Page 1

Liebert® DS

Designed To A Higher Standard Of Performance And Reliability

™

Page 2

Emerson Network Power Understands The Need For

Precision And Reliability...

And Why This Is So Important To You

For sensitive electronics, environmental

control is more than simple cooling.

“Comfort” air conditioning systems are

designed to cool people and office space.

They simply cannot provide the kind of

environment required by high performance

computer or communication equipment.

Why You Can’t Take Chances When

Cooling Your Critical Space

Standard building cooling systems are designed

to keep people comfortable 8-12 hours each

day from spring to autumn with no provision

for winter operation. A precision cooling system

is designed to operate over a wide range of

ambient temperatures from as low as -30°F

(-34.4°C) up to 120°F (48.9°C).

Sensitive electronics must be maintained in a

stable environment of 64.4°F to 80.6°F (18°C to

27°C) with moisture between 41.9°F (5.5°C) dew

point and 60% relative humidity with 59°F (15°C)

dew point. Computers and communications

equipment generate six to ten times the

heat density of normal of ce space, the air

conditioning system must have more than just

enough cooling capacity.

Liebert DS Is Ideally Suited For:

Data Centers

Computer Rooms

Network Operations

Telecom/CATV

Labs And Testing

Production Facilities

Centers

A Tradition Of Reliability You Can Count On

Liebert Precision Cooling equipment is the

standard by which all others are judged.

The number of units that are in the eld

far exceeds the combined number of all

other brands. Nine out of ten Fortune 500

Companies use Liebert cooling systems.

Liebert Precision Cooling Systems are used

in the most demanding, critical applications

in the world. From banking to government

to corporate computer and communications

centers, when it has to be the best—this is

the brand of choice.

It must have the precision to react quickly to

a drastic change in heat load and prevent wide

temperature fluctuations—something a large

building HVAC system cannot do.

Liebert® DS TM delivers Ef ciency Without Compromise

TM

Efficiency Without Compromise provides a path to optimize data center infrastructure around design, operating and

management efficiencies – while maintaining or improving availability. This is achieved through the proper selection and

utilization of cooling, power and monitoring technologies, supported by key services and local expertise.

INFRASTRUCTURE

MANAGEMENT

Improving performance

of the IT infrastructure

and environment

ECO AVAILABILITY

Balancing high levels of

availability and efficiency

FLEX CAPACITY

Adapting to IT changes for

continuous optimization

and design flexibility

HIGH DENSITY

Delivering architectures

from 10–60 kW/Rack to

minimize space and cost

2

Page 3

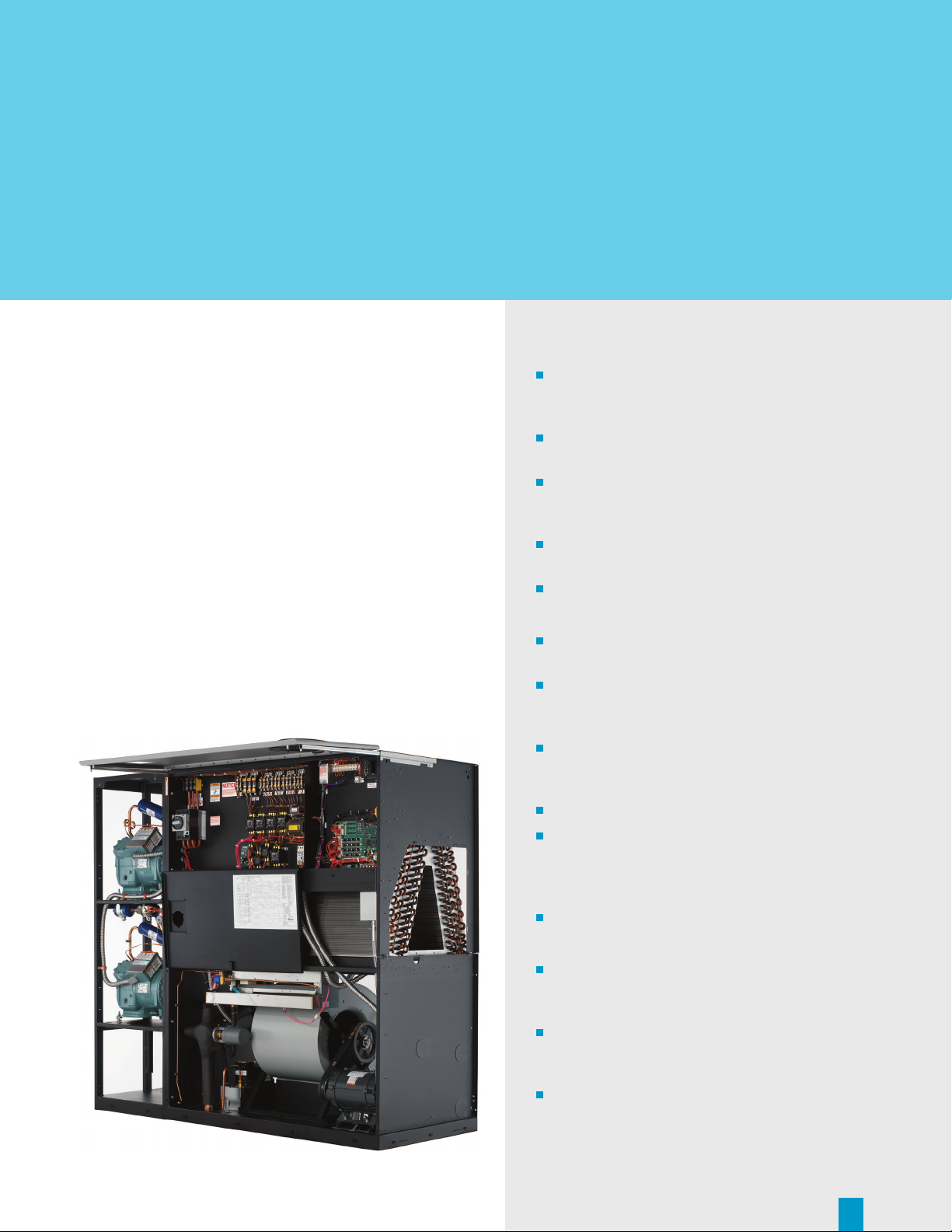

The Liebert® DS™ is Designed and Built

Like No Other

Why You Should Specify Liebert DS Over

Competitive Precision Systems

Proper protection of critical facilities takes more than

bolting together pre-engineered computer room cooling

modules. In many cases, your critical systems are only

as reliable as the support equipment protecting them.

Compromising on a less capable precision cooling system

can compromise your operations. Your critical operations

demand support equipment that can provide the highest

level of reliability.

Engineering Excellence Goes Into Every Liebert DS

The Liebert DS is based on the proven design and

technology of Liebert Deluxe Systems used in thousands of

critical data centers around the world since 1965. Full scale

analysis and evaluation of the Liebert DS during all phases

of development and production is your assurance of the

most advanced performance and highest quality. Units are

thoroughly tested under a wide variety of temperature and

humidity conditions.

Reliability:

The Liebert DS is designed with the highest quality

components selected for their proven reliability and

performance.

Microprocessor technology adds automatic sequencing

of components to even wear and extend service life.

An alarm system and self-diagnostics provide rapid

troubleshooting and can prevent a problem before it

affects the electronic equipment room environment.

Air delivery system designed for optimized air

distribution and long service life.

Corrosion resistant frame and cabinet.

Flexibility:

Available in both downow and upow congurations

to cover a wide range of room applications.

Choice of compressors to match performance and

energy efciency requirements.Front access provides

easy serviceability and saves valuable oor space.

Modular frame construction allows even more exibility

in meeting specic needs for installation—frame can be

eld-separated into three sections.

Built-in humidity control and reheat function.

Liebert iCOM control system brings high-level

supervision to multiple units allowing them to

work together as a single system to optimize room

performance.

R-407C environmentally friendly refrigerant.

Low Total Cost Of Ownership:

Energy efciency options and congurations can save

money and even pay back part of your investment over

the life of the product.

Built for serviceability, with many components—such as

the Paradenser™ cleanable condenser—designed to be

maintained rather than replaced.

Specically designed for the demanding requirements

of year-round operation, the Liebert DS is actually

less expensive to operate over its life cycle compared

to both comfort cooling equipment and competitive

precision air conditioning products.

3

Page 4

Engineered For Precision, Efciency And Strength

The Liebert® DS™ is designed to fit room applications

requiring high level precision control of the room

environment, including temperature, humidity,

filtration and airflow.

Precise Temperature And Humidity Control

The environmental control system must be able to sense

and react to temperature and humidity uctuations far too

small for building HVAC systems to control. The Liebert

DS is capable of control to within ±1°F (°C) and ±1% RH. By

analyzing the rate of change in temperature or the moisture

content in the environment, the control system anticipates

what is going to happen in the room, not simply responding

to what has happened.

Designed For Energy Efficiency

Liebert DS provides maximum energy efciency

without compromising the accuracy and reliability

demanded by sensitive electronics. All enhancements

to energy efciency are designed to reduce operating

time of key components and increase the Mean

Time Between Failure. This is accomplished by

taking advantage of alternate sources of cooling by

minimizing compressor operation when heat loads in

the conditioned space are lower. Energy savings is also

gained through the use of high efciency components

such as advanced digital scroll and 4-step semihermetic compressors.

Quality, Rugged Construction

The durable design of the Liebert DS provides a stable,

virtually vibrationless platform for compressor and fan

operation:

Autophoretic

corrosion for years of reliable service.

Welded frame—14 gauge steel provides rugged

construction, proven to withstand shipping and

handling through ISTA (International Safe Transit

Association) certied ship testing.

®

frame coating—protects frame against

Durable powder coated exterior panels—look good

and stay that way.

Slot and tab sheet metal—for consistent, quality

construction.

Optional double-skin panels—eliminate insulation in

the air stream. This allows for easy panel cleaning.

Optional floorstands—Adjustable standard and

seismic-rated oorstands allow for installation and

connection of the system prior to the installation of

the raised oor. Available in heights from 6” to 36”, a

eld installed turning vane may be specied.

4

Page 5

Front Access And Serviceability Save

Valuable Floor Space

Total front access provides space and

serviceability bene ts not found on

previous models or competitive units.

The Liebert

®

DS™ can be placed

adjacent to or in back of other

equipment or against a wall or

partition.

All key components are visible and

accessible—from the front of the unit

for easy maintenance and removal.

Compressors are removable from

front—isolated from air stream for

easier maintenance.

Modular Frame Construction

The unit’s modular frame

construction allows even more

exibility in meeting speci c needs

for installation, energy ef ciency and

other special requirements.

The frame can be eld-separated into

three sections—enabling the unit to

t into small elevators or through

other tight spaces.

5

Page 6

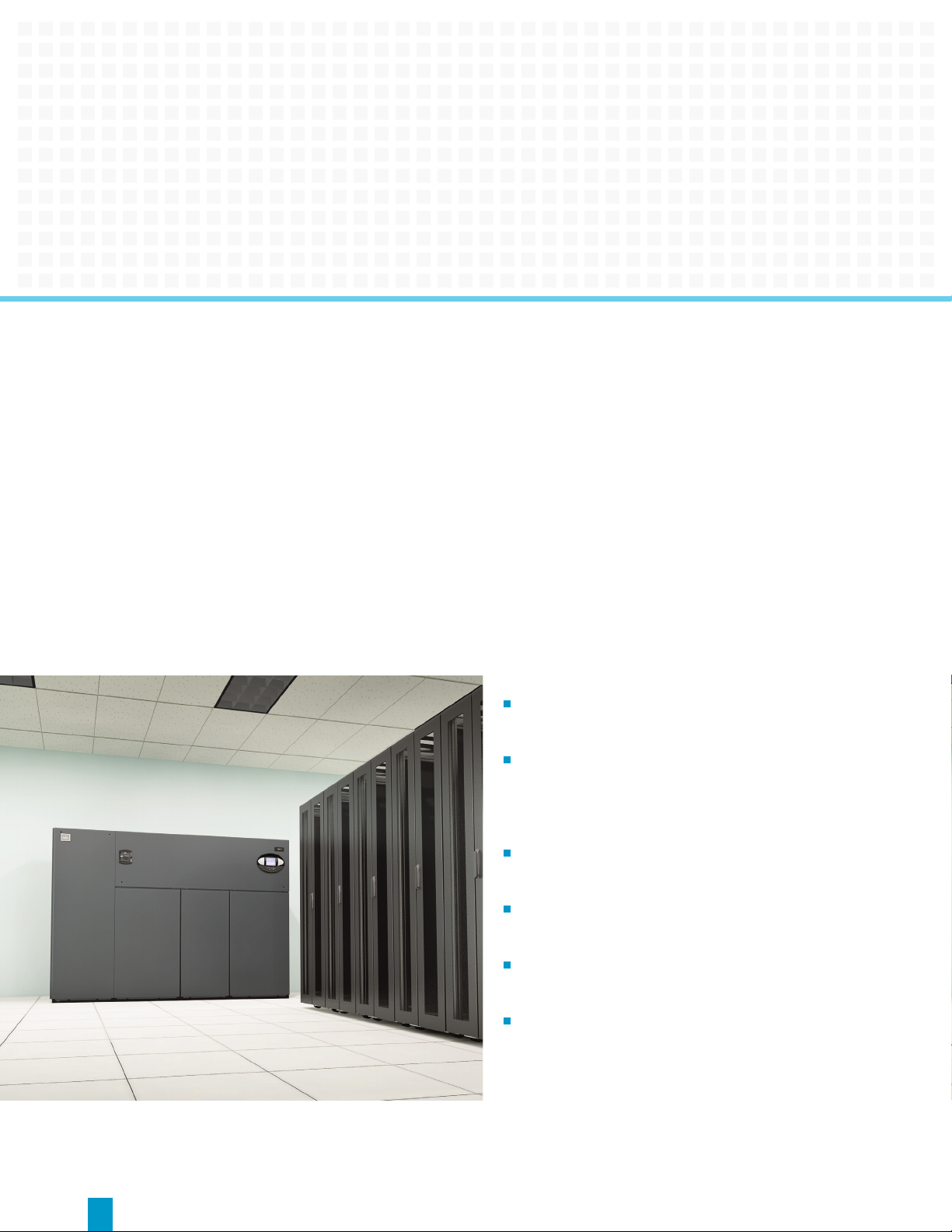

Flexible Cooling Congurations

The Liebert® DS™ provides a complete environmental

control package, including both precision air

conditioning as well as humidity control. Both upow

and downow congurations are available to cover

raised oor and non-raised applications.

The Liebert DS product line has been designed

to cover the widest possible range of application

requirements. These include choice of airow

conguration, cooling method options and many

other selections that will create the most effective and

efcient system for your facility.

Liebert DS Units Can Be Configured For Optimum

Cooling Of Any Type Of Space

Downflow congurations are designed for use in raised

oor applications such as data centers and other

facilities housing sensitive electronic equipment.

The Liebert DS downow conguration combines

top air return with bottom air supply to circulate air

underneath the oor.

Liebert DS Downflow

Upflow units can be specied in situations where

the oors are not raised, such as communications

facilities, industrial control rooms and laboratories.

These units can supply air directly into the room or be

connected to distribution ductwork.

Compressorized Systems Offer Flexibility,

Efficiency, Reliability

Long recognized as the standard in environmental

control systems for data center operations, Liebert

DS compressorized systems are built to the highest

specications in the industry with proven components

and design. They feature direct expansion operation in

four types of cooling congurations: air cooled, water

cooled, glycol cooled and our exclusive GLYCOOL freecooling option.

Liebert DS Upflow

6

Page 7

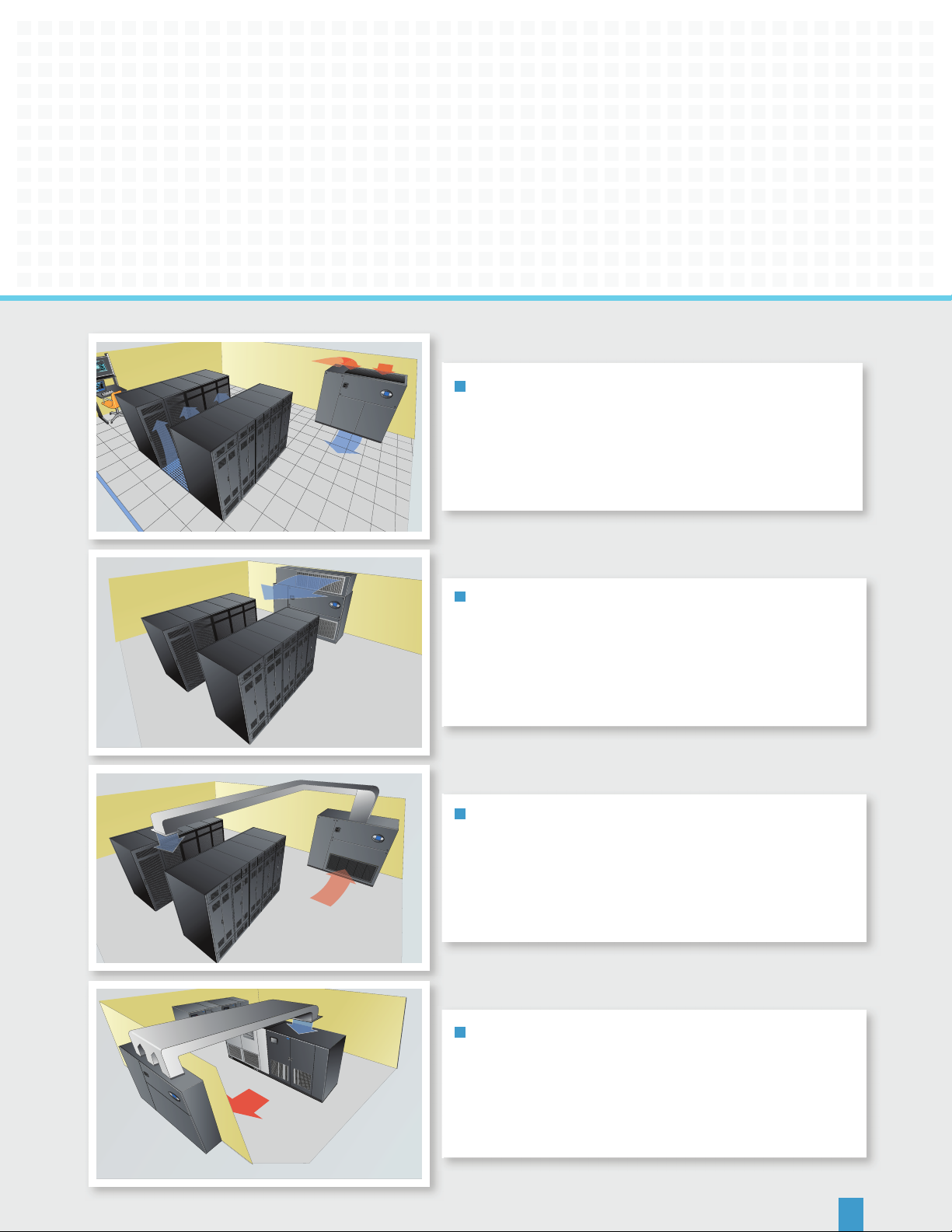

The Widest Variety Of Air Supply Choices

Downflow Supply

Designed for raised- oor applications, the down ow

air supply con guration is commonly found in data

centers and other similar facilities housing sensitive

electronic equipment.

Top Front Supply with Plenum & Grille

and Front Return

In-the-space applications without ductwork, such as

Telecommunications, Networks and Switching Centers,

bene t from this economical con guration. Optional high

ltration may be desirable.

Top Front Supply and Front Return

Engineered for in-the-space applications utilizing

duct work, this air ow design is commonly used for

Telecommunications or Industrial applications. High

static pressure and ltering options may be selected.

Top Rear Supply and Rear Return

Designed for use in out-of-space applications, this

con guration is typical for Industrial Processes such as

Control Rooms, and Labs. Many of these sites will select a

higher static pressure and optional high ef ciency lters.

(Customer ducted supply and return)

7

Page 8

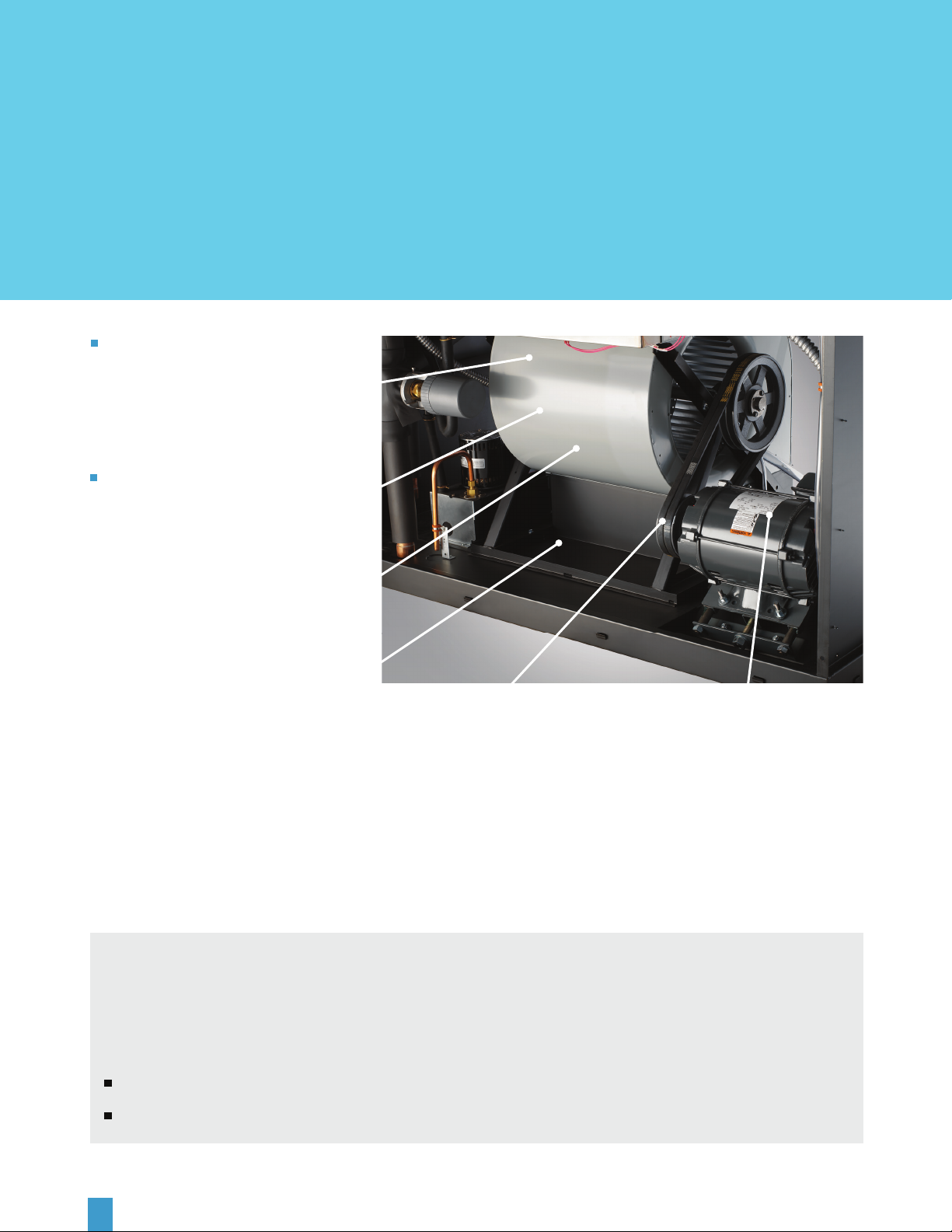

Air Delivery System Designed For Optimized Air

Distribution And Long Service Life

Constant delivery of

full air ow to keep

delivering cold air

when needed.

Flexibility for high

ltration or external

static pressures up to

2.5”(625 Pa).

5-YEAR WARRANTY

on drive components

(bearings, belts, shaft,

pulleys).

Centrifugal blowers

enable performance

over a wide range of

air volume and static

pressure ranges.

Pillow block fan

bearing with

minimum L3 life of

200,000 hours.

Static regain duct

improves under oor air

distribution.

Pentadrive™ Blower - Special 5-year Liebert Belt.

Automatic self-tensioning motor base increases

belt life and reliability of shaft and bearings.

Computers and other sensitive electronics require greater

air volumes than comfort air conditioning can provide. The

high density heat load in the relatively small space of a data

center requires more air changes to remove heat properly.

A key to the outstanding performance of the Liebert® DS™ is

its optimized air delivery design. It combines high efficiency

and effective air handling to deliver reliable, constant cooling

under the most demanding conditions.

High ef ciency motor

meets NEMA Premium

motor standard.

Pentadrive™ Blower System

Large capacity fans are dynamically balanced

to minimize vibration and provide even air

distribution. The low velocity fans use less fan

motor energy and operate more quietly than

forced air blowers. Filtered air at the right

temperature and humidity is fed positively and

evenly into the room.

Motors

The Liebert DS features fan motors that are optimized for reliability and energy ef ciency.

High-efficiency open drip-proof motor meets National Electrical Manufacturers Association (NEMA) Premium

motor standard.

Motor Options

Optional TEFC (Totally Enclosed Fan-Cooled) motors—for rugged industrial environments.

Optional larger horsepower motors available—for higher air volume or higher static pressures.

8

Page 9

Variable Speed Drive (VSD)

Fan Motor

Liebert® DS™ models with

digital scroll are available with

an optional variable speed drive

(VSD) on the fan motor used to

drive the centrifugal blowers,

matching the motor speed to

the room cooling requirements.

This feature allows the unit to

use far less motor energy to

move room air. The VSD drive is

controlled by the Liebert iCOM

control system to match the

speed of the blower with the

compressor load consequently

the load in the room. This

option eliminates excessive

energy use due to an oversized

design or changing room

conditions.

Energy Ef cient Fan Selections

The downflow floormount Liebert DS models, larger than 12 tons, are

now available with energy efficient EC Plug Fans.

These energy efficient fans add to the superior efficiency already

achieved by the use of a traditional variable speed drive system. In fact,

many utility companies offer a rebate for using these energy efficient

options – check with your local utility for details.

The Liebert DS with EC Plug Fan

delivers energy ef ciency gains via

the fan system. These electrically

commutated fans are a backward

curved motorized impeller powered

by a direct drive DC Motor with

integrated AC-DC conversion.

This design uses less energy than

standard centrifugal blowers by

lowering motor kW. The EC Plug Fan

uses 10-30% less energy on average

than standard AC motors.

The EC Plug Fan is located in the area

beneath the raised oor or within the

unit. Superior energy savings can be

realized with the fans located beneath

the raised oor. Placing the fan in

the raised oor space, is 30 percent

more energy ef cient than centrifugal

blowers. The EC Plug Fan also provides

greater energy savings than variable

speed drives.

9

Page 10

Dependable, Effective Cooling System

Draw-through design pulls

air evenly through the

cooling coil, reheat and

humidication systems.

Optional polymeric coating on

coils protects against corrosion

due to harsh environments.

A-frame coil design maximizes

coil area, reduces air velocity,

lowers chance of water

blowing off coil, results in far

less turbulence with superior

efciencies in heat transfer.

At the heart of the Liebert® DS™ are its cooling system components, each designed to provide

maximum reliability.

A-Frame Coil

This Liebert designed and manufactured

Refrigeration System Features

Each refrigeration circuit includes:

A-Frame coil features a large face area/low face

velocity design for precise control of cooling and

dehumidication— and is designed to optimize

heat transfer and minimize pressure drop.

Dual Refrigeration Circuits For Redundancy

Dual compressors and refrigeration circuits

assure reliability and feature automatic

sequencing for even wear of components.

Components include dual compressors and dual

refrigeration circuits enabling the system to

operate even if one circuit fails.

Pump-down evacuation of refrigerant from

compressor crankcase

shields the compressors

from the “hard starts” that can shorten

their life.

Sight glasses serve as a means of quick visual inspection to

determine if there is moisture in the system and if the system is

properly charged.

Refrigerant dehydrators assure a moisture-free refrigerant

system for extended component life.

Expansion valves – Externally equalized expansion valves

smoothly control refrigerant ow during indoor heat loads and

outdoor ambients by controlling evaporator superheat.

Muffler – Specially engineered mufers afford a quiet pulsation-

free refrigeration system.

Safety controls – Each compressor has an automatic reset high

pressure switch which locks-out after the third trip. A low

pressure transducer protects against coil freezing and low

refrigerant pressure.

10

Page 11

Hybrid Designs Deliver Maximum Energy Ef ciency

Optional 70/30 Cu/Ni free-cooling

coil must be speci ed to prevent tube

corrosion when used with a cooling

tower loop or other open water system.

Provides redundancy

and energy savings for

increased ROI.

Optional econo-coil rests on an

A-frame coil to minimize air pressure

drop and increase ef ciency.

For even greater efficiency and reduced operating

costs, Liebert® DS™ offers energy saving alternatives

such as our GLYCOOL and Dual Cool options. Used

where the climate permits, a conventional air or water

cooled direct expansion system adds a second cooling

coil which utilizes a building chiller supply to reduce

compressor operation.

GLYCOOL™ System

The Liebert GLYCOOL freecooling system incorporates a

conventional glycol cooled unit along with the addition

of a second cooling coil, control valves and a comparative

temperature monitor. This allows the system to take

advantage of cooler outdoor temperatures to reduce or

eliminate compressor runtime.

During colder months, the glycol solution returning from

the outdoor drycooler is routed to the second coil by a

pre-piped modulating three-way valve. Located upstream

of the evaporator coil, the second coil becomes the primary

Dual Cooling coil increases availability

by using building chilled water as

primary, compressor as back-up.

source of cooling for the room. This coil is suf ciently sized

to offer the identical cooling capacity as is obtained during

the refrigeration cycle of both compressors.

Dual Cool

Utilizing this option, a conventional air cooled Liebert DS is

converted to a dual source cooling system by the addition

of a second coil that utilizes a central building chiller supply.

Using a modulating control valve and a comparative

temperature sensor, the unit can function either as a

chilled water system, as a compressorized system—or a

combination of both.

During times when the chiller supply is available,

compressor operation is eliminated, reducing energy costs.

Switchover between the two cooling modes is performed

automatically by a microprocessor control and temperature

sensor. In addition to energy ef ciency, this option can

provide increased redundancy and exibility to the

environmental control system.

11

Page 12

Air Delivery System Designed For Optimized Air

Distribution And Long Service Life

A key to the ability of a quality

Precision Cooling system to control

conditions within the critical space is

its high “sensible heat ratio.”

Unlike people, computers generate dry or

“sensible” heat, but not humidity. With

a large percentage of their total capacity

devoted to the removal of moisture,

comfort systems can lower room

humidity far below acceptable standards

for electronic equipment— and they have

no provisions for adding moisture.

To correct this situation, precision air

conditioning systems typically have a

high ratio of sensible-to-total cooling

capacity to remove heat from the air. This

capability is provided through the use

of integrated humidication systems to

provide the necessary level of moisture

control, higher air supply capacity

and larger coil size.

Standard

Infrared

Humidifier

Humidity Control

Maintaining the correct humidity level in the room is just as important

as maintaining proper temperature. Inadequate humidity control can

cause static electricity if it’s too dry—or condensation that can corrode

circuitry if the air is too moist. The Liebert® DS™ utilizes an integrated

humidication system to provide the necessary level of moisture control.

Humidier makeup

valve controls ow

of water to the

humidier pan.

Pure water

vapor provides

most effective

humidication.

Does not depend on water

quality. High-intensity

quartz lamps shine on water

creating instantaneous

moisture using almost any

water quality.

12

Standard Infrared Humidifier

Instant Humidication—on when needed, off when not needed.

Optional Steam Generating Canister Humidifier

Utilizes replaceable bottle—requires a specic water quality level for

optimum operation.

Utilizes a drain and rell cycle—to maintain a current setpoint.

Dehumidification Control

The compressors operate at full capacity during dehumidication. The

precision control of the Liebert DS saves energy by tightly regulating

compressor operation and avoiding over dehumidication that causes the

humidier to come on when not needed.

Page 13

Natural air-gap. No

need for back- ow

prevention.

Auto ush system

reduces build-up

of mineral deposits

and impurities in the

water pan.

High water oat

switch shuts down

humidi er upon

high water.

Bypass air slots

ensure that moisture

can be introduced

into air stream.

Cleanable stainless

steel humidi er

pan. Removable

from front.

Filtration System

The Liebert® DS™ features integral air ltration to protect against airborne

contaminants within the critical environment. Without proper air ltration,

even small amounts of dust and other particles can damage storage media

and charged electronic components.

High-efficiency air-filtration—removes damaging particles from air.

Standard filter—4” deep, Merv 8. (45% ASHRAE 52.1).

Optional high-efficiency filter—4” deep, Merv Merv 11 (60-65%

ASHRAE 52.1)

Optional 2” Merv 8 pre-filter with 2” Merv 11 lter.

V bank filter arrangement—reduces air pressure drop, top lter access.

Reheat Function

The reheat function of the Liebert DS is

primarily used to keep the temperature

from going too low during the

dehumidi cation cycle.

Standard Reheat

Three-stage electric reheat—low watt-

density, 304 stainless-steel n-tubular

reheat, location maximizes air ow to

maximize element life and improve

reliability.

Reheat Options

SCR electric reheat—For specialized

applications requiring tight temperature

control. Multiple pulses of reheat vs.

three equal stages provide smooth

temperature adjustment.

Optional hot water reheat—Uses

existing building hot water, saving

energy.

Reheat/humidifier lockout—Reduces

power requirements during emergency

power operation.

13

Page 14

A Choice Of Compressors Offers Higher Ef ciency, Adaptability

60% Load

70% Load

80% Load

90% Load

Cumulative Compressor Cycles

And Reliable Operation

It Starts With Reliable Scroll

Compressor Technology

The scroll compressor design provides high ef ciency,

low sound levels and excellent durability. The Liebert

®

DS™ precision cooling system is available with either:

A standard xed-capacity scroll compressor.

An optional Digital Scroll compressor with energy

saving, variable capacity operation.

The Standard Scroll Compressor: Rugged, Quiet,

Efficient

The standard scroll compressor offers ef cient, reliable

performance with a robust design that contains only

a few moving parts. Quiet operation is accomplished

through a continual, smooth compression process.

Discharge gas and vibration are kept at a low level.

The Digital Scroll Compressor: A New Standard For

Performance and Reliability

The exclusive digital scroll compressor option on

the Liebert DS utilizes the latest control technology

to deliver precise operation and signi cantly higher

energy ef ciency. In addition to the advantages of the

dependable scroll design, Digital Scroll technology

provides in nitely variable capacity modulation that

enables the output to precisely match the changing

cooling demands of the room. This approach is as

much as 30 percent more ef cient than traditional hotgas bypass. Bene ts include:

Cumulative Compressor Cycles As Load Grows

From 50% To 100%

140000

120000

100000

80000

60000

40000

20000

0

Year 1 Year 2 Year 3 Year 4

Single Compressor

Two CompressorsTwo Compressors

Digital Compressor

Increasing compressor cycling takes a toll on compressor

life. Liebert Four-Step Semi-Hermetic compressors and

Digital Scroll compressors automatically adjust to yearly

increases in heat load, providing signi cantly greater

component life than other compressor technologies.

Greater energy savings—variable capacity system

allows maximum load tracking for higher ef ciency.

Improved reliability—by reducing compressor cycling

and component wear.

Improved performance—the compressor can easily

adapt to changing load conditions, providing precise

temperature control.

Digital Scroll

Capa

Diagram

city Control

50% Load

33% Load

7.5 secs

5 secs

15 secs

10 secs

7.5 secs

100%

capacity

0%

capacity

Digital Scroll Capacity

adapts as load changes

10%

Initial Load

Future Load

Load

100%

Capacity

14

Page 15

Four-Step Semi-Hermetic Compressors:

Proven Performance

®

The Liebert

DS™ Four-Step system achieves high

levels of energy ef ciency through the integration of

two high-ef ciency semi-hermetic compressors with

capacity control valves, an advanced microprocessor

control system and a computer-optimized cooling coil.

New Refrigerants To Meet Government Regulations

Without the ability to utilize newer environmentallyfriendly refrigerants, your cooling equipment could

become obsolete and “out of compliance.” The Montreal

Protocol and EPA Clean Air Act require cooling equipment

manufacturers to switch to environmentally-friendly

refrigerants by 2010.

The Four-Step system reduces compressor cooling

capacity and energy consumption during periods of

low room load conditions. As a result, four distinct

stages of cooling are activated to more closely respond

to changing room conditions. Reliability is enhanced by

fewer and less stressful compressor starts for

reduced wear.

Energy Savings

100%

100%

Step Four

Capacity Energy Energy Savings

88%

75%

Step Three Step Two Step One

76%

50%

38%

25%

4-Step Compressor Operation Improves

Energy Ef ciency Ratio

105°F

22.4

R-407C environmentally-friendly refrigerant is the

standard in the Liebert DS.

110°F

115°F

120°F

125°F

Saturated Condensing Temperature

130°F

11.7

45°F

Saturated Evaporator Temperature

12.8

50°F

14.0

55°F

Semi-Hermetic Compressors

15

Page 16

Operating Standby

Liebert iCOM

®

Small Graphic Display

The Liebert iCOM control system

®

featured on the Liebert

DS™ brings

high-level supervision to multiple

units allowing them to work together

as a single system to optimize room

performance. The Liebert iCOM

control system offers a variety of

advantages.

Various Intelligent Control Methods

Return Air Temperature is a traditional

method that changes the unit

capacity based on the return air

temperature to the unit

Supply Air Temperature is a method

that changes the unit capacity based

on the unit outlet air temperature.

Static Pressure Control uses a single

pressure sensor to adjust the fan

speed. The air ow compensates for

oor tile layout changes.

Dynamic Cold Aisle Management

(DCAM) separates the fan speetd and

cooling capacity to meet the server air

volume and heat load. This allows less

energy to be used forthe same amount

of cooling.

The standard Small Graphic Display features a 128x64 dot matrix backlit

screen. Advanced monitoring can be achieved with the addition of the

Optional Wall Mounted Display.

The Optional Wall Mounted

Large Graphic Display provides

centralized monitoring and control

of connected Liebert DS units.

The optional vNSA with iCOM

combines a Wall Mounted Large

Graphic Display along with a

network switch to facilitate U2U

wiring in one convenient cabinet.

U2U Configuration 2

Liebert DS units with Small Graphic Display may be centrally

monitored and controlled with the Optional Wall Mounted Display.

Power

Operating

Standby

Operating

Alarm

Intelligent Communications And

Monitoring

Saves Energy using Predictive

Humidity Control.

Built-in Lead/Lag Functions for

enhanced system reliability.

Wellness Calculation alerts service

personnel before problems occur.

Unit to Unit Communications allows

Lead/Lag and optional teamwork

settings for maximum exibility of

control of up to 32 units per zone and

up to 99 zones per network.

16

Teamwork: Mode 2

Units work together to provide precision cooling in rooms with

unbalanced loads.

Page 17

STANDB Y SETTINGS / LEAD-LAG

to change parameter

to confirm

to select parameter

for next/previous unit

then

SYSTEM

PASSWOR D (Actual Level 0) ????

Number of Standby Unit s 0

Rotation Frequency No

Rotate at ( hour) 00

Rotate at ( minute) 00

Rotate by 1

Perform one Rotation No

Cascade Units No

Start all Standby U nits by HT No

S501

S502

S503

S504

S505

S506

S507

S508

S509

S510

S511

Maintenance /

Large Graphic Display

Wellness Setup

The optional Large Graphic Display features a 320x240 dot matrix

backlit screen with helpful system and maintenance views.

Additional Views Available with

Large Graphic Displays

System View—Allows you to see the average operation of the

“system” or all units that are working together in Unit to Unit

(U2U) Communication mode for Teamwork or Lead/Lag from a

centralized location.

Spare Parts List—Critical spare part numbers are saved in unit

memory and may be displayed on the Large Graphic Display,

speeding identication of parts.

Unit Diary—Free eld area within the unit memory where unit

maintenance shares history with any authorized users or loggedin service contacts, including record of what others have done.

Spare Parts

Unit Diary

Removable display makes

troubleshooting servicing easier.

Parts list available on control

for easier maintenance.

On-board Unit Diary provides

a maintenance history to any

authorized user.

Standby Settings (Lead/Lag Set-up)

Monitors all key system

functions and reports to alarm,

if needed.

On-board Unit Diary provides

a maintenance history to any

authorized user.

17

Page 18

Easy Component and Control Option Access

Electric Panel

The electric panel of the Liebert® DS™ is designed for easy access to critical electrical and control components.

Optional

disconnect switch

available as nonlocking or locking.

Location for

optional secondary

disconnect switch for

non-critical loads.

Deadfront panel

folds down for easy

viewing of electrical

schematic.

Unit Monitoring And Control Options

Dual oat condensate pump—installed in unit, with

secondary oat to shut down unit and trigger alarm if

high water detected.

Optional low voltage terminal package—two extra n/o

common alarm contacts, two extra remote shutdown

terminals, one main fan auxiliary contact. When

connected to an optional water sensor, shuts down unit

and provides dry contact closure.

High temperature sensor—alerts users to any high

temperature situations within the system. Senses

return air temperature and shuts down unit if

temperature exceeds 125°F (51.7°C).

Smoke sensor—senses the return air, shuts down the

unit upon detection, and sends visual and audible

™

Optional solidstate

contactors used

on SCR reheat for

tight temperature

applications.

Individually-fused components

high-rated fuses for maximum

reliability, high interrupt rating,

and cooler operating fuses for

maximum reliability.

IntelliSlot

easy plug-in

of optional

communication

cards.

Low voltage

terminal strip

provides

connection

exibility.

Control interface

board for easy

access.

alarm. Dry contacts are available for a remote customer

alarm. This smoke sensor is not intended to function as,

or replace, any room smoke detection system that may

be required by local or national codes.

Analog input wiring—includes four customer-accessible

analog inputs for sensors provided by others. The

analog inputs accept a 4 to 20 mA signal. Gains

Calibration for each input are programmable from the

front panel.

Compressor overload—activates an audible and visual

alarm in the event of a compressor overload.

Main Fan Overload—activates an audible and visual

alarm in the event of a motor overload.

for

18

Page 19

Paradenser™ Cleanable Condenser Provides Liebert® DS™

With Longer Service Life

Liebert DS offers the new Paradenser™ condenser for

use in water/glycol systems. This patented component

utilizes a counter-flow design and features a shell and

tube type construction.

Fully cleanable—eliminates costly condenser failures

due to plugging and providing a longer service life. This

reduces fouling and scaling which can degrade heat

rejection performance and result in cooling system

shutdown.

Large water passages prevent plugging and allow for

conventional tube cleaning methods.

Sturdy, corrosion-resistant materials—Steel shell, copper

tubes, and nickel-plated plug are durable,

non-corrosive and easy to clean.

Shell side of the condenser acts as a receiver—holds

refrigerant charge during pumpdown.

Utilizes no gaskets—offers further reliability by

preventing leaks.

Fully cleanable Paradenser tubes are

located for convenient maintenance.

19

Page 20

Liebert Heat Rejection Systems—Flexible

CongurationsTo Meet Application Requirements

Liebert Condensers & Drycoolers

Emerson Network Power manufactures its own high-

efciency Liebert air cooled condensers and drycoolers

that are precisely matched to the heat rejection

requirements of our precision air conditioning systems.

Constructed with an aluminum cabinet and a copper-

tube aluminum-n coil, these exceptionally dependable

units are corrosion resistant and designed to operate

for prolonged periods of exposure to the worst weather

conditions. Liebert condensers and drycoolers are fully

factory wired and tested for easy installation.

Wide range of heat rejection solutions—vertical or

horizontal airows, indoor or outdoor models,

freestanding or ducted congurations.

Standard units—Sized for maximum outdoor

ambient temperatures of 85 °F (29.4°C) to 105°F

(40.6°C).

Liebert VFD Control Condenser—Features a

variable frequency drive (VFD) and an inverter

duty fan motor with ceramic bearings. The VFD

control integrates pressure variations from

either compressor operation, including digital

scroll compressors, using pressure transducers

and modulates the condenser fan motor speed

to hold condensing temperatures constant.

This system allows for operation at ambient

temperatures as low as -20°F (-28.9°C).

Fan Speed Control Condenser—A fan-speed

control varies the variable speed fan motor

based on compressor head pressure to maintain

constant condensing temperatures. This system

allows for operation at ambient temperatures as

low as -20°F (-28.9°C).

Drycoolers, Pumps, Tanks and Controls—Complete

heat rejection solutions for glycol-cooled and

GLYCOOL units consist of drycoolers, glycol

pumps, expansion tanks and integral or separate

pump electrical control boxes.

Quiet-Line™ Condenser/Drycooler—Operate

with the lowest noise level of any heat rejection

available, offering levels of less than 57 dBA.

Indoor Piggyback Condenser/Drycooler—Indoor

condensers/drycoolers designed to provide

heat rejection by ducting air from outside the

building, such as high-rise buildings.

Outdoor Centrifugal Condenser/Drycooler—

Centrifugal drycoolers suitable for outdoor or

indoor mounting, providing heat rejection for

unique applications requiring ducted airow.

High Ambient Condensers—Utilize increased coil

surfaces for operation in outdoor climates up to

120 °F (48.9 °C).

20

Page 21

The Liebert DS Has A Solution

GLYCOOL™ System with free-cooling cool

To Meet Your Critical Needs

No Other Precision Cooling System

Offers This Much Flexibility

Long recognized as the standard in environmental

control systems for data center operations, the Liebert

DS is built to the most demanding speci cations in the

industry with proven components and design.

Water Cooled

Remote

cooling

tower

A-frame

coil

Paradenser

Tubes

Compressors

Liebert® DS™ features compressorized direct expansion

operation in air cooled, water cooled and glycol cooled

con gurations, as well as GLYCOOL™ free-cooling

models and chilled water systems.

Glycol Cooled

Glycol circulating

pump

A-frame

coil

Liebert

drycooler

Compressors

Centrifugal

Blower

Centrifugal

Blower

Air Cooled

Condenser

with optional

Lee-Temp

Package

GLYCOOL™ System with free-cooling cool

Glycol

circulating

pump

Liebert

drycooler

Paradenser

Tubes

Compressors

A-frame coil inside

Centrifugal

Blower

Glycol-cooled

condensers

Econ-ocoil rests

on

A-frame

coil

Piggyback Heat Rejection Configurations

Air-cooled or

Glycol-cooled

configurations

available

Fan

Coil

21

Page 22

Stand-Alone Monitoring And Leak Detection Solutions

Autonomous microprocessor controlled modules are

available to provide supervision, control and remote

notification of Liebert® precision cooling equipment.

These stand-alone devices include:

Liebert Universal Monitor

The Liebert Universal Monitor is an all-purpose, easy-to-use

microprocessor-based monitoring panel with connections for

up to 8 digital inputs, 8 digital outputs and 4 analog inputs.

Designed to bring critical monitoring information directly to

your facility or offsite location, the unit includes an on-board

modem to provide remote monitoring while minimizing

con guration and installation requirements. It features a

built-in LCD user interface, making the panel self contained

and accessible without additional hardware and software.

Contact Closure Alarm Panels

The Liebert RCM series of contact closure alarm panels

provides customized alarm indication at a single location

for any dry contact input from environmental, power and

UPS systems, including Liebert units. These remote systems

continuously monitor your most critical support equipment

and instantly alert you to alarm conditions. Three different

system con gurations are available for monitoring up to

eight points with communications and pager interface plus

eight digital outputs.

Liqui-tect 410 Point Leak Detection Con guration

Liqui-tect 460 Zone Leak Detection Con guration

Liebert Universal Monitor

22

Liebert Leak Detection Modules

Liebert Liqui-tect® leak detection systems

provide quick sensing and accurate reporting

of leaks below the oor or above the ceiling

in critical facilities. These reliable systems

provide immediate warning and precise

location, allowing you to nd and correct a

leak before moisture can damage computers,

wiring connections or other sensitive

electronics.

Temperature and Humidity Recorder

A seven-day temperature and humidity recorder

permits close examination of computer room

environment condition and can be used as a

permanent record of the environmental control

system’s operation ef ciency.

Page 23

Maximizing Your Investment Through Adaptive Monitoring

Distributed Management With

Liebert IntelliSlot

For enchanced remote communications

and control of your Liebert units, the

Liebert IntelliSlot Web and 485 Cards

deliver the communication capabilities

you require.

Monitoring and control through your

existing Network with no additional

software required.

Each Liebert system equipped with an

Liebert IntelliSlot Web Card takes full

advantage of your Ethernet network,

allowing remote monitoring from your

computer desktop, network operations

center or wherever network access is

permitted, without the need for frontend software.

Monitoring integration with your

existing Building Management

System.

A Liebert system equipped with an

IntelliSlot 485 Card can be seamlessly

integrated with your existing Building

Management System.

®

Interface Cards

Centralized Management With

Liebert Nform™ Software

As business grows, your critical

equipment infrastructure will

expand, thus the need for centralized

management of this equipment will

be key to your business success.

Connecting to equipment in the

distributed critical space is only part of

the monitoring challenge.

Liebert Nform leverages the

network connectivity capabilities of

your Liebert equipment to provide a

centralized monitoring view of your

distributed equipment.

Utilizing the SNMP and Web

technologies built into each of the

Liebert IntelliSlot communication

cards, Nform will centrally manage

alarm notications to provide you

with an easy interface to access critical

status information.

Liebert Nform puts critical systems

information at the ngertips of

support personnel—wherever they

are—increasing responsiveness to

alarm-event conditions, thus allowing

IT organizations to maximize their

system availability.

Enterprise Management with Liebert

SiteScan® Web Software

For customers who require extensive

management of critical system equipment

that may span multiple locations in an

ever-moving global enterprise, Liebert

SiteScan Web will centrally manage your

critical equipment and give you the power

to move beyond the event-responsive

service paradigm.

SiteScan Web does it all—

Real-Time Monitoring and Control

Event Management and Reporting

Data Analysis and Trending

Building Management Integration

Liebert SiteScanWeb is a comprehensive

critical systems management solution

dedicated to ensuring reliability through

graphics, event management and data

extrapolation. The standard Web interface

allows users easy access from anywhere at

anytime.

Single- and multi-site applications.

Event management and unit control.

Trend and historical data captures and

reporting.

Full ASHRAE BACnet compatibility.

Java based.

Windows 2000, XP and 2003

compatible.

Liebert IntelliSlot Web Liebert Nform

Liebert SiteScan Web

23

Page 24

Emerson Network Power, a business of Emerson (NYSE:EMR), delivers software, hardware and

services that maximize availability, capacity and efficiency for data centers, healthcare and

industrial facilities. A trusted industry leader in smart infrastructure technologies, Emerson

Network Power provides innovative data center infrastructure management solutions that

bridge the gap between IT and facility management and deliver efficiency and uncompromised

availability regardless of capacity demands. Our solutions are supported globally by local

Emerson Network Power service technicians. Learn more about Emerson Network Power

products and services at www.EmersonNetworkPower.com

Emerson Network Power

Global Headquarters

1050 Dearborn Drive

P.O. Box 29186

Columbus, Ohio 43229

800 877 9222 Phone (U.S. & Canada Only)

614 888 0246 Phone (Outside U.S.)

Contact@EmersonNetworkPower.com

Emerson Network Power

Caribbean and Latin America

Office – United States of America

+1-954-984-3452 Phone

Ask.Cala@Emerson.com

Emerson Network Power Canada

3580 Laird Rd Unit 1

Mississauga

Ontario L5L 5Z7

Ask@EmersonNetworkPower.com

+1 905 569 8282

liebert.com

24 x 7 Tech Support

800 222 5877 Phone

614 841 6755 (outside U.S.)

EmersonNetworkPower.com

While every precaution has been taken to ensure

accuracy and completeness in this literature,

Liebert Corporation assumes no responsibility, and

disclaims all liability for damages resulting from use

of this information or for any errors or omissions. All

names and logos referred to herein are trade names,

trademarks or registered trademarks of their respective

owners. ® Liebert is a registered trademark of the

© 2014 Liebert Corporation. All rights reserved

throughout the world. Specications subject to change

Emerson Network Power and the Emerson Network

Power logo are trademarks and service marks of

SL- 18810 (R08/14) Printed in USA

Liebert Corporation.

without notice.

Emerson Electric Co.

©2014 Emerson Electric Co.

Loading...

Loading...