Endress+Hauser TMR31 Specifications

TI00123R/09/EN/17.18

71416618

Products Solutions Services

Technical information

Easytemp TMR31, TMR35

Compact thermometer, Pt100, Class A

Optionally with integrated 4 to 20 mA

transmitter, programmable via PC

Application

The Easytemp TMR31 and TMR35 compact thermometers are used to measure

temperatures from -50 °C to 150 °C (-58 °F to 302 °F), or up to 200 °C (392 °F) with

neck. The most common installation locations are tanks and pipes.

• TMR31 with process connections for general applications.

• TMR35 with process connections for hygienic applications.

Benefits at a glance

Quick installation and easy commissioning:

• Small, compact design made entirely of stainless steel

• M12 connector with IP69K for an easy electrical connection

• 4-wire, Pt100 or PC-programmable transmitter with 4 to 20 mA output

• Configuration and visualization with ReadWin 2000 PC operating software,

which is free of charge

• Preset measuring range is available for order

• Variable insertion lengths from 40 mm to 600 mm (1.6 to 23.6 in)

Outstanding metrological properties thanks to innovative sensor technology:

• Extremely short response times

• Highly accurate even with short insertion lengths

• Thin film sensor element Pt100, accuracy class A (IEC 60751)

Safe operation with approvals and certificates:

• UL recognized component

• Meets all EMC requirements according to NAMUR NE21

• Breakdown information in event of sensor break or sensor short-circuit, adjustable

as per NAMUR NE43

• TMR35: Hygienic compatible design with 3-A marking and EHEDG certification

• Marine approval

TMR31, TMR35

HAW562

3 OUT 4

1 IN 2

HAW562

3 OUT 4

1 IN 2

Ecograph T

RN221 N

HAW562

HAW562

TMR31

ENDRESS+HAUSER

RN 221 N

ENDRESS+HAUSER

RN 221 N

Function and system design

Measuring principle Electronic recording and conversion of Pt100 input signals in industrial temperature measurement.

Measuring system The compact thermometer uses a Pt100 (Class A) sensor element for measurement. The device is

available with a Pt100 4-wire connection or, optionally, with an analog, temperature-linear 4 to 20

mA output signal. A built-in transmitter in the device converts the Pt100 input signal into the 4 to 20

mA signal and can be programmed using a PC via the M12 connector. The compact thermometer has

different process connections for general (TMR31) and hygienic applications (TMR35).

The Easytemp TMR31, TMR35 has a new kind of thin film sensor element that is soldered directly into

the sensor tip. This innovative sensor design ensures ideal heat transfer from the process to the sensor

element. This means that extremely fast response times and high levels of accuracy can be achieved

even with short insertion lengths.

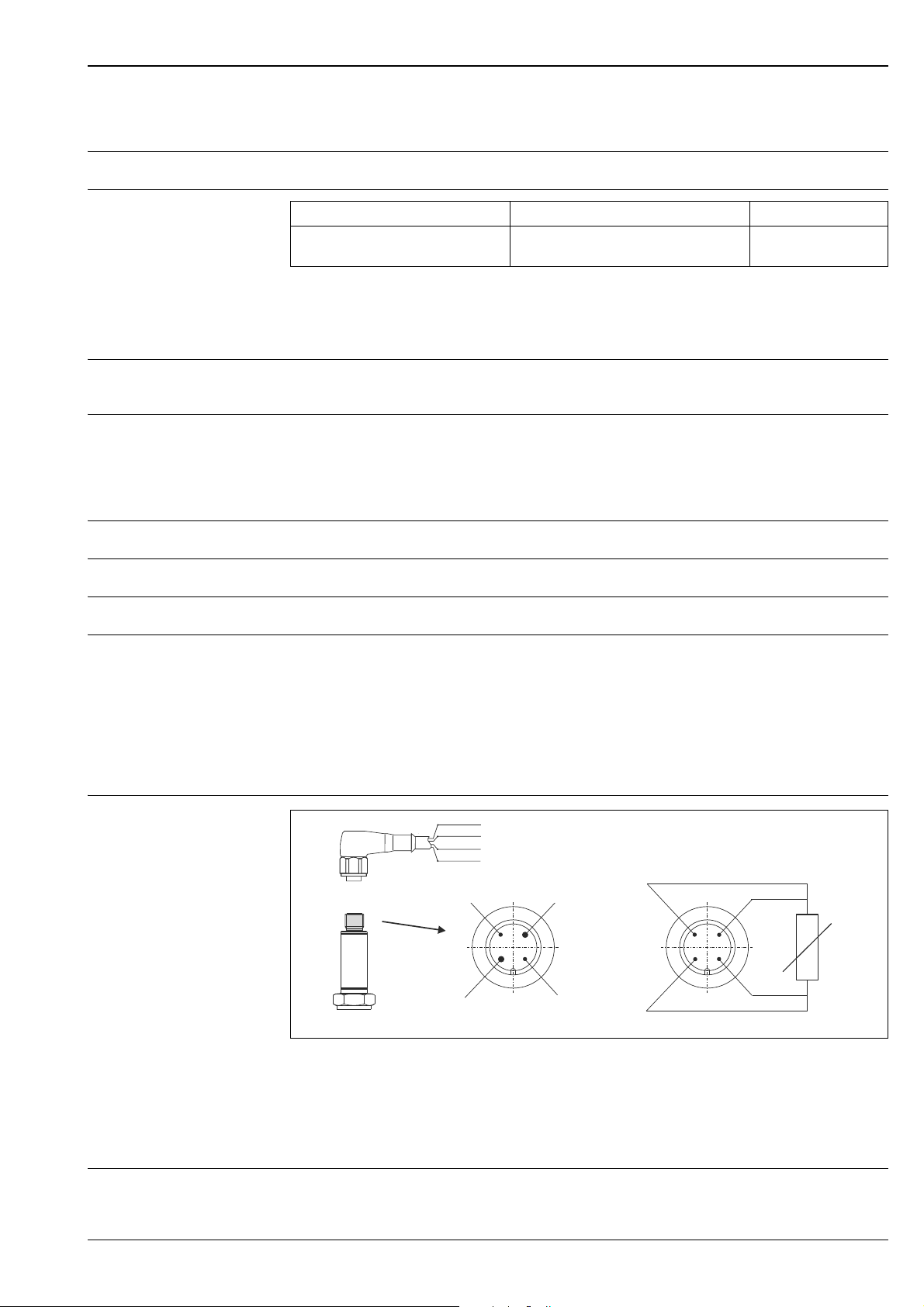

Measuring point layout (example) for Easytemp compact thermometer TMR31 with additional Endress+Hauser components

Ecograph T, active barrier RN221 N and HAW562 surge arrester

A0006994

Multi Channel Recorder Ecograph T

Multi-channel recorder Ecograph T in 144 x 144 mm (5.7 x 5.7 in) panel-mounted housing for the

electronic detection, display, recording, analysis, remote transmission and archiving of analog and

digital input signals. Data recording system on CompactFlash card, multi-colored LCD display, 120 mm

(4.72 in) screen size. Configuration and measured value display via interfaces (USB, Ethernet, RS232/

485) and ReadWin 2000 PC operating software.

Active barrier RN221 N

Active barrier with power supply for the safe separation of 4 to 20 mA standard signal circuits with

optional intrinsically safe input. The current applied by the transmitter of the compact thermometer in

the input circuit (4 to 20 mA) is transmitted linearly to the output.

Surge arrester HAW562

Protects consumer installations or measuring devices as well as signal lines and components against

overvoltage which is induced by lightning striking in the distance or through switching operations. The

HAW562 module acts as an overvoltage protection system in terminal block systems to protect signal

lines and components and is installed on a module carrier (HAW560).

2 Endress+Hauser

TMR31, TMR35

M12x1

J

Pt100

A

B

1

10...35 VDC

(4-20 mA)

3

0 V

(4-20 mA)

4

2

1 (BN) +

2 (WH) nc

3 (BU) 4 (BK) nc

Input

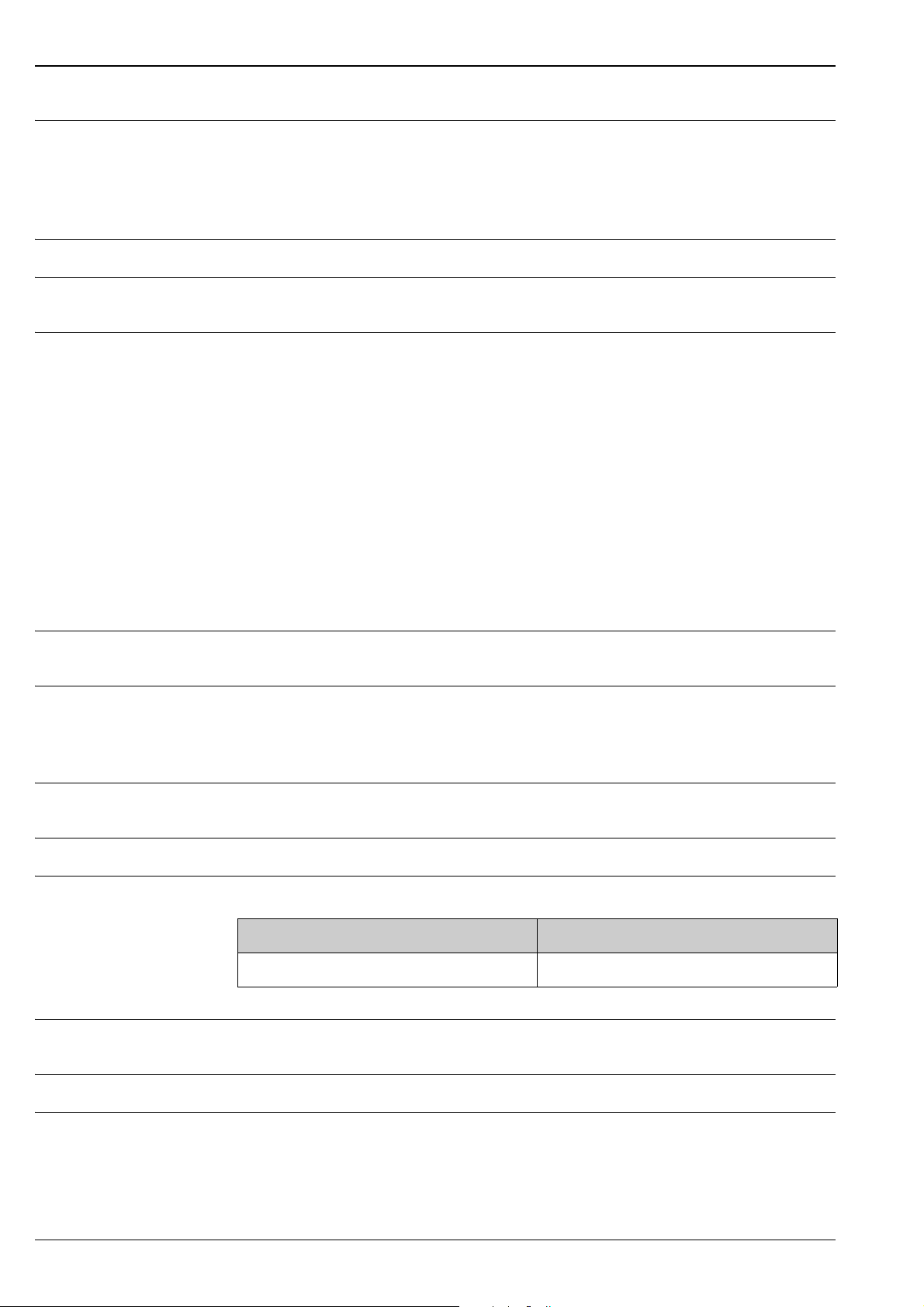

Measuring principle Temperature (temperature-linear transmission behavior)

Measuring range

Designation Measuring range limits Min. span

Pt100 as per IEC 60751 -50 to 150 °C (-58 to 302 °F) without neck

Output

Output signal • Standard: Pt100, Class A, 4-wire

• Optional: 4 to 20 mA or 20 to 4 mA

Signal on alarm Signal on alarm as per NAMUR NE43

• Underranging: Linear drop to 3.8 mA

• Overranging: Linear rise to 20.5 mA

• Sensor break; sensor short-circuit:

3.6 mA or 21.0 mA (at settings 21.0 mA, 21.5 mA output is guaranteed)

Maximum load (U

power supply

Min. current consumption 3.5 mA

Current limit 23 mA

Switch-on delay 2 s

- 10 V) / 0.023 A (current output)

-50 to 200 °C (-58 to 392 °F) with neck

10 K (18 °F)

Power supply

Electrical connection cables must comply with 3-A sanitary standard, must be smooth, corrosion

resistant and cleanable.

Electrical connection

A: with electronics, M12 plug, 4-pin

Pin 1: power supply 10 to 35 V DC; current output 4 to 20 mA (cable connection, wire color brown = BN)

Supply voltage Ub= 10 to 35 V DC

Pin 2: connection of PC configuration cable - shortened pin (cable connection, wire color white = WH)

Pin 3: power supply 0 V DC; current output 4 to 20 mA (cable connection, wire color blue = BU)

Pin 4: connection of PC configuration cable - shortened pin (cable connection, wire color black = BK)

B: without electronics, Pt100, 4-wire connection

A0020176

Endress+Hauser 3

TMR31, TMR35

Residual ripple Permitted residual ripple Uss 3 V at Ub 13 V, f

Performance characteristics

Response time 3 s with transmitter

Reference operating conditions

Maximum measured error Electronics

• Matching temperature (ice bath) 0 °C (32 °F) for Pt100 sensor

• Ambient temperature 25 °C ± 5 °C (77 °F ± 9 °F) for transmitter

0.1 K (0.18 °F) or 0.08%. % relates to the set span. The larger value applies.

Sensor (Pt100) for version without transmitter

• Tolerance class A as per IEC 60751, operating temperature range -50 to 200 °C (-58 to 392 °F) with

neck

• Maximum measured error in °C = 0.15 + 0.002 T

T = Numerical value of the temperature in °C without regard to the leading sign.

Total deviation of electronics + sensor

• Operating temperature range:

-50 to 150 °C (-58 to 302 °F) without neck

-50 to 200 °C (-58 to 392 °F) with neck

• 0.25 K + 0.002 T

max.

= 1 kHz

Long-term stability of electronics

Influence of ambient temperature (temperature drift)

0.1 K (0.18 °F)/year or 0.05%/year

Data under reference conditions. % relates to the set span. The larger value applies.

• Pt100 resistance thermometer:

= ±(15 ppm/K * (full scale value of measuring range + 200) + 50 ppm/K * set measuring range)

T

d

* T

T= deviation of ambient temperature from the reference operating condition.

Influence of load ± 0.02%/100

Specifications refer to the full scale value of the measuring range.

Transmitter response time 1 s

Sensor response time Measured as per IEC 60751, in water flowing at 0.4 m/s (1.3 ft/s)

t

50

< 1.0 s < 2.0 s

t

90

Influence of supply voltage ± 0.01%/V deviation from 24 V

Specifications in percent refer to the full scale value of the measuring range.

Self-heating Negligible small

Sensor current 0.6 mA

4 Endress+Hauser

TMR31, TMR35

AB

C

L

L

³ 3°

C

12

3

4

R0.4 R0.4

Sensor with

milk pipe

connection

Sensor with Varivent

connection

Shaped

gasket

Companion

connection

O-ring

Groove

slip-on nut

Centering ring

Sealing

Companion

connection

Companion

connection

Gasket

(O-ring)

Welding boss

Leak detection hole

Vessel wall

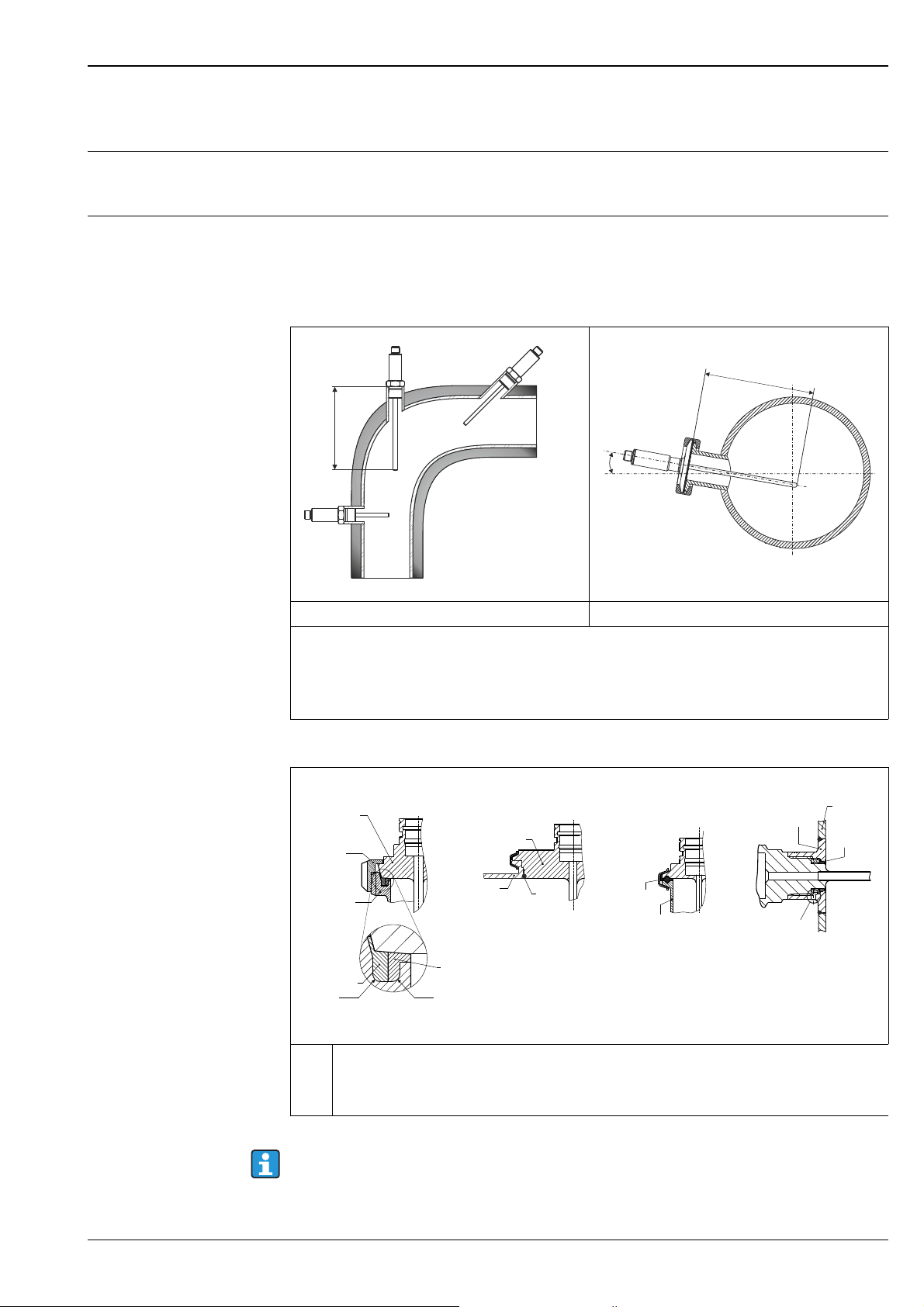

Installation conditions

Orientation No restrictions. However, self-draining in the process must be guaranteed. If there is an opening to

detect leaks at the process connection, this opening must be at the lowest possible point.

Installation instructions Mounting location

The insertion length of the compact thermometer can have a substantial influence on the accuracy. If

the insertion length is insufficient, heat dissipation via the process connection and the container wall

can cause measurement errors. To minimize errors caused by heat dissipation, a minimum insertion

length of L

= 40 mm (1.6 in) is recommended.

min

A0020345

TMR31 - general applications TMR35 - hygienic applications

Pipe installation of the compact thermometer:

• A: On angle brackets

• B: In smaller pipes, inclined

• C: Perpendicular to the direction of flow, TMR35 with minimal 3° inclination because of self draining

• L = Insertion length

Mounting instructions for installation in various hygienic processes

Milk pipe connection as per DIN 11851 only in connection EHEDG certified and self centering ring

1

to EHEDG position paper

2

Clamp as per ISO 2852, only in connection with seal according to EHEDG position paper

3

Liquiphant-M G1" process connection, horizontal installation

4

The matches for the process connections as well as the gaskets are not included in the scope of delivery

of this assembly. Welding adapter for process connections with associated O-ring sets are available as

accessories, 14.

Endress+Hauser 5

A0012591

A0011758-EN

Procedure in case of seal failure indicated by leak detection port:

• Disassembling of the thermometer, validated cleaning procedure of thread and sealing ring groove

• Replacement of the seal or sealing ring

• CIP after re-assembly

In the case of weld-in connections, exercise the necessary degree of care when performing the welding

work on the process side:

• Suitable weld material.

• Flush welding or with welding radius > 3.2 mm.

• Absence of pits, folds, crevices.

• Ground and polished surface (R

As a general rule, the thermometers should be installed in such a way that does not adversely affect

their cleanability (3-A requirements must be adhered to). The required flush-mounting can be

achieved by the connection Varivent®, Liquiphant (+ weld-in adapter).

Environment conditions

Ambient temperature limits -40 to +85 °C (-40 to 185 °F)

0.76 μm).

a

TMR31, TMR35

Storage temperature -40 to +85 °C (-40 to 185 °F)

Altitude

Up to 2000 m (6600 ft) above mean sea level

Climate class As per IEC 60654-1, Class C

Degree of protection IP66/67 with coupling and connecting cable (not evaluated by UL) 14

IP69K with cordset (not evaluated by UL) 14

Shock resistance 4g / 2 to 150 Hz as per DIN EN60068-2-6

Vibration resistance Refer to ’Shock resistance’

Electromagnetic compatibility (EMC)

EMC to all relevant requirements of the IEC/EN 61326- series and NAMUR NE21. For details see

declaration of conformity.

ESD (Electrostatic discharge) IEC/EN 61000-4-2 6 kV cont., 8 kV air

Electromagnetic fields IEC/EN 61000-4-3 0.08 to 2 GHz 10 V/m

Burst (fast transient) IEC/EN 61000-4-4 2 kV

Surge IEC/EN 61000-4-5 0.5 kV sym.

Conducted RF IEC/EN 61000-4-6 0.01 to 80 MHz 10 V

All EMC measurements were performed with a turn down (TD) = 2:1. Maximum fluctuations during

EMC- tests: < 1 % of measuring span.

Interference immunity to IEC/EN 61326 - series, requirements for industrial areas

Interference emission to IEC/EN 61326 - series, electrical equipment Class B.

Condensation Permitted

Electrical safety • Protection class III

• Overvoltage category II

• Pollution degree 2 III

6 Endress+Hauser

Loading...

Loading...