Emerson 627F Instruction Manual

Instruction Manual

Form 5282

April 2012

Type 627F Pilot-Operated

Pressure Reducing Regulator

Type 627F

W5607

Figure 1. Type 627F Pilot-Operated Pressure Reducing Regulators

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion

and/or re causing property damage and

personal injury or death.

Fisher® regulators must be installed,

operated, and maintained in

accordance with federal, state, and

local codes, rules and regulations,

and Emerson Process Management

Regulator Technologies, Inc. (Regulator

Technologies) instructions.

W5641

If the regulator vents gas or a leak

develops in the system, service to the

unit may be required. Failure to

correct trouble could result in a

hazardous condition.

Call a gas service person to service

the unit. Only a qualied person must

install or service the regulator.

Introduction

Scope of the Manual

This manual provides instructions for installation,

adjustment, maintenance, and parts ordering

information for the Type 627F regulator.

www.sherregulators.com

D101545X012

Type 627F

Specications

The Specications section gives some general specications for the Type 627F regulator. The nameplates

give detailed information for a particular regulator as it comes from the factory.

Body Sizes and End Connection Styles

Ductile iron: 3/4, 1, or 2 NPT

Steel: 3/4, 1, or 2 NPT;

NPS 1 or 2 / DN 25 or 50, CL150 RF,

CL300 RF, CL600 RF, PN 16/25/40 RF Flanged

Minimum Pressure Differential

20 psid / 1.4 bar d

Maximum Inlet and Differential Pressures

(1)

See Table 2

Maximum Emergency Outlet Pressure

(1)

250 psig / 17.2 bar for all Type 627F actuators and

Type 6351F pilot components

Outlet Pressure Ranges

5 to 100 psig / 0.34 to 6.9 bar

See Table 1

Orice Sizes

3/8 x 1/8, 3/8 x 1/4, 3/8, or 1/2 inch /

9.5 x 3.2; 9.5 x 6.4; 9.5; or 13 mm

Temperature Capabilities

(1)

-20 to 180°F / -29 to 82°C

Flow Coefcients

See Table 4

IEC Sizing Coefcients

See Table 5

Pressure Registration

External

Pilot Supply Connection

1/4 NPT

Pilot Sense Connection

1/4 NPT

Body Tap Connection

1/4 NPT (ductile iron body only)

Approximate Weights

NPT body with Ductile iron or steel casings:

10 pounds / 4 kg

NPT body with aluminum casings:

6.3 pounds / 3 kg

Flanged body with steel casings:

18 pounds / 8 kg

Flanged body with Ductile iron casings:

14 pounds / 6 kg

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

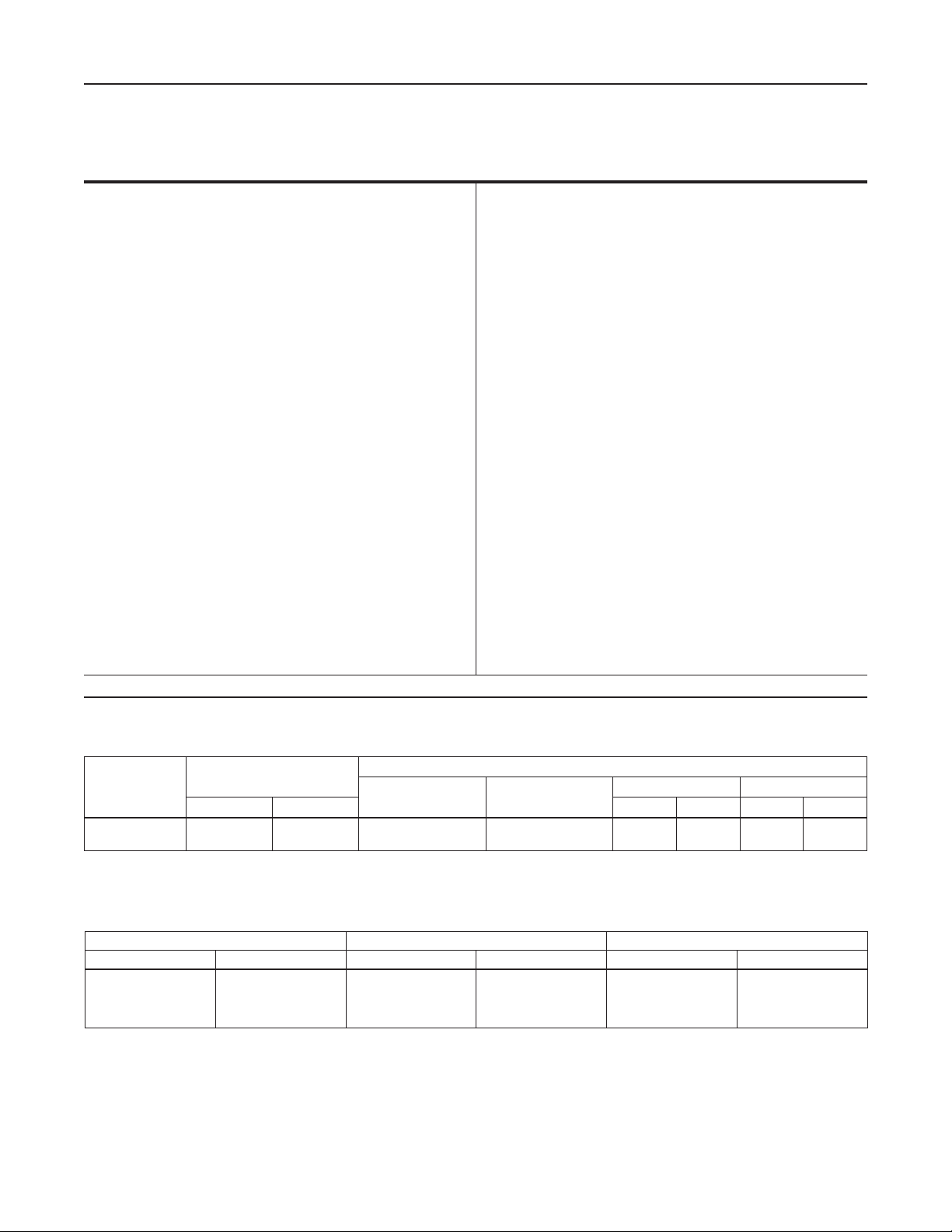

Table 1. Outlet Pressure Ranges

PILOT CONTROL SPRING INFORMATION

Wire Diameter Free Length

Unpainted

Red

0.142

0.192

3.61

4.88

PILOT TYPE

6351F

OUTLET PRESSURE RANGE

psig bar inches mm inches mm

5 to 35

35 to 100

0.34 to 2.4

2.4 to 6.9

Part Number Color Code

1B788327022

1K748527022

Table 2. Maximum Allowable Inlet Pressures and Pressure Differential

ORIFICE SIZE MAXIMUM INLET PRESSURE MAXIMUM PRESSURE DIFFERENTIAL

inch mm psig bar psig bar

3/8 x 1/8

3/8 x 1/4

3/8

1/2

9.5 x 3.2

9.5 x 6.3

9.5

13

250

250

250

125

17.2

17.2

17.2

8.6

250

250

250

125

2.13

2.19

54.1

55.6

17.2

17.2

17.2

8.6

2

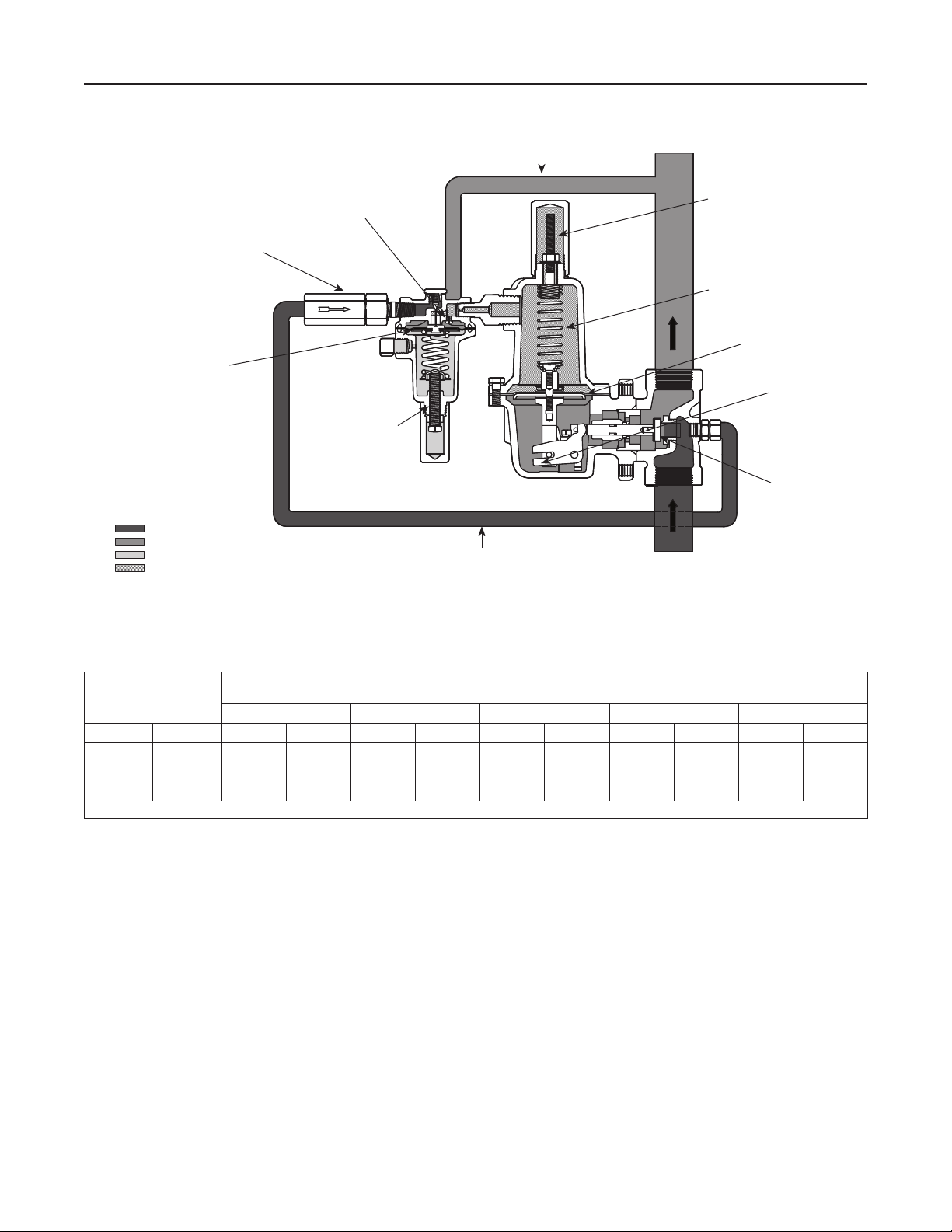

FIELD INSTALLED

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

DOWNSTREAM

CONTROL LINE

Type 627F

FILTER (FACTORY

INSTALLATION

OPTIONAL)

PILOT DIAPHRAGM

A6558

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

RESTRICTION

(BLEED)

PILOT ADJUSTING

SCREW

TYPE 6351F PILOT

TYPE 627F REGULATOR

PILOT SUPPLY TUBING

(FACTORY INSTALLATION OPTIONAL)

SPRING SEAT BOLT

(THIS IS NOT AN

ADJUSTING SCREW)

TENSION SPRING

Figure 2. Type 627F Pilot-Operated Pressure Reducing Regulator Operational Schematic

MAIN REGULATOR

DIAPHRAGM

LEVER

VALVE DISK

Table 3. Additional Specications

ALLOWABLE INLET PRESSURE RANGE FOR MAINTAINING OUTLET PRESSURE

ORIFICE SIZE

5 psig / 0.34 bar 30 psig / 2.1 bar 40 psig / 2.8 bar 60 psig / 4.1 bar 100 psig / 6.9 bar

inch mm psig bar psig bar psig bar psig bar psig bar

3/8 x 1/8

3/8 x 1/4

3/8

1/2

1. For best performance, outlet pressure setting should be made using an inlet pressure that is midway between the highest and lowest expected inlet pressure.

9.5 x 3.2

9.5 x 6.4

9.5

13

30 to 250

30 to 250

30 to 250

25 to 125

2.1 to 17.2

2.1 to 17.2

2.1 to 17.2

1.7 to 8.6

Description

WITHIN ±1% OF THE ABSOLUTE OUTLET PRESSURE SETTING

55 to 250

55 to 250

55 to 250

50 to 125

3.8 to 17.2

3.8 to 17.2

3.8 to 17.2

3.4 to 8.6

65 to 250

65 to 250

65 to 250

60 to 125

4.5 to 17.2

4.5 to 17.2

4.5 to 17.2

4.1 to 8.6

85 to 250

85 to 250

85 to 250

80 to 125

repositions the valve disk to provide fast response to

(1)

5.9 to 17.2

5.9 to 17.2

5.9 to 17.2

5.9 to 8.6

125 to 250

125 to 250

125 to 250

120 to 125

system changes. Simultaneously, the pilot amplies

The Type 627F pilot-operated (Type 6351F pilot)

pressure reducing regulator (Figure 1) provides

economical, accurate pressure control in a wide variety

of applications using pressure factor measurement

(xed factor billing). The regulator can be used with

natural gas, air, or a variety of other gases.

system pressure changes to position the main

regulator valve disk for precise pressure control.

Inlet pressure is used for the pilot supply pressure.

If downstream ow increases, lowering the outlet

pressure below the regulator setpoint, pressure on

the pilot diaphragm and the lever side of the main

regulator diaphragm decreases. The pilot opens to

Principle of Operation

The superior performance of a Type 627F regulator is

due to the amplifying effect of the pilot and the two-path

control system (Figure 2). Changes in outlet pressure

act quickly on the main regulator diaphragm which

supply the required loading pressure increase. The

increased loading pressure from the pilot overcomes

the main regulator spring force, and the main

regulator valve disk moves farther open to supply the

required ow.

8.6 to 17.2

8.6 to 17.2

8.6 to 17.2

8.3 to 8.6

3

Type 627F

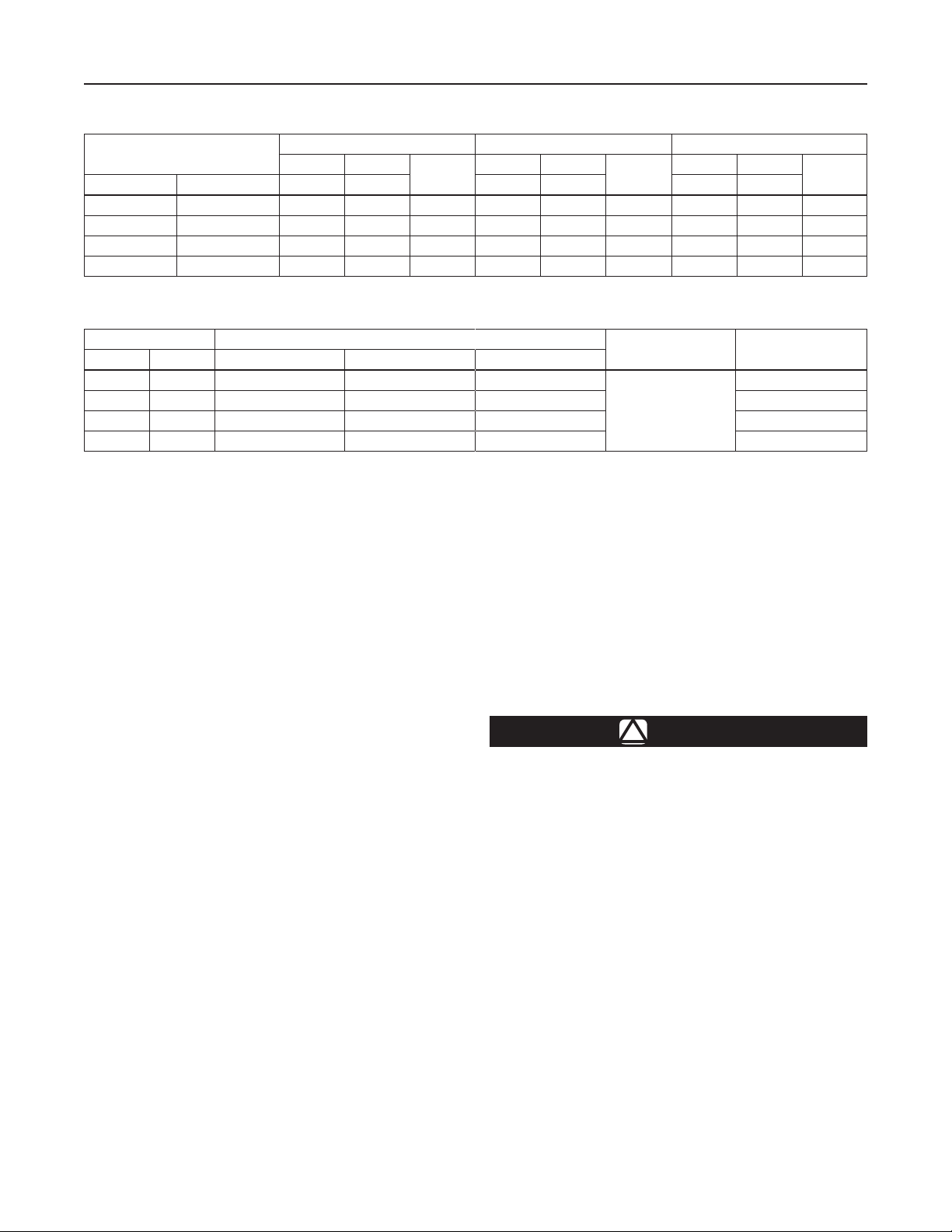

Table 4. Flow Coefcients

ORIFICE SIZE

inches mm C

3/8 x 1/8 9.5 x 3.2 12.5 0.43 29.1 12.5 0.43 29.4 12.5 0.43 29.2

3/8 x 1/4 9.5 x 6.4 50 1.63 30.6 50 1.71 29.3 52 1.66 31.3

3/8 9.5 108 2.99 36.1 108 3.42 31.6 11.5 3.39 33.9

1/2 13 190 4.87 39.0 190 5.29 35.9 200 5.01 39.9

ORIFICE SIZE X

inches mm 3/4 NPT Body NPS 1 / DN 25 Body NPS 2 / DN 50 Body

1/8 3.2 0.54 0.55 0.54

1/4 6.4 0.59 0.54 0.62 0.87

3/8 9.5 0.82 0.63 0.73 0.89

1/2 13 0.96 0.82 1.01 0.86

Wide-Open Wide-Open

When downstream pressure increases due to lowered

demand, greater pressure is registered on the pilot

diaphragm and the lever side of the main regulator

diaphragm. The pilot closes, and the excess loading

pressure bleeds off to downstream, through the pilot

restriction. With the lower loading pressure, the spring

can move the main regulator disk closer to the orice.

Under no ow conditions, the excess loading pressure

bleeds through the pilot restriction to the downstream

system until the loading pressure and outlet pressure

equalize. The main valve is closed by the spring and

3/4 NPT BODY NPS 1 / DN 25 BODY NPS 2 / DN 50 BODY

Wide-Open Wide-Open

C

g

C

v

Table 5. IEC Sizing Coefcients

1

T

C

g

C

v

Wide-Open Wide-Open

C

1

F

0.50

C

D

g

4. Make sure that there is no damage to, or foreign

material in the regulator. Ensure that all tubing

and piping have been blown free of foreign debris.

5. The regulator may be installed in any position as

long as the ow through the body is in the direction

indicated by the arrow cast on the body and both

pilot openings are connected.

6. If continuous operation is required during

inspection or maintenance, install a three-valve

bypass around the regulator.

C

v

the bleed stops.

WARNING

!

F

0.79

C

1

L

Installation

Only personnel qualied through training and

experience should install, operate, or maintain this

regulator. Regulator operation within ratings does

not preclude the possibility of damage from debris

in the lines or from external sources. Key numbers

referenced in this section are shown in Figures 3 and 4.

1. A regulator should be inspected for damage

periodically and after any overpressure condition.

2. Ensure that the operating temperature capabilities

listed in the Specications section are not exceeded.

3. A pressure-relieving or pressure-limiting device

must be provided by the user if the inlet pressure

can exceed the outlet pressure rating of the

downstream equipment.

4

A regulator may vent some gas to

the atmosphere. In hazardous or

ammable gas service, vented gas may

accumulate and cause personal injury,

death, or property damage due to re or

explosion. Vent a regulator in hazardous

gas service to a remote, safe location

away from air intakes or any hazardous

area. The vent line or stack opening

must be protected against condensation

or clogging.

To keep the pilot spring case vent from being plugged

or the spring case from collecting moisture or other

foreign material, point the vent down or otherwise

protect it. To change vent orientation, remove the

spring case and remount it on the pilot body.

Loading...

Loading...