Page 1

Liebert® DS™ Thermal Management Unit

System Design Manual - 28-105kW (8-30 Tons), Downflow/Upflow, 60Hz

Floor Mounted, Air-Cooled, Water/Glycol-Cooled, GLYCOOL Economizer Coil, Dual-Cool DX with

Secondary Chilled Water Coil

Page 2

Page 3

TABLE OF CONTENTS

LIEBERT DS MODEL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 COOLING CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.0 BLOWER CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3.0 AIR-COOLED SYSTEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 Capacity and Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Standard Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Optional Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Optional Low-Voltage Terminal Package Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Dimensions—Liebert DS 028-042, Downflow, Air-Cooled Models . . . . . . . . . . . . . . . . . . . . 16

3.6 Dimensions—Liebert DS 053-077, Downflow, Air-Cooled Models . . . . . . . . . . . . . . . . . . . . 23

3.7 Dimensions—Liebert DS 105, Downflow, Air-Cooled Models . . . . . . . . . . . . . . . . . . . . . . . . 32

3.8 Dimensions—Liebert DS 028-042, Upflow, Air-Cooled Models. . . . . . . . . . . . . . . . . . . . . . . 38

3.9 Dimensions—Liebert DS 053-077, Upflow, Air-Cooled Models. . . . . . . . . . . . . . . . . . . . . . . 45

3.10 Dimensions—Liebert DS 105, Upflow, Air-Cooled Models . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.11 Heat Rejection—Liebert MC, Fin/Tube and Piggyback Condensers. . . . . . . . . . . . . . . . . . . 57

3.11.1 Liebert MC Microchannel Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.12 Piping—Liebert MC™ Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.12.1 Fin/Tube Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.12.2 Piggyback Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.13 Ancillary Items—Air-Cooled Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4.0 WATER-COOLED, GLYCOL-COOLED AND GLYCOOL SYSTEMS . . . . . . . . . . . . . . . . . . . . .91

4.1 Capacity and Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.2 Standard Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

4.3 Optional Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4.4 Optional Low-Voltage Terminal Package Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4.5 Dimensions—Liebert DS 028-042, Downflow, Water/Glycol/GLYCOOL Models . . . . . . . . 107

4.6 Dimensions—Liebert DS 053-077, Downflow, Water/Glycol/GLYCOOL Models . . . . . . . . 111

4.7 Dimensions—Liebert DS 105, Downflow, Water/Glycol/GLYCOOL-Cooled Models . . . . . 116

4.8 Dimensions—Liebert DS 028-042, Upflow, Water/Glycol/GLYCOOL-Cooled Models . . . . 121

4.9 Dimensions—Liebert DS 053-077, Upflow, Water/Glycol/GLYCOOL-Cooled Models . . . . 125

4.10 Dimensions—Liebert DS 105, Upflow, Water/Glycol/GLYCOOL Models. . . . . . . . . . . . . . 129

4.11 Heat Rejection—Drycoolers and Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

4.11.1 Drycooler Selection—Prop Fan Drycoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

4.11.2 Dimensions—Prop Fan Drycoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

4.11.3 Electrical Data—Prop Fan Drycoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4.11.4 Piping—Prop Fan Drycoolers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.11.5 Pump Packages & Expansion Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

4.11.6 Drycooler Selection—Indoor Piggyback Drycoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4.11.7 Weights and Dimensions—Indoor Piggyback Drycoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4.11.8 Electrical Data—Piggyback Drycoolers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

4.11.9 System Piping—Piggyback Drycoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

4.12 Ancillary Items—Water-Cooled Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

i

Page 4

5.0 GUIDE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

1.0 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

2.0 PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

3.0 EXECUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

ii

Page 5

LIEBERT DS MODEL NUMBER

Cooling Type

A = Air-Cooled

D = Dual-Cooling, Air-Cooled

W = Water/Glycol

K = GLYCOOL (Liebert Economizer Coil)

H = Dual-Cooling, Water-Cooled

Nominal kW

028, 035, 042, 053, 070, 077, 105

(8, 10, 12, 15, 20, 22, 30 tons)

Air Distribution

DS = Downflow Standard

VS = Upflow Standard

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

DS035AUA0EI****

Compressor

U - Semi-Hermetic with Four-Step, R-407C

S - Scroll, R-407C

D - Digital Scroll, R-407C

Fan Type

0 = Centrifugal Fans

1 = Electronically

Commutated (EC)

Fans

Humidification

0 - None

I - Infrared

S - Steam Generating

Canister

Reheat Type

0 - None

E - 3-Stage Electric

S - SCR

Voltag e

A - 460/3/60

B - 575/3/60

C - 208/3/60

D - 230/3/60

2 - 380/3/60

Factory Configuration

Number

Liebert DS Model Number

Not all combinations of options are available on all units.

Digital Scroll Compressors

• Not available on 077 and 105 models

• Not compatible with SCR reheat because digital scroll provides variable capacity control

EC Fans, Direct-Drive

• Not available on upflow (VS) configuration

• Liebert Econ-O-Coil

Steam Generating Canister Humidifier

• Not available on upflow (VS) configurations

• Not available on EC fan configurations

575 Volt Option Limitations

• Digital scroll compressors available only on 053, 070 models

GLYCOOL Liebert Economizer Models

• 105 model requires semi-hermetic compressors only, so as to prevent potential coil freezing

Turning Vanes

• Not available on floor stands 6" (152.4mm) tall

• Not available or required on units with EC fans

™

not available on 028, 035, 042 models with 208/230V

1Liebert

®

DS

™

Page 6

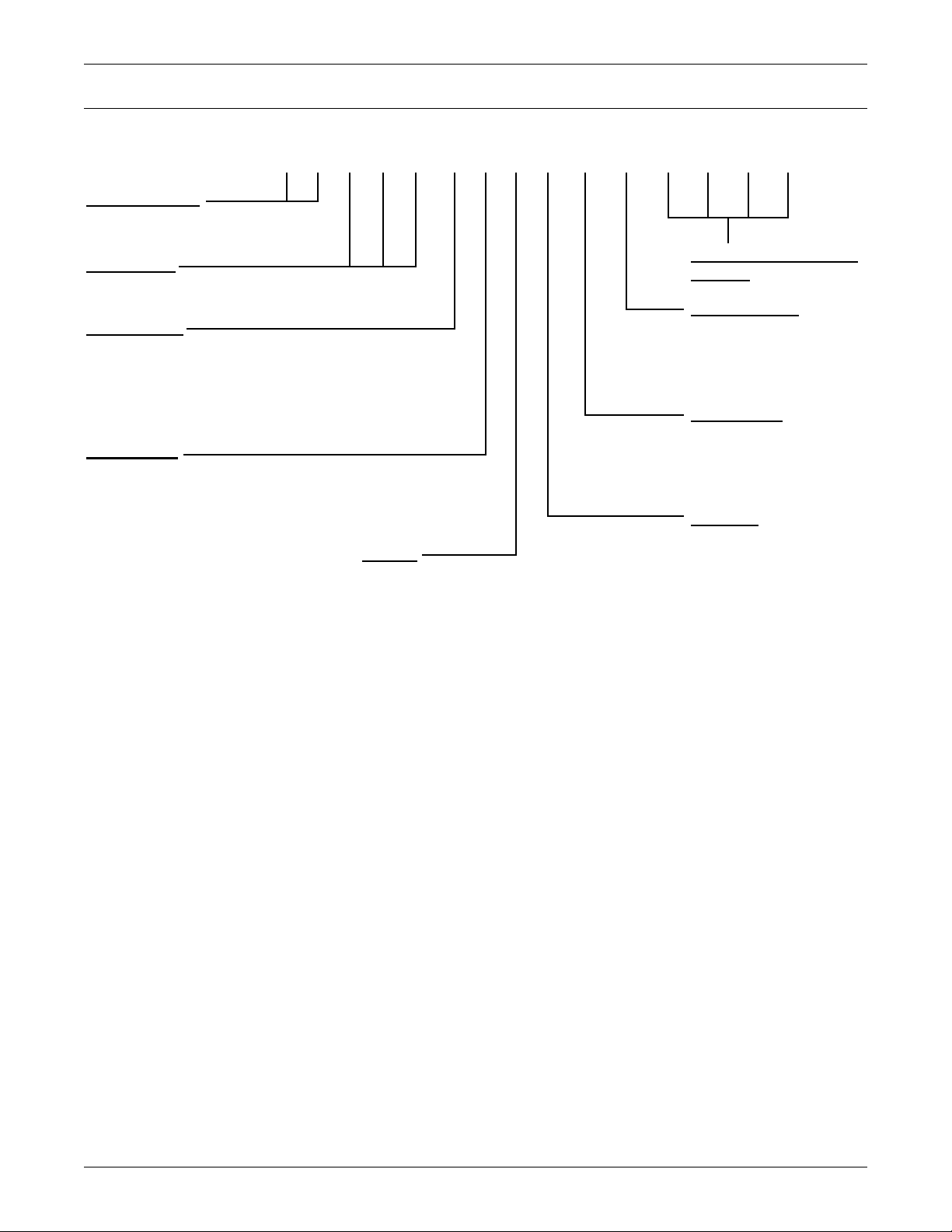

1.0 COOLING CONFIGURATIONS

AIR-COOLED

Air-cooled unit piping is spun closed from the

factory and contains a nitrogen holding charge.

Each installation requires field-supplied

refrigerant and piping to a condenser.

GLYCOL-COOLED

Glycol-cooled units are factory-charged and

tested. Field-supplied and field-installed piping is

required from the unit to the drycooler and pump

package.

WATER-COOLED

Water-cooled units are factory-charged and

tested. Field-supplied and field-installed

water piping is required from the unit to the

cooling tower.

GLYCOOL-INTEGRATED FLUID ECONOMIZER

GLYCOOL units are factory-charged and tested. Field-supplied

and field-installed piping is required from the unit to the

drycooler and pump package. An additional Liebert Economizer

coil is included for use when fluid temperatures are sufficiently

low (below room temperature). Economizer cooling is provided

by circulating cold glycol through this second coil, reducing or

eliminating compressor operation.

DUAL-COOL

This system has all of the features of a compressorized

system, but adds a second cooling coil that is connected

to a source of chilled water. Cooling is provided by

circulating chilled water, when available, through this

second coil and reducing compressor operation.

NOTE

All field-installed piping must comply with applicable local, state and federal codes.

Cooling Configurations

Liebert® DS

™

2

Page 7

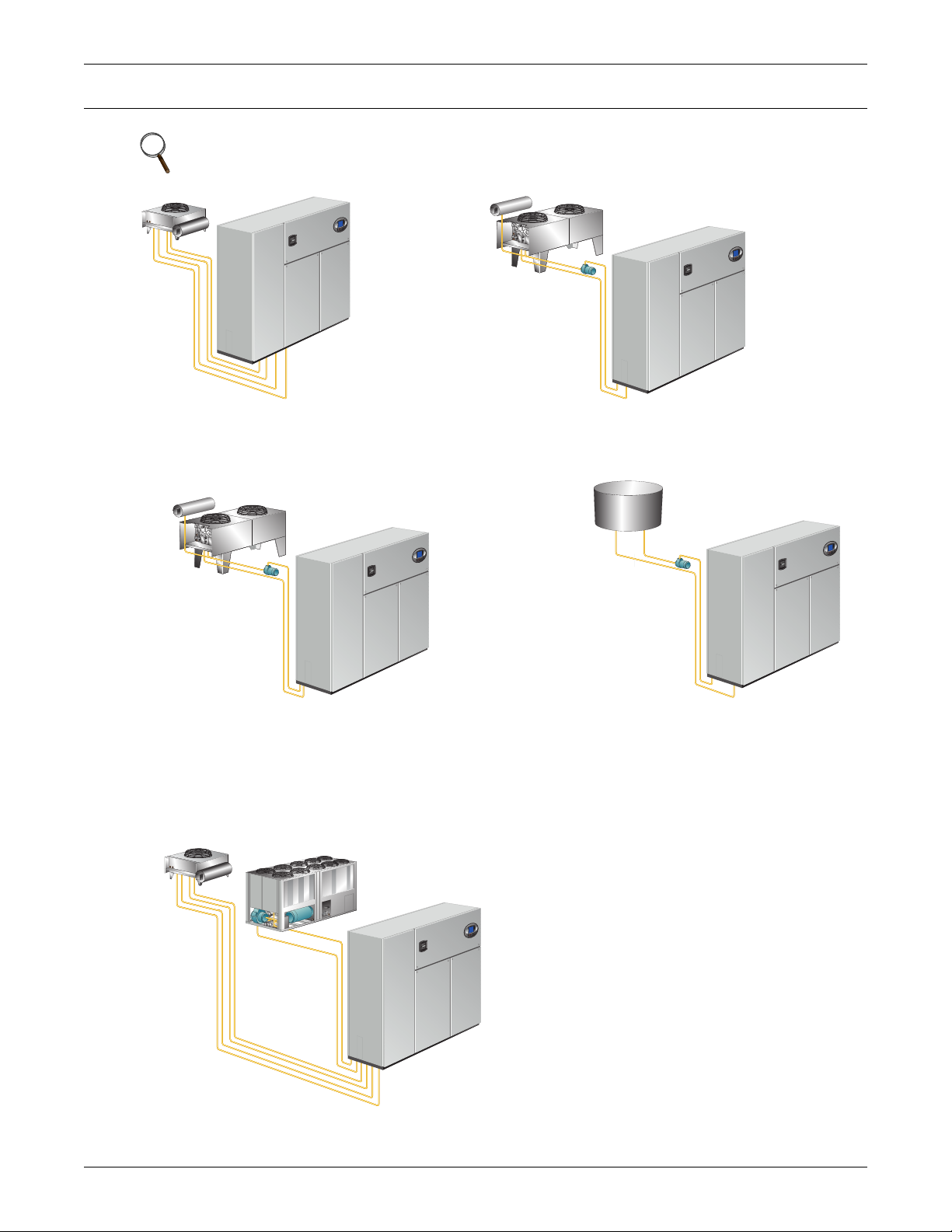

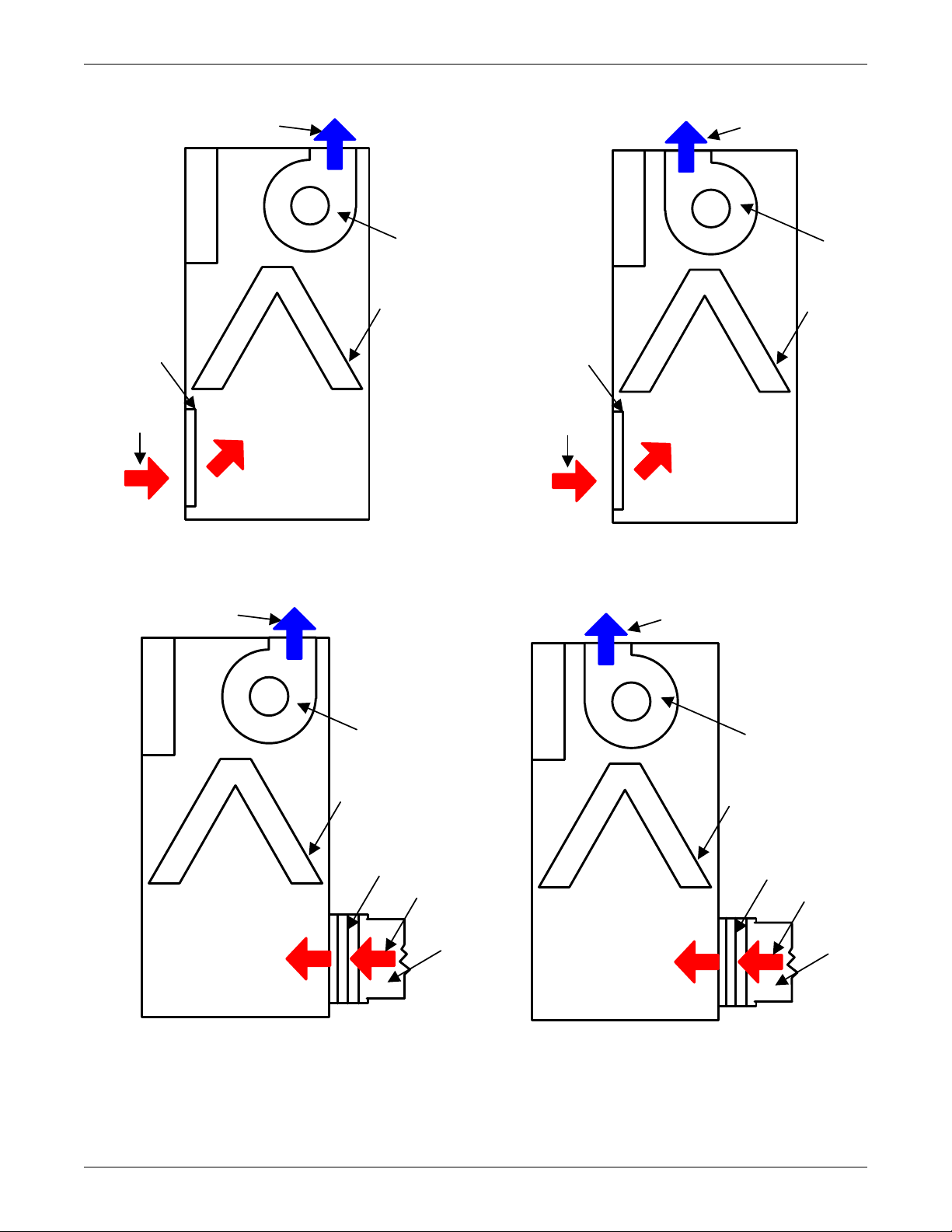

2.0 BLOWER CONFIGURATIONS

Front

Filter

Coil

Blower

Raised

Floor

Return Air

Supply

Air

Front Supply, EC Fans

Front

Filter

Coil

Blower

Raised

Floor

Return Air

Supply

Air

Rear Supply, EC Fans

Applicable to installations

without raised floors

Applicable to installations

without raised floors

Front

Filter

Coil

Blower

Floor

Stand

(optional )

Raised

Floor

Return Air

Supply

Air

Front

Filter

Coil

Blower

Floor Stand

(optional )

Raised

Floor

Return Air

Supply Air

Supply

Air

Under-Floor Supply, EC Fans

Bottom Supply, EC Fans

Figure 1 Blower configurations—Downflow, front and rear supply models, EC fans

Blower Configurations

Figure 2 Blower configurations—Downflow, bottom supply and under-floor supply models, EC fans

3Liebert

®

DS

™

Page 8

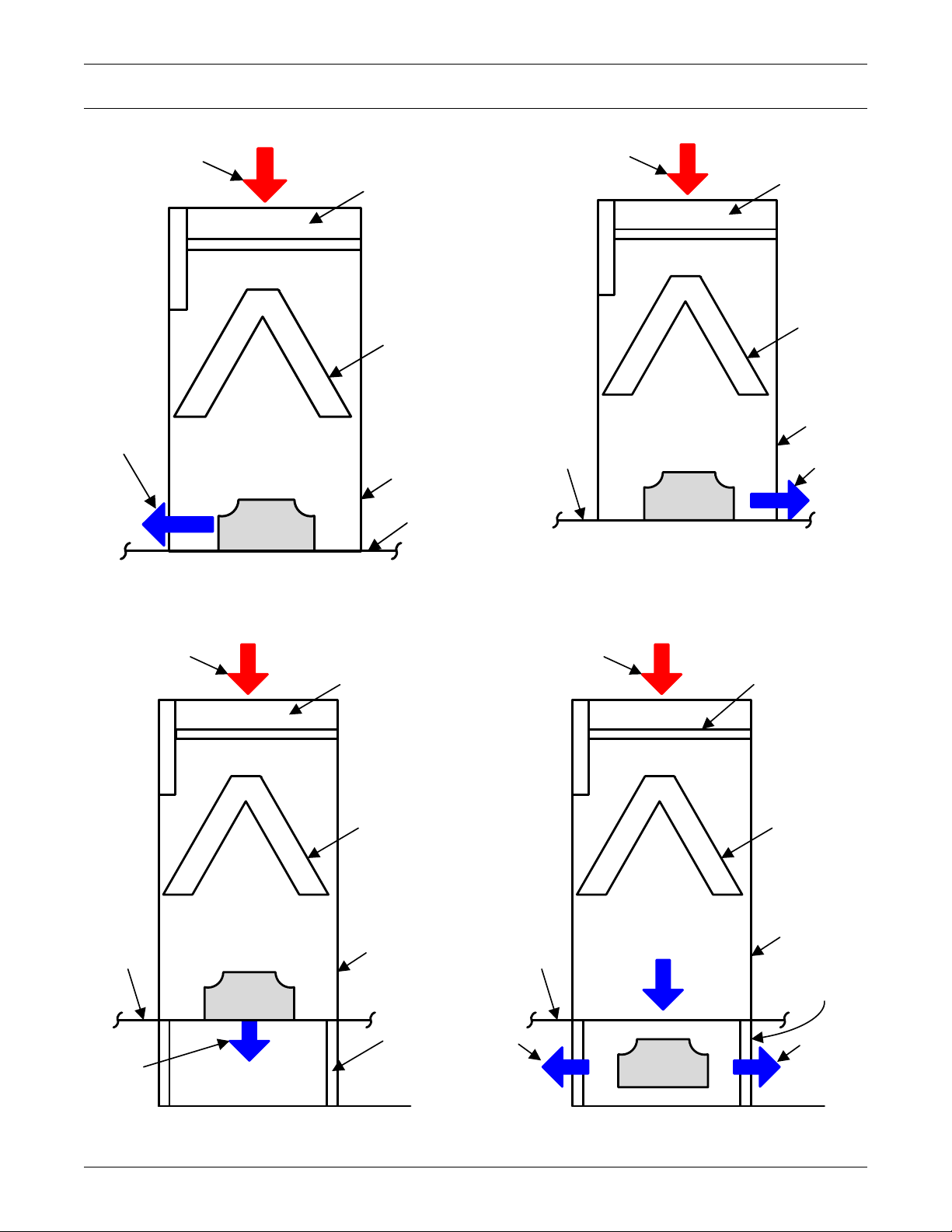

Blower Configurations

Front

Filter

Coil

Blower

Floor

Stand

(optional )

Raised

Floor

Return Air

Supply Air

Turning Vane

(optional )

Front Supply, Forward-Curved Fans

Front

Filter

Coil

Blower

Floor

Stand

(optional )

Raised

Floor

Return Air

Supply Air

Turning Vane

(optional )

Rear Supply, Forward-Curved Fans

Figure 3 Blower configurations—Downflow, front and rear supply models, centrifugal fans

Liebert® DS

™

4

Page 9

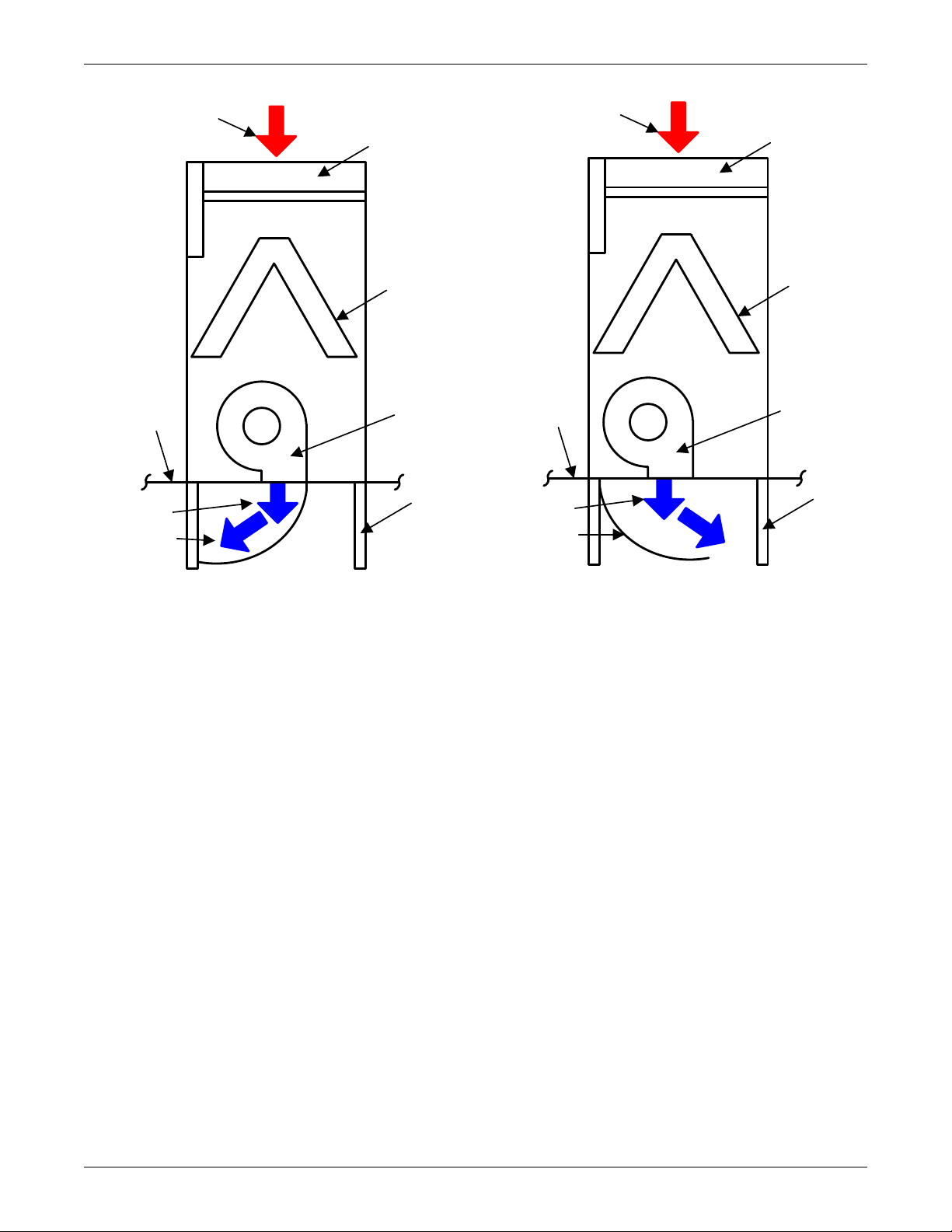

Figure 4 Blower configurations—Upflow, front return models, centrifugal fans

Front

Coil

Return

Air

Supply Air

Blow er

Filter

Front

Coil

Return

Air

Supply Air

Blow er

Filter

Top Supply, Front Throw Forward-Curved Fans Top Supply, Rear Throw Forward-Curved Fans

Front

Coil

Supply Air

Blower

Filter

Return

Air

Ductwork

Front

Coil

Supply Air

Blower

Filter

Return

Air

Ductwork

Top Supply, Rear Throw, Forward-Curved FansTop Supply, Front Throw, Forward-Curved Fans

Blower Configurations

Figure 5 Blower configurations—Upflow, rear return models, centrifugal fans

5Liebert

®

DS

™

Page 10

Air-Cooled Systems

3.0 AIR-COOLED SYSTEMS

3.1 CAPACITY AND PHYSICAL DATA

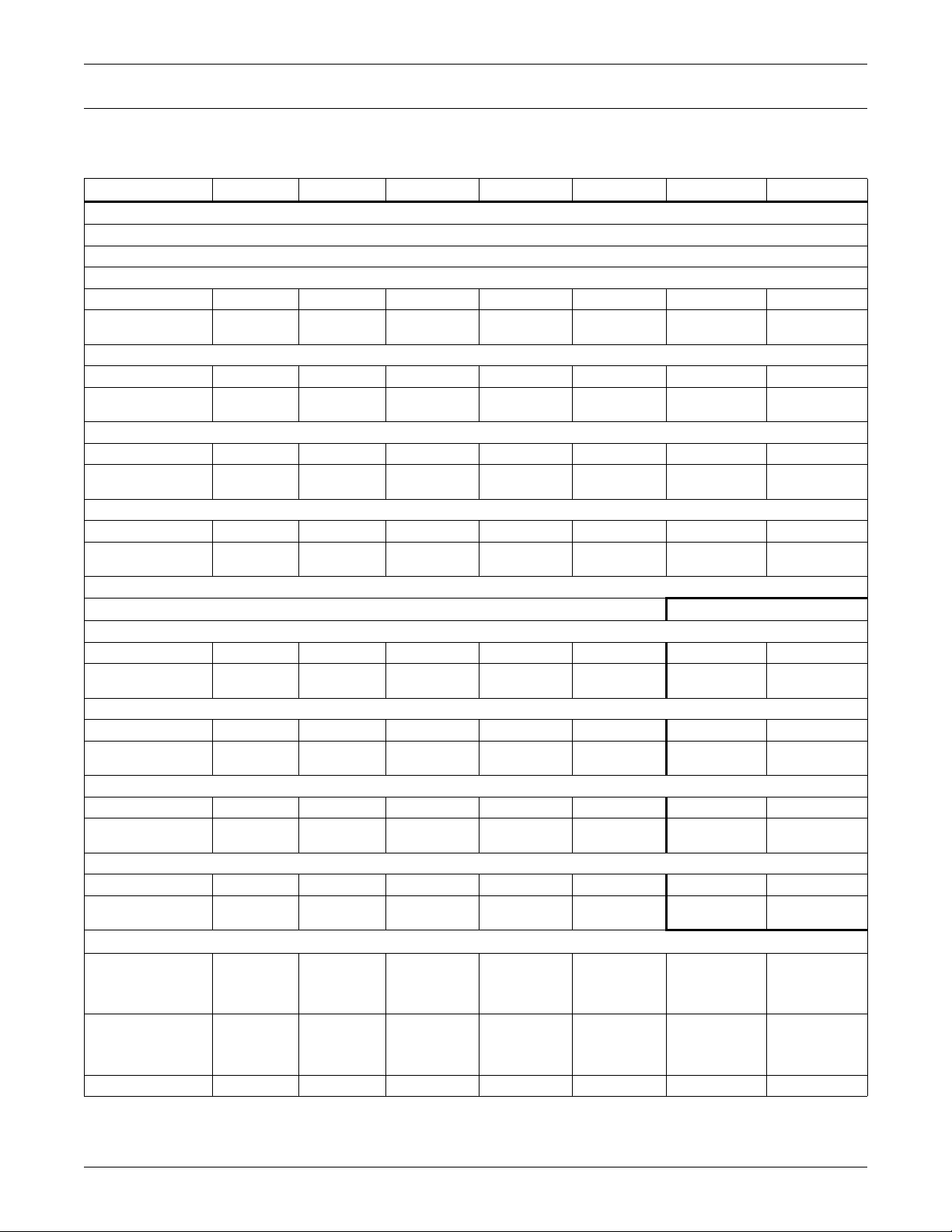

Table 1 Performance Data—Air-cooled, EC fan, under-floor discharge

Model Size 028 035 042 053 070 077 105

CAPACITY DATA with EC Fans

Net Capacity Data kW (BTUH), Standard Air Volume and Evaporator Fan Motor

Semi Hermetic Compressors with EC Fans

85°F DB, 64.5°F WB, 52.3°F DP (29.4°C DB, 18.1°C WB) 32.4% RH

Total kW (kBTUH) 34.1 (116.4) 42.1 (143.6) 47.9 (163.6) 61.7 (210.6) 72.4 (247.1) 79.2 (270.3) 103.3 (352.5)

Sensible kW

(kBTUH)

80°F DB, 62.9°F WB, 52.3°F DP (26.7°C DB, 17.1°C WB) 38.2% RH

Total kW (kBTUH) 32.4 (110.5) 40.1 (136.8) 45.7 (156.1) 58.3 (198.9) 68.8 (234.8) 75.3 (257.1) 99.1 (338.2)

Sensible kW

(kBTUH)

75°F DB, 61.1°F WB, 52.3°F DP (23.9°C DB, 16.2°C WB) 45.1% RH

Total kW (kBTUH) 30.9 (105.3) 38.3 (130.8) 43.8 (149.5) 55.4 (189) 65.6 (223.9) 72 (245.8) 95.2 (325)

Sensible kW

(kBTUH)

72°F DB, 60.0°F WB, 52.3°F DP (22.2°C DB, 15.6°C WB) 49.9% RH

Total kW (kBTUH) 30 (102.5) 37.3 (127.4) 42.7 (145.8) 53.8 (183.6) 63.9 (218) 70.2 (239.7) 93.1 (317.6)

Sensible kW

(kBTUH)

Net Capacity Data kW (BTUH), Standard Air Volume and Evaporator Fan Motor

Scroll or Digital Scroll Compressors with EC Fans

85°F DB, 64.5°F WB, 52.3°F DP (29.4°C DB, 18.1°C WB) 32.4% RH

Total kW (kBTUH) 35.4 (120.8) 40.2 (137.1) 45.5 (155.3) 63.5 (216.8) 75.8 (258.6) 81.3 (277.6) 103.6 (353.7)

Sensible kW

(kBTUH)

80°F DB, 62.9°F WB, 52.3°F DP (26.7°C DB, 17.1°C WB) 38.2% RH

Total kW (kBTUH) 33.4 (113.9) 38.2 (130.4) 43.4 (148.1) 60.5 (206.5) 72.7 (248) 77.9 (265.8) 99.7 (340.2)

Sensible kW

(kBTUH)

75°F DB, 61.1°F WB, 52.3°F DP (23.9°C DB, 16.2°C WB) 45.1% RH

Total kW (kBTUH) 31.6 (107.8) 36.5 (124.7) 41.6 (141.9) 57.8 (197.4) 69.9 (238.4) 74.9 (255.5) 96 (327.8)

Sensible kW

(kBTUH)

72°F DB, 60.0°F WB, 52.3°F DP (22.2°C DB, 15.6°C WB) 49.9% RH

Total kW (kBTUH) 30.6 (104.3) 35.6 (121.5) 40.6 (138.5) 56.4 (192.6) 68.3 (233) 73.2 (249.9) 93.8 (320.3)

Sensible kW

(kBTUH)

Standard Air

Volume,

CFM (CMH)

0.2" External Static

Standard Fan

Motor,

Nominal kW

(total for all fans)

Number of Fans 1 1 1 2 2 2 3

1. Capacity data is rated and factory-certified per ASHRAE 127-2012 with a 5% tolerance.

2. Some options or combinations of options may result in reduced air flow—consult factory for recommendations.

3. Digital scroll not available on 077 and 105 models; units available with semi-hermetic and standard scroll compressors only.

34 (116) 41.4 (141.2) 47.9 (160.9) 61.6 (210.2) 72 (245.9) 78.9 (269.2) 98.9 (337.5)

31 (105.9) 37.5 (128.1) 45.7 (146.2) 56.8 (193.9) 66.4 (226.6) 72.9 (248.8) 90 (307.2)

27.5 (93.9) 33.3 (113.8) 43.8 (129.9) 50.8 (173.3) 59 (201.3) 64.9 (221.5) 80 (273.1)

25.3 (86.3) 30.7 (104.8) 42.7 (119.7) 46.7 (159.3) 54.2 (184.9) 59.7 (203.6) 73.8 (251.8)

Scroll Compressors Only

35.2 (120) 40 (136.4) 45.3 (154.7) 63.2 (215.7) 74.9 (255.6) 80.6 (275.1) 99.1 (338.3)

31.8 (108.7) 36.5 (124.6) 41.6 (141.9) 58.3 (199.1) 68.9 (235) 74.1 (253) 90.3 (308.2)

28.2 (96.1) 32.5 (110.8) 37 (126.3) 52 (177.6) 61.4 (209.4) 65.9 (224.9) 80.4 (274.3)

25.8 (88.2) 29.9 (102.1) 34.1 (116.3) 47.9 (163.6) 56.5 (192.9) 60.6 (206.9) 74.1 (253)

FAN SECTION - Downflow Models - EC Fans Under Floor

4,400

(7,476)

2.8 2.8 2.8 2.5 4.0 5.9 7.8

5,200

(8,835)

6200

(10533.9)

8,000

(13,592)

9,600

(16,310)

11,000

(18,689)

13,700

(23,276)

Liebert® DS

™

6

Page 11

Air-Cooled Systems

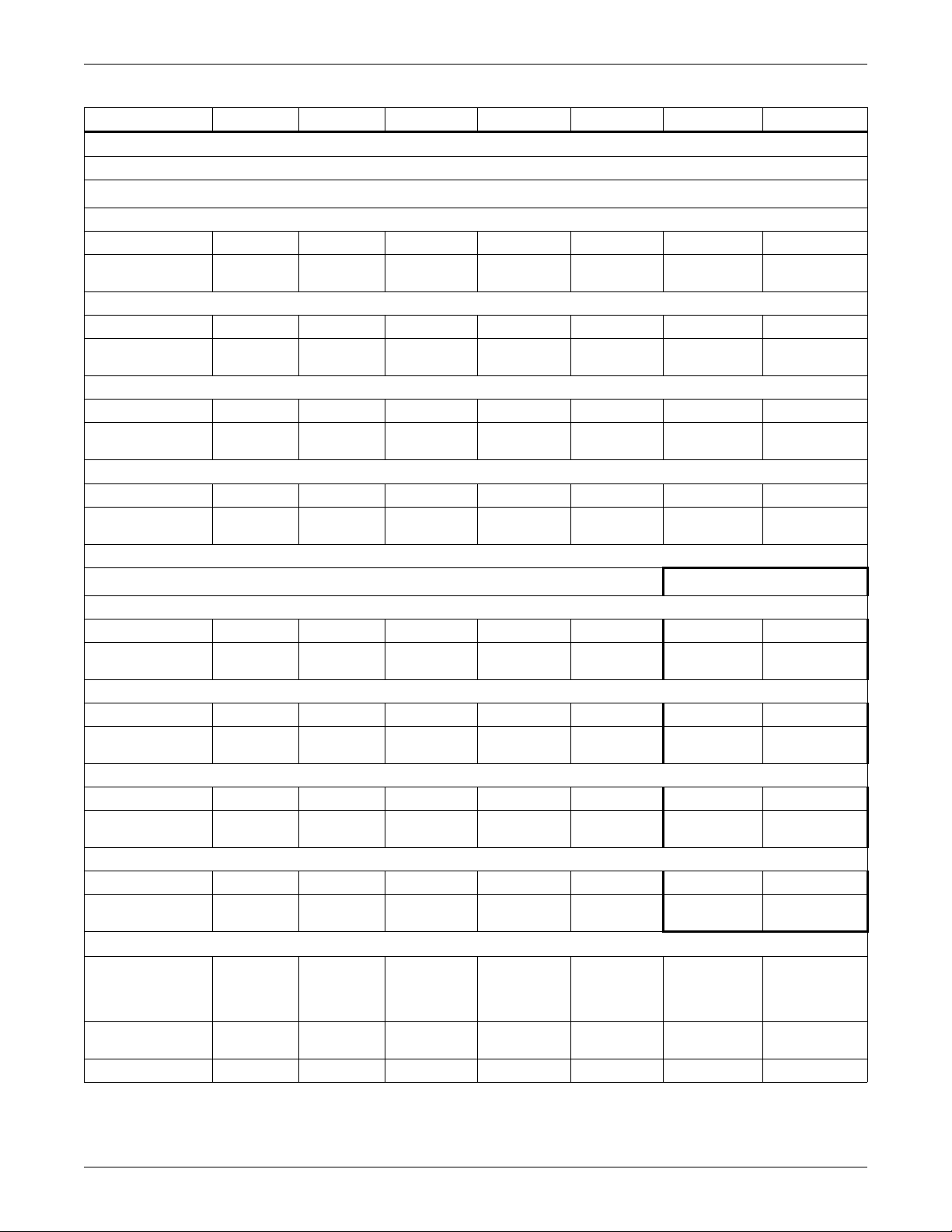

Table 2 Performance data—Air-cooled, centrifugal fan

Model Size 028 035 042 053 070 077 105

CAPACITY DATA with Centrifugal Fans

Net Capacity Data kW (BTUH), Standard Air Volume and Evaporator Fan Motor

Semi Hermetic Compressors with Centrifugal Fans

85°F DB, 64.5°F WB, 52.3°F DP (29.4°C DB, 18.1°C WB) 32.4% RH

Total kW (kBTUH) 40.3 (137.6) 41.0 (140.0) 46.2 (157.6) 60.2 (205.3) 70.5 (240.6) 76.9 (262.6) 101.3 (345.6)

Sensible kW

(kBTUH)

38.0 (129.6) 40.3 (137.6) 45.5 (155.3) 59.7 (203.8) 69.7 (237.9) 76.2 (259.9) 96.6 (329.6)

80°F DB, 62.9°F WB, 52.3°F DP (26.7°C DB, 17.1°C WB) 38.2% RH

Total kW (kBTUH) 38.6 (131.8) 39.1 (133.3) 43.9 (150) 57.2 (195.1) 67.2 (229.3) 73.4 (250.6) 97.1 (331.5)

Sensible kW

(kBTUH)

34.3 (117.2) 36.5 (124.6) 41.2 (140.5) 54.8 (187.1) 63.8 (217.7) 69.8 (238.2) 87.7 (299.4)

75°F DB, 61.1°F WB, 52.3°F DP (23.9°C DB, 16.2°C WB) 45.1% RH

Total kW (kBTUH) 37.1 (126.5) 37.3 (127.2) 42 (143.3) 54.4 (185.6) 64.1 (218.9) 70.2 (239.7) 93.3 (318.4)

Sensible kW

(kBTUH)

30.5 (104.2) 32.3 (110.3) 36.4 (124.2) 48.7 (166.2) 56.5 (192.9) 61.8 (210.9) 77.8 (265.4)

72°F DB, 60.0°F WB, 52.3°F DP (22.2°C DB, 15.6°C WB) 49.9% RH

Total kW (kBTUH) 36.1 (123.3) 36.3 (123.8) 40.9 (139.6) 52.9 (180.6) 62.5 (213.2) 68.6 (234) 91.0 (310.6)

Sensible kW

(kBTUH)

28.2 (96.3) 29.7 (101.3) 33.4 (113.9) 44.7 (152.7) 51.9 (177.2) 56.7 (193.6) 71.5 (244.1)

Net Capacity Data kW (BTUH), Standard Air Volume and Evaporator Fan Motor

Scroll or Digital Scroll Compressors with Centrifugal Fans

85°F DB, 64.5°F WB, 52.3°F DP (29.4°C DB, 18.1°C WB) 32.4% RH

Total kW (kBTUH) 34.1 (116.4) 39.7 (135.5) 43.7 (149.2) 62.1 (212.1) 74.0 (252.6) 79.1 (270.1) 101.6 (346.9)

Sensible kW

(kBTUH)

40.1 (136.9) 34.0 (116.0) 43.6 (148.9) 61.3 (209.3) 72.3 (246.6) 77.8 (265.6) 96.8 (330.4)

80°F DB, 62.9°F WB, 52.3°F DP (26.7°C DB, 17.1°C WB) 38.2% RH

Total kW (kBTUH) 32.4 (110.5) 38.3 (130.8) 41.6 (141.9) 59.3 (202.5) 71.2 (243) 75.9 (259) 97.7 (333.5)

Sensible kW

(kBTUH)

31.0 (105.9) 36.1 (123.2) 39.9 (136.1) 56.1 (191.6) 65.9 (225) 71.1 (242.6) 88.0 (300.4)

75°F DB, 61.1°F WB, 52.3°F DP (23.9°C DB, 16.2°C WB) 45.1% RH

Total kW (kBTUH) 30.9 (105.3) 36.7 (125.4) 39.8 (135.7) 56.9 (194.2) 68.5 (233.9) 73 (249.3) 94.1 (321.1)

Sensible kW

(kBTUH)

27.5 (93.9) 32.1 (109.4) 35.3 (120.6) 49.9 (170.4) 58.6 (200.1) 63.1 (215.2) 78.1 (266.6)

72°F DB, 60.0°F WB, 52.3°F DP (22.2°C DB, 15.6°C WB) 49.9% RH

Total kW (kBTUH) 30.0 (102.5) 35.9 (122.4) 38.8 (132.3) 55.5 (189.5) 67 (228.7) 71.4 (243.7) 91.9 (313.7)

Sensible kW

(kBTUH)

25.3 (86.3) 29.5 (100.6) 32.4 (110.5) 46.0 (157) 54.0 (184.3) 58.0 (197.8) 71.9 (245.5)

FAN SECTION - Downflow Models - Fixed Pitch, Two Belts

Standard Air

Volume - CFM

(CMH) 0.2"

4,400

(7,476)

5,200

(8,835)

6,300

(10,704)

7,500

(12,743)

9,000

(15,291)

external static

Standard Fan

Motor hp (kW)

2 (1.5) 3 (2.2) 5.0 (3.7) 3 (2.2) 5 (3.7) 7.5 (5.6) 10.0 (7.5)

Number of Fans 1 1 1 2 2 2 3

1. Capacity data is rated and factory-certified per ASHRAE 127-2012 with a 5% tolerance.

2. Some options or combinations of options may result in reduced air flow—consult factory for recommendations.

3. Digital scroll not available on 077 and 105 models; units available with semi-hermetic and standard scroll compressors only

Scroll Compressors Only

10,400

(17,670)

13,700

(23,276)

®

7Liebert

DS

™

Page 12

Air-Cooled Systems

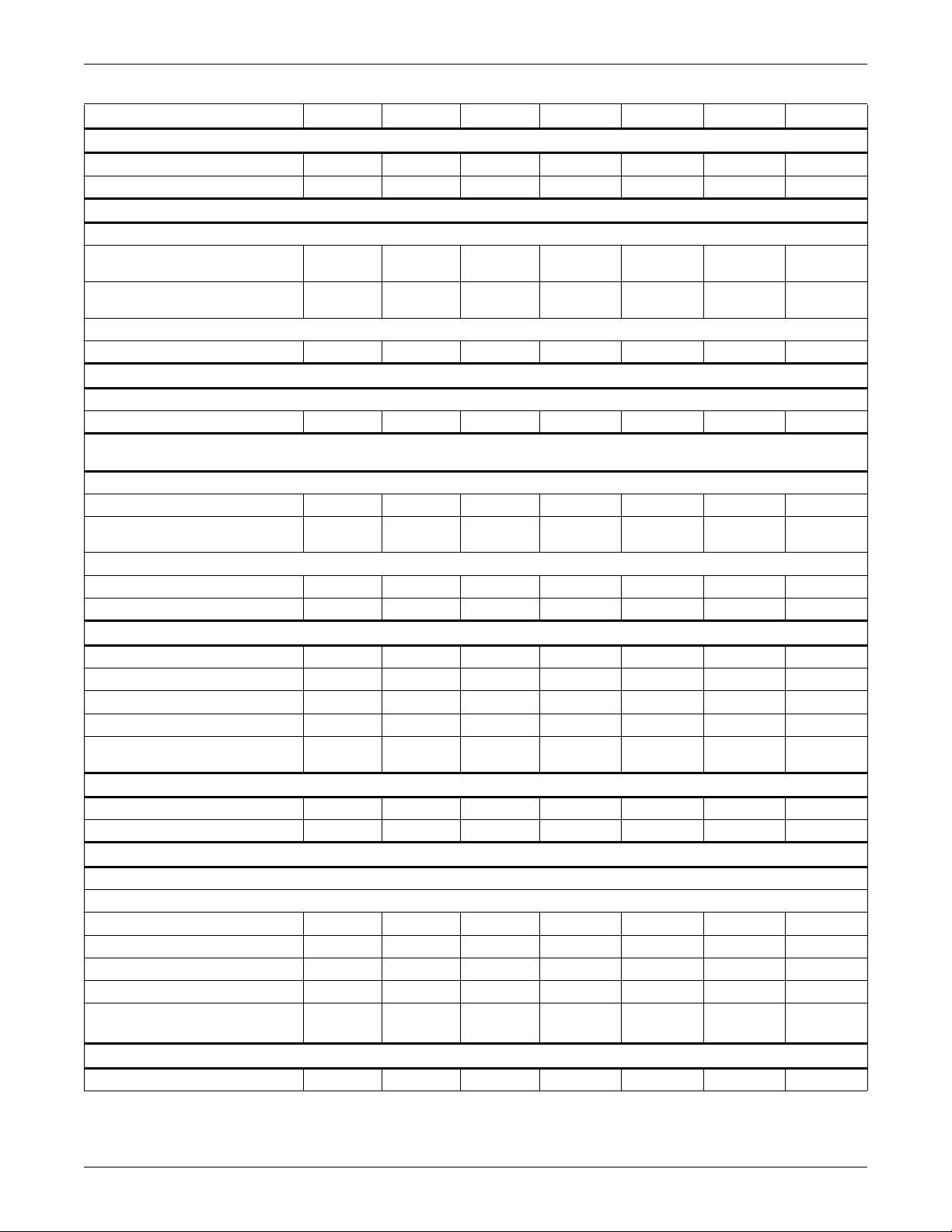

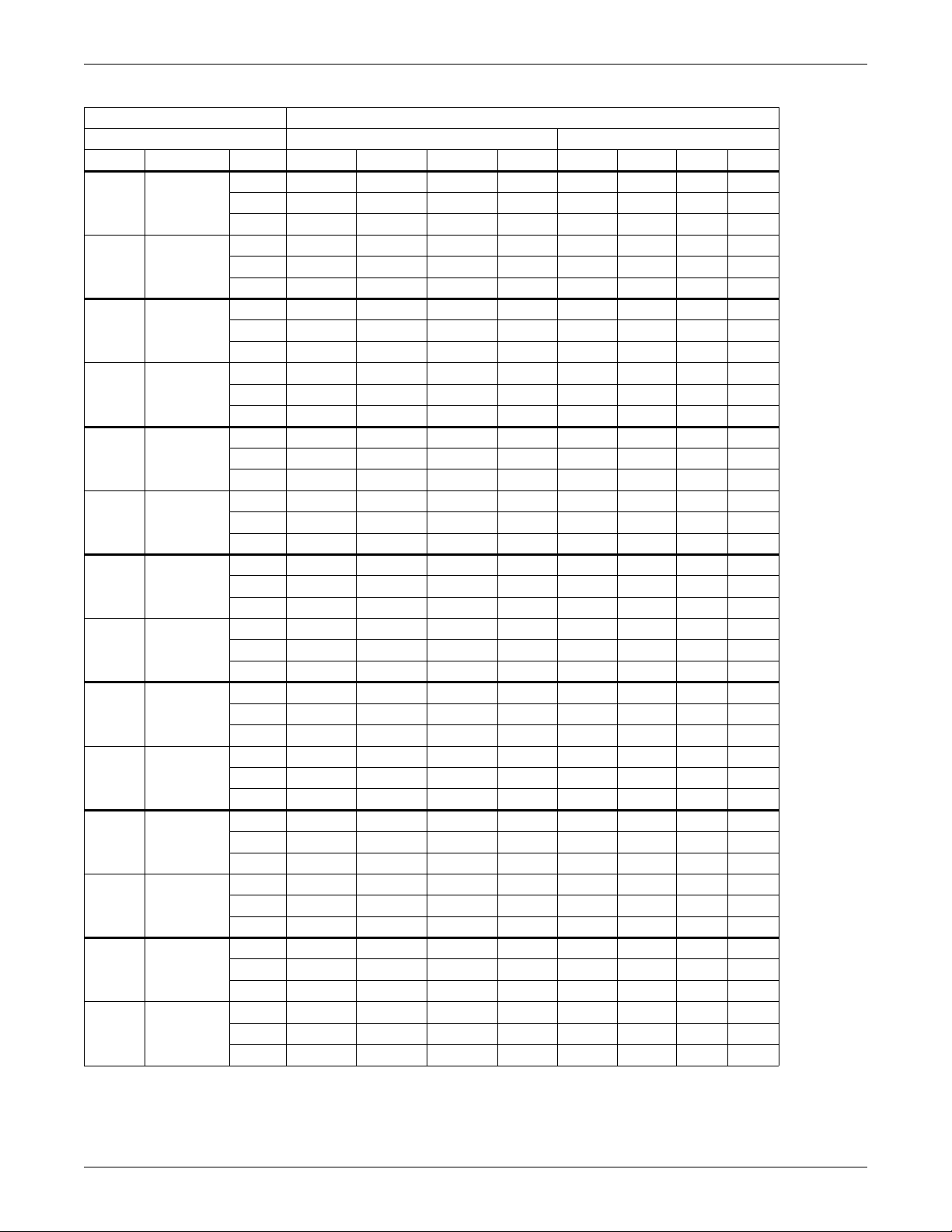

Table 3 Physical data—Air-cooled systems

Model Size 028 035 042 053 070 077 105

EVAPORATOR COIL- A-Frame - Copper Tube/Aluminum Fin

Face Area, sq. ft. (sq. m)

Rows of Coil

Electric Reheat - Three-Stage, Stainless Steel Fin Tubular, capacity does not include fan motor heat

Capacity - kW (kBTUH) - Standard

Selection

Capacity, kW (kBTUH) - Optional

Selection

Electric Reheat - SCR Control, Stainless Steel Fin Tubular (optional selection)

Capacity, kW (kBTUH)

Infrared Humidifier (Steam canister humidifiers available on downflow models with centrifugal fans)

Capacity, lb./hr. (kg/h)

FILTER SECTION - Disposable Type - Nominal Sizes and Quantities, Standard MERV 8 or Optional MERV 11

(filter types cannot be mixed, must be all MERV 8 or all MERV 11)

Downflow Models

Quantity

Nominal Size, inches

Upflow Models (Front & Rear return) Filters located in separate filter box on rear return, located on lower unit panel

Quantity

Nominal Size, inches 25x20 25x20 25x20 25x20 25x20 25x20 25x20

PIPING CONNECTION SIZES - Air-cooled Liebert DS Indoor Unit (Not External Line Sizes)

Liquid Line, O.D. Copper (2/unit) 1/2 1/2 1/2 5/8 5/8 5/8 5/8

Hot Gas Line, O.D. Copper (2/unit) 5/8 5/8 5/8 7/8 7/8 7/8 1-1/8

Infrared Humidifier, O.D. Copper

Condensate Drain, FPT

Condensate Drain w/Optional

Condensate Pump, OD

OUTDOOR AIR-COOLED CONDENSER, STANDARD 95°F AMBIENT SELECTION; see Tables 44 and 49 for other selections

Model (R-407C refrigerant) MCM080_8 MCM080_8 MCM080_8 MCM080_8 MCM080_8 MCM080_8 MCL110_8

Number of Fans 222 2 2 2 2

DUAL-COOL UNITS DATA, Water (0% Glycol), Net Capacity Data kW (kBTUH)

CAUTION: CuNi coil option must be specified when Econ-O-Coil is applied to open water tower.

75°F DB, 61.1 WB (23.9°C DB, 16.2°C WB) 45% RH, 45°F EWT, 55°F LWT Based on Centrifugal Fans

Total Capacity, kW (kBTUH)

Sensible Capacity, kW (kBTUH) 24.9 (85) 28.8 (98.2) 31.6 (107.8) 46 (157.1) 51.7 (176.4) 54.3 (185.4)

Flow Rate GPM (I/m) @ 10°F Rise 19 (71.9) 22.4 (84.8) 25.5 (96.5) 36.4 (138) 41.7 (158) 46 (174)

Pressure Drop, ft. (kPa), valve, coil 6.1 (18.23) 8.3 (24.81)

Airflow, CFM (CMH) 4400 (7475) 5500 (9344)

Econ-O-Coil fluid volume, gal (l)

Capacity data is rated per ASHRAE 127-2012 with a 5% tolerance

17.1 (1.6) 17.1 (1.6) 17.1 (1.6) 24.7 (2.3) 24.7 (2.3) 24.7 (2.3) 32.3 (3.0)

333 3 3 3 3

REHEAT SECTION

15.0 (51.2) 15.0 (51.2) 15.0 (51.2) 25.0 (85.3) 25.0 (85.3) 25.0 (85.3) 30.0 (102.4)

10.0 (34.1) 10.0 (34.1) 10.0 (34.1) 15.0 (51.2) 15.0 (51.2) 15.0 (51.2) 20.0 (68.3)

15.0 (51.2) 15.0 (51.2) 15.0 (51.2) 25.0 (85.3) 25.0 (85.3) 25.0 (85.3) 30.0 (102.4)

HUMIDIFIER SECTION

11.0 (5.0) 11.0 (5.0) 11.0 (5.0) 22.0 (10.0) 22.0 (10.0) 22.0 (10.0) 22.0 (10.0)

333 4 4 4 4

2 @ 25x20

1 @ 25x16

444 6 6 6 8

1/4 1/4 1/4 1/4 1/4 1/4 1/4

3/4 3/4 3/4 3/4 3/4 3/4 3/4

1/2 1/2 1/2 1/2 1/2 1/2 1/2

26.2 (89.2) 29.8 (101.6) 32.2 (109.8) 49.9 (170.4) 55.3 (188.8) 57.7 (196.8)

2 @ 25x20

1 @ 25x16

2 @ 25x20

1 @ 25x16

10.50 (31.39) 10.40 (31.09)

6600

(11213)

4 @ 25x20 4 @ 25x20 4 @ 25x20 4 @ 25x20

8000

(13592)

13.3 (39.8) 15.9 (47.6)

9600

(16310)

11000

(18689)

75.8 (258.8)

73 (249.1)

59.4 (225)

15.9 (47.5)

13,700

(23,256)

Fluid Volumes

5 (19.0) 5 (19.0) 5 (19.0) 8 (30.4) 8 (30.4) 8 (30.4) 10 (38.0)

Liebert® DS

™

8

Page 13

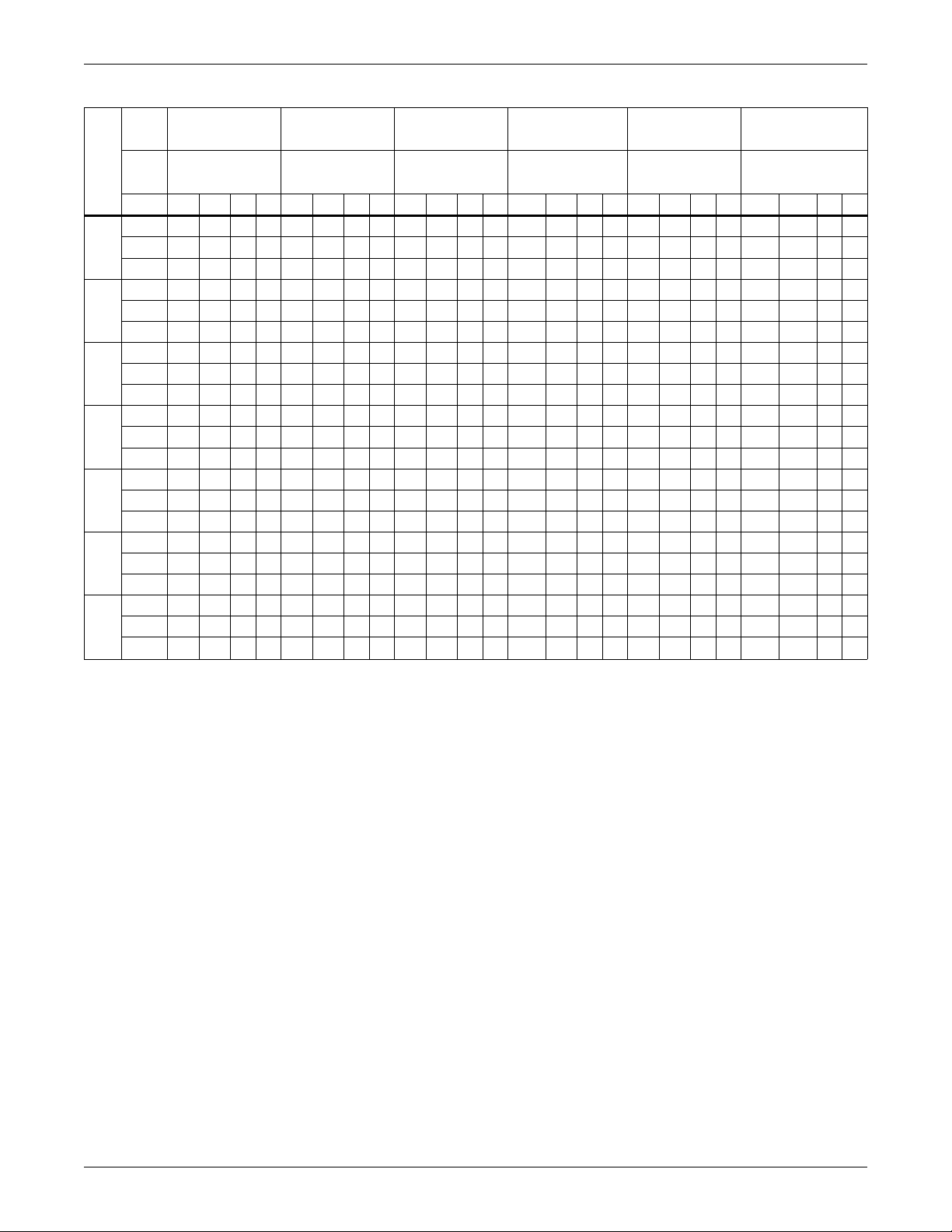

Table 4 Electrical data—Air-cooled systems with EC fans

Air-Cooled Systems

Reheat

Options

Humid-

ifier

Options Infrared Infrared None None Humidifier No Humidifier

Model

#

Volts 208 230 460 575 208 230 460 575 208 230 460 575 208 230 460 575 208 230 460 575 208 230 460 575

FLA 67.3 64.8 32.1 25.5 56.3 54.1 26.9 24.2 67.3 64.8 32.1 25 43 43 21.1

DS028

WSA 82 78.9 39.2 31.9 60.6 58.4 29.1 25.9 82 78.9 39.2 30.5 47.3 47.3 23.3

OPD 80804030707035308080403060 6030

FLA 70.7 68.2 33.4 25.5 63.1 60.9 29.5 25.2 70.7 68.2 33.4 25.5 49.8 49.8 23.7

DS035

WSA 86.3 83.2 40.8 31.9 68.3 66.1 32 27.1 86.3 83.2 40.8 31.1 55 55 26.2

OPD 90904530808040309090453070 7035

FLA 78.2 75.9 37.7 33 78.1 75.9 37.7 33 78.2 75.7 37.5 29.4 64.8 64.8 31.9

DS042

WSA 95.7 92.5 46 36 85.2 83 41.2 35.8 95.7 92.5 46 36 71.9 71.9 35.4

OPD 110 110 50 45 110 110 50 45 110 110 50 40 100 100 45

FLA 119.9 116 57.1 43.5 109.2 104.8 52.4 42 119.9 116 57.1 43.5 82.6 82.6 40.8

DS053

WSA 145.3 140.4 69.4 53.9 117.2 112.8 56.5 45 145.3 140.4 69.4 52.8 90.6 90.62 44.9

OPD 150 150 70 50 125 125 70 50 150 150 70 50 110 110 60

FLA 129.2 125.3 59.9 46.4 127.8 123.4 58 46.4 129.2 125.3 59.9 45.7 101.2 101.2 46.4

DS070

WSA 156.9 152 72.9 55.5 138.2 133.8 62.8 50 156.9 152.0 72.9 55.5 111.6 111.6 51.2

OPD 175 175 80 60 175 175 80 60 175 175 80 60 150 150 70

FLA 139.2 134.8 61.4 50 139.2 134.8 61 50 134.9 131 61.4 47.5 112.6 112.6 49.4

DS077

WSA 164 159.2 74.8 57.8 151. 146.6 66.2 54 164.0 159.2 74.8 57.8 124.37 124.4 54.6

OPD 175 175 80 70 175 175 80 70 175 175 80 60 150 150 70

FLA 171.5 167.1 83.7 69.1 171.5 167.1 83.7 69.1 164 163.5 79.8 62.6 144.9 144.9 72.1

WSA 198.8 198.2 97.4 76.4 186.5 182.1 91.6 75.4 198.8 198.2 97.4 76.4 159.9 159.9 80

DS105

OPD 225 225 110 100 225 225 110 100 225 225 110 90 200 200 110

1. Reduced reheat for 028, 035, and 042 models is 10kW.

2. Reduced reheat for 053, 070, and 077 models is 15kW.

3. Consult local representative for SCR reheat values.

4. Reduced reheat for 105 kW models is 20kW.

5. SCCR - Short Circuit Current Rating 65,000 amps rms symmetrical maximum.

6. Steam canister humidifiers not available on models with EC fans.

Electric

Standard, kW None

Electric

Standard kW None

16.8 56.3

18.5 64.8

25 70

17.8 63.1

19.7 69

25 80

25.6 78.1

28.4 85.2

35 110

30.4 109.2

33.4 117.2

45 125

34.8 127.8

38.4 138.2

50 175

38.4 139.2

42.4 151

50 175

57.5 171.5

63.8 186.5

80 225

Electric,

Downsized kW

54.1 26.9 24.2 53.5 51.9 25.6 19.9

62.8 31.1 25.9 64.8 62.8 31.1 24.1

70 35 30 70 70 35 25

60.9 29.5 25.2 56.9 55.3 26.9 20.4

67 32.7 27.1 69 67 32.7 24.8

80 40 30 80 80 35 25

75.9 37.7 33 64.8 64.8 31.9 25.6

83 41.2 35.8 78.4 76.4 37.8 29.6

110 50 45 100 100 45 35

104.8 52.4 42 92.1 89.6 44.1 33.5

112.8 56.5 45 110.52 107.4 53.1 40.3

125 70 50 125 125 60 45

123.4 58 46.4 101.4 101.2 46.9 35.7

133.8 62.8 50 122.15 119.02 56.6 43

175 80 60 150 150 70 50

134.8 61 50 112.6 112.6 49.4 38.4

146.6 66.2 54 129.27 126.15 58.5 45.3

175 80 70 150 150 70 50

167.1 83.7 69.1 144.9 144.9 72.1 57.5

182.1 91.6 75.4 169.3 165.5 81.3 63.9

225 110 100 200 200 110 80

Electric,

Downsized kW

®

9Liebert

DS

™

Page 14

Air-Cooled Systems

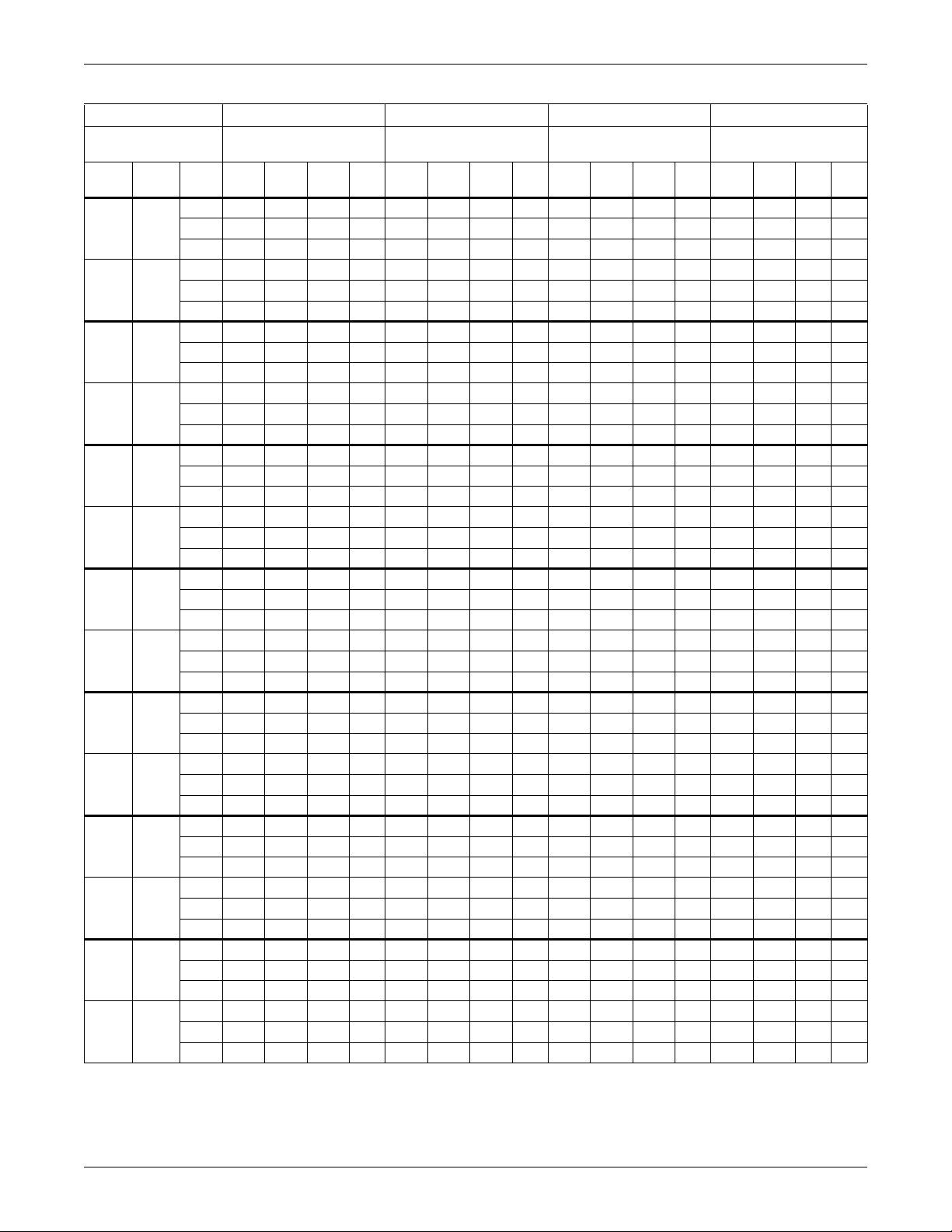

Table 5 Electrical data—Air-cooled systems with centrifugal fans

Reheat Options Electric, Std. kW None Electric, Std. kW None

Humidifier

Options

Motor

Model

hp Volts 208 230 460 575 208 230 460 575 208 230 460 575 208 230 460 575

FLA 66.4 63.2 31.8 25.2 55.4 52.5 26.6 23.9 66.4 63.2 31.8 24.7 42.1 41.4 20.8 16.5

028 2.0

WSA 81.1 77.3 38.9 31.5 59.7 56.8 28.8 25.6 81.1 77.3 38.9 30.2 46.4 45.7 23 18.2

OPD80804030707035308080403060603025

FLA 69.5 66.0 33.2 26.4 58.5 55.3 28.0 25.1 69.5 66.0 33.2 25.9 45.2 44.2 22.2 17.7

028 3.0

WSA 84.2 80.1 40.3 33 62.8 59.6 30.2 26.8 84.2 80.1 40.3 31.4 49.5 48.5 24.4 19.4

OPD90804030807035309080403060603025

FLA 72.9 69.4 34.5 26.4 65.3 62.1 30.6 26.1 72.9 69.4 34.5 26.4 52.0 51.0 24.8 18.7

035 3.0t

WSA 88.5 84.4 41.9 33.0 70.5 67.3 33.1 28.0 88.5 84.4 41.9 32.0 57.2 56.2 27.3 20.6

OPD90904535908040359090453570703525

FLA 79.0 75.0 37.3 28.6 71.4 67.7 33.4 28.3 79.0 75.0 37.3 28.6 58.1 56.6 27.6 20.9

035 5.0

WSA 94.6 90.0 44.7 35.8 76.6 72.9 35.9 30.2 94.6 90.0 44.7 34.2 63.3 61.8 30.1 22.8

OPD 100 100 45 35 90 90 45 35 100 100 45 35 80 80 40 30

FLA 86.5 82.7 41.6 36.1 86.4 82.7 41.6 36.1 86.5 82.5 41.4 32.5 73.1 71.6 35.8 28.7

042 5.0

WSA 104 99.3 49.9 39.1 93.5 89.8 45.1 38.9 104.0 99.3 49.9 39.1 80.2 78.7 39.3 31.5

OPD 110 110 50 50 110 110 50 50 110 110 50 45 100 100 50 40

FLA 94.0 89.5 45.0 39.0 93.9 89.5 45.0 39.0 94.0 89.3 44.8 35.4 80.6 78.4 39.2 31.6

042 7.5

WSA 111.5 106.1 53.3 42.0 101.0 96.6 48.5 41.8 111.5 106.1 53.3 42.0 87.7 85.5 42.7 34.4

OPD 125 110 60 50 125 110 60 50 125 110 60 45 110 110 50 45

FLA 112.1 107.2 53.9 41 101.4 96 49.2 39.5 112.1 107.2 53.9 41 74.8 73.8 37.6 27.9

053 3.0

WSA 137.5 131.6 66.2 50.8 109.4 104.0 53.3 42.5 137.5 131.6 66.2 50.3 82.8 81.8 41.7 30.9

OPD 150 125 70 50 125 125 60 50 150 125 70 50 110 110 50 40

FLA 118.2 112.8 56.7 43.2 107.5 101.6 52.0 41.7 118.2 112.8 56.7 43.2 80.9 79.4 40.4 30.1

053 5.0

WSA 143.6 137.2 69.0 53.5 115.5 109.6 56.1 44.7 143.6 137.2 69.0 52.5 88.9 87.4 44.5 33.1

OPD 150 150 70 50 125 125 70 50 150 150 70 50 110 110 60 45

FLA 127.5 122.1 59.5 46.1 126.1 120.2 57.6 46.1 127.5 122.1 59.5 45.4 99.5 98 46 34.5

070 5.0

WSA 155.2 148.8 72.5 55.2 136.5 130.6 62.4 49.7 155.2 148.8 72.5 55.2 109.9 108.4 50.8 38.1

OPD 175 150 80 60 175 150 80 60 175 150 80 60 150 125 70 50

FLA 135.0 128.9 62.9 49.0 133.6 127.0 61.0 49.0 135.0 128.9 62.9 48.3 107.0 104.8 49.4 37.4

070 7.5

WSA 162.7 155.6 75.9 58.1 144.0 137.4 65.8 52.6 162.7 155.6 75.9 58.1 117.4 115.2 54.2 41.0

OPD 175 175 80 60 175 175 80 60 175 175 80 60 150 150 70 50

FLA 145 138.4 64.4 52.6 145.0 138.4 64.0 52.6 140.7 134.6 64.4 50.1 118.4 116.2 52.4 41.0

077 7.5

WSA 169.8 162.8 77.8 60.4 156.8 150.2 69.2 56.6 169.8 162.8 77.8 60.4 130.2 128.0 57.6 45.0

OPD 200 175 90 70 200 175 80 70 175 175 90 70 175 175 70 60

FLA 151.6 144.4 67.4 54.6 151.6 144.4 67.0 54.6 147.3 140.6 67.4 52.1 125.0 122.2 55.4 43.0

077 10.0

WSA 176.4 168.8 80.8 62.4 163.4 156.2 72.2 58.6 176.4 168.8 80.8 62.4 136.8 134.0 60.6 47.0

OPD 200 200 90 70 200 200 90 70 200 175 90 70 175 175 80 60

FLA 177.4 170.2 88.4 72.6 177.4 170.2 88.4 72.6 169.9 166.6 84.5 66.1 150.8 148 76.8 61.0

105 10.0

WSA 204.7 201.3 102.1 79.9 204.7 201.3 102.1 79.9 204.7 201.3 102.1 79.9 165.8 163.0 84.7 67.3

OPD 250 225 125 100 250 225 125 100 225 225 110 90 225 200 110 90

FLA 192.3 184.2 95.4 78.6 192.3 184.2 95.4 78.6 185.3 180.6 91.5 72.1 166.2 162.0 83.8 67.0

105 15.0

WSA 220.1 215.3 109.1 85.9 220.1 215.3 109.1 85.9 220.1 215.3 109.1 85.9 181.2 177.0 91.7 73.3

OPD 250 250 125 100 250 250 125 100 250 250 125 100 225 225 110 90

1. Reduced reheat for 028, 035, and 042 models is 10kW.

2. Reduced reheat for 053, 070, and 077 models is 15kW.

3. Consult local representative for SCR reheat values.

4. Reduced reheat for 105 kW models is 20kW.

5. SCCR - Short Circuit Current Rating 65,000 amps rms symmetrical maximum.

Infrared or Steam

Generating Canister

Infrared or Steam

Generating Canister None None

Liebert® DS

™

10

Page 15

Table 5 Electrical data—Air-cooled systems with centrifugal fans (continued)

Reheat Options Electric, Downsized kW

Humidifier Options Infrared or Steam Generating Canister None

Model Motor, hp Volts 208 230 460 575 208 230 460 575

FLA 55.4 52.5 26.6 23.9 52.6 50.3 25.3 19.6

028 2.0

028 3.0

035 3.0

035 5.0

042 5.0

042 7.5

053 3.0

053 5.0

070 5.0

070 7.5

077 7.5

077 10.0

105 10.0

105 15.0

1. Reduced reheat for 028, 035, and 042 models is 10kW.

2. Reduced reheat for 053, 070, and 077 models is 15kW.

3. Consult local representative for SCR reheat values.

4. Reduced reheat for 105 kW models is 20kW.

5. SCCR - Short Circuit Current Rating 65,000 amps rms symmetrical maximum.

WSA 63.9 61.2 30.8 25.6 63.9 61.2 30.8 23.8

OPD 70 70 35 30 70 70 35 25

FLA 58.5 55.3 28 25.1 55.7 53.1 26.7 20.8

WSA 67.0 64.0 32.2 26.8 67.0 64.0 32.2 25.0

OPD 80 70 35 30 70 70 35 25

FLA 65.3 62.1 30.6 26.1 59.1 56.5 28.0 21.3

WSA 71.2 68.2 33.8 28.0 71.2 68.2 33.8 25.7

OPD 90 80 40 35 80 80 40 30

FLA 71.4 67.7 33.4 28.3 65.2 62.1 30.8 23.5

WSA 77.3 73.8 36.6 30.2 77.3 73.8 36.6 27.9

OPD 90 90 45 35 90 80 40 30

FLA 86.4 82.7 41.6 36.1 73.1 71.6 35.8 28.7

WSA 93.5 89.8 45.1 38.9 86.7 83.2 41.7 32.7

OPD 110 110 50 50 100 100 50 40

FLA 93.9 89.5 45.0 39.0 80.6 78.4 39.2 31.6

WSA 101.0 96.6 48.5 41.8 94.2 90.0 45.1 35.6

OPD 125 110 60 50 110 110 50 45

FLA 101.4 96.0 49.2 39.5 84.3 80.8 40.9 31

WSA 109.4 104.0 53.3 42.5 102.7 98.6 49.9 37.8

OPD 125 125 60 50 110 110 60 45

FLA 107.5 101.6 52.0 41.7 90.4 86.4 43.7 33.2

WSA 115.5 109.6 56.1 44.7 108.8 104.2 52.7 40.0

OPD 125 125 70 50 125 125 60 45

FLA 126.1 120.2 57.6 46.1 99.7 98 46.5 35.4

WSA 136.5 130.6 62.4 49.7 120.5 115.8 56.2 42.7

OPD 175 150 80 60 150 125 70 50

FLA 133.6 127.0 61.0 49.0 107.2 104.8 49.9 38.3

WSA 144.0 137.4 65.8 52.6 128.0 122.6 59.6 45.6

OPD 175 175 80 60 150 150 70 50

FLA 145 138.4 64.0 52.6 118.4 116.2 52.4 41.0

WSA 156.8 150.2 69.2 56.6 135.1 129.8 61.5 47.9

OPD 200 175 80 70 175 175 70 60

FLA 151.6 144.4 67.0 54.6 125.0 122.2 55.4 43.0

WSA 163.4 156.2 72.2 58.6 141.7 135.8 64.5 49.9

OPD 200 200 90 70 175 175 80 60

FLA 177.4 170.2 88.4 72.6 150.8 148 76.8 61.0

WSA 192.4 185.2 96.3 78.9 175.2 168.6 86.0 67.4

OPD 250 225 125 100 225 200 110 90

FLA 192.8 184.2 95.4 78.6 166.2 162.0 83.8 67.0

WSA 207.8 199.2 103.3 84.9 190.6 182.6 93.0 73.4

OPD 250 250 125 100 225 225 110 90

Air-Cooled Systems

11 Liebert® DS

™

Page 16

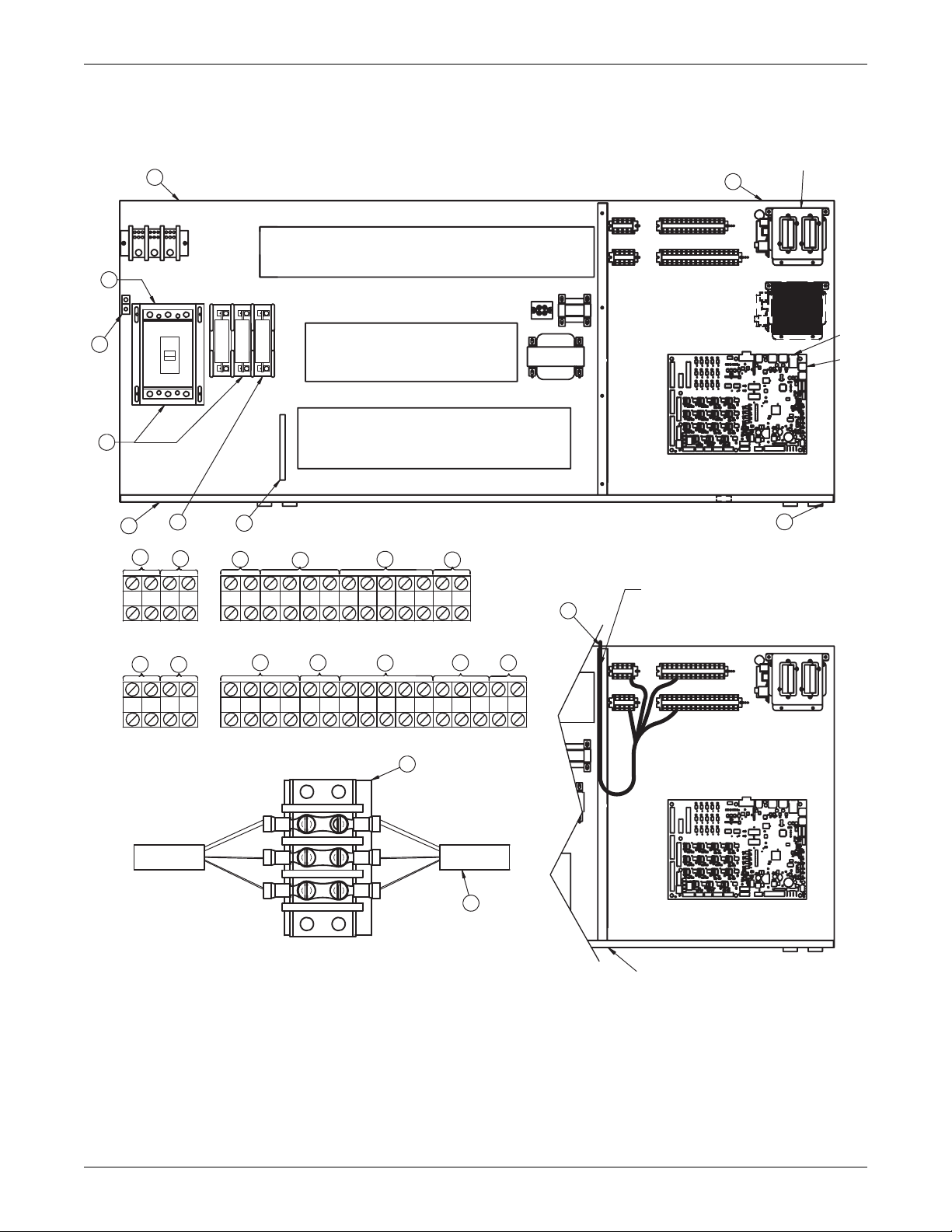

Air-Cooled Systems

See 3.2 - Standard Electrical Connections, 3.3 Optional Electrical Connections and 3.4 - Optional

Low-Voltage Terminal Package Connections for keys

to numbered components.

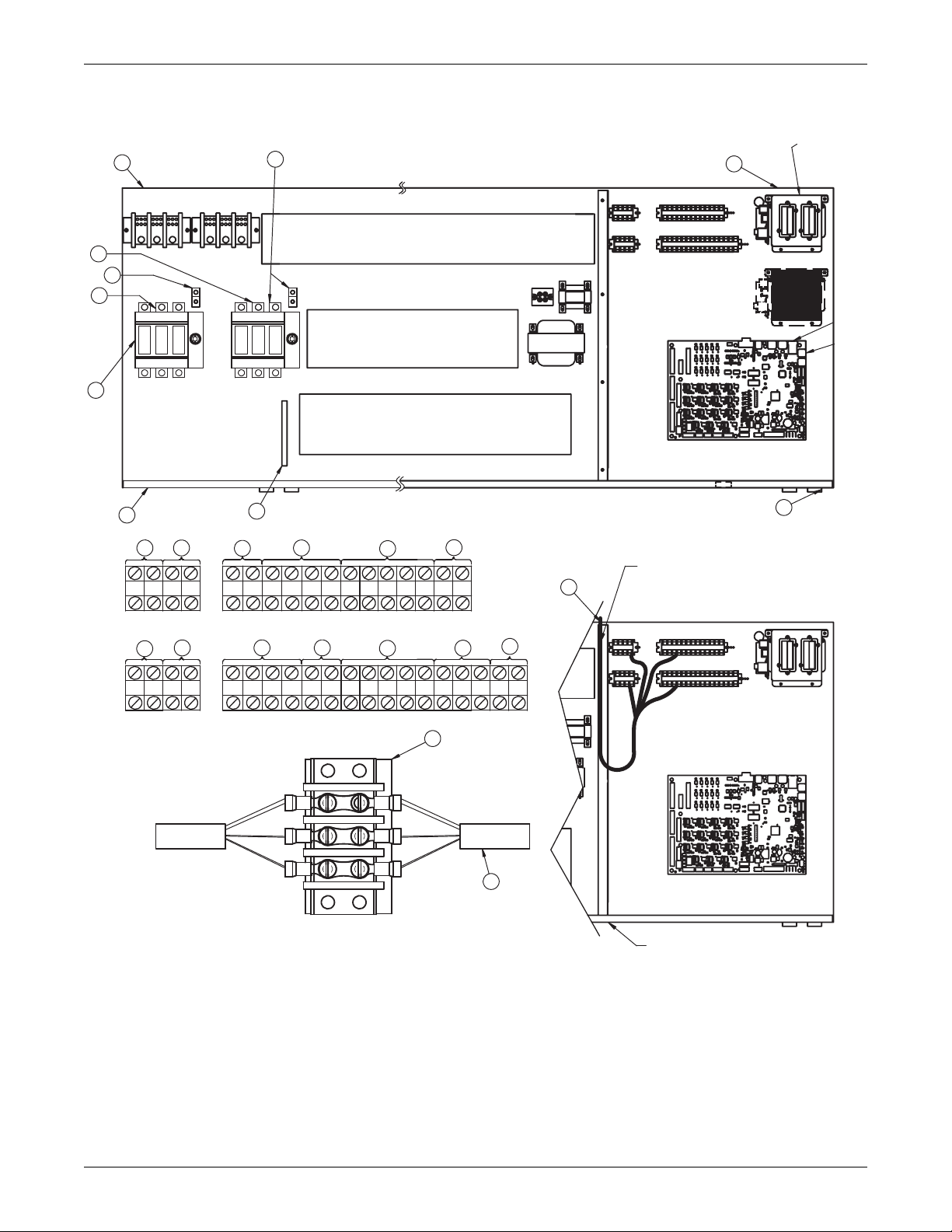

Figure 6 Electrical field connections—Upflow and downflow models, single molded case switch

disconnect with main fuses

2

4

Liebert

IntelliSlot

Housing

15

6

60Hz

13

17

5

18

83

88

1

82 89

A

24

23

OVERCURRENT PROTECTION DEVICES

CONTACTORS

CONTACTORS, RELAYS, &

OVERLOAD PROTECTORS

Typical orientation of components shown.

6

Component location varies by option and unit size

9

7576949596 97 91

22

16

92

93

80

19

81

12

11

UPFLOW

B

21

7

8

10

20

A

B

CD

Alternate

Location

P64

P67

E

DOWNFLOW

3

DOWNFLOW LOW-VOLT SECTION

CAUTION

Risk of broken or shorted low-voltage

3

wiring. Field-installed low-voltage wiring

must be routed with loop as shown

to allow electric box to swing.

50

59

84

58 85

37C

38C

37B

38B

37 38 24

51

56

55

7071230

CD

11

SH49-1

49-3

12

Item 12 Installation Conditions

1. Follow all local installation codes.

2. Do not run CAN cables in same conduit, raceway, or

chase as high voltage wires (120-600V).

3. Separate high-voltage wires from CAN wires by 12" (305mm).

4. For runs greater than 350ft (107m), contact Emerson factory.

E

73

72

Point of Hinged Low-Voltage Electric Box

DS UPFLOW LOW VOLT SECTION

DPN000807

Pg. 2, Rev. 8

Liebert® DS

™

12

Page 17

Air-Cooled Systems

See 3.2 - Standard Electrical Connections, 3.3 Optional Electrical Connections and 3.4 - Optional

Low-Voltage Terminal Package Connections for keys

to numbered components.

Figure 7 Electrical field connections—Upflow and downflow models, dual fused disconnect switches

Liebert

2

14

4

IntelliSlot

Housing

15

15

13

60 Hz

6

1

17 18

82 89

24

PRIMARY

83

A

B

Alternate

Alternate

Location

Location

P64

P67

OVERCURRENT PROTECTION DEVICES

SECONDARY

CONTACTORS

A

CD

CONTACTORS, RELAYS and

OVERLOAD PROTECTORS

E

Typical orientation of components shown.

6

Component location varies by option and unit size

9

22

16

19

DOWNFLOW LOW-VOLTAGE SECTION

UPFLOW

92

88

7576949596 97 91

93

80

81

12

11

3

DOWNFLOW

CAUTION:

Risk of broken or shorted low-voltage

wiring. Field-installed low-voltage wiring

must be routed with loop as shown

to allow electric box to swing.

3

B

23

21

7

8

10

20

50

E

51

56

55

7071230

11

SH49-1

49-3

72

12

37C

37B

59

84

58 85

38C

38B

37 38 24

CD

Item 12 Installation Conditions

1. Follow all local installation codes.

2. Do not run CAN cables in same conduit, raceway or

chase as high-voltage wires (120-600V).

3. Separate high-voltage wires from CAN wires by 12" (305mm).

4. Contact Liebert factory for runs greater than 350ft. (107m).

5. All electrical loads may not be capable of being connected to both

power feeds, with automatic transfer switch.

Consult local representative for dual power configurations available.

73

Point of Hinged Low-Voltage

Electric Box

DS UPFLOW LOW-VOLTAGE SECTION

DPN000807

Pg. 3, Rev. 8

13 Liebert® DS

™

Page 18

3.2 STANDARD ELECTRICAL CONNECTIONS

Source: DPN000807, Rev. 8

1. Primary high voltage entrance—2.5" (64mm); 1.75" (44mm); 1.375" (35mm) diameter

concentric knockouts located in bottom of box.

2. Secondary high voltage entrance—2.5" (64mm); 1.75" (44mm); 1.375" (35mm) diameter

concentric knockouts located in top of box.

3. Primary low voltage entrance—Quantity (3) 1.375" (35mm) diameter knockouts located in

bottom of unit.

4. Secondary low voltage entrance—Quantity (3) 1. 375" (35mm) diameter knockouts located in

top of box.

5. Three phase electrical service—Terminals are on main fuse block (disregard if unit has

optional disconnect switch). Three-phase service not by Emerson.

6. Earth ground—Terminal for field-supplied earth grounding wire. Earth grounding required for

Liebert units.

7. Remote unit shutdown—Replace existing jumper between Terminals 37 & 38 with

field-supplied normally closed switch having a minimum 75VA, 24VAC rating. Use field-supplied

Class 1 wiring.

8. Customer alarm inputs—Terminals for field-supplied, normally open contacts, having a

minimum 75VA, 24VAC rating, between Terminals 24 & 50, 51, 55 & 56. Use field-supplied

Class 1 wiring. Terminal availability varies by unit options.

9. Common alarm—On any alarm, normally open dry contact is closed across Terminals 75 & 76

for remote indication. 1A, 24VAC maximum load. Use Class 1 field-supplied wiring.

10. Heat rejection interlock—On any call for compressor operation, normally open dry contact is

closed across Terminals 70 & 71 (Circuit 1), 230 (Circuit 2) to heat rejection equipment. 1A,

24VAC maximum load. Use field-supplied Class 1 wiring. When a Liebert DS unit is paired with a

Liebert MC series condenser, remove jumper between Terminal 71 and Terminal 230. Three

wires must connect Terminals 70, 71 and 230 of the indoor unit to Terminals 70, 71 and 230 of the

Liebert MC series condenser.

Air-Cooled Systems

Liebert® DS

™

14

Page 19

3.3 OPTIONAL ELECTRICAL CONNECTIONS

Source: DPN000807, Rev. 8

11. Unit factory installed disconnect switch, Fuse Block and Main Fuses—Two types of

disconnect switches are available: Non-Locking and Locking. The Non-Locking Type consists of a

non-automatic molded case switch operational from the outside of the unit. Access to the

high-voltage electric panel compartment can be obtained with the switch in either the On or Off

position. The Locking Type is identical except access to the high-voltage electric panel

compartment can be obtained only with the switch in the Off position. Units with fused

disconnects are provided with a defeater button that allows access to the electrical panel when

power is On. The molded case switch disconnect models contain separate main fuses. Units with

fused disconnect have main fuses within the disconnect. Only fused disconnects are used on dual

disconnect options.

12. Secondary disconnect switch and earth ground

13. Three-phase electrical service—Terminals are on top of disconnect switch. Three-phase

service not by Emerson.

14. Smoke sensor alarm—Factory-wired dry contacts from smoke sensor are 91-common, 92-NO,

and 93-NC. Supervised contacts, 80 & 81, open on sensor trouble indication. This smoke sensor is

not intended to function as or replace any room smoke detection system that may be required by

local or national codes. 1A, 24VAC maximum load. Use field-supplied Class 1 wiring.

15. Reheat and humidifier lockout—Remote 24VAC required at Terminals 82 & 83 for lockout of

reheat and humidifier.

16. Condensate alarm (with condensate pump option)—On pump high water indication,

normally open dry contact is closed across Terminals 88 & 89 for remote indication. 1A, 24VAC

maximum load. Use field-supplied Class 1 wiring.

17. Remote humidifier—On any call for humidification, normally open dry contact is closed across

Terminals 11 & 12 to signal field-supplied remote humidifier. 1A, 24VAC maximum load. Use

Class 1 field-supplied wiring.

18. Auxiliary cool contact—On any call for Econ-O-coil operation, normally open dry contact is

closed across Terminals 72 & 73 on dual cool units only. 1A, 24VAC maximum load. Use

field-supplied Class 1 wiring.

Air-Cooled Systems

3.4 OPTIONAL LOW-VOLTAGE TERMINAL PACKAGE CONNECTIONS

Source: DPN000807, Rev. 8

19. Remote unit shutdown—Two additional contact pairs available for unit shutdown (labeled as

37B & 38B, 37C and 38C). Replace jumpers with field-supplied, normally closed switch having a

minimum rating of 75VA, 24VAC. Use field-supplied Class 1 wiring.

20. Common alarm—On any alarm, two additional normally open dry contacts are closed across

Terminals 94 & 95 and 96 & 97 for remote indication. 1A, 24VAC maximum load. Use

field-supplied Class 1 wiring.

21. Main fan auxiliary switch—On closure of main fan contactor, normally open dry contact is

closed across Terminals 84 & 85 for remote indication. 1A, 24VAC maximum load. Use

field-supplied Class 1 wiring.

22. Liebert Liqui-tect

open dry contact is closed across Terminals 58 & 59 for remote indication (Liebert Liqui-tect

sensor ordered separately). 1A, 24VAC maximum load. Use field-supplied Class 1 wiring.

™

shutdown and dry contact—On Liebert Liqui-tect activation, normally

15 Liebert® DS

™

Page 20

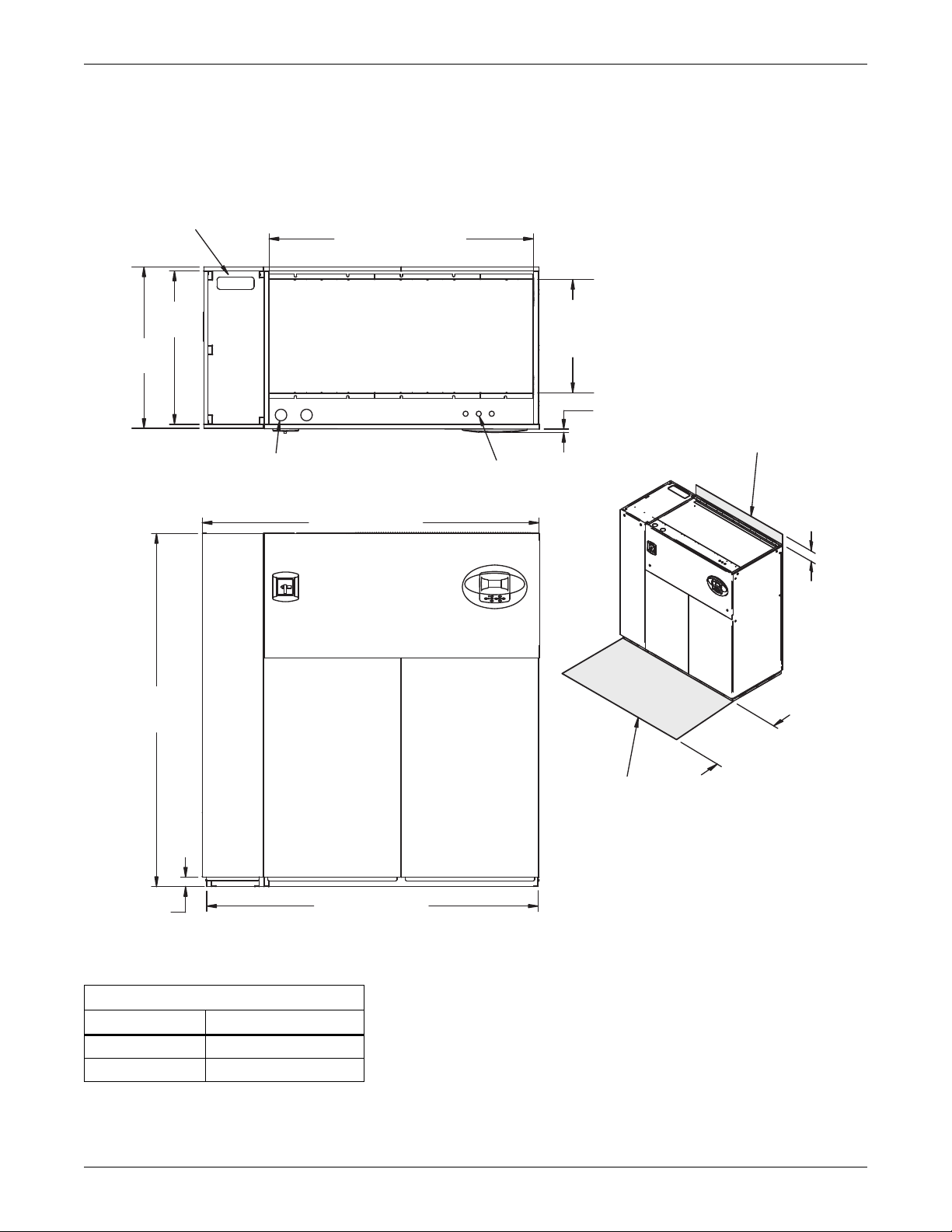

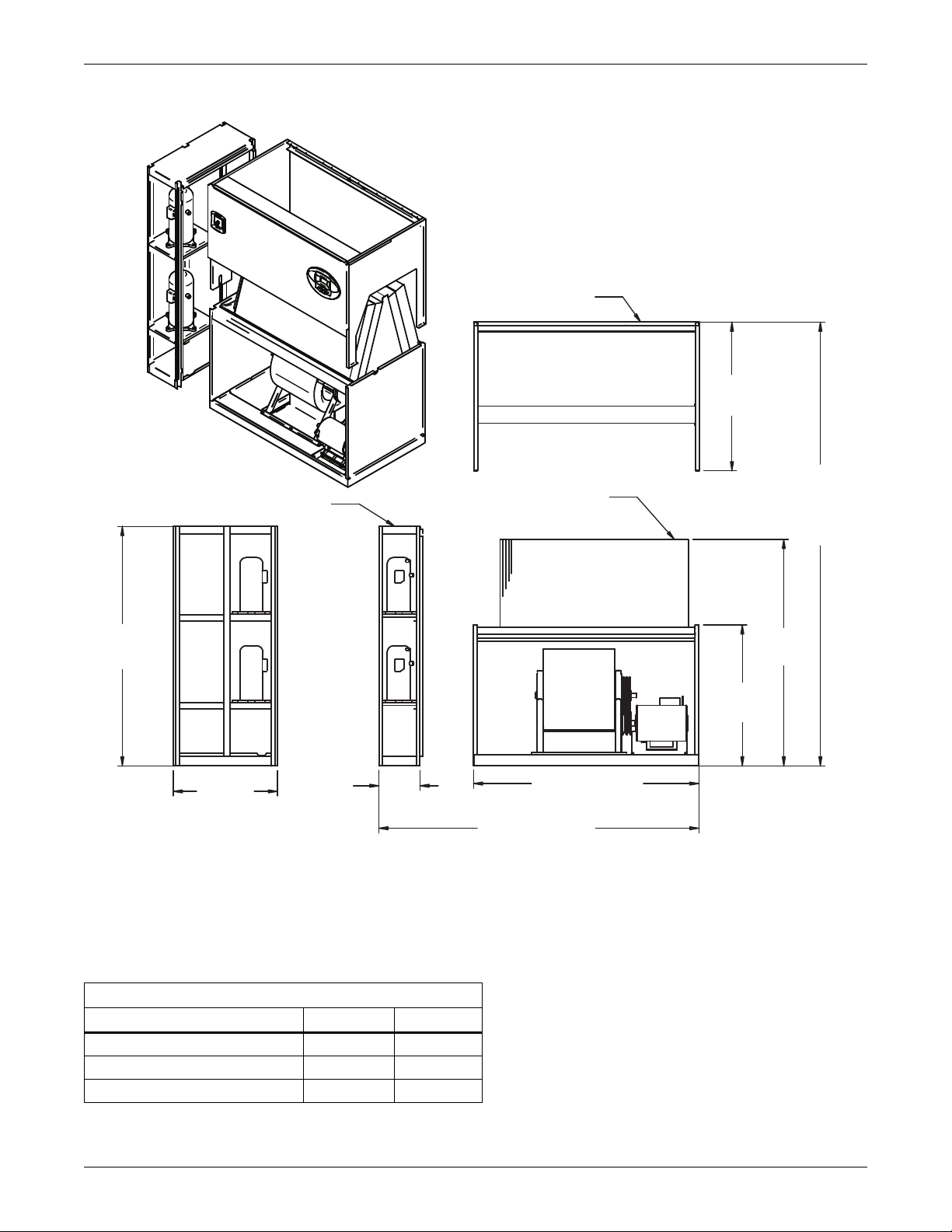

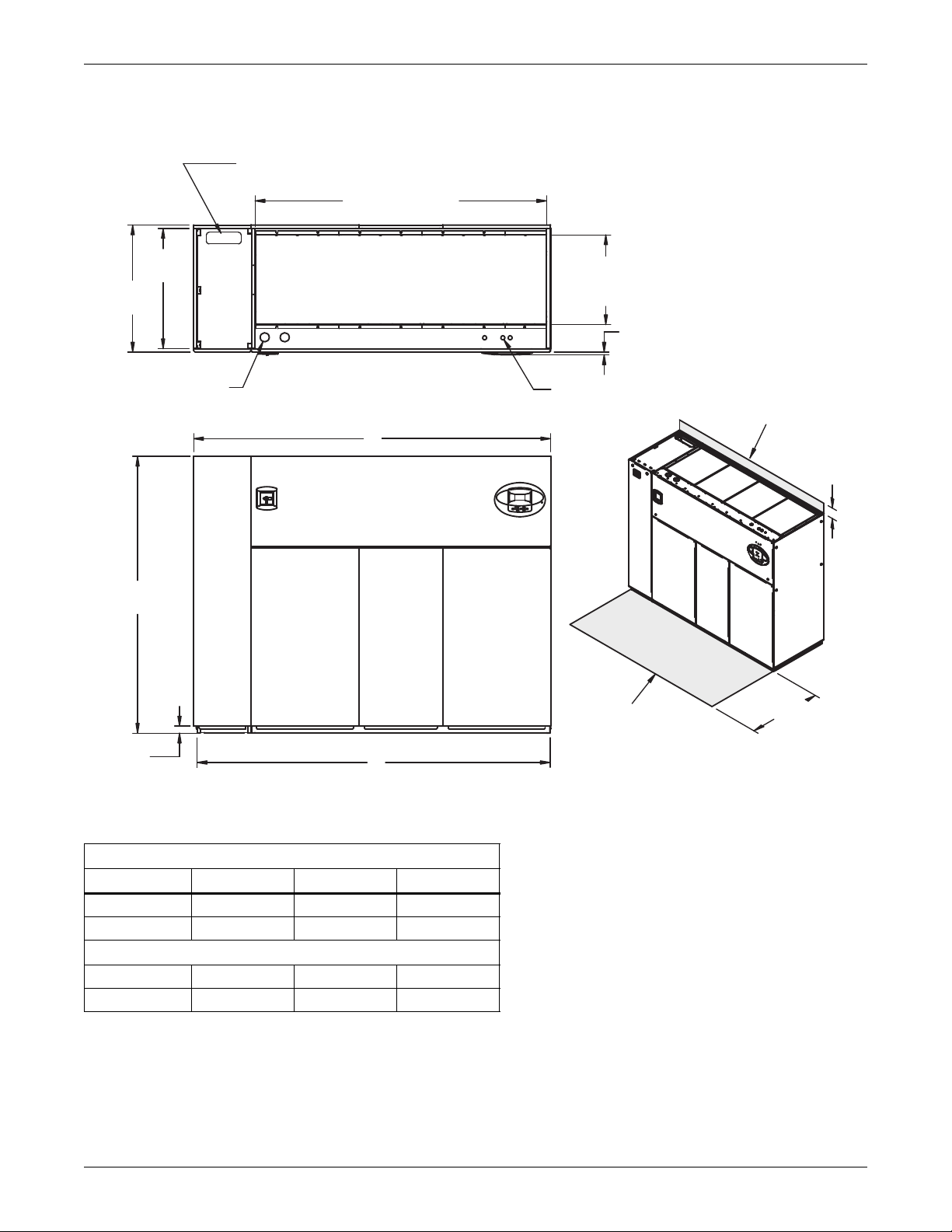

3.5 DIMENSIONS—LIEBERT DS 028-042, DOWNFLOW, AIR-COOLED MODELS

Secondary Refrigerant

Piping Entrance

DPN000796

Rev. 3

Filters are accessible

through top of unit only.

Downflow electrical

connections can be made

from top or bottom of unit.

Shaded area indicates a

recommended minimum

clearance for component

access.

TOP VIEW

Air Inlet Opening

Secondary Entrance

High-Volt Connection(s)

Secondary Entrance

Low-Volt Connections

Minimum required

for filter replacement

73" (1854mm)

72" (1829mm)

76"

(1930mm)

35"

(889mm)

56-7/8"

(1445mm)

Opening

Opening

3/4"

(19mm)

24-3/8"

(619mm)

34" (864mm)

33"

(838mm)

5"

(127mm)

Bezels

FRONT VIEW

2"

(51mm)

The following figures are general illustrations that show the dimensional layout for a Liebert DS unit.

Figure 8 Dimensions—downflow, air-cooled, 28-42kW (8-12 ton), scroll or digital scroll compressors

with centrifugal fans

Air-Cooled Systems

Table 6 Weights—downflow, air-cooled, 28-42kW (8-12 ton), scroll/digital scroll compressors

Dry Weight, Approximate, lb. (kg)

Model Type Model Size: 028-042

Air-Cooled 1470 (668)

Dual-Cool 1620 (736)

Source: DPN000796, Rev. 3

Liebert® DS

™

16

Page 21

Air-Cooled Systems

Figure 9 Dimensions—downflow, air-cooled, 28-42kW (8-12 ton), front and/or rear discharge models

Minimum required

for filter replacement

Filters are accessible

only through top of unit.

5"

(127mm)

Secondary Refrigerant

Piping Entrance

(1445mm) Opening

56-7/8"

24" (610mm)

Required for Condenser

cleanout on Water/Glycol or

GLYCOOL/Dual Cool

3"

(77mm)

24-3/8"

(619mm)

Opening

3/4"

(19mm)

Bezels

Shaded area indicates a

recommended minimum

clearance for component access.

3"

(76mm)

(483mm)

19"

3-1/4"

(81mm)

33-3/8"

(848mm)

Air Outlet

Opening

REAR VIEW

33"

(838mm)

35"

(889mm)

Secondary Entrance

High-Voltage Connection(s)

76"

(1930mm)

2"

(51mm)

FRONT VIEW

AIR INLET OPENING

TOP VIEW

Secondary Entrance

Low-Voltage Connections

A

33-1/2"

(851mm)

19"

(483mm)

Air Outlet

Opening

3-1/4"

(83mm)

B

Customer Piping and Wiring Connections

1. For primary connection locations see standard submittals DPN000803, DPN000804 or DPN000900.

A floor stand at least 9" high is recommended if primary connections locations are to be used.

2. If no floor stand is used and unit is placed directly on the floor, then do the following:

a) Use secondary connection locations (shown on standard floor planning submittals).

b) Order a condensate pump.

c) Field pipe condensate and humidier line (if ordered) to secondary connection point in

compressor section.

d) Or order additional SFA's to relocate connection locations

34"

(864mm)

310697

Pg. 1, Rev. 0

Dry Weight, lb (kg) Approximate Dimensions, In. (mm)

Compressor Type Model

Semi-Hermetic

Scroll / Digital

Source: 310697, Pg. 1, Rev. 0

028-042 A B

Air-Cooled 1780 (809)

Dual Cool 1930 (877)

Air-Cooled 1470 (668)

Dual Cool 1620 (736)

86 (2184mm) 85 (2159)

73 (1854) 72" (1829)

17 Liebert® DS

™

Page 22

Air-Cooled Systems

Figure 10 Primary connection locations—downflow, air-cooled, 28-42kW (8-12 ton), scroll or

digital scroll compressors with centrifugal fans

NOTE: Drawing not to scale.

Tolerance on

all piping dimensions

is ± 1/2" (13mm).

G1

L1

4" (102mm)

L2

11-3/16"

(284mm)

G2

A

FRONT VIEW

SECTION A-A

BLOWER

R

ECS

HUM

CD

E2

ECR

E1

OUTLET

16-1/16"

(408mm)

B

FRONT OF UNIT

73" (1854mm)

A

All dimensions from

rear corner of unit,

including panels

X

LV1

LV2

LV3

O

Y

35"

(889mm)

DPN000804

Rev. 3

Table 7 Piping data—downflow, air-cooled, 28-42kW (8-12 ton), scroll/digital scroll

Point Description

in. (mm)

R Refrigerant Access 59-5/16 (1507) 14-3/4 (375) 11-3/16 x 4 (284 x 102)

L1 Liquid Line System 1 69-15/16 (1776) 16-13/16 (411) 1/2" Cu Sweat

L2 Liquid Line System 2 67-5/8 (1718) 16-13/16 (411) 1/2" Cu Sweat

G1 Hot Gas Discharge 1 65-1/2 (1664) 16-13/16 (411) 5/8" Cu Sweat

G2 Hot Gas Discharge 2 62-7/16 (1586) 16-13/16 (411) 5/8" Cu Sweat

X

CD

Condensate Drain

(infrared humidifier or no humidifier) *

Condensate Drain

(steam generating humidifier) *

46 (1168) 29-1/2 (749) 3/4" FPT

46 (1168) 29-1/2 (749) 1-1/4" FPT

W/ Optional Pump 46 (1168) 29-1/2 (749) 1/2" Cu Sweat

HUM Humidifier Supply Line 53-1/2 (1359) 29 (737) 1/4" Cu Sweat

ECS Econ-O-Coil Supply 54-7/8 (1394) 22-9/16 (573) 1-5/8" Cu Sweat

ECR Econ-O-Coil Return 49-3/8 (1254) 30-3/4 (781) 1-5/8" Cu Sweat

E1 Electrical Conn. (High Volt) 55-1/2 (1410) 31-1/4 (794) 2-1/2"

E2 Electrical Conn. (High Volt) 52-7/16 (1332) 31-1/4 (794) 2-1/2"

LV1 Electrical Conn. (Low Volt) 2-1/4 (57) 27 (686) 7/8"

LV2 Electrical Conn. (Low Volt) 2-1/4 (57) 29 (737) 7/8"

LV3 Electrical Conn. (Low Volt) 2-1/4 (57) 31 (787) 7/8"

B Blower Outlet 21-15/16 (557) 18-1/16 (459) 18-3/4 x 16-1/16 (476 x 408)

* Field pitch condensate drain line a minimum of 1/8" (3.2 mm) per foot (305 mm). All units contain a factory-installed condensate trap. Do

not trap external to the unit. Drain line may contain boiling water. Select appropriate drain system materials. The drain line must comply

with all local codes.

Piping dimensions shown are connection sizes; field piping sizes may be different depending on distance. Refer to user manual, SL-18825.

Source: DPN000804, Rev. 3

Y

in. (mm)

Connection Size / Opening

in. (mm)

Liebert® DS

™

18

Page 23

Air-Cooled Systems

59" (1499mm)

DPN000802

Rev. 2

33"

(838mm)

13"

(330mm)

76"

(1930mm)

72" (1829mm)

Assembled Length

76"

(1930mm)

Assembled

Height

60-3/16"

(1529mm)

37"

(940mm)

39"

(991mm)

Compressor Assembly

Filter & Electric

Box Assembly

Blower & Coil

Assembly

NOTES: Drawing views are simplified with panels removed to show overall dimensions.

See disassembly and handling instructions in installation manual.

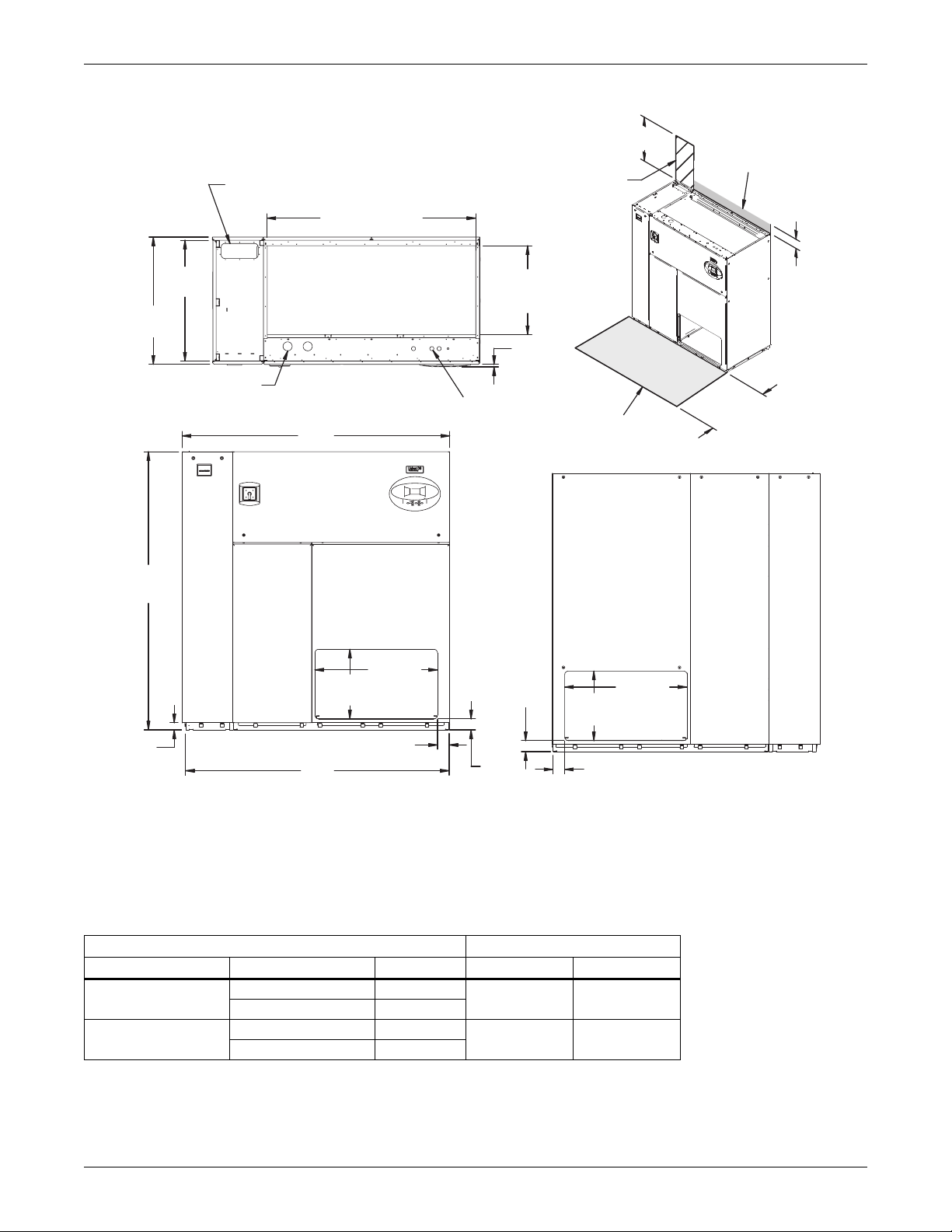

Figure 11 Disassembly dimensions—downflow, air-cooled, 28-42kW (8-12 ton), scroll or digital scroll

compressors with centrifugal fans

Table 8 Component weights—downflow, air-cooled, 28-42kW (8-12 ton), scroll or digital scroll

compressors

Dry Weight, Approximate, lb. (kg)

Component

Compressor Assembly 490 (223) 490 (223)

Filter and Electric Box Assembly 210 (96) 210 (96)

Blower and Coil Assembly 770 (350) 920 (418)

Source: DPN000802, Rev. 2

Air-Cooled Dual-Cool

19 Liebert® DS

™

Page 24

DPN000795

Rev. 4

Filters are accessible

through top of unit only.

Downflow electrical

connections can be made

from top or bottom of unit.

Shaded area indicates a

recommended minimum

clearance for component

access.

TOP VIEW

FRONT VIEW

Air Inlet Opening

Secondary Entrance

High Volt Connection(s)

Secondary Refrigerant

Piping Entrance

Secondary Entrance

Low Volt Connections

Minimum required

for filter replacement

86" (2184mm)

85" (2159mm)2"

(51mm)

76"

(1930mm)

35"

(889mm)

56-7/8"

(1445mm)

Opening

3/4"

(19mm)

Opening

34"

(864mm)

33"

(838mm)

5"

(127mm)

Bezels

24-3/8"

(619mm)

Air-Cooled Systems

Figure 12 Dimensions—downflow, air-cooled, 28-42kW (8-12 ton), semi-hermetic compressors with

centrifugal fans

Table 9 Weights—downflow, air-cooled, 28-42kW (8-12 ton), semi-hermetic compressors

Dry Weight, Approximate, lb. (kg)

Model Type Model Size: 028-042

Air-Cooled 1780 (809)

Dual-Cool 1930 (877)

Source: DPN000795, Rev. 4

Liebert® DS

™

20

Page 25

Air-Cooled Systems

L1

L2

G1

G2

R

E1

E2

HUM

B

O

X

Y

A

A

ECS

ECR

CD

FRONT VIEW

LV1

NOTE: Drawing not to scale.

Tolerance on

all piping dimensions

is ± 1/2" (13mm).

4" (102mm)

BLOWER

OUTLET

All dimensions from

rear corner of unit

including panels

16-1/16"

(408mm)

35"

(889mm)

LV2

LV3

SECTION A-A

FRONT OF UNIT

16-7/16"

(418mm)

86"

(2184mm)

DPN000803

Rev. 4

Figure 13 Primary connection locations—downflow, air-cooled, 28-42kW (8-12 ton), semi-hermetic

compressors with centrifugal fans

Table 10 Piping data—downflow, air-cooled, 28-42kW (8-12 ton), semi-hermetic compressors

Point Description

R Refrigerant Access 63 (1600) 13-13/16 (351) 16-7/16 x 4 (418 x 102)

L1 Liquid Line System 1 79-3/16 (2011) 16-3/4 (425) 1/2" Cu Sweat

L2 Liquid Line System 2 76-1/2 (1943) 16-3/4 (425) 1/2" Cu Sweat

G1 Hot Gas Discharge 1 73-7/8 (1876) 16-3/4 (425) 5/8" Cu Sweat

G2 Hot Gas Discharge 2 70-1/8 (1780) 16-3/4 (425) 5/8" Cu Sweat

CD

HUM Humidifier Supply Line 53-1/2 (1359) 29 (737) 1/4" Cu Sweat

ECS Econ-O-Coil Supply 54-7/8 (1394) 22-9/16 (573) 1-5/8" Cu Sweat

ECR Econ-O-Coil Return 49-3/8 (1254) 30-3/4 (781) 1-5/8" Cu Sweat

E1 Electrical Conn. (High Volt) 55-1/2 (1410) 31-1/4 (794) 2-1/2"

E2 Electrical Conn. (High Volt) 52-7/16 (1332) 31-1/4 (794) 2-1/2"

LV1 Electrical Conn. (Low Volt) 2-1/4 (57) 27 (686) 7/8"

LV2 Electrical Conn. (Low Volt) 2-1/4 (57) 29 (737) 7/8"

LV3 Electrical Conn. (Low Volt) 2-1/4 (57) 31 (787) 7/8"

B Blower Outlet 21-15/16 (558) 18-1/16 (459) 18-3/4 x 16-1/16 (476 x 408)

* Field pitch condensate drain line a minimum of 1/8" (3.2 mm) per foot (305 mm). All units contain a factory-installed condensate trap. Do

not trap external to the unit. Drain line may contain boiling water. Select appropriate drain system materials. The drain line must comply

with all local codes.

Piping dimensions shown are connection sizes; field piping sizes may be different depending on distance. Refer to user manual, SL-18825.

Source: DPN000803, Rev. 4

Condensate Drain

(infrared humidifier or no humidifier)*

Condensate Drain

(steam generating humidifier)*

W/ Optional Pump 46 (1168) 29-1/2 (749) 1/2" Cu Sweat

X

in. (mm)

Y

in. (mm)

Connection Size / Opening

in. (mm)

46 (1168) 29-1/2 (749) 3/4" FPT

46 (1168) 29-1/2 (749) 1-1/4" FPT

21 Liebert® DS

™

Page 26

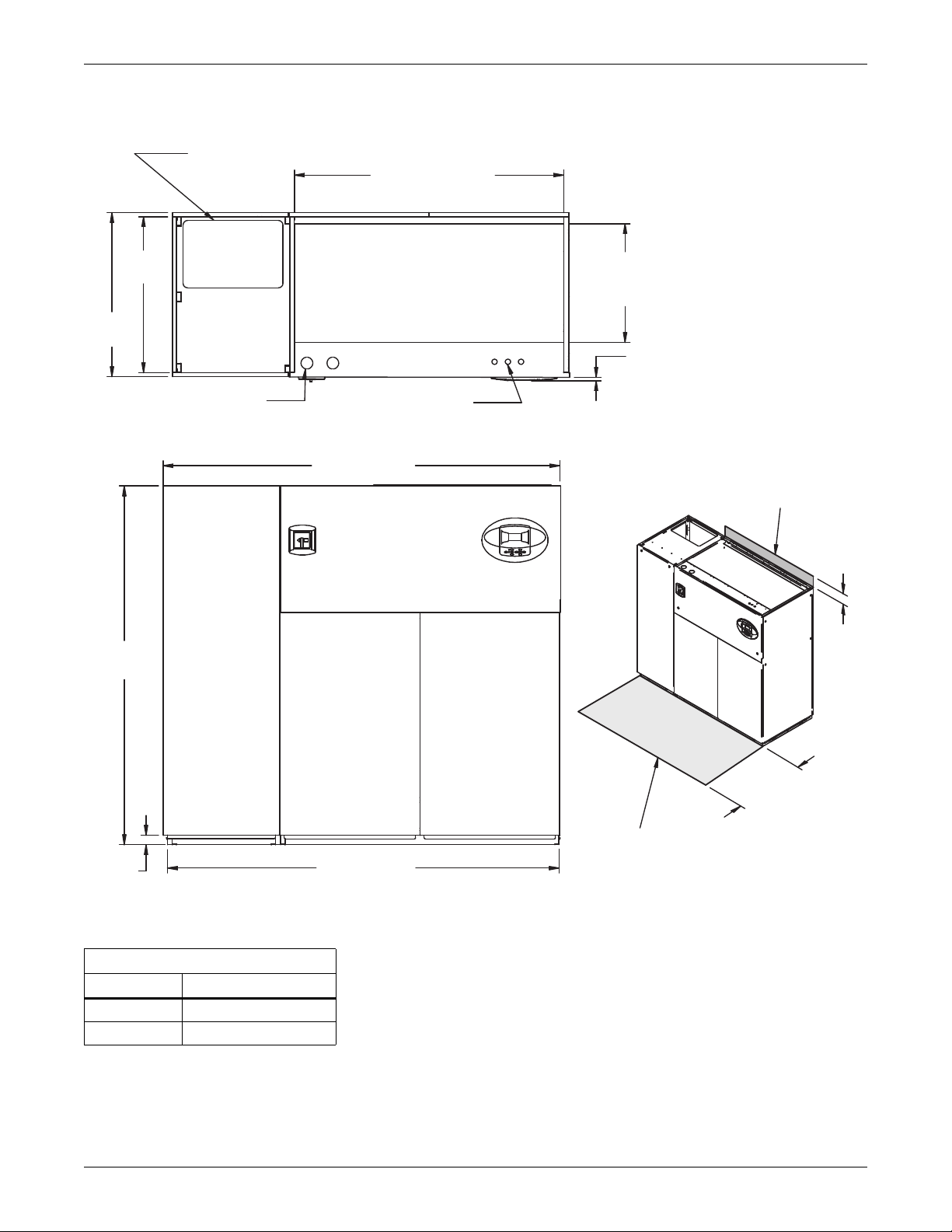

Air-Cooled Systems

39"

991mm

59" (1499mm)

DPN000801

Rev. 2

33"

(838mm)

76"

(1930mm)

26"

(660mm)

85" (2159mm)

Assembled Length

76"

(1930mm)

Assembled

Height

60-3/16"

(1529mm)

37"

(940mm)

39"

(991mm)

Compressor Assembly

Filter & Electric

Box Assembly

Blower & Coil

Assembly

NOTES: Drawing views are simplified with panels removed to show overall dimensions.

See disassembly and handling instructions in installation manual.

Figure 14 Disassembly dimensions—downflow, air-cooled, 28-42kW (8-12 ton), semi-hermetic

compressors with centrifugal fans

Table 11 Component weights—downflow, air-cooled, 28-42kW (8-12 ton), semi-hermetic compressors

Dry Weight, Approximate, Including Panels, lb (kg)

Component

Compressor Assembly 800 (364) 800 (364)

Filter and Electric Box Assembly 210 (96) 210 (96)

Blower and Coil Assembly 770 (350) 920 (418)

Source: DPN000801, Rev. 2

Air-Cooled Dual-Cooled

Liebert® DS

™

22

Page 27

Air-Cooled Systems

33"

(838mm)

35"

(889mm)

A

76"

(1930mm)

2"

(51mm)

B

34"

(864mm)

Shaded area indicates a

recommended minimum

clearance for component access.

5"

(127mm)

3/4"

(19mm)

Bezels

24-5/8"

(619mm)

Opening

80"

(2032mm)

Second Refrigerant

Piping Entrance

AIR INLET OPENING

Opening

Secondary Entrance

Low-Volt Connections

Minimum required

for filter replacement

Secondary Entrance

High-Volt Connection(s)

TOP VIEW

FRONT VIEW

Notes: Filters are accessible

through top of unit only.

Downflow electrical

connections can be made

from top or bottom of unit.

DPN000925

Rev. 2

Digital scroll compressors

not available on DS 077.

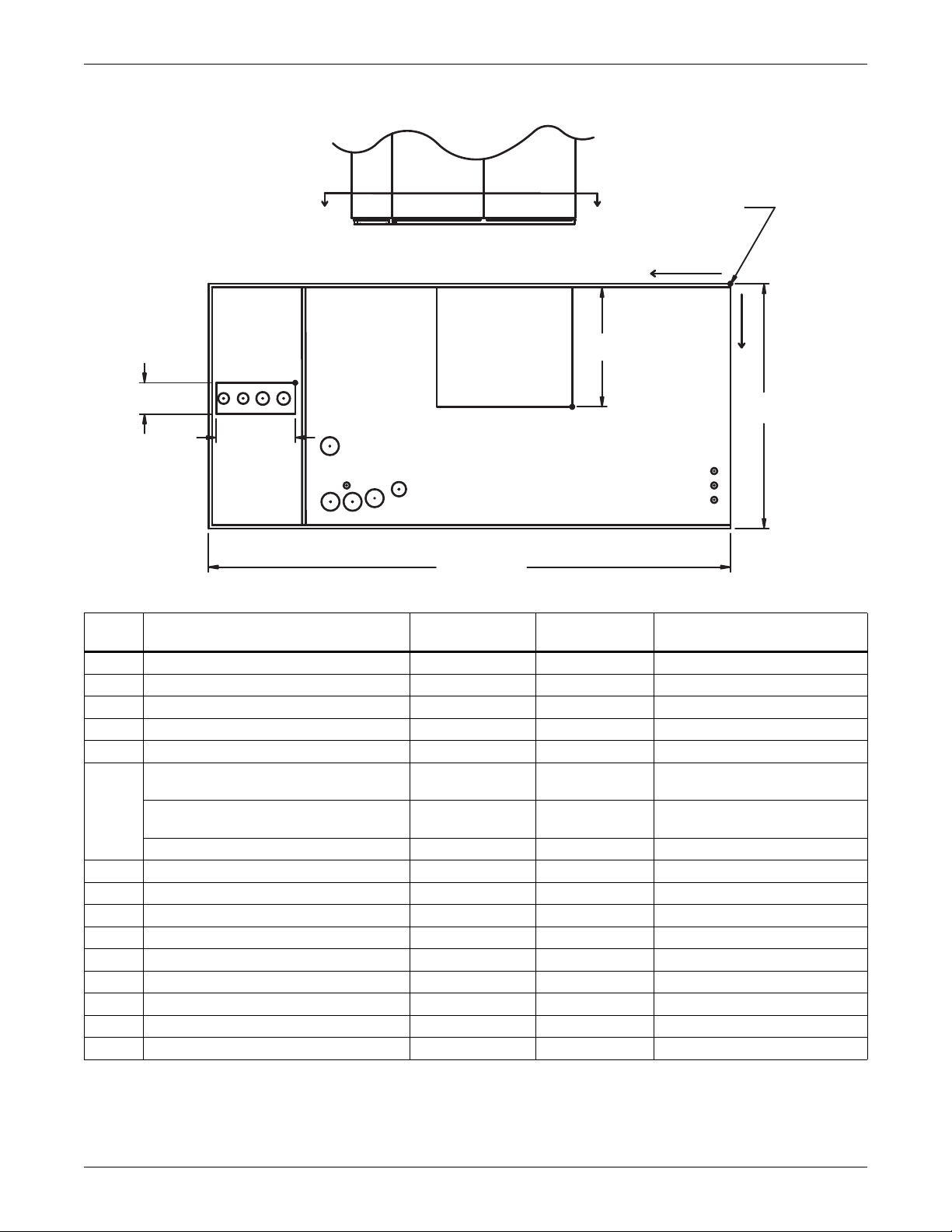

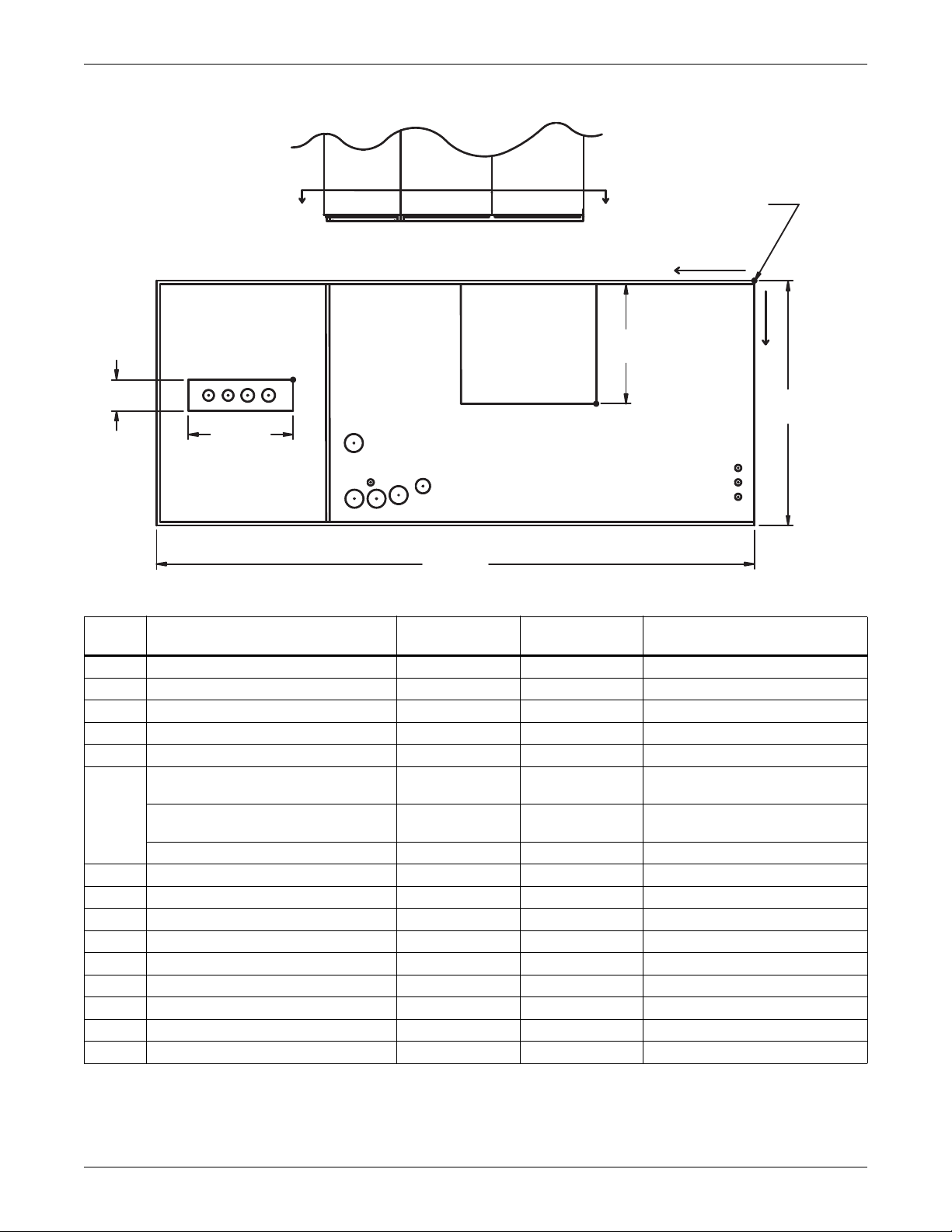

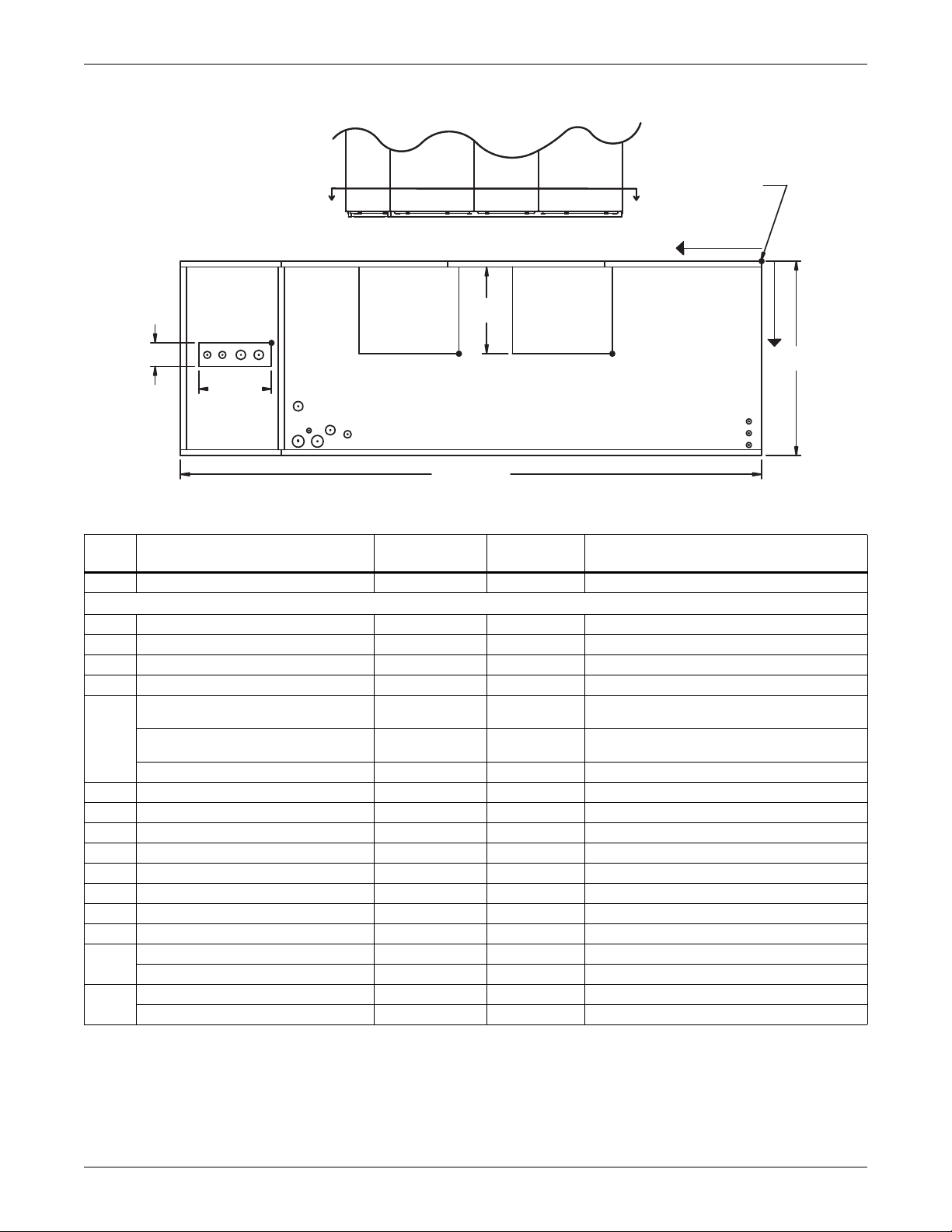

3.6 DIMENSIONS—LIEBERT DS 053-077, DOWNFLOW, AIR-COOLED MODELS

Figure 15 Dimensions—downflow, air-cooled, 53-77kW (15-22 ton), scroll or digital scroll compressors

with centrifugal fans

Table 12 Weights—downflow, air-cooled, 53-77kW (15-22 ton), scroll or digital scroll compressors

Model No. DS 053 DS 070 DS 077 *

Air Cooled 1920 (871) 1970 (894) 2020 (916)

Dual Cool 2100 (953) 2150 (975) 2200 (998)

Air Cooled “A” 98 (2489) 98 (2489) 98 (2489)

Air Cooled “B” 97 (2464) 97 (2464) 97 (2464)

* Digital scroll compressors not available on DS 077

Source: DPN000925, Rev. 2

Dry Weight, lb (kg) Approximate

Dimensions, in (mm)

23 Liebert® DS

™

Page 28

Air-Cooled Systems

A

A

L1

L2

G1

G2

R

ECS

ECR

E1

E2

HUM

CD

B1

O

X

Y

B2

FRONT VIEW

LV1

NOTE: Drawing not to scale.

Tolerance on

all piping dimensions

is ± 1/2" (13mm).

4"

(102mm)

BLOWER

OUTLET

All dimensions from

rear corner of unit

including panels

16-1/16"

(408mm)

35"

(889mm)

LV2

LV3

SECTION A-A

FRONT OF UNIT

12-3/16"

(310mm)

98" (2489mm)

BLOWER

OUTLET

DPN000929

Rev. 4

Digital scroll compressors

not available on DS 077.

Figure 16 Primary connection locations—downflow, air-cooled, 53-77kW (15-22 ton), scroll or digital

scroll compressors with centrifugal fans

Table 13 Piping data—downflow, air-cooled, 53-77kW (15-22 ton), scroll or digital scroll compressors ***

Point Description

R Refrigerant Access 81-3/4 (2076) 14-3/4 (374) 12-3/16 x 4 (310 x 102)

L1 Liquid Line System 1 94-11/16 (2405) 16-3/4 (425) 1/2" / 5/8" Cu Sweat

L2 Liquid Line System 2 91-7/8 (2334) 16-3/4 (425) 1/2" / 5/8" Cu Sweat

G1 Hot Gas Discharge 1 88-3/4 (2254) 16-3/8 (416) 7/8" / 1-1/8" Cu Sweat

G2 Hot Gas Discharge 2 85-9/16 (2173) 16-3/8 (416) 7/8" / 1-1/8" Cu Sweat

CD

HUM Humidifier Supply Line 76-1/2 (1943) 29 (736) 1/4" Cu Sweat

ECS** Econ-O-Coil Supply 78-5/8 (1997) 22-1/4 (565) 2-1/8" Cu Sweat

ECR** Econ-O-Coil Return 72 (1829) 29 (737) 2-1/8" Cu Sweat

E1 Electrical Conn. (High Volt) 78-1/2 (1994) 31-1/8 (790) 2-1/2"

E2 Electrical Conn. (High Volt) 75-3/8 (1915) 31-1/8 (790) 2-1/2"

LV1 Electrical Conn. (Low Volt) 1-7/8 (48) 28-1/2 (724) 7/8"

LV2 Electrical Conn. (Low Volt) 1-7/8 (48) 30-1/4 (768) 7/8"

LV3 Electrical Conn. (Low Volt) 1-7/8 (48) 32 (813) 7/8"

B1

B2

* Field pitch condensate drain line a minimum of 1/8" (3.2 mm) per foot (305 mm). All units contain a factory-installed condensate trap. Do

** Supplied on Dual-Cooling systems only (four-pipe system)

*** Digital scroll compressors not available on DS 077.

Piping dimensions shown are connection sizes; field piping sizes may be different depending on distance. Refer to user manual, SL-18825.

Source: DPN000929, Rev 4

Liebert® DS

X

in. (mm)

Y

in. (mm)

Connection Size / Opening

in. (mm)

53kW (15 ton) / 70& 77kW (20 & 22 ton)

Condensate Drain

(infrared humidifier or no humidifier)*

Condensate Drain

(steam generating humidifier)*

67-11/16 (1719) 30-1/2 (775) 3/4" FPT

67-11/16 (1719) 30-1/2 (775) 1-1/4" FPT

W/ Optional Pump 67-11/16 (1719) 30-1/2 (775) 1/2" Cu Sweat

Blower Outlet (15 x 15) 23-1/8 (587) 18-1/16 (459) 18-3/4 x 16-1/16 (476 x 408)

Blower Outlet (15 x 11) 27-3/4 (705) 18-1/16 (459) 14-3/4 x 16-1/16 (375 x 408)

Blower Outlet (15 x 15) 50-3/8 (1280) 18-1/16 (459) 18-3/4 x 16-1/16 (476 x 408)

Blower Outlet (15 x 11) 54-3/8 (1381) 18-1/16 (459) 14-3/4 x 16-1/16 (375 x 408)

not trap external to the unit. Drain line may contain boiling water. Select appropriate drain system materials. The drain line must comply

with all local codes.

™

24

Page 29

Air-Cooled Systems

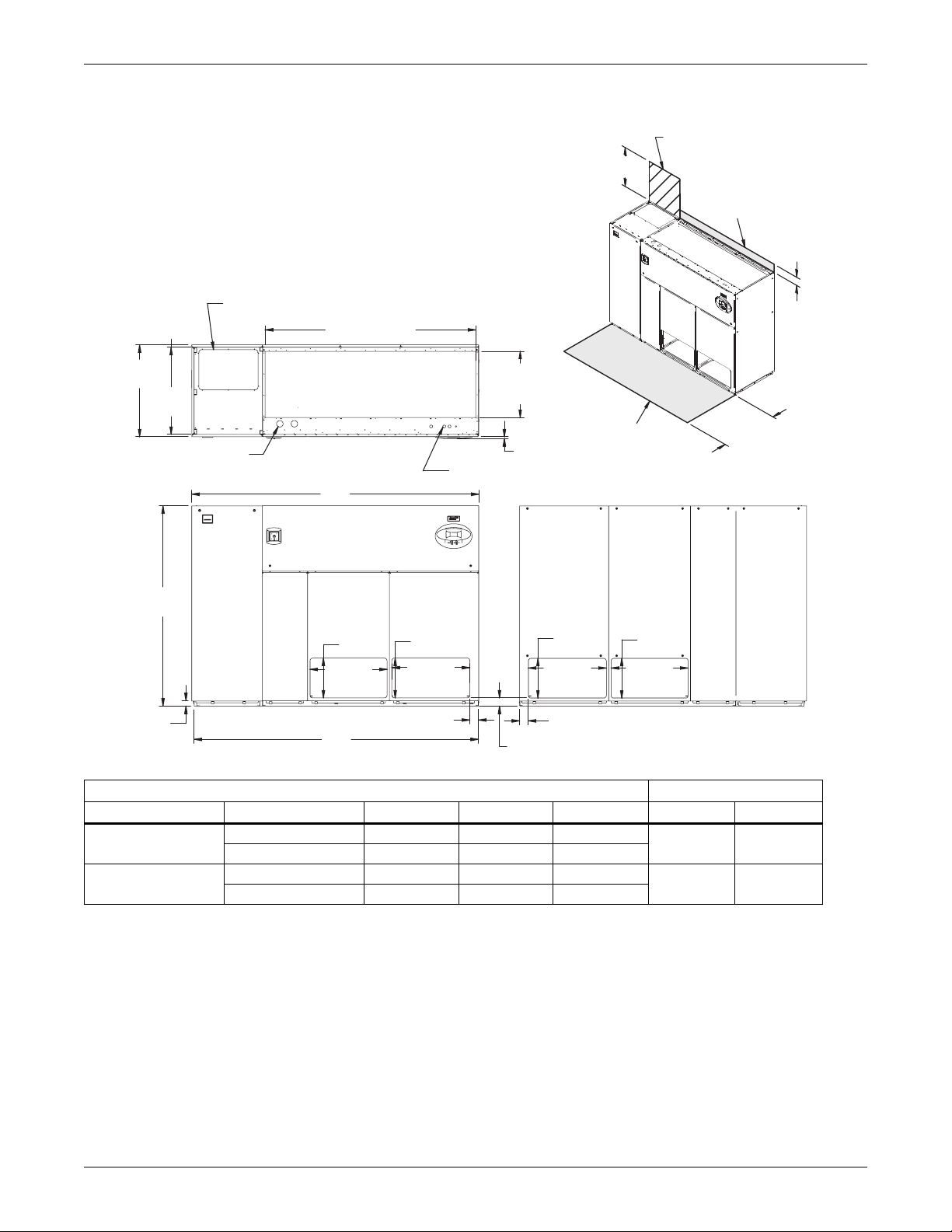

Figure 17 Dimensions—downflow, air-cooled, 53-77kW (15-22 ton), front and/or rear discharge models

with EC fans

Required for Condenser

cleanout on Water/Glycol or

Customer Piping and Wiring Connections

1. For primary connection locations see standard submittals DPN000928,

DPN000929 or DPN000933.

A floor stand at least 9" high is recommended if primary connections locations are to be used.

2. If no floor stand is used and unit is placed directly on the floor, then do the following:

a) Use secondary connection locations (shown on standard floor planning submittals).

b) Order a condensate pump.

c) Field pipe condensate and humidier line (if ordered) to secondary connection point in

compressor section.

d) Or order additional SFA's to relocate connection locations

Secondary Refrigerant

Piping Entrance

80" (2032mm)

Opening

24" (610mm)

GLYCOOL/Dual Cool

Minimum required

for filter replacement

Filters are accessible

only through top of unit.

5"

(127mm)

35"

(889mm)

33"

(838mm)

Secondary Entrance

High-Voltage Connection(s)

AIR INLET OPENING

TOP VIEW

A

76"

(1930mm)

15-1/8"

(384mm)

29-1/4"

(743mm)

Air Outlet

Opening

2"

(51mm)

FRONT VIEW

B

Dry Weight, lb (kg) Approximate Dimensions, in. (mm)

Compressor Type

Semi-Hermetic

Scroll / Digital

* Digital scroll compressors not available on 077 models

Source: 310697, Pg. 2, Rev. 0

Model 53 70 77 * A B

Air-Cooled 2350 (1069) 2400 (1091) 2450 (1114)

Dual Cool 2530 (1150 2580 (1173) 2630 (1196)

Air-Cooled 1920 (873) 1970 (896) 2020 (919)

Dual Cool 2100 (955) 2150 (978) 2200 (1000)

15-1/8"

(384mm)

29-5/8"

(752mm)

3-1/4"

(83mm)

25-5/8"

(619mm)

Opening

3/4"

Secondary Entrance

Low-Voltage Connections

Air Outlet

Opening

(19mm)

3-1/8"

(79mm)

Shaded area indicates a

recommended minimum

clearance for component access.

15-1/8"

(384mm)

29-5/8"

(752mm)

3-1/4"

(83mm)

Air Outlet

Opening

15-1/8"

(384mm)

29-1/4"

(743mm)

Air Outlet

Opening

REAR VIEW

109 (2769) 108 (2743)

34"

(864mm)

310697

Pg. 2, Rev. 0

98 (2489) 97 (2464)

25 Liebert® DS

™

Page 30

Air-Cooled Systems

12-3/16"

(310mm)

FRONT OF UNIT

FRONT VIEW

DPN002182

Rev. 1

SECTION A-A

NOTE: Drawing not to scale.

Tolerance on

all piping dimensions

is ± 1/2" (13mm).

ECS

ECR

E1

E2

CD

R

LV1

LV2

LV3

X

AA

Y

O

All dimensions from

rear corner of unit

including panels

35"

(889mm)

BLOWER

OUTLET

HUM

L1 L2 G1

G2

B1

4" (102mm)

98" (2489mm)

Digital scroll compressors not

available on 077 models.

Figure 18 Primary connection locations—downflow air-cooled 53-77kW (15-22 ton), scroll or digital

scroll compressors with EC fans, front, rear or bottom discharge

Table 14 Piping details—downflow air-cooled 53-77kW (15-22 ton) with EC fans, scroll or digital scroll

Point Description

R Refrigerant Access 81-3/4 (2076) 14-3/4 (374) 12-3/16x4 (310x102)

L1 Liquid Line System 1 94-11/16 (2405) 16-3/4 (425) 1/2 / 5/8 Cu Sweat

L2 Liquid Line System 2 91-7/8 (2334) 16-3/4 (425) 1/2 / 5/8 Cu Sweat

G1 Hot Gas Discharge 1 88-3/4 (2254) 16-3/8 (416) 7/8 / 1-1/8 Cu Sweat

G2 Hot Gas Discharge 2 85-9/16 (2173) 16-3/8 (416) 7/8 / 1-1/8 Cu Sweat

CD

HUM Humidifier Supply Line 76-1/2 (1943) 29 (736) 1/4 Cu Sweat

ECS** Econ-O-Coil Supply (DS Only) 78-5/8 (1997) 22-1/4 (565) 2-1/8 Cu Sweat

ECR** Econ-O-Coil Return (DS Only) 73-15/16 (1862) 26-9/16 (675) 2-1/8 Cu Sweat

E1 Electrical Conn. (High Volt) 78-1/2 (1994) 31-1/8 (790) 2-1/2

E2 Electrical Conn. (High Volt) 75-3/8 (1915) 31-1/8 (790) 2-1/2

LV1 Electrical Conn. (Low Volt) 2 (51) 29 (737) 7/8

LV2 Electrical Conn. (Low Volt) 2 (51) 30-7/8 (784) 7/8

LV3 Electrical Conn. (Low Volt) 2 (51) 32 (813) 7/8

B1 Blower Outlet 4-1/2 (114) 33 (838) 58-3/8x30 (1483x762)

* Field pitch condensate drain line a minimum of 1/8" (3.2 mm) per foot (305 mm). All units contain a factory-installed condensate trap. Do

not trap external to the unit. Drain line may contain boiling water. Select appropriate drain system materials. The drain line must comply

with all local codes.

** Supplied on Dual-Cooling systems only (four-pipe system)

*** Digital scroll compressors not available on DS 077

Piping dimensions shown are connection sizes; field piping sizes may be different depending on distance. Refer to user manual, SL-18825.

Source: DPN002182, Rev. 1

Liebert® DS

compressors ***

Condensate Drain

(Infrared Humidifier or No Humidifier)*

W/ Optional Pump 68-3/8 (1737) 31-3/8 (797) 1/2 Cu Sweat

™

X

in. (mm)

Y

in. (mm)

Connection Size / Opening

53kW (15 ton)/ 70 & 77kW (20 & 22 ton)

68-3/8 (1737) 31-3/8 (797) 3/4 FPT

26

in. (mm)

Page 31

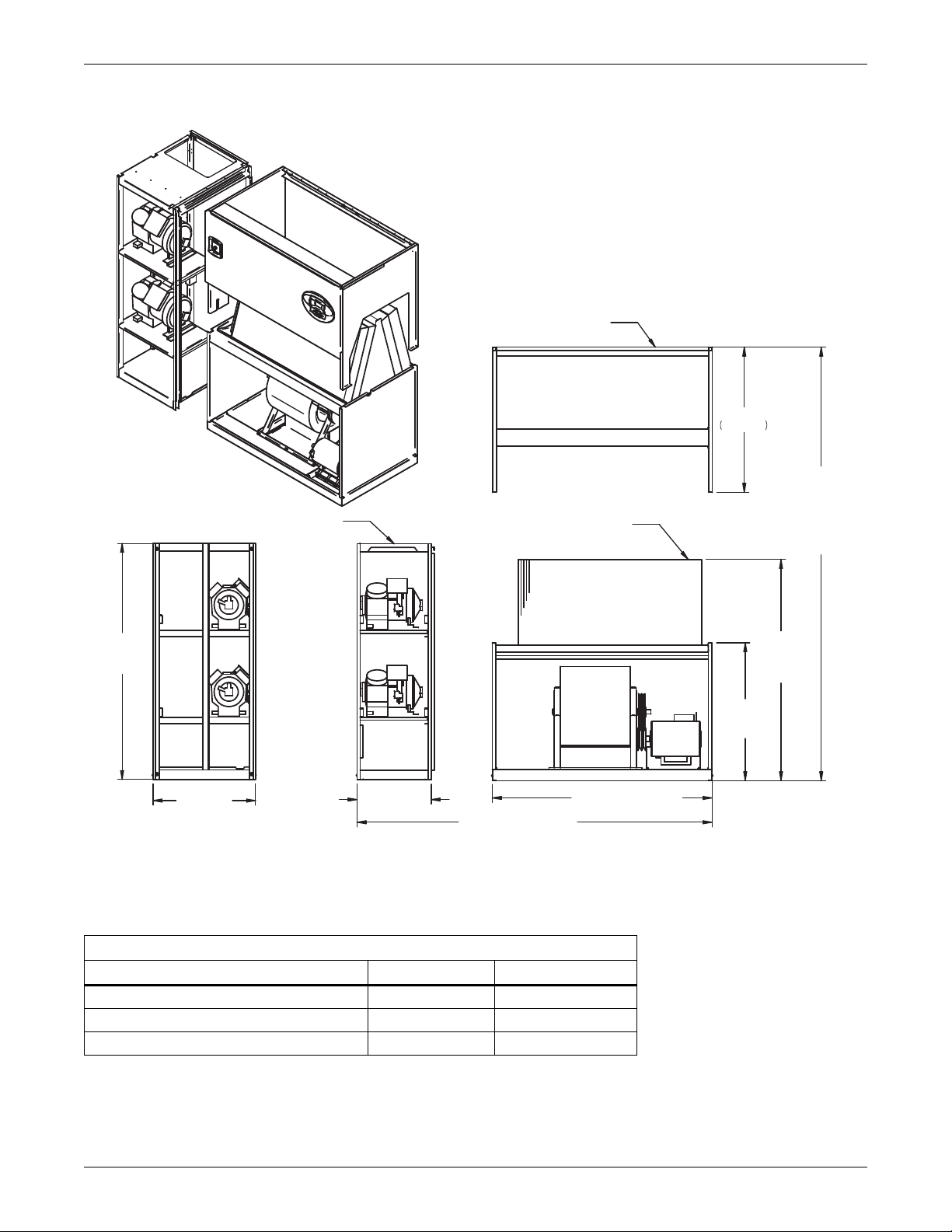

Air-Cooled Systems

Digital scroll compressors

not available on DS 077.

Figure 19 Disassembly dimensions—downflow, air-cooled, 53-77kW (15-22 ton), scroll or digital scroll

compressors

Filter & Electric

Box Assembly

Forward curved

blowers shown.

DA units only

available with EC

blowers, optional

on DS units.

Compressor Assembly

Blower & Coil

Assembly

76"

(1930mm)

33"

(838mm)

DS053-DS077 =

15" (381mm)

DA080,DA085 =

17" (432mm)

Assembled Length

97" (2464mm)

82" (2083mm)

NOTES: Drawing views are simplified with panels removed to show overall dimensions.

See disassembly and handling instructions in installation manual.

39"

(991mm)

76"

(1930mm)

Assembled

Height

59-7/16"

(1509mm)

37"

(940mm)

DPN000927

Rev. 4

Table 15 Component weights—downflow, air-cooled, 53-77kW (15-22 ton), scroll or digital scroll

compressors *

Dry Weight, Approximate, Including Panels, lb (kg)

Component

Compressor Assembly 540 (246) 540 (246)

Filter and Electric Box Assembly 250 (114) 250 (114)

Blower and Coil Assembly 1230 (560) 1410 (641)

* Digital scroll compressors not available on DS 077

Source: DPN00927, Rev. 4

Air-Cooled Dual-Cool

27 Liebert® DS

™

Page 32

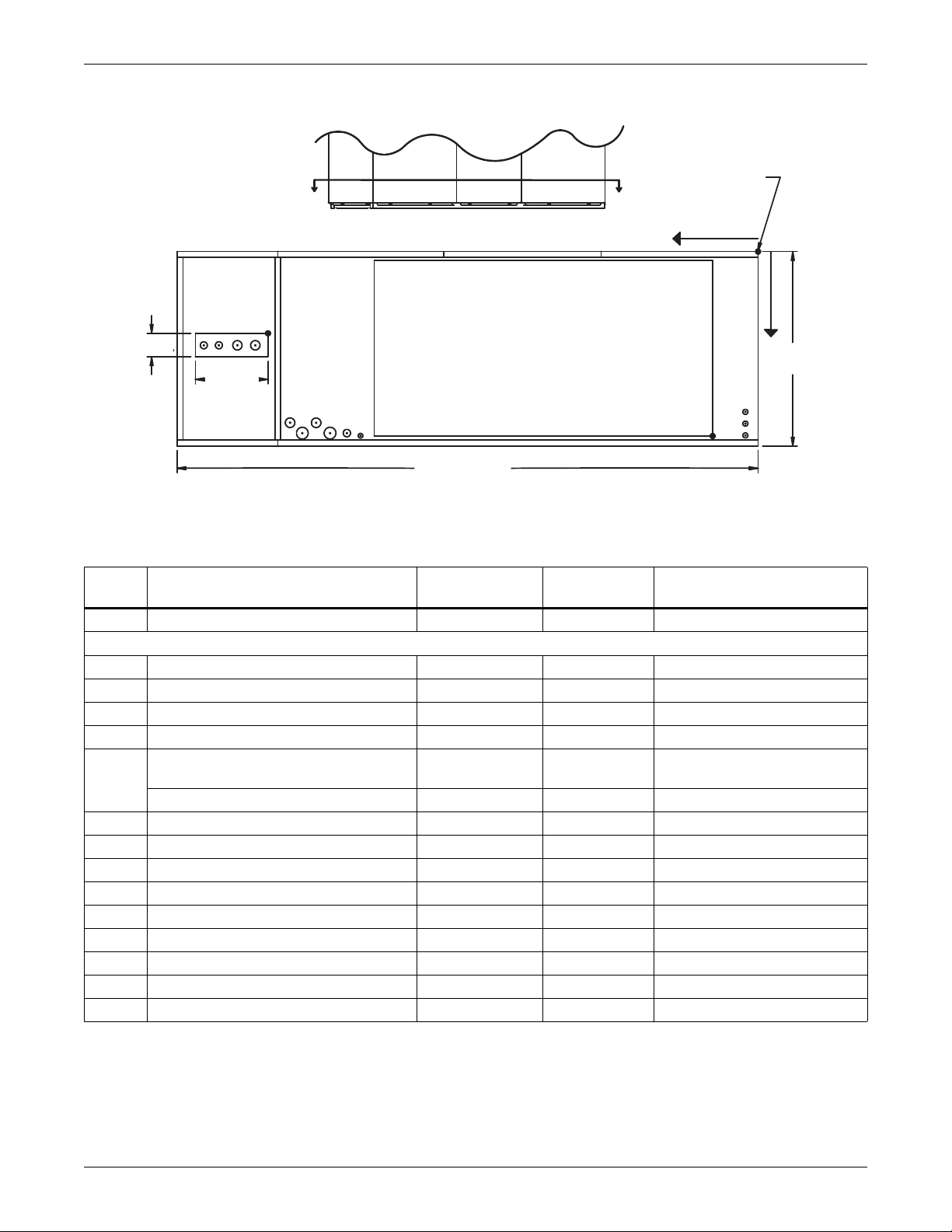

Air-Cooled Systems

33"

(838mm)

35"

(889mm)

109" (2769mm)

76"

(1930mm)

2"

(51mm)

108" (2743mm)

34"

(864mm)

Shaded area indicates a

recommended minimum

clearance be provided for

component access.

5"

(125mm)

3/4"

(19mm)

24-5/8"

(625mm)

Opening

80"

(2032mm)

Second Refrigerant

Piping Entrance

AIR INLET OPENING

Opening

Bezels

Secondary Entrance

Low-Volt Connections

Minimum required

for filter replacement

Secondary Entrance

High-Volt Connection(s)

TOP VIEW

FRONT VIEW

Notes: Filters are accessible

through top of unit only.

Downflow electrical

connections can be made

from top or bottom of unit.

DPN000924

Rev. 3

Figure 20 Dimensions—downflow, air-cooled, 53-77kW (15-22 ton) with centrifugal fans, semi-hermetic

compressors with centrifugal fans

Table 16 Weights—downflow, air-cooled, 53-77kW (15-22 ton), semi-hermetic compressors

Model Type

Air-Cooled 2350 (1069) 2400 (1091) 2450 (1114)

Dual-Cool 2530 (1150) 2580 (1173) 2630 (1196)

Source: DPN000924, Rev. 3

Dry Weight, Approximate, lb. (kg)

Model Size

053 070 077

Liebert® DS

™

28

Page 33

Air-Cooled Systems

L1

L2

G1

G2

R

B1

O

X

Y

B2

ECS

ECR

E1

E2

HUM

CD

FRONT VIEW

LV1

NOTE: Drawing not to scale.

Tolerance on

all piping dimensions

is ± 1/2" (13mm).

BLOWER

OUTLET

All dimensions from

rear corner of unit

including panels

LV2

LV3

SECTION A-A

FRONT OF UNIT

AA

BLOWER

OUTLET

16-1/16"

(408mm)

16-7/16"

(418mm)

4" (102mm)

109" (2769mm)

35"

(889mm)

DPN000928

Rev. 4

Figure 21 Primary connection locations—downflow, air-cooled, 53-77kW (15-22 ton), semi-hermetic

compressors with centrifugal fans

Table 17 Piping data—downflow, air-cooled, 53-77kW (15-22 ton), semi-hermetic compressors

Point Description

R Refrigerant Access 82-3/4 (2102) 13-7/8 (352) 16-7/16 x 4 (418 x 102)

L1 Liquid Line System 1 97 (2464) 16-7/8 (428) 1/2" / 5/8" Cu Sweat

L2 Liquid Line System 2 93-5/16 (2370) 16-7/8 (428) 1/2" / 5/8" Cu Sweat

G1 Hot Gas Discharge 1 90-5/8 (2302) 16-5/8 (422) 7/8" / 1-1/8" Cu Sweat

G2 Hot Gas Discharge 2 88 (2235) 16-5/8 (422) 7/8" / 1-1/8" Cu Sweat

CD

HUM Humidifier Supply Line 76-1/2 (1943) 29 (736) 1/4" Cu Sweat

ECS** Econ-O-Coil Supply 78-5/8 (1997) 22-1/4 (565) 2-1/8" Cu Sweat

ECR** Econ-O-Coil Return 72 (1829) 29 (737) 2-1/8" Cu Sweat

E1 Electrical Conn. (High Volt) 78-1/2 (1994) 31-1/8 (790) 2-1/2"

E2 Electrical Conn. (High Volt) 75-3/8 (1915) 31-1/8 (790) 2-1/2"

LV1 Electrical Conn. (Low Volt) 1-7/8 (48) 28-1/2 (724) 7/8"

LV2 Electrical Conn. (Low Volt) 1-7/8 (48) 30-1/4 (768) 7/8"

LV3 Electrical Conn. (Low Volt) 1-7/8 (48) 32 (813) 7/8"

B1

B2

* Field pitch condensate drain line a minimum of 1/8" (3.2 mm) per foot (305 mm). All units contain a factory-installed condensate trap. Do

not trap external to the unit. Drain line may contain boiling water. Select appropriate drain system materials. The drain line must comply

with all local codes.

** Supplied on Dual-Cooling Systems only (four-pipe system)

Piping dimensions shown are connection sizes; field piping sizes may be different depending on distance. Refer to user manual, SL-18825.

Source: DPN000928, Rev. 4

X

in. (mm)

Y

in. (mm)

Connection Size / Opening

in. (mm)

53kW (15 tons) / 70 & 77kW (20 & 22 tons)

Condensate Drain

(infrared humidifier or no humidifier) *

Condensate Drain

(steam generating humidifier)*

67-11/16 (1719) 30-1/2 (775) 3/4" FPT

67-11/16 (1719) 30-1/2 (775) 1-1/4" FPT

W/ Optional Pump 67-11/16 (1719) 30-1/2 (775) 1/2" Cu Sweat

Blower Outlet (15 x 15) 23-1/8 (587) 18-1/16 (459) 18-3/4 x 16-1/16 (476 x 408)

Blower Outlet (15 x 11) 27-3/4 (705) 18-1/16 (459) 14-3/4 x 16-1/16 (375 x 408)

Blower Outlet (15 x 15) 50-3/8 (1280) 18-1/16 (459) 18-3/4 x 16-1/16 (476 x 408)

Blower Outlet (15 x 11) 54-3/8 (1381) 18-1/16 (459) 14-3/4 x 16-1/16 (375 x 408)

29 Liebert® DS

™

Page 34

Air-Cooled Systems

16-7/16"

(418mm)

FRONT OF UNIT

FRONT VIEW

DPN002179

Rev. 0

SECTION A-A

NOTE: Drawing not to scale.

Tolerance on

all piping dimensions

is ± 1/2" (13mm).

ECS ECR

E1

CD

R

LV1

LV2

LV3

X

AA

Y

O

All dimensions from

rear corner of unit

including panels

35"

(889mm)

BLOWER

OUTLET

HUM

L1

L2 G1 G2

B1

4" (102mm)

109" (2769mm)

Figure 22 Primary connection locations—downflow, air-cooled 53-77kW (15-22 ton), semi-hermetic

compressors with EC fans, front, rear or bottom discharge

Table 18 Piping details—downflow, air-cooled 53-77kW (15-22 ton) with EC fans, semi-hermetic

Point Description

G1 Hot Gas Discharge 1 90-5/8 (2302) 16-5/8 (422) 7/8 / 1-1/8 Cu Sweat

G2 Hot Gas Discharge 2 88 (2235) 16-5/8 (422) 7/8 / 1-1/8 Cu Sweat

CD

HUM Humidifier Supply Line 76-1/2 (1943) 29 (736) 1/4 Cu Sweat

ECS** Econ-O-Coil Supply 78-5/8 (1997) 22-1/4 (565) 2-1/8 Cu Sweat

ECR** Econ-O-Coil Return 73-15/16 (1862) 26-9/16 (675) 2-1/8 Cu Sweat

E1 Electrical Conn. (High Volt) 78-1/2 (1994) 31-1/8 (790) 2-1/2

E2 Electrical Conn. (High Volt) 75-3/8 (1915) 31-1/8 (790) 2-1/2

LV1 Electrical Conn. (Low Volt) 2 (51) 29 (737) 7/8

LV2 Electrical Conn. (Low Volt) 2 (51) 30-7/8 (784) 7/8

LV3 Electrical Conn. (Low Volt) 2 (51) 32 (813) 7/8

B1 Blower Outlet 4-1/2 (114) 33 (838) 58-3/8 x 30 (1483x762)

* Field pitch condensate drain line a minimum of 1/8" (3.2 mm) per foot (305 mm). All units contain a factory-installed condensate trap. Do

** Supplied on Dual-Cooling systems only (four-pipe system)

Piping dimensions shown are connection sizes; field piping sizes may be different depending on distance. Refer to user manual, SL-18825.

Source: DPN002179, Rev. 0

Liebert® DS

compressors

X

in. (mm)

R Refrigerant Access 82-3/4 (2102) 13-7/8 (352) 16-7/16 x 4 (4181x102)

L1 Liquid Line System 1 97 (2464) 16-7/8 (428) 1/2 / 5/8 Cu Sweat

L2 Liquid Line System 2 93-5/16 (2370) 16-7/8 (428) 1/2 / 5/8 Cu Sweat

Condensate Drain

(Infrared Humidifier or No Humidifier)*

68-3/8 (1737) 31-3/8 (797) 3/4 FPT

W/ Optional Pump 68-3/8 (1737) 31-3/8 (797) 1/2 Cu Sweat

Y

in. (mm)

Connection Size / Opening

in. (mm)

53kW (15 ton) /70 & 77kw (20 & 22 ton)

not trap external to the unit. Drain line may contain boiling water. Select appropriate drain system materials. The drain line must comply

with all local codes.

™

30

Page 35

Air-Cooled Systems

Figure 23 Disassembly dimensions—downflow, air-cooled, 53-77kW (15-22 ton), semi-hermetic

compressors with centrifugal fans

Filter & Electric

Box Assembly

39"

(991mm)

Compressor Assembly

Blower & Coil

Assembly

76"

(1930mm)

Assembled

Height

76"

(1930mm)

59-7/16"

(1509mm)

37"

(940mm)

33"

(838mm)

26"

(660mm)

82" (2083mm)

108" (2743mm)

Assembled Length

NOTES: Drawing views are simplified with panels removed to show overall dimensions.

See disassembly and handling instructions in installation manual.

DPN000926

Rev. 4

Table 19 Component weights—downflow, air-cooled, 53-77kW (15-22 ton), semi-hermetic compressors

Dry Weight, Approximate, Including Panels, lb (kg)

Component

Compressor Assembly 970 (441) 970 (441)

Filter and Electric Box Assembly 250 (114) 250 (114)

Blower and Coil Assembly 1230 (560) 1410 (641)

Source: DPN000926, Rev. 4

Air-Cooled Dual-Cool

31 Liebert® DS

™

Page 36

Air-Cooled Systems

5"

(127mm)

Notes: Filters are accessible

through top of unit only.

Downflow electrical

connections can be made

from top or bottom of unit.

TOP VIEW

AIR INLET OPENING

Shaded area indicates a

recommended minimum

clearance be provided for

component access.

24-3/8"

(619mm)

Opening

3/4"

(19mm)

Bezels

Secondary Entrance

High-Volt Connection(s)

76"

(1930mm)

FRONT VIEW

DPN0001012