ESM-9944-N / ESM-9945-N

COOKING CONTROLLERS

ESM-9944-N / ESM-9945-N Cook�ng Controllers

- 4 d�g�ts d�splay

- J type Thermocouple Input or

K type Thermocouple Input or

R type Thermocouple Input or

S type Thermocouple Input or

2 or 3 w�re PT 100 Input

- Adjustable Process Offset Value

- Programmable ON/OFF, P, PI, PD ve PID control types

- Adaptat�on of PID coeff�c�ents to the system by Auto Tune/Self Tune

- Work�ng t�me select�on �n m�nutes or seconds

- Vo�ced warn�ng v�a �nternal buzzer

- Cover sw�tch �nput

- Steam output (ESM-9945-N)

ESM-9944-N / ESM-9945-N cook�ng controllers are ma�nly used for Bakery

appl�cat�ons, fermantat�on cab�nets, ceram�cs and glass ovens, gra�n dr�er

cab�net, �ndustr�al fryer, �ncubators. Accurate and advanced controll�ng �s

performed w�th selectable ON-OFF, P, PI, PD ve PID, Self-Tune PID, AutoTune PID funct�ons.

SPECIFICATIONS

INPUT

Process Input: TC/RTD

Thermocouple (TC): J, K, R and S (IEC584.1)(ITS90)

Thermores�stance (RTD): 2 or 3 w�re Pt100 ( IEC 751) (ITS90)

Measurement Range: Please refer to parameter �n parameters sect�on.

Accuracy: ± 0.25% of scale for thermocouple and thermores�stance.

Cold Junct�on Compensat�on: Automat�cally ±0.1°C/1°C

L�ne Compensat�on: Max�mum 10 Ohm

Sensor Break Protect�on: Upscale

Sampl�ng Cycle: 0.1 second

CONTROL

Control Forms: ON/OFF, P, PI, PD veya PID (Control form can be

programmed by the user.)

OUTPUT

Temperature Control Output : Relay (7A@250VV at res�st�ve load) or opt�onal

SSR Dr�ver Output (Max�mum 10mA, 17VZ )

T�me Output : Relay (5A@250VV at res�st�ve load) or opt�onal SSR Dr�ver

Output (Max�mum 10mA, 17VZ )

Steam Output(ESM-9945) : Relay (5A@250VV at res�st�ve load) or opt�onal

SSR Dr�ver Output (Max�mum 10mA, 17VZ )

Bes�des these, there �s an �nternal buzzerfor vo�ced warn�ng.

SUPPLY VOLTAGE

230VV (±15%) 50/60Hz - 3VA

115VV (±15%) 50/60Hz - 3VA

24VV (±15%) 50/60Hz - 3VA

(Must be determ�ned �n order.)

DISPLAY

Temperature D�splay: 16 mm Red 4 d�g�ts LED D�splay

Led Ind�cators: O1 (Temperature Control Output Status LED), O2 (T�me Control

Output Status LED), Steam Output LED(ESM-9945-N), T�me Ind�cator,

Temperature Ind�cator, P(Programm�ng Mode LED),ºC, ºF LEDs

ENVIRONMENTAL RATINGS and PHYSICAL SPECIFICATIONS

Operat�ng Temperature: 0...50ºC

Hum�d�ty : 0-90%RH (none condens�ng)

Protect�on Class: IP65 at front , IP20 at rear

We�ght: 370 gr.

D�mens�on: 96 x 96 mm, Depth: 100 mm

Panel CutOut: 92 x 92 mm

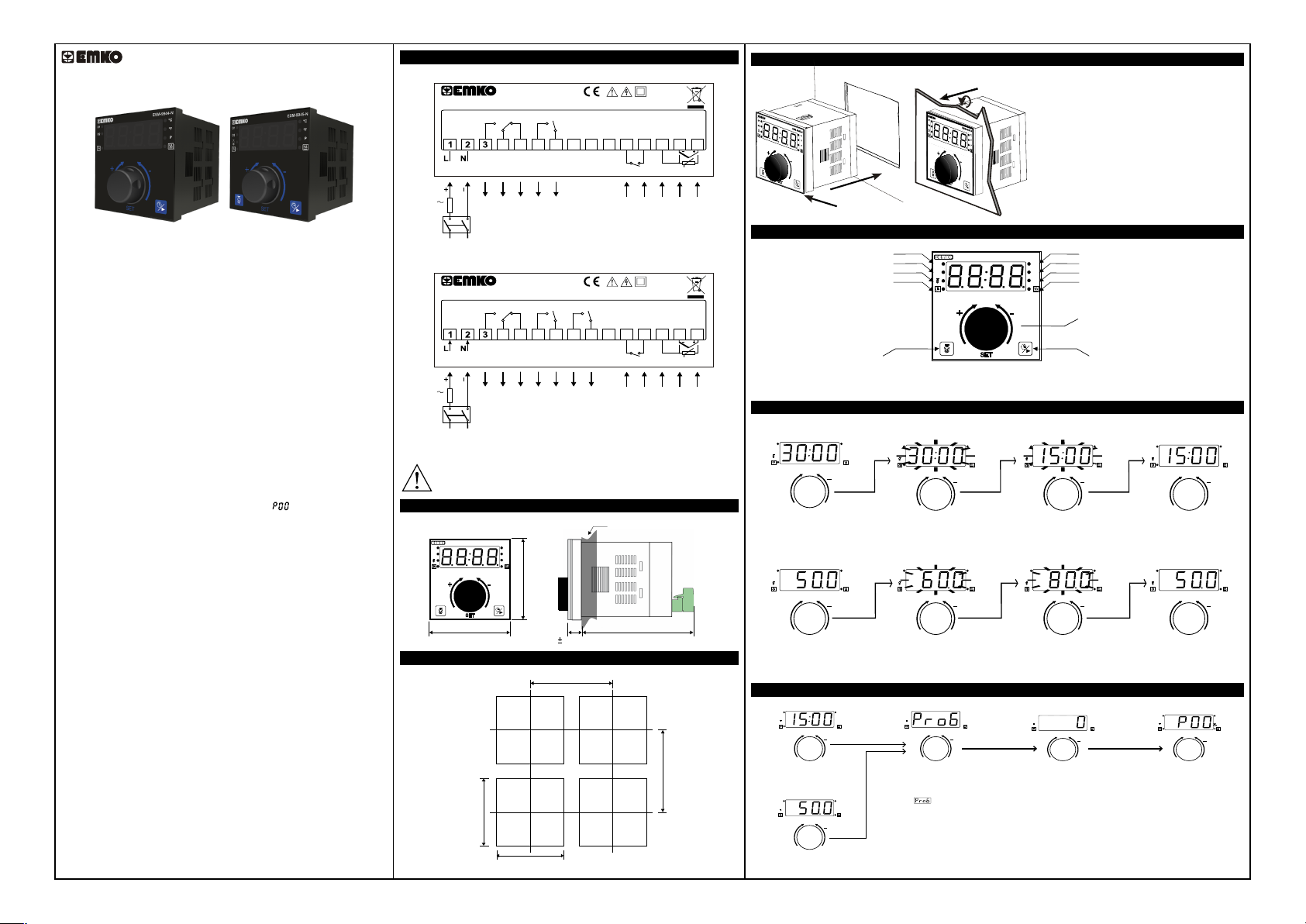

Electr�cal W�r�ngs

ESM-9944-N

7A@250VV 5A@250VV

NCCNO

CNO

5

6 7 8 9

4

Output-1

Output-2

L

N

1A T

Supply

Voltage

Sw�tch

Supply

Voltage

Sw�tch

S�gorta

1A T

S�gorta

(Temperature Control

Output)

Supply

Voltage

ESM-9945-N

7A@250VV 5A@250VV5A@250VV

Output-1

L

N

(Temperature Control

Output)

Supply

Voltage

To reduce the effect of electr�cal no�se on dev�ce, low voltage l�ne (espec�ally sensor

�nput cables) w�r�ng must be separately from h�gh current and voltage l�ne. If

poss�ble, use sh�elded cable abd sh�eld must be connected to ground only one s�de.

O1

4

O1

O2

(T�me End

Output)

NCCNO

5

6 7 8 9

Output-2

O2

(T�me End

Output)

CNO CNO

Output-3

O3

(Steam

Output)

10

10

CAT II

11 121314

D�g�tal Input

Temperature

Cover

Sensor Input

Sw�tch

CAT II

11 121314

D�g�tal Input

Temperature

Cover

Sensor Input

Sw�tch

D�mens�ons

ESM-9945-N

O1

O2

°C

°F

P

Max�mum 15 mm / 0.59 �nch

+ -

SET

96 mm / 3.78 �nch

96 mm / 3.78 �nch

11.5 1mm / 0.45 �nch

84 mm / 3.31 �nch

Panel Cut-out

129 mm / 5.08 �nch(m�n)

92 mm / 3.62 �nch(m�n)

92 mm / 3.62 �nch(m�n)

PT-100

PT-100

129 mm / 5.08 �nch(m�n)

Panel Mount�ng

1

4

5

15

TC

3

2

1- Before mount�ng the dev�ce �n your panel, make

sure that the cutouts �s of the r�ght s�ze.

2- Check front panel gasket pos�t�on.

3- Insert the dev�ce through the cutout. If the

mount�ng clamps are on the un�t, put out them before

�nsert�ng the un�t to the panel.

4- Insert the mount�ng clamps to the two of

des�gnated holes that located on four s�des of dev�ce.

5- Drag the mount�ng clamps �n d�rect�on 5 unt�l the

dev�ce completely �mmob�le w�th�n the panel.

6- In order to remove dev�ce push on the mount�ng

clamp as shown w�th arrow 6 and pull back.

Front Panel Def�n�t�on

Temperature Control Output Status

T�me End Output Status

Steam Output Status(ESM9945N)

T�me �nd�cator

O1

O2

ESM-9945-N

+ -

15

TC

Steam Start-Stop Button

(ESM9945N)

SET

Temperature Un�t Ind�cator

Temperature Un�t Ind�cator

°C

Programm�ng Mode Ind�cator

°F

Temperature Ind�cator

P

Encoder Button

T�me Start-Stop Button

If cooking time is not active, starts

cooking time. If cooking time is

started, cooking time is cancelled

and buzzer is silenced.

Access and Change Set Value

Time Set Value

Ma�n Screen

O1

O2

++

+

Press encoder button

to observe the set value.

°C

°F

P

SET

Temperature Set Value

O1

O2

++

+

Press encoder button

to observe the set value.

°C

°F

P

Note : If no operat�on for 10 seconds, dev�ce automat�cally ex�ts from Set Value Screen w�thout sav�ng the value.

Set Value Screen

O1

O2

++

+

SET

Turn left encoder button

to decrease or turn right

to increase the set value.

Set Value Screen

O1

O2

++

+

Turn left encoder button

to decrease or turn r�ght

to �ncrease the set value.

Set Value Screen

°C

°F

P

°C

°F

P

O1

O2

++

+

Press encoder button

to save new set value

and return main screen.

Set Value Screen

O1

O2

++

+

Press encoder button

to save new set value

and return ma�n screen.

°C

°F

SET

°C

°F

P

P

Ma�n Screen

O1

O2

++

+

Ma�n ScreenMa�n Screen

O1

O2

++

+

°C

°F

P

SET

ESD-9950-N

°C

°F

P

SET

Access the Parameters

Ma�n Screen

O1

O2

+

Press encoder

button dur�ng 10 seconds.

Ma�n Screen

O1

O2

+

Press encoder

button dur�ng 10 seconds.

°C

°F

P

++

SET

°C

°F

P

++

SET

O1

O2

+

If no pr�vacy lock �dent�f�cat�on

Parameters Screen w�ll be

observed. If pr�vacy lock �s

�dent�f�ed, w�ll be observed.

Press encoder button to access

Password Screen.

°C

°F

P

++

SET

Password Screen

O1

O2

+

Enter the password using

encoder button. Turn left

encoder button to decrease or

turn right to increase value.

Approve password using

encoder button.

°C

°F

P

++

Instruct�on Manual. ENG ESM-994X-N 01 V02 02/18

Parameters Screen

O1

O2

+

If Parameters Screen is

active, "P" led blinks. To

observe previous parameter,

turn encoder button left. To

observe next parameter, turn

encoder button right. Press

encoder button to observe

parameter value.

°C

°F

P

++

Access, Change and Record the Parameter Values

Parameter Values Screen

O1

O2

++

+

SET

To increase parameter

value, turn encoder button

right. Press encoder button

to save.

Parameters Screen

O1

O2

++

+

Turn encoder button

left to observe

previous parameter or

turn right to observe

next parameter.

Note1: PID control parameters ( , , , , , ) are not seen when

output control type parameter ( ) �s set as .

Note2: ON/OFF control parameters ( , ) are not seen when output control type

parameter ( ) �s set as .

Note3: parameter �s not seen when parameter set as . parameter can be

seen after parameter.

Note4: parameter �s not seen �n ESM9944N dev�ce. parameter can be seen after

parameter.

Note5: If �s d�fferent from and user enters on password screen, parameter values

except are observed but can not be changed.

Note6: If no operat�on for 20 seconds on Parameters Screen, dev�ce automat�cally returns

Ma�n Screen .

°C

°F

P

SET

Parameter Values Screen

O1

°C

°F

O2

P

++

+

To decrease parameter

value, turn encoder button

left. Press encoder button

to save.

°C

°F

P

SET

Parameters Screen

O1

O2

++

+

SET

Turn encoder button

left to observe

previous parameter or

turn right to observe

next parameter.

°C

°F

P

Parameters Descr�pt�ons

: Process �nput type select�on parameter. (Default: )

J type (Fe,Cu,N�) Thermocouple; -200ºC,900ºC ; -328ºF,1652ºF

J type (Fe,Cu,N�) Thermocouple; -199.9ºC,900.0ºC ; -199.9ºF,999.9ºF

K type (N�,Cr,N�) Thermocouple; -200ºC,1300ºC ; -328ºF,2372ºF

K type (N�,Cr,N�) Thermocouple; -199.9ºC,999.9ºC ; -199.9ºF,999.9ºF

R type (Pt13%RhPt) Thermocouple; 0ºC,1700ºC ; 32ºF,3092ºF

R t�p� (Pt13%RhPt) Thermocouple; 0.0ºC,999.9ºC ; 32.0ºF,999.9ºF

S t�p� (Pt10%RhPt) Thermocouple; 0ºC,1700ºC ; 32ºF,3092ºF

S t�p� (Pt10%RhPt) Thermocouple; 0.0ºC,999.9ºC ; 32.0ºF,999.9ºF

PT100 Thermores�stance; -200ºC,650ºC ; -328ºF,1202ºF

PT100 Thermores�stance; -199.9ºC,650.0ºC ; -199.9ºF,999.9ºF

: Un�t select�on parameter. or can be chosen. (Default: )

: Operat�on scale m�n�mum(Low L�m�t) value. It changes accord�ng to

the process �nput type and scale. (Default: -200)

: Operat�on scale max�mum(H�gh L�m�t) value. It changes accord�ng to

the process �nput type and scale. (Default: 900)

: Process set value low l�m�t parameter. It can be adjusted between

Operat�on Scale M�n�mum( ) and Process Set Value H�gh L�m�t( ).

(Default:-200)

: Process set value h�gh l�m�t parameter. It can be adjusted between

Process Set Value Low L�m�t( ) and Operat�on Scale Max�mum( )

and (Default: 900)

: Process offset value. It can be adjusted as a degree( or ), from

-10% of scale to 10% of scale.It �s added to the process value. (Default: 0)

: Output control type parameter. It can be selected or .

(Default: )

: Hysteres�s value. It can be adjusted from 1º(po�nt representat�on:

0.1º) to 20º. (Default: 3)

: M�n�mum ON/OFF control output t�me parameter. It can be adjusted

from 0 to 60 seconds. (SSR Default: 0 ; Relay Default: 5)

: Proport�onal band (P). It can be adjusted from %1.0 to %100.0.

(Default: 10.0)

: Output Control Per�od. If control output �s SSR, It can be adjusted

from 0.5 to 150.0 seconds. If control output �s Relay, It can be adjusted 60.0

to 150.0 seconds. (SSR Default: 10.0 ; Relay Default: 60.0)

: Proport�onal Offset value. Th�s parameter �s used for sh�ft�ng the

proport�onal band. It can be adjusted from (-Operat�on Scale Max�mum /2)

to (Operat�on Scale Max�mum /2). (Default: 0)

: Integral T�me. It can be adjusted from 0 to 3600 seconds.

(Default: 100)

: Der�vat�ve T�me. It can be adjusted from 0.0 to 999.9 seconds.

(Default: 25.0)

: If tune parameter �s set to or , dev�ce starts to calculate

PID parameters automat�cally. (Default: )

: Dev�ce does not calculate PID parameters.

: Step Response Tun�ng operat�on.

: L�m�t Cycle Tun�ng operat�on.

:Temperature - T�me d�splay form. If parameter value set as ,only

Temperature or T�me value �s d�splayed accord�ng to selected page. If

parameter value set as d�fferent from , Temperature and T�me value �s

d�splayed alternately dur�ng parameter value. It can be adjusted from

0 to 99 seconds. (Default: )

: T�mer d�splayed form. If parameter value set as , t�mer form �s

M�nute-Second. If parameter value set as , t�mer form �s Hour-M�nute.

(Default: )

: T�mer counts d�rect�on parameter. If the parameter set as , t�mer

counts downt-to-up. If the parameter set as , t�mer counts up-to-down.

(Default: )

: T�mer count�ng method parameter. If the parameter set as , t�mer

counts act�ve t�me. If the parameter set as , t�mer counts set t�me.

If parameter set as , th�s parameter �s not seen. (Default: )

: T�mer Relay Pos�t�on Parameter. If the parameter �s , T�mer relay

becomes act�ve pos�t�on w�th the t�me start and becomes pass�ve at the

end of the t�me. If the parameter �s , then t�me relay becomes act�ve at

the end of the t�me. (Default: )

: Relay act�ve t�me parameter. If parameter value set as then

T�me End Output w�ll be act�ve cont�nously. If value set as a d�fferent

value(from 1 to 9999 seconds), T�me End Output w�ll be act�ve dur�ng the

entered t�me. (Default: )

: Buzzer act�ve t�me parameter. If parameter value set as ,

Buzzer w�ll be act�ve cont�nously. If parameter value set as a d�fferent

value (from 1 to 9999 seconds), Buzzer w�ll be act�ve dur�ng the entered

t�me. (Default: )

: D�g�tal �nput c�rcu�t parameter. If the parameter set as , c�rcu�t �s

Normally Open (NO). If the parameter set as , c�rcu�t �s Normally Closed

(NC). (Default: )

: Type of command when d�g�tal �nput act�vated. If the parameter set

as , t�mer stops count�ng and resets t�me. If the parameter set as ,

t�mer pauses count�ng. (Default: )

: Steam durat�on parameter (ESM9945N). If the Steam Durat�on

Parameter �s selected as then the steam output w�l be on dur�ng the

Steam button �s pressed. If the parameter value set as a d�fferent value

(from 1 to 9999 seconds), after press�ng the steam button, output w�ll be

on dur�ng the Steam Durat�on Parameter value. If Steam button �s

pressed when steam output �s on, steam output w�ll be off. (Default: )

: Password for access�ng to the parameters sect�on. It can be

adjusted from 0 to 9999. If parameter value �s , password screen �s not

seen. If parameter value �s d�fferent from and ;

-If user enters d�fferent value from saved value, dev�ce w�ll return to

ma�n screen automat�cally.

-If user enters , all parameters can be observed except .

But dev�ce does not allow to do any changes �n parameters. (Default: )

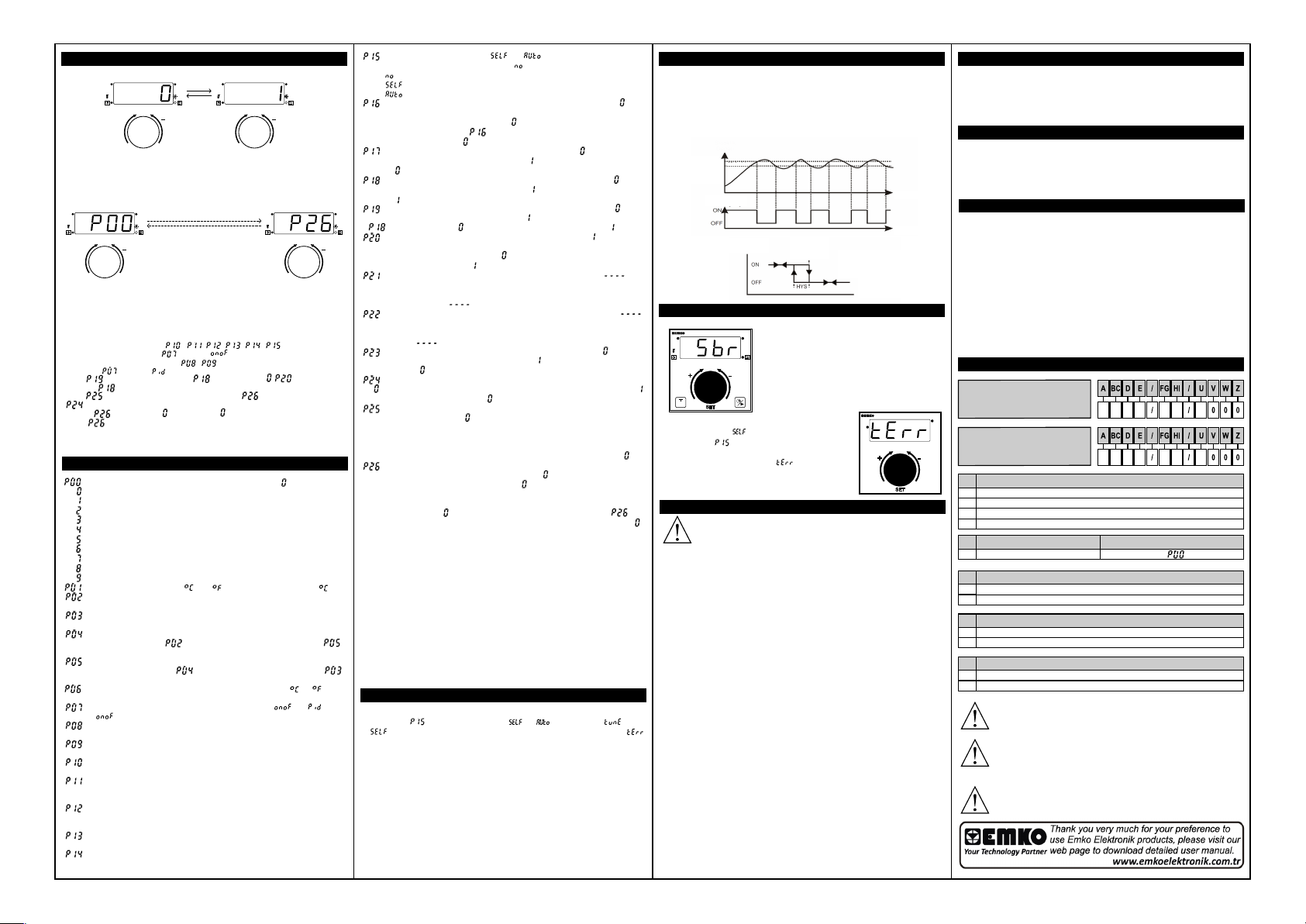

Tune Operat�on

Start�ng the Tune operat�on

1- Enter the parameter and select or . Observe that bl�nks.

(If �s selected and start cond�t�ons are not okay for Tune operat�on,

bl�nks dur�ng 10 seconds.)

2- Dev�ce calculates PID control coeff�c�ents and sets the process value to

wanted value.

Cancell�ng tune operat�on:

1- If sensor breaks;

2-If tune operat�on can not be completed �n 8 hours;

3-Wh�le tune operat�on �s runn�ng, �f process value becomes greater than

process set value;

4-Wh�le tune operat�on �s runn�ng, �f user changes the process set value;

5-Wh�le tune operat�on �s runn�ng, �f user changes the parameter �n menu;

Then tune operat�on �s canceled and dev�ce cont�nues to run w�th former PID

parameters w�thout chang�ng PID parameters.

Adjustment of Hysteres�s Value for ON/OFF Control

In ON/OFF control algor�thm, temperature value �s tr�ed to keep equal to set

value by open�ng or clos�ng com pletely last control element. ON/OFF controlled

system, temperature value osc�llates cont�nuously. Temperature value’s

osc�llat�on per�od or ampl�tude around set value changes accord�ng to controlled

system. For reduc�ng osc�llat�on per�od of temperature value, a threshold zone

�s formed below or around set val ue and th�s zone �s named hysteres�s. Act�on

of control output �s descr�bed w�th f�gures below.

Temperature

Temperature

Set Value

Hysteresis

Temperature

Control Output

Temperature

Control Output

Temperature

Set Value

ON/OFF

Conrol Form

with

Hysteresis

Temperature

Time

Time

Error Messages

ESM-9945-N

O1

O2

+ -

Tune fa�lure. If �s selected �n PID Tune

Parameter( ) and start cond�t�ons are not

okay for Tune operat�on, the temperature value

�s d�splayed alternately w�th message on

d�splay dur�ng 10 seconds.

°C

°F

P

Sensor fa�lure �n analog �nput. If there �s no

sensor connect�on or the value that �s read from

the analog �nput goes out of the dev�ce scale,

warn�ng �s observed.

SET

O1

O2

ESD-9950-N

+ -

SET

Installat�on

Before beg�nn�ng �nstallat�on of th�s product, please read

the �nstruct�on manual and warn�ngs below carefully.

In package,

-One piece unit

-Two pieces mounting clamp

-One piece instruciton manual

A visual inspection of this product for possible damage occured

during shipment is recommended before installation. It is your

responsibility to ensure that qualified mechanical and electrical

technicians install this product.

If there is danger of serious accident resulting from a failure or

defect in this unit, power off the system and the electric al

connection of the device from the system.

The unit is normally supplied without a power switch or a fuse.

Use power switch and fuse as required.

Be sure to use the rated power supply voltage to protect the unit

against damage and to prevent failure.

Keep the power off until all of the wiring is completed so that

electric shock and trouble with the unit can be prevented.

Never attempt to disassemble, modify or repair this unit.

Tampering with the unit may results in malfunction, electric shock

or fire.

Do not use the unit in combustible or explosive gaseous

atmospheres. During the equipment is put in hole on the metal

panel while mechanical installation some metal burrs can cause

injury on hands, you must be careful.

Montage of the product on a system must be done with it's

mounting clamp. Do not do the montage of the device with

inappropriate mounting clamp. Be sure that device will not fall

while doing the montage.

It is your responsibility if this equipment is used in a manner not

specified in this instruction manual.

Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects

in material and workmanship. This warranty is provided for a period of two

years. The warranty period starts from the delivery date.

This warranty is in force if duty and responsibilities which are

determined in warranty document and instruct on manual performs by the

customer completely.

Ma�ntenance

Repairs should only be performed by trained and specialized personnel. Cut

power to the device before accessing internal parts. Do not clean the case

with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a

cloth dampened in ethyl alcohol or water to clean the external plastic

case.

Other Informat�ons

Manufacturer Informat�on:

a

Emko Elektron�k Sanay� ve T�caret A.Ş.

Dem�rtaş Organ�ze Sanay� Bölges� Karanf�l Sk. No:6 16369

BURSA/TURKEY

a

Phone : +90 224 261 1900

Fax : +90 224 261 1912

a

Repa�r and Ma�ntenance Serv�ce Informat�on:

a

Emko Elektron�k Sanay� ve T�caret A.Ş.

Dem�rtaş Organ�ze Sanay� Bölges� Karanf�l Sk. No:6 16369

Bakım

BURSA/TURKEY

a

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Order�ng Informat�ons

ESM-9944-N(96x96 DIN 1/4)

°C

°F

P

S

ESM-9945-N(96x96 DIN 1/4)

Supply Voltage

A

24VV (±%15) 50/60Hz

3

115VV (±%15) 50/60Hz

4

230VV (±%15) 50/60Hz

5

9

Customer

Input Type

BC

Conf�gurable20

Output-1 (Temperature Control Output)

E

Relay Output (7A@250VV at Res�st�ve Load) (NO,NC,C)

1

SSR Dr�ver Output (Max. 10mA, 17VZ)

2

Output-2 (T�me Output)

FG

Relay Output (5A@250VV at Res�st�ve Load) (NO,C)

01

SSR Dr�ver Output (Max. 10mA, 17VZ)

02

Output-3 (Steam Output) (ESM-9945-N)

HI

Relay Output (5A@250VV at Res�st�ve Load) (NO,C)

01

SSR Dr�ver Output (Max. 10mA, 17VZ)

02

Before comm�ss�on�ng the dev�ce, parameters must be set �n

accordance w�th des�red use. Incomplete or �ncorrect conf�gurat�on

can cause dangerous st�uat�ons.

Because of l�m�ted mechan�cal l�fe of relay output contact, SSR output

�s recommended wh�ch the dev�ce use PID control algor�tm. The

dev�ce w�th ON/OFF control algor�tm, hysteres�s parameter must be

set a su�table value for your system, to avo�d too much relay sw�tch�ng.

V → Vac,

Z → Vdc,

W → Vdc or Vac can be appl�ed.

20

20

Scale

See Parameters ( )

00

0

0

1

1

Loading...

Loading...