Endress+Hauser PROline promag 50 w, PROline promag 53 W Technical Information

Technical

The PowerofKnowHo w

Information

TI 046D/24/ae

Electromagnetic

Flow Measuring System

PROline promag 50/53 W

Flow measurement in

water or wastewater applications

Features and benefits

• Nominal diameters 1” to 78”

• Hard rubber or polyurethane liners

• PFA for high-temperature applications up to +355°F (+180°C)

• Fitting lengths to ISO and DVGW

• High measuring accuracy for

improved process control:

– Promag 50: ± 0.5%

(option: ± 0.2%)

– Promag 53: ± 0.2%

• Robust field housing, NEMA 4X

(IP 67)

• NEMA 4X (IP 67) wall-mount housing

for straight-forward installation of the

remote version

• NEMA 6P (IP 68) sensor version

• Promag 53 with Touch Control:

operation without opening the

housing - also for explosion proof

applications

• Expandable software packages:

– electrode cleaning

– pulsating flow

• Quick setup menus for straightforward commissioning in the field

• Potable-water approvals:

KTW , WRC, etc.

• Interfaces for integration into all

major process-control systems:

– HART

®

interface as standard

– Promag 50: PROFIBUS-PA

– Promag 53: PROFIBUS-PA/-DP,

FOUNDATION fieldbus

• Explosion proof approval for

installation in Division 1 (FM, CSA,

A TEX, etc.)

Application

All fluids with a minimum conductivity of

≥ 5 µS/cm can be measured:

• Drinking water

• Wastewater

• Wastewater sludge, etc.

A minimum conductivity of ≥ 20 µS/cm is

required for measuring demineralized

water.

Liner specific applications

• Polyurethane lining for applications

with cold water and for slightly

abrasive fluids

• Hard rubber lining for all applications

with water (especially for drinking

water)

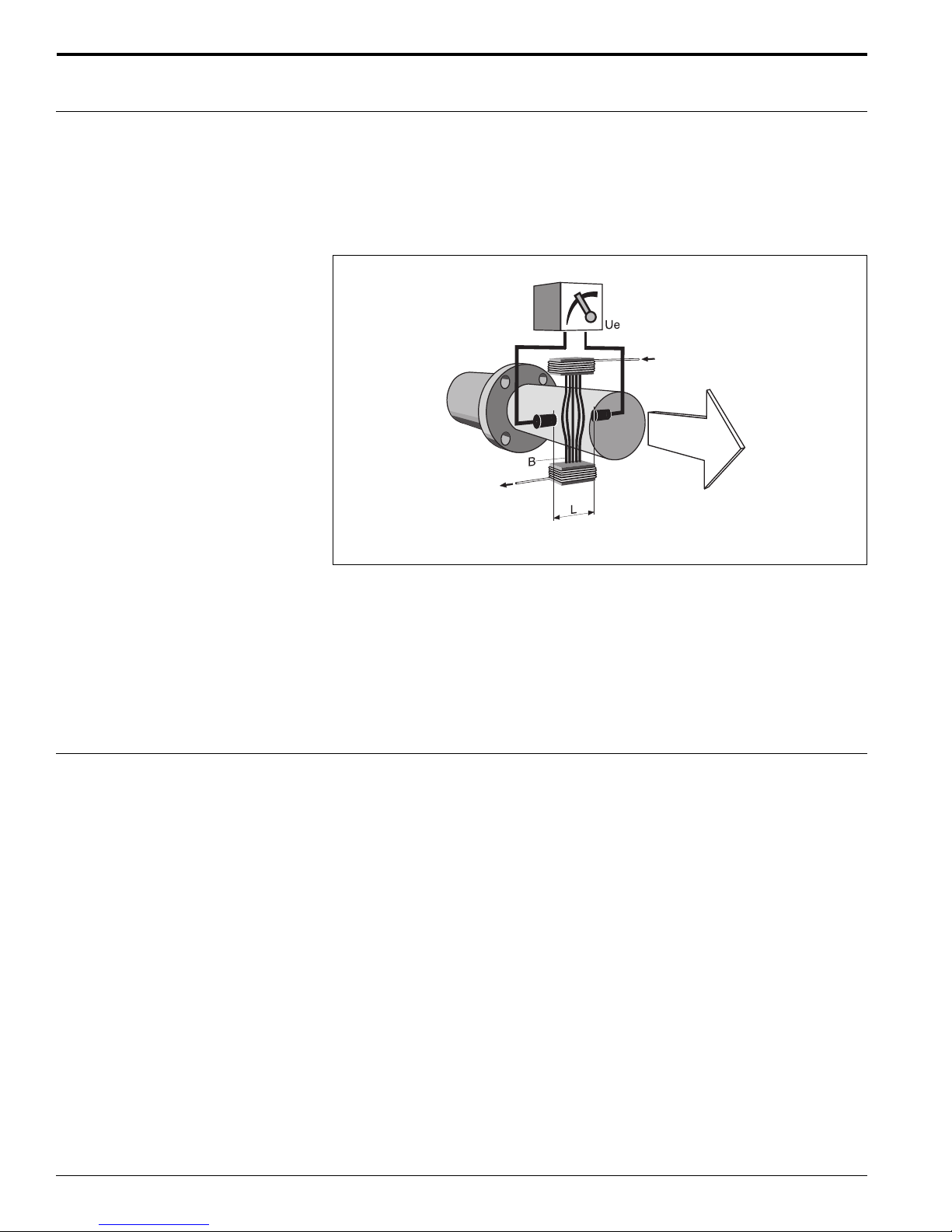

Function and system design

Promag 50/53 W

Measuring principle

Faraday’s law of induction

states that a voltage is induced in a conductor moving in a

magnetic field.

In electromagnetic measuring, the flowing medium corresponds to the moving

conductor. The induced voltage is proportional to the flow velocity and is detected by

two measuring electrodes and transmitted to the amplifier. Flow volume is computed

on the basis of the pipe’s diameter. The constant magnetic field is generated by a

switched direct current of alternating polarity.

I

V

I

Measuring system

Ue = B · L · v

Q = A · v

U e = induced voltage

B = magnetic induction (magnetic field)

L = electrode gap

v = flow velocity

Q = volume flow

A = pipe cross-section

I = current strength

The measuring system consists of a transmitter and a sensor.

Two versions are available:

• Compact version: transmitter and sensor form a single mechanical unit.

• Remote version: transmitter and sensor are installed separately.

Transmitter:

• Promag 50 (user interface with push buttons for operation, two-line display)

• Promag 53 (“Touch Control” without opening the housing, four-line display)

Sensor:

• Promag W, 1” to 78” (DN 25 to 2000)

2

Endress+Hauser

Promag 50/53 W

Input

Measured variable

Measuring range

Operable flow range

Input signal

Output signal

Flow rate (proportional to induced voltage)

Typically v = 0.033 to 33 ft/s (0.01 to 10 m/s) with the specified measur ing accuracy

Over 1000 : 1

Status input (auxiliary input):

U = 3 to 30 V DC, R

Configurable for: totalizer(s) reset, measured-value suppression, error-message

= 5 kΩ, galvanically isolated.

i

reset

Current input (for Promag 53 only):

Active/passive selectable, galvanically isolated, full scale value selectable,

µ

resolution: 3

A

Temperature coefficient: typically 0.003% o.r./°F (0.005% o.r./°C) (o.r = of reading)

Active: 4 to 20 mA, Ri ≤ 150 Ω, U

Passive: 0/4 to 20 mA, Ri ≤ 150 Ω, U

= 24 VDC, short-circuit proof

out

= 30 VDC

max

Output

Promag 50

Current output:

Active/passive selectable, galvanically isolated, time constant selectable

(0.01 to 100 s), full scale value selectable, temperature coefficient: typically

0.003% o.r./°F (0.005% o.r./°C); resolution: 0.5 µA

• active: 0/4 to 20 mA, R

• passive: 4 to 20 mA, max. 30 V DC, Ri ≤ 150 Ω

< 700 Ω (HART®: RL ≥ 250 Ω)

L

Pulse/frequency output:

Passive, open collector, 30 V DC, 250 mA, galvanically isolated.

Frequency output:

pulse width max. 10 s

Pulse output:

full scale frequency 2 to 1000 Hz (f

= 1250 Hz), on/off ratio 1:1,

max

pulse value and pulse polarity selectable, max. pulse width

configurable (0.5 ms to 2 s), maximum pulse frequency selectable

PROFIBUS-PA interface

• PROFIBUS-PA in accordance with EN 50170 Volume 2, IEC 61158-2 (MPB),

galvanically isolated

• Current consumption: 11 mA

• Permissible supply voltage: 9 to 32 V

• FDE (Fault Disconnection Electronic): 0 mA

• Data transmission rate, supported bauderate: 31.25 kBit/s

• Signal encoding: Manchester II

• Function blocks: 1 x Analog Input, 1 x Totalizer

• Output data: Volume flow , Totalizer

• Input data: Positive zero return (ON/OFF), Control totalizer, Value for local display

• Bus address adjustable via DIP switches at the measuring device

Endress+Hauser

3

Promag 50/53 W

Promag 53

Current output:

Active/passive selectable, galvanically isolated, time constant selectable

(0.01 to 100 s), full scale value selectable, temperature coefficient: typically

0.003% o.r./°F (0.005% o.r./°C); resolution: 0.5 µA

• active: 0/4 to 20 mA, R

• passive: 4 to 20 mA, max. 30 V DC, Ri ≤ 150 Ω

< 700 Ω (HART®: RL ≥ 250 Ω)

L

Pulse/frequency output:

Active/passive selectable, galvanically isolated (I.S. version: passive only)

• active: 24 V DC, 25 mA (max. 250 mA during 20 ms), R

• passive: open collector, 30 V DC, 250 mA

Frequency output:

full scale frequency 2 to 10,000 Hz (f

on/off ratio 1:1, pulse width max. 10 s

Pulse output:

pulse value and pulse polarity selectable, pulse width configurable

> 100 Ω

L

= 12,500 Hz),

max

(0.05 ms to 2 s), on/off ratio is 1:1 as of a frequency of 1 / (2 x pulse width)

PROFIBUS-DP interface:

• PROFIBUS-DP/PA in accordance with EN 50170 Volume 2, IEC 61158-2 (MPB),

galvanically isolated

• Data transmission rate, supported baudrate: 9.6 kBaud to 12 MBaud

• Automatic data transmission rate recognition

• Signal encoding: NRZ-Code

• Function blocks: 2 x Analog Input, 3 x Totalizer

• Output data: Volume flow, Corrected volume flow, Totalizer 1 to 3

• Input data: Positive zero return (ON/OFF), Totalizer control, Value for local display

• Bus address adjustable via DIP switches at the measuring device

PROFIBUS-PA interface:

• PROFIBUS-PA in accordance with EN 50170 Volume 2, IEC 61158-2 (MPB),

galvanically isolated

• Current consumption: 11 mA

• Permissible supply voltage: 9 to 32 V

• Data transmission rate, supported baudrate: 31.25 kBit/s

• Error current FDE (Fault Disconnection Electronic): 0 mA

• Signal encoding: Manchester II

• Function blocks: 2 x Analog Input, 3 x Totalizer

• Output data: Volume flow, Corrected volume flow, Totalizer 1 to 3

• Input data: Positive zero return (ON/OFF), Totalizer control, Value for local display

• Bus address adjustable via DIP switches at the measuring device

FOUNDATION Fieldbus interface:

• FOUNDATION Fieldbus H1, IEC 61158-2 (MBP), galvanically isolated

• Current consumption: 12 mA

• Permissible supply voltage: 9 to 32 V

• Error current FDE (Fault Disconnection Electronic): 0 mA

• Data transmission rate, supported buadrate: 31.25 kBit/s

• Signal encoding: Manchester II

• Function blocks: 5 x Analog Input, 1 x Discrete Output, 1 x PID

• Output data: Volume flow, Corrected volume flow, Totalizer 1 to 3

• Input data: Positive zero return (ON/OFF), Reset totalizer

• Link Master (LM) functionality is supported

Endress+Hauser4

Promag 50/53 W

Signal on alarm

Load

Switching output

Low flow cutoff

Galvanic isolation

• Current output → failure response selectable

• Pulse/frequency output → failure response selectable

• Status output (Promag 50) → non-conductive by fault or power supply failure

• Relay output (Promag 53) → de-energized by fault or power supply failure

See “Output signal”

Status output (Promag 50):

Open collector, max. 30 V DC / 250 mA, galvanically isolated

Configurable for: error messages, Empty Pipe Detection (EPD), flow direction, limit

values

Relay output (Promag 53):

Normally closed (NC or break) or normally open (NO or make) contacts available

(default: relay 1 = NO, relay 2 = NC),

max. 30 V / 0.5 A AC; 60 V / 0.1 A DC, galvanically isolated.

Configurable for: error messages, Empty Pipe Detection (EPD), flow direction, limit

values, batching contacts

Switch points for low flow cutoff are selectable

All circuits for inputs, outputs, and power supply are galvanically isolated from each

other.

Endress+Hauser 5

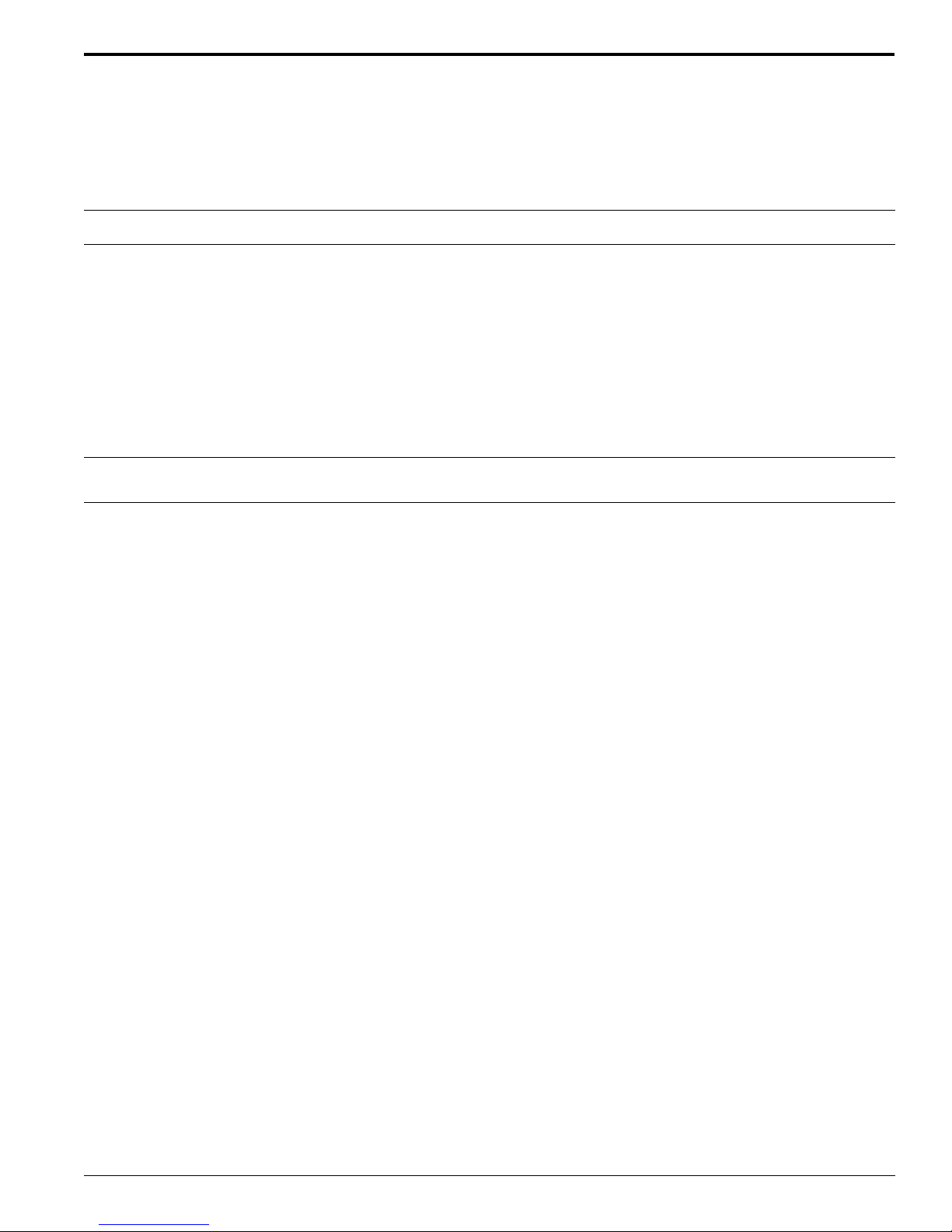

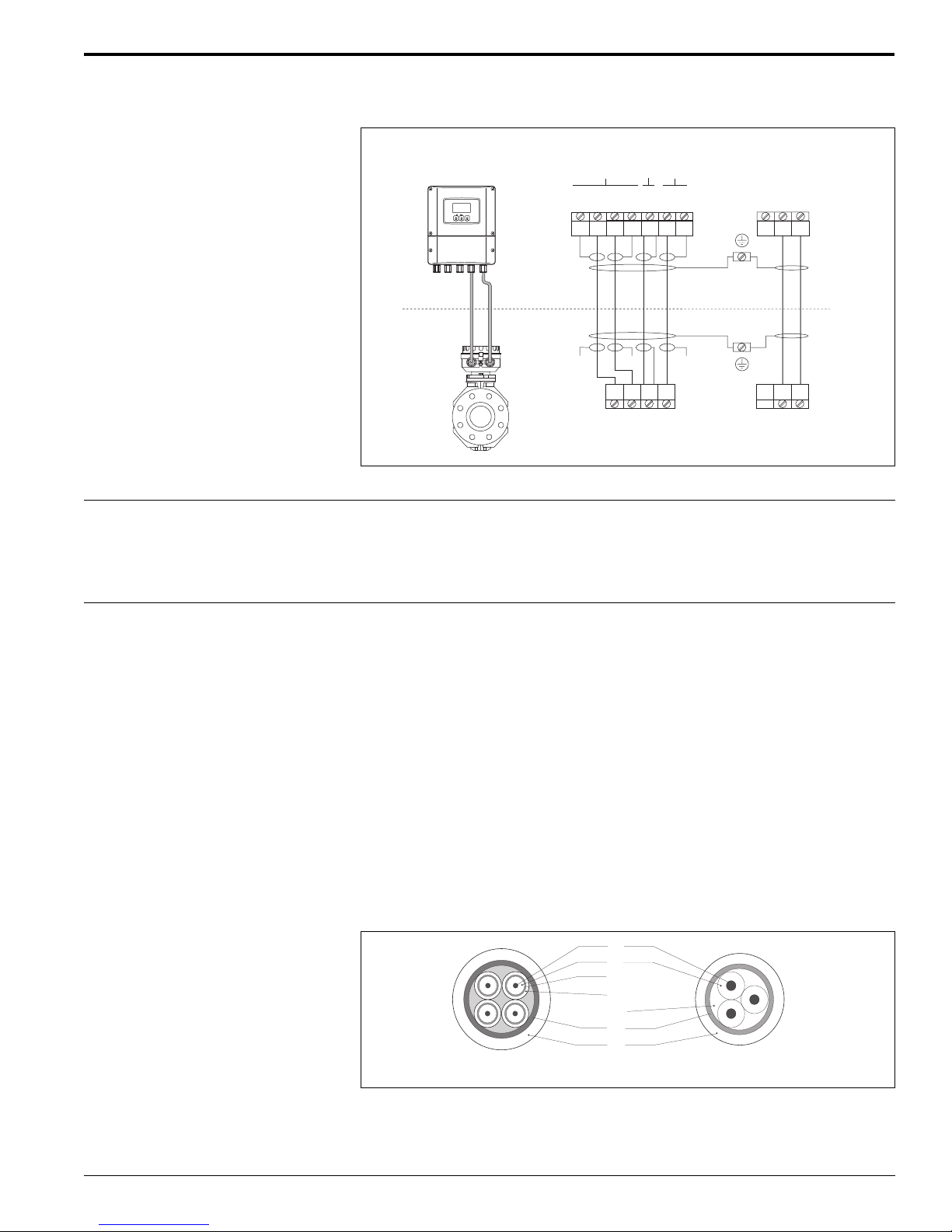

Electrical connection

measuring unit

Power supply

b

a

Promag 50/53 W

−27

f

+26

−25

e

+24

−23

+22

−21

+20

b

d

N (L-)

g

L1 (L+)

2

1

c

a

N (L-)

L1 (L+)

1

222320

21 24

+ − + − + − + −

2

27

26

25

e

f

a

b

Top: field housing

Bottom: wall-mount housing

a Cable for power supply: 85 to 260 VAC, 20 to 55 VAC, or 16 to 62 VDC; power consumption: 15 VA / 15 W

Terminal No. 1: L1 fo AC, L+ for DC

Terminal No. 2: N for AC, L- for DC

b Signal cable: terminals No. 20 to 27 ´® see Page 8

c Grounding terminal for protective conductor

d Grounding terminal for signal-cable shield

e Service connection for connecting service interface FXA 193 (FieldChec k, ToF T ool-Field Tool Package)

f Cover for wiring compartment

g Cover securing clamp

cda

b

Endress+Hauser6

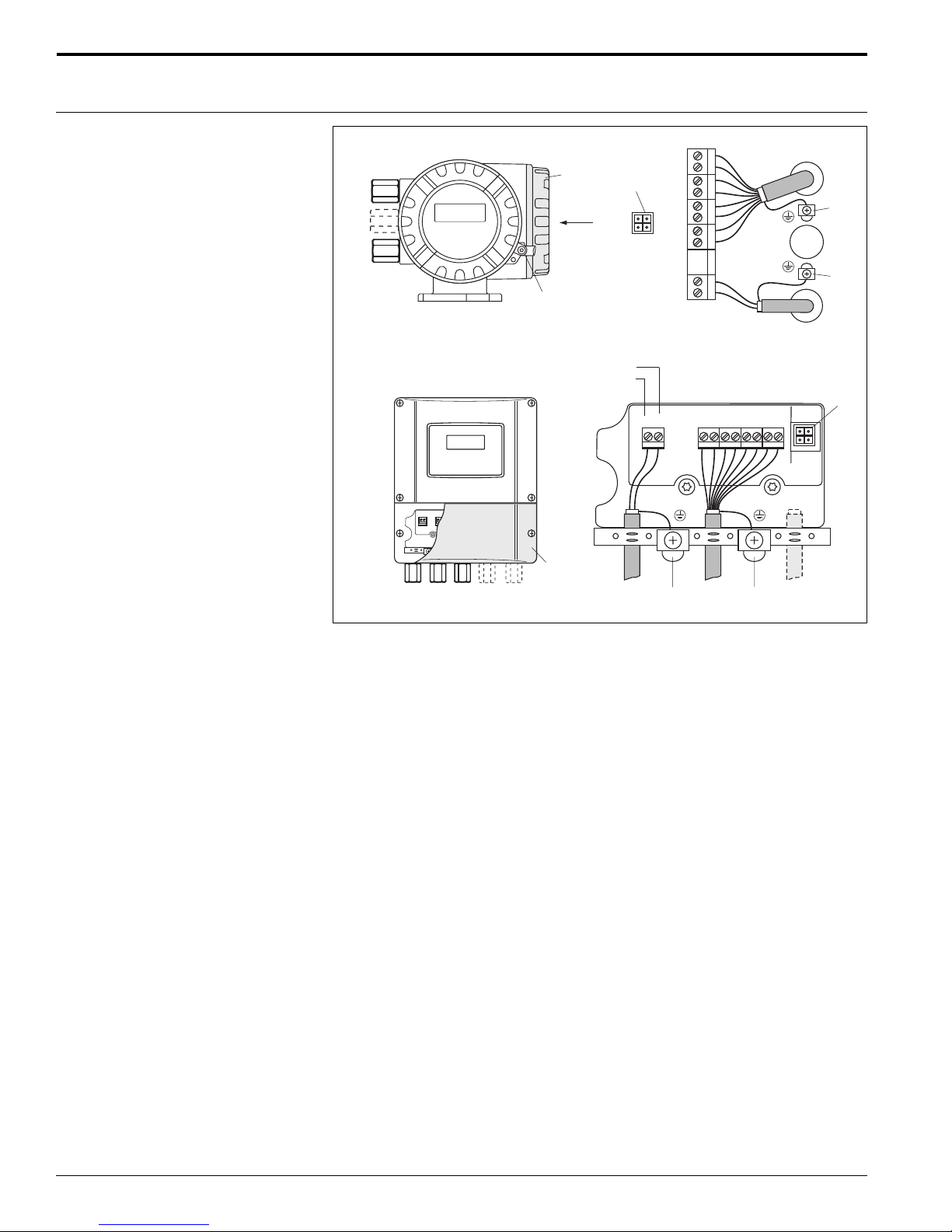

Promag 50/53 W

Electrical connection

Measuring unit (bus communication)

f

DP (A)/PA (–)/FF (–)

DP (B)/PA (+)/FF (+)

b

g

e

a

h

N (L–)

L1 (L+)

Esc

-

+

E

(DGND)

(+5 V)

N (L-)

L1 (L+)

2

1

27

26

25

24

23

22

21

20

2

1

222320 21 242526

27

b

d

g

c

a

(+5 V)

(DGND)

DP (B)/PA (+)/FF (+)

DP (A)/PA (–)/FF (–)

e

f

cd

a

bg

a

g

b

T op: Field housing

Bottom: Wall-mount housing

a Cable for power supply: 85 to 260 VAC, 20 to 55 VAC, or 16 to 62 VDC; power consumption:15 VA / 15 W

Terminal No. 1: L1 fo AC, L+ for DC

Terminal No. 2: N for AC, L- for DC

b Fieldbus cable:

Terminal No. 26: DP (B) / PA (+) / FF (+) (with polarity protection)

Termianl No. 27: DP (A) / PA (-) / FF (-) (with reverse polarity protection)

DP (A) = RxD/TxD-N; DP (B) = RxD/TxD-P

c Grounding terminal for protective conductor

d Grounding terminal for signal-cable shield

e Service connector for connecting service interface FXA 193 (FieldChec k, ToF T ool-Field Tool Package)

f Cover for connection compartment

g Cable for external termination (PROFIBUS only)

h Cover securing clamp

Endress+Hauser 7

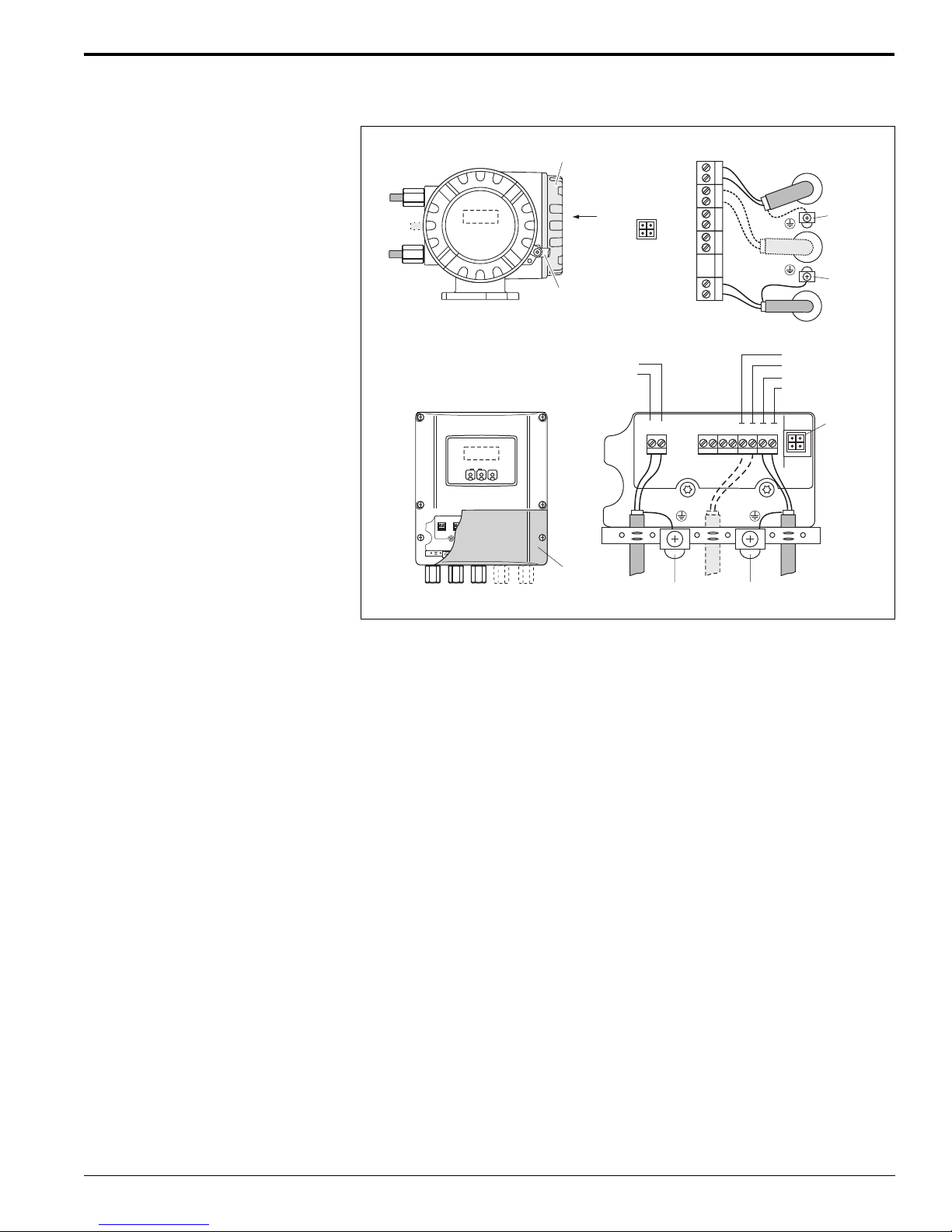

Promag 50/53 W

Terminal assignment Promag 50

Terminal No. (inputs / outputs)

Order variant 20 (+) / 21 (-) 22 (+) / 23 (-) 24 (+) / 25 (-) 26 (+) / 27 (-)

50***-***********W - - - Current output

HART

50***-***********A - - Frequency output Current output

HART

50***-***********D Status input Status output Frequency output Current output

HART

50***-***********S - - Frequency output Current output

IS, passive HART

50***-***********T - - Frequency output Current output

Intrinsically Safe HART

®

®

®

®

®

Ground connection, power supply → refer to illustration on top of page 6

Terminal assignment Promag 53

The inputs and outputs on the communication board can be either permanently

assigned or variable, depending on the version ordered (see table). Replacement

for modules which are defective or which have to be replaced can be ordered as

accessories.

Terminal No. (inputs / outputs)

Order variant 20 (+) / 21 (-) 22 (+) / 23 (-) 24 (+) / 25 (-) 26 (+) / 27 (-)

Fixed communication boards (fixed assignment)

53***-***********A - - Frequency output Current output

HART

53***-***********B Relay output 2 Relay output 1 Frequency output Current output

HART

53***-***********F - - - Profibus-PA

IS

53***-***********G - - - Foundation

Fieldbus IS

53***-***********H - - - Profibus-PA

53***-***********J - - - Profibus-DP

53***-***********K - - - Foundation

Fieldbus

53***-***********S - - Frequency output Current output

Intrinsically safe IS, active

HART

53***-***********T - - Frequency output Current output

Intrinsically safe IS, passive

HART

®

®

®

®

8

Flexible communication boards

53***-***********C Relay output 2 Relay output 1 Frequency output Current output

HART

53***-***********D Status input Relay output Frequency output Current output

HART

53***-***********L Status input Relay output 2 Relay output 1 Current output

HART

53***-***********M Status input Frequency output 2 Frequency output 1 Current output

HART

53***-***********2 Relay output Current output 2 Frequency output Current output

1 HART

53***-***********4 Current input Relay output Frequency output Current output

HART

53***-***********5 Status input Current input Frequency output Current output

HART

®

®

®

®

®

®

®

Ground connection, power supply → refer to illustration on top of page 6

Endress+Hauser

Promag 50/53 W

Electrical connection

remote version

Electrode Circuit

EPDMeas.signal Pipe

Cable entry

Cable specifications

remote version

Esc

-

+

E

n.c. = cable shields to be isolated and not to be connected

S1

6

n.c. n.c.n.c.

5

brown

E2

7

white

5

E1E1E2

S2

8

7

4

green

4

E

GND

373736

yellow

GND

S

E

Coil circuit

424241

2

1

41

Power-supply and signal cables (inputs/outputs):

• 1/2" NPT

Connecting cable for remote version:

• 1/2" NPT

Coil cable:

• 2 x 18 AWG (0.75 mm2) PVC cable with common, braided copper shield,

approximately 0.28” diameter (Ø approx. 7 mm)

• Conductor resistance: ≤ 0.011 Ω/ft (37 Ω/km)

• Capacitance: core/core, shield grounded: ≤ 36 pF/ft (120 pF/m)

• Permanent operating temperature: -5° to +180°F (–20 to +80°C)

• Cable cross-section: maximum 16 AWG (2.5 mm2)

Endress+Hauser

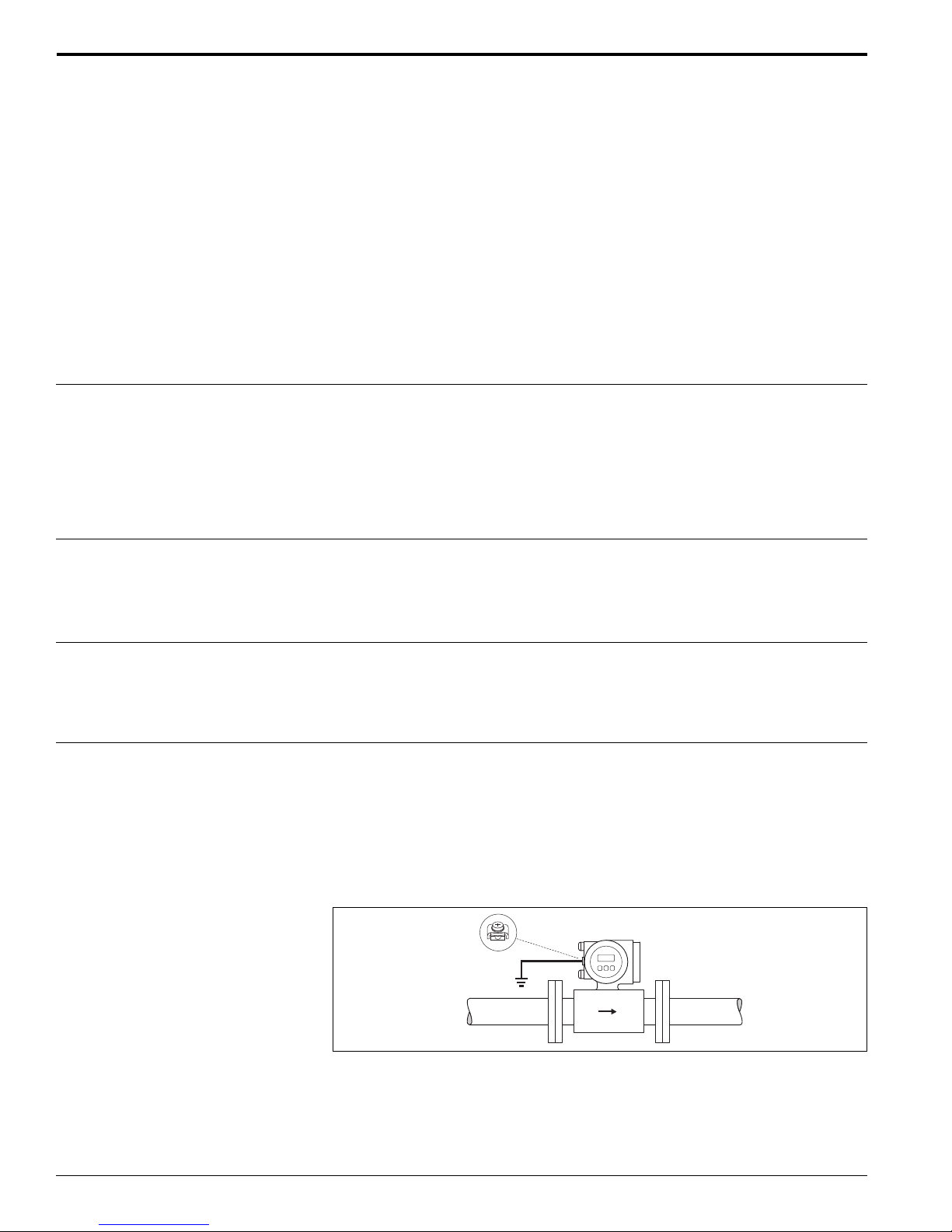

Signal cable:

• 3 x 20 AWG (0.38 mm

2

) PVC cable with common, braided copper shield,

approximately 0.28” diameter (Ø approx. 7 mm) and individually shielded cores.

• With Empty Pipe Detection (EPD): 4 x 20 AWG (0.38 mm2) PVC cable with

common, braided copper shield, approximately 0.28” diameter (Ø approx. 7 mm)

and individually shielded cores.

• Conductor resistance: ≤ 0.015 Ω/ft (50 Ω/km)

• Capacitance: core/shield: ≤ 128 pF/ft (420 pF/m)

• Permanent operating temperature: -5° to +180°F (–20 to +80 °C)

• Cable cross-section: maximum 16 AWG (2.5 mm2)

1

2

3

4

5

6

7

a

a = signal cable, b = coil current cable (maximum 16 AWG (2.5 mm2)

1 = Core 5 = Core strengthening

2 = Core insulation 6 = Cable shield

3 = Core shield 7 = Outer jacket

4 = Core jacket

b

9

Promag 50/53 W

Endress+Hauser optionally supplies reinforced connecting cables with an additional

metal braid. We recommend such cables for the following cases:

• Underground laid cables

• Danger of rodent attack

• Device used with NEMA 6P (IP 68) ingress protection

Operation in areas of severe electrical interference:

The measuring device complies with the general safety requirements in accordance

with EN 61010, the EMC requirements of EN 61326, and NAMUR recommendation

NE 21.

Caution:

Grounding is by means of the ground terminals provided for that purpose inside the

connection housing. Keep the stripped and twisted lengths of cable shield to the

terminals as short as possible.

Supply voltage

Power consumption

Power supply failure

Potential equalization

85 to 260 VAC, 45 to 65 Hz

20 to 55 VAC, 45 to 65 Hz

16 to 62 V DC

PROFIBUS-PA and FOUNDATION Fieldbus

Nonhazardous: 9 to 32 VDC

Intrinsically safe: 9 to 24 VDC

Explosion proof: 9 to 32 VDC

AC: <15 VA (including sensor)

DC: <15 W (including sensor)

Switch-on current:

• maximum 13.5 A (< 50 ms) at 24 V DC

• maximum 3 A (< 5 ms) at 260 V AC

Lasting minimum 1 power cycle:

• EEPROM or T-DAT™ (Promag 53 only) retain the measuring-system data in the

event of a power supply failure

• S-DAT™ = exchangeable data storage chip which stores the data of the sensor:

nominal diameter, serial number, calibration factor, zero point, etc.

Standard case

Perfect measurement is only ensured when the medium and the sensor have the

same electrical potential. Most Promag sensors have a standard installed reference

electrode which guarantees the required potential matching. This usually means that

additional potential matching measures are unnecessary.

NOTE: For installation in metal pipes, it is advisable to connect the ground terminal

of the transmitter housing to the piping.

Caution:

For sensors without reference electrodes or without metal process terminals, carry

out potential matching as per the instructions for special cases described below.

These special measures are particularly important when standard grounding

practice cannot be ensured or extremely strong matching currents are expected.

Endress+Hauser10

Loading...

Loading...