Page 1

Product Bulletin

2100 and 2100E Level Switches

D200032X012

32.2:2100

February 2014

Fisherr 2100 Pneumatic and 2100E Electric

Liquid Level Switches

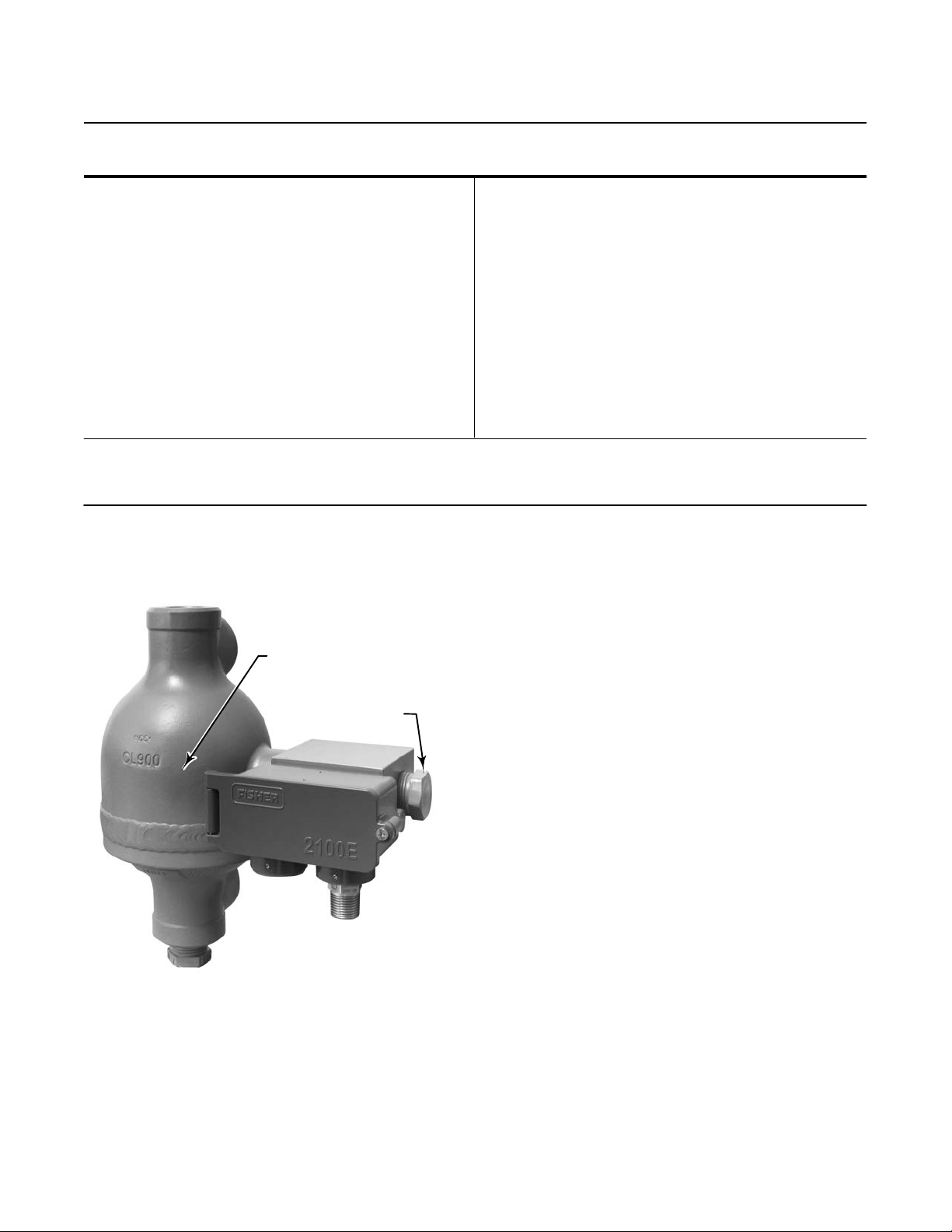

Fisher 2100 on-off pneumatic switch and 2100E

electric switch sense (shown in figure 1) high or low

liquid levels. Typically, these switches pneumatically or

electrically operate safety shutdown systems for field

processing equipment in oil and gas production

applications. 2100 and 2100E switches both use a

displacer‐style sensor located in an external cage that

mounts on the outside of a vessel.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

Features

n Proven Rugged Construction—The switch is isolated

and sealed from the process through a

corrosion‐resistant displacer and torque tube

assembly for maximum reliability. The displacer can

withstand up to 1‐1/2 times the maximum working

pressure, allowing it to remain in the cage during

hydrostatic testing.

n Sour Service Capability—Materials are available for

applications handling sour fluids and gases. These

constructions comply with the metallurgical

requirements of NACE MR0175‐2002.

Environmental restrictions may apply.

n Application Versatility—The 2100 and 2100E switch

construction comes in a left‐hand as well as a

right‐hand mounting version. The explosion‐proof,

hermetically sealed 2100E switch is offered as both

a factory mounting and as an electric switch retrofit

to the proven 2100 switch.

FISHER 2100 PNEUMATIC LIQUID LEVEL SWITCH

n Installation Versatility—The displacer cage has two

1 NPT pipe plugs that you can remove and relocate

for horizontal instead of vertical equalizing piping,

or for installation of a bleed or drain valve.

n Easy Reversibility—Switching action for both the

2100 and 2100E switches is field‐reversible from

high‐level to low‐level or vice versa without

additional parts.

www.Fisher.com

Page 2

Product Bulletin

32.2:2100

February 2014

Specifications

2100 and 2100E Level Switches

D200032X012

Input Signal

Liquid level

Minimum Process Liquid Specific Gravity

0.5 (consult your Emerson Process Management sales

office for specific gravities below this value)

Output Signal

2100: Equal to the supply pressure when the switch is

in the normal position (flapper against nozzle) and

reduced to approximately atmospheric pressure,

depending upon the bleed orifice size and the piping

configuration, when the switch is activated

2100E: Same as supply signal

Supply Signal

2100:

J 2.1 to 4.1 bar (30 to 60 psig), J 4.1 to

6.9 bar (60 to 100 psig) or

J 6.9 to 10.3 bar (100 to

150 psig)

2100E: 11 amperes, 1/4 horsepower at 125/250 volts

ac; 5 amperes resistive, 3 amperes inductive at 28

volts DC

Supply Medium (2100)

Air or Natural Gas

Steady‐State Air Consumption

Less than 0.03 normal m

(1)

(2)

(2100)

3

/hour (1.0 scfh) for all

supply pressures when the liquid level is 25.4 mm

(1 inch) below the normal switch position (flapper

against nozzle) for high‐level switching or 25.4 mm

(1 inch) above the normal switch position for

low‐level switching

Maximum Working Pressure

153 bar (2220 psig) WOG

J

(3)

(4)

except J 24 bar

(350 psig) WOG is the maximum working pressure for

sight window construction

Operative Temperature Range

(3)

2100: –29 to 204_C (–20 to 400_F)

2100E: –29 to 82_C (–20 to 180_F)

Displacer Diameter

102 mm (4 inches)

-continued -

Process Connection Size

(4)

153 bar (2220 psig) WOG

: J1 NPT internal

JDN 50 (NPS 2) Schedule 80 buttwelding ends, or

JDN 50 (NPS 2) Schedule 160 buttwelding ends

2100 Switch Supply Pressure Connection Size

1/4 NPT internal

2100E Switch Electrical Connection Size

1/2 NPT external

Hazardous Area Classification

Approvals on the electrical switch component in the

2100E, supplied by ITT NEO‐DYN are as follows:

CSA— Class I Division 1, Groups A,B,C,D

Class II Division 1, Groups E,F,G ; Dual Seal

FM— EXP - Class I Division 1 Groups A,B,C,D

DIP - Class II Division 1 Groups E,F,G

UL— Class I Division 1 Groups A,B,C,D

Class II Division 1 Groups E,F,G

ATEX— Ex d IIC

IECEx— Ex d IIC

Approvals on the complete 2100E assembly are as

follows:

Russian GOST-R—1ExdIICT4/T5/T6

Russian FSETAN

Contact your Emerson Process Management sales

office if additional information is required.

Construction Materials

Cage:

J SA216 Cast Steel (WCC) cage, J SA216 Cast

Steel (WCC) cage (NACE MR01752002) and

J SA351

316 SST (CF8M) cage

Displacer:

J S31603 solution annealed stainless steel (NACE

J S30400 stainless steel (standard)

MR0175‐2002)

Torque Rod & Tube Assembly: N05500

Bearing: Glass‐filled PTFE

O‐Rings: Fluorocarbon

Cover Gasket:

2100: Chloroprene

2100E: Silicone rubber

Other Gaskets: Silicone rubber

Nozzle Block Assembly (2100 only): Aluminum &

stainless steel

Nozzle (2100 only): Stainless steel

2

Page 3

2100 and 2100E Level Switches

D200032X012

Specifications (continued)

Product Bulletin

32.2:2100

February 2014

Construction Materials (continued)

Flapper & Clamp Assembly (2100 only): Stainless

steel

Flapper Seat (2100 only): Fluorocarbon

Magnet (2100 only): Special material

Body Block: Steel

Cover:

2100: Clear plastic

2100E: Aluminum

orifice (when it is not desired to supply several level

switches from one common block and bleed

restriction)

Sight Window Option: A sight window is available for

either the 2100 or 2100E that installs in place of the

pipe plug, as illustrated in figure 1.

NACE Option: Constructions are available which

comply with the metallurgical requirements of NACE

MR0175‐2002. Environmental restriction may apply.

Housing (2100E only): Aluminum

Other Metal Parts: Stainless steel

Options

2100 Switch Option: Individual street tee and bleed

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. Natural gas should contain no more than 20 ppm of H

2. Normal m

3. Pressure and temperature limits in this document and any applicable standards or code limitations should not be exceeded.

4. Water, Oil, Gas maximum working pressure. Corresponds to Cold Working Pressure: the maximum pressure rating allowed under normal ambient temperature conditions, which are usually

understood to be -29 to 38_C (-20 to 100_F). Refer to MSS SP‐25.

3

/‐‐normal cubic meters per hour at 0_C, 1.01325 bar, absolute (Scfh‐‐standard cubic feet per hour at 60_F, 14.7 psia)

S.

2

Figure 1. Fisher 2100E Electric Liquid Level Switch

Shipping Weights

17.2 kg (38 pounds)

Principle of Operation

Figure 2 shows the 2100 switch with the nozzle,

flapper, and magnet positioned for high level

APPROXIMATE

SWITCHING POINT

LOCATION OF

OPTIONAL

SIGHT WINDOW

activation. When the switch is in the normal position

with the flapper against the nozzle, output pressure

cannot bleed off and remains the same as full supply

pressure. Rising liquid level exerts a buoyant force on

the displacer, producing a torque on the torque tube.

When the torque transmitted by the torque tube

exceeds the torque exerted on the flapper by the

magnet, the flapper snaps away from the nozzle,

allowing output pressure to bleed through the nozzle

faster than supply pressure can enter through the

bleed orifice. The reduced pressure in the output

signal line activates the shutdown or alarm system.

When the liquid level lowers, the falling displacer

forces the flapper into the field of the magnet, letting

the magnet snap the flapper against the nozzle and

causing output pressure to build to full supply

pressure.

X0682

3

Page 4

Product Bulletin

32.2:2100

February 2014

Figure 2. Principle of Operation for High‐Level Fisher 2100 Switch

2100 and 2100E Level Switches

D200032X012

DISPLACER

FLAPPER

MAGNET

A3619‐2

TORQUE TUBE

NOZZLE

OPTIONAL

STREET TEE

Figure 3. Construction Details of Low‐Level Fisher 2100 Switch

SUPPLY

OPTIONAL

BLEED ORIFICE

SHUTDOWN

VALVE (OR ALARM

SYSTEM)

OUTPUT SIGNAL

TORQUE TUBE ASSEMBLY

CAGE

DISPLACER

O‐RINGS

GE59150

4

FLAPPER & CLAMP ASSEMBLY

FLAPPER SEAT

GASKET

NOZZLE

NOZZLE BLOCK ASSEMBLY

Page 5

2100 and 2100E Level Switches

D200032X012

Figure 4. Construction Details of Fisher 2100E Switch

CAGE

DISPLACER

Product Bulletin

32.2:2100

February 2014

TORQUE TUBE

ASSEMBLY

SWITCH ARM

40B6593

GE59290

Figure 3 shows a sectional view of the 2100 switch

positioned for low level activation. The nozzle, flapper,

and magnet are on the opposite side of the torque

tube, so that downward displacer travel moves the

flapper away from the nozzle.

With the 2100E switch (figure 4), rising liquid level

exerts a buoyant force on the torque tube that either

activates or deactivates an electrical SPDT or DPDT

switch depending on the switching action desired.

Falling liquid level deactivates or activates the same

switch depending on the action desired.

Installation

The forged‐in horizontal line on a 2100 or 2100E

displacer cage indicates the approximate switching

point. When mounted, the 2100 or 2100E switch is

positioned so that the horizontal line corresponds to

the level at which switching is desired. Isolating valves

should be installed in the equalizing piping between

the tank and the cage. Dimensions are shown in figure

5 and table 1.

ELECTRIC

SWITCH ASSEMBLY

Ordering Information

Application

When ordering, specify:

n Supply pressure (2100 switch only)

n SPDT or DPDT switch construction (2100E switch

only)

n Maximum working pressure and temperature

n Switching action for high or low level alarming

Construction

Refer to the specifications. Review the information

under each specification and in the referenced figures;

specify the desired selection whenever there is a

choice to be made. High level switching and

right‐hand mounting will be supplied automatically

unless otherwise specified. Always specify the

complete type number of the desired equipment.

5

Page 6

Product Bulletin

32.2:2100

February 2014

Figure 5. Dimensions (also see table 1)

2100 and 2100E Level Switches

D200032X012

287

(11.31

GE59300

140

(5.50)

152

(6.00)

216

(8.51)

A

1/4 NPT AIR CONNECTION

0N BACK (2100 SWITCH ONLY)

32

(1.25)

C

B

43

(1.69)

1 NPT

TAPPED & PLUGGED

38

(1.50)

102

(4.00)

211

(8.31)

1 NPT

TAPPED & PLUGGED

mm

(INCH)

Table 1. Dimensions

DIMENSIONS

TYPE

2100 127 108 103 5.00 4.25 4.06

2100E 130 57 111 5.12 2.25 4.38

mm Inches

A B C A B C

6

Page 7

2100 and 2100E Level Switches

D200032X012

Product Bulletin

32.2:2100

February 2014

7

Page 8

Product Bulletin

32.2:2100

February 2014

2100 and 2100E Level Switches

D200032X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1971, 2014 Fisher Controls International LLC. All rights reserved.

8

Loading...

Loading...