Endress+Hauser TM402 Specifications

TI01349T/09/EN/02.18

71418572

2018-11-05

Products

Solutions Services

Technical Information

iTHERM TM402

Resistance thermometer for hygienic and aseptic

applications

Imperial version with basic technology

for all standard applications, permanent insert

Applications

• Specially designed for use in hygienic and aseptic applications in the Food &

Beverages and Life Sciences industries

• Measuring range: –50 to +200 °C (–58 to +392 °F)

• Pressure range up to 40 bar (580 psi)

• Protection class: up to IP69K

• Can be used in non-hazardous areas

Temperature transmitter

All Endress+Hauser transmitters are available with enhanced accuracy and reliability

compared to directly wired sensors. Easy customizing by choosing one of the

following outputs and communication protocols:

• Analog output 4 to 20 mA, HART

• Field transmitters with HART® or FOUNDATION Fieldbus™ protocol for highest

reliability in harsh industrial environments. Backlit display with large measured

value, bargraph and fault condition indication for ease of reading.

Your benefits

• Excellent value for money and fast delivery

• User-friendly and reliable from product selection to maintenance

• International certification: hygiene standards as per 3-A®, EHEDG, ASME BPE,

FDA, TSE Certificate of Suitability

• Wide range of process connections

®

Table of contents

iTHERM TM402

Function and system design ................... 3

iTHERM Hygiene line ........................... 3

Measuring principle ............................ 3

Measuring system ............................. 3

Input ..................................... 4

Measured variable ............................. 4

Measuring range .............................. 4

Output ................................... 4

Output signal ................................ 4

Family of temperature transmitters ................. 4

Wiring ................................... 5

Wiring diagrams for RTD ........................ 5

Cable entries ................................ 6

Connector .................................. 6

Overvoltage protection .......................... 6

Performance characteristics ................... 6

Reference conditions ........................... 6

Maximum measured error ....................... 7

Influence of ambient temperature .................. 7

Self heating ................................. 7

Response time ............................... 8

Calibration .................................. 9

Insulation resistance ........................... 9

Certificates and approvals ................... 19

CE mark ................................... 19

Hygiene standard ............................ 19

Other standards and guidelines ................... 19

Parts in contact with the medium .................. 19

CRN approval ............................... 19

Surface purity ............................... 19

Material resistance ........................... 19

Material certification .......................... 19

Calibration ................................. 19

Ordering information ....................... 20

Accessories ............................... 21

Device-specific accessories ...................... 21

Communication-specific accessories ................ 21

Service-specific accessories ...................... 22

System components ........................... 23

Documentation ............................ 24

Installation ................................ 9

Orientation ................................. 9

Installation instructions ......................... 9

Environment .............................. 11

Ambient temperature range ..................... 11

Storage temperature .......................... 11

Humidity .................................. 11

Climate class ............................... 11

Degree of protection .......................... 11

Shock and vibration resistance .................... 12

Electromagnetic compatibility (EMC) ............... 12

Process .................................. 12

Process temperature range ...................... 12

Thermal shock .............................. 12

Process pressure range ......................... 12

Medium - state of aggregation .................... 13

Mechanical construction .................... 14

Design, dimensions ........................... 14

Weight ................................... 14

Material .................................. 14

Surface roughness ............................ 15

Terminal heads .............................. 15

Process connections ........................... 16

2 Endress+Hauser

iTHERM TM402

mm

inch

mm

inch

Function and system design

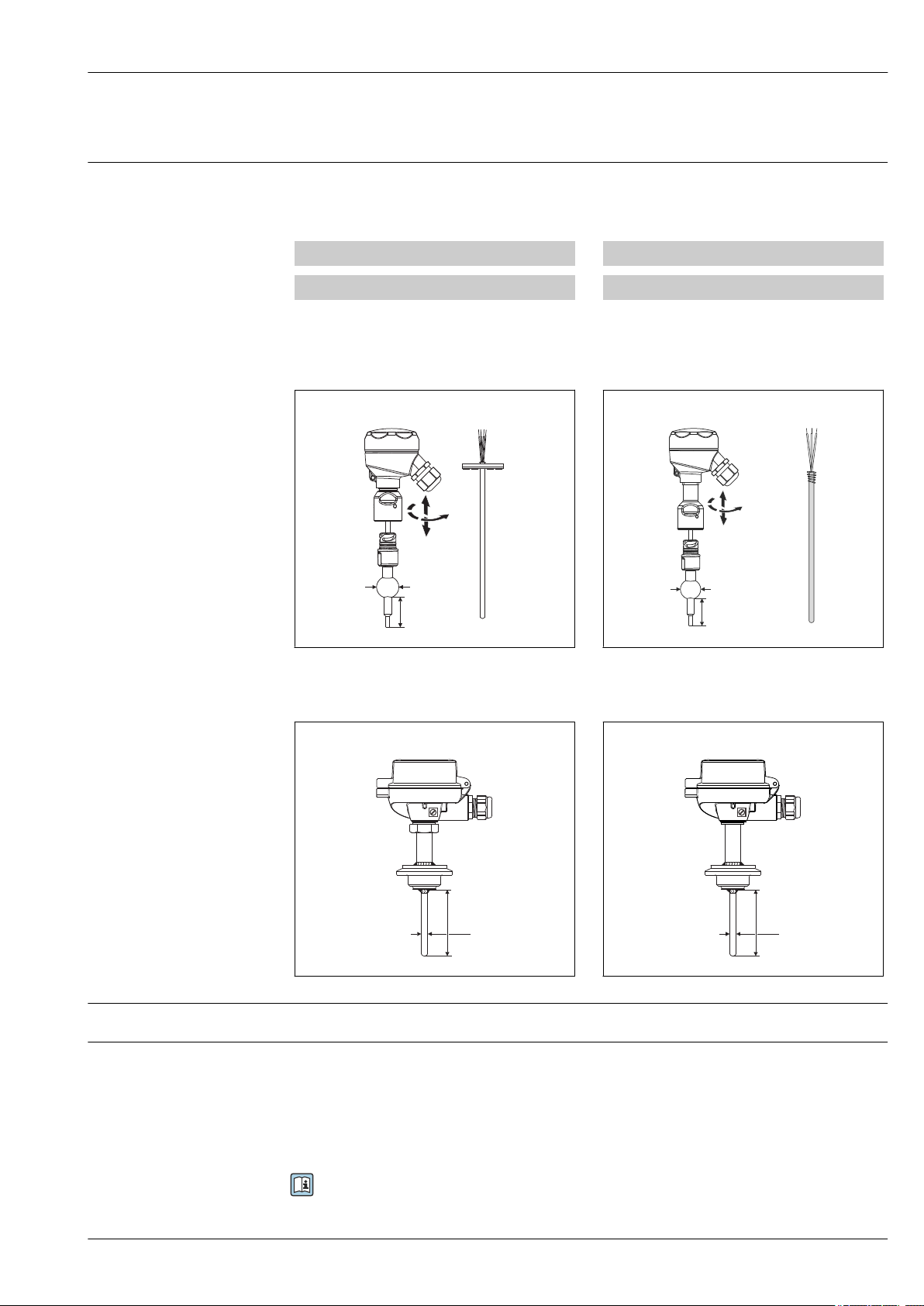

iTHERM Hygiene line

This thermometer is part of the product line of modular thermometers for hygienic and aseptic

applications.

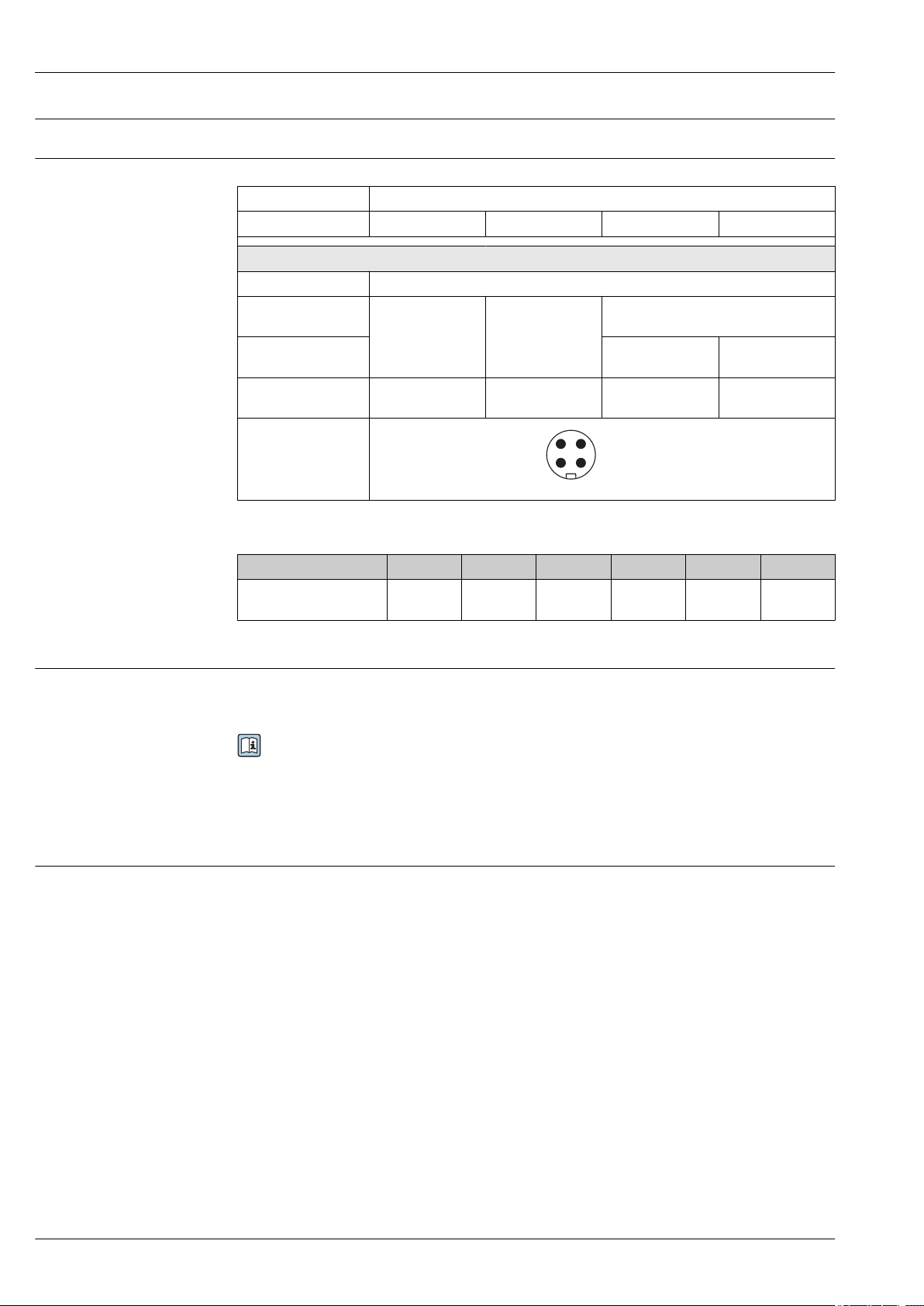

Differentiating factors when selecting a suitable thermometer

TM4x1 TM4x2

Metric version Imperial version

↓ ↓

TM41x characterizes the device that uses cutting-edge technology, with features such as a replaceable insert,

quick-fastening extension neck (iTHERM QuickNeck), vibration-resistant and fast-response sensor technology

(iTHERM StrongSens and QuickSens) and approval for use in hazardous areas

TM411

TM412

Measuring principle

Measuring system

A0018239

↓ ↓

TM40x characterizes the device that uses basic technology, with features such as a fixed, non-replaceable

insert, application in non-hazardous areas, standard extension neck, low-cost unit

TM401

A0018692

TM402

A0018691

A0018693

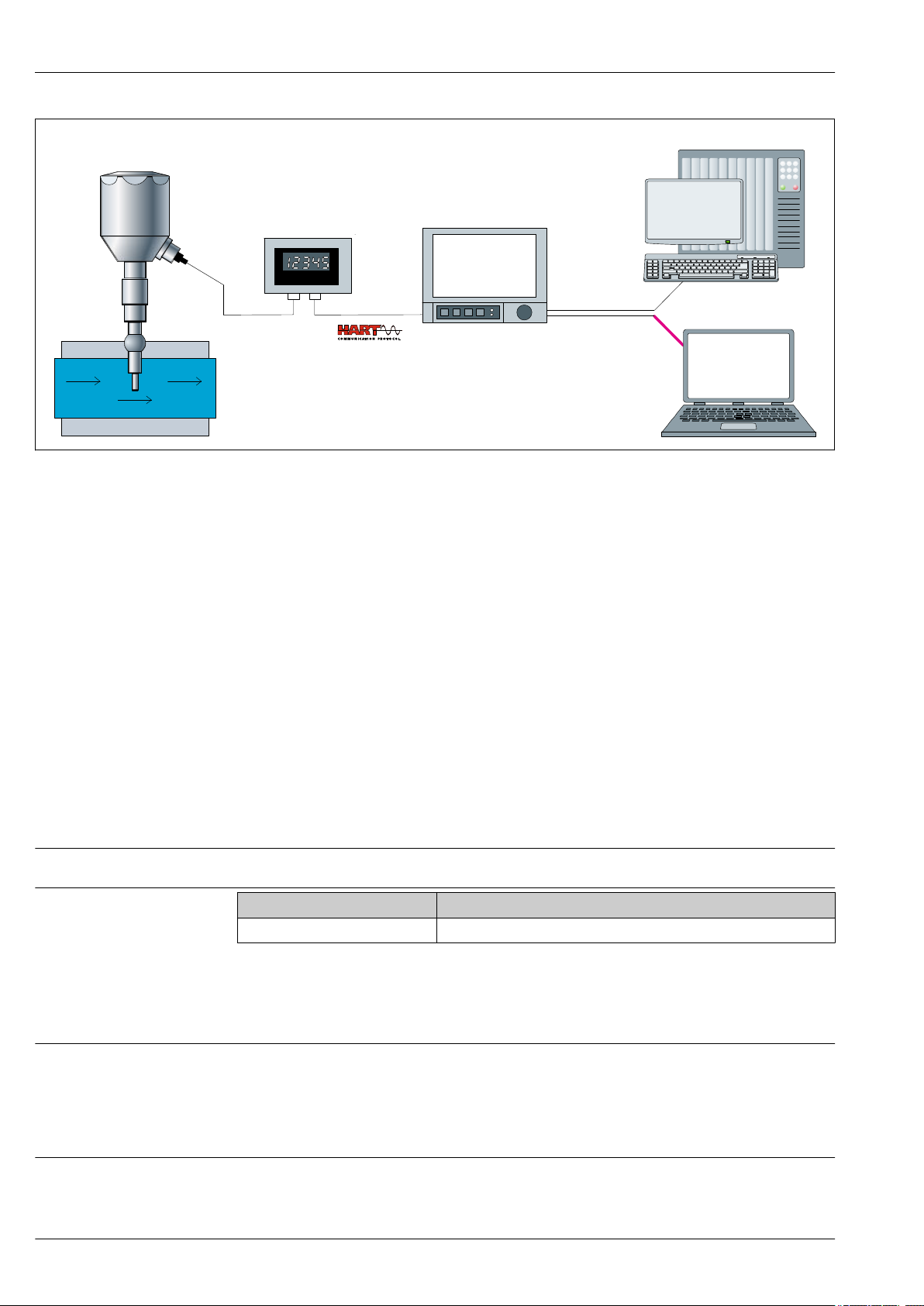

Endress+Hauser offers a complete portfolio of optimized components for the temperature measuring

point – everything you need for the seamless integration of the measuring point into the overall

facility. This includes:

• Power supply unit/barrier

• Display units

• Data managers

• Overvoltage protection

For more information, see the brochure 'System Products and Data Managers - Solutions for the

loop' (FA00016K)

Endress+Hauser 3

iTHERM TM402

FieldCare

Memograph M

RSG45

RIA15

TM4xx

PLC

1 Example of application, measuring point layout with additional Endress+Hauser components

A0033768

Measured variable

Measuring range

• iTHERM TM4x2: Installed RTD thermometer with integrated HART® head transmitter

• Display unit RIA15:

- Display of 4 to 20 mA measured values or HART® process variables

- Loop-powered

- Voltage drop ≤1 V (HART® ≤1.9 V)

• Data Management Memograph M RSG45:

- Tamper-proof data storage and access (FDA 21 CFR 11)

- HART® gateway functionality; Up to 40 HART® devices connected at a time

- Communication capabilities: Modbus, Profibus DP, PROFINET, EtherNet/IP

• PLC / FieldCare: Field Data Manager Software MS20 - Automatic service for report generation,

printing reports, read out of data, storing of data, secure export, pdf generation Read out

measured data via online interface or from mass storage Online visualization of instantaneous

values (“live data”) . More information on this can be found in the Technical Information, see

"Documentation".

Input

Temperature (temperature-linear transmission behavior)

Sensor type Measuring range

Pt100 thin-film –50 to +200 °C (–58 to +392 °F)

Output signal

Family of temperature transmitters

Output

Generally, the measured value can be transmitted in one of two ways:

• Directly-wired sensors - sensor measured values forwarded without a transmitter.

• Via all common protocols by selecting an appropriate Endress+Hauser iTEMP temperature

transmitter. All the transmitters listed below are mounted directly in the terminal head and wired

with the sensory mechanism.

Thermometers fitted with iTEMP transmitters are an installation-ready complete solution to

improve temperature measurement by significantly increasing accuracy and reliability, when

compared to direct wired sensors, as well as reducing both wiring and maintenance costs.

4 Endress+Hauser

iTHERM TM402

3

5

6

RTD

3

4

5

6

RTD

1

2

3-wire

4-wire

Power supply

head transmitter and

analog output 4 to 20 mA,

or bus connection

(red) (red)

(red) (red)

(white) (white)

(white)

mA

1 x Pt 100

1 x Pt 100

red

red

white

4 wires 3 wires

red

white

red

white

PC programmable head transmitters

They offer a high degree of flexibility, thereby supporting universal application with low inventory

storage. The iTEMP transmitters can be configured quickly and easily at a PC. Endress+Hauser offers

free configuration software which can be downloaded from the Endress+Hauser Website. More

information can be found in the Technical Information. → 24

HART® programmable head transmitters

The transmitter is a 2-wire device with one or two measuring inputs and one analog output. The

device not only transfers converted signals from resistance thermometers and thermocouples, it also

transfers resistance and voltage signals using HART® communication. It can be installed as an

intrinsically safe apparatus in Zone 1 hazardous areas and is used for instrumentation in the

terminal head (flat face) as per DIN EN 50446. Swift and easy operation, visualization and

maintenance by using universal device configuration tools like FieldCare, DeviceCare or

FieldCommunicator 375/475. For more information, see the Technical Information. → 24

Advantages of the iTEMP transmitters:

• Dual or single sensor input (optionally for certain transmitters)

• Unsurpassed reliability, accuracy and long-term stability in critical processes

• Mathematical functions

• Monitoring of the thermometer drift, sensor backup functionality, sensor diagnostic functions

• Sensor-transmitter matching for dual sensor input transmitter, based on Callendar/Van Dusen

coefficients

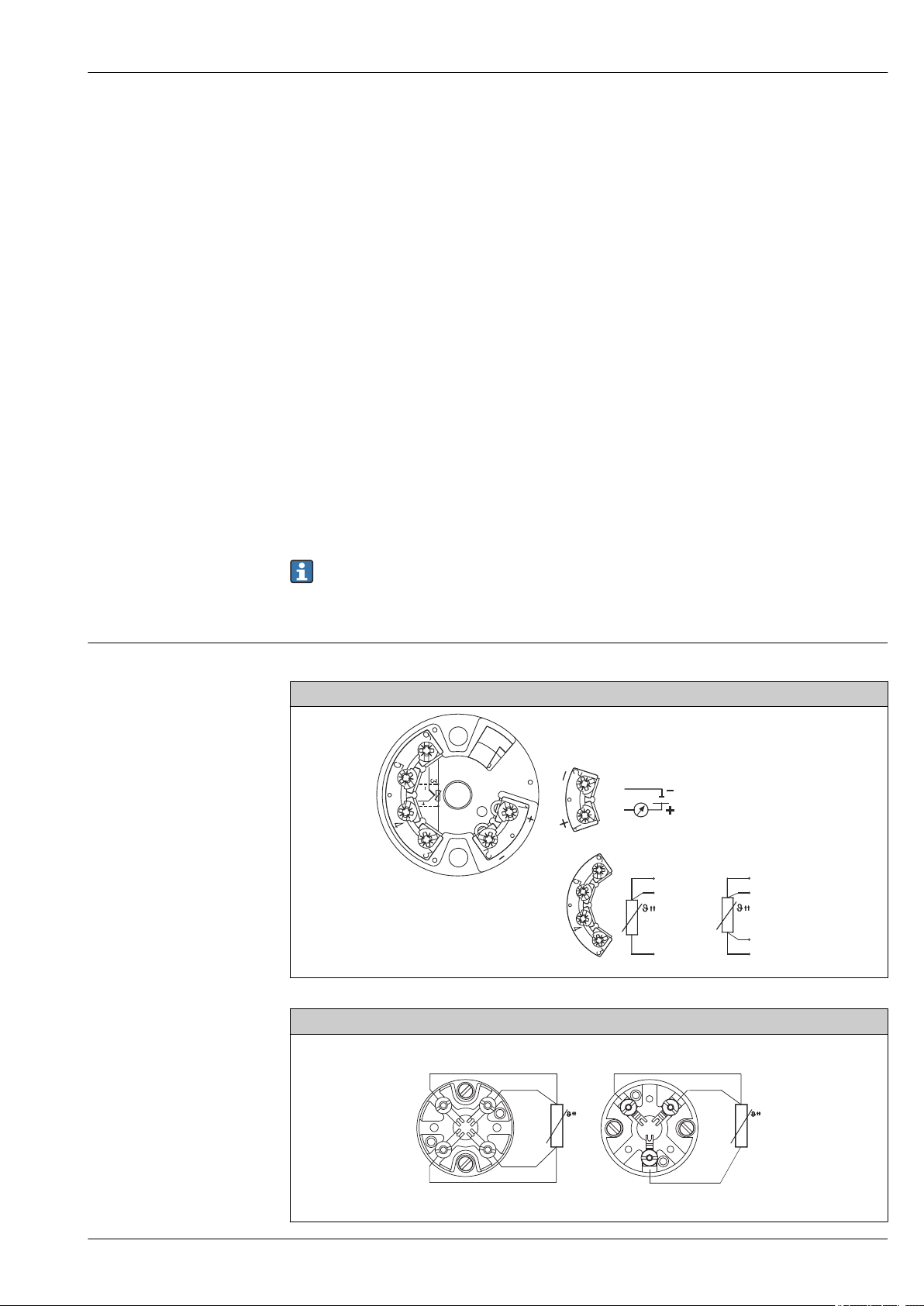

Wiring diagrams for RTD

Wiring

• According to the 3-A® Standard electrical connecting cables must be smooth, corrosionresistant and easy to clean.

• Grounding or shield connections are possible via special ground terminals on the terminal

head. → 15

Type of sensor connection

Head mounted transmitter TMT18x (single input)

A0016433-EN

Endress+Hauser 5

Terminal block mounted

A0019262-EN

iTHERM TM402

1 BN

2 GNYE

3 BU

4 GY

1

4 3

2

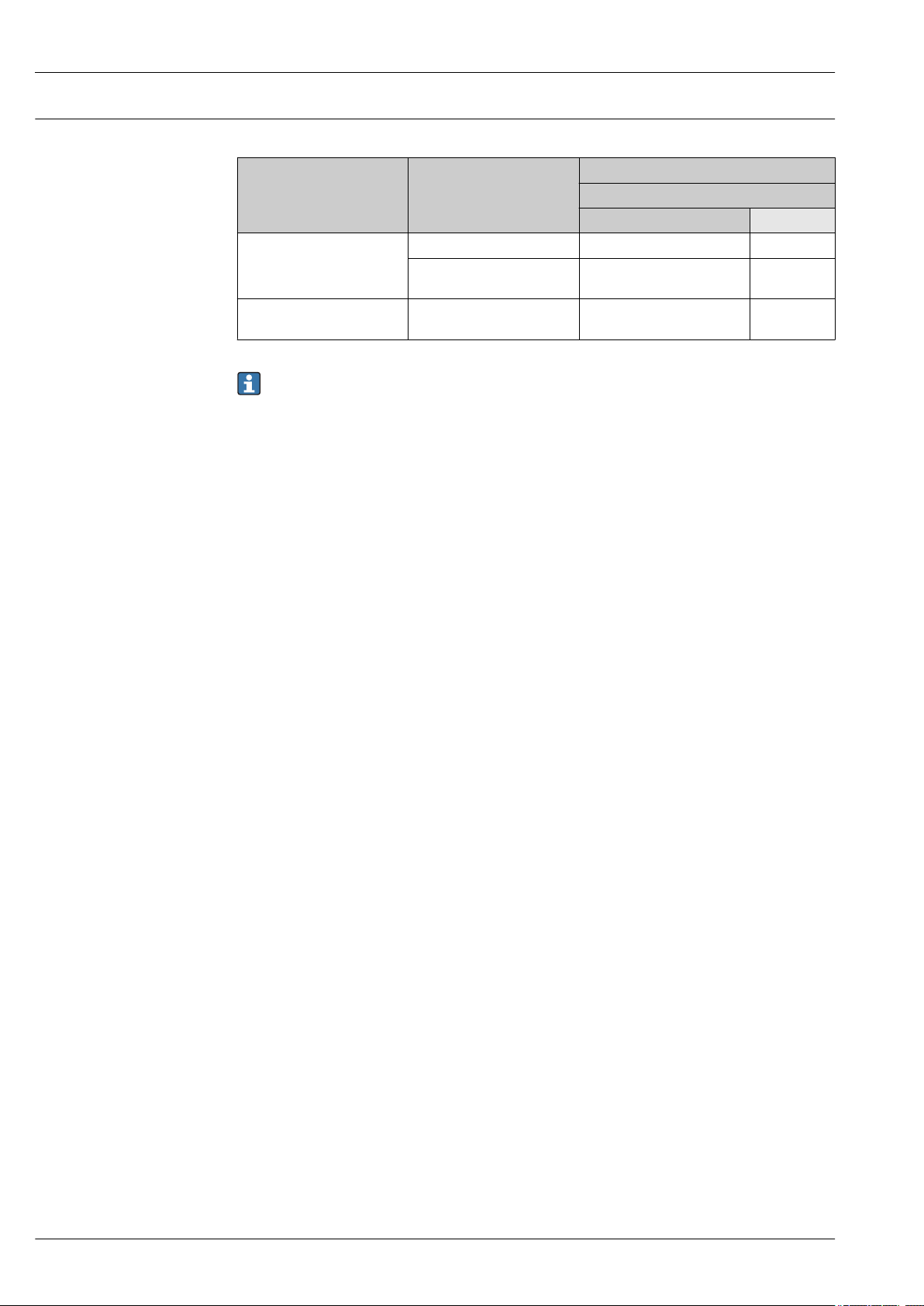

Cable entries

Connector

See the 'Terminal head' section → 15

PIN assignment of the M12 connectors, connection combinations

Connector M12 connector 4‐pin

PIN number 1 2 3 4

Electrical connection (terminal head)

Flying leads Not connected (not insulated)

3-wire terminal block

(1x Pt100)

4-wire terminal block

(1x Pt100)

1x TMT 4 to 20 mA or

PIN position and color

HART

code

®

RD RD

WH WH

+ i - i

WH

Abbreviations

i RD WH BN GNYE BU GY

Insulated

1)

Red White Brown Green-

yellow

Blue Gray

A0018929

Overvoltage protection

Reference conditions

1) Wires marked 'i' are not connected and are insulated with heat shrink tubes.

To protect against overvoltage in the power supply and signal/communication cables for the

thermometer electronics, Endress+Hauser offers the HAW562 surge arrester for DIN rail mounting

and the HAW569 for field housing installation.

For more information see the Technical Information 'HAW562 Surge arrester' TI01012K and

'HAW569 Surge arrester' TI01013K.

Performance characteristics

These data are relevant for determining the accuracy of the temperature transmitters used. More

information on this can be found in the Technical Information of the iTEMP temperature

transmitters.

6 Endress+Hauser

iTHERM TM402

A

AA

-200 -100 0 100 200 300 400 500 600°C

0.5

1.0

1.5

2.0

B

2.5

3.0

- 0.5

- 1.0

- 1.5

- 2.0

- 2.5

- 3.0

B

A

AA

Max. deviation (°C)

Max. deviation (°C)

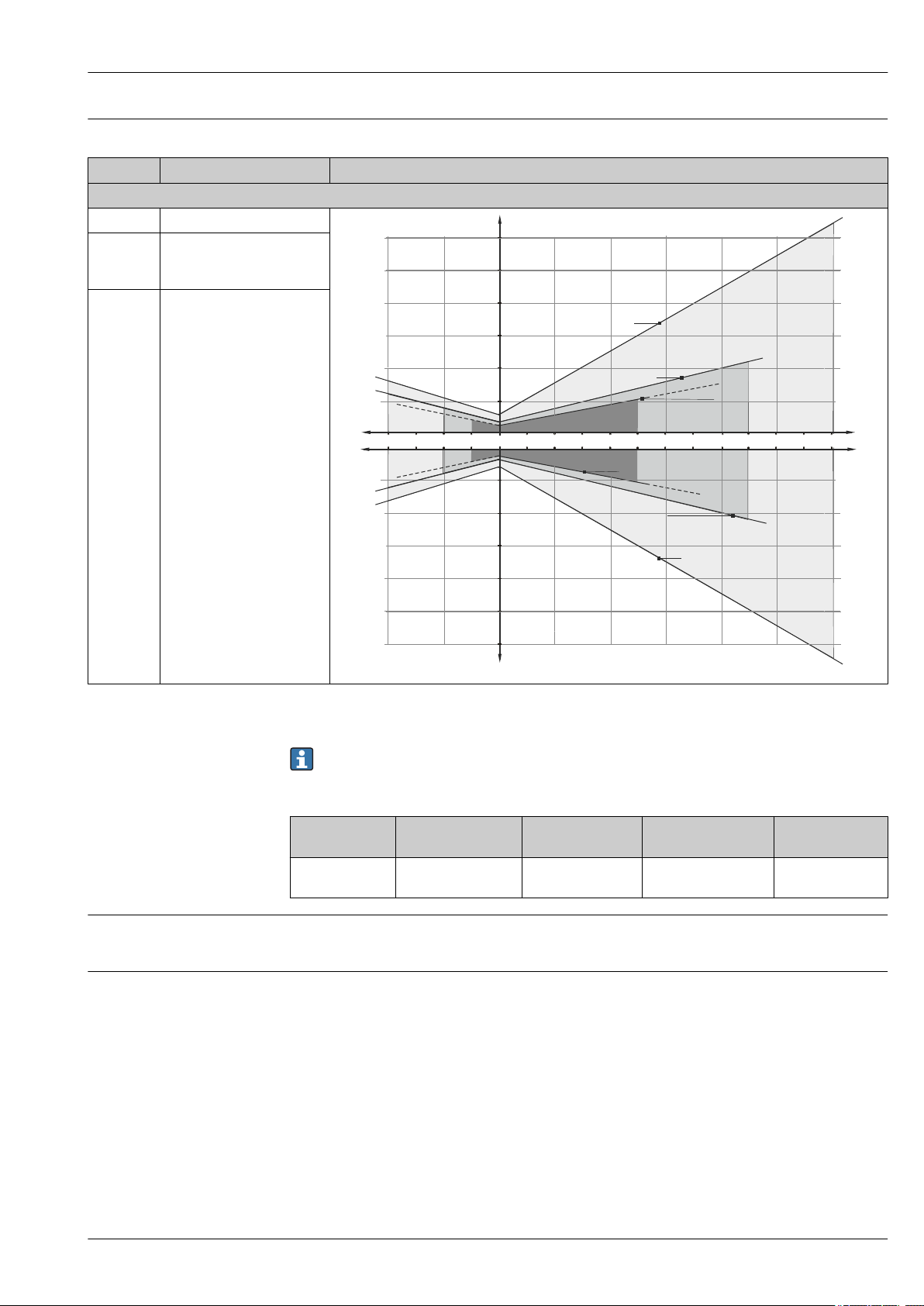

Maximum measured error

RTD resistance thermometer corresponding to IEC 60751

Class max. Tolerances (°C) Characteristics

RTD maximum error type TF

Cl. A ± (0.15 + 0.002 · |t|

Cl. AA,

± (0.1 + 0.0017 · |t|)

1)

)

1)

former 1/3

Cl. B

Cl. B ± (0.3 + 0.005 · |t|

1)

)

1) |t| = absolute value °C

For measurement errors in °F, calculate using equations in °C, then multiply the outcome by 1.8.

Temperature ranges for compliance with the tolerance classes

Sensor type Operating

temperature range

Influence of ambient temperature

Self heating

Pt100 thin film

sensor (TF)

–50 to 200 °C

(–58 to 392 °F)

Depends on the head transmitter used. For details, see Technical Information. → 24

RTD elements are passive resistances that are measured using an external current. This

measurement current causes a self-heating effect in the RTD element itself which in turn creates an

additional measurement error. In addition to the measurement current, the size of the measurement

error is also affected by the temperature conductivity and flow velocity of the process. This selfheating error is negligible when an Endress+Hauser iTEMP temperature transmitter (very small

measurement current) is connected.

Class B Class A Class AA

- –30 to 200 °C

-

(–22 to 392 °F)

A0008588-EN

Endress+Hauser 7

iTHERM TM402

Response time

Tests in water at 0.4 m/s (1.3 ft/s), according to IEC 60751; 10 K temperature step change.

1x Pt100 thin-film sensor

Pipe diameter Shape of tip

Straight 5 s 11 s

6.35 mm (¹⁄₄ in)

9.53 mm (³⁄₈ in)

Reduced 4.76 mm (³⁄₁₆ in) x

19.05 mm (0.75 in)

Reduced 4.76 mm (³⁄₁₆ in) x

19.05 mm (0.75 in)

Response time

t

50

3.5 s 9 s

5 s 10.5 s

Response time without transmitter.

t

90

8 Endress+Hauser

iTHERM TM402

Calibration

Calibration of thermometers

Calibration involves comparing the measured values of a device under test (DUT) with those of a

more precise calibration standard using a defined and reproducible measurement method. The aim is

to determine the deviation of the DUT's measured values from the true value of the measured

variable. Two different methods are used for thermometers:

• Calibration at fixed-point temperatures, e.g. at the freezing point of water at 0 °C,

• Calibration compared against a precise reference thermometer.

The thermometer to be calibrated must display the fixed point temperature or the temperature of

the reference thermometer as accurately as possible. Temperature-controlled calibration baths with

very homogeneous thermal values, or special calibration furnaces into which the DUT and the

reference thermometer, where necessary, can project to a sufficient degree, are typically used for

thermometer calibrations.

The measurement uncertainty can increase due to heat dissipation errors and short immersion

lengths. The existing measurement uncertainty is listed on the individual calibration certificate.

For accredited calibrations according to ISO17025, the measurement uncertainty shouldn’t be twice

as high as the accredited measurement uncertainty. If this is exceeded, only a factory calibration can

be performed.

Evaluation of thermometers

If a calibration with an acceptable uncertainty of measurement and transferable measurement

results is not possible, Endress+Hauser offers customers a thermometer evaluation measurement

service, if technically feasible. This is the case when:

• The process connections/flanges are too big or the immersion length (IL) is too short to allow the

DUT to be immersed sufficiently in the calibration bath or furnace (see the following table), or

• Due to heat conduction along the thermometer tube, the resulting sensor temperature generally

deviates significantly from the actual bath/furnace temperature.

The measured value of the DUT is determined using the maximum possible immersion depth and the

specific measuring conditions and measurement results are documented on an evaluation certificate.

For the device, Endress+Hauser offers standard calibrations at a reference temperature of

–20 to +200 °C (–4 to +392 °F) based on the ITS90 (International Temperature Scale). Calibrations in

other temperature ranges are available from your Endress+Hauser sales center on request.

Calibrations are traceable to national and international standards. The calibration certificate is

referenced to the serial number of the thermometer.

Insulation resistance

Orientation

Installation instructions

Insulation resistance ≥ 100 MΩ at ambient temperature.

Insulation resistance between the terminals and the outer jacket is measured with a minimum

voltage of 100 V DC.

Installation

No restrictions. However, self-draining in the process must be guaranteed. If there is an opening to

detect leaks at the process connection, this opening must be at the lowest possible point.

The immersion length of the thermometer can influence the accuracy. If the immersion length is too

small then errors in the measurement are caused by heat conduction via the process connection and

the container wall. If installing into a pipe then the immersion length should ideally be half of the

pipe diameter.

Installation possibilities: Pipes, tanks or other plant components

Endress+Hauser 9

Loading...

Loading...