Endress+Hauser NMR84 Operating Manual

BA01453G/00/EN/04.18

71410290

2018-07-13

01.03.zz (Device firmware)

Products Solutions Services

Operating Instructions

Micropilot NMR84

Tank Gauging

Micropilot NMR84

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

A0023555

2 Endress+Hauser

Micropilot NMR84 Table of contents

Table of contents

1 About this document ................ 4

1.1 Document function ..................... 4

1.2 Symbols .............................. 4

1.3 Documentation ........................ 7

1.4 Registered trademarks ................... 9

2 Basic safety instructions ........... 10

2.1 Requirements for the personnel ........... 10

2.2 Designated use ....................... 10

2.3 Workplace safety ...................... 11

2.4 Operational safety ..................... 11

2.5 Product safety ........................ 11

3 Product description ................ 12

3.1 Product design ........................ 12

4 Incoming acceptance and product

identification ..................... 13

4.1 Incoming acceptance ................... 13

4.2 Product identification .................. 13

4.3 Storage and transport .................. 15

5 Installation ....................... 16

5.1 Installation conditions .................. 16

5.2 Post-installation check .................. 17

6 Electrical connection .............. 18

6.1 Terminal assignment ................... 18

6.2 Connecting requirements ................ 33

6.3 Ensuring the degree of protection .......... 34

6.4 Post-connection check .................. 34

9.2 Initial settings ........................ 54

9.3 Configuring the measuring device .......... 57

9.4 Configuring the tank gauging application .... 59

9.5 Advanced settings ..................... 81

9.6 Simulation ........................... 81

9.7 Protecting settings from unauthorized

access .............................. 81

10 Operation ......................... 82

10.1 Reading off the device locking status ....... 82

10.2 Reading off measured values ............. 82

11 Diagnostics and troubleshooting ... 83

11.1 General trouble shooting ................ 83

11.2 Diagnostic information on local display ...... 84

11.3 Diagnostic information in FieldCare ........ 87

11.4 Overview of the diagnostic messages ....... 89

11.5 Diagnostic list ........................ 95

11.6 Reset measuring device ................. 96

11.7 Device information .................... 96

11.8 Firmware history ...................... 96

12 Maintenance ...................... 97

12.1 Maintenance tasks ..................... 97

12.2 Endress+Hauser services ................ 97

13 Repair ............................ 98

13.1 General information on repairs ............ 98

13.2 Spare parts .......................... 98

13.3 Endress+Hauser services ................ 99

13.4 Return .............................. 99

13.5 Disposal ............................ 99

7 Operability ........................ 35

7.1 Overview of the operation options ......... 35

7.2 Structure and function of the operating

menu .............................. 36

7.3 Access to the operating menu via the local or

remote display and operating module. ...... 37

7.4 Access to the operating menu via the service

interface and FieldCare ................. 49

7.5 Access to the operating menu via Tankvision

Tank Scanner NXA820 and FieldCare ....... 50

14.1 Device-specific accessories .............. 100

14.2 Communication-specific accessories ....... 101

14.3 Service-specific accessories .............. 101

14.4 System components ................... 101

15 Operating menu .................. 102

15.1 Overview of the operating menu .......... 102

15.2 "Operation" menu ..................... 111

15.3 "Setup" menu ........................ 120

15.4 "Diagnostics" menu .................... 236

8 System integration ................ 53

14 Accessories ...................... 100

8.1 Overview of the Device Description files

(DTM) .............................. 53

Index ................................. 248

9 Commissioning .................... 54

9.1 Terms related to tank measurement ........ 54

Endress+Hauser 3

About this document Micropilot NMR84

DANGER

WARNING

CAUTION

NOTICE

1 About this document

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

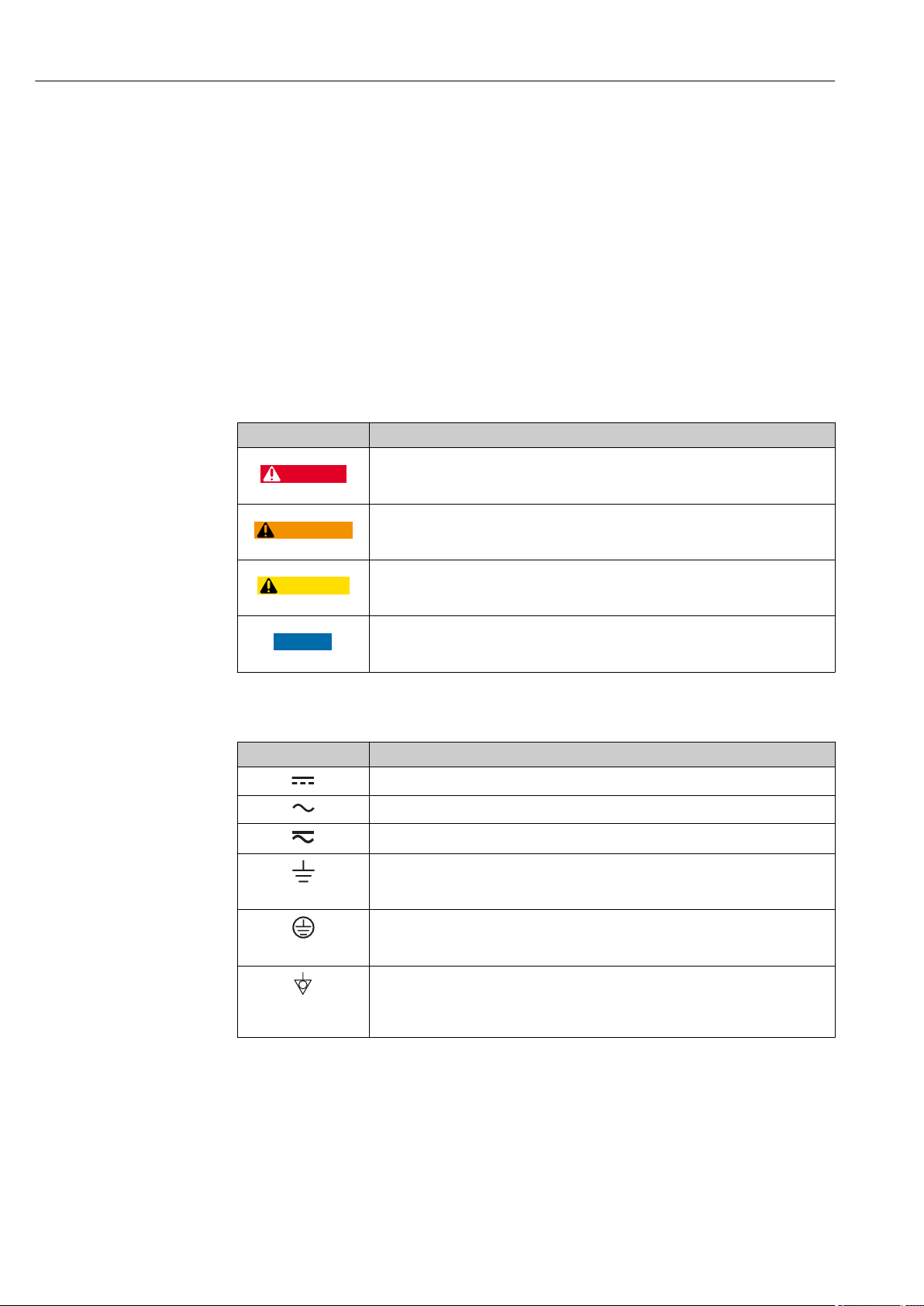

1.2 Symbols

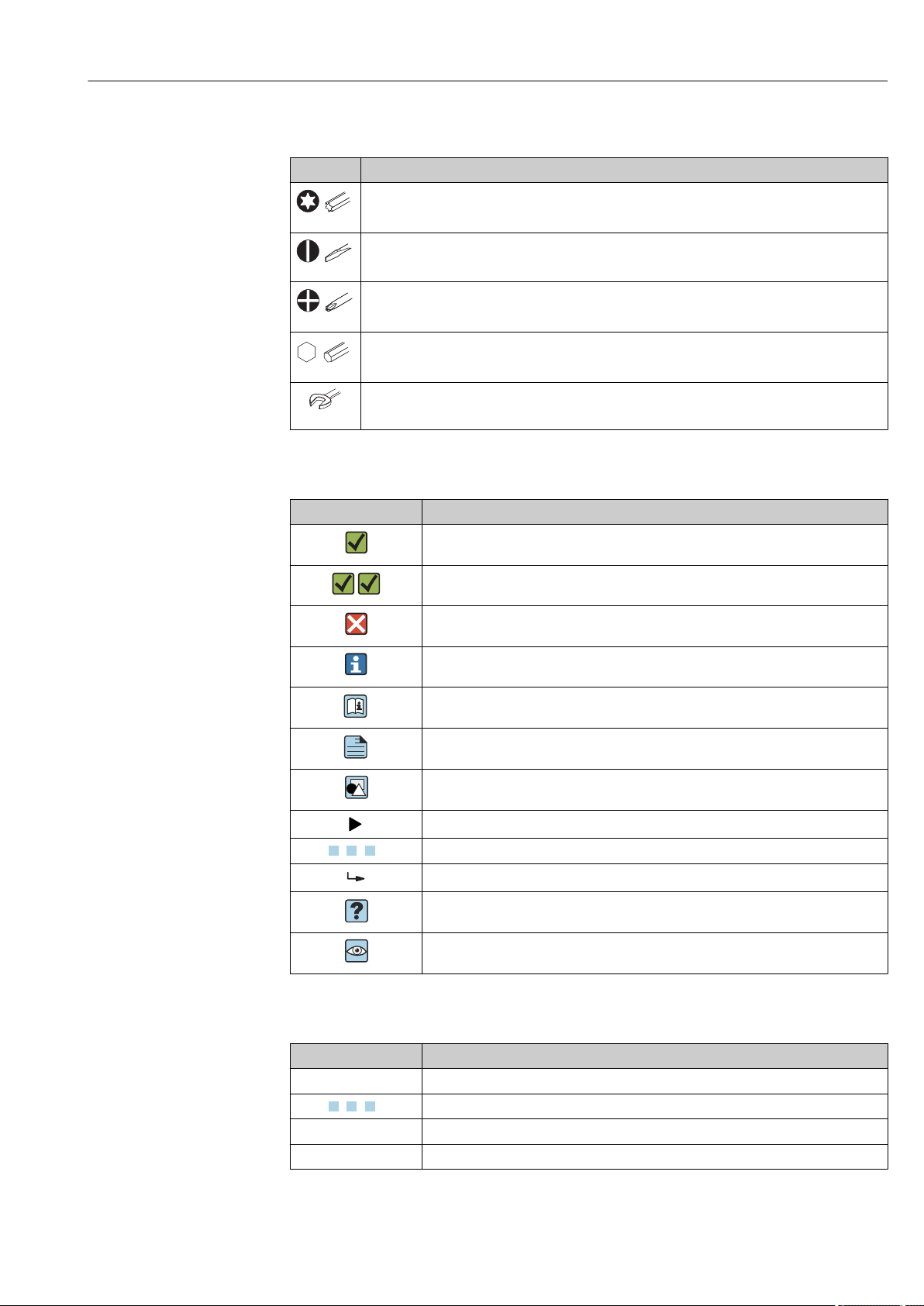

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a

potential equalization line or a star grounding system depending on national or

company codes of practice.

4 Endress+Hauser

Micropilot NMR84 About this document

A

1.

1.

1.2.3 Tool symbols

Symbol Meaning

Torx screwdriver

A0013442

Flat blade screwdriver

A0011220

Cross-head screwdriver

A0011219

Allen key

A0011221

Hexagon wrench

A0011222

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Notice or individual step to be observed

, 2., 3.… Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Endress+Hauser 5

About this document Micropilot NMR84

-

.

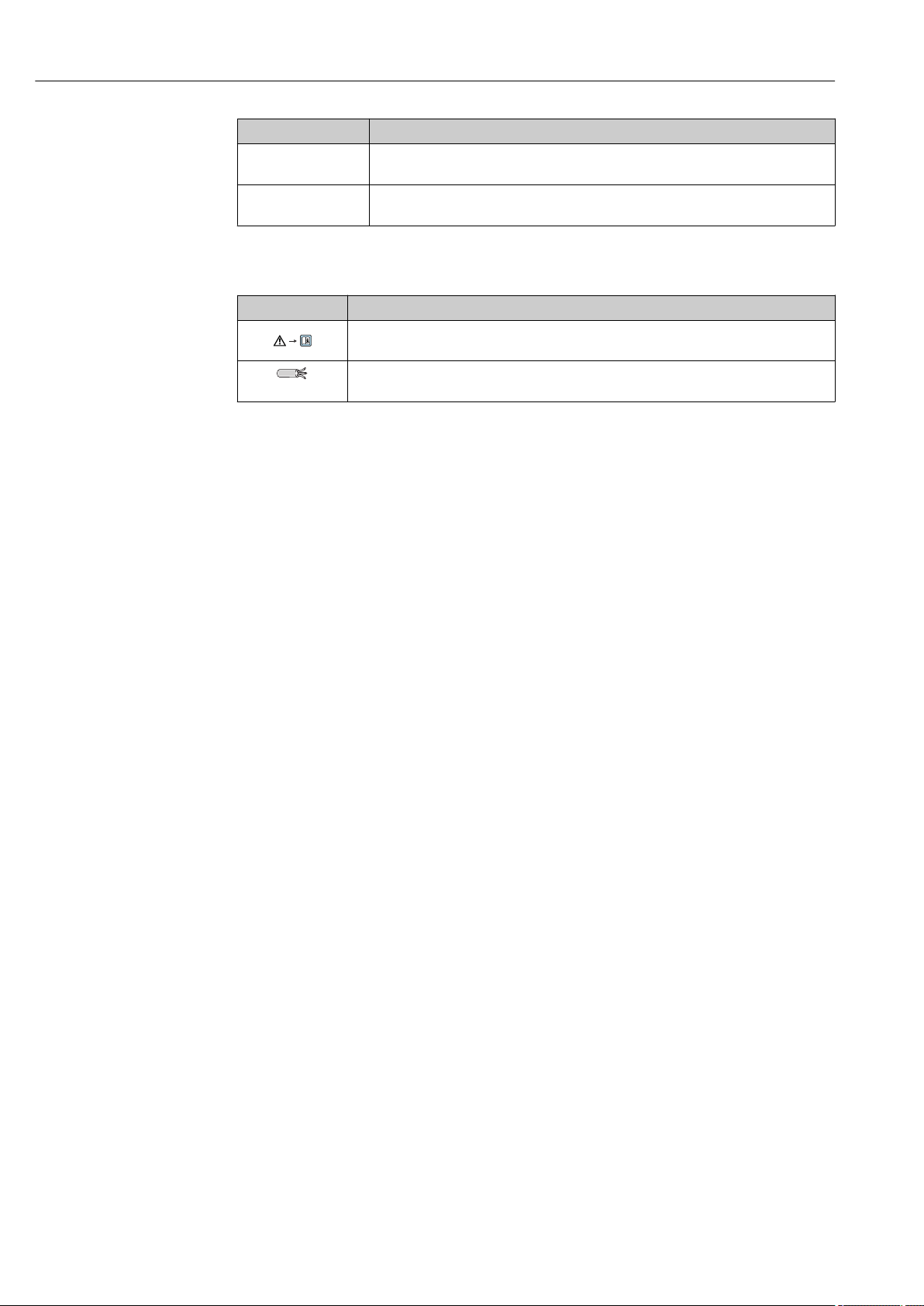

Symbol Meaning

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

1.2.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

6 Endress+Hauser

Micropilot NMR84 About this document

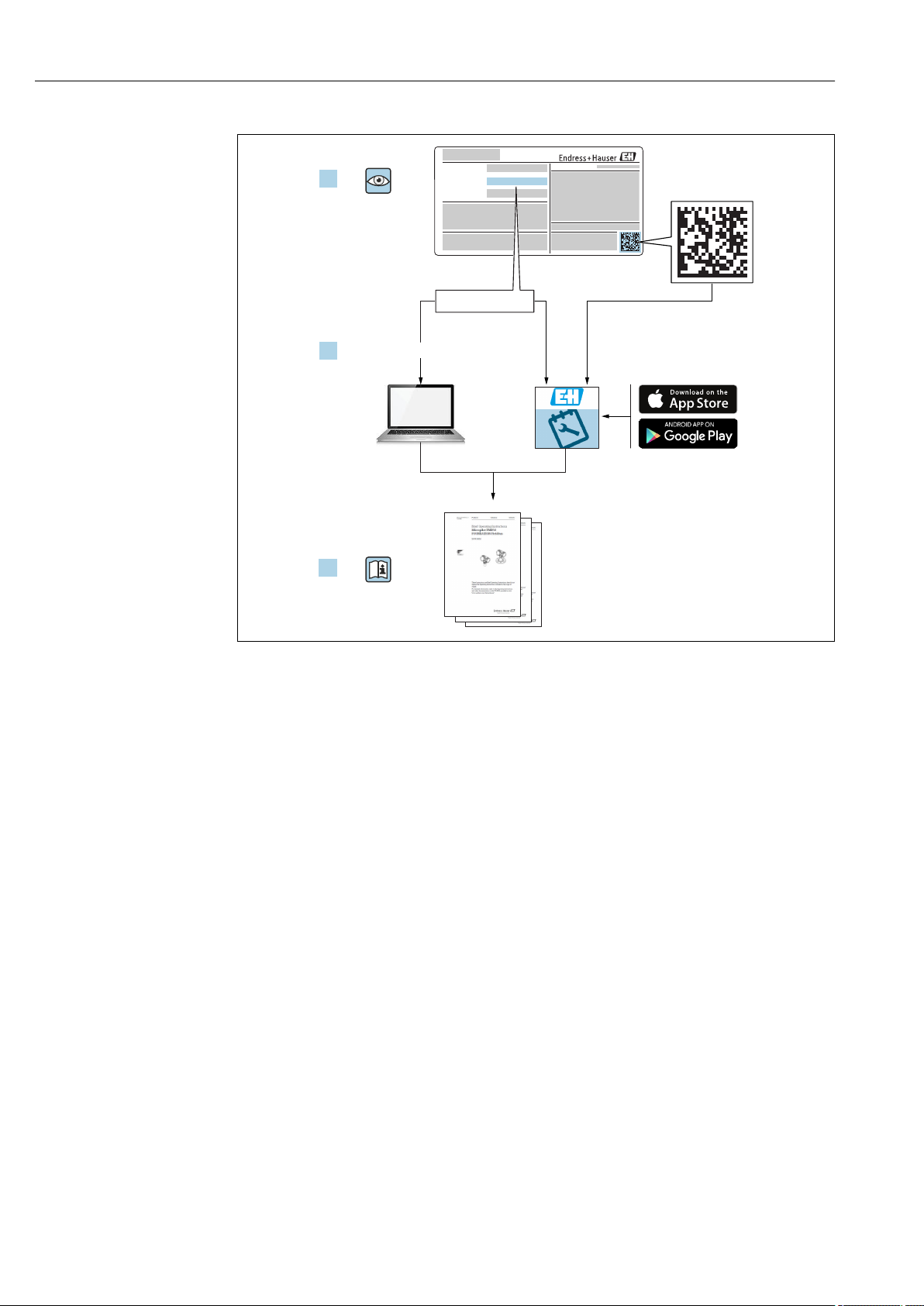

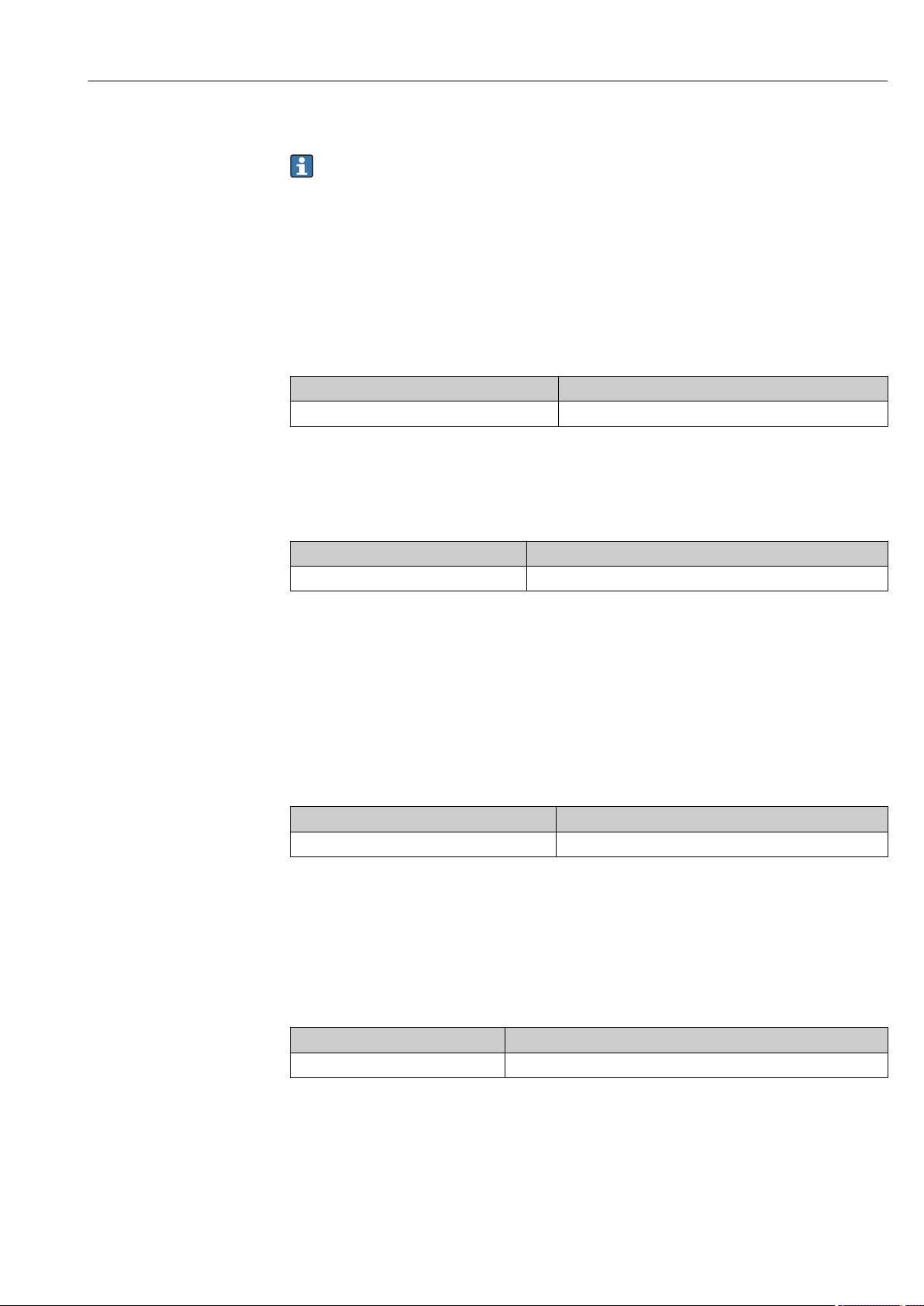

1.3 Documentation

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The W@M Device Viewer : Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate

or scan the 2-D matrix code (QR code) on the nameplate.

1.3.1 Technical Information (TI)

The Technical Information contains all the technical data on the device and provides an

overview of the accessories and other products that can be ordered for the device.

Device Technical Information

Micropilot NMR84 TI01253G

1.3.2 Brief Operating Instructions (KA)

The Brief Operating Instructions contain all the essential information from incoming

acceptance to initial commissioning.

Device Brief Operating Instructions

Micropilot NMR84 KA01197G

1.3.3 Operating Instructions (BA)

The Operating Instructions contain all the information that is required in various phases of

the life cycle of the device: from product identification, incoming acceptance and storage,

to mounting, connection, operation and commissioning through to troubleshooting,

maintenance and disposal.

It also contains a detailed explanation of each individual parameter in the operating menu

(except the Expert menu). The description is aimed at those who work with the device

over the entire life cycle and perform specific configurations.

Device Operating Instructions

Micropilot NMR84 BA01453G

1.3.4 Description of Device Parameters (GP)

The Description of Device Parameters provides a detailed explanation of each individual

parameter in the 2nd part of the operating menu: the Expert menu. It contains all the

device parameters and allows direct access to the parameters by entering a specific code.

The description is aimed at those who work with the device over the entire life cycle and

perform specific configurations.

Device Description of Device Parameters

Micropilot NMR84 GP01071G

Endress+Hauser 7

About this document Micropilot NMR84

1.3.5 Safety instructions (XA)

Ordering feature 010 "Approval" Meaning XA

BC ATEX II 1/2G Ex ia/db IIC T6 Ga/Gb

ATEX II 2 (1)G Ex db [ia Ga] IIC T6 Gb

FC FM C/US XP-AIS Cl.I Div.1 Gr.BCD T6

AEx d[ia] IIC T6

GC EAC Ga/Gb Ex ia/db IIC T6...T1 X

EAC 1 Ex db [ia] IIC T6...T1 X

IC IEC Ex ia/db IIC T6 Ga/Gb

IEC Ex db [ia Ga] IIC T6 Gb

KC KC Ex d[ia] IIC T6 Ga/Gb

KC Ex db [ia Ga] IIC T6 Gb

MC INMETRO Ex ia/db IIC T6 Ga/Gb

INMETRO Ex db [ia Ga] IIC T6 Gb

NC NEPSI Ex ia/db IIC T6 Ga/Gb

NEPSI Ex db [ia Ga] IIC T6 Gb

TA TIIS Ex d[ia] IIC T6 Ga/Gb in preparation

TC TIIS Ex d[ia] IIC T4 Ga/Gb in preparation

TE TIIS Ex d[ia] IIC T2 Ga/Gb in preparation

XA01410G

XA01436G

XA01582G

XA01410G

XA01579G

XA01580G

XA01581G

8 Endress+Hauser

Micropilot NMR84 About this document

1.4 Registered trademarks

FieldCare

Registered trademark of the Endress+Hauser Process Solutions AG, Reinach, Switzerland

MODBUS

Registered trademark of the MODBUS-IDA, Hopkinton, MA, USA

®

®

Endress+Hauser 9

Basic safety instructions Micropilot NMR84

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the

application).

Follow instructions and comply with basic conditions.

‣

The operating personnel must fulfill the following requirements:

Are instructed and authorized according to the requirements of the task by the facility's

‣

owner-operator.

Follow the instructions in this manual.

‣

2.2 Designated use

Application and measured materials

The measuring device described in these Operating Instructions is intended for the

continuous, contact-less level measurement of liquids. The device must be installed in

metallic stilling wells. Operation is completely harmless to humans and animals.

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or in applications

where there is an increased risk due to process pressure, are labeled accordingly on the

nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

Only use the measuring device in full compliance with the data on the nameplate and

‣

the general conditions listed in the Operating Instructions and supplementary

documentation.

Check the nameplate to verify if the device ordered can be put to its intended use in the

‣

approval-related area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media against which the process-wetted materials

‣

are adequately resistant.

If the measuring device is not operated at atmospheric temperature, compliance with

‣

the relevant basic conditions specified in the associated device documentation is

absolutely essential.

Protect the measuring device permanently against corrosion from environmental

‣

influences.

Observe the limit values in the "Technical Information".

‣

The manufacturer is not liable for damage caused by improper or non-designated use.

Residual risk

During operation the sensor may assume a temperature near the temperature of the

measured material.

Danger of burns due to heated surfaces!

For high process temperatures: Install protection against contact in order to prevent

‣

burns.

10 Endress+Hauser

Micropilot NMR84 Basic safety instructions

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with the manufacturer.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from the manufacturer only.

‣

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the

hazardous area (e.g. explosion protection, pressure vessel safety):

Based on the nameplate, check whether the ordered device is permitted for the

‣

intended use in the hazardous area.

Observe the specifications in the separate supplementary documentation that is an

‣

integral part of these Instructions.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate. It meets general safety standards and legal requirements.

2.5.1 CE mark

The measuring system meets the legal requirements of the applicable EC guidelines. These

are listed in the corresponding EC Declaration of Conformity together with the standards

applied.

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

Endress+Hauser 11

Product description Micropilot NMR84

1 1

2 2

4

5

3

4

3

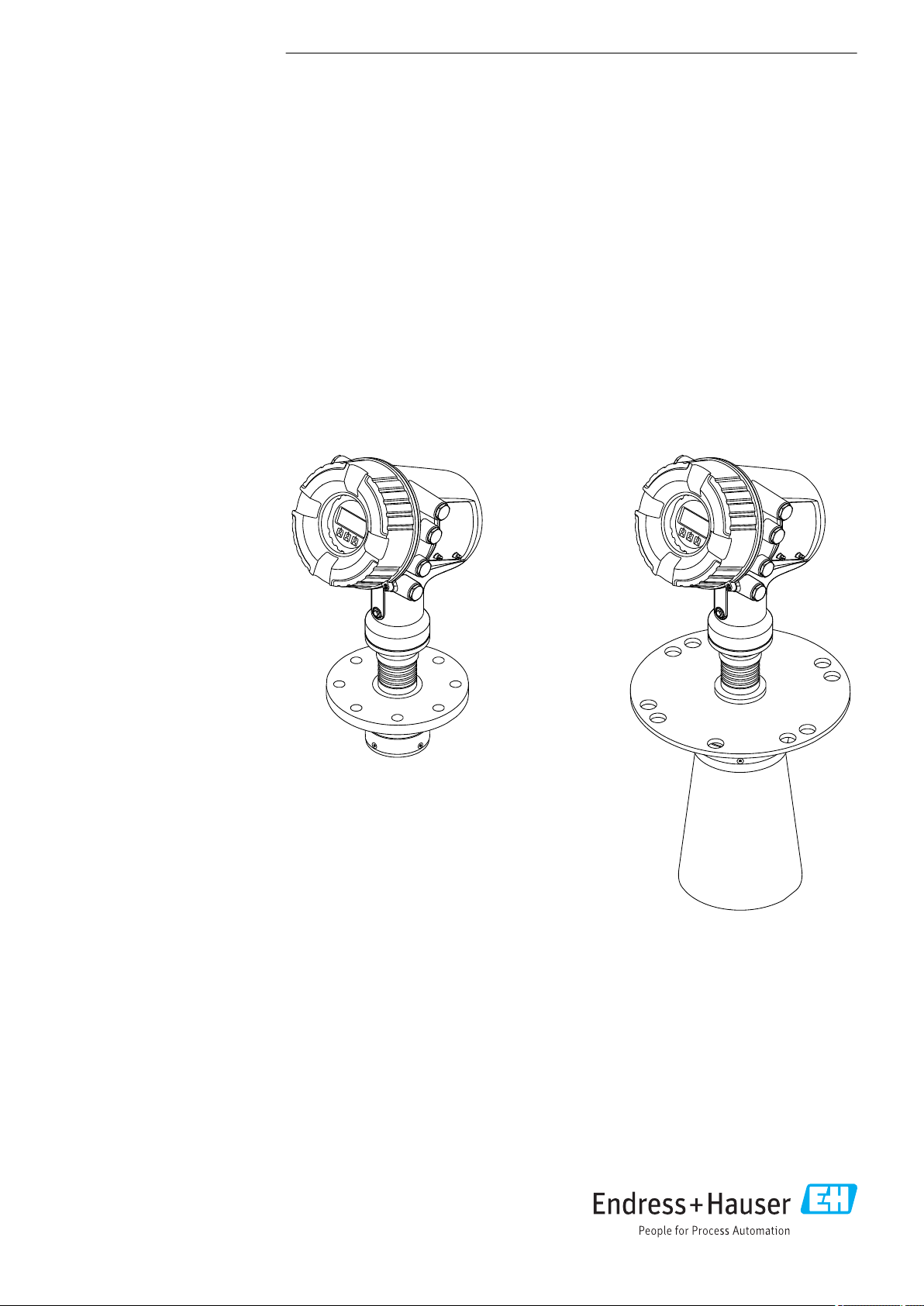

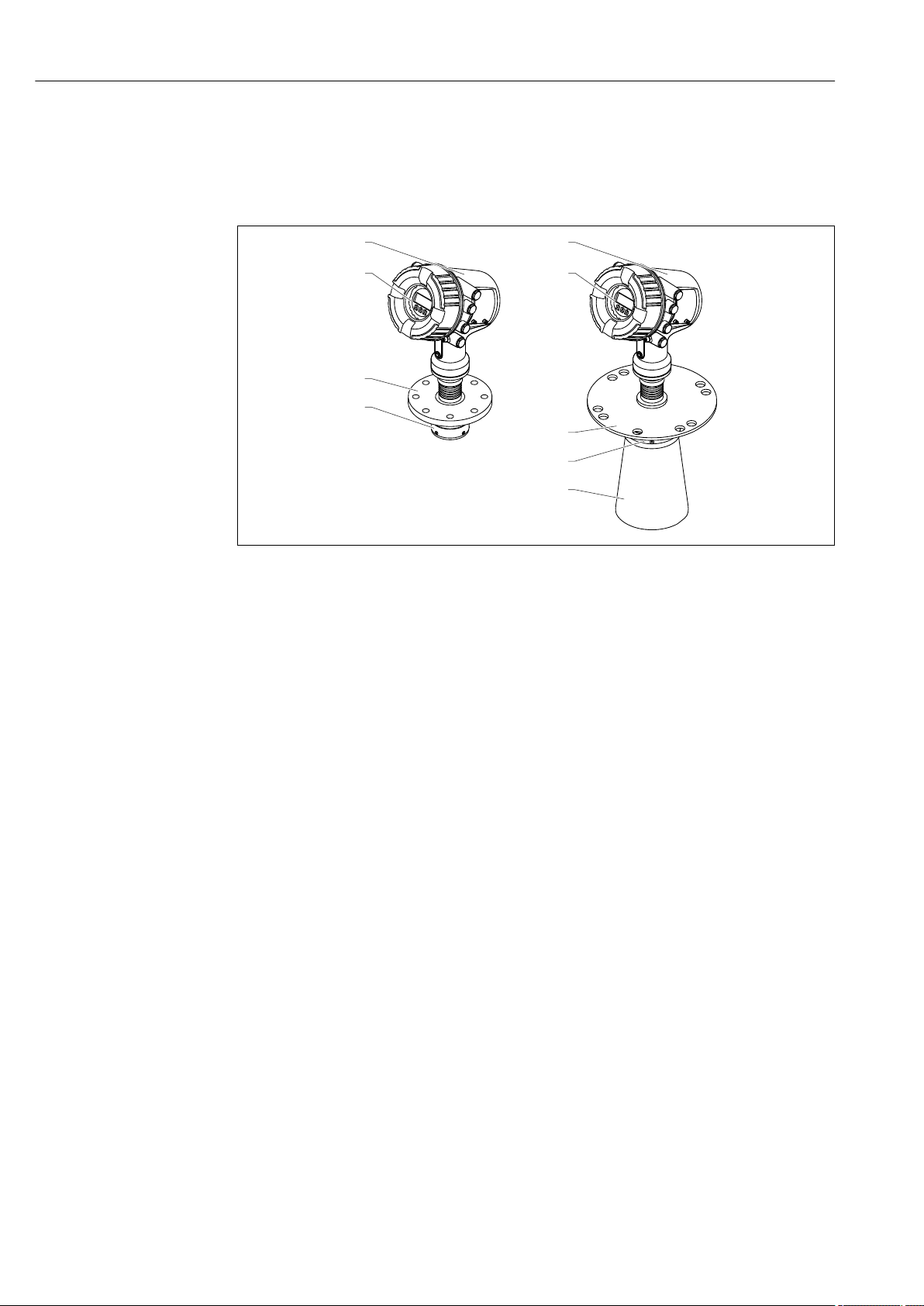

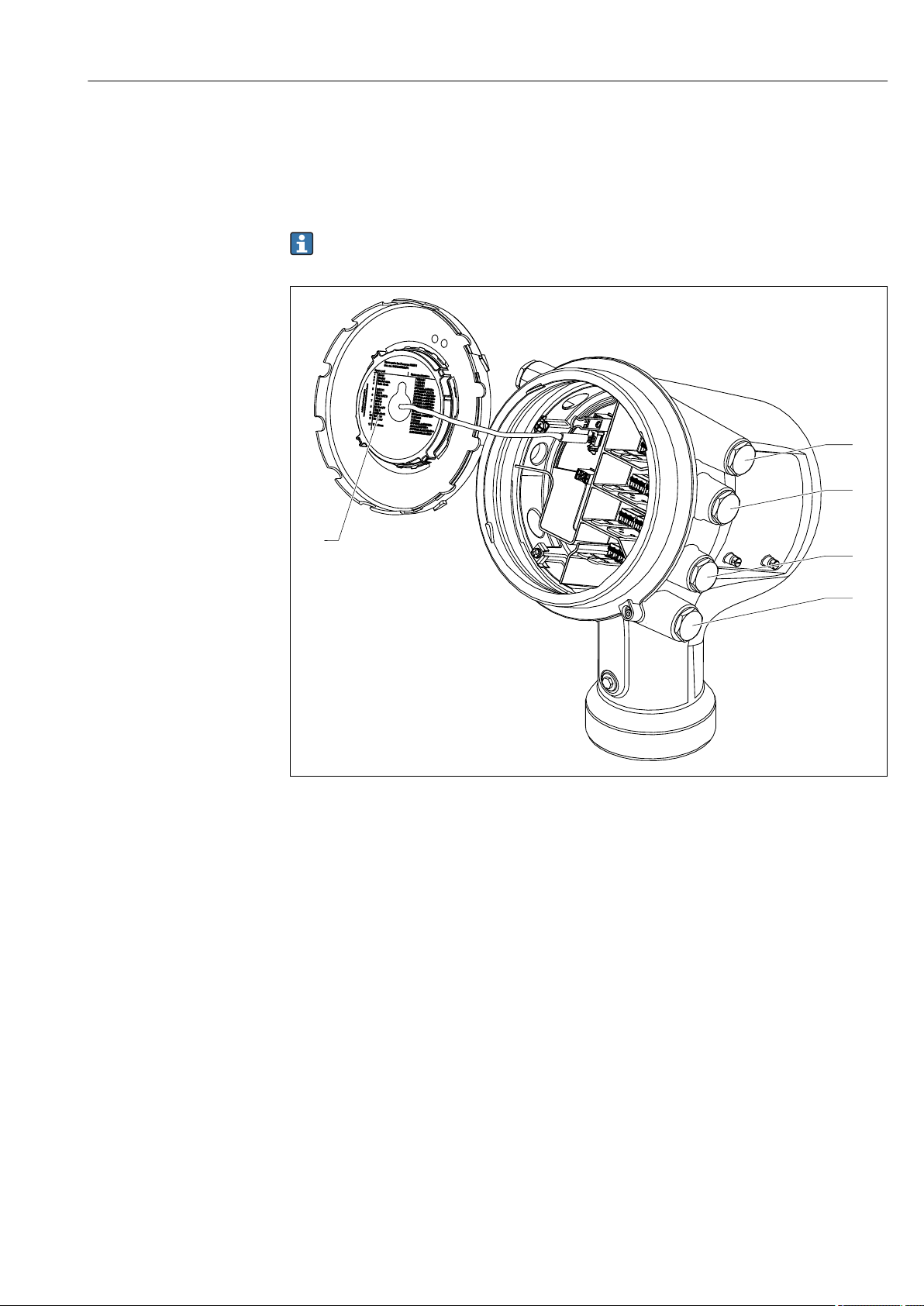

3 Product description

3.1 Product design

1 Design of Micropilot NMR84

1 Electronics housing

2 Display and operating module (can be operated without opening the cover)

3 Process connection (flange)

4 Planar antenna

5 Antenna extension (for antennas ≥ 200 mm (8 in))

A0027766

12 Endress+Hauser

Micropilot NMR84 Incoming acceptance and product identification

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

Upon receipt of the goods check the following:

• Are the order codes on the delivery note and the product sticker identical?

• Are the goods undamaged?

• Do the nameplate data match the ordering information on the delivery note?

• If required (see nameplate): Are the Safety Instructions (XA) enclosed?

If one of these conditions is not satisfied, contact your Endress+Hauser Sales Center.

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Extended order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

( www.endress.com/deviceviewer ): All information about the measuring device is

displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App

or scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser

Operations App: all the information for the measuring device is displayed.

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The W@M Device Viewer: Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate or

scan the 2-D matrix code (QR code) on the nameplate.

Endress+Hauser 13

Incoming acceptance and product identification Micropilot NMR84

1

3

21

22

23

6

7

8

9

14

16

15

19

20

11

18

12

13

24

25

26

28

27

4

5

Ext. ord. cd.:

Order code:

Ser. no.:

Tp max.:

Mat.:

Date:

FW:

Dev.Rev.:

ex works

DeviceID:

Ta

Ta:

if modification

see sep. label

X =

MWP:

Tank ID:

Tank ref.height:

2

Density range:

Kg/m³

17

10

4.2.1 Nameplate

A0027791

2 Nameplate

1 Manufacturer address

2 Device name

3 Order code

4 Serial number

5 Extended order code

6 Supply voltage

7 Maximum process pressure

8 Maximum process temperature

9 Permitted ambient temperature (Ta)

10 Temperature resistance of cable

11 Thread for cable entry

12 Material in contact with process

13 Device ID

14 Firmware version

15 Device revision

16 Metrology certification numbers

17 Customized parametrization data

18 Ambient temperature range

19 CE mark / C-tick mark

20 Additional information on the device version

21 Ingress protection

22 Certificate symbol

23 Data concerning the Ex approval

24 General certificate of approval

25 Associated Safety Instructions (XA)

26 Manufacturing date

27 RoHS mark

28 QR code for the Endress+Hauser Operations App

4.2.2 Manufacturer address

Endress+Hauser SE+Co. KG

Hauptstraße 1

79689 Maulburg, Germany

Address of the manufacturing plant: See nameplate.

14 Endress+Hauser

Micropilot NMR84 Incoming acceptance and product identification

4.3 Storage and transport

4.3.1 Storage conditions

• Storage temperature: –50 to +80 °C (–58 to +176 °F)

• Store the device in its original packaging.

4.3.2 Transport

NOTICE

Housing or antenna may be damaged or break away.

Risk of injury

Transport the measuring device to the measuring point in its original packaging or at

‣

the process connection.

Do not fasten lifting devices (hoisting slings, lifting eyes etc.) at the housing or the

‣

antenna but at the process connection. Take into account the mass center of the device

in order to avoid unintended tilting.

Comply with the safety instructions, transport conditions for devices over 18kg

‣

(39.6lbs) (IEC61010).

Endress+Hauser 15

Installation Micropilot NMR84

øD1 øD1

øD2 øD2

L

L

500 (19.7)

500 (19.7)

1 1

≤5 (0.2)

A

B

≤5 (0.2)

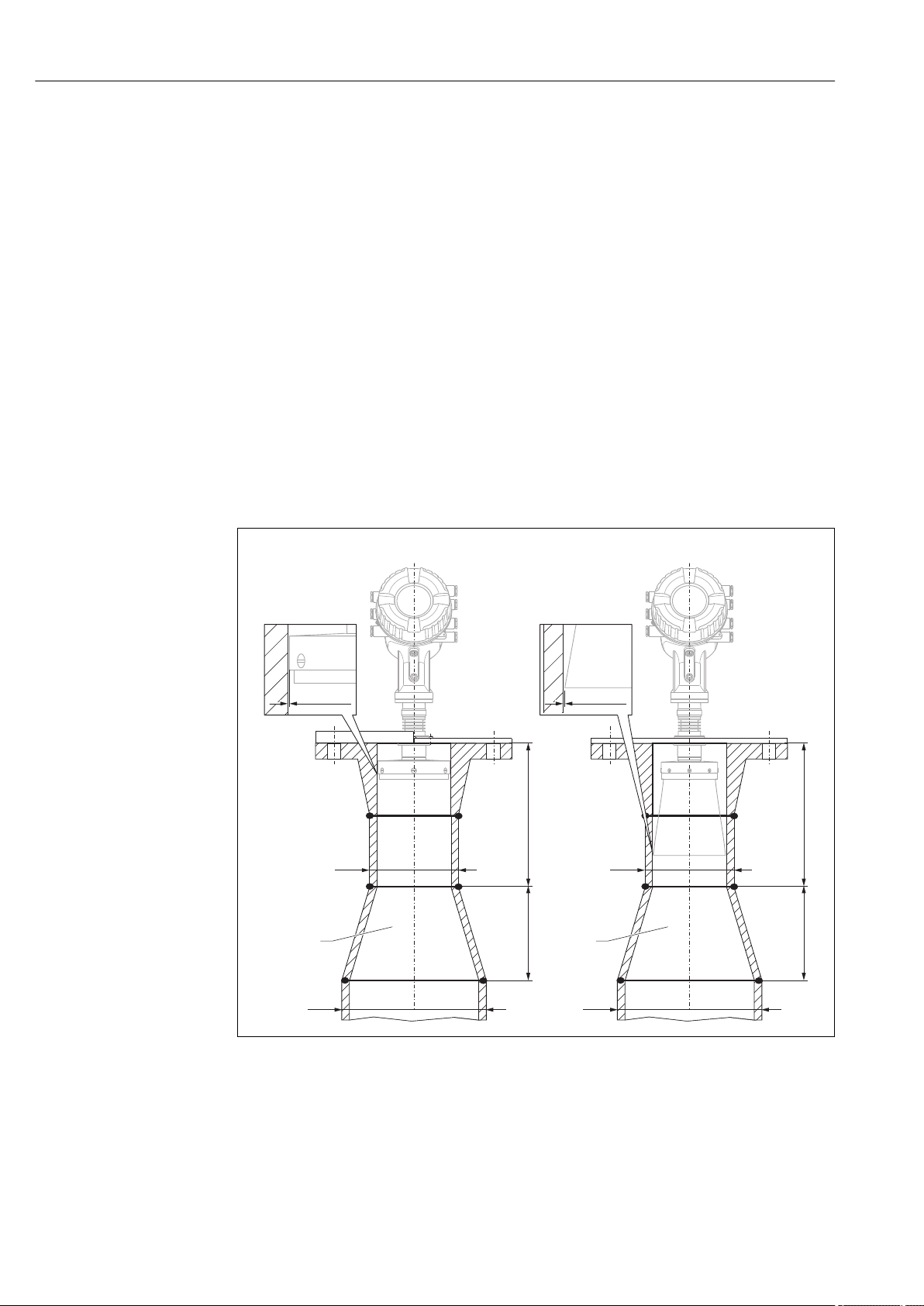

5 Installation

5.1 Installation conditions

5.1.1 Conditions for the stilling well

• Metal (no enamel coating)

• Constant diameter (no rectangular stilling wells)

• Weld seam as smooth as possible

• For best radar propagation behavior it is recommended to have holes instead of slots. If

slots can not be avoided, they should be as thin and short as possible.

• Maximum gap between antenna/horn and wall of the stilling well: 5 mm (0.2 in).

• At any transition (e.g. when using a ball valve or mending pipe segments) gaps must not

exceed 1 mm (0.04 in).

• The stilling well must be smooth on the inside. Average roughness ≤ 6.3 µm (0.248 µin)

• Length and number of the holes do not affect the measurement. The hole diameter

(deburred) can be 1/7 of the well diameter, but should not exceed 30 mm (1.2 in).

• An increase of the pipe diameter is possible if the minimum lengths according to the

following figure and table are taken into account:

3 Installation of NMR84 in stilling wells with a larger diameter

A Antenna ≤150 mm (6 in) (without horn extension)

B Antenna ≥ 200 mm (8 in) (with horn extension)

1 Extension from ØD1 to ØD2

A0023596

16 Endress+Hauser

Micropilot NMR84 Installation

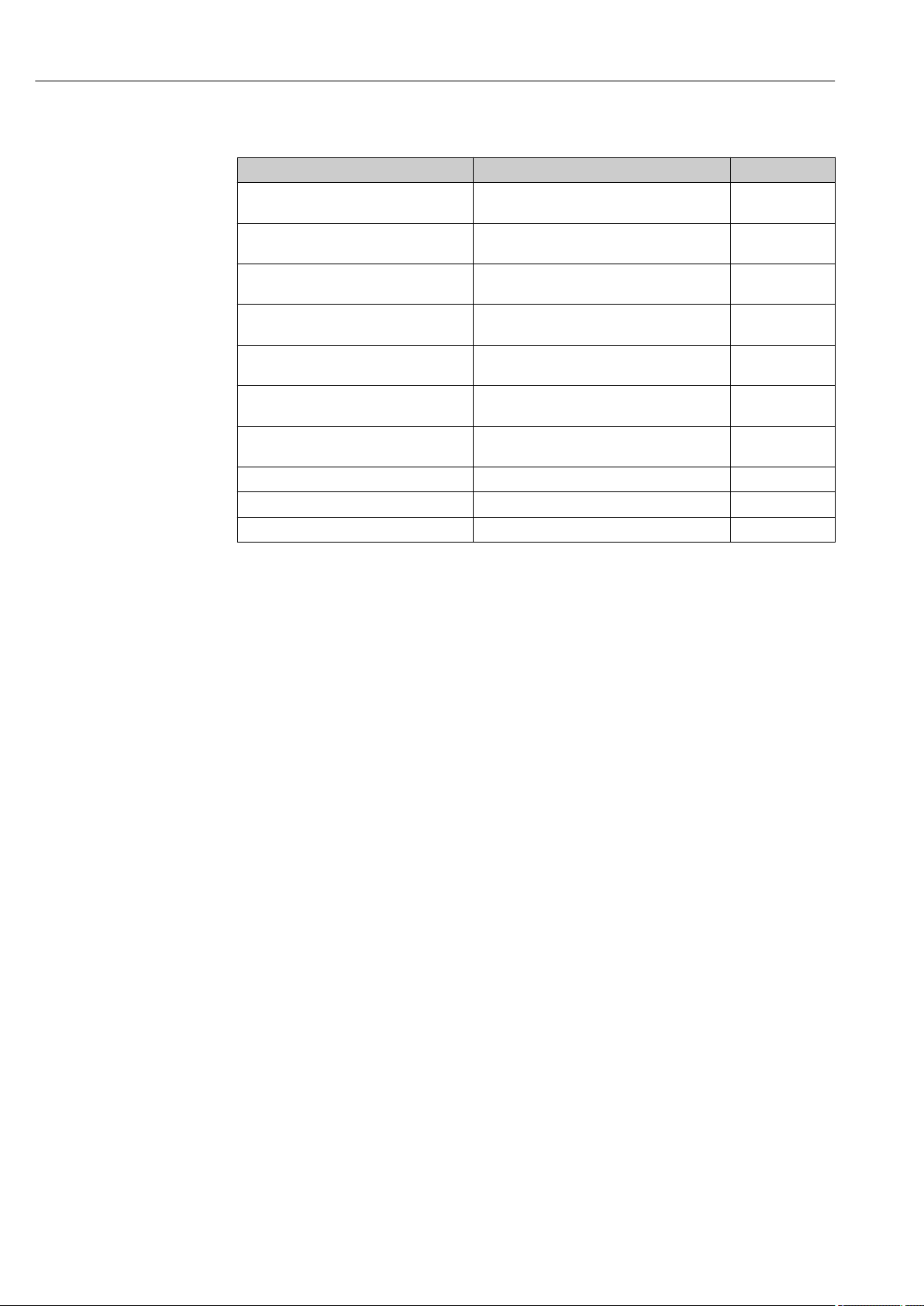

D1 (= antenna size) D2 L

100 mm (4 in) 150 mm (8 in) 300 mm (12 in)

150 mm (6 in) 200 mm (8 in) 300 mm (12 in)

200 mm (8 in) 250 mm (10 in) 300 mm (12 in)

250 mm (10 in) 300 mm (12 in) 450 mm (18 in)

5.2 Post-installation check

Is the device undamaged (visual inspection)?

m

Does the device conform to the measuring point specifications?

For example:

• Process temperature

m

• Process pressure (refer to the chapter on "Material load curves" of the "Technical Information"

document)

• Ambient temperature range

• Measuring range

Are the measuring point identification and labeling correct (visual inspection)?

m

Is the device adequately protected from precipitation and direct sunlight?

m

Endress+Hauser 17

Electrical connection Micropilot NMR84

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

G

1

3

2

POWER

G1 N

G3 L

AC 85...264 V

6 Electrical connection

6.1 Terminal assignment

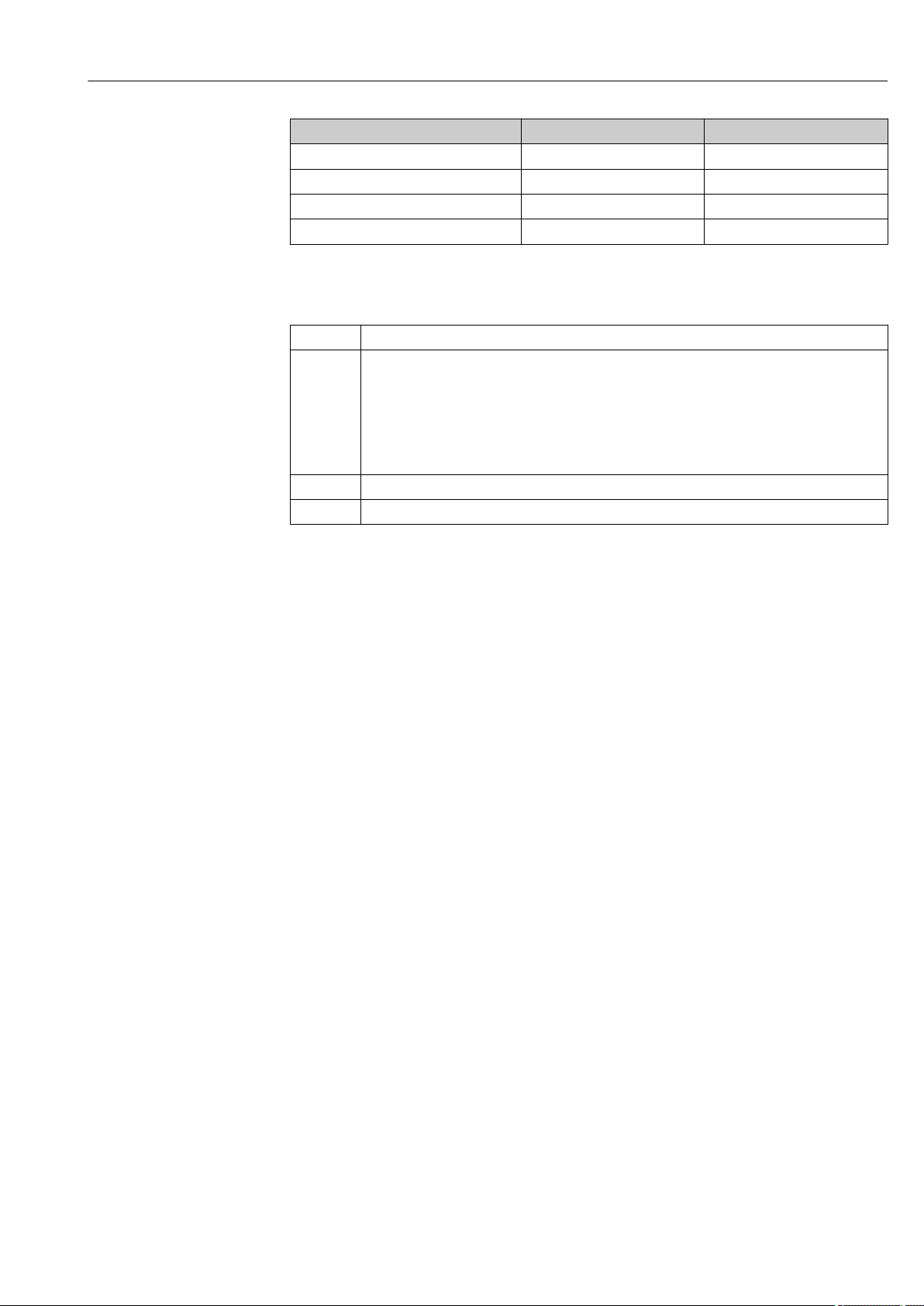

4 Terminal compartment (typical example) and ground terminals

Terminal area Module

Up to four I/O modules, depending on the order code

A/B/C/D

(slots for I/O

modules)

• Modules with four terminals can be in any of these slots.

• Modules with eight terminals can be in slot B or C.

The exact assignment of the modules to the slots is dependent on the device version

→ 21.

E HART Ex i/IS interface

• E1: H+

• E2: H-

F Remote display

• F1: VCC (connect to terminal 81 of the remote display)

• F2: Signal B (connect to terminal 84 of the remote display)

• F3: Signal A (connec t to terminal 83 of the remote display)

• F4: Gnd (connect to terminal 82 of the remote display)

Power supply: 85 to 264 V

G

• G1: N

• G2: not connected

AC

• G3: L

Protective ground connection (M4 screw)

A0018339

A0026372

18 Endress+Hauser

Micropilot NMR84 Electrical connection

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

4

F

1

1 3

2

2 4

HR

CDI

WP

SIM

G

1

3

2

POWER

1

3

Vcc

Gnd

A B

2

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

F

1 3

2 4

HR

WP

Vcc

Gnd

A

B

81 82 83 84

F1 F2 F3 F4

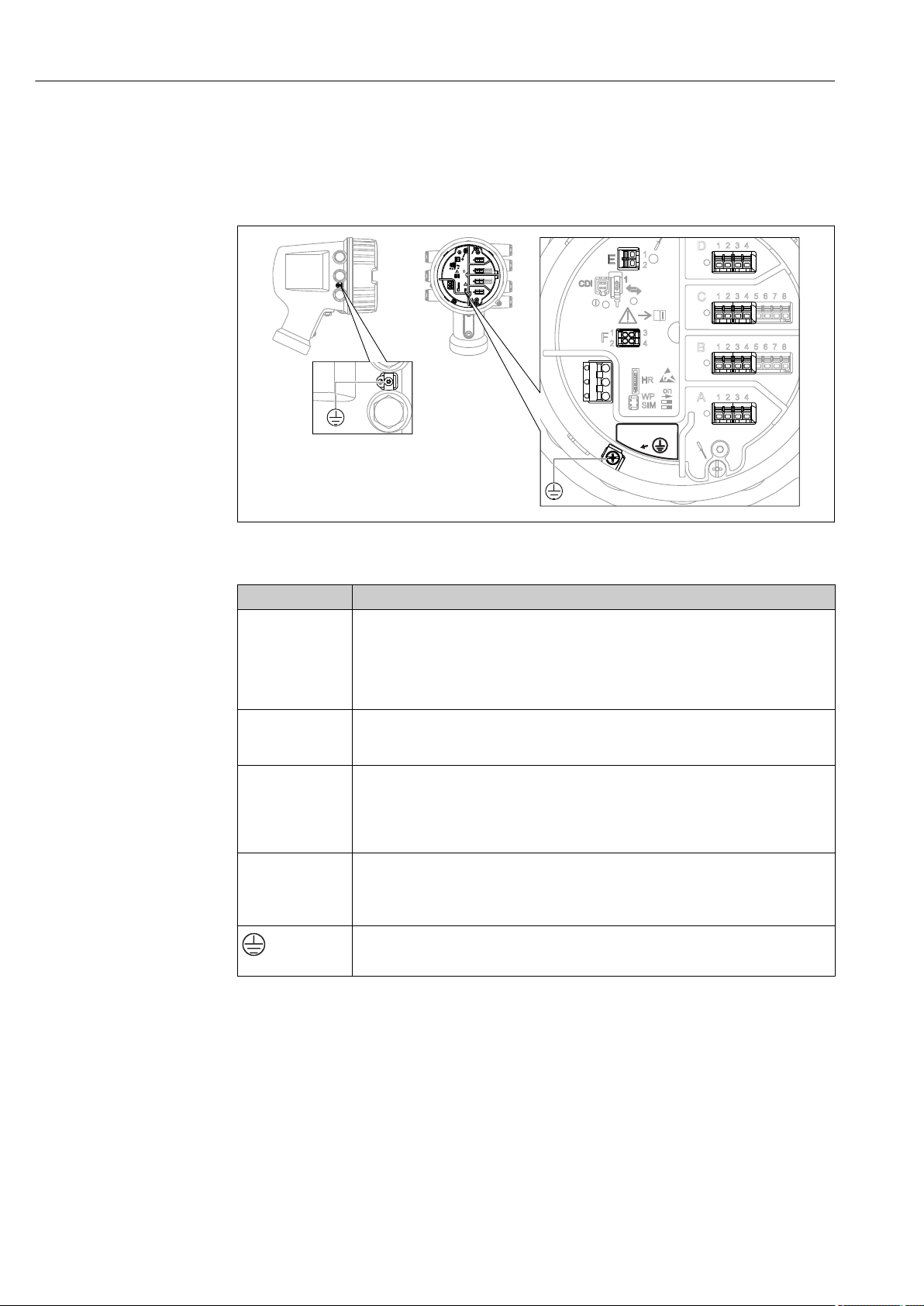

6.1.1 Power supply

A0033413

G1 N

G2 not connected

G3 L

4 Green LED: indicates power supply

Supply voltage

85 to 264 VAC, 50/60 Hz, 28.8 VA

1)

The supply voltage is also indicated on the nameplate.

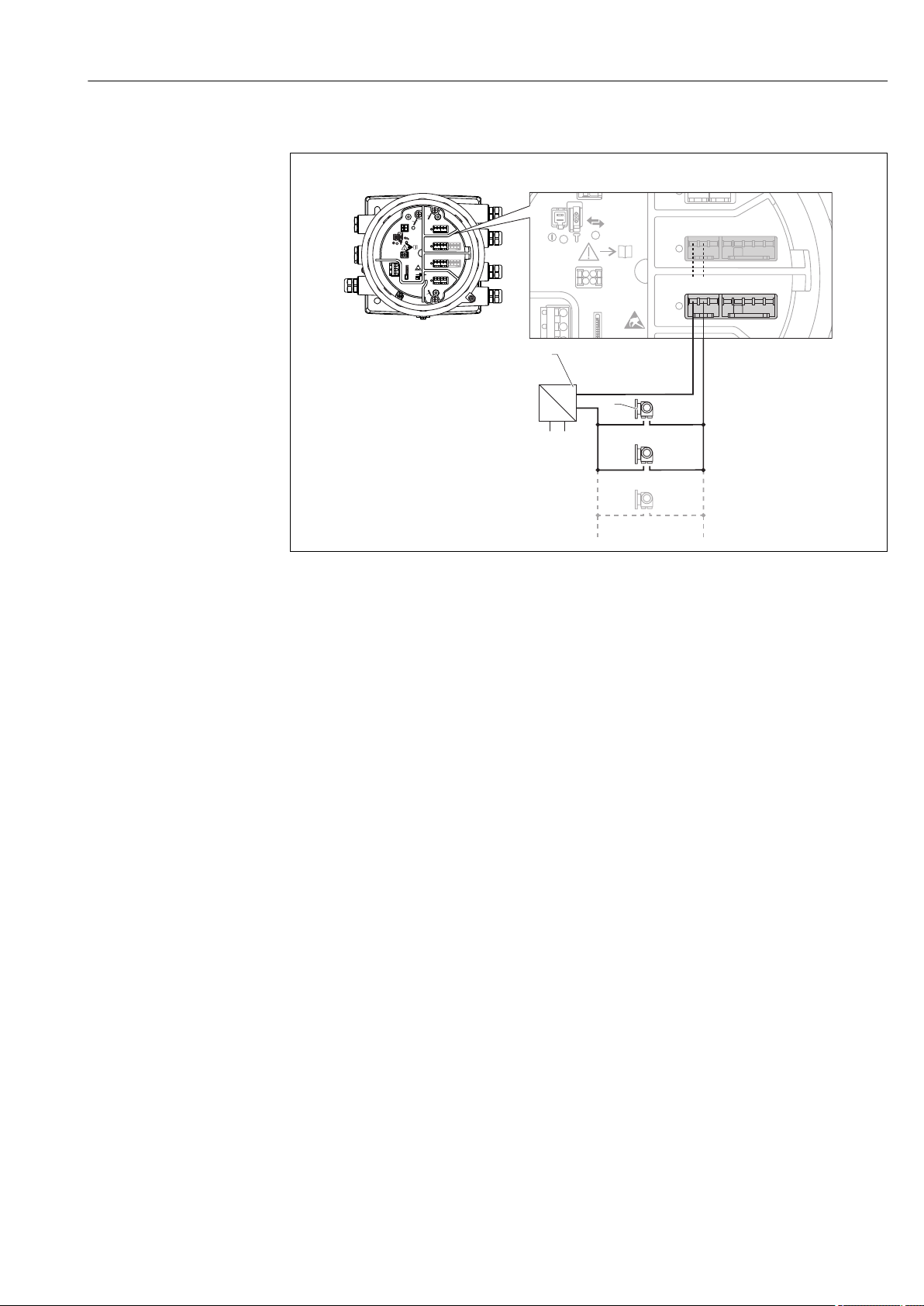

6.1.2 Remote display and operating module DKX001

5 Connection of the remote display and operating module DKX001 to the Tank Gauging device (NMR8x,

NMS8x or NRF8x)

1 Remote display and operating module

2 Connecting cable

3 Tank Gauging device (NMR8x, NMS8x or NRF8x)

A0037025

The remote display and operating module DKX001 is available as an accessory. For

details refer to SD01763D.

• The measured value is indicated on the DKX001 and on the local display and

operating module simulataneously.

• The operating menu cannot be accessed on both modules at the same time. If the

1) maximum value; actual value depending on modules installed. 28.8 VA includes the nominal power, and the cabling specification has to meet

Endress+Hauser 19

this value. On the other hand, the effective power consumption is 12 W.

operating menu is entered in one of these modules, the other module is

automatically locked. This locking remains active until the menu is closed in the

first module (back to measured value display).

Electrical connection Micropilot NMR84

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

E

1

1

2

CDI

i

G

1

3

2

POWER

3

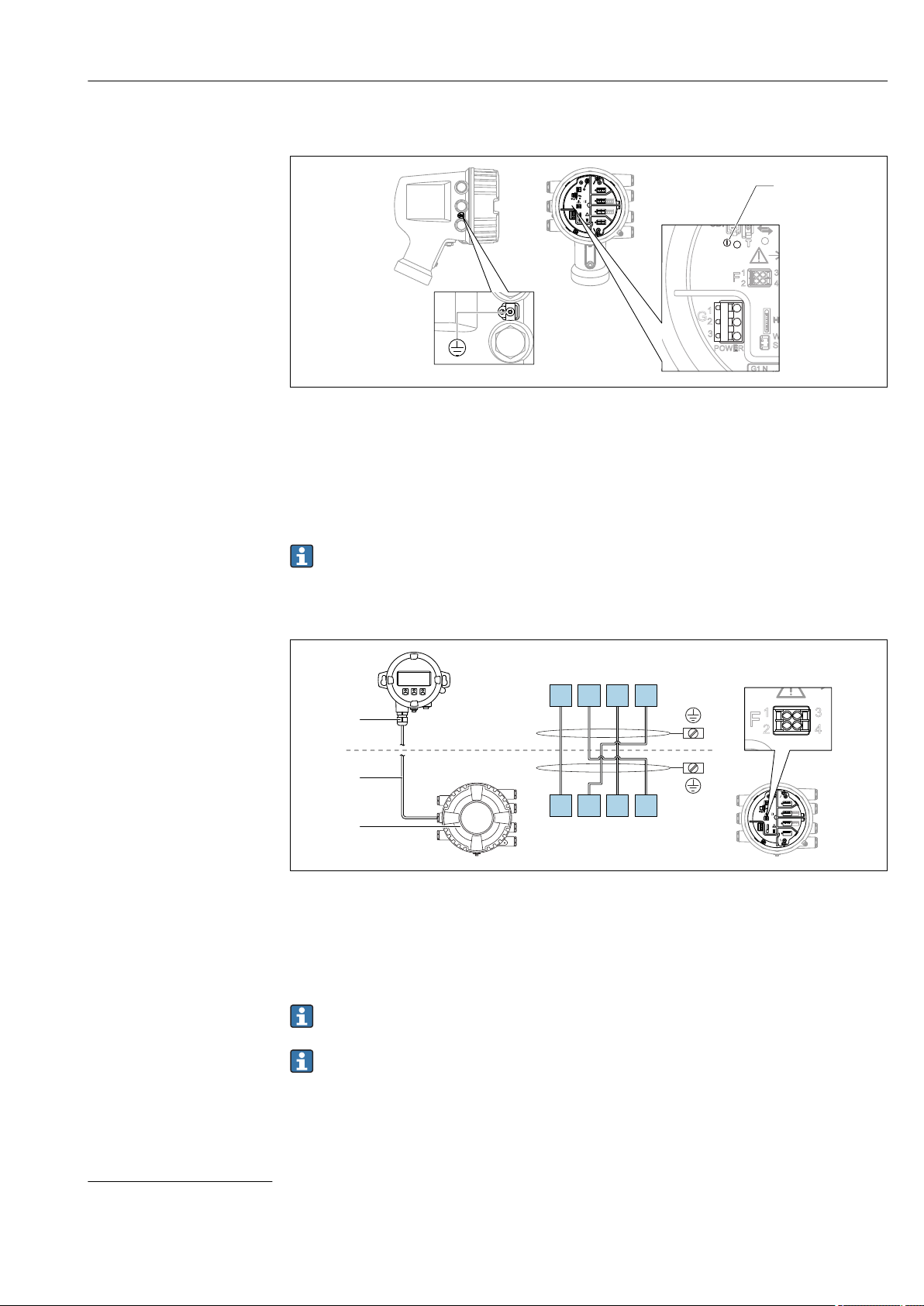

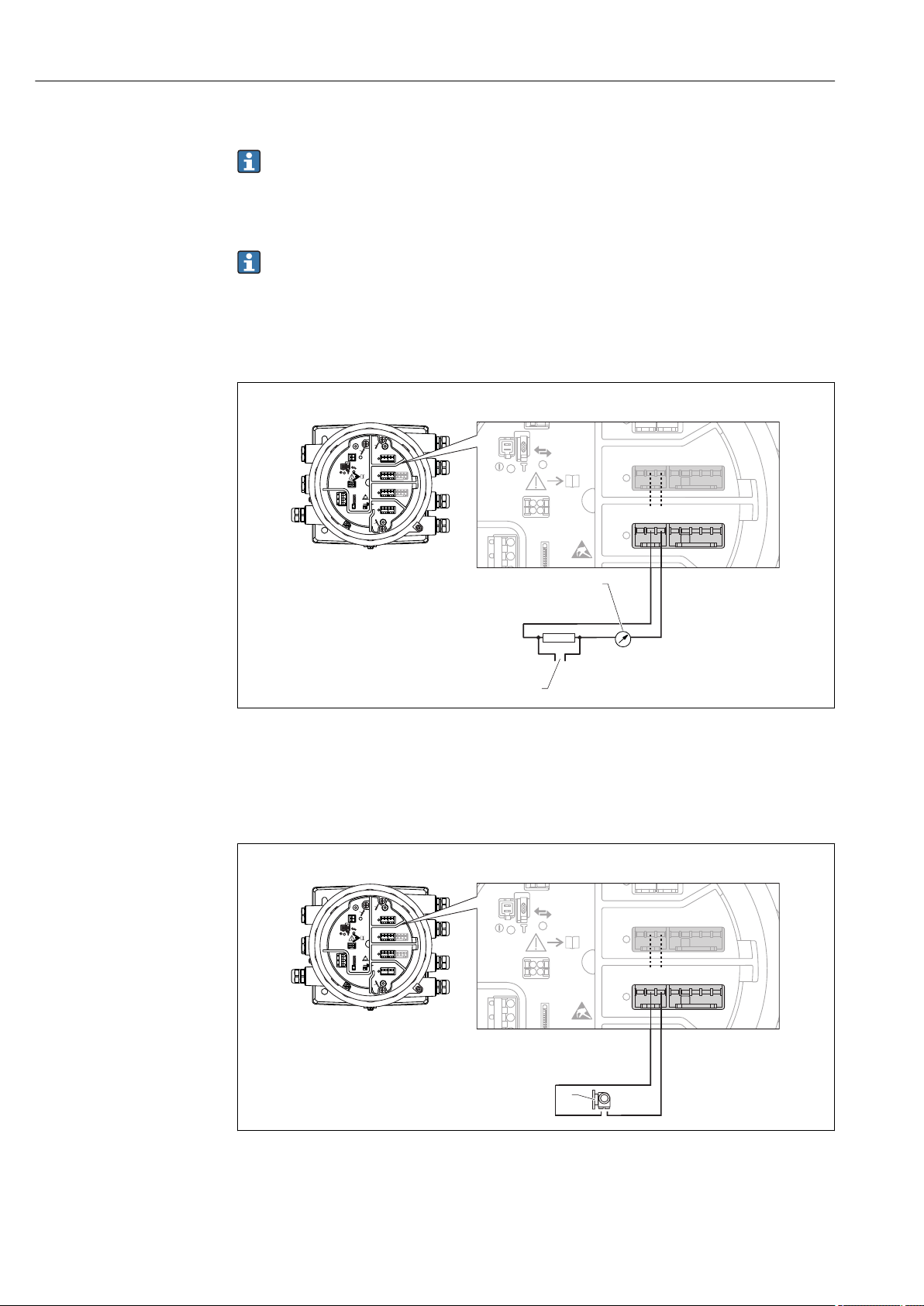

6.1.3 HART Ex i/IS interface

A0033414

E1 H+

E2 H3 Orange LED: indicates data communication

This interface always operates as the main HART master for connected HART slave

transmitters. The Analog I/O modules, on the other hand, can be configured as a

HART master or slave → 28 → 30.

20 Endress+Hauser

Micropilot NMR84 Electrical connection

Spare parts for: Proservo NMS81

Ser.-no.:

8A21AC098AF4

Spare part

Spare no./structure

Displacer

Wire Drum

Additional information:

XPF0002-AABICR+

AAEAEBEFLALC76

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

XPF0002-AABEFEG+

71273689

7122xxxx

XPF0002-AABEFEG+

AAAAACDEFEG+

XPF0002-AAACABADJ+

AAHAHCHRIJJAJBKP

71023451

71023451

71023451

Cover

IOM-V1

IOM-A/RTD

IOM-D

SlotA

Slot B

Slot C

Slot D

IO Mod FF

Display

Display asm.

Detector

Main electr.

SMS electr.

6

7

8

9

10

11

12

5

4

3

2

1

www.endress.com/deviceviewer

1

D

C

B

A

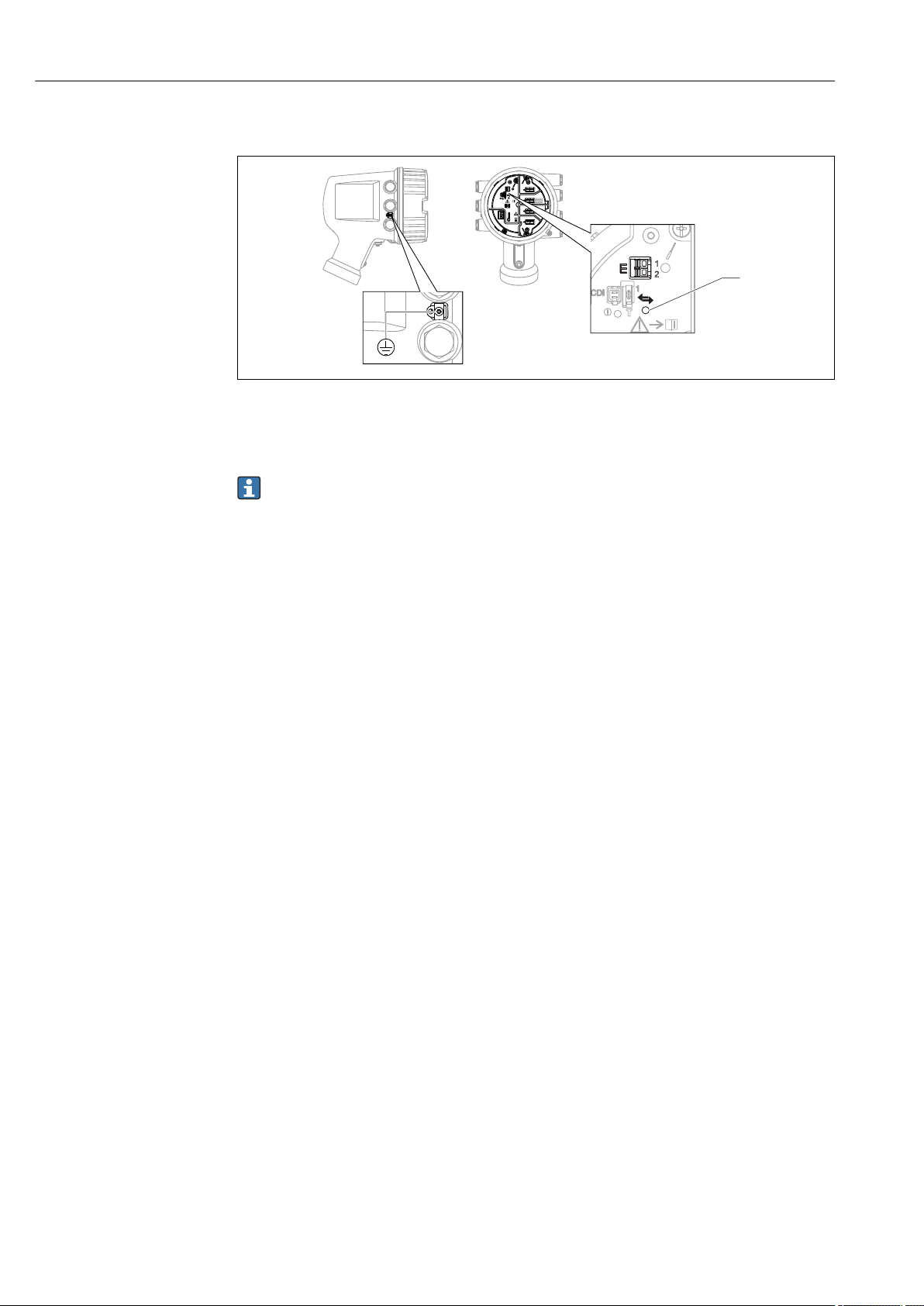

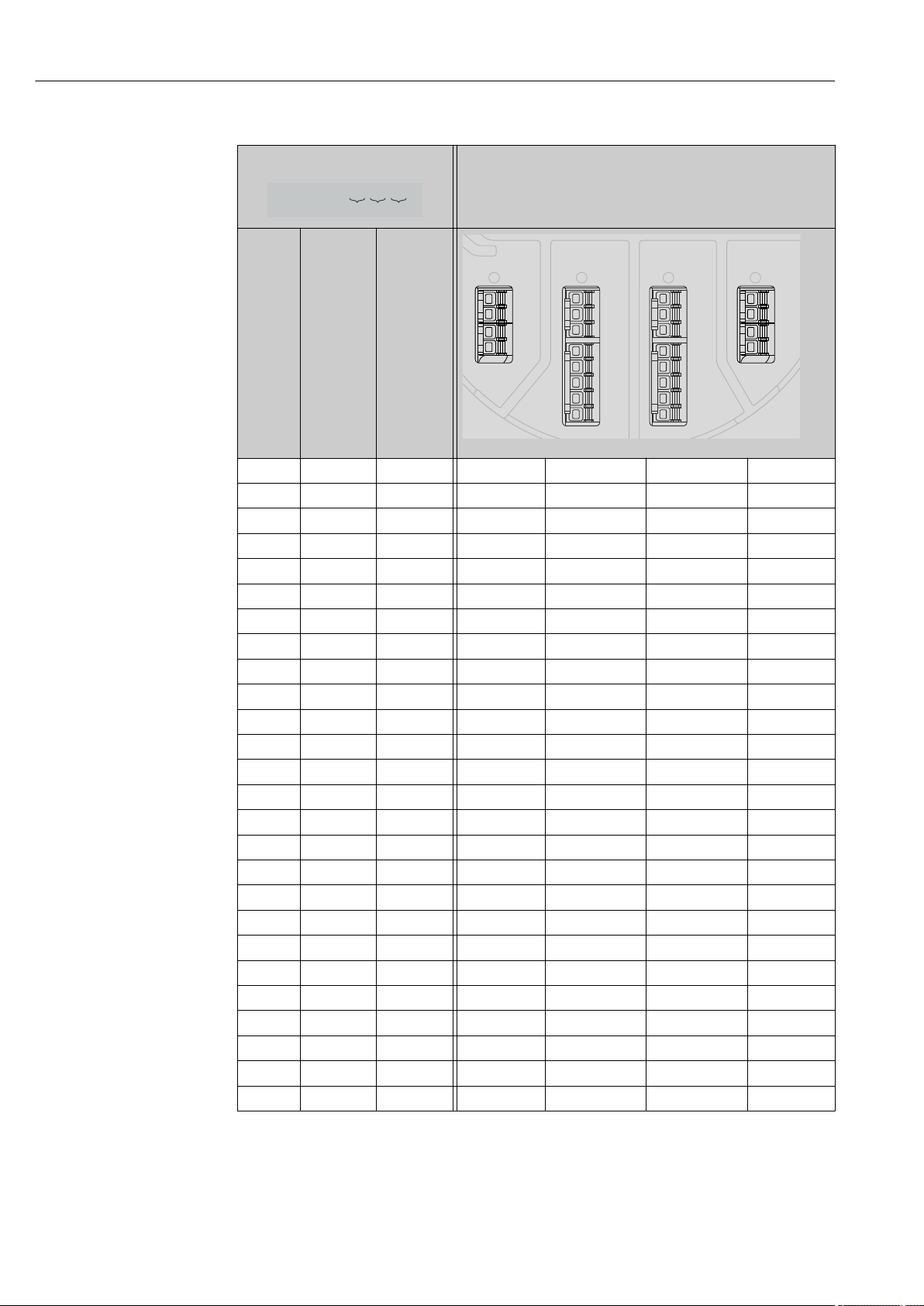

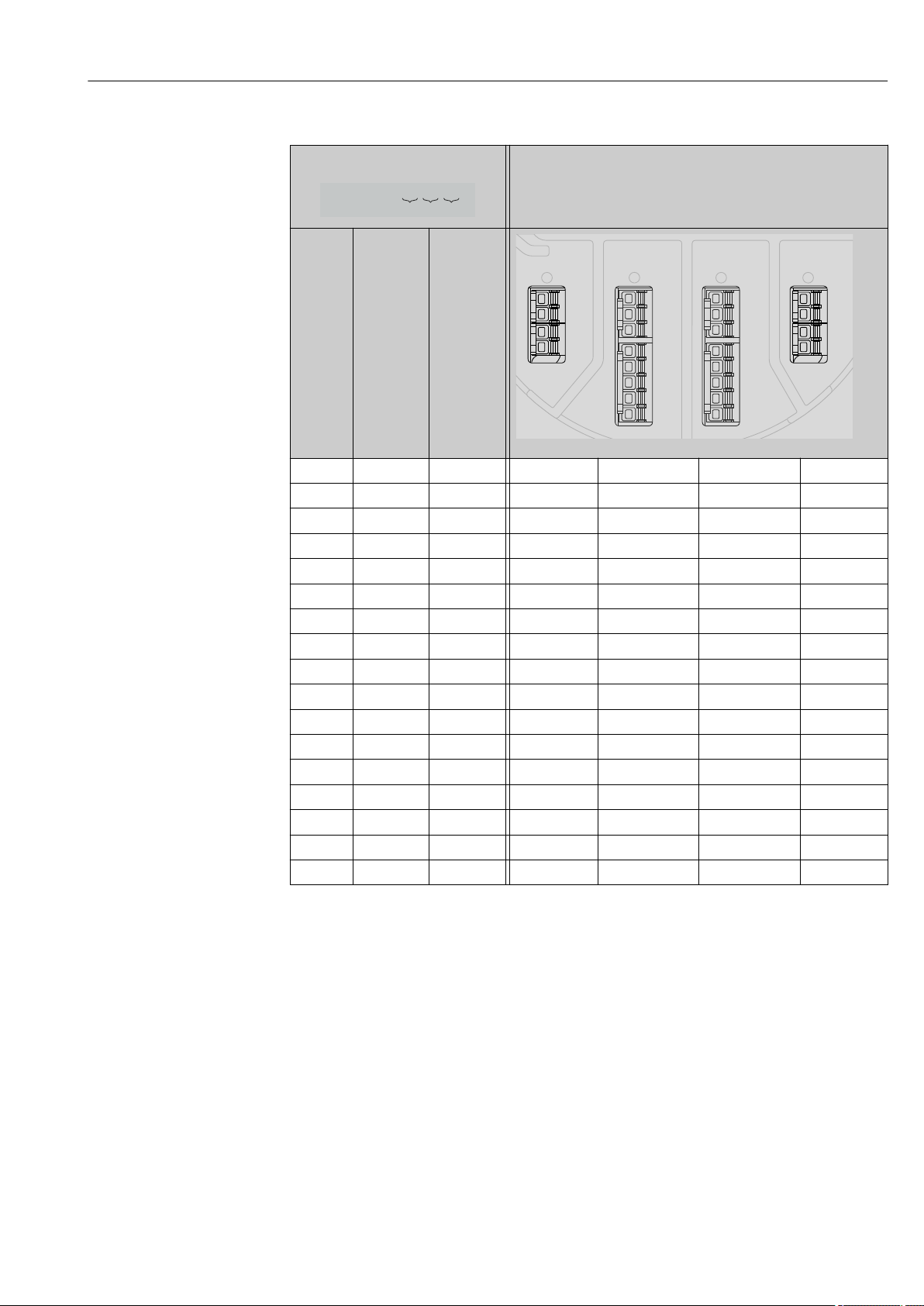

6.1.4 Slots for I/O modules

The terminal compartment contains four slots (A, B, C and D) for I/O modules. Depending

on the device version (ordering features 040, 050 and 060) these slots contain different

I/O modules. The table below shows which module is located in which slot for a specific

device version.

The slot assignment for the device is also indicated on a label attached to the back

cover of the display module.

A0030070

1 Label showing (among other things) the modules in the slots A to D.

A Cable entry for slot A

B Cable entry for slot B

C Cable entry for slot C

D Cable entry for slot D

Endress+Hauser 21

Electrical connection Micropilot NMR84

NMx8x - XX XX XXxxxx ...

060050040

D

C

B

A

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

"Primary Output" (040) = "Modbus" (A1)

Ordering feature

040

Primary

Output

A1 X0 X0 Modbus - - -

A1 X0 A1 Modbus - - Digital

A1 X0 A2 Modbus - Digital Digital

A1 X0 A3 Modbus Digital Digital Digital

A1 X0 B1 Modbus Modbus - -

A1 X0 B2 Modbus Modbus - Digital

A1 X0 B3 Modbus Modbus Digital Digital

A1 A1 X0 Modbus Analog Ex d/XP - -

A1 A1 A1 Modbus Analog Ex d/XP - Digital

A1 A1 A2 Modbus Analog Ex d/XP Digital Digital

A1 A1 B1 Modbus Modbus Analog Ex d/XP -

A1 A1 B2 Modbus Modbus Analog Ex d/XP Digital

A1 A2 X0 Modbus Analog Ex d/XP Analog Ex d/XP -

A1 A2 A1 Modbus Analog Ex d/XP Analog Ex d/XP Digital

A1 A2 B1 Modbus Analog Ex d/XP Analog Ex d/XP Modbus

A1 B1 X0 Modbus Analog Ex i/IS - -

A1 B1 A1 Modbus Analog Ex i/IS - Digital

A1 B1 A2 Modbus Analog Ex i/IS Digital Digital

A1 B1 B1 Modbus Modbus Analog Ex i/IS -

A1 B1 B2 Modbus Modbus Analog Ex i/IS Digital

A1 B2 X0 Modbus Analog Ex i/IS Analog Ex i/IS -

A1 B2 A1 Modbus Analog Ex i/IS Analog Ex i/IS Digital

A1 B2 B1 Modbus Analog Ex i/IS Analog Ex i/IS Modbus

A1 C2 X0 Modbus Analog Ex i/IS Analog Ex d/XP -

A1 C2 A1 Modbus Analog Ex i/IS Analog Ex d/XP Digital

A1 C2 B1 Modbus Analog Ex i/IS Analog Ex d/XP Modbus

050

Secondary

IO Analog

060

Secondary

IO Digital

Ex d/XP

Terminal area

A0023888

22 Endress+Hauser

Micropilot NMR84 Electrical connection

NMx8x - XX XX XXxxxx ...

060050040

D

C

B

A

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

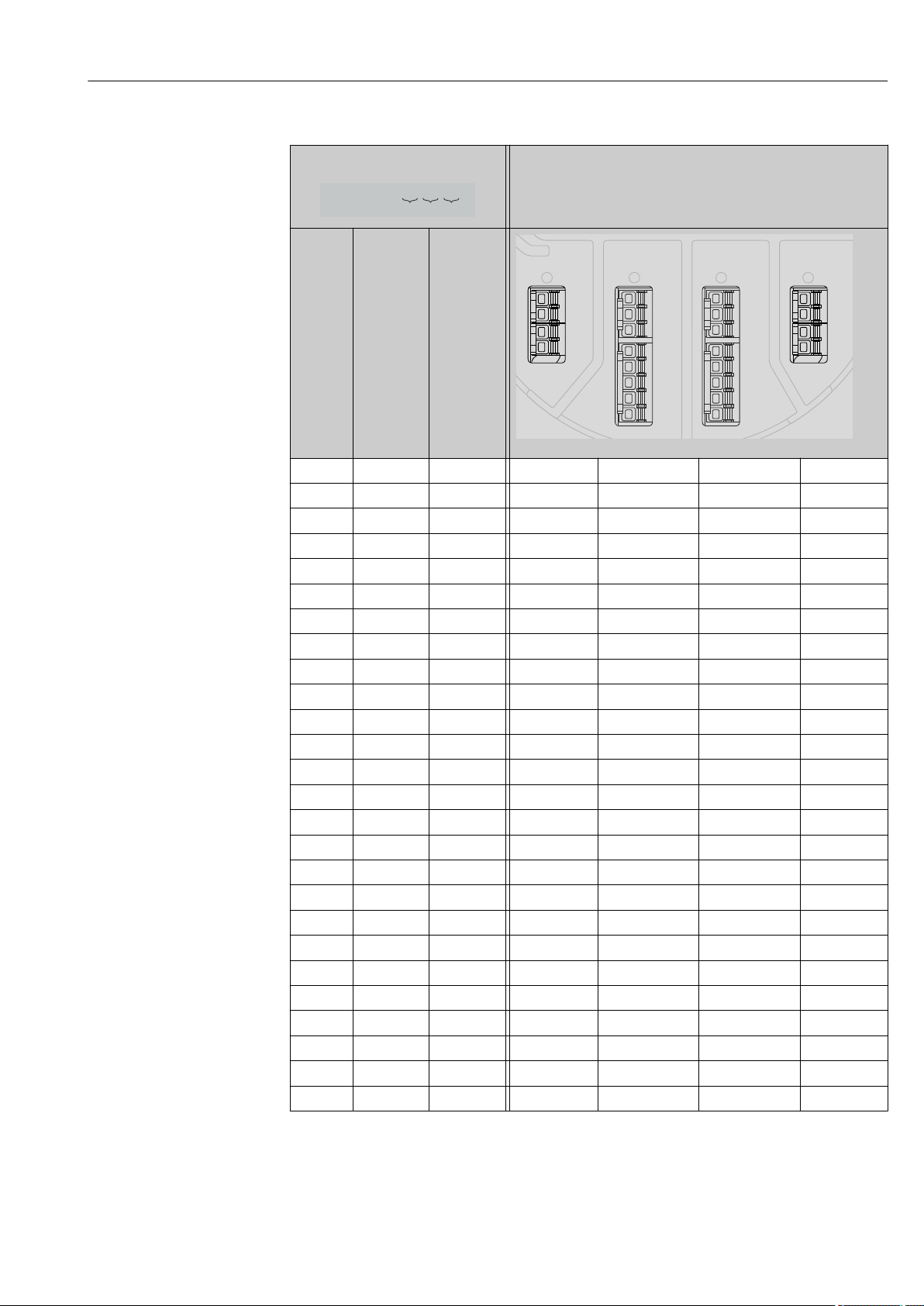

"Primary Output" (040) = "V1" (B1)

Ordering feature

040

Primary

Output

B1 X0 X0 V1 - - -

B1 X0 A1 V1 - - Digital

B1 X0 A2 V1 - Digital Digital

B1 X0 A3 V1 Digital Digital Digital

B1 X0 B1 V1 Modbus - -

B1 X0 B2 V1 Modbus - Digital

B1 X0 B3 V1 Modbus Digital Digital

B1 A1 X0 V1 Analog Ex d/XP - -

B1 A1 A1 V1 Analog Ex d/XP - Digital

B1 A1 A2 V1 Analog Ex d/XP Digital Digital

B1 A1 B1 V1 Modbus Analog Ex d/XP -

B1 A1 B2 V1 Modbus Analog Ex d/XP Digital

B1 A2 X0 V1 Analog Ex d/XP Analog Ex d/XP -

B1 A2 A1 V1 Analog Ex d/XP Analog Ex d/XP Digital

B1 A2 B1 V1 Analog Ex d/XP Analog Ex d/XP Modbus

B1 B1 X0 V1 Analog Ex i/IS - -

B1 B1 A1 V1 Analog Ex i/IS - Digital

B1 B1 A2 V1 Analog Ex i/IS Digital Digital

B1 B1 B1 V1 Modbus Analog Ex i/IS -

B1 B1 B2 V1 Modbus Analog Ex i/IS Digital

B1 B2 X0 V1 Analog Ex i/IS Analog Ex i/IS -

B1 B2 A1 V1 Analog Ex i/IS Analog Ex i/IS Digital

B1 B2 B1 V1 Analog Ex i/IS Analog Ex i/IS Modbus

B1 C2 X0 V1 Analog Ex i/IS Analog Ex d/XP -

B1 C2 A1 V1 Analog Ex i/IS Analog Ex d/XP Digital

B1 C2 B1 V1 Analog Ex i/IS Analog Ex d/XP Modbus

050

Secondary

IO Analog

060

Secondary

IO Digital

Ex d/XP

Terminal area

A0023888

Endress+Hauser 23

Electrical connection Micropilot NMR84

NMx8x - XX XX XXxxxx ...

060050040

D

C

B

A

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

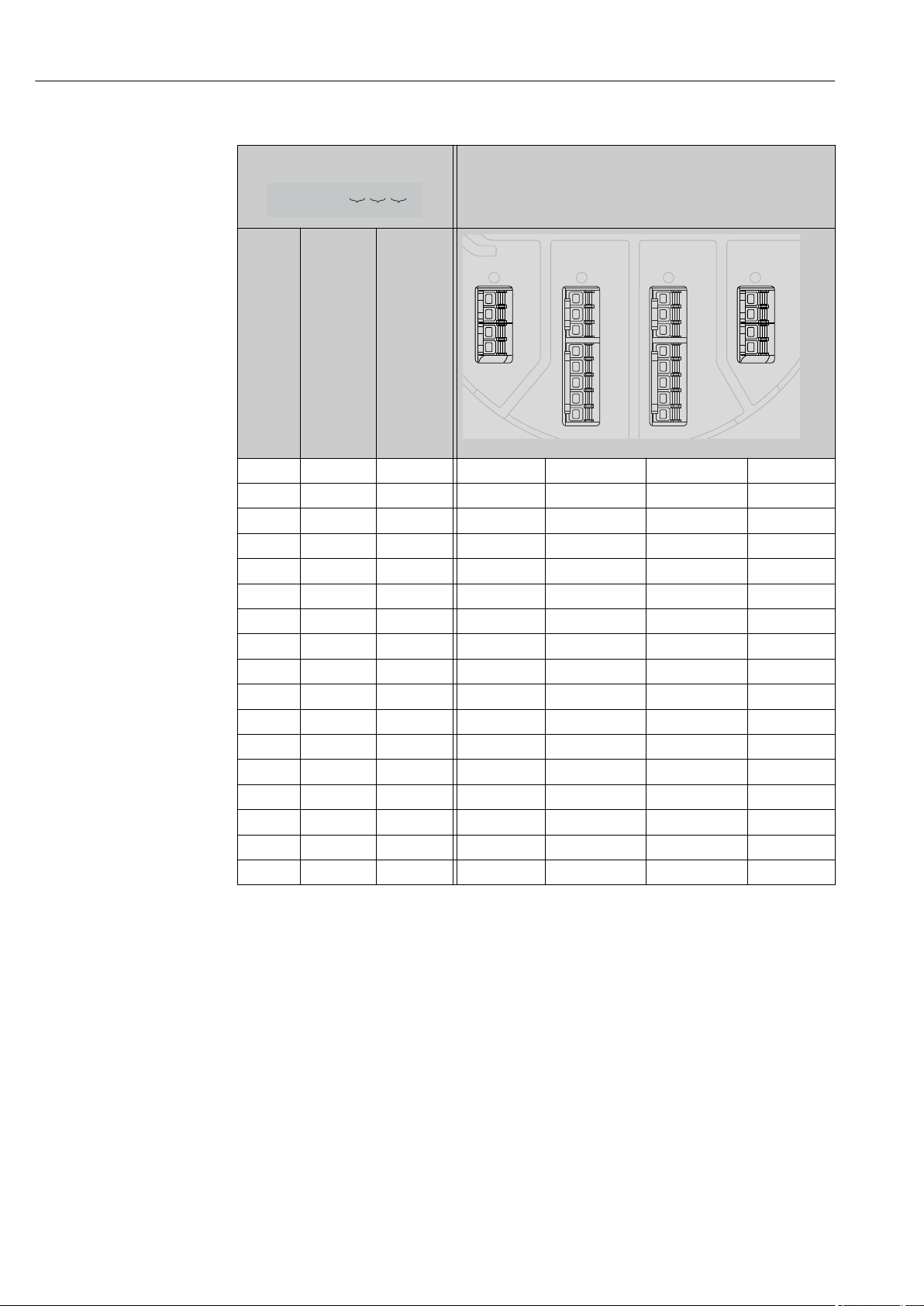

"Primary Output" (040) = "4-20mA HART Ex d" (E1)

Ordering feature

040

Primary

Output

E1 X0 X0 - Analog Ex d/XP - -

E1 X0 A1 - Analog Ex d/XP - Digital

E1 X0 A2 - Analog Ex d/XP Digital Digital

E1 X0 A3 Digital Analog Ex d/XP Digital Digital

E1 X0 B1 Modbus Analog Ex d/XP - -

E1 X0 B2 Modbus Analog Ex d/XP - Digital

E1 X0 B3 Modbus Analog Ex d/XP Digital Digital

E1 A1 X0 - Analog Ex d/XP Analog Ex d/XP -

E1 A1 A1 - Analog Ex d/XP Analog Ex d/XP Digital

E1 A1 A2 Digital Analog Ex d/XP Analog Ex d/XP Digital

E1 A1 B1 Modbus Analog Ex d/XP Analog Ex d/XP -

E1 A1 B2 Modbus Analog Ex d/XP Analog Ex d/XP Digital

E1 B1 X0 - Analog Ex d/XP Analog Ex i/IS -

E1 B1 A1 - Analog Ex d/XP Analog Ex i/IS Digital

E1 B1 A2 Digital Analog Ex d/XP Analog Ex i/IS Digital

E1 B1 B1 Modbus Analog Ex d/XP Analog Ex i/IS -

E1 B1 B2 Modbus Analog Ex d/XP Analog Ex i/IS Digital

050

Secondary

IO Analog

060

Secondary

IO Digital

Ex d/XP

Terminal area

A0023888

24 Endress+Hauser

Micropilot NMR84 Electrical connection

NMx8x - XX XX XXxxxx ...

060050040

D

C

B

A

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

"Primary Output" (040) = "4-20mA HART Ex i" (H1)

Ordering feature

040

Primary

Output

H1 X0 X0 - Analog Ex i/IS - -

H1 X0 A1 - Analog Ex i/IS - Digital

H1 X0 A2 - Analog Ex i/IS Digital Digital

H1 X0 A3 Digital Analog Ex i/IS Digital Digital

H1 X0 B1 Modbus Analog Ex i/IS - -

H1 X0 B2 Modbus Analog Ex i/IS - Digital

H1 X0 B3 Modbus Analog Ex i/IS Digital Digital

H1 A1 X0 - Analog Ex i/IS Analog Ex d/XP -

H1 A1 A1 - Analog Ex i/IS Analog Ex d/XP Digital

H1 A1 A2 Digital Analog Ex i/IS Analog Ex d/XP Digital

H1 A1 B1 Modbus Analog Ex i/IS Analog Ex d/XP -

H1 A1 B2 Modbus Analog Ex i/IS Analog Ex d/XP Digital

H1 B1 X0 - Analog Ex i/IS Analog Ex i/IS -

H1 B1 A1 - Analog Ex i/IS Analog Ex i/IS Digital

H1 B1 A2 Digital Analog Ex i/IS Analog Ex i/IS Digital

H1 B1 B1 Modbus Analog Ex i/IS Analog Ex i/IS -

H1 B1 B2 Modbus Analog Ex i/IS Analog Ex i/IS Digital

050

Secondary

IO Analog

060

Secondary

IO Digital

Ex d/XP

Terminal area

A0023888

Endress+Hauser 25

Electrical connection Micropilot NMR84

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

WP

on

SIM

2

23344

112233445566778

8

A

1 2 3 4

A1-4

i

D

1

2 3 4

D1-4

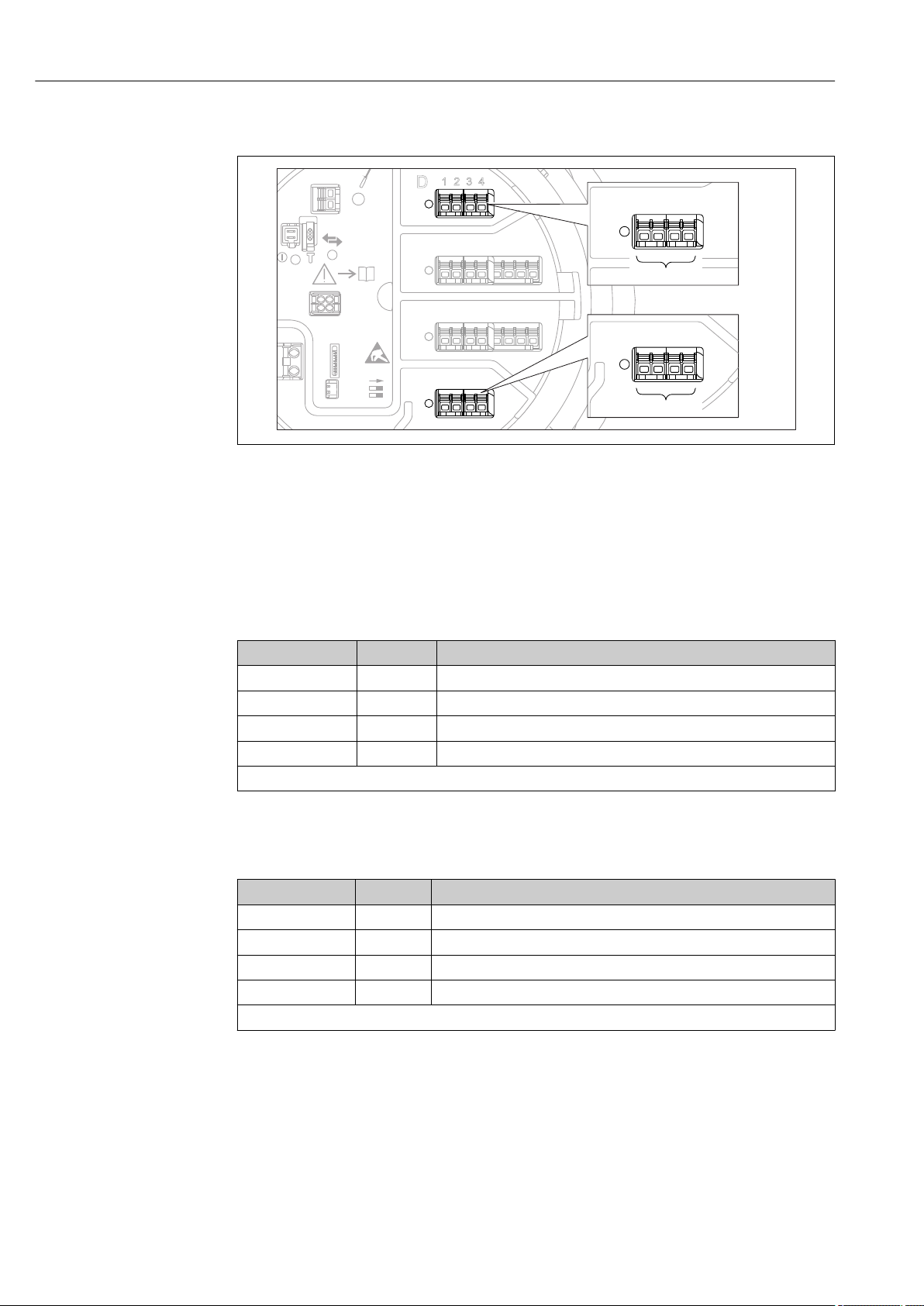

6.1.5 Terminals of the "Modbus" or "V1" module

A0031200

6 Designation of the "Modbus" or "V1" modules (examples); depending on the device version these modules

may also be in slot B or C.

Depending on the device version, the "Modbus" and/or "V1" module may be in different

slots of the terminal compartment. In the operating menu the "Modbus" and "V1" interfaces

are designated by the respective slot and the terminals within this slot: A1-4, B1-4, C1-4,

D1-4.

Terminals of the "Modbus" module

Terminal

X1 S Cable shielding connected via a capacitor to EARTH

X2 0V Common reference

X3 B- Non-inverting signal line

X4 A+ Inverting signal line

Designation of the module in the operating menu: Modbus X1-4; (X = A, B, C or D)

1) In this column, "X" stands for one of the slots "A", "B", "C", or "D".

1)

Name Description

Terminals of the "V1" module

Terminal

X1 S Cable shielding connected via capacitor to EARTH

X2 not connected

X3 B- Protocol loop signal -

X4 A+ Protocol loop signal +

Designation of the module in the operating menu: V1 X1-4; (X = A, B, C or D)

1)

Name Description

26 Endress+Hauser

1) In this column, "X" stands for one of the slots "A", "B", "C", or "D".

Micropilot NMR84 Electrical connection

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

WP

on

SIM

22334

4

112233445566778

8

i

B

1 2 3 4 5 6 7 8

B1-3 B4-8

C

1 2 3 4 5 6 7 8

C1-3 C4-8

6.1.6 Terminals of the "Analog I/O" module (Ex d /XP or Ex i/IS)

A0031168

Terminals Function Connection diagrams Designation in the operating menu

B1-3 Analog input or output

C1-3 Analog I/O C1-3 (→ 140)

B4-8 Analog input RTD: → 31 Analog IP B4-8 (→ 134)

C4-8 Analog IP C4-8 (→ 134)

(configurable)

• Passive usage: → 28

• Active usage: → 30

Analog I/O B1-3 (→ 140)

Endress+Hauser 27

Electrical connection Micropilot NMR84

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

ca

b

-

+

!

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

a

+

–

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

b

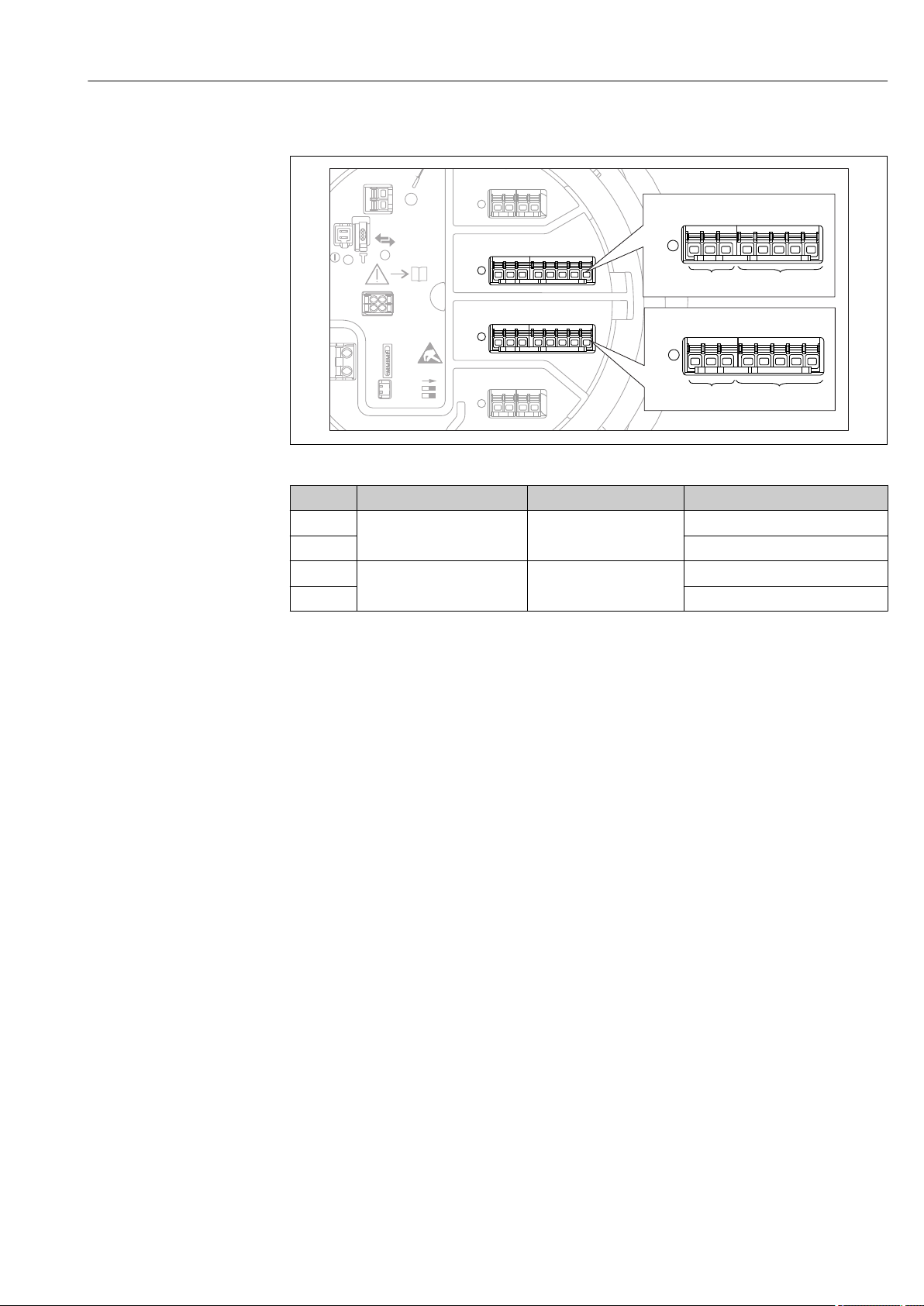

6.1.7 Connection of the "Analog I/O" module for passive usage

• In the passive usage the supply voltage for the communication line must be supplied

by an external source.

• The wiring must be in accordance with the intended operating mode of the Analog

I/O module; see the drawings below.

• Screened cable must be used for the 4...20mA signal line.

"Operating mode" = "4..20mA output" or "HART slave +4..20mA output"

A0027931

7 Passive usage of the Analog I/O module in the output mode

a Power supply

b HART signal output

c Analog signal evaluation

"Operating mode" = "4..20mA input" or "HART master+4..20mA input"

28 Endress+Hauser

8 Passive usage of the Analog I/O module in the input mode

a Power supply

b External device with 4...20mA and/or HART signal output

A0027933

Micropilot NMR84 Electrical connection

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

a

+

–

!

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

b

"Operating mode" = "HART master"

A0027934

9 Passive usage of the Analog I/O module in the HART master mode

a Power supply

b Up to 6 external devices with HART signal output

Endress+Hauser 29

Electrical connection Micropilot NMR84

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

b

a

-

+

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

-

+

a

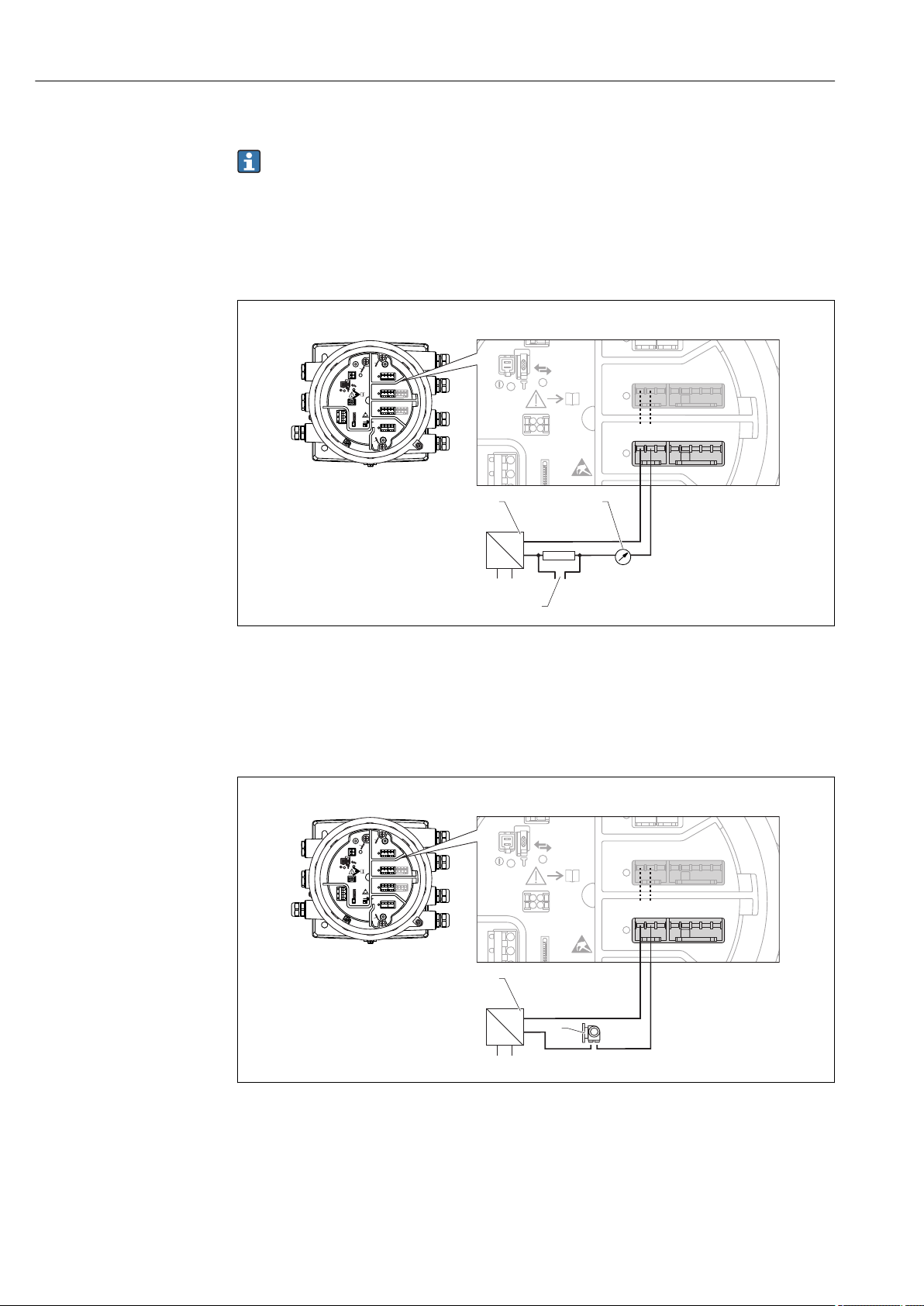

6.1.8 Connection of the "Analog I/O" module for active usage

• In the active usage the supply voltage for the communication line is supplied by the

device itself. There is no need of an external power supply.

• The wiring must be in accordance with the intended operating mode of the Analog

I/O module; see the drawings below.

• Screened cable must be used for the 4...20mA signal line.

• Maximum current consumption of the connected HART devices: 24 mA

(i.e. 4 mA per device if 6 devices are connected).

• Output voltage of the Ex-d module: 17.0 V@4 mA to 10.5 V@22 mA

• Output voltage of the Ex-ia module: 18.5 V@4 mA to 12.5 V@22 mA

"Operating mode" = "4..20mA output" or "HART slave +4..20mA output"

A0027932

10 Active usage of the Analog I/O module in the output mode

a HART signal output

b Analog signal evaluation

"Operating mode" = "4..20mA input" or "HART master+4..20mA input"

30 Endress+Hauser

11 Active usage of the Analog I/O module in the input mode

a External device with 4...20mA and/or HART signal output

A0027935

Loading...

Loading...