Enermax ELC-LT240-HP User manual

2 Years Warranty

ELC-LT240

Index

Limited Warranty

Specificaon

Part list

Intel Installaon

AMD Installaon

1

2

3

4

16

Limited Warranty

Please read this limited warranty carefully. Warranty is subject to void under following

criteria:

1. The serial number label or warranty seal is defaced, modified, or removed.

2. Taking apart of the product and/or modificaon of any component or cable without

ENERMAX’s wrien authorizaon.

3. Ignoring connector’s faulty-inseron-prevenon design by aaching a connector to a

device under incorrect orientaon.

4. Damage caused by natural phenomena or uncontrollable forces, such as lightning,

flooding, fire, earthquake, or misuse, abuse, negligence, accident, wear and tear,

mishandling, misapplicaon.

This ENERMAX Technology Corporaon product is warranted to be free from defects in

material and workmanship for a period of two (2) years from the date of purchase. ENERMAX

Technology Corporaon agrees to repair or replace the product, at its own opon and at no

charge, if, during the warranty period, it is returned to nearest ENERMAX Technology Corporaon subsidiary/agent with all shipping charges prepaid and if inspecon reveals that the

product is defecve. Please present the proof of purchase for requesng RMA. Charges for

removing or installing the product are excluded under the terms of this warranty agreement.

This warranty shall not apply to any product, which has been subject to connecon to a faulty

power source, alteraon, negligence, or accident, or to any product, which has been installed

other than in accordance with these instrucons. In no event shall ENERMAX Technology

Corporaon, or its subsidiaries, or agents be liable for damages for a breach of warranty in an

amount exceeding the purchase price of this product.

If you are uncertain whether or not your ENERMAX liquid cooler is defecve, please contact

your dealer/reseller for support!

Web Site: hp://www.enermax.com

E-mail: enermax@enermax.com.tw

ENERMAX Technology Corporaon, 15F-2, No. 888, Jing-Guo Road, Taoyuan City (330),

Taiwan (R.O.C.), Tel. +886-3-316-1675, Fax. +886-3-346-6640

©2013 ENERMAX Technology Corporaon. All rights reserved. Specificaons are subject to

change without prior noce. Actual product and accessories may differ from illustraons.

Omissions and prinng errors excepted. Content of delivery might differ in different countries

or areas. Some trademarks may be claimed as the property of others. Reproducon in any

manner without the wrien permission of ENERMAX is strictly forbidden.

- 1 -

Specificaon

Cold Plate

Pump

Radiator

Tube

Weight (w/o fan)

Bracket

Fan

Model

Material

Bearing

MTBF

Motor Speed

Rated Voltage

Rated Current

Dimension

Material

Material

Length

Compability

Dimension

Bearing

MTBF

Speed

Rated Voltage

Rated Current

Air Flow

Stac Pressure

Noise Level

Connector

ELC-LT240-HP

Copper

Ceramic Bearing

50,000 hrs

2500 rpm

12V

0.3A

273 x 120 x 27 mm

Aluminium

Polyamide (PA) rubber

310 mm

1095 g

®

Intel

LGA 775/1150/1155/1156/1366/2011

AMD® AM2/AM2+/AM3/AM3+/FM1/FM2/FM2+

120 x 120 x 25 mm

Twister Bearing

≧160,000 hrs

600-1300/2000/2500 rpm

12V

0.13A/0.27A/0.45A

28.6~60.3/88.9/111.0 CFM

48.5~102.4/150.9/188.7 m

0.8~1.7/4.7/7.4 mm-H

15~21.5/27/30 dBA

4 pin PWM

2O

3

/h

- 2 -

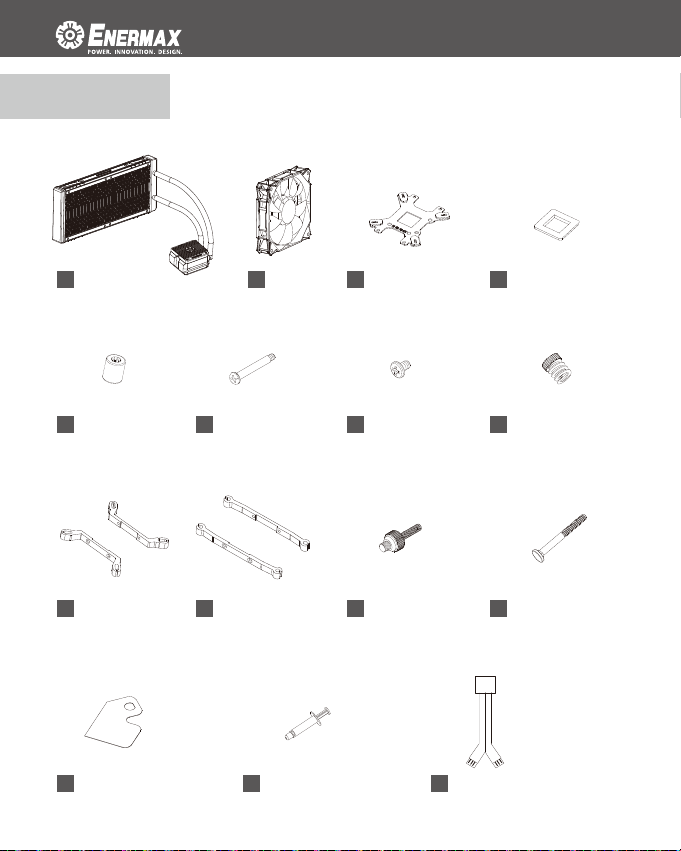

Part list

A Cooler x 1 B Fan x 2 C Back Plate x 1 D Square Spacer x 1

E Stand-off x 4

I Intel Clip x 2

M Insulang sheet x 4

F Fan Screw x 8

J AMD Clip x 2

N Thermal Grease x 1

G Case Screw x 8

K Intel LGA 2011

Screw x 4

- 3 -

H Spring Screw x 4

L Posion Screw x 4

O PWM Y cable x 1

Intel Installation

- 4 -

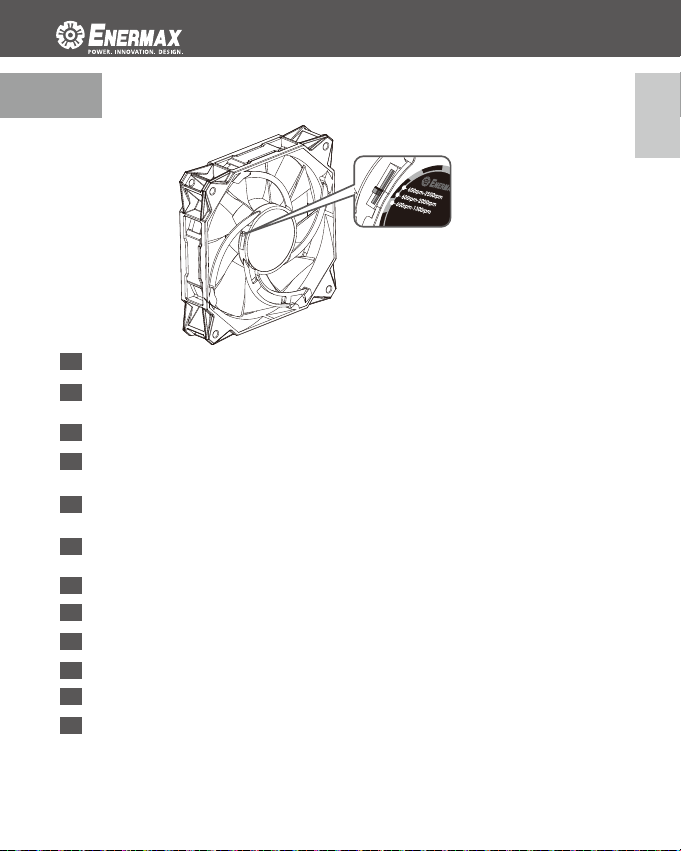

Step

1

– Silent mode: 600~1300 rpm

– Performance mode: 600~2000 rpm

– OverClock mode: 600~2500 rpm

Choose your desired max. fan speed by adjusng the speed control at the fan hub.

EN

Wählen Sie die gewünschte Maximaldrehzahl des Lüers über den kleinen Regler an der

DE

Lüernabe.

Déterminez la vitesse de rotaon maximale du venlateur en réglant le disposif central.

FR

Selezionare la velocità massima della ventola araverso il regolatore di velocità nella parte

IT

posteriore della ventola

Seleccione la velocidad máxima del venlador a través del control de velocidad en la parte

ES

trasera del venlador

Według wymagań systemu wybierz maksymalną prędkość wentylatora za pomocą małego

PL

przełącznika z tyłu wentylatora.

於扇框中心控制鈕選擇PWM風扇所需最高轉速

TN

CN

在扇框中心设有

JP

ファン中心部分に搭載されているスイッチで、お好みに合った回転範囲を選択して下さい。

팬 허브에서 속도 조정 장치를 조절하여 원하는 최대 팬 속도를 선택하십시오.

KR

ID

Pilih kecepatan kipas yg anda inginkan dengan menyesuaikan kontrol kecepatan pada fan hub.

Выберите скорость вращения вентилятора маленьким переключателем на обратной

RU

стороне вентилятора.

PWM风扇调速开关,可自由调整风扇转速

Intel

- 5 -

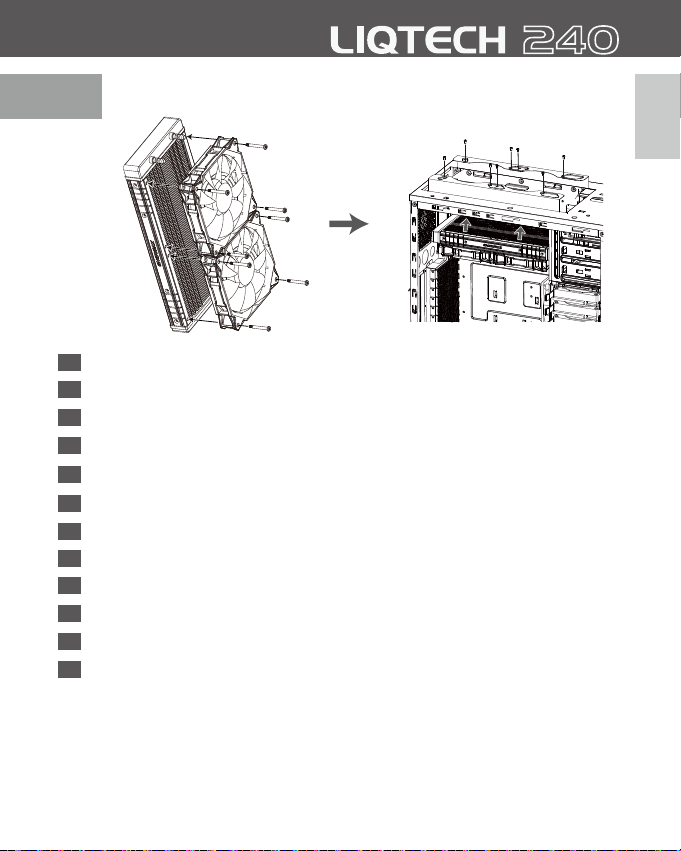

Step

2

Aach the fan and the radiator to the chassis

EN

DE

Schrauben Sie den Lüer und den Radiator am Gehäuse fest.

FR

Fixez le venlateur et le radiateur sur le châssis

IT

Fissare la ventola e il radiatore al case

Fijar el venlador y el radiador a la caja

ES

Zamontuj wentylator i radiator na obudowie komputerowej.

PL

安裝風扇及散熱排於機殼

TN

将风扇以及散热排安装在机箱上

CN

ファンをラジエーターに設置してケースに取り付けて下さい。

JP

팬과 방열기를 PC 케이스에 부착하십시오.

KR

Pasang kipas dan radiator ke casing

ID

Закрепите вентилятор и радиатор на корпусе.

RU

Intel

- 6 -

Step

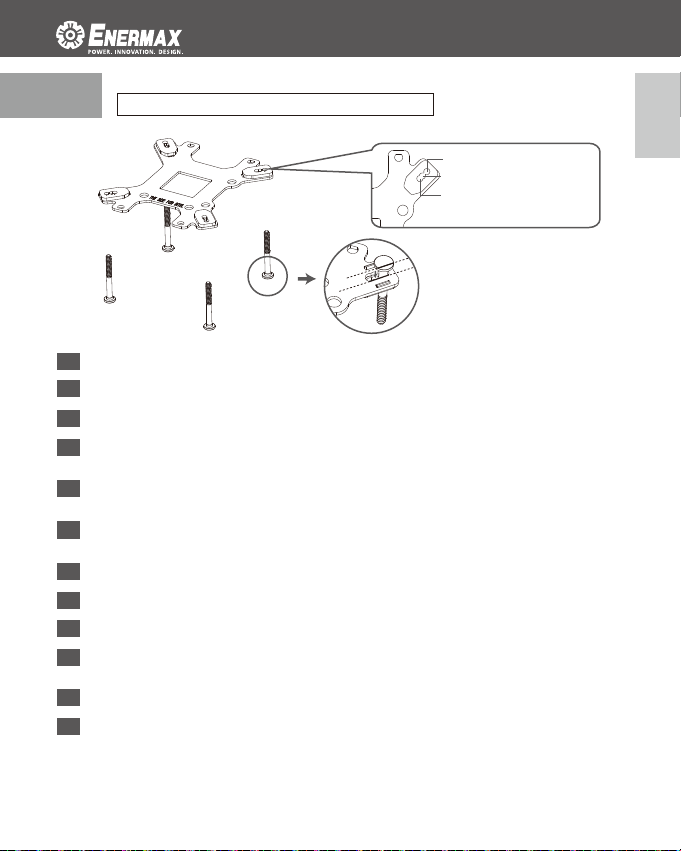

*LGA775/1150/1155/1156/1366

3-1

LGA1366

LGA1150/1155/1156

LGA775

*Aligning

EN

Insert the posion screw into the appropriate hole on the back plate for your CPU socket.

DE

Drehen Sie die Montageschrauben in die zu Ihrem Sockel passende Bohrung in der Backplate.

Insérez la vis de fixaon à l'emplacement prévu sur la plaque arrière de votre CPU

FR

Inserire le vi di montaggio nel foro appropriato nella piastra posteriore per il socket della

IT

vostra CPU.

Inserte los tornillos de montaje en el agujero correspondiente en la placa trasera del socket

ES

de la CPU.

PL

W zależności od plaormy procesora wkręć śruby dystansowe w odpowiednie otwory na

płycie mocującej (Backplate).

TN

依系統CPU腳位將定位螺絲固定於背板相對應孔位

根据系统CPU针脚,将定位螺丝固定在背板相应孔位

CN

CPUソケットに合ったバックプレートと専用ネジをお使いください。

JP

CPU 소켓 설치를 위해 백 플레이트를 적절한 홀에 위치 후 나사를 이용해 고정해

KR

주십시오.

ID

Posisikan sekrup pada lubang yang sesuai di back plate untuk socket CPU anda

Установите винты для крепёжной пластины в соответствующие отверстия для вашего

RU

процессора.

Intel

- 7 -

Loading...

Loading...