales 10 x 35 mm

5 – rondelles plates 10 mm

5 – rondelles d’arrêt 10 mm

5 – écrous 10 mm

Attachez au moyen des boulons M10 à travers les fentes dans

les fixations de support dorsal et le côté de la table du rail 52

po (132,08 cm). Fixez chaque boulon avec une rondelle plate,

une rondelle d’arrêt et un écrou, en positionnant les rondelles

et les écrous à l’intérieur. Serrez pour ajuster les articles de

quincaillerie attachant à la table de la scie en conservant le

serrage manuel pour les autres. (Si vous ajoutez aussi une

table coulissante, montez-la avant de l’attacher au rail dorsal.

Lors de l’addition d’une table de sortie, vérifiez que vous avez

attaché les fixations pour suspendre de la table de sortie à la

table de la scie et non aux fixations de support dorsal et continuez.)

FIG. 14

FIG. 15

FIG. 16

FIG. 16

FIG. 18

FIG. 19

RONDELLE PLATE M10

Page 17

Français

13

Information supplémentaire

Réglage :

• Si vous ajoutez un socle mobile à votre scie, il vous sera

nécessaire de régler la longueur des jambes sur le système

de rails 52 po (132,08 cm) :

• Placez un socle mobile sous votre scie conformément aux

instructions du guide du socle mobile.

• Déplacez la scie jusqu’au lieu où elle sera le plus probable-

ment utilisée et libérez le socle.

• Desserrez la vis porte pastille M8 traversant chaque fente à

extrémités ouvertes de chaque rail latéral et le trou carré

dans les jambes (Fig. 6). Utilisez les articles d’ajustement à

travers le haut des jambes pour descendre le jeu de jambes

jusque en bas ou jusqu’à ce que les vis M8 soient en bas des

fentes à extrémités ouvertes.

• Resserrez les articles M8.

• Pour chaque jambe (Fig. 19): Desserrez les deux vis qui

attachent le pied sur la jambe. Laissez le pied tomber par

terre. Resserrez les deux vis maintenant le pied sur la jambe.

Régler la bande de glissement

arrière du guide

Au besoin, régler la bande de glissement arrière pour

l’appuyer correctement sur le rail arrière en desserrant

les deux vis qui le fixent à la poutrelle du guide. L’étrier

en plastique est légèrement dérivé quand la bande de

glissement est bien placée. Ce réglage est nécessaire

uniquement si le rail arrière est replacé après l’ajout

d’un accessoire optionnel.

Nettoyage :

• Le panneau de la table du système de rails 52 po (132,08 cm)

est constitué d’un matériau composé et une humidité exces-

sive peut le détériorer. Le nettoyage avec une éponge humide

ou un solvant doux de la surface du panneau est acceptable

mais les bords du panneau ne doivent pas être mouillés.

Page 18

Español

14

DeWalt… GARANTIZADO RESISTENTE

Las herramientas de alto rendimiento industrial de DeWalt están fabricadas para soportar las más rudas aplicaciones en la industria y la construcción en los Estados Unidos. El diseño de cada herramienta de la línea

–desde los taladros, las lijadoras y hasta las sierras de mesa– son el resultado de riguroso uso en los sitios de trabajo y a través de la industria. Cada

herramienta es producida con ardua precisión, usando los más avanzados

sistemas de manufactura y un intenso control de calidad. Cada herramienta es revisada antes de salir de la fábrica para asegurarle que cumple

con sus estándares de durabilidad, confiabilidad y potencia.

DeWALT Fabricado fuerte como el lugar de trabajo…LO

GARANTIZAMOS.

ADVERTENCIA: PARA SU PROTECCIÓN PERSONAL, LEA EL MANUAL DE INSTRUCCIONES ANTES DE OPERAR LA SIERRA • USE SIEMPRE PROTECCIÓN PARA LOS OJOS • NO USE GUANTES,

CORBATAS, JOYERÍA O ROPA SUELTA • AMARRE EL CABELLO LARGO • MANTENGA LAS MANOS Y DEDOS FUERA DEL CAMINO DE LA SIERRA — ESPECIALMENTE AL BISELAR • USE SIEMPRE EL PROTECTOR DE LA HOJA Y EL SEPARADOR PARA CADA OPERACIÓN DONDE PUEDA SER USADA, INCLUYENDO EL CORTE FRANCO • USE UNA «VARILLA DE EMPUJE» CUANDO SE

REQUIERA • APRENDA COMO EVITAR LOS CONTRAGOLPES — VEA EL MANUAL • APOYE SIEMPRE EL TRABAJO CON LA MESA Y GUARDA O EL MEDIDOR DE LA ESCUADRA DE INGLETES •

NUNCA USE EL MEDIDOR DE LA ESCUADRA DE INGLETES Y LA GUARDA AL MISMO TIEMPO • NUNCA ALCANCE ALREDEDOR O SOBRE LA SIERRA • ASEGURE LA SIERRA MONTADA ANTES DE

OPERAR • NUNCA QUITE PIEZAS ATORADAS O ATASCADAS HASTA DESCONECTAR LA SIERRA Y QUE ÉSTA SE HAYA DETENIDO • NO EXPONGA A LA LLUVIA O LUGARES HÚMEDOS • NO

OPERE ESTA MÁQUINA BAJO LA INFLUENCIA DEL ALCOHOL O DROGAS • EL INCUMPLIMIENTO CON ESTAS ADVERTENCIAS PUEDE RESULTAR EN GRAVES LESIONES PERSONALES.

ADVERTENCIA: EL USO DE ESTA HERRAMIENTA PUEDE GENERAR POLVO QUE CONTENGA

COMPUESTOS QUÍMICOS QUE PUEDEN CAUSAR CÁNCER, DEFECTOS DE NACIMIENTO U

OTROS DAÑOS AL SISTEMA REPRODUCTIVO. USE LA PROTECCIÓN RESPIRATORIA APROPIADA.

Page 19

Español

15

Artículos incluidos

Caja #1

• (1) Subconjunto del sistema de mesa con rieles de 52” (1.32 m)

• (1) Charola de soporte

• (1) Puntal de soporte

• (2) Riel inferior de soporte

• (3) Sopporte trasero

Caja #2 (Caja de rieles)

• (1) Subconjunto de riel delantero

• (1) Riel posterior

• (2) Patas

• (2) Bases

• (1) Bolsa con herrajes

Herramientas incluidas

• Llave hexagonal de 6mm

• Llave Torx T40

• Llave Torx T50

Herramientas requeridas

• Llave de extremo abierto de 17mm

• (2) Llave de extremo abierto de 16mm

• Llave de extremo abierto de 13mm

• Regla

• Martillo suave o regular y bloque de madera

• Destornillador pequeño de hoja plana

Para hacer más rápido el ensamblado, lo siguiente sería de

ayuda:

• Dado de 16mm

• Dado de 13mm

• Maneral Torx T25

Herrajes necesarios

Las bolsas de herrajes incluidos contienen todas las tuercas, pernos y arandelas necesarias para ensamblar los

componentes incluidos con el sistema de rieles DW7464

52” (1.32m) y para sujetarlo al Banco de Aserrar para

Carpinteros DW746. (Cuando se agregue como accesorio

adicional, use herrajes nuevos en lugar de los herrajes

que se quiten).

Para facilitar el ensamblado de su banco/sierra, iguale las

tuercas, pernos y arandelas con la gráfica de herrajes.

Antes de cada paso, revise sus herrajes contra la gráfica

e identifique las piezas que necesita. Pueden haber

piezas adicionales en la bolsa con los accesorios de ferretería.

M 10 TUERCA HEXAGONAL

17 MM DE SEGURIDAD

(6 PIEZAS)

PERNO

10MM X 25MM

(5 PIEZAS)

PERNO

10MM X 35MM

(8 PIEZAS)

PERNO TORX T50 DE

CABEZA PLANA

10MM X 30MM

(6 PIEZAS)

PERNO DE CARRUAJE

8MM X 20MM

(11 PIEZAS)

TORNILLO DE CABEZA

8MM X 20MM

(15 PIEZAS)

10 MM ARANDELA

PLANA

(22 PIEZAS)

10 MM ARANDELA

DE SEGURIDAD

(20 PIEZAS)

8 MM ARANDELA

PLANA

(19 PIEZAS)

8 MM ARANDELA

DE SEGURIDAD

(25 PIEZAS)

M 8 TUERCA

HEXAGONAL 13MM

(25 PIEZAS)

M 10 TUERCA

HEXAGONAL 16MM

(13 PIEZAS)

DE CABEZA PLANA

6MM HEXAGONAL

10MM X 80MM

(2 PIEZAS)

Herrajes incluidos con el Sistema de Rieles de 52” (1.32m) DW7464 52”

Page 20

Español

16

LLAVE TORX

T40 (1)

LLAVE TORX

T50 (1)

LLAVE HEXAGONAL

6 MM (1)

Preparación del banco de aserrar: Si compró usted el Sistema

de Rieles de 52” (1.32m) como accesorio adicional, empiece con

esta sección. Si compró usted el Sistema de Rieles de 52”

(1.32m) con su Banco de Aserrar para Carpinteros DW746, no

haga este paso y vaya a la sección de ensamblado.

• Quite el riel posterior y los herrajes asociados. Si su sierra

tiene una mesa de salida, quite el riel y cualquier puntal de

soporte posterior, pero deje los soportes colgantes en su

lugar (Fig. 1).

Ensamblado

Si tiene otros accesorios (Mesa deslizante y/o Mesa de salida)

ensamble primero el sistema de rieles de 52” (1.32m), excepto

por el riel posterior. La mesa de salida deberá ser ensamblada al

final.

ANTES DE PROCEDER, LEA TODA LA SECCIÓN

DE ENSAMBLADO.

PASO 1. Retire la caja de partes, la cubierta del motor, guía, y las

mesas laterales del paquete de la sierra.

PASO 2. Voltee la sierra con el lado derecho hacia arriba.

Necesitará ayuda. El peso combinado de la cubierta de la

mesa y el motor es de 90 kilos aproximadamente.

PASO 3. Corte y retire los flejes plásticos que sujetan el motor.

PASO 4. Usando la manivela del frente, baje un poco el motor y

retire el material de espuma de empaque entre el motor y el

mecanismo.

PASO 5. Instale la manivela para biselar. (Fig. 2) Para hacer

esto, instale primero la manivela (A) en la flecha (B), gire ligeramente para enganchar el pasador de la flecha. Atornille la

perilla de seguridad (C) en su lugar hasta que esté completamente asentada en su lugar y luego afloje 1/4 a 1/2 vuelta.

PASO 6. Usando la manivela de altura, levante el mecanismo tan

alto como llegue.

PASO 7. Instale el gancho para llave. (Fig. 3) En la pata

delantera derecha, cerca de la parte de arriba hay un injerto

de plástico roscado. Enrosque uno de los ganchos de llave en

forma de «L» hasta que sólo unas cuantas vueltas de rosca

sean visibles.

• Quite el riel delantero, soltando los cuatro pernos de cabeza

plana M10 x 25 de la parte superior de cada soporte de riel

delantero. Si su sierra tiene un accesorio deslizante, será

necesario quitar también los pernos de carruaje M8 x 20 de

los soportes delanteros del riel.

• Quite los soportes delanteros del riel delantero. Afloje las

tuercas M8 hasta que sólo unas cuantas vueltas las sostengan en su lugar. Deslice el perno de carruaje fuera de la ranura en el riel y quite los herrajes de los soportes. Guarde los

soportes del riel delantero para el ensamble de su Sistema de

rieles de 52” (1.32m).

• Retire la cubierta del motor quitando los dos tornillos y aran-

delas de la parte superior de la cubierta en la parte de arriba

de las dos patas laterales. Estire la parte superior de la

cubierta de la sierra y desenganche las lengüetas de las

ranuras en el travesaño derecho. Reinstale los tornillos y

arandelas para uso posterior.

• Quite la mesa de soporte del lado derecho. Afloje los tres

pernos M10 que sujetan la mesa de soporte con el banco de

aserrar. Ahora puede levantar y quitar la mesa de soporte.

Termine de quitar los herrajes. (Si también está agregando un

accesorio deslizante, puede ahora quitar la mesa de soporte

del lado izquierdo).

• Continúe con el ensamble empezando en el paso 8.

REMOVE

REMOVE

FIG. 1

A

B

C

FIG. 2

FIG. 3

Page 21

Español

17

PASO 8. Desempaque la caja de rieles y el banco del Sistema de

Rieles de 52” (1.32m) de la caja del subconjunto.

PASO 9. Ensamble las bases de las patas.

Necesitará: 4 tornillos de 8mm de cabeza

4 arandelas planas de 8mm

4 arandelas de seguridad de 8mm

4 tuercas de 8mm

Coloque una base sobre el extremo de la pata como se muestra en la fig. 4 y asegure con los herrajes, dejando las arandelas y tuercas en el lado interior. Asegure que la base está

en posición hacia arriba y apriete los herrajes. Repita para la

otra pata.

PASO 13. Afiance la mesa de soporte del lado izquierdo (Fig. 7).

(Si tiene usted una mesa deslizante omita este paso).

Usted necesitará:

3 tornillos de 10 x 25mm de cabeza hexagonal

3 arandelas planas de 10mm

3 arandelas de seguridad de 10mm

Sin la mesa de soporte en su lugar, instale los tres pernos con

arandelas del lado izquierdo como se muestra dejando un

claro de 6mm. Descanse una mesa de soporte en los pernos,

acomodando en las muescas. Usando la cara extruida de la

guía como regla, ajuste la mesa de soporte al paño con la orilla

de la mesa de aserrar y apriete el perno del frente. Repita

este procedimiento para el perno trasero y el perno central.

Apriete los herrajes.

PASO 11. Ensamble los herrajes de nivelación en la mesa

(Fig. 5).

Necesitará: 2 pernos de cabeza plana de 10 x 80mm.

2 arandelas de seguridad de 10mm

2 tuercas de seguridad de 10mm

Inserte los pernos de cabeza plana desde el lado superior.

Asegure cada perno con una arandela de seguridad y tuerca.

Apriete los herrajes, tenga cuidado de no dañar la mesa apretando demasiado.

PASO 10. Ensamblado del conjunto de patas.

Necesitará: 8 tornillos de 8 mm de cabeza

8 arandelas planas de 8mm

8 arandelas de seguridad de 8mm

8 tuercas de 8mm

Ensamble las patas a la charola de soporte (Fig. 4) usando

los 8 tornillos de cabeza M8. Asegure que los orificios

cuadrados en la charola de soporte estén orientados más

cerca de las bases de las patas. Asegure cada perno con una

arandela plana, arandela de seguridad y tuerca, dejando las

arandelas y tuercas del lado interior. Apriete los herrajes.

PASO 12. Una el juego de patas al subconjunto de la mesa.

Necesitará: 2 tornillos de 8mm de cabeza

2 arandelas planas de 8mm

2 arandelas de seguridad de 8mm

2 tuercas de 8mm

4 arandelas planas de 10mm

2 arandelas de seguridad de 10mm

4 tuercas de seguridad de 10mm

Coloque la mesa en el piso, con el lado plano hacia abajo. A

cada perno de nivelación agregue una tuercas de seguridad

M10 y una arandela plana (Fig. 5) y enrosque las tuercas de

seguridad hasta 6.4mm de la tuerca enroscada previamente.

Coloque el juego de patas, viendo hacia afuera, sobre los pernos de nivelación. El juego de patas no está asegurado aún,

estabilícelo mientras que agrega una arandela plana, una

arandela de seguridad y tuercas de seguridad a cada perno y

apriete al llegue solamente. Agregue un perno de cabeza M8

a través de la ranura abierta en cada riel lateral y en el orifico

cuadrado de las patas. Asegure cada perno con una arandela

plana, arandela de seguridad y tuerca, dejando las arandelas

y tuerca en el lado interno de la pata (Fig. 6). Apriete a mano.

FIG. 4

FIG. 5

FIG. 6

FIG. 7

6.4MM

(1/4”)

6.4MM

(1/4”)

Page 22

Español

PASO 17. Sujete el riel delantero de 52”(1.32m) con soportes

a la parte superior de la mesa (Fig. 12).

Necesitará: 2 tornillos de cabeza plana de 10 x 30mm

2 arandelas planas de 10mm

2 arandelas de seguridad de 10mm

2 tuercas de 10mm

Asegure cada tornillo a través del orificio superior en los puntales de soporte del riel, como se muestra, dejando las arandelas planas, arandelas de seguridad y tuercas en el interior

de la mesa. Apriete un poco pero no mucho. Apriete las tuercas de 8mm de los soportes del riel, dejando las de afuera

apretadas a mano.

PASO 15. Afiance el puntal de soporte (Fig. 9).

Necesitará: 3 pernos de cabeza plana de 10mm x 30

Afiance el lado derecho de la sierra de banco usando la llave

torx T50 incluida. Atornille directamente a la mesa, no necesita arandelas o tuercas.

PASO 16. Ensamblado del riel de 52” (1.32m) delantero y

soportes (Fig. 10).

Necesitará: 7 pernos de carruaje de *8mm

(8 si agrega una mesa lateral)

5 arandelas de seguridad de 8mm

5 tuercas de 8mm

5 soportes del riel delantero

PASO 18. Alinee el riel delantero a la mesa de aserrar. (Fig.

13). Use la cara de la cara de la guía o una regla para exten-

der la superficie de la mesa sobre el riel, cerciórese que la distancia desde la parte superior de la mesa al lado superior del

riel es igual del lado izquierdo y derecho de la mesa. Si el riel

no está alineado correctamente, afloje ligeramente los tornillos

de montaje y golpee en el riel con un martillo suave o martillo

regular con un bloque de madera hasta que las distancias

sean iguales. Apriete y asegure los herrajes.FIG. 13

PASO 19. Afiance el soporte del riel delantero a la mesa de

soporte (Fig. 12). (Si tiene usted una mesa deslizante, omita

este paso)

Necesitará: 1 tornillo de cabeza plana de 10 x 30 mm

1 arandela plana de 10mm

1 arandela de seguridad de 10mm

1 tuerca de 10mm

Una la mesa de soporte al puntal de soporte externo del riel

delantero, dejando las arandelas y tuerca del lado interno de

la mesa. Usando la cara de la guía como regla, asegúrese

que la esquina exterior delantera de la mesa de soporte está

nivelada con la orilla interna y la superficie principal de la

mesa. Apriete los herrajes, incluyendo la tuerca de 8 mm del

puntal de soporte del riel.

PASO 20. Con cuidado mueva la mesa a su posición (Fig. 14).

Necesitará: 2 Pernos de 10 x 25mm de cabeza hexagonal

4 arandelas planas de 10mm

2 arandelas de seguridad de 10mm

2 tuercas de 10mm

2 arandelas de seguridad de 8mm

2 tuercas de 8mm

Permita que la mesa descanse contra el puntal de soporte y

sobre los pernos de carruaje M8 x 20 instalados previamente

a través de los soportes del riel delantero.

FIG. 9

FIG. 10

NOT NEEDED WITH SLIDING TABLE

TAPE

M8 x 20

FIG. 11

FIG. 12

FIG. 13

PASO 14. Afiance los tres puntales de soporte trasero (Fig. 8)

a la mesa de soporte y parte posterior de la mesa de aserrar.

Necesitará: 3 tornillos de 10 x 35mm de cabeza hexagonal

3 arandelas planas de 10mm

3 arandelas de seguridad de 10mm

3 tuercas de 10mm

Asegure el perno a través del orificio redondo en cada soporte

con una arandela plana, arandela de seguridad y tuerca,

dejando las arandelas y tuerca en el lado interno. Cuando

apriete las tuercas, mantenga los soportes cuadrados con la

mesa. (El accesorio deslizante tomará el lugar de uno de los

soportes posteriores, el riel posterior se unirá directamente a

este accesorio. Si está agregando una mesa de salida, use

los soportes colgantes para mesa de salida en lugar de los

dos puntales de soporte posterior en la mesa de aserrar).

FIG. 8

(4 retirados previamente del riel + 1 de la bolsa de herrajes)

Ensamble los pernos de carruaje, arandelas y tuercas a los

soportes del riel delantero (sólo unas cuantas roscas).

Coloque la cabeza de los pernos de carruaje en las ranuras

en el riel delantero y deslice para enganchar la parte cuadrada del perno. Enrosque la tuerca hasta que apriete a mano,

repita para los otros cuatro soportes (Si también está instalando un accesorio deslizante, no necesita el soporte

delantero de extrema izquierda). Cuando coloque los

soportes en el riel, el riel debe estar colocado de manera que

la escala para corte al hilo esté con el lado derecho hacia arriba. Además, los cinco soportes deberán ver en la misma

dirección.

*Dos de los soportes del riel delantero se unirán a la mesa del

Sistema de Rieles de 52” y necesitarán un perno M8 x 20 de

carruaje a través del orificio cuadrado (Fig. 11). (Si también

está agregando un accesorio deslizante, agregue pernos M8

de carruaje a los soportes del riel delantero que se unen a la

mesa de la sierra). Puede ser útil sostener los pernos de

carruaje con tiras de cinta.

18

Page 23

Español

19

PASO 24. Alinee en paralelo el riel posterior con la superficie

de la mesa de aserrar (Fig. 13). Usando su la cara de la

guía o una regla para extender la superficie de la mesa sobre

el riel, asegúrese que la distancia desde la superficie de la

mesa de aserrar a la parte superior del riel sea la misma en

ambos lados de la mesa de aserrar. Si el riel no está alineado

correctamente, afloje ligeramente los tornillos de montaje y

golpee suavemente con un martillo suave o un martillo regular

y un bloque de madera hasta que la distancia sea la misma.

Apriete los herrajes. Repita para los tres puntos de fijación

remanentes, revisando la distancia a todo lo largo del riel.

PASO 25. Instale la cubierta del motor(Fig. 18). Quite los dos

tornillos y arandelas de la parte superior de las dos patas laterales con un pequeño destornillador de hoja plana (o el maneral torx T25). Enganche las dos lengüetas inferiores de la

cubierta en las ranuras del travesaño derecho. Los rieles de

soporte inferior están muy cercanos a las ranuras del travesaño

y puede ser necesario aflojar un poco los pernos de carruaje

que sostienen los rieles para enganchar las lengüetas.

Coloque la cubierta en posición y reinstale los tornillos y arandelas.

PASO 26. Vea el manual DW746 para las instrucciones de

operación y ajuste de la mesa de aserrar.

Asegure el lado de la mesa de rieles de 52” (1.32m) a los

soportes delanteros del riel usando los dos pernos de carruaje

M8 x 20, las arandelas planas de 10mm, arandelas de seguridad de 8mm y tuercas. Apriete a mano. Fije la mesa del riel de

52” (1.32m) al puntal de soporte (Fig. 15) usando los pernos

M10 x 25mm. Asegure cada perno con una arandela plana,

arandela de seguridad y tuerca. Apriete al llegue solamente.

PASO 21. Fije los rieles de soporte inferior.

Necesitará: 4 pernos de carruaje de 8mm

4 arandelas planas de 8mm

4 arandelas de seguridad de 8mm

4 tuercas de 8mm

Fije los rieles inferiores de soporte entre la parte inferior de la

charola de soporte y el travesaño derecho (Fig. 16) con dos

pernos de carruaje M8 x 2. Asegure cada perno con una arandela plana, arandela de seguridad y tuerca. Apriete completamente.

PASO 22. Alinee en paralelo la mesa del riel de 52” (1.32m) a

la mesa de aserrar. La mesa deberá estar nivelada con la

superficie superior de la mesa de aserrar. Para la orilla más

cercana a la mesa de aserrar use una regla o la cara de la

guía para extender la superficie de la mesa de aserrar sobre

la mesa del riel. Para alinear las mesas, golpee suavemente

sobre la mesa del riel usando un martillo suave o un bloque

de madera hasta que estén niveladas. Apriete los herrajes

M10 a través del puntal de soporte (Fig. 15. Usando los herrajes de ajuste en la parte superior del juego de patas (Fig. 5)

ajuste la mesa del riel, a lo largo, midiendo contra el riel

delantero (Fig. 13). Una vez nivelado, el frente y atrás, apriete los herrajes de ajuste, los tornillos M8 de cabeza en la

parte superior de las patas y los pernos de carruaje M8 x 20

a través de los soportes del riel delantero.

PASO 23. Fije el riel de 52” (1.32m) trasero (Fig. 17).

Necesitará: 5 tornillos de cabeza hexagonal de 10 x 35mm

5 arandelas planas de 10mm

5 arandelas de seguridad de 10mm

5 tuercas de 10mm

Fije a través de los orificios ranurados en los puntales de

soporte traseros y el lado de la mesa del riel de 52” (1.32m)

usando los pernos M10. Asegure cada perno con arandela

plana, arandela de seguridad y tuerca dejando las arandelas

y tuercas del lado interno. Apriete los herrajes que fijan a la

mesa de aserrar, dejando los remanentes apretados a mano.

(Isi está agregando un accesorio de mesa de deslizante,

ensámblela antes de fijar al fiel trasero. Si está agregando un

accesorio de mesa de salida, revise que tiene los soportes

colgantes fijos en la mesa de aserrar en lugar de los puntales

de soporte posterior y continúe).

FIG. 14

FIG. 15

FIG. 16

FIG. 16

FIG. 18

FIG. 19

10 MM ARANDELA PLANA

Page 24

20

IInformación adicional

Ajuste:

• Si usted agrega una base móvil a su sierra será necesario

ajustar la altura de las patas de su sistema de rieles de 52”

(1.32m).:

• Coloque la base móvil bajo su sierra como se describe en el

manual de instrucciones de la base móvil.

• Mueva la sierra al lugar más probable de uso y desenganche

la base.

• Afloje los pernos M8 de cabeza a través de la ranura de

extremo abierto en cada riel lateral y el orificio cuadrado en

las patas (Fig. 6). Use los herrajes de ajuste a través de la

parte superior de las patas para ajustar las patas hasta abajo

o hasta que los tornillos M8 estén en la parte inferior de las

ranuras de extremo abierto.

• Vuelva a apretar los herrajes M8.

• Para cada pata (Fig. 19): Afloje los dos tornillos que fijan la

base a la pata. Deje que la base caiga a la superficie del piso.

Vuelva a apretar los tornillos sosteniendo la base contra la

pata.

Ajuste el deslizador de la gua

trasera

En caso necesario, ajuste el deslizador trasero para colocarlo correctamente contra el riel trasero aflojando los dos

tornillos que lo fijan a la viga de la gua. La pinza de

retencin de plstico debe inclinarse cuando el deslizador

queda correctamente colocado. Este ajuste solamente es

necesario si el riel trasero se ha movido por la adicin de

un accesorio opcional.

Limpieza:

• El tablero de la mesa de sus sistema de rieles de 52” (1.32m)

es de un material compuesto, la humedad excesiva lo puede

deteriorar. La limpieza con un paño húmedo o un solvente

suave en la superficie de la mesa es aceptable, pero no

deberá humedecer las orillas del tablero.

Español

Loading...

Loading...