Page 1

Operating Instructions

Model OUM980 Photometric Analyzer/

Model OUSAF21 Dual Beam Inline

Low Level Color Sensor

Analyzer/Sensor to measure Spectral Absorbance

P/N 71105623 Rev 1

BA930C/07/en/10.09

Page 2

Model OUM980 with OUSAF21 Inline Sensor

2

Page 3

Model OUM980 with OUSAF21 Inline Sensor

Table of Contents

1. SAFETY INSTRUCTIONS........................................................................................................................................... 5

1.1 DESIGNATED USE ................................................................................................................................................................5

1.2 INSTALLATION, START-UP AND OPERATION .............................................................................................................................5

1.3 OPERATIONAL SAFETY ..........................................................................................................................................................5

1.4 RETURN .............................................................................................................................................................................6

2. GENERAL INFORMATION ....................................................................................................................................... 7

2.1 HOW THE MODEL 980 PHOTOMETRIC ANALYZER WORKS .........................................................................................................7

2.2 CONCENTRATION AND ABSORBANCE UNITS .............................................................................................................................7

2.3 EASY INTERFACING ..............................................................................................................................................................7

3. INSTALLATION......................................................................................................................................................... 9

3.1 MODEL OUM980 ANALYZER INSTALLATION...........................................................................................................................9

3.2 MODEL OUM980 CABLES AND WIRING ..............................................................................................................................10

3.3 DC INPUT POWER OPTION .................................................................................................................................................11

3.4 MODEL OUSAF21 SENSOR INSTALLATION............................................................................................................................ 12

3.5 CABLE OUK20 STRUCTURE AND TERMINATION OF MEASUREMENT CABLE................................................................................. 13

3.6 POST-CONNECTION CHECK ................................................................................................................................................14

4. OPERATION ............................................................................................................................................................ 15

4.1 QUICK OPERATION GUIDE ..................................................................................................................................................15

4.2 DISPLAY AND OPERATING ELEMENTS ....................................................................................................................................15

4.2.1 Operating Elements................................................................................................................................................15

4.2.2 Operation Legend...................................................................................................................................................16

4.3 LOCAL OPERATION ............................................................................................................................................................16

4.3.1 Measuring Mode ....................................................................................................................................................16

4.3.2 Configuration Mode ............................................................................................................................................... 18

4.4 REMOTE OPERATION..........................................................................................................................................................19

5. COMMISSIONING .................................................................................................................................................. 20

5.1 FUNCTION CHECK .............................................................................................................................................................20

5.2 SWITCHING ON.................................................................................................................................................................20

5.3 ANALYZER CONFIGURATION AND OPERATION ........................................................................................................................21

5.3.1 Factory Default Setting ........................................................................................................................................... 22

5.3.2 Sensor Calibration .................................................................................................................................................. 22

5.3.2.1 Liquid Calibration Procedure..............................................................................................................................22

5.3.2.2 Filter calibration Set up and Calibration .............................................................................................................. 24

5.3.3 Change Pathlength Setting......................................................................................................................................26

5.3.4 Setup Output Span ................................................................................................................................................. 27

5.3.5 Output Relay Set Point and Configuration...............................................................................................................28

5.3.6 Current Output Calibration ....................................................................................................................................30

5.3.7 Date and Time Setting............................................................................................................................................30

5.3.8 Configuration and Use of Digital Inputs...................................................................................................................31

5.3.9 Process Control ......................................................................................................................................................31

5.3.9.1 Access of Process Control...................................................................................................................................31

5.3.9.2 Baseline (AutoZero)............................................................................................................................................32

5.3.9.3 Optical Zero.......................................................................................................................................................32

5.3.9.4 Lamp Switch...................................................................................................................................................... 33

5.3.9.5 Optical Check ....................................................................................................................................................33

5.3.9.6 Password Protection........................................................................................................................................... 33

3

Page 4

Model OUM980 with OUSAF21 Inline Sensor

5.3.9.7 Process Value Correlation...................................................................................................................................34

6. MAINTENANCE ...................................................................................................................................................... 37

6.1 MAINTENANCE OUTLINE ....................................................................................................................................................37

6.2 OUSAF21 MEASUREMENT DETECTOR/FILTER REPLACEMENT.................................................................................................40

6.3 SENSOR WAVELENGTH CHANGE ..........................................................................................................................................40

6.4 SENSOR WINDOW AND GASKET REPLACEMENT ......................................................................................................................41

7. REPLACEMENT PARTS LIST .................................................................................................................................. 42

7.1 MODEL 980 PHOTOMETRIC ANALYZER.................................................................................................................................42

7.2 MODEL OUSAF21 INLINE SENSOR ......................................................................................................................................42

8. TECHNICAL INFORMATION ................................................................................................................................. 43

8.1 PHOTOMETRIC ANALYZER OUM980....................................................................................................................................43

8.1.1 Input......................................................................................................................................................................43

8.1.2 Output...................................................................................................................................................................43

8.1.3 Power Supply.........................................................................................................................................................43

8.1.4 Performance...........................................................................................................................................................44

8.1.5 Environment ..........................................................................................................................................................44

8.1.6 Mechanical Construction........................................................................................................................................44

8.2 ABSORBANCE SENSOR OUSAF21......................................................................................................................................... 45

8.2.1 Sensor Dimensions .................................................................................................................................................45

8.2.2 Input and Output ...................................................................................................................................................45

8.2.3 Mechanic Construction ..........................................................................................................................................45

8.2.4 Environment ..........................................................................................................................................................46

8.2.5 Power Supply.........................................................................................................................................................46

8.2.6 Optical Specifications..............................................................................................................................................46

9. ORDERING INFORMATION ................................................................................................................................... 47

9.1 COLOR ANALYZER OUM980 ..............................................................................................................................................47

9.2 SENSOR OUSAF21............................................................................................................................................................48

9.3 OUK20 CABLE SET ...........................................................................................................................................................49

4

Page 5

Model OUM980 with OUSAF21 Inline Sensor Safety Instructions

1. Safety Instructions

1.1 Designated Use

Integra Model OUM980 is an analyzer for determining the absorbance of a liquid medium at a specific wavelength

The analyzer is particularly suited for use in the following areas:

Bio-Technology industry

Waste water processing

Chemical processing industry

Food industry

Pharmaceutical industry

Any other use than the one described here compromises the safety of persons and the entire measuring system and is, therefore,

not permitted. The manufacturer is not liable for damage caused by improper or non-designated use.

1.2 Installation, Start-Up and Operation

Please note the following items:

Installation, electrical connection, start-up, operation and maintenance of the measuring system must only be carried out

by trained technical personnel. The technical personnel must be authorized for the specified activities by the system

operator.

Technical personnel must have read and understood these Operating Instructions and must adhere to them.

Before commissioning the entire measuring point, check all the connections for correctness. Ensure that electrical cables

and hose connections are not damaged.

Do not operate damaged products and secure them against unintentional commissioning. Mark the damaged product as

being defective.

Measuring point faults may only be rectified by authorized and specially trained personnel.

If faults can not be rectified, the products must be taken out of service and secured against unintentional commissioning.

Repairs not described in these Operating Instructions may only be carried out at the manufacturers or by the service

organization.

1.3 Operational Safety

Relevant regulations and standards have been met. As the user, you are responsible for complying with the following safety

conditions:

Installation instructions

Local prevailing standards and regulations.

EMC

This instrument has been tested for electromagnetic compatibility in industrial use according to applicable standards.

Protection against interference as specified above is valid only for an instrument connected according to the instructions in these

Operating Instructions.

5

Page 6

Model OUM980 with OUSAF21 Inline Sensor Safety Instructions

1.4 Return

If the device requires repair, please contact your local sales and service representative. Refer to the website on the back page of this

manual on where to find your local sales and service support office. Please use the original packaging, if possible.

Notes on safety icons and symbols

Safety icons

Warning!

This symbol alerts you to hazards. They can cause serious damage to the instrument or to persons if ignored.

Caution!

This symbol alerts you to possible faults which could arise from incorrect operation. They could cause damage

to the instrument if ignored.

Note!

This symbol indicates important items of information.

Electrical symbols

Direct Current (DC)

A terminal at which DC is applied or through which DC flows.

Alternating Current (AC)

A terminal at which (sine-form) AC is applied or through which AC flows.

Ground connecting

A terminal is already grounded using a grounding system.

Protective earth terminal

A terminal which must be grounded before other connections may be set up.

Alarm relay

Input

Output

6

Page 7

Model OUM980 with OUSAF21 Inline Sensor General Information

L

2. General Information

The Model OUM980 Photometric Analyzer is used in conjunction with a Model OUSAF21 sensor to measure the spectral

absorbance of process liquid in the VIS/NIR region of the electromagnetic spectrum.

Dependent upon the optical pathlength of the connected sensor, the instrument can measure up to 50 Optical Density (OD) units.

The Model OUM980 Photometric Analyzer is manufactured from state of the art digital electronics. Plant interface is through quick

disconnect screw terminals on the back of the module. The user interface is comprised of a 6-button tactile feel keypad and 4 x 20

character alphanumeric LCD display.

2.1 How the Model 980 Photometric Analyzer Works

The Model OUSAF21 sensor generates two photocurrent (nA) detector signals based upon the amount of energy present at its lamp

source (reference) and measurement point internally. The Model OUM980 unit computes the logarithmic ratio of these two signals

and determines the absorbance of the liquid passing through the sensor. The absorbance value is expressed in optical density units

(OD) and is displayed on the front panel. Two galvanic isolated analog current outputs, proportional to the OD reading, are

simultaneously transmitted for connection to other instrumentation and recording devices.

2.2 Concentration and Absorbance Units

The concentration of an optically absorbing material in a mixture can be determined since it is related to the amount of light

absorbed from a beam of light passing through it. The absorbance of a substance is directly proportional to the concentration of the

material that causes the absorption. The Lambert-Beer Law describes this relationship of absorbance (A) to concentration.

Essentially, the amount of radiation transmitted through the absorbing material decreases logarithmically with its increasing

concentration.

Where

A log

1

log

T

The above assumes that the optical pathlength remains constant. The optical density (OD) however, is defined as Absorption per

unit length. Normalizing to an optical pathlength of 1cm, it follows that:

Io

Ir

and

T

Ir

Io

OD

Where OD = Optical Density

A = Absorbance

L = pathlength in cm

2.3 Easy Interfacing

The Model OUM980 Photometric Analyzer incorporates a front panel display and two analog current output signals. The display on

the front panel is an alphanumeric 4 x 20 character LCD. The display may be configured for process variable or analog current

output measurements. Optical Density (OD) readings are normalized to a 1cm pathlength.

)(1A

7

Page 8

Model OUM980 with OUSAF21 Inline Sensor General Information

There are two analog current outputs from the unit. The range of each can be independently set to be any range within the

measurement range of the instrument. One output is configured to operate with measurement baseline shift commands, while the

other tracks full scale of the instrument.

The analog current outputs (4-20mA) will operate with loads up to 750 ohms. These outputs are galvanically isolated and conform

to NAMURi Standard.

Model OUM980 is supplied as standard with four digital inputs and three digital output relays.

The digital inputs can be configured to perform a variety of functions such as baseline and sensor lamp off/on.

The outputs can be connected to a PLC for inclusion in a control scheme, for simple valve operation or for local indication (alarms)

and annunciation. Alarm status indication is provided on the front panel display.

All digital inputs are optically isolated.

i

NAMUR standard limit detection when enabled is set to a BAD if the signal level is above 21 mA or below 3.6 mA for more than 4 seconds. The BAD status is cleared

when the signal returns to the normal 4-20 mA range.

8

Page 9

Model OUM980 with OUSAF21 Inline Sensor Installation

3. Installation

3.1 Model OUM980 Analyzer Installation

Before starting installation, inspect the analyzer, sensor, and supplied cable set for any signs of shipping damage. Report any visual

damage or discrepancies to the factory and the shipper immediately.

The Model OUM980 analyzer is a ¼ DIN enclosure which can be installed a variety of panel, wall and bench top housings. Refer

to figure 3.1 for mounting dimensions. Mount or install the analyzer into an enclosure or area that is not subject to excessive

vibration or shock and will protect the instrument from materials such as water and chemicals. Allow enough clearance behind it

for cable access.

Figure 3.1: OUM980 Analyzer Mounting

9

Page 10

Model OUM980 with OUSAF21 Inline Sensor Installation

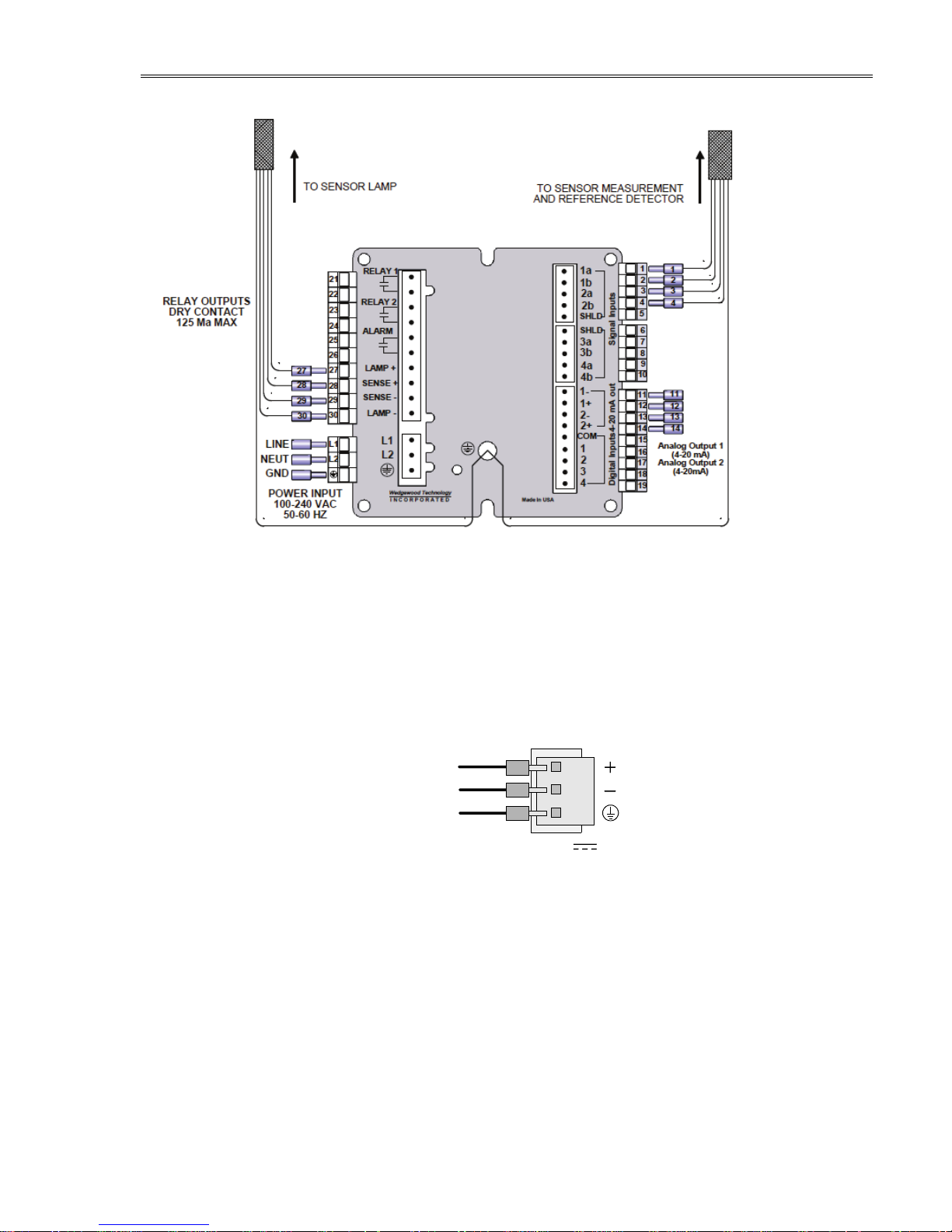

3.2 Model OUM980 Cables and Wiring

All wiring terminals are located on the back panel of the Model OUM980. The analyzer/sensor interconnection cables supplied

with the system have all been pre-terminated and labeled for ease of installation. The Model OUM980 has two (2) analog current

outputs of 4 to 20mA. Both are capable of driving loads up to 750 ohms.

In addition to the analog outputs, three (3) galvanic isolated digital outputs (N.O.) are available. These outputs are rated for both

AC and DC voltages up to 280 volts at 125mA. These outputs are intended for dry contact or pilot applications.

Insert Terminal

Here

1

2

3

4

5

6

7

Connector

8

9

Phoenix Cambion

10

11

12

Wire Pin

Terminal

Figure 3.2: Wire Terminal Preparations

Cables installed for signal connection (i.e. analog outputs, lamp fail output) should be shielded twisted pairs.

Warning!

When routing the cables, separate signal cables from power wiring!

Caution!

Use dry contact only when connect digital input to analyzer!

Refer Figure 3.3 for wiring connection.

10

Page 11

Model OUM980 with OUSAF21 Inline Sensor Installation

Figure 3.3: Model OUM980/OUSAF21 Dual Beam Wiring Diagram (AC Input Version)

3.3 DC Input Power Option

For instruments supplied for 24VDC operation, only the power input connection is changed. Figure 3.3 shows the connection

detail for a 24VDC unit.

Input Power

+24VDC

DC RTN

Ground

24 VDC

Figure 3.4: Integra DC Power Connection

11

Page 12

Model OUM980 with OUSAF21 Inline Sensor Installation

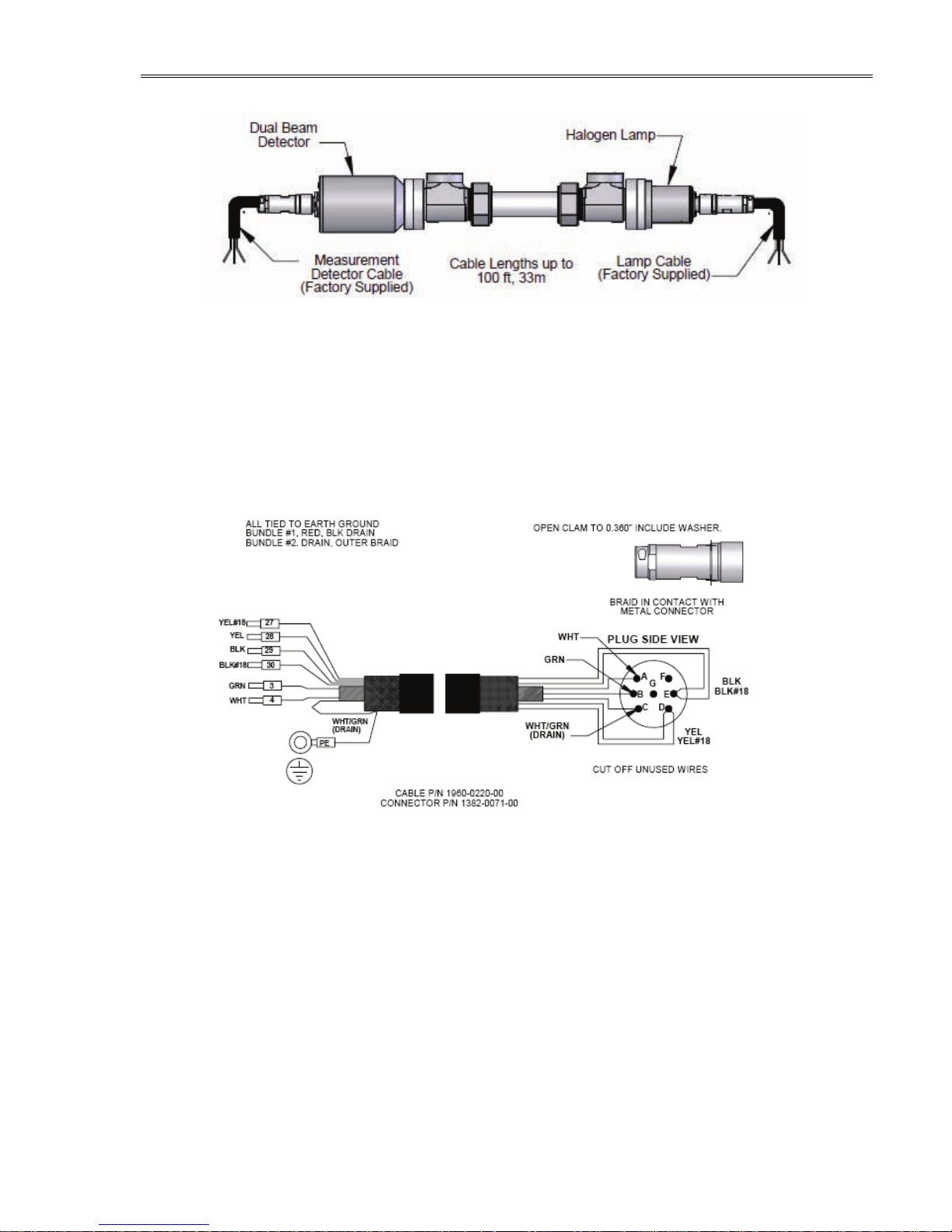

3.4 Model OUSAF21 Sensor Installation

Sensors can be installed either directly in a process line or in a by-pass line. They can be mounted either horizontally or at an angle.

If mounted horizontally, the sensor lamp and detector housings must be horizontal. This will insure that the optical window

surfaces are in a vertical position, which will help prevent build up on the window surfaces. The sensor should be located upstream

of pressure regulators. Operating sensors under pressure will help to avoid the possibility of air or gas bubble evolution, which can

cause measurement noise and error.

When installing, allow adequate space for the connection of cables at the ends of the lamp and detector housings. Access to these

areas is also important for connection/disconnection purposes. Sensor bodies should be supported when in line and care should be

taken to ensure they are protected against damage caused by external forces such as carts on adjacent walkways.

Figure 3.5: Recommended Orientation for Sensor Installation

12

Page 13

Model OUM980 with OUSAF21 Inline Sensor Installation

Figure 3.6: Typical OUSAF21 Sensor With Cables Connected.

3.5 Cable OUK20 Structure and Termination of Measurement Cable

Figure 3.7: OUSAF21 Cable at Lamp Side

13

Page 14

Model OUM980 with OUSAF21 Inline Sensor Installation

Figure 3.8: OUSAF21 Cable at Detector Side

3.6 Post-Connection Check

After wiring up the electrical connection, carry out the following checks:

Device Status and Specifications

Is the analyzer or the cable externally damaged?

Electrical connection Remarks

Are the installed cables strain-relieved?

No loops or cross-overs in the cable run?

Are the signal cables correctly connected according to the wiring

diagram?

Are all screw terminals tightened?

Are all cable entries installed, tightened and sealed?

Are the PE distributor rails grounded (if present)? Grounding at place

of installation

Caution!

Improperly grounding will lead to unreliable measurement result!

Remark

Visual inspection

Remark

Grounding at place of installation

14

Page 15

Model OUM980 with OUSAF21 Inline Sensor Operation

4. Operation

4.1 Quick Operation Guide

User has the following ways of operating the analyzer:

On site via the keypad

Via the digital input interface to perform process control functions remotely.

4.2 Display and Operating Elements

4.2.1 Operating Elements

Figure 4.1: Operating Controls

1. LED for lamp warning functions and limit relay status.

2. Menu/ESC key serves two functions. Pressing Menu/ESC will always exit out of a screen and will not save any changes

Entered. Pressing Menu/ESC from the main PVii or Output screen will open the Sub-Menu screen.

3. Ack/ENT key accepts changes in a screen and continue forward through the screen

4. 4 keys navigate the user through the menus and screens.

5. LC display for displaying the measured values and configuration data LED.

ii

PV is the Process Value for PV1 and PV2 and corresponds to Output 1 and Output 2 respectively.

15

Page 16

Model OUM980 with OUSAF21 Inline Sensor Operation

4.2.2 Operation Legend

In this manual, the following operation legend will be used when describing operation procedure.

Enter/Acknowledge key

Escape/Menu key

Left or Right key

Up or Down key

Figure 4.2: Operation Legend for Operation Instruction

4.3 Local Operation

4.3.1 Measuring Mode

The analyzer normally operates in measuring mode. Here, the relays and alarm LED are triggered by the analyzer according to

process status. The analyzer will take configurable digital input to trigger certain function like BaseLine Zero

During the measuring mode, the LCD screen will display as figure 4.3. The process value, unit and analyzer label will be displayed

permanently. BaseLine, Alarm and Lamp Status will be display when conditions are met.

iii

, Optical Zeroiv etc...

Figure 4.3: LCD display on measuring mode

iii

BaseLine Zero when enabled offsets the PV to zero. This often used to subtract background absorbance prior to initiating a process.

iv

Optical Zero is established during calibration and the set with a non-absorbing liquid in the flow cell, i.e. de-ionized water.

16

Page 17

Model OUM980 with OUSAF21 Inline Sensor Operation

Table 4.1 shows the status display description and display condition.

Status Area Name Displayed symbol

Description and Display criteria

Analyzer Label “xxxxxxxxxxxx” Editable up to 12 characters for user

analyzer identification.

“OD” Display “OD” under normal condition, Process Unit

“xxxxxx” Displays user configured engineering unit

if PV correlation function is activated.

Over Range Symbol “OVER” Displays if measurable range is reached.

BaseLine Status

“BL OFF”

Displays if BaseLine is not activated.

“BL ON” Displays if BaseLine function is activated.

“BL SFT” Displays if BaseLine and BaseLine Shift

function are both activated.

Alarm “AL x” Displays if corresponding relays (1, 2, or

both) are triggered.

Lamp Status

“LAMP LOW” Flash if reference voltage is lower than

80% of initial value.

“LAMP FAIL” Displays if lamp reference signal is lost.

“LAMP OFF” Displays if lamp is turned off.

Cable Status “CABLE FAULT” Displays if lamp or signal cable has a faulty

connection.

Table 4.1: Operation screen under measuring mode

Under measuring mode, press

control routine. The detail of process control function will be listed in Chapter 6.

Figure 4.4: Operations under Measuring Mode

button will let you enter the process control screen, where user can operate process

17

Page 18

Model OUM980 with OUSAF21 Inline Sensor Operation

4.3.2 Configuration Mode

The configuration and calibration functions are arranged as function groups.

Use

Use

key to enter the function group menu from measurement screen.

arrow key to select the group from process set-up, maintenance, or system data.

Use to confirm the change and input the value.

If a modified setting is confirmed with , the old setting is retained.

Menu

ESC

Ack

ENT

Menu

ESC

Ack

ENT

Menu

ESC

Ack

ENT

Figure 4.5: Diagram of configuration structure

Input data

During the system configuration and set up procedure, user will need to input the data into the screen.

In the data input screen

Use

to move the cursor to select the digit to edit.

To change the decimal point of the input data, place the cursor on decimal point, use

point to the left or right.

Figure 4.6: Decimal Point Position Placement

to move the decimal

18

Page 19

Model OUM980 with OUSAF21 Inline Sensor Operation

4.4 Remote Operation

Remote operation function will provide user the ability to use off site dry contact to perform the process control. Short input

channel pin to COMMON pin will trigger the input the channel.

Refer section 5.3.8 to configure and use digital input function for remote control.

Digital Input #

1 Lamp On/Off

2 Enable BaseLine function

3 Update BaseLine value

1-

12

1+

2-

2+

COM

1

2

3

4

Figure 4.7: Typical Digital Input Wiring Diagram

Description and Display criteria

Optical Zero 4

Hold current process measurement

(both display and analog output)

Table 4.2: Digital Input Functions

13

C hannel 1 & 2

11

14

15

16

17

18

19

Analog Outputs

(4-2 0 Ma)

D ry Contact or

Panel Switch

19

Page 20

Model OUM980 with OUSAF21 Inline Sensor Commissioning

5. Commissioning

5.1 Function Check

Warning!

Check all connections for correctness.

Make sure that the supply voltage is identical to the voltage written on the technical information!

5.2 Switching On

Familiarize yourself with the operation of the analyzer before it is first switched on. Please refer in particular to the "Safety

Instructions" and "Operation" sections. After power-up, the device performs a diagnosis for 30 seconds and then goes to the

measuring mode.

Lamp Initial Set-Up

If the analyzer is first time switched on with a new lamp, a “LAMP LOW” symbol will be shown on the display screen. And the

frond LED will be flashing and lamp alarm relay will be toggled. To remove this warning message, the lamp status has to be

initialized from the software. The lamp low warning shows as follow

Figure 5.1: Lamp status during start-up

20

Page 21

Model OUM980 with OUSAF21 Inline Sensor Commissioning

Reset New UV Lamp

Press , enter function group selection menu. Move the cursor

to MAINTENANCE and press to enter.

Press

.

The current lamp voltage will be displayed on the right upper

corner. The timer will start counting down once the is

pressed to warm up the lamp.

Wait 30 minutes until the timer goes to 0:00

The current lamp voltage will be displayed in the first line and lamp

low threshold voltage will be calculated and display on the third

line.

to navigate to LAMP REPLACE, and press

Press to accept the setting and use to go back to

measurement screen. The LED and lamp alarm relay will be reset.

5.3 Analyzer Configuration and Operation

After power-up and lamp setting, you must make some settings to configure the most important functions of the analyzer which are

required for correct measurement.

The analyzer/sensor will be Plug& Play if been ordered together as complete solution!

If OUM980 Photometric Analyzer is ordered with OUSAF21 sensor and OUK20 cable, the factory will perform:

New lamp set up

Pathlength adjustment in analyzer according to sensor order

Calibrate analyzer

If application data has been given, factory will perform optical density to engineering unit correlation and deliver correlation data

with analyzer. There will be an additional charge if sample preparation is required. Span and relay setting also can be performed in

factory if requested. If analyzer ordered separately, the factory default setting will be loaded into the analyzer when analyzer is

delivered.

21

Page 22

Model OUM980 with OUSAF21 Inline Sensor Commissioning

5.3.1 Factory Default Setting

Parameters Factory Default Value

Measurement Unit

Measurement Pathlength

Output Span 1 5.0000 OD

Output Span 2 5.0000 OD

Relay 1 Set Point/Status 1.0000 OD/ Disabled

Relay 2 Set Point/Status 1.0000 OD/ Disabled

Process Value Correlation Off (Curve #0)

BaseLine Disabled

Password Disabled

Table 5.1: Factory Default Setting

OD

100mm to 250mm

5.3.2 Sensor Calibration

Model OUM980 analyzer supports 2 different calibration procedures: Liquid calibration and Filter Calibration.

5.3.2.1 Liquid Calibration Procedure

A liquid solution of a known optical density (at the wavelength of the sensor) must be used for instrument calibration. The

following procedure is used in factory. Calibration liquid can be chosen by user depending on application.

22

Page 23

Model OUM980 with OUSAF21 Inline Sensor Commissioning

The Liquid Calibration screen appears only if a Filter Calibration system is not installed and configured in the System Data section.

Liquid Calibration Procedure

Enter MAINTENANCE sub-menu to access

SENSOR CAL function. Press to ent.

Use to select LIQUID CAL, Press to

enter liquid calibration process.

Fill the sensor with a zero fluid.

Press to record zero point.

Enter the value of the standard solution being used to

calibrate the system. The solution should be

approximately ½ of the full range of the system.

Press to continue.

Fill the sensor with the standard calibrating solution.

Wait until OD reading increase and stabilize. Press

to record the data.

Remove the calibration solution, and rinse repeatedly

with a zero solution. OD reading should decrease and

stabilize. Press

to proceed.

Remove the cover screw on the measurement detector

and install the reference rod. Press to proceed.

Remove the reference rod and install the cover screw on

the measurement detector. Press to proceed.

The unit records the values of the calibration solution and

ref rod value and displays these values. The standard

solution is used for calibration, while the ref rod is for

checking calibration. Press

to accept these values.

23

Page 24

Model OUM980 with OUSAF21 Inline Sensor Commissioning

5.3.2.2 Filter calibration Set up and Calibration

The EasycalTM unit contains an optical that was selected based on laboratory measurement of the customers submitted sample.

This filter is placed into the optical measurement path of the instrument and displays an absorbance ratio process related. This filter

has been scanned with a traceable source and actual absorbance at individual (measurement) wavelengths is ascertained.

The Easycal

noted on the Calibration Certificate supplied with the unit. The absorbance value should be entered into the Model OUM980 as

part of the configuration setup.

TM

allows the calibration without using liquid standards. Refer to the actual value of the EasycalTM optical filter as

Figure 5.2: EasycalTM Control for the OUSAF22 Dual Beam Sensor.

24

Page 25

Model OUM980 with OUSAF21 Inline Sensor Commissioning

EasycalTM Installation

Enter SYSTEM DATA sub-menu to access

CHANGE EASYCAL CNFG function.

Press to continue.

Use

to select [YES] or [NO] to decide if the

Easycal™ is installed. To install, select [YES] and confirm.

This screen displays the present NIST Filter Absorbance

values and the re-certification date. Press to change

the date and filter values starting with the next screen.

Move cursor to edit the day, month and year. Save data

and move to next step.

Refer NIST filter high absorption value listed on NIST filter

certificate delivered with Easycal™. The value should be

close to 1.0000 AU. Press to continue and use the

same procedure to input the low filter absorption value,

close to 0.5000 AU.

After put in both filter data use to confirm the

setting. Easycal™ data installation is finished.

25

Page 26

Model OUM980 with OUSAF21 Inline Sensor Commissioning

EasycalTM Calibration Procedure

Enter MAINTENANCE sub-menu to access

SENSOR CAL function. Press

If Easycal has been installed. Analyzer will automatically

enter Easycal

TM

procedure.

to change.

Both high and low NIST filters absorption value will be

displayed in this screen. User set certificate due date is

displayed also. Press after review the data.

Assure both high and low filters are in OUT position.

Press

to record zero point.

Move HI filter adjustment screw to IN position.

Press to record high filter value.

Move LO filter adjustment screw to IN position.

Press to record HI+LO value.

Move HI filter adjustment screw to OUT position.

Press

calibration calculation.

to record low filter value and perform

The screen then displays the low, high and high+low

readings and % deviation from the certified value of each

value. Review the deviation level and press to

accept the calibration result.

5.3.3 Change Pathlength Setting

If sensor pathlength need to be changed by user, the corresponding change will need to be performed to OUM980 analyzer also.

Refer to Chapter 6 Sensor and Analyzer Maintenance to perform sensor pathlength adjustment. This section only covers

corresponding analyzer setting to match the measurement result.

26

Page 27

Model OUM980 with OUSAF21 Inline Sensor Commissioning

Pathlength Setting

Enter SYSTEM DATA sub-menu to access

PATHLENGTH function. Press

The FROM value is the present pathlength Value. Use

position the cursor and

each digit position. When new pathlength has been selected, press

to confirm the change.

The SYS DATA: PATHLENGTH is displayed together with the new

values for pathlength and OD MIN/MAX.

to continue.

to select wanted digit. Repeat for

5.3.4 Setup Output Span

The 4~20mA span setting will provide user capability to achieve maximum resolution for preferred measurement range.

Change 4~20mA Output Span

Enter PROCESS SET-UP sub-menu to access OUTPUT SPANS

to

function. Use to move the cursor to O1 and press

to select.

Use same procedure above to change Channel 2 output span.

This screen will display the current output span MIN/MAX span based

on pathlength or process value correlation setting. Press to

change the span.

In this screen the current value for span is the FROM value. Position

the cursor as done previously and select the number for that position.

Repeat as needed for each digit position. When the new span has been

entered, press

and confirm the sanity check to accept.

27

Page 28

Model OUM980 with OUSAF21 Inline Sensor Commissioning

5.3.5 Output Relay Set Point and Configuration

Change Output Relay Set Point

Change Relay Set Point

Enter PROCESS SET-UP sub-menu to access

OUTPUT SPANS function.

Use

Configure Output Relays

The Alarm Setup screen allows configuration of PV, Hi/Lo/Off, and NO/NC operation. is used to select the

parameter and is used to change the state. Press to continue.

Functions Description

Trigger Condition

Hysteresis Set relay hysteresis

Delay Delay trigger timer (Sec)

HIGH Triggered if process value higher than set point.

LOW Triggered if process value higher than set point.

OFF Relay disabled

PV1 Process value #1 Input Mapping

PV2 Process value #2

NO Normally open Relay Operation Mode

NC Normally close

In this screen the current value for span is the FROM value. Position the

cursor as done previously and select the number for that position.

Repeat as needed for each digit position. When the new relay set point

has been entered, press and confirm the sanity check to accept.

Table 5.2: Output Relay Configuration

to move the cursor to ALx and press to select.

28

Page 29

Model OUM980 with OUSAF21 Inline Sensor Commissioning

Configure Output Relay

Enter from MAITENANCE sub-menu. Scroll to the ALARM CONFIG

screen. Use

and confirm.

to select the ALx line. Press to select

The ‘ALARM 1 SETUP’ screen will appear. Select the SOURCE option,

PV1 or PV2.

Next with

select the CONFIG option. Use

to select OFF, HIGH and LOW.

Press

(N/C) alarm state of the relay contacts. Select the N/O option and

to scroll down to ALARM 1 SETUP STATE screen.

selects either normally open (N/O) or normally closed

press to accept and confirm.

The CHANGE ALARM 1 DELAY is next displayed. Set the needed

delay. Delay time unit is second. Press to accept and confirm.

The CHANGE ALARM 1 HYSTS option controls the alarm hysteresis. If

the alarm set point is set 1.00 OD and the hysteresis is 0.100 OD, an

alarm condition exists at 1.00 OD and will stay in alarm until the PV is

0.90 OD or less. Hysteresis can be called the deadband between an

alarm on and off condition. Set the hysteresis to 0.100 OD and

press

to accept and confirm.

29

Page 30

Model OUM980 with OUSAF21 Inline Sensor Commissioning

5.3.6 Current Output Calibration

This function calibrates 4~20mA current output to assure the measurement accuracy.

Calibrate 4~20mA Output

Enter MAINTENANCE Sub-Menu to access

5.3.7 Date and Time Setting

Set Clock

OUTPUT CAL function. Move cursor to OUTPUT 1 and press

select this channel.

Move the cursor up and down to select the value need to be trimmed.

Use

The trimming resolution is 1% per step. Press

to trim 4mA or 20mA.

to accept and

confirm the trimming.

Follow same procedure to trim OUTPUT 2.

Enter MAINTENANCE sub-menu to access SET CLOCK function. Use

to select the CUR DATE line.

to

Press

Screen is displayed with the current date. Use

the cursor and

to select the DATE option and then the CHANGE DATE

to change the mm/dd/yy numbers. When

the wanted date is entered, press to accept and confirm.

Press to select the TIME option and then the CHANGE TIME

Screen is displayed with the current time. Use

the cursor and

the wanted time is entered, press

to change the hh/mm/ss numbers. When

to accept and confirm.

to position

to position

30

Page 31

Model OUM980 with OUSAF21 Inline Sensor Commissioning

5.3.8 Configuration and Use of Digital Inputs

Configure Digital Input

Enter MAINTENANCE sub-menu to access DIGITAL IN function. Press

to continue.

The following screen displays the current configuration of the external

digital inputs. Use the

STANDARD CONFIG When disabled the external digital inputs are

inoperative.

to scroll through the DISABLE and

When in STANDARD CONFIG, the digital inputs are configured as;

1 Lamp On-Off

2 Baseline On-Off

3 Baseline Update

4 Hold/Optical Zero

Digital Input #4 can be set as Optical Zero function if wanted. Press

to accept and confirm.

5.3.9 Process Control

From main measurement screen, press

Functions Status Description Remote Trigger

BaseLine

ON Enable baseline Digital Input 2

UPDATE Update baseline value Digital Input 3

OFF Disable baseline Digital Input 2

ON Turn on lamp Digital Input 1 Lamp Switch

OFF Turn off lam Digital Input 1

Optical Zero - Make current measurement at 0. Digital Input 4

Optical Check - Start sensor check -

5.3.9.1 Access of Process Control

The authority of access of process control function can be configured in OUM980 analyzer. The access control is password

protected. See 5.3.9.6 for password protection.

to enter process control screen.

Table 5.3: Process Control Functions

31

Page 32

Model OUM980 with OUSAF21 Inline Sensor Commissioning

Configure Process Control Access

Enter SYSTEM DATA sub-menu to access ACCESS function. Press

to continue.

Select the option to configure.

Note: The Response is in brackets [ ]. With bracketed responses use

options to configure. When all changes are made, press

and confirm the entries and return to top screen.

for changes. Select ‘YES’ for each option. There are 4

to accept

5.3.9.2 Baseline (AutoZero)

To operate the baseline function, the Process Control Screen must be assigned as an authority for the user. If assigned the authority,

use

baseline use “On”, to remove an existing baseline use “Off”. To change an existing baseline setting to a new setting use “Update”.

If the baseline was previously “On” when a power interruption occurred, the analyzer will retain its last saved baseline setting and

return to that setting when power is restored, and the analyzer and the baseline control will remain “On”. Baseline function

replaced the AutoZero function in the 800 series analyzer.

If a Baseline Shift value has been entered, activating the baseline shift will cause the 4~20mA output channel 2 to “Shift” to the

entered % value. Both PV display would indicate “0” The PV screen will also indicate BL SFT in lieu of BL ON when a shift value

has been entered (>0%).

Configure Process Control Access

to open the Process Control Screen. Use to select baseline and select as follows: To initiate a new

Enter SYSTEM DATA sub-menu to access ACCESS function. Press

5.3.9.3 Optical Zero

Optical Zero is a function to provide an over all zero to offset the initial background optical noise in OUSAF21 sensor. User can also

use optical zero to setup the process zero (e.g. DI water optical density etc...).

to continue.

Select the option to configure.

Note: The Response is in brackets [ ]. With bracketed responses use

options to configure. When all changes are made, press to accept

and confirm the entries and return to top screen.

for changes. Select ‘YES’ for each option. There are 4

32

Page 33

Model OUM980 with OUSAF21 Inline Sensor Commissioning

5.3.9.4 Lamp Switch

Use this function to switch lamp on and off.

Note!

Lamp alarm relay status will be affected.

5.3.9.5 Optical Check

When the Easycal

secondary standard for routine system checking. Calibration can be traced to the controlled standard used to verify the original

calibration solutions or process samples and can therefore satisfy validation procedures. During initial calibration of a

sensor/analyzer pair, liquid standards should be used to calibrate the full-scale response of the system. After calibration, by filling

the sensor with water and ensuring the analyzer reads zero, a value for the Easycal

the ‘ON’ position (see Fig 5.2) and note the analyzer display reading. At any time in the future, setting the Easycal

the instrument will display the the same value when the sample cell is filled with clear water.

Note!

All analyzers must be re-calibrated with liquid standards if there are any changes made to the optical chain, including replacement

of seals or lamp.

TM

is used in conjunction with an initial liquid standard calibration procedure, the EasycalTM can be deemed a

TM

can be obtained by setting the EasycalTM in

TM

‘ON’ position

5.3.9.6 Password Protection

OUM980 support the password function to protect the analyzer from unauthorized operation.

Figure 5.3: Password protection level

33

Page 34

Model OUM980 with OUSAF21 Inline Sensor Commissioning

Password Protection

Enter SYSTEM DATA sub-menu to access PASSWORD function. Press

to continue.

When in the ENTER OLD PASSWORD screen, the CURSOR highlights the

left digit position. Use the

to scroll thru 0-9 for each digit position. Move the cursor to

to wanted digit position. Use

the desired digit and enter a number. When the old password number has

been entered, press

to accept.

Note: When “0000” is set a password, the password protection mode is

disabled.

When in the ER NEW PASSWORD screen, the CURSOR highlights

the left digit position. Use the

to wanted digit position. The

scrolls thru 0-9 for each digit position. Move the cursor to

the desired digit and enter a number. Repeat as wanted for each cursor

position. Any password number up to 4 digits can be entered. When the

password number has been selected, press twice to accept. The

Password for MENU access is now the number entered.

5.3.9.7 Process Value Correlation

In OUM980 analyzer, user can define and store 3 linearization tables to correlate the optical density measurement to specified

process parameter measurement. Each table supports up to 16 points of measurement value. User can switch correlation curves to

fit different application.

Caution!

The overall course of the curve must be continuously rising. Horizontal or vertical segments or a zigzagging of the curve are not

permitted.

Data points may be entered into the linearization table randomly; the software performs sorting automatically as needed. It is

possible to increase accuracy in a certain segment of a linearization table later. To do so it is not necessary to enter all data points

again, but to enter only additional data points.

34

Page 35

Model OUM980 with OUSAF21 Inline Sensor Commissioning

Process Value Correlation Set Up

Enter PROCESS SET-UP sub-menu to access PV CORRELATE

function. Press

to continue.

The next screen asks which curve (1-3) you want to edit and store the

correlation table. Scroll with

Press to continue.

to select curve number.

If the original sample value is not put in yet. Select SAMPLE IN CELL?

By scrolling with to select. Press to continue.

The next screen asks if process sample is in the cell and displays

measurement value. If this value is within the Min/Max acceptable

press to read and store.

The next screen asks if another sample is to be measured. Press

to read another sample, press if finished all samples.

Confirm the number of point to build correlation curve and press

to store original sample data.

SAMPLE EDIT is used to put in the target correlation value and unit.

Press

to continue to put in data.

The next screen asks if the user would like to change the original

sample point OD value. If this value needs to be changed, use

continue.

and to change value. Press to

35

Page 36

Model OUM980 with OUSAF21 Inline Sensor Commissioning

The next screen is for entry of target correlation values that can be

assigned to the original correlated measured value. i.e. 1.32 measured

units to 9999.9 units. The FROM value is the last entered value on the

‘ENTER USER VALUE’ screen. Enter the new value using

and to position the cursor and select the

number for each required position. If a different position is required for

the decimal point, do this first. Press

twice to change and

accept.

Repeat above procedure until all correlation points have been entered.

When all the sample points have been edited, the Change Units screen

is next. The engineering unit can be entered is limited to 6 alpha-

numeric characters.( i.e. gr/l, %, mg/l, cel/cc, etc.). Press

twice to change and accept entry.

The Max/Min values are calculated for entered values and units.

These values are the new limits for output span and relay setting and

the displayed Process Display PV value and units.

Note!

If the OD to correlation unit table is predefined and does not need liquid sampling, use MANUAL EDIT option to entry the table to

analyzer. The procedure is similar to SAMPLE EDIT.

Switch Correlation Curves

Enter PROCESS SET-UP sub-menu to access RUN CAL CURVE

function. Press

to continue.

The next screen asks which curve (0-3) you want to execute. Curve

#0 is the default OD measurement. Curves 1-3 are user defined. Scroll

with

confirm.

to select curve number. Press to select and

NOTE:

Entering a curve with Process Correlate will automatically set it as the

current active curve.

36

Page 37

Model OUM980 with OUSAF21 Inline Sensor Maintenance

6. Maintenance

6.1 Maintenance Outline

Once the unit is in operation, there is no requirement to access the interior of the Model OUM980 Photometric Analyzer housing

for normal day-to-day operation and calibration.

Certain maintenance needs to be performed for OUSAF21 sensor. The service and maintenance interval time is application

dependant.

Figure 6.1: Cross-Sectional View of a Typical OUSAF21 Sensor

Note!

Check list of maintenance!

Lamp Replacement

O-Ring Replacement

Filter Replacement

Sensor window and gasket replacement

37

Page 38

Model OUM980 with OUSAF21 Inline Sensor Maintenance

Caution!

The procedures described in this section should only be carried out by qualified maintenance staff.

Model OUSAF21 sensors contain sensitive optical components and should be handled carefully. Particular care must be taken to

prevent contamination of these components.

Warning!

Please refer to EXP-1 lamp instructions to replace lamp for hazardous area versions.

Caution!

Clean all optical components with a suitable lint free lens cleaning tissue and ethanol.

Both the High Luminescence and Gas-Filled Lamps are replaced identically.

38

Page 39

Model OUM980 with OUSAF21 Inline Sensor Maintenance

Figure 6.2: Illustrative Standard Lamp Replacement Procedure

39

Page 40

Model OUM980 with OUSAF21 Inline Sensor Maintenance

6.2 OUSAF21 Measurement Detector/Filter Replacement

Figure 6.6 – OUSAF21 Detector Assembly

1. The detector assembly is attached to the sensor with a threaded window ring. The detector assembly is removed

by unscrewing it off the window ring. Removal of the detector assembly does not break the liquid integrity of the

sample cell.

2. After removal of the detector assembly, unscrew the detector endplate from the detector housing.

3. To replace either filter, remove the retaining screw on the detector, and carefully remove the detector. Remove the

o-rings in the cavity and gently tap the filter out of the detector block (note: the “mirror” side is directed towards

the light source).

3. Replace filter/detector in reverse order.

5. After detector/filter replacement, the detector assembly may require alignment and the system to be re-calibrated.

6.3 Sensor Wavelength Change

Should it be required to change the operating wavelength of the sensor, both the measurement and reference filters must be

changed. When changing filter wavelength, follow the same procedures as describe above.

40

Page 41

Model OUM980 with OUSAF21 Inline Sensor Maintenance

6.4 Sensor Window and Gasket Replacement

Sensor optical pathlength is established by the window type(s) used. Each analyzer-sensor pair is configured for a given pathlength.

Windows must be replaced with the same type to maintain pathlength. The illustration below is a typical flowcell assembly. Figure

the available window types and possible pathlengths for sensors up to 2" line sizes.

Replacement of windows or window seals, changing window spacing or other maintenance requiring the disassembly of the sensor

uses the following procedure:

Note:

To replace and/or change the windows and seals, the sensor must be removed from the process line.

Figure 6.3: Typical Flowcell/Window Replacement

1. Remove the lamp and the detector housings from the sensor body.

2. Remove the 4 socket head screws from each window retaining ring and remove the rings. Be careful to loosen the screws

evenly and alternately around the window retaining ring. If the window is ‘stuck’, apply Acetone to the window seal area and

let soak for several minutes. This may assist in freeing the windows from the seals.

3. Gently push/ease the windows out of the sensor.

4. Inspect the window area and clean as necessary. Inspect the windows for any signs of abrasive wear or chipping. If any is

apparent, replace the windows. Discard the 'O' rings and replace with new ones of the same material type. Re-assemble the

sensor in the reverse order, taking care to cross-tighten the window retaining ring screws evenly to prevent uneven seating. If

the sensor pathlength has been changed, the analyzer module must be configured to reflect the new pathlength. After every reassembly of an OUSAF21 sensor, it is necessary to carry out a liquid or Easycal™ calibration with its associated analyzer.

Note!

Upon re-assembly, insure that the lamp assembly is mounted on to the side of the flow cell with the “shorter” length of the two

windows.

5. Remove the lamp and the detector housings from the sensor body.

6. Remove the 4 socket head screws from each window retaining ring and remove the rings. Be careful to loosen the screws

evenly and alternately around the window retaining ring. If the window is ‘stuck’, apply Acetone to the window seal area and

let soak for several minutes. This may assist in freeing the windows from the seals.

7. Gently push/ease the windows out of the sensor.

8. Inspect the window area and clean as necessary. Inspect the windows for any signs of abrasive wear or chipping. If any is

apparent, replace the windows. Discard the 'O' rings and replace with new ones of the same material type. Re-assemble the

sensor in the reverse order, taking care to cross-tighten the window retaining ring screws evenly to prevent uneven seating. If

the sensor pathlength has been changed, the analyzer module must be configured to reflect the new pathlength. After every reassembly of an OUSAF21 sensor, it is necessary to carry out a liquid or Easycal

TM

calibration with its associated analyzer.

Note!

Some window faces may not be parallel to each other. This is normal, especially with fire-polished quartz windows. Take care to

ensure pathlength gauge does not scratch window faces.

41

Page 42

Model OUM980 with OUSAF21 Inline Sensor Replacement Parts

7. Replacement Parts List

7.1 Model 980 Photometric Analyzer

DESCRIPTION Reference No. Part Number

Fuse, AC Input 3.15A GDA Ceramic 1678-0017-00 63006917

Fuse, DC Input 1A MST 1678-1000-00 63006930

Fuse, Relays/Alarm 125mA MSF 1678-0125-00 63006925

7.2 Model OUSAF21 Inline Sensor

DESCRIPTION Reference No. Part Number

High Luminescence Lamp A011-0680-22 63009261

Gas-Filled Lamp A011-2200-00 63009277

Standard Lamp A011-0610-22 63009226

Interference Filter - 400nm 1410-0400-00 63006556

Interference Filter - 420nm 1410-0420-00 63006559

Interference Filter - 430nm 1410-0430-00 63006560

Interference Filter - 720nm 1410-0720-00 63006583

Type 'C' Pyrex Window 1420-0240-00 63006658

Type 'C' Quartz Window 1420-0240-03 63006659

Type 'C' Sapphire Window 1420-0240-04 63006660

Window Gasket Kit, Viton A000-0662-01 63009117

Window Gasket Kit, Kalrez A000-0662-03 71041399

Window Gasket Kit, EPR(EDPM) A000-0662-05 63009119

Window Gasket Kit, Silicone A000-0610-00 63009100

42

Page 43

Model OUM980 with OUSAF21 Inline Sensor Technical Information

8. Technical Information

8.1 Photometric Analyzer OUM980

8.1.1 Input

Measured Variable

Range

Digital Input

Keyboard

8.1.2 Output

Current Output

Dual Channel Current from Model OUSAF21 Inline Sensor

5 decades of absorbance signal from each detector

4 Channels, dry contact

6 push buttons keyboard

2 channel, 4~20mA NAMUR Compatible

Resolution

Isolation

Signal on Lamp Alarm

Actual Current

Output Range

Load

Front Panel Display

Alarm LED

General Relay Output

Relay Operation

Relay Delay

Lamp Alarm Relay

Lamp Power Supply

8.1.3 Power Supply

Supply Voltage

Power Consumption

Mains Fuse

12bit

O1 to PE 500 VDC

O2 to PE 500 VDC

O1 to O2 500 VDC

3.6mA or 21.5mA in case of error

3.8mA to 20.5mA

750 ohm Max.

4x20 Character LCD display

On front Panel, Red LED

2 Channel, Solid State Relays

Above/Below trigger configurable; NO/NC configurable

0~60 sec configurable

1 Channel, NC

3 to 5 vdc, 1.5A Max.

85~265 VAC, 24VDC as option

12 VA Max.

3.15 A

43

Page 44

Model OUM980 with OUSAF21 Inline Sensor Technical Information

8.1.4 Performance

Sensor Photo Current Input

100pA to 700uA

Linearity

Repeatability

Accuracy

Initial Drifting

8.1.5 Environment

Temperature

(Monitor)

Temperature

(Sensor)

Relative Humidity

Altitude

Degree of Protection

8.1.6 Mechanical Construction

Dimensions

0.3% Max.

0.3% Max.

0.3% Max.

<0.5% for first 24 hours

0~55°C

0~55 °C

95%

2000 m

IP 65 (front panel), IP 30 (housing)

L x W x D: 102 x 102 x 177 mm

Weight

Material

Degree of Protection

1.213 kg

Aluminum (polyester coating on front panel)

IP 65 (front panel), IP 30 (housing)

44

Page 45

Model OUM980 with OUSAF21 Inline Sensor Technical Information

8.2 Absorbance Sensor OUSAF21

8.2.1 Sensor Dimensions

FLOWCELL PATHLENGTH “A” DIMENSION

10cm Pathlength 5.9 in/150mm

15 cm Pathlength 7.9in/200mm

20 cm Pathlength 9.8in/250mm

25 cm Pathlength 11.8in/300mm

30 cm Pathlength 13.7in/350mm

35 cm Pathlength 15.7in/400mm

LAMP ASSY TYPE “B” DIMENSION

Standard Lamp 2.41in/61.2mm

EXP-1 Lamp 6.5in/165.0mm

DETECTOR ASSY “C” DIMENSION

OUSAF21 4.05in/102.8mm

8.2.2 Input and Output

Measured Input Variable

Process absorption and optical density

Output Signal

Photo detector current (100pA~ 700 μA)

8.2.3 Mechanic Construction

Weight

Housing Material

1.225 kg (flow cell not included)

Stainless steel 316L

45

Page 46

Model OUM980 with OUSAF21 Inline Sensor Technical Information

8.2.4 Environment

Temperature

(Process)

Relative Humidity

0~90 °C Continuous

up to130°C for 2 hours

95%

Altitude

Degree of Protection

Maximum Pressure in Flow

Cell

8.2.5 Power Supply

Supply Voltage

Power Consumption

8.2.6 Optical Specifications

Wavelengths Available

Filters

Detectors

Lamp

2000m

IP 65

6.8 Bar/100 PSI

3-5 vdc

4 VA continuous

8 VA start up in-rush

400 nm / 720 nm

420 nm / 720 nm

430 nm / 720 nm

520 nm / 720 nm

Interference filters, stray light .01% maximum.

Blue Enhanced Silicon, hermetically sealed.

Lens End Halogen Lamp

46

Page 47

Model OUM980 with OUSAF21 Inline Sensor Ordering Information

9. Ordering Information

9.1 Color Analyzer OUM980

Power Supply

1 100-250 VAC

424 VDC

Transmitter Unit

A Optical Density

Y Special version, TSP no.to be spec

Calibration

1 Single order/spare part

2 With sensor/cable order position

9 Special version, TSP no.to be spec

OUM980

Complete Order Code

47

Page 48

Model OUM980 with OUSAF21 Inline Sensor Ordering Information

9.2 Sensor OUSAF21

48

Page 49

Model OUM980 with OUSAF21 Inline Sensor Ordering Information

9.3 OUK20 Cable Set

Sensor

1OUSTF10

2 OUSAF21/OUSAF22

3OUSAF23

Transmitter

A OUS900 Serie

B OUS600 Serie

C OUS700 Serie

Cable Length

10 10 ft / 3m

15 15 ft / 4,5 m

25 25 ft / 7,5 m

50 50 ft / 15 m

88 ..... ft; cable

89 ..... m; cable

Barriere

A Standard (non-hazardous area)

BFM, Busbar

CATEX, Busbar

D FM, DIN Rail

E ATEX, DIN Rail

OUK10

Complete Order Code

49

Page 50

www.endress.com/worldwide

Loading...

Loading...