Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in U.S.A. (JUN00-CD-1) Form No. 390268-00

DW746 Copyright © 2000

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW746

Woodworker’s Table Saw

Scies circulaires à table d’entrepreneur

Sierra de banco para madera

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTIA. ADVERTENCIA: LEASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO. SI TIENE DUDAS, POR FAVOR LLAME.

Before returning this

product call

1-800-4-DEWAL T

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PURCHASE,

CALL 1-800-4 DEW AL T.

IN MOST CASES, A DEW AL T REPRESENTA TIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

IF YOU HA VE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VIT AL TO THE SUCCESS OF DEW ALT'S

QUALITY IMPROVEMENT PROGRAM.

See our catalog on the World Wide Web. www.dewalt.com

Page 3

English

DEW ALT…GUARANTEED TOUGH

DEWALT high performance industrial tools are made for America’s

toughest industrial and construction applications. The design of

every tool in the line – from drills to sanders to table saws – is the

result of rigorous use on job sites and throughout industry. Each

tool is produced with painstaking precision using advanced

manufacturing systems and intense quality control. Every tool is

checked before it leaves the factory to make sure that it meets your

standards for durability, reliability and power.

D

EWALT Built Job site Tough…WE GUARANTEE IT.

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING SAW • ALWAYS WEAR EYE PROTECTION • DO NOT WEAR

GLOVES, NECKTIES, JEWELRY OR LOOSE CLOTHING • CONTAIN LONG HAIR • KEEP HANDS AND FINGERS OUT OF THE SAW BLADE PATH — USE

EXTRA CAUTION WHEN BEVELING • ALWAYS USE BLADE GUARD AND SPREADER FOR EVERY OPERATION FOR WHICH IT CAN BE USED, INCLUDING

THROUGH SAWING • USE A “PUSH STICK” WHEN REQUIRED • KNOW HOW TO AVOID KICKBACKS — SEE MANUAL • ALWAYS SUPPORT WORK WITH

TABLE AND FENCE OR MITER GAUGE • NEVER USE FENCE AND MITER GAUGE TOGETHER • NEVER REACH AROUND OR OVER SAW BLADE • SECURELY

MOUNT SAW BLADE BEFORE OPERATING • NEVER REMOVE JAMMED OR CUT-OFF PIECES UNTIL POWER IS OFF AND BLADE HAS STOPPED • DO NOT

EXPOSE TO RAIN OR USE IN DAMP LOCATIONS • DO NOT OPERATE THIS MACHINE WHILE UNDER THE INFLUENCE OF ALCOHOL OR DRUGS • FAILURE

TO COMPLY WITH THESE WARNINGS MAY RESULT IN SERIOUS PERSONAL INJURY.

WARNING: USE OF THIS TOOL CAN GENERATE DUST CONTAINING CHEMICALS

KNOWN TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

USE APPROPRIATE RESPIRATORY PROTECTION.

Page 4

WARNING: FOR YOUR OWN SAFETY READ INSTRUCTION MANUAL BEFORE

OPERATING SAW.

WARNING: When using electric tools, basic safety precautions should always

be followed to reduce risk of fire, electric shock, and personal injury, including the

following:

Grounding Instructions

In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and grounding plug. The plug must be plugged

into a matching outlet that is properly installed and grounded in accordance with all local

codes and ordinances. Do not modify plug provided — if it will not fit the outlet, have the

proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool’s plug.

REPAIR OR REPLACE DAMAGED OR WORN CORDS IMMEDIATELY.

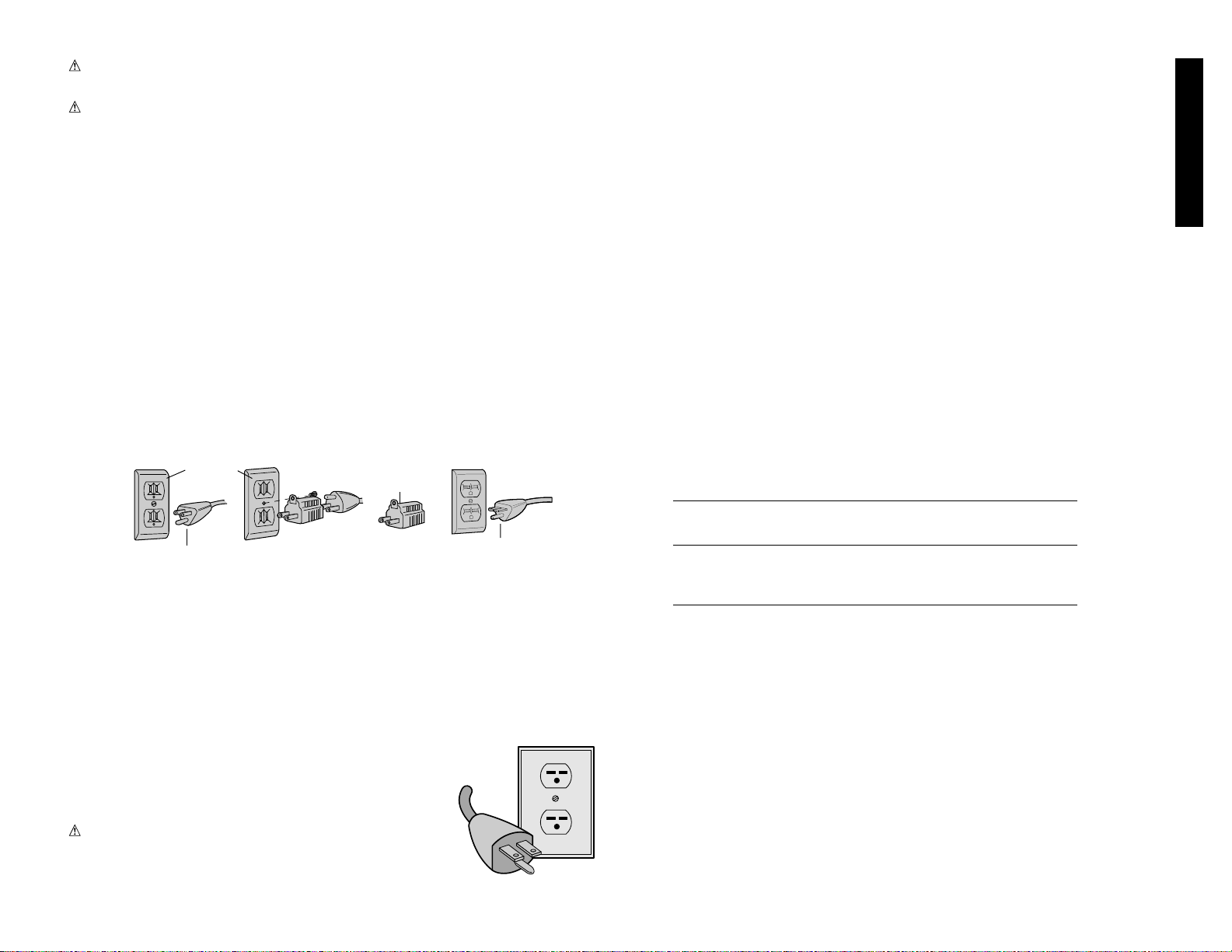

Grounded tools intended for use on a supply circuit having a nominal rating less than 150

volts: This tool is intended for use on a circuit that has an outlet that looks like the one

illustrated in Figure A. The tool has a grounding plug that looks like the plug illustrated in

Figure A. A temporary adapter, which looks like the adapter illustrated in Figures B and C,

may be used to connect this plug to a 2-pole receptacle as shown in Figure B if a properly

grounded outlet is not available. The temporary adapter should be used only until a

properly grounded outlet can be installed by a qualified electrician. The green-colored rigid

ear, lug, and the like, extending from the adapter must be connected to a permanent

ground such as a properly grounded outlet box.

The adapter (C) is not for use in Canada.

240 Volt Operation

The motor supplied with your saw is a dual voltage, 120, 240 volt

motor. If it is desired to operate your saw at 240 volts, single

phase, it is necessary to reconnect the motor leads in the motor

junction box by following the instructions given on the motor

nameplate.

WARNING: Make sure motor is disconnected from power

source before reconnecting motor leads.

It is also necessary to replace the 120 volt plug, supplied with the

motor, with a UL/CSA listed plug suitable for 240 volts and the

rated current of the saw as shown. Contact your local DEWALT Service Center or qualified

electrician for proper procedures to install the plug. The saw must comply with all local and

national electrical codes after the 240 volt plug is installed.

The saw with the 240 volt plug should only be connected to an outlet having the same

configuration as the plug illustrated. No adapter is available or should be used with the 240

volt plug.

Important Safety Instructions

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys

and adjusting wrenches are removed from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet

locations, or expose them to rain. Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

• MAKE WORKSHOP CHILD PROOF with padlocks, master switches, or by removing starter

keys.

• DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When

using an extension cord, be sure to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number,

the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact resistant lenses, they are not safety glasses.

• SECURE WORK. Use clamps or a vise to hold work when practical.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

• DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits,

cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position

before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped over or if the cutting

tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

1

English

AB CD

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

GROUNDING PIN

ADAPTER

Page 5

• No special wood is needed to make a push-stick as long

as it’s sturdy and long enough. A length of 12 inches is

recommended with a notch that fits against the edge of

the workpiece to prevent slipping. It’s a good idea to

have several push sticks of the same length (12 inches)

with different size notches for different workpiece

thicknesses.

• See the inside back cover for a picture of a push stick.

The shape can vary to suit your own needs as long as it

performs its intended function of keeping your hands

away from the blade.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Specifications

Horsepower 1-3/4

Table Size 27" x 40 3/4"

Miter Angle 60° L&R

Bevel Angle -2° to 47° Left

Blade Size 10" (254mm)

Max. Cut Depth 0° Bevel ..............3 1/8" (79mm)

Max. Cut Depth 45° Bevel ............2-1/8" (54mm)

RPM, no load 3000

DW746 Basic Unit

Assembling custom accessories to this unit is covered in the

instructions packed with them. Assemble any accessories

first. Operating instructions and adjustments are covered in

this manual starting with step 16, on page 4.

Tools Included

To aid you with assembly of your new saw, we have

included the following tools.

• T50 torx wrench

• 5mm hex wrench

• Combination wrench with 16mm, 13mm 10mm

and 22mm openings

• Blade wrench with 15/16” and 10mm box ends.

Tools You Will Need to Supply

• Flat blade screwdrivers

• 16mm or 5/8” open end wrench or pliers

• Ruler

• Square

• Soft hammer, or regular hammer and block of wood

To speed assembly, the following would be helpful:

• 16mm or 5/8” socket wrench, with 6” extension

• 13mm or 1/2” socket wrench

2

function–check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or other part

that is damaged should be properly repaired or replaced.

• DIRECTION OF FEED. Feed work into a blade or cutter

against the direction of rotation of the blade or cutter only.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don’t leave tool until it comes to a complete

stop.

Additional Safety Rules for Table

Saws

• Wear eye protection.

• Use saw-blade guard and spreader for every operation for

which it can be used, including all through sawing.

• Keep hands out of line of saw blade.

• Use a push-stick when required.

• Know how to reduce risk of kickback.

• Do not perform any operation freehand.

• Never reach in back of or over saw blade.

CAUTION: Some wood contains preservatives such as

copper chromium arsenate (CCA) which can be toxic. When

cutting these materials extra care should be taken to avoid

inhalation and minimize skin contact.

• USE A DUST MASK and safety glasses when sawing. This

saw is capable of generating large amounts of sawdust.

WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals

are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

Kickbacks

HOW TO AVOID THEM AND PROTECT YOURSELF

FROM POSSIBLE INJURY:

a) Be certain that the rip fence is parallel to the saw blade.

b) Do not rip by applying the feed force to the section of the

workpiece that will become the cut-off (free) piece. Feed

force when ripping should always be applied between

the saw blade and the fence; use a push stick for short

work, 6” (152mm) wide or less. For less than 2" (51mm)

wide, you must use a special fixture.

c) Keep saw blade guard, splitter and anti-kickback pawls

in place and operating properly. Keep pawls sharp. If

pawls are not operational, return your unit to the nearest

D

EWALT Service Center for repair. The splitter must be

in alignment with the saw blade and the pawls must stop

a kickback once it has started. Check their action before

ripping.

d) Plastic and composition (like hardboard) materials may

be cut on your saw. However, since these are usually

quite hard and slippery, the anti-kickback pawls may not

stop a kickback. Therefore, be especially attentive to

following proper set up and cutting procedures for

ripping.

e) Use saw blade guard and splitter for every operation for

which it can be used, including all through sawing.

Saw Blade Guard and Spreader

Your table saw is equipped with a blade guard and

spreader assembly that covers the blade and prevents

accidental contact. The spreader is a flat plate that fits into

the cut made by the saw blade and effectively fights

kickback by lessening the tendency of the blade to bind in

the cut. The spreader can only be used when making

through cuts that sever the wood. When making dadoes,

rabbits and other cuts that make less than through cuts, the

blade guard and spreader assembly must be removed from

the saw.

Two anti-kickback pawls are located on the sides of the

spreader that allow the wood to pass through the blade in

the cutting direction but lock it if it tries to move backwards

toward the operator.

TERMS:

The following terms will be used throughout the

manual and you should become familiar with them.

• Through-Sawing refers to any cut that completely severs

the workpiece.

• Push-Stick refers to a wooden stick, usually home-made,

that is used to push small workpieces through the saw and

keeps the operator’s hands clear of the blade.

• Kickback occurs when the saw blade binds in the cut and

violently thrusts the workpiece back toward the operator.

• Freehand refers to cutting without the use of a miter gauge

or rip fence or any other means of guiding or holding the

workpiece other than the operator’s hand.

Making a Push Stick (Back Page)

• In order to operate your table saw safely you must use

a push-stick whenever the size or shape of the

workpiece would cause your hands to be within 6 inches

of the saw blade or other cutter.

English

Page 6

• 10 mm open end wrench

• T20 and T25 Torx drivers

• T40 Torx wrench.

Your will also need:

• Mild solvent cleaner such as mineral spirits, paint

thinner or denatured alcohol.

• High quality paste wax

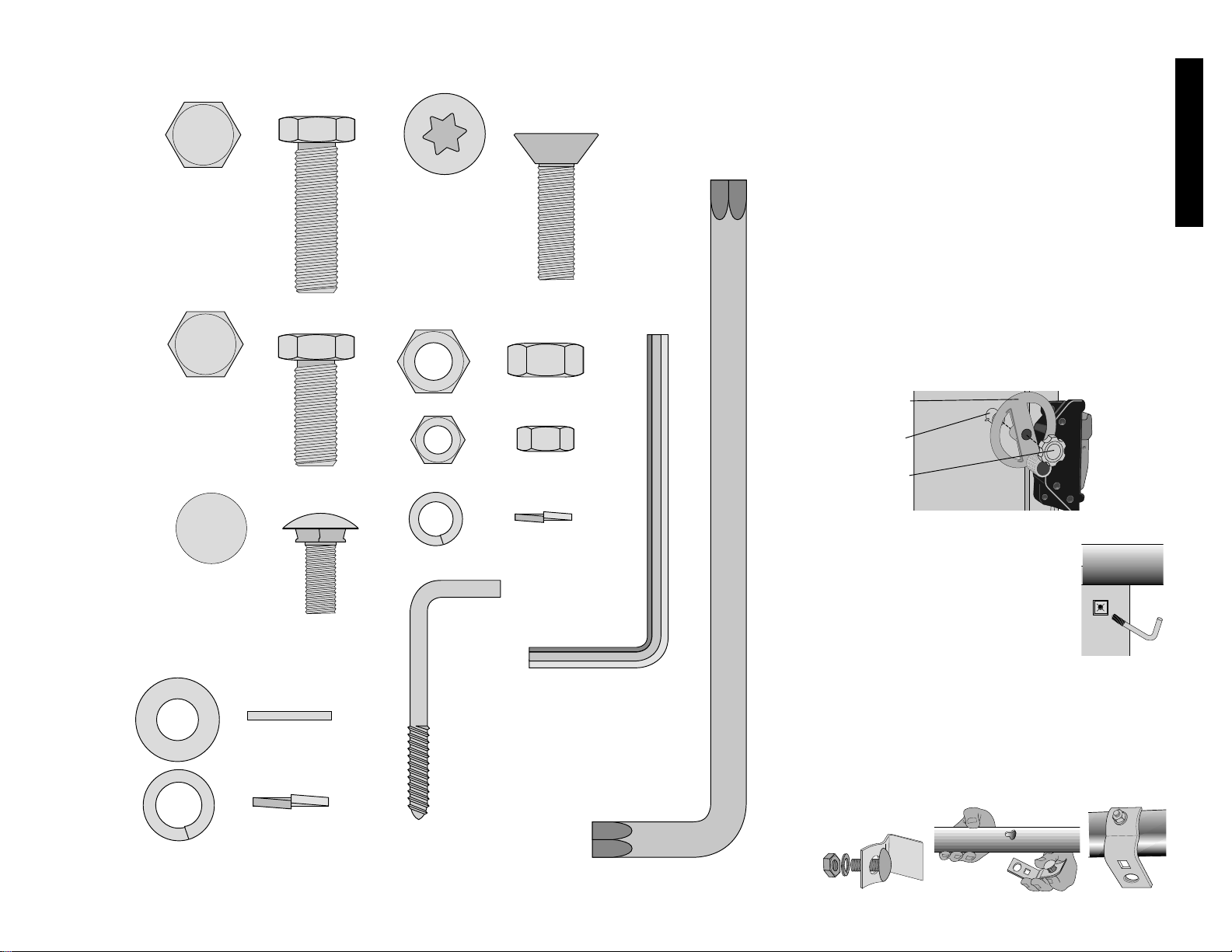

Necessary Hardware

Your hardware bag, located in the parts box, contains all

the necessary nuts, bolts and washers to assemble the

components included with the DW746 Woodworker’s Table

Saw.

To make assembly of your saw easier, match the nuts,

bolts and washers with the chart on the next page.

Separate them by size so that you can easily locate the

item you need. Before each step, check your hardware

against the chart and identify the pieces you need.

Assembly for DW746

PLEASE READ ENTIRE ASSEMBLY

SECTION

BEFORE PROCEEDING.

STEP 1. Remove parts box, motor cover,

fence beam and side tables from saw.

STEP 2. Turn the saw right side up. You will

need help. The combined weight of the

table top and motor assembly is

approximately 200 lbs.

STEP 3. Cut and remove plastic strap holding the motor.

STEP 4. Using front hand crank, lower the motor some

and remove the foam packing material between the

motor and the mechanism.

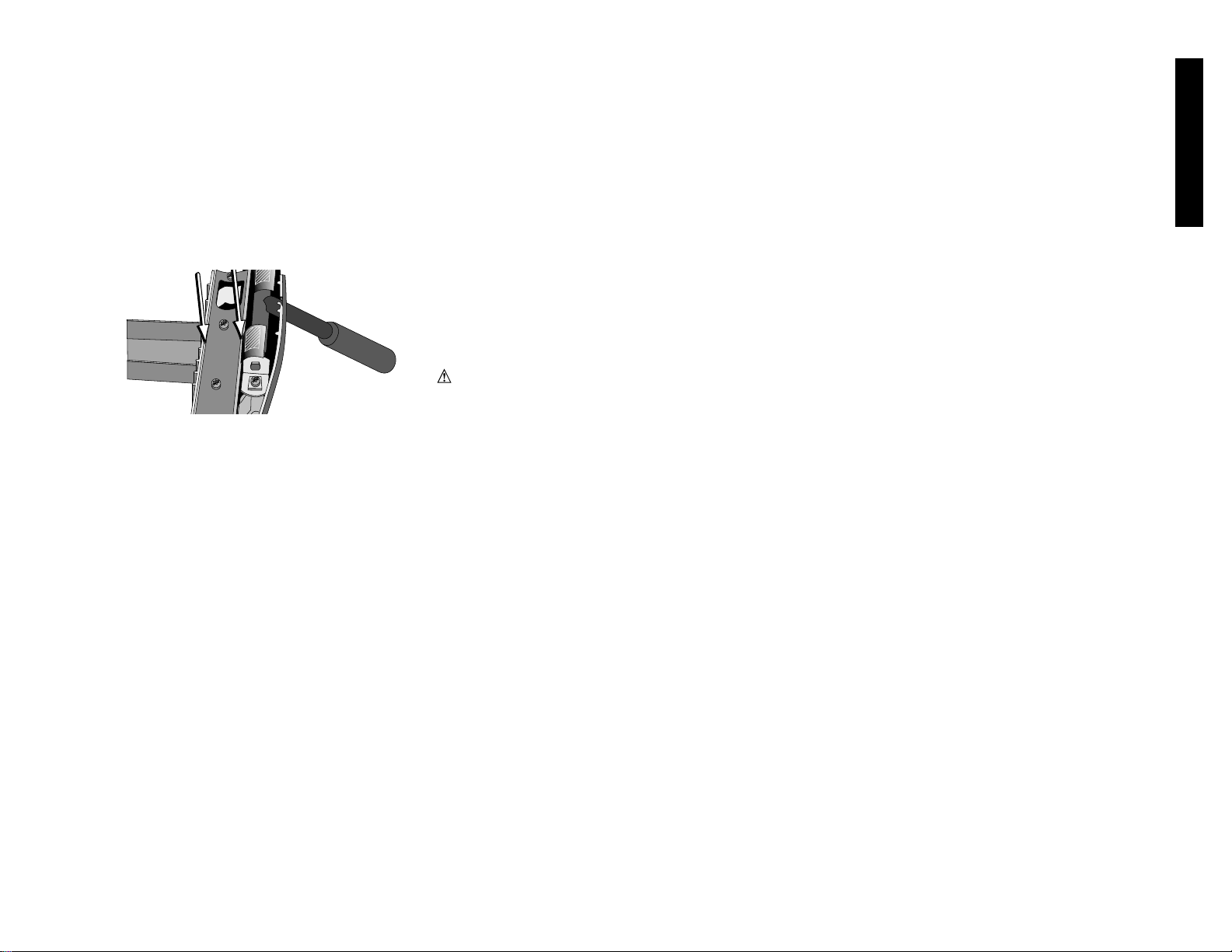

STEP 5. Install bevel crank. (Fig. 1) To do this, first install

the crank handle (A) over the shaft (B), rotate it slightly

to fully engage the shaft pin. Screw the lock knob (C)

3

English

FIG. 2

A

B

C

FIG. 1

Hardware Included with the DW746 Woodworker’s Table Saw

Bolt

10 mm x 35 mm

(2 pieces)

Bolt

10 mm x 25 mm

(8 pieces)

Carriage Bolt

8 mm x 20 mm

(4 pieces)

T50 Torx

Flat Head Screw

10 mm x 30 mm

(4 pieces)

FLAT WASHER

(14 PIECES)

10 MM LOCK WASHER

(14 PIECES)

8 MM LOCK WASHER

(4 PIECES)

5 MM

HEX

WRENCH

( 1 )

T50

TORX

WRENCH

(1)

M 10 NUT 16 MM HEX

(8 PIECES)

M 8 NUT 13 MM HEX

(4 PIECES)

WRENCH

HOOK

(1)

PARTS SHOWN ARE FULL SIZE - EXTRA FASTENERS MAY HAVE BEEN INCLUDED

Page 7

English

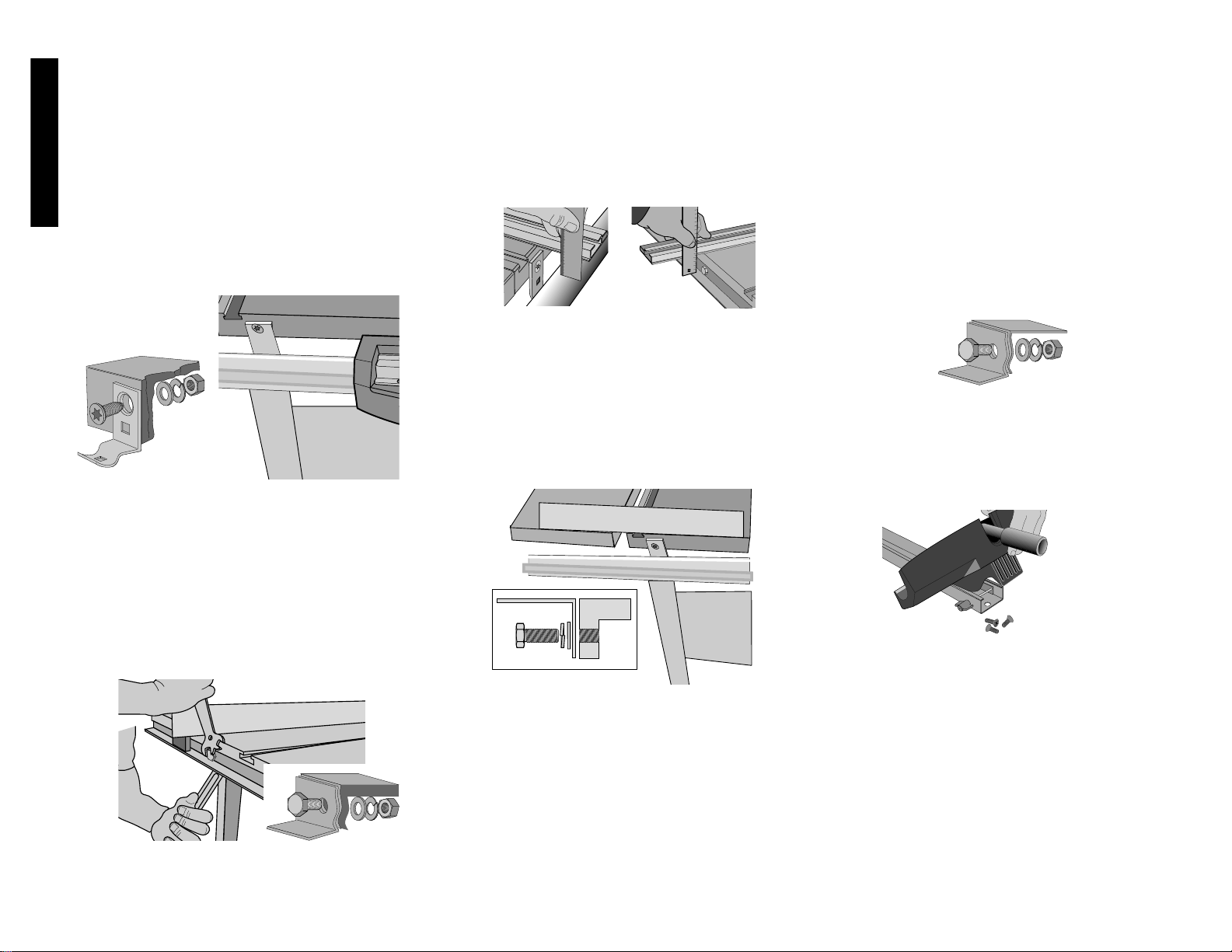

STEP 13. Attach the left & right Support Tables. (Fig. 6)

You will need: 6 - 10 x 25 mm Hex Head Bolts

6 - 10 mm Flat Washers

6 - 10 mm Lock Washers

Without support table in place, install the 3 bolts per side

with washers as shown keeping 1/4” gap. Rest a side

table on the bolts, fitting into the notches. Using the

extruded fence face as a guide, flush the support table

to the main table edge and snug the front bolt. Repeat

this process for the rear bolt. Tighten the center bolt.

Repeat on the other side.

STEP 14. Attach front rail brackets to Support Tables.

You will need: 2 - 10 x 30 mm Flat Head Screws

2 - 10 mm Flat Washers

2 - 10 mm Lock Washers

2 - 10 mm Nuts

Align front brackets with the support table and tighten

bracket nuts to the rail. Attach the wing tables to the

outer front rail support brackets, keeping the washers

and nut on the inside of the table. Using the fence face

as a straight edge, make sure the front outer corner of

the wing table is level with the inner edge and main table

surface. Repeat this procedure for the other support

table.

STEP 15. Attach rear rail to support tables.

You will need: 2 - 10 x 25 mm Hex Head Bolts

2 - 10 mm Flat Washers

2 - 10 mm Lock Washers

2 - 10 mm Nuts

Attach the wing tables to the outer rear rail support

brackets, again, keeping the washers and nut on the

inside. Using the fence face as a straight edge, make

sure the rear outer corner of the wing table is level with

the inner edge and the main table surface. Repeat this

procedure for the other side table.

STEP 16. Assemble the fence beam to the fence head

mm Lock Washers

2 - 10 mm Nuts

Secure each screw through the upper hole in the center

brackets keeping the flat washer, lock washer and nut

on the inside of the table. Tighten snug but not very

tight.Tighten center rail bracket nuts, leaving the outer

ones finger tight.

STEP 11. Attach rear rail. (Fig. 4)

You will need: 2 - 10 x 35 mm Hex Head Bolts

2

-

10 mm Flat Washers

2 - 10 mm Lock Washers

2 - 10 mm Nuts

Secure rear rail to main table top using hex head bolts,

washers, lock washers and nuts. Keeping the washers

and nuts on the inside of the table. The flat side should

be down unless you are also mounting an accessory

(consult accessory instructions for rail mounting

details.). Make sure ends of the rear rail line up with

the ends of the front rail. Tighten snug but not very tight.

STEP 12. Parallel the rails to the table top (Fig. 5). Using

your fence face or a straightedge to extend the table

surface over the rail, make sure the distance from the

table top to the rail top is the same at both the left and

right side of the table. If the rails are not lined up

correctly, loosen the mounting screws slightly and tap

on the rail brackets with a soft hammer or regular

hammer and a block of wood until the distances are the

same. Tighten fasteners securely. Repeat for the rear

rail.

into place until it is fully seated, then back it off 1/4 to 1/2

turn.

STEP 6. Using height crank, raise mechanism up as high

as it will go.

STEP 7. Install wrench hook. On the front right leg, near

the top is a plastic threaded insert. Thread the “L”

shaped wrench hook in until only a few threads are

visible.

STEP 8. Unpack rail carton. (contains front & rear rail)

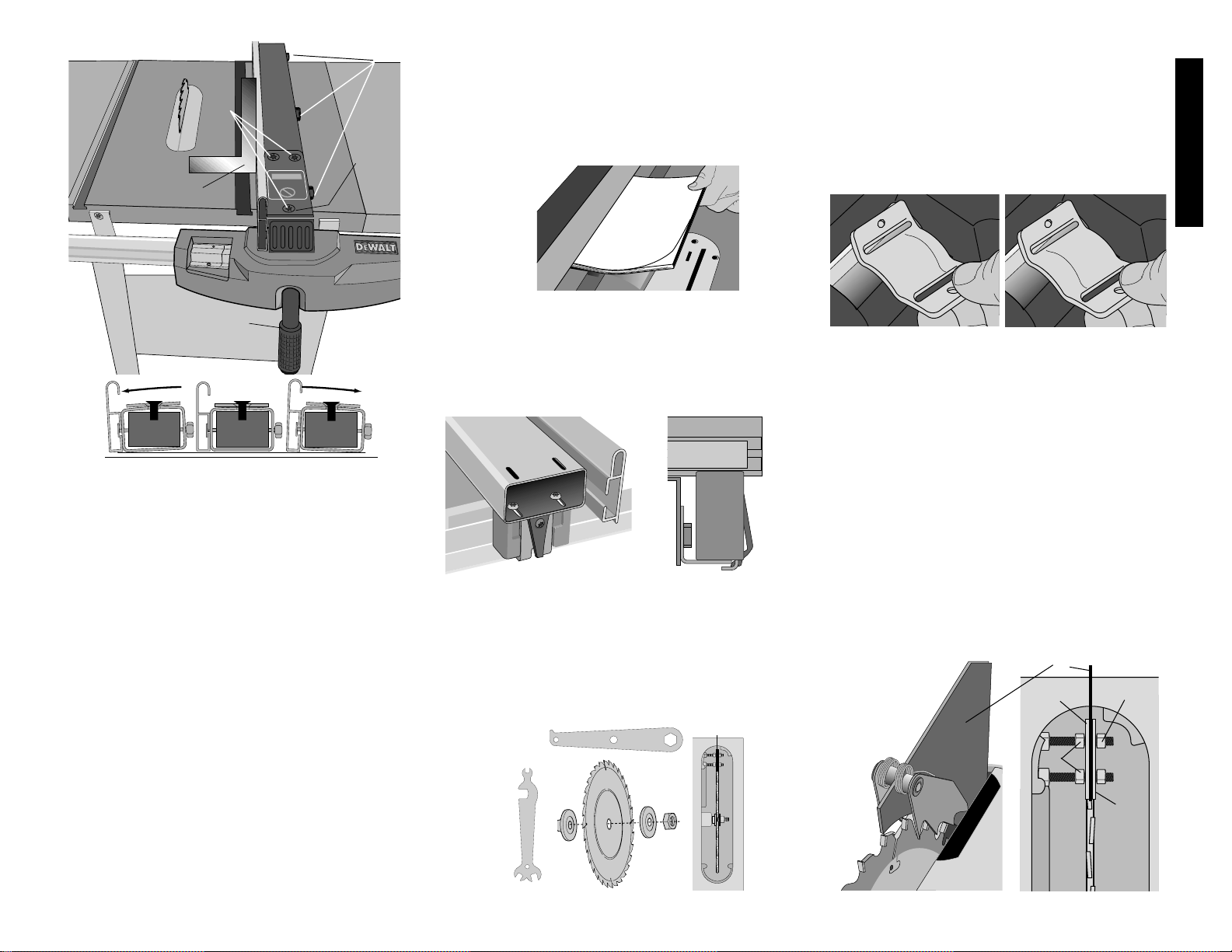

STEP 9.Assemble front rail and brackets (Fig. 2).

You will Need: 4 - 8 mm Carriage Bolts

4 - 8 mm Lock Washers

4 - 8 mm Nuts

Assemble carriage bolts, lock washers and nuts to front

rail brackets (just a few threads). Put the head of the

carriage bolt into keyhole slots in the front rail and slide

to engage the square part of the bolt. Run nut in until it

is finger tight. Repeat for other 3 brackets. When

attaching brackets to the rail, the rail must be positioned

correctly so that the rip scale is right side-up. Also all 4

brackets should face the same direction.

STEP 10. Attach front rail with brackets to the table top.

(Fig. 3) You will need:

2 - 10 x 30 mm Flat Head Screws

2 - 10 mm Flat Washers

2 10

FIG. 4

FIG. 7

FIG. 6

FIG. 3

4

FIG. 5

Page 8

A

C

B

D

PIVOTING

SCREW

DETAIL A

beam, allow the face to rest on the table top, and

retighten the wing nuts.

3. Slide the fence so the face is in line with the edge of the

miter slot.

4. Adjust the beam angle to the miter slot as follows;

a. Loosen the farthest two torx screws (A) so the beam

will pivot on the third. Don’t over loosen the screws,

slightly loose works best.

b. Loosen the pivot screw (A) just enough to pivot

beam, but snug enough not to prevent beam from

moving side to side.

c. Lock fence head to front rail.

d. Parallel the fence face to the miter slot.

e. Tighten all three screws (A) which hold the fence

beam to the head, starting with the rearmost two.

Now the beam is square to the table.

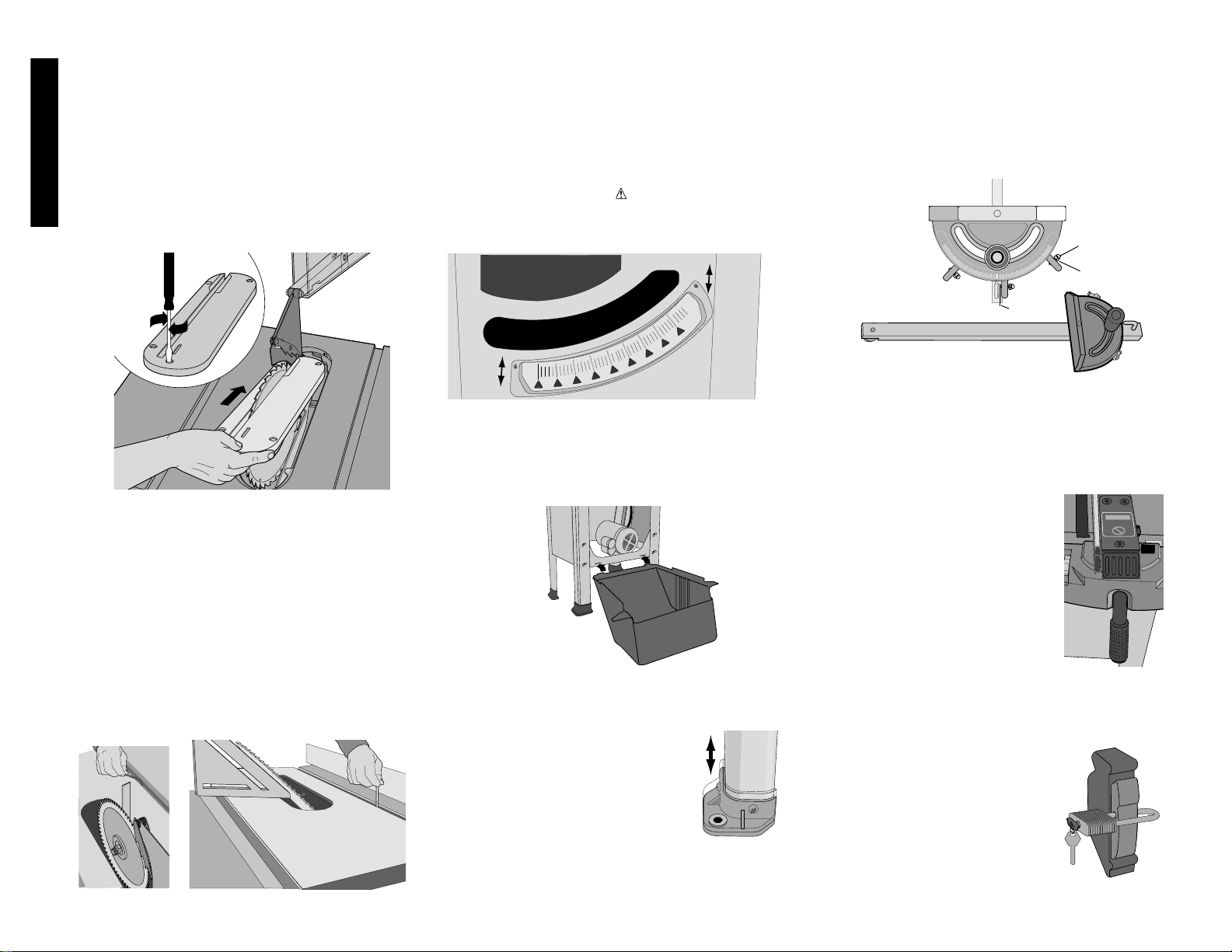

STEP 18. Adjust the fence face height and position

(Fig. 9). Loosen the wing nuts that retain the fence face

to the beam. Lift the fence face and slide 16 pages of the

instruction manual or other paper between the face and

(Fig. 7). Remove the three flat head screws which

secure the cover plate to the fence head with the

T50 Torx wrench. Turn the beam upside down.

Slide the fence head into the beam as shown. Flip

the beam over and install the cover plate and three

screws snug but not tight.

STEP 17. Adjusting Fence to Table Top (Fig. 8)

Check alignment of beam and fence face before each

cutting session.

SQUARE FENCE FACE TO TABLE TOP

1. Make sure all surfaces are clean of sawdust.

2. Make sure the lock knobs (B) are secure.

3. Lock the beam in place with handle (C).

4. Using a square (D), check the fence face angle to the

table top.

5. If an adjustment is necessary, loosen the three torx

screws (A) just slightly and slide the beam to re-align the

face (See Detail A).

6. Tighten the three torx screws (A).

7. Recheck alignment to the table.

PARALLEL FENCE TO BLADE

1. Place fence on rails, near the right-hand miter slot.

Ensure that the rear glide is located correctly. See step

19.

2. Loosen the wing nuts (B) retaining the face to the fence

English

5

FIG.9

the table. This will set the height of the face

approximately 1/16” off of the table top. The face can

also be adjusted forward and back to suit your

preference. Tighten the wing nuts to secure the face.

When cutting very thin material, the fence face can be

adjusted so that it rests on the table top. Be sure to readjust the face to about 1/16” before sliding the fence.

STEP 19. Adjust the rear fence glide (Fig. 10). If

necessary, adjust the rear glide to locate it correctly

against the rear rail by loosening the two screws which

secure it to the fence beam. The plastic retaining clip

should be deflected somewhat when the glide is

positioned correctly. This adjustment should only be

necessary if the rear rail has been relocated by the

addition of an optional accessory.

STEP 20. To install the saw blade (Fig.11), remove the

arbor nut (A) and outer clamp washer(B), then slip the

blade over the spindle and re-install the washer and nut.

Use the spindle lock wrench to hold the shaft while

tightening the nut with the blade wrench. Make sure the

blade is installed correctly for the rotation of your saw.

The cutting teeth should face the front of the saw.

STEP 21. Adjust the fence scale indicator (Fig. 12).

Slide the fence until it just touches the blade. Loosen the

fence indicator screw and slide it until the hairline aligns

with the “0” line on the scale. Tighten the screw. If the

FIG.10

FIG. 8

SPINDLE

LOCK

WRENCH

BLADE WRENCH

FIG. 11

FIG. 13

A

B

B

C

D

A

B

FIG. 12

Page 9

the table and lower the plate into its opening. The throat

plate includes four adjustment screws which raise or

lower it. When properly adjusted, the front of the throat

plate should be flush or slightly below the surface of the

table top, and the rear of the throat plate should be

flush or slightly above the table top. The center front

screw, when turned clockwise, will engage a cam under

the front lip of the table, locking the throat plate in

place. Rotate the screw counterclockwise 1/2 turn to

remove the throat plate. CAUTION: THE THROAT

PLATE MUST BE IN PLACE AT ALL TIMES.

STEP 24. Adjust the bevel stops (Fig. 15). Using a

square, set the blade to exactly “0” degrees. If the

blade stops beveling before it gets to 0, back the stop

set screw up with the 5 mm allen wrench and then

proceed to “0” degrees. The set screw is located in the

left miter guide slot. With the blade set at 0, slowly turn

the zero stop screw in until you feel resistance. Bevel

the blade away from 0 a little then back to the stop. Remeasure the angle and repeat the stop adjustment as

necessary until the blade stops at 0 degrees. Set the 45

stop the same way. The set

screw for the 45˚ stop is located

in the right hand miter guide slot.

NOTE: For some special cuts,

the stops can be backed out and

the saw will bevel from -2

degrees to 47 degrees.

STEP 25. Adjust the bevel scale

(Fig. 16). Bevel the saw until it hits the zero bevel stop.

low profile fence face accessory or a wider homemade

fence face is used which is out of the adjustment range

of the pointer, the pointer can be removed completely,

turned 180 degrees, re-installed, and aligned with the “0”

line.

STEP 22. Install the guard and splitter assembly (Fig.

13). Raise the blade to its highest point. Loosen the

outer guard retaining nuts (A) enough so that the splitter

will fit between the two guard retaining plates (B). Install

the splitter (C) and ensure that it is aligned with the

blade. If not, the position is adjusted by moving the inner

guard clamp nuts (D) which changes the location where

the splitter mounts. Make sure the splitter is centered

and parallel to the blade by lining up the parts with a

straightedge. Also make sure there is some clearance

between the splitter and the blade and that the blade

spins freely. If the splitter is tilted relative to the blade,

the splitter plate can be bent until it lines up correctly.

IMPORTANT: THE GUARD SHOULD BE IN PLACE

FOR ALL POSSIBLE CUTS. When making non-through

cuts, the guard can be easily removed by slightly

loosening the outer guard nuts (A). The guard can easily

be replaced without having to readjust the inner nuts.

STEP 23. Install and adjust the throat plate (Fig. 14).

Align the throat plate as shown and insert the tabs on

the back of the throat plate into the holes at the back of

English

6

Remove the height crank lock knob and height crank.

Adjust the red pointer by loosening the screw where it

attaches to its shaft, move the pointer until it lines up

with the 0 line on the scale, and re-tighten the screw.

The pointer should be positioned just barely off of the

scale surface. Bevel the saw to the 45 degrees stop. If

the pointer doesn’t point to 45 degrees, loosen the two

screws which hold the scale to the saw front panel and

slide the scale up or down until the pointer lines up with

the 45 line. Re-tighten the scale screws. Replace the

height crank and lock knob.

STEP 26. Install the motor cover (Fig. 17). Remove the

two cover screws and washers from the top of the two

side legs with a small flat blade screwdriver. Snap the

two bottom tabs of the cover into the slots in the right

lower crossmember. Place the cover

in position and re-install the screws

and washers.

STEP 27. Level the saw (Fig. 18). Move

the saw to the location you want to

keep it. If the saw rocks on the floor,

the foot not touching the floor can be

lowered to compensate for the uneven

floor. Loosen the two screws that hold

the foot to the leg. Let the foot fall to

the floor surface. Re-tighten the

screws holding the foot to the leg.

If your saw will have a permanent location, we

recommend that the feet be bolted to the floor using the

holes provided.

STEP 28. Adjustment and use of miter gage (Fig. 19).

Your miter gauge features adjustable

stops at 90° and 45° left and right. To

adjust these stops, loosen the lock

nuts (A) and tighten or loosen the

three adjusting screws (B). Check the

gauge with a square against the

blade and tighten the three adjusting

screws. To set the miter gauge past

the 45 degree stops, flip up the stop

plate (C) and continue to the required

FIG. 17

FIG. 18

FIG. 16

30

30

45

60

75

75

90

60

45

FIG. 19

A

B

C

FIG. 15

FIG. 14

Page 10

English

angle.

STEP 29. Clean the table top. Your saw was shipped with

a rust preventive coating which should be removed. Clean

the top with mineral spirits or denatured alcohol and apply

paste wax. Apply and remove soon afterward to prevent a

sticky build-up.

Rip Fence Operation

FENCE LOCK LEVER

The fence lock lever locks the rip fence in place, preventing

movement. To lock the fence, push down. To unlock the

lever, pull it up. NOTE: When ripping, always lock the fence

to the rail.

RIP SCALE POINTER

NOTE: The rip scale pointer will need to be readjusted

whenever a thicker or thinner blade is installed. Should

you decide to use a thicker face, or the D

EWALT low fence

face accessory, the scale pointer may be removed and

turned 180˚ to line up with the scale. (Fig. 12)

RIP FENCE CAPACITY

The fence will slide beyond the end of the rails in either

direction without falling off. Stops are provided to keep the

fence attached.

On-Off Switch

Pull out the switch paddle to turn your saw ON and push it

in to turn your saw OFF. A hole is provided in the switch

for insertion of a padlock to lock the saw off.

WARNING: Be sure switch is in the OFF position before

plugging machine in.

Saw Blades

THIS SAW IS INTENDED FOR THE USE WITH SAW

BLADES 10” IN DIAMETER OR SMALLER.

1. The saw blade furnished with your new saw is a 10"

(254mm) fine ripping blade, used for ripping (with the

grain) through the material, and occasional cross cuts.

The center hole to fit on the arbor is 5/8" (16mm)

diameter (.625"). This blade will produce a good quality

cut for many applications.

2. There are many types of blades available to do specific

and special jobs such as cross cut only, rip only, hollow

ground, thin plywood, paneling, etc.

3. Use only saw blades designed for maximum safe

operating speeds of 5,000 RPM or greater.

4. Saw blades should always be kept sharp. It is

recommended that you locate a reputable sharpening

service to sharpen your blades when needed.

5. Never stack blades on top of one another to store. Place

material such as cardboard between them to keep the

blades from coming in contact with one another.

CAUTION: Abrasive wheels should not be used on this

saw.

Operation

Plain sawing includes ripping and cross cutting, plus a few

other standard operations of fundamental nature. With all

power tools, respecting the tool, using caution and following

safe practices will considerably lessen the possibility of

personal injury. However, if normal safety precautions are

overlooked or completely ignored, personal injury to the

operator can result. Read and follow all warnings indicated

on the saw. Familiarize yourself with all the components

and features before attempting any cuts. Know how to

make adjustments before turning the saw on. Observe the

safety rules included in this manual.

THIS SAW IS NOT INTENDED FOR CUTTING METAL.

Operating Instructions

There are two basic types of cuts: ripping and crosscutting.

In general, cutting with the grain is ripping and across the

grain is crosscutting. However, with man made materials

this distinction is somewhat difficult to make. Therefore,

cutting a piece of wood to a different width is ripping and

cutting across the short dimension is crosscutting. Neither

ripping or crosscutting may be done safely freehand!

Ripping requires the use of the rip fence and crosscutting

uses the miter gauge.

CAUTION: Before using the saw each and every time

verify the following:

1. Blade is tight.

2. Bevel angle and height lock knobs are tight.

3. If ripping, ensure fence lock lever is tight and fence is

parallel to the blade.

4. If crosscutting, miter gauge knob is tight.

5. Safety glasses are being worn.

6. The blade guard is properly attached and the

anti-kickback teeth are functioning.

Failure to adhere to these common safety rules can greatly

increase the likelihood of injury.

Ripping

1. Lock the rip fence by pressing the fence lock lever

down. Remove the miter gauge.

2. Raise the blade so it is about 1/8"(3.2mm) higher than

the top of the workpiece.

3. Hold the workpiece flat on the table and against the

fence. Keep the workpiece about 1" (25.4mm) away

from the blade.

CAUTION: The workpiece must have a straight edge

against the fence and must not be warped, twisted or

bowed. Keep both hands away from the blade and away

from the path of the blade.

4. Turn the saw on and allow the blade to come up to

speed. Both hands can be used in starting the cut.

When there is approximately twelve (12) inches

(305mm) left to be

ripped, use only one hand, with your thumb pushing the

material, your index and second finger holding the

material down and your other fingers hooked over the

fence. Always keep your thumb along side your first two

fingers and near the fence.

5. Keeping the workpiece against the table and fence,

slowly feed the workpiece rearward all the way through

the saw blade. Continue pushing the workpiece until it is

clear of the guard and it falls off the rear of the table. Do

not overload the motor.

6. NEVER try to pull the workpiece back with the blade

turning. Turn the switch off, allow the blade to stop, raise

the anti-kickback teeth on each side of the splitter if

necessary and slide the workpiece out.

7. When sawing a long piece of material or a panel, always

use a work support. A sawhorse, rollers, or out feed

assembly provides adequate support for this purpose. The

work support must be at the same height as the saw

table.

CAUTION: Never push or hold onto the “free” or “cut

off” side of the workpiece.

Bevel Ripping

This operation is the same as ripping except the bevel

angle is set to an angle other than zero degrees.

WARNING: Before connecting the table saw to the

power source or operating the saw, always inspect the

guard and splitter for proper alignment and clearance with

saw blade. Check alignment after each change of bevel

angle.

Ripping Small Pieces

It is unsafe to rip small pieces. It is not safe to put your hands

close to the blade. Instead, rip a larger piece to obtain the

desired piece. When a small width is to be ripped and the hand

cannot be safely put between the blade and the rip fence, use

one or more push sticks. A pattern is

included on the back cover to make

push sticks. Use them to hold the

workpiece against the table and

fence, and push the workpiece fully

past the blade

Crosscutting

1. Remove the rip fence and place

the miter gauge in the desired

slot.

2. Adjust the blade height so that

the blade is about 1/8" (3.2mm)

higher than the top of the

workpiece.

3. Hold the workpiece firmly

against the miter gauge with the path of the blade in line

with the desired cut location. Keep the workpiece an inch

7

Page 11

narrow cut-offs or when cutting with a dado blade, clean the

dust collection port each time. If you find you are clogging

the port often, the dust port elbow may be removed by

loosening the two screws where it attaches to the dust

shroud. A dust collection hose can then be attached directly

to the shroud as long as the saw is not beveled past 35˚.

Maintenance, Cleaning

Care of the table top

Protect your investment. Keep your table saw clean. If you

notice signs of rust, steel wool the areas, clean with mineral

spirits or denatured alcohol and apply paste wax.

8

English

or so in front of the blade. KEEP

BOTH HANDS ON THE MITER

GAUGE, AWAY FROM THE

BLADE AND THE PATH OF THE

BLADE.

4. Start the saw motor and allow the

blade to come up to speed.

5. While using both hands to keep the workpiece against the

face of the miter gauge, and holding the workpiece flat

against the table, slowly push the workpiece through the

blade.

6. NEVER try to pull the workpiece back with the blade

turning. Turn the switch off, allow the blade to stop, and

carefully slide the workpiece out.

CAUTION: Never touch or hold onto the “free” or “cut

off” end of the workpiece.

Bevel Crosscutting

This operation is the same as crosscutting except that the

bevel angle is set to an angle other than 0 degrees.

WARNING: Before connecting the table saw to the

power source or operating the saw, always inspect the guard

and splitter for proper alignment and clearance with saw

blade. Check alignment after each change of bevel angle.

Mitering

This operation is the same as crosscutting except the

miter gauge is locked at an angle other than 0°. Hold the

workpiece FIRMLY against the miter gauge and feed the

workpiece slowly into the blade (to prevent the workpiece

from moving).

MITER GAUGE OPERATION

To set your miter gauge, loosen the lock handle and move

the miter gauge to the desired angle. The miter gauge has

set stops and 90° and 45° left and right. To rotate the miter

gauge beyond these stops, flip the stop plate up, as shown.

Compound Mitering

This is a combination of bevel crosscutting and mitering.

Follow the instruction for both, bevel crosscutting and

mitering.

Dado Cutting

CAUTION: Do not attempt to stack dado blades thicker

than 13/16" (20mm). Do not use dado blades larger than

8" (200mm) diameter. Since dado cuts are not through

cuts, the cuts must be performed with the blade guard

removed. To remove the blade guard, loosen the two bolts

(A) shown in Figure 13 and remove the guard assembly.

Anytime a cut is required that is considerably wider than the

saw kerf, a dado is used. When using the dado, the special

dado insert (also sold as an accessory) must be used.

When installing the dado blade set, it may be necessary to

eliminate the outer clamp washer from the assembly in

order to capture sufficient thread to safely hold the dado

blade set.

A dado cut is commonly used to add support and line up a

shelf for a cabinet, bookcase or some such project. When

using the dado, the guard must be removed. Use EXTREME

care when using the dado without the guard. If a deep cut is

required, use several successive passes rather than

attempting to make it with one pass. Maximum dado width

on this saw is 13/16" (20mm). DO NOT USE WIDER

COMBINATIONS.

When cutting with a dado blade use dust collection to prevent

heavy dust loads from piling up under the saw and on the fan

intake on the motor. Clean these areas often.

CAUTION: Always check dado blade clearance before

plugging in the saw.

Be sure to place the guard and standard throat plate back in

position and check adjustments when the dado cuts are

complete.

Dust Collection

Your table saw is equipped with a dust shroud and dust

collection port. For best results, connect a vacuum to the

port at the rear of the saw.

If the saw is operated without a vacuum attached, most of the

dust will be blown out the dust collection port. After extended

use, the saw’s dust collection system may become clogged.

To clear the dust collection system:

a) Unplug the saw.

b) Use a paint stick or long screwdriver to loosen debris

and cut-offs and pass it out through the port.

When cutting wet wood without a vacuum, making long

A

B

D

E

F

FIG. 22

A

B

E

FIG. 21

C

Page 12

If the fence head glide strips (arrows below) become worn

or damaged, it can easily be replaced. Consult your local

D

EWALT Service Center for parts and assistance.

Accessories

Recommended accessories for use with your tool are

available at extra cost from your distributor or local service

center.

D

EWALT manufactures the following accessories for your

saw:

DW7460 - Mobile base

DW7461 - Sliding Table and Premium Gauge

DW7462 - Iron Wing

DW7463 - Outfeed Table

DW7464 - 52” Rail System with Legs and Table Board

DW7466 - Dado Throat Plate

DW7467 - Steel Wing

DW7468 - 30” Rail System with Legs and Table Board

DW7469 - Low Profile Fence Face

DW7471 - Enhanced Miter Gauge

CAUTION: The use of any non-recommended

accessory may be hazardous.

If you need assistance in locating any accessory, please

contact D

EWALT Industrial Tool Co., 701 East Joppa

Road, Baltimore, MD 21286 or call

1-800-4-D

EWALT (1-800-433-9258).

Important

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment should be performed by

authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

This saw warranted for two years from date of purchase.

We will repair, without charge, any defects due to faulty

materials or workmanship. For warranty repair information,

call 1-800-4-D

EWALT. This warranty does not apply to

accessories or damage caused where repairs have been

made or attempted by others. This warranty gives you

specific legal rights and you may have other rights which

vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by

our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of

9

English

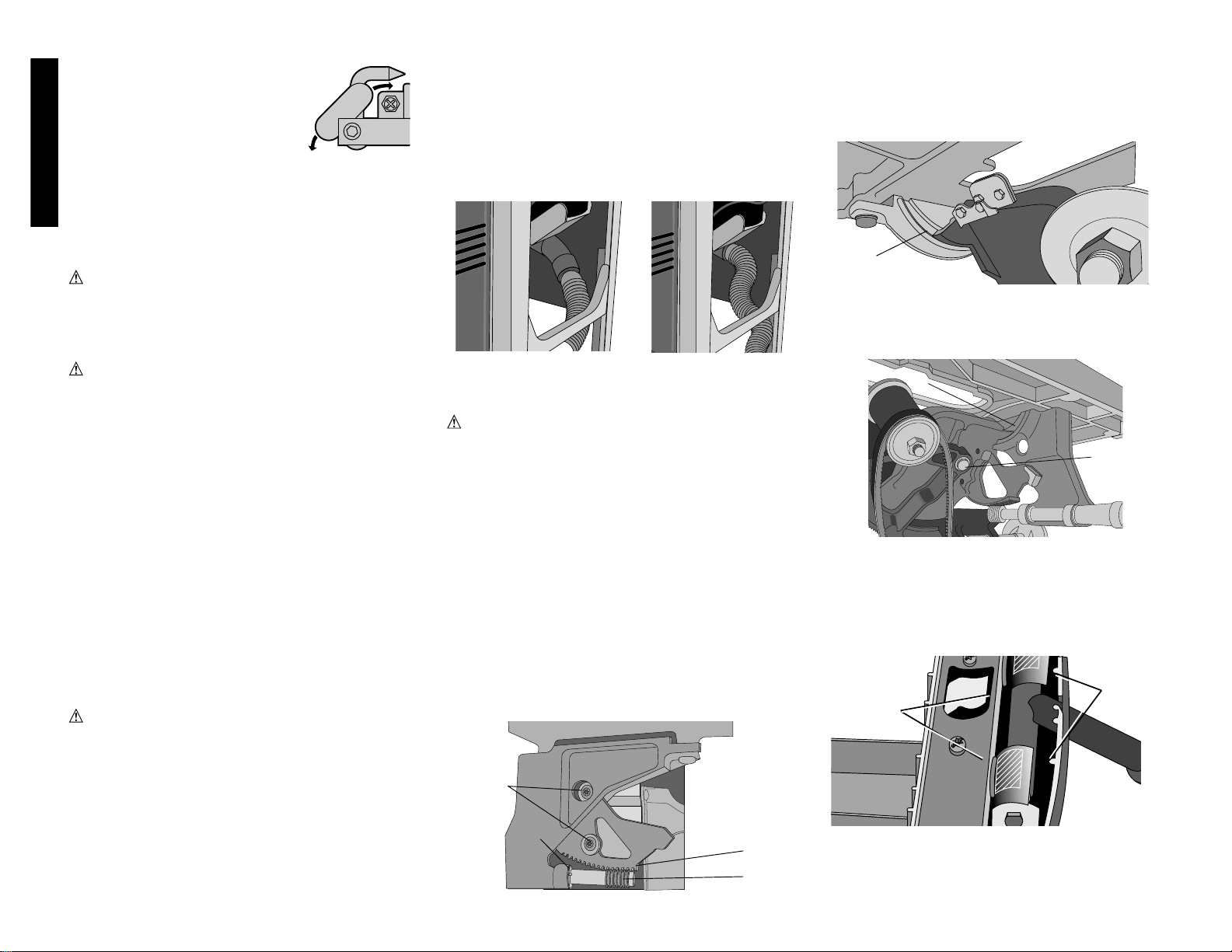

Over time, the lubricants used in the mechanism of

your tablesaw may need to be replenished.

HEIGHT AND BEVEL GEAR (FIG. 22):

First clean off any accumulated sawdust from the gears

and the worms with a stiff brush. Next, remove any pitch or

resin which has built up. You may need to use a solvent

such as mineral spirits to remove it. Next, re-apply grease

to the worms (A) to the gears (B) and the washer/pin

assembly(C). You can also apply paste wax to the gears if

you find that the grease is attracting too much sawdust. If

any backlash has occurred in the bevel system, you can readjust the bevel gear clearance by loosening the two

screws (D) which hold the gear to the cradle, letting the

gear fall into tighter mesh, lightly tightening the screws,

rotating the worm one full turn to set the gear height, then

fully tightening the gear retaining screws. This adjustment

must be made at 0˚ bevel.

BEVEL PIVOT:

The bevel pivot trunnions, both front and back should also

be maintained. First clean them like the gears were

cleaned. Then apply grease into the curved slots (E) and

bevel the saw back and forth to distribute the grease.

ARBOR PIVOT:

You may also need to lubricate the arbor pivot pin (F). This

can be done by applying a light oil at both the base and

top of the pivot pin.

Lubricating Fence Head

The moving parts of your fence head should be periodically

greased. This includes the area between the cams and

locking levers (A), and between the cams and the fence

head casting (B).

Maintaining Fence System

Your fence should always slide freely. If it seems to require

excessive force to slide or if it feels rough, wipe the rails

and fence head gliding surface with a cloth or paper towel.

Check the movement again. If it still feels rough, clean the

fence head with a mild solvent such as denatured alcohol

or mineral spirits. Re-coat the rail with a heavy coat of

paste wax or a light oil. Slide the fence head back and

forth several times to coat the rail and fence. Wipe off any

excess wax or oil from the rail.

your DEWALTheavy duty industrial tool, simply return it to the

participating seller within 30 days for a full refund. Please

return the complete unit, transportation prepaid. Proof of

purchase may be required.

Page 13

10

English

Troubleshooting

SAW WILL NOT START WHAT TO DO:

1. Saw not plugged in. 1. Plug in saw.

2. Fuse blown or circuit breaker tripped. 2. Replace fuse or reset circuit breaker.

3. Cord damaged. 3. Have cord replaced by authorized service

center.

SAW MAKES UNSATISFACTORY CUTS WHAT TO DO:

1. Dull blade. 1. Replace blade. Page 5.

2. Blade mounted backwards 2. Turn blade around. Page 5.

3. Gum or pitch on blade. 3. Remove blade and clean with turpentine

and coarse steel wool or household oven

cleaner.

4. Incorrect blade for work being done. 4. Change blade type. Page 6.

BLADE DOES NOT COME UP TO SPEED WHAT TO DO:

1. Extension cord too light or too long. 1. Replace with adequate size cord. Page 1.

2. Low house current 2. Contact your electric power company.

3. Belt worn or broken. 3. Replace belt. See D

EWALT service center

MACHINE VIBRATES EXCESSIVELY WHAT TO DO:

1. Saw on uneven floor 1. Reposition on flat surface. Adjust feet to

stabilize. See page 6.

2. Damaged saw blade. 2. Replace blade. Page 5.

3. Saw not secured to floor. 3. Fasten saw to floor.

4. Damaged belt. 4. Replace belt.

INACCURATE MITER CUTS WHAT TO DO:

1. Miter gauge not adjusted correctly 1. Check and adjust. Page 6.

2. Miter gauge not square to blade. 2. Check and adjust. Page 6.

3. Blade not perpendicular to table. 3. Check and adjust bevel stops. Page 6.

4. Workpiece moving. 4. Clamp workpiece to miter head face.

Glue 120 grit sandpaper to miter head

face.

MATERIAL BINDING DURING CUT WHAT TO DO:

1. Cutting bowed material. 1. Material should be laid flat at the point of

cut and supported with scrap and/or miter

gauge.

2. Fence not aligned parallel to blade. 2. Align fence. Page 4.

3. Splitter not aligned with blade. 3. Align splitter. Page 5.

INACCURATE RIP CUTS WHAT TO DO:

1. Rip scale pointer not aligned. 1. Adjust pointer. Page 5.

INACCURATE BEVEL CUTS WHAT TO DO:

1. Bevel scale not adjusted. 1. Adjust scale. Page 6.

2. Bevel stops not adjusted. 2. Adjust bevel stops. 6.

REAR OF FENCE POPS UP

WHEN FENCE LOCKS WHAT TO DO:

1. Rear clip not engaged with rear rail. 1. Re-attach fence. Be sure clip is engaged.

Page 5.

2. Rear cap/clip not positioned correctly 2. Adjust rear cap position. Page 5.

FENCE DOES NOT SLIDE FREELY WHAT TO DO:

1. Fence drags or hops as it is moved. 1. Clean front and rear rails. Reapply wax. Pg. 8

2. Rear cap/clip interferes rear of saw. 2. Adjust rear cap position. Page 5.

FENCE HITS TABLE TOP OR GAP CHANGES

AS IT IS SLID ALONG THE RAILS WHAT TO DO:

1. Front and/or rear rail not parallel to table. 1. Adjust rails so that they are parallel. Page 4.

2. Support tables not aligned with table top 2. Adjust support tables to align with top.

Page 4.

3. Fence face drags along table surface. 3. Adjust fence face. Page 5.

HEIGHT OR BEVEL CRANKS

HARD TO TURN WHAT TO DO:

1. Crank locks engaged. 1. Loosen lock knob 1/4 to 1/2 turn.

2. Sawdust, pitch on height or bevel gears

making operation difficult. 2. See Maintenance, page 8.

DUST PORT CLOGS WHAT TO DO:

1. Vacuum not attached 1. Attach vacuum. Page 8

2. Cutting small slivers or chunks 2. Remove dust port. Use paint stick or

screwdriver to dislodge debris or leave

port off. Page 8

Page 14

11

Français

DEW ALT… CONÇU POUR LE CHANTIER

Les outils industriels è rendement élevé D

EWALT répondent aux pires exigences de

l’industrie et de la construction en Amérique du Nord. La conception de chacun des outils

de la gamme (des perceuses aux ponceuses, en passant par les rectifieuses) résulte de

leur utilisation rigoureuse sur le chantier et dans l’industrie. Chaque outil est construit

avec une précision laborieuse à l’aide de systèmes de fabrication de pointe et un intense

contrôle de la qualité. Chacun d’eux est soigneusement vérifié avant de quitter l’usine afin

de s’assurer que l’outil répond aux normes de durabilité, de fiabilité et de puissance des

utilisateurs.

D

EWALT:

Conçu pour le chantier … NOUS LE ARANTISSONS.

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET OUTIL OU TOUT AUTRE

OUTIL D

EWALT, COMPOSER SANS FRAIS LE NUMÉRO:

1 800 4-DEWALT (1 800 433-9258)

AVERTISSEMENT : PAR MESURE DE SÉCURITÉ PERSONNELLE, LIRE LE GUIDE D’UTILISATION AVANT D’UTILISER LA SCIE. TOUJOURS PORTER DES LUNETTES DE

SÉCURITÉ. NE PAS PORTER DE GANTS, DE CRAVATE, DE BIJOUX NI DE VETEMENTS AMPLES. PROTÉGER LA CHEVELURE LORSQU’ELLE EST LONGUE. ÉLOIGNER LES

DOIGTS ET LES MAINS DE LA TRAJECTOIRE DE LA LAME; PRENDRE PARTICULIEREMENT SOIN LORS DES COUPES EN BISEAU. TOUJOURS UTILISER LE PROTECTEUR ET

LE RÉPARTITEUR POUR TOUTES LES COUPES, Y COMPRIS LES COUPES COMPLETES. UTILISER UN BATON POUR POUSSER LE MATÉRIAU LE CAS ÉCHÉANT. SAVOIR

COMMENT ÉVITER LES REBONDS; CONSULTER LE GUIDE. TOUJOURS SOUTENIR LA PIECE À DÉCOUPER À L’AIDE DE LA TABLE ET DU GUIDE, OU DE L’INDICATEUR

D’ONGLETS. NE JAMAIS UTILISER SIMULTANÉMENT LE GUIDE ET L’INDICATEUR D’ONGLETS. NE JAMAIS S’ÉTIRER AU-DESSUS NI AUTOUR DE LA LAME. BIEN FIXER LA

LAME AVANT D’UTILISER L’OUTIL. NE JAMAIS RETIRER DES PIECES COINCÉES NI COUPÉES AVANT D’AVOIR MIS L’OUTIL HORS TENSION ET DE S’ETRE ASSURÉ DE

L’IMMOBILISATION DE LA LAME. PROTÉGER DE LA PLUIE ET NE PAS UTILISER DANS DES ENDROITS HUMIDES. BIEN FIXER L’OUTIL AFIN D’EN ÉVITER DES MOUVEMENTS

IMPRÉVUS. NE PAS SE SERVIR DE L’OUTIL APRES AVOIR CONSOMMÉ DE L’ALCOOL OU DES DROGUES. LE NON-RESPECT DU PRÉSENT AVERTISSEMENT COMPORTE DES

RISQUES DE BLESSURES GRAVES.

AVERTISSEMENT : PAR MESURE DE SÉCURITÉ, NE PAS UTILISER LA SCIE AVANT LE MONTAGE FINAL CONFORME AUX INSTRUCTIONS NI AVANT D’AVOIR LU ET

COMPRIS LES POINTS SUIVANTS.

Page 15

12

AVERTISSEMENT : Par mesure de sécurité personnelle, lire le guide d'utilisation avant d'utiliser la

scie.

AVERTISSEMENT : Afin de réduire les risques d'incendie, de secousses électriques ou de

blessures lorsqu'on utilise des outils électriques, il faut toujours respecter les mesures de sécurité

suivantes.

Mise à la terre

En cas de défaillance ou de bris, la mise à la terre procure un chemin de moindre résistance au

courant électrique afin de réduire le risque de secousses électriques. L'outil est muni d'un cordon

comportant un conducteur de terre et d'une fiche de terre. Il faut brancher la fiche dans une prise

correspondante bien installée et mise à la terre selon les lois et règlements de la région. Il ne faut pas

modifier la fiche de l’outil; lorsque la fiche ne s’insère pas dans la prise, faire installer une prise

appropriée par un électricien certifié.

Une mauvaise connexion du fil de terre présente des risques de secousses électriques. Le conducteur

vert (ou vert et jaune) du cordon constitue la mise à la terre. Si la réparation ou le remplacement d’un

cordon d’électrique ou d’une fiche s’avèrent nécessaires, ne pas brancher la mise à la terre dans une

borne sous tension.

Consulter un électricien certifié ou un représentant du service à la clientèle si les instructions de mise

à la terre ne sont pas parfaitement assimilées ou si un doute réside quant à la mise à la terre. Utiliser

seulement des cordons de rallonge trifilaires ayant une fiche à 3 broches ainsi qu'une prise à 3 trous

acceptant la fiche de l'outil.

Réparer ou remplacer immédiatement tout cordon endommagé ou usé.

Outils mis à la terre conçus pour être alimentés à une tension maximale de 150 volts : Cet outil est

conçu pour être alimenté par un circuit dont la fiche ressemble à celle illustrée à la figure A. L’outil

comporte une fiche de mise à la terre qui ressemble à celle illustrée à la figure A. On peut utiliser un

adaptateur temporaire (figures B et C) pour brancher ce type de fiche dans des prises à deux trous

(figure B). Utiliser l’adaptateur temporaire uniquement en attendant l’installation d’une prise mise à la

terre par un électricien certifié. L'oreille ou la cosse rigide et verte de l’adaptateur doit être reliée à une

mise à la terre permanente, comme une prise bien mise à la terre. L’adaptateur (C) ne peut être utilisé

au Canada.

Fonctionnement à 240 volts

Le moteur de la scie est à double voltage, 120 ou 240 volts. Pour un

fonctionnement monophasé de la scie à 240 volts, reconnecter les fils du

moteur dans la boîte de dérivation conformément aux instructions énoncées

sur la plaque signalétique du moteur.

AVERTISSEMENT : Débrancher le moteur de sa source d’alimentation

avant d’en connecter les fils.

Il faut également remplacer la fiche 120 volts fournie avec le moteur par

une fiche approuvée par UL/CSA convenant à une tension de 240 volts et au

courant requis. Communiquer avec le centre de service DEWALT de la

région ou avec un électricien certifié pour connaître la méthode d’installation de la fiche. La scie doit

être conforme aux codes électriques local et national une fois la prise de 240 volts installée.

Brancher la scie munie d’une fiche de 240 volts uniquement à une prise semblable à celle de

l’illustration. Aucun adaptateur n’existe ou ne doit être utilisé avec la fiche de 240 volts.

Importantes mesures de sécurité

• S’ASSURER QUE LES PROTECTEURS sont en place et en bon état.

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l'habitude de vérifier si les clés de réglage ont

été retirées avant de faire démarrer l'outil.

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et des établis encombrés

peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Ne pas se servir des outils électriques dans des

endroits humides ou mouillés. Les protéger de la pluie. Bien éclairer la surface de travail.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus à l'écart de l'aire de travail.

• GARDER L’ATELIER À L’ÉPREUVE DES ENFANTS en y installant des cadenas, des

interrupteurs généraux ou en retirant les clés des démarreurs.

• NE JAMAIS FORCER L'OUTIL. Afin d'obtenir un rendement sûr et efficace, utiliser l'outil à son

rendement nominal.

• UTILISER L'OUTIL APPROPRIÉ. Ne jamais exiger d'un petit outil ou d'un accessoire le

rendement d'un outil de fabrication plus robuste.

• CORDONS DE RALLONGE. S'assurer que le cordon de rallonge est en bon état. Lorsqu'on

se sert d'un cordon de rallonge, s'assurer qu'il est de calibre approprié pour la tension

nécessaire au fonctionnement de l'outil. L'utilisation d'un cordon de calibre inférieur occasionne

une baisse de tension entraînant une perte de puissance et la surchauffe. Le tableau suivant

indique le calibre approprié selon la longueur du cordon et les mentions de la plaque

signalétique de l'outil. En cas de doute, utiliser un cordon de calibre supérieur. Le chiffre

indiquant le calibre est inversement proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Courant

Au moins Au plus AWG

0- 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 1 16 14 12

12 - 16 14 12 Non recommandé

PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des vêtements amples, des

gants, des cravates, des bracelets ou tout autre bijou qui peuvent être happés par les pièces

en mouvement. Il est conseillé de porter des chaussures à semelle antidérapante. Protéger

la chevelure si elle est longue.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Porter également un masque

respiratoire si le travail de coupe produit de la poussière. Les lentilles des verres correcteurs

résistent seulement aux chocs; ce NE sont PAS des lunettes de sécurité.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l'aide de brides ou d'un étau.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une position stable et garder son

équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et affûtés pour qu'ils donnent un

rendement supérieur et sûr. Suivre les directives concernant la lubrification et le remplacement

des accessoires.

• DÉBRANCHER LES OUTILS avant de les réparer ou d’en changer un accessoire (comme une

lame, un foret ou un couteau).

• ÉVITER LES DÉMARRAGES ACCIDENTELS. S'assurer que l'interrupteur est à la position

hors circuit lorsqu'on branche l'outil.

• UTILISER LES ACCESSOIRES RECOMMANDÉS. Consulter le guide d’utilisation pour

connaître la liste des accessoires recommandés. L’utilisation d’accessoires inappropriés peut

présenter des risques de blessures.

• NE JAMAIS SE TENIR SUR L’OUTIL. Cela présente des risques de blessures graves si l’outil

bascule ou si on touche à la lame par inadvertance.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à utiliser l'outil, il faut vérifier

Français

AB CD

BROCHE DE PRISE

MISE À LA TERRE

BROCHE DE PRISE

MISE À LA TERRE

PRISE MISE

À LA TERRE

DISPOSITIF DE

MISE À LA TERRE

ADAPTATEUR

Page 16

si le protecteur ou toute autre pièce endommagée remplit

bien la fonction pour laquelle il a été prévu. Vérifier

l'alignement et les attaches des pièces mobiles, le degré

d'usure des pièces et leur montage, ainsi que tout autre

facteur susceptible de nuire au bon fonctionnement de

l'outil. Faire réparer ou remplacer tout protecteur ou toute

autre pièce endommagée dans un centre de service

autorisé.

• DIRECTION D’ALIMENTATION. Appliquer le matériau

sur la lame uniquement dans la direction opposée à la

rotation de la lame.

• TOUJOURS SURVEILLER L’OUTIL. LE METTRE HORS

TENSION. Laisser l’outil seulement lorsqu’il est

complètement immobilisé.

Mesures de sécurité propres aux

scies circulaires à table

• Porter des lunettes de sécurité.

• Utiliser le protecteur et le répartiteur à chaque coupe

lorsque c'est possible, y compris les coupes complètes du

matériau.

• Éloigner les mains de la trajectoire de la lame.

• Utiliser un bâtonnet pour pousser le cas échéant.

• Savoir comment minimiser les risques de rebonds.

• Ne pas effectuer de tâches à main levée.

• Ne jamais s'étirer derrière ni au-dessus de la lame.

AVERTISSEMENT : Certains outils, tels que les

sableuses électriques, les scies, les meules, les perceuses

ou certains autres outils de construction, peuvent soulever

de la poussière contenant des produits chimiques

susceptibles d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres

produits de maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi

un traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon

la fréquence avec laquelle on effectue ces travaux. Pour

réduire l’exposition à de tels produits, il faut travailler dans

un endroit bien ventilé et utiliser l’équipement de sécurité

approprié tel un masque anti-poussières spécialement

conçu pour filtrer les particules microscopiques.

• PORTER UN MASQUE RESPIRATOIRE et des lunettes

de sécurité. Le travail de coupe peut produire d'importantes

quantités de sciure.

Rebonds

COMMENT LES ÉVITER ET SE PROTÉGER DES RISQUES

DE BLESSURES QU'ILS PRÉSENTENT.

a) S'assurer que la lame est parallèle au guide de refente.

b) Ne pas couper en refente en exerçant la pression

d'alimentation à la section de la pièce qui est inutile. Il

faut toujours exercer la poussée d'alimentation entre

la lame et le guide pendant les coupes de refente, en

utilisant un bâtonnet pour les petits travaux (largeur

d'au plus 152 mm (6 po). Lorsque la largeur est

inférieure à 51 mm (2 po), il faut se servir d'un dispositif

spécial.

c) Laisser le protecteur, le répartiteur et les cliquets

d'arrêt en place et en bon état de fonctionnement.

S'assurer que les cliquets sont tranchants. Lorsque les

cliquets ne sont pas fonctionnels, confier la réparation

de l'outil au personnel du centre de service DeWalt de

la région. Le répartiteur doit être aligné sur la lame et

les cliquets doivent arrêter un rebond dès qu'il

commence. Vérifier leur fonctionnement avant

d'effectuer des coupes en refente.

d) La scie peut découper des plastiques et des

agglomérés (comme des panneaux rigides). Toutefois,

comme ces matériaux sont très rigides et glissants, il

arrive que les cliquets n'arrêtent pas les rebonds. Il

faut donc accorder une attention particulière au

montage et aux directives de coupe en refente.

e) Utiliser le protecteur et le répartiteur à chaque coupe

lorsque c'est possible, y compris les coupes complètes

du matériau.

Protecteur et répartiteur

La scie à table est munie d’un ensemble de protecteur et de

répartiteur qui couvre la lame et en empêche le contact

accidentel. Le répartiteur est une plaque plane qui s’insère dans

la fente creusée par la lame de la scie et prévient efficacement les

rebonds en atténuant la tendance qu’a la lame à se coincer dans

la coupe. Le répartiteur peut seulement servir lors de coupes

complètes qui séparent le bois. Lorsqu’on fait des

embrèvements, des feuillures ou d’autres coupes qui ne

traversent pas le bois, retirer l’ensemble de protecteur et

répartiteur de la scie. Deux cliquets d’arrêt se trouvent sur les

côtés du répartiteur et permettent au bois de se déplacer dans la

direction de coupe mais le bloquent s’il se dirige en direction de

l’utilisateur.

TERMES

Il faut se familiariser avec les termes suivants, qui sont utilisés

tout au long du présent guide.

• La coupe complète consiste en une coupe divisant le

matériau en deux.

• Le bâtonnet désigne un bâton de bois, généralement

fait main, dont on se sert pour pousser les petites

pièces à ouvrer vers la scie tout en éloignant les mains

de l'utilisateur de la lame.

• Les rebonds se produisent lorsque la lame bloque dans

la coupe et repousse violemment la pièce à ouvrer vers

l’utilisateur.

• On dit qu’une coupe est faite à main levée lorsqu’on

n’utilise ni guide d’onglet, ni guide de refente, ni tout

autre moyen pour guider ou assujettir la pièce à ouvrer.

13

Français

Fabrication d’un bâtonnet (page

arrière)

• Pour se servir de la scie à table de façon sûre, il faut

utiliser un bâtonnet pour pousser toute pièce dont les

dimensions ou la forme exigeraient que les mains de

l’utilisateur se rapprochent à moins de 6 pouces de la

lame.

• La fabrication d’un bâtonnet ne demande aucun type

de bois particulier. Il doit cependant être solide et

suffisamment long. Le bâtonnet mesure idéalement 12

po et comporte une encoche qui s’appuie sur l’arête

de la pièce à ouvrer pour l’empêcher de glisser. Il est

pratique d’avoir plusieurs bâtonnets de la même

longueur (12 pouces) comportant des encoches de

dimensions différentes pouvant convenir aux pièces

d’épaisseurs différentes.

• Un bâtonnet est illustré sur la couverture intérieure

arrière. La forme peut varier en fonction des besoins

de l’utilisateur, tant qu’il permet d’éloigner efficacement

les mains de la lame.

CONSERVER CES MESURES

À TITRE DE RÉFÉRENCE.

Fiche technique

Puissance (HP) 1 3/4

Dimensions de la table 27 po sur 40 3/4 po

Angle des onglets 60°à gauche et à droite

Angle des biseaux De -2°à 47°à gauche

Dimension de la lame 254 mm (10 po)

Prof. de coupe max. 0° en biseau..........79 mm (3 1/8 po)

Prof. de coupe max. 45° en biseau........54 mm (2 1/8 po)

Régime sous vide (tr/min) 3 000

Unité de base DW746

L’assemblage des accessoires complémentaires à cet outil est

expliqué dans les instructions qui les accompagnent. Les

instructions d’utilisation et de réglage sont énoncées dans ce

guide à partir de l’étape 16 de la page 21.

Outils compris

Nous avons joint les outils suivants à la nouvelle scie pour en

faciliter l’assemblage.

• Clé Torx T50

• Clé hexagonale de 5 mm

• Clé mixte à ouvertures de 16 mm, 13 mm, 10 mm et

22 mm

• Clé polygonale à embouts de 15/16 po et 10 mm.

Outils requis

• Tournevis à lame plate

• Clé à fourches de 16 mm ou 5/8 po ou pinces

• Règle

Page 17

14

•Équerre

•Massette ou marteau et bloc de bois

Les outils suivants accéléreront le montage

•Clé à douille de 16 mm ou 5/8 po avec rallonge de 6 po

•Clé à douille de 13 mm ou 1/2 po

•Clé à fourches de 10 mm

• Tournevis Torx T20 et T25

• Clé Torx T40

Autres articles requis

• Solvant doux, comme du white-spirit, du décapant ou

de l’alcool dénaturé.

• Cire en pâte de haute qualité

Ferrures requises

Le sac de ferrures qui se trouve dans la boîte de pièces contient

tous les écrous, boulons et rondelles nécessaires à l’assemblage

des composants de la scie circulaire à table d’entrepreneur

DW746.

Pour faciliter l’assemblage de la scie, identifier les écrous,

boulons et rondelles sur le tableau de la page suivante. Les

séparer par dimensions pour pouvoir les identifier plus

rapidement. Avant chaque étape, identifier les pièces requises.

Montage du DW746

LIRE TOUTE LA SECTION SUR LE MONTAGE AVANT DE

COMMENCER.

ÉTAPE 1. Retirer la boîte de pièces, le couvercle du

moteur, la poutrelle du guide de refente et les tables

latérales de la scie.

ÉTAPE 2. Tourner la scie à l’envers avec de l’aide. Le

poids combiné de la table et du moteur totalise environ

200 lb.

ÉTAPE 3. Couper la courroie de

plastique qui tient le moteur et la

retirer.

ÉTAPE 4. À l’aide de la manivelle qui

se trouve à l’avant, abaisser le

moteur et retirer la mousse

d’emballage qui le sépare du

Français

BOULONS

HEXAGONAUX

10 MM X 35 MM (2)

Tornillera incluida con la sierra de banco para madera DW746

VIS Á TÊTE PLATE

(4)

BOULONS

HEXAGONAUX

10 MM X 25 MM

(8)

CLÉ HEXAGONAL

5 MM (1)

ÉCROUS 10 MM (8)

ÉCROUS DE 8 MM

(4 PIEZAS)

CLÉ TORX

T50 (1)

BOULONS Á TÊTE

BOMBÉE

8 MM (4)

RONDELLES DE

BLOCAGE 10 MM

(14)

RONDELLES

PLATES (14)

CROCHET Á

CLÉ (1)

RONDELLES DE

BLOCAGE DE

8 MM (4)

Å

B

C

FIG. 1

Page 18

mécanisme.

ÉTAPE 5. Installer la manivelle de biseau (figure 1).

Pour ce faire, installer d’abord la poignée de la

manivelle (A) sur l’arbre (B) et la tourner légèrement

pour engager la goupille de l’arbre. Visser la poignée

de verrouillage (C) en place jusqu’au bout, puis la

dévisser de 1/4 à 1/2 tour.

ÉTAPE 6. À l’aide de la manivelle de réglage en hauteur,

soulever le mécanisme au maximum.

ÉTAPE 7. Installer le crochet à clé. Sur la patte avant

droite, presque en haut, se trouve un orifice fileté en

plastique. Y visser le crochet à clé en forme de L

jusqu’à ce que seuls quelques filets soient visibles.

ÉTAPE 8. Ouvrir la boîte des rails (qui contient les rails

avant et arrière).

ÉTAPE 9. Assembler le rail avant et les supports

(fig.2). Ferrures requises :

4 boulons à tête bombée de 8 mm

4 rondelles de blocage de 8 mm

4 écrous de 8 mm

Assembler les supports de rail avant (en ne vissant que

quelques filets). Placer la tête du boulon à tête bombée

dans les trous en poire du rail avant et faire glisser les

boulons pour en insérer la partie carrée. Visser l’écrou à

la main. Répéter pour les trois autres supports. Placer les

supports sur le rail en s’assurant que l’échelle de refente

est orientée vers le dessus de la table. Les quatre

supports doivent être orientés dans la même direction.

ÉTAPE 10. Fixer le rail avant et les supports sur la

table (figure 3). Ferrures requises :

4 vis à tête plate de 10 x 30 mm

4 rondelles plates

4 rondelles de blocage de 10 mm

4 écrous de 10 mm

Fixer chaque vis dans le trou supérieur du support. En

laissant les rondelles et écrous à l’intérieur de la table,

installer une rondelle plate, une rondelle de blocage et un

écrou. Serrer les écrous du support de rail central et

serrer les autres à la main.

ÉTAPE 11. Fixer le rail arrière (figure 4). Ferrures

requises :

2 boulons hexagonaux de 10 x 35 mm

2 rondelles plates

2 rondelles de blocage de 10 mm

2 écrous de 16 mm

Fixer le rail arrière à la table à l’aide de boulons

hexagonaux, de rondelles, de rondelles de blocage et

d’écrous, en gardant les rondelles et les écrous à

l’intérieur de la table. Le côté plat devrait être orienté

15

Français

vers le bas, à moins de monter également un accessoire

(consulter les détails des instructions des accessoires

relatifs au montage des rails). S’assurer que les

extrémités du rail arrière s’alignent sur celles du rail avant.

Bien serrer, mais sans forcer.

ÉTAPE 12. Installer les rails parallèlement sur la

table (figure 5). En utilisant la face du guide ou une

règle à niveler pour prolonger la surface de la table

au-delà du rail, s’assurer que la distance entre la table

et le rail est la même des deux côtés de la table. Si

les rails ne sont pas bien alignés, desserrer les vis de

montage légèrement et tapoter les supports des rails à

l’aide d’une massette ou d’un marteau et d’un bloc de

bois jusqu’à ce que les distances soient égales. Bien

serrer les vis. Répéter pour le rail arrière.

ÉTAPE 13. Fixer les tables de soutien de gauche et de

droite (figure 6). Ferrures requises :

6 boulons hexagonaux de 10 x 25 mm

6 rondelles plates

6 rondelles de blocage de 10 mm

6 écrous de 10 mm

Avant d’installer la table de soutien, installer 3 boulons et

rondelles par côté, comme le montre l’illustration, en

conservant un jeu de 1/4 po. Déposer une table latérale

sur les boulons en les insérant dans les encoches. En se

guidant sur la face de guide extrudé, placer la table de

FIG. 2

FIG. 3

FIG. 4

FIG. 5

FIG. 6

Page 19

l’onglet.

e. Serrer les trois vis (A) qui retiennent le longeron du

guide à la tête, en commençant avec les deux vis

arrière. Le longeron est maintenant monté en parallèle

au plateau.

ÉTAPE 18. Régler la hauteur et la position de la face

du guide (figure 9). Desserrer les écrous à oreilles qui

fixent la face du guide à la poutrelle. Soulever la face

du guide et glisser 16 pages de ce guide d’utilisation ou

d’autres papiers entre la face

et la table. La hauteur de la face sera ainsi réglée à

environ 1/16 po de la table. L’utilisateur peut choisir

d’avancer ou de reculer la face du guide. Serrer les

écrous à oreilles pour fixer la face. On peut régler la

face du guide pour qu’elle repose sur la surface de la

table lors de la coupe de matériaux très minces.

S’assurer de régler la face à environ 1/16 po avant de

la faire glisser.

16

Français

soutien à égalité avec le bord de la table principale et

serrer le boulon avant. Répéter pour le boulon arrière.

Serrer le boulon du centre. Répéter de l’autre côté.

ÉTAPE 14. Fixer les supports du rail avant aux tables

de soutien. Ferrures requises :

2 vis à tête plate de 10 x 30 mm

2 rondelles de blocage de 10 mm