Page 1

Precision Cooling

For Business-Critical Continuity

Liebert XDF

™

User Manual - 14kW Nominal Capacity, 60 Hz

?

ESC

Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 GLOSSARY OF SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Operational Overview—Self-Contained, Air Cooled Model . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Operational Overview - Water/Glycol Cooled Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 XDF COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1 Standard Components—Self-Contained, Air Cooled and Water/Glycol Cooled Models. . . . . 9

3.1.1 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.2 Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.3 Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.4 Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.5 Environmental Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.6 Control—Liebert’s iCOM Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Coolant Source—Water/Glycol Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Closed-Loop Water System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Drycooler Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Optional Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.1 General Enclosure Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.2 Power Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.1 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Recommended Setup Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Unloading the XDF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.1 Handling the Unit While It is Packaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.2 Unpack the XDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.3 Removing the XDF from Skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 XDF Site Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Voltage Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.5.1 Voltage Input Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.5.2 Uninterruptible Power Supply—Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5.3 MP Advanced Power Strips—Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5.4 Condensate Drain Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.6 Drycooler Installation—Water/Glycol Cooled Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.7 Equipment Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.8 Frame and Enclosure Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.8.1 Internal Mounting Rails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.8.2 Rear-Mount Rails—Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.9 Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.10 Door—Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.10.1 Remove the Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.10.2 Quick Door Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

i

Page 4

4.11 Side Panels—Remove and Replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.11.1 Remove the Left Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.11.2 Remove the Right Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.11.3 Replace a Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.0 PIPING CONSIDERATIONS—WATER/GLYCOL MODELS ONLY . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Closed Loop Water System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.1 Expansion Tanks, Fluid Relief Valves and Other Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.2 Corrosion Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.3 Freeze Protection—Coolant Type and Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3 Drycooler Loop System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3.1 Glycol Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.0 FILLING THE XDF WITH COOLANT—WATER OR GLYCOL . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.1 Preparing the System for Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.1 XDF Water/Glycol Cooled Unit Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.2 Filling the System with Water or Glycol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.0 ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.1 Utility Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1.1 Route Input Power Cables Through the XDF’s Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.0 CABLE MANAGEMENT OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.1 Cable Management Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2 Cable Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3 Cable Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.3.1 Top Cover and Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.4 Optional Cable Management Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.0 STARTUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1 XDF Startup Inspection Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1.1 Site Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.2 Starting the XDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

10.1 Environmental Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.2 iCOM Components and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.3 Navigating Through the iCOM Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.3.1 Accessing Menus and Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.3.2 Entering the Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.4 Changing Operational Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10.5 Changing iCOM’s Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.6 Changing the XDF’s Default Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.7 Operation With the Door Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.8 Backup Ventilation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.9 XDF Compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ii

Page 5

10.10 Uninterruptible Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

11.1 Periodic Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

12.0 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

12.1 Optional Power Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

12.2 Optional Managed Power - Advanced Power Strips, Vertical- or Horizontal-Mount . . . . . . 52

FIGURES

Figure 1 Component location, general operational layout of self-contained, air cooled model . . . . . . . . . . . 3

Figure 2 Component location of water/glycol cooled model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3 Component location, rear of XDF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

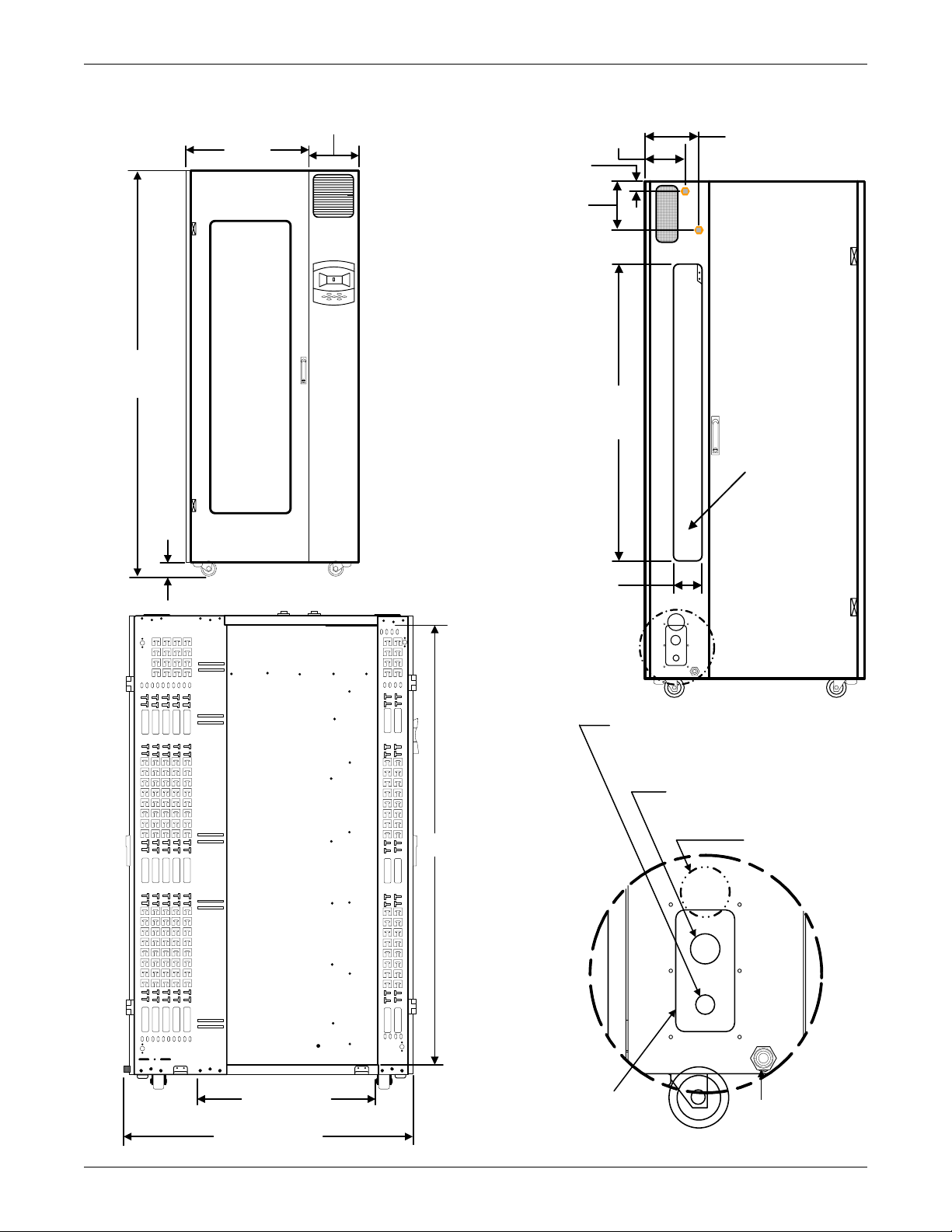

Figure 4 Dimensional data, self-contained, air cooled model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5 Dimensional data, water/glycol cooled model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

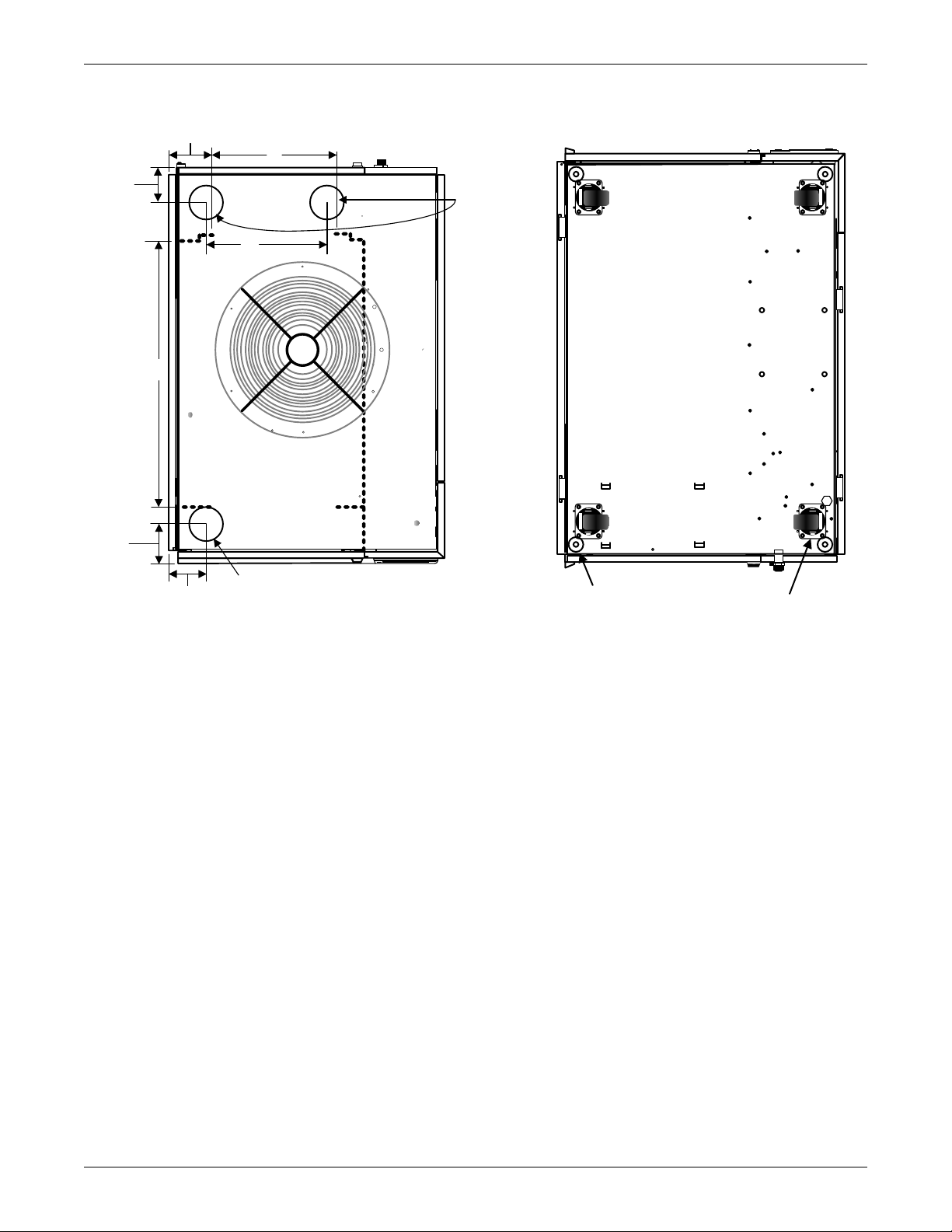

Figure 6 Dimensional data, all models—top, bottom and cable entry cutouts. . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 7 Cooling system components—self-contained, air cooled models . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8 Cooling system components—water cooled models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

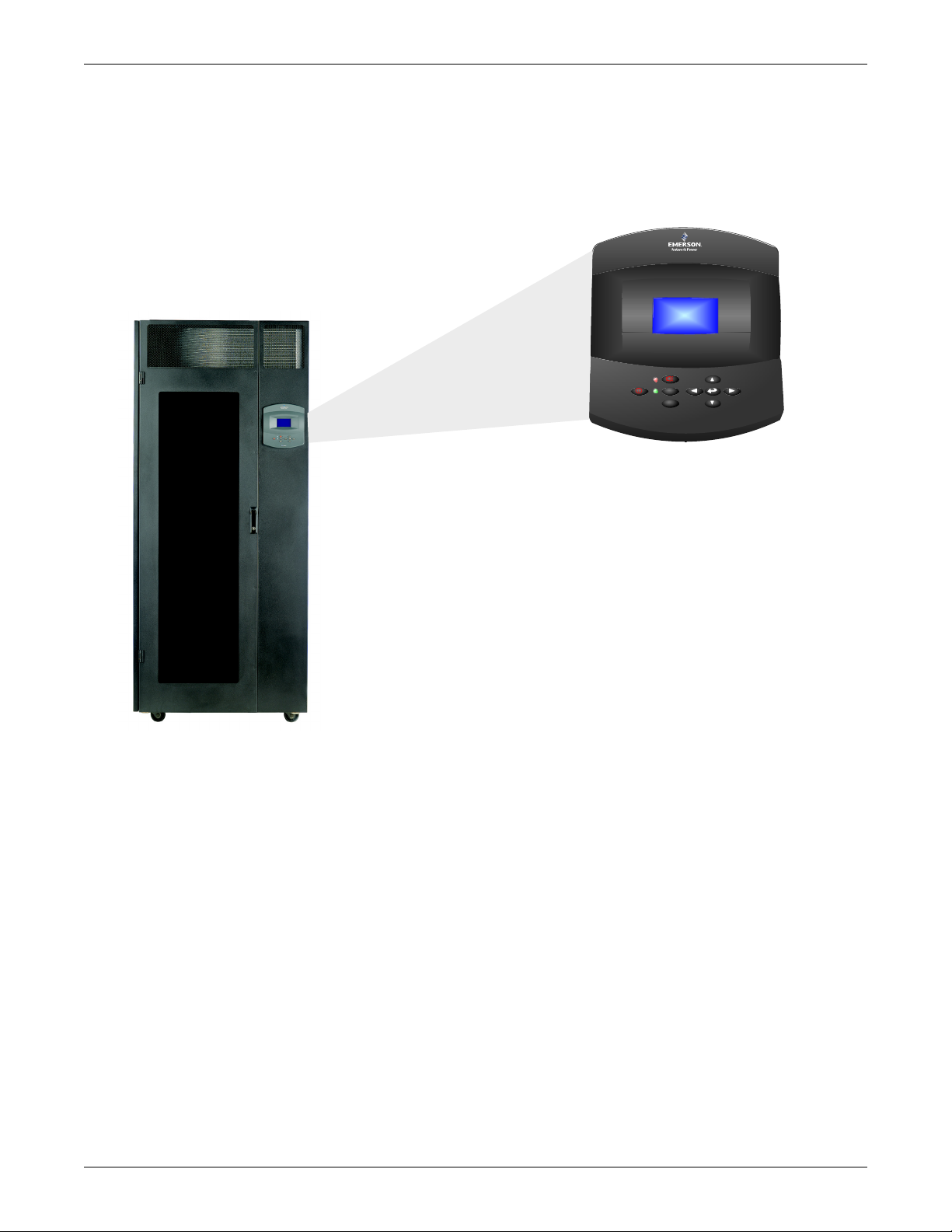

Figure 9 XDF with iCOM controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10 Water/glycol XDF supplied by closed-loop water system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 11 Water/glycol cooled general arrangement with drycooler as coolant source . . . . . . . . . . . . . . . . . 14

Figure 12 Optional power equipment, examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 13 Recommended unit handling equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 14 Removing XDF packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 15 Remove lag bolts and brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 16 Roll XDF off the shipping skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 17 XDF clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 18 Alternate condenser fan power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 19 Condensate drain connection and adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 20 Recommended equipment arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 21 Customer electrical connections and cable entry points—self-contained, air cooled units. . . . . . 31

Figure 22 Customer electrical connections and cable entry points—water/glycol cooled units . . . . . . . . . . 32

Figure 23 Route input power cords through XDF top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 24 Cable rings, Velcro straps on XDF rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 25 Cable Management Channel lengths. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 26 Cable management mounting locations and options: Velcro cable straps, Cable Spools . . . . . . . 36

Figure 27 Cable management accessories: Cable Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 28 iCOM controller keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 29 iCOM display components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 30 iCOM graphical display default screen components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 31 iCOM simple display default screen components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 32 iCOM user menu, Page 1 of 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 33 Accessing additional menu lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 34 Display setup screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 35 Airflow pattern, backup ventilation operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 36 XDF model numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

iii

Page 6

TABLES

Table 1 Optional condensate pump performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 2 Water supply flow rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 3 Ethylene glycol concentrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 4 Glycol supply flow rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 5 Drycooler selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 6 Volume in standard Type “L” copper piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 7 Keyboard icons and functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 8 User menu icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 9 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 10 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 11 Total heat rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 12 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 13 UPS performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 14 MP Advanced Power Strip specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

iv

Page 7

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that must be closely followed during installation and

maintenance of this unit to maintain compliance with agency listings. Read all safety and operating

instructions before attempting to operate the XDF. Adhere to all warnings on the unit and in this

manual. Follow all operating and user instructions.

This product is designed for commercial / industrial use only. This product is not intended for use

with life support or other U.S. FDA designated “critical” devices. Maximum loads must not exceed

those shown on the Liebert XDF serial tag.

Operate this product in an indoor environment at an ambient temperature between 35°F and 104°F

(1.6°C to 40°C). Install in a clean environment, free from moisture, flammable liquids, gases and corrosive substances.

This product must be connected to and powered by suitable AC supplies, rated in accordance with the

unit’s serial tag. It must be suitably grounded and protected by circuit breakers or fuses.

Power extension cables, if used, must be rated for the load and must not exceed 20 ft. (6.1m) in length.

Liebert recommends using shielded cables for all external communication interfaces.

Ensure that the XDF has proper ventilation. Never block or insert objects into the ventilation holes or

other openings. Maintain a minimum clearance of 36 in. (915mm) in front, behind, on the right side

and above the self-contained, air cooled XDF for proper airflow and service. The water/glycol cooled

XDF requires 36 in. (915mm) clearance in front, behind and on the right side. It does not require top

clearance.

1

Page 8

1.0 GLOSSARY OF SYMBOLS

Hazardous Voltage Present

Note following instructions

Consult user manual for additional information

Indicates weight

Glossary of Symbols

Indicates ground connection

Indicates alternating current

2

Page 9

Product Description

2.0 PRODUCT DESCRIPTION

Congratulations on purchasing a Liebert XDF. The XDF is an integrated equipment cabinet with

built-in cooling and intelligent control to protect mission-critical enterprise systems from extreme

heat. The XDF provides an organized, secure, controlled environment for your sensitive electronic

equipment. The unit is available in a variety of configurations to suit your electronic equipment’s

environmental requirements.

The self-contained, air cooled Liebert XDF is intended for installation in open areas. Installation in

closed-in areas, such as in a closet, alcove or similar space, requires field-supplied ducting, an external booster fan and sufficient makeup air. Contact your local Liebert representative before installing

the XDF in an area that might inhibit heat dissipation.

The water/glycol cooled unit, however may be installed in closed-in areas, subject to clearances of

three feet in the front, rear and right side. See Figure 6. This is possible because heat rejected from

the XDF cabinet is carried away in the coolant.

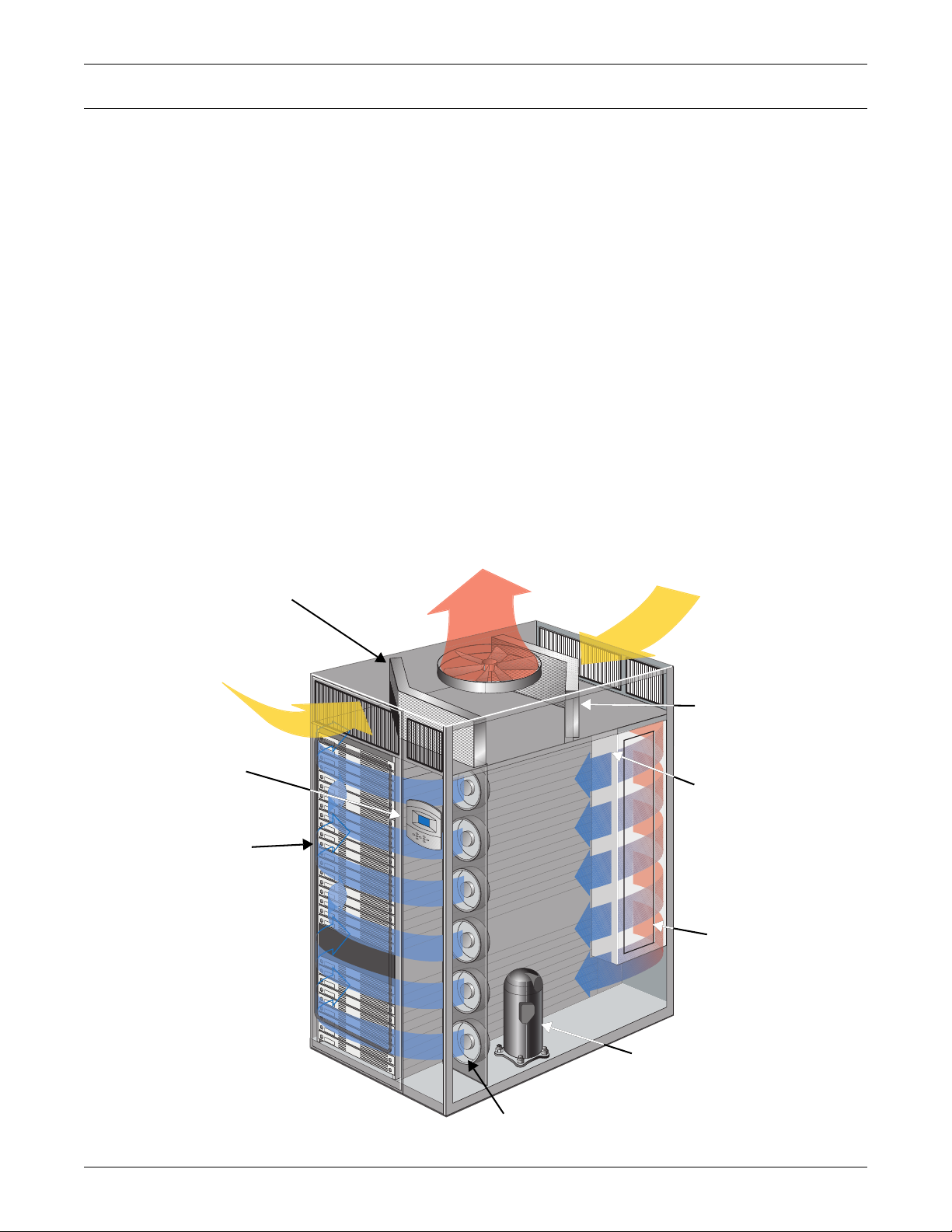

2.1 Operational Overview—Self-Contained, Air Cooled Model

The self-contained, air cooled XDF model employs a compressorized, direct expansion cooling system

rated at 14kW to supply cooling air to rack-mounted equipment. A bank of fans circulates this cooling

air through the electronic equipment in the XDF (see Figure 1). An evaporator coil extracts heat

from the circulating air. That heat is transferred to a condenser at the top of the XDF and exhausted

into the room.

The XDF’s backup ventilation system operates automatically if power fails or if any XDF cooling system component fails.

Figure 1 Component location, general operational layout of self-contained, air cooled model

Condenser Coil transfers

heat extracted from

electronic equipment

cabinet to incoming air

Heated Air Exhaust

Condenser Air

Entry Point

iCOM Controller

Rack-Mount Equipment

Compartment (isolated

from external air and top

condenser section)

Condenser Air

Entry Point

Condenser

Coil - 1 of 2

Evaporator Coil

extracts heat from

air circulated through

the rack equipment

compartment

Backup Ventilation

Air Intake

Compressor

Evaporator Fans

circulate cooling air

3

Page 10

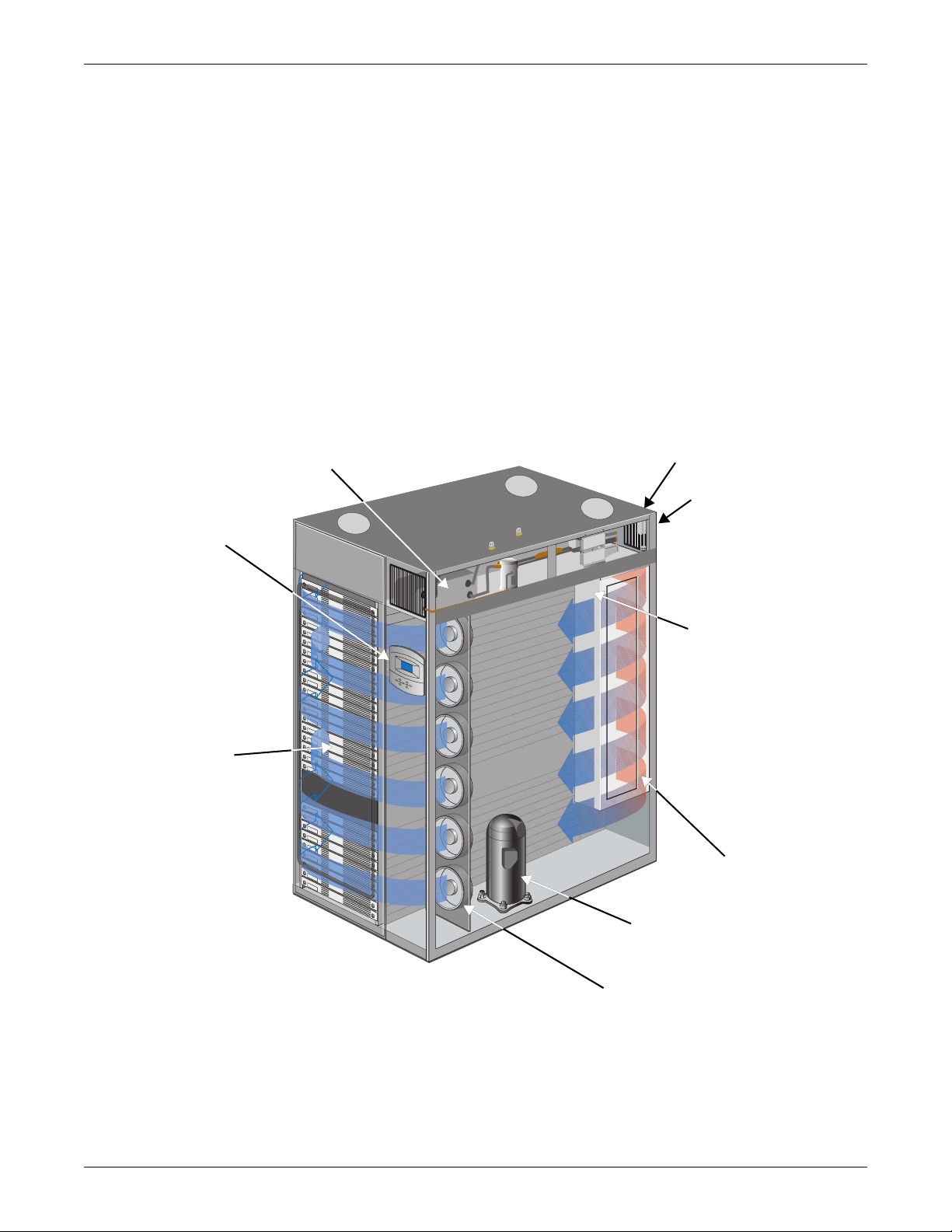

2.2 Operational Overview - Water/Glycol Cooled Model

The water/glycol cooled XDF model employs a single-stage cooling system rated at 14kW to supply

cooling air to the rack-mounted equipment. A bank of fans circulates this cooling air through the electronic equipment in the XDF (see Figure 1).

An evaporator coil extracts heat from the circulating air. That heat is transferred to a brazed plate

condenser at the top of the XDF, transferred to the cooling water or glycol solution and is piped out of

the unit.

Coolant is piped through the back of the XDF through supply and return pipes with 1" female NPT

connections (refer to Figure 2 or Figure 6).

The XDF’s backup ventilation system operates automatically if power fails or if any XDF cooling system component fails.

If water is used as the coolant, Liebert recommends employing a closed system connected to an external condensing unit. A closed water supply system protects the XDF from particles and other contaminants that might reduce cooling efficiency and damage the XDF.

Figure 2 Component location of water/glycol cooled model

Brazed Plate

Condenser

(behind grille)

Product Description

Coolant Return - in rear

Coolant Supply - in rear

iCOM Controller

Rack-Mount

Equipment

Compartment

(isolated from

external air)

Front of XDF

Evaporator Coil

extracts heat from

air circulated

through

the rack equipment

compartment

Backup Ventilation

Air Intake

Compressor

Evaporator Fans

circulate cooling air

4

Page 11

Figure 3 Component location, rear of XDF

SELF-CONTAINED

AIRCOOLEDMODEL

Condenser air intakes,

perforated grilles

Product Description

Condenser fan

(removable to reduce

height temporarily)

Backup ventilation

damper (air exit)

Service access for

gauges to be inserted

for testing

Three-phase electrical

cord, 10 feet (3m)

Single-phase electrical cord,

10 feet (3m)

WATER/GLYCOL COOLED MODEL

Return Line

(1" female,

NPT)

Casters

Door handle

Rear door

Condensate drain

Stabilizing foot

(one of four)

Supply Line

(1" female, NPT)

Backup ventilation

damper (air exit)

Service access for

gauges to be inserted

for testing

Three-phase electrical

cord, 10 feet (3m)

Single-phase electrical cord,

10 feet (3m)

Door handle

Rear door

Condensate drain

Stabilizing foot

Casters

5

(one of four)

Page 12

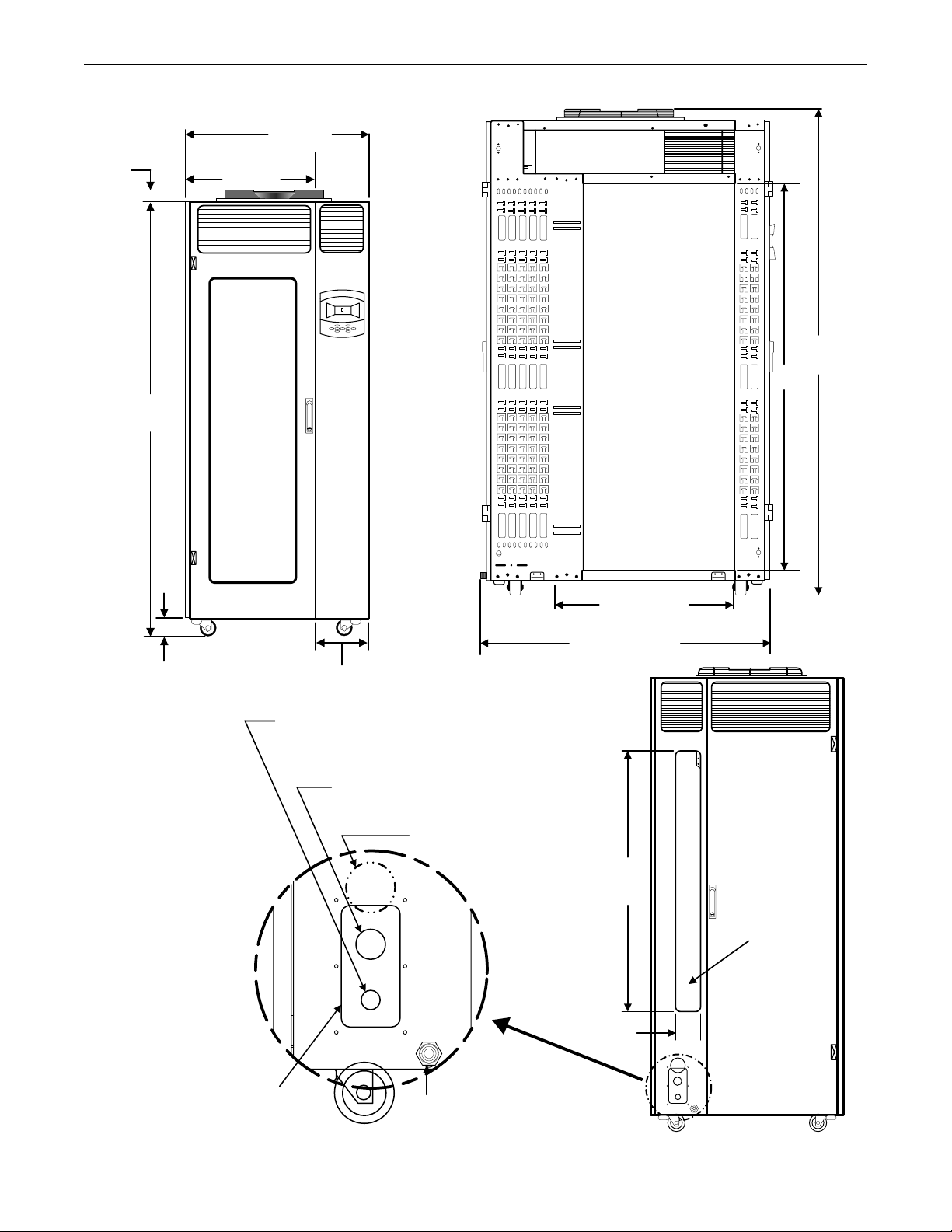

Figure 4 Dimensional data, self-contained, air cooled model

34-1/8"

(867mm)

24-1/8"

Control

Side

2-1/2"

(64mm)

(2026mm)

Rack Section

(613mm)

79-3/4"

Product Description

82-1/4"

(2089mm)

36U

2-5/8"

(68mm )

FRONT

Cooling Section

9-5/16" (252mm)

Single -Phase Power Cord

Entrance ; factory-supplied ,

10' (3m) NEMA 5- 15P

3-Phase Power Cord

Entrance ; factory - supplied ,

10' ( 3m) NEMA L21-30P

Capped Service

Gauge Access

LEFT SIDE

24-3/8" to 32-11/32

(620-821mm)

mounting depth

49-1/2” (1257mm)

45-3/4”

(1162mm)

Backup

Ventilation

Air Outlet

4-1/2”

(114mm)

Cover

Plate

DETAIL A

Condensate Drain

Connection

6

Detail

Area

“A”

REAR VIEW

Page 13

Figure 5 Dimensional data, water/glycol cooled model

Rack Section

24-1/8"

(613mm)

79-3/4"

(2026mm)

2-5/8"

(68mm)

Cooling Section

9-5/16" (252mm)

Control

Side

5-1/2”

(139.7mm)

1.88”

(47.6mm)

7”

(177mm)

45-3/4”

(1162mm)

Product Description

6.95”

(176.5mm)

Backup

Ventilation

Air Outlet

FRONT

42U

4-1/2”

(114mm)

Detail

Area

“A”

REAR VIEW

Single -Phase Power Cord

Entrance ; factory-supplied ,

10' (3m) NEMA 5- 15P

3-Phase Power Cord

Entrance ; factory - supplied ,

10' ( 3m) NEMA L21-30P

Capped Service

Gauge Access

LEFT SIDE

24-3/8" to 32-11/32

(620-821mm)

mounting depth

49-1/2” (1257mm)

Cover

Plate

Condensate Drain

Connection

DETAIL A

7

Page 14

Figure 6 Dimensional data, all models—top, bottom and cable entry cutouts

Product Description

4-3/8"

(112mm)

4"

(102mm)

4-1/2"

(114mm)

B

TOP VIEW

A

15"

(381mm)

BOTTOM VIEW

Front

Cable

Entry

Cutouts

4-1/2"

(114mm)

Self-contained, air cooled model shown; water cooled unit

dimensions are identical; water cooled unit does not have

condenser fan.

Cable Entry Cutout

Front

Stabilizing Foot,

1 of 4

A - Rack-Mount Width

EIA Nominal: 19" (483mm)

Inside Dimension: 17-13/16 (452)

B - Adjustable Mounting Depth

Minimum: 24" (620mm)

Maximum: 32-11/32 (821)

Caster, 1 of 4

8

Page 15

XDF Components

3.0 XDF COMPONENTS

3.1 Standard Components—Self-Contained, Air Cooled and Water/Glycol Cooled

Models

3.1.1 Frame

The self-contained, air cooled XDF is 82-1/4 inches (2089mm) tall; the water/glycol cooled unit, 79-3/4

(2026) tall. The self-contained, air cooled XDF has 36U (63 inches) of usable rack height. The

water/glycol cooled XDF has 42U (73-1/2 inches) of usable rack height. Both the self-contained, air

cooled and water/glycol cooled XDF units have a standard EIA rack width of 19 inches (483mm).

The XDF frame consists of heavy-duty, riveted, 12-gauge steel. The unit has fixed front rails and

adjustable rear rails with square holes for installing rack-mount equipment. The front and rear vertical frame members accommodate internal mounting rail options and provide space to route and manage cabling.

Cutouts in the top (front and rear) permit customer cable entry (Figure 6). All units have casters,

stabilizing feet and a grounding lug.

3.1.2 Enclosure

The XDF is equipped with seals to maintain a separate air volume inside the equipment compartment.

NOTE

Preventing air infiltration into the XDF will significantly improve overall performance and

reduce the amount of condensate generated. Ensure that all cable entrances are sealed and that

doors are closed securely. Check to ensure that all panels are properly installed; this is

especially important if panels have been removed in the field.

3.1.3 Doors

The front and rear doors are framed from sheet metal and are removable. A multi-point latch with

key lock is provided for security. The front door may be either solid sheet metal or have a Plexiglas

window for viewing installed equipment. The rear door is solid, full-height sheet metal.

3.1.4 Side Panels

Side panels are constructed of sheet metal and use special fasteners to permit removal for maintenance. Insulation is included to provide improved thermal and sound insulation, as well as to prevent

condensate formation on the outside of the unit.

™

9

Page 16

3.1.5 Environmental Control

The XDF supplies cooling air—68°F to 77°F (20-25°C)—to electronic equipment in the rack-mount

equipment compartment.

In normal operation, six fans at the right front corner of the XDF circulate cooling air through the

equipment compartment. The laterally circulating air absorbs heat generated by the electronic equipment and transfers the heat to an evaporator coil at the right rear of the XDF. The heat is removed

differently in the self-contained, air cooled and water/glycol cooled units.

Heat Removal—Self-Contained, Air Cooled XDF

Heat removed from the self-contained, air cooled XDF cabinet is transferred to condenser coils at the

top of the XDF, in a section separated from the equipment compartment. The condenser fan on top of

the self-contained, air cooled XDF draws ambient air through the condenser coils and exhausts the

heat-laden air into the room.

Heat Removal—Water/Glycol Cooled XDF

The water/glycol cooled XDF transfers the heat captured by the evaporator coil to a brazed plate condenser at the top of the unit, also separate from the equipment compartment. That heat is then carried away by the cooling water or glycol to a condenser or drycooler.

Figure 7 Cooling system components—self-contained, air cooled models

XDF Components

Condenser Fan

Condenser Coil

Condenser Air

Intake Vent for

Normal Operation

Backup Ventilation Intake

Vent (exhaust vent is on

rear)

Evaporator Coil (behind

damper) extracts heat

from circulated air

10

RearFront

Page 17

Figure 8 Cooling system components—water cooled models

Brazed Plate

Condenser

XDF Components

Coolant

Return Connection

Coolant

Supply

Connection

Backup Ventilation Intake

Vent (exhaust vent is on

rear)

Evaporator Coil

(behind damper)

extracts heat from circulated air

RearFront

11

Page 18

3.1.6 Control—Liebert’s iCOM Controller

The XDF is equipped with Liebert’s iCOM controller for all programming functions on the XDF. The

menu-driven, 128 x 64 dot matrix graphic display shows the status of the conditioned space, setpoints, alarm status and settings, event histories and the time.

Refer to 10.2 - iCOM Components and Functions and 10.3 - Navigating Through the iCOM

Display for details or call 800-543-2778.

Figure 9 XDF with iCOM controller

XDF Components

?

ESC

Liebert iCOM controller

12

Page 19

3.2 Coolant Source—Water/Glycol Models

The XDF water/glycol cooled models may be connected to either of two types of coolant sources:

• a closed-loop water system (cooling tower)

• a drycooler loop

3.2.1 Closed-Loop Water System

A closed water supply system is required for efficiency and to protect the equipment from particles

and other contaminants that might obstruct the system’s piping.

CAUTION

!

Risk of dirt and debris contamination. May cause condenser clogging.

Do not install the XDF on an open-loop water supply system. Debris carried by the fluid will

clog the XDF’s brazed plate condenser.

Figure 10 Water/glycol XDF supplied by closed-loop water system

Closed-Loop

Water System

XDF Components

XDF

Return

Line

XDF

Supply

Line

Hose Bibs

13

Page 20

3.2.2 Drycooler Loop

The water/glycol cooled XDF model requires an external supply of coolant, either water or glycol, to

remove heat extracted from the XDF.

Contact the factory for drycooler requirements when connecting multiple XDF units. For information

on setting up a drycooler system, contact your local Liebert representative.

Figure 11 Water/glycol cooled general arrangement with drycooler as coolant source

Expansion Tank

(install at highest

point in system)

Supply

Line

Drycooler

XDF Components

XDF

Water/Glycol

Cooled

Pump

Return Line

14

Page 21

3.3 Optional Equipment

3.3.1 General Enclosure Options

• Sealed entrance cable bundle

• Cable tray

• Cable Management Channels

•Cable rings

• Velcro cable management straps

• Fixed shelves, vented, 250lb (113kg) capacity

• Pullout shelves, vented, 130lb (59kg) capacity

• Fixed rails, 150lb (68kg) capacity

• Internal keyboard tray

• Mounting clip nuts and screws 10-32 or M6 thread

• Condensate Pump

3.3.2 Power Options

MP Advanced Power Strips and Controllers

Power distribution to equipment in your XDF may be eased with optional Liebert MP Advanced

Power Strips. These power strips are available in single- and three-phase power options; some units

offer remote monitoring and individual receptacle control. For details, see Table 14 - MP Advanced

Power Strip specifications or refer to the MP Advanced Power Strip user manual, SL-28015.

MP Advanced Power Strips may be monitored and controlled with these Liebert units:

MP Advanced Access Servers—Monitors and controls up to 32 MP Advanced Power Strips.

This unit permits control of the full strip or single outlets to reboot or turn equipment On or Off.

It also sets parameters for alarms and status notifications.

OpenComms EM——Monitors and controls up to two MP Advanced Power Strips. This unit permits control of the full strip or single outlets to reboot or turn equipment On or Off. It also sets

parameters for alarms and status notifications.

XDF Components

Uninterruptible Power Supply

An Uninterruptible Power Supply (UPS) can provide your electronic equipment with surge protection

and suppression, as well as voltage and frequency regulation, preventing damage to the hardware. A

UPS provides time to perform a controlled shutdown of your operating system, allowing you to save

valuable data. Liebert online, double-conversion UPS systems also condition utility power, eliminating damaging power transients.

The following Liebert UPS models are available for installation in the XDF:

On-Line UPS Systems

• GXT2 - 500, 700, 1000, 1500, 2000, 2700 and 3000RT120

• GXT2-6000RT208, GXT2-10000RT208

Line Interactive Systems

• PS1000, 1440, 2200 and 3000RT2-120

Refer to the UPS user manual for further details.

Figure 12 Optional power equipment, examples

Liebert

U

P

S

ta

tio

n

G

X

T

+

–

A

C

I

N

P

U

T

B

A

T

T

E

R

Y

U

P

S

O

N

B

Y

P

A

S

S

GXT2U UPS and Additional Battery Cabinet

!

UPStation GXT

15

GXT2-10000RT208 UPS

and Additional Battery Cabinet

Page 22

4.0 INSTALLATION

4.1 Inspection

Upon arrival of the unit, and before unpacking it, verify that the delivered equipment matches the bill

of lading. Examine the packaging for any signs of mishandling or damage. Inspect all items for damage, visible or concealed. Report any damage immediately to the carrier and file a damage claim. Send

a copy to Liebert Corporation or to your sales representative.

Packing Material

All material used to package this unit is recyclable. Please save the material for future use or dispose

of it appropriately.

4.2 Recommended Setup Equipment

• pallet jack or forklift

• utility knife

• 3/8" ratchet or wrench

4.3 Unloading the XDF

WARNING

!

Risk of top-heavy unit falling over. Can cause death, injury and equipment damage.

Installation

Read all of the following instructions before attempting to move, lift or remove packaging

from the unit.

CAUTION

!

Risk of sharp edges, splinters and exposed fasteners. Can cause personal injury.

Only trained personnel wearing appropriate safety headgear, gloves, shoes and glasses should

attempt to move, lift or remove packaging from the unit or prepare the unit for installation.

CAUTION

!

Risk of overhead interference. Can damage the unit and structure.

The unit may be too tall to fit through a doorway while on the skid. Measure the unit and

doorway heights and refer to the installation plans to verify clearances before moving the

unit.

CAUTION

!

Risk of frozen fluids. Can cause equipment damage.

Keep the unit upright, indoors and protected from dampness, freezing temperatures and

contact damage.

16

Page 23

4.3.1 Handling the Unit While It is Packaged

• If possible, transport the XDF using a forklift or pallet jack. Otherwise use a crane with belts or

cables and spreader bars to protect the XDF’s sides from damage.

• If using a forklift or pallet jack, make sure the forks (if adjustable) are spread to the widest distance that fit under the skid. Also, ensure the fork length is suitable for the unit length.

• When moving the packaged XDF, do not lift it any higher than 6" (152mm) off the ground. Exercise great care if the XDF must be lifted higher than 6" (152mm); any personnel not directly

involved in lifting the XDF must be at least 20' (5m) from the unit.

Figure 13 Recommended unit handling equipment

Fork Lift Pallet Jack

4.3.2 Unpack the XDF

1. Remove the exterior stretch-wrap packaging material from around the XDF, exposing the

protective corner and side packaging planks (see Figure 14).

2. Remove the corner and side packaging planks from the XDF, exposing the bag over the unit.

The bag may remain in place to protect the XDF from dust and scratches or removed for immedi-

ate unit installation.

Ensure the metal ramps stay with the XDF for removal from the skid.

3. Remove the bag from the XDF when ready to remove the skid and install the unit.

Installation

Figure 14 Removing XDF packaging

1. Remove the exterior

stretch-wrap packaging

2. Remove the corner and

side packaging planks

Self-contained, air cooled unit shown;

steps apply to all XDF units

3. Remove the bag

17

Page 24

4.3.3 Removing the XDF from Skid

This unit is on casters—to prevent it from rolling, ensure that the skid is on a flat surface before

removing the XDF from the skid.

1. Remove eight lag bolts from the unit tie-down brackets on the controls side of the unit.

2. Remove the four tie-down brackets from the controls side of the unit (see Figure 15).

3. Find the ramps that were shipped with the unit.

4. Insert the two tabs on each ramp into the holes on the skid.

5. Remove eight lag bolts from the unit tie-down brackets on the side opposite the controls.

6. Remove the four tie-down brackets from the side opposite the controls.

Unit weight when empty is 710 lb (322kg). Weight may differ if optional equipment has been

installed. Refer to the packing slip for the unit’s exact weight.

7. Remove the XDF by rolling it off of the ramp using an appropriate number of personnel and

rigging based on the unit weight (see Figure 16).

Once off of the skid, the unit can be rolled to the installation site.

NOTE

If the self-contained, air cooled XDF is too tall to pass through a doorway, the condenser fan

assembly may be removed, reducing the height by 2-1/2" (64mm).

Figure 15 Remove lag bolts and brackets

Installation

Right front corner detail

(controls side of XDF)

Four (4) Lag Bolts and Two Brackets Per Corner

18

Page 25

Figure 16 Roll XDF off the shipping skid

Fit tabs on ramps

into holes on

front of skid

Installation

Appropriate number of

workers roll XDF ...

Self-contained, air cooled unit shown;

steps apply to all XDF units

... off the skid onto level surface

and roll unit to installation location

19

Page 26

4.4 XDF Site Preparation

When deciding where to place your Liebert XDF, keep in mind these factors:

• electricity is required to operate the compressor (208V-3ph-60Hz) and the controls and evaporator

fans (120V-1ph-60Hz)

• adequate ventilation and makeup air are necessary for proper equipment operation and protection

• service clearance must be provided

• the XDF must be on a level surface to ensure proper operation

• condensate must be drained, either by gravity-fed drain or optional condensate pump

• water/glycol cooled units require connection to a water or drycooler loop

Liebert’s self-contained, air cooled XDF is intended for installation in open areas. Field-supplied ducting, an external booster fan and sufficient makeup air are required for installing a self-contained, air

cooled model in closed-in areas, such as in a closet, alcove or similar space. Contact your local Liebert

representative before installing the XDF in an area that might inhibit heat dissipation.

Note the dimensions of your XDF to determine the space required. The self-contained, air cooled XDF

requires clearance of 36 in. (915mm) at the top, front, back and right side for equipment access and

service (see Figure 17). The water/glycol XDF requires clearance of 36 in. (915mm) at the front, back

and right side for equipment access and service; no top clearance is required.

Figure 17 XDF clearances

Installation

Self-Contained, Air Cooled

model shown.

Water/Glycol models do not

require top clearance.

36" (915mm)

Emerson

Network Power

36"

(915mm)

36"

(915mm)

20

36"

(915mm)

Page 27

4.5 Voltage Requirements

All XDF systems require two input power circuits. Each power cord is 10 feet (3m) long. For the full load

amp requirements of each option, refer to 12.1 - Optional Power Systems or the component’s user

manual.

4.5.1 Voltage Input Requirements

The first input connection provides power—120V-1ph-60Hz, line-to-neutral—to the controls, evaporator fans and condenser fan. This input’s power cord has a NEMA 5-15P plug. This power cord should

be connected to a UPS-protected power source.

The second input connection on 60Hz XDF units provides power—208V-3ph-60Hz, with neutral—to

the compressor, optional condensate pump and an alternate connection for the condenser fan. (The

alternate connection for the condenser fan permits reducing the load on the UPS-protected power

source.) The 208V power cord has a NEMA L21-30P locking plug.

Changing Condenser Fan Power Source—Self-Contained, Air Cooled Units

WARNING

!

Risk of electric shock. Can cause death or injury.

Disconnect all local and remote electric power before working within and/or installing

equipment.

To change the power source connections:

1. Open the front door panel and look for two screws with Torx heads that secure the hinged corner

panel. The Torx-head screws are on the front doorjamb.

2. Extract the two screws and swing the panel open.

3. Remove the protective covering over the electrical connections (see Figure 18). The cover is

secured with two screws.

4. Find the connectors (see Figure 18) and pull apart the snap connection made at the factory.

5. Connect the alternate power source connector to the supply that feeds the condenser fan.

6. Reinstall the protective cover over the electrical connections.

7. Close the outer panel and reinsert the two Torx screws.

8. Close the front door.

Installation

Figure 18 Alternate condenser fan power connection

Power supply

to condenser fan

Default circuit connector

(connection made

at factory)

Protective cover

over high voltage

electrical

connections

Alternate circuit

connector to

condenser fan

21

Page 28

4.5.2 Uninterruptible Power Supply—Optional

If your XDF is equipped with a UPS, it will require connection to a dedicated electrical circuit. Review

the UPS’s user manual before connecting utility power to the unit.

4.5.3 MP Advanced Power Strips—Optional

MP Advanced Power Strips are available in several power ranges. Consult Table 14 in 12.0 - Specifications or the MP Advanced Power Strip user manual, SL-28015, for your model’s power require-

ments.

4.5.4 Condensate Drain Connection

The XDF cooling process removes humidity from the air inside the cabinet. The moisture is collected

in a pan and must be removed from the cabinet. The condensate may be fed into a gravity drain or

pumped away with an optional, factory-installed condensate pump.

The gravity-fed drain line must be pitched a minimum of 1/8" per foot (11mm per meter).

Table 1 Optional condensate pump performance

Maximum Head,

Model

60Hz 18 (5.49)

50Hz 14 (4.27)

The standard XDF condensate drain is a 1/2" NPT female pipe connector. A factory-supplied adapter

permits connecting a 3/4" hose, the same size as a standard garden hose. The adapter is shipped with

the cabinet (see Figure 19).

feet (m)

Installation

Figure 19 Condensate drain connection and adapter

Bottom Right Rear Corner of XDF

Condensate Drain Connection

1/2” NPT female connector

or 3/4” garden hose with

adapter (as shipped)

4.6 Drycooler Installation—Water/Glycol Cooled Model

For details on installing the drycooler, contact your local Liebert representative.

22

Page 29

4.7 Equipment Layout

WARNING

!

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power before working within and/or installing

equipment.

Before installing or rearranging equipment, ensure the equipment and the UPS are switched

off. Ensure that all electrical sources are disconnected.

The lateral, circular flow of cooling air permits arranging equipment as required for stability if the

XDF is filled or nearly filled with equipment. Install heavier equipment first, placing it in the lower

racks of the XDF. This keeps the XDF from having a high center of gravity, which could make it easier to tip over (see Figure 20).

The XDF may be filled to capacity as long as the maximum heat load of 14kW is not exceeded. If the

XDF will not be filled with equipment, the equipment should be installed with a 1U space above and

below each unit. Again, install heavier equipment first, placing it in the bottom racks.

After all equipment has been installed, any remaining spaces larger than 5U at the top of the XDF

should be closed with optional blanking panels. (Panels are available in 1U, 2U, 3U, 4U, 5U and 10U.)

This arrangement prevents large, open expanses in the equipment compartment that would reduce

cooling efficiency by channeling airflow around the electronic gear.

Figure 20 Recommended equipment arrangement

Installation

Blanking Panels

in empty spaces

larger than 5U

Equipment

spaced 1U

apart

RECOMMENDED SPACING

Regular spacing of equipment 1U

apart and blanking panels

enhance cooling air distribution.

Heavier equipment at bottom

promotes stability

Large expanses

channel airflow

around equipment

INEFFICIENT SPACING

Irregular equipment spacing

prevents proper airflow for cooling.

Heavier equipment too high for

best stability

CAUTION

!

Risk of top-heavy unit falling over. Can cause death, injury and equipment damage.

Read all of the following instructions before attempting to move, lift or remove packaging

from the unit.

NOTE

All electrical receptacles and sockets in the vicinity of where the XDF will be used must be

ground/earth type.

23

Page 30

4.8 Frame and Enclosure Configurations

4.8.1 Internal Mounting Rails

The XDF can accommodate rack-mounted or free-standing computer and network equipment. The

unit features 19-inch (483mm) rear-mount rack rails. These internal mounting rails are designed in

accordance with the EIA 310D rack standard. The rails are adjustable for equipment of different

sizes.

Liebert offers these optional mounting hardware kits: fixed shelf, fixed rails, pullout shelf, 19-inch

(483mm) rack rail adapters and keyboard trays. Each kit includes installation hardware.

4.8.2 Rear-Mount Rails—Position

The XDF’s front rails are fixed into position, while rear-mount rails are

secured by carriage bolts that pass through horizontal slots in the frame.

These slots permit you to change the front-to-rear distance between the rails

as your application requires.

To position the rails:

1. Determine the proper location of the rails.

2. Loosen the bolts securing a rail to the frame.

3. Move the rail to the desired position (be sure to get the rail square).

4. Tighten the bolts securing the rails to the frame.

5. Repeat for the other rail.

6. Install your rack-mounted equipment or the shelves to hold your freestanding equipment.

Installation

NOTE

Before installing any electrical equipment, make sure that the

equipment is switched off.

4.9 Mounting Hardware

Optional mounting clip nuts and screws are available for mounting equipment

to the mounting rails. Clip nuts are metal clips with captive nuts that fit over

vertical rack rail holes, allowing individual placement of the mounting hardware. Each clip nut and screw package includes 10 clip nuts (Type 10/32 or

M6 threads) and screws.

Detail of Rack Rail

24

Page 31

4.10 Door—Remove

The XDF’s doors are removable for convenience when installing equipment.

4.10.1 Remove the Door

1. Remove the bolts securing the lower half of

each two-piece hinge to the door.

2. Remove the lower half of each hinge.

3. Lift the door straight up until the pins clear

the hinges.

4. Set the door in a safe place.

4.10.2 Quick Door Removal

For minimum-security installations that also

require frequent and fast removal of the door, the

lower half of the hinge assembly may be permanently removed. This allows for quick removal of

an open door by lifting the door straight up until

the pins clear the hinge mount.

4.11 Side Panels—Remove and Replace

XDF side panels are simple to remove and replace,

making it easier to install equipment and to service the XDF. Panel removal also improves access

for equipment maintenance and replacement.

Installation

Remove

this bolt

first

4.11.1 Remove the Left Panel

WARNING

!

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power before working within and/or installing

equipment.

To remove the left panel from the XDF:

1. The left panel is secured with two internal security quarter-turn fasteners and four panel

retainers. Open the doors and locate the internal security quarter-turn fasteners on the left side

panel. The security fasteners are at the top front and top rear corners of the panel.

2. Using the factory-supplied T-handle Allen wrench, turn the internal security fasteners

counterclockwise 90 degrees.

3. Locate the four panel retainers on the outside of the left XDF panel. One retainer is in each corner

of the panel.

4. Using the factory-supplied T-handle Allen wrench, turn the panel retainers counterclockwise

90 degrees.

CAUTION

!

Risk of heavy panel falling off. Can cause injury and/or equipment damage.

Support the panel when removing it. Unlocking the security fasteners and removing the panel

retainers will allow unsupported panel to fall.

5. Lift the panel off the lip at the bottom of the XDF and set it in a safe location.

25

Page 32

4.11.2 Remove the Right Panel

WARNING

!

Risk of electric shock. Can cause injury or death.

Disconnect all local and remote electric power before working within and/or installing

equipment.

To remove the right panel from the XDF:

1. Locate the four panel retainers on the outside of the right XDF panel. One retainer is in each

corner of the panel.

2. Using the factory-supplied T-handle Allen wrench, turn the panel retainers counterclockwise

90 degrees.

CAUTION

!

Risk of heavy panel falling off. Can cause injury and/or equipment damage.

Support the panel when removing it. Unlocking the security fasteners and removing the panel

retainers will allow unsupported panel to fall.

3. Lift the panel off the lip at the bottom of the XDF and set it in a safe location.

4.11.3 Replace a Panel

1. Set the panel on the lip at the bottom of the XDF frame.

2. Using the factory-supplied T-handle Allen wrench, turn each of the four panel retainers clockwise

90 degrees.

3. Left panel only: Using the factory-supplied T-handle Allen wrench, turn the internal security

fasteners clockwise 90 degrees.

Installation

26

Page 33

Piping Considerations—Water/Glycol Models Only

5.0 PIPING CONSIDERATIONS—WATER/GLYCOL MODELS ONLY

The XDF’s supply and return fittings are on the upper portion of the rear of the unit (see Figure 6).

The 1-1/8" diameter pipes have one-inch female NPT fittings. The pipes are capped at the factory. Piping connections to the XDF should be done by qualified personnel. All work must be done in compliance with all national and local regulations.

5.1 General

Equipment damage and personal injury can result from improper piping installation, leak checking,

fluid chemistry and fluid maintenance.

• Follow local piping codes, safety codes and Liebert unit installation and maintenance instructions.

• Qualified personnel must install and inspect system piping.

• Contact a local water consultant regarding water quality, corrosion protection and freeze protection requirements.

CAUTION

!

Risk of dirt and debris contamination. May cause condenser clogging.

Do not install the XDF on an open-loop water supply system. Debris carried by the fluid

will clog the XDF’s brazed plate condenser.

CAUTION

!

Risk of piping stress. Can cause leaks and equipment damage.

To help prevent piping failures, supply and return lines must be supported so that their

weight does not bear on the XDF’s piping, on the drycooler or on the pumps.

5.2 Closed Loop Water System

Where water will be used as a coolant medium, Liebert recommends use of a closed-loop water system

with a cooling tower or similar heat dissipation method. For flow rates for the XDF water/glycol unit,

see Table 2.

Table 2 Water supply flow rates

Entering Water Temp.

EWT

65°F (18°C) 105°F (41°C) 15.0 (.95) 4.6 (13.8)

75°F (24°C) 105°F (41°C) 15.0 (.95) 4.6 (13.8)

85°F (29°C) 110°F (43°C) 15.0 (.95) 4.6 (13.8)

Table assumes 95°F ambient, 77°F discharge air, 10°F temperature rise on the heat transfer media.

Saturated Cond. Temp.

SCT

Flow Rate

GPM (l/s)

Pressure Drop

ft (kPa)

27

Page 34

Piping Considerations—Water/Glycol Models Only

5.2.1 Expansion Tanks, Fluid Relief Valves and Other Devices

An expansion tank must be provided for expansion and contraction of the fluid due to temperature

change in this closed system. Vents are required at system high points to vent trapped air when filling the system. A relief valve is also necessary.

Depending on the complexity of the system, various other devices may be specified. Pressure gauges,

flow switches, automatic air separator, tempering valves, standby pumps, sensors for electrical controls and flow switches are just a few of these devices.

Manual shutoff valves should be installed on the supply and return lines. In addition, multiple pump

packages require a check valve at the discharge of each pump to prevent back-flow through the

standby pump(s). These check valves permit isolating units for routine maintenance or in an emergency.

Liebert also recommends installing these items in the system:

• cleanable, 60 mesh filters—These filters will trap the particles in the coolant supply line and

extend the service life of the water cooled condenser.

• floor drains with wet traps or a leak-detection system, such as Liebert’s Liqui-tect

• hose bibs at the lowest point of the system to facilitate filling

• relief valve—to protect against burst water pipes

5.2.2 Corrosion Protection

Read and follow individual unit installation instructions for precautions regarding fluid system

design, material selection and use of field-provided devices. Liebert systems contain iron and copper

alloys that require appropriate corrosion protection.

Contact a local water consultant regarding water quality, corrosion and freeze protection requirements. Water chemistry varies greatly by location, as do the required additives, called inhibitors that

reduce the corrosive effect of the fluids on the piping systems and components. The chemistry of the

water used must be considered because water may contain corrosive elements that reduce the effectiveness of the inhibited formulation.

Surface waters that are classified as soft and are low in chloride and sulfate ion content (less than 100

parts per million each) should be used. Proper inhibitor maintenance must be performed to prevent

corrosion of the system. Consult glycol manufacturer for testing and maintenance of inhibitors.

Commercial ethylene glycol, when pure, is generally less corrosive to the common metals of construction than water itself. It will, however, assume the corrosivity of the water from which it is prepared

and may become increasingly corrosive with use if not properly mixed with corrosion inhibitors. For

further details on corrosion prevention, see 5.3.1 - Glycol Solutions.

Idle fluid allows the collection of sediment and that prevents the formation of a protective oxide layer

on the inside of tubes. Keep the unit switched On and the system pump operating.

5.2.3 Freeze Protection—Coolant Type and Insulation

Glycol solutions should be considered for use as a coolant to protect the coil against freezing and corrosion from water.

CAUTION

!

Risk of frozen fluid. Can cause piping rupture and equipment damage.

When the field piping or unit can be exposed to freezing temperatures, charge the system with

the proper percentage of glycol and water for the coldest design ambient to prevent freezing.

CAUTION

!

Risk of frozen fluid. Can cause piping rupture and equipment damage.

Immediately after using water for leak testing or system cleaning, charge the tested

system with the proper percentage of glycol and water for your coldest design ambient.

Complete system drain-down cannot be ensured and damage to the system could result

from freezing of residual water.

The minimum coolant temperature to be supplied to the XDF will determine whether the supply and

return lines require insulation to prevent condensation.

28

Page 35

5.3 Drycooler Loop System

5.3.1 Glycol Solutions

The percentage of glycol to water must be determined by using the lowest design outdoor temperature in

which the system is operating. Table 3 indicates the solution freeze point at several concentration levels

of ethylene glycol. Propylene glycol concentrations should be 1% higher than the ethylene glycol table values to find the freeze point. For example, 41% propylene glycol freezes at -10°F (-12°C).

Table 3 Ethylene glycol concentrations

% Glycol by Volume 0 * 10 20 30 40 50

Freezing Point °F (°C) 32 (0) 25 (-3.9) 16 (-8.9) 5 (-15.0) -10 (-23.3) -32 (-35.5)

Apparent Specific Gravity

@ 50°F (10°C)

* A minimal amount of glycol should be considered for inhibitive coil protection.

The user must determine whether the planned use of glycol complies with national, state and local

regulations.

CAUTION

!

Risk of material reaction. Can cause piping damage.

Galvanized pipe must not be used in or with systems or units that contain glycol.

Phosphates in the inhibitor can react with zinc in the galvanized pipe, precipitating an

insoluble material that can foul the system.

Piping Considerations—Water/Glycol Models Only

1 1.014 1.028 1.042 1.057 1.071

NOTE

When mishandled, glycol products pose a threat to the environment. Before using any glycol

products, review the latest Material Safety Data Sheets and ensure that you can use the

product safely. For Material Safety Data Sheets and other product safety information, contact

the nearest supplier.

Glycol manufacturers request that the customer read, understand and comply with the

information on the product packaging and in the current Material Safety Data Sheets. Make

this information available to anyone responsible for operation, maintenance and repair of the

drycooler and related equipment.

Typical inhibited formula ethylene glycol and propylene glycol manufacturers and suppliers are

Union Carbide (Ucartherm) or Dow Chemical (Dowtherm SR-1, Dowfrost). These glycols are supplied

with corrosion inhibitors and do not contain a silicone anti-leak formula. Do not use glycols with silicone anti-leak additives because they reduce cooling performance. Commercial ethylene glycol, when

pure, is generally less corrosive to the common metals of construction than water itself. Aqueous solutions of these glycols, however, assume the corrosivity of the water from which they are prepared and

may become increasingly corrosive with use if not mixed with corrosion inhibitors.

NOTE

Automotive antifreeze is unacceptable and must NOT be used.

Table 4 Glycol supply flow rates

Glycol Type

Ethylene (40%) 115°F (46°C) 135°F (57°C) 15.0 (.95) 11.6 (34.6)

Propylene (40%) 115°F (46°C) 135°F (57°C) 15.0 (.95) 18.5 (55.4)

Table assumes 95°F ambient, 77°F discharge air, 10°F temperature rise on the heat transfer media.

Entering Coolant

Temperature

Saturated Cond.

Temperature (SCT)

Flow Rate

GPM (l/s)

Pressure Drop

ft (kPa)

Table 5 Drycooler selection

Ambient

Temperature,

°F (°C)

95 (35.0) D** 092A 3/4 P13-0030 P02-0340

105 (40.6) D** 174A 3/4 P13-0030 P02-0340

110 (43.3) D** 225A 16 3/4 P13-0030 P02-0340

Drycooler

Model

Glycol Pump

HP

Standard Pump Model

1-Phase

(57 ft @ 15GPM)

High Head Pump Model

3-Phase

(70 ft @ 15GPM)

29

Page 36

Filling the XDF with Coolant—Water or Glycol

6.0 FILLING THE XDF WITH COOLANT—WATER OR GLYCOL

6.1 Preparing the System for Filling

It is important to remove any dirt, oil or metal filings that may contaminate the cooling system piping

in order to prevent contamination of the coolant and fouling of the drycooler piping (IF USED). The

system should be flushed thoroughly using a mild cleaning solution or high-quality water and then

completely drained before charging with coolant.

Cleaning new systems is just as important as cleaning old ones. New systems might be coated with oil

or a protective film; dirt and scale are also common. Any residual contaminants could adversely affect

the heat transfer stability and performance of your system. In many cases, in both old and new systems, special cleaners are needed to remove scale, rust and hydrocarbon foulants from pipes, manifolds and passages. Clean heat transfer surfaces are important in maintaining the integrity of the

cooling system. For more information on cleaners and degreasers, contact your sales representative.

Calculate the internal volume of the system as closely as possible. See Table 6 and Table 3 for unit

volumes. Use volume in Table 6 for glycol piping volumes.

6.1.1 XDF Water/Glycol Cooled Unit Volume

The water/glycol cooled XDF’s coolant capacity is 0.56 of a gallon (2.1 liters). In closed systems, additional coolant will be required for the piping. Refer to Table 6 for required amounts for various piping

sizes.

Table 6 Volume in standard Type “L” copper piping

Diameter (in.) Volume

Outside Inside Gal/Ft L/M

1/2 0.123 0.008 0.01

5/8 0.555 0.012 0.15

3/4 0.666 0.018 0.22

7/8 0.785 0.025 0.31

1-1/8 1.025 0.043 0.53

6.1.2 Filling the System with Water or Glycol

When filling the XDF with either water or glycol, keep air to a minimum. Air in glycol turns to foam

and is difficult and time-consuming to remove. (Anti-foam additives are available and may be considered.)

1. Open all operating systems to the loop.

2. With the top vent(s) open, fill the system from the bottom of the loop. This will allow the coolant to

push the air out of the top of the system, minimizing trapped air.

3. Fill to approximately 80% of calculated capacity.

Fill slowly from this point, checking fluid levels until the system is full.

NOTE

For glycol solution preparation and periodic testing, follow manufacturer's recommendations.

Do not mix products of different manufacturers.

30

Page 37

Electrical Connections

A

7.0 ELECTRICAL CONNECTIONS

Power is supplied to the XDF through two factory-connected power cords (120V and 208V). For more

information, refer to 4.5.1 - Voltage Input Requirements

Additional electrical connections required for operation depend on the equipment installed in the

XDF and remote communications desired.

The XDF has slots for two communication cards, such as Liebert’s Intellislot card, and two

alarm/warning hardwire connections. These connections are at the top left corner of the self-contained, air cooled XDF, inside the area housing the condenser coil (see Figure 21). For details, see

10.1 - Environmental Control. Water cooled XDF units have the connections on the top of the unit,

near the middle of the compartment (see Figure 22).

Alarm and warning contacts may be connected to monitoring equipment, such as Liebert’s Universal

Monitor and SiteLink equipment, as well as to building management systems. Consult the monitoring equipment’s user manual for details.

Figure 21 Customer electrical connections and cable entry points—self-contained, air cooled units

mbient

Temperature/Humidity

Sensor

Customer Connections:

75 & 76 Customer Alarm Contacts

94 & 95 Customer Warning Contacts

37 & 38 Remote Shutdown Contacts

(all contacts rated 1A, 24VAC maximum)

Communication

Card Slots (cards

Detail Area

provided when

option is selected)

Customer

Cable Entry

Points

Service

Gauge

Access

Three-Phase Power

Cord Entrance

Dashed line delineates

equipment compartment

Single-Phase Power

Cord Entrance

REAR of XDF

31

Move plate to back panel

LEFT SIDE of XDF

for alternate power cable routing

Page 38

Electrical Connections

Figure 22 Customer electrical connections and cable entry points—water/glycol cooled units

Ambient

Temperature/Humidity

Sensor

Customer Connections:

37 & 38 Remote Shutdown Contacts

75 & 76 Customer Alarm Contacts

94 & 95 Customer Warning Contacts

(Contacts listed from top to bottom;

All contacts rated 1A, 24VAC maximum)

Communication

Card Slots (cards

provided when

option is selected)

Customer

Cable Entry

Points

Dashed line

delineates

equipment

compartment

TOP VIEW

Rear

RETURN

(OUT)

SUPPLY

(IN)

Move plate to back panel for alternate

power cord routing (see also Figure 23)

Power connection locations

(refer to Figure 21 for details)

32

Page 39

7.1 Utility Power Supply

The XDF’s 120V and 208V input power cords are stored for shipment in a compartment at the bottom

left of the rear of the XDF. The 10 feet (3m) cords may be routed to power outlets on the floor or wall.

If the power connections are overhead, the cables may be routed inside the unit and out the top. Liebert recommends pulling the cables across the floor of the rack-mounted equipment compartment and

up the right rear side. This permits securing cables to the cable management cutouts along the inside

of the XDF.

WARNING

!

Before beginning any work inside the XDF, disconnect all power inputs to the XDF and

installed equipment.

7.1.1 Route Input Power Cables Through the XDF’s Top

To route the factory-supplied input power cables inside the unit and out the top:

1. Open the rear door, revealing the back of the rack-mount equipment compartment.

2. Remove the six Phillips screws securing the small metal plate at the bottom left (inside the rackmount equipment compartment; see Figures 21 and 23).

3. Remove the cable entry snap bushing at the top right side of the rack-mount equipment

compartment to access the condenser coil compartment.

4. Remove the cable entry snap bushing from the top of the XDF.

5. Attach an optional cable bundle to the top of the panel that separates the rack-mount equipment

compartment from the condenser compartment.

6. Feed the input power cords through the opening at the bottom of the XDF and route them through

the optional cable bundle and out the top (see Figure 23).

7. Secure the cable bundle seal around the input power cords.

8. Secure the input power cables to the side of the XDF with optional Velcro ties or cable rings.

9. Install the small plate removed in Step 2 on the back of the XDF just above the condensate drain

(see Figure 23).

10. Connect the input power cables to appropriate utility supplies.

Electrical Connections

Figure 23 Route input power cords through XDF top

Plate moved from inside

rack-mount equipment area

Route input power cables across

bottom of XDF to right rear side

Attach optional

cable bundle to

upper side of

cable entry cutout

Secure input

power cables

to side panel

33

Page 40

8.0 CABLE MANAGEMENT OPTIONS

The XDF is able to host many of the components of the Foundation cable management products. These

optional items deliver a flexible solution to rack-enclosure cable problems by utilizing a patent pending

platform to provide adaptive equipment and cabling support. Cable and equipment mounting options

are available to meet changing requirements.

8.1 Cable Management Considerations

When designing the equipment layout in the XDF, consider how cables must be run for each configuration and how cable runs affect cooling, access and operational factors. Separate power and communication cables to reduce electromagnetic interference.

Good cable management contributes to:

• Effective airflow for cooling

• Easier cable identification

• Improved access

• Reduced electromagnetic interference

• Proper bend radii, particularly for fiber optic cables

• Adequate support for large cables and heavy cable bundles

Several Foundation options are designed to facilitate structured cable management. These are

described in 8.4 - Optional Cable Management Channel.

NOTE

When installing cables, leave enough slack for the unit to be rolled forward or sideways.

Do not block or restrict cooling system discharge or return airflow.

Do not defeat the ground/earth connections between the utility/mains outlet and the XDF.

Cable Management Options

8.2 Cable Management

Once your equipment has been installed, you are ready to connect cables for power and communication. Before making any connections, check the equipment to ensure that all power switches are in

the OFF position.

Numerous cable entrances and management provisions are built into the XDF to ease cable installation.

Optional cable rings and Velcro straps, along with some components for routing cables, can be used

with the XDF. These help not only to keep your cables organized but also separate power and communications cables, reducing electromagnetic interference. A wide area is provided on the left rear side of

the frame to mount cable rings, Velcro straps and cable trays. This location contributes to cooling efficiency by keeping equipment cables out of the cooling air pattern (see Figure 26).

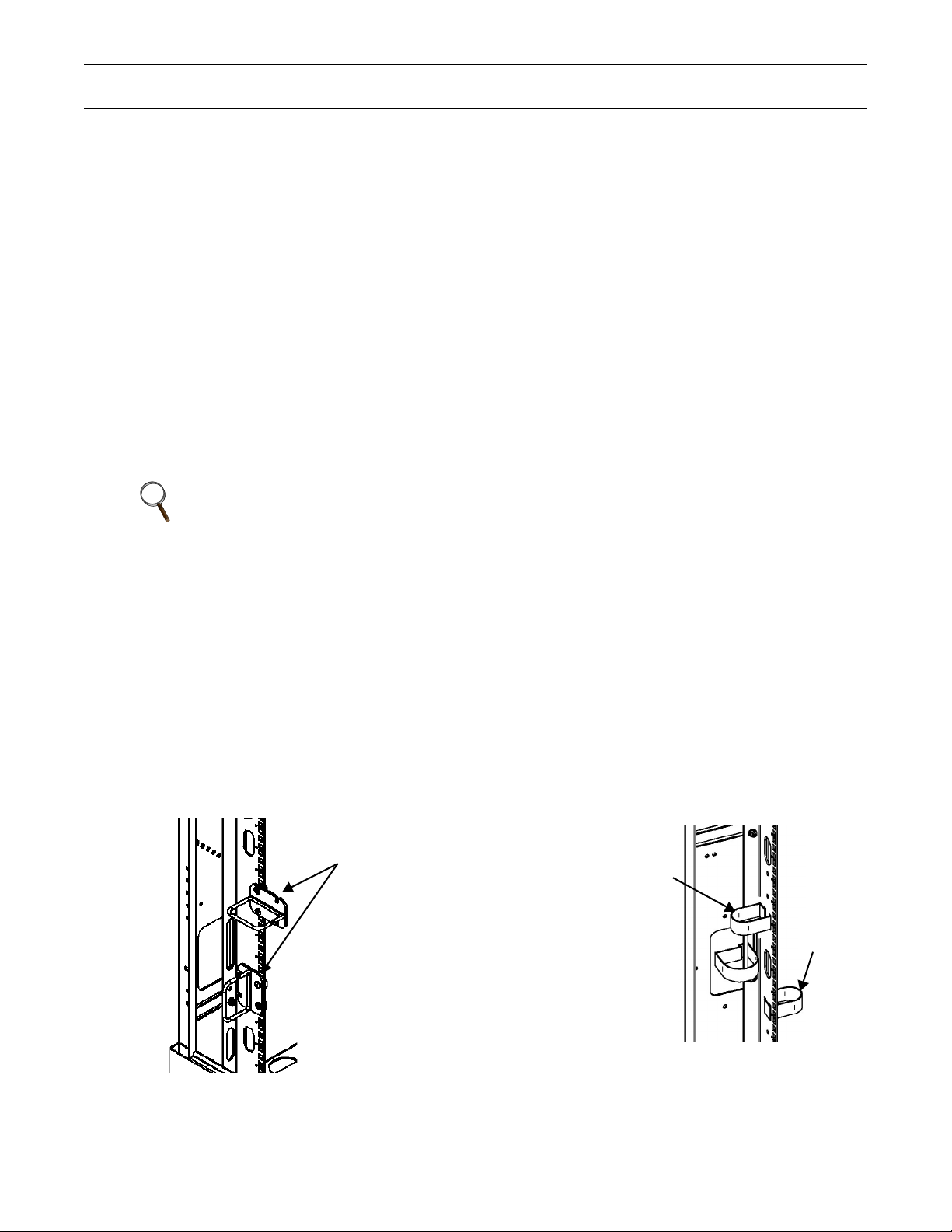

Figure 24 Cable rings, Velcro straps on XDF rails

Cable Rings

Mounted on Rail

Front

Strap

Optional Velcro Strap

Positioning on Rails Front

or Rear

Rear

Strap

34

Page 41

8.3 Cable Access

8.3.1 Top Cover and Back

Optional sealed entrance cable bundles (cone-shaped seals and clamps)

permit use of the round openings on the top of the XDF for cable entry.

To bring cable through these holes:

1. Replace the plug with a sealed entrance cable bundle.

2. Pull the cable through the bundle.

3. The cable bundle can be trimmed to accommodate various quantities

of cables.

4. Use the clamp to secure the bundle around the cables.

Cable Management Options

8.4 Optional Cable Management Channel

The optional Foundation Cable Management Channel (CMC) combines