Page 1

MHM-97125-PBF-EN, Rev 0

AMS 6500 Machinery Health Monitor

A6560R Processor Module and A6510 Signal Input Module

Reference Manual

May 2017

Page 2

Copyright

©

2017 by Emerson. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written permission of Emerson.

Disclaimer

This manual is provided for informational purposes. EMERSON MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. Emerson shall not be liable for errors, omissions, or inconsistencies that may be contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material. Information in this document is

subject to change without notice and does not represent a commitment on the part of Emerson. The information in this manual is

not all-inclusive and cannot cover all unique situations.

Trademarks and Servicemarks

See http://www2.emersonprocess.com/siteadmincenter/PM Central Web Documents/marks.pdf

All other marks are property of their respective owners.

Patents

The product(s) described in this manual are covered under existing and pending patents.

Page 3

Contents

Contents

Chapter 1 Introduction ...................................................................................................................1

1.1 About this manual ........................................................................................................................1

1.2 Documentation conventions .......................................................................................................1

1.3 Technical Support and Customer Service ..................................................................................... 2

1.5 China RoHS Compliance ...............................................................................................................3

Chapter 2 Product Introduction ......................................................................................................5

2.1 AMS 6500 front view ....................................................................................................................6

2.2 System walkthrough .................................................................................................................... 7

2.3 System documentation ................................................................................................................7

Chapter 3 Sensor installation ........................................................................................................13

Chapter 4 Enclosure mounting ..................................................................................................... 15

4.1 Junction boxes ........................................................................................................................... 15

4.2 Wall mount enclosures .............................................................................................................. 18

4.3 AMS 6500 rack chassis ............................................................................................................... 19

Chapter 5 Cabling requirements ...................................................................................................25

5.1 Guidelines for conduit installation ..............................................................................................25

5.2 Online instrumentation cable .....................................................................................................26

5.3 Pull cable from the junction box to the unit ................................................................................27

5.4 Physical network segment for the unit ....................................................................................... 28

5.5 Power circuit guidelines for the unit enclosure ...........................................................................28

5.6 Recommendations for improving signal quality ......................................................................... 30

Chapter 6 Wire terminations ........................................................................................................33

6.1 Terminate instrumentation wiring ............................................................................................. 33

6.2 Terminate bundled cable ........................................................................................................... 36

6.3 Wire termination at the AMS 6500 .............................................................................................37

6.4 Signal routing from the monitoring panel to the prediction panel ..............................................43

6.5 Terminate discrete I/O ............................................................................................................... 44

6.6 Rear shield/Adapter panel—A6500-M-RSH .................................................................................46

6.7 Terminate +24 V power for the A6560 and A6510 modules ....................................................... 46

6.8 Eddy Current sensor: -24 V power supply ................................................................................... 47

6.9 SysFail relay termination ............................................................................................................ 48

6.10 Loop interconnection for 4-20 mA current ................................................................................. 48

6.11 Terminate Ethernet connection ................................................................................................. 49

6.12 Default schema for network addressing .....................................................................................50

Chapter 7 Hardware configuration ...............................................................................................53

7.1 Hardware configuration: overview ............................................................................................. 53

7.2 The A6560R and A6510 modules ............................................................................................... 54

7.3 Configure the A6560R with a terminal emulator ........................................................................ 62

Chapter 8 Software configuration ................................................................................................ 67

8.1 System overview diagram .......................................................................................................... 67

8.2 System configuration overview ..................................................................................................68

8.3 Install AMS Machinery Manager ................................................................................................. 69

MHM-97125-PBF-EN, R0 i

Page 4

Contents

8.4 Configure the FTP server to download firmware .........................................................................69

8.5 Connect the A6560R CPU to AMS Machinery Manager ...............................................................73

Chapter 9 Data collection and analysis ..........................................................................................75

9.1 Online database diagram .......................................................................................................... 75

9.2 View or edit IP addresses with the unit ....................................................................................... 77

9.3 Verify or assign a unit IP address to the Online Server in RBM Network Administration ...............78

9.4 Add a unit's IP address to the Online Server in RBM Network Administration .............................. 79

9.5 Online database configuration: overview ................................................................................... 79

9.6 Online Watch overview .............................................................................................................. 83

9.7 Archive management ................................................................................................................ 86

9.8 Create an archive manually ........................................................................................................ 87

9.9 Disable archive predicates ..........................................................................................................87

9.10 Stop transient acquisition .......................................................................................................... 88

9.11 Remove an archive from the Transient Archive Status tab ..........................................................88

9.12 Change databases when moving the AMS 2600 to a new machine .............................................89

Chapter 10 Specifications ...............................................................................................................91

10.1 AMS 6500 Machinery Health™ Monitor specifications ................................................................ 91

10.2 Environmental specifications ..................................................................................................... 92

10.3 A6560R Processor module LEDs .................................................................................................92

10.4 A6510 Signal Input module LEDs ............................................................................................... 95

Chapter 11 System calibration ....................................................................................................... 97

11.1 System calibration overview ...................................................................................................... 97

Chapter 12 Data types ..................................................................................................................101

12.1 Gross Scan analysis .................................................................................................................. 101

12.2 Spectral analysis .......................................................................................................................102

12.3 Time Waveform analysis .......................................................................................................... 103

12.4 Non-Vibration unit analysis types .............................................................................................104

12.5 Set DC offset ............................................................................................................................104

Index ................................................................................................................................................107

ii MHM-97125-PBF-EN, R0

Page 5

1 Introduction

Topics covered in this chapter:

• About this manual

• Documentation conventions

• Technical Support and Customer Service

• Disclaimer

• China RoHS Compliance

1.1 About this manual

This document covers the standard system components of the prediction system. For

some installations, non-standard components may be purchased with the online system;

for each of these components, Emerson will include an installation guide supplement. If

the product component cannot be found in the installation guide, please contact your

project manager to request an installation guide supplement.

Introduction

Other available manuals detail protection capabilities.

WARNING!

All wiring should be installed by a qualified electrician. Wiring must conform to all applicable

local codes and regulations. Local codes and regulations regarding wire type, wire size, color

codes, insulation voltage ratings, and any other standards must be followed.

1.2 Documentation conventions

The following conventions are used throughout:

Note

A note paragraph contains special comments or instructions.

CAUTION!

A caution paragraph alerts you to actions that can have a major impact on the equipment or

stored data.

WARNING!

A warning paragraph alerts you to actions that can have extremely serious consequences for

equipment and/or personnel.

MHM-97125-PBF-EN, R0 1

Page 6

Introduction

1.3 Technical Support and Customer Service

When you contact Technical Support, be ready with a screen capture of the error message

and details such as when and how the error occurred.

Hardware Technical Help

Have the number of the current version of your firmware ready when you call.

Software Technical Help

Provide the software version numbers of both your Microsoft® Windows operating system

and AMS Machinery Manager, and your AMS Machinery Manager serial number. To find

AMS Machinery Manager version and serial numbers, select Help > About.

Be at your computer when you call. We can serve you better when we can work through

the problem together.

Software Technical Support

Emerson provides technical support through the following for those with an active support

agreement:

• Telephone assistance and communication via the Internet.

• Mass updates that are released during that time.

• Interim updates upon request. Please contact Emerson Technical Support for more

information.

Customer Service

Contact Customer Service for all non-technical issues, such as ordering replacement parts.

Contact us

For Emerson Technical Support and Customer Service Toll Free numbers, email addresses,

and hours of operation, please visit

http://www2.emersonprocess.com/en-US/brands/sureservice/Pages/TechnicalSupport.aspx

1.4 Disclaimer

This manual is provided for informational purposes. EMERSON MAKES NO WARRANTY OF

ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Emerson shall not be liable for errors, omissions, or inconsistencies that may be contained

herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this material. Information in this document is subject to change

without notice and does not represent a commitment on the part of Emerson. The

information in this manual is not all-inclusive and cannot cover all unique situations.

2 MHM-97125-PBF-EN, R0

Page 7

1.5 China RoHS Compliance

Our products manufactured later than June 30, 2016 and which are sold in the People's

Republic of China are marked with one of the following two logos to indicate the

Environmental Friendly Use Period in which it can be used safely under normal operating

conditions.

Products without below mentioned marking are either manufactured before June 30 or are

non Electrical Equipment Products (EEP).

Circling arrow symbol with "e": The product contains no hazardous substances over

the Maximum Concentration Value and it has an indefinite Environmental Friendly

Use Period.

Circling arrow symbol with a number: This product contains certain hazardous

substances over the Maximum Concentration Value and it can be used safely under

normal operating conditions for the number of years indicated in the symbol. The

names and contents of hazardous substances can be found in folder "China RoHS

Compliance Certificates" on the documentation CD or DVD enclosed with the

product.

Introduction

MHM-97125-PBF-EN, R0 3

Page 8

Introduction

4 MHM-97125-PBF-EN, R0

Page 9

2 Product Introduction

Topics covered in this chapter:

• AMS 6500 front view

• System walkthrough

• System documentation

Product Introduction

MHM-97125-PBF-EN, R0 5

Page 10

Product Introduction

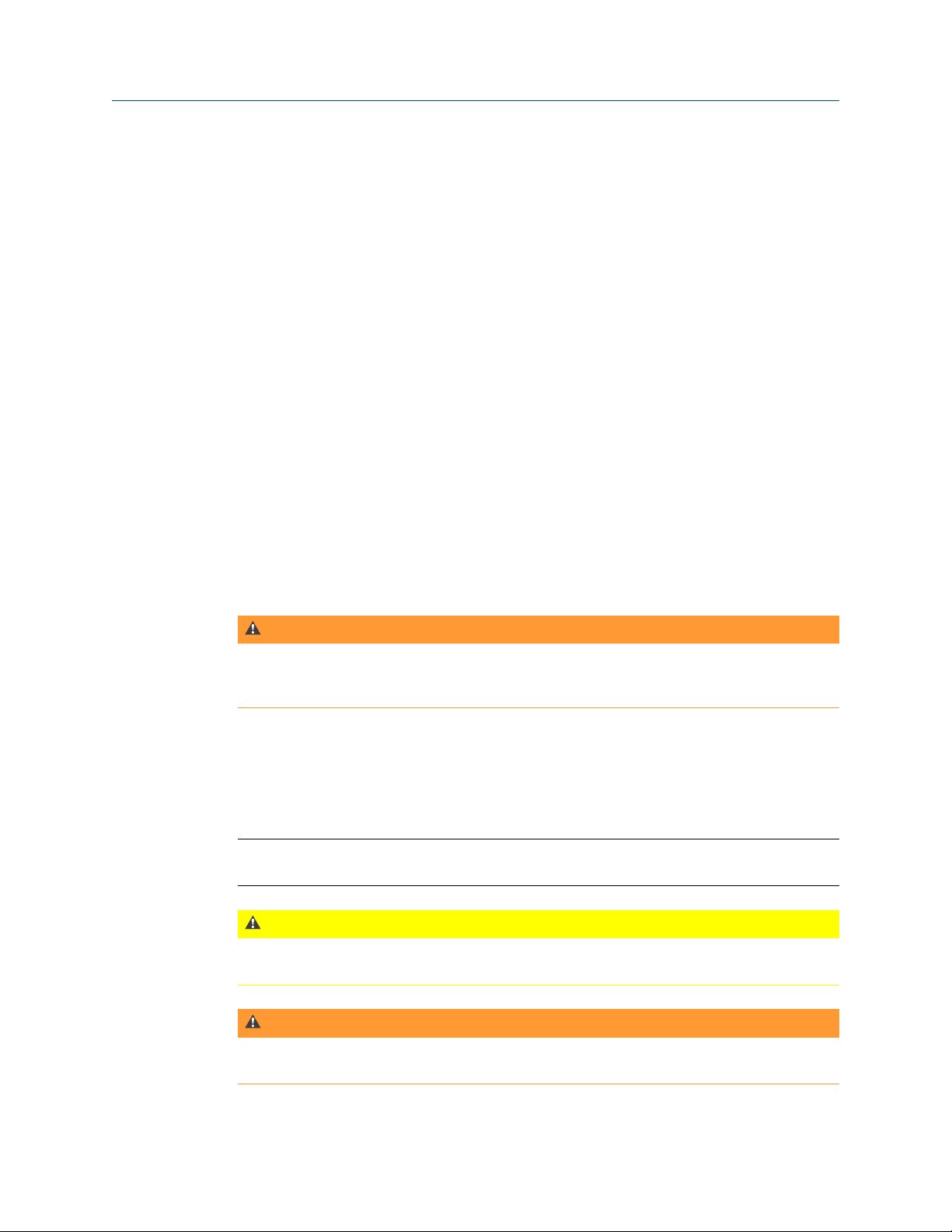

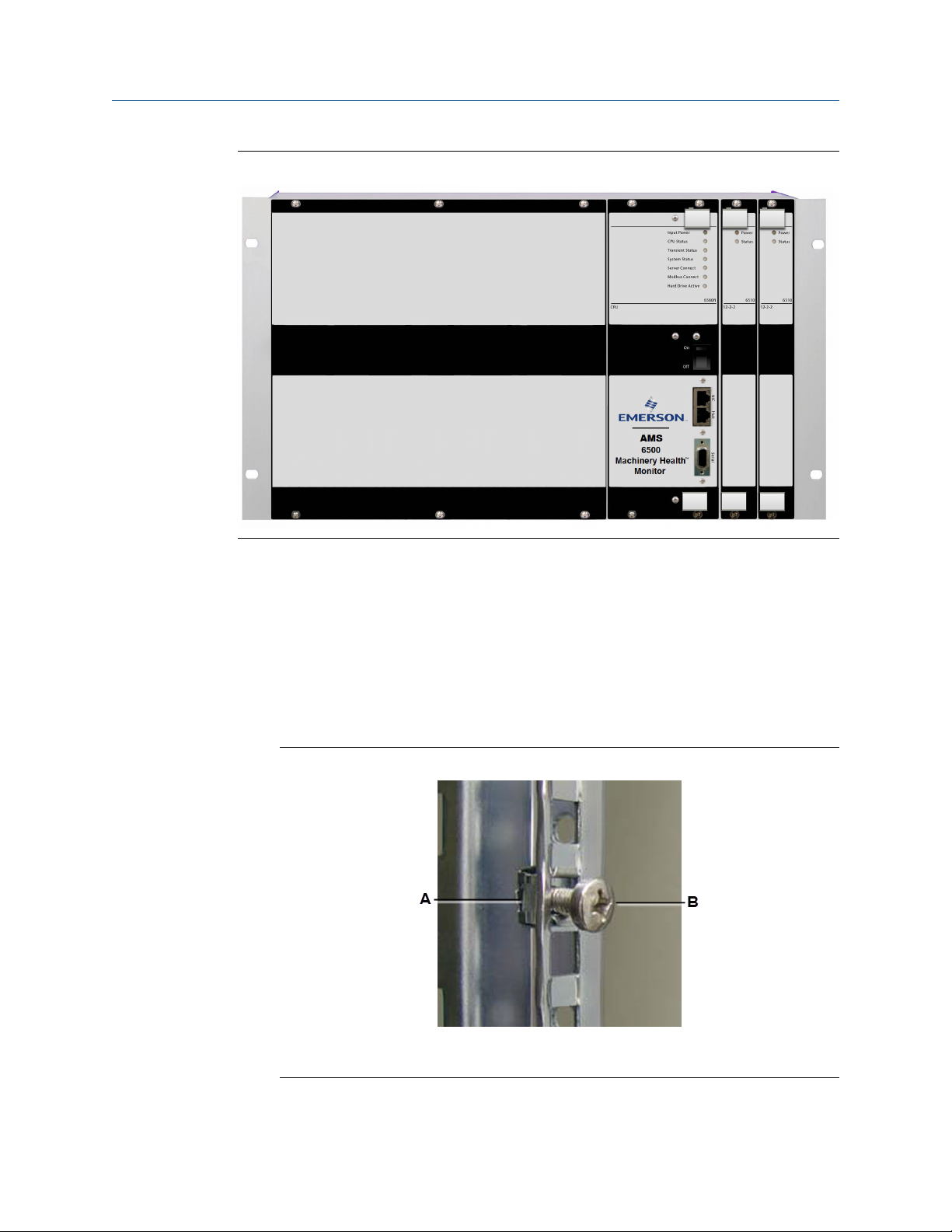

2.1 AMS 6500 front view

AMS 6500 front view with A6560R and A6510 modulesFigure 2-1:

A. Front power switch

B. A6560R Status LEDs

C. A6510 Status LEDs

D. Module name

E. 2 Ethernet ports — NIC and Hub

F. Serial port

G. Handles

6 MHM-97125-PBF-EN, R0

Page 11

2.2 System walkthrough

Perform a system component review to ensure that the proper system components have

been shipped, and that nothing has been lost or damaged during shipment. Unpack and

inspect to confirm all system components are present. After installation, physically walk

through each part of the installation to review:

Sensor mounting locations

□

Cable pulls

□

Conduit/cable tray use

□

Enclosure mounting locations

□

Environmental concerns

□

2.3 System documentation

Typical system documentation includes at least a System Overview Drawing, System

Layout Drawings, a Cable Administration Chart.

Product Introduction

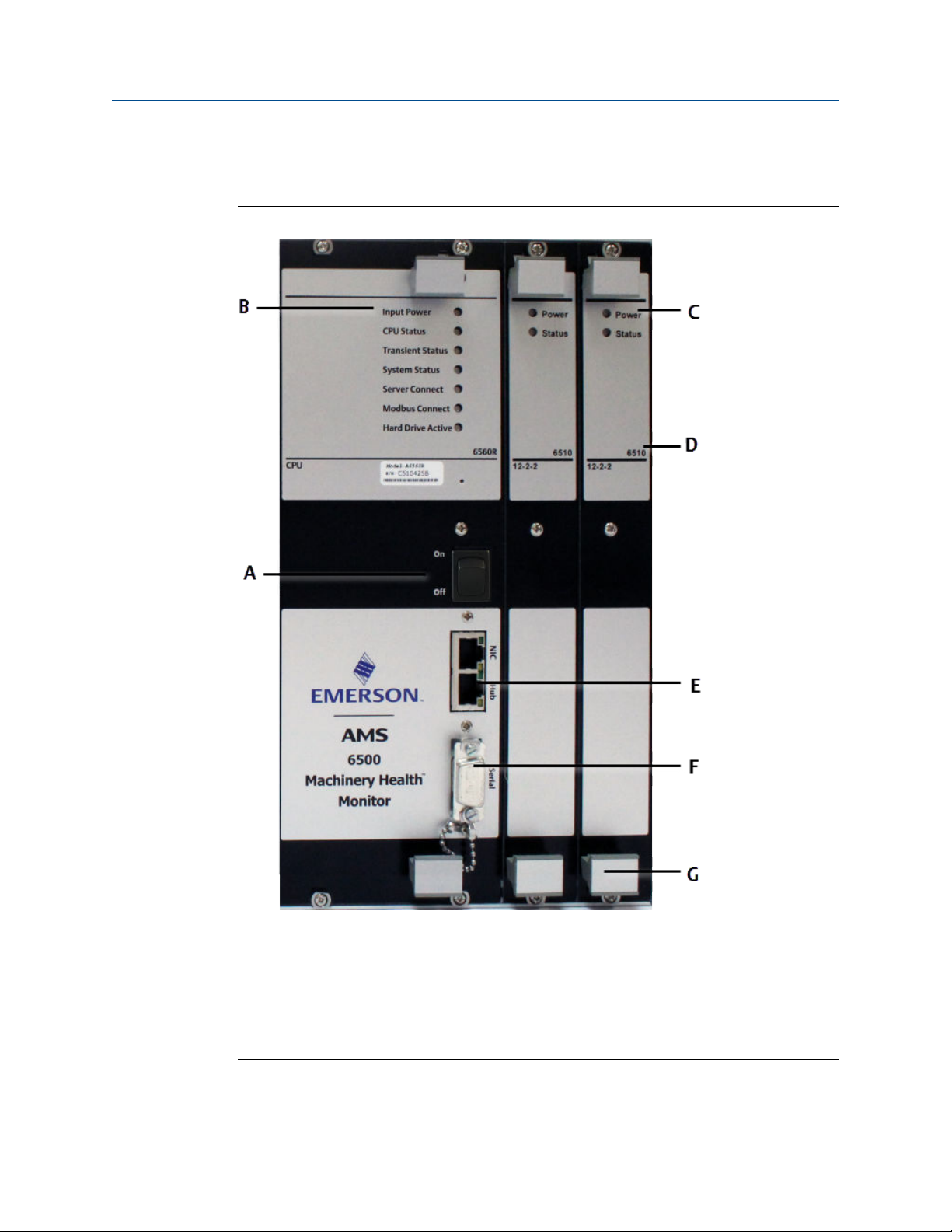

2.3.1 System overview drawings

AMS 6500 system documentation should include system overview drawings that illustrate

how system components interconnect. Create system overview drawings for your system

and update them as you make any changes to your system.

MHM-97125-PBF-EN, R0 7

Page 12

Product Introduction

Example system overview drawingFigure 2-2:

A system overview drawing typically includes the following information:

• AMS 6500 units

• Junction/switch boxes

• Cables

• AMS 6500 Network Segment Cables

• Tags for each AMS 6500, junction/switch box, and cable

2.3.2 System layout drawings

The system layout drawings illustrate exact locations for enclosure mounting, conduit

installation, cable pulls, and sensor mounting. The most common method for preparing

these drawings is to copy blueprints of the plant floor/production line and mark the system

installation locations. Use color-coded highlights and symbols to mark the different types

of cable runs and enclosure mountings.

8 MHM-97125-PBF-EN, R0

Page 13

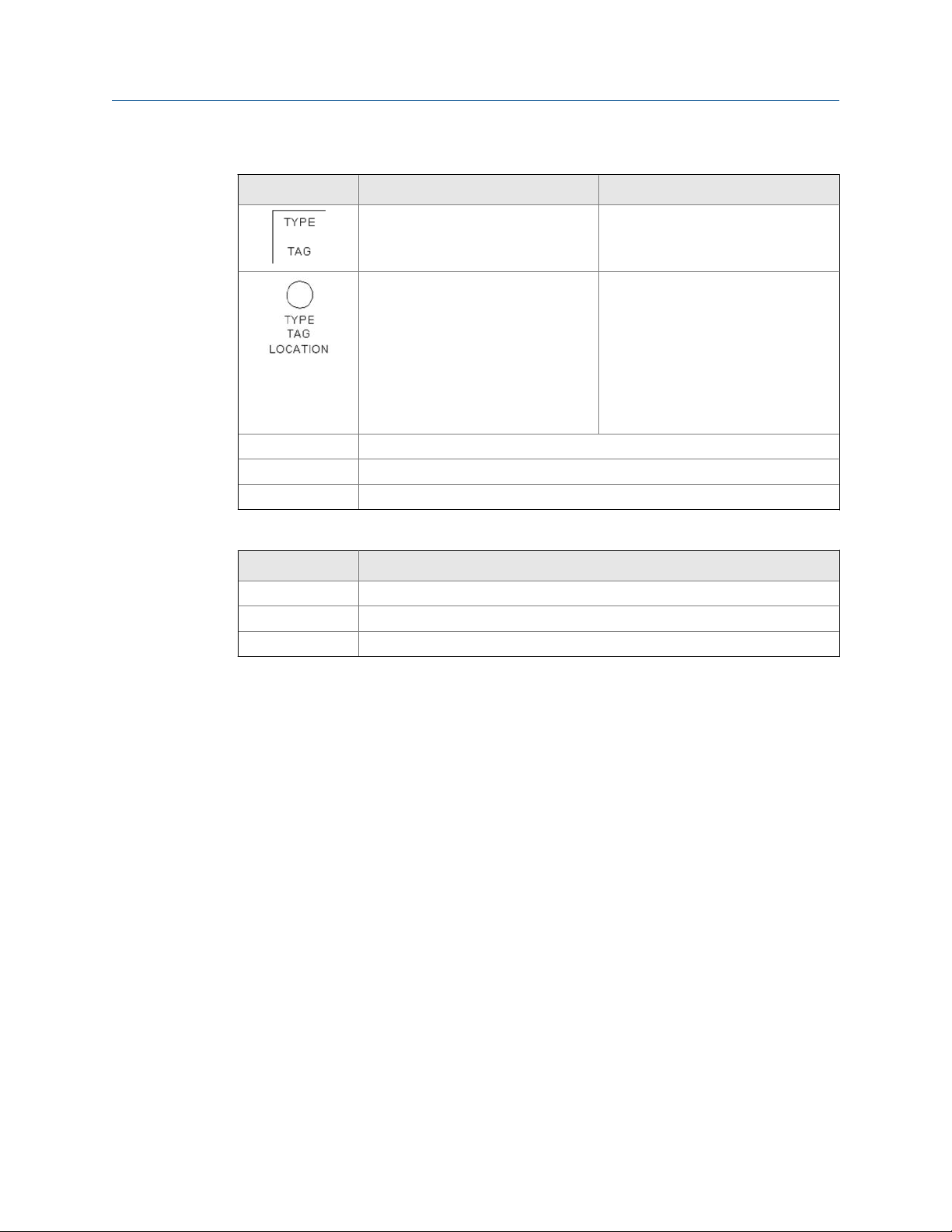

Example system layout marking guidelinesTable 2-1:

Symbol Description Labels

Enclosure Type: 701 (2,3), 745, 6500

Tag: defined by plant

Instrumentation Type: sensor part #

Tag: defined by plant

Location:

• I—Inboard

• O—Outboard

• A—Axial

• H—Horizontal

• V—Vertical

——————— Exposed cable

– – – – – – – – Cable in conduit

— - — - — - — Cable tray

Example system layout marking guidelinesTable 2-1:

Product Introduction

Color codes Cable type

Red Instrumentation

Blue Multi-pair bundled cable

Green AMS 6500 network cabling

2.3.3 Cable administration charts

Cable administration charts document wire terminations within system enclosures. Tag

names should be consistent and represent physical locations or machines. For instance,

instead of naming a sensor 23001, use a name like FAN1OV (fan number 1 outboard

vertical) to make system maintenance and troubleshooting easier. After tags are assigned,

document them in cable administration charts. All enclosures for the system need cable

administration charts.

There are two types of cable administration charts for the online system: junction box and

AMS 6500 enclosure.

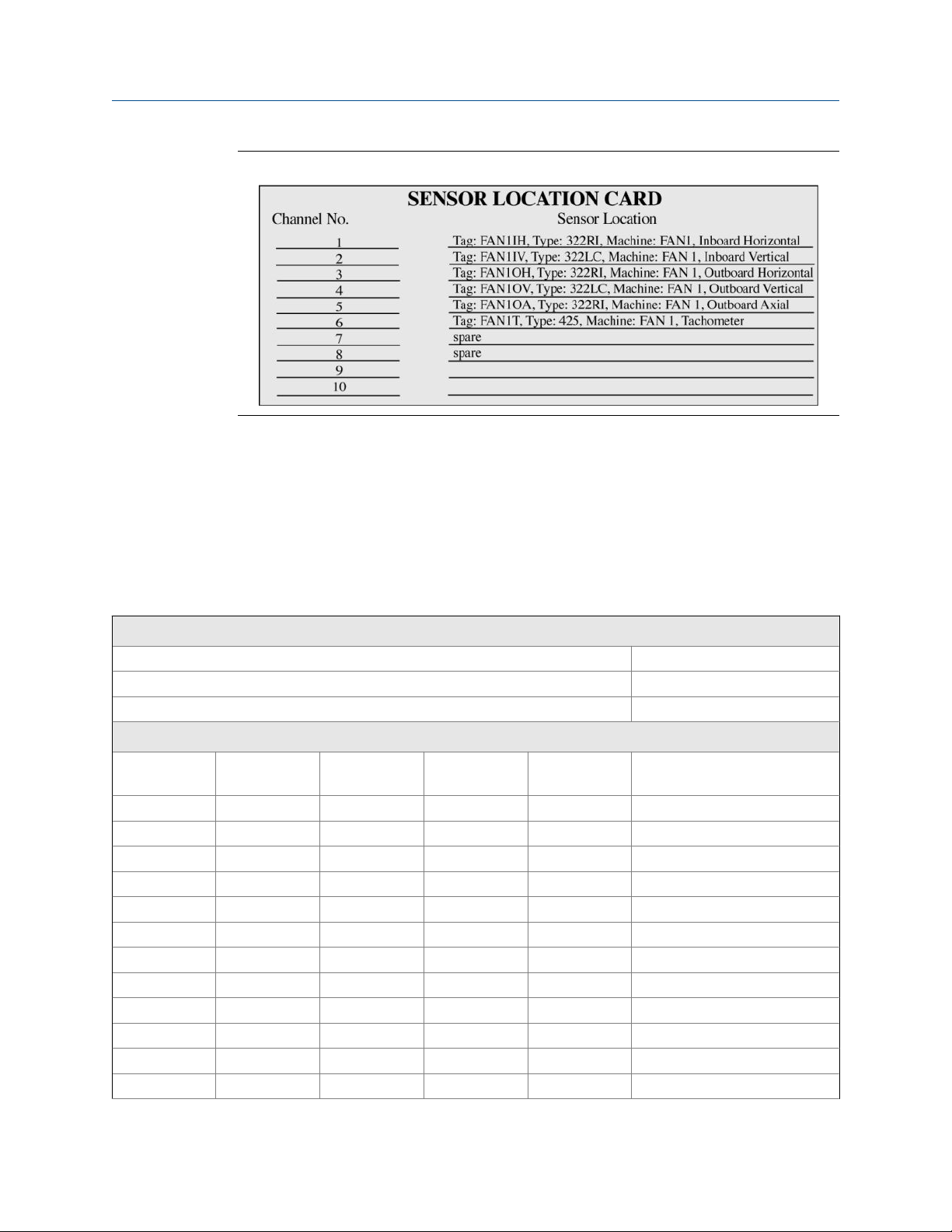

Junction box cable administration chart

The online system junction boxes provide a junction between the instrumentation cable

and the multi-pair bundled cable that is pulled back to the AMS 6500. The cable

administration chart for a junction box documents the channel number, wire tag, sensor

type, and sensor location if the wire tag does not contain location information. Figure 2-3

shows a typical installation.

MHM-97125-PBF-EN, R0 9

Page 14

Product Introduction

Junction box cable administration chartFigure 2-3:

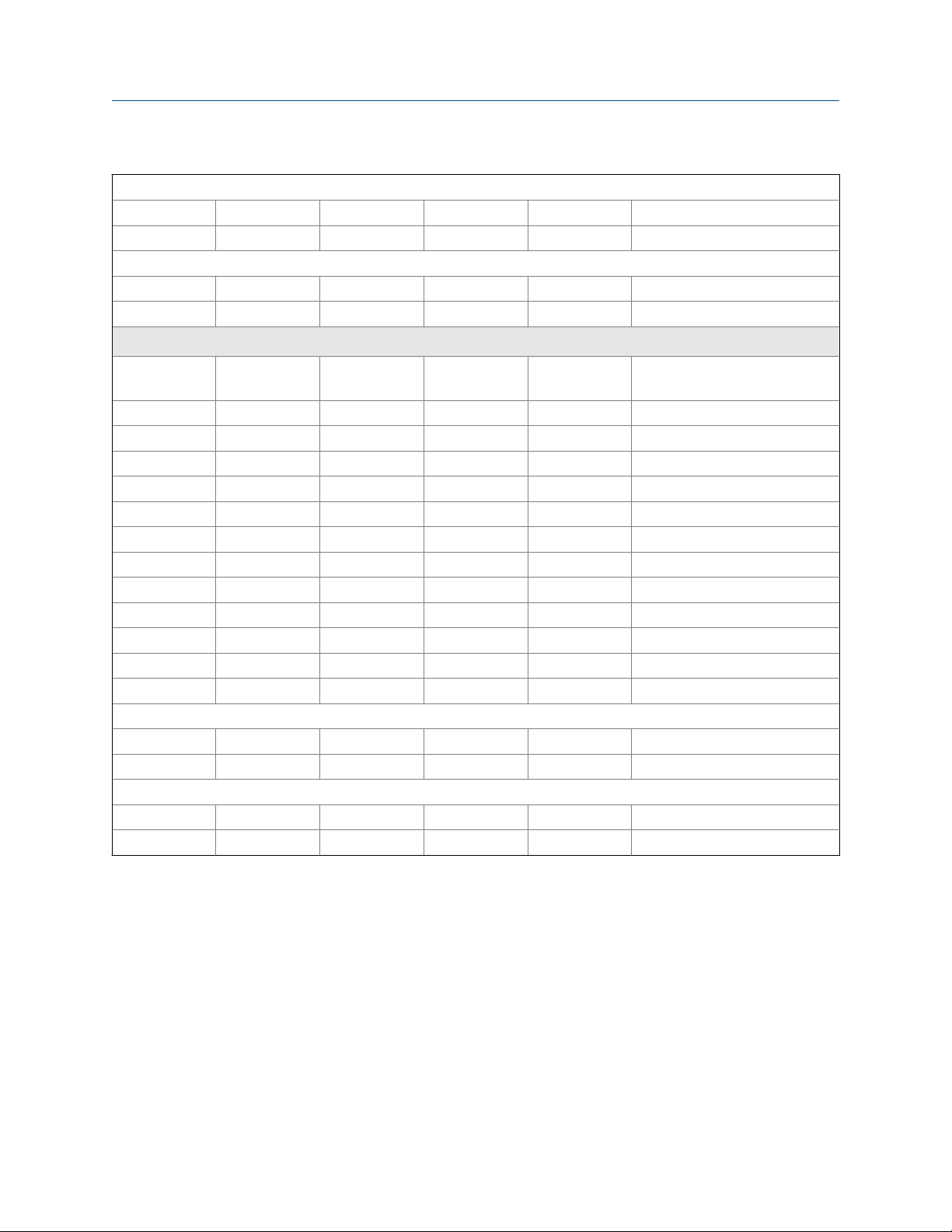

AMS 6500 enclosure cable administration chart

The AMS 6500 has cable terminations for sensors, tachometers, discrete I/O, network, and

power; it also has configurable DIP switches and jumpers.

The cable terminations and DIP switch settings should be documented in cable

administration charts or CAD drawings.

Example AMS 6500 cable administration chartTable 2-2:

Processor module

AMS 6500 tag name:

A6560R CPU module MAC address:

Network cable tag:

MSIG #1 sensor inputs

Channel # Junction box

tag

1

2

3

4

5

6

7

8

9

10

11

12

Wire tag Sensor type DIP setting Sensor location

10 MHM-97125-PBF-EN, R0

Page 15

Example AMS 6500 cable administration chart (continued)Table 2-2:

1

2

1

2

MSIG #2 sensor inputs

Channel # Junction box

tag

1

2

3

4

5

6

7

8

9

10

11

12

1

2

1

2

Product Introduction

Tachometer inputs

Discrete I/O

Wire tag Sensor type DIP setting Sensor location

Tachometer inputs

Discrete I/O

2.3.4 Documentation storage

Make copies of system overview drawings, system layout drawings, and mechanical and

electrical drawings. Keep them in the system enclosure to allow easy reference by analysts

and service personnel.

MHM-97125-PBF-EN, R0 11

Page 16

Product Introduction

12 MHM-97125-PBF-EN, R0

Page 17

3 Sensor installation

Ensure sensors are installed according to instructions provided by the sensor manufacturer

and industry best practices.

Sensor installation

MHM-97125-PBF-EN, R0 13

Page 18

Sensor installation

14 MHM-97125-PBF-EN, R0

Page 19

4 Enclosure mounting

Topics covered in this chapter:

• Junction boxes

• Wall mount enclosures

• AMS 6500 rack chassis

4.1 Junction boxes

Junction boxes are used to terminate online instrumentation wiring. Emerson

recommends junction boxes with 12 channels, housed in a fiberglass or stainless steel

enclosure. They should consist of individual, 3-lug terminal blocks mounted on a DIN rail.

4.1.1 Mount junction boxes

Enclosure mounting

1. Ensure the chosen mounting location is well lit and allows proper clearance for

maintenance access.

MHM-97125-PBF-EN, R0 15

Page 20

Enclosure mounting

Junction box access requirementsFigure 4-1:

Junction boxes require a 180° opening.

2. Prepare the mounting bracket using the outline drawing as a template for the

mounting hole locations.

3. Use the machine screws to attach the mounting feet to the back of the enclosure.

Align mounting feet vertically to ensure proper access.

Torque screws to 31 in-lb.

4. Using bolts provided by the contractor, attach the enclosure to the mounting

bracket.

4.1.2 Junction box wiring notes

CAUTION!

Never cross-connect shields from different sensors in junction boxes.

16 MHM-97125-PBF-EN, R0

Page 21

Enclosure mounting

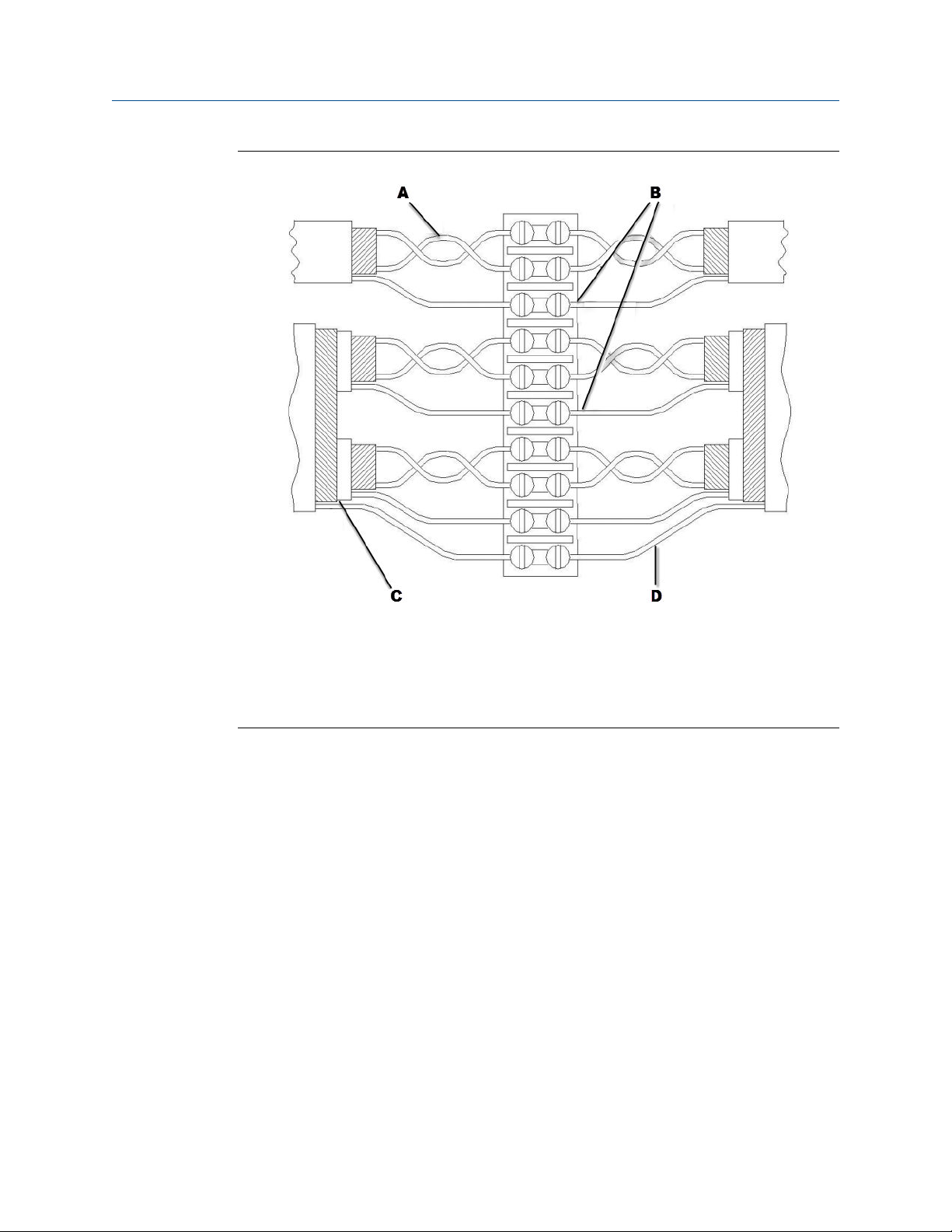

Junction box wiring notesFigure 4-2:

A. Maintain cable pair twists as close to the terminal block as possible.

B. Do not allow shield drain wires or foil from individual cables to short. Use heat shrink and dress

wire ends as necessary.

C. Strip the insulation and shield as close to the terminal block as possible.

D. Connect multiple-pair shield drain wire individually. Do not allow shield drain wires or foil from

individual cables to short. Use heat shrink and dress wire ends as necessary.

MHM-97125-PBF-EN, R0 17

Page 22

Enclosure mounting

Modifications for junction box wiringFigure 4-3:

A. Connecting the shield line to the sensor "-" conductor at the sensor end may reduce RF and static

interference. You must isolate sensor shield and "-" conductors from earth ground or the shield

connection at the 6500 side may cause ground loops.

B. Connecting a multi-pair cable overall shield to earth ground at both ends may reduce RF and static

interference. This connection may cause ground loops.

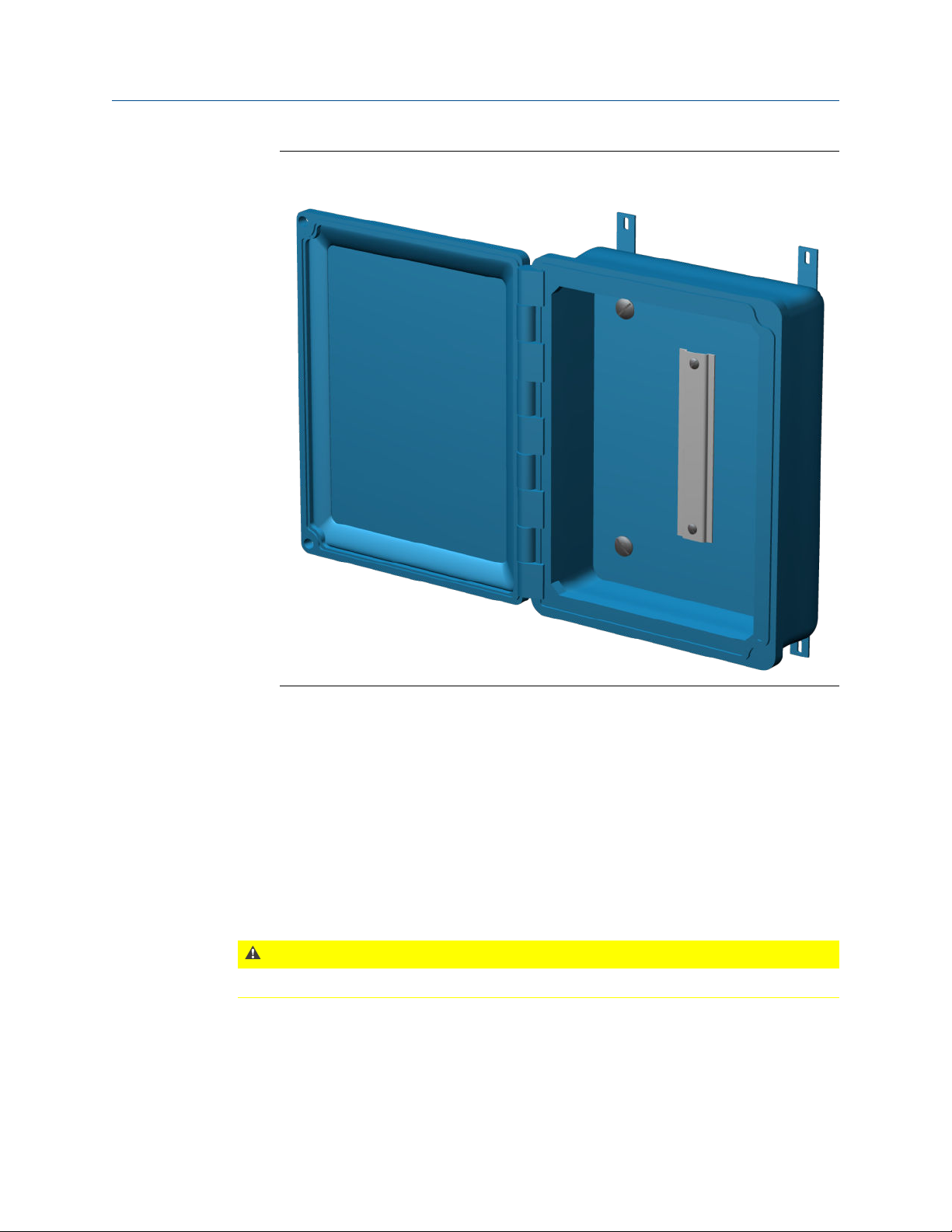

4.2 Wall mount enclosures

The prediction racks are designed to easily mount inside a standard size enclosure.

Emerson offers pre-wired wall mount enclosures for AMS 6500 prediction systems:

Wall mount cabinet System Channels Dimensions Rack size

A6500MS-24-ENCL-IC A6500MS 12 or 24 24”H x 16”W x 12”D 7.5 inch

A6500PRE-SS-WM-24-IC A6500MR 12 or 24 36”H x 24”W x 12”D 19 inch

A6500PRE-SS-WM-48-IC A6500MR 36 or 48 36”H x 24”W x 12”D 19 inch

Note

Install cabinets using guidelines provided by Emerson projects.

• Install at a reasonable height for easy access.

• All cable and conduit piercing should be through the bottom of the cabinet. See Chapter 5.

18 MHM-97125-PBF-EN, R0

Page 23

Enclosure mounting

A6500MS in a compact wall-mount enclosureFigure 4-4:

A6500MR in a full wall-mount enclosure (48 channels shown)Figure 4-5:

4.3 AMS 6500 rack chassis

To protect it from harsh industrial environments, the AMS 6500 rack chassis is either

mounted on 19 in. rack mounting rails in a cabinet enclosure with rear termination panels,

or in a stainless steel housing with a front termination panel.

Note

All AMS 6500 enclosures must be grounded to earth. Ground the enclosure through conduit or

mounting structure if it is grounded to earth. Otherwise, use a bonding wire to connect the

enclosure to earth ground.

4.3.1 Mount the rack chassis in a 19 in. cabinet enclosure

The AMS 6500 is generally installed in a cabinet enclosure with 19 in. rack mounting rails.

Mounting hardware includes four each of cage nuts, finishing washers, and screws.

MHM-97125-PBF-EN, R0 19

Page 24

Enclosure mounting

AMS 6500 for mounting in a 19 in. cabinet enclosureFigure 4-6:

Prerequisites

You need two people to lift the unit and place it on the mounting rails.

Procedure

1. Attach the cage nuts in the mounting rails.

2. Using the screws and finishing washers, fasten the system frame to the mounting

rails through the two oblong holes on each side of the frame.

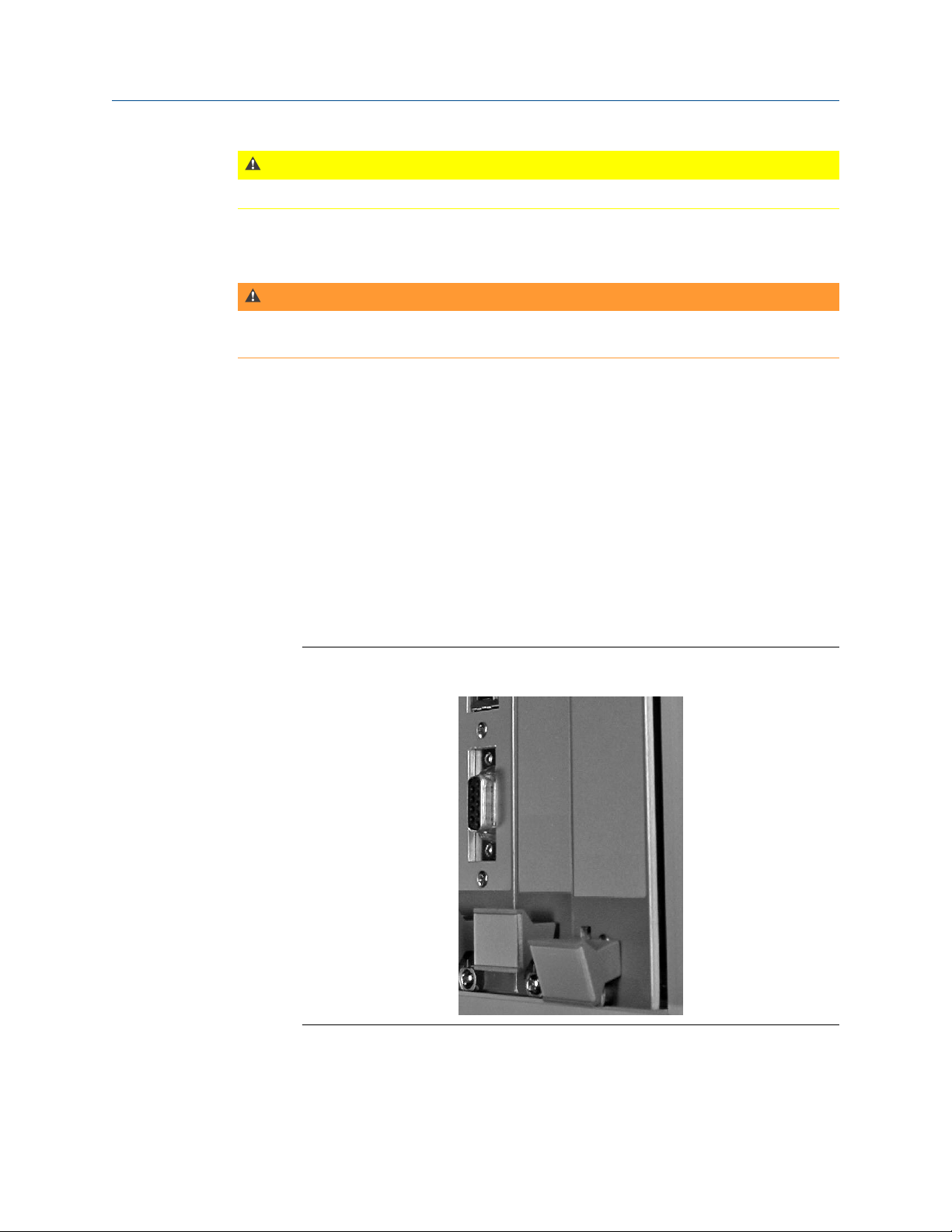

Cage nuts and screws in the mounting railsFigure 4-7:

A. Cage nut

B. Screw

20 MHM-97125-PBF-EN, R0

Page 25

Enclosure mounting

3. When mounting multiple units in one cabinet, place a cooling fan rack between

each unit to maintain the specified environmental operating conditions for all

components.

4.3.2 Mount the rack chassis in a stainless steel enclosure

Prerequisites

If you are not running conduit into a stainless steel enclosure, confirm that the mounting

location provides a path to earth ground.

Procedure

1. Ensure the mounting location allows the door to open completely and allows

enough room to run conduit into the bottom of the box.

2. Using hardened steel bolts, attach all four mounting feet to unistrut rails.

3. Torque lock washers to 50 ft-lb.

4.3.3 Cable access

As a best practice, conduit should enter from the bottom of the enclosure. Power, sensor,

and communication cables should enter through separate conduit and be routed

separately inside the enclosure.

Prepare multi-pair bundled cable pulls

1. Determine the number of pulls you need based on the size and number of channels

supported by the junction box. In general, you need one pull per 6 channels. Do not

exceed 40% conduit fill.

The multi-pair cable normally has a diameter of 0.5 in., and will require a 1.5 in.

conduit run. Two multi-pair cable pulls will require a 2 in. conduit run.

2. Make multi-pair sensor cable pulls on the bottom left so you can easily route cables

along left side of enclosure.

Prepare power cables

1. Size the conduit according to plant codes and local regulations for running power in

the plant.

2. Make the power line pull to the bottom right rear of the enclosure to route power

cable along the right rear of the enclosure.

Prepare Ethernet cables

1. The CAT5 cable requires a minimum 0.5 in. conduit run.

2. Route the CAT5 cable along the bottom right front so that it is as far as possible from

the unit's power supply.

MHM-97125-PBF-EN, R0 21

Page 26

Enclosure mounting

Prepare discrete input/output cables

AMS 6500 discrete input/output cable pulls are low voltage DC only, so they can be routed

with sensor cables or routed separately. They consist of either multi-pair bundled cable

pulls or single twisted pair cable.

Procedure

1. For multi-pair bundled cable pulls, prepare 1.5 in. conduit for one cable and 0.5 in.

extra for each additional cable.

2. Run single twisted-pair cable in conduit or pull through the enclosure using 0.25 in.

cord grips.

4.3.4 Install and remove modules

The AMS 6500 system cabinet can be configured to contain both prediction and

protection modules. In Figure 4-8, the protection modules (3U high modules) are shown on

the left; the prediction modules (6U high modules) are shown on the right.

AMS 6500 with 3U and 6U high modulesFigure 4-8:

Install or remove 3U high protection module

Install or remove protection monitor cards, relay modules, and communication modules.

Protection modules are hot-swappable and can be installed or removed while the rack is

powered. Refer to the A6500 protection cards manual for instructions.

22 MHM-97125-PBF-EN, R0

Page 27

Enclosure mounting

CAUTION!

Any work at the system may impair machine protection.

Install or remove a 6U high module

WARNING!

Turn off power before installing or removing prediction cards. Prediction cards are NOT hot

swappable.

Procedure

• Install a module:

1. Line up the guide rails and push the module into the slot until fully seated.

2. Tighten the mounting screws.

• Remove a module:

1. Loosen the mounting screws.

2. Push outward on the handles to eject the module from the backplane

connectors.

3. Pull the module out of the slot by the handle.

Install or remove a moduleFigure 4-9:

Use the handles to install or remove modules.

MHM-97125-PBF-EN, R0 23

Page 28

Enclosure mounting

24 MHM-97125-PBF-EN, R0

Page 29

5 Cabling requirements

Topics covered in this chapter:

• Guidelines for conduit installation

• Online instrumentation cable

• Pull cable from the junction box to the unit

• Physical network segment for the unit

• Power circuit guidelines for the unit enclosure

• Recommendations for improving signal quality

This chapter covers conduit installation guidelines, network cabling guidelines, power line

specifications, and pulling the online instrumentation cabling and multi-pair bundled cable

from junction boxes to the AMS 6500.

Cabling requirements

5.1 Guidelines for conduit installation

Note

All conduit must be bonded to earth ground and adhere to IEEE 1100 specifications for grounding.

• The following cables must be pulled in conduit:

- any cable between junction boxes and the unit

- any AMS 6500-dedicated network segment cables not pulled in existing plant

network infrastructure

- power cables for the unit power supplies

- any instrumentation cables that exceed 50 ft

• The conduit must be sized to not exceed a 40% fill.

• Steel conduit must be used. If plant codes will not allow steel conduit, contact the

project manager.

• Route conduit away from power trays according to the following guidelines:

Distance from power tray Voltage

6 in. 110 VAC

12 in. 220 VAC

24 in. 440 VAC

• Conduit must enter the unit enclosure and junction boxes from the bottom of

enclosures.

MHM-97125-PBF-EN, R0 25

Page 30

Cabling requirements

Proper conduit installationFigure 5-1:

5.2 Online instrumentation cable

The online instrumentation wiring is a polyurethane-jacketed, twisted-pair, shielded

instrumentation cable used to transmit millivolt level instrumentation signals to the online

system. The cable is designed to provide noise shielding and protection within harsh

industrial environments. It is pulled to the junction/switch boxes where it is joined to

bundled, multi-pair cabling routed back to the unit. Typically, the instrumentation-tojunction box pull is relatively short (<50 ft) and close to the machinery. It is not enclosed in

conduit except when conduit is required for specific applications. Secure exposed cabling

to machinery and plant infrastructure to avoid maintenance hazards and safety hazards.

5.2.1 Install online instrumentation cable

CAUTION!

If you are installing through conduit, the cable pull force should not exceed 25 lbs. Excessive

force will deform twisted-pair cable and degrade performance.

Procedure

1. If you are using the A612-NA-09-0 cable, apply a thin coating of dielectric grease to

the connector and screw into sensor housing using hand force only.

2. Label the cable on both ends using plant-approved wire labels. The wire label

designation must be the same on both ends of the cable.

26 MHM-97125-PBF-EN, R0

Page 31

Cabling requirements

3. Choose a physical path for the sensor cable pull according to the following

guidelines:

• Follow plant standards for segregating instrumentation, communication, and

power cable runs.

• Do not pull cable across machinery maintenance access areas such as guards,

shields, and access panels.

• Do not pull cable in machinery control/starting cable trays.

• Do not run any cable on the floor.

• Do not run cable near pathways where it will be exposed to damage from moving

machinery.

4. Starting at the sensor housing, use cable tie-downs to secure cable at 2 ft intervals

to machinery and plant infrastructure.

5. At junction/switch boxes, pull the cable through an existing PGME07 cord grip.

• Tighten the cord grip with 9/16 in. wrench until cable is secure. Do not

overtighten.

• Blunt cut the cable, leaving approximately 2 ft inside the box. Relabel the wire if

necessary.

• If you are using armored cable, remove the armor before pulling the cable

through the cord grip; cut the end of the armor with wire cutters and unravel the

length to remove. Use a heat shrink to seal the end of the armor.

5.3 Pull cable from the junction box to the unit

Use the cables in Section 5.3.1 to extend the online instrumentation wiring from the

junction boxes to the unit enclosure.

Procedure

1. Starting at the junction box, pull the cable through the conduit run.

2. At the unit enclosure, blunt cut the cable, leaving enough cable inside the enclosure

for routing to terminal connectors.

3. Label wire according to project specifications and place the label within 6 in. of the

cable access plate, with the label facing the front of the enclosure.

4. At the junction box, blunt cut the cable, leaving 2 ft inside the box for routing.

5.3.1 Recommendations for junction box-to-unit cables

Note

For cables with overall braided shield, ground the shield to the AMS 6500 enclosure.

MHM-97125-PBF-EN, R0 27

Page 32

Cabling requirements

Cable recommendationsTable 5-1:

Cable pull location Belden # Application Description

In steel conduit 9732 V707 / V727 9-pair, 24 AWG, individual foil shield, PVC jacket

9731 V727 / V745 12-pair, 24 AWG, individual foil shield, PVC jacket

In tray or aluminum

conduit

8168 V707 8-pair, 24 AWG, individual foil shield, PVC jacket, overall braid

shield

8175 V727 / V745 15-pair, 24 AWG, individual foil shield, PVC jacket, overall braid

shield

5.4 Physical network segment for the unit

Emerson recommends that customers run a dedicated physical network segment between

the database server and the unit, and follow these guidelines:

• Handling & Care Guidelines, per EIA/TIA 568/569.

Note

EIA/TIA 568/569 requires only CAT5 cabling, but Emerson recommends that customers run at

least CAT5e to be compatible with future upgrades.

• Pathways & Cable Trays, per EIA/TIA 569.

Note

Network cabling to the AMS 6500 should be in steel conduit.

5.5 Power circuit guidelines for the unit enclosure

The AMS 6500 is a laboratory grade instrument measuring millivolt level instrument

signals. The quality of the power provided to the unit is very important; follow specific

plant guidelines when running power to the unit enclosure.

Note

Adhere to IEEE 1100 specifications for powering and grounding electronic equipment.

Prediction side power specificationsTable 5-2:

DC

Nominal input voltage range 12 VDC – 24 VDC

Absolute input voltage range 10 VDC – 36 VDC

Maximum current draw 3.5 A

Nominal current draw 1.5 A

28 MHM-97125-PBF-EN, R0

Page 33

Cabling requirements

Prediction side power specifications (continued)Table 5-2:

DC

Minimum wire gauge 16 AWG

Cable Shielded twisted pair

AC

Nominal voltage 110 VAC to power 24 V power supply

Circuit breaker 10 A (with duplex receptacle)

Power ground Isolated (from production equipment)

5.5.1 Power and ground wiring on AMS 6500 backplane

CAUTION!

You cannot use the same 24 VDC source for both +24 VDC and -24 VDC. You must use separate

power supplies, or a power supply with separate, isolated outputs.

Power and ground wiring on AMS 6500 backplaneFigure 5-2:

A. +24 VDC

B. 24 VDC return

C. Cable shield or rack ground—use 14 AWG minimum wire size and ring type terminal lugs to ground

wires. Use 14 AWG minimum wire size for power wiring.

D. To rack ground—you must connect both backplane ground wires to the cabinet ground. You should

connect a separate ground wire to the 6500 rack chassis.

MHM-97125-PBF-EN, R0 29

Page 34

Cabling requirements

5.6 Recommendations for improving signal quality

The data collected by the AMS 6500 system can only be as good as the signals presented at

the AMS 6500 inputs. The system is capable of resolving microvolt-level dynamic signal

components. Typically, signals from accelerometers mounted on operating machinery are

millivolt level signals. Signals of a magnitude this low can easily be overwhelmed by

interference from many sources in an industrial environment.

5.6.1 Choosing a sensor cable

Emerson recommends low capacitance shielded-twisted-pair cable for all AMS 6500

system sensor inputs. This cable protects from low frequency interference such as 50

Hz–60 Hz sources due to conductor twisting, and from RF and static discharge sources due

to overall shielding. Conductor size may vary from 22–16 AWG.

Excessive cable capacitance will affect the high frequency response of accelerometer

signals. Emerson recommends low capacitance cable (<15 pF/ft) for longer cable runs,

especially for channels used for PeakVue measurements. There is evidence that braided

shield cables are more effective than foil shield cables because they reduce impedance of

the shield conductor. Consider using braided shield cable for long cable runs, electrically

noisy installations, or critical sensor channels.

Emerson does not recommend coaxial cable or other non-twisted cable types because

they have lower immunity to 50 Hz–60 Hz interference than twisted pair cable. When

using multiple-conductor cable, consider individual isolated shields for each twisted signal

pair and an overall shield isolated from all cable pair shields.

5.6.2 Routing sensor cables

Route sensor cables in grounded conduit or in cable trays reserved for low voltage control

type signals. Do not route sensor cables in conduit or in cable trays containing AC power

lines, including the unit enclosure cable entries. If low voltage sensor cables are routed in

cable trays containing AC power cables, line frequency components will likely be induced

into the sensor signals.

When electrical equipment is switched on or off, the changes in current can induce large

spikes in nearby sensor signals. Maintain a minimum of 3 ft between sensor lines and AC

power lines. Allow larger distances for higher voltage AC power lines.

Limit the distance of accelerometer, velometer, and passive magnetic tachometer cable to

500 ft. Limit the distance between the displacement sensor cable and the amplifier to

1,000 ft.

Note

When high amplitude, high frequency signals are measured, particularly for PeakVue measurements,

the maximum cable length may be much shorter unless low capacitance cable is used.

30 MHM-97125-PBF-EN, R0

Page 35

5.6.3 Routing Ethernet cables

Route Ethernet cables in grounded conduit or in cable trays reserved for low voltage

control type signals. Do not route Ethernet cables through conduit or cable trays

containing AC power lines. If ethernet cables are routed in cable trays containing AC power

cables, line frequency components will likely be induced into the ethernet cable.

5.6.4 Shield terminations

The shield termination of each shielded twisted pair cable requires a particular installation.

Some installations require the shield drain wire to be tied in only at the AMS 6500 input. If

the sensor cable shield drain wire is grounded at the sensor side, do not connect the shield

drain wire at the AMS 6500 input side. The shield connection at the AMS 6500 input is

connected directly to the AMS 6500 chassis ground. Therefore, if a grounded shield

connection has also been made at the sensor side, a noise current, typically at line

frequency, can flow in the shield conductor. This noise current flow will induce a noise

voltage into the sensor signal lines, causing a ground loop.

To reduce the effects of RF and static interferences, tie the sensor side shield to the sensor

side negative (–) conductor; isolate both the sensor side negative conductor and shield

from ground to prevent ground loops.

Cabling requirements

There is no comprehensive way to terminate cable shields. You may need to determine the

shield termination method on a sensor-by-sensor basis to correct the noise problems of a

particular installation.

5.6.5 Cable terminations

Terminate cables at the AMS 6500 system inputs. Do not strip the outer cable coverings

farther than necessary, and do not allow the exposed cable shields to touch. Cut the

shields to expose a minimum of unshielded signal conductors.

Clearly mark cables at the AMS 6500 inputs with labels indicating the sensor location.

Note

Do not cut unused shield drain wires; instead, fold back and tape unused shield drain wires. Later, it

may be necessary to make a double shield tie to reduce RF or static interference.

Tie overall shields in multiple conductor cables to earth ground at one end.

5.6.6 Junction boxes

In most installations, sensor cables are routed through junction boxes. When using a

junction box, maintain the cable +, –, and shield connections from input to output. Do not

allow exposed shield cables to touch, or connect to the local junction box earth ground.

Ground junction box enclosures to earth ground. If possible, route accelerometer cables

through junction boxes dedicated for accelerometers cables only. Do not route AC power

signals through a sensor junction box.

MHM-97125-PBF-EN, R0 31

Page 36

Cabling requirements

5.6.7 System grounding

Bolt the unit enclosure to a grounded beam or wall. Connect a ground bonding wire from

the unit enclosure to a nearby earth ground. Use a minimum 14 AWG stranded cable for

grounding.

Inside the unit enclosure, verify that grounding wires from the unit chassis, the unit power

supply, the enclosure frame, the enclosure door, and the AC power cable ground have

been installed; connect them to the main enclosure earth ground.

5.6.8 Operating temperature

The AMS 6500 system is designed to withstand moderate industrial conditions. To prevent

condensation and water leaks, seal the unit system enclosure and do not mount it in direct

sunlight.

AMS 6500 operation guidelines based on air temperature inside enclosureTable 5-3:

Air temperature Guideline

<-20°C (-4°F) The system should be enclosed and actively heated above -20°C (-4°F)

49-60°C

(120-140°F)

>60°C (140°F) Actively cool the system enclosure to keep system electronics below 60°C

Install a AMS 6500 cooling fan in the system enclosure.

(140°F).

Note

To maintain a consistent temperature for system operation, install a thermostat in system

enclosures that are being actively heated or cooled; keep temperatures between 10–38°C

(50–100°F).

CAUTION!

The AMS 6500 system has been tested to operate reliably up to 60°C (140°F), but the unit's

electronics will age more quickly than electronics maintained below 38°C (100°F).

32 MHM-97125-PBF-EN, R0

Page 37

6 Wire terminations

Topics covered in this chapter:

• Terminate instrumentation wiring

• Terminate bundled cable

• Wire termination at the AMS 6500

• Signal routing from the monitoring panel to the prediction panel

• Terminate discrete I/O

• Rear shield/Adapter panel—A6500-M-RSH

• Terminate +24 V power for the A6560 and A6510 modules

• Eddy Current sensor: -24 V power supply

• SysFail relay termination

• Loop interconnection for 4-20 mA current

• Terminate Ethernet connection

• Default schema for network addressing

Wire terminations

6.1 Terminate instrumentation wiring

Junction boxes have single twisted-pair instrumentation wire pulled through cable grips on

the left side of the box, and one or more bundled 9 twisted-pair cable pulled through a 1.5

in. conduit fitting on the right side of the box. Route cables through the box, leaving a

service loop, and terminate them to 3-lug terminal blocks or industry standard Phoenix

connectors.

MHM-97125-PBF-EN, R0 33

Page 38

Wire terminations

Junction box routingFigure 6-1:

A. Service loops

B. Permanent cable tie-downs

C. Sensor cables

D. Multi-pair cables

CAUTION!

Use correct gauge strippers on individual conductors. Do not strip more than 0.25 in. off a

conductor. Do not over-tighten. Turn terminal screw clockwise until you make contact with

the wire, then make an additional ¼ turn.

Note

Shield connections pass through junction boxes and are not grounded at the box.

Procedure

1. Starting at the cord grip, pull the wire to the top of the box on the left side. Pull the

service loop as shown in Figure 6-1.

2. Strip one inch of polyurethane jacket from the cable.

3. Carefully pull twisted-pair conductors out of the braided shield without removing

the braided shield.

34 MHM-97125-PBF-EN, R0

Page 39

Wire terminations

Prepare twisted-pair conductors for terminationFigure 6-2:

Spread braided shield apart and pull the conductors through the separation. Twist the braided

shield together before termination.

4. Strip 0.25 in. from each conductor and twist the end of the braided shield.

5. Terminate the wire into the proper terminal block according to the following:

a. Connect sensor positive input to the upper level of the terminal block.

b. Connect sensor negative input to the middle level of the terminal block.

c. Connect braided shield to the lower level of the terminal block.

A. Wire tag

B. White

C. Black

D. Shield

E. +

F. G. Shield

Make terminal connections with 24 AWG twisted-pair conductorsFigure 6-3:

6. Relabel the wire at the phoenix connector.

7. After all cables are terminated, bundle cables and secure against the side of the

junction box using a cable tie down.

MHM-97125-PBF-EN, R0 35

Page 40

Wire terminations

6.2 Terminate bundled cable

CAUTION!

Use correct gauge strippers on individual conductors. Do not strip more than 0.25 in. off a

conductor. Do not over-tighten. Turn terminal screw clockwise until you make contact with

the wire, then make an additional ¼ turn.

Procedure

1. Starting at the cord grip, strip cable jacket and braided shield off the cable.

2. Pull cable to the terminal block, using the following pair sequence:

Terminal block conductor pairsTable 6-1:

Terminal

Blocks Positive Conductor Negative Conductor Shield Drain

1 and 9 Yellow Black Black

2 and 10 Blue Black Blue

3 and 11 Brown Black Blue

4 and 12 Orange Black Blue

5 and 13 White Black Red

6 and 14 Red Black Red

7 and 15 Green Black Green

8 and 16 Red White Blue

Note

For a 16-channel box, start the sequence over on terminal block 9.

3. Pull individual twisted-pair (with foil shield in place) to the top of the box on the right

side. Pull service loop as shown in Figure 6-1.

4. Pull to the terminal block and blunt cut any extra wire.

5. Remove one inch of foil shield from twisted-pair and seal the foil shield using heat

shrink or electrical tape.

6. Strip 0.25 in. from each conductor and terminate to the terminal block as follows:

a. Positive Conductor on the upper level of the terminal block

b. Negative Conductor on the middle level of the terminal block

c. Shield Drain on the lower level of the terminal block

36 MHM-97125-PBF-EN, R0

Page 41

Prepare individual twisted pair cable for terminationFigure 6-4:

Measurements are not to scale.

Foil shield requires wire tag or heat shrink to prevent unraveling.

A. Foil shield

B. 24 AWG

C. Shield drain

6.3 Wire termination at the AMS 6500

Wire terminations

AMS 6500 sensor cables terminate in three different ways:

1. Directly into the 12-2-2 modules at a A6500-M-RTRM rear termination panel.

2. At the inputs on the A6500-P-RTRM termination panel. Buffered outputs can then

be routed to the 12-2-2 modules with DIP switches.

3. At DIN rail-mounted terminal blocks inside the cabinet/enclosure, then connected

to prediction modules or protection module inputs with additional short wiring

runs.

6.3.1 Rear termination panel

The rear termination panel plugs directly onto the backplane. This termination panel has

connectors for sensor inputs, tachometer inputs, and discrete input/output relays into the

12-2-2 modules. All these connections are available through BNC connectors on the rear of

the AMS 2600.

MHM-97125-PBF-EN, R0 37

Page 42

Wire terminations

A6500-M-RTRMFigure 6-5:

A6500-M-RTRMTable 6-2:

Termination panel

A

Sensor inputs: MSIG1 (Ch1–12)

B

Sensor inputs: MSIG2 (Ch13–24)

C

D

E

F

Tach inputs

Tach inputs

Relay I/O

Relay I/O

(1)

: MSIG1 (Ch1–2)

(1)

: MSIG2 (Ch 3–4)

(1)

: MSIG1 (I/O 1–2)

(1)

: MSIG2 (I/O 3–4)

38 MHM-97125-PBF-EN, R0

Page 43

Wire terminations

A6500-M-RTRM (continued)Table 6-2:

Termination panel

G DIP switches for routing buffered sensor/tach inputs from the A6500-P-RTRM side of the

rack

H DIP switches for configuring sensor power On or Off

(SW1, SW2, SW3, SW5, SW6, and SW7)

I Calibration test signal output port

(SMB connector)

J -24 V sensor power input for eddy current sensors

(1) For Tach and Relay channels, leave the sensor power DIP switches in the OFF position.

(2) SW4 and SW8 correspond to tach and relay channels, and are not used.

(2)

A6500-M-BP backplane componentsTable 6-3:

Backplane

K SysFail relay connector

L DC Power input connector for Prediction Side

M HUB network connector

N Chassis Ground lug

O NIC network connector

P Power On LED

Q +24 V Input LED

R Status LED

6.3.2 Terminate bundled cable instrumentation wiring

CAUTION!

Use correct gauge strippers on individual conductors. Do not strip more than 0.25 in. off a

conductor. Do not over-tighten. Turn terminal screw clockwise until you make contact with

the wire, then make an additional ¼ turn.

Each signal input channel has an associated DIP switch for connecting accelerometer

power. For accelerometer channels that require power, set the associated DIP switch to

the ON position. For sensor channels that do not require power from the unit, set the

associated DIP switch to the OFF position.

Procedure

1. Pull cable to the terminal blocks.

2. Secure the cable to the side of the enclosure with a cable tie down.

MHM-97125-PBF-EN, R0 39

Page 44

Wire terminations

3. Blunt cut any excess wire. Strip the cable jacket beginning where it first reaches the

terminal blocks.

4. Pull individual pairs down to the proper channel inputs on the terminal blocks.

5. Remove 1 in. of foil shield and place a wire label around the end of the foil shield.

Wire label must match the sensor wire label in the junction box.

6. Strip 0.25 in. from each conductor and terminate to the screw terminals following

the pinouts in Section 6.3.3.

7. Document the sensor name, wire label name, and unit channel number on the cable

administration chart.

Signal, Tachometer, and I/O module wiring notes

Signal, Tachometer, and I/O module wiring notesFigure 6-6:

A. Strip the insulation and shield as close to the terminal block as possible.

B. Maintain cable pair twists as close to the terminal block as possible.

C. Connect the cable shield on only one end. Prioritize connecting the shield on the sensor end.

D. Connect the multiple-pair cable shield drain wire to earth ground on only one end.

E. Do not allow shield drain wires or foil from individual cables to short. Use heat shrink and dress

wire ends as necessary.

6.3.3 Terminal descriptors

Each channel has five terminals. The first two are for the plus (+) and minus (-) signal

inputs. If the associated DIP switch is set to ON, these terminals will also supply +24 V

constant current accelerometer power.

40 MHM-97125-PBF-EN, R0

Page 45

Wire terminations

The second two are for the -24 V power supply for eddy current probes. These terminals

only supply power if an external -24 V power supply is connected to the J19 power input

terminal at the edge of the termination panel.

The last terminal for each channel is a chassis ground for connecting the sensor cable

shield.

MHM-97125-PBF-EN, R0 41

Page 46

Wire terminations

Terminal descriptors for MSIG 1Table 6-4:

J1 J2 J3 J4

SIG+1/+24 V

SIG-1/+24 V return SIG-5/+24 V return SIG-9/+24 V return Tach-1

CH1

-24 V -24 V -24 V -24 V

Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return)

Chassis GND (Shield) Chassis GND (Shield) Chassis GND (Shield) Chassis GND (Shield)

SIG+2/+24 V

SIG-2/+24 V return SIG-6/+24 V return SIG-10/+24 V return Tach-2

CH2

-24 V -24 V -24 V -24 V

Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return)

Chassis GND (Shield) Chassis GND (Shield) Chassis GND (Shield) Chassis GND (Shield)

SIG+3/+24 V

SIG-3/+24 V return SIG-7/+24 V return SIG-11/+24 V return I/O-1

CH3

-24 V -24 V -24 V -24 V

Gnd (-24 V return

(1)

) Gnd (-24 V return

Shield Shield Shield Shield

SIG+4/+24 V

SIG-4/+24 V return SIG-8/+24 V return SIG-12/+24 V return I/O-2

CH4

-24 V -24 V -24 V -24 V

Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return)

Chassis GND (Shield) Chassis GND (Shield) Chassis GND (Shield) Chassis GND (Shield)

CH5

CH6

CH7

CH8

SIG+5/+24 V

SIG+6/+24 V

SIG+7/+24 V

SIG+8/+24 V

SIG+9/+24 V

CH9

SIG+10/+24 V

CH10

SIG+11/+24 V

CH11

(1)

) Gnd (-24 V return

SIG+12/+24 V

CH12

Tach+1

TACH1

Tach+2

TACH2

I/O+1

I/O1

(1)

) Gnd (-24 V return

I/O+2

I/O2

(1)

)

(1) -24 V terminals on I/O channels are not used for I/O connections.

42 MHM-97125-PBF-EN, R0

Page 47

Terminal descriptors for MSIG 2Table 6-5:

J5 J6 J7 J8

SIG+13/+24 V

SIG-13/+24 V return SIG-17/+24 V return SIG-21/+24 V return Tach-3

CH13

-24 V -24 V -24 V -24 V

Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return)

Shield Shield Shield Shield

SIG+14/+24 V

SIG-14/+24 V return SIG-18/+24 V return SIG-22/+24 V return Tach-4

CH14

-24 V -24 V -24 V -24 V

Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return)

Shield Shield Shield Shield

SIG+15/+24 V

SIG-15/+24 V return SIG-19/+24 V return SIG-23/+24 V return I/O-3

CH15

-24 V -24 V -24 V -24 V

Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return)

Shield Shield Shield Shield

SIG+16/+24 V

SIG-16/+24 V return SIG-20/+24 V return SIG-24/+24 V return I/O-4

CH16

-24 V -24 V -24 V -24 V

Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return) Gnd (-24 V return)

Shield Shield Shield Shield

CH17

CH18

CH19

CH20

SIG+17/+24 V

SIG+18/+24 V

SIG+19/+24 V

SIG+20/+24 V

CH21

CH22

CH23

CH24

SIG+21/+24 V

SIG+22/+24 V

SIG+23/+24 V

SIG+24/+24 V

Tach+3

TACH3

Tach+4

TACH4

I/O+3

I/O3

I/O+4

I/O4

Wire terminations

6.4 Signal routing from the monitoring panel to the prediction panel

You can set DIP switches on the A6500-M-RTRM termination panel to route sensor and

tachometer signals from the A6500-P-RTRM termination panel. Set these switches to the

ON position to connect to their respective A6500-P-RTRM buffered outputs. See

Rear termination panel for DIP switch locations.

The external input connectors on the A6500-M-RTRM are connected to the 12-2-2 module

signal inputs, regardless of whether the DIP switches are set to ON or OFF. Therefore, if a

DIP switch is set to route an input from the A6500-P-RTRM, do not connect an external

sensor to the associated external input of the A6500-M-RTRM. Set the DIP switches for

accelerometer power to OFF while routing inputs from the A6500-P-RTRM.

MHM-97125-PBF-EN, R0 43

Page 48

Wire terminations

6.4.1 Signal input cross reference

AMS 6500 rear termination panel with signal input cross referencesFigure 6-7:

A6500-M-RTRM signal inputsTable 6-6:

A6500-M-RTRM inputs Output Connector label

Sensor inputs 1–12 A6500-P-RTRM buffered output, monitor positions 1–6 XR11–XR64

Sensor inputs 13–24 A6500-P-RTRM buffered output, monitor positions 7–12 XR71–XR125

Tach inputs 1 and 3 (T1 &

T3)

Tach inputs 2 and 4 (T2 &

T4)

Relay I/O channels 1–4 not connected not used

A6312 pulse output, channel 1 (T1) XR131

A6312 pulse output, channel 2 (T2) XR132

6.5 Terminate discrete I/O

CAUTION!

Use correct gauge strippers on individual conductors. Do not strip more than 0.25 in. off a

conductor. Do not over-tighten. Turn terminal screw clockwise until you make contact with

the wire, then make an additional ¼ turn.

44 MHM-97125-PBF-EN, R0

Page 49

Wire terminations

Procedure

1. Pull cable to the I/O relay channel inputs on the termination panel.

2. Blunt cut excess wire. Strip 1 in. from the cable jacket and 0.25 in. from each

conductor.

3. Terminate according to Table 6-4, and the following:

Relay Excitation Voltage SIG+

Voltage Return SIG-

Shield Drain Shield

4. Relabel wire at the connector.

5. After all wires are pulled, bundle the wires, and secure the bundle to the side of the

enclosure.

6. Document the discrete I/O name, wire label name, and the AMS 6500 channel

number on the cable administration chart.

Discrete I/O cable terminationFigure 6-8:

MHM-97125-PBF-EN, R0 45

Page 50

Wire terminations

6.6 Rear shield/Adapter panel—A6500-M-RSH

The rear shield panel is a modified version of the front termination panel. It routes signals

to the backplane (A6500-M-BP) from the front termination panel instead of the rear

termination panel.

If you will route all sensor and tach inputs from the A6500-P-RTRM, you can use the rear

shield panel (A6500-M-RSH) instead of the rear termination panel (A6500-M-RTRM). The

rear shield panel provides a simpler adapter for Jumper connections to the A6500-P-RTRM

sensor and tach signals, and connectors for the 4 external relay I/O termination.

6.7 Terminate +24 V power for the A6560 and A6510 modules

The +24 V power input for the A6560 and A6510 prediction modules is located on the

A6500-M-BP backplane. This connector is isolated from the protection modules, which are

powered separately. Emerson recommends a separate power supply for protection

modules.

CAUTION!

• The AMS 6500 +24 V power terminals are not wired the same as the CSI 4500 power

terminals. Do not use a connector that was previously wired for a CSI 4500 without

reconfiguring the wiring.

• The +24 V power input for the A6560 and A6510 modules requires a +24 V power supply.

Do not connect the -24 V power supply intended to power the Eddy Current sensor to

this input. Verify all power supply connections are wired and connected properly before

powering the unit.

Procedure

1. Route cable to the power connector.

2. Leave a service loop.

3. Strip conductors 0.25 in. and terminate to Phoenix connections according to the

following diagram:

Power termination for A6560 and A6510 prediction modulesTable 6-7:

Wire Termination panel

+DC +

-DC -

Shield SHLD

46 MHM-97125-PBF-EN, R0

Page 51

Note

When connecting a 24 V power supply to the AMS 6500, connect the DC side of the power

supply to the AMS 6500 before connecting the AC side of the power supply to AC line power.

4. Secure the power cable to the side of the enclosure with a cable tie-down.

6.7.1 Power input specifications

Power input specificationsTable 6-8:

Power requirement Range

DC input voltage 18–31 VDC

(24 VDC nominal)

DC input current (with Transient) 1.0 A @ 24 VDC (no termination panel)

1.25 A @ 24 VDC (with termination panel, all channels

powered)

DC input current (without Transient) 0.65 A @ 24 VDC (no termination panel)

0.9 A @ 24 VDC (with termination panel, all channels

powered)

Maximum input surge current (all

versions)

Maximum power dissipation 22 W

7 A @ 24 VDC for 1 ms

3 A @ 24 VDC for 20 ms

30 W with Transient

Wire terminations

6.8 Eddy Current sensor: -24 V power supply

The power input connector for Eddy Current sensors is located on the A6500-M-RTRM.

When using Eddy Current sensors, feed in a -24 V sensor supply at this connector. This

connector then supplies all the -24 V sensor supply terminals on the termination panel.

The supply terminals at each channel have built-in auto-resetting breakers to protect

against a short circuit on one channel disrupting the power supply for all channels.

Note

The AMS 6500 performs an internal test to verify that -24 V power is connected. If a -24 V supply is

not connected, the CPU Status LEDs on the CPU, and the Status LED on the left side of the

termination panel will turn from green to red. If Eddy Current sensor power is not required, this

internal test can be disabled by installing a jumper on the termination panel at the pins labeled -24

V Disable.

MHM-97125-PBF-EN, R0 47

Page 52

Wire terminations

CAUTION!

The -24 V Eddy Current sensor power input requires a -24 V power supply. Do not connect the

+24 V power supply intended for powering the A6560, A6560R, or A6510 to this input. Verify

all power supply connections are wired and connected properly before powering the unit.

6.9 SysFail relay termination

The SysFail relay output connector is labeled SYSFAIL RELAY, and located on the

bottom left corner of the A6500-M-BP backplane.

The SysFail relay output can be terminated as either normally-open (terminate to C and

NO) or normally-closed (terminate to C and NC).

CAUTION!

The SysFail relay connection is an output for relays only. Do not connect the +24 V power

supply intended for powering the A6560, A6560R or A6510, or the -24 V power supply

intended for Eddy Current Probe power to this output. Verify all power supply connections are

wired and connected properly before powering the unit.

6.10 Loop interconnection for 4-20 mA current

To convert the milliamp signal to a voltage signal, install a 250 ohm resistor between the +

and - signal inputs when connecting 4-20 mA signal inputs.

48 MHM-97125-PBF-EN, R0

Page 53

Wire terminations

AMS 6500 transmitter connection for 4-20 mA currentFigure 6-9:

A. AMS 6500 input sensors

B. 250 ohm resistor

C. 4-20 mA transmitter

Note

AMS 6500 MUX (SIG) channels do not provide loop power to 4-20 mA devices. A separate module is

required to provide loop power.

6.11 Terminate Ethernet connection

CAUTION!

Do not daisy-chain multiple units using the NIC or HUB. If one network connection fails, it will

disrupt network communication for multiple units.

Procedure

1. Route the network cable to RJ45 connectors, at either the front of the A6560

module, or at the rear of the A6500-M-BP backplane.

2. Blunt cut excess wire and attach the RJ45 CAT5 according to your plant's standards

for 10/100 Base-T connections.

MHM-97125-PBF-EN, R0 49

Page 54

Wire terminations

3. Connect the terminated Ethernet cable to the NIC.

4. Secure the network cable to the right side of enclosure using a cable tie-down.

NIC and HUB connectorsFigure 6-10:

A. Rear HUB connector

B. Rear NIC connector

Use the NIC connector when connecting to an Ethernet hub or switch.

Use the HUB connector when connecting directly to a PC (the HUB connector provides the

same function as a crossover cable).

6.12 Default schema for network addressing

The network arrangement shown assumes one of the AMS 6500 units include Transient

functionality.

50 MHM-97125-PBF-EN, R0

Page 55

Wire terminations

Default schema for network addressingFigure 6-11:

MHM-97125-PBF-EN, R0 51

Page 56

Wire terminations

52 MHM-97125-PBF-EN, R0

Page 57

7 Hardware configuration

Topics covered in this chapter:

• Hardware configuration: overview

• The A6560R and A6510 modules

• Configure the A6560R with a terminal emulator

7.1 Hardware configuration: overview

The AMS 6500 Machinery Health™ Monitor (A6560R CPU module, in combination with the

A6510 Signal Input module), is a multi-channel, multi-tasking, multi-processor data

acquisition system primarily intended for monitoring heavy industrial rotating machinery.

Typical signal inputs are dynamic AC machine vibration signatures from accelerometers,

velocity probes, or eddy current sensors. These signals include two components: the

dynamic AC component, which represents machine vibration, and a DC component, which

represents the sensor bias level. In the case of an eddy current sensor, the DC component

represents the gap, or average distance between the probe tip and the machine shaft.

Other signal inputs include process signals; these are DC parameters such as temperature

or pressure.

Hardware configuration

Tachometer inputs are used to determine machine speed. These tachometer signals are

typically generated from an eddy current sensor or passive magnetic sensor positioned at

a machine shaft keyway or gear, producing a pulse train (not necessarily 1x machine

speed) representing the machine phase and running speed.

Discrete inputs represent machine states such as running, off, and starting. These inputs

are used to control or modify the data acquisition based on machine state. Common state

control inputs are relay closures or machine RPM. AC or DC signal levels can also be used

for state control.

7.1.1 Gross Scan monitoring

Gross Scan monitoring includes:

• the acquisition of the overall level of the dynamic AC vibration signal, typically the

RMS value of the signal.

• the DC sensor bias level.

• the measurement of a DC process signal.

All these signal inputs are DC values (the RMS value is a DC value proportional to the

overall energy content of the AC signal). The Gross Scan inputs are multiplexed into a fast

successive approximation ADC controlled by the A6560R CPU module. Gross Scan

monitoring measures all input channels AC+DC twice per second. When the Transient

option is included, true waveform peak-to-peak may be included in Gross Scan

monitoring.

MHM-97125-PBF-EN, R0 53

Page 58

Hardware configuration

7.1.2 Spectral Scan

Spectral Scan is defined as the acquisition and analysis of dynamic AC signals only. The

signals are acquired, two channels at a time (referred to as CHX and CHY). Preprogrammed

groups of Spectral Scan measurement parameters (AP Sets) may be assigned to specific

machine state conditions to tailor data acquisition to specific machine operational states.

7.1.3 Transient data capture

Transient data capture is the acquisition of continuous time waveforms of dynamic AC

signals. Transient data is captured in parallel for all channels. Other data stored along with

the Transient data include Gross Scan data captured once per second, tach pulse records,

and acquisition timestamps. The Transient data is stored on hard disk, and is available for

real-time analysis via Ethernet.

7.2 The A6560R and A6510 modules

The AMS6500M has an A6560R Processor module and either one or two A6510 Signal

Input modules.

The AMS6500T has an A6560R Processor module with a solid-state drive and either one or

two A6510 Signal Input modules, each with Transient Filter Boards.

7.2.1 A6560R Processor module

The A6560R Processor module provides all data acquisition, data storage, and data

communication functions for the AMS 6500 system and the AMS 2600 system. The

A6560R is capable of up to 24 simultaneous, continuous waveform measurements for

detailed Spectral analysis, up to 24 RMS and DC values for Gross Scan measurements, up

to 4 tachometers for machine speed measurement, and up to 4 digital state inputs.

Gross Scan values, tachometer values, and digital input states may be combined logically

to determine machine operating state and define specific data acquisition states. The

system can be configured to transmit and store data on either time interval or based on

the amount of change of the data values.

The Processor module provides four 100 Base-T Ethernet ports and one RS-232 serial port

for system communications and diagnostics. Additional connections are available for the

calibration signal and a dry contact SPDT SysFail relay. This relay is energized when the

Processor CPU successfully boots. On a CPU failure or power loss, the relay will deenergize.

The Processor module may be configured to download its operational firmware via

Ethernet upon boot, or to operate on firmware that has been stored in FLASH memory.

The Processor module has an on-board signal generator capable of producing sinusoidal

and DC signals that are routed to the input modules during system calibration and on

Power On Self Test (POST).

54 MHM-97125-PBF-EN, R0

Page 59

Hardware configuration

Note

If the unit experiences frequent extreme temperature changes, recalibrate the signal generator

more frequently.

The Processor module automatically detects input module type and configuration, and

only permits database configuration based on the existing channel set.

A6560R Processor moduleFigure 7-1:

MHM-97125-PBF-EN, R0 55

Page 60

Hardware configuration

Transient capability

The A6560R CPU module, is capable of parallel, continuous time waveform acquisition on

all channels. All collected time waveform data, along with Gross Scan data and up to four

tachometer pulse records, is stored on an internal solid-state drive (SSD). The SSD is

specially rated for industrial operation and provides approximately 100 hours of DCR

(Digital Condition Recorder) transient data. There is also room on the drive to store

transient archives manually and automatically.

Transient data can be streamed via Ethernet to analysis applications in near real time,

without affecting data collection or on-board data storage.

While collecting time waveforms and tachometer pulses, the processor continuously

calculates the peak-to-peak value of each channel's waveform. When configured, this

value can be used as the Gross Scan instead of the RMS value produced by the A6510

Signal Input module.

A6560R CPU module with and without Transient capabilityFigure 7-2:

An A6560RT with mounted SSD. An A6560R next to the older A6560RT.

A. SSD

Replace the Transient SSD

Only replace the Transient SSD if directed by Emerson Product Support.

CAUTION!

Follow the same safety precautions as replacing a card in the unit. Always power down the

unit.

56 MHM-97125-PBF-EN, R0

Page 61

Hardware configuration

Procedure

Replace the SSD as directed by Emerson Product Support.

Postrequisites

Format the Transient SSD.

Format the Transient SSD

You must format the new solid-state drive before you can use it.

Procedure

1. Power on the system and ignore any hard drive error messages on the

HyperTerminal monitor.

2. When the system has booted, launch DHM_III.exe.

DHM_III.exe is located at C:\inetpub\ftproot\bin\Tools directory.

3. In DHM, connect to the unit in "Single User" mode.

4. From the main menu, select Transient > Format Hard Drive.

5. When the drive has been formatted, reboot the unit. Ignore any hard drive error

messages.

When the POST process is complete, the firmware automatically prepares the hard

drive with the Transient File System. This process can take up to 15 minutes.

6. Disconnect DHM.

The unit will reboot automatically.

When the unit boots, there should be no hard drive error messages. If configured,

Transient data collection should begin, indicated by a flashing hard drive indicator on the

A6560R CPU module front panel.

7.2.2 A6510

The A6510 combines the features of Signal Input, Tachometer Input, and I/O Relays to

allow a combination of sensor and relay types in one module.

The A6510 provides 12 channels of vibration or process sensor inputs, 2 channels of

tachometer sensor inputs, and 2 optically-isolated I/O relay channels.

MHM-97125-PBF-EN, R0 57

Page 62

Hardware configuration

A6510Figure 7-3:

Transient Filter Board for the A6510

The Transient Filter Board provides parallel anti-aliasing filters for the signal channels on

the Signal Input module. Either one or two Transient Filter Boards may be used to

configure either a 12- or 24-channel Transient System.

When installing the Transient Filter Board on the Signal Input module, make sure both

mating connectors are fully engaged, then install all six mounting screws.

58 MHM-97125-PBF-EN, R0

Page 63

Hardware configuration

Transient Filter Board PCB mounted on a Signal Input moduleFigure 7-4: