Page 1

BA01349C/07/EN/03.18

71430357

2018-10-31

Products Solutions Services

Operating Instructions

OUSAF46

Optical sensor with the OUA260 flow assembly for

the measurement of UV absorption

Page 2

Table of contents OUSAF46

Table of contents

1 About this document ........... 3

1.1 Warnings ........................... 3

1.2 Symbols ............................ 3

1.3 Symbols on the product ............... 4

2 Basic safety instructions ....... 4

2.1 Requirements for the personnel ........ 4

2.2 Designated use ...................... 4

2.3 Occupational safety .................. 4

2.4 Operational safety ................... 5

2.5 Product safety ....................... 5

3 Product description ............. 6

3.1 Measuring principle .................. 6

9 Repair .......................... 30

9.1 Return ............................ 30

9.2 Disposal ........................... 30

10 Accessories .................... 30

10.1 Flow assembly ...................... 31

10.2 Cable ............................. 31

10.3 Calibration ......................... 31

11 Technical data ................. 31

11.1 Input .............................. 31

11.2 Environment ....................... 32

11.3 Process ............................ 32

11.4 Mechanical construction ............. 32

4 Incoming acceptance and

product identification .......... 7

4.1 Incoming acceptance ................. 7

4.2 Product identification ................. 7

4.3 Manufacturer's address ............... 8

4.4 Scope of delivery ..................... 8

4.5 Certificates and approvals ............. 8

5 Installation ...................... 9

5.1 Installation conditions ................ 9

5.2 Mounting the sensor ................ 11

5.3 Post-installation check ............... 12

6 Electrical connection .......... 12

6.1 Connecting the sensor ............... 13

6.2 Lamp voltage ....................... 14

6.3 Ensuring the degree of protection ..... 14

6.4 Post-connection check ............... 15

7 Commissioning ................ 16

7.1 Function check ..................... 16

7.2 Calibrating/adjusting the sensor ...... 16

8 Maintenance .................. 18

8.1 Maintenance schedule ............... 19

8.2 Replacing the hazardous area lamp .... 19

8.3 Replacing the mercury lamp .......... 19

8.4 Replacing the reference filter ......... 22

8.5 Replacing the measurement filter ..... 24

8.6 Replacing the sensor window and

seal ............................... 28

Index ................................. 34

2 Endress+Hauser

Page 3

OUSAF46 About this document

1 About this document

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of noncompliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to property.

1.2 Symbols

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

Endress+Hauser 3

Page 4

Basic safety instructions OUSAF46

1.3 Symbols on the product

Symbol Meaning

Reference to device documentation

2 Basic safety instructions

2.1 Requirements for the personnel

• Installation, commissioning, operation and maintenance of the measuring system may be

carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the specified

activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions and

must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

The sensor measures the spectral absorption of process liquids in the ultraviolet region of the

electromagnetic spectrum. The sensor is suitable for use in a wide range of applicationsin a

variety of industrial sectors , such as:

• Measurement of protein concentrations

• Chromatography monitoring

• Filtration monitoring

• Concentration measurement of organic compounds

• Detection of aromates

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

4 Endress+Hauser

Page 5

OUSAF46 Basic safety instructions

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable European standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

2.5.2 Versions with hazardous area lamp

Also observe the safety instructions in the XA for these Operating Instructions.

Safety instructions for electrical apparatus in hazardous areas, photometer sensors,

XA01403C/07/A3

Endress+Hauser 5

Page 6

Product description OUSAF46

1

OPL

2

3

4

5

68

7 2

3 Product description

3.1 Measuring principle

Light absorption

The measuring principle is based on the Lambert-Beer law.

There is a linear dependency between the absorption of light and the concentration of the

absorbing substance:

A = -log(T) = ε . c . OPL

T = I/I

0

T ... Transmission

I ... Intensity of received light at detector

I0 ... Intensity of transmitted light of light source

A ... Absorption

ε ... Extinction coefficient

c ... Concentration

OPL ... Optical path length

A light source emits radiation through the medium and the incident radiation is measured on

the detector side.

The subsequent conversion to absorbance units (AU, OD) is performed in the associated

transmitter.

1 Absorption measurement with reference

1 Light source

2 Optical windows

3 Measurement filter

4 Measuring detector

5 Lens

6 Medium flow

7 Reference filter

8 Reference detector

OUSAF46 has 2 pairs of reference and measuring detectors (= 2 channels). Only one

channel is shown for the sake of simplicity.

6 Endress+Hauser

A0029412

Page 7

OUSAF46 Incoming acceptance and product identification

4 Incoming acceptance and product identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Serial number

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

4.2.2 Product identification

Product page

www.endress.com/ousaf46

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

Endress+Hauser 7

Page 8

Incoming acceptance and product identification OUSAF46

4. Search.

The product structure is displayed in a popup window.

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

4.3 Manufacturer's address

Endress+Hauser Conducta Inc.

4123 East La Palma Avenue, Suite 200

Anaheim, CA 92807 USA

4.4 Scope of delivery

The scope of delivery consists of the following :

• Detector and lamp module without flow assembly or

• Detector and lamp module mounted on flow assembly

• Operating Instructions

Ordering the sensor together with a transmitter:

If you select the calibration option in the Product Configurator for the transmitter, the

complete measuring system (transmitter, sensor, cable) is factory-calibrated and shipped

as one package.

If you have any queries:

‣

Please contact your supplier or local sales center.

4.5 Certificates and approvals

4.5.1 mark

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EU directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

4.5.2 Hazardous area approvals

• ATEX II 2G Ex db IIC T5 Gb

• FM Cl.1, Div. 1, Groups B, C, D

4.5.3 FDA conformity

All non-metal parts in contact with medium, such as rubber and plastic parts, meet the

requirements of FDA 21 CFR 177.2600. The plastic and elastomer parts of the sensor in

contact with medium have passed the biological reactivity tests according to USP <87> and

<88> Class VI.

8 Endress+Hauser

Page 9

OUSAF46 Installation

1 2

3

7

5

4

6

5 Installation

5.1 Installation conditions

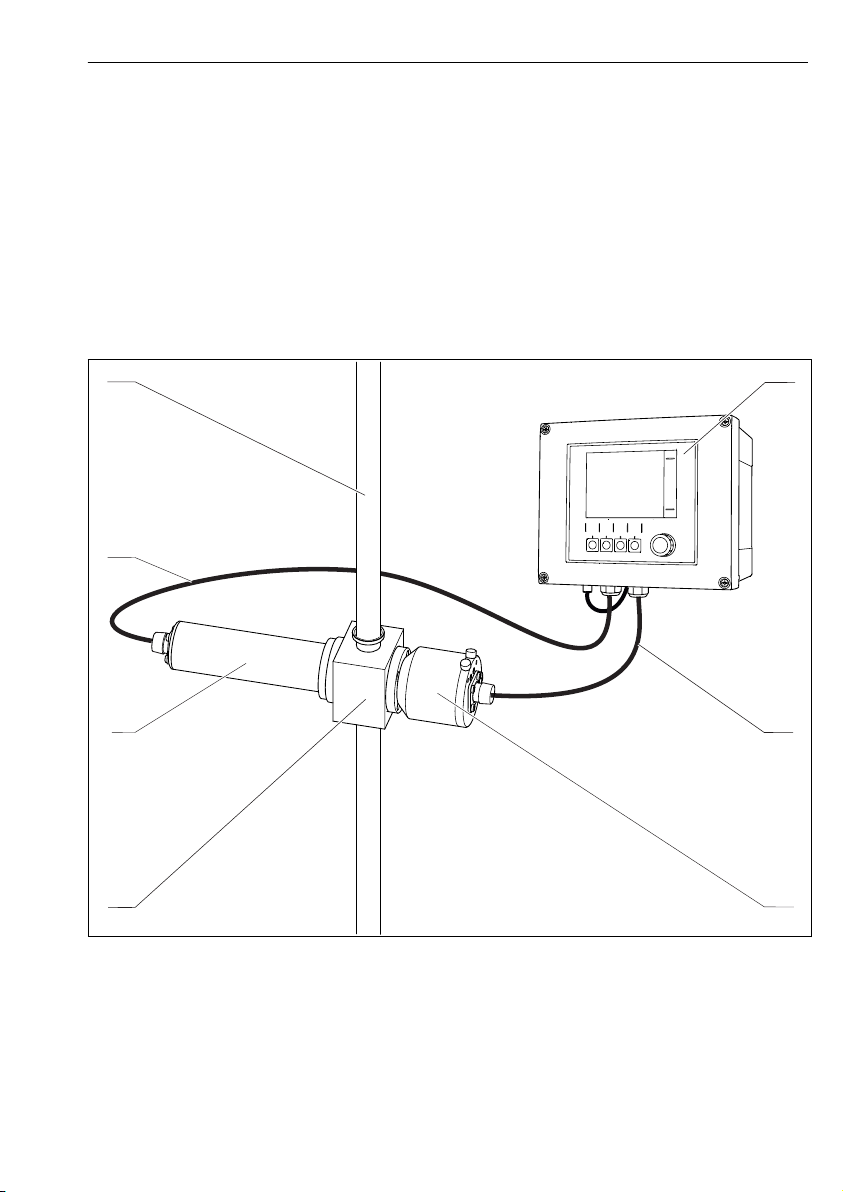

5.1.1 Measuring system

An optical measuring system comprises:

• Sensor (photometer) OUSAF46

• Transmitter, e. g. Liquiline CM44P

• Cable set, e. g. CUK80

• Assembly OUA260

2 Example of a measuring system with a photometer sensor

1 pipe 5 Flow assembly OUA260

2 Transmitter CM44P 6 Sensor: light source (lamp)

3 CUK80 cable set 7 CUK80 cable set

4 Sensor: detector

Endress+Hauser 9

Page 10

Installation OUSAF46

A B

C

5.1.2 Dimensions

A0035258

3 Sensor module

A Dimension of lamp → Table

B Dimension of detector → Table

C Assembly, see Technical Information for assembly

Lamp type Dimension A in mm (inch)

Standard lamp 146.1 (5.75)

Detector type Dimension B in mm (inch)

Standard version with test filter 80 (3.15)

Easycal 94 (3.70)

The total length of the sensor module is derived from the lengths of the lamp, the

detector and the assembly.

The dimensions of the OUA260 assembly are provided in Technical Information,

TI00418C.

Allow an additional gap of 5 cm (2") on both the lamp side and detector side of the sensor

‣

to connect the sensor cable.

10 Endress+Hauser

Page 11

OUSAF46 Installation

A

B

C

D

E

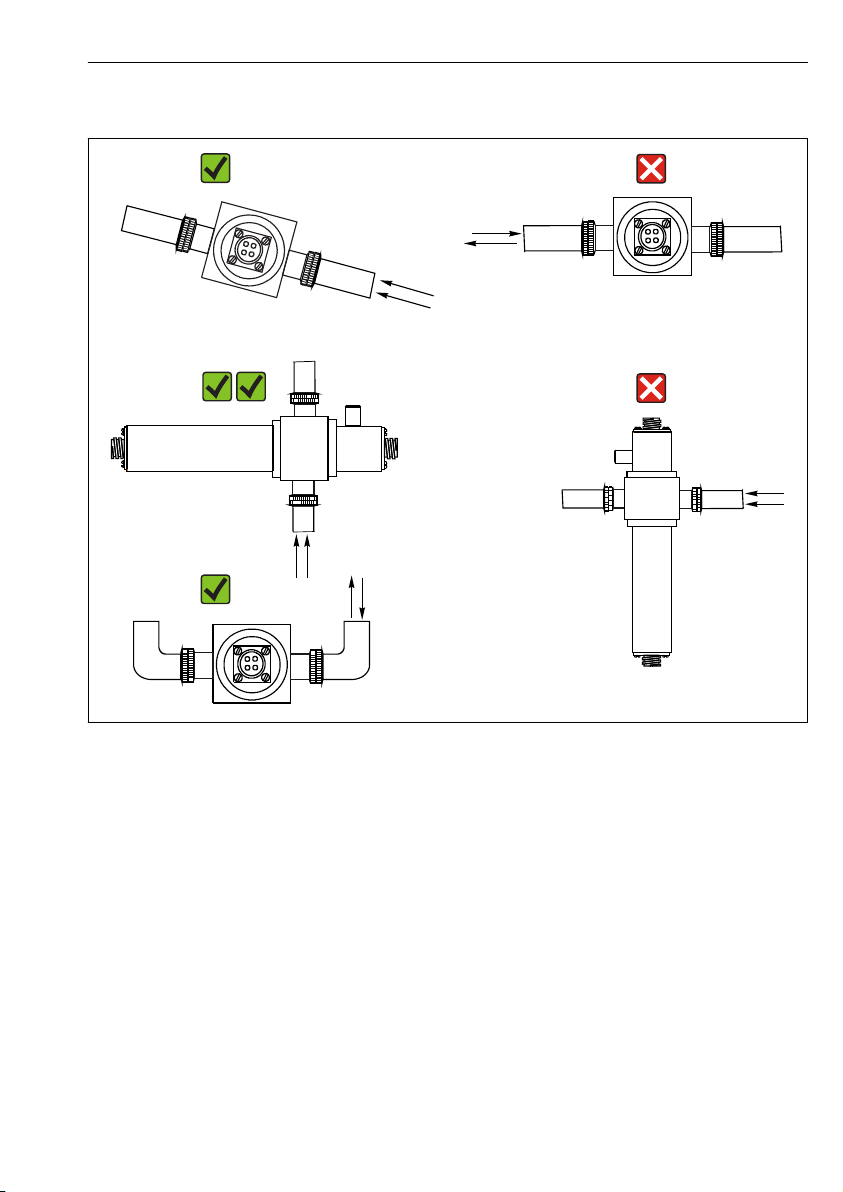

5.1.3 Mounting angles

4 Mounting angles. The arrows indicate the direction of medium flow in the pipe.

A Suitable mounting angle, better than C

B Optimum mounting angle, best installation position

C Acceptable mounting angle

D Mounting angle to be avoided

E Forbidden mounting angle

5.2 Mounting the sensor

The sensors have been specifically designed so that they can be installed in the process

together with a flow assembly, such as the OUA260. The flow assembly can be installed either

directly in a process line or in a bypass line.

The sensor cannot be used without an assembly.

Make sure that the sensor housing and detector housing are aligned horizontally. This

‣

ensures that the optical windows are vertically aligned as this prevents buildup on the

window surfaces.

Endress+Hauser 11

A0028250

Page 12

Electrical connection OUSAF46

Install the sensor upstream from the pressure regulators.

‣

Leave enough room for the cable connector at the end of the lamp and at the end of the

‣

detector housing. Unimpeded access to these areas is also required for connection/removal

tasks.

The operation of sensors under pressure prevents the formation of air or gas bubbles.

‣

NOTICE

Mounting errors

Possibility of sensor damage, twisted cables or similar

Make sure that the sensor bodies are protected against damage from external forces - such

‣

as trolleys on adjacent paths.

Remove the cable before you screw the lamp or detector onto the flow assembly.

‣

Make sure to avoid exerting excessive tensile force on the cable (e.g. from jerky pulling

‣

movements).

Make sure to observe the national grounding regulations when using metal assemblies.

‣

If the sensor is ordered together with the assembly OUA260, the flow assembly is readymounted on the sensor upon delivery. The sensor is ready for use immediately.

If the sensor and assembly are ordered separately, you must mount the sensor as follows:

1. Install flow assembly OUA260 in the process via the process connections.

2. Make sure to fit the O-ring seals on the lamp and detector.

Screw the lamp and detector onto the flow assembly.

The lamp and detector can be installed in and removed from the assembly without this

affecting the process line.

5.3 Post-installation check

Put the sensor into operation only if you can answer "yes" to the following questions:

• Are the sensor and cable undamaged?

• Have you chosen a correct mounting angle?

6 Electrical connection

WARNING

L

Device is live!

Incorrect connection may result in injury or death!

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions and

‣

must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

12 Endress+Hauser

Page 13

OUSAF46 Electrical connection

BK

GY

RD

A

B

YE

YE

BK

BK

GY

RD

BK

B

GY

WH

GN

GN

GY

WH

6.1 Connecting the sensor

The sensor is connected to the transmitter using the pre-terminated or labeled cable set

CUK80 (for connection to CM44P) or OUK (for connection to CVM40) . The terminals and

labeling may vary depending on the transmitter in use. The cable set must be ordered

separately.

A0033423

5 OUSAF46 connecting cable

A Light source (lamp) power supply

B Signals of measurement and reference detector

CM44P terminal CVM40 terminal Cable color Assignment

PEM module 1

P+ V1.1 YE (thick) Lamp voltage +

S+ V1.3 YE (thin) Detection of lamp voltage +

S- V1.4 BK (thin) Detection of lamp voltage -

P- V1.2 BK (thick) Lamp voltage -

A (1) S1.1 RD Channel 1 Sensor measuring detector +

C(1) S1.2 BK Channel 1 Sensor measuring detector -

Endress+Hauser 13

Page 14

Electrical connection OUSAF46

CM44P terminal CVM40 terminal Cable color Assignment

SH (1) S1.S GY Channel 1 Shield

A (2) S2.1 WH (lamp) Channel 1 Sensor reference +

C(2) S2.2 GN (lamp) Channel 1 Sensor reference -

SH (2) S2.S GY (lamp) Channel 1 Shield

PEM module 2

A (1) S3.1 WH Channel 2 Sensor measuring detector +

C(1) S3.2 GN Channel 2 Sensor measuring detector -

SH (1) S3.S GY Channel 2 Shield

A (2) S4.1 RD (lamp) Channel 2 Sensor reference +

C(2) S4.2 BK (lamp) Channel 2 Sensor reference -

SH (2) S4.S GY (lamp) Channel 2 Shield

6.2 Lamp voltage

Sensor version Lamp type Lamp voltage [V]

OUSAF46-xxxx Low-pressure mercury lamp 10.0 ± 0.1

6.3 Ensuring the degree of protection

Only the mechanical and electrical connections which are described in these instructions and

which are necessary for the required, designated use, may be carried out on the device

delivered.

Exercise care when carrying out the work.

‣

Individual types of protection permitted for this product (impermeability (IP), electrical safety,

EMC interference immunity, Ex protection) can no longer be guaranteed if, for example :

• Covers are left off

• Different power units to the ones supplied are used

• Cable glands are not sufficiently tightened (must be tightened with 2 Nm (1.5 lbf ft) for the

permitted level of IP protection)

• Unsuitable cable diameters are used for the cable glands

• Modules are not fully secured

• The display is not fully secured (risk of moisture entering due to inadequate sealing)

• Loose or insufficiently tightened cables/cable ends

• Conductive cable strands are left in the device

14 Endress+Hauser

Page 15

OUSAF46 Electrical connection

6.4 Post-connection check

Device condition and specifications Notes

Are the sensor, assembly and cable free from damage on the outside? Visual inspection

Electrical connection Notes

Does the supply voltage of the connected transmitter match the data on the

nameplate?

Are the installed cables strain-relieved and not twisted?

Has the cable been routed without loops and cross-overs? Check that it is firmly seated (by

Are the signal cables connected correctly according to the connection diagram?

Are all cable entries mounted, tightened and leak-tight? For lateral cable entries, make sure

Are the PE distributor rails grounded (if present)? Grounding at the point of

Visual inspection

pulling gently)

the cables loop downwards to allow

water to drip off.

installation

Endress+Hauser 15

Page 16

Commissioning OUSAF46

7 Commissioning

7.1 Function check

Prior to initial commissioning, ensure that:

• The sensor is correctly installed

• The electrical connection is correct.

7.2 Calibrating/adjusting the sensor

Measuring points consisting of a photometer sensor, flow assembly (if provided) and a

transmitter are adjusted at the factory. Normally adjustment is not required when

commissioning for the first time.

If an adjustment is desired nevertheless, you have the following adjustment options:

• Adjustment with calibration standards

• Use of Easycal

7.2.1 Calibration/adjustment with standard solutions

Use solutions with a known absorbance (at the sensor wavelength) for the calibration/

adjustment.

WARNING

L

Potassium dichromate is toxic, flammable, carcinogenic and has mutagenic effects!

Can cause cancer, genetic defectives, affect fertility, harm the unborn child and intensify fires.

Potentially life-threatening if inhaled, toxic if swallowed, harmful if it comes into contact with

skin. Causes severe skin burns and severe eye damage!

When working with potassium dichromate, always wear protective gloves and protective

‣

goggles.

Seek special advice before use.

‣

Follow all of the instructions on the manufacturer's safety data sheet.

‣

Use calibration solutions that are suitable for the measuring task. Examples of solutions which

are commonly used include:

Potassium dichromate, K2Cr2O

A solution of 182 ml 0.1N K2Cr2O7, diluted to one liter, has an absorbance of approx. 10 OD at

280 nm. By diluting the solution, you can produce a series of calibration solutions which you

can use to adjust the measuring point.

AU = OD*OPL[cm]

AU ... absorbance units, OD ... optical density, OPL .... optical path length

Instead of potassium dichromate you can also use your process medium for calibrating/

adjusting and for application calibration. Here, also produce a series of dilutions of

known concentration and determine the absorbance in the laboratory.

16 Endress+Hauser

7

Page 17

OUSAF46 Commissioning

1 2

34

7.2.2 Easycal

Easycal enables you to perform a calibration/an adjustment which is traceable to NIST

without any liquid standards.

Detector with Easycal: function

6 Filter in "out" position

1 NIST-traceable filter (high)

2 Locking screw

Every Easycal device has two traceable filters - one filter with a nominal 0.5 AU and another

filter with 1 AU (absorbance unit) - which are placed individually or together in the device

measuring path. These filter(s) are scanned with traceable testing equipment and the actual

absorbance at individual wavelengths is determined.

It is very important that you use the actual values of the optical Easycal filter. These values are

given in the calibration certificate supplied.

Enter the absorbance values (CM44P): Menu/Setup/Inputs/Photometer/Extended

‣

setup/Measurement channel/Calib. settings/EasyCal = Yes, NIST filter high and NIST

filter low.

Send Easycal in to your Service Center once a year for recertification. This comprises

complete functional testing and the recertification of the filters in accordance with

sources that are traceable to NIST.

7.2.3 Visual inspection

A reference rod is included in the delivery for every standard sensor (sensor without Easycal).

In this way, it is possible to perform a functional test on the device without having to use

calibration solutions.

A0033709

7 Filter in "in" position

3 Positioning pin

4 Lens assembly

A0033708

Endress+Hauser 17

Page 18

Maintenance OUSAF46

The reference rod is screwed into the sensor detector housing, thereby partially blocking the

sensor light. This simulates the absorbance in the optical chain.

The cross-sectional view of the measuring detector below illustrates the position of the

reference rod and its blocking effect.

A0035261

8 Cross-section of detector module with reference rod inserted

Proceed as follows to obtain a value for the reference rod during commissioning:

1. Fill the flow assembly with water. Make sure that the measured value "zero" is displayed.

2. Insert the reference rod into the detector housing.

Make a note of the measured value.

You can check the calibration any time later on by filling the flow assembly with water again

and re-inserting the reference rod. The measured value should be equal to the value noted

down.

8 Maintenance

Take all the necessary precautions in time to ensure the operational safety and reliability of

the entire measuring system.

NOTICE

Effects on process and process control!

When carrying out any work on the system, bear in mind any potential impact this could

‣

have on the process control system and the process itself.

For your own safety, only use genuine accessories. With genuine parts, the function,

‣

accuracy and reliability are also ensured after maintenance work.

18 Endress+Hauser

Page 19

OUSAF46 Maintenance

NOTICE

Sensitive optical components

If you do not proceed with care, you can damage or severely dirty the optical components.

Maintenance work may only be carried out by appropriately qualified staff.

‣

Use ethanol and a lint-free cloth which is suitable for cleaning lenses to clean all the

‣

optical components.

8.1 Maintenance schedule

• Maintenance and servicing intervals are based on the individual application.

• Cleaning intervals depend on the medium.

Maintenance checklist

• Replace lamp

The lamp is typically replaced after 1000 to 3000 operating hours (→ 33).

• Replace sensor window and seal

The window only needs to be replaced if it is damaged.

• Replace O-rings in contact with the medium

The replacement of O-rings in contact with the medium depends on the specific

requirements of the process.

Never re-use a used O-ring.

8.2 Replacing the hazardous area lamp

The disassembly and assembly process for the hazardous area lamp is the same as for the

non-hazardous area version.

Make sure you use the right spare parts kit.

8.3 Replacing the mercury lamp

WARNING

L

Dangerous voltage

Risk of serious or fatal injury from electric shock!

Before performing any maintenance work on the lamp, remove all the cables and

‣

disconnect the power supply to the sensor.

Only replace the lamp in a current-free state.

‣

CAUTION

L

Mercury lamp

UV radiation can damage the eyes!

Protect your eyes with protective goggles suitable for UV radiation.

‣

Never look directly into a mercury lamp when it is switched on.

‣

Endress+Hauser 19

Page 20

Maintenance OUSAF46

Removing the used lamp

Switch off the lamp using the software function on the transmitter.

‣

Remove the lamp cable.

‣

Allow the lamp to cool down (30 minutes).

‣

1.

Turn the lamp module counterclockwise to remove it from the flow assembly.

2.

Use a 1" open-ended wrench. With the wrench, hold the base plate of the cable

connector in position and unscrew the lamp housing in a counterclockwise direction by

hand.

Remove the lamp and reflector unit from the housing.

3.

Loosen the securing screw holding the lamp by 1-2 rotations.

20 Endress+Hauser

Page 21

OUSAF46 Maintenance

4.

Hold the lamp socket in the gap between the lamp power supply unit and the reflector

and press it out of its fitting. Do not damage the cable of the circuit board! Then press

the lamp out completely through the reflector.

Dispose of the used lamp in accordance with local regulations for lamps containing

mercury.

5. Check whether the cables of the lamp module are worn, or whether the reflector is

damaged.

Inserting a new lamp

When working with the lamp, use a cloth for lenses or wear talc-free latex gloves.

1.

Clean the new lamp and the reflector with ethanol and a cloth for cleaning the lens.

Do not touch optical surfaces once they have been cleaned!

2.

Guide the new lamp carefully through the reflector and into the socket.

Make sure that the lamp is securely seated in the correct position.

Endress+Hauser 21

Page 22

Maintenance OUSAF46

3.

Retighten the securing screw.

This screw is only used to hold the lamp in position. Therefore, do not tighten it too

tightly as to do so could damage or break the lamp.

4. Make sure that the lamp contact area is completely clean and dry before re-closing.

5.

Screw the lamp and reflector group back into its housing and tighten it by hand.

6.

Mount the complete lamp module back into the flow assembly.

After replacing the lamp, the system needs to be adjusted. In addition, you must reset the

operating hours counter for the lamp on the CM44P: CAL/Photometer/Lamp operating

time/Reset.

8.4 Replacing the reference filter

WARNING

L

Dangerous voltage

Risk of serious or fatal injury from electric shock!

Before performing any maintenance work on the lamp, remove all the cables and

‣

disconnect the power supply to the sensor.

Only replace the filter in a current-free state.

‣

22 Endress+Hauser

Page 23

OUSAF46 Maintenance

1

2

3

4

CAUTION

L

Mercury lamp

UV radiation can damage the eyes!

Protect your eyes with protective goggles suitable for UV radiation.

‣

Never look directly into a mercury lamp when it is switched on.

‣

Switch off the lamp using the software function on the transmitter.

‣

Remove the lamp cable.

‣

Allow the lamp to cool down (30 minutes).

‣

Remove the lamp module from the flow assembly, disassemble the lamp housing and

‣

remove the lamp and reflector unit from the housing. Proceed in the exact same way as

described for replacing the mercury lamp.→ 20

9 Replacing the reference filter

1 Screw on circuit board

2 O-ring

3 Reference filter

4 Lamp holder

1. Remove both screws (item 1), and release the circuit board from the lamp holder (item

4).

2. Turn over the lamp holder and allow the filter (item 3) to fall into your hand.

3. Insert the new filter. In doing so, make sure that the "reflective" side is facing towards

the light source. Use the correct filter (reference filter) from the spare parts kit!

4. Fit the circuit board back on and tighten the screws slightly.

5. Reassemble the lamp module and mount it back on the assembly.

You must then recalibrate/readjust the measuring system.

Endress+Hauser 23

Page 24

Maintenance OUSAF46

In addition, you must reset the counter for filter replacement in the case of the CM44P: CAL/

Photometer/Filter change/Reset

8.5 Replacing the measurement filter

Versions with Easycal:

If the Easycal detector module is sent in for recertification, a diagnostic scan of the

measurement filter is performed and the measurement filter is replaced if necessary.

Do not replace the filter yourself.

Versions with a standard detector

Please note that the measurement filters are not identical. Their arrangement in the

measuring channels must correspond to the arrangement of the reference filters in the lamp.

Measuring channel 1 is always reserved for the filter with the wavelength 280 nm.

The wavelength is indicated on the socket of the filters. In addition, the measuring channels

are marked on the bottom of the detector module on leaving the factory.

To avoid any confusion, replace the filters one after the other.

1.

Release sensor cable from detector and unscrew detector from flow assembly.

2.

Release the four screws holding the detector housing.

24 Endress+Hauser

Page 25

OUSAF46 Maintenance

3.

Remove housing along with lens assembly.

4.

Release two anodized (black) screws.

5.

Carefully pull apart. Do not damage or break wires!

6.

Release screws on board.

Endress+Hauser 25

Page 26

Maintenance OUSAF46

7.

Remove board.

8.

Loosen securing screw.

9.

Press out filter.

The wavelength of the filter is indicated on the socket.

10.

Use filters that have the same wavelength.

The arrow on the socket indicates the installation direction.

26 Endress+Hauser

Page 27

OUSAF46 Maintenance

11.

Tighten securing screw for filter.

12. 2. Replace the measurement filter in the same way (release screw, press out filter, insert

new filter, tighten screw).

13.

Re-install board. Pay attention to wires.

14.

Re-secure the filter holder using the two anodized screws.

15.

Insert the entire assembly into the detector housing and screw down.

Endress+Hauser 27

Page 28

Maintenance OUSAF46

16.

Re-attach the detector to the flow assembly, screw on sensor cable.

Then recalibrate/readjust the measuring system.

In addition, reset the counter for filter replacement in the case of the CM44P: CAL/

Photometer/Filter change/Reset

8.6 Replacing the sensor window and seal

Operating Instructions for Flowcell OUA260, BA01600C

Operating Instructions for CUA261, BA01652C

If you have mounted the sensor in a VARIVENT flow assembly using the CUA261

adapter, refer to the Operating Instructions of the adapter for information on removal

and on replacing the optical windows.

Removing optical windows and seals

Always replace windows with windows of the same type in order to maintain the path length.

The following applies for OUA260:

The flow assembly must be removed from the process line in order to replace the windows

and seals.

1. In the case of OUA260 only:

Stop the flow in the process pipe and remove the assembly from the dry process line.

2. Remove the lamp and detector housing from the assembly.

28 Endress+Hauser

Page 29

OUSAF46 Maintenance

The following description applies for both sides, i.e. the detector side and the lamp side.

Always change O-rings or optical windows

1)

on both sides.

3.

Remove the 4 Allen screws (1/8" or 3 mm) from the window ring. Make sure to loosen

the screws evenly and alternately around the window ring.

4.

Remove the window ring .

5.

Gently push the optical window out of the assembly. If the window jams, apply some

acetone around the window seal (O-ring) and wait a few minutes for it to take effect.

This should help release the window. The seal cannot be reused afterwards!

Checking or replacing optical windows and seals

1. Check the window area for residue or fouling. Clean if necessary.

2. Check the optical windows for signs of chipping or abrasion.

Replace the windows if signs of chipping/abrasion are found.

3. Dispose of all the O-rings and replace them with new O-rings from the relevant

maintenance kit.

1) Optical windows only need to be replaced if they are damaged.

Endress+Hauser 29

Page 30

Repair OUSAF46

4. Mount the optical window and then the window ring, along with the new seals, on the

assembly. Make sure to tighten the screws of the window ring uniformly in a diagonally

opposite sequence. In this way, you ensure that the ring is seated correctly.

5. If the optical windows and the window rings are not identical, make sure the lamp is on

the right side. The lamp should be on the side with the "shorter" window length.

Then mount the lamp and detector on the assembly.

If you have changed the path length by installing other optical windows, you then have

to configure the measuring system appropriately.

In any case, you must always perform an adjustment with liquids after disassembling and

assembling the windows.

9 Repair

9.1 Return

The product must be returned if repairs or a factory calibration are required, or if the wrong

product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure the swift, safe and professional return of the device:

Refer to the website www.endress.com/support/return-material for information on the

‣

procedure and conditions for returning devices.

9.2 Disposal

The device contains electronic components. The product must be disposed of as electronic

waste.

Observe the local regulations.

‣

10 Accessories

The following are the most important accessories available at the time this documentation

was issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

30 Endress+Hauser

Page 31

OUSAF46 Technical data

10.1 Flow assembly

OUA260

• Flow assembly for hygienic sensors

• For sensor installation in pipes

• Materials: stainless steel 316, 316L or Kynar (other materials available on request)

• Wide variety of process connections and path lengths available

• Product Configurator on the product page: www.endress.com/oua260

Technical Information TI00418C

10.2 Cable

CUK80 cable set

• Pre-terminated and labeled cables for connecting analog photometer sensors

• Product Configurator on the product page: www.endress.com/cuk80

10.3 Calibration

Kit OUSAF46 EasyCal retrofit kit

• Patented system traceable to NIST for the calibration of UV absorption sensors

• Order numbers:

– 254 nm: 71210149

– 280 nm: 71210150

– 295 nm: 71210156

– 313 nm: 71210151

Reference rod

Order number: 71108543

11 Technical data

11.1 Input

11.1.1 Measured variable

UV-absorption

11.1.2 Measuring range

• 0 to 2.5 AU

• Max. 50 OD (depending on the optical path length)

11.1.3 Wavelength

Discrete wavelength at 254, 280, 295 or 313 nm

Endress+Hauser 31

Page 32

Technical data OUSAF46

11.2 Environment

11.2.1 Ambient temperature range Non-hazardous area versions

0 to 55 °C (32 to 131 °F)

Hazardous area versions

2 to 40 °C (36 to 104 °F)

11.2.2 Storage temperature

-10 to +70 °C (+10 to +160 °F)

11.2.3 Humidity

5 to 95 %

11.2.4 Degree of protection

IP66 and NEMA 4X

11.3 Process

11.3.1 Process temperature

0 to 90 °C (32 to 194 °F) continuous

Max. 130 °C (266 °F) for 2 hours

11.3.2 Process pressure

Max. 100 bar (1450 psi) absolute, depending on the material, pipe size and process

connection of the flow assembly

11.4 Mechanical construction

11.4.1 Dimensions

→ 10

11.4.2 Weight

Sensor

UV lamp 0.58 kg (1.28 lbs)

UV lamp with wire-braided cable

(1.2 m (4 ft)) and junction box (sensor

for hazardous area)

Easycal detector 0.53 kg (1.17 lbs)

Standard detector 0.78 kg (1.71 lbs)

32 Endress+Hauser

3.2 kg (6.66 lbs)

Page 33

OUSAF46 Technical data

11.4.3 Materials

Sensor housing Stainless steel 316

Assembly OUA260 Stainless steel 316, 316L or Kynar

Cable connector ends Nickel-plated brass

11.4.4 Light source

Low-pressure mercury lamp

Lamp operating life: typically 3000 h

The lamp will not operate at full capacity until a warm-up period of 30 minutes has

elapsed.

11.4.5 Detector

UV silicon detector, hermetically sealed

11.4.6 Filter

Multilayer interference filter, designed for extreme UV conditions

Endress+Hauser 33

Page 34

Index OUSAF46

Index

A

Accessories ..................... 30

C

Check

Connection .................. 15

Installation .................. 12

Connection

Check ..................... 15

Measuring device ...............13

D

Declaration of Conformity ............. 8

Designated use ....................4

Device description .................. 6

Dimensions ..................... 10

Disposal ....................... 30

E

Easycal ........................17

Ensuring the degree of protection ........ 14

F

Function check ................... 16

I

Incoming acceptance ................ 7

Installation

Check ..................... 12

Installation conditions ............... 9

L

Lamp voltage .................... 14

O

Occupational safety ................. 4

Operational safety ..................5

P

Power supply

Connecting the measuring device ..... 13

Product identification ................ 7

Product safety .................... 5

R

Reference rod ....................17

Replacing

Mercury lamp .................19

Sensor window and seal ...........28

Requirements for the personnel .......... 4

Return ........................ 30

S

Safety

Occupational safety .............. 4

Operation ....................5

Product ..................... 5

Safety instructions ..................4

Scope of delivery ...................8

Symbols ...................... 3, 4

T

Technical personnel ................. 4

U

Use

Designated ................... 4

M

Maintenance schedule ...............19

Measured variable ................. 31

Measuring principle .................6

Measuring range ..................31

Measuring system .................. 9

Mounting angles ..................11

Mounting the sensor ................11

W

Warnings ....................... 3

Wavelength .....................31

N

Nameplate ...................... 7

34 Endress+Hauser

Page 35

Page 36

*71430357*

71430357

www.addresses.endress.com

Loading...

Loading...