Page 1

IF YOU SHOULD EXPERIENCE A PROBLEM WITH

YOUR D

EWALT PURCHASE,

Before returning this

product call

1-800-4-DEWALT

See our catalog on the World Wide Web at www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

CALL 1-800-4 DEWALT

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE YOUR

PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF D

IMPROVEMENT PROGRAM.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE

SERVICIO Y PÓLIZA DE GARANTIA. ADVERTENCIA:

LEASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO. SI TIENE DUDAS, POR FAVOR LLAME.

EWALT'S QUALITY

DW746, DW746X

Woodworker’s Table Saw

Scies circulaires à table d’entrepreneur

Sierra de banco para madera

Page 2

Page 3

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read

the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY D

TOOL, CALL US TOLL FREE AT: 1-800-4-D

EWALT (1-800-433-9258)

EWALT

General Safety Rules

WARNING: Read all instructions before operating product. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

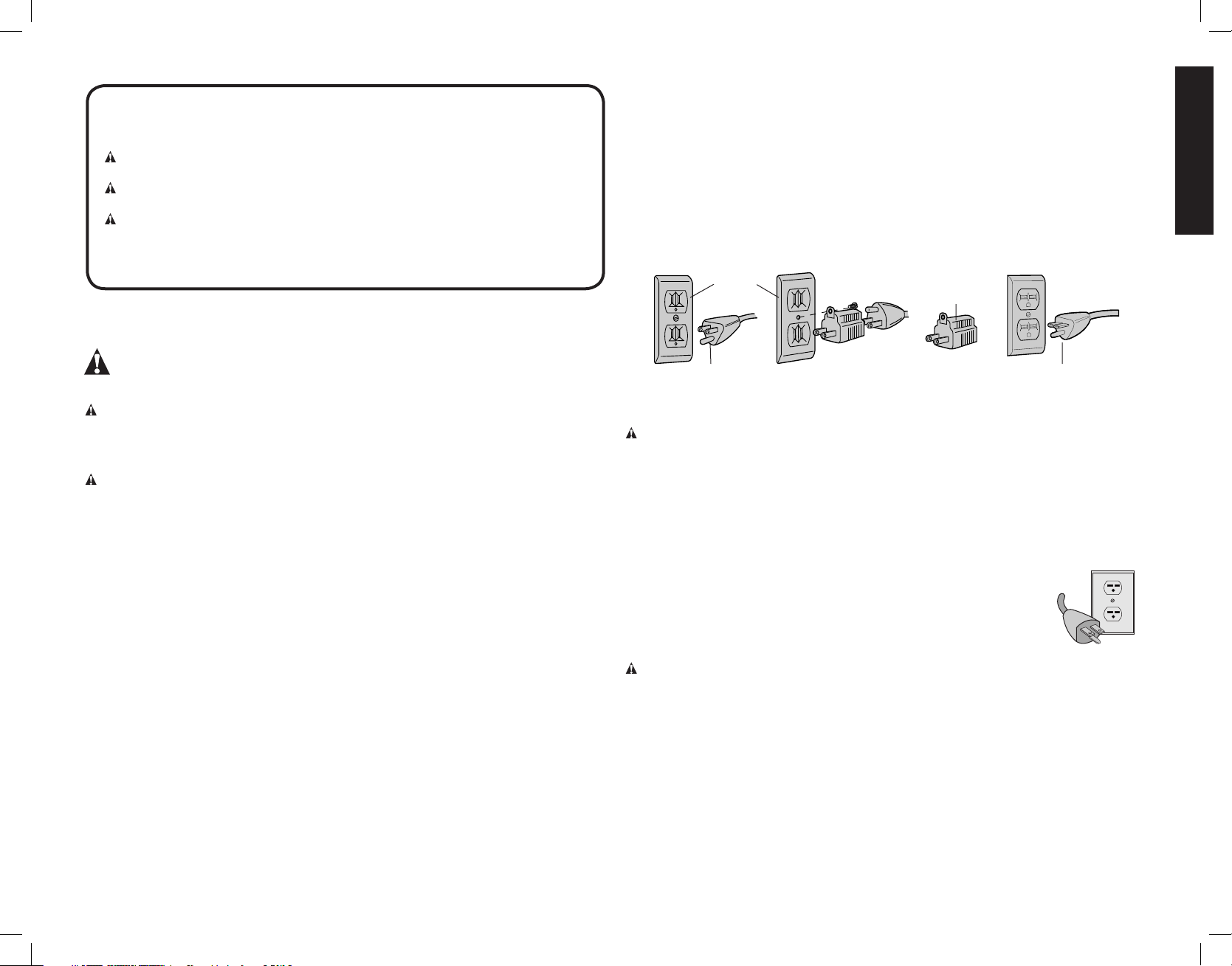

WARNING: FOLLOW ALL WIRING CODES and recommended electrical connections to

prevent shock or electrocution.

Grounding Instructions

If saw is of grounded construction, read the following instructions.

DANGER: SHOCK HAZARD. THIS MACHINE MUST BE GROUNDED WHILE IN USE.

SERIOUS INJURY COULD RESULT.

ALL GROUNDED, CORD-CONNECTED MACHINES

In the event of a malfunction or breakdown, grounding provides a path of least resis-

tance for electric current to reduce the risk of electric shock. This machine is equipped

with an electric cord having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into a matching outlet that is properly installed and grounded

in accordance with all local codes and ordinances. Do not modify the plug provided - if it

will not fit the outlet, have the proper outlet installed by a qualified electrician. Improper

connection of the equipment-grounding conductor can result in risk of electric shock.

The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal. Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the machine is properly

grounded. Use only three-wire extension cords that have three-prong grounding type

plugs and matching three-conductor receptacles that accept the machine’s plug, as

shown in Fig. A. Repair or replace damaged or worn cord immediately.

GROUNDED, CORD-CONNECTED MACHINES INTENDED FOR USE ON A SUPPLY

CIRCUIT HAVING A NOMINAL RATING LESS THAN 150 VOLTS

If the machine is intended for use on a circuit that has an outlet that looks like the one

illustrated in Fig. A, the machine will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like the adapter illustrated in Fig. B,

may be used to connect this plug to a matching two-conductor receptacle as shown in

Fig. B if a properly grounded outlet is not available. The temporary adapter should be

used only until a properly grounded outlet can be installed by a qualified electrician. The

green-colored rigid ear, lug, and the like, extending from the adapter must be connected

to a permanent ground such as a properly grounded outlet box. Whenever the adapter

is used, it must be held in place with a metal screw.

A

GROUNDED

OUTLET

BOX

GROUNDING PIN

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian

Electric Code.

DANGER: IN ALL CASES, MAKE CERTAIN THAT THE RECEPTACLE IN QUESTION IS

PROPERLY GROUNDED. IF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN

CHECK THE RECEPTACLE.

B

C D

GROUNDING

MEANS

ADAPTER

GROUNDING PIN

240 Volt, Single-Phase Operation

The motor supplied with your machine is a dual voltage, 120/240 volt motor. It is shipped

ready-to-run for 120 volt operation. However, it can be converted for 240 volt operation. A

qualified electrician should perform the conversion or take the machine to an authorized

D

EWALT service center. When conversion is complete, the machine must conform to the

National Electric Code and all local codes and ordinances.

The machine is converted by rewiring the motor for 240 volts, installing a

240-volt plug on the power supply cord and replacing the switch (if necessary) with one that is rated for 240-volt operation.

The saw with the 240-volt plug should ONLY be connected to an outlet

having the same configuration as the plug illustrated. No adapter is available or should be used with the 240-volt plug.

DANGER: IN ALL CASES, MAKE CERTAIN THAT THE RECEPTACLE

IN QUESTION IS PROPERLY GROUNDED. IF YOU ARE NOT SURE, HAVE A QUALIFIED

ELECTRICIAN CHECK THE RECEPTACLE.

Double Insulation

If saw is of double-insulated construction, read the following instructions.

Double insulated tools are constructed throughout with two separate layers of electrical

insulation or one double thickness of insulation between you and the tool’s electrical system.

Tools built with this insulation system are not intended to be grounded. As a result, your tool

is equipped with a two prong plug which permits you to use extension cords without concern

for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety precautions when operating this tool. The insulation system is for added protection against injury resulting from a

possible electrical insulation failure within the tool.

English

1

Page 4

POLARIZED PLUGS

To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider

than the other). This plug will fit in a polarized outlet only one way. If the plug does not fit fully

into the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install

the proper outlet. Do not change the plug in any way.

Important Safety Instructions

English

• TO REDUCE THE RISK OF KICKBACK AND OTHER INJURIES, KEEP GUARDS IN

PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from spindle before turning tool on. Tools,

scrap pieces and other debris can be thrown at high speed, causing injury.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

• DO NOT USE THE MACHINE IN A DANGEROUS ENVIRONMENT. The use of power

tools in damp or wet locations or in rain can cause shock or electrocution. Keep your

work area well-lit to avoid tripping or placing arms, hands and fingers in danger.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area.

Your shop is a potentially dangerous environment.

• MAKE WORKSHOP CHILDPROOF with padlocks, master switches, or by removing

starter keys. The unauthorized start-up of a machine by a child or visitor may result in

injury.

• DO NOT FORCE TOOL. It will do the job better and be safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not

designed. Using the incorrect tool or attachment may result in personal injury.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. If your product is equipped with a cord set, use only three-wire extension cords

that have three-prong grounding-type plugs and three-pole receptacles that accept the

tool’s plug. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

MINIMUM GAUGE FOR CORD SETS

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

• WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets or

other jewelry to get caught in moving parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair. Air vents may cover moving parts and

should also be avoided.

• ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask if cutting operation is dusty. ALWAYS wear certified safety

equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3)

• ANSI S12.6 (S3.19) hearing protection

• NIOSH/OSHA respiratory protection.

• DO NOT OVERREACH. Keep proper footing and balance at all times. Loss of balance

may cause personal injury.

• MAINTAIN TOOLS WITH CARE. Keep blades sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories. Poorly maintained blades and machines can further damage the blade or machine and/or cause

injury.

• TURN THE MACHINE “OFF”, AND DISCONNECT THE MACHINE FROM THE

POWER SOURCE before installing or removing accessories, before adjusting or

changing set-ups, when making repairs or changing locations. Do not touch the plug’s

metal prongs when unplugging or plugging in the cord. An accidental start-up can cause

injury.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure that the switch is

in the “OFF” position before plugging in the power cord. In the event of a power failure,

move the switch to the “OFF” position. An accidental start-up can cause injury.

• USE RECOMMENDED ACCESSORIES. Use only accessories that are recommended

by the manufacturer for your model. Accessories that may be suitable for one tool may

be hazardous when used on another tool. Consult the instruction manual for recommended accessories. The use of improper accessories may cause risk of injury to

persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting

tool is unintentionally contacted.

• CHECK FOR DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate properly

and perform its intended function—check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and any other conditions that may affect

its operation. A guard or other part that is damaged should be properly repaired or

replaced. Do not use tool if switch does not turn it on and off. Damaged parts can cause

further damage to the machine and/or personal injury.

• DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation

of the blade or cutter only.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave

tool until it comes to a complete stop. Serious injury can result.

• DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN

GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors and switches in these tools may

spark and ignite fumes.

• STAY ALERT, WATCH WHAT YOU ARE DOING AND USE COMMON SENSE. DO

NOT USE THE MACHINE WHEN YOU ARE TIRED OR UNDER THE INFLUENCE OF

DRUGS, ALCOHOL OR MEDICATION. A moment of inattention while operating power

tools may result in serious injury.

• DO NOT ALLOW FAMILIARITY (gained from frequent use of your saw) TO

REPLACE SAFETY RULES. Always remember that a careless fraction of a second is

sufficient to inflict severe injury.

Additional Safety Rules for Table Saws

• AVOID AWKWARD POSITIONS, where a sudden slip could cause a hand to move into

a saw blade or other cutting tool.

• NEVER REACH IN BACK OF, OR AROUND, THE CUTTING TOOL with either hand to

hold down the workpiece.

2

Page 5

• KEEP ARMS, HANDS AND FINGERS AWAY from the blade to prevent serious injury.

• USE A PUSH STICK OR PUSH BLOCK THAT IS APPROPRIATE TO THE APPLICA-

TION TO PUSH WORKPIECES THROUGH THE SAW. A push stick is a wooden or

non-metallic stick, usually homemade, that should be used whenever the size or shape

of the workpiece would cause you to place your hands within six inches of the blade.

Use hold-downs, jigs, fixtures or feather boards to help guide and control the

workpiece when the guard cannot be used. Use saw-blade guard and spreader for

every operation for which it can be used, including all through sawing.

• DO NOT PERFORM RIPPING, CROSSCUTTING OR ANY OTHER OPERATION

FREEHAND.

• NEVER reach around or over saw blade.

• STABILITY. Make sure the table saw is firmly mounted to a secure surface before use

and does not move. If the mobility kit is installed, raise the moveable caster(s) so saw

is in its stationary position.

• NEVER CUT FERROUS METALS (those with any iron or steel content) or masonry.

Damage to the saw and personal injury may result.

• THE PROPER THROAT PLATE MUST BE IN PLACE AT ALL TIMES to reduce the

risk of a thrown workpiece and possible injury.

• USE THE CORRECT SAW BLADE FOR THE INTENDED OPERATION. The blade

must rotate toward the front of the saw. Always tighten the blade arbor nut securely.

Before use, inspect the blade for cracks or missing teeth. Do not use a damaged

blade.

• NEVER ATTEMPT TO FREE A STALLED SAW BLADE WITHOUT FIRST TURNING

THE MACHINE OFF. If a workpiece or cut-off piece becomes trapped inside the guard,

turn saw off and wait for blade to stop before lifting the guard and removing the piece.

• NEVER START THE MACHINE with the workpiece against the blade to reduce the risk

of a thrown workpiece and personal injury.

• NEVER run the workpiece between the fence and a molding cutterhead to reduce the

risk of a thrown workpiece and personal injury.

• AVOID AWKWARD OPERATIONS AND HAND POSITIONS where a sudden slip

could cause a hand to move into the blade.

• NEVER have any part of your body in line with the path of the saw blade. Personal

injury will occur.

• NEVER PERFORM LAYOUT, ASSEMBLY OR SET-UP WORK on the table/work area

when the machine is running. A sudden slip could cause a hand to move into the blade.

Severe injury can result.

• CLEAN THE TABLE/WORK AREA BEFORE LEAVING THE MACHINE. Lock the

switch in the “OFF” position to prevent unauthorized use.

• DO NOT leave a long board (or other workpiece) unsupported so the spring of

the board causes it to shift on the table resulting in loss of control and possible

injury. Provide proper support for the workpiece, based on its size and the type of

operation to be performed. Hold the work firmly against the fence and down against

the table surface. If supports are attached to the saw, be certain saw will not tip under

load.

• DO NOT OPERATE THIS MACHINE until it is completely assembled and installed

according to the instructions. A machine incorrectly assembled can cause serious

injury.

• OBTAIN ADVICE from your supervisor, instructor or another qualified person if you are

not thoroughly familiar with the operation of this machine. Knowledge is safety.

• ADDITIONAL INFORMATION regarding the safe and proper operation of power

tools (i.e., a safety video) is available from the Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851 (www.powertoolinstitute.com). Information is also

available from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-

3201. Please refer to the American National Standards Institute ANSI 01.1 Safety

Requirements for Woodworking Machines and the U.S. Department of Labor OSHA

1910.213 Regulations.

TERMS: THE FOLLOWING TERMS WILL BE USED THROUGHOUT THE MANUAL

AND YOU SHOULD BECOME FAMILIAR WITH THEM.

• Through-sawing refers to any cut that completely severs the workpiece.

• Push Stick refers to a wooden stick, usually homemade, that is used to push small

workpiece through the saw and keeps the operator’s hands clear of the blade.

• Kickback occurs when the saw blade binds in the cut and violently thrusts the work-

piece back toward the operator.

• Freehand refers to cutting without the use of a miter gauge or rip fence or any other

means of guiding or holding the workpiece other than the operator’s hand.

SAW BLADE GUARD AND SPREADER

Your table saw is equipped with a blade guard and spreader assembly that covers the blade

and prevents accidental contact. The spreader is a flat plate that fits into the cut made by

the saw blade and effectively fights kickback by lessening the tendency of the blade to bind

in the cut. The spreader can only be used when making through cuts that sever the wood.

When making dadoes, rabbits and other cuts that make less than through cuts, the blade

guard and spreader assembly must be removed from the saw. Two anti-kickback pawls are

located on the sides of the spreader that allow the wood to pass through the blade in the

cutting direction but lock it if it tries to move backwards toward the operator.

MAKING A PUSH STICK (INSIDE BACK COVER)

WARNING: When ripping work less than 6" (152 mm) wide, a push stick should be used

to complete the feed and could easily be made from scrap material by following the pattern

on the inside back cover.

• In order to operate your table saw safely you must use a push-stick whenever the size

or shape of the workpiece would cause your hands to be within 6" (152 mm) of the saw

blade or other cutter.

• No special wood is needed to make a push-stick as long as it’s sturdy and long enough.

A length of 12" (305 mm) is recommended with a notch that fits against the edge of the

workpiece to prevent slipping. It’s a good idea to have several push sticks of the same

length [12" (305 mm)] with different size notches for different workpiece thicknesses.

• See the inside back cover for a picture of a push stick. The shape can vary to suit your

own needs as long as it performs its intended function of keeping your hands away from

the blade.

KICKBACKS

How to Avoid Them and Protect Yourself from Possible Injury

a. Be certain that the rip fence is parallel to the saw blade.

b. Do not rip by applying the feed force to the section of the workpiece that will become

the cut-off (free) piece. Feed force when ripping should always be applied between the

saw blade and the fence; use a push stick for short work, 6" (152 mm) wide or less. For

less than 2" (51 mm) wide, you must use a special fixture.

c. Keep saw blade guard, splitter and anti-kickback teeth in place and operating properly.

Keep teeth sharp. If teeth are not operational, return your unit to the nearest authorized

D

EWALT service center for repair. The splitter must be in alignment with the saw blade

and the teeth must stop a kickback once it has started. Check their action before ripping

by pushing the wood under the anti-kickback teeth. The teeth must prevent the wood

from being pulled toward the front of the saw.

English

3

Page 6

d. Plastic and composition (like hardboard) materials maybe cut

on your saw. However, since these are usually quite hard and

slippery, the anti-kickback pawls may not stop a kickback.

Therefore, be especially attentive to following proper set up and

cutting procedures for ripping.

e. Use saw blade guard and splitter for every operation for which it

English

can be used, including all through-sawing.

f. Push the workpiece past the saw blade prior to release.

g. NEVER rip a workpiece that is twisted or warped, or does not have

a straight edge to guide along the fence.

h. Use featherboards when the anti-kickback device or the guard and

splitter cannot be used.

i. NEVER sawing a large workpiece that cannot be controlled.

j. NEVER use the fence as a guide or length stop when

crosscutting.

k. NEVER saw a workpiece with loose knots, flaws, nails or other

foreign objects.

l. NEVER rip a workpiece shorter than 10" (254 mm).

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work

in a well-ventilated area and work with approved safety equipment,

such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, saw-

ing, grinding, drilling and other construction activities. Wear

protective clothing and wash exposed areas with soap and

water. Allowing dust to get into your mouth, eyes or lay on the skin

may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

Always operate tool in well-ventilated area and provide for proper dust

removal. Use dust collection system wherever possible.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

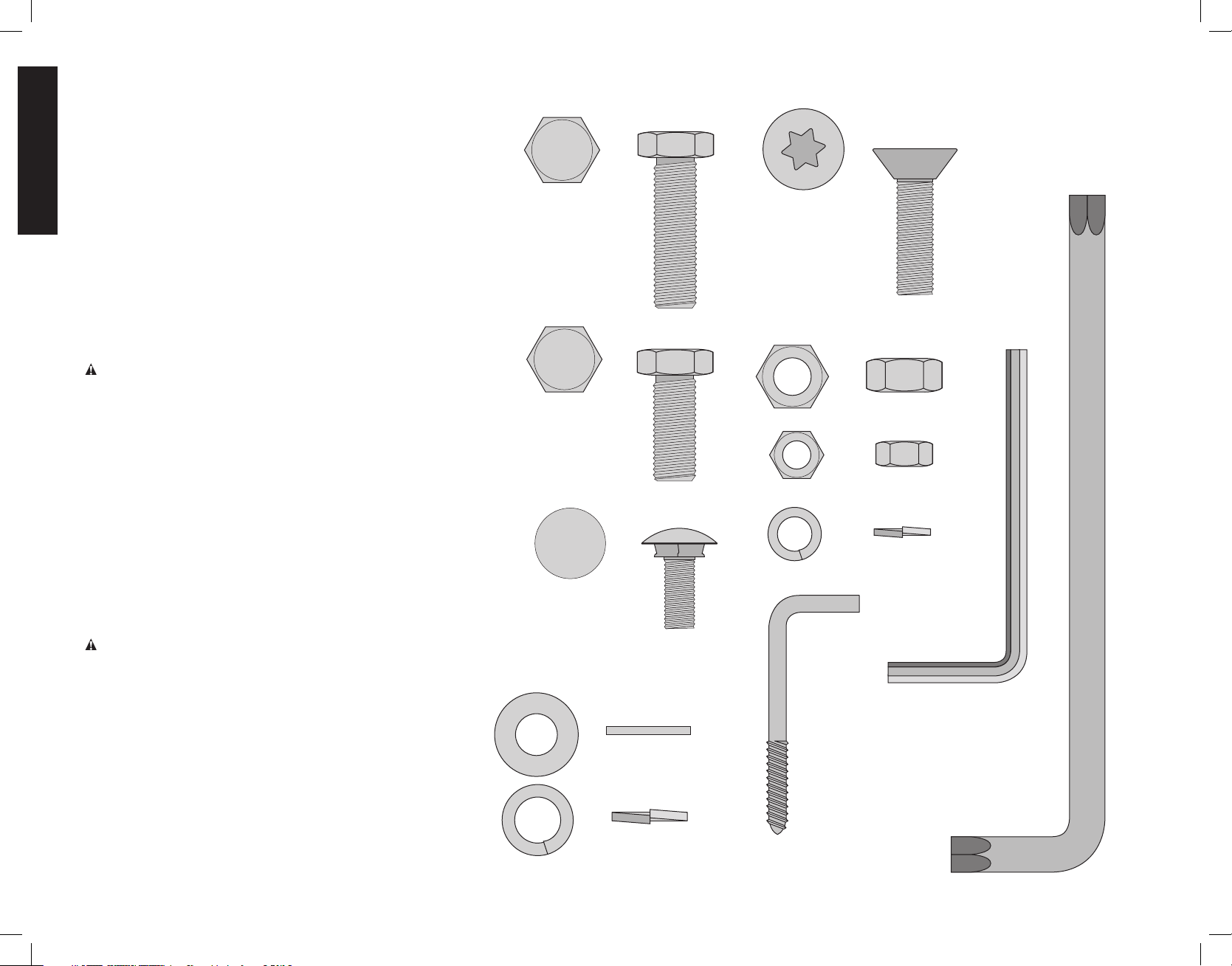

Hardware Included with the DW746 Woodworker’s Table Saw

BOLT

10 MM X 35 MM

(2 PIECES)

BOLT

10 MM X 25 MM

(8 PIECES)

CARRIAGE BOLT

8 MM X 20 MM

(4 PIECES)

FLAT WASHER

(14 PIECES)

T50 TORX

FLAT HEAD SCREW

10 MM X 30 MM

(4 PIECES)

8 MM LOCK WASHER

WRENCH

HOOK

(1)

PARTS SHOWN ARE

FULL SIZE - EXTRA

FASTENERS MAY HAVE

BEEN INCLUDED

5 mm

HEX

WRENCH

( 1 )

M 10 NUT

16 mm HEX

(8 PIECES)

M 8 NUT

13 MM HEX

(4 PIECES)

(4 PIECES)

T50

TORX

WRENCH

(1)

10 MM LOCK WASHER

(14 PIECES)

4

Page 7

Specifications

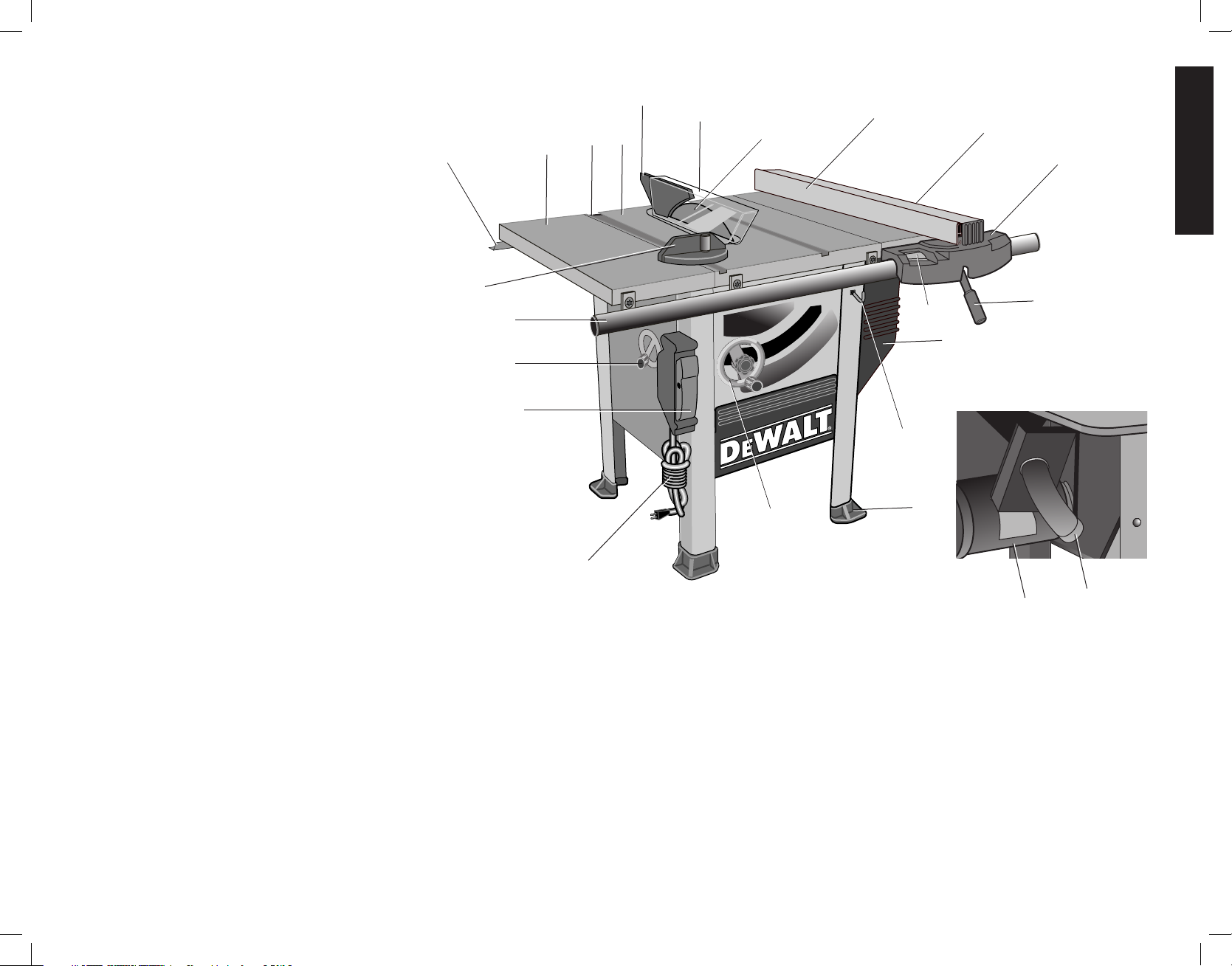

FIG. 1

Horsepower 1-3/4

Table Size 27" x 40-3/4"

Miter Angle 60° L&R

Bevel Angle -2° to 47° Left

A

W

V

Blade Size 10" (254 mm)

Max. Cut Depth 0° Bevel ............... 3-1/8" (79 mm)

Max. Cut Depth 45° Bevel ............. 2-1/8" (54 mm)

RPM, no load 3000

DW746 Basic Unit

Always follow the instructions included with the accessory when asssembling custom accessories to this unit.

Assemble any accessories first.

Tools Included

To aid you with assembly of your new saw, we have included

R

Q

the following tools.

• T50 torx wrench

• 5 mm hex wrench

P

• Combination wrench with 16 mm, 13 mm, 10 mm

and 22 mm openings

O

• Blade wrench with 15/16" and 10 mm box ends.

Tools You Will Need to Supply

• Flat blade screwdrivers

• 16 mm or 5/8" open end wrench or pliers

• Ruler

• Square

• Soft hammer, or regular hammer and block of wood

TO SPEED ASSEMBLY, THE FOLLOWING WOULD BE

HELPFUL:

N

• 16 mm or 5/8" socket wrench, with 6" extension

• 13 mm or 1/2" socket wrench

• 10 mm open end wrench

• T20 and T25 Torx drivers

• T40 Torx wrench.

YOUR WILL ALSO NEED:

• Mild solvent cleaner such as mineral spirits, paint thinner or denatured alcohol.

• High-quality paste wax

Necessary Hardware

Your hardware bag, located in the parts box, contains all the necessary nuts, bolts and

washers to assemble the components included with the DW746 Woodworker’s Table Saw.

To make assembly of your saw easier, match the nuts, bolts and washers with the chart on

the previous page. Separate them by size so that you can easily locate the item you need.

Before each step, check your hardware against the chart and identify the pieces you need.

C

E

B

D

M

F

G

H

U

J

K

L

I

S

T

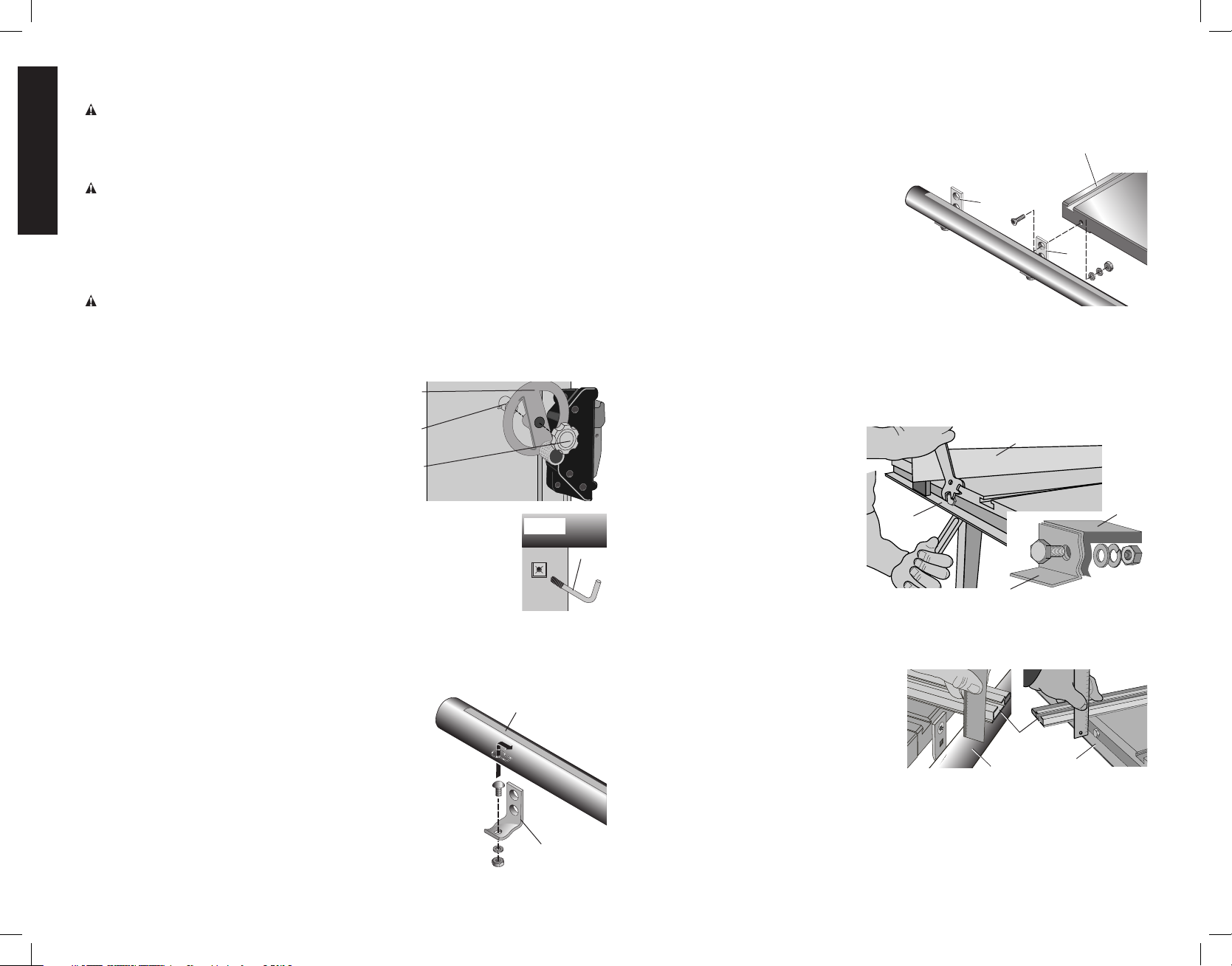

FEATURES (Fig. 1)

Examine Figure 1 to become familiar with the saw and its various parts. The following sections on assembly and adjustments will refer to these terms and you must know what and

where the parts are.

A. Rear fence rail (included with DW746X)

B. Table top

C. Splitter

D. Blade

E. Blade guard

F. Fence face

G. Rip fence

H. Fence beam

I. Rail lock lever

J. Motor cover

K. Wrench hook

L. Adjustable feet

M. Blade height adjustment wheel

N. Power cord

O. On/Off Switch

P. Blade tilt crank

Q. Front Fence Rail

(included with DW746X)

R. Miter gauge

S. Motor

T. Dust collection port

U. Rip scale pointer

V. Side support table

W. Miter slot

English

5

Page 8

Unpacking

WARNING: To reduce the risk of injury, do not connect the machine to the power

source until the machine is completely assembled and you read and understand the entire

instruction manual.

1. Remove parts box, motor cover, fence beam, side tables and fence rails (DW746X).

2. Turn the saw to the upright position.

English

CAUTION: Use a minimum of two people to prevent personal injury when turning the saw

and stand upright. The combined weight of the table top and motor assembly is approximately 200 lbs (91 kg).

3. Cut and remove plastic strap holding the motor.

4. Using front hand crank, lower the motor some and remove the foam packing material

between the motor and the mechanism.

Assembly

WARNING: To reduce the risk of injury, do not connect the machine to the power

source until the machine is completely assembled and you read and understand the entire

instruction manual.

PLEASE READ ENTIRE ASSEMBLY SECTION BEFORE PROCEEDING.

INSTALL BEVEL CRANK (FIG. 2)

1. Install the blade height adjustment wheel (M)

over the shaft (AA), rotate it slightly to fully

engage the shaft pin.

2. Screw the lock knob (BB) into place until it is

fully seated, then back it off 1/4 to 1/2 turn.

3. Turn blade height adjustment wheel (M) to raise

mechanism as high as it will go.

INSTALL WRENCH HOOK (FIG. 3)

NOTE: Always hang the blade wrench, spindle lock

wrench and push stick on wrench hook when not in use.

1. Located the plastic threaded insert at the top of the front right leg.

2. Thread the “L” shaped wrench hook (K) in until only a few threads are

visible.

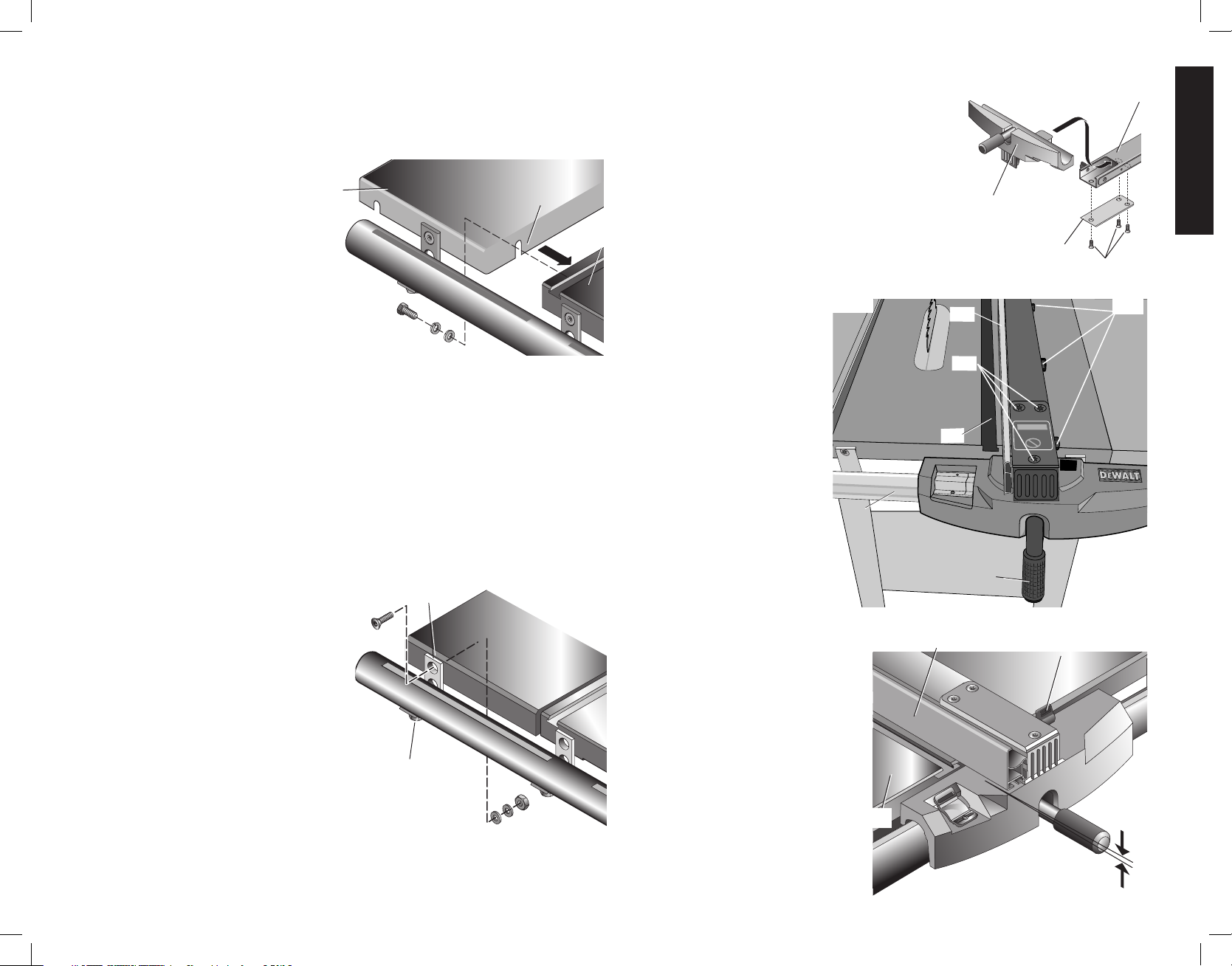

ASSEMBLE FRONT RAIL AND BRACKETS (FIG. 4)

IMPORTANT: DW746X includes a 30" precision fence rail system. A 30" or

52" precision rail system for the DW746 may be purchased at additional cost. Always follow the instructions included with the accessory. After assembling the rail system, refer to

Parallel the Rails to the Table Top.

If you need assistance with this accessory, please call 1-800-4-D

or visit our website www.dewalt.com.

You will Need: 4 – 8 mm Carriage Bolts

4 – 8 mm Lock Washers

4 – 8 mm Nuts

1. Unpack rail carton (contains front and rear rail).

2. Place the carriage bolts into each rail bracket (CC) as

shown.

3. Place lock washers and nuts onto carriage bolts and

tighten the nuts a few threads.

4. Place the head of the carriage bolt into keyhole slots in

the front rail and slide to engage the square part of the

bolt. Make sure the rip scale (DD) on the front rail and all

four brackets are facing up.

FIG. 2

M

AA

BB

FIG. 3

EWALT (1-800-433-9258)

DD

CC

K

FIG. 4

5. Tighten nut finger tight.

6. Repeat for other three brackets.

ATTACH FRONT RAIL WITH BRACKETS TO THE TABLE TOP (FIG. 5)

You will need: 2 – 10 x 30 mm Flat Head

FIG. 5

Screws

2 –10 mm Flat Washers

2 – 10 mm Lock Washers

2 – 10 mm Nuts

CC

1. Secure each screw through the upper hole

in the center rail brackets (CC) keeping the

flat washer, lock washer and nut on the

inside of the table (B).

2. Tighten snug, do not overtighten. Tighten

center rail bracket nuts, leaving the outer

nuts finger tight.

ATTACH REAR RAIL TO THE TABLE TOP (FIG. 6)

You will need: 2 – 10 x 35 mm

Hex Head Bolts

2 – 10 mm Flat Washers

2 – 10 mm Lock Washers

2 – 10 mm Nuts

1. Secure rear fence rail (A) to

FIG. 6

B

table top (B) using hex head

bolts, washers, lock washers

and nuts. Keep the washers

and nuts on the inside of the

table. The flat side should be

down unless you are also

A

mounting an accessory

(consult accessory instructions

for rail mounting details). Make

sure ends of the rear rail line

up with the ends of the

A

front rail.

2. Tighten snug, do not overtighten.

PARALLEL THE RAILS TO THE TABLE TOP (FIG. 7)

1. Use the fence face (F) to extend the table

FIG. 7

surface over the front fence rail (Q).

2. Use a ruler to measure the distance between

the table top and the rail at both ends of the

table top. The distance should be equal at

both ends.

F

3. If adjustment is needed, loosen the mount-

ing screws slightly and tap on the rail brack-

Q

ets with a soft hammer or regular hammer

and a block of wood until the distances are the same.

4. Tighten fasteners securely.

5. Repeat for the rear fence rail (A).

B

CC

B

A

6

Page 9

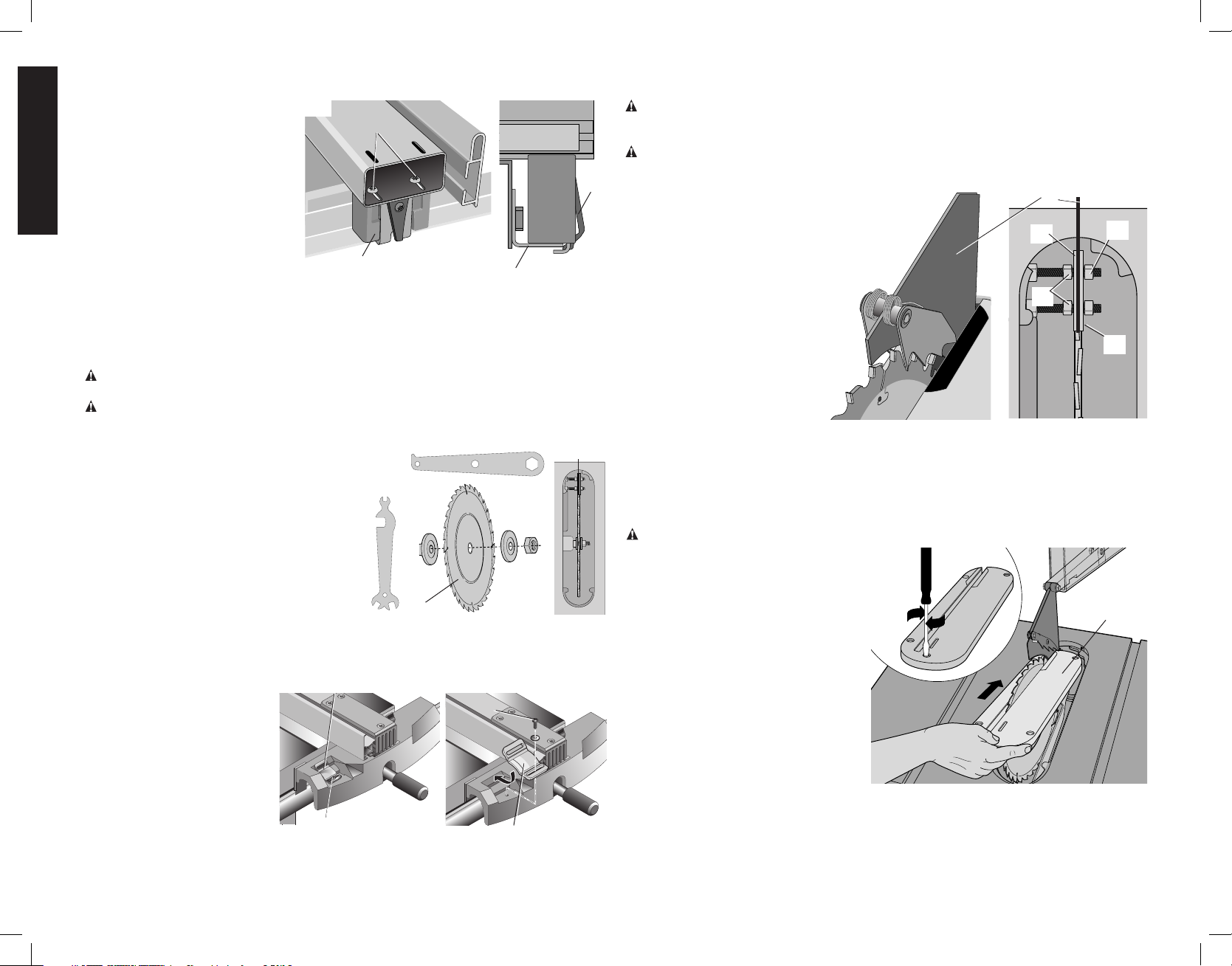

ATTACH THE LEFT & RIGHT SIDE SUPPORT TABLES (FIG. 8)

You will need: 6 – 10 x 25 mm Hex Head Bolts

6 – 10 mm Flat Washers

6 – 10 mm Lock Washers

1. Install the three bolts, flat washers

and lock washers in the holes in

the side of the table top (B) as

shown. Keep a 1/4" (6.4 mm)

FIG. 8

V

gap between the table top and

bolt heads.

2. Slide the side support table (V)

on the bolts, fitting into the

notches (FF). Do tighten nuts.

3. Use the fence face as a guide

to flush the support table to the

main table edge and snug the

front bolt. Repeat this process

for the rear bolt. Tighten the center bolt.

4. Repeat on the other side.

ATTACH FRONT AND REAR RAILS TO SUPPORT TABLES (FIG. 9)

You will need for front rail:

2 – 10 x 30 mm Flat Head Screws

2 – 10 mm Flat Washers

2 – 10 mm Lock Washers

2 – 10 mm Nuts

You will need for rear rail:

2 – 10 x 25 mm Hex Head Bolts

2 – 10 mm Flat Washers

2 – 10 mm Lock Washers

2 – 10 mm Nuts

1. Align front rail brackets (CC) with the side

support table (V) and tighten bracket nuts

(GG) to the rail.

FIG. 9

CC

2. Attach the support table to the outer front

rail brackets with the screws, flat washers,

lockwashers and nuts. Keep the washers

and nut on the inside of the table.

3. Attach the support table to the outer

rear rails with the bolts, flat washers,

lockwashers and nuts, Keep the washers

and nut on the inside of the table.

4. Using the fence face as a straight edge

make sure the support table is level with

or slightly below the table top. Adjust if

GG

needed and tighten all fasteners.

5. Repeat this procedure for the other support table.

FF

ASSEMBLE THE FENCE BEAM TO THE FENCE HEAD

(FIG. 10).

1. Remove the three flat head screws (HH) securing the

cover plate (JJ) to the fence beam with the T50 Torx

wrench.

2. Turn the rip fence (G) upside down. Slide the fence

beam (H) into the rip fence as shown.

3. Flip the fence beam over and install the cover plate

and three screws. Tighten snug, do not overtighten.

ADJUSTING FENCE TO TABLE TOP (FIG. 11)

B

IMPORTANT: Check alignment of beam and fence face

before each cutting session.

ALIGNING THE RIP FENCE

1. Place the fence face (F) on the

FIG. 11

front rail (Q) and rear rail (A)

close to the miter slot (W) at

the right-hand side of the

table.

2. Loosen the three locking knobs

(KK). Allow the fence face to

rest on the table top, then tighten the locking knobs (KK).

3. Slightly loosen the three screws

(HH).

4. Slide the fence and adjust the

beam angle until the fence

face is in line with the miter

slot (W).

Q

5. Lock the fence beam (H) in

place by pushing the rail locking lever (I) down.

6. Tighten the locking knobs (KK),

starting with the rearmost two.

ADJUSTING THE FENCE FACE

(FIG. 12)

1. Loosen the locking knobs (KK).

FIG.12

2. Set the fence face (F) so it clears the

table top (B) by approx. 1/16"

(1.6 mm).

3. If desired, adjust the fence face forward or backward.

4. Tighten the locking knobs (KK).

NOTE: For very thin workpieces, the

fence face can be set so it rests on the

table top. Make sure to set the fence

face so it clears the table top by approximately. 1/16" (1.6 mm) before moving

the fence.

B

FIG. 10

G

English

H

JJ

HH

KK

F

HH

W

I

F

KK

7

Page 10

ADJUSTING THE REAR FENCE GLIDE (FIG. 13)

1. Slide the rip fence (G) back

and forth to check if it slides

FIG.13

MM

freely over the rails.

2. Lock the rip fence in place

using the rail locking lever (I).

English

If there is excessive up/down

movement in the rear of the fence

when locking, the rear fence

bracket (LL) needs adjustment.

To adjust:

1. Loosen the screws (MM).

2. Set the retaining clip (NN) so

LL

A

that it slightly pushes on the rear rail (A).

3. Tighten the screws.

4. Ensure the fence still slides smoothly. If it does not, the retaining clip (NN) is pushing on

the rear rail (A) too strongly.

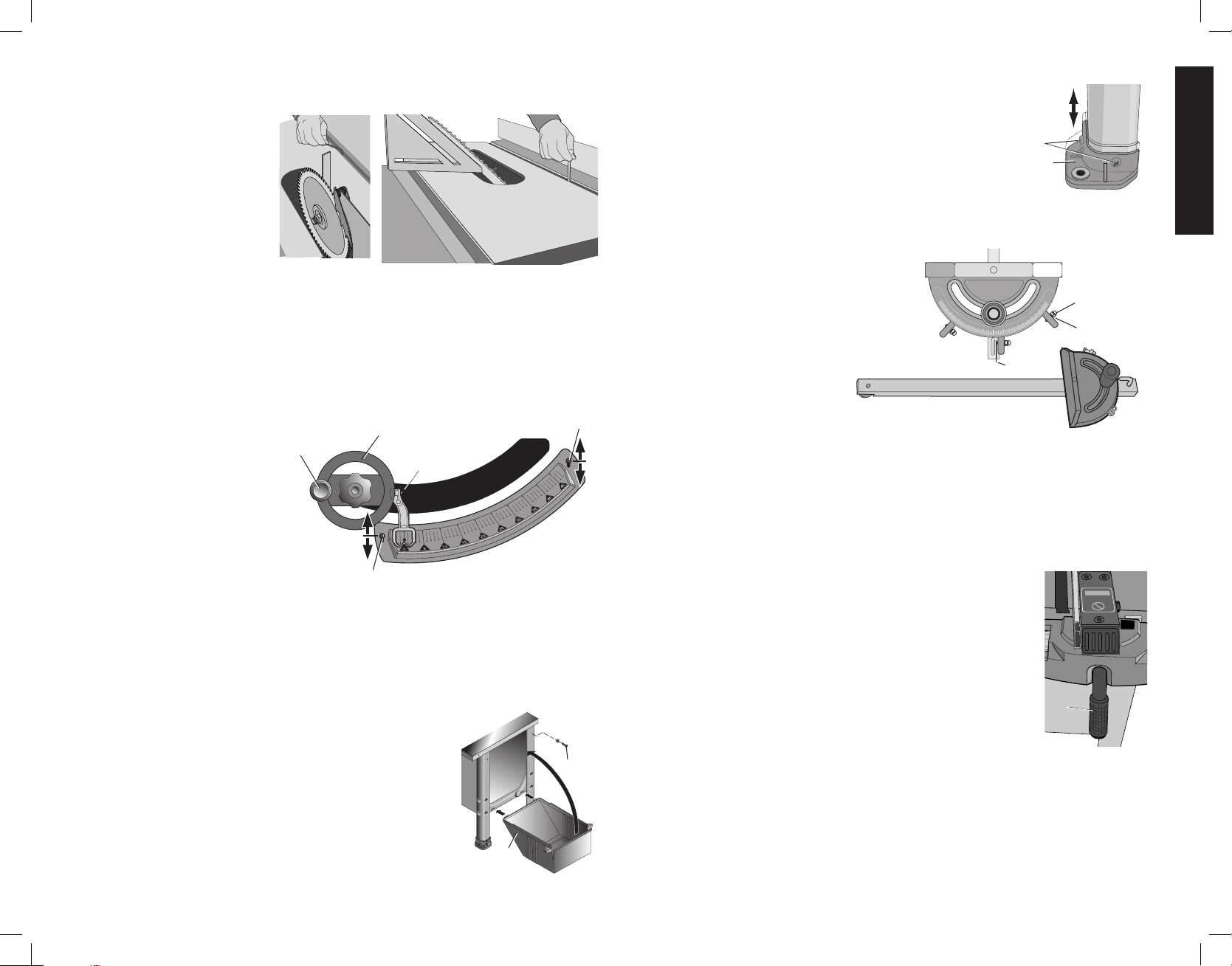

TO INSTALL THE SAW BLADE (FIG.14)

WARNING: Use ONLY 10" (254 mm) diameter blades with 5/8" (16 mm) arbor holes,

rated at 3600rpm or higher.

WARNING: To reduce the risk of injury. Wear gloves when handling saw blades.

1. Set the blade arbor highest position

using the blade height adjustment

wheel (M).

2. Remove the nut (OO) and outer clamp

washer (PP)

FIG. 14

SPINDLE

LOCK

WRENCH

BLADE WRENCH

3. Place the blade (D) onto the arbor with

the teeth pointing towards the front of

the saw.

QQ

PP

OO

4. Remount the outer clamp washer (PP)

and nut (OO) as shown. Make sure

that the saw blade is piloted on the

outer clamp washer hub (QQ).

5 Use the spindle lock wrench and blade

wrench to tighten the nut.

D

NOTE: If the nut fall into the interior of the saw, carefully remove it though the dust port.

ADJUST THE FENCE SCALE INDICATOR (FIG. 15).

1. Slide the fence until it just

touches the blade.

2. Loosen the fence indicator

FIG. 15

U

RR

screw (RR) and slide it until

the hairline aligns with the “0”

line on the scale.

3. Tighten the screw.

4. If the low profile fence face

accessory or a wider homemade fence face is used

which is out of the adjustment range of the pointer, the

RR

U

pointer (U) can be removed completely, turned 180 degrees, re-installed, and aligned

with the “0” line.

INSTALL THE GUARD AND SPLITTER ASSEMBLY (FIG. 16)

CAUTION: To prevent snagging of the workpiece, the table insert should be flush or

slightly below the surface of the table top and secured in place. The rear of the throat plate

should be flush or slightly above the table top. Refer to Install and Adjust Throat Plate.

CAUTION: When installing the throat plate, always make certain to hold on to the blade

guard. The insert will automatically release the holding action on the splitter and lower the

blade guard when it is installed in the table opening.

NN

1. Raise the blade to its highest

FIG. 16

C

point.

2. Loosen the outer guard

retaining nuts (SS) enough so

TT

the splitter (C) will fit between

the two guard retaining plates

(TT).

3. Install the splitter (C).

UU

4. Using a straight edge, check

to ensure the splitter is properly aligned with the blade. If

not, the position is adjusted

by moving the inner guard

clamp nuts (UU) to change

the location the splitter. Make

sure there is some clearance

between the splitter and the blade and the blade spins freely. If the splitter is tilted relative to the blade, the splitter plate can be bent until it lines up correctly. IMPORTANT:

THE GUARD SHOULD BE IN PLACE FOR ALL POSSIBLE CUTS. When making nonthrough cuts, the guard can be easily removed by slightly loosening the outer guard nuts

(SS). The guard can easily be replaced without having to readjust the inner nuts.

INSTALL AND ADJUST THE THROAT PLATE (FIG. 17)

CAUTION: To reduce the risk of injury. The throat plate must be in place at all times.

1. Align the throat plate (VV) as shown

FIG. 17

and insert the tabs on the back of the

throat plate into the holes at the back

of the table and lower the plate into its

opening.

2. The throat plate includes four adjustment screws which raise or lower it.

When properly adjusted, the front

of the throat plate should be flush

or slightly below the surface of the

table top, and the rear of the throat

plate should be flush or slightly above

the table top. The center front screw,

when turned clockwise, will engage

a cam under the front lip of the

table, locking the throat plate in place.

Rotate the screw counterclockwise

1/2 turn to remove the throat plate.

SS

TT

VV

8

Page 11

ADJUST THE BEVEL STOPS (FIG. 18)

1. Using a square, set the blade

FIG. 18

to exactly “0” degrees. If the

blade stops beveling before it

gets to 0, loosen the stop set

screw (located in the left

miter guide slot) with the

5 mm hex wrench and then

proceed to “0” degrees. With

the blade set at 0, slowly turn

the zero stop screw in until

you feel resistance. Bevel the

blade away from 0 a little

then back to the stop.

2. Remeasure the angle and repeat the stop adjustment as necessary until the blade

stops at 0 degrees.

3. Set the 45 stop the same way. The set screw for the 45° stop is located in the right

hand miter guide slot.

For some special cuts, the stops can be backed out and the saw will bevel from –2 degrees

to 47 degrees.

ADJUST THE BEVEL SCALE (FIG. 19)

1. Bevel the saw until it hits the

zero bevel stop.

2. Remove the lock knob (BB)

and blade height adjustment

FIG. 19

BB

M

WW

XX

wheel (M).

3. Adjust the red pointer by

loosening the screw (WW)

where it attaches to its shaft,

move the pointer until it lines

up with the 0 line on the

scale, and retighten the

screw. The pointer should

XX

be positioned just barely off

of the scale surface.

4. Bevel the saw to the 45º stop. If the pointer doesn’t point to 45º, loosen the two screws

(XX) which hold the scale to the saw front panel and slide the scale up or down until

the pointer lines up with the 45 line. Retighten the scale screws.

5. Replace the blade height adjustment wheel and lock knob.

INSTALL THE MOTOR COVER (FIG. 20)

1. Remove the two cover screws and washers (YY) from

the top of the two side legs with a small flat blade

FIG. 20

screwdriver.

2. Snap the two bottom tabs of the cover (J) into the slots

in the right lower crossmember.

YY

3. Place the cover in position and reinstall the screws and

washers.

LEVEL THE SAW (FIG. 21)

FIG. 21

1. Place the saw in the location it is going to be used.

2. If the saw rocks on the floor, the foot not touching the floor can

be lowered to compensate for the uneven floor.

a. Loosen the two screws (ZZ) that hold the foot (L) to the leg.

Let the foot fall to the floor surface.

ZZ

L

b. Retighten the screws holding the foot to the leg.

If your saw will have a permanent location, we recommend bolting

the feet to the floor using the holes provided.

ADJUSTMENT AND USE OF MITER GAUGE (FIG. 22)

Your miter gauge features adjustable

FIG. 22

stops at 90° and 45° left and right.

To adjust these stops:

a. Loosen the lock nuts (A1) and

tighten or loosen the three

adjusting screws (A2).

30

45

60

75

90

30

45

60

75

A2

A1

b. Check the gauge with a square

against the blade and tighten

the three adjusting screws.

A3

c. To set the miter gauge past

the 45 degree stops, flip up the

stop plate (A3) and continue to

the required angle.

CLEAN THE TABLE TOP

Your saw was shipped with a rust preventive coating which should be removed. Clean the top

with mineral spirits or denatured alcohol and apply paste wax. Apply and remove soon afterward to prevent a sticky build-up.

Rip Fence Operation

RAIL LOCK LEVER (FIG. 23)

The rail lock lever (I) locks the fence in place preventing movement during

cutting. To lock the rail lever, push it down and toward the rear of the

saw. To unlock, pull it up and toward the front of the saw.

NOTE: When ripping, always lock the rail lock lever.

RIP SCALE POINTER

NOTE: The rip scale pointer will need to be readjusted whenever a

thicker or thinner blade is installed. Should you decide to use a thicker

face, or the D

EWALT low fence face acces sory, the scale pointer may be

removed and turned 180° to line up with the scale. Refer to Adjust the

Fence Scale Indicator under Assembly.

RIP FENCE CAPACITY

The rip fence will slide beyond the end of the rails in either direction without falling off. Stops are provided to keep the fence attached.

FIG. 23

I

English

J

9

Page 12

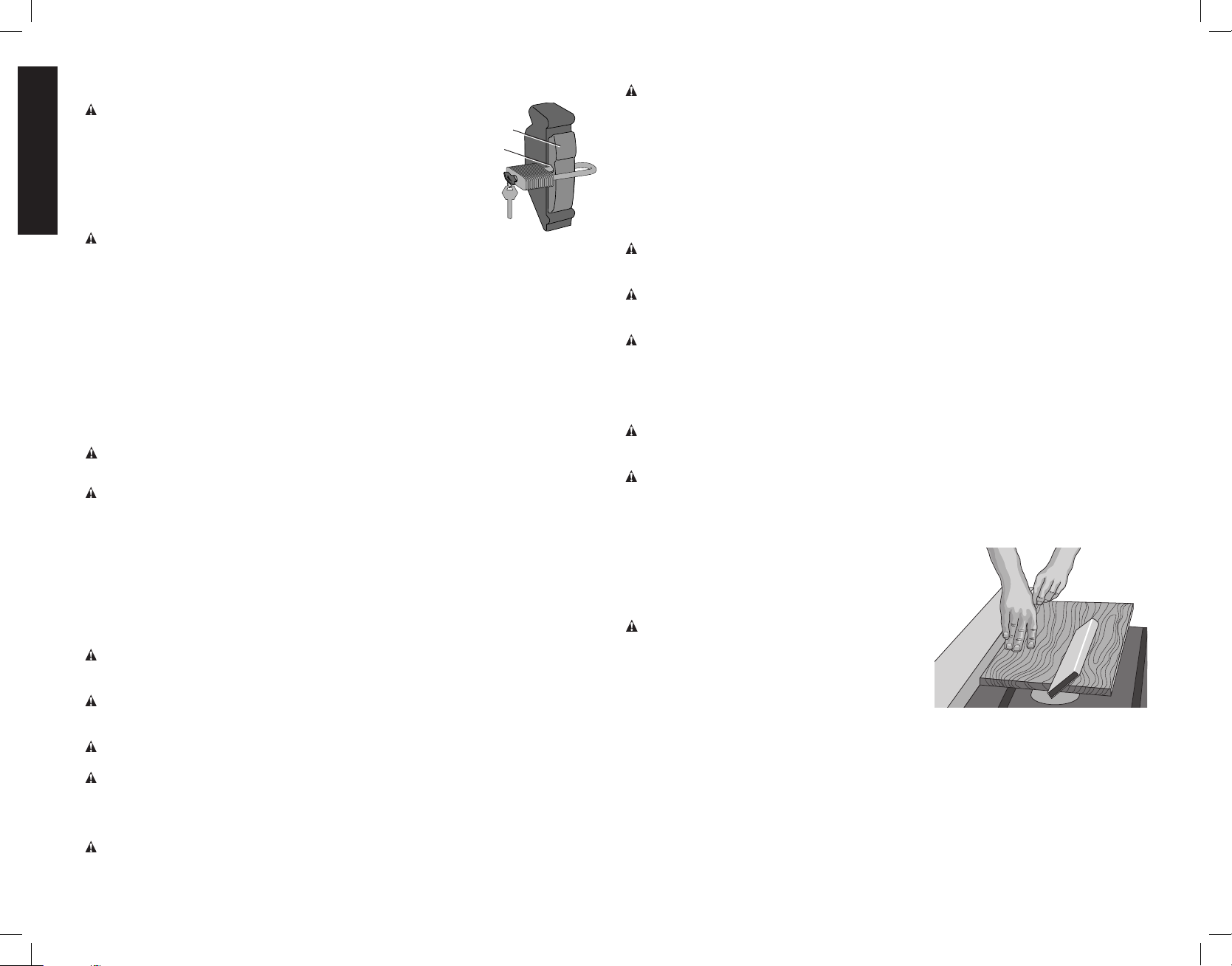

On-Off Switch (Fig. 24)

WARNING: To reduce the risk of injury, be sure switch is in the

OFF position before plugging machine in.

Lift the ON/OFF switch (O) paddle up to turn your saw ON and push

it down to turn your saw OFF.

A hole (A4) is provided in the switch for insertion of a padlock with

English

a removable shank to lock the saw off.

NOTE: A conventional padlock will not fit.

FIG. 24

O

A4

Saw Blades

CAUTION: Use ONLY 10" (254 mm) diameter blades with 5/8"

(16 mm) arbor holes, rated at 3600rpm or higher.

1. The saw blade furnished with your new saw is a 10" (254 mm) fine ripping blade, used

for ripping (with the grain) through the material, and occasional cross cuts. The center

hole to fit on the arbor is 5/8" (16 mm) diameter. This blade will produce a good quality

cut for many applications.

2. There are many types of blades available to do specific and special jobs such as

cross cut only, rip only, hollow ground, thin plywood, paneling, etc.

3. Use only saw blades designed for maximum safe operating speeds of 5,000 RPM or

greater.

4. Saw blades should always be kept sharp. It is recommended that you locate a reputable sharpening service to sharpen your blades when needed.

5. Never stack blades on top of one another to store. Place material such as cardboard

between them to keep the blades from coming in contact with one another.

CAUTION: Abrasive wheels should not be used on this saw.

Operation

WARNING: Before using the saw, verify the following each and every time:

1. ALWAYS wear proper eye, hearing and respiratory equipment.

2. Blade is tight.

3. Bevel angle and height lock knobs are tight.

4. If ripping, ensure rail fence lock lever is tight and fence is parallel to the blade.

5. If crosscutting, miter gauge knob is tight.

6. The blade guard is properly attached and the anti-kickback teeth are functioning.

7. ALWAYS inspect the guard and splitter for proper alignment operation and clearance with

saw blade.

Failure to adhere to these common safety rules can greatly increase the likelihood of injury.

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or changing set-

ups or when making repairs. An accidental start-up can cause injury.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the guard and splitter for proper operation alignment and clearance with saw

blade. Personal injury may result.

CAUTION: If your saw makes an unfamiliar noise or if it vibrates excessively, cease operating

immediately until the source has been located and the problem corrected.

CAUTION: The proper throat plate must be in place at all times to reduce the risk of a thrown

workpiece and possible injury.

THIS SAW IS NOT INTENDED FOR CUTTING METAL.

Cutting

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from power

source before installing and removing accessories, before adjusting or changing set-ups or

when making repairs. An accidental start-up can cause injury.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the guard and splitter for proper operation alignment and clearance with saw

blade. Personal injury may result.

There are two basic types of cuts: ripping and crosscutting. In general, cutting with the

grain is ripping and across the grain is crosscutting. However, with man made materials this

distinction is somewhat difficult to make. Therefore, cutting a piece of wood to a different

width is ripping and cutting across the short dimension is crosscutting. Neither ripping or

crosscutting may be done safely freehand! Ripping requires the use of the rip fence and

crosscutting uses the miter gauge.

Ripping

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or changing

set-ups or when making repairs. An accidental start-up can cause injury.

WARNING: Never touch the “free end” of the workpiece or a “free piece” that is cut off,

while the power is ON and/or the saw blade is rotating. Piece may contact the blade resulting in a thrown workpiece of possible injury

WARNING: Keep saw blade guard, splitter and anti-kickback teeth in place and operat-

ing properly. Keep teeth sharp. If teeth are not operational, return your unit to the nearest

authorized D

blade and the teeth must stop a kickback once it has started. Check their action before ripping by pushing the wood under the anti-kickback teeth. The teeth must prevent the wood

from being pulled toward the front of the saw.

WARNING: A rip fence should ALWAYS be used for ripping operations to prevent loss

of control and personal injury. NEVER perform a ripping operation freehand. ALWAYS lock

the fence to the rail.

WARNING: When bevel ripping and whenever possible, place the fence on the side of

the blade so that the blade is tilted away from the fence and hands. Keep hands clear of the

blade and use a push stick to feed the workpiece if there is less than 6" (152 mm) between

the fence and the blade.

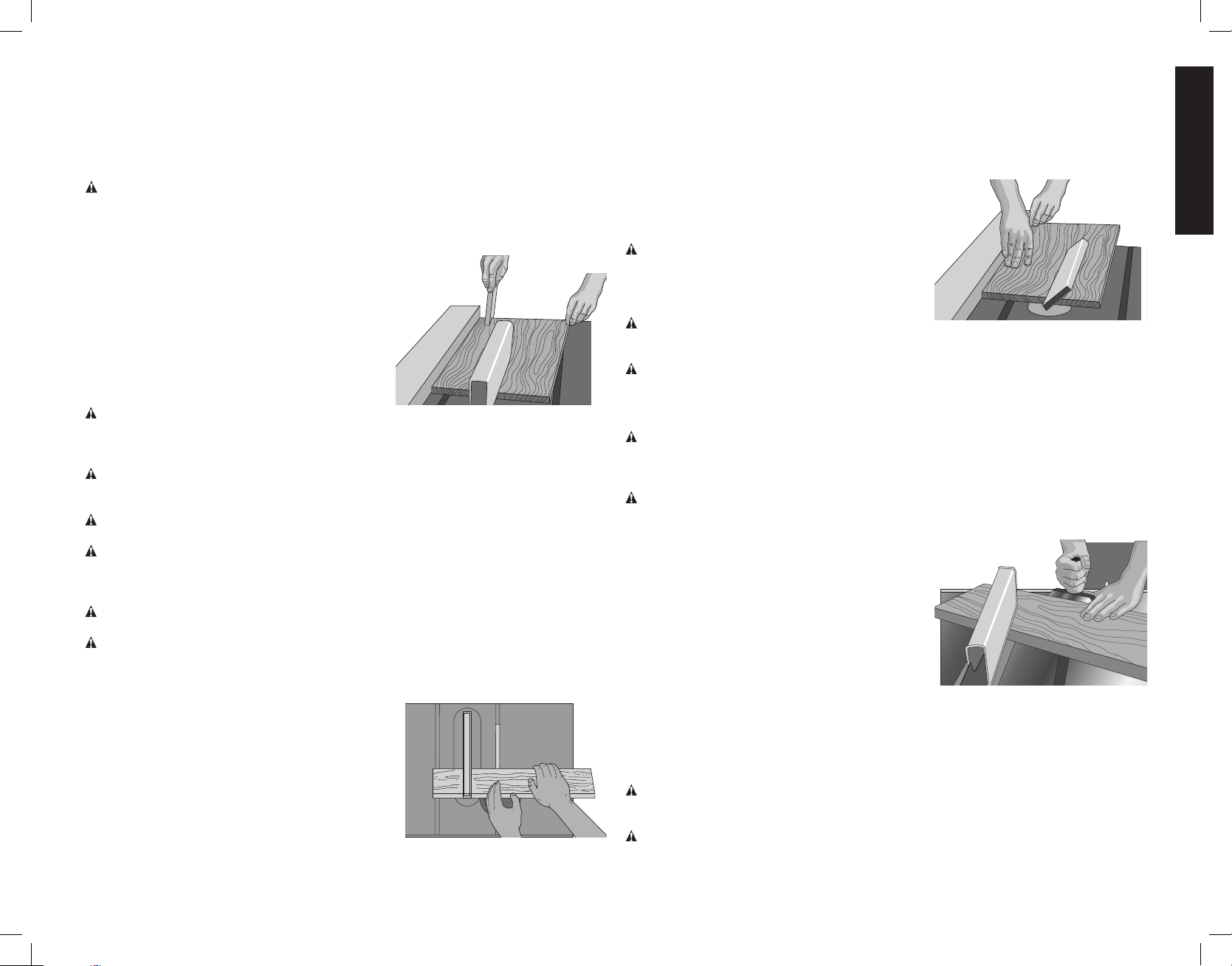

1. Lock the rip fence by pressing the rail lock lever down. Remove the miter gauge.

2. Raise the blade so it is about 1/8" (3.2 mm)

higher than the top of the workpiece.

3. Hold the workpiece flat on the table and against

the fence. Keep the workpiece about 1" (25.4 mm)

away from the blade.

CAUTION: The workpiece must have a straight

edge against the fence and must not be warped,

twisted or bowed. Keep both hands away from the

blade and away from the path of the blade.

4. Turn the saw on and allow the blade to come up

to speed. Both hands can be used in starting the

cut. When there is approximately 12" (305 mm) left to be ripped, use only one hand,

with your thumb pushing the material, your index and second finger holding the material

down and your other fingers hooked over the fence. Always keep your thumb along side

your first two fingers and near the fence.

5. Keeping the workpiece against the table and fence, slowly feed the workpiece rearward

all the way through the saw blade. Continue pushing the workpiece until it is clear of the

guard and it falls off the rear of the table. Do not overload the motor.

6. NEVER try to pull the workpiece back with the blade turning. Turn the switch off, allow

the blade to stop, raise the anti-kickback teeth on each side of the splitter if necessary

and slide the workpiece out.

EWALT service center for repair. The splitter must be in alignment with the saw

FIG. 25

10

Page 13

7. When sawing a long piece of material or a panel, always use a work support. A sawhorse,

rollers or out feed assembly provides adequate support for this purpose. The work sup-

port must be at the same height as the saw table.

Bevel Ripping

This operation is the same as ripping except the bevel angle is set to an angle other than

zero degrees.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the guard and splitter for proper alignment and clearance with saw blade.

Check alignment after each change of bevel angle.

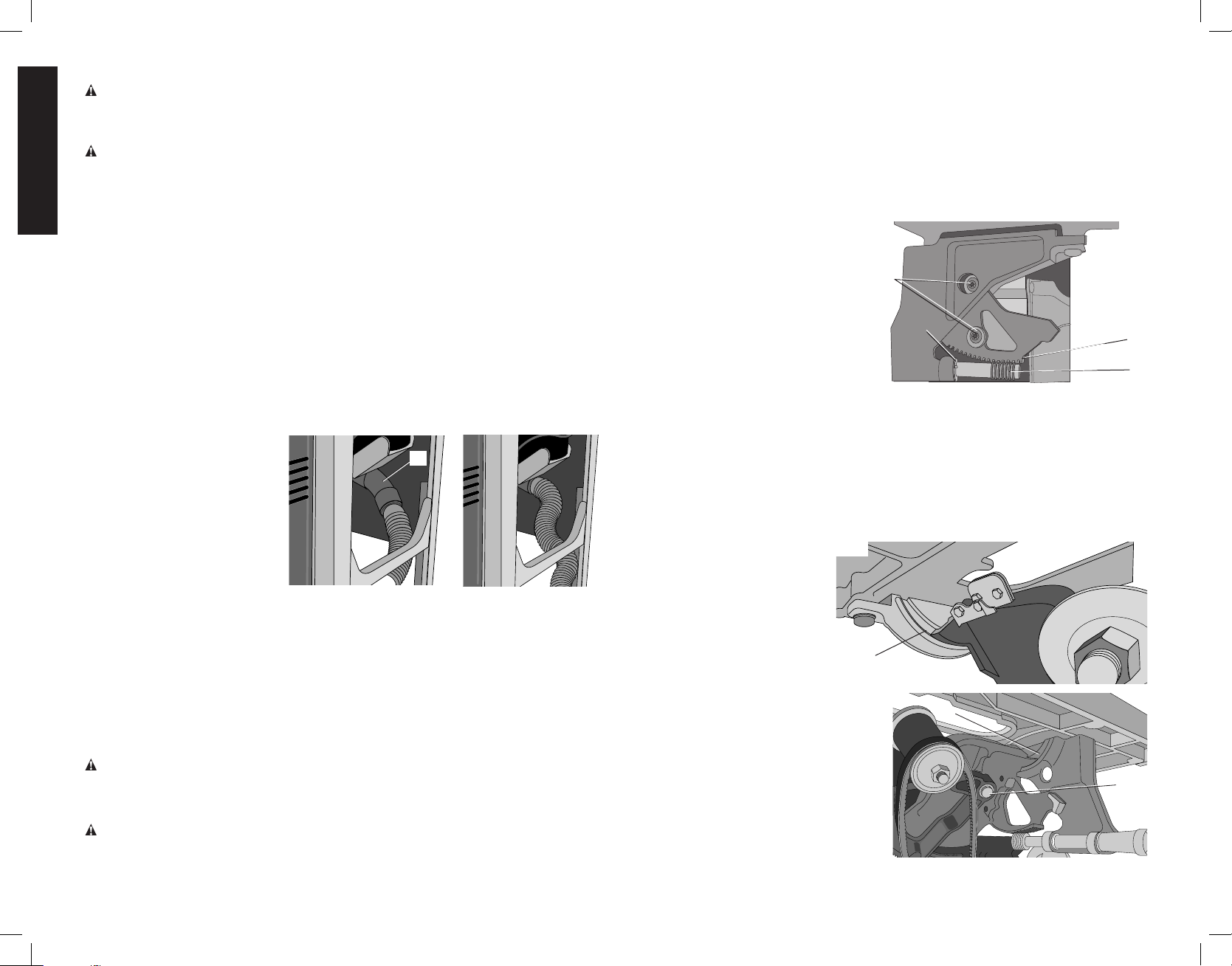

Ripping Small Pieces

It is unsafe to rip small pieces. It is not safe to put your

hands close to the blade. Instead, rip a larger piece to

obtain the desired piece. When a small width is to be

ripped and the hand cannot be safely put between the

blade and the rip fence, use one or more push sticks.

A pattern is included on the inside back cover to make

push sticks. Use them to hold the workpiece against

the table and fence, and push the workpiece fully past

the blade

FIG. 26

Crosscutting

WARNING: To reduce the risk of injury, turn unit

off and disconnect machine from power source before installing and removing accessories,

before adjusting or changing set-ups or when making repairs. An accidental start-up can

cause injury.

WARNING: NEVER touch the “free end” of the workpiece or a “free piece” that is cut off,

while the power is ON and/or the saw blade is rotating. Piece may contact the blade resulting in a thrown workpiece and possible injury.

WARNING: To reduce the risk of injury, NEVER use the fence as a guide or length stop

when crosscutting.

WARNING: NEVER use a length stop on the free end of the workpiece when crosscutting.

In short, the cut-off piece in any through-sawing (cutting completely through the workpiece)

operation must never be confined — it must be allowed to move away from saw blade to

prevent contact with blade resulting in a thrown workpiece and possibly injury.

WARNING: Use caution when starting the cut to prevent binding of the guard against the

workpiece resulting in damage to saw and possible injury.

CAUTION: When using a block as a cut-off gauge, the block must be at least 3/4" (19 mm)

thick and is very important that the rear end of the block be positioned so the workpiece is

clear of the block before it enters the blade to prevent contact with blade resulting in a thrown

workpiece and possibly injury.

1. Remove the rip fence and place the miter gauge

in the desired slot.

2. Adjust the blade height so that the blade is about

1/8" (3.2 mm) higher than the top of the workpiece.

3. Hold the workpiece firmly against the miter gauge

with the path of the blade in line with the desired

cut location. Keep the workpiece an inch or so in

front of the blade. KEEP BOTH HANDS ON THE

MITER GAUGE, AWAY FROM THE BLADE AND

THE PATH OF THE BLADE.

4. Start the saw motor and allow the blade to come up to speed.

FIG. 27

5. While using both hands to keep the workpiece against the face of the miter gauge,

and holding the workpiece flat against the table, slowly push the workpiece through the

blade.

6. NEVER try to pull the workpiece back with the blade turning. Turn the switch off, allow

the blade to stop, and carefully slide the workpiece out.

Bevel Crosscutting

This operation is the same as crosscutting except

that the bevel angle is set to an angle other than 0

degrees. For proper hand position, refer to

Figure 28.

WARNING: To reduce the risk

unit off and

source before installing and removing accessories,

before adjusting or changing set-ups or when making repairs. An accidental start-up can cause injury.

WARNING: Use caution when starting the cut to

prevent binding of the guard against the workpiece resulting in damage to saw and possible

personal injury.

WARNING: Before connecting the table saw to the power source or operating the saw,

always inspect the guard and splitter for proper operation alignment and clearance with saw

blade. Check alignment after each change of bevel angle.

disconnect machine from power

of injury, turn

FIG. 28

Mitering

WARNING: Miter angles greater than 45˚ may force the guard into the saw blade causing

damage to the guard and personal injury. Before starting the motor, test the operation by

feeding the workpiece into the guard. If the guard contacts the blade, place the workpiece

under the guard, not touching the blade, before starting the motor.

CAUTION: Certain workpiece shapes, such as molding may not lift the guard properly.

Feed the workpiece slowly to start the cut. If the guard contacts the blade, place the workpiece under the guard, not touching the blade, before starting the motor.

This operation is the same as crosscutting except the

miter gauge is locked at an angle other than 0°. Hold

the workpiece FIRMLY against the miter gauge and

feed the workpiece slowly into the blade (to prevent

the work piece from moving).

MITER GAUGE OPERATION

To set your miter gauge, loosen the lock handle and

move the miter gauge to the desired angle. The miter

gauge has set stops and 90° and 45° left and right.

To rotate the miter gauge beyond these stops, flip the

stop plate up.

FIG. 29

Compound Mitering

This is a combination of bevel crosscutting and mitering. Follow the instruction for both,

bevel crosscutting and mitering.

Dado Cutting

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from power

source before installing and removing accessories, before adjusting or changing set-ups or

when making repairs. An accidental start-up can cause injury.

WARNING: Use push sticks, hold-downs, jigs, fixtures or feather boards to help guide and

control the workpiece when the guard cannot be used to prevent personal injury.

English

11

Page 14

WARNING: For non-through cutting operations, such as dadoing and molding, the blade

guard and splitter assembly MUST BE removed. ALWAYS return and fasten the blade

guard and splitter assembly to its proper operating position for normal through-sawing

operations.

CAUTION: DO NOT attempt to stack or adjust dado blades thicker than 13/16" (20 mm).

Do not use dado blades larger than 8" (200 mm) diameter. Always check dado blade clearance before plugging in the saw to prevent damage to saw and personal injury.

English

Because dado cuts are not through cuts, the cuts must be performed with the blade guard

removed. To remove the blade guard, loosen the two bolts (SS) shown in Figure 16 and

remove the guard assembly.

Anytime a cut is required that is considerably wider than the saw kerf, a dado is used. When

using the dado, the special dado insert (also sold as an accessory) must be used. When

installing the dado blade set, it may be necessary to eliminate the outer clamp washer from

the assembly in order to capture sufficient thread to safely hold the dado blade set.

A dado cut is commonly used to add support and line up a shelf for a cabinet, bookcase or

some such project. When using the dado, the guard must be removed. Use EXTREME care

when using the dado without the guard. If a deep cut is required, use several successive

passes rather than attempting to make it with one pass. Maximum dado width on this saw

is 13/16" (20 mm). DO NOT USE WIDER COMBINATIONS.

When cutting with a dado blade use dust collection to prevent heavy dust loads from piling

up under the saw and on the fan intake on the motor. Clean these areas often.

Dust Collection

Your table saw is equipped with a

dust shroud and dust collection

port. For best results, connect a

vacuum to the port (T) at the rear

of the saw.

If the saw is operated without a

vacuum attached, most of the dust

will be blown out the dust collection port. After extended use, the

saw’s dust collection system may

become clogged.

TO CLEAR THE DUST COLLECTION SYSTEM

a. Unplug the saw.

b. Use a paint stick or long screwdriver to loosen debris and cut-offs and pass it out

through the port.

When cutting wet wood without a vacuum, making long narrow cut-offs or when cutting with

a dado blade, clean the dust collection port each time. If you find you are clogging the port

often, the dust port elbow may be removed by loosening the two screws where it attaches to

the dust shroud. A dust collection hose can then be attached directly to the shroud as long

as the saw is not beveled past 35°.

FIG. 30

T

MAINTENANCE

WARNING: To reduce the risk of injury, turn unit off and disconnect machine

from power source before installing and removing accessories, before adjusting or

changing set-ups or when making repairs. An accidental start-up can cause injury.

Cleaning

WARNING: When cleaning, use only mild soap and a damp cloth on plastic parts. Many

household cleaners contain chemicals which could seriously damage plastic. Also, do not

use gasoline, turpentine, lacquer or paint thinner, dry cleaning fluids or similar products

which may seriously damage plastic parts. Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid.

TABLE TOP

Protect your investment. Keep your table saw clean. If you notice signs of rust, steel wool the

areas, clean with mineral spirits or denatured alcohol and apply paste wax.

Over time, the lubricants used in the mechanism of your table saw may need to be

replenished.

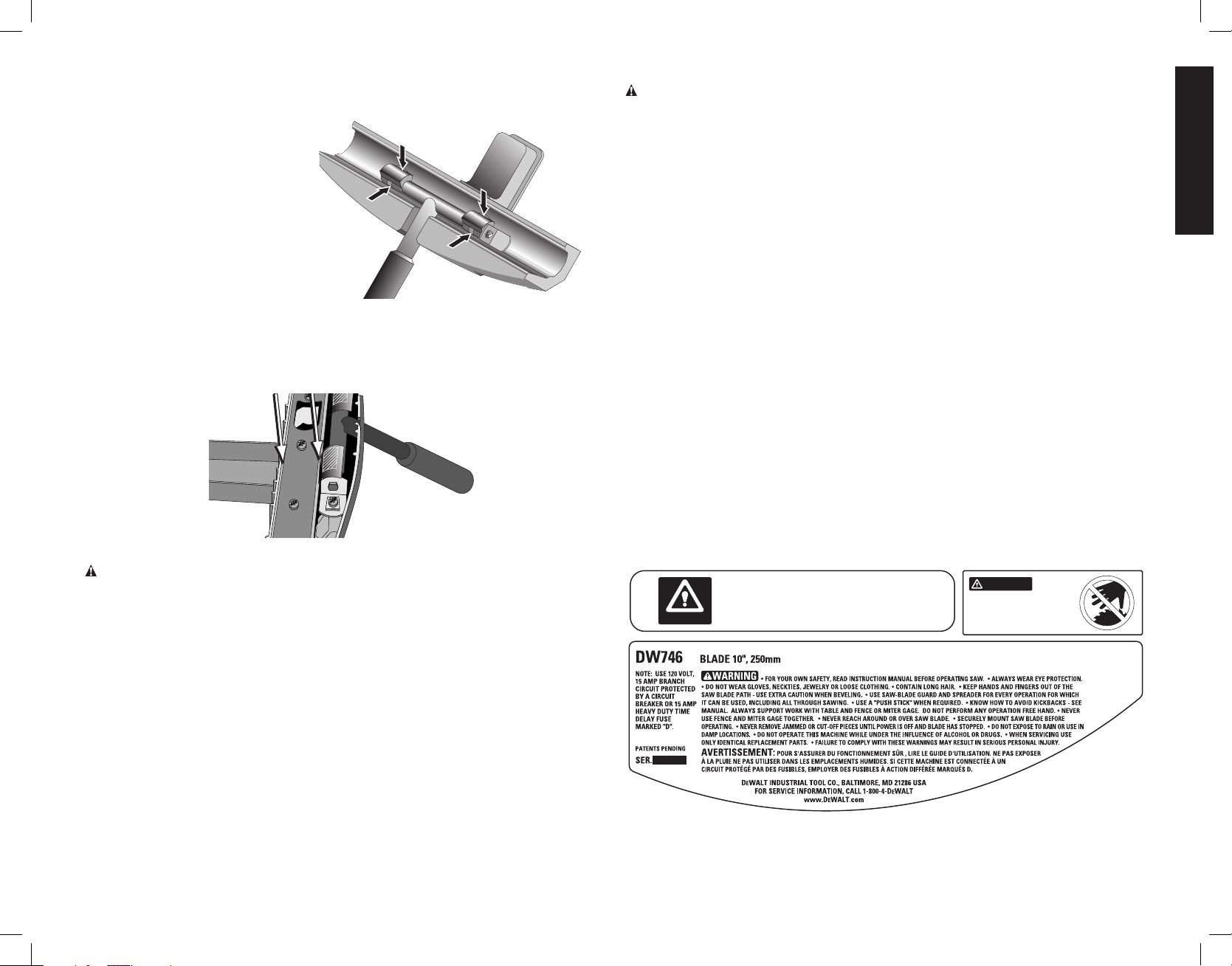

HEIGHT AND BEVEL GEAR (FIG. 31)

1. Clean accumulated sawdust

from the gears and the worms

with a stiff brush.

2. Remove built up pitch or resin

from the gears and the worms

with a stiff brush. You may need

to use a solvent such as mineral

spirits to remove it.

3. Reapply grease to the worms

(A8), gears (A7) and the washer/

pin assembly (A6). You can also

apply paste wax to the gears if

you find that the grease is attracting too much sawdust.

4. If any backlash has occurred in the bevel system, you can readjust the bevel gear clearance. To adjust:

a. Loosen the two screws (A5) holding the gear to the cradle, let the gear fall into tighter

mesh

b. Lightly tighten the screws and rotate the worm one full turn to set the gear height.

Tighten the gear retaining screws. NOTE: This adjustment must be made at 0°

bevel.

BEVEL PIVOT

The bevel pivot trunnions, both

front and back should also be

maintained. First clean them like

the gears were cleaned. Then

apply grease into the curved

slots (A9) and bevel the saw

back and forth to distribute the

grease.

ARBOR PIVOT

You may also need to lubricate the

arbor pivot pin (A10). This can be

done by applying a light oil at both

the base and top of the pivot pin.

FIG. 31

A5

A6

A7

A8

FIG. 32

A9

FIG. 33

A9

A10

12

Page 15

Lubricating Fence Head

The moving parts of your fence head

should be periodically greased. This

includes the area between the cams

and locking levers, and between the

cams and the fence head casting.

FIG. 34

Maintaining Fence

System

Your fence should always slide freely. If

it seems to require excessive force to

slide or if it feels rough, wipe the rails

and fence head gliding surface with a

cloth or paper towel. Check the movement again. If it still feels rough, clean

the fence head with a mild solvent such as denatured alcohol or mineral spirits. Re-coat the

rail with a heavy coat of paste wax or a light oil. Slide the fence head back and forth several

times to coat the rail and fence. Wipe off any excess wax or oil from the rail.

If the fence head glide strips (arrows, Figure 35) become worn or damaged, it can easily be

replaced. Consult your local D

FIG. 35

EWALT Service Center for parts and assistance.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the

risk of injury, only D

If you need assistance in locating any accessory for your tool, please contact D

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-D

(1-800-433-9258) or visit our website www.dewalt.com.

D

EWALT manufactures the following accessories for your saw:

Mobile base

Sliding Table and Premium Gauge

Iron Wing

Outfeed Table

52" Rail System

Dado Throat Plate

Steel Wing

30" Rail System

Low Profile Fence Face

Enhanced Miter Gauge

EWALT, recommended accessories should be used with this product.

EWALT

EWALT

WARNING: Accessories mounted to the arbor shaft must be rated at a higher rpm than

that shown on the tool (not motor) nameplate. Destruction to accessory and possibly injury

may result.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement) should be performed by a D

center, a D

EWALT authorized service center or other qualified service personnel. Always

use identical replacement parts.

EWALT factory service

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4-D

not apply to accessories or damage caused where repairs have been made or attempted

by others. This warranty gives you specific legal rights and you may have other rights which

vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any

D

time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your D

or Nailer for any reason, you can return it within 90 days from the date of purchase with a

receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-D

WARNING

EWALT for a free replacement.

• USE SAW BLADE GUARD AND SPLITTER FOR EVERY

OPERATION WHICH IT CAN BE USED, INCLUDING ALL

THROUGH SAWING.

• KEEP HANDS OUT OF THE LINE OF SAW BLADE.

• USE A PUSH-STICK WHEN REQUIRED.

EWALT (1-800-433-9258). This warranty does

EWALT Power Tool, Laser,

DANGER PELIGRO

KEEP HANDS AWAY

FROM BLADE

MANTENGASE ALEJADO

DE LA HOJA DE SIERRA

English

13

Page 16

Troubleshooting

SAW WILL NOT START WHAT TO DO

1. Saw not plugged in. 1. Plug in saw.

2. Fuse blown or circuit breaker tripped. 2. Replace fuse or reset circuit breaker.

3. Cord damaged. 3. Have cord replaced by authorized

English

SAW MAKES UNSATISFACTORY CUTS WHAT TO DO

1. Dull blade. 1. Replace blade. Page 8.

2. Blade mounted backwards 2. Turn blade around. Page 8.

3. Gum or pitch on blade. 3. Remove blade and clean with turpen-

4. Incorrect blade for work being done. 4. Change blade type. Page 8.

BLADE DOES NOT COME UP TO SPEED WHAT TO DO

1. Extension cord too light or too long. 1. Replace with adequate size cord.

2. Low house current 2. Contact your electric power company.

3. Belt worn or broken. 3. Replace belt. See D

MACHINE VIBRATES EXCESSIVELY WHAT TO DO

1. Saw on uneven floor 1. Reposition on flat surface. Adjust feet

2. Damaged saw blade. 2. Replace blade. Page 8.

3. Saw not secured to floor. 3. Fasten saw to floor.

4. Damaged belt. 4. Replace belt.

INACCURATE MITER CUTS WHAT TO DO

1. Miter gauge not adjusted correctly 1. Check and adjust. Page 9.

2. Miter gauge not square to blade. 2. Check and adjust. Page 9.

3. Blade not perpendicular to table. 3. Check and adjust bevel stops.

4. Workpiece moving. 4. Clamp workpiece to miter head face.

MATERIAL BINDING DURING CUT WHAT TO DO

1. Cutting bowed material. 1. Material should be laid flat at the

2. Fence not aligned parallel to blade. 2. Align fence. Page 7.

3. Splitter not aligned with blade. 3. Align splitter. Page 8.

service center.

tine and coarse steel wool or household oven cleaner.

Page 1.

EWALT service

center

to stabilize. Page 9.

Page 9.

Glue 120 grit sandpaper to miter

head face.

point of cut and supported with scrap

and/or miter gauge.

INACCURATE RIP CUTS WHAT TO DO

1. Rip scale pointer not aligned. 1. Adjust pointer. Page 8.

INACCURATE BEVEL CUTS WHAT TO DO:

1. Bevel scale not adjusted. 1. Adjust scale. Page 9.

2. Bevel stops not adjusted. 2. Adjust bevel stops. Page 9.

REAR OF FENCE POPS UP WHEN

FENCE LOCKS

1. Rear clip not engaged with rear rail. 1. Re-attach fence. Be sure clip is

2. Rear cap/clip not positioned correctly 2. Adjust rear cap position. Page 8.

FENCE DOES NOT SLIDE FREELY WHAT TO DO

1. Fence drags or hops as it is moved. 1. Clean front and rear rails. Reapply

2. Rear cap/clip interferes rear of saw. 2. Adjust rear cap position. Page 7.

FENCE HITS TABLE TOP OR GAP

CHANGES AS IT IS SLID ALONG THE

RAILS

1. Front and/or rear rail not parallel to table. 1. Adjust rails so that they are parallel.

2. Support tables not aligned with table top 2. Adjust support tables to align with

3. Fence face drags along table surface. 3. Adjust fence face. Page 7.

HEIGHT OR BEVEL CRANKS

HARD TO TURN

1. Crank locks engaged. 1. Loosen lock knob 1/4 to 1/2 turn.

2. Sawdust, pitch on height or bevel gears

making operation difficult.

DUST PORT CLOGS WHAT TO DO

1. Vacuum not attached 1. Attach vacuum. Page 12.

2. Cutting small slivers or chunks 2. Remove dust port. Use paint stick

WHAT TO DO

engaged. Page 8.

wax. Page 13.

WHAT TO DO

Page 6.

top. Page 7.

WHAT TO DO

2. See Maintenance, page 12.

or screwdriver to dislodge debris or

leave port off. Page 12.

14

Page 17

Définitions : lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur

employé. Veuillez lire le mode d’emploi et porter une attention particulière à ces

symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas

évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si

elle n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

MISE EN GARDE : indique une situation potentiellement dangereuse

qui, si elle n’est pas évitée pourrait se solder par des blessures mineures ou

modérées.

MISE EN GARDE : utilisé sans le symbole d’alerte à la sécurité, indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder par des

dommages à la propriété.

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FAIRE PART DE VOS

COMMENTAIRES CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL D

COMPOSEZ SANS FRAIS LE : 1-800-4-D

EWALT (1-800-433-9258).

EWALT,

Règles de sécurité générales

AVERTISSEMENT : lire toutes les directives avant d’utiliser le produit. Tout

manquement aux directives suivantes pose des risques de choc électrique, d’incendie

et/ou de blessure grave.

CONSERVER CES DIRECTIVES

AVERTISSEMENT : SUIVRE TOUS LES CODES DE CÂBLAGE et les branchements

électriques recommandés afin d’éviter tout choc électrique ou électrocution.

Directives relatives à la mise à la terre

Si la scie est mise à la terre (intégré), lire les directives suivantes.

DANGER : RISQUE D’ÉLECTROCUTION. LE PRÉSENT APPAREIL DOIT ÊTRE

MIS À LA TERRE LORS DE SON UTILISATION. DE GRAVES BLESSURES PEUVENT

SURVENIR.

POUR TOUS LES APPAREILS MIS À LA TERRE, BRANCHÉS À UN CORDON

D’ALIMENTATION :

En cas de défaillance ou de panne, la mise à la terre permet un cheminement de moindre

résistance pour le courant électrique afin de réduire le risque de choc électrique. Cet

appareil est muni d’un cordon d’alimentation doté d’un conducteur de mise à la terre

d’équipement et d’une fiche de mise à la terre. La fiche doit être branchée sur une prise

de courant correspondante qui est installée et mise à la terre conformément à tous les

codes et à toutes les ordonnances à l’échelle locale. Ne pas modifier la fiche fournie;

si elle ne s’insère pas dans la prise de courant, faire installer une prise appropriée par

un électricien professionnel. Si le conducteur de mise à la terre d’équipement n’est

pas correctement connecté, ceci peut provoquer un choc électrique. Le conducteur

de mise à la terre d’équipement est le conducteur avec isolation qui a une surface

extérieure verte avec ou sans rayures jaunes. S’il est nécessaire de faire réparer ou

remplacer le cordon électrique ou la fiche, ne pas connecter le conducteur de mise à

la terre d’équipement à une borne sous tension. Vérifier auprès d’un électricien ou d’un

personnel de réparation professionnel si les directives de mise à la terre ne sont pas

parfaitement comprises ou en cas de doute sur le fait que l’appareil soit correctement

mis à la terre ou non. Utiliser uniquement une rallonge à 3 fils pourvue d’une fiche de

mise à la terre à 3 lames et une prise à 3 conducteurs correspondant à la fiche de

l’appareil comme le montre la fig. A. Réparer ou remplacer immédiatement le cordon

s’il est endommagé ou usé.

POUR LES APPAREILS MIS À LA TERRE ET BRANCHÉS À UN CORDON

D’ALIMENTATION UTILISÉ SUR UN CIRCUIT D’ALIMENTATION DE RÉGIME

NOMINAL INFÉRIEUR À 150 V :

Si l’appareil est utilisé sur un circuit dont la prise de courant ressemble à celle de la fig.

A, il aura alors une fiche de mise à la terre semblable à celle de la fig. A. Un adaptateur

temporaire, qui ressemble à celui de la fig. B, peut être utilisé pour connecter cette fiche

à une prise à 2 conducteurs, comme le montre la fig. B, s’il n’existe aucune prise de

courant correctement mise à la terre. L’adaptateur temporaire ne doit être utilisé que

jusqu’à ce qu’un électricien qualifié puisse installer une prise électrique correctement

mise à la terre. La patte rigide verte, la cosse et tout élément semblable sortant de

l’adaptateur doivent être correctement branchés à une masse permanente comme

une boîte de sortie mise à la terre. Chaque fois que l’adaptateur est utilisé, il doit être

maintenu en place par une vis métallique.

A

BOÎTE DE

SORTIE DE

MISE À LA

TERRE

GOUPILLE DE MISE

À LA TERRE

B

C D

MOYENS DE

MISE À LA

TERRE

ADAPTATEUR

GOUPILLE DE MISE

À LA TERRE

REMARQUE : Au Canada, l’utilisation d’un adaptateur temporaire n’est pas autorisée

par le Code électrique canadien.

DANGER: DANS TOUS LES CAS, S’ASSURER QUE LA PRISE DE COURANT

EN QUESTION EST CORRECTEMENT MISE À LA TERRE. EN CAS DE DOUTE,

DEMANDER À UN ÉLECTRICIEN PROFESSIONNEL DE VÉRIFIER LA PRISE.

Fonctionnement monophasé à 240 volts

Le moteur fourni avec la machine est un moteur bitension de 120/240 volts. Il est livré, prêt

à fonctionner, sous tension de 120 volts. Toutefois, il peut être converti au fonctionnement

sous 240 volts. La conversion doit être réalisée par un électricien qualifié, ou il faut apporter

la machine à une centre de réparation D

doit être conforme au Code électrique national et à tous les codes et à toutes les ordonnances à l’échelle locale.

La conversion exige un recâblage du moteur pour 240 volts grâce à

l’installation d’une fiche de 240 volts sur le cordon d’alimentation et le

remplacement de l’interrupteur (le cas échéant) par un autre homologué

pour un fonctionnement à 240 volts.

La scie avec la fiche de 240 volts doit être branchée UNIQUEMENT à

une prise de même configuration que celle indiquée dans l'illustration.

Aucun adaptateur n’est disponible ou ne devrait être utilisé avec la fiche

de 240 volts.

DANGER : DANS TOUS LES CAS, S’ASSURER QUE LA PRISE DE COURANT

EN QUESTION EST CORRECTEMENT MISE À LA TERRE. EN CAS DE DOUTE,

DEMANDER À UN ÉLECTRICIEN QUALIFIÉ DE VÉRIFIER LA PRISE.

EWALT autorisé. Suite à la conversion, la machine