Page 1

Product Bulletin

51.3:V250

November 2007

Design V250 Rotary Control Valve

The Design V250 Hi-Ball rotary control valve

(figure 1) is designed for heavy-duty throttling and

on-off applications. Depending on size, this valve

installs between two CL600 or CL900 pipeline

flanges. The Design V250 valve is available with a

single ball seal, flow ring, or dual-seal construction.

Single-seal constructions are used in tight shutoff

applications; the flow ring construction can satisfy

higher temperature requirements. The dual-seal

construction, with a seal in the inlet and outlet

openings, is used in bidirectional flow-shutoff

applications. The Design V250 Hi-Ball valve is

typically used for throttling and controlled flow

applications in gas transmission lines, gas

distribution, or liquid pipelines.

V250 Valve

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use and maintenance of any

product. Responsibility for the

selection, use, and maintenance of any

product remains with the purchaser

and end-user.

Features

High Pressure Drop Capabilities—Depending

on the construction, a Design V250 valve is capable

of a maximum static pressure differential of 103 bar

(1500 psi) at 82°C (180°F) for CL600, and 155 bar

(2250 psi) for CL900 constructions at 38°C (100°F)

for LCC steel and CF8M (316 stainless steel).

Efficient Operation—Tapered-polygon

ball-to-shaft connection (see figure 5) and clamped

splined actuator connection (see figure 6) remove

lost motion or deadband from the drive train for

throttling control applications.

W4177 / IL

Figure 1. Design V250 Valve with Type 1061 Actuator

Tight Shutoff—Shutoff with the Design V250

ball seal is 0.0001 percent of maximum capacity.

Greater Capacities—Design V250 ball valve

construction offers greater capacities than

conventional globe valves for both compressible and

incompressible fluids.

Sour Service Capability—Materials are

available for applications handling sour service.

These materials comply with the requirements of

NACE MR0175-2002.

Long Service Life—Pressure-balanced drive

shaft design with PTFE-lined bearings and

pressure-assisted shaft sealing arrangement

provides for a long life of reliable service.

Minimum Maintenance—Two-piece ball and

shaft assembly allows for complete trim overhaul;

parts replacement is kept to a minimum.

Excellent Flow Control—Reduced ball port

design provides a modified equal percentage flow

characteristic and an excellent response

characteristic.

www.Fisher.com

Excellent Environmental Capabilities—The

optional live loaded packing system is designed with

very smooth shaft surfaces and live loading to

provide excellent sealing.

D100053X012

Page 2

V250 Valve

Specifications

Product Bulletin

51.3:V250

November 2007

Available Configuration

Flangeless ball valve assembly with

flow ring, or dual ball seal

seal,

single ball

Valve Body Sizes and End Connection Styles

NPS 4 through 12 flangeless valves retained by

line flange bolts and designed to fit between

CL600 or CL900

raised-face or ring-type

joint flanges (ASME B16.5)

NPS 16 through 24 flangeless valves retained by

line flange bolts and designed to fit between

CL600

raised-face or ring-type joint flanges

(ASME B16.5)

Maximum Inlet Pressure

(1)

NPS 4 through 12 consistent with CL600 or

CL900 (ASME B16.34)

NPS 16 through 24 consistent with CL600

(ASME B16.34)

Maximum Allowable Shutoff Pressure Drop

(1,2)

Single-Seal and Dual-Seal Construction: See

figure 3.

Flow Ring Construction: Limited by the

pressure-temperature rating of the valve body

Flow Characteristic

Modified equal percentage

Flow Direction

Single Seal Construction: Forward-flow only

(see figure 4)

Flow Ring Construction: Forward- or

reverse-flow (see figure 4)

Dual Seal Construction: Required to provide

shutoff for bi-directional flow

Flow Coefficients

See the section titled Coefficients in this bulletin,

or see Catalog 12

Noise Levels

Shutoff Classification

Single-Seal and Dual-Seal Constructions:

0.0001% of maximum valve capacity (less than

1% of Class IV, ANSI/FCI 70-2 and IEC 60534-4)

Flow Ring Construction: 1% of maximum valve

capacity

Construction Materials

See table 1

Seal Material Temperature Capability

(1)

Single-Seal and Dual-Seal Construction:

–46 to 82°C (–50 to 180°F) for LCC steel and

CF8M [316 stainless steel (SST)] valve bodies

Flow Ring with Nitrile O-Rings:

(

–50 to 200°F) for LCC steel and CF8M valve

–46 to 93°C

bodies

Flow Ring with Fluorocarbon O-Rings:

to 204°C (

–50 to 400°F) for LCC steel and CF8M

–46

valve bodies

See Catalog 12 for sound pressure level

prediction

Maximum Ball Rotation

90 degrees

Actuator Mounting

Right-hand or left-hand mounted as viewed

from the valve inlet for forward-flow

Shaft and Bore Diameters

See figure 8

(continued)

2

Page 3

Product Bulletin

51.3:V250

November 2007

Specifications (continued)

V250 Valve

Approximate Weights

See table 2

Options

Line flange bolts, Sour service trim

(3)

,

seal configuration for bi-directional shutoff (this

configuration incorporates a tapped and plugged

connection which can be used in a double block

and bleed system to test seal integrity),

Live

Loaded PTFE Packing

Buried service actuator adaptation, and Dual

1. The pressure or temperature limits in this bulletin and any applicable standard or code limitations should not be exceeded.

2. The maximum allowable shutoff pressure drops are further limited for the following constructions. The NPS 12 with S20910 drive shaft is limited to 128 bar (1862 psi) from –46 to 59°C (–50

to 139°F) and to 103 bar (1490 psi) at 93°C (200°F). The NPS 16 with 17-4PH steel, with 2-1/2 inch splined driveshaft is limited to 1000 psi (69 bar), and with the S20910, 2-1/2 inch splined

drive shaft is limited to 55 bar (795 psi) at all service temperatures. The NPS 24 with S20910 drive shaft is limited to 92 bar (1336 psi) at all service temperatures.

3. See table 1 for sour service trim materials.

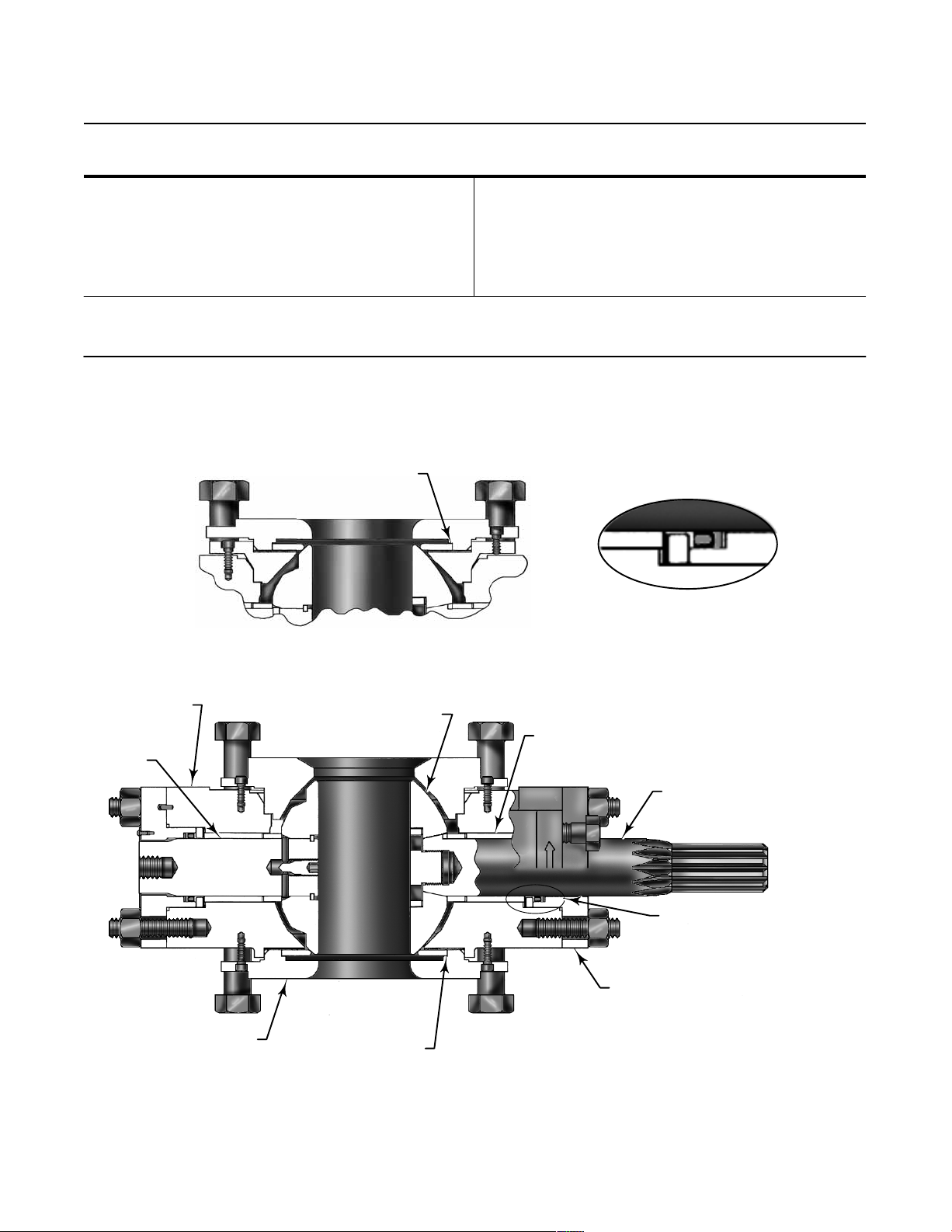

OUTLET

BALL

SEAL

W7169-1 / IL

W7170-1 / IL

OUTLET SIDE OF VALVE BODY FOR

OPTIONAL DUAL SEAL CONSTRUCTION

VIEW A

SEAL DETAIL

FOLLOWER

SHAFT

W7169-1 / IL

VALVE

BODY

SEAL PROTECTOR

RING OR FLOW RING

BALL

MAIN SHAFT

BEARING

VALVE

INLET

INLET

BALL

SEAL

Figure 2. Sectional View of Design V250 Valve

SEAL

CARRIER

DRIVE SHAFT

SEE VIEW A

3

Page 4

V250 Valve

y,

Valve Body

Body Outlet, and Seal Protector

Ball

O Rings

Seal Carrier Stud Bolts

Seal Carrier Hex Nuts

(2)

(2)

VALVE SIZE

Table 1. Construction Materials

Part Construction Material

Valve Bod

Body Outlet, and Seal Protector

Ring or Flow Ring

Drive Shaft, Follower Shaft,

and Shaft Retainer

Ball

Ball Seal All Trims POM (polyoxymethylene)

Bearings All Trims PTFE/Composition-lined S31600

O-Rings

Shaft Seal

Seal Carrier All Trims S31600 SST

Seal Carrier Stud Bolts

Seal Carrier Hex Nuts

Line Bolts

Line Nuts

1. As detailed in NACE MR0175-2002.

2. Line bolts and nuts are not included as part of the standard package. Specify line bolts and nuts as an option.

,

Standard LCC carbon steel

Sour Service Trim

Optional WCC carbon steel or S31600 [316 stainless steel (SST)]

Standard S17400 (17-4PH SST)

Sour Service Trim

Optional S20910 stainless steel

Standard Chrome-plated WCC steel

Sour Service Trim

Optional Chrome-plated S31600

Standard Nitrile

Sour Service Trim

Optional Fluorocarbon

Std. with Backup Ring PTFE R30003 / PEEK

Live Loaded Packing PTFE / SST

Standard Grade B7 steel

Sour Service Trim

Optional Grade B8M stainless steel

Standard Grade 2H steel

Sour Service Trim

Optional Grade 8M stainless steel

Standard Grade B7 steel

Sour Service Trim

Standard Grade 2H steel

Sour Service Trim

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

LCC steel, heat-treated

S17400 (17-4PH SST) H1150 DBL

Chrome-plated WCC steel, heat-treated

Fluorocarbon

Grade B7M steel

Grade 2HM steel

Grade B7M steel

Grade 2HM

Product Bulletin

51.3:V250

November 2007

Table 2. Approximate Weights

VALVE SIZE,

4

,

NPS

4 73 160

6 132 290

8 222 490

10 345 760

12 431 950

16 771 1700

20 1814 4000

24 2404 5300

Kilograms Pounds

WEIGHT

Installation

Install the Design V250 valve in any position, but the

recommended orientation is in a horizontal pipeline

with the shaft positioned horizontally and the ball

closing in the downward direction (see figure 1). The

actuator can be either right- or left-hand mounted as

viewed from the valve inlet for forward-flow. For

bidirectional flow, install the valve so that the highest

pressure condition will flow as shown by the flow

direction arrow on the valve body.

Dimensions are shown in figure 8.

Page 5

Product Bulletin

51.3:V250

November 2007

V250 Valve

O-RING

W3701-1*/IL

A4947-1 / IL

SHIM SEALS

VALVE BODY

NOTE:

DO NOT EXCEED THE LIMITS IN THIS CURVE OR THE BODY RATING, WHICHEVER IS LOWER.

Figure 3. Maximum Allowable Shutoff Pressure Drop for Single and Dual POM Seal Construction

BALL SEAL

BALL SEAL

SEAL

PROTECTOR

RING

FORWARD

FLOW

BALL

W3700-1*/IL

O-RING

VALVE BODY BALL

SHIM SEALS

FLOW RING

FLOW RING

Figure 4. Ball Seal and Flow Ring Constructions

FORWARD

FLOW

5

Page 6

V250 Valve

Product Bulletin

51.3:V250

November 2007

SPLINED END FOR

CONNECTION WITH ACTUATOR

TAPERED POLYGON END FOR

CONNECTION WITH VALVE BALL

W6029-1/IL

Figure 5. Drive Shaft for Design V250 Valve

CLAMPED SPLINED

ACTUATOR

CONNECTION

VALVE SHAFT

W2563-1*/IL

Figure 6. Clamped Splined Actuator Connection on

Type 1061 Actuator

BELLEVILLE

SPRING STACK

PACKING

BOX

BOLTING

A7193 / IL

PACKING

RINGS

Figure 7. Live Loaded PTFE Packing

6

Page 7

Product Bulletin

VALVE

51.3:V250

November 2007

Table 3. Dimensions

VALVE

SIZE,

NPS

4 194 208 197 162 76.2 279 31.8 31.8 235 46 5/8-UNC

6 229 356 238 194 101.6 327 50.8 50.8 273 51 3/4-UNC

8 243 356 327 270 152.4 413 63.5 63.5 337 76 7/8-UNC

10 297 356 343 287 187.5 445 69.9 63.5 337 76 7/8-UNC

12 338 356 381 324 228.6 483 76.2 63.5 337 76 7/8-UNC

16 400

20 533 508 546 480 371.3 864 127.0 88.9 533 127 1-1/4—8UN

24 679 508 629 546 438.2 991 152.4 88.9 533 127 1-1/4—8UN

4 7.62 8.19 7.75 6.38 3.00 11.00 1.25 1.25 9.25 1.81 5/8-UNC

6 9.00 14.00 9.38 7.62 4.00 12.88 2.00 2.00 10.75 2.00 3/4-UNC

8 9.56 14.00 12.88 10.62 6.00 16.25 2.50 2.50 13.25 3.00 7/8-UNC

10 11.69 14.00 13.50 11.31 7.38 17.50 2.75 2.50 13.25 3.00 7/8-UNC

12 13.31 14.00 15.00 12.75 9.00 19.00 3.00 2.50 13.25 3.00 7/8-UNC

16 15.75

20 21.00 20.00 21.50 18.88 14.62 34.00 5.00 3.50 21.00 5.00 1-1/4—8UN

24 26.75 20.00 24.75 21.50 17.25 39.00 6.00 3.50 21.00 5.00 1-1/4—8UN

1. Use this dimension to select compatible Fisher rotary actuators.

A D G K

470

508

18.50

20.00

460 392 292.1 613 101.6

18.12 15.44 11.50 24.12 4.00

L (BORE

DIAMETER)

R

Diameter

mm

Inches

Shaft

S

Spline

Diameter

63.5

88.9

2.50

3.50

(1)

21.00 5.00 1-1/4—8UN

V250 Valve

T U W

533 127 1-1/4—8UN

18A5915-B

18A5916-C

B1609-2

NPS 4 THROUGH 16

NPS 20 AND 24

Figure 8. Dimensions (also see table 3)

7

Page 8

V250 Valve

Valve Size

4

6

8

10

12

16

20

24

Coefficients

Table 4. Design V250

Forward or Reverse Flow

Coefficients

C

v

K

v

F

d

F

L

X

T

C

v

K

v

F

d

F

L

X

T

C

v

K

v

F

d

F

L

X

T

C

v

K

v

F

d

F

L

X

T

C

v

K

v

F

d

F

L

X

T

C

v

K

v

F

d

F

L

X

T

C

v

K

v

F

d

F

L

X

T

C

v

K

v

F

d

F

L

X

T

Valve Size,

NPS

4

6

8

10

12

16

20

24

,

10 20 30 40 50 60 70 80 90

- - - 6.74 19.0 39.9 68.9 114 182 335 499

- - - 5.83 16.4 34.5 59.6 98.6 157 290 432

- - - 0.49 0.69 0.84 0.92 0.96 0.98 1.00 1.00

0.90 0.90 0.90 0.90 0.85 0.78 0.68 0.57 0.45

- - - 0.66 0.77 0.76 0.71 0.59 0.47 0.26 0.17

- - - 15.7 42.8 76.1 130 203 308 567 855

- - - 13.6 37.0 65.8 112 176 266 490 432

- - - 0.54 0.69 0.83 0.90 0.94 0.97 .098 0.99

0.90 0.90 0.90 0.90 0.85 0.78 0.68 0.57 0.45

- - - 0.99 0.83 0.90 0.76 0.64 0.54 0.28 0.17

1.48 27.9 91.8 177 308 478 720 1220 2190

1.28 24.1 79.4 153 266 413 623 1060 1890

- - - 0.59 0.75 0.85 0.92 0.96 0.98 0.99 0.99

0.90 0.90 0.90 0.90 0.85 0.78 0.68 0.57 0.45

0.35 0.92 0.81 0.85 0.63 0.58 0.48 0.29 0.14

42.8 85.5 174 306 484 764 1150 1800 3055

37.0 74.0 151 265 419 661 995 1560 2640

- - - 0.62 0.77 0.86 0.92 0.96 0.98 0.99 1.00

0.90 0.90 0.90 0.90 0.85 0.78 0.68 0.57 0.45

0.33 0.59 0.75 0.72 0.68 0.57 0.43 0.29 0.15

40.6 122 267 499 812 1230 1870 3060 5800

35.1 106 231 432 702 1060 1620 2650 5020

0.44 0.64 0.78 0.87 0.93 0.97 0.98 0.99 1.00

0.90 0.90 0.90 0.90 0.85 0.78 0.68 0.57 0.45

0.24 0.88 0.88 0.78 0.60 0.49 0.38 0.23 0.10

68.3 203 447 813 1340 2030 3010 4630 8130

59.1 176 387 703 1160 1760 2600 4000 7030

0.43 0.66 0.79 0.87 0.93 0.97 0.98 0.99 1.00

0.90 0.90 0.90 0.90 0.85 0.78 0.68 0.57 0.45

0.46 0.71 0.87 0.83 0.66 0.51 0.42 0.27 0.13

132 330 726 1320 2180 3300 4880 7520 13,200

114 285 628 1140 1890 2850 4220 6500 11,400

0.45 0.66 0.80 0.88 0.93 0.97 0.99 1.00 1.00

0.90 0.90 0.90 0.90 0.85 0.78 0.68 0.57 0.45

0.29 0.71 0.82 0.86 0.67 0.51 0.42 0.27 0.13

183 458 1010 1830 3020 4580 6770 10,400 18,300

158 396 874 1580 2610 3960 5860 9000 15,800

0.47 0.67 0.80 0.88 0.93 0.97 0.99 1.00 1.00

0.90 0.90 0.90 0.90 0.85 0.78 0.68 0.57 0.45

0.29 0.71 0.82 0.86 0.67 0.51 0.42 0.27 0.13

Product Bulletin

51.3:V250

November 2007

Approximately Equal

Percentage Characteristic

Valve Rotation, Degrees

8

Page 9

Product Bulletin

51.3:V250

November 2007

Note

Neither Emerson, Emerson Process

Management, nor any of their affiliated

entities assumes responsibility for the

selection, use and maintenance of any

product. Responsibility for the

selection, use, and maintenance of any

product remains with the purchaser

and end-user.

V250 Valve

9

Page 10

V250 Valve

Product Bulletin

51.3:V250

November 2007

Fisher is a mark owned by Fisher Controls International LLC, a member of the Emerson Process Management business division of Emerson

Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co.

All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability.

We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use and

maintenance of any product. Responsibility for the selection, use and maintenance of any product remains with the purchaser and end-user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Cernay 68700 France

Sao Paulo 05424 Brazil

Singapore 128461

www.Fisher.com

10

Fisher Controls International LLC 1982, 2007; All Rights Reserved Printed in USA

Loading...

Loading...