Page 1

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L Logic Transmitter

with F

OUNDATION

™

Fieldbus

www.rosemount.com

Page 2

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Rosemount 848L Discrete Logic

Temperature Transmitter with

OUNDATION Fieldbus

F

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure to thoroughly understand the contents before

installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one international number.

Customer Central

1-800-999-9307 (7:00 a.m. to 7:00 P.M. CST)

National Response Center

1-800-654-7768 (24 hours a day)

Equipment service needs

International

1-(952) 906-8888

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact a Emerson Process

Management Sales Representative.

Cover photo: 848-848C004

www.rosemount.com

Page 3

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

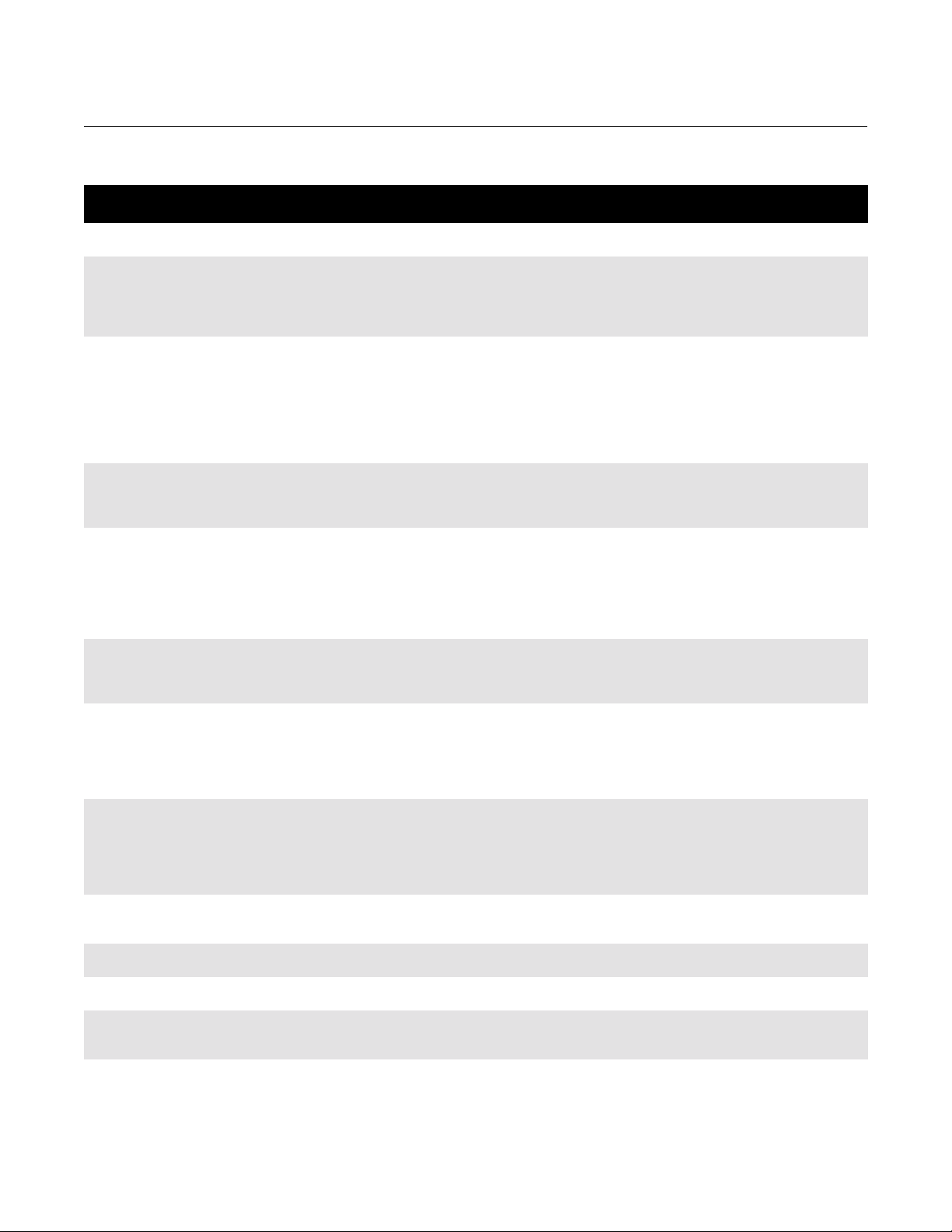

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mounting to a DIN Rail Without an Enclosure. . . . . . . . . . . . . . . . . . . . . 2-2

Mounting to a Panel with a Junction Box . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mounting to a 2-Inch Pipe Stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Surges/Transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

I/O Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Transmitter Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Using Cable Glands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Using Conduit Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

SECTION 3

Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

General Block Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Link Active Scheduler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Block Instantiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

FEATURES and FEATURES_SEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

MAX_NOTIFY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

PlantWeb

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

I/O Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Logic Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Discrete Input Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Discrete Output Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Multiple Discrete Input Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Multiple Discrete Output Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

™

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

www.rosemount.com

Page 4

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

SECTION 4

Operation and

Maintenance

APPENDIX A

Reference Data

APPENDIX B

Product Certifications

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Foundation Fieldbus Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Commissioning (Addressing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Hardware Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Sensor Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Communication/Power Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Resetting the Configuration (RESTART) . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Foundation Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

I/O Transducer and Logic Block Troubleshooting . . . . . . . . . . . . . . . . . . 4-3

NAMUR Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Function Blocks Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Hazardous Locations Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

North American Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

European Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

APPENDIX C

Function Blocks

Resource Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

I/O Transducer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Logic Transducer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-8

Discrete Input Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9

Discrete Output Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-11

Supported Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-11

Multiple Discrete Input Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12

Multiple Discrete Output Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-13

TOC-2

Page 5

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

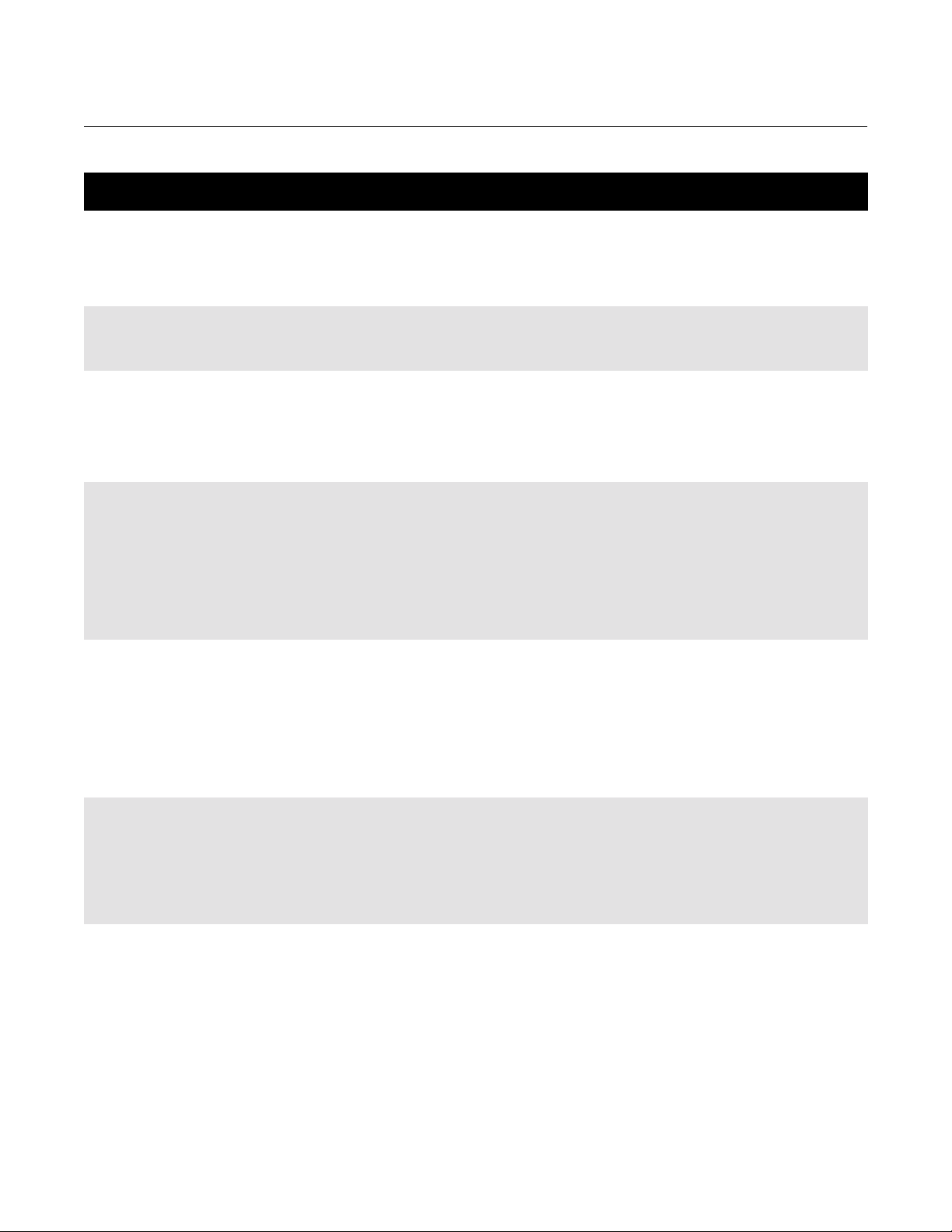

APPENDIX D

Logic Equation Syntax

APPENDIX E

Motor Control

APPENDIX F

Valve Control

Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

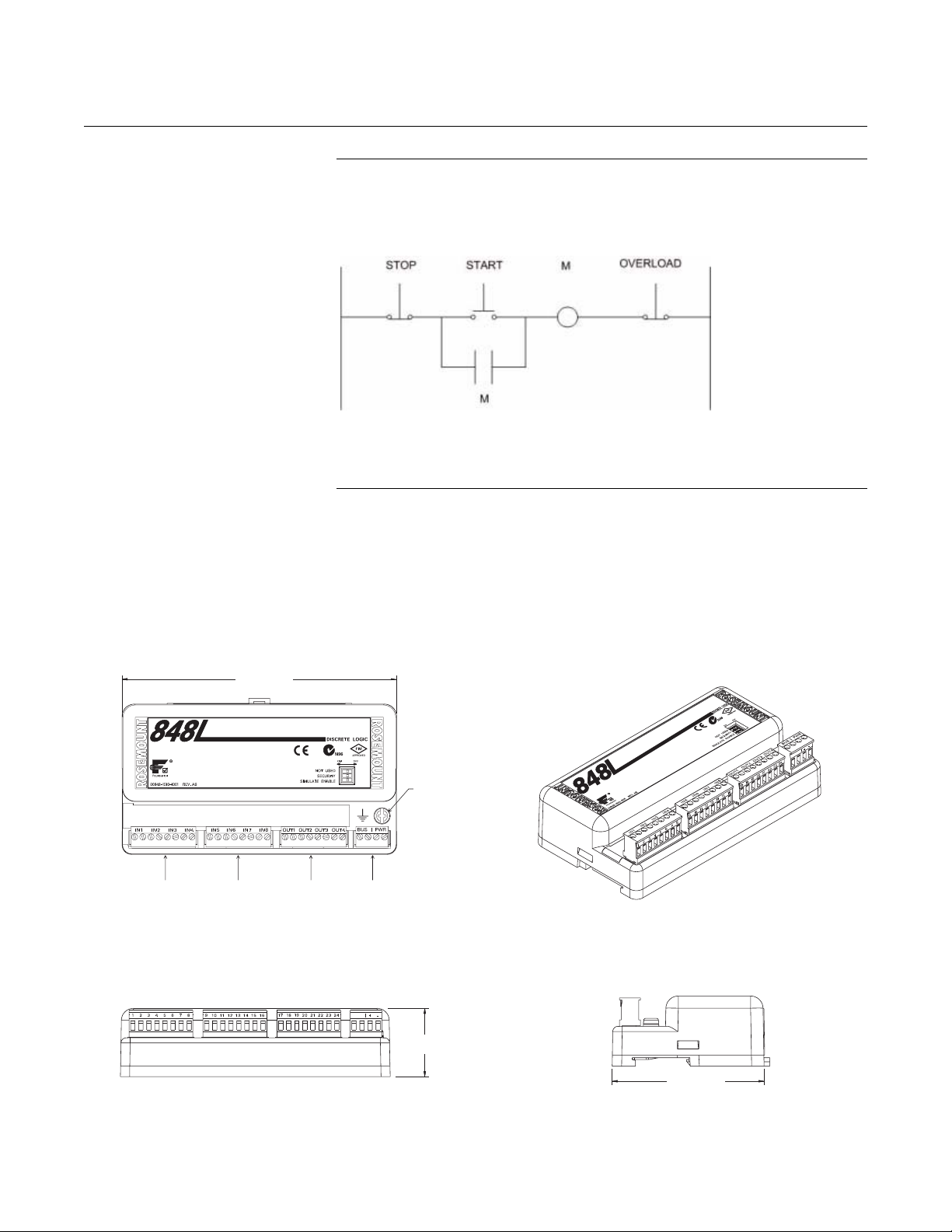

Introduction to Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

Variations on Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-2

Writing 848L Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-4

Basic Motor Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Permissive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Emergency Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-5

Restart Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-6

Maximum Restarts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-7

Winding Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-8

Hand-Off-Auto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-9

Intermediate Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-10

Redundant Motors - Alternate Start . . . . . . . . . . . . . . . . . . . . . . . . . . .E-11

Redundant Motors - Timed Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-12

Redundant Motors - Switch on Failure . . . . . . . . . . . . . . . . . . . . . . . . .E-14

Introduction to Valve Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-1

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-2

Variations on Valve Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Boolean Expressions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Basic Valve Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Open-Auto-Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Alarm Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Output Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-4

Output with Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Simple Valve Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Permissive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Double Block and Bleed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Motorized Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7

Heat Exchange Medium Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-7

TOC-3

Page 6

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

TOC-4

Page 7

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Section 1 Introduction

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

potentially raises safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Warnings

Failure to follow these installation guidelines could result in death or

serious injury.

• Make sure only qualified personnel perform the installation.

Electrical shock could cause death or serious injury.

• If the device or senors are installed in a high voltage environment and a fault

condition or installation error occurs, high voltage may be present on transmitter

leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

www.rosemount.com

Page 8

Reference Manual

00809-0100-4696, Rev AA

Rosemount 848L

September 2004

OVERVIEW

Transmitter The 848L provides a cost effective field mounted interface for discrete inputs

and outputs on a Foundation Fieldbus H1 network. The 848L allows you to

leverage the fieldbus network to reduce discrete input and output wiring and

eliminate the need for a separate bus for discrete inputs and outputs. The

848L can communicate with other devices on the segment to provide logic

interactions independent of any upper level controller.

The 848L also has logic capability allowing it to independently control outputs

based on the state of one or more of it's inputs or discrete signals from other

devices on the network. A Logic Block allows for up to 20 Boolean equations,

8 Inputs, and 4 Outputs.

Manual This manual is designed to assist in the installation, operation, and

maintenance of the Rosemount 848L Logic Transmitter.

Section 1: Introduction

• Overview

• Considerations

• Return of Materials

Section 2: Installation

• Mounting

• Installation

• Wiring

• Power Supply

• Commissioning

Section 3: Configuration

OUNDATION fieldbus Technology

•F

• Configuration

• Function Block Configuration

Section 4: Operation and Maintenance

• Hardware Maintenance

• Troubleshooting

1-2

Page 9

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Appendix A: Specification and Reference Data

• Specifications

• Dimensional Drawings

• Ordering Information

Appendix B: Product Certificates

• Hazardous Locations Certificates

• Intrinsically Safe and Non-Incendive Installations

• Installation Drawings

Appendix C: Function Blocks

• Device Descriptions

• Block Operation

Appendix D: Logic Equation Syntax

• Error Handling

• Examples

Appendix E: Motor Control

• Variations of Motor Control

• Writing 848L Equations

Appendix F: Valve Control

RETURN OF MATERIALS To expedite the return process in North America, call the Emerson Process

Management National Response Center toll-free at 800-654-7768. This

center, available 24 hours a day, will assist with any needed information or

materials.

The center will ask for the following information:

• Product model

• Serial numbers

• The last process material to which the product was exposed

The center will provide

• A Return Material Authorization (RMA) number

• Instructions and procedures that are necessary to return goods that

were exposed to hazardous substances

For other locations, please contact an Emerson Process Management sales

representative.

NOTE

If a hazardous substance is identified, a Material Safety Data Sheet (MSDS),

required by law to be available to people exposed to specific hazardous

substances, must be included with the returned materials.

1-3

Page 10

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

1-4

Page 11

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Section 2 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-5

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-5

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-7

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-8

Transmitter Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-9

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

potentially raises safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Warnings

Failure to follow these installation guidelines could result in death or

serious injury.

• Make sure only qualified personnel perform the installation.

Electrical shock could cause death or serious injury.

• If the device or sensors are installed in a high voltage environment and a fault

condition or installation error occurs, high voltage may be present on transmitter

leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

MOUNTING The 848L is always mounted remote from the sensors and output devices.

There are three mounting configurations:

• To a DIN rail without an enclosure

• To a panel with an enclosure

• To a 2-in pipe stand with an enclosure using a pipe mounting kit

www.rosemount.com

Page 12

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

Mounting to a DIN Rail

Without an Enclosure

Figure 2-1. Mounting the 848L to

a DIN Rail

Mounting to a Panel with

a Junction Box

To mount the 848L to a DIN rail without an enclosure, follow these steps:

1. Pull up the DIN rail mounting clip located on the top back side of the

transmitter.

2. Hinge the DIN rail into the slots on the bottom of the transmitter.

3. Tilt the 848L and place onto the DIN rail. Release the mounting clip.

The transmitter should be securely fastened to the DIN rail.

848L without

enclosure

DIN Rail Mounting Clip

DIN Rail

When inside of a plastic or aluminum junction box, the 848L mounts to a panel

1

using four

/4-20 x 1.25-in. screws.

When inside of a stainless steel junction box, the 848L mounts to a panel

using two

1

/4-20 x 1/2-in. screws.

Figure 2-2. Mounting the 848L

junction box to a panel

848L with aluminum or plastic box

Cover

Screws (4)

Mounting

Screws (4)

Panel

Aluminum/Plastic Stainless Steel

848L with a stainless steel box

Mounting

Screws (2)

Panel

2-2

Page 13

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Mounting to a 2-Inch

Pipe Stand

Use the optional mounting bracket (option code B6) to mount the 848L to a

2-inch pipe stand when using a junction box.

Aluminum/Plastic Junction Box

(styles JA and JP)

Front View Side View Front View Side View

5.1

(130)

10.2

(260)

Aluminum/Plastic Junction Box

Mounted on a Vertical Pipe

6.6 (167)

fully

assembled

Dimensions are in inches (millimeters)

Stainless Steel Junction Box

4.5

(114)

Stainless Steel Junction Box

Mounted on a Vertical Pipe

(style JS)

7.5 (190)

fully

assembled

848_848A52A, B, 53A, B

848_848A54A, 55A

2-3

Page 14

Reference Manual

00809-0100-4696, Rev AA

Rosemount 848L

September 2004

WIRING If the device or sensors are installed in a high-voltage environment and a fault

condition or installation error occurs, the sensor leads and transmitter

terminals could carry lethal voltages. Use extreme caution when making

contact with the leads and terminals.

NOTE

Do not apply high voltage (e.g. AC line voltage) to the transmitter bus or I/O

power terminals. Abnormally high voltage can damage the unit (bus and I/O

power terminals are rated to 42.4 VDC).

Figure 2-3. 848L Transmitter

Fieldbus Wiring

Integrated Power

Conditioner

and Filter

Power

Supply

6234 ft (1900 m) max

(depending upon cable

characteristics)

Terminators

(Trunk)

Power Supply

Connections

FOUNDATION

fieldbus Host or

configuration tool

(Spur)

Devices 1 through 16*

(Spur)

Signal

Wiring

The transmitter requires both a fieldbus connection and power for the discrete

I/O channels.

Fieldbus Connection

The fieldbus connection requires between 9 and 32VDC to operate the

electronics. The dc power supply should provide power with less than 2%

ripple. A fieldbus segment requires a power conditioner to isolate the power

supply filter and decouple the segment from other segments attached to the

same power supply. Signal wiring should be shielded, twisted pair for best

results in electrically noisy environments. Do not use unshielded signal wiring

in open trays with power wiring or near heavy electrical equipment. Use

ordinary copper wire of sufficient size to ensure that the voltage across the

bus terminals does not go below 9 VDC. The power terminals are not polarity

sensitive. To power the electronics and establish communications:

1. Connect the fieldbus wires to the terminals marked "Bus" as shown in

Figure 2-4 on page 2-5.

2. Tighten the terminal screws to ensure adequate contact.

848-848_01A

2-4

Page 15

Reference Manual

00809-0100-4696, Rev AA

September 2004

Figure 2-4. “Bus” location on the

Rosemount 848L

Rosemount 848L

848/848L/848L_19_AA.EPS

Input/Output Power:

The discrete I/O requires a 9-32VDC power supply that is separate from the

fieldbus power. The voltage level will depend on the type of sensors being

used and outputs being driven. To power the I/O:

1. Connect the positive lead from the power supply to the (+) terminal

marked "PWR".

2. Connect the return lead to the (-) terminal marked "PWR"

3. Tighten the terminal screws to ensure adequate contact.

Surges/Transients The transmitter will withstand electrical transients encountered through static

discharges or induced switching transients. However, a transient protection

option (option code T1) is available to protect the 848L against high-energy

transients. The device must be properly grounded using the ground terminal.

GROUNDING Although not required, a ground terminal is provided that can be connected to

earth ground for optimal EMC performance. A wire of 14AWG or larger is

recommend using appropriate terminal connectors at both ends.

Transmitter Enclosure (optional)

Ground the transmitter in accordance with local electrical requirements.

SWITCHES

Figure 2-5. Switch Location on

the Rosemount 848L

NOT USED

SECURITY

SIMULATE ENABLE

2-5

848/848L/848L_17_AA.EPS

Page 16

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

Security

After configuring the transmitter, the data can be protected from unwarranted

changes. Each 848L is equipped with a security switch that can be positioned

“ON” to prevent the accidental or deliberate change of configuration data.

This switch is located on the front side of the electronics module and

is labeled SECURITY.

See Figure 2-5 on page 2-5 for switch location on the transmitter label. Refer

to Section 3: Configuration, “SOFT WRITE LOCK and HARD WRITE LOCK”

on page 3-5.

Simulate Enable

The switch labeled SIMULATE ENABLE is used in conjunction with the with

the Discrete Input (DI) and Discrete Output (DO) function blocks. This switch

is used to simulate input status. As a lock-out feature, the switch must

transition from “OFF” to “ON” after power is applied to the transmitter. This

feature prevents the transmitter from being left in simulator mode.

NOT USED

The switch labeled NOT USED is only used for product engineering and

development purposes and should always remain in the “OFF” position. If the

switch is turned to the “ON” position and power is applied, the 848L will not be

present on the fieldbus segment.

2-6

Page 17

Reference Manual

00809-0100-4696, Rev AA

September 2004

I/O WIRING

Rosemount 848L

DISCRETE INPUT WIRING CONFIGURATION

2-Wire NAMUR Sensors

1 of 2 Input Connectors

3-Wire NAMUR Sensors

1 of 2 Input Connectors

Dry Contact Switches

1 of 2 Input Connectors

9-32 VDC Sensors

1 of 2 Input Connectors

DISCRETE OUTPUT WIRING CONFIGURATION

9-32 VDC Outputs

848/848L/848L_10_AA, 848L_11_AA, 848L_12_AA, 848L_13_AA, 848L_14_AA.EPS

2-7

Page 18

Rosemount 848L

TAGGING Commissioning Tag

The 848L is supplied with a removable commissioning tag that contains both

the Device ID (the unique code that identifies a particular device in the

absence of a device tag) and a space to record the device tag (the operational

identification for the device as defined by the Piping and Instrumentation

Diagram (P&ID)).

When commissioning more than one device on a fieldbus segment, it can be

difficult to identify which device is at a particular location. The removable tag,

provided with the transmitter, can aid in this process by linking the Device ID

to its physical location. The installer should note the physical location of the

transmitter on both the upper and lower location of the commissioning tag.

The bottom portion should be torn off for each device on the segment and

used for commissioning the segment in the control system.

Figure 2-6. Commissioning Tag

Reference Manual

00809-0100-4696, Rev AA

September 2004

Device ID

Device Tag

to denote

physical

location

Transmitter Tag

Hardware

• tagged in accordance with customer requirements

• permanently attached to the transmitter

Software

• the transmitter can store up to 30 characters

• if no characters are specified, the first 30 characters of the hardware tag

will be used

Sensor Tag

Hardware

• a plastic tag is provided to record identification of the I/O

• in the field, the tag can be removed, printed on, and reattached to the

transmitter

Software

• the I/O Transducer Block provides the ability to record the I/O tags.

2-8

Page 19

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

TRANSMITTER LABEL

Figure 2-7. Transmitter Label

INSTALLATION

Using Cable Glands Use the following steps to install the 848L with Cable Glands:

1. Remove the junction box cover by unscrewing the four cover screws.

2. Run the sensor and power/signal wires through the appropriate cable

glands using the pre-installed cable glands (see Figure 2-8).

3. Install the I/O wires into the correct screw terminals.

4. Install the power/signal wires onto the correct screw terminals. Bus

power is polarity insensitive, allowing the user to connect positive (+)

or negative (–) to either Fieldbus wiring terminal labeled “Bus.” I/O

power is polarity sensitive and must be connected correctly to avoid

damage to the transmitter. See Figure 2-4 on page 2-5.

5. Replace the enclosure cover and securely tighten all cover screws.

848/848_21_AA.EPS

Figure 2-8. Installing the 848L

with Cable Glands

Enclosure Cover

Screw (4)

Cable Gland

I /O

Power/Signal

848_848A19A

2-9

Page 20

Reference Manual

00809-0100-4696, Rev AA

Rosemount 848L

September 2004

Using Conduit Entries Use the following steps to install the 848L with Conduit Entries:

1. Remove the junction box cover by unscrewing the four cover screws.

2. Remove the five conduit plugs and install five conduit fittings

(supplied by the installer).

3. Run sensor and output wires through each conduit fitting.

4. Install the I/O wires into the correct screw terminals.

5. Install the power/signal wires into the correct screw terminals. Bus

power is polarity insensitive, allowing the user to connect positive (+)

or negative (–) to either Fieldbus wiring terminal labeled “Bus.” I/O

power is polarity sensitive and must be connected correctly to avoid

damage to the transmitter. See Figure 2-4 on page 2-5.

6. Replace the junction box cover and securely tighten all cover screws.

Figure 2-9. Installing the 848L

with Conduit Entries

I /O

Enclosure

Cover Screw

Power/Signal

Conduit

848_848A09A

2-10

Page 21

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Section 3 Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

General Block Information . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

I/O Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-9

Logic Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-10

Discrete Input Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-20

Discrete Output Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-21

Multiple Discrete Input Block . . . . . . . . . . . . . . . . . . . . . . page 3-21

Multiple Discrete Output Block . . . . . . . . . . . . . . . . . . . . . page 3-21

OVERVIEW This section covers basic operation, software functionality, and basic

configuration procedures for the Rosemount 848L transmitter with

F

OUNDATION fieldbus. This section is organized by block information. For

detailed information about the function blocks used in the Rosemount 848L

logic transmitter, refer to “Foundation Fieldbus Block Information” on page A-1

and the Foundation Fieldbus Function Block manual (00809-0100-4783).

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the following safety messages before performing an operation preceded by

this symbol.

Warnings

Explosions can result in death or serious injury.

Before connecting a configuration tool in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with nonincendive field wiring

practices.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be present

on leads can cause electrical shock.

www.rosemount.com

Page 22

Reference Manual

00809-0100-4696, Rev AA

Rosemount 848L

September 2004

GENERAL BLOCK

INFORMATION

Modes The Resource, Transducer, and all function blocks in the device have modes

of operation. These modes govern the operation of the block. Every block

supports both automatic (AUTO) and out of service (OOS) modes. Other

modes may also be supported.

Changing Modes

To change the operating mode, set the MODE_BLK.TARGET to the desired

mode. After a short delay, the parameter MODE_BLOCK.ACTUAL should

reflect the mode change if the block is operating properly.

Permitted Modes

It is possible to prevent unauthorized changes to the operating mode of a

block. To do this, configure MODE_BLOCK.PERMITTED to allow only the

desired operating modes. It is recommended to always select OOS as one of

the permitted modes.

Types of Modes

For the procedures described in this manual, it will be helpful to understand

the following modes:

AUTO

The functions performed by the block will execute. If the block has any

outputs, these will continue to update. This is typically the normal

operating mode.

Out of Service (OOS)

The functions performed by the block will not execute. If the block has any

outputs, these will typically not update and the status of any values passed

to downstream blocks will be “BAD”. To make some changes to the

configuration of the block, change the mode of the block to OOS. When

the changes are complete, change the mode back to AUTO.

MAN

In this mode, variables that are passed out of the block can be manually

set for testing or override purposes.

Other Types of Modes

Other types of modes are Cas, RCas, ROut, IMan and LO. Some of these

may be supported by different function blocks in the Rosemount 848L. For

more information, see the Function Block manual, document

00809-0100-4783.

NOTE

When an upstream block is set to OOS, this will impact the output status of all

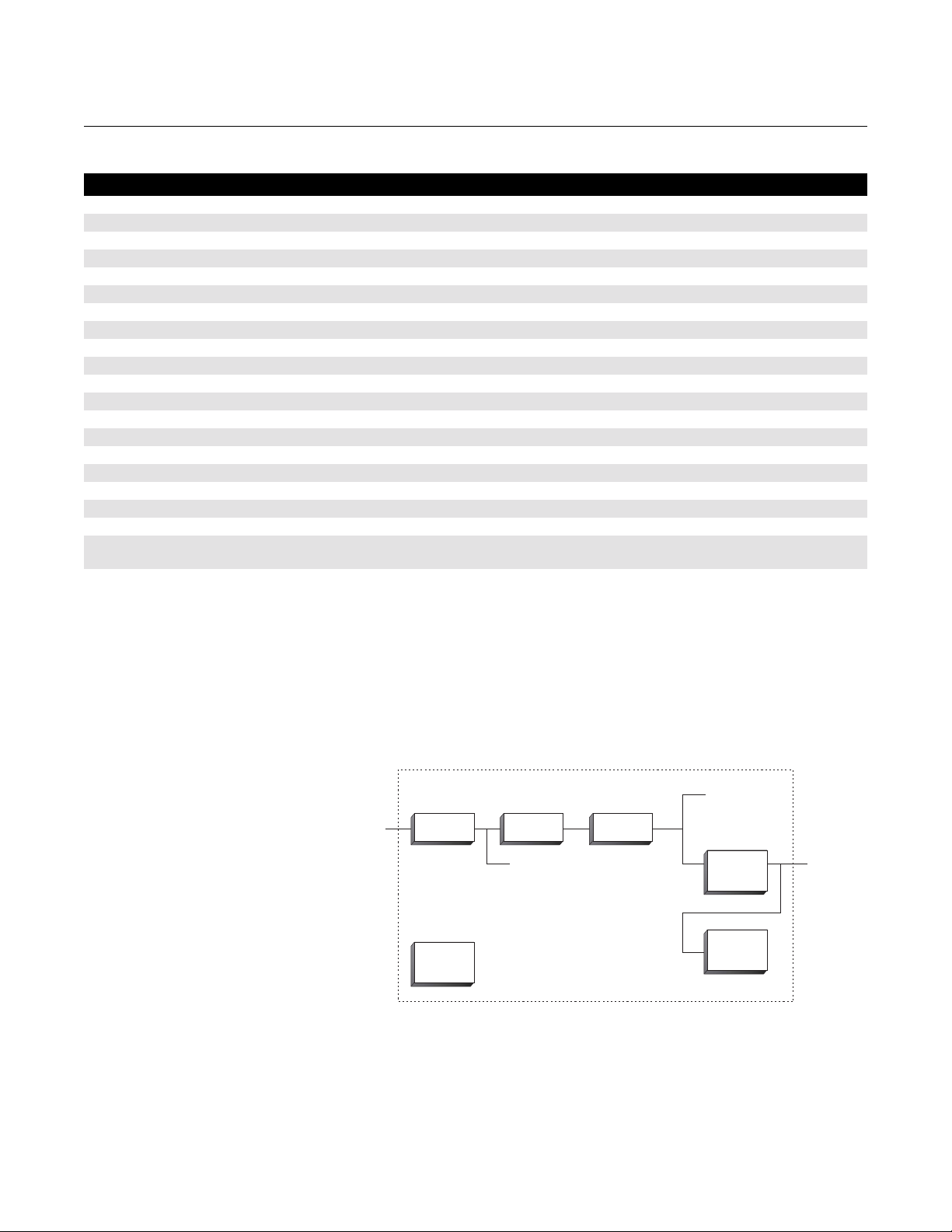

downstream blocks. The figure below depicts the hierarchy of blocks:

3-2

Resource

Block

Transducer

Block

Discrete Input

(DI Block)

Other

function

blocks

Page 23

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Link Active Scheduler The Rosemount 848L can be designated to act as the backup Link Active

Scheduler (LAS) in the event that the LAS is disconnected from the segment.

As the backup LAS, the Rosemount 848L will take over the management of

communications until the host is restored.

The host system may provide a configuration tool specifically designed to

designate a particular device as a backup LAS. Otherwise, this can be

configured manually as follows:

1. Access the Management Information Base (MIB) for the Rosemount

848L.

2. To activate the LAS capability, write 0x02 to the

BOOT_OPERAT_FUNCTIONAL_CLASS object (Index 605). To

deactivate, write 0x01.

3. Restart the processor.

Block Instantiation Rosemount devices are pre-configured with function blocks at the factory, the

default permanent configuration for the Rosemount 848L is listed below. The

Rosemount 848L can have one additional instantiated function block.

• 8 Discrete Input Blocks

• 4 Discrete Output Blocks

• Multiple Discrete Input Block

• Multiple Discrete Output Block

The Rosemount 848L supports the use of Function Block Instantiation. When

a device supports block instantiation, the number of blocks and block types

can be defined to match specific application needs.The number of blocks that

can be instantiated is only limited by the amount of memory within the device

and the block types that are supported by the device. Instantiation does not

apply to standard device blocks like the Resource, I/O Transducer, and Logic

Transducer Block.

Block instantiation is done by the host control system or configuration tool, but

not all hosts are required to implement this functionality. Please refer to your

specific host or configuration tool manual for more information.

3-3

Page 24

Rosemount 848L

Capabilities Virtual Communication Relationship (VCRs)

There are a total of 20 VCRs. Two are permanent and 18 are fully

configurable by the host system. 25 link objects are available.

Network Parameter Value

Slot Time 8

Maximum Response Delay 4

Maximum Inactivity to Claim LAS Delay 60

Minimum Inter DLPDU Delay 7

Time Sync class 4 (1ms)

Maximum Scheduling Overhead 21

Per DLPDU PhL Overhead 4

Maximum Inter-channel Signal Skew 0

Required Number of Post-transmission-gap-ext Units 0

Required Number of Preamble-extension Units 1

Host timer recommendations

T1 = 96000

T2 = 1920000

T3 = 480000

Reference Manual

00809-0100-4696, Rev AA

September 2004

RESOURCE BLOCK

FEATURES and

FEATURES_SEL

Block Execution times

Discrete Input = 40 ms

Discrete Output = 40 ms

Multiple Discrete Input = 40 ms

Multiple Discrete Output = 40 ms

The parameters FEATURES and FEATURE_SEL determine optional

behavior of the Rosemount 848L.

FEATURES

The FEATURES parameter is read only and defines which features are

supported by the Rosemount 848L. Below is a list of the FEATURES the

Rosemount 848L supports.

UNICODE

All configurable string variables in the Rosemount 848L, except tag names,

are octet strings. Either ASCII or Unicode may be used. If the configuration

device is generating Unicode octet strings, you must set the Unicode option

bit.

REPORTS

The Rosemount 848L supports alert reports. The Reports option bit must be

set in the features bit string to use this feature. If it is not set, the host must

poll for alerts.

3-4

Page 25

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

SOFT WRITE LOCK and HARD WRITE LOCK

Inputs to the security and write lock functions include the hardware security

switch, the hardware and software write lock bits of the FEATURE_SEL

parameter, the WRITE_LOCK parameter, and the DEFINE_WRITE_LOCK

parameter.

The WRITE_LOCK parameter prevents modification of parameters within the

device except to clear the WRITE_LOCK parameter. During this time, the

block will function normally updating inputs and outputs and executing

algorithms. When the WRITE_LOCK condition is cleared, a WRITE_ALM

alert is generated with a priority that corresponds to the WRITE_PRI

parameter.

The FEATURE_SEL parameter enables the user to select a hardware or

software write lock or no write lock capability. To enable the hardware security

function, enable the HW_SEL bit in the FEATURE_SEL parameter. When this

bit has been enabled the WRITE_LOCK parameter becomes read only and

will reflect the state of the hardware switch. In order to enable the software

write lock, the SW_SEL bit must be set in the FEATURE_SEL parameter.

Once this bit is set, the WRITE_LOCK parameter may be set to “Locked” or

“Not Locked.” Once the WRITE_LOCK parameter is set to “Locked” by either

the software or the hardware lock, all user requested writes as determined by

the DEFINE_WRITE_LOCK parameter shall be rejected.

The DEFINE_WRITE_LOCK parameter allows the user to configure whether

the write lock functions (both software and hardware) will control writing to all

blocks, or only to the resource and transducer blocks. Internally updated data

such as process variables and diagnostics will not be restricted by the

security switch.

The following table displays all possible configurations of the WRITE_LOCK

parameter.

FEATURE_SEL

HW_SEL bit

0 (off) 0 (off) NA 1 (unlocked) Read only NA All

0 (off) 1 (on) NA 1 (unlocked) Read/Write NA All

0 (off) 1 (on) NA 2 (locked) Read/Write Physical Function

0 (off) 1 (on) NA 2 (locked) Read/Write Everything None

1 (on) 0 (off)

1 (on) 0 (off) 1 (locked) 2 (locked) Read only Physical Function

1 (on) 0 (off) 1 (locked) 2 (locked) Read only Everything None

(1) The hardware and software write lock select bits are mutually exclusive and the hardware select has the highest priority. When the HW_SEL bit if set to 1

(on), the SW_SEL bit is automatically set to 0 (off) and is read only.

FEATURE_SEL

SW_SEL bit

(1)

WRITE_LOCK

SECURITY SWITCH WRITE_LOCK

0 (unlocked) 1 (unlocked) Read only NA All

Read/Write

DEFINE_WRITE_LOCK

Write access

to blocks

Blocks only

Blocks only

FEATURE_SEL

FEATURE_SEL is used to turn on any of the supported features. The default

setting of the Rosemount 848L does not select any of these features. Choose

one of the supported features if any.

MAX_NOTIFY The MAX_NOTIFY parameter value is the maximum number of alert reports

that the resource can have sent without getting a confirmation, corresponding

to the amount of buffer space available for alert messages. The number can

be set lower, to control alert flooding, by adjusting the LIM_NOTIFY

parameter value. If LIM_NOTIFY is set to zero, then no alerts are reported.

3-5

Page 26

Reference Manual

00809-0100-4696, Rev AA

Rosemount 848L

September 2004

PlantWeb™ Alarms The Resource Block will act as a coordinator for PlantWeb alarms. There will

be three alarm parameters (FAILED_ALARM, MAINT_ALARM, and

ADVISE_ALARM) which will contain information regarding some of the device

errors which are detected by the transmitter software. There will be a

RECOMMENDED_ACTION parameter which will be used to display the

recommended action text for the highest priority alarm. FAILED_ALARM will

have the highest priority followed by MAINT_ALARM and ADVISE_ALARM

will be the lowest priority.

FAILED_ALARMS

A failure alarm indicates a failure within a device that will make the device or

some part of the device non-operational. This implies that the device is in

need of repair and must be fixed immediately. There are five parameters

associated with FAILED_ALARMS specifically, they are described below.

FAILED_ENABLED

This parameter contains a list of failures in the device which makes the

device non-operational that will cause an alarm to be sent. Below is a list

of the failures with the highest priority first.

1. Electronics Failure

2. NV Memory Failure

3. No I/O Power

4. Primary Value Failure

5. Secondary Value Failure

FAILED_MASK

This parameter will mask any of the failed conditions listed in

FAILED_ENABLED. A bit on means that the condition is masked out from

alarming and will not be reported.

FAILED_PRI

Designates the alarming priority of the FAILED_ALM. The default is 0 and

the recommended value is between 8 and 15.

FAILED_ACTIVE

This parameter displays which of the alarms is active. Only the alarm with

the highest priority will be displayed. This priority is not the same as the

FAILED_PRI parameter described above. This priority is not user

configurable.

FAILED_ALM

Alarm indicating a failure within a device which makes the device

non-operational.

3-6

Page 27

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

MAINT_ALARMS

A maintenance alarm indicates the device or some part of the device needs

maintenance soon. If the condition is ignored, the device will eventually fail.

There are five parameters associated with MAINT_ALARMS, they are

described below.

MAINT_ENABLED

The MAINT_ENABLED parameter contains a list of conditions indicating

the device or some part of the device needs maintenance soon. If the

condition is ignored, the device will eventually fail.

Below is a list of the conditions with the highest priority first.

1. Secondary Value Degraded

2. Configuration Error

MAINT_MASK

The MAINT_MASK parameter will mask any of the failed conditions listed

in MAINT_ENABLED. A bit on means that the condition is masked out

from alarming and will not be reported.

MAINT_PRI

MAINT_PRI designates the alarming priority of the MAINT_ALM. The

default is 0 and the recommended value is 3 to 7.

MAINT_ACTIVE

The MAINT_ACTIVE parameter displays which of the alarms is active.

Only the condition with the highest priority will be displayed. This priority is

not the same as the MAINT_PRI parameter described above. This priority

is not user configurable.

MAINT_ALM

An alarm indicating the device needs maintenance soon. If the condition is

ignored, the device will eventually fail.

Advisory Alarms

An advisory alarm indicates informative conditions that do not have a direct

impact on the device's primary functions There are five parameters

associated with ADVISE_ALARMS, they are described below.

ADVISE_ENABLED

The ADVISE_ENABLED parameter contains a list of informative

conditions that do not have a direct impact on the device's primary

functions. Below is a list of the advisories with the highest priority first.

1. Prescaler Overflow

2. NV Write Deferred

3. PWA Simulate Active

ADVISE_MASK

The ADVISE_MASK parameter will mask any of the failed conditions listed

in ADVISE_ENABLED. A bit on means the condition is masked out from

alarming and will not be reported.

ADVISE_PRI

ADVISE_PRI designates the alarming priority of the ADVISE_ALM. The

default is 0 and the recommended value is 1 or 2.

3-7

Page 28

Rosemount 848L

Table 3-1.

RB.RECOMMENDED_ATION

Reference Manual

00809-0100-4696, Rev AA

September 2004

ADVISE_ACTIVE

The ADVISE_ACTIVE parameter displays which of the advisories is

active. Only the advisory with the highest priority will be displayed. This

priority is not the same as the ADVISE_PRI parameter described above.

This priority is not user configurable.

ADVISE_ALM

ADVISE_ALM is an alarm indicating advisory alarms. These conditions do

not have a direct impact on the process or device integrity.

Recommended Actions for PlantWeb Alarms

RECOMMENDED_ACTION

The RECOMMENDED_ACTION parameter displays a text string that will

give a recommended course of action to take based on which type and

which specific event of the PlantWeb alarms is active.

Alarm Type

NONE None No action required

ADVISORY

MAINTENANCE

FAILED

Failed/Maint/Advise

Active Event

Prescaler Overflow Check the Divisor parameter of all PS function

NV Write Deferred Reduce the frequency in which applications

PWA Simulate Active Disable PWA_SIMULATE parameter in the

Secondary Value

Degraded

Configuration Error Verify that the Logic equations are correct in

Electronics Failure Replace the electronics

NV Memory Failure Replace the electronics

No I/O Power Check the IO Power supply, polarity, wiring,

Primary Value Failure Check the sensor, configuration, wiring, and

Secondary Value

Failure

Recommended Action

Text String

calls in the logic equations

write to NV Memory

Resource Block

Ensure that the transmitter is not too close to

extreme hot or cold environments

the Logic transducer block

and connections.

connection for open or shorted sensors.

Verify that the body temperature is within the

operating limits of this device.

3-8

Page 29

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Alarms Use the following steps to configure the alarms, which are located in the

Resource Block.

1. Set the resource block to OOS.

2. Set WRITE_PRI to the appropriate alarm level (WRITE_PRI has a

selectable range of priorities from 0 to 15. Set the other block alarm

parameters at this time.

1

3. Set CONFIRM_TIME to the time, in

device will wait for confirmation of receiving a report before trying

again (the device does not retry if CONFIRM_TIME is 0).

4. Set LIM_NOTIFY to a value between zero and MAX_NOTIFY.

LIM_NOTIFY is the maximum number of alert reports allowed before

the operator needs to acknowledge an alarm condition.

5. Enable the reports bit in FEATURE_SEL.

6. Set the resource block to AUTO.

/32 of a millisecond, that the

I/O TRANSDUCER

BLOCK

The 848L is ordered with either Dry Contact, VDC or NAMUR Inputs. Each

input can have a filter which determines the minimum time a contact needs to

be at a given state to be acknowledged as a state change.

The following procedure allows the sensors to be configured:

1. Set MODE_BLK.TARGET to OOS

2. For each Input “n” select the parameter IN_n_CONFIG.FILTER

a. Select the desired filter time in the range of 0 to 128msec

3. Set MODE_BLK.TARGET to AUTO

3-9

Page 30

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

The 848L can force the outputs to a predetermined state in the event of a

device malfunction.

The following procedure can be used to set the fail safe condition for each

output:

1. Set MODE_BLK.TARGET to OOS

2. For each Output "n" select the parameter

OUT_n_CONFIG.FAIL_SAFE

3. Select False, True or Last Good Value

4. Set MODE_BLK.TARGET to AUTO

Latching

Most often the inputs are scanned and the logic equations processed at a rate

greater than the macrocycle frequency. To be certain that positive or negative

transitions are communicated, the inputs, equation results, and output values

can be latched until read by the function blocks.

The following procedure is used to set the latching state of each input,

equation or output:

LOGIC TRANSDUCER

BLOCK

1. Set MODE_BLK.TARGET to OOS

2. Select the appropriate parameter for either inputs, equations, or

outputs:

a. Inputs use parameter MACRO_IN_LATCH

b. Outputs use parameter MACRO_OUT_LATCH

c. Equations use parameter MACRO_EQ_LATCH

For each input, output or equation select either "Latch Positive Pulses" or

"Latch Negative Pulses" or “disabled”.

Logic Equations

The 848L provides for 16 Logic Equations and 4 Output Equations. The

Output Equations drive the hardware outputs. Each logic equation consists of

up to 80 characters with a semicolon as the last character. The equations are

evaluated at a nominal rate of 100msec. However this will vary based on the

number and complexity of the equations used. The logic block consists of

variables that are connected to the hardware I/O, obtain values or send

values over the bus and internally calculated variables as shown in

Figure 3-1.

The value or state of the logic block variables can be communicated on the

bus by assigning the appropriate channel number of a DI or MDI block. The

DO variables can be set externally by assigning the appropriate channel

number in a DO or MDO function block. The DO function blocks do not drive

the outputs directly. The DO function block can drive the output by referencing

the appropriate DO variable in the output equations.

3-10

Page 31

Reference Manual

00809-0100-4696, Rev AA

September 2004

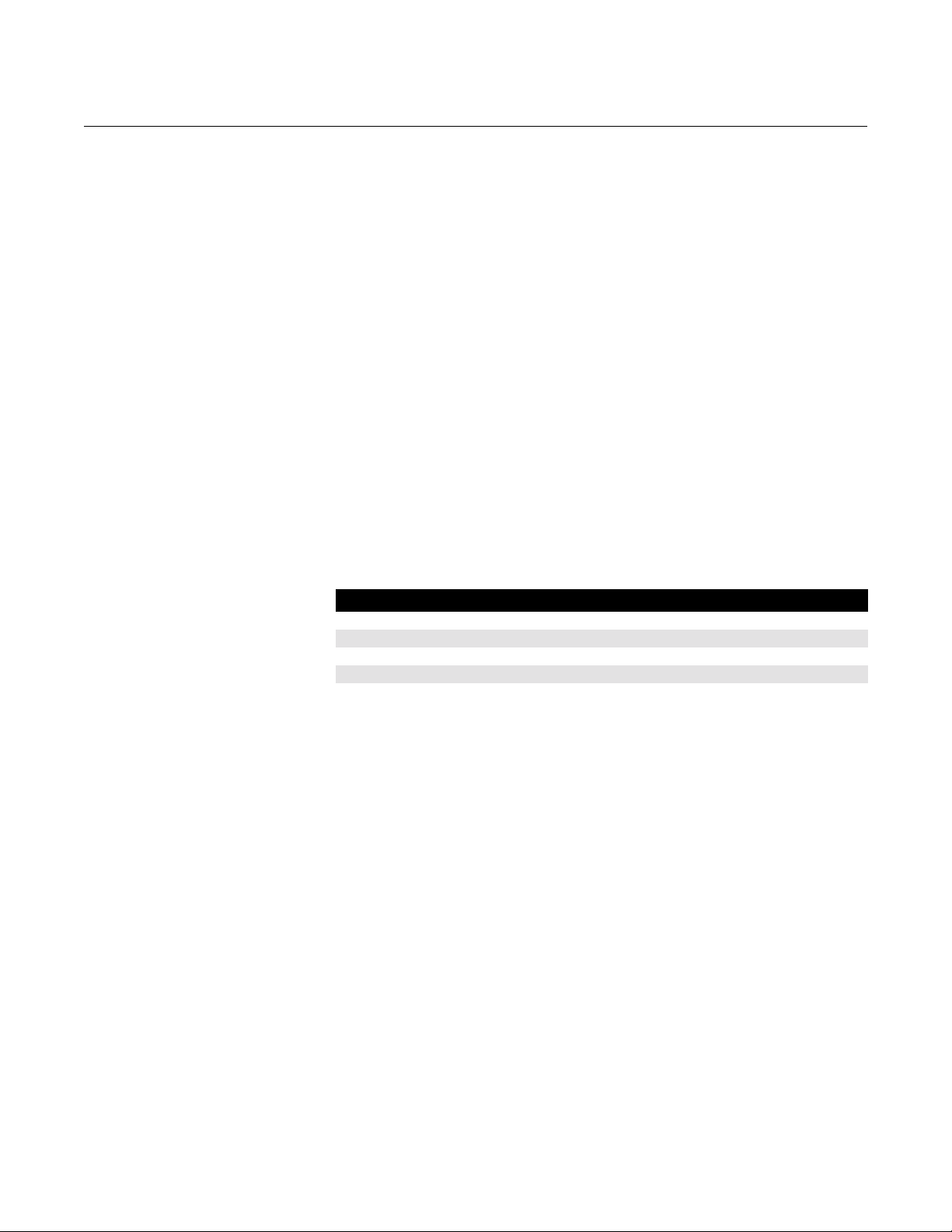

Figure 3-1. 848L Logic

Transmitter Data Flow

Rosemount 848L

Logic Transducer Block

Hardware

Inputs

Hardware

Outputs

IN_1

IN_2

IN_3

IN_4

IN_5

IN_6

IN_7

IN_8

DO_1

DO_2

DO_3

DO_4

DO_5

DO_6

DO_7

DO_8

EQ_1

EQ_16

OUT_1

OUT_2

OUT_3

OUT_4

16 Logic

Equations

4 Output

Equations

DI Channel

Any IN

Any EQ

Any OUT

---------------

8 Pack ed INs

First 8 Packed EQs

Last 8 P acked EQs

4 Pack ed OUTs

MDI Channels

ALL INs

First EQs

Last E Qs

All OUTs

DO Channel

Any DO

-----------------

8 Packed DOs

MDO Channe l

All DOs

DI Block

MDI Block

8 Inputs

DO Block

MDO Block

8 Outputs

OUT

OUT_1

OUT_8

IN

IN_1

IN_8

Sensor Transducer Block

Sensor & Output Confi guration

3-11

Page 32

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

The following characters are allowed in a logic equation:

• Uppercase and lowercase alphabet, case insensitive, used to specify

functions

• Digits 0-9, used to specify channel numbers and unsigned integer

constants

• Comma, used to separate parameters in a function parameter list

• Parentheses() used to define the extent of the parameter list of a

function

• Semicolon; used to terminate an equation

• Space (not tab), ignored by parser, may be used to make an equation

more readable but counts as a character

The following characters are specifically not allowed in a logic:

• The period (dot) character is not allowed. There are no decimal

numbers.

• The unary minus (-) character is not allowed. There are no negative

integers.

• The math operators (+, -, *, /, **) are not allowed, nor are symbols for

any logic operators (&, |, <, >, ...).

Functions must be from the list of Logic Functions below, and must have the

specified number of parameters.

Channel Functions

The following functions read channel value and status. The number of

instances of these functions is unlimited, except for PS. A channel value and

status is set by the I/O processor at the beginning of an equation evaluation

cycle, by the equations as they complete evaluation, or by macrocycle

evaluations of any DO blocks attached to channels 9 through 16. The status

of channels 9-16 is always good, even if the DO block has a bad status.

IN - The input hardware sets the values of channels 1-8. Configured DI blocks

may specify these channels in order to read the specified hardware input. The

value of an input may be referenced in an equation by the IN (i) function,

where the channel number is placed between the parentheses. The range of

‘i’ is 1 to 8. Multiple references to any channel are allowed.

ICR, ICF - I/O samples are taken every millisecond, which is considerably

faster than equation executions. It is possible for an input to turn on and turn

off during an equation evaluation cycle, so that it would not be seen by an

IN (i) function. Each input has a counter for transitions (rise or fall). A

transition is based on the output of the debounce filter, not the raw input.

Filtering can be set to zero. The counter is read and cleared at the beginning

of each evaluation cycle. The method relies completely on the counter and

does not use the latch configuration. The ICR (i) function is true for one

evaluation cycle if a rising transition occurred, and its opposite ICF (i) is true

for a falling transition.

3-12

Page 33

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

PS - When the hardware input consists of a continuous train of pulses at a

rate less than 500 PPS, a prescaler can be used to reduce the pulse rate to

something that does not change faster than the equation evaluation rate. The

function is PS (i, divisor) where ‘i’ is the channel number (1-8) and ‘divisor’ is

the number of pulses to count before setting its output true for one equation

evaluation cycle. The counter rolls over at ‘divisor’ and keeps counting. The

user must assure that there is always at least one execution cycle with a false

value from PS for every true value. If the pulse rate exceeds the divisor times

two, then the function returns Bad status and optionally a PlantWeb alert can

be sent. Only ten of these functions are available because they require

storage for previous values.

DO - Channels 9-16 are zero unless set by configured DO or MDO function

blocks. This allows a function block link to set the value from a remote

function block output or HMI screen switch. The values may be referenced in

equations by the DO (d) function. The range of ‘d’ is 1 to 8. To directly drive an

output from an external device the Output Equation would reference DO(d).

NOTE

The value of DO can change during an evaluation cycle if the macrocycle

evaluates the DO block. This may require referencing the DO value in a single

equation to “save” its state.

3-13

Page 34

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

EQ - Channels 17-32 are set by the result of an equation specified by up to 80

characters and stored in parameter EQx, where x is the equation number. The

equation results are available as a discrete value and status in parameter

EQx_VALUE. They may be referenced by the EQ (u) function. The range of

‘u’ is 1 to 16. These are intended to be intermediate values that are used

because the value is used in other equations or because the equation text

was too long. A configured DI block may use an equation channel (range 17

to 36) in order to make the result available to other devices.

OUT – The value will be the same as the requested output.

Additional Channels

The ten channels that are used for connecting multiple in or out function

blocks can not be referred to by equation functions. Each has a status that is

Bad if any Input status is Bad. Channels 37 to 41 pack the values into one

byte so that a DI or DO function block can read or write them. Any block linked

to a DI block with packed data must be capable of handling the packed

boolean values. Channels 42 to 46 may be used with standard MDI or MDO

blocks.

Channel Typ e FB

37 All IN DI

38 All DO DO

39 First 8 EQ DI

40 Last 8 EQ DI

41 All OUT DO

42 All IN MDI

43 All DO MDO

44 First 8 EQ MDI

45 Last 8 EQ MDI

46 All Out MDO

Reading a channel value will reset all of the channel latches that are

configured. Channels 38 and 43 do not have latches. If a DI and a MDI are

both used they will interfere with the latches, but the user is expected to use

one or the other, never both.

3-14

Page 35

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Logic Functions

A function has a name and a set of one or more arguments contained within a

closed set of parentheses. The seven channel reference functions (IN, ICF,

ICR, PS, DO, EQ, and OUT) have been described above. These are the only

functions that take a channel number as an argument. The other functions

require functions for all arguments unless the last argument is a constant

number.

When a function is evaluated, it leaves its true or false value behind to be

evaluated by the next function or used as the result of evaluating the

equation. This is the result of using a simple and fast evaluation method

known as Reverse Polish Notation (RPN). The RPN method requires nesting

the functions like OR(IN(1),IN(2)) rather than using operator notation like

IN(1) | IN(2). This can lead to the following:

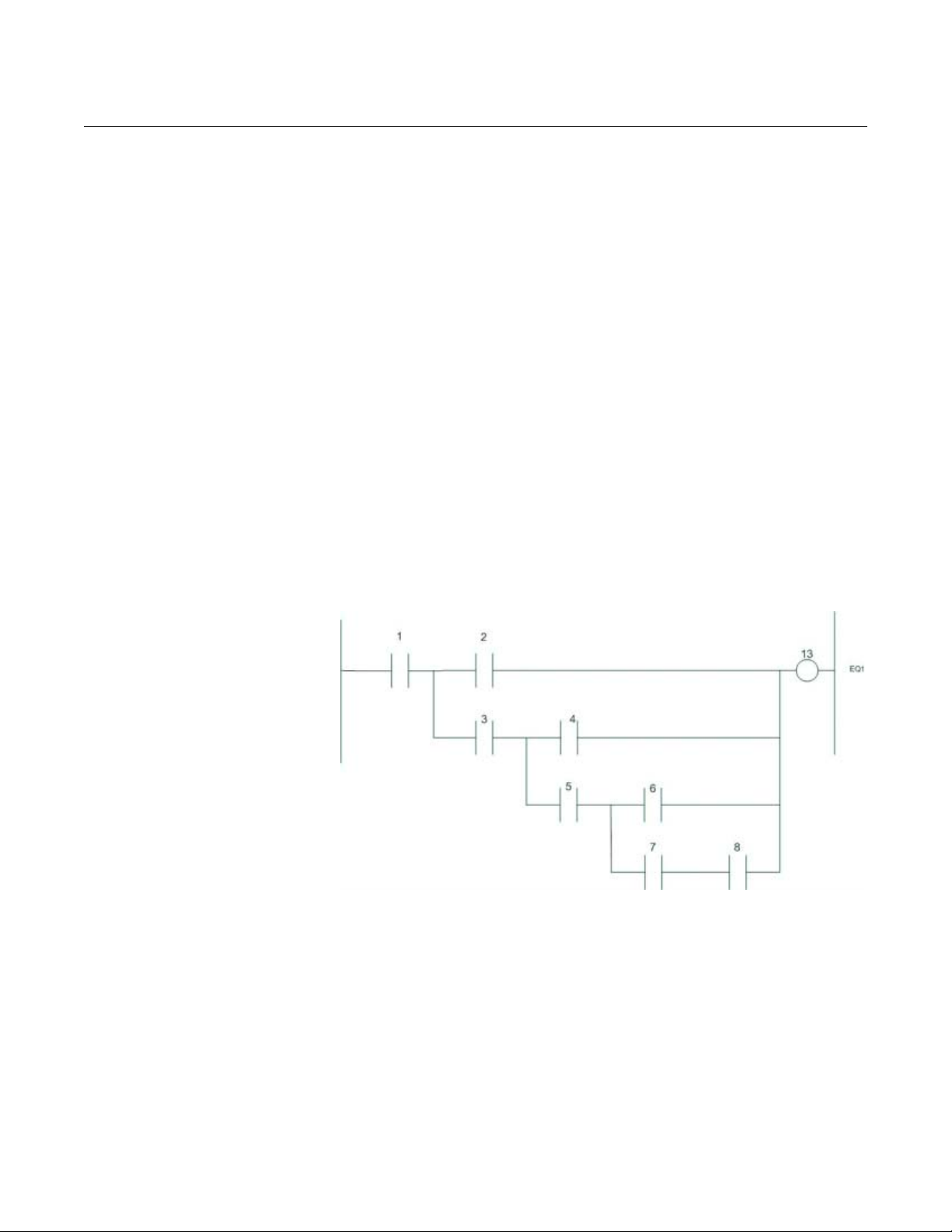

AND(IN(1),OR(IN(2),AND(IN(3),OR(IN(4),AND(IN(5),OR(IN(6),AND(IN(7),

(IN(8))))))));

The equation is evaluated by evaluating the deepest functions first, IN(7) and

(IN(8). If they are both true then the AND function evaluates to true. Then

IN(6) is evaluated, then the OR evaluates to true, and so on working up from

the deepest level in reverse order until the first (and top level) AND can be

evaluated. The result is stored in the channel specified by EQx, which

contains the text of the equation as explained above.

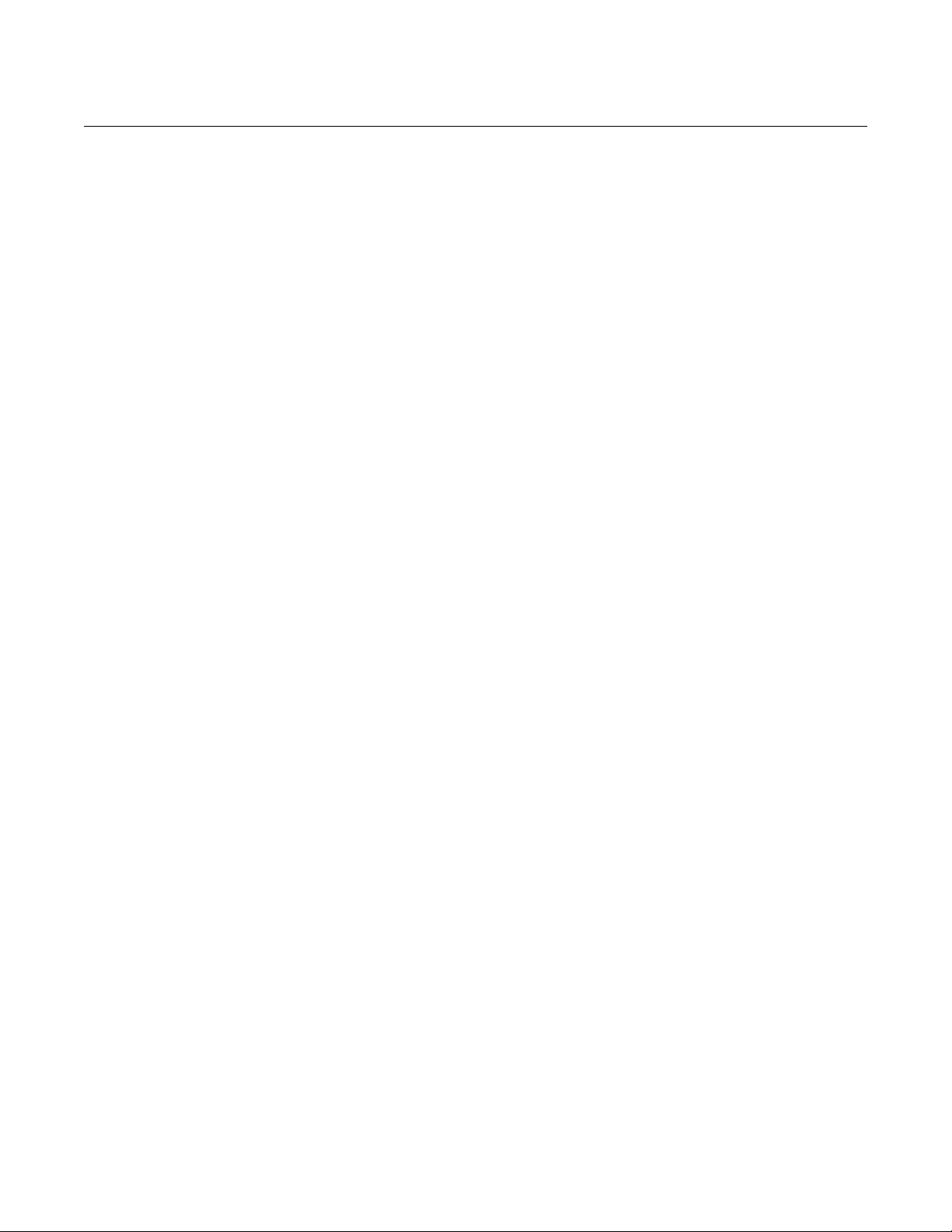

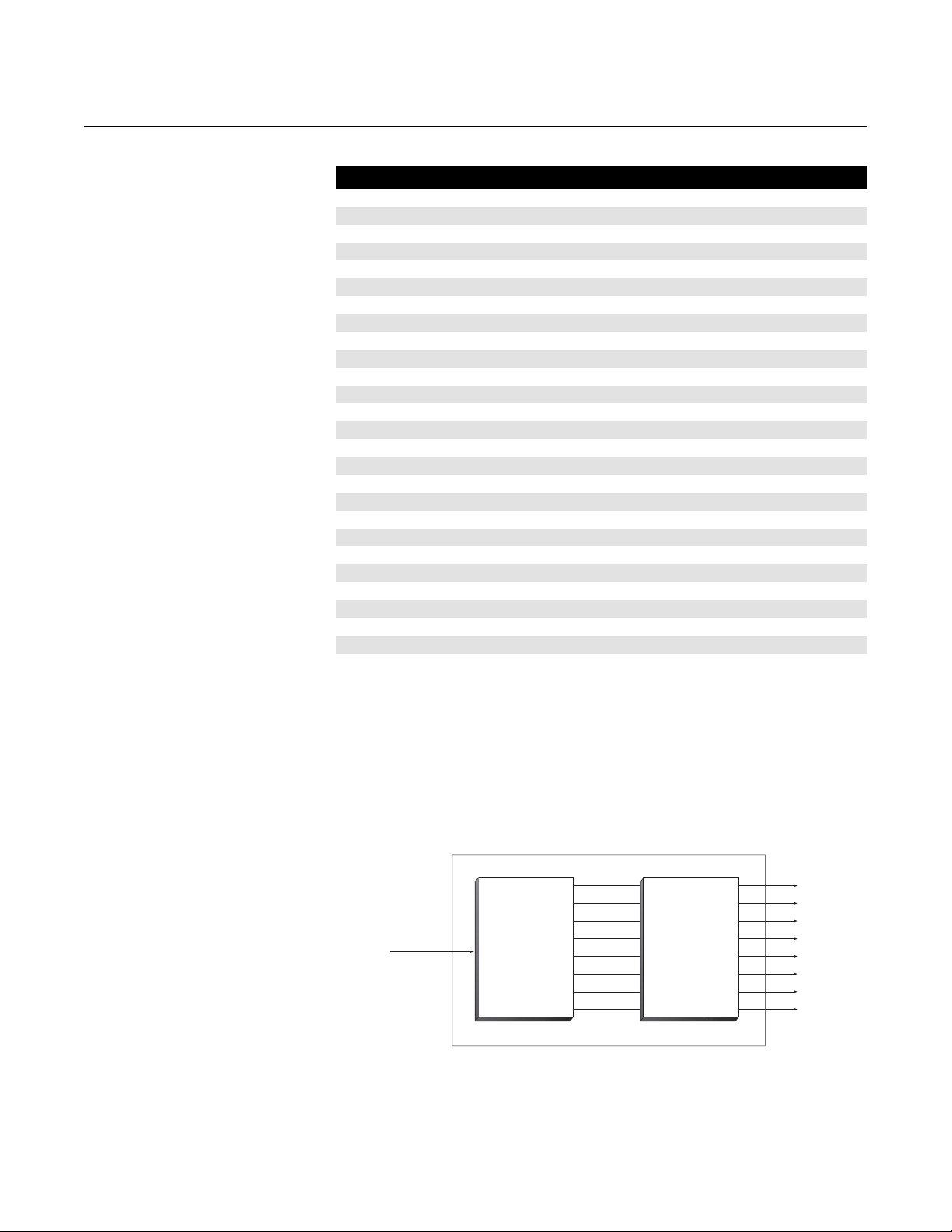

Drawn as a ladder logic, the equation would look like the figure below:

848L/LOGIC_FUNC_EXAMPLE.JPG

3-15

Page 36

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

Logic Operator Functions

The following combinatorial operators require a minimum of 2 and a maximum

of 10 functions between the parentheses, each separated by a comma.

AND ( ) - Performs the logical ‘and’ of the argument functions.

OR ( ) - Performs the logical ‘or’ of the argument functions.

XOR ( ) - Performs the logical exclusive ‘or’ of the argument functions. An

XOR function is false if all of the arguments are the same value, either all true

or all false. Otherwise it is true.

The following unary operator requires just one argument:

NOT ( ) - Performs the logical inversion of the argument function.

Limits on Functions

There is no limit to the number of functions described above, as long as they

fit within the 20 equations described by 80 character strings. The following

functions are limited to 10 of each within the entire set of 20 equations. This is

because the functions require memory to store constants or last values. The

size of a memory element is 16 bits, so the maximum size of a constant value

is 65535. There are no signed numbers.

Edge Detection Functions

RISE ( ) - This function evaluates as false unless the previous value of the

argument was false and now the argument evaluates to true. This function is

true for only one equation evaluation cycle. It will always be false on the

following cycle.

FALL( ) - This function evaluates as false unless the previous value of the

argument was true and now the argument evaluates to false. This function is

true for only one equation evaluation cycle. It will always be false on the

following cycle.

Clock Function

NOTE

All arguments of time are in tenths of a second.

CLOCK (onTime,offTime) - The parameters onTime and offTime are

constants. This function does not take other functions. CLOCK runs

unconditionally with a period determined by onTime plus offTime. Time is

specified in tenths of a second. The function will be true for onTime tenths of a

second. On the first evaluation cycle after the device starts up, the onTime

interval will start because all of the dynamic values are zero. Use the NOT

function to invert this behavior, and swap the on and off times.

3-16

Page 37

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

Counter Functions

CTU (clock, reset, target)- The parameters clock and reset are functions. The

target is a 16 bit constant. Whenever reset is true, the internal counter is set to

zero and the value of the function is false. The value of clock is ignored while

reset is true. If reset is false, the internal counter will increment once for each

rise of the clock parameter. When the internal counter equals the target value,

the value of the function is true and the counter stops counting in order to

avoid rollover. The value of the function is false if the internal counter does not

equal the target.

The internal counter is not visible from Fieldbus and is not available to any

other function. The value of the internal counter is not retained during a device

restart. This function is not suitable for a totalizer, but can be used as a

prescaler to adjust the external mechanical counter rate. The pulse rate must

be less than five per second.

The following expression increments the counter whenever hardware input 1

turns on. The counter is reset whenever hardware input 2 is on. If input one is

from a mechanical displacement flowmeter that delivers 76.54 pulses per

gallon, then the highest flow rate is 3.5 gallons per minute. The following

equation will deliver one 0.1 second pulse per 100 gallons:

OUT1_EQ contains CTU(IN(1),OUT(1),7654);

Starting at zero, 7653 pulses go by and then pulse 7654 turns on the output.

On the next evaluation cycle, the counter is reset because Output 1 is on.

This is a result of the order of execution of equations. Output 1 becomes true

because the count is reached, but the OUT(1) function has already been

evaluated as false. The counter must reset before the next pulse comes in.

The output pulse may be extended with a TP function.

TON (power, target) - Whenever power is false, the value of the internal timer

is set to zero and the value of the function is false. When power is true then

the value of the function will become true after the target amount f time has

elapsed. This condition persists as long as power is true. The timer resets

when power is false.

The following equation filters the level switch in a stirred tank so that high

level bouncing of the float does not create nuisance alarms for the operator.

Hardware input 1 senses the level switch and hardware output 1 drives the

alarm annunciator with its big horn. The level switch must stay closed for 5

minutes before the alarm is energized and the operator is startled by the horn.

OUT1_EQ contains: TON(IN(1),3000);

TOF (power, target) - Whenever power is true, the value of the internal timer is

set to the target and the value of the function is true. The value of the function

will become false after the target amount of time has elapsed. This condition

persists as long as power is false.

The following equation keeps the outlet valve open for about 5 seconds after

the pump is shut off, so that the pressure across the pump can equalize.

Hardware output 1 runs the pump and hardware output 2 opens the valve

OUT1_EQ contains: <something that controls the pump>;

OUT2_EQ contains: TOF(OUT(1),50);

3-17

Page 38

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

TP (power, target) - Whenever power transitions from false to true, the value

of the internal timer is set to the target and the value of the function is true.

The value of the function will become false after the target amount of time has

elapsed. This function is similar to TOF except that a timing cycle is only

initiated by the rise of power. Power may go false or stay true without affecting

the timing cycle. The cycle is restarted anytime that power goes true after the

function has had at least one evaluation cycle as false.

Latching Functions

A latch is a two state device that can be set to true or reset to false. It will

retain its state when both commands are false. It will not retain its state

through a device restart. The initial state is Reset. Two latch functions are

required to define the behavior when both commands are true, depending on

which state should be dominant. The result of the function is the state of the

latch.

SR (set, reset) - The parameters set and reset are functions. If both are true

then set wins and the result of the function is true.

RS (set, reset) - The parameters set and reset are functions. If both are true

then reset wins and the result of the function is false.

Shifting Functions

A shift register is a set of bits that moves each bit to the next bit position when

the command to shift is given. The vacant bit is filled with the value of the

input. The 848L shift functions contain 8 bit registers. The bit parameter

selects the bit in the register to test. The value of the function is the value of

the tested bit. The shift may be to the left or the right. The following table

shows the state of the register for three shifts after the register has been

reset. The input is true during the first shift evaluation and false thereafter.

The right most bit is bit 1 and the left most bit is bit 8.

Direction Reset Shift 1 Shift 2 Shift 3

Left 00000000 00000001 00000010 00000100

Right 00000000 10000000 01000000 00100000

The reset parameter clears the register, overriding both input and shift. Reset

is an optional parameter, but the function can be written with three parameters

or four. Do not use an extra comma if reset is omitted.

The register data will be cleared on a processor restart (i.e. power cycle).

SHL (input, shift, reset, testbit) - The parameters input, shift, and reset are

functions. The parameter testbit is a constant that is constrained to be in the

range of 1 to 8. The reset function is optional. If reset is present and true, the

8 bit register is cleared to zero and the result of the function is false.

Otherwise, if shift is true then bit 7 will be moved to bit 8, bit 6 to bit 7, bit 5 to

bit 6, bit 4 to bit 5, bit 3 to bit 4, bit 2 to bit 3, bit 1 to bit 2, and the value of input

will become the value of bit 1. Then the bit specified by testbit will be tested to

determine the value of the function.

3-18

Page 39

Reference Manual

00809-0100-4696, Rev AA

September 2004

Rosemount 848L

SHR (input, shift, reset, testbit) - The parameters input, shift and reset are

functions. The parameter testbit is a constant that is constrained to be in the

range of 1 to 8. The reset function is optional. If reset is present and true, the

8 bit register is cleared to zero and the result of the function is false.

Otherwise, if shift is true then bit 2 will be moved to bit 1, bit 3 to bit 2, bit 4 to

bit 3, bit 5 to bit 4, bit 6 to bit 5, bit 7 to bit 6, bit 8 to bit 7, and the value of input

will become the value of bit 8. Then the bit specified by testbit will be tested to

determine the value of the function.

The following procedure is used to enter the logic equations.

1. Set MODE_BLK.TARGET to OOS

2. Enter the equations in parameters EQn where n=1 to 16 or

OUT1_EQ, OUT2_EQ, OUT3_EQ or OUT4_EQ. Each equation

ending with a semicolon.

3. Set the MODE_BLK.TARGET to AUTO

The equations will then be evaluated and the status of the evaluation shown

in the parameter PARSE_RESULT. If any errors were found the block will

remain in the OOS mode.

Status Propagation

The contact and Boolean value has a binary value and a good/bad status.

A status is applied to a channel value in one of the following ways:

The hardware input device maybe able to tell if it is shorted or open, in

addition to on or off. If the hardware cannot tell then the status is always

good, unless a device failure prevents reading the I/O data.

The evaluation of an equation propagates either Good Non-cascade or

Bad, both Non-specific.

Each function that is evaluated determines both a value and a status of either

good or bad. The functions that provide status are the functions that test a

channel number - IN, ICF, ICR, OUT, DO, PS and EQ. If any of the function’s

parameters have a Bad or Uncertain status with any sub-status then the

function terminates and returns a bad status, otherwise it returns a good value

and status.

When an equation (set of functions) is evaluated, if a function returns a bad

status then evaluation of that equation stops, and the equation channel status

is set to Bad, Non-specific. If evaluation goes to completion, the channel

status will be set to Good Process, Non-specific, not limited.

Status propagates forward, in the direction of the last output equation. If a

function references an equation that is the equation being evaluated or a later

equation, then the status of that equation will be ignored. The function will use

the last good value of the referenced equation and call its status Good. This

prevents forward references to equations that reference this equation from

locking both equations into Bad status if either ever sets Bad status.

During initialization of the logic transducer block, before the first execution,

each equation channel status is set to Bad, Non-specific, constant and the

value is set to False.

3-19

Page 40

Rosemount 848L

Reference Manual

00809-0100-4696, Rev AA

September 2004

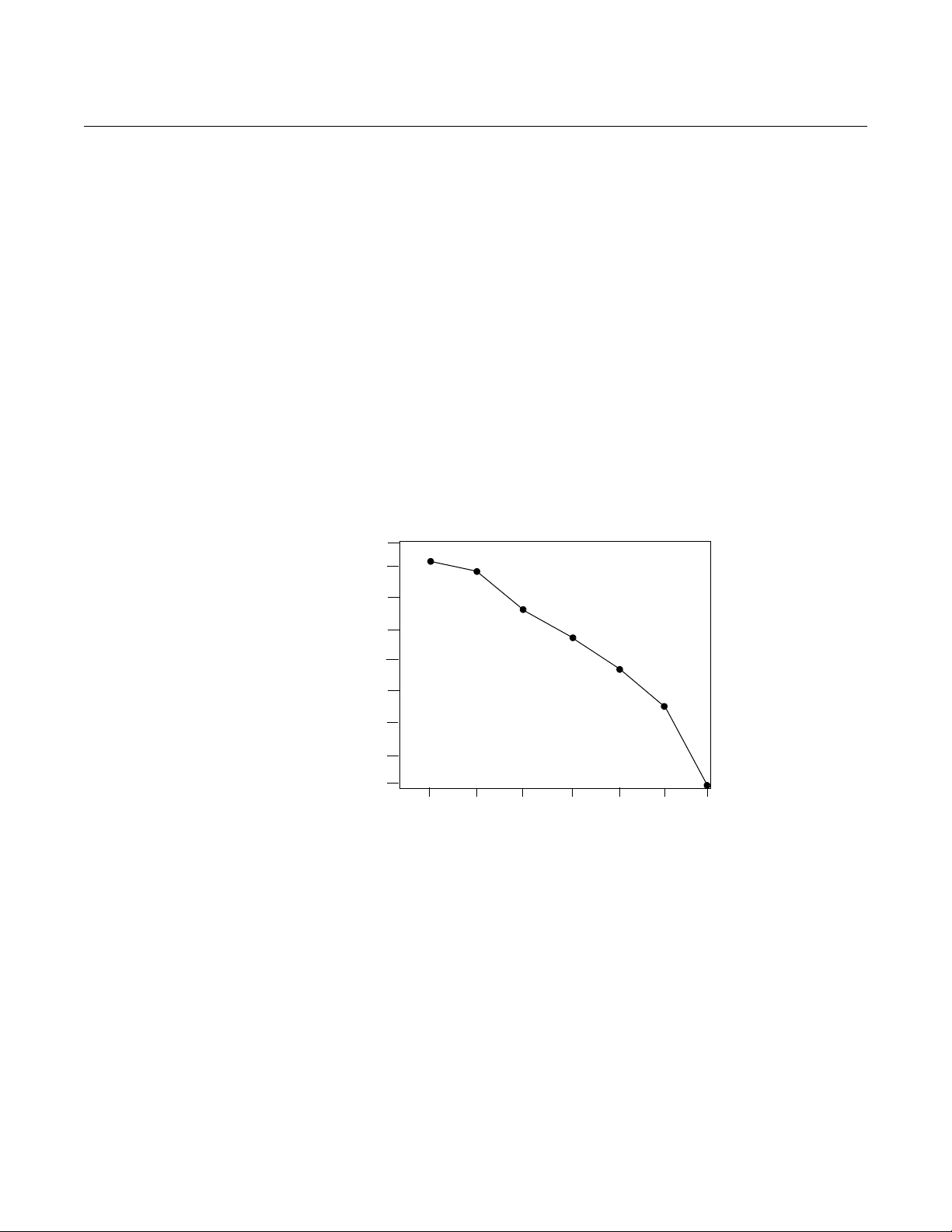

Logic Execution Timing

The Logic transducer block reads the hardware inputs, processes the

equations and drives the outputs on a continuous cycle. The cycle time or

frequency of execution will vary depending on the number and type of logic

functions used in the equations.

DISCRETE INPUT

BLOCKS

The DI blocks are used to communicate the current value of a contact, the

state of one of the Boolean equations, or the state of an output. The DI block

chooses the value through the Channel parameter. Alternatively, the DI block

can be configured to pass 8 values in a packed format to the host system

(DeltaV) by using channels 7 to 41. To set the channel number use the

following procedure for each DI block.

1. Set MODE_BLK.TARGET to OOS

2. Select the Channel parameter

3. Select the desired channel number

4. Set MODE_BLK.TARGET to AUTO

Channel 1= “Input 1” Channel 24= “EQ 8”

Channel 2= “Input 2” Channel 25= “EQ 9”

Channel 3= “Input 3” Channel 26= “EQ 10”

Channel 4= “Input 4” Channel 27= “EQ 11”

Channel 5= “Input 5” Channel 28= “EQ 12”

Channel 6= “Input 6” Channel 29= “EQ 13”

Channel 7= “Input 7” Channel 30= “EQ 14”

Channel 8= “Input 8” Channel 31= “EQ 15”

Channel 9= “DO 1” Channel 32= “EQ 16”

Channel 10= “DO 2” Channel 33= “Output 1”

Channel 11= “DO 3” Channel 34= “Output 2”

Channel 12= “DO 4” Channel 35= “Output 3”

Channel 13= “DO 5” Channel 36= “Output 4”

Channel 14= “DO 6” Channel 37= “Packed Inputs”

Channel 15= “DO 7” Channel 38= “Packed DO”

Channel 16= “DO 8” Channel 39= “Packed EQ1”

Channel 17= “EQ 1” Channel 40= “Packed EQ2”

Channel 18= “EQ 2” Channel 41= “Packed Outputs”

Channel 19= “EQ 3” Channel 42= “Array Inputs” (MDI Only)

Channel 20= “EQ 4” Channel 43= “Array DO” (MDI Only)

Channel 21= “EQ 5” Channel 44= “Array EQ1” (MDI Only)