TI01253G/00/EN/02.17

71355020

Products

Solutions Services

Technical Information

Micropilot NMR84

Tank Gauging

Application

Micropilot NMR8x Series intelligent tank gauges are designed for high accuracy

liquid level measurement in storage and process applications. They fulfill the

exacting demands of tank inventory management, inventory control, custody

transfer, loss control, total cost saving, and safe operation.

Typical areas of application

• Precise level measurement of oil (fuels), chemicals, and alcohol in stilling wells

• Tank mounted intelligence makes NMR8x ideal for single or multi-task

installations, measuring the liquid level and integrating a wide range of tank

sensor measurement functions including: Liquid level, Water level, Temperature

and Pressure.

Your benefits

• SIL2 certified (Min, Max, Continuous level)

• SIL3 (in preparation)

• Up to 6 SIL relay outputs

• Measures liquid level to an accuracy of +/- 0.5 mm (0.02 in)

• Wetted parts are completely separated from the electronic circuit

• Tank top mounting as small as 4"/DN100 flange

• Wide range of output signals including V1, Modbus RS 485, and HART protocol

• Suitable for atmospheric and high pressure applications up to 25 bar/2.5 MPa/

362 psi

• Maintenance prediction of the instrument

• Integration of e.g. temperature, water level, pressure, overfill prevention sensor

• Direct connection of spot or average temperature sensor

• Robust IP66/68, NEMA Type 4x/6P enclosure

• Operation and display in a wide variety of local languages

Table of contents

Micropilot NMR84

Document information ....................... 3

Symbols .................................... 3

Function and system design ................... 5

Measuring principle ............................ 5

Integration of tank sensors ....................... 6

Measuring system ............................. 7

Input/output ............................... 8

Level measurement ............................ 8

HART Ex ia/IS active input ....................... 9

I/O modules ................................ 10

Power supply ............................. 16

Terminal assignment .......................... 16

Supply voltage .............................. 16

Cable entries ............................... 17

Cable specification ............................ 17

Overvoltage protection ......................... 17

Performance characteristics .................. 18

Reference operating conditions ................... 18

Measured value resolution ...................... 18

Maximum measured error ....................... 18

Hysteresis ................................. 18

Repeatability ............................... 18

Linearity .................................. 18

Long-term drift .............................. 18

Influence of ambient temperature ................. 18

Installation ............................... 19

Installation conditions ......................... 19

Environment .............................. 20

Ambient temperature range ..................... 20

Ambient temperature limits ..................... 20

Classification of environmental conditions according to

DIN EN 60721-3-4 ........................... 21

Storage temperature .......................... 21

Humidity .................................. 21

Degree of protection .......................... 21

Shock resistance ............................. 21

Vibration resistance ........................... 21

Electromagnetic compatibility (EMC) ............... 21

Operability ............................... 32

Operating concept ............................ 32

Operating options ............................ 32

Local operation .............................. 32

Remote operation ............................ 33

Operation via service interface .................... 33

Certificates and approvals ................... 34

CE mark ................................... 34

RCM-Tick marking ............................ 34

Ex approval ................................ 34

Single seal according to ANSI/ISA 12.27.01 ........... 34

Functional Safety (SIL) ......................... 34

WHG ..................................... 34

Weight & Measure approval ..................... 34

Radio standard EN302372-1/2 ................... 34

FCC / Industry Canada ......................... 34

Non-ionizing radiation protection .................. 35

CRN approval ............................... 35

Pressure equipment with allowable pressure

≤ 200 bar (2 900 psi) .......................... 35

Test, certificate .............................. 35

Other standards and guidelines ................... 36

Ordering information ....................... 37

Ordering information .......................... 37

Calibration certificate .......................... 37

Marking .................................. 37

Application packages ....................... 38

Advanced tank measurement methods .............. 38

Accessories ............................... 41

Device-specific accessories ...................... 41

Communication-specific accessories ................ 42

Service-specific accessories ...................... 42

System components ........................... 42

Documentation ............................ 43

Technical Information (TI) ...................... 43

Brief Operating Instructions (KA) .................. 43

Operating Instructions (BA) ..................... 43

Description of Device Parameters (GP) ............... 43

Safety instructions (XA) ........................ 44

Process .................................. 22

Process temperature range ...................... 22

Process pressure range ......................... 22

Dielectric constant ............................ 22

Registered trademarks ...................... 45

Custody transfer approval ................... 23

Mechanical construction .................... 24

Dimensions ................................ 24

Weight ................................... 28

Materials .................................. 29

2 Endress+Hauser

Micropilot NMR84

DANGER

WARNING

CAUTION

NOTICE

A

Document information

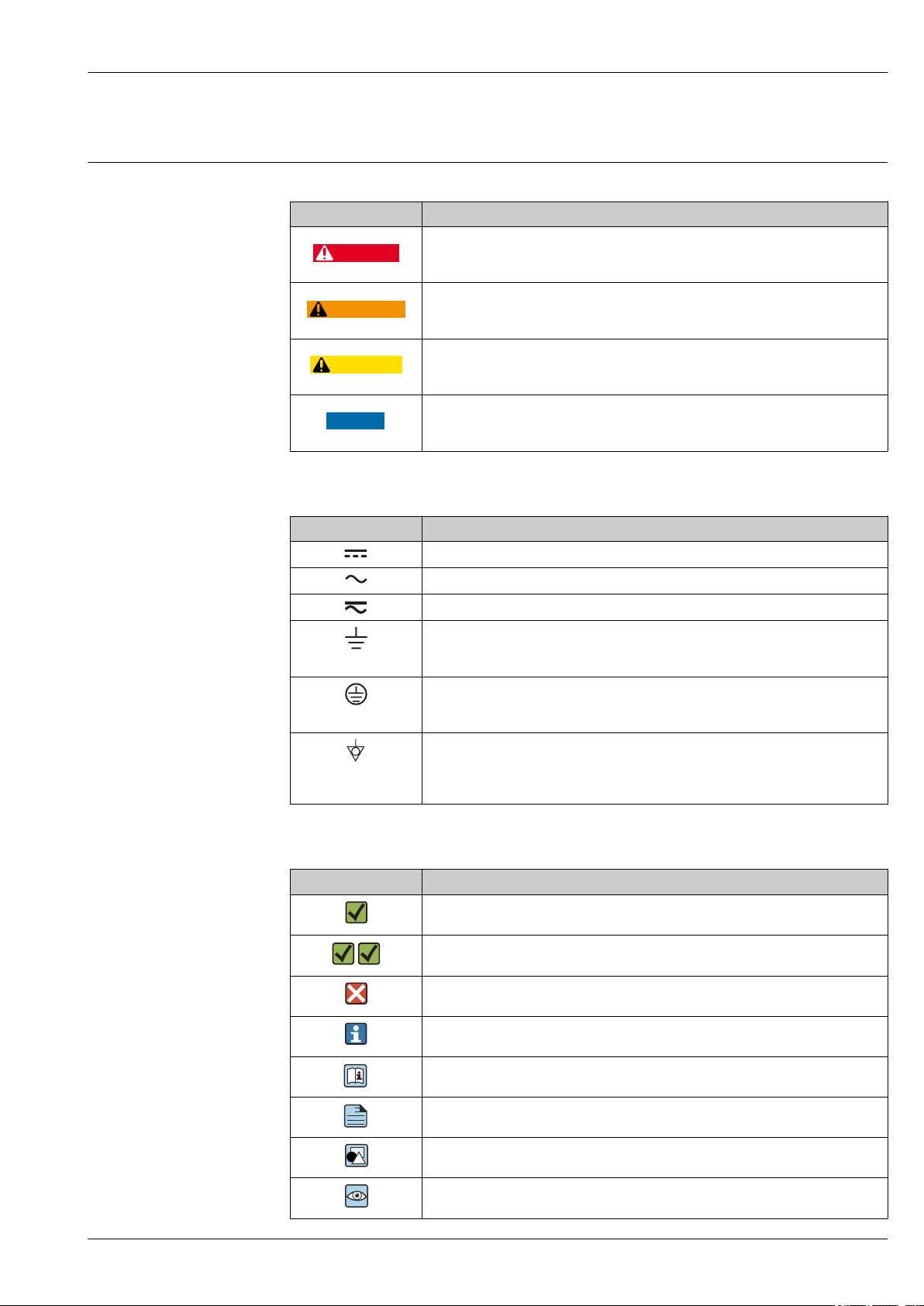

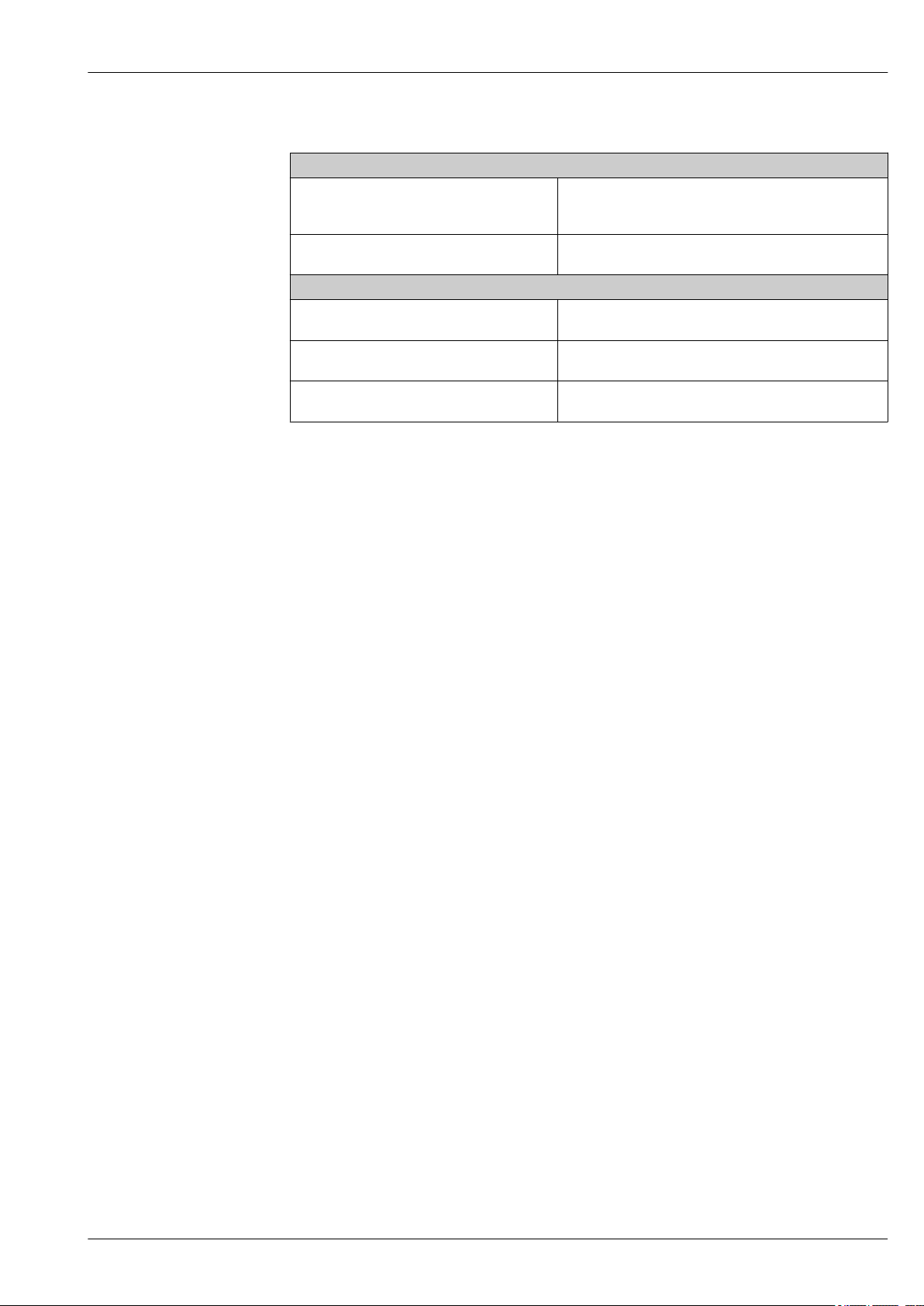

Symbols Safety symbols

Symbol Meaning

Electrical symbols

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a

potential equalization line or a star grounding system depending on national or

company codes of practice.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Visual inspection

Endress+Hauser 3

Symbols in graphics

1.

-

.

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

Micropilot NMR84

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

4 Endress+Hauser

Micropilot NMR84

D

R

f

t

1

2

f

2

f

1

Δt

Δf

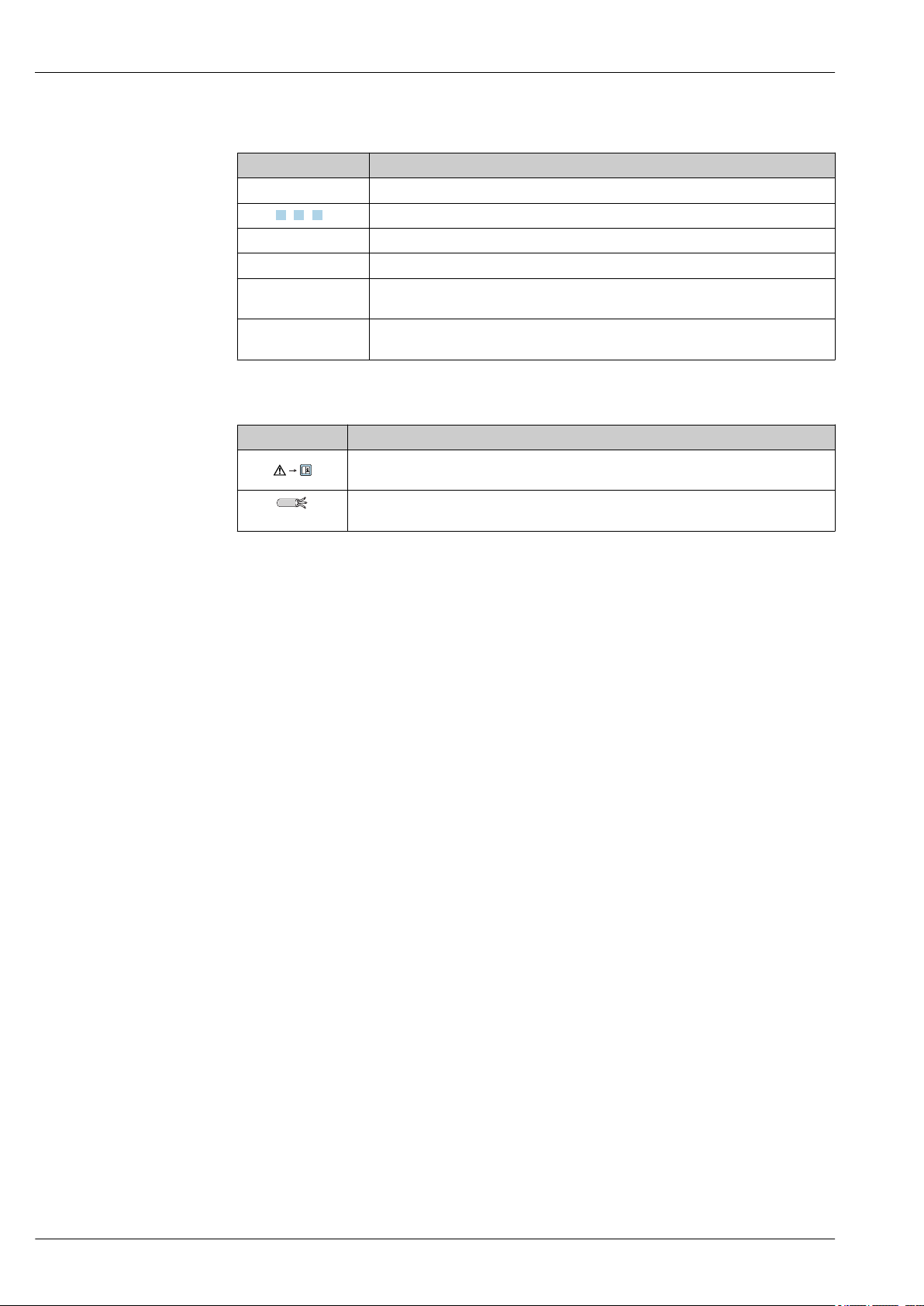

Function and system design

Measuring principle

Micropilot is a directional level radar, operating based on the "Frequency-Modulated Continuous

Wave" principle (FMCW). The radar emits a precise crystal-oscillated, continuously varying frequency

wave from the antenna. The wave is reflected off the product surface and received again by the radar

system.

A0023768

1 FMCW principle: Emission and reflection of the continuous wave.

R Reference point of the measurement

D Distance between R and the product surface

The frequency of this wave is precisely modulated in the form of a sawtooth signal between two limit

frequencies f1 and f2:

A0023771

2 FMCW principle: Results of the frequency modulation

1 Emitted signal

2 Received signal

Thus, at any given time the frequencies of the emitted and the received signal differ by

Δf = k Δt

where Δt is the transit time and k is the known slope of the frequency modulation.

Δt, on the other hand, is determined by the distance D between the reference point R and the

product surface:

D = (c Δt) / 2

where c is the speed of propagation of the wave.

In summary, D can be calculated from the measured frequency shift Δf. D is then used to calculate

the contents of the tank.

Endress+Hauser 5

Micropilot NMR84

3 3

4 4

2 2

1 1

HART 4-20 mA

A

B

HART HART

5 5

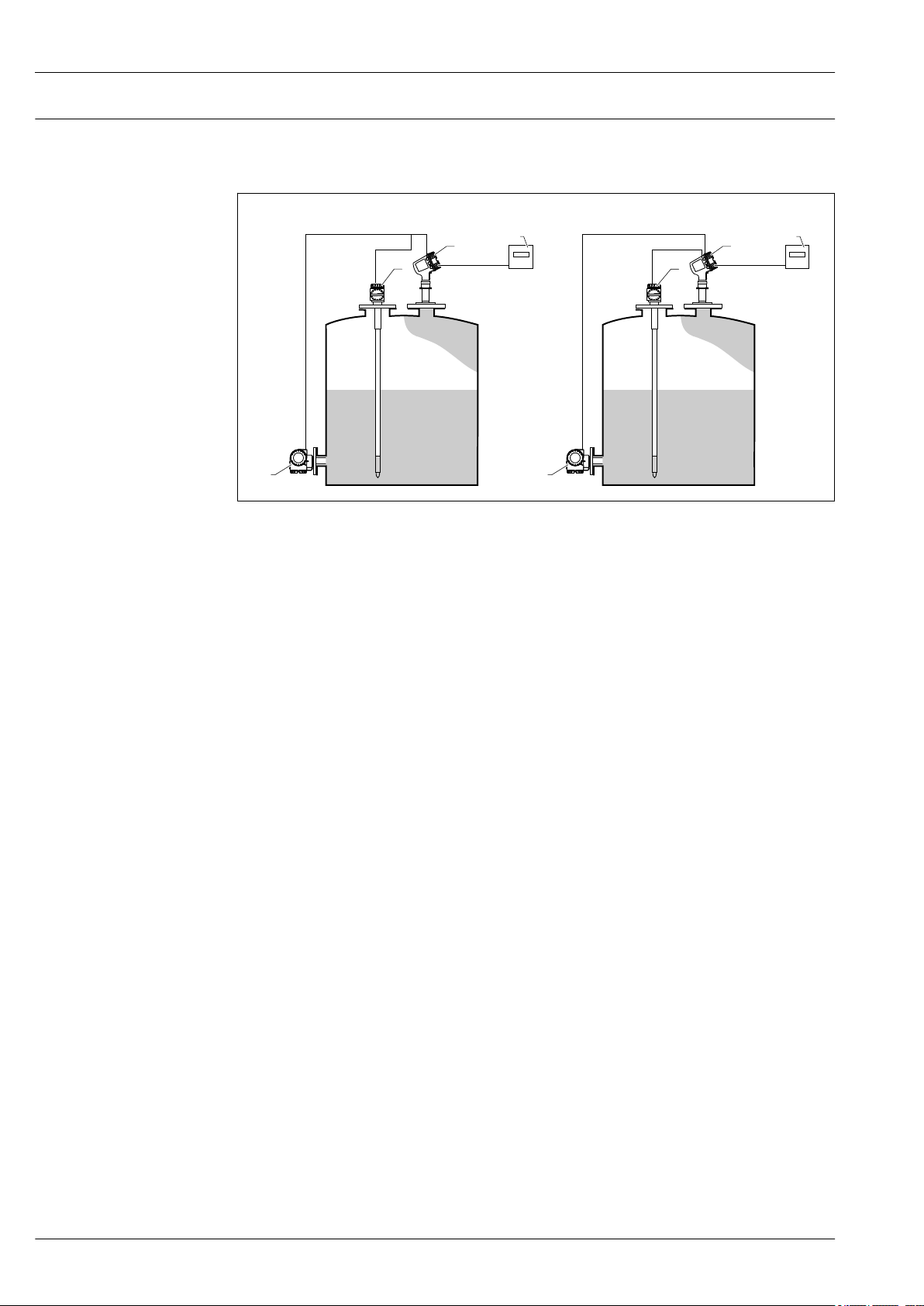

Integration of tank sensors

In addition to measuring the level, the device can also be used for the integration of tank sensors

into tank inventory systems. All measured and calculated values can be displayed at the built-in

display. Via a field communication protocol, they can be transferred to an inventory control system.

A0023767

3 Integration of tank sensors with Micropilot (Example)

A HART multidrop mode

B HART and analog mode

1 Pressure transmitter

2 Average temperature transmitter

3 Micropilot

4 Field protocol transmits data to an inventory control system

5 Inventory control system (e.g. Tankvision NXA820 or Tankvision Professional NXA85)

6 Endress+Hauser

Micropilot NMR84

NXA820

NXA820

NXA820

NXA820

8

9

10

12

7

1

2

23 3 5 2 3

4 6

8

13

11

15

14

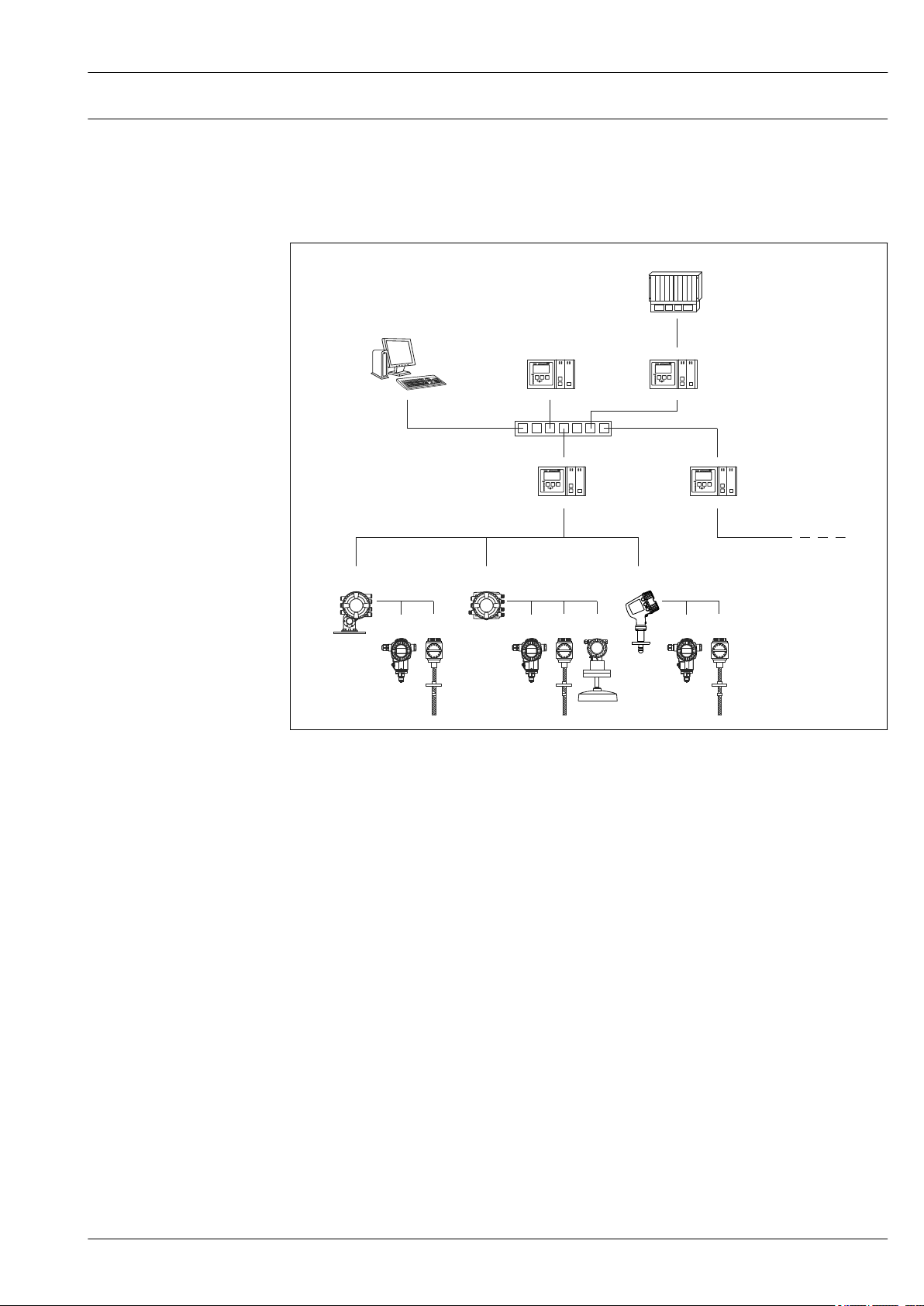

Measuring system

• From single tank level measurement to the largest oil refinery applications, Endress+Hauser tank

gauging devices are an integral part of tank farm management solutions. A wide variety of data

output protocols are available for seamless integration into many commonly used systems.

• A primary example is Tankvision from Endress+Hauser. Tankvision is a scalable system offering

local tank management for multiple loops via Modbus or V1 protocols. Accumulated data is

available to DCS and other plant management systems via a Host Link.

A0027700

4 Integration of tank gauging devices into an inventory management system (typical example)

1 Proservo NMS8x

2 Pressure transmitter (e.g. Cerabar)

3 Temperature transmitter (e.g. Prothermo)

4 Tankside Monitor NRF81

5 Micropilot S FMR5xx

6 Micropilot NMR8x

7 Field protocol (e.g. Modbus, V1)

8 Tankvision Tank Scanner NXA820

9 Ethernet

10 Ethernet switch

11 Internet Browser

12 Tankvision Data Concentrator NXA821

13 Tankvision Host Link NXA822

14 Modbus

15 DCS or PLC

Endress+Hauser 7

Input/output

Level measurement Measured variable

The measured variable is the distance between a reference point (mounting flange) and a reflective

surface (e.g. product surface).

Maximum measuring range

Micropilot NMR84

Antenna

BD: Planar 100mm/4" any 0.8 to 20 m (2.6 to 66 ft)

• BF: Planar 150mm/6"

• BG: Planar 200mm/8"

• BH: Planar 250mm/10"

• BJ: Planar 300mm/12"

1) Ordering feature 100: "Antenna"

2) Ordering feature 150: "Accuracy, Weight + Measure Approval"

1)

Weight+Measure approval

w/o 0.8 to 40 m (2.6 to 131 ft)

• NTA/NTC: NMi type approval

• PTA/PTC: PTB type approval

2)

Maximum measuring range

0.8 to 30 m (2.6 to 98 ft)

Operating frequency

Device Operating frequency

NMR84 approx. 6 GHz

Transmitting power

Device Peak pulse power Average output power

NMR84 1.4 mW 21 µW

8 Endress+Hauser

Micropilot NMR84

D

E

G

F

C

B

A

1

1

1

1

1 3

2

3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

POWER

i

E

1

1

2

CDI

D

C

1 2 3 4

1 2 3 4

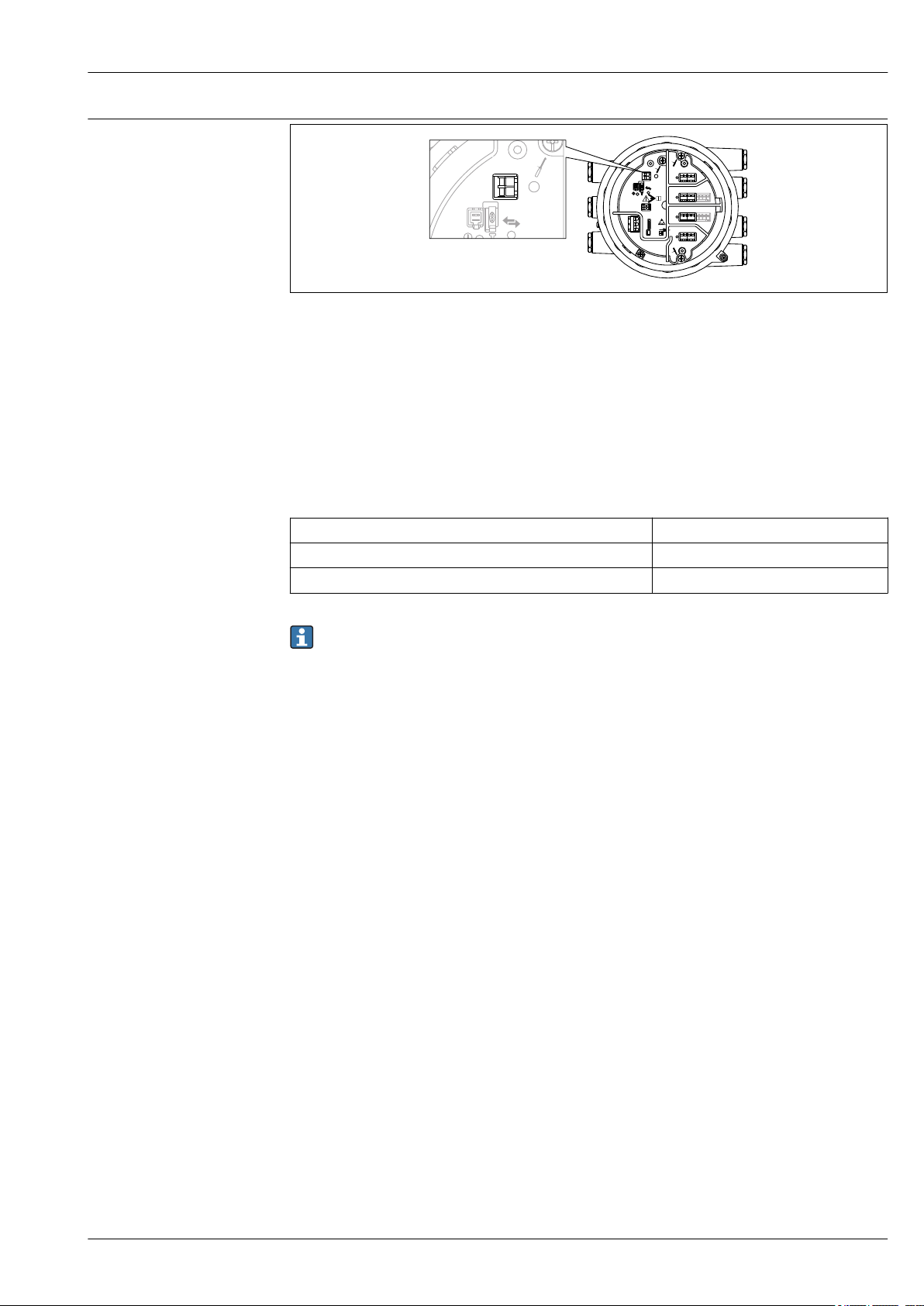

HART Ex ia/IS active input

A0027364

5 HART Ex ia/IS active input

E1 HART +

E2 HART -

The device has a HART Ex ia/IS active input. Additional features are provided if the following

Endress+Hauser devices are connected:

Prothermo NMT

The measured level is transmitted to the Prothermo. Prothermo uses this level to calculate the

average temperature of the product.

Technical data

Transmitter power supply voltage 23.0 V - 380 Ω ⋅ I

load

Maximum load 500 Ω including signal line

Maximum current of all connected devices 24 mA

The HART Ex ia/IS active input is available by default. It needs not to be chosen explicitly when

ordering a device.

Endress+Hauser 9

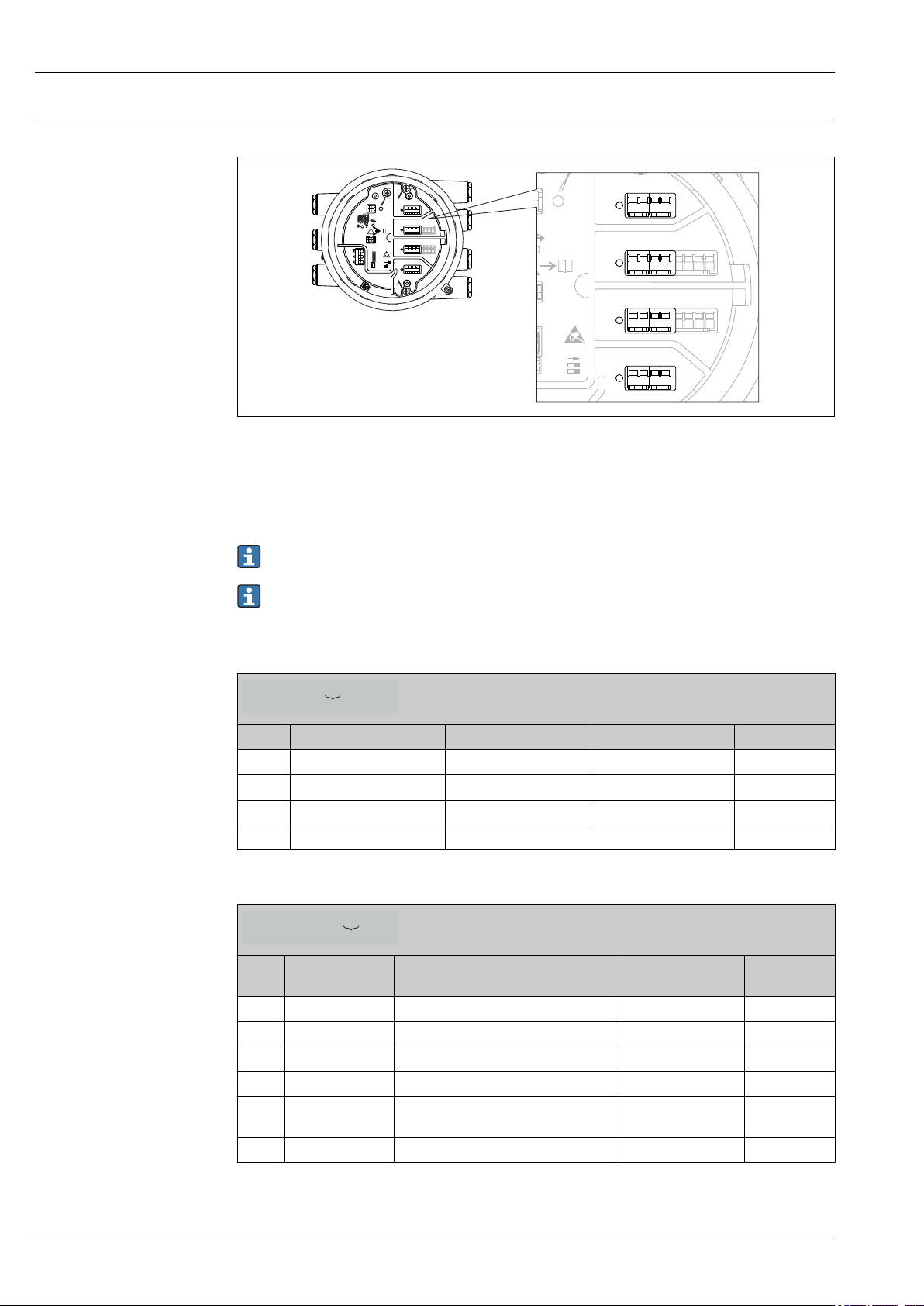

I/O modules Overview

E

G

F

1

1

1

1 3

2

2

2 4

HR

CDI

WP

on

SIM

POWER

i

D

C

B

A

1122334

4

112233445566778

8

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

NMx8x - XX xx xxxxxx ...

040

NMx8x - xx XX xxxxxx ...

050

6 Position of the I/O modules in the terminal compartment

The terminal compartment contains up to four I/O modules, depending on the order code.

• Modules with four terminals can be in any of these slots.

• Modules with eight terminals can be in slot B or C.

The exact assignment of the modules to the slots is dependent on the device version. For a

detailed description refer to the Operating Instructions of the device in question.

The following restrictions apply when selecting the modules:

• The device may contain a maximum of four I/O modules.

• A maximum of two I/O modules with 8 terminals is possible.

Micropilot NMR84

A0027363

Ordering feature 040: "Primary Output"

Option Number of I/O modules Type of I/O module Number of terminals Technical data

A1 1 Modbus RS485 4 → 11

B1 1 V1 4 → 12

E1 1 4-20mA HART Ex d/XP 8 → 13

H1 1 4-20mA HART Ex i/IS 8 → 13

Ordering feature 050: "Secondary IO Analogue"

Option Number of I/O

modules

A1 1 1 x "Ex d/XP 4-20mA HART + RTD input" 1 x 8 → 13

A2 2 2 x "Ex d/XP 4-20mA HART + RTD input" 2 x 8 → 13

B1 1 1 x "Ex i/IS 4-20mA HART+ RTD input" 1 x 8 → 13

B2 2 2 x "Ex i/IS 4-20mA HART+ RTD input" 2 x 8 → 13

C2 2 1 x "Ex i/IS 4-20mA HART + RTD input"

X0 0 none 0 -

Type of I/O module Number of terminals Technical data

2 x 8 → 13

1 x "Ex d/XP 4-20mA HART + RTD input"

10 Endress+Hauser

Micropilot NMR84

NMx8x - xx xx XXxxxx ...

060

Ordering feature 060: "Secondary IO Digital Exd"

Option Number of I/O modules Type of I/O module Number of terminals Technical data

A1 1 1 x "2x relay + 2x discrete I/O" 1 x 4 → 15

A2 2 2 x "2x relay + 2x discrete I/O" 2 x 4 → 15

A3 3 3 x "2x relay + 2x discrete I/O" 3 x 4 → 15

B1 1 1x "Modbus RS485" 1 x 4 → 11

B2 2 1x "Modbus RS485"

1 x "2x relay + 2x discrete I/O"

B3 3 1x "Modbus RS485"

2 x "2x relay + 2x discrete I/O"

X0 0 none 0 -

2 x 4 → 11

→ 15

3 x 4 → 11

→ 15

"Modbus RS485": Technical data

No. of units Maximum 15 instruments per loop

Baud rate Selectable:

• 600 bit/s

• 1 200 bit/s

• 2 400 bit/s

• 4 800 bit/s

• 9 600 bit/s

• 19 200 bit/s

Parity Selectable:

• Odd

• Even

• None

Cable Three-wire cable with screening. The screening must be connected inside the housing.

Termination resistors To be set as required in specific environments

Topology • Serial bus

• Tree structure

Transmission distance Maximum 1 200 m (3 900 ft) including limbs or branches;

branches under 3 m (9.8 ft) are negligible

Instrument address Each transmitter has an individual bus address configured in the software of the

transmitter.

Isolation Bus inputs are electrically isolated from the other electronics.

Error on alarm Error message classified according to NAMUR NE 107

Endress+Hauser 11

Micropilot NMR84

"V1": Technical data

No. of units Maximum 10 instruments per loop

Baud rate 3 300 bit/s

Parity Selectable:

• Odd

• Even

• None

Cable • Two-wire twisted pair; screening recommended

• Two-wire unscreened

Termination resistors Not required

Topology • Serial bus

• Tree structure

Transmission distance Maximum 6 000 m (19 700 ft)

Instrument address Each transmitter has an individual bus address configured in the software of the

transmitter.

Isolation Serial communication circuit isolated from other circuits

Error on alarm Error message classified according to NAMUR NE 107

12 Endress+Hauser

Micropilot NMR84

"4-20mA HART" I/O module (Ex d/XP or Ex i/IS): Technical data

General data

No. of units Max. 6 instruments per loop

Baud rate 1 200 bit/s

Cable Two-wire, twisted pair screened cable;

Core cross section: 0.2 to 2.5 mm2 (24 to 13 AWG)

Topology • Serial bus

• Tree structure

Transmission distance Maximum 1 200 m (3 900 ft)

Instrument address Each transmitter on a signal loop has an individual bus address. This is defined within

the transmitter software and / or auxiliary configuration environment such as host

system or Field Communicator 475.

Isolation Bus inputs are electrically isolated from the other electronics

Input data

Input operating modes • 4..20mA input (1 external device)

• HART master+4..20mA input (1 external device)

• HART master (up to 6 external devices)

Internal load (to ground) 400 Ω

Measuring range 0 to 26 mA

Accuracy ±15 µA (after linearization and calibration)

Connection of a Prothermo NMT The measured level is transmitted to the Prothermo. Prothermo uses this

level to calculate the average temperature of the product.

Connection of a RTD temperature

probe

2-, 3- or 4-wire connection

Output data

Output operating modes • 4..20mA output

• HART slave +4..20mA output

Output current 3 to 24 mA

Accuracy ±15 µA (after linearization and calibration)

Error on alarm HART error message classified according to NAMUR NE 107

Endress+Hauser 13

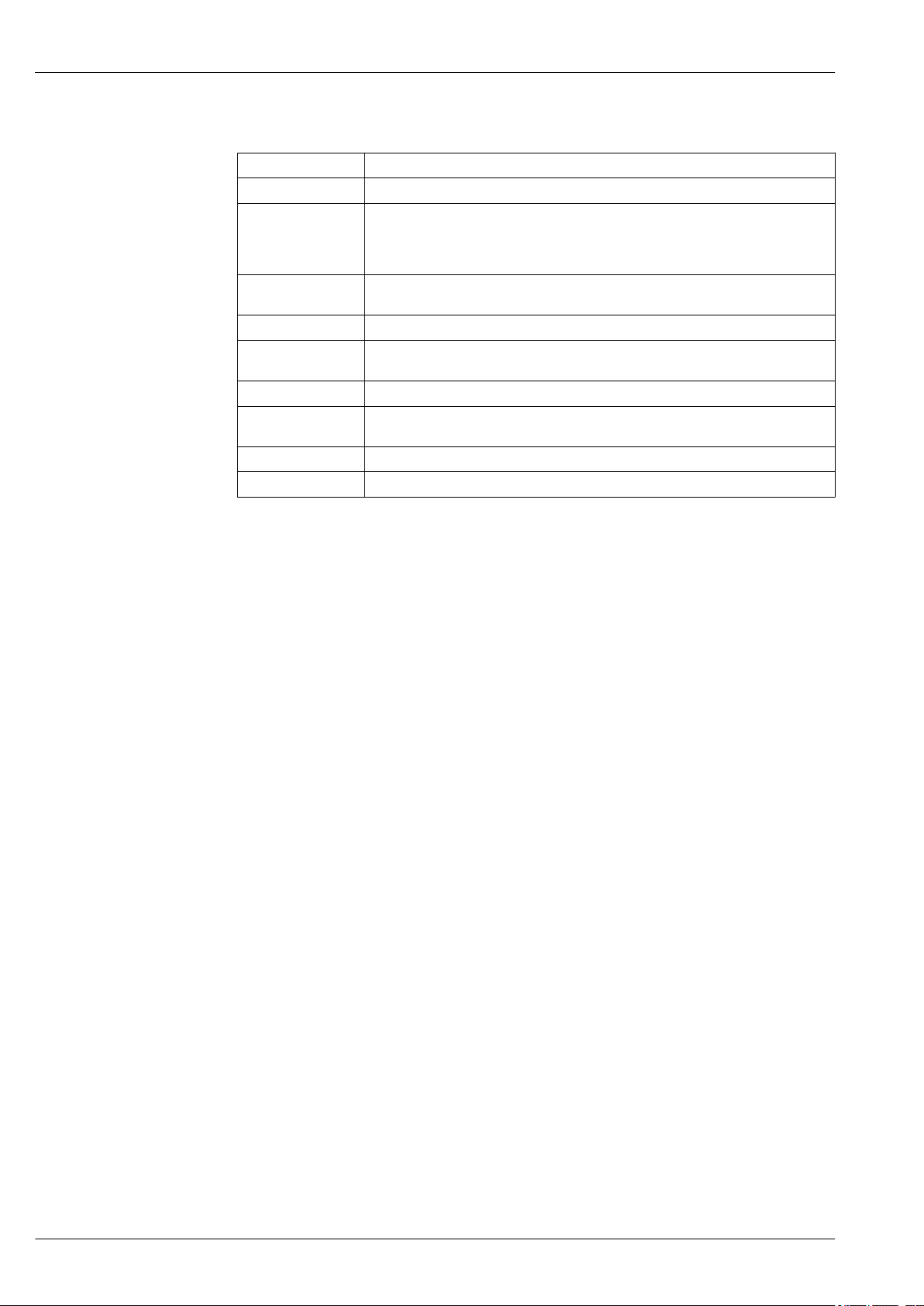

Data for passive usage (input or output)

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

-

+

!

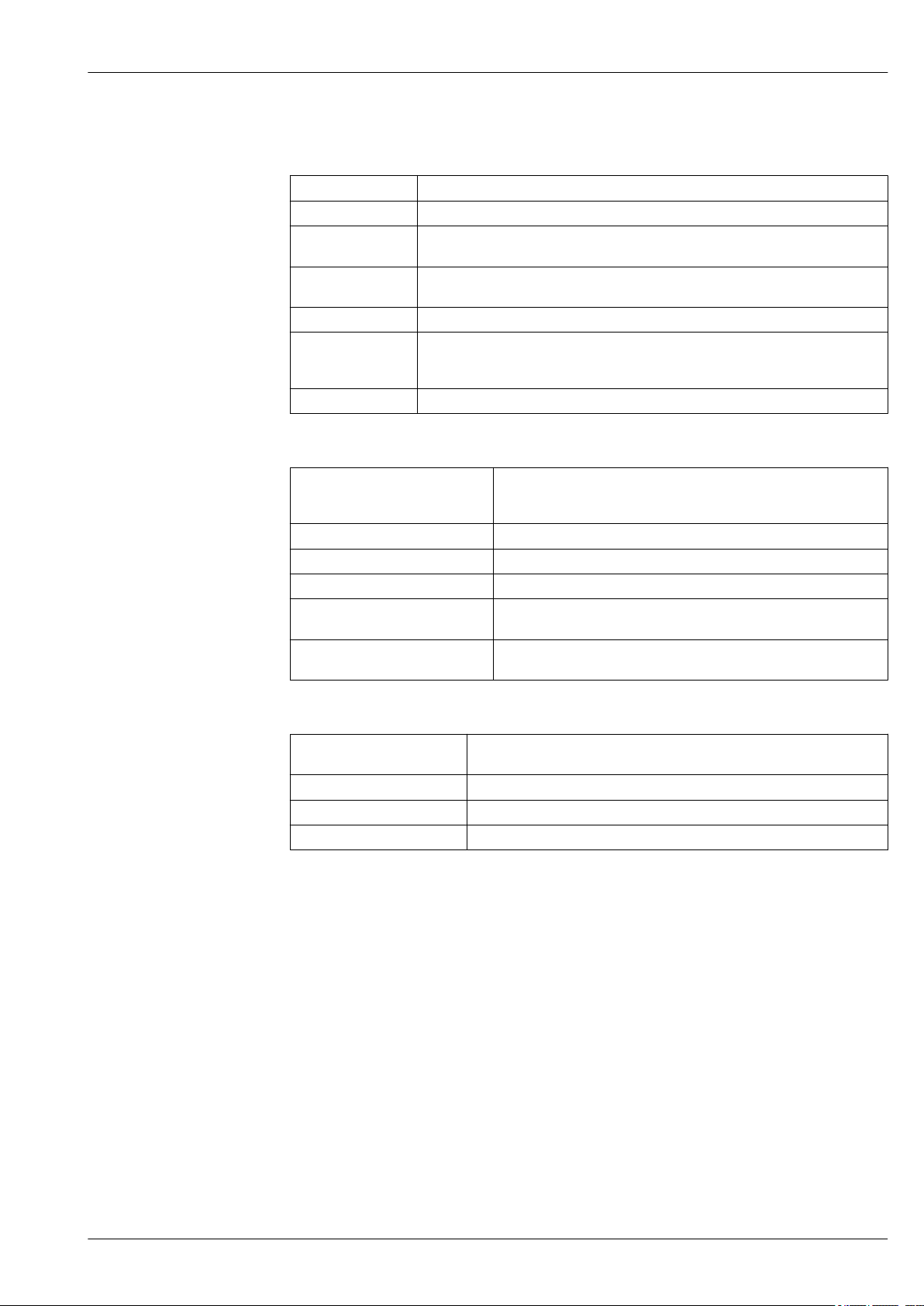

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

-

+

E

G

F

1

1

1 3

2

2 4

HR

CDI

WP

on

SIM

i

D

C

B

A

1122334

4

112233445566778

8

G

1

3

2

POWER

7 Passive input or output: Use terminals 1 and 2

Minimum terminal voltage 10.4 V

Maximum terminal voltage 29 V

Micropilot NMR84

A0033030

Data for active usage (input or output)

8 Active input or output: Use terminals 2 and 3

Transmitter power supply voltage

(Ex d/XP)

Transmitter power supply voltage

(Ex i/IS)

Output load max. 500 Ω including signal line

18.5 V - 360 Ω ⋅ I

20.0 V - 360 Ω ⋅ I

load

load

A0033031

14 Endress+Hauser

Micropilot NMR84

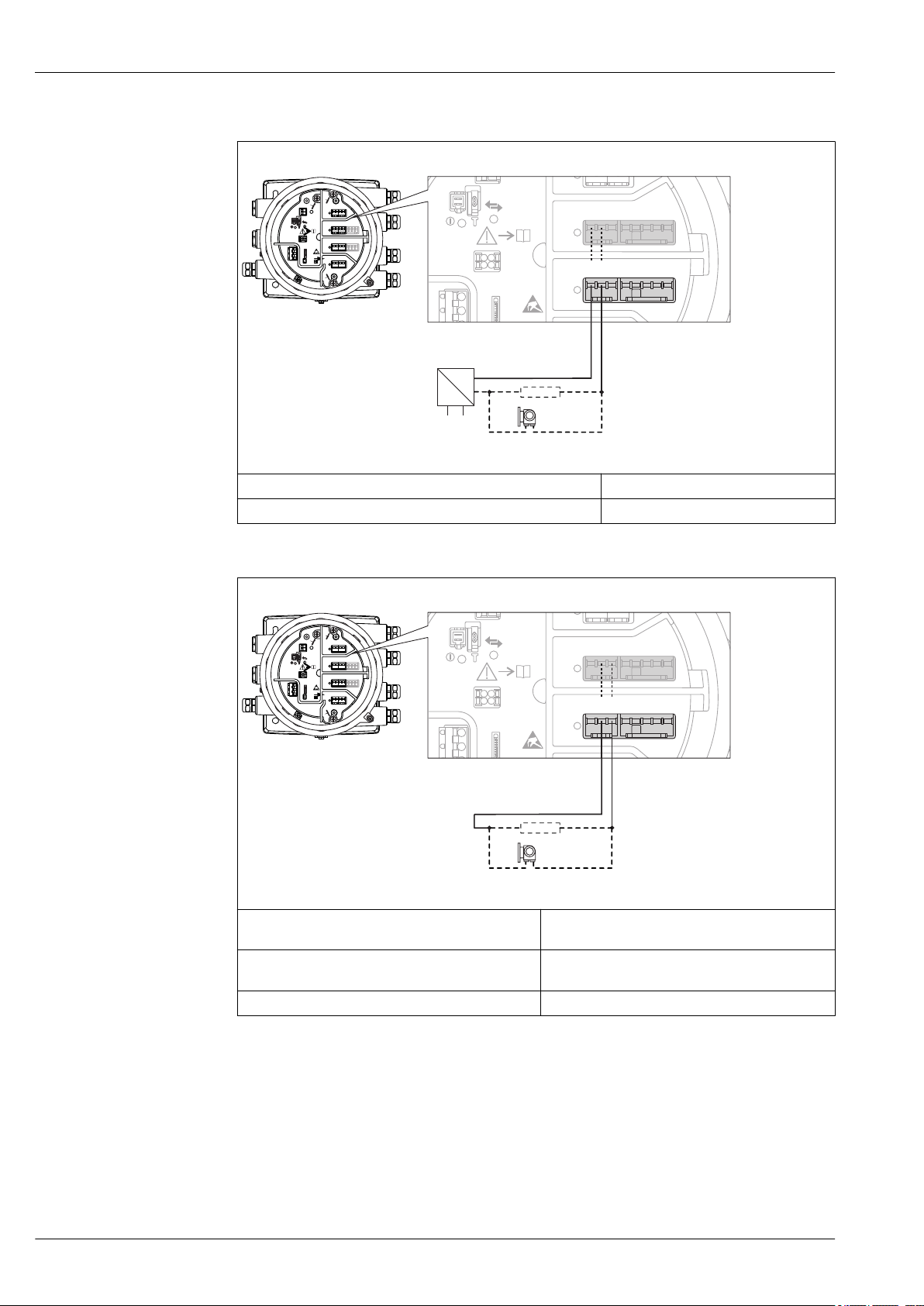

"Digital I/O module": Technical data

Output

Relay switching power for resistive load • 30 VDC @ 2 A

• 250 VDC @ 0.1 A

• 250 VAC @ 2 A

Relay type normally open;

can be set to "normally closed" by a software option

Input

Maximum pick-up voltage • 250 V

Minimum pick-up voltage • 25 V

• 250 V

• 5 V

DC

AC

DC

AC

Current consumption at maximum voltage • ≤ 1 mA (DC)

• ≤ 2 mA (AC)

1) In case of a power supply failure, the switching state is always "open", irrespectiv of the selected software

option.

1)

Endress+Hauser 15

Loading...

Loading...