Page 1

Group 5 Controller

User’s Guide

for 4000 & 7000 Series

Automatic Transfer Switch Products

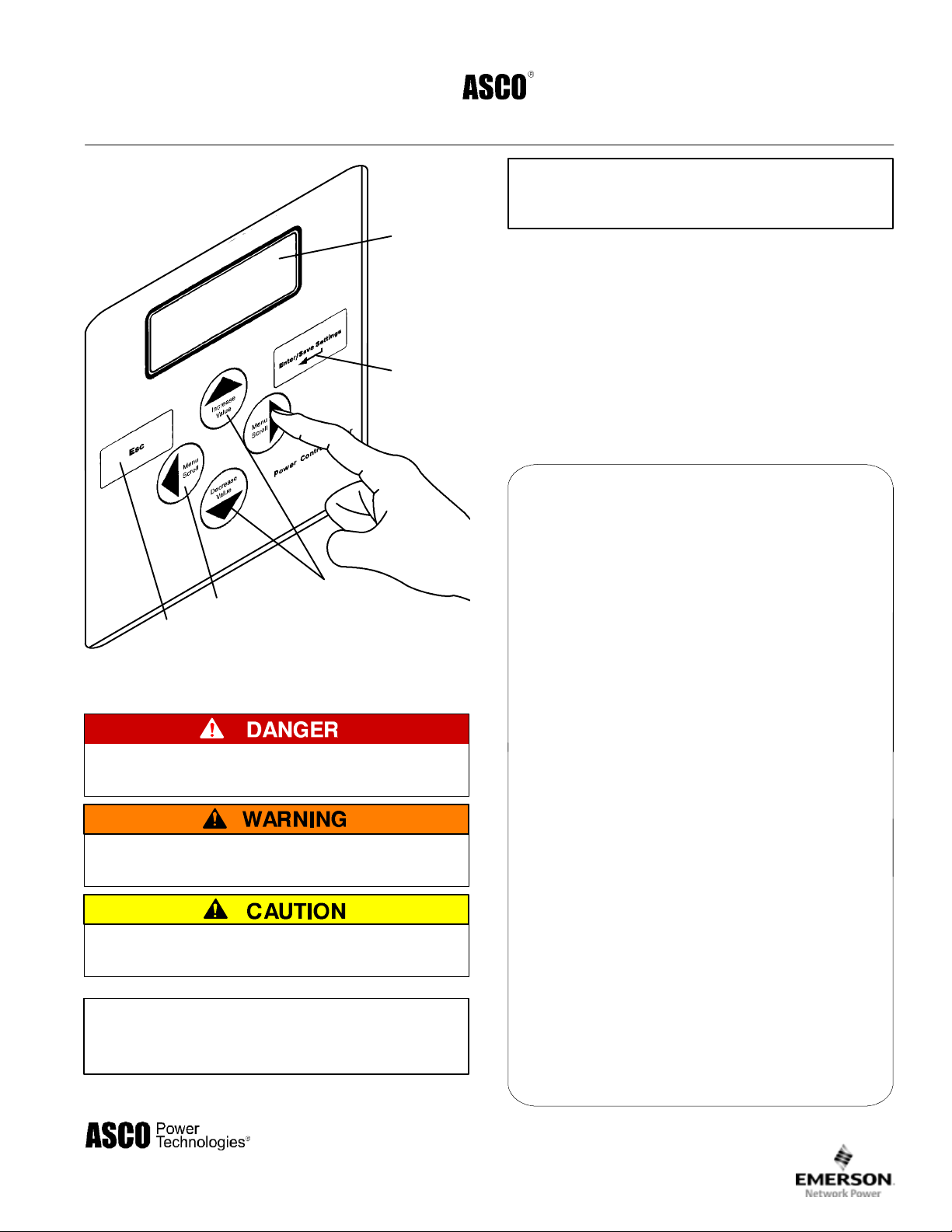

cut–out opening

in enclosure

door

Increase (up)/

Decrease (down)

Value keys

Esc

key

Menu Scroll

(left/right)

keys

Power Control Center keypad and display

DANGER is used in this manual to warn of high

voltages capable of causing shock, burns, or death.

4–line

LCD

display

Enter/Save

Settings

key

Refer to the Operator’s Manual for the ASCO 4000 or

7000 Series ATS product for installation, functional

testing, sequence of operation,and troubleshooting.

Description

ASCO 4000 & 7000 Series Automatic Transfer Switch

products utilize the Group 5 Controller for sensing,

timing, and control functions. This state–of–the art

microproce ssor– based controller includes a built–in

keypad and a four–line LCD display. All monitoringand

control functions can be done with the enclosure door

closed for greater convenience. In addition, all changes

in voltage settings (except for nominal voltage) and time

delayscanbemadethroughasystemofmenus.

TABLE OF CONTENTS

section-page

OVERVIEW

Controls 1-1..............................

Settings 1-2..............................

SETTINGS

How to Change a Setting 2-1...............

Voltage & Frequency 2-2...................

Time Delays 2-4..........................

Features 2-6..............................

General 2-8..............................

Engine Exerciser 2-10.....................

View Event Log 2-12.......................

Service — Statistics / Diagnostics 2-13......

OPERATING the CONTROLS

Status of ATS and Sources 3-1.............

WARNINGisusedinthismanualtowarn

of possible personal injury.

CAUTIONisusedinthismanualtowarn

of possible equipment damage.

Refer to the outline and wiring drawings provided with

the 4000 or 7000 Series ATS product for all inst allation

and connection details and accessories.

50 Hanover Road, Florham Park, New Jersey 07932–1591 USA

For sales or service call 1 800 800–2726 (ASCO) www.ascopower.com

ASCO POWER TECHNOLOGIES CANADA PO Box 1238, 17 Airport Road, Brantford, Ontario, Canada N3T 5T3

telephone 519 758–8450, fax 519 758–0876, for service call 1 888 234–2726 (ASCO) www.asco.ca

Display Messages and Their Meanings 3-2...

DESCRIPTION of OPERATION

Open–Transition 4-1.......................

Closed–Transition 4-3......................

Delayed–Transition 4-6....................

APPENDIX

DIP switch actuators A-2...................

Voltage jumper blocks A-4.................

INDEX back page..........................

381333–126 K

Page 2

1--1 Overview

Control Overview

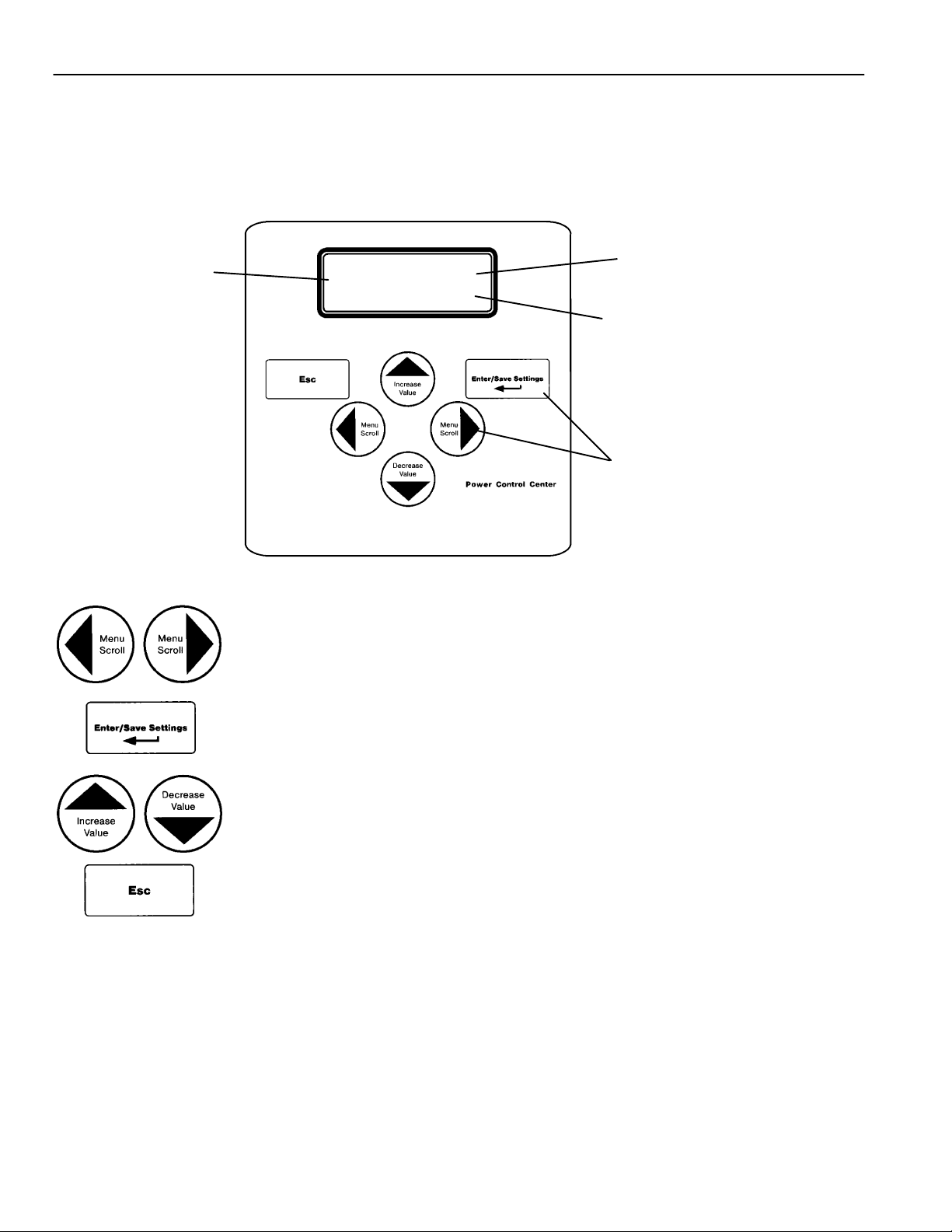

4–line LCD display

On the Power Control Center, six keys allow access to all monitoring and setting

functions. Two levels of screens are used. The status level provides information

about the automatic transfer switch. The settings level allows configuration of the

controller. Access to some settings may require entering a password (if the

controller is set for one – see page 2–1 and Appendix A–3).

top 2 lines show the

cause of any action

lower 2 lines show the

status of transfer sequence

tactile keys

(see below)

Power Control Center display and keypad.

Left–Right Arrows

The left A and right " arrow keys (Menu Scroll) navigate through the screens.

Enter/Save Settings

The Enter/Save Settings ¿ key move from the status level to the settings level

screens. It also is used to enter a new s etting.

Up–Down Arrows

The up Y and down B arrow keys (Increase Value and Decrease Value) modifies

a setting (setup parameter) while in the settings level screens.

Esc key

The Esc key ignores a change and returns to the status level.

Page 3

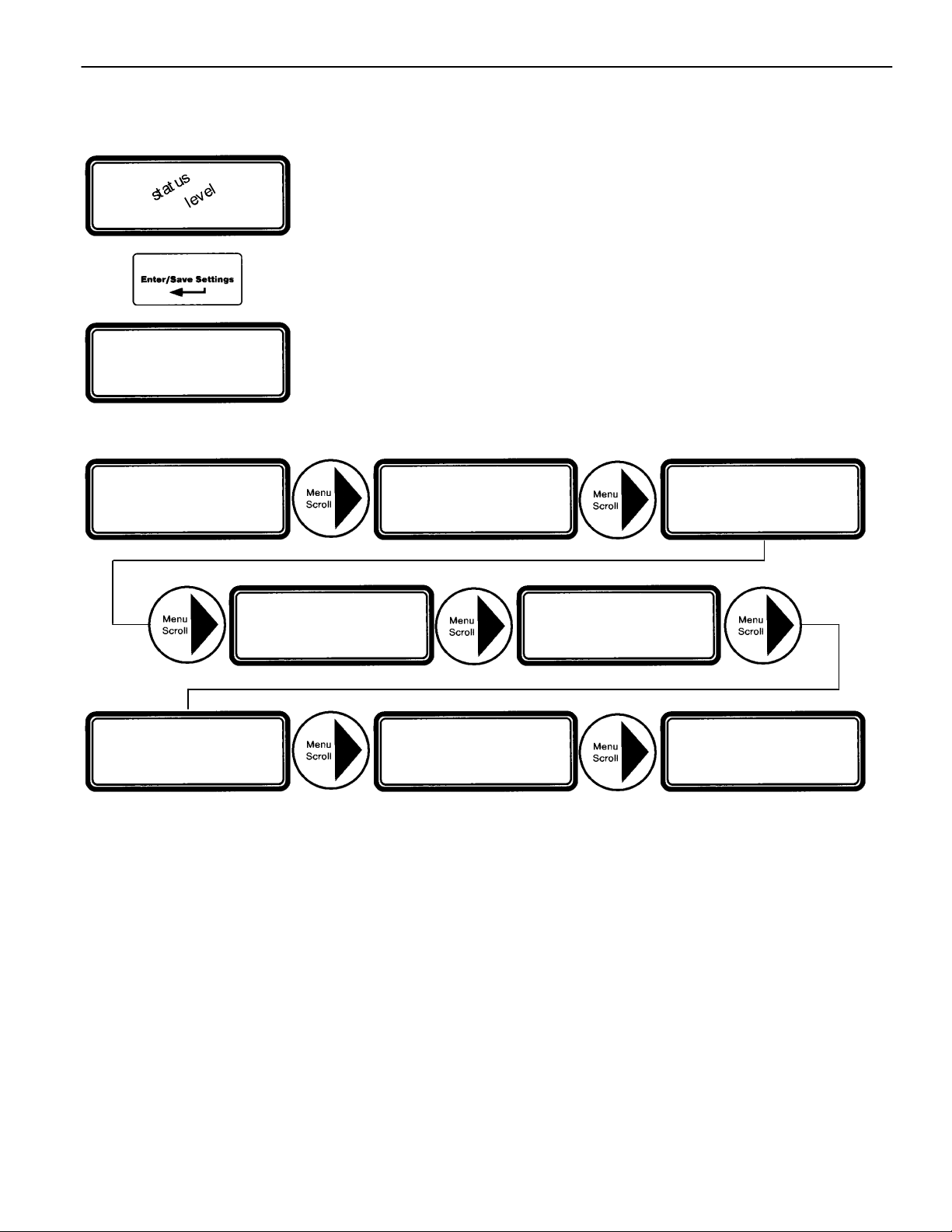

Settings Overview

1--2Overview

The controller settings can be displayed and changed from the keypad.

Some settings may require a password (if the controller is set up for one).

From the ATS Status display, press Enter/Save Settings ¿ keytomovetothe

Settings level of menus.

SETTINGS

SETTINGS

Voltage DO PU

Frequency DO PU

VIEW

Event Log

Press the right arrow key " to see the eight parameter information headings (as

shown below). An overview of each setting is listed below. The detailed menus

for each setting are on the following pages.

8 Parameter Menus (loop back to beginning)

SETTINGS

General

SETTINGS

Time Delays

SETTINGS

Engine Exerciser

SERVICE

Statistics

Diagnostics

SETTINGS

Features

SERVICE

Factory

Selectable Features

Voltage and Frequency Settings seepage2–2

CP settings and Normal & Emergency voltage and frequency pickup & dropout.

Time Delay Settings seepage2–4

Bypass running time delay, and settings for all standard time delays.

Features Settings seepage2–6

Commit on transfer, shed load, phase rotation, and inphase monitor settings.

General Settings seepage2–8

Reset settings, language, communication, logging, and password.

Engine Exerciser Settings seepage2–10

Present date and time, seven exercise programs each with six parameters.

View Event Log seepage2–12

Last 99 events in date and time order; six types and seven reasons are logged.

Service Statistics/Diagnostics, Factory Selectable Features

For factory service use only. see pages 2–13

Page 4

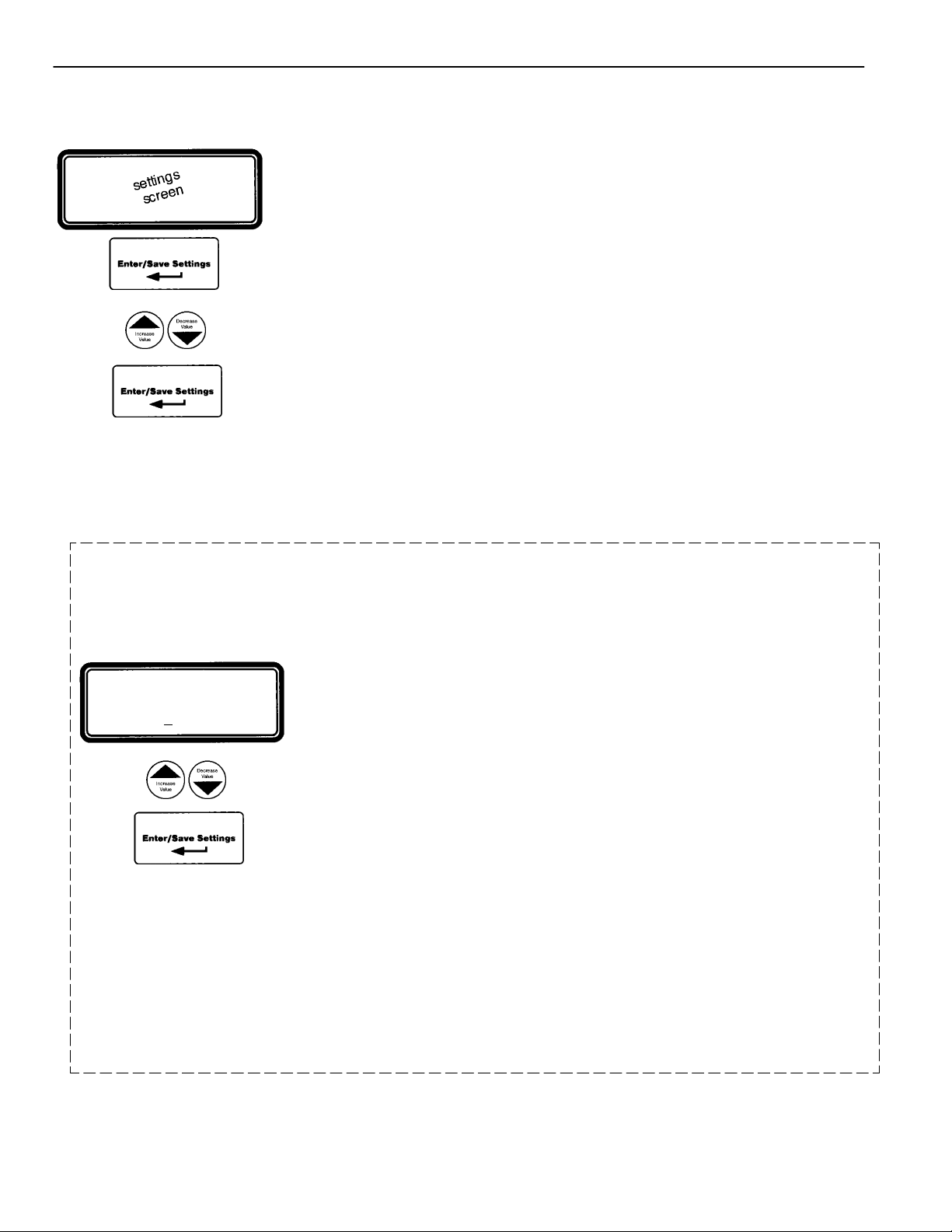

2--1 Settings

How to Change a Setting

¡

©

¢

£

Tips

☞

To change a setting in the controller (CP):

¡ Navigate to the settings screen that you want to change (see page 1–2).

© Press Enter/Save Settings ¿ key to start the first field blinking. If the controller

requires a password, see below.

¢ Press up Y and downB arrow keys to changeflashing digit(s)or word and press

Enter/Save Settings ¿ keytomovetonextfield.

£ Repeat step ¢ until all the fields have been entered.

If a field is blinking, the CP is waiting for information to be entered.

The Esc key will end the editing session.

Tip

Enter

Password

0

000

Tip

☞

☞

Password

Default password is 1111 (see page 2–8)

If Enter Password displays, y ou must enter the correct password first.

Use the up Y and down B arrow keys to change the flashing digit of the

password. Press the Enter/Save Settings ¿ keytomovetonextnextdigit

(left to right). When the correct password is displayed, press the Enter/

Save Settings ¿ key.

If WRONG PASSWORD !!! displays, you are returned to the first flashing

digit. When the correct password is displayed, press the Enter/Save

Settings ¿ key.

You can now change the settings on the selected screen.

Once the password is entered it will stay unlocked for 5 minutes after last

key is pushed so that you do not have to keep entering it. So, to save time,

plan to make all your settings at one time.

Page 5

Voltage & Frequency Settings

S

S

Frequency

Frequency

Unless otherwise specified on the order, the controller voltage and frequency

settings are set at the factory to the default values. If a setting must be changed,

carefully follow the procedure on the next page. Some settings may require a

password (if the controller is set up for one).

Any indiscriminate change in these settings may affect the normal

operation of the Automatic Transfer Switch. This change could allow

the load circuits to remain connected to an inadequate source.

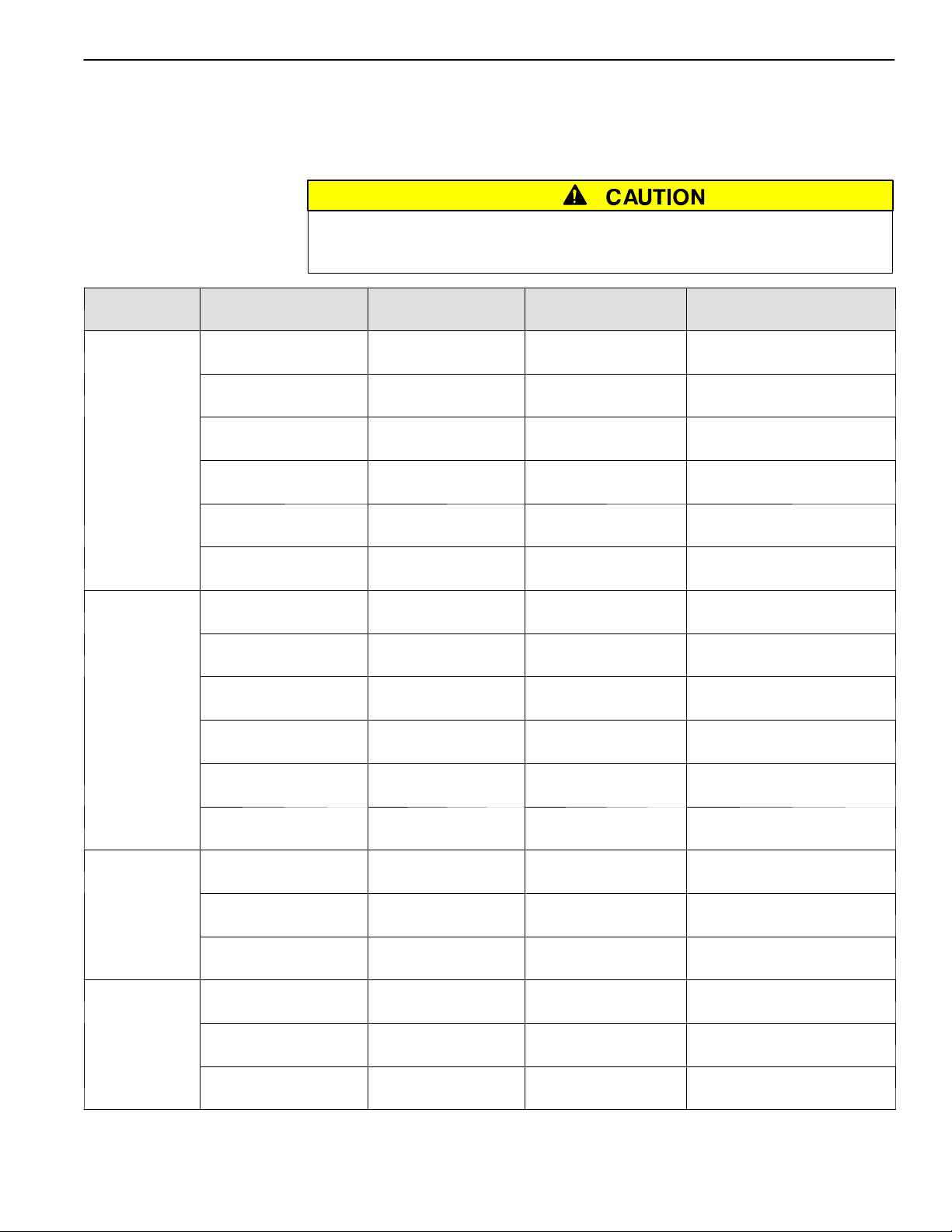

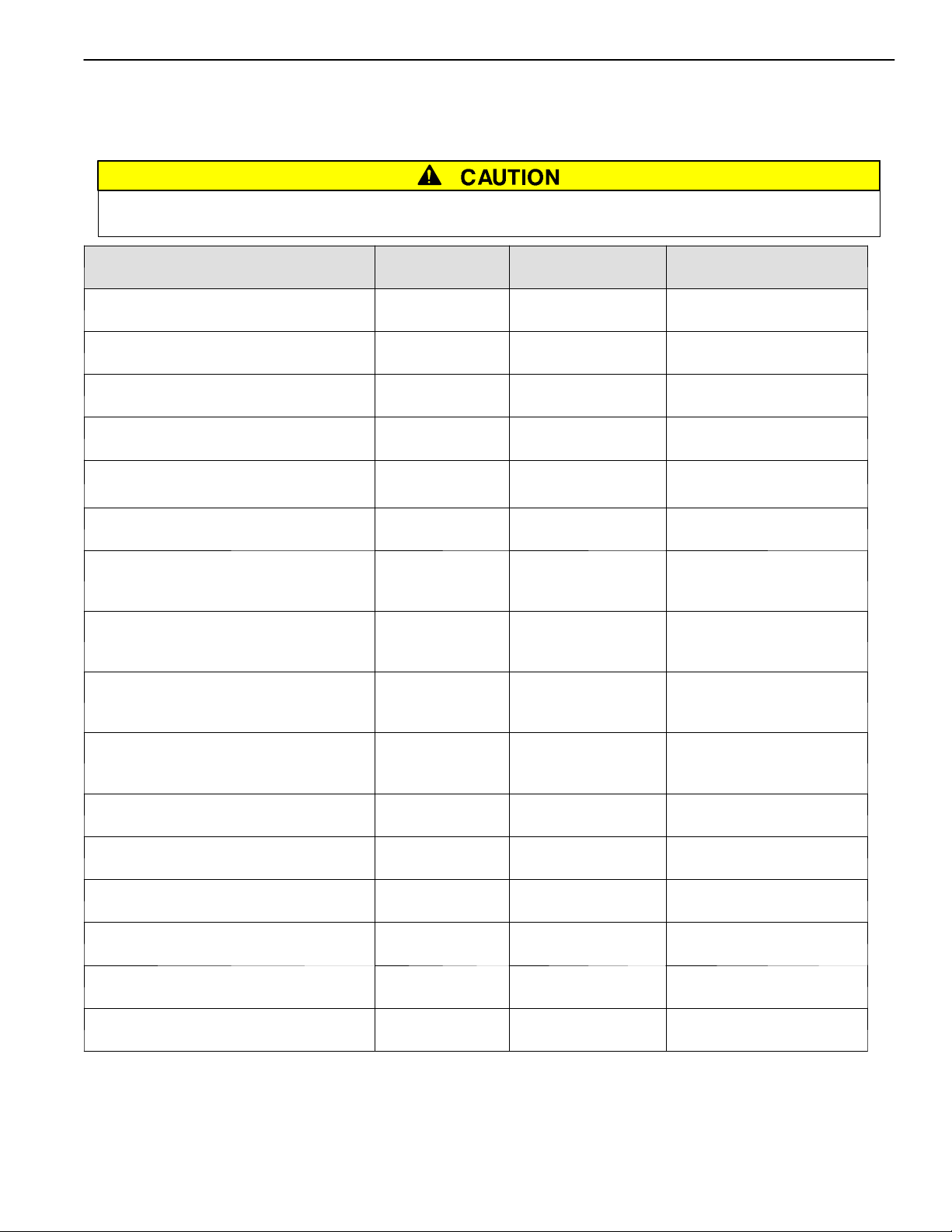

2 --- 2Settings

Description Settings

Dropout 85 % 70 to 98 %

Pickup 90 % 85 to 100 %

Normal

ource

Voltage

Emergency

ource

Voltage

Normal

Source

Emergency

Source

Over Voltage Trip * off 102 to 115 %

Unbalance Enable no yes or no

Unbalance Dropout 20 % 5to20%

Unbalance Pickup 10 % 3to18%

Dropout 75 % 70 to 98 %

Pickup 90 % 85 to 100 %

Over Voltage Trip * off 102 to 115 %

Unbalance Enable no yes or no

Unbalance Dropout 20 % 5to20%

Unbalance Pickup 10 % 3to18%

Dropout 90 % 85 to 98 %

Pickup 95 % 90 to 100 %

Over Frequency Trip * off 102 to 110 %

Dropout 90 % 85 to 98 %

Pickup 95 % 90 to 100 %

Over Frequency Trip * off 102 to 110 %

Default Setting

%ofnominal

Adjustment Range

increments of 1%

Display Screen

(see next page)

NORMAL VOLTAGE

Dropout

NORMAL VOLTAGE

Pickup

NORMAL VOLTAGE

OV Trip

NORMALVOLTAGEUNBAL

Enable

NORMALVOLTAGEUNBAL

Dropout

NORMALVOLTAGEUNBAL

Pickup

EMERG VOLTAGE

Dropout

EMERG VOLTAGE

Pickup

EMERG VOLTAGE

OV Trip

EMERG VOLTAGE UNBAL

Enable

EMERG VOLTAGE UNBAL

Dropout

EMERG VOLTAGE UNBAL

Pickup

NORMAL FREQUENCY

Dropout

NORMAL FREQUENCY

Pickup

NORMAL FREQUENCY

OF Trip

EMERG FREQUENCY

Dropout

EMERG FREQUENCY

Pickup

EMERG FREQUENCY

OF Trip

* The Over Voltage and Over Frequency reset is fixed at 2% below the trip setting.

Page 6

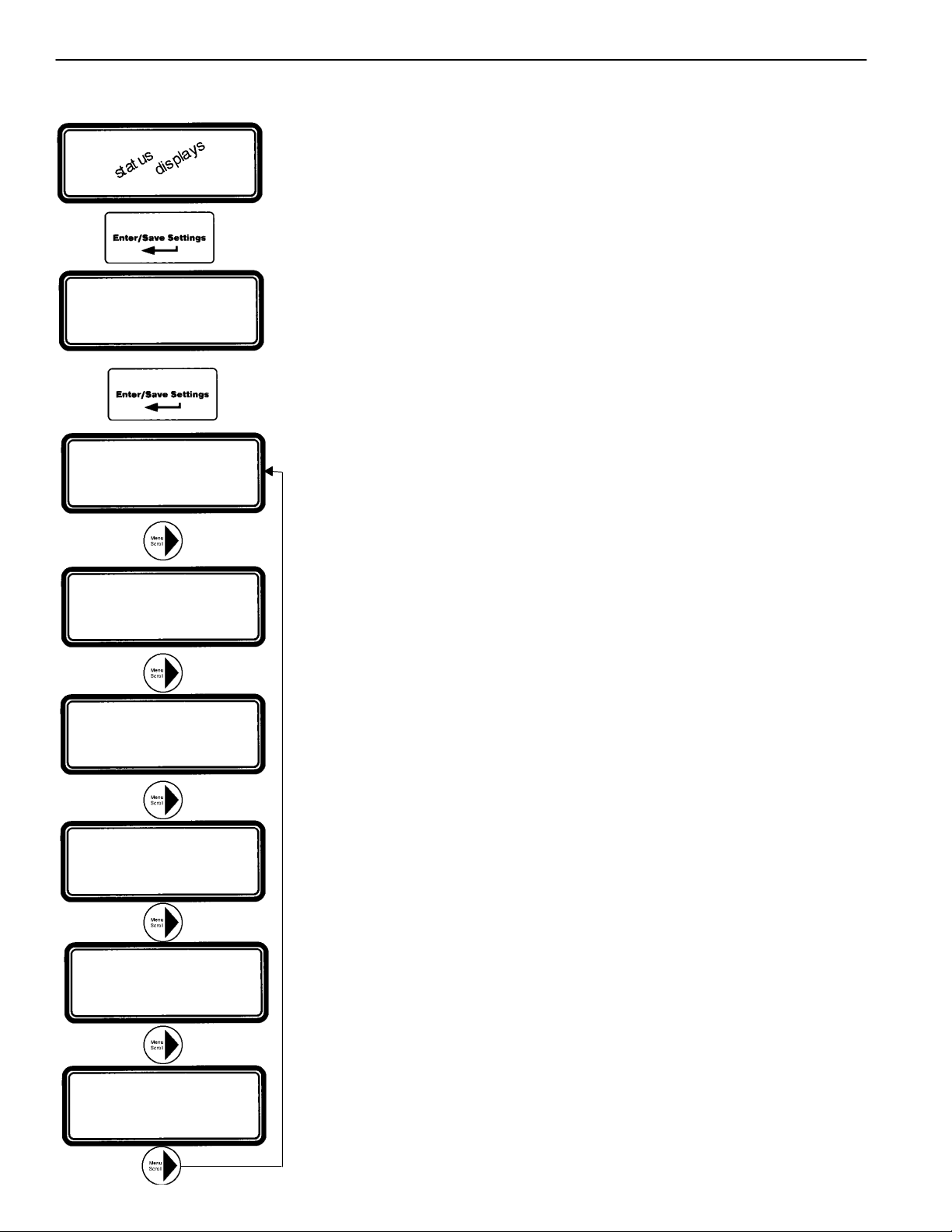

2--3 Settings

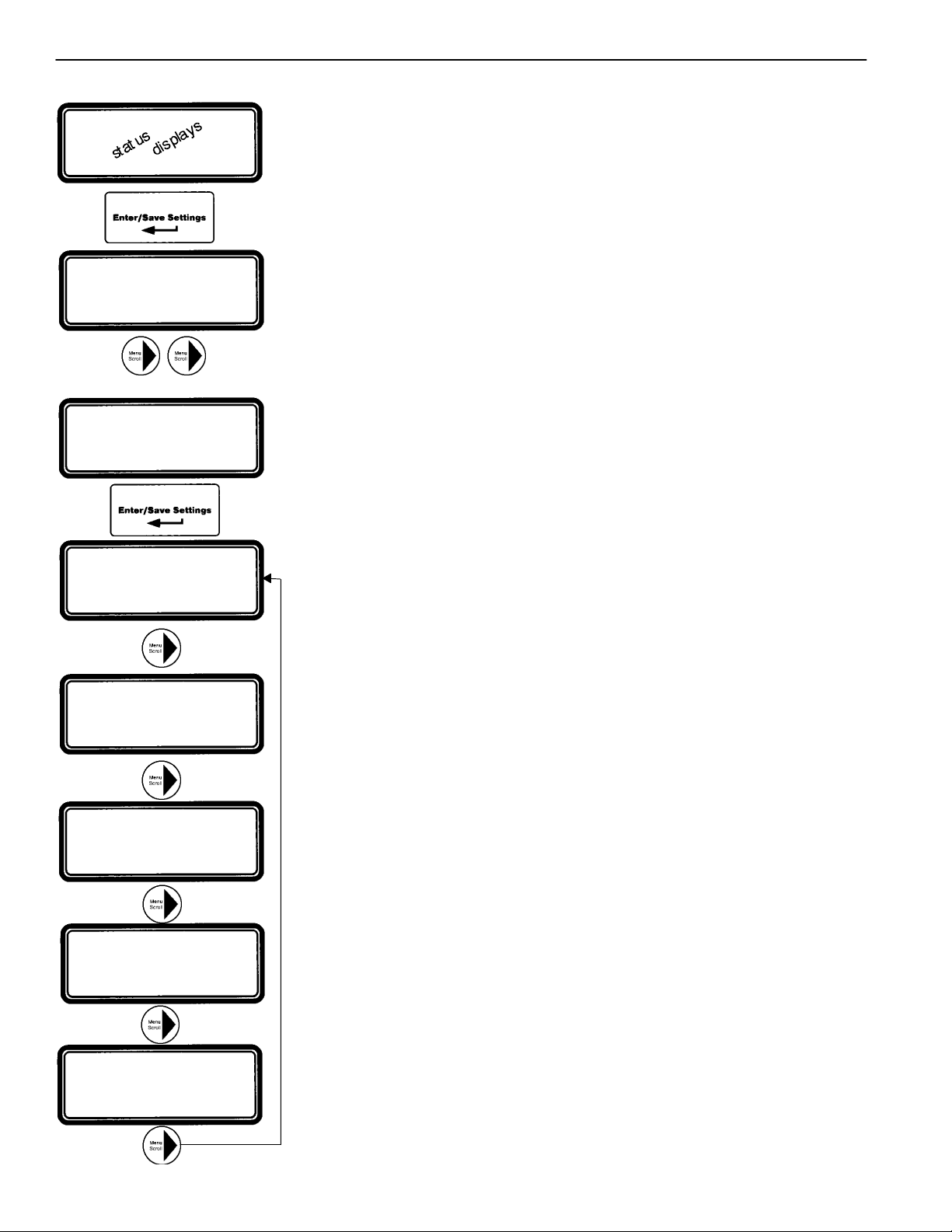

Voltage & Frequency Settings

The controller (CP) voltage and frequency setting can be displayed and changed

from the keypad. See the table on the previous page. Some settings may require

a password (if the controller is set up for one).

¡ From any of the Status displays, press the Enter/Save Settings ¿ key to move

¡

SETTINGS

Voltage DO PU

Frequency DO PU

to the Settings level of menus.

© Press the Enter/Save Settings ¿ keytomovetotheCP Settings display.

¢ Thenyou can press the right arrow " key to see the othervoltage andfrequency

displays (as shown below). An overview explanation of each setting is listed

below.

©

CP SETTINGS

Volt= V Freq= Hz

Phase= N: Ph E:Ph

ATS Type= TS

¢

NORMAL VOLTAGE

Dropout: % V

Pickup: % V

OV Trip: _

NORMAL FREQUENCYDropout: % Hz

Pickup: % Hz

OF Trip: _

NORMAL VOLTAGE UNBAL

Enable: NO

Dropout: 20%

Pickup: 10%

_

EMERG VOLTAGE

Dropout: % V

Pickup: % V

OV Trip: _

EMERG FREQUENCYDropout: % Hz

Pickup: % Hz

OF Trip: _

5 Voltage & Frequency Menus (last menu loops back to first)

CP Settings seepage2–1

This display shows the base configuration of the controller. These settings are

hardware activated and cannot be changed from the keypad:

Nominal source voltage — Normal and Emergency sources

Nominalsourcefrequency—50or60Hz

Normal & Emergency source sensing — single or 3 phase

Switch type — open, closed, or delayed transition

Normal Voltage seepage2–1

This display shows pickup, dropout, and over–voltage trip settings for the

Normal source. They are in percentage of nominal voltage and volts rms.

Normal Frequency seepage2–1

This display shows pickup, dropout, and over–frequency trip settings for the

Normal source. They are in percentage of nominal frequency and Hz.

Normal Voltage Unbalance seepage2–1

This display appears only if the CP is set for3 phase sensing onNormal. When

enabled, the CP considers the Normal source unacceptable if the calculated

voltage unbalance is greater than the specified dropout.

Emerg Voltage seepage2–1

This display shows pickup, dropout, and over–voltage trip settings for the

Emergency source. They are in percent of nominal voltage and volts rms.

Emerg Frequency seepage2–1

This display shows pickup, dropout, and over–frequency trip settings for

Emergency source. They are in percentage of nominal frequency and Hz.

Emerg Voltage Unbalance (not shown)see page 2–1

This display appears only if the CP is set for 3 phase sensing on Emergency.

When enabled, the CP considers the Emergency source unacceptable if the

calculated voltage unbalance is greater than the specified dropout.

Page 7

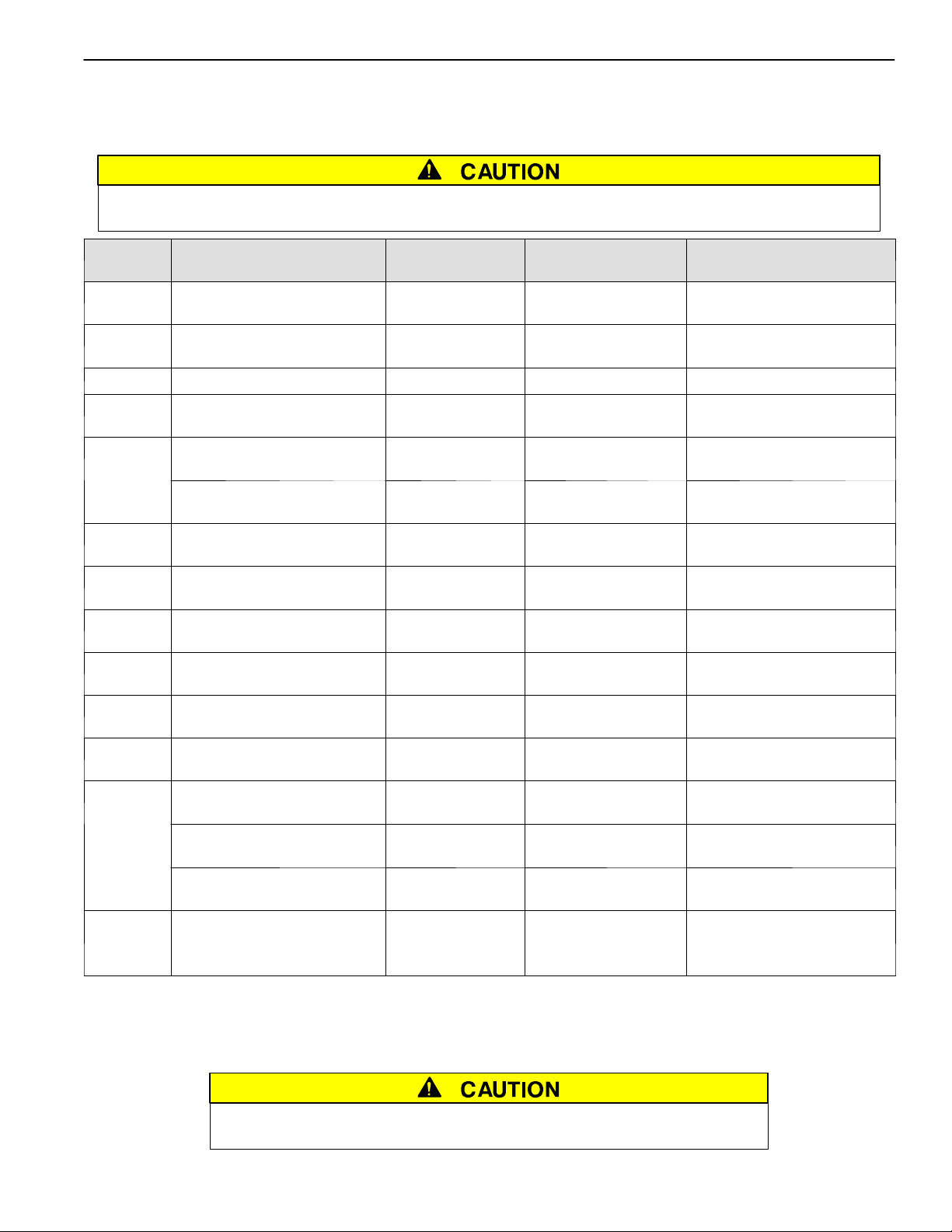

Time Delay Settings

A

4ACTS

Unless otherwise specified on the order, the Controller time delay settings are set at the

factory to the default values. If a setting must be changed, follow the procedure on the

next page. Some settings may require a password (if controller is set up for one).

Any indiscriminate change in these settings may affect the normal operation of the Automatic Trans-

fer Switch. This change could allow the load circuits to remain connected to an inadequate source.

2 --- 4Settings

Feature Time Delay Default Setting

1C ③

1F

2B transfer to Emergency 0 0to60min59sec TD N>E

2E

3

31F ④

31M ④

31F, 31M

31G ④

31N ④

31G, 31N

,

7ACTS,

7ACTB

only①

4ADTS,

7ADTS/B

only

②

override momentary

Normal source outages

override momentary

Emergency source outages

unloaded running

(engine cooldown)

retransfer to Normal

(if Normal fails)

retransfer to Normal

(if just a test)

Normal to Emergency

pre–transfer signal

Normal to Emergency

post–transfer signal

bypass 31F & 31M

if Normal fails

Emergency to Normal

pre–transfer signal

Emergency to Normal

post–transfer signal

bypass 31G & 31N

if Emergency fails

in sync 1.5 second

failure to s ynchronize 5 minutes 0to5min59sec

extended parallel time 0.5 second

delay transition time 0 0to5min59sec

1second

0 0to60min59sec TD EmrgFail

5 minutes 0to60min59sec TD EngCool

30 minutes 0to60min59sec

30 seconds

0 0to5min59sec

0 0to5min59sec

no yes or no

0 0to5min59sec

0 0to5min59sec

no yes or no

Adjustment Range

1 sec. increments

0to6sec

see CAUTION below

0 to 9 hours

59 min 59 s ec

0to3.0seconds

0.1 sec increments

0.100 to 1.000 sec

0.01 sec increments

Display Screen

(see next page)

TD NormFail

TD E>N if

Normal Fail

TD E>N if

Tes t M od e

TD N>E Xfer Signal

TD N>E Xfer Signal

TD N>E Xfer Signal

BypassIfNFail

TD E>N Xfer Signal

TD E>N Xfer Signal

TD E>N Xfer Signal

BypassIfEFail

CTTS TD

SyncMonitorTD

CTTS TD

FailToSyncTD

CTTS TD

XtdParallelTD

DTTS TD

LoadDisconnDelay

PreXfer

PostXfer

PreXfer

PostXfer

① These time delays appear only on the display for a 4ACTS, 7ACTS, or 7ACTB closed–transition transfer switch.

② This time delay appears only on the display for a 4ADTS, 7ADTS, or 7ADTB delayed–transition transfer switch

③ Standard adjustment up to 6 seconds (total power outage). For additional time delay contact ASI. See CAUTION.

④ If output contacts required, contact ASI at 1–800–800–2726.

Do not set Feature 1C TD longer than 6 sec. unless an external 24 V dc

power supply is included. Contact ASI if longer than 6 sec. is required.

Page 8

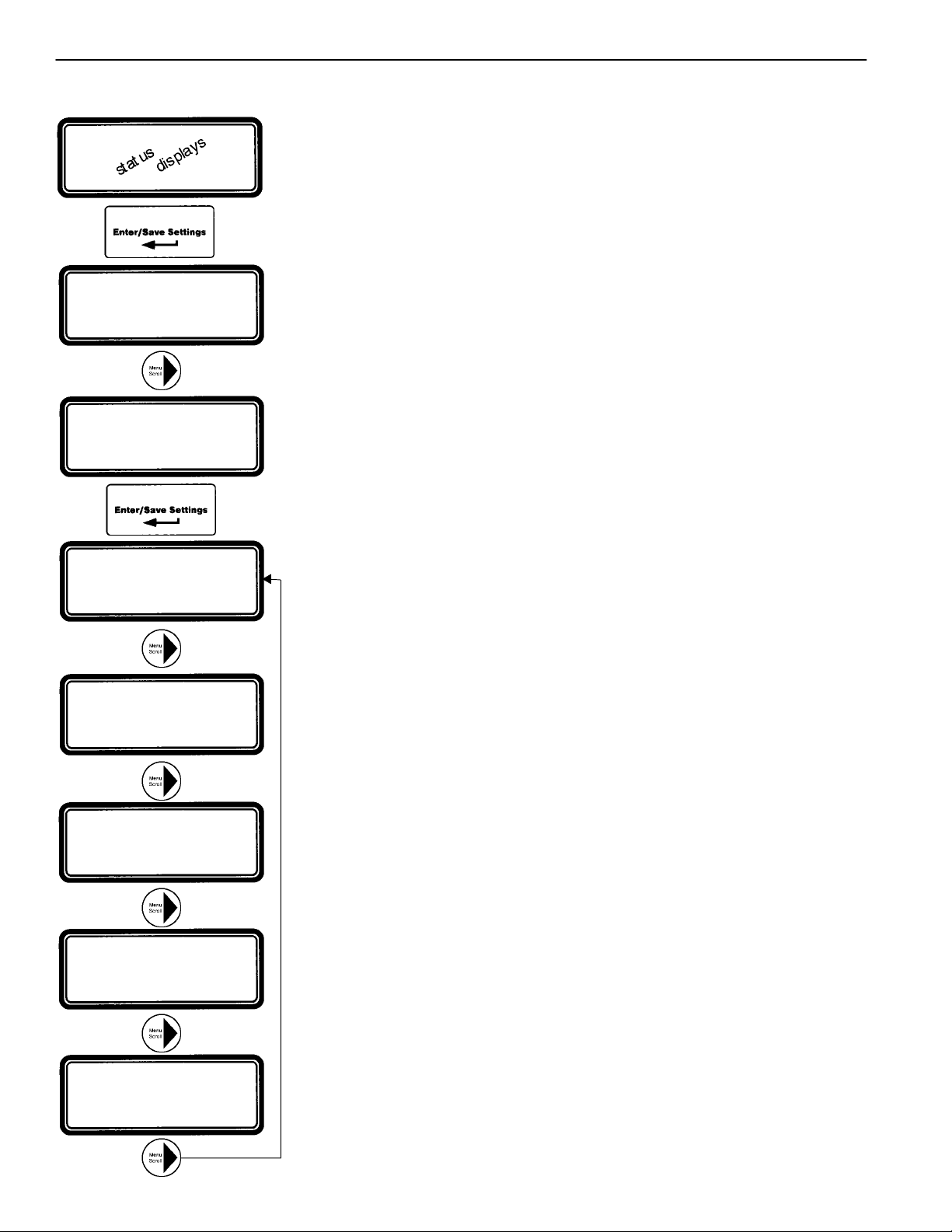

2 --- 5

Settings

Time Delay Settings

The controller time delay (TD) settings can be displayed and changed from the

keypad. Some settings may require a password (if the control panel is set up for

one).

①

SETTINGS

Voltage DO PU

Frequency DO PU

②

SETTINGS

Time Delays

③

Bypass Currently

Running TD: _

External Battery: No

④

TD NormFail: min s

TD N>E: min s

TD EmrgFail: min s

TD EngCool: min s

① From any of the Status displays, press the Enter/Save Settings key to move to

the Settings level of menus.

② Press the right arrow keytomovetotheSetting Time Delays display.

③ Now press Enter/Save Settings keytomovetothefirstTime Delay menu.

④Yo u c a n p r e s s t h e right arrow key to see the other time delay menus (as shown

below). An overview explanation of each setting is listed below.

5 Time Delay Menus (last menu loops back to first)

Bypass Currently Runni ng TD seepage2–1

This display allows you to bypass some time delays. When the display is set

to Yes the controller will bypass any of these time delays

Feature 1C — Momentary Normal failure time delay

Feature 2B — Normal to Emergency transfer time delay

Feature 3A — Emergency to Normal transfer time delay

External Battery: see CAUTION on bottom of page 2–4

Ye s means externalbattery connected, Feature 1C can be set longer than 6 sec.

No mean there is no external battery, Feature 1C can be set for 0–6 sec. only

Standard Time Delays seepage2–1

This display shows the settings for the following standard time delays:

Feature 1C — Momentary Normal source failure time delay

Feature 2B — Normal to Emergency transfer time delay

Feature1F—MomentaryEmergencysourcefailuretimedelay

Feature 2E — Engine cooldown time delay

TD E>N if

Normal Fail: min s

Test Mode: h min s

TD N>E X fer Signal

BypassIfNFail:

PreXfer: min s

PostXfer: min s

TD E>N X fer Signal

BypassIfEFail:

PreXfer: min s

PostXfer: min s

TD E>N if seepage2–1

This display shows the settings for Feature 3A retransfer to Normal time

delay. There are two modes:

Normal source outage — retransfer TD if Normal fails

Transfer Test — retransfer TD if just a test

TD N>E Xfer Signal seepage2–1

This display shows the settings for the time delays used to signal external

equipment before and after transfer from Normal to Emergency:

Feature 31F — Pre–transfer time delay signal

Feature 31M — Post–transfer time delay signal

TD E>N Xfer Signal seepage2–1

This display shows the settings for the time delays used to signal external

equipment before and after retransfer from Emergency to Normal:

Feature 31G — Pre–transfer time delay signal

Feature 31N — Post–transfer time delay signal

CTTS TDs (not shown) see page 2–1

DTTS TD (not shown) see page 2–1

Page 9

Features Settings

Unless otherwise specified on the order, the controller features settings are set at the

factory to the default values. If a setting must be changed, follow the procedure on the

next page. Some settings may require a password (if the controller is set up for one).

Any indiscriminate change in these settings may affect the normal operation of the Automatic Trans-

fer Switch. This change could allow the load circuits to remain connected to an inadequate source.

2 --- 6Settings

Feature Default Setting Adjustment Range

commit to transfer no yes or no

shed load direction from E from N or from E

shed load in phase no yes or no

shed load in phase time delay 1.5 second

shed load isolate load

on source failure

shed load isolate load on test 17 ②

phase rotation monitor enable ③

phase rotation monitor reference ③

inphase monitor enable ④

②

0to3.0seconds

0.1 sec increments

yes yes or no

no yes or no

no yes or no

ABC ABC or CBA

no yes or no

Display Screen

(see next page)

Commit to Xfer After

TD Norm Fail

SHED LOAD

Direction

SHED LOAD

InPhase

SHED LOAD

TD

SHED LOAD

IsoLoadOnSrcFail

SHED LOAD

IsoLoadOnTest17

PHASE ROTATION

MONITOR

Enable

PHASE ROTATION

MONITOR

Reference

IN–PHASE

MONITOR

Enable

inphase monitor time delay ④

failure to sync auto bypass ①

bypass time delay ①

bypass in phase ①

Y–Y primary failure detection enable no yes or no

Y–Y primary failure sensing time delay 1.0 second

Y–Y primary failure retransfer time delay 1.0 hour

1.5 second

no yes or no

0second

no yes or no

0to3.0seconds

0.1 sec increments

0to59seconds

1 sec increments

0to9.9seconds

0.1 sec increments

0to23hrs59min.

1 min. increments

CTTS BYPASS/SHED LD

CTTS BYPASS/SHED LD

CTTS BYPASS/SHED LD

IN–PHASE

MONITOR

Time Delay

FailSyncAutoByps

Bypass DT Delay

Bypass InPhase

Y–Y PRI FAIL DETECT

Enable

Y–Y PRI FAIL DETECT

Sense Delay

Y–Y PRI FAIL DETECT

TD E>N Y–Y

① These features appear only on the display for a 4ACTS, 7ACTS, or 7ACTB closed–transition transfer switch.

② These features appear only on the display for a 4ACTS, 7ACTS or 7ACTB closed–transition transfer switch

or a 4ADTS, 7ADTS, or 7ADTB delayed–transition transfer switch.

③ These features do not appear on the display unless both sources have 3 phase sensing enabled.

④ These features appear only on a 4ATS, 7ATS, or 7ATB (open–transition automatic transfer switch).

Page 10

2--7 Settings

Features Settings

¡

SETTINGS

Voltage DO PU

Frequency DO PU

©¢

SETTINGS

Features

£

Commit to Xfer After

TD Normal Fail: _

The controller (CP) Features settings can be displayed and changed from the keypad. Some settings may require a password (if the controller is set up for one).

¡ From any of the Status displays, press the Enter/Save Settings ¿ key to move

to the Settings level of menus.

© Then press the right arrow " key to move to Setting Time Delays menu.

¢ Press the right arrow " key again to move to Settings Features menu.

£ Now press Enter/Save Settings ¿ keytomovetothefirstFeatures display

¤ You can press the rightarrow " key to see the other Features menus (as shown

below). An overview explanation of each setting is listed below.

7 Features Menus (last menu loops back to first)

Commit to Xfer After TD Normal Fail seepage2–1

This display shows the commit to transfer setting. It affects the transfer

sequence as follows:

Ye s — If Normal fails, CP continues transfer sequence to emergency

even if Normal returns before Emergency becomes acceptable.

No — If Normal fails, C P cancels the transfer sequence to emergency

if Normal returns before Emergency becomes acceptable.

Shed Load seepage2–1

This display shows status of 3 load shed parameters:

Direction — from Emergency or from Normal

InPhase — yes means transfer delayed until sources are in phase

TD — 3 second default time delay

¤

SHED LOAD

Direction:

InPhase: TD: s

SHED LOAD

IsoLoadOnSrcFail yes

IsoLoadOnTest17 no

PHASE ROTATION

MONITOR

Enable:

Reference:

IN--PHASE

MONITOR

Enable:

Time Delay: s

Shed Load Options seepage2–1

This display appears only for 4ACTS, 4ADTS, 7ACTS, 7ACTB, 7ADTS, or

7ADTB. It determines switch position after the shed load transfer.

IsoLoadOnSrcFail — determines switch position during a source failure.

IsoLoadOnTest17 — deterines switch position during feature 17 activation.

Ye s — Load is not connected to eithersource. (see wiring diagram

No — Load is connected to the opposite source. for feature 17 desc.)

Phase Rotation Monitor seepage2–1

This display shows status of phase rotation monitor and desired reference

phase rotation. It only appears if both sources are set to 3–phase sensing.

Enabled — Ye s means phase rotation is considered as part of the

source acceptability criteria for each source. If the phase rotation of the

source does not match the reference phase rotation, that source is considered

unacceptable. If phase rotation of the two sources is different, the load will

be transferred to the source with the reference phase rotation.

Reference — phase rotation order: ABC or CBA (ABC is default)

In–Phase Monitor seepage2–1

This display appears only for 4ATS, 7ATS or 7ATB. This display shows status

of in–phase monitor and in–phase time delay (1.5 seconds is default setting).

Enabled — Ye s means in–phase transfer is initiated when any of these

conditions are met: Transfer Test (Feature 5) signal, connected source fails,

retransfer to acceptable Normal occurs and Emergency source acceptable.

CTTS Bypass / Shed Load (not shown)see page 2–1

This display shows status of the closed–transition bypass options.

FailSyncAutoBy pass — Ye s means if the fail to sync alarm occurs, the controller

will bypass the closed–transition mode and will make a delayed–transiton

transfer. The load disconnect time is set by the Bypass DT Delay parameter.

Bypass InPhase — Ye s means the inphase monitor is active during load transfer.

Page 11

General Settings

2 --- 8Settings

Y–YPrimaryFailureDetection(not shown) see page 2–1

This display shows status of a special control algorithm which is described in

Application Note 381339–276.

Enable – Ye s means the algorithm is activated to detect Normal primary single

phase failure in Y–Y systems.

Sense Delay — 1 second default time delay.

TD E>N Y–Y — 1 hour default time delay.

Note: This function should only be considered for use where the Normal source

is provided through a Y–Y transformer. This function requires the Normal

source voltage unbalance monitoring to be enabled.

Unless otherwise specified on the order, the controller general settings are set at

the factory to the default values. If a setting must be changed, follow the procedure

on the next page. Some settings may require a password (if the controller is set

up for one).

Any indiscriminate change in these settings may affect the normal

operation of the Automatic Transfer Switch. This change could allow

the load circuits to remain connected to an inadequate source

Parameter Default Setting Adjustment Range

ENGLISH

FRENCH CDN

ENGLISH EU

language ENGLISH*

serial communications baud rate 19.2k

serial communications address 1 0to63

event log enable no yes or no

print enable no yes or no

clear log no yes or no

door–mounted user controls locked

but not the Power Control Center

(this setting on 4000 Series only)

no yes or no Keypad Locked

ENGLISH EU S1–S2

ENGLISH S1–S2*

SPANISH

GERMAN

PORTUGUESE

off, x9600, 9600,

19.2k, Mbus9600,

Mbus19.2k

Display Screen

(see next page)

Menu Language

ENGLISH

SERIAL

COMMUNICATION

Baud Rate

SERIAL

COMMUNICATION

Address

EVENT LOGGING

Enable

EVENT LOGGING

Print Enable

EVENT LOGGING

Clear Log

password 1111

4characters

letters or numbers

Change

Password

* Note: If the language setting ENGLISH S1–S2 is selected the usual display words

Normal (N) and Emergency (E) are changed to Source 1 (S1) and Source 2 (S2).

Page 12

2--9 Settings

General Settings

¡

SETTINGS

Voltage DO PU

Frequency DO PU

£

¢

©

The controller (CP) general setting can be displayed and changed from the keypad.

Some settings may require a password (if the controller is set up for one).

¡ From any of the Status displays, press Enter/Save Settings ¿ key to move to

the Settings level of menus.

© Press the right arrow " key to move to Setting Time Delays menu.

¢ Press the right arrow " key again to move to Settings Features menu.

£ Press the right arrow " key again to move to Settings General menu.

¤ Now press Enter/Save Settings ¿ keytomovetothefirstGeneral display

SETTINGS

General

¤

Default to Factory

Settings:

Reset Engine Exerc

Programs:

¥

SERIAL

COMMUNICATION

Baud Rate:

Address:

EVENT LOGGING

Enable:

Print Enable:

Clear Log:

User Ctrls Lckd:

¥ You can press the right arrow " key to see the other General menus (as shown

below). An overview explanation of each setting is listed below.

6 General Settings Menus (last menu loops back to first)

Default to Factory Settings seepage2–1

This display (upper half) allows the user to reset the majority of controller

settings to their factory default values.

Reset Engine Exerc Programs seepage2–1

This display (lower half) also allows the user to reset the engine exerciser

routines. YES means reset. NO means do not reset.

Menu Language (not shown) see page 2–1

Thisdisplayshowsthelanguageinwhichthemessageswillbeshown.

English is the default language.

Serial Communication seepage2–1

This display allows the user to configure the serial communications port of the

controller.

Baud Rate — off, 9600, x9600. 19.2 k, Mbus9600, Mbus19.2k

x9600 selects 9600 and the Group 1/7 CP protocol

Address — can be set from 0 to 63

Event Logging seepage2–1

This display allows the user to enable the event logging feature of the

controller and to clear the event log.

Enable — YES means to start event logging; NO means turn it off.

Print Enable — YES means enables printer option; NO turns it off.

Clear Log — YES means erase the event log; NO means keep it.

Change

Password:

0001

PrintEventLog(not shown) see page 2–1

This display shows the status of the optional printer.

Also see Printer Interface Module instructions 381339---218.

User Controls Locked (on 4000 Series only)

seepage2–1

This display allows the user to lock or unlock the door–mounted user controls.

(not the Power Control Center). YES means locked. NO means unlocked.

Change Password seepage2–1

This display allows the user to change the controller password.

Page 13

Engine Exerciser Settings

Unless otherwise specified on the order, the controller engine exerciser settings

are set at the factory to the default values. If a setting must be changed, follow the

procedure on the next page. Some settings may require a password (if the

controllerissetupforone).

Any indiscriminate change in these settings may affect the normal

operation of the Automatic Transfer Switch. This change could allow

the load circuits to remain connected to an inadequate source

2 --- 1 0Settings

Parameter Default Setting Adjustment Range

month JAN

day 1 1to31

year * 1 00 to 99

hour 1 0to23

minute 1 0to59

engine exerciser enable

(P1 to P7)

engine exerciser transfer load

(P1 to P7)

engine exerciser start hour

(P1 to P7)

engine exerciser start minute

(P1 to P7)

engine exerciser run week

(P1 to P7)

JAN, FEB, MAR,

APR, MAY, JUN, JUL,

AUG, SEP, OCT ,

NOV, DEC

no yes or no

no yes or no

0 0to23

0 0to59

all, alternate,

all

first, second, third,

fourth, or fifth

Display Screen

(see next page)

PRESENT DATE/TIME

Date

PRESENT DATE/TIME

Date

PRESENT DATE/TIME

Date

PRESENT DATE/TIME

Time

PRESENT DATE/TIME

Time

P1 ENGINE EXERCISER

Enable

P1 ENGINE EXERCISER

wLoad

P1 ENGINE EXERCISER

Start h

P1 ENGINE EXERCISER

Start min

engine exerciser run day

(P1 to P7)

engine exerciser duration hours

(P1 to P7)

engine exerciser duration minutes

(P1 to P7)

SUN

0 0to23

0 0to59

SUN, MON, TUE,

WED, THU, FRI, SAT

* For the year 2000, enter 00.

P1 ENGINE EXERCISER

Run TIme h

P1 ENGINE EXERCISER

Run TIme min

Page 14

2 --- 1 1 Settings

Engine Exerciser Settings

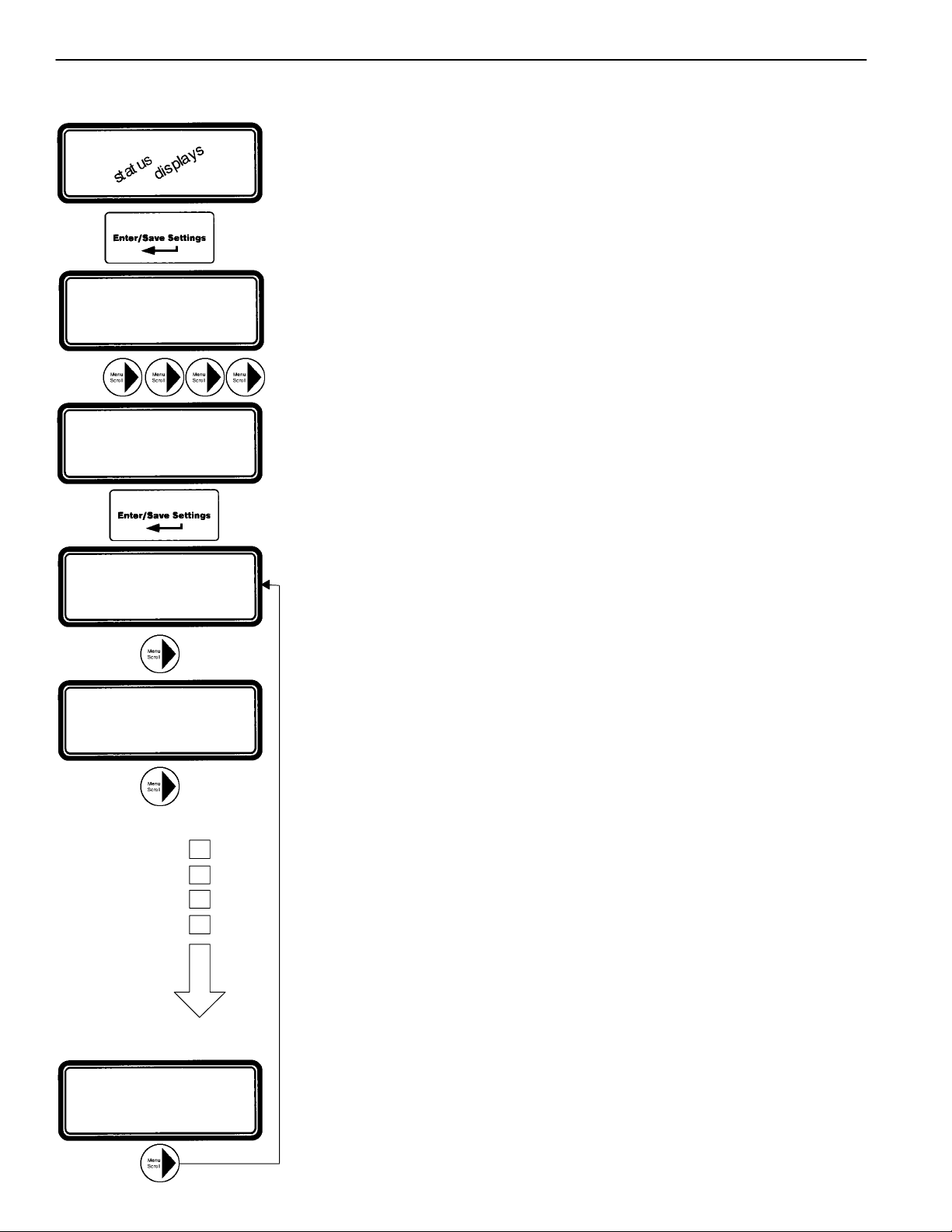

The controller (CP) engine exerciser setting can be displayed and changed from

the keypad. Some settings may require a password (if the controller is set up for

one).

① From any of the Status displays, press Enter/Save Settings keytomovetothe

①

Settings level of menus.

SETTINGS

Voltage DO PU

Frequency DO PU

②③

④⑤

SETTINGS

Engine Exerciser

➅

PRESENT DATE/TIME

US DST:

Date:

Time:

➆

P1 ENGINE EXERCISER

Enable: wLoad:

Start: h

Run Time: h min

Set the seven

independent

engine exercise

routines,

if desired.

② Press the right arrow key to move to Setting Time Delays menu.

③ Press the right arrow key again to move to Settings Features menu.

④ Press the right arrow key again to move to Settings General menu.

⑤ Press the right arrow key again to move to Settings Engine Exerciser.

➅Now press Enter/Save Settings keytomovetothefirstEngine Exerciser menu.

➆ You can press the right arrow key to see the other Engine Exerciser menus

(as shown below). An overview explanation of each setting is listed below.

8 Engine Exerciser Settings Menus

(last menu loops back to first)

Present Date/Time seepage2–1

This display allows the user to change the controller date and time.

US DST — US Daylight Saving Time. APR – OCT, MAR – NOV, or OFF.

MAR – NOV begins in 2007.

P(1—7) Engine Exerciser(s) seepage2–1

These displays (P1 through P7) allow the user to set the controller’s seven

independent engine exerciser routines. Each routine functions in the same

manner. Six parameters need to be configured for each routine (P1, P2, P3,

P4, P5, P6, P7 — not all have to be used).

Enable — YES enables the routine; NO turns it off.

wLoad — YES transfers load to Emergency; NO = no transfer.

P7 ENGINE EXERCISER

Enable: wLoad:

Start: h

Run Time: h min

Start — when the routine will start the generator

– time (hour, minute)

– week (all, alternate, 1st, 2nd, 3rd, 4th, or 5th week)

–dayoftheweek(mon,tue,wed,thu,fri,sat,sun)

Run Time — duration (length of time) that the generator will run.

Page 15

View Event Log

¡

2--12Settings

The controller event logging feature can be displayed from the keypad. Some

settings may require a password (if the controller is set up for one).

¡ From any of the Status displays, press Enter/Save Settings key to move to

the Settings level of menus.

SETTINGS

Voltage DO PU

Frequency DO PU

©¢£¤¥

VIEW

Event Log

¦

1

No Event Recorded

2

No Event Recorded

§

Scroll "

to show the

last 99 logged

events.

98

No Event Recorded

99

No Event Recorded

© Press the right arrow " key to move to Setting Time Delays menu.

¢ Press the right arrow " key again to move to Settings Features menu.

£ Press the right arrow " key again to move to Settings General menu.

¤ Press the right arrow " key again to move to Settings Engine Exe rciser.

¥ Press the right arrow " key again to move to View Event Log.

¦ Now press Enter/Save Settings keytomovetotheeventsloggeddisplay.

§ You can press the right arrow " key to see the other events logged.

An overview explanation of each setting is listed below.

Logged Events

This display shows the last 99 logged events. Each event display shows the

event number (1 is the most recent, 99 is the oldest), the time and date of the

event, the event type, and the event reason (if applicable).

Event Types

Nine types of events are logged. They are (displayed event & meaning) :

Eng Start The controller has signaled the engine to start

Xfer N>E The controller has initiated transfer from normal to emergency

Xfer E>N The controller has initiated transfer from emergency to normal

Eng Stop The controller has signaled the engine to stop

EmergAcc The emergency source has become acceptable

EmergNAccThe emergency source has become not acceptable

NormAcc The normal source has become acceptable

NormNAcc The normal source has become not acceptable

XfrAbort The transfer has been aborted

Event Reasons

Twenty–onereasons for events are logged. They are (displayed r eason & meaning):

LoadShed Load shed requested

NormFail Normal source failure NormOF Normal source over frequency

ManualXfr Manual transfer NormPHR Normal source phase rotation

Test 5 Test requested (Feature 5) NormVUNB Normal source voltage unbalance

Test 17 Test requested (Feature 17) EmergUV Emergency source under voltage

Comm Serial communications EmergOV Emergency source over voltage

EngExerc Engine Exerciser EmergUF Emergency source under frequency

EmergFail Emerg source failure EmergOF Emergency source over frequency

NormUV Normal source under voltage EmergPHR Emergency source phase rotation

NormOV Normal source over voltage EmergVUNB Emergency source voltage unbalance

NormUF Normal source under frequency Feature 6 Feature 6 activated

Page 16

2--13 Settings

Service — Statistics / Diagnostics

The controller service statistics / diagnostics can be displayed from the keypad.

Some settings may require a password (if the controller is set up for one).

¡ From any of the Status displays, press Enter/Save Settings key to move to

¡

the Settings level of menus.

SETTINGS

Voltage DO PU

Frequency DO PU

©¢£

¤¥¦

Diagnostics

press 6 times

SERVICE

Statistics

§

ATS STATISTICS

ATS Total Xfers:

SrcFailTotXfers:

Days Energized:

¨

SOURCE STATISTICS

TimeNAvl: h min

TimeEAvl: h min

©¢£¤¥¦ Press right arrow " key six times to move to Service menu.

§ Now press Enter/Save Settings keytomovetothefirstService menu.

¨ You can press the right arrow " key to see the other Service menus (as shown

below). An overview explanation of each setting is listed below.

7 Service Menus (last menu loops back to first)

ATS Statistics

This display shows the total number of transfers, the total number of transfers

due to source failures, and the total number of days that the ATS has been energized since the controller has been installed. These values cannot be reset.

Source Statistics

This display shows the total time that the normal and emergency sources have

been acceptable since installation of the controller. These values cannot be

reset.

View Service Data

This display is for service personnel only.

VIEW SERVICE DATA

Addr:

Data:

SERIAL

COMMUNICATION

Loop Test:

CP SOFTWARE

Version:

Date:

Serial Communication

This display allows the user to test the serial communications port of the

controller. To perform the test, the transmit lines of the serial

communications port are connected to the receive lines so that the signals sent

by the controller are also received by the controller. The test is activated by

pressing the Enter/Save Settings key while viewing this display. If the

controller receives the same information that it sent, test is passed, otherwise

it fails.

I/O Status (not shown)

These displays show the status of several of the controller’s input and output

lines.

CP Software

This display shows the version of the loaded software and the date of its

release.

Page 17

Service — Factory Selectable Features

The controller service factory selectable features can be displayed from the

membrane controls. These factory settings should not be changed by the customer

NORMAL OK

¡

(they cannot be changed without entering the factory password).

¡ From the ATS Status display (NORMAL OK), press Enter/Save Settings

button to move down to the Settings level of menus.

2--14Settings

SETTINGS

Voltage DO PU

Frequency DO PU

©¢£

¤¥¦§

SERVICE

Factory

Selectable Features

¨

ATS INFORMATION

ATS:

TEST OR MANUAL MODE

INPUT

Test Operation:

Manual Operation:

RETRANSFER MODE

INPUT

TD Bypass:

Manual Re Xfer:

XFER TO NORMAL

INHIBIT

Enable:

press

7times

©¢£¤¥¦§ Press right arrow " button 7 times

to move to Service menu.

¨ Now press Enter/Save Settings button to move down to the first Service

factory selectable feature.

You can press the right arrow " button to see the other Service menus (as shown

below). An overview explanation of each setting is listed below.

8 Service Menus (last menu loops back to first)

ATS Information

This display shows the transfer switch ampere size, whether the switch is a

bypass switch or a non–bypass switch, and any name or description inform–

ation that has been assigned to it through the serial communications port.

Test or Manual Mode Input

This display shows the setting of the Feature 5/6Z input. This input can be

used for either Feature 5 or 6Z. Yes means active; no means not used.

Test Operation — Feature 5

Manual Operation — Feature 6Z

This Feature is not available for automatic operation.

Retransfer Mode Input

This display shows the settings for Features 6B/6C inputs. This input can be used

for either Feature 6B or 6C. Yes means active; no means not used.

TD Bypass — Feature 6B

Manual R e Xfer — Featu re 6C

These Features are typically set to Ye s with the inhibit Feature overridden with

external factory wiring. These Features are not available for customer use.

Xfer to Normal Inhibit and Emergency (not shown)

This display shows whether the Feature 34A input is enabled (yes) or disabled

(no).

Likewise, the next display Xfer to Emergshows whether the Feature 34B input

is enabled (yes) or disabled (no).

Temp Calibr:

ATS Idle Time: ms

CT Parallel TD: ms

Factory Calibration (not shown)

This display is for factory calibration only and should be used by factory

personnel only.

Other

These displays show various parameters that should be accessed by factory

personnel only.

Page 18

3--1 Operating the Controls

Status Information

The controller (CP) provides the status of the automatic transfer switch (ATS) and

of both the normal and emergency sources. This information is at the status level

of all screens and no password is required to view them.

Youcan press the right arrow " key to see the status of the Normal Source or press

the left arrow A key to see the status of the Emergency source (the menus loop

back).

EMERG SOURCE

Tip

☞

NORMAL OK

NORMAL SOURCE

ATS Status

The ATS Status is the primary display. It shows the present status of the AT S.

Transfer sequence status and running time delays are shown. For inphase or

closed–transition transfers, phase relation between the sources is also shown.

The A TS Status display can be directly reached from anywhere in the menu

structure by pressing the Esc key three times.

Normal Source Status

The Normal Source Status display shows the rms voltage of each of the phases, the

source frequency in Hz, and the phase rotation. If enabled, the voltage unbalance

will also be displayed.

Emergency Source Status

The Emergency Source Status display shows the rms voltage of each of the phases,

the source frequency in Hz, and the phase rotation. If enabled, the voltage

unbalance will also be displayed.

Source Acceptability

The CP considers a source unacceptable if any of these conditions are true:

S Any phase voltage of the source is less than the voltage dropout setting.

S Any phase voltage is greater than voltage trip setting for more than 3 sec.

S Frequency of the source is less than the frequency dropout setting.

S Frequency is greater than frequency trip setting for more than 3 seconds.

S Phase rotation does not match specified phase rotation (only if enabled).

S The phase unbalance is greater than the unbalance dropout setting (only if enabled).

The CP considers a source acceptable

S Each phase voltage is greater than the voltage pickup setting.

S Each phase voltage is less than trip voltage setting by more than 2% of nom

S The frequency of the source is greater than the frequency pickup setting.

S Frequency is less than the frequency trip setting by more than 2% of nom.

S Phase rotation matches the specified phase rotation (only if enabled).

S The phase unbalance is less than the unbalance pickup setting (only if enabled).

again when all these conditions are true:

Page 19

Display Messages and their Meaning

The following messages (in alphabetical order) can appear on the CP display:

Display Message Meaning or Explanation Also Refer To

3--2Operating the Controls

An error condition has occurred and the controller

ATS LOCKED OUT!

EMERG SOURCE

ENGINE EXERCISE WITH LOAD

ENGINE EXERCISE WITHOUT LOAD

Enter Password:

FAI LURE TO SYNCHRONIZE ALA RM

Load Disconnected The load is disconnected (4ADTS,7ADTS,7ADTB)

has locked out all further attempts to transfer the

load. Press the Alarm Reset pushbutton to clear

this message.

The emergency status display shows the

emergency voltages, voltage unbalance

(if enabled), and frequency.

The engine exerciser is running the engine–

generator set with load (the transfer switch

transfers the load to the generator).

The engine exerciser is running the engine–

generator set without load (the transfer switch

does not

A password is required to proceed further in the

change process. Enter the correct password to

continue or press the Esc key to clear this

message.

Thefailuretosynchronizetimedelayhasexpired.

This alarm occurs when the sources fail to

synchronize within the specified time. Press the

Alarm Reset pushbutton to clear this message.

(4ACTS, 7ACTS, 7ACTB)

transfer the load to the generator).

Transfer

Switch

Operator’s

Manual

page 3–1

pages

2–10, 2–11

pages

2–10, 2–11

pages

2–1, 2–8

pages

4–4, 4–5

pages

4–6, 4–7

Load on Emerg The load is connected to the emergency source.

Load on Normal The load is connected to the normal source.

LOAD SHED FROM EMERG

LOAD SHED FROM NORMAL

NORMAL FAILED The normal source is not acceptable. page 3–1

NORMAL OK The normal source is accepted. page 3–1

NORMAL SOURCE

POWER–UP INHIBIT stays on

TD Emerg>Normal:

TD Engine Cooldown:

TD Load Disconnect:

The load shed signal is active and the load has

been shed from the emergency source.

The load shed signal is active and the load has

been shed from the normal source.

The normal status display shows the normal

source voltages, voltage unbalance (if enabled),

and frequency.

Thecontrollerhaspoweredupandhas

recognized an error condition.

The emergency to normal load transfer time delay

(Feature 3A) is running. The amount of time

remaining is shown.

The engine–generator set unloaded cooldown

time delay (Feature 2E) is running. The amount

of time remaining is shown.

The load disconnect time delay is running.

The amount of time remaining is shown.

(4ADTS, 7ADTS, 7ADTB)

page 2–6

page 2–6

page 3–1

Contact

ASI

page 2–4

page 2–4

pages

4–6, 4–7

continued on next page

Page 20

3--3 Operating the Controls

Display Messages and their Meaning (continued)

The following messages (in alphabetical order) can appear on the CP display:

Display Message Meaning or Explanation Also Refer To

Thenormalsourcefailuretimedelay(Feature1C)

TD Normal Fail:

TD Normal>Emerg:

TD Post Transfer

TD Pre Transfer

is running. The amount of time remaining is

shown.

The normal to emergency load transfer time delay

(Feature 2B) is running. The amount of time

remaining is shown.

The post–transfer time delay (Feature 31M or

31N) is running. The amount of time remaining is

shown.

The pre–transfer time delay (Feature 31F or 31G)

is running. The amount of time remaining is

shown.

page 2–4

page 2–4

page 2–4

page 2–4

TEST MODE SERIAL COMM

TEST MODE TEST CIRCUIT 5 Test circuit Feature 5 is a ctive (Transfer Test).

TEST MODE TEST CIRCUIT 17 Test circuit Feature 17 is active (remote test). page 2–6

Transfer to Emerg I nhibited Load transfer to emergency is inhibited.

Transfer to Normal Inhibited Load transfer to normal source is inhibited.

Waiting for Emerg Acceptable

Waiting for In–Phase

Waiting for In–Sync

A test has been initiated via the serial commu-

nications port.

The controller is waiting for the emergency source

to become acceptable so that it can continue in

the transfer sequence.

The controller is waiting for the sources to come

in phase so that it can make an in phase load

transfer. The phase angle and frequency

difference are also displayed. This message will

be displayed until the s ources come in phase.

(4ATS, 7ATS, 7ATB)

The controller is waiting for the sources to come

into synchronism so that it can make a

closed–transition load transfer. The three

parameters required for synchronization (phase

angle, frequency difference, and voltage

difference) are also displayed. If the sources do

not have the same rotation, this will also be

displayed. (4ACTS, 7ACTS, 7ACTB)

page 2–13

Transfer

Switch

Operator’s

Manual

page 3–1

pages

4–1, 4–2

pages

4–4, 4–5

WRONG P ASSWORD !!! An incorrect password has been entered. page 2–1

The extended parallel time delay has expired,

which indicates that the sources have been

XTD P ARALLEL ALARM

PA RM CHCKSUM ERROR

UNKNOWN ERROR System error.

paralleled for longer than the specified extended

parallel time. Press the Alarm Reset pushbutton

to clear this message. (4ACTS, 7ACTS, 7ACTB)

An internal memory error has been detected. On

occurance of this error message, memory is

cleared and all parameters need to be reset.

pages

4–4, 4–5

Contact

ASI

Contact

ASI

Page 21

4--1Description of Operation

Open–Transition (2–position) Automatic Transfer (4ATS,7ATS,7ATB)

Load Transfer To Emergency

NORMAL FAILED

TEST MODE

TEST CIRCUIT 5

Waiting for Emerg

Acceptable

Feature 31F

NORMAL FAILED

TD PreTransfer

__ min, __ s

NORMAL FAILED

Load on Emerg

NORMAL FAILED

The sequence for load transfer to the emergency source begins automatically when the

controller detects a normal source failure or a transfer test signal.

Normal Source Failure. The Normal source is considered unacceptable when any one

of six voltage, frequency, or phase rotation conditions occur (see page 3–1).

Transfer Test Signal. Te st transfer signal can be from the Tr a n sf e r C on t ro l switch

(Feature 5), the engine–generator exerciser clock (Feature 11C), or via the serial port

(Feature 72A). When using the Tr a n sf e r C o nt r ol switch,itmustbeheld

in the TransferTest

position until the emergency source becomes available (within 15 seconds).

The controller begins the load transfer sequence by de–energizing the SE relay and

starting the Feature 1C time delay. Feature 1C time delay on engine starting prevents

nuisance starting of the engine–generator set and load transfer to emergency due to

momentary failures of the normal source. If the normal source is restored (voltage returns

above the dropout point) while Feature 1C time delay is running, the SE relay is

re–energized and the transfer sequence is terminated. (For transfer test the Feature 1C

time delay is bypassed.)

Engine Start Signal. When the Feature 1C time delay ends, the controller de–energizes

the NR relay which signals the engine–generator to start. The cont roller monitors the

emergency source, waiting for it to become acceptable. Usually about 10 seconds elapse

from dropout of the NR relay to acceptance of the emergency source. This interval occurs

because the engine–generator must crank, start, and run up to nominal pickup points. If

the emergency source is available immediately, the controller will accept it as soon as the

NR relay drops out.

When the emergency source becomes acceptable, the controller starts the Feature 2B time

delay on transfer to emergency (if desired). Feature 2B time delay allows the emergency

sourceto stabilize before load transfer. If the emergencysourcefails whileFeature2B time

delay is running, the controller again waits for the emergency source to become acceptable

again and restarts Feature 2B.

At the conclusionof the Feature 2B time delay, the controller is ready to transfer the load

to emergency. If enabled, Feature 31F time delay will run prior to transfer and the Feature

31 output will be active while the time delay runs. Also, if Feature 27 inphase monitor

control (for motor loads) is enabled, the controller will inhibit transfer until the sources

are in phase.

Load Transfer. To transfer the load to the emergency source the controllerenergizes ER

relay. The transfer switch TS coil energizes, and all transfer switch contacts (mains,

controls, auxiliaries) reverse position. Transfer switch is now supplying the load from

emergency source.

If enabled, Feature 31M time delay will run after the transfer and the Feature 31

output will be active while the time delay runs.

TD PostTransfer

__ min, __ s

Feature 31M

Page 22

4--2 Description of Operation

Open–Transition (2–position) Automatic Transfer Switches continued

Load Retransfer To Normal

NORMAL OK

Load on Emerg

NORMAL OK

TD Emerg>Normal

__min __s

NORMAL OK

TD Engine Cooldown

__min __s

Thesequenceforloadretransfertothenormalsourcebeginsautomaticallywhenthe

controller detects a restored normal source or a cancelled transfer test signal.

Normal Source Restoratio n. The Normal source is considered acceptable again when

all

six voltage, frequency, or phase rotation conditions occur (see page 3–1).

Cancel Transfer Test. Removal of the test transfer signal can be by the Tr an s fe r C o n t ro l

switch (Feature 5), engine–generator exerciser clock (Feature 11C), or via serial port

(Feature 72A). When using the Tra ns f er C o nt r ol switch, it must be released

from the

Transfer Test position.

The controller begins the load retransfer sequence by starting the Feature 3A time delay.

Feature 3A time delay on retransfer to normal allows the normal source to stabilize. If the

normal source fails while the Feature 3A time delay is running, the controller waits for the

normal source again to become acceptable and restarts the Feature 3A time delay. If the

emergency source fails while Feature 3A is running, the controller bypasses the time delay

for immediately load retransfer. To bypass Feature 3A time delay, turn the Tr a n s fe r

Control switch to the Retransfer Delay Bypass position.

At the conclusionof the Feature 3A time delay, the controller is ready to transfer the load

to normal. If Feature 27 inphase monitor control is enabled, the controller will inhibit

transfer until the sources are in phase.

Load Retransfer. To retransfe r the load to the normal source the controller de–energizes

ER relay and energizes SE relay. The transfer switch TS coil energizes, and all transfer

switch contacts (mains, controls, auxiliaries) reverse position. The transfer switch is now

supplying the load from the normal source again

Engine Cooldown & Stop. After load retransfer to the normal source, the controller

starts Feature 2E time delay. Feature 2E time delay provides an unloaded cooldown

running period for the engine–generator. At t he end of the time delay, the controller

energizes the NR relay and the engine–generator is signalled to shutdown.

NORMAL OK

Load on Normal

Page 23

Closed–Transition Automatic Transfer (4ACTS, 7ACTS, 7ACTB)

The 4ACTS, 7ACTS, and 7ACTB provides load transfer in either closed (make–before–break) or open (break–before–make) transition modes depending upon the condition

of the two power sources. Control logic automatically determines whether the load trans-

NORMAL FAILED

TEST MODE

TEST CIRCUIT 5

Load on Emerg

fer should be open or closed transition. If both

transfer test or when retransferring back to Normal, closed–transition transfer occurs

without interrupting the electrical loads. If either source is not

mal fails, open–transition load transfer occurs in the break–before–make mode.

Open–Transition Load Transfer to Emergency Source

due to Normal Source Failure

The sequence for open–transition load transfer to the emergency source begins

automatically when the controller detects an unacceptable normal source. The Normal

source is considered unacceptable when any one of six voltage, frequency, or phase

rotation abnormal conditions occur (see page 3–1).

Normal Source Failure. An under voltage condition on any phase of the normal source

means that the voltage has fallen below the preset dropout point.

The controller begins the load transfer sequence by de–energizing the SE and SE2 relays

and starting the Feature 1C time delay. Feature 1C time delay on engine starting prevents

nuisance starting of the engine–generator set and load transfer to emergency due to

momentary failures of the normal source. If the normal source is restored (voltage returns

above the dropout point) while Feature 1C time delay is running, the SE and SE2 relays

are re–energized and the transfer sequence is terminated. (For transfer test the Feature

1C time delay is bypassed.)

Engine Start Signal. When the Feature 1C time delay ends, the controller de–energizes

the NR relay which signals the engine–generator to start. The cont roller monitors the

emergency source, waiting for it to become acceptable. Both

reach preset pickup points before the emergency source is accepted. Usually about 10

seconds elapse from dropout of the NR relay to acceptance of the emergency source. This

interval occurs because the engine–generator must crank, start, and run up to nominal

pickup points. If the emergency source is available immediately, the controller will accept

it as soon as the NR relay drops out.

When the emergency source becomes acceptable, the controller starts the Feature 2B time

delay on transfer to emergency (if desired). If the emergency source fails while Feature 2B

time delay is running, the controller again waits for the emergency source to become

acceptable again and restarts Feature 2B.

At the conclusionof the Feature 2B time delay, the controller is ready to transfer the load

to emergency. If enabled, Feature 31F time delay will run prior to transferand the Feature

31F output will be active while the time delay runs.

Load Transfer. To transfer the load to the emergency source the controller energizes the

ER relay. The transfer switch CN coil energizes, and all CN transfer switch contacts

(mains, controls, auxiliaries) reverse position to disconnect the Normal source. Then the

controller energizes the ER2 relay. The transfer switch CE coil energizes, and all CE

transfer switch contacts (mains, controls, auxiliaries) reverse position to connect the

Emergency source. The transfer switch is now supplying the load from emergency source.

If enabled, Feature 31M time delay will run after the transfer and the Feature 31M output

will be active while the time delay runs.

sources are acceptable, such as during a

present, such as when nor-

voltage and frequency must

4--3Description of Operation

Page 24

4--4 Description of Operation

Closed–Transition Automatic Transfer Switches continued

Closed–Transition Load Transfer to Emergency Source

due to Transfer Test

The sequence for closed–transition load transfer to the emergency source begins

automatically when the controller detects a transfer test signal.

Transfer Test Signal. Te st transfer signal can be from the Tr a n sf e r C on t ro l switch

TEST MODE

TEST CIRCUIT 5

Waiting for Emerg

Acceptable

TEST MODE

TEST CIRCUIT 5

Load on Emerg

(Feature 5), the engine–generator exerciser clock (Feature 11C), or via the serial port

(Feature 72A). When using the Tr a n sf e r C o nt r ol switch,itmustbeheld

position until the emergency source becomes available (within 15 seconds).

The controller begins the load tra nsfer sequence by de–energizing the SE, SE2, and NR

relays. Feature 1C engine starting time delay is bypassed during transfer test.

Engine Start Signal. When the NR relay de–energizes it signals the engine–generator

to start. The controller monitors the emergency source, waiting for it to become

acceptable. Both

emergency source is accepted. Usually about 10 seconds elapse from dropout of the NR

relay to acceptance of the emergency source. This interval occurs because the

engine–generatormust crank, start, and run up to nominal pickup points. If the emergency

source is available immediately, the controller will accept it as soon as the NR relay drops

out.

When the emergency source becomes acceptable, the controller starts the Feature 2B time

delay on transfer to emergency (if desired). If the emergency source fails while Feature 2B

time delay is running, the controller again waits for the emergency source to become

acceptable again and restarts Feature 2B.

At the conclusion of the Feature 2B time delay, the controller starts the synchronization

time delay which allows both sources to stabilize. After the synchronization time delay,

the controller starts the in–sync monitor. Three criteria must be met for the sources to be

consideredin–sync. The phase difference between thesources mustbe less than 5degrees,

thefrequencydifferencemustbelessthan0.2Hz,andthevoltagedifferencemustbeless

than 5%. These parameters are displayed. The controller waits for the sources to become

in–sync. At the same time, the failure to sync time delay is running. If the failure to sync

time exceeds the user selected time, the failure to sync output is activated and remains

active until it is reset via the alarm reset. The controller continues the transfer sequence

even after the failure to synchronize alarm becomes active.

Whenthe sourcesbecome in–sync the controller is ready to transfer the load to emergency.

Load Transfer. To transfer the load to the emergency source the controller energizes the

ER2 relay. The transfer switch CE coil energizes, and all CE transfer switch contacts

(mains, controls, auxiliaries) reverse position. The load is connected to both the Normal

and Emergency sources. The extended parallel time delay is started and the controller

energizes the ER relay. The transfer switch CN coil energizes, and all CN transfer swi tch

contacts (mains, control, auxiliaries) reverse position to disconnect the Normal source.

The load is now only connected to the Emergency source. If the sources are paralleled

longerthan the extended paralleltime setting the controlleractivates an extended parallel

output. It also deenergizes the ER and ER2 relays, energizes the SE and SE2 relays, and

it locks out any further transfer operations. This lock–out condition is reset via the alarm

reset.

voltage and frequency must reach preset pickup points before the

in the TransferTest

Page 25

Closed–Transition Automatic Transfer Switches continued

Closed–Transition Load Retransfer To Normal

Thesequenceforloadretransfertothenormalsourcebeginsautomaticallywhenthe

controller detects a restored normal source or a cancelled transfer test signal.

NORMAL OK

Load on Emerg

NORMAL OK

TD Emerg>Normal

__min __s

NORMAL OK

TD Engine Cooldown

__min __s

NORMAL OK

Load on Normal

Normal Source Restoratio n. The Normal source is considered acceptable again when

all

six voltage, frequency, or phase rotation conditions occur (see page 3–1).

Cancel Transfer Test. Removal of the test transfer signal can be by the Tr an s fe r C o n t ro l

switch (Feature 5), engine–generator exerciser clock (Feature 11C), or via serial port

(Feature 72A). When using the Tra ns f er C o nt r ol switch, it must be released

Transfer Test position.

The controller begins the load retransfer sequence by starting the Feature 3A time delay.

Feature 3A time delay on retransfer to normal allows the normal source to stabilize. If the

normal source fails while the Feature 3A time delay is running, the controller waits for the

normal source again to become acceptable and restarts the Feature 3A time delay. If the

emergency source fails during while Feature 3A is running, the controller bypasses the

time delay for immediately load retransfer. To bypass Feature 3A time delay, turn the

Tra ns f er Co nt r ol switch to the Retransfer Delay Bypass position.

At the conclusion of the Feature 3A time delay, the controller starts the synchronization

time delay which allowsboth sources to stabilize. After the synchronizationtime delay the

controller starts the in–sync monitor and the failure to sync time delay. When the sources

become in–sync the controller i s ready to transfer the load to normal.

Load Retransfer. To retransfer the load to the normal source the controller de–energize

the ER and ER1 relays and energizes the SE relay. The transfer switch CN coil energizes,

and all CN transfer switch contacts (mains, controls, auxiliaries) reverse position to

connect the Normal source. The load is now connected to both sources. The extended

parallel time delay is started and the SE2 relay is energized. The transfer switch CE coil

energizes, and all CE transfer switch contacts (mains, controls, auxiliaries) reverse

position to disconnect the Emergencysource. The transfer switch i s now supplying the load

from the normal source again. If the sources are paralleled longer than the extended

parallel time setting the controller activates an extended parallel output. It also

deenergizes the SE and SE2 relays, energizes the ER and ER2 relays, and it locks out any

further transfer operations. This lock–out condition is reset via the alarm reset.

Engine Cooldown & Stop. After load retransfer to the normal source, the controller

starts Feature 2E time delay. Feature 2E time delay provides an unloaded cooldown

running period for the engine–generator. At t he end of the time delay, the controller

energizes the NR relay and the engine–generator is signalled to shutdown.

4--5Description of Operation

from the

Bypass Closed–Transition Load Transfer

A pendi ng closed–transiti on load transfer can be bypassed by using the Closed Transi tion

Bypass switch. Depending upon the configuration of the controller, bypassing the

closed–transition load transfer sequence will result in either an open or delayed–

transition transfer.

Page 26

4--6 Description of Operation

Delayed–Transition Automatic Transfer (4ADTS, 7ADTS, 7ADTB)

Load Transfer To Emergency

NORMAL FAILED

TEST MODE

TEST CIRCUIT 5

Waiting for Emerg

Acceptable

TEST MODE

TEST CIRCUIT 5

TD Load Disconnect

__min __s

TEST MODE

TEST CIRCUIT 5

Load on Emerg

The sequence for load transfer to the emergency source begins automatically when the

controller detects a normal source failure or a transfer test signal.

Normal Source Failure. The Normal source is considered unacceptable when any one

of six voltage, frequency, or phase rotation conditions occur (see page 3–1).

Transfer Test Signal. Te st transfer signal can be from the Tr a n sf e r C on t ro l switch

(Feature 5), the engine–generator exerciser clock (Feature 11C), or via the serial port

(Feature 72A). When using the Tr a n sf e r C o nt r ol switch,itmustbeheld

in the TransferTest

position until the emergency source becomes available (within 15 seconds).

The controller begins the load transfer sequence by de–energizing the SE and SE2 relays

and starting the Feature 1C time delay. Feature 1C time delay on engine starting prevents

nuisance starting of the engine–generator set and load transfer to emergency due to

momentary failures of the normal source. If the normal source is restored (voltage returns

above the dropout point) while Feature 1C time delay is running, the SE and SE2 relays

are re–energized and the transfer sequence is terminated. (For transfer test the Feature

1C time delay is bypassed.)

Engine Start Signal. When the Feature 1C time delay ends, the controller de–energizes

the NR relay which signals the engine–generator to start. The cont roller monitors the

emergency source, waiting for it to become acceptable. Both

voltage and frequency must

reach preset pickup points before the emergency source is accepted. Usually about 10

seconds elapse from dropout of the NR relay to acceptance of the emergency source. This

interval occurs because the engine–generator must crank, start, and run up to nominal

pickup points. If the emergency source is available immediately, the controller will accept

it as soon as the NR relay drops out.

When the emergency source becomes acceptable, the controller starts the Feature 2B time

delay on transfer to emergency (if desired). Feature 2B time delay allows the emergency

sourceto stabilize before load transfer. If the emergencysourcefails whileFeature2B time

delay is running, the controller again waits for the emergency source to become acceptable

again and restarts Feature 2B.

At the conclusionof the Feature 2B time delay, the controller is ready to transfer the load

to emergency.

Load Transfer. To transfer the load to the emergency source in a delayed–transition

mode the controller energizes ER relay first. The transfer switch CN coil energizes and

opens the CN transfer switch contacts. The load is disconnected from both sources. The

load disconnect time delay starts. When this time delay ends, the controller energizes the

ER relay. The transfer switch CE coil energizes and closes the CE transfer switch main

contacts. The transfer switch is now supplying the load from emergency source.

Page 27

Delayed–Transition Automatic Transfer Switches continued

Load Retransfer To Normal

4--7Description of Operation

NORMAL OK

Load on Emerg

NORMAL OK

TD Emerg>Normal

__min __s

TEST MODE

TEST CIRCUIT 5

TD Load Disconnect

__min __s

NORMAL OK

TD Engine Cooldown

__min __s

Thesequenceforloadretransfertothenormalsourcebeginsautomaticallywhenthe

controller detects a restored normal source or a cancelled transfer test signal.

Normal Source Restoratio n. The Normal source is considered acceptable again when

all

six voltage, frequency, or phase rotation conditions occur (see page 3–1).

Cancel Transfer Test. Removal of the test transfer signal can be by the Tr an s fe r C o n t ro l

switch (Feature 5), engine–generator exerciser clock (Feature 11C), or via serial port

(Feature 72A). When using the Tra ns f er C o nt r ol switch, it must be released

from the

Transfer Test position.

The controller begins the load retransfer sequence by starting the Feature 3A time delay.

Feature 3A time delay on retransfer to normal allows the normal source to stabilize. If the

normal source fails while the Feature 3A time delay is running, the controller waits for the

normal source again to become acceptable and restarts the Feature 3A time delay. If the

emergency source fails during while Feature 3A is running, the controller bypasses the

time de lay for immediately load retransfer. To bypass Feature 3A time delay , turn the

Tra ns f er Co nt r ol switch to the Retransfer Delay Bypass position

At the conclusionof the Feature 3A time delay, the controller is ready to transfer the load

to normal.

Load Retransfer. To retransfer the load to the normal source in a delayed–transition

mode the controller de–energizes the ERand ER2 relaysand energizesthe SE2 relay. The

transfer switch CE coil energizes and opens the CE transfer switch main contacts. The

load is disconnected from both sources. The load disconnect time delay starts. When this

time delay ends the controller energizes the ER relay. The transfer switch CN coil

energizes and closes the CN transfer switch main contacts. The transfer switch is now

supplying the load from the normal source again

Engine Cooldown & Stop. After load retransfer to the normal source, the controller

starts Feature 2E time delay. Feature 2E time delay provides an unloaded cooldown

running period for the engine–generator. At t he end of the time delay, the controller

energizes the NR relay and the engine–generator is signalled to shutdown.

NORMAL OK

Load on Normal

Page 28

A --- 1 Appendix

Controller Cover Removal

Hazardous voltage capable of causing shock,

burns, or death is connected to controller.

Deenergize all power before removing cover.

NOTICE

ATTENTION

Observe precautions for

handing electrostatic

sensitive devices.

Touch ground first !

Electrostatic

sensitive device.

The Group 5 controller (CP) is used for sensing, timing,

and control functions with 4000 & 7000 Series Automatic

Transfer Switches. This Appendix shows the controller

DIP switch actuator settings and jumper block settings

for input voltage, frequency, phases, and type of transfer

switch used (open, closed, delayed transition). These

controls should only be used by trained technicians from

ASCO Services, Inc. (ASI 1–800–800–2726).

DIP switch actuators see page A–2

Voltage jumper blocks see page A–4

base with circuit

boards & membrane

controls

press latches

(both sides)

cover with pocket

for manual & drawings

Figure A–1. Cover release latches.

Any indiscriminate change in DIP switch and jumper block set-

tings may damage the controller and/or cause an inoperative ATS.

Risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to local ordinances.

Page 29

A --- 2Appendix

i

tch

DIP Switch Actuators

DIP switch

(10 actuators)

right side of

controller

The DIP switch in the Group 5 controller is located on

the right side through a opening in the base. The

following tables show what each actuator does.

Transfe r Swit ch Type

DIP switch actuators 1 and 2 select the type of transfer

switch used with the controller (open–transition,

closed–transition, or delayed–transition). See Table A.

TableA. Transferswitchtype—DIPactuators1&2.

DIP

switch

actuator

1

2

* For open–transition, both actuators 1 & 2 must be

in the same position (either both right or both left).

open

transition

or *

closed

transition

delayed-

transition