Page 1

Form Number A6241

Part Number D301258X012

September 2007

FloBoss™ 107 Flow Manager

LCD

User Manual

Remote Automation Solutions

Page 2

FloBoss™ 107 Flow Manager LCD Program User Manual

Revision Tracking Sheet

September 2007

This manual may be revised periodically to incorporate new or updated information. The

revision date of each page appears at the bottom of the page opposite the page number. A

change in revision date to any page also changes the date of the manual that appears on the

front cover. Listed below is the revision date of each page (if applicable):

Page Revision

Initial issue Sep-07

NOTICE

Remote Automation Solutions (“RAS”), division of Emerson Process Management shall not be liable for technical or editorial errors

in this manual or omissions from this manual. RAS MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THIS

MANUAL AND, IN NO EVENT SHALL RAS BE LIABLE FOR ANY INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL

DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS, LOSS OF REVENUE OR USE

AND COSTS INCURRED INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF THIRD

PARTIES.

Bristol, Inc., Bristol Babcock Ltd, Bristol Canada, BBI SA de CV and the Flow Computer Division are wholly owned subsidiaries of

Emerson Electric Co. doing business as Remote Automation Solutions (“RAS”), a division of Emerson Process Management.

FloBoss, ROCLINK, Bristol, Bristol Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS, PlantWeb and the

PlantWeb logo are marks of Emerson Electric Co. The Emerson logo is a trademark and service mark of the Emerson Electric Co.

All other trademarks are property of their respective owners.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure

informational accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or

services described herein or their use or applicability. RAS reserves the right to modify or improve the designs or specifications of

such products at any time without notice. All sales are governed by RAS’ terms and conditions which are available upon request.

RAS does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use

and maintenance of any RAS product remains solely with the purchaser and end-user.

© 2007 Remote Automation Solutions, division of Emerson Process Management. All rights reserved.

ii Issued Sep-07

Page 3

FloBoss 107 LCD User Manual

Contents

Chapter 1 – Introduction 1-1

1.1 Scope and Organization...................................................................................................1-1

1.2 Overview...........................................................................................................................1-1

1.2.1 Display Mode......................................................................................................1-4

1.2.2 Power Savings Mode .........................................................................................1-5

1.2.3 Touchpad and ROCLINK 800 Security..............................................................1-6

Chapter 2 – Configuration 2-1

2.1 Configuring the Port Owner..............................................................................................2-1

2.2 Configuring Touchpad Options.........................................................................................2-4

2.3 Configuring Basic List Mode (BLM)..................................................................................2-5

2.4 Configuring Standard or Normal Mode.............................................................................2-7

2.5 Configuring Chart Mode ...................................................................................................2-8

2.6 Configuring Touchpad Security........................................................................................2-9

Chapter 3 – Using The Touchpad 3-1

3.1 Touchpad Screens ...........................................................................................................3-1

3.1.1 Menu Screens ....................................................................................................3-1

3.1.2 Parameter Screens ............................................................................................3-2

3.1.3 Dynamic Charts..................................................................................................3-3

3.1.4 Operational Screens...........................................................................................3-5

3.1.5 Touchpad Time Out............................................................................................3-5

3.2 Logging On.......................................................................................................................3-6

3.3 User Lists........................................................................................................................3-10

3.4 Meter Runs.....................................................................................................................3-12

3.4.1 Displaying Meter Information............................................................................3-13

3.4.2 Changing a Plate..............................................................................................3-14

3.5 Module Information.........................................................................................................3-15

3.5.1 Viewing I/O and Diagnostic Information...........................................................3-15

3.5.2 Viewing RTD Information .................................................................................3-16

3.5.3 Viewing COMM Information .............................................................................3-17

3.5.4 Viewing Multiple Variable Sensor (MVS) Information......................................3-18

3.5.5 Viewing Meter Information................................................................................3-19

3.5.6 Viewing System Information.............................................................................3-20

3.5.7 Viewing Dual Variable Sensor (DVS) Information............................................3-21

3.5.8 Calibrating a Point............................................................................................3-22

3.6 Charts.............................................................................................................................3-26

3.6.1 Viewing Historical Data ....................................................................................3-27

3.6.2 Viewing Dynamic Data.....................................................................................3-28

3.7 PID Loops.......................................................................................................................3-29

3.7.1 Setting Basic PID Loops...................................................................................3-30

3.7.2 Setting Advanced PID Loops ...........................................................................3-32

3.8 System Information.........................................................................................................3-34

3.8.1 Displaying System Information.........................................................................3-34

3.8.2 Saving a Configuration.....................................................................................3-35

3.8.3 Performing a Warm Start..................................................................................3-36

3.8.4 Forcing End of Day...........................................................................................3-36

Issued Sep-07 Contents iii

Page 4

FloBoss 107 LCD User Manual

3.8.5 Adjusting Touchpad Contrast...........................................................................3-37

3.9 Logging Off.....................................................................................................................3-38

Index I-1

iv Contents Issued Sep-07

Page 5

Chapter 1 – Introduction

This chapter describes the structure of this manual and presents an

overview of the Liquid Crystal Display (LCD) for the FloBoss™ 107

Flow Manager.

1.1 Scope and Organization

This document serves as the user manual for the FloBoss™ 107 Flow

Manager Liquid Crystal Display (LCD), which is intended for use with

the FloBoss 107 Flow Manager (“FB107”). This manual describes how

to install, configure, and use the FB107 LCD (the “Touchpad”). You

initially access and configure the Touchpad using ROCLINK™ 800

Configuration software loaded on an IBM-compatible personal

computer running Windows® 98, NT 4.0 (with Service Pack 6), 2000

(with Service Pack 2), or XP. Once configured, the Touchpad provides

access to many FB107 system parameters and functions.

FB107 LCD User Manual

1.2 Overview

The chapters in this manual provide information in a sequence

appropriate for first-time users. Once you become familiar with the

device and the procedures, the manual becomes a reference tool.

This manual has the following major sections:

Chapter 1 – Introduction

Chapter 2 – Configuration

Chapter 3 – Using the Touchpad

This manual assumes that you are familiar with the FB107 and its

configuration. For more information, refer to the following specification

sheet and manuals:

™

FloBoss

107 Flow Manager Instruction Manual (Form A6206)

FloBoss™ 107 LCD Specification Sheet (5.5:LCD)

ROCLINK 800 Configuration Software User Manual (for FB107)

(Form A6217)

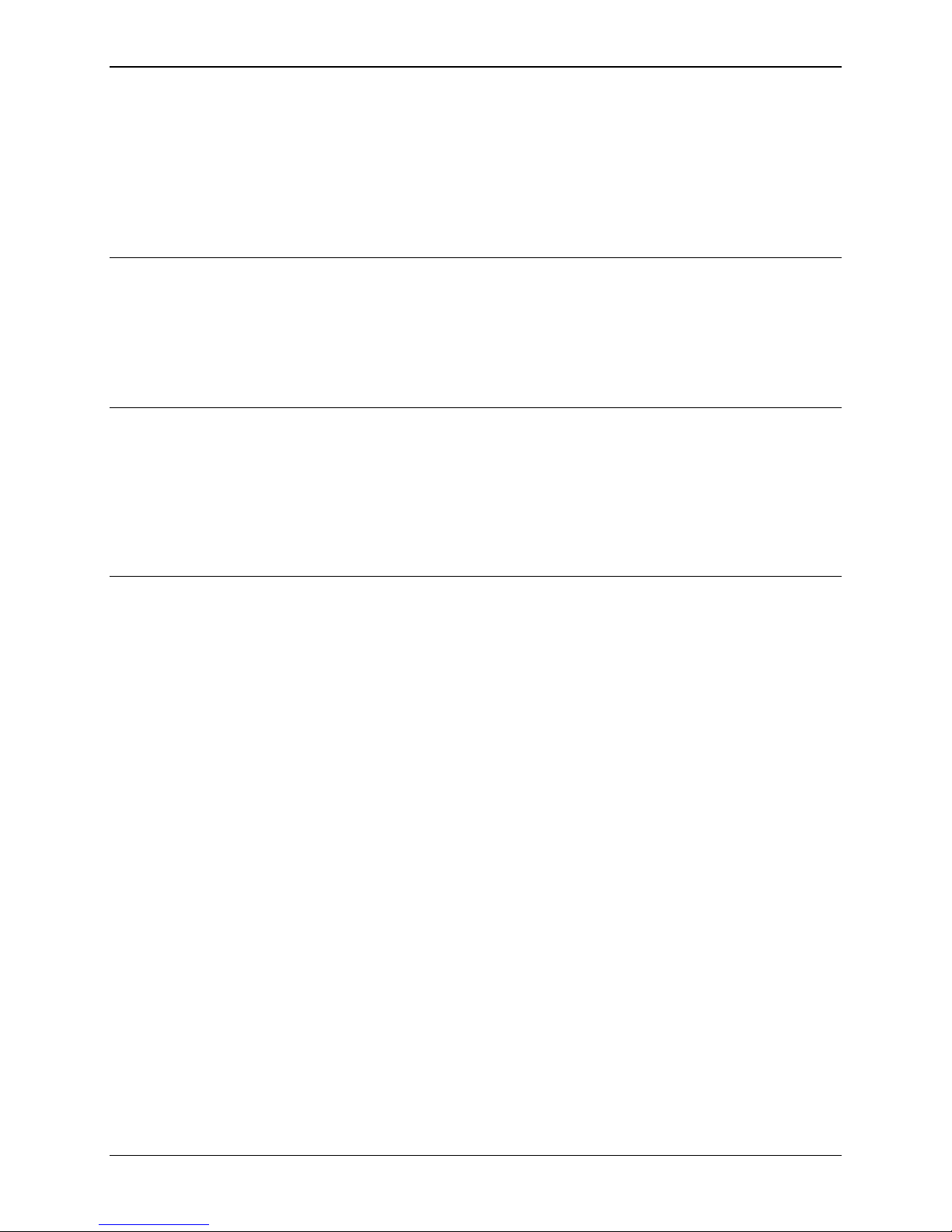

The Touchpad enables you to access FB107 process and operational

information and to view and change FB107 parameters. The Touchpad

is a touch-sensitive liquid crystal display (LCD) screen. It fits behind a

protective covering that is mounted to an enclosure (see Figure 1-1).

Issued Sep-07 Introduction 1-1

Page 6

FB107 LCD User Manual

Figure 1-1. FB107 Touchpad, Enclosure-Mounted

Note: The Touchpad (with FB107) is designed to be mounted to an

enclosure. Remote Automation Solutions has an enclosure

designed for the Touchpad. If you choose to use your own

enclosure, contact your local sales representative for a template

and appropriate specifications.

The Touchpad communicates with the FB107 through a dedicated RS232 connection located on the FB107 base unit (see Figure 1-2). The

Touchpad’s RS-232 connection is permanently configured with a baud

rate of 19200, 1 stop bit, 1 start bit, 8 data bits, and no parity.

1-2 Introduction Issued Sep-07

Page 7

FB107 LCD User Manual

Display

connection

Figure 1-2. FB107 Base Unit, Display Connection

The Touchpad is a transreflective LCD. To maintain readability in

direct sunlight, it reflects most of the sunlight and increases or decreases

the brightness of its display based on the amount of light. This reduces

your need to manually adjust the screen. It also has a backlight to

increase readability during low-light use conditions or during critical

operations (such as when you enter a PIN code). During idle periods,

the backlight automatically enters a power-saving mode to conserve

energy.

The Touchpad requires no manual calibration. Internal firmware

provides the coordinates to assure display communications between the

Touchpad and your FB107.

Issued Sep-07 Introduction 1-3

Page 8

FB107 LCD User Manual

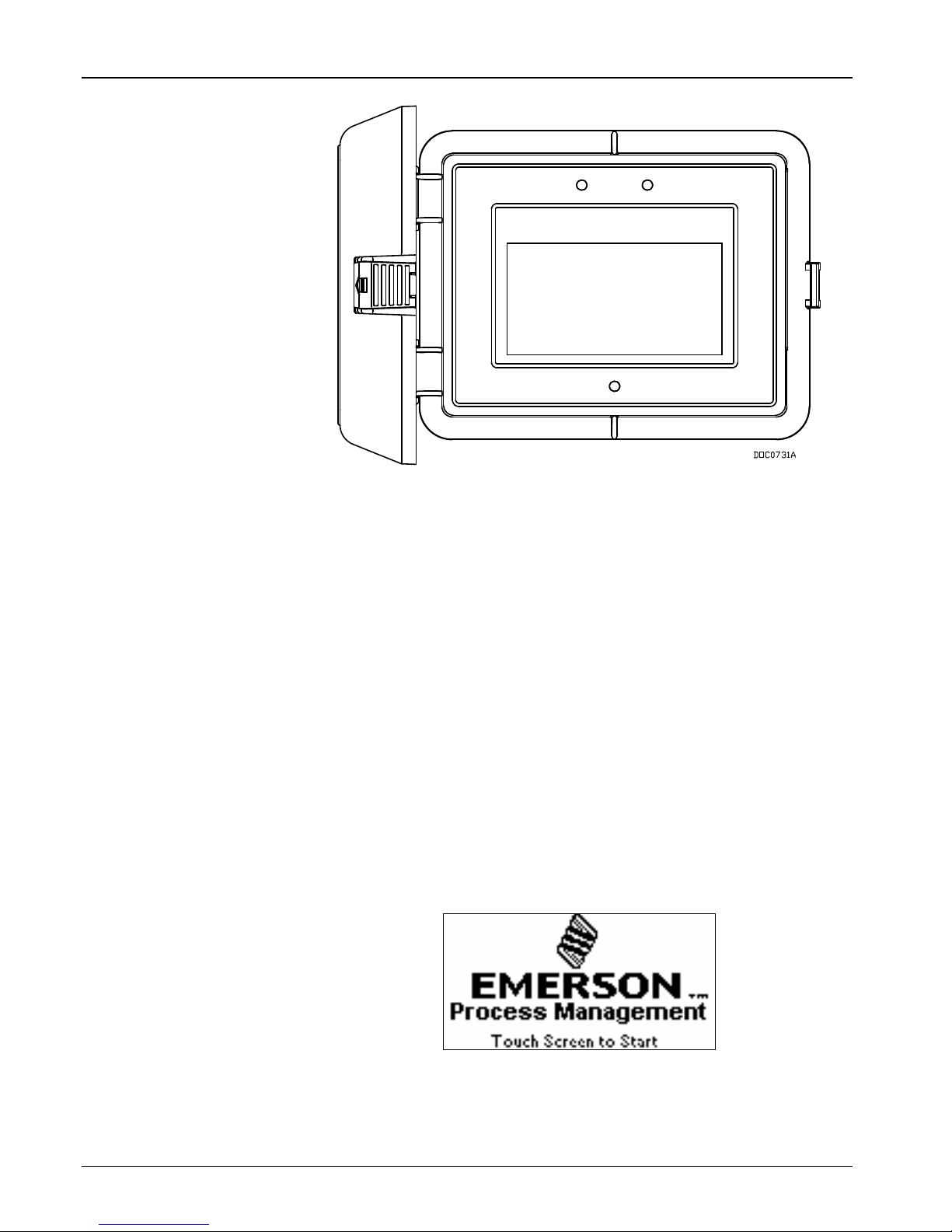

ALARMKEY ACK

Figure 1-3. FB107 Touchpad with Open Cover

To use the Touchpad, you open its protective cover and touch the

screen. Two light-emitting diodes (LEDs) at the top of the Touchpad

provide visual signals on the Touchpad’s operational status. The green

LED indicates successful “touches”: each time you touch the screen, the

green LED flashes to verify that the Touchpad has acknowledged your

entry. The green LED also can flash once every three seconds if you

have set the power savings mode (see Section 1.2.2). The red LED

signals alarm or integrity issues, and coordinates with other visual

Touchpad clues (such as an on-screen asterisk, i, or a) to identify the

area of concern. See Chapter 3, Using the Touchpad.

1.2.1 Display Mode

The Touchpad has two operational modes, Normal and Basic List

Mode (BLM). When you open the cover, the Touchpad displays the

“idle state display” (typically the Emerson Process Management logo):

TOUCH SCREEN

TO ACTIVATE

1-4 Introduction Issued Sep-07

Figure 1-4. Touchpad “Idle State” Display

Page 9

FB107 LCD User Manual

When you touch the screen, you see either a list of system parameters or

a number grid.

Figure 1-5. Initial Active Touchpad Displays

BLM mode (indicated by the on-screen BLM List label) provides an

auto-scrolling list of read-only parameters, which displays up to 32 userdefined parameters (refreshed once per second) without requiring a log

on process. (At any time you can interrupt the auto-display and log on

through the Touchpad.)

Note: BLM mode also includes a dynamic chart mode. Technicians can

touch a parameter and the Touchpad displays a dynamic chart

related to that parameter. See Chapter 3, Using the Touchpad,

for further details on this feature.

Normal mode requires a sign-in process before displaying any

information. Refer to Chapter 3, Using the Touchpad, for further

information.

1.2.2 Power Savings Mode

The Touchpad also provides an optional power-savings mode, which

activates whenever the idle state display occurs. (This power savings

mode works with either Normal or BLM display mode.) Select this

option on the Advanced tab of the LCD Controller screen (see Figure 1-

6).

Issued Sep-07 Introduction 1-5

Page 10

FB107 LCD User Manual

Figure 1-6. Power Savings Modes

When you click Low Power (and then click Update to apply the

change), ROCLINK 800 performs a warm start and shuts down the

Touchpad. While the Touchpad is blank, the green LED blinks once

every three seconds to indicate the Touchpad is active. The Touchpad

“awakens” when you touch it, and shows the idle state display. At that

point log on and proceed to use the Touchpad normally. Whenever the

Touchpad “times out” and would normally show the idle state display,

the Touchpad is blank. This reduces the energy required to continually

show the idle state display.

1.2.3 Touchpad and ROCLINK 800 Security

ROCLINK 800 security enables you can determine which user IDs can

access which Touchpad features. You can define up to 16 user IDs, each

of which can have read-only, read-write, or no access to the four user

lists and standard features of the Touchpad. See Section 2.6,

Configuring Touchpad Security.

1-6 Introduction Issued Sep-07

Page 11

Chapter 2 – Configuration

This chapter provides instructions for configuring Touchpad options.

The FB107 is factory-configured to accept the Touchpad. Until you

connect the Touchpad to the FB107, the Display port displays an

integrity (“red I”) error (see Figure 2-1, Section 2-1).

After connecting the Touchpad, you can configure additional display

options as well as Touchpad security (see Sections 2-2 through 2-6).

2.1 Configuring the Port Owner

1. Log onto and open ROCLINK 800. The FB107 graphic displays.

FB107 LCD User Manual

Issued Sep-07 Configuration 2-1

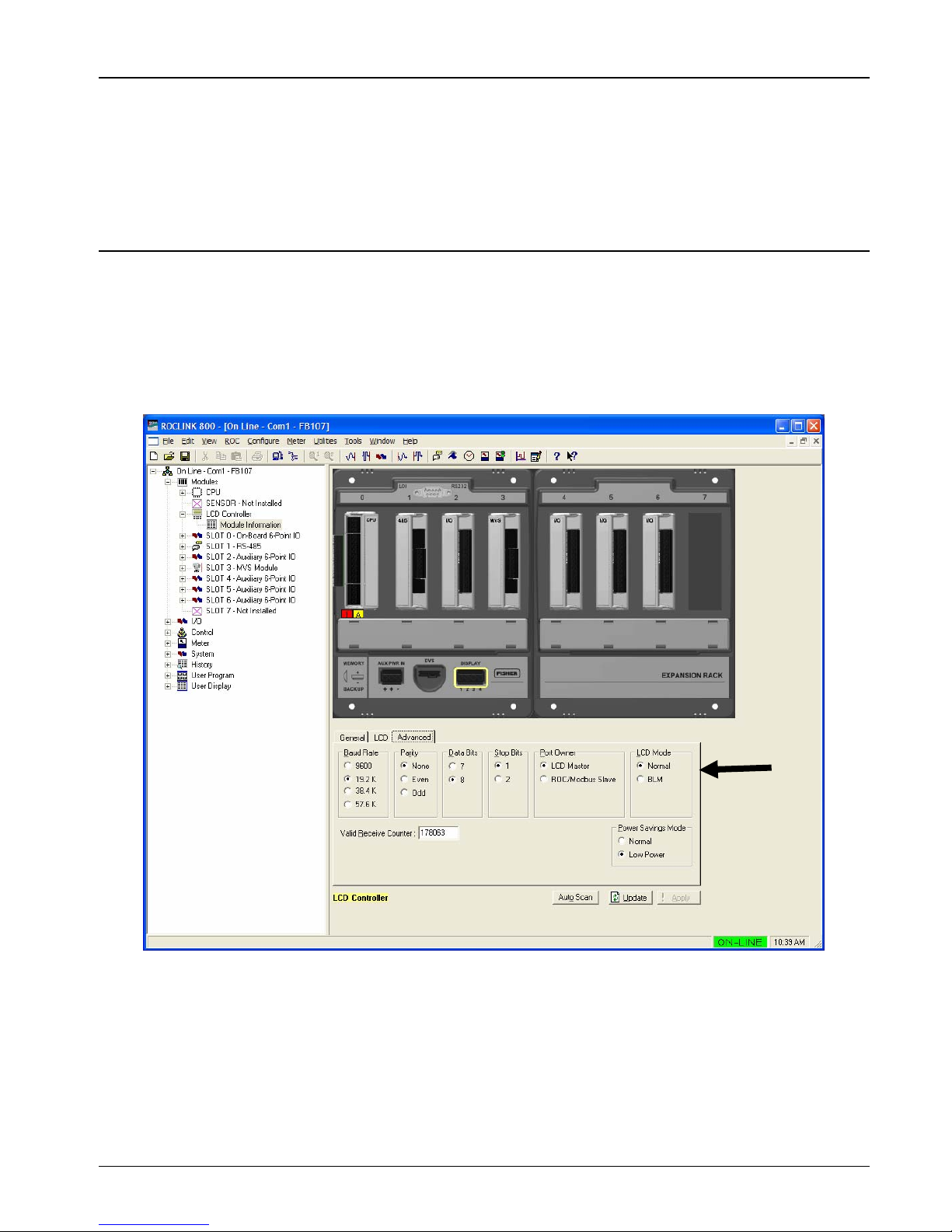

Figure 2-1. FB107 Graphic Display

2. Plug the connector for the Touchpad into the Display port on your

FB107 (see Figure 2-1). The Touchpad activates and displays the

message “Waiting for Comms…”

Page 12

FB107 LCD User Manual

Figure 2-2. Touchpad Activation

3. Click the Display port on the FB107 graphic. The LCD Controller

screen appears at the bottom of the FB107 graphic display.

Note that the FB107 graphic highlights the Display port and

removes the integrity error on the display port.

4. Select the Advanced tab. The Advanced screen displays.

2-2 Configuration Issued Sep-07

Figure 2-3. LCD Controller

Page 13

FB107 LCD User Manual

Figure 2-4. LCD Controller, Advanced tab

5. Verify that LCD Master in the Port Owner frame is the port owner

(this is the default value).

Note: Figure 2-4 also shows the other default comm values (Baud

Rate, Parity, Data Bits, Stop Bits, and LCD Mode) for the

FB107.

6. Click Apply if you changed any values on this screen. ROCLINK

800 performs a warm start, and the Touchpad displays the Emerson

Process Management logos.

Issued Sep-07 Configuration 2-3

Figure 2-5. Emerson Process Management Logos

Proceed to Sections 2.2 through 2.6 to configure display options.

Page 14

FB107 LCD User Manual

2.2 Configuring Touchpad Options

When configuring Touchpad options, you determine both the default

display mode (Sections 2.3 through 2.5) and which user IDs may access

which Touchpad features (Section 2.6).

You use the Configure option on the ROCLINK menu bar to select one

of two possible default display modes for the Touchpad.

Figure 2-6. ROCLINK 800 LCD User List Configuration Options

Option Description

Standard

BLM

Chart

Requires you to first log onto the Touchpad. Displays

(based on pre-defined ROCLINK 800 security

parameters) select system values and allows you

modify select system parameters.

Note: This is also called “Normal” mode.

Automatically displays up to 32 parameter values.

Allows you (based on pre-defined ROCLINK 800

security parameters) to log onto the Touchpad and

display select system values and modify select

system parameters.

Requires you to first log onto the Touchpad.

Displays, in a chart recorder format, historical or

dynamic values for up to 16 user-defined parameters.

Note: For convenience, a dynamic charting function

is available for the parameters displayed in

basic list mode. However, this is not the fullfunction charting facility.

2-4 Configuration Issued Sep-07

Page 15

2.3 Configuring Basic List Mode (BLM)

In Basic List Mode (BLM), the Touchpad displays up to 32 parameter

values, automatically scrolling through the list at a speed you define.

(The Touchpad displays up to two parameters per screen.) This mode

allows service technicians to quickly review a dynamic display of

current values without logging onto the Touchpad.

1. Select the Advanced tab of the LCD Controller screen. The

Advanced screen displays.

FB107 LCD User Manual

Figure 2-7. ROCLINK 800 LCD User List Configuration Options

Issued Sep-07 Configuration 2-5

2. Select BLM in the LCD Mode frame. Click Apply to save your

change. ROCLINK 800 performs a warm start.

3. Select Configure > LCD User List > BLM from the ROCLINK

800 Menu bar. The LCD User List – BLM screen displays.

Page 16

FB107 LCD User Manual

Figure 2-8. LCD User List – BLM

4. Complete the following fields to define the contents of the BLM list.

Field Description

Title

Scroll Time

Device

Parameter

Text

Units

Sets a 10-character alphanumeric identifier for the

list.

Indicates the number of seconds the Touchpad

displays each parameter set before scrolling to

the next parameter set. (The Touchpad displays

up to two parameters at a time.) Valid values are

0 (do not scroll) to 255; the default is 4.

Note: If you set this value to 0, you must use the

Ï and Ð keys on the Touchpad to

manually scroll through the parameters

defined in the list.

Sets the parameter that you want to display on the

Touchpad. Click … to display a Select TLP screen

you use to define the parameter.

Sets a 10-character alphanumeric identifier for the

parameter.

Shows the engineering units for the associated

parameter.

5. Click the 17-32 tab to define 16 additional parameters.

2-6 Configuration Issued Sep-07

Page 17

6. Click Apply if you make any changes to this screen.

7. Click OK to close the LCD User List – BLM screen.

8. Proceed to Chapter 3, Using the Touchpad.

2.4 Configuring Standard or Normal Mode

In Standard or Normal mode, the Touchpad displays the Emerson

Process Management logos. When you touch the screen, a logon grid

displays. You then enter a PIN number to log on to the Touchpad.

1. Select the Advanced tab of the LCD Controller screen. The

Advanced screen displays.

FB107 LCD User Manual

Figure 2-9. ROCLINK 800 LCD User List Configuration Options, Advanced tab

Issued Sep-07 Configuration 2-7

2. Verify that Normal is selected in the LCD Mode frame. (This is the

factory default value for the Touchpad.)

3. Click Apply if you have needed to change the setting. ROCLINK

800 performs a warm start. The Touchpad now starts in Normal

mode.

Page 18

FB107 LCD User Manual

4. Proceed to Chapter 3, Using the Touchpad.

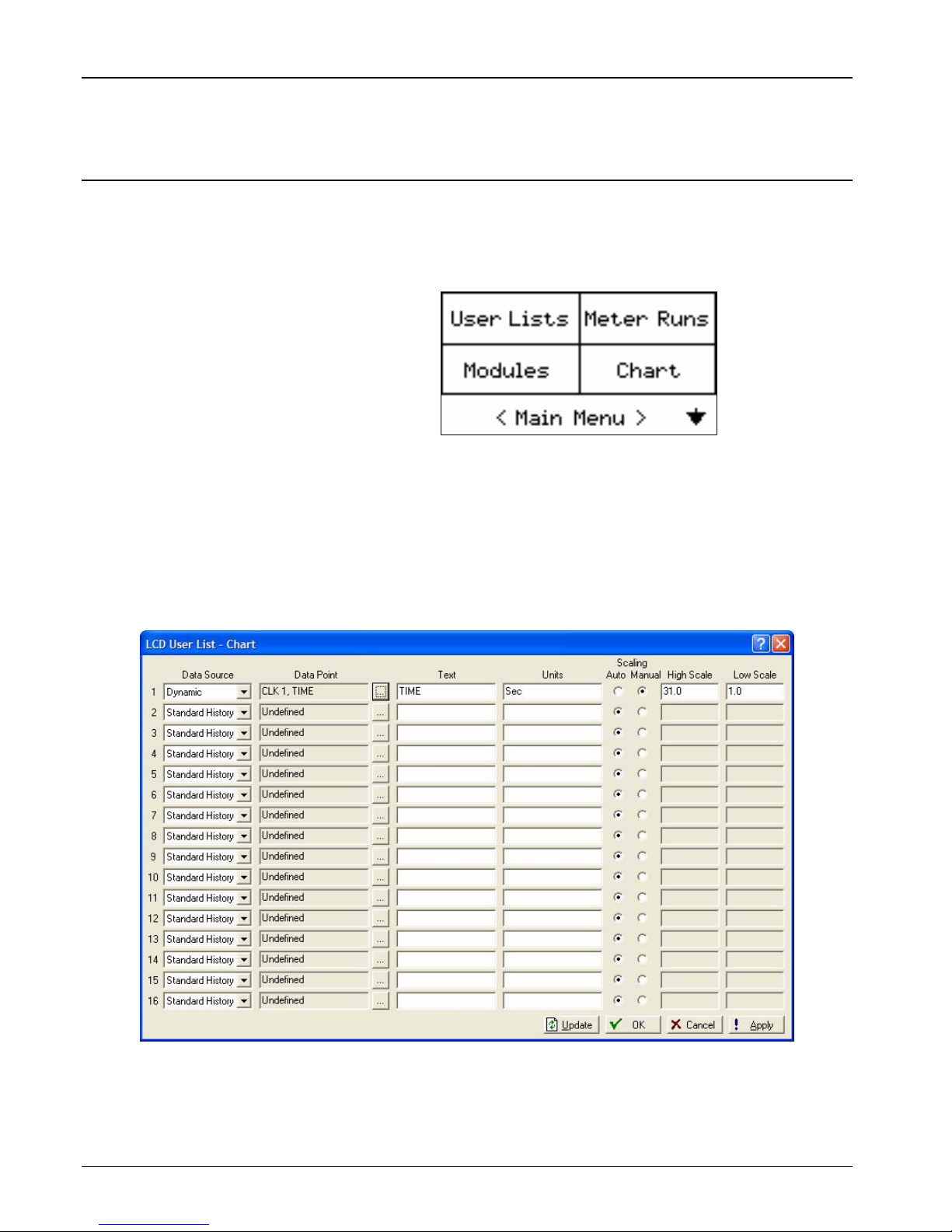

2.5 Configuring Chart Mode

Chart mode allows the Touchpad to emulate a chart recorder. After you

log on normally, Chart is one of the options displayed on the Main

Menu:

Figure 2-10. Touchpad Main Menu

The Touchpad can display up to 16 historic or dynamic system values.

Use this procedure to define the displayed values.

1. Select Configure > LCD User List > Chart from the ROCLINK

800 Menu bar. The LCD User List – Chart screen displays.

2-8 Configuration Issued Sep-07

Figure 2-11. LCD User List - Chart

Page 19

FB107 LCD User Manual

2. Complete the following fields to define the chart display values.

Field Description

Data Source

Dynamic

Data Point

Text

Units

Scaling

HighScale

Sets the source for data included in the chart. Valid

values are:

Standard

History

Extended

History

Shows the data point selected.

Sets a 10-character alphanumeric identifier for the

data point.

Shows the engineering units for the associated

parameter.

Indicates whether the system applies automatic or

manual value limit factors to the charted results.

Valid values are Auto (apply automatic values) or

Manual (apply defined values).

Sets the high value for the data point.

Note: This field is available only if you select

Manual as a scaling option.

Sets a standard history point to

chart. Click … to open a Select

History Point dialog box you can use

to select a valid standard history

point.

Sets an extended history point to

chart. Click … to open a Select

History Point dialog box you can use

to select a valid extended history

point.

Sets a dynamic data point to chart.

Click … to open a Select TLP dialog

box you can use to select a valid

TLP.

Low Scale

Sets the low value for the data point.

Note: This field is available only if you select

Manual as a scaling option.

3. Click Apply if you make any changes to this screen.

4. Click OK to close the LCD User List – Chart screen.

5. Proceed to Chapter 3, Using the Touchpad.

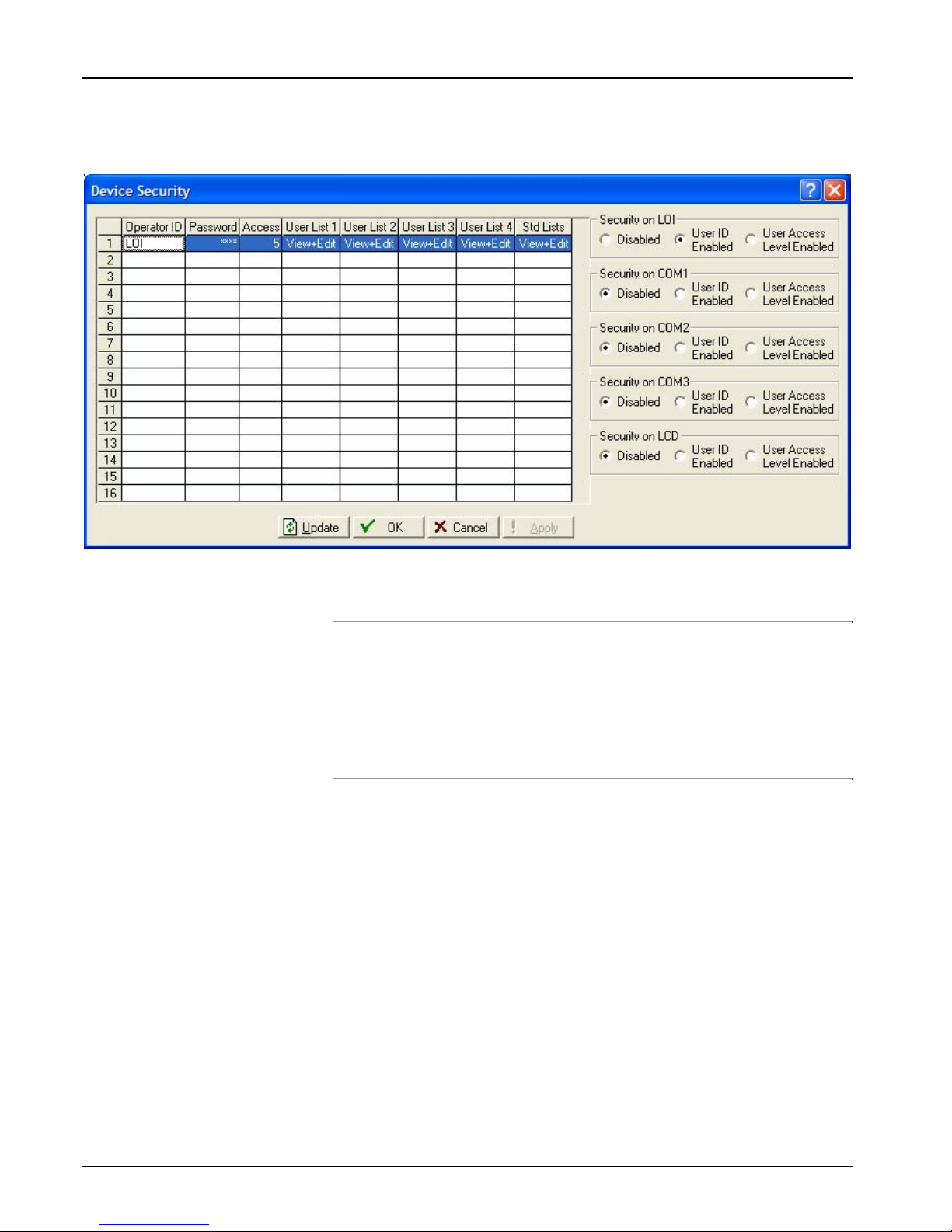

2.6 Configuring Touchpad Security

Touchpad security enables you to selectively restrict or permit access to

Touchpad functions for up to 16 user IDs you define. To do this, you

use ROCLINK 800’s Device Security screens (Figures 2-12 and 2-13).

You can define an ID which can access all or only one user list or just

the Touchpad’s “standard lists.” Additionally, the ID can have edit

capability or just view capability. You define IDs and their accesses to

meet your organization’s needs.

Issued Sep-07 Configuration 2-9

Page 20

FB107 LCD User Manual

1. Select ROC > Security from the ROCLINK 800 Menu bar. The

Device Security screen displays.

Figure 2-12. Device Security

Note: Use only the left-hand side of this screen to define Touchpad

security. The right-hand fields (Security on LOI, Security on

COM1, etc.) do not apply to the Touchpad (but do apply to

security levels on the FB107). Leave the Security on LCD

field disabled. It applies only if you are connecting a display

other than the LCD from Remote Automation Solutions. If

that is the case, contact Product Support.

2. Click in the first empty Operator ID field. The Device Security

dialog box displays.

2-10 Configuration Issued Sep-07

Page 21

FB107 LCD User Manual

Figure 2-13. Device Security, User Level

3. Complete the following fields to define the access permissions for

the new user ID.

Field Description

Operator ID

Password

Confirm

Password

Access Level

User List 1

through 4

Disabled

View Only

View+Edit

Standard Lists

Disabled

View Only

View+Edit

Sets the three alphanumeric characters for the

password.

Sets the four-digit password associated with this ID.

Confirms the four-digit password associated with

this ID.

Note: The contents of this field must match the

contents of the Password field.

This field does not apply to the FB107 Touchpad.

Indicates whether the ID can access the user-

defined User Lists. Valid values are:

Removes the user list from the

displayed options.

Displays the user list but does not

allow edits to displayed data.

Displays the user list and allows

edits to displayed data.

Indicates whether the ID can access the standard

Touchpad functions (that is, the options on the Main

Menu screen: Meter Runs, Modules, Charts, PID,

System, and Log Off). Valid values are:

Removes the user list from the

displayed options.

Displays the user list but does not

allow edits to displayed data.

Displays the user list and allows

edits to displayed data.

Issued Sep-07 Configuration 2-11

Page 22

FB107 LCD User Manual

4. Click OK to apply these edits. The system displays the updated

Device Security screen.

Figure 2-14. Device Security

5. Repeat steps 2 and 3 to add up to 14 more IDs.

6. Click OK to display the FB107 graphic.

2-12 Configuration Issued Sep-07

Page 23

Chapter 3 – Using The Touchpad

This chapter describes the day-to-day use of the Touchpad.

3.1 Touchpad Screens

The Touchpad uses several major screen formats to present information.

Included are menu screens, parameter screens, and dynamic charts.

Note: System security settings controls which options display on your

Touchpad and whether you can edit parameter values. Refer to

Section 2.6, Configuring Touchpad Security, for further

information.

3.1.1 Menu Screens

Menu screens are basically two or more options placed in a grid.

Typically, an Exit option may appear in the menu’s lower left corner. A

menu label (such as Main Menu or Slot #0 in Figure 3-1) is centered

between brackets, and arrows (to access additional menu options) may

appear in the right corner of the menu. Figure 3-1 shows two examples of

menu screens.

FB107 LCD User Manual

Figure 3-1. Sample Menu Screens

Touching an option on the menu screen’s grid may lead to another menu

or to a parameter screen.

Notes:

A blinking asterisk (*) in the upper right corner of a menu box (as in

the Modules option in Figure 3-1) indicates an integrity or alarm issue

in this module.

A blinking i, ia, or a in the upper right corner of a menu box (as in AI

2 and AO 1 in Figure 3-1) indicates an integrity or alarm issue with

this point.

Issued Sep-07 Using the Touchpad 3-1

Page 24

FB107 LCD User Manual

(

y)

(

)

3.1.2 Parameter Screens

Parameter screens primarily display values, but provide other ways to

display information. A label typically appears at the top of a parameter

screen indicating where that parameter belongs. The bottom of the screen

contains two or more boxes, usually providing an Exit option on the lefthand side, a Hold option (to prevent the screen from auto-scrolling to the

next set of parameters) in the center, and Ï and Ð options on the righthand side so you can move more quickly from parameter to parameter

(see Figure 3-2).

Up to two parameter values display in the center of the screen. The values

are dynamic and refresh each second.

Parameter tag

or label

Parameter

units

Parameter values are usually read-only. However, you can edit a value in

a box (as in the case of 534.57 in Figure 3-3). Touch the box to display a

numeric keypad screen (Figure 3-4).

Figure 3-2. Sample Parameter Screens

Figure 3-3. Sample Parameter Screen

Parameter

value

read-onl

Parameter

value

editable

3-2 Using the Touchpad Issued Sep-07

Figure 3-4. Numeric Keypad

Page 25

FB107 LCD User Manual

As you enter a new value, the numeric keypad changes (as shown in

Figure 3-4). When you are finished, touch Done. The Touchpad displays

a screen to confirm the new value (see Figure 3-5).

Figure 3-5. Edited Parameter

When you touch Yes, the new value appears in the parameter screen’s

editable field.

Note: The Touchpad uses this “value inside a box” signal extensively to

indicate a field you can edit.

Finally, you can touch the parameter tag on any parameter screen to

display a chart screen that dynamically displays the values of that

parameter (see Section 3.1.3).

3.1.3 Dynamic Charts

The Touchpad can display any parameter you select in a dynamic “chart

recorder” format. Touch the label or units on a parameter screen to

display the chart. Charting begins from the moment of touch and

continues either for 30 minutes or until you touch Exit.

Figure 3-6. Edited Parameter

Issued Sep-07 Using the Touchpad 3-3

Page 26

FB107 LCD User Manual

Current

upper and

lower scale

Current

date and

time

Figure 3-7. Sample Dynamic Chart

The parameter label displays in the upper center of the screen, and

alternates with a display of the units every four seconds. The current

parameter value displays in the lower center of the screen. The current

date appear in the upper right-hand corner of the screen. The current time

appears in the lower right-hand corner of the screen. The values in the

upper and lower left-hand corners of the screen display the chart’s current

scale. You can modify the scale by touching the asterisk (*) just below

the upper scale value. The Touchpad displays a numeric keypad you use

to define first a new upper range, then a new lower range.

Figure 3-8. Chart Scale Ranges

When you exit the numeric keypads, the parameter screen reflects the

new values.

Figure 3-9. Revised Scales

Note: These new values are valid only for the current viewing. The

Touchpad restores the original scale values when you exit the

parameter screen.

3-4 Using the Touchpad Issued Sep-07

Page 27

3.1.4 Operational Screens

The Touchpad provides a complement of message screens, confirmation

screens, and other screen types to support system processing. Refer to

Sections 3.2 through 3.9 for examples of these screens.

3.1.5 Touchpad Time Out

For both security and to save power, the Touchpad display goes blank (or

“times out”) at specific intervals if left untouched. Touching a timed-out

screen restores the idle state display (see Figure 1-4), from which you

must log on again.

Screen Display Duration

PIN (Figure 3-12) 1 minute

Menu (Figure 3-1) 10 minutes

Calibrate (Figure 3-43) 60 minutes

Plate Change (Figure 3-42) 30 minutes

FB107 LCD User Manual

You can also access a power savings mode to enable the Touchpad to

time out more frequently (see Section 1.2.2).

Issued Sep-07 Using the Touchpad 3-5

Page 28

FB107 LCD User Manual

3.2 Logging On

In daily operation, the Touchpad normally displays the Emerson Process

Management logo in its “idle” or waiting state.

Figure 3-10. Idle State Display

1. Touch the screen. A second screen displays, depending on the mode

you’ve selected (Normal or BLM). If you’ve configured BLM mode,

the Touchpad begins to auto-scroll through the parameters you

defined on ROCLINK 800’s LCD User List – BLM screen (see

Section 2.3. If you’ve configured Normal mode, the Touchpad

displays a log on screen:

Figure 3-11. Log On

Note: The Touchpad displays this log on screen for 60 seconds. If

you do not enter a PIN in that time, the idle state screen

displays.

2. Enter a valid log on PIN. As you touch each number, the Key

Acknowledgement LED (Key Ack, Figure 1-3) should blink green

and the Touchpad reverses the numeric image (see Figure 3-12).

3-6 Using the Touchpad Issued Sep-07

Page 29

FB107 LCD User Manual

Figure 3-12. Touched Value

If you enter an incorrect PIN number, the Touchpad displays a

message. Click OK and re-enter the PIN.

Figure 3-13. Invalid PIN Message

Note: The default PIN is 1000. If you have disabled that PIN or

replaced it with another PIN to establish security for your

organization, use those values with the Touchpad.

Figure 3-14 provides a map of all Touchpad options.

Issued Sep-07 Using the Touchpad 3-7

Page 30

FB107 LCD User Manual

3-8 Using the Touchpad Issued Sep-07

Figure 3-14. Touchpad Options Map

Once you enter a valid PIN on the log on screen, the Touchpad’s

Main Menu screen displays:

Page 31

FB107 LCD User Manual

Figure 3-15. Touchpad Main Menu

Option Description

User Lists

Meter Runs

Modules

Chart

PID

System

Log Off

Displays a list of 16 parameter values. You can

define up to four lists, for a total of up to 64

parameters.

Note: Configure these values using the LCD User

List screen.

Displays values for up to four meter runs.

Note: These are read-only values. You configure

the number of valid meters on the Points tab

on the Device Information screen (ROC >

Device Information) and the meter content

itself on the Meter Setup screen (Meter >

Setup).

Displays parameter values associated with each

module installed in the FB107.

Displays historical or dynamic information in a chart

format.

Note: These are read-only values. You define the

format, scale, and content of the charts using

the LCD User List – Chart screen (Configure

> LCD User List > Chart).

Displays and permits changes to defined PID

parameters. .

Note: You must first define PID parameters on the

PID Loop screen (Configure > Control > PID

Loop).

Enables you to access and modify some general

system parameters.

Logs you off the Touchpad; redisplays the idle logos

screen.

Sections 3.3 through 3.9 discuss these options.

Issued Sep-07 Using the Touchpad 3-9

Page 32

FB107 LCD User Manual

3.3 User Lists

User lists are groups of up to 16 system parameters. You can define up to

four user lists, for a total of 64 parameters. You first define the user lists

in ROCLINK 800 and update your ROCLINK 800 configuration file.

When you next log onto the Touchpad, the User List menu option reflects

those changes. Alternately, you can log off the Touchpad and log back on

to see your changes.

To define user lists:

1. Select Configure > LCD User List > Standard on the ROCLINK

800 menu bar. The LCD User List screen displays.

2. Complete the following fields to define the contents of each user list.

3-10 Using the Touchpad Issued Sep-07

Figure 3-16. LCD User List

Field Description

List No.

Title

Sets the number of the LCD User List you want to

configure. Click d to display all defined lists. You

can define up to four user lists.

Sets a 10-character alphanumeric identifier for the

user list.

Page 33

FB107 LCD User Manual

Field Description

Scroll Time

Device

Parameter

Text

Units

Indicates the number of seconds the Touchpad

displays each parameter set before scrolling to the

next parameter set. (Typically the Touchpad

displays two parameters at a time.) Valid values

are 0 (do not scroll) to 255.

Note: If you set this value to 0, you must use the Ï

and Ð keys on the Touchpad to manually

scroll through the parameters defined in the

list.

Sets the parameter that you want to display on the

Touchpad. Click … to display a Select TLP screen

you can use to define the parameter.

Sets a 10-character alphanumeric identifier for the

parameter.

Shows the engineering units for the associated

parameter.

3. Click Apply if you make any changes to this screen. To define

additional lists, repeat step 2.

4. Click OK to close the LCD User List screen.

Once you have defined your user lists and sent the changes to the

Touchpad, you can view them on the Touchpad and, if appropriate, edit

the values.

Note: These steps assume you have successfully logged onto the

Touchpad and are starting at the Main Menu.

1. Touch User Lists on the Touchpad. The User List menu displays.

Figure 3-17. User List Menu

2. Touch the number of a User List. A parameters screen displays.

Issued Sep-07 Using the Touchpad 3-11

Page 34

FB107 LCD User Manual

Figure 3-18. User List Parameters)

3. The Touchpad automatically scrolls through the defined values in the

user list. You can touch Hold to pause the display (and restart the

scroll by pressing Scroll), or touch Ð or Ï to move more quickly

through the parameter values.

In this example, note that the value for the second parameter (Pid 1

SetPt) has a box around it. This means you can edit it. If you touch

this value, a numeric keypad screen displays.

3.4 Meter Runs

Figure 3-19. Numeric Keypad

If appropriate, use the keypad to enter a new value for the indicated

field. Touch Done to apply the edited value to the parameters

screen.The Touchpad requires your confirmation before it applies any

changes to the parameter values.

4. Touch Exit to display the User List menu.

5. Touch Exit to display the Touchpad Main Menu.

You can define up to four meter runs for the FB107. You configure the

number of valid meters on the Points tab on the Device Information

screen (ROC > Device Information) and the meter information itself on

the Meter Setup screen (Meter > Setup). Once you have defined and

configured the meter runs using ROCLINK 800, you can use the

Touchpad to view and change the information.

1. Touch Meter Runs on the Main Menu. The Meter Run menu

displays.

3-12 Using the Touchpad Issued Sep-07

Page 35

FB107 LCD User Manual

Figure 3-20. Meter Run Menu

2. Touch a meter run. An option screen displays. Note that the selected

meter displays at the bottom of the screen.

Figure 3-21. Meter Menu

Note: In this example, Well #100 is defined as using an orifice meter.

The Plate Chg option displays only for orifice meters. For turbine

meters, you see only the Values option.

3.4.1 Displaying Meter Information

Use this option to display meter information.

1. Touch Values on the Meter Run menu. The meter-specific parameters

screen displays.

2. Touch Ð or Ï to scroll through a number of meter-specific

Issued Sep-07 Using the Touchpad 3-13

Figure 3-22. Meter Parameters

parameters, including:

Differential pressure (orifice meters only)

Uncorrected flow (turbine meters only)

Page 36

FB107 LCD User Manual

3.4.2 Changing a Plate

Static pressure

Temperature

Flowrate

Energy rate

Flow today

Energy today

Alarms

3. Touch Exit to display the Meter Run menu.

Note: This option is available only for orifice meters.

Although you can also accomplish this process using the Plate Change

screen in ROCLINK 800 (Meter > Plate Change), the Touchpad

provides this function as a convenience for service technicians who may

need to change orifice plates without access to ROCLINK 800.

1. Touch Plate Chg on the Meter Run menu. The Plate Change Menu

displays.

Figure 3-23. Plate Change Menu

2. Touch the condition under which the plate change occurs.

Note: If you select Flowing, the system freezes input values for the

duration of the change to provide constant values to the flow

calculations and displays a notification screen. When you exit

this activity, the system restores the meter values.

3. The system then displays three parameter values screens.

Figure 3-24. Plate Change Parameters

3-14 Using the Touchpad Issued Sep-07

Page 37

4. Touch Exit to display the Plate Change menu screen.

5. Touch Exit to display the Meter menu.

6. Touch Exit to display the Meter Run menu.

3.5 Module Information

Use this option to view information for each module installed in the

FB107. The Modules menu shows only the modules you have installed

on your FB107. For example, Figure 3-25 shows a fully equipped FB107

with expansion plate. If your FB107 has an open module slot, the

Touchpad shows the slot number but does not include a module

identifier. If your FB107 does not have an expansion plate, the Touchpad

displays the second row (slots 4 through 7) but omits the numbers,

indicating those slots are not available.

FB107 LCD User Manual

Note: You can edit the orifice diameter value. These parameter

screens remain active for 30 minutes, after which the

Touchpad displays the idle state screen.

You can also use this menu to display information on meter runs (refer to

Section 3.5.5, Viewing Meter Information) and to diagnose alarm

conditions (refer to Section 3.5.8, Calibrating a Point).

3.5.1 Viewing I/O and Diagnostic Information

1. Touch Modules on the Main Menu. The Modules menu displays.

Figure 3-25. Modules Menu

Notes:

A blinking asterisk (*) in the upper right corner of a module box

(as in slots 0 and 3 in Figure 3-25) indicates an integrity or alarm

issue in this module. This mirrors a blinking asterisk that may

appear in the upper right corner of the Modules option on the

Main Menu.

Issued Sep-07 Using the Touchpad 3-15

The content of the Modules menu corresponds to your installed

system. The example in Figure 3-25 shows a fully loaded FB107.

Page 38

FB107 LCD User Manual

2. Touch a module. The Touchpad displays a screen showing all the I/O

points defined for that module (Figure 3-26 shows the options for the

CPU module).

Figure 3-26. Module I/O Points

Note: A blinking i, ia, or a in the upper right corner of a point box

(as in AI 2 and AO 1 in Figure 3-26) indicates an integrity or

alarm issue with this point.

3. Touch an I/O point. The Touchpad displays a series of screens

showing the parameters for that point.

Figure 3-27. I/O Point Parameters

Note: The Touchpad places a box around any parameter value you

can edit (as with AO or DO points). See Figure 3-18.

4. Review the points. To resolve an error condition (if one exists), use

ROCLINK 800 to correct the situation.

5. Touch Exit to display the Module I/O Points screen.

6. Touch Exit to display the Modules Menu screen.

3.5.2 Viewing RTD Information

Use this option to review data on the CPU module’s Resistance

Temperature Detector (RTD).

1. Touch Modules on the Main Menu. The Modules menu displays.

3-16 Using the Touchpad Issued Sep-07

Page 39

FB107 LCD User Manual

Figure 3-28. Modules Menu

2. Touch Cpu. An I/O points screen for the CPU module displays.

Figure 3-29. Module I/O Points

3. Touch RTD. A parameter screen for the RTD module displays.

Figure 3-30. RTD Parameters

4. Touch Ð or Ï to view additional RTD parameter values.

5. Touch Exit to display the Module I/O Points screen.

6. Touch Exit to display the Module menu.

3.5.3 Viewing COMM Information

Your FB107 can have up to two communications modules (RS-232 or

RS-485) which you must place in slots 1 or 2. Use this procedure to

verify the status of these modules.

1. Touch Modules on the Main Menu. The Modules menu displays.

Issued Sep-07 Using the Touchpad 3-17

Page 40

FB107 LCD User Manual

Figure 3-31. Modules Menu

2. Touch rs232 or rs485 (depending on which communications module

you have installed). A status screen displays.

Figure 3-32. Communication Status

3. Touch OK to display the Modules menu.

3.5.4 Viewing Multiple Variable Sensor (MVS) Information

The FB107 supports up to six MVS transmitters. Use this option to

review the parameters for each transmitter.

1. Touch Modules on the Main Menu. The Modules menu displays.

Figure 3-33. Modules Menu

2. Touch Mvs. The MVS menu displays.

3-18 Using the Touchpad Issued Sep-07

Page 41

FB107 LCD User Manual

Figure 3-34. MVS Menu

Note: A blinking i, ia, or a in the upper right corner of an MVS

box (as in Mvs-1 and Mvs-3 in Figure 3-34) indicates an

integrity or alarm issue with this transmitter.

3. Touch a transmitter box. A parameter screen for the MVS transmitter

displays.

Figure 3-35. MVS Parameters

4. Touch Ð or Ï to view additional parameter values.

5. Touch Exit to display the MVS menu.

6. Touch Exit to display the Modules menu.

3.5.5 Viewing Meter Information

The FB107 supports up to four meters. Use this option to view flow rate

and alarm information for each defined meter run.

1. Touch Meter on the Modules menu. The Meter Run menu displays.

Issued Sep-07 Using the Touchpad 3-19

Figure 3-36. Meter Run Menu

Page 42

FB107 LCD User Manual

3.5.6 Viewing System Information

Note: A blinking a in the upper right corner of a run box (as in

Run 2 in Figure 3-36) indicates an active alarm.

2. Touch a meter run. A parameter screen for the meter run displays.

Figure 3-37. Meter Run Parameters

3. Touch Exit to display the Meter Run menu.

4. Touch Exit to display the Modules menu.

Use the SysAI option on the Modules menu to view the following

information on the FB107’s battery, charging status, and board

temperature.

Battery Charging Board Temperature

Volts

Alarms

Low Volts

High Volts

A/D Counts

Volts

Alarms

Low Volts

High Volts

A/D Counts

Degrees

Alarms

Low Degrees

High Degrees

A/D Counts

1. Touch SysAi on the Modules menu. The System AI menu displays.

Figure 3-38. System AI Menu

2. Touch an option. A parameters screen displays.

3-20 Using the Touchpad Issued Sep-07

Page 43

FB107 LCD User Manual

Figure 3-39. System AI Parameters

3. Touch Ð or Ï to view additional parameter values.

4. Touch Exit to display the System AI menu.

5. Touch Exit to display the Modules menu.

3.5.7 Viewing Dual Variable Sensor (DVS) Information

Use the Dvs option on the Modules menu to view the following

differential or static pressure information:

Differential Pressure (DP) Static Pressure (SP)

Current Pressure

Alarms

Low Pressure

High Pressure

A/D Counts

Current Pressure

Alarms

Low Pressure

High Pressure

A/D Counts

1. Touch Dvs on the Modules menu. The DVS menu displays.

Figure 3-40. DVS Menu

Note: A blinking i, ia, or a in the upper right corner of a run box

indicates an integrity or alarm issue.

2. Touch an option. A parameters screen displays.

3. Touch Ð or Ï to view additional parameter values.

4. Touch Exit to display the DVS menu.

5. Touch Exit to display the Modules menu.

Issued Sep-07 Using the Touchpad 3-21

Page 44

FB107 LCD User Manual

3.5.8 Calibrating a Point

In the process of troubleshooting an integrity error, you might find it

necessary to calibrate or verify a point. Various screens (such as the AI

parameter screen in Figure 3-27 or the RTD parameter screen in Figure

3-41) provide Calibrate as an option.

Figure 3-41. RTD Parameters

Note: Refer to Chapter 8, Utilities, in the ROCLINK 800 Configuration

Software User Manual (for FloBoss 107) (A6217) for a complete

discussion of both calibration and verification.

Calibrate

For calibration, you define a zero point, a span, and up to three

midpoints. To calibrate a point:

1. Touch Calibrate on the parameter screen. The Touchpad displays the

Calibrate menu.

Figure 3-42. Calibrate Menu

Note: Whether you select Calibrate or Verify, ROCLINK 800

freezes the current value and displays a notification screen.

When you exit the utility, ROCLINK 800 restores the live

values.

2. Touch Calibrate. The Touchpad displays a message screen (starting

the calibration and freezing the EU value) and then displays a

parameter screen.

3-22 Using the Touchpad Issued Sep-07

Page 45

FB107 LCD User Manual

Figure 3-43. Set Zero Calibration Point

Note: You can touch the value displayed in the Tester Value field

to edit it. The FB107 continues to update the Live Value

field and calculate the deviation percentage.

3. Touch Set Zero when the displayed values are appropriate. The

Touchpad prompts you to set a span point.

Figure 3-44. Set Span Calibration Point

Note: You can touch the value displayed in the Tester Value field

to edit it. The FB107 continues to update the Live Value

field and calculate the deviation percentage.

4. Touch Set Span when the displayed values are appropriate. The

Touchpad prompts you to set the first of three calibration midpoints.

Figure 3-45. Set Midpoint 1 Calibration Point

Issued Sep-07 Using the Touchpad 3-23

Note: For calibrations, you can set up to three midpoints (the

Touchpad presents a screen on which you can set each

midpoint) or none at all by touching Done. You can also

touch Cancel at any time to cancel the calibration.

Page 46

FB107 LCD User Manual

5. When you touch Done, the Touchpad evaluates the calibration,

displays a completion message indicating whether the calibration was

successful, and displays the Calibrate menu.

6. Touch Exit to display the parameter screen from which you began the

calibration.

Figure 3-46. RTD Parameters

Verify

To verify a point:

1. Touch Verify on the Calibrate menu. The Touchpad first displays a

message screen (starting the verification and freezing the EU value)

and then displays a parameter screen.

Figure 3-47. RTD Verification Parameters

2. Touch Verify. The Touchpad displays a message and generates an

event for the event log.

3. Monitor the relationship between the live and test values, touching

3-24 Using the Touchpad Issued Sep-07

Figure 3-48. Verification Message Parameters

Verify until you have enough events to ensure verification.

Page 47

FB107 LCD User Manual

4. Touch Done. The Touchpad displays a completion message and then

displays the Calibrate menu

Figure 3-49. Verification Message Parameters

5. Touch Exit on the Calibrate menu to display the parameter screen

from which you began the calibration.

Figure 3-50. RTD Parameters

Issued Sep-07 Using the Touchpad 3-25

Page 48

FB107 LCD User Manual

3.6 Charts

Use this option to display historic or dynamic FB107 information in a

chart format. You must first use the ROCLINK 800 LCD User List –

Chart screen (Configure > LCD User List > Chart) to define up to 16

points for charting (see Figure 3-51).

Figure 3-51. LCD User List – Chart

Note: Refer to Chapter 7 in the ROCLINK 800 Configuration Software

User Manual (for FloBoss 107) (A6217) for complete instructions

on configuring this screen.

Once you have configured the points on this screen, you can view them

on the Touchpad.

Touch Chart on the Modules menu. The Chart menu displays.

Figure 3-52. Chart Menu

3-26 Using the Touchpad Issued Sep-07

Page 49

3.6.1 Viewing Historical Data

Use this option to view defined historical data points you have defined on

the LCD User List – Chart screen.

1. Touch Historic on the Chart menu. The History menu displays.

Figure 3-53. History Menu

Note: This menu enables you to view historical data either on an

hourly or daily basis. The menu options on the subsequent

screens are the same.

FB107 LCD User Manual

Upper scale

Lower scale

2. Touch Daily on the History menu. The Daily History menu displays.

Figure 3-54. Daily History Menu

3. Touch an option on the Daily History menu. A history charting screen

displays.

MM/DD at

scroll point

Value’s label

Value at current

Time at

scroll point

Issued Sep-07 Using the Touchpad 3-27

Figure 3-55. History Chart

The vertical dotted line indicates the current point on the historical

record. The arrows on the right side of the chart allow you to scroll

forward (X) or backward (W) on the historical record (up to 60 days,

Page 50

FB107 LCD User Manual

3.6.2 Viewing Dynamic Data

as defined on the ROCLINK 800 History Setup screen’s Setup tab).

Touch an arrow once to move in daily (or hourly) steps; touch and

hold an arrow to “fast scroll” through the chart.

The date for the current scroll point appears in the upper right-hand

corner of the screen. The time for the current scroll point appears in

the lower right-hand corner of the screen. The value for the current

scroll point appears in the lower middle of the screen. The label for

the value appears in the upper middle of the screen, and alternates

with the units for that label every four seconds.

4. Touch Exit to display the Daily History menu.

5. Touch Exit to display the History menu.

6. Touch Exit to display the Chart menu.

7. Touch Exit to display the Modules menu.

Use this option to view dynamic data points you have defined on the LCD

User List – Chart screen.

1. Touch Dynamic on the Chart menu. The Dynamic Data menu

displays.

Figure 3-56. Dynamic Data Menu

Note: The titles on the Dynamic Data menu items correspond to what

you have used–or entered–in the Text field on the LCD User

List – Chart screen. You can define as many as 16 Dynamic

points. The Touchpad configures each defined point as a menu

option. You can touch Ð or Ï to display additional menu

options.

2. Touch a selection on the Dynamic Data menu. A dynamic charting

screen displays.

3-28 Using the Touchpad Issued Sep-07

Page 51

FB107 LCD User Manual

Figure 3-57. Dynamic Chart

Each chart can display up to 54 most recent data values. The

Touchpad alternates the chart header (here, FLOWHR) with the EU

value (MCF), if units are available. The asterisk on the screen

indicates that you can set the upper and lower scale values for the

display.

3. Touch the asterisk to set new upper and lower scale values. The

Touchpad displays two screens, in sequence.

3.7 PID Loops

Figure 3-58. Upper and Lower Scale Ranges

4. Use each screen to enter a new upper and new lower range for the

display, if necessary. The Dynamic Chart displays.

5. Touch Exit to display the Dynamic Data menu.

6. Touch Exit to display the Chart menu.

7. Touch Exit to display the Modules menu.

This option provides two methods—basic and advanced—for displaying

and changing Proportional, Integral, and Derivative (PID) loops. You can

define up to eight PID loops on an FB107.

Note: Use the Points tab on the ROCLINK 800 Device Information

screen (ROC > Information) to define the total number of active

PID loops; use the PID Loop screen (Configure > Control > PID

Loop) to initially define the PID loops.

Issued Sep-07 Using the Touchpad 3-29

Page 52

FB107 LCD User Manual

3.7.1 Setting Basic PID Loops

To use this option, touch PID on the Main Menu. The PID menu

displays.

Figure 3-59. PID Menu

The Basic method accesses a series of parameter screens you use to

establish primary and override process variables and setpoints. The

Advanced method accesses a single graphical screen that use you perform

the same tasks.

Use this option to access a series of parameter screens to establish the

PID process variables and setpoints.

1. Touch Basic on the PID Menu. The PID Loop menu displays.

Figure 3-60. PID Loop Menu

2. Touch a PID loop on the PID Loop menu. The PID Parameters menu

displays.

3-30 Using the Touchpad Issued Sep-07

Figure 3-61. PID Parameters Menu

Page 53

FB107 LCD User Manual

Use these four options – Primary, Override, Mode, and Output – to

refine PID parameters for each defined PID loop. You can modify

individual parameters or (as in this example) proceed through each

screen in sequence.

3. Touch Primary. The Primary PID Loop Parameters screen displays.

Figure 3-62. Primary PID Loop Parameters

Use this screen to display the primary process variable and redefine

(if necessary) the primary setpoint.

4. Touch Exit to display the PID Parameters menu.

5. Touch Override. The Override Parameters screen displays.

Figure 3-63. Override PID Loop Parameters

Use this screen to display the override process variable and redefine

(if necessary) the override setpoint.

6. Touch Exit to display the PID Parameters menu.

7. Touch Mode to display the PID Mode screen.

Issued Sep-07 Using the Touchpad 3-31

Figure 3-64. PID Mode

Page 54

FB107 LCD User Manual

Use this screen to switch the PID Control mode between Automatic

and Manual.

8. Touch Exit to display the PID Parameters menu.

9. Touch Output to display the PID Output screen.

Figure 3-65. PID Output

Use this screen to review the current output for the PID loop.

10. Touch Exit to display the PID Parameters menu.

11. Touch Exit to display the PID Loop menu.

12. Touch Exit to display the PID Menu.

3.7.2 Setting Advanced PID Loops

Use this option to access a graphic display (and supporting screens) that

enables you to quickly review and adjust PID parameters.

1. Touch Advanced on the PID menu. The PID Loop menu displays.

Figure 3-66. PID Loop Menu

2. Touch a PID loop on the PID Loop menu. The graphical PID Loop

displays.

3-32 Using the Touchpad Issued Sep-07

Page 55

Loop selector

Loop control

indicator

Output bar graph

FB107 LCD User Manual

PID

Mode

indicator

PV bar

graph

Figure 3-67. Graphical PID Loop

This display provides a “dashboard” view of the selected PID loop.

The left vertical bar graph represents the output value for the PID

loop; the right bar graph represents the process variable value for the

loop. Units for each bar graph display at the top of each graph. The

upper and lower EU values for each bar graph display at the top and

bottom of the graph. This is a dynamic display: as the output or PV

values change, the graphic changes.

Touch the Output or PV vertical bar graph to access charts that

display these values.

Touch S or T to modify the output or setpoint, depending on the

PID loop’s current mode (Auto or Manual, indicated by the boxed

value in the upper right corner of the display). If the PID mode is

Manual, the buttons change the output parameter. If the PID mode is

Automatic, the buttons change the PID setpoint. Touch and release a

button to change the value by one percent; touch and hold the button

down to more quickly change the value.

To change the PID mode (from Auto to Manual or Manual to Auto),

touch and hold down the Auto/Man value for two seconds. The green

Key Acknowledgement light blinks, indicating that the value has

changed. This two-second touch prevents you from accidentally

changing the PID mode. The indicator arrow on the bar graph also

moves, indicating which value you can now change.

The upper right corner of the display indicates whether the Touchpad

is displaying information from the PID loop’s Primary or Override

control loop. Touch this field to switch between the loops. (This is an

option only if you have selected Override Control as the Control Type

on the General tab on the PID Loop screen in ROCLINK 800.) An

asterisk (*) in the upper left corner of the graphic indicates whether

the selected loop is in control.

3. Touch Exit to display the PID Loop menu.

4. Touch Exit to display the PID menu.

Issued Sep-07 Using the Touchpad 3-33

Page 56

FB107 LCD User Manual

3.8 System Information

This option enables you to view a variety of system information, adjust

system parameters, and perform common tasks.

System Information.

Saving a configuration.

Perform a warm start.

Forcing end-of-day processing.

Adjust Touchpad contrast.

To use this option, touch System on the Main Menu. The System menu

displays.

Figure 3-68. System Menu

Each of these options is discussed in detail below.

3.8.1 Displaying System Information

Use this option to display pertinent system information, including:

Time and date

ROC Name

Firmware revision

LCD revision

Device address

Device group

Contract Hour

CPU Load

1. Touch Info on the System menu. The System Parameters screen

displays.

3-34 Using the Touchpad Issued Sep-07

Page 57

Figure 3-69. System Parameters

2. Touch Ð and Ï to display various system parameters.

Note: You can change the Contract Hour parameter. Also, you can

touch the CPU Load option to display a chart of the current

CPU load.

3. Touch Exit to display the System menu.

3.8.2 Saving a Configuration

FB107 LCD User Manual

Use this option to save the currently active FB107 configuration to Flash

memory.

1. Touch Save Cfg on the System menu. The Save Configuration menu

displays.

Figure 3-70. Save Configuration Menu

2. Touch Yes. The Touchpad displays a confirmation message.

3. The Touchpad then displays the System menu.

Issued Sep-07 Using the Touchpad 3-35

Figure 3-71. Confirmation Message

Page 58

FB107 LCD User Manual

3.8.3 Performing a Warm Start

Use this option to warm start the system from the Touchpad.

1. Touch Warm Start on the System menu. The Warm Start menu

displays.

Figure 3-72. Warm Start Menu

2. Touch Yes. The Touchpad displays a confirmation message.

Figure 3-73. Confirmation Message

3. When the warm start completes, the Touchpad displays the default

idle state display.

Figure 3-74. Idle State Display

Note: After a warm start, you must log onto the Touchpad again.

3.8.4 Forcing End of Day

Use this option to force end-of-day processing from the Touchpad.

3-36 Using the Touchpad Issued Sep-07

Page 59

FB107 LCD User Manual

1. Touch End of Day from the System menu. The Force End of Day

menu displays.

Figure 3-75. Force End of Day Menu

2. Touch Yes. When the end of day processing completes, the Touchpad

displays a confirmation message.

Figure 3-76. Confirmation Message

3. The Touchpad then displays the System menu.

3.8.5 Adjusting Touchpad Contrast

Use this option to adjust the displayed brightness of the Touchpad. The

FB107 stores the contrast value in a section of Flash memory that is

protected from firmware upgrades.

1. Touch Contrast on the System menu. The Contrast Control

Parameters screen displays.

Issued Sep-07 Using the Touchpad 3-37

Figure 3-77. Contrast Control Parameters

Page 60

FB107 LCD User Manual

2. Touch S or T to increase or decrease the contrast on the Touchpad.

The current contrast value (limited between 110 and 86) displays

below the Contrast label.

Note: Above 110 the Touchpad contrast becomes too dark; below 86

the contrast is too light.

3. Touch Save to place the current contrast setting in protected Flash

memory. The Touchpad displays a confirmation message.

Figure 3-78. Confirmation Message

3.9 Logging Off

4. Touch Exit to display the System menu.

This option enables you to immediately log off the system.

Touch Log off from the Main Menu. The Touchpad immediately displays

the idle state screen.

3-38 Using the Touchpad Issued Sep-07

Page 61

Index

FB107 LCD User Manual

A

Access Levels................................................... 2-11

Adjusing Touchpad contrast.............................3-37

Advanced PID Loops........................................ 3-32

Asterisk

blinking ..................................................3-1, 3-15

B

Basic List Mode (BLM)........................................ 1-5

Basic PID Loops............................................... 3-30

Blinking asterisk......................................... 3-1, 3-15

BLM

Configuring..................................................... 2-5

BLM list

parameter text ................................................ 2-6

Parameters..................................................... 2-6

BLM list title......................................................... 2-6

BLM mode........................................................... 2-4

C

Calibration......................................................... 3-22

Changing a Plate.............................................. 3-14

Chart

Data source.................................................... 2-9

Chart mode.........................................................2-4

Chart Mode

Configuring..................................................... 2-8

Charts ............................................................... 3-26

Comm Information............................................ 3-17

Configurations, saving...................................... 3-35

Configuring BLM.................................................2-5

Configuring Chart Mode...................................... 2-8

Configuring Normal Mode................................... 2-7

Configuring the Touchpad ...........................2-1, 2-4

Configuring Touchpad Security.......................... 2-9

D

Daily Use............................................................. 3-6

Data point............................................................ 2-9

Display

BLM................................................................ 1-5

Normal............................................................ 1-5

Displaying Meter Parameters ........................... 3-13

DVS Information ............................................... 3-21

Dynamic charts.................................................3-28

Dynamic Charts .................................................. 3-3

E

End of Day Processing..................................... 3-36

F

Figures

1-1. FB107 Touchpad, Enclosure Mounted....1-2

1-2. FB107 Base Unit, Display Connection.... 1-3

1-3. FB107 Touchpad..................................... 1-4

1-4. Touchpad Idle State Display ................... 1-4

1-5. Initial Active Touchpad Displays ............. 1-5

1-6. Initial Active Touchpad Displays ............. 1-6

2-1. FB107 Graphic Display...........................2-1

2-2. Touchpad Activation................................ 2-2

2-3. LCD Controller......................................... 2-2

2-4. LCD Controller, Advanced tab ................ 2-3

2-5. Emerson Process Management Logos... 2-3

2-6. RL800 LCD User List Configuration Options

......................................................................2-4

2-7. RL800 LCD User List Configuration Options

......................................................................2-5

2-8. LCD User List - BLM ............................... 2-6

2-9. RL800 LCD User List Configuration

Options, Advanced tab................................. 2-7

2-10. Touchpad Main Menu............................2-8

2-11. LCD User List - Chart............................ 2-8

2-12. Device Security ................................... 2-10

2-13. Device Security, User Level................2-11

2-14. Device Security ................................... 2-12

3-1. Sample Menu Screens............................ 3-1

3-2. Sample Parameter Screens....................3-2

3-3. Sample Parameter .................................. 3-2

3-4. Numeric Keypad......................................3-2

3-5. Edited Parameter .................................... 3-3

3-6. Edited Parameter .................................... 3-3

3-7. Sample Dynamic Chart ........................... 3-4

3-8. Chart Scale Ranges................................3-4

3-9. Revised Scales........................................ 3-4

3-10. Idle State Display .................................. 3-6

3-11. Log On................................................... 3-6

3-12. Touched Value......................................3-7

3-13. Invalid PINMessage .............................. 3-7

3-14. Touchpad Options Map......................... 3-8

3-15. Touchpad Main Menu............................3-9

3-16. LCD User List...................................... 3-10

3-17. User List Menu....................................3-11

3-18. User List Parameters........................... 3-12

3-19. Numeric Keypad..................................3-12

3-20. Meter Run Menu..................................3-13

3-21. Meter Menu.........................................3-13

3-22. Meter Parameters................................3-13

3-23. Plate Change Menu.............................3-14

3-24. Plate Change Parameters................... 3-14

3-25. Modules Menu.....................................3-15

3-26. Modules I/O Points.............................. 3-16

3-27. I/O Point Parameters........................... 3-16

Issued Sep-07 Index I-1

Page 62

FB107 LCD User Manual

3-28. Modules Menu..................................... 3-17

3-29. Module I/O Points................................ 3-17

3-30. RTD Parameters................................. 3-17

3-31. Modules Menu..................................... 3-18

3-32. Communication Status........................ 3-18

3-33. Modules Menu..................................... 3-18

3-34. MVS Menu .......................................... 3-19

3-35. MVS Parameters................................. 3-19

3-36. Meter Run Menu ................................. 3-19

3-37. Meter Run Parameters........................ 3-20

3-38. System AI Menu.................................. 3-20

3-39. System AI Paramters.......................... 3-21

3-40. DVS Menu........................................... 3-21

3-41. RTD Parameters................................. 3-22

4-42. Calibrate Menu.................................... 3-22

3-43. Set Zerol Calibration Point..................3-23

3-44. Set Span Calibration Point.................. 3-23

3-45. Set Midpoint 1 Calibration Point.......... 3-23

3-46. RTD Parameters................................. 3-24

3-47. RTD Verification Parameters.............. 3-24

3-48. RTD Parameters................................. 3-24

3-49. RTD Parameters................................. 3-25

3-50. RTD Parameters................................. 3-25

3-51. LCD User List - Chart.......................... 3-26

3-52. Chart Menu ......................................... 3-26

3-53. History Menu.......................................3-27

3-54. Daily History Menu.............................. 3-27

3-55. History Chart....................................... 3-27

3-56. Dynamic Data Menu............................ 3-28

3-57. Dynamic Chart .................................... 3-29

3-58. Scale Ranges...................................... 3-29

3-59. PID Menu............................................ 3-30

3-60. PID Loop Menu................................... 3-30

3-61. PID Parameters Menu ........................ 3-30

3-62. Primary PID Loop Parameters............ 3-31

3-63. Override PID Loop Parameters........... 3-31

3-64. PID Mode............................................ 3-31

3-65. PID Output .......................................... 3-32

3-66. PID Loop Menu................................... 3-32

3-67. Graphical PID Loop............................. 3-33

3-68. System Menu...................................... 3-34

3-69. System Parameters............................. 3-35

3-70. Save Configuration Menu ................... 3-35

3-71. Confirmation Message........................ 3-35

3-72. Warm Start Menu................................ 3-36

3-73. Confirmation Message........................ 3-36

3-74. Idle State Display................................ 3-36

3-75. Force End of Day Menu...................... 3-37

3-76. Confirmation Message........................ 3-37

3-77. Contrast Control Parameters.............. 3-37

3-78. Confirmation Message........................ 3-38

Forcing End of Day processing ........................ 3-36

H

Hardware

Overview ........................................................ 1-1

High Scale .......................................................... 2-9

Historical charts................................................ 3-27

L

List Number....................................................... 3-10

Logging Off ....................................................... 3-38

Low Scale ........................................................... 2-9

M

Menu Map........................................................... 3-8

Menu screens ..................................................... 3-1

Meter Info

Displaying.....................................................3-13

Meter Information.............................................. 3-19

Meter Plates

Changing......................................................3-14

Meter Runs ....................................................... 3-12

Module Information...........................................3-15

MVS Information...............................................3-18

N

Normal Display Mode ......................................... 1-5

Normal Mode

Configuring..................................................... 2-7

O