Page 1

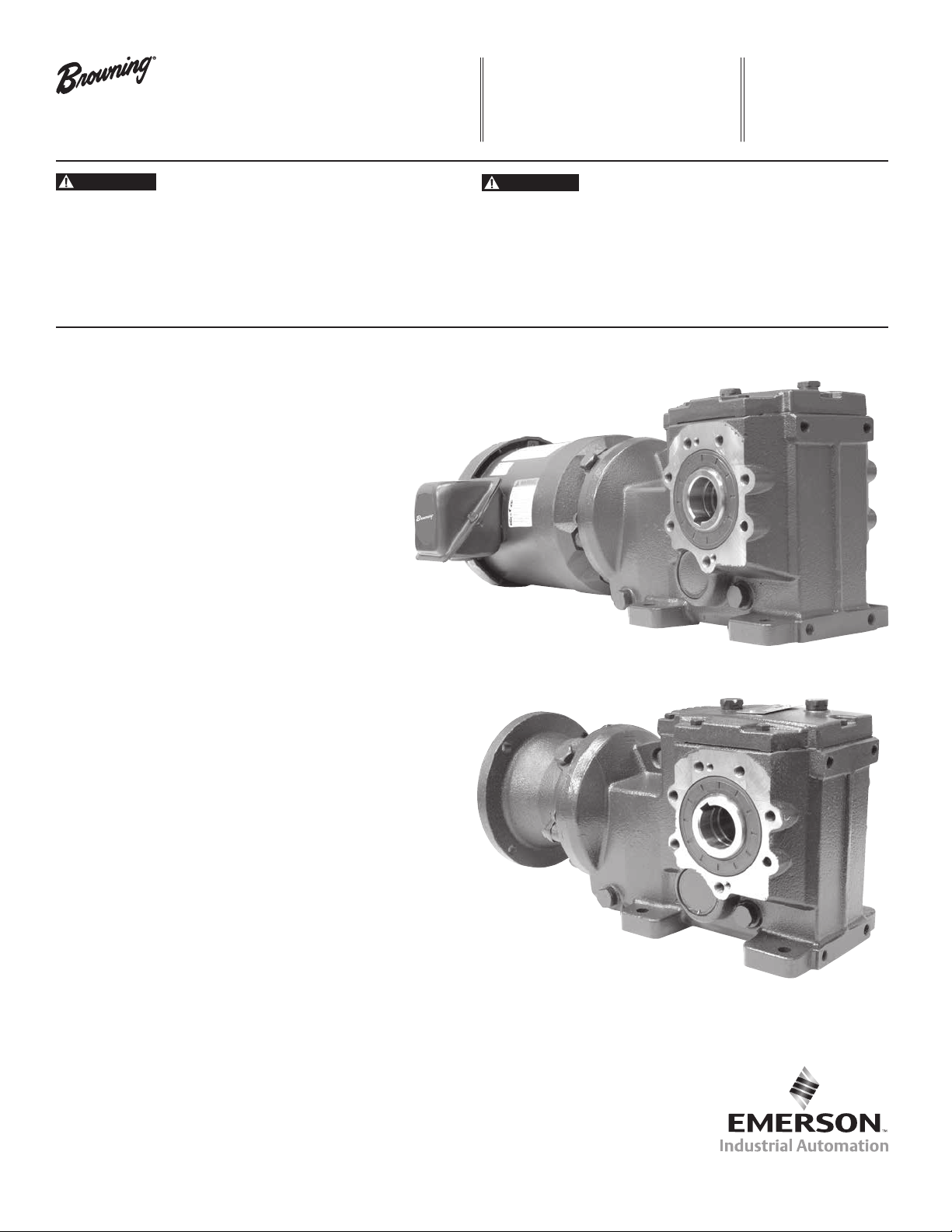

OtN Series 3000

CAUTION

WARNING

Gearmotors and Reducers

Emerson Industrial Automation

7120 New Bufngton Road

Florence, KY 41042

Application Engineering: 800 626 2093

www.PowerTransmissionSolutions.com

F O R M

9020E

Revised

January 2014

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation and maintenance.

Working on or near energized equipment can result in severe injury or death.

• Avoid contact with energized circuits or rotating parts.

• Be sure shaft key is fully captive before unit is energized.

• Do not operate equipment without guards in place. Exposed equipment can

result in severe injury or death.

• Periodic inspections should be performed. Failure to perform proper maintenance

can result in premature product failure and personal injury.

• All electrical work should be performed by qualied personnel and compliant with

local and national electrical codes.

Thank you for choosing an OtN Series 3000 gearmotor or reducer.

Installation Instructions

Start-Up

• Before operating the reducer or gearmotor, the following

must be done:

• If foot or ange mount, install the drive on a rigid

and vibration-free surface. If shaft mounted, install

the drive onto a rigidly supported drive shaft.

• Remove the protective coating on the shaft and

ange. Use solvent if necessary.

• Carefully install coupling, sheaves, sprockets, or pinions on

shaft. Mount as close to the shaft shoulder as possible.

• It is preferable to use heat instead of force. Do not hammer

on shaft!

• Check shaft alignment when using direct coupling.

• Check shaft parallelism when using belt or chain drive.

CAUTION : Refer to belt manufacturer’s recommendation

for belt tension. (Tension should not be applied on chain

drives.)

• Check oil level in oil lubricated reducer.

• Install breather plug in the plug hole per recommendations

shown on page (5).

Maintenance

To provide safe operation and to avoid problems, it is

recommended the reducer or gearmotor be inspected every 50

hours of operating time.

• Check mounting bolts and belt tension (if applicable).

The preventative maintenance list below should be performed

every 5000 hours of operating time:

• Check oil level and add oil if necessary.

• Make sure the vent hole in the breather is clean

Browning, Emerson and Emerson Industrial Automation are trademarks of Emerson

Electric Co. or one of its affiliated companies.

©2007, 2009, 2010, 2011, 2012, 2014 Emerson Power Transmission, All Rights Reserved.

MCIM14001E • Form 9020E • Printed in USA

1

Page 2

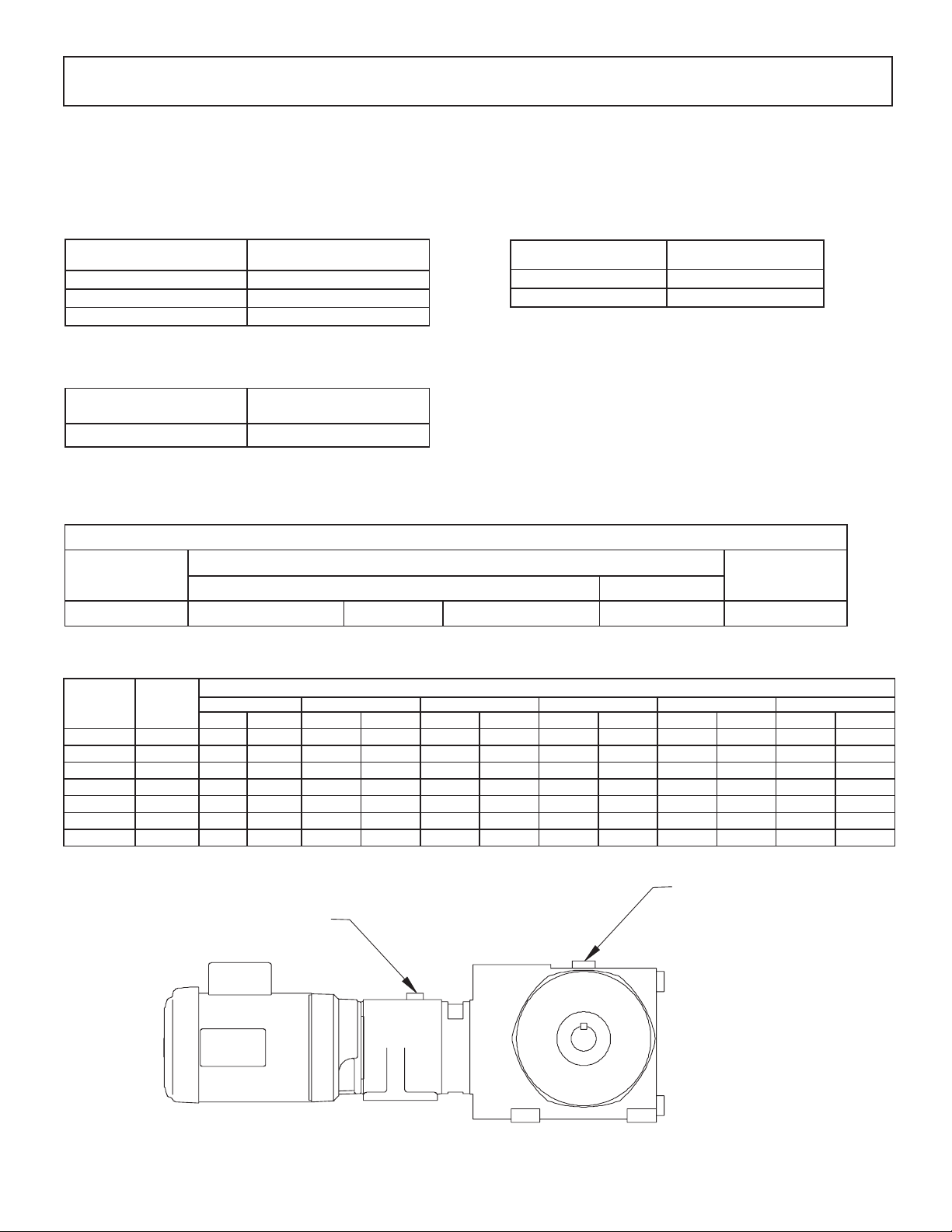

Combined Reduction

Lubricants

Series 3000 OtN gearing is shipped with one of the following synthetic lubricants per the table below and tted with a magnetic drain.

Each reducer is lled according to the mounting position specied when ordered. Refer to unit nameplate and the chart and table on

page 4 and 5 for mounting position arrangement for your unit.

In the case of synthetic oil, the lubricant does not require changing but it is recommended that proper oil level be checked periodically.

Standard Synthetic Gear Oil (Non - Food Grade)

No Backstop

Manufacturer

Fuchs* Sintogear

Mobil* Mobilgear

Shell* Omala

-25° F to 125° F

(-30° C to 50° C)

*

125

*

SHC 150

*

S4 GX 150

Standard Synthetic Gear Oil (Food Grade)

No Backstop

Manufacturer

22° F to 125° F

(-20° C to 50° C)

Mobil SHC Cibus 150

CAUTION: Never mix synthetic oil and mineral oil.

(1) Never use extreme pressure (EP) oil in a reducer with a backstop.

Acceptable Mineral Oil Lubricants

With Backstop (1)

Manufacturer

Shell Morlina S4 B 700

Mobil SHC 629

-25° F to 125° F

(-30° C to 50° C)

Ambient Range of Installation

-4°F to 14°F

(-20°C to 10°C)

14°F to 122°F (-10°C to 50°C)

No Backstop With Backstop (1)

122°F and Above

(50°C +)

ISO VG 68 ISO VG 100 ISO VG 150 ISO VG 220 ISO VG 150 ISO VG 320

Combined OtN 3000 Gearing

Consists of an OtN primary gear housing and a CbN secondary gear housing. The table below provides the CbN oil volumes in quarts.

OtN

Frame

Size

3245 CbN 30 ** 0.64 ** 0.64 ** 0.64 ** 0.64 ** 0.64 ** 0.64

3365 CbN 31 ** 0.63 ** 1.16 ** 0.90 ** 1.00 ** 1.22 ** 1.48

3475/3476 CbN 31 ** 0.63 ** 1.16 ** 0.90 ** 1.00/1.30 ** 1.22 ** 1.48

3585/3586 CbN 31 ** 0.63 ** 1.16 ** 0.90 ** 1.00/1.30 ** 1.22 ** 1.48

3695/3696 CbN 32 ** 1.00 ** 2.38 ** 1.64 ** 1.85/2.43 ** 2.38 ** 2.85

3705/3706 CbN 32 ** 1.00 ** 2.38 ** 1.64 ** 1.85/2.43 ** 2.38 ** 2.85

3825/3826 CbN 32 ** 1.00 ** 2.38 ** 1.64 ** 1.85/2.43 ** 2.38 ** 2.85

Sec.

Gear

Size

B P H T V W

Prim. Sec. Prim. Sec. Prim. Sec. Prim. Sec. Prim. Sec. Prim. Sec.

** Refer to table on page 5 for the OtN oil volume based on frame size, Mounting Conguration, Mounting Position and Type of

Mounting ( i.e. Foot, Flange, etc.) of your unit.

Combined Reduction

Secondary

Mounting Position

Primary

* The following trade names, trademarks and/or registered trademarks are used in this material by Emerson Power Transmission Corporation are NOT owned or controlled by Emerson Power Transmission

Corporation and are believed to be owned by the following parties: Fuchs and Sintogear: Fuchs Corporation; Mobil and Mobilgear: Exxonmobil Oil Corporation; Shell and Omala: Shell Petroleum Incorporated.

Emerson Power Transmission Corporation cannot and does not represent or warrant the accuracy of this information.

2

Page 3

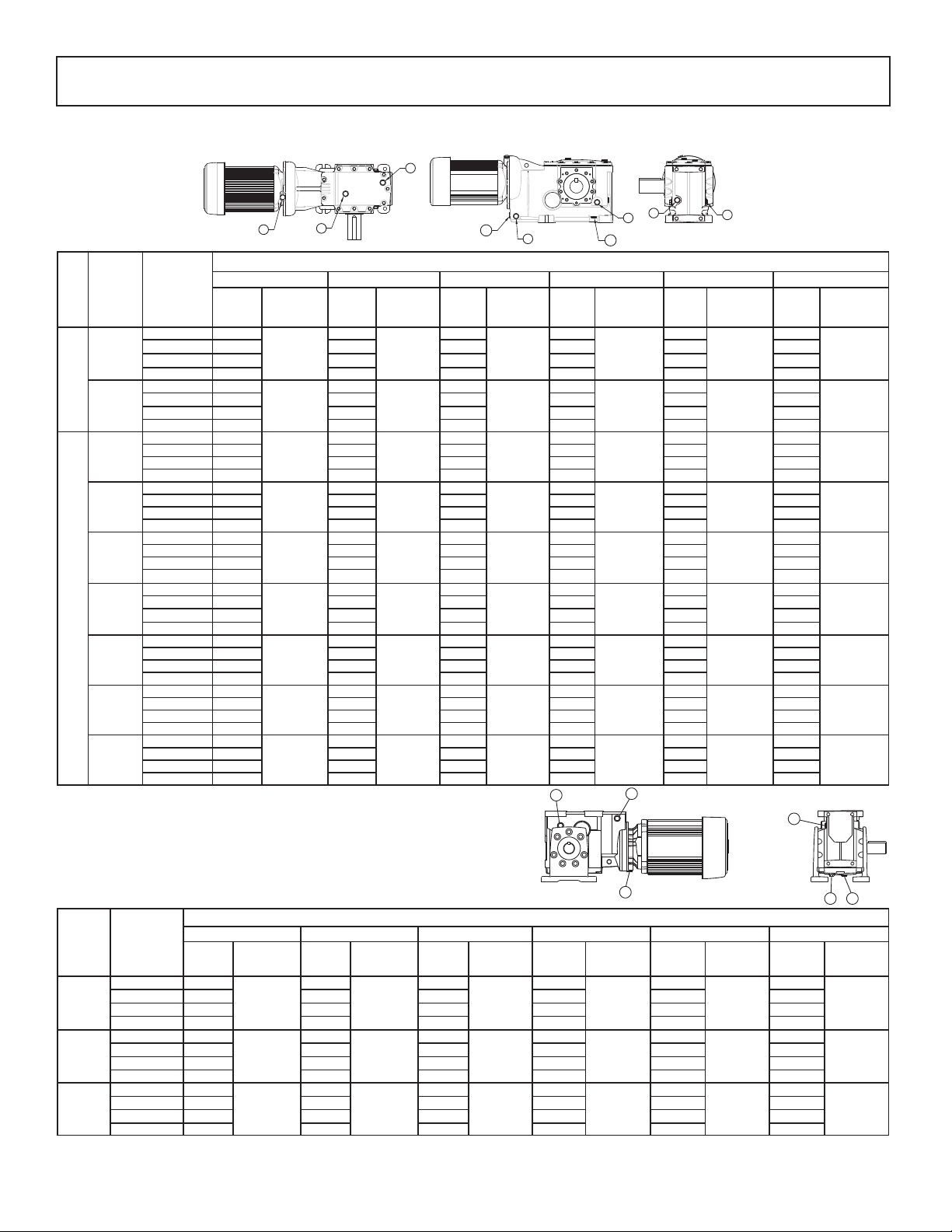

Plug Location and Oil Volume

10

S2 Conguration - All mounting styles

S1 Conguration - All mounting styles (except foot mounted 33, 34, and 35 – see below)

5

9

8

6

11

2

3

4

Mounting Position

Gear

Frame

Design

Plug Type

Size

Level 12

Drain 2 6 2 12 5 2

31 Breather 6 2 8*D 8*G 8 5

B P H T V W

Plug #

Oil Volume

Quarts

+

0.95

Plug #

12

Oil Volume

Quarts

+

1.06

Plug #

6

Oil Volume

Quarts

+

0.95

Plug #

6

Oil Volume

Quarts

+

0.8

Plug #

2

Oil Volume

Quarts

1.64

Fill 5 2 12 2 12 5

32 Drain 2 6 2 4 4 2

Double Reduction

Breather 6 2 4 2 8 5

Fill 5 2 4 2 2 5

1.96

Level 4

Level 4

32 Drain 2 5 2 8 5 8

Breather 6 3 4 3 8 5

0.55

4

2.06

4

1.82

6

1.74

5

1.5

6

2.06

6

1.5

2

3.12

2

2

Fill 5 3 4 2 8 4

33 (A) Drain 2 5 2 4 5 8

Breather 6 4 4 3 4 5

1.16

Level 3

3

3.7

5

3.49

6

2.96

2

3.96

Fill 5 2 4 2 2 4

34 Drain 2 5 2 4 or 8 5 8

Breather 6 3 4 3 8 5

1.37

Level 3

3

6.45

5

5.39

6

4.65

2

6.76

Fill 5 2 4 2 8 5

35 Drain 2 5 2 8 5 8

Breather 6 3 5 3 8 5

2.85

Level 3

3

8.88

6

5.39

6

7.72

2

11.42

Fill 5 2 5 2 8 5

Triple Reduction

36 Drain 2 5 3 4 5 2

Level 5**

Breather 5 10 4 3 11 9

6.08

10**

19.24

4**

14.28

3**

12.9

11**

23.36

Fill 5 10 4 3 11 9

37 Drain 2 5 3 4 5 2

Breather 5 10 4 3 11 9

10.58

Level 5**

10**

25

4**

20.3

3**

17.97

11***

35.94

Fill 5 2 4 3 11 9

Level 5**

38

Drain 11 5 3 4 5 2

Breather 5 10 4 3 11 9

10.57

10**

34.87

4**

29.06

3**

22.19

11**

43.32

Fill 5’ 11 4 3 11 9

3

2

+

Plug #

6

6

6

6

6

6

9**

9**

9**

4

Oil Volume

Quarts*

1.11

2.48

1.4

2.75

3.91

6.61

13.95

25.05

25.36

S1 Congurations 33D,33G,33X for Frames 33,34 and 35.

See above for all other mounting.

Gear

Frame

Size

33

Plug

Type

Level 3

Draining 6 2 4 2 5 8

Breather 2 6 3 4 4 5

B P H T V W

Plug#Oil Volume

Quarts

Plug#Oil Volume

+

Quarts

Plug#Oil Volume

+

3

3.7

1.16

Filling 2 5 2 4 2 4

34

Level 3

Draining 6 2 4 or 8 2 5 8

Breather 2 6 3 5 8 5

6.45

3

1.37

Filling 2 5 2 5 8 5

Level 3

35

+

Adaptor is assembled to position breather location on top when mounted in this position

** This is location for dipstick to check oil level

*** This location for dipstick with extension added to check oil level

Draining 6 2 8 2 5 8

Breather 2 6 3 5 8 5

8.88

Filling 2 5 2 5 8 5

3

2.65

Mounting Position

Quarts

6

2.96

6

4.65

6

7.72

Plug#Oil Volume

+

5

6

6

Quarts

3.49

5.39

5.39

8

Plug#Oil Volume

+

5

6

Plug#Oil Volume

+

Quarts

2

6

3.96

2

6

6.76

2

6

11.42

Quarts

2.75

3.91

6.61

+

3

Page 4

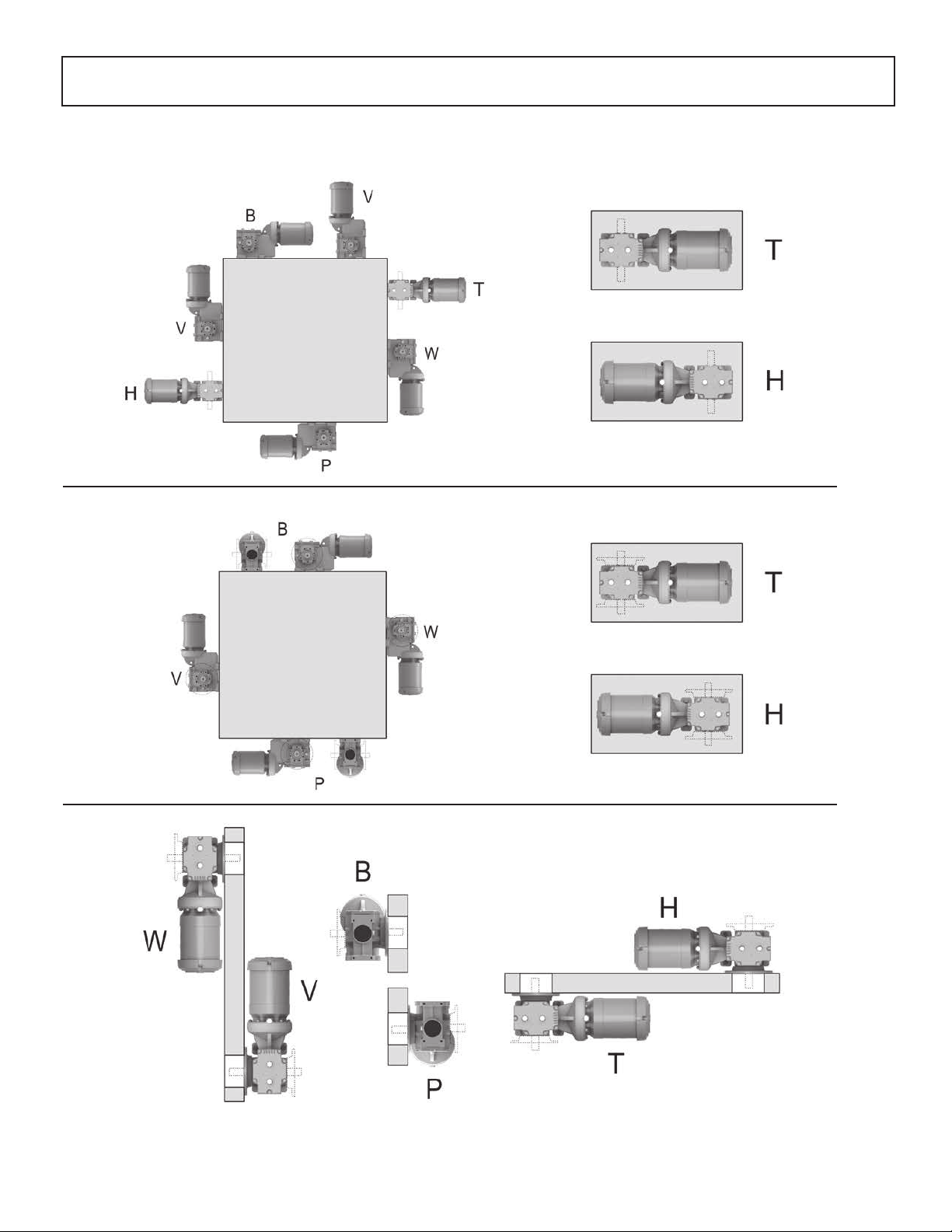

Gearbox Mounting Positions

Foot Mount

Foot Mount with Face or Flange

Flange, Face or Shaft Mount

4

Page 5

1. OtN Shaft Mount Reducer Installation

For long service and dependable performance, an OtN shaft

mounted gear unit must be properly supported and accurately

aligned. The following instructions are a step-by-step guide to

meeting these requirements for an OtN 3000 design shaft mounted

product. If there is a need to vary or deviate from any of these

installation instructions, contact Application Engineering Department

at 1-800-626-2093 before completing the installation.

CAUTION: When the driven shaft is smaller than the maximum

bushing size for a gear frame, check the driven shaft and key

stress per ANSI/AGMA Std. 6001-D97 for the application.

1.1 Reducer and Driven Shaft Preparation

1.1.1 The driven shaft diameter is to be within the commercial

tolerances for turned, ground and polished bars. The key and

keyseat in the driven shaft are to be in accordance with commercial

standards for the size, depth, offset, and parallelism.

1.1.2 The driven shaft on which the gear unit is to be mounted must

be straight, clean, and free of burrs.

1.1.3 Rotate the driven shaft on which the gear unit is to be mounted

so that the shaft keyseat is in the upward position.

1.1.4 A lifting lug is provided to lift the gear reducer or gearmotor

into position.

WARNING! Never lift the gear unit by the input or output

shaft. The lifting lug is designed for lifting only the gear reducer

or gearmotor. Do not use the lifting lug to lift attached assemblies.

Do not apply grease, oil, or any anti-seize compounds to the taper

bore of the reducer, barrel of the bushing, driven shaft or the bushing

bore. If any of these substances are applied, equipment failure and

personal injury may result.

1.2 Determine Mounting Conguration – Bushed Bore Models

Due to the unique design of OtN bushed shaft mounted product,

the reducer may be mounted to the driven shaft in a variety of

congurations. The following instructions will help to determine the

correct mounting conguration based on the available shaft and

key length

1.2.1 Measure the available driven shaft length “H” (in inches)

starting with the end of the driven shaft to the rst obstruction or

point of interference.

1.2.2 Measure the length of available keyseat “K” in the driven

shaft (in inches) starting from the end of the shaft to the end of the

useable keyseat.

1.2.3 The following sections 1.3, 1.4, 1.5 show the three standard

mounting congurations for the Browning

®

OtN tapered bushed

“33B” gearing. Refer to the following sections in sequence to

determine the optimum mounting conguration for your application.

1.2.4 Compare the measured values of H and K of the driven shaft

to the tabulated values of H and K. If the measured values for H and

K are greater than the tabulated values, the mounting conguration

shown in the gure may be used. If the measured values for H and

K are less than the tabulated values, proceed to the next gure

and repeat this step.

Note: If the measured values for H and K are less than the

tabulated values shown in 1-5, contact the Application Engineering

Department at 1-800-626-2093.

1.2.5 Tightening torque for bushing components.

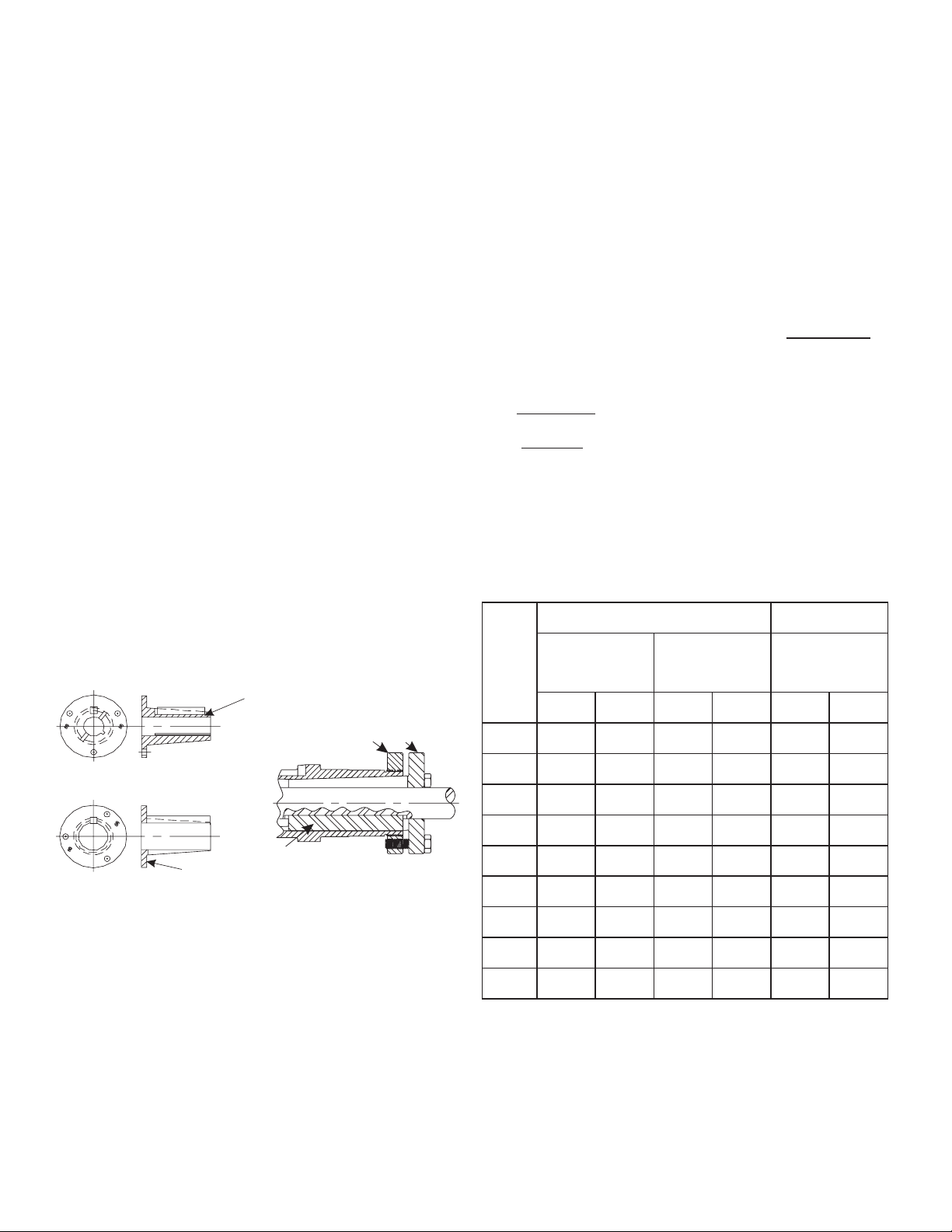

Table 1.2.5

33B Taper Bushed Screw Conveyor

EXTERNAL KEY FURNISHED

TYPE 1

BUSHING

TYPE 2

BUSHING

THROUGH KEY FURNISHED

Figure 1-1

BUSHING

FLANGE

EXTERNAL KEY

KEY SHOWN

FOR TYPE 2

BUSHING

BUSHING

RING

TYPE 2

BUSHING

Figure 1-2

BUSHING

Gear

Frame

Tapered

Bushing Cap

screws

End Cap

Setscrews

(nylon tipped)

Keeper

Bolts

Size Ft.-Lbs Size In-Lbs Size Ft.-Lbs

31 5/16-18 16 1/4-20 60 - -

32 5/16-18 16 1/4-20 60 1/2-13 99

1

5/16-18 16 1/4-20 60 1/2-13 99

33

33A 3/8-16 29 1/4-20 60 - -

34 3/8-16 29 1/4-20 60 5/8-11 200

35 3/8-16 29 1/4-20 60 3/4-10 350

36 3/8-16 29 1/4-20 60 3/4-10 350

37 1/2-13 70 1/4-20 60 1-8 600

38 1/2-13 70 1/4-20 60 1-8 600

1

This design is replaced by 33A design effective Jan. 2010 for 33B output

5

Page 6

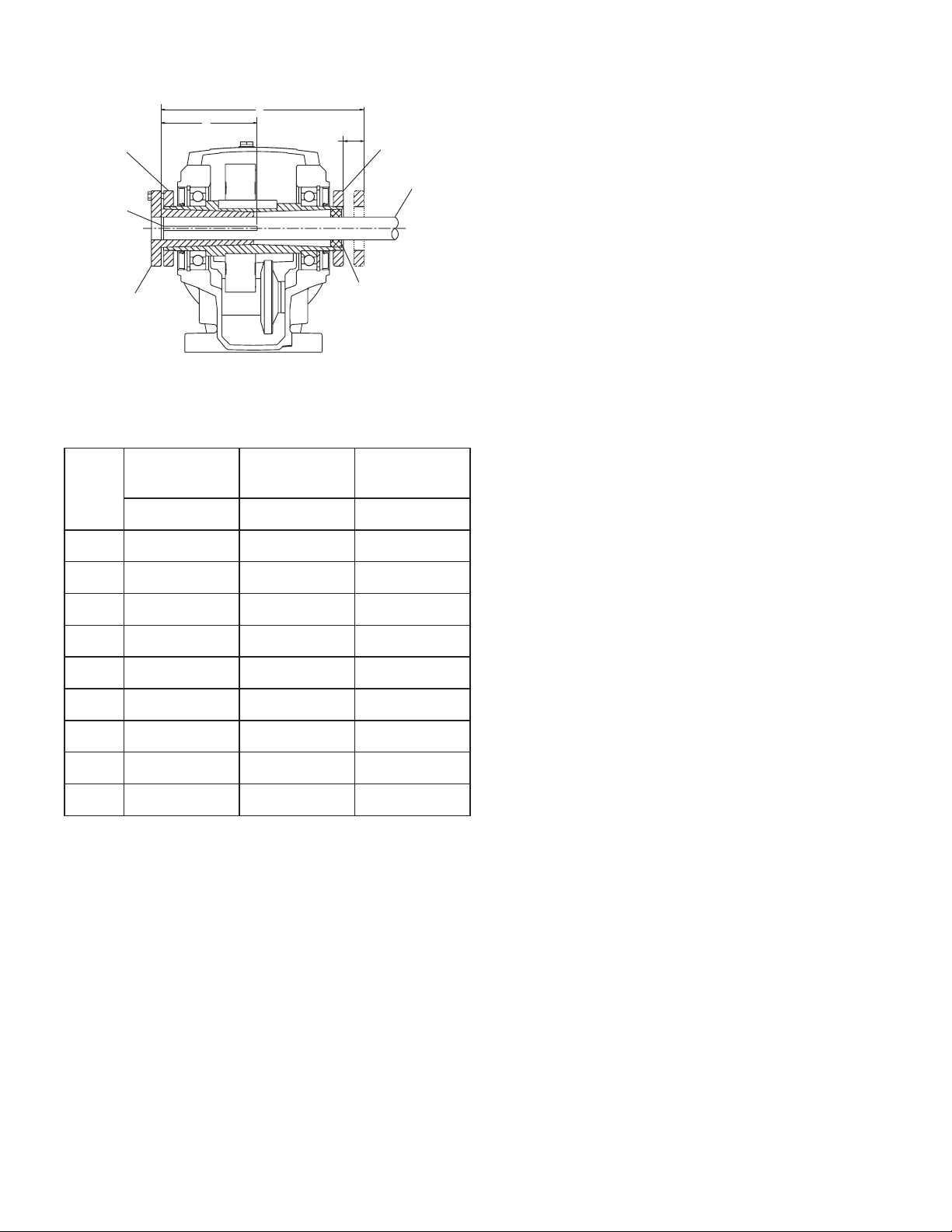

1.3 Mounting Conguration with Bushing Outboard

of Load

H

MC

Endcap

Driven

Stabilizer Ring

Shaft

Bushing

Ring

Driven

Shaft Key

Bushing

K

Figure 1-3

Table 1-3 Dimensions for Mounting Conguration

with Bushing Outboard of Load

Minimum Shaft

Mounting

Length

Gear

Frame

End cap

Clearance

MC H K

31 0.85 8.23 2.88

32 0.97 9.28 4.38

33

1

0.97 9.21 4.38

33A 1.03 11.16 4.63

34 1.03 11.34 4.63

35 1.21 12.23 5.63

36 1.31 16.75 6.13

37 1.44 18.08 7.38

38 1.69 18.43 7.38

1

This design is replaced by 33A design effective Jan. 2010

1.3.1 On the input shaft side, thread the bushing ring onto the

hollow reducer quill until the bushing ring is ush with the end of

the reducer quill shaft.

1.3.2 Place the end cap on the driven shaft with the threaded bore

facing the end of the shaft. Slide the stabilizer ring on the driven

shaft with the small end of the taper toward the end of the shaft.

1.3.3 Install Key(s)

Type 1 Bushing (2 keys):

• Install the external bushing key into the bushing as shown in

Figure 1-1 (external bushing key is supplied with the bushing kit)

• Install the driven shaft key (customer supplied) into the driven

shaft keyseat. Position the end of the driven shaft key even with

the end of the driven shaft. Retain this key to prevent movement.

1.3.4 Install Reducer

Type 1 Bushing

• Mount the reducer on the driven shaft with the bushing ring

facing outward toward the end of the driven shaft

6

Minimum Key

Connection

Length

• Locate the reducer on the driven shaft such that approximately

.50 inch of the driven shaft extends out beyond the end of the

reducer quill.

• Start the bushing (small end rst) by aligning the keyway in the

bushing with the key previously installed in the driven shaft.

• Continue moving the bushing into position and rotate the input

of the reducer as required to align the external bushing key with

the keyway in the reducer quill.

• Rotate the bushing ring clockwise to align the clearance holes

in the bushing with the threaded holes in the bushing ring. (This

will require less than 1/2 turn of the bushing ring).

• Install the bushing cap screws and hand tighten. Reposition

the reducer until the end of the driven shaft is even with the

end of the bushing ring.

• Slide the stabilizer ring into the reducer quill and thread the

end cap on hand tight.

• Tighten the bushing cap screws evenly around the bushing

ange to the recommended torque as shown Table 1.2.5. See

bolt torque specications section.

• Tighten the end cap again until hand tight. Tighten the setscrew

in the end cap to the recommended torque from Table 1.2.5.

Type 2 Bushing

• Mount the reducer on the driven shaft with the bushing ring

facing outward toward the end of the driven shaft.

• Rotate the input of the reducer as required to align the external

bushing key with the keyway in the reducer quill.

• Locate the reducer on the driven shaft such that approximately

.50 inch of the driven shaft extends out beyond the end of the

reducer quill.

• Start the bushing (small end rst) by aligning the keyway in the

bushing with the key previously installed in the driven shaft.

• Rotate the bushing ring clockwise to align the clearance holes

in the bushing with the threaded holes in the bushing ring. (This

will require less than 1/2 turn of the bushing ring).

• Install the bushing cap screws and hand tighten. Reposition

the reducer until the end of the driven shaft is even with the

end of the quill.

• Slide the stabilizer ring into the reducer quill and thread the

end cap on hand tight.

• Tighten the bushing cap screws evenly around the bushing

ange to the recommended torque as shown in Table 1.2.5.

• Tighten the end cap again until hand tight. Tighten the setscrew

in the end cap to the recommended torque from Table 1.2.5.

Note: The key length must be sufcient to engage the full length of

the bushing. The shaft must engage the full length of the reducer

shaft (Refer to “H” in Figure 1-3).

Note: There are three (3) series of bushing keys used in the

Type 2 bushing system: rectangular, square and offset. In most

cases, the key supplied will be rectangular or offset. Use caution

when installing rectangular keys as some may visually appear

square. The key should install in the bushing keyway with a sliding

type t. The key in the driven shaft keyseat should be retained

to prevent movement.

WARNING! The cap screws must thread into the bushing ring and

not the bushing. Threaded holes in the bushing are for removal

only. If assembled incorrectly, equipment failure and personal

injury may result.

Page 7

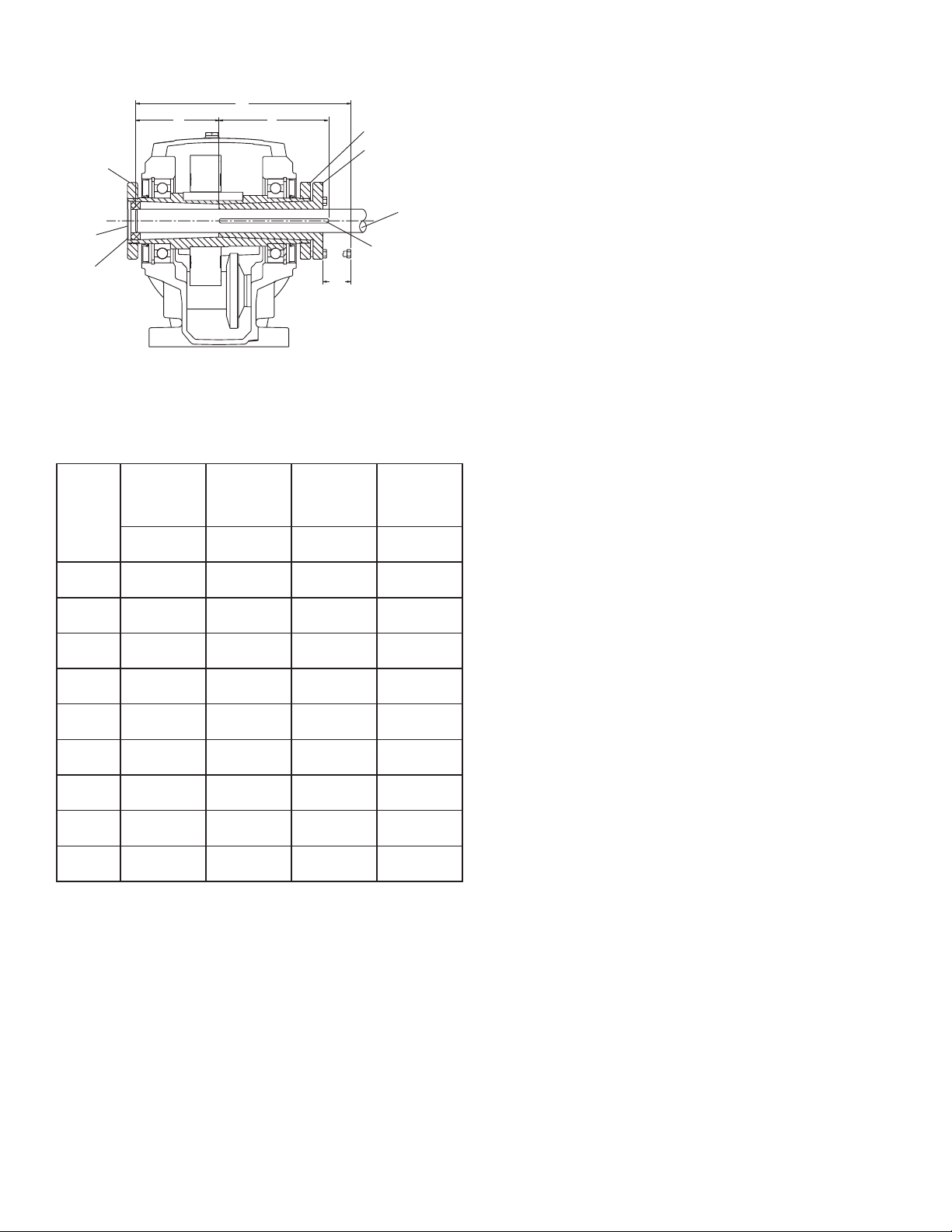

1.4 Mounting Conguration with Bushing on Load

Side of Reducer and Using Stabilizer Ring

H

Endcap

Dirt

Cover

Stabilizer

Ring

J

K

MC

Bushing Ring

Bushing

Driven

Shaft

Driven

Shaft Keyseat

Figure 1-4

Table 1-4 Dimensions for Mounting Conguration

with Bushing on Load Side of Reducer and

Using Stabilizer Ring

Minimum

Gear

Frame

Bolt

Clearance

Shaft

Mounting

Length

MC H K J

31 1.50 9.11 2.88 4.73

32 1.75 10.54 4.38 4.28

1

33

1.75 10.47 4.38 4.21

33A 1.88 12.23 4.63 5.83

34 1.88 12.51 4.63 6.01

35 1.88 13.13 5.63 5.62

36 1.88 17.50 6.13 9.49

Minimum

Key

Connection

Length

Max.

Note: Key length must be sufcient to engage the full length of

the bushing. The shaft must engage the full length of the bushing.

1.4.2 For Type 2 bushings which require one through key:

Install the bushing on the shaft, anged end rst. Align the keyway

in the bushing with the keyseat in the shaft and install the shaft key.

Position the shaft key ush against the inside ange surface of the

bushing. See Figure 1-2 Shaft Key and Bushing Location.

Note: There are three (3) series of bushing keys used in the Type

2 bushing system: rectangular, square and offset. In most cases,

the key supplied will be rectangular or offset. Use caution when

installing rectangular keys as some may visually appear square.

The key should install in the bushing keyway with a sliding type

t. The key in the driven shaft keyseat should be retained to

prevent movement.

Note: The shaft must be engaged the full length of the bushing.

1.4.3 On the side where the driven shaft enters, thread the bushing

ring onto the hollow quill until the bushing ring is ush with the end

of the hollow shaft. Rotate the gear unit input to align the keyway in

the hollow quill with the bushing/shaft key. Position the reducer on

the shaft with the bushing ring toward the bushing.

1.4.4 Slide the stabilizer ring onto the driven shaft with the small end

of the taper toward the reducer. Insert the stabilizer ring into the quill.

1.4.5 Thread the end cap and the dirt cover (not used if driven shaft

extends beyond the end of the hollow quill) onto the hollow quill until

hand tight. Do not tighten the end cap.

1.4.6 Rotate the bushing ring clockwise until the tapped holes align

with the drilled holes in the bushing ange. Prior to tightening the cap

screws, make sure the bushing key is as close as possible to the

inside ange of the bushing as shown in Figure 1-2 and the bushing

is positioned on the shaft as required in Figure 1-4. Dimensions for

rear mounting conguration with the stabilizer ring.

1.4.7 Install the bushing cap screws and tighten all the cap

screws evenly around the bushing ange to the required

torque. See bolt torque specications Table 1.2.5.

1.4.8 Tighten the end cap again until hand tight. Tighten

the setscrews to the recommended torque. See bolt torque

specications Table 1.2.5.

37 2.25 19.76 7.38 10.13

38 2.75 19.05 7.38 7.74

1

This design is replaced by 33A design effective Jan. 2010

1.4.1 For Type 1 bushings which require an external key and a

shaft key: Install the key (supplied with the bushing) in the external

keyseat of the bushing as shown in Figure 1-1. Install the shaft key

(not supplied) in the shaft keyseat and retain to prevent movement.

Install the bushing onto the shaft, anged end rst, align the bushing

keyway with the shaft key and position the bushing over the key.

WARNING! The cap screws must thread into the bushing ring

and not the bushing. Threaded holes in the bushing are for

removal only. If assembled incorrectly, equipment failure and

personal injury may result.

7

Page 8

1.5 Mounting Conguration with Bushing on Load

Side of Reducer and without Stabilizer Ring

H

K

Endcap

Driven

Shaft Keyseat

MC

Figure 1-5

Table 1-5 Dimensions for Conguration with bushing

on Load Side and no Stabilizer Ring

Minimum Shaft

Mounting

Length

Gear

Frame

Bolt

Clearance

MC H K

31 1.50 4.38 2.88

32 1.88 6.25 4.38

33 1.88 6.25 4.38

33A 1.88 6.50 4.63

34 1.88 6.5 4.63

35 1.88 7.5 5.63

36 1.88 8 6.13

Minimum Key

Connection

Length

1.5.1 For Type 1 bushings which require an external key and

a shaft key: Install the key (supplied with the bushing) in the

external keyseat of the bushing as shown in Figure 1-1. Install

the shaft key (not supplied) in the shaft keyseat and retain to

prevent movement. Install the bushing onto the shaft, anged

end rst, align the bushing keyway with the shaft key and position

the bushing over the key.

Note: Key length must be sufcient to engage the full length

of the bushing. The shaft must engage the full length of the

bushing.

1.5.2 For Type 2 bushings which require one through key:

Install the bushing on the shaft, anged end rst. Align the

keyway in the bushing with the keyseat in the shaft and install the

shaft key. Position the shaft key ush against the inside ange

surface of the bushing. See Figure 1-2 Shaft Key and Bushing

Location.

Note: There are three (3) series of bushing keys used in the

Type 2 bushing system: rectangular, square and offset. In

most cases, the key supplied will be rectangular or offset. Use

caution when installing rectangular keys as some may visually

appear square. The key should install in the bushing keyway

with a sliding type t. The key in the driven shaft keyseat

should be retained to prevent movement.

Note: The shaft must be engaged the full length of the

bushing.

1.5.3 On the side opposite the driven shaft entry, thread the

bushing ring onto the hollow quill until the bushing ring is ush

with the end of the hollow shaft. Rotate the gear unit input to align

the keyway in the hollow quill with the bushing/shaft key. Position

the reducer on the shaft with the bushing ring toward the bushing.

1.5.4 Thread the end cap and the dirt cover (not used if driven

shaft extends beyond the end of the hollow quill) onto the

hollow quill until it bottoms out. Tighten the setscrew to the

recommended torque. See bolt torque specications Table 1.2.5.

1.5.5 Rotate the bushing ring clockwise until the tapped

holes align with the drilled holes in the bushing ange. Prior to

tightening the cap screws, make sure the bushing key is as close

as possible to the inside ange of the bushing as shown in Figure

1-2 and the bushing is positioned on the shaft as required in

Table 1-5. Dimensions for rear mounting conguration with the

stabilizer ring.

1.5.6 Install the bushing cap screws and tighten all the cap screws

evenly around the bushing ange to the required torque. See bolt

torque specications Table 1.2.5.

37 2.25 9.75 7.38

38 2.75 11.31 7.38

8

WARNING! The cap screws must thread into the bushing ring and

not the bushing. Threaded holes in the bushing are for removal

only. If assembled incorrectly, equipment failure and personal

injury may result.

Page 9

Taper Bushing Selection

Each Series 3000 OtN can be ordered with an inch or metric Tapered

Bushed Output. This “33B” mounting conguration will include the

appropriate bushing kit when a bore is dened at order entry. The

table below shows the various stocked bushing bores for each

OtN frame that can be specied. Each bushing kit is supplied with

bushing, hardware for mounting and a stabilizer ring unassembled. If

bushings are required as a spare or bore changed in the eld, refer

to the OtN 3000 frame and bore to select the required kit below.

OtN

Frame

Meas.

Unit

Bushing

Number

Bore

1

Shaft Keyseat

Required

Type

OtN

Frame

Meas.

Unit

Bushing

Number

Bore

1

Shaft Keyseat

Required

Type

105TBP100 1” 1/4 x 1/8 x 2 1/2 2

Inch

31

Metric * 105TBP30MM 30 mm 8 x 3.5 x 65 (mm) 2

Inch

32

&

33

Metric *

Inch

33A

Metric *

Inch

34

Metric * 115TBP45MM 45 mm 14 x 4.5 x 105 (mm) 2

1

Bushing bore shown must be selected by customer based on

105TBP103 1 3/16” 1/4 x 1/8 x 2 1/2 2

105TBP104 1 1/4” 1/4 x 1/8 x 2 1/2 2

105TBP105 1 5/16” 5/16 x 5/32 x 2 1/2 2

107TBP105 1 5/16” 5/16 x 5/32 x 3 7/8 2

107TBP106 1 3/8” 5/16 x 5/32 x 3 7/8 2

107TBP107 1 7/16” 3/8 x 3/16 x 3 7/8 2

107TBP30MM 30 mm 8 x 3.5 x 100 (mm) 2

107TBP35MM 35 mm 10 x 4 x 100 (mm) 2

115TBP107 1 7/16 3/8 x 3/16 x 4 1/8 2

115TBP108 1 1/2 3/8 x 3/16 x 4 1/8 2

115TBP110 1 5/8 3/8 x 3/16 x 4 1/8 2

115TBP111 1 11/16 3/8 x 3/16 x 4 1/8 2

115TBP112 1 3/4 3/8 x 3/16 x 4 1/8 2

115TBP114 1 7/8 1/2 x 1/4 x 4 1/8 2

115TBP115 1 15/16 1/2 x 1/4 x 4 1/8 2

115TBP40MM 40 mm 12 x 4 x 105 (mm) 2

115TBP45MM 45 mm 14 x 4.5 x 105 (mm) 2

115TBP111 1 11/16 3/8 x 3/16 x 4 1/8 2

115TBP112 1 3/4 3/8 x 3/16 x 4 1/8 2

115TBP114 1 7/8 1/2 x 1/4 x 4 1/8 2

115TBP115 1 15/16 1/2 x 1/4 x 4 1/8 2

complete application details

* Metric bushings have metric bores and require metric keyseats

as shown in mm.

207TBP200 2 1/2 x 1/4 x 5 1/8 2

207TBP202 2 1/8 1/2 x 1/4 x 5 1/8 2

Inch

35

Metric *

Inch

36

Metric *

Inch

37

Metric *

Inch

38

Metric * 315TBP90MM 90mm 25 x 7 x 190 (mm) 2

207TBP203 2 3/16 1/2 x 1/4 x 5 1/8 2

207TBP204 2 1/4 1/2 x 1/4 x 5 1/8 2

207TBP207 2 7/16 5/8 x 5/16 x 5 1/8 2

207TBP50MM 50 mm 14 x 4.5 x 130 (mm) 2

207TBP60MM 60 mm 18 x 5.5 x 130 (mm) 2

215TBP207 2 7/16 5/8 X 5/16 X 5 5/8 2

215TBP208 2 1/2 5/8 X 5/16 X 5 5/8 2

215TBP211 2 11/16 5/8 X 5/16 X 5 5/8 2

215TBP215 2 15/16 3/4 X 3/8 X 5 5/8 2

215TBP60MM 60 mm 18 x 5.5 x 140 (mm) 2

215TBP70MM 70 mm 20 x 6 x 140 (mm) 2

307TBP214 2 7/8 3/4 x 3/8 x 6 3/4 2

307TBP215 2 15/16 3/4 x 3/8 x 6 3/4 2

307TBP300 3 3/4 x 3/8 x 6 3/4 2

307TBP306 3 3/8 7/8 x 7/16 x 6 3/4 2

307TBP307 3 7/16 7/8 x 7/16 x 6 3/4 2

307TBP75MM 75 mm 20 x 6 x 170 (mm) 2

307TPB80MM 80 mm 22 x 7 x 170 (mm) 2

307TBP85MM 85 mm 22 x 7 x 170 (mm) 2

315TBP215 2 15/16 3/4 x 3/8 x 7 15/16 2

315TBP300 3 3/4 x 3/8 x 7 15/16 2

315TBP303 3 3/16 3/4 x 3/8 x 7 15/16 2

315TBP307 3 7/16 7/8 x 7/16 x 7 15/16 2

315TBP315 3 15/16 1 x 1/2 x 7 15/16 2

9

Page 10

NOT SUPPLIED

REMOVAL

Finished Bore Mounting

1.6 Mounting Of Reducer with Finished Bore Shaft

1.6.1 Check the internal bore of the reducer and make sure the

snap ring and washer are in the end of the shaft bore opposite

the entry side of the driven shaft.

1.6.2 Check the driven shaft to make sure it is free from

burrs and any rust preventative coating. Lubricate the driven

shaft to ease mounting with reducer. (Anti-Fretting grease is

recommended only for nished bore designs). A lifting lug is only

for lifting the weight of the reducer/gearmotor.

WARNING! (Do not use the lifting lug on the gear housing to

lift additional attached assemblies to avoid overloading the

lifting lug). Never lift gear unit by its output shaft.

1.6.3 Check the driven shaft to ensure the end is tapped. Install

the shaft key in the keyseat.

1.6.4 Rotate the OtN input until the hollow output shaft is aligned

with the key in the driven shaft.

1.6.5 The OtN gear shaft is mounted on the driven shaft using a

threaded rod, and screwed into the shaft.

By then threading a nut down onto the washer in the reducer

shaft, the shaft is smoothly inserted into the cylindrical bore of the

reducer shaft.

1.6.6 Replace the threaded rod with the bolt that is supplied with

the OtN unit. Thread it into the driven shaft and tighten to the

required torque. See bolt torque as shown in Table 1.2.5.

1.6.7 Install the hollow shaft cover onto the gear housing

opposite the driven shaft with the two (2) screws provided with

the cover.

1.6.8 Drive Shaft Recommendations - Its best to use the keeper

bolt to pull the driven shaft into the quill up against a shoulder on

the driven shaft.

NOT

SUPPLIED

MOUNTING

1.7 Dismounting of the Reducer from driven shaft

1.7.1 Secure the reducer weight.

1.7.2 Thread in a long bolt that has the same thread design as

the threaded core of the reducer shaft’s washer (see Table 7-1

below). By tightening down that bolt, the driven shaft will be

separated smoothly from the reducer shaft bore.

Key

UF U

UY

Gear

Frame

1

the key for the frame 34 is supplied by Browning

Version

31 S2 5.12 1.250 1.77 1.372 4.31 0.37 1/4 x 1/4 x 1-1/2 7/16-14 x 1.00 5/8

32

33 S2 6.94 1.500 2.16 1.674 5.96 0.49 3/8 x 3/8 x 2-1/4 5/8-11 x 1.75 3/4

34 S2 8.97 2.000 2.56 2.210 7.44 0.72 1/2 x 7/16 x 2-5/8 5/8-11 x 1.75 3/4

35 S2 9.66 2.375 3.54 2.638 8.15 0.85 5/8 x 5/8 x 3-3/8 3/4-10 x 2.0 7/8

36 S2 12.44 2.750 3.93 3.037 10.89 1.23 5/8 x 5/8 x 5-1/2 3/4-10 x 2.0 1

37 S2 13.59 3.625 4.72 4.019 11.9 1.23 7/8 x 7/8 x 5-1/2 3/4-10 x 2.0 1

38 S2 13.74 4.00 5.50 4.316 11.69 1.58 1 x 1 x 6 1-8 x 2.5 1.25

S2 5.94 1.375 1.96 1.523 5.06 0.37 5/16 x 5/16 x 1-13/16 1/2-13 x 1.00 5/8

S3 5.94 1.250 1.96 1.372 5.19 0.37 1/4 x 1/4 x 1-13/16 7/16-14 x 1.00 5/8

Output Shaft

Reducer Shaft Driven Shaft

EH U UF UY VG MH Key

EH

M

VG

MH

1

M (inches)

Keeper Washer

Thread UNC

10

Page 11

Torque Arm Assembly Instructions

Mounting Instructions

1. For Series 3000, mount the torque arm as shown in Figure 5 to side of the reducer where the driven shaft enters. Apply Loctite*

432 or equal to the threads of each bolt before assembly.

2. Connect the reducer to the driven shaft.

3. Attach torque arm to the mounting plate or attachment point.

4. Tighten the cap screws to the recommended torque.

Series 3000 Torque Arm Kits

Table 1

Table 2

OtN Frame Kit Part ID#

31 ROC100KT001

32 ROC200KT001

33 ROC300KT001

34 ROC400KT001

35 ROC500KT001

36 ROC600KT001

37 ROC700KT001

38 ROC800KT001

Fastener Size Torque ( Ft. Lbs)

M10 49

M12 87

M16 220

M20 430

90°

Table 3

OtN Frame(s) Kit Hardware

Screws (4)

31 and 32

Roll Pin (1)

Screws (3)

33, 34, 35

Roll Pin (1)

Screws (4)

36 and 37

Roll Pin (1)

Screws ( 8 )

38

Roll Pin ( 2 )

180°

270°

* The following trade names, trademarks and/or registered trademarks are used in this material by Emerson Power Transmission Corporation are NOT owned or controlled by Emerson Power Transmission

Corporation and are believed to be owned by the following parties: LOCTITE: Henkel Corporation. Emerson Power Transmission Corporation cannot and does not represent or warrant the accuracy of

this information.

Figure 5

0°

Anchoring of the

Torque Arm

(Top View)

11

Page 12

TWO STAGE OtN SERIES 3000

OtN SERIES 3000 GEARMOTORS AND REDUCER

282

254

193

2

99

251

254

264

130

113

120

61

51

76

77

31

62

121

151

131

91

3

213

187

31

128

127

126

51

62

131

91

255

284

1

1

257

132

115

118

41

80

63

148

64

155

154

90

122

130

61

93

9

129

125

76

153

117

111

138

52

2

139

12

76

31

123

124

3

123

Page 13

Parts List - Two Stage Frames 31 and 32

Qty Per Frame

Item # Description

31 32

1 Main housing 1 1

2 Top cover 1 1

9 Output ange (primary) 1 1

10 Output ange (secondary) 1 1

15 Output shaft cover (hollow design) 1 1

31 Output shaft 1 1

41 Bevel pinion 1 1

51 Bevel Gear 1 1

52 Primary gear axis 2 1 1

61 Bearing axis 4 1 1

62 Bearing axis 4 1 1

63 Bearing axis 2 front 1 1

64 Bearing axis 2 rear 1 1

76 Key for gear 1 1

77 Output shaft key D or G 1 1

80 Key primary gear 1 1

90 Output oil seal left 1 1

91 Output oil seal right 1 1

93 Output seal - ange option 1 1

99 Top cover gasket 1 1

111 Shim 1 1

113 Spacer 1 1

115 Shim 1 1

117 Shim axis 2 rear 1 1

118 Shim axis 2 front 1 1

120 Bearing shim 1 1

121 Bearing shim 1 1

122 End cap for B design 1 1

Item # Description

123 Internal snap ring 2 2

124 Extraction washer 1 1

125 Stabilizer collar for B design 1 1

126 Bushing cap screws 3 3

127 Bushing for B design 1 1

129 Dust cover 1 1

130 Bearing snap ring axis #4 1 1

131 Bearing snap ring axis #4 1 1

132 Bearing snap ring axis 2 1 1

136 Snap ring MD axis 4 1 2

138 Bearing snap ring axis 2 1 1

139 Snap ring for primary gear 1 1

148 Spacer axis 2 1 1

151 Spacer 1 1

153 Snap ring axis 2 1 1

154 Washer axis 2 1 1

155 Shim axis 2 1 1

187 Flange bolts 4 6

193 Top cover screws 6 7

203 Cover screws for Rep #15 2 2

213 Flange roll pin 1 1

251 Bore Plug 0 1

254 Plain plugs 4 4

255 Breather 1 1

257 Magnetic drain plug 1 1

264 Bore plug axis 4 for D and G 1 1

282 Nameplate 1 1

284 Nameplate rivets 2 2

Qty Per Frame

31 32

Common Replacement Parts

Frame Size Shaft

G-D 32009 32009 45 x 75 x 8 *

31

32

* Bore plug utilized

X 32009 32009 45 x 75 x 8 45 x 75 x 8

C-B 6009 2RS 6009 2RS 45 x 75 x 8 45 x 75 x 8

G-D 32010 32010 50 x 80 x 10 *

X 32010 32010 50 x 80 x 10 50 x 80 x 10

C-B 6010 2RS 6010 2RS 50 x 80 x 10 50 x 80 x 10

Bearings Oil Seals

61 62 90 91

Top Cover Gasket

JOI156JN001

JOI185JN003

13

Page 14

THREE STAGE OtN SERIES 3000

OtN 32-35 Three Stages (Quantity Per Unit)

284

282

255

2

264

130

113

120

61

501

76

31

77

51

502

62

121

151

131

91

4

133

112

3

53

66

152

114

134

253

51

62

131

91

126

127

81

41

128

119

65

122

129

76

31

252

254

187

90

130

61

132

213

115

193

118

9

99

1

1

257

63

43

93

Ring sealed

reinforced option

148

166

165

80

64

155

117

154

111

153

138

139

2

52

14

332

4

125

124

123

31

90

76

130

61

303

51

62

76

121

131

91

305

325

76

301

331

300

330

302

Page 15

Parts List - Three Stage Frame 32 through 35

Item # Description

1 Main housing 1 1 1 1 129 Dust cover 1 1 1 1

2 Top cover 1 1 1 1 130 Bearing snap ring axis #4 1 1 1 1

9 Output ange (primary) 1* 1* 1* 1* 131 Bearing snap ring axis #4 1 1 1 1

10 Output ange (secondary) + 1* 1* 1* 1* 132 Bearing snap ring axis 2 1 1 1 1

15 Output shaft cover (hollow design) 1 1 1 1 133 Bearing snap ring axis 3 1 1 1 1

31 Output shaft 1 1 1 1 134 Snap ring axis #4 1 1 1 1

41 Pinion axis 3 1 1 1 1 136 Snap ring MD axis 4 2 2 2 2

43 Bevel pinion axis 2 1 1 1 1 138 Bearing snap ring axis 2 1 1 1 1

51 Gear axis 4 1 1 1 1 139 Primary gear xing snap ring 1 1 1 1

52 Gear axis 2 1 1 1 1 142 Primary Gear xing screw 0 0 0 0

53 Bevel gear axis 3 1 1 1 1 148 Spacer axis 2 1 1 1 1

61 Bearing axis 4 left 1 1 1 1 152 Shims axis 3 1 or 2 4 2 or 3 3

62 Bearing axis 4 right 1 1 1 1 153 Snap ring axis 2 1 1 1 1

63 Bearing axis 2 front 1 1 1 1 154 Washer axis 2 1 1 1 1

64 Bearing axis 2 rear 1 1 1 1 155 Shim axis 2 2 2 2 2

65 Bearing axis 3 right 1 1 1 1 165 Nut (rep 64) 0 0 0 0

66 Bearing axis 3 left 1 1 1 1 166 Lock washer (rep 165) 0 0 0 0

76 Key for axis 4 gear (rep 51) 1 1 1 1 187 Flange screws 4 6 6 6

77 Output shaft key D or G 1 1 1 1 193 Top cover screws 7 7 7 7

80 Key (prim. gear) 1 1 1 1 213 Roll pin (ange) 1 1 1 1

81 Key (rep. 53) 1 1 1 1 251 Bore Plug 0 1 0 0

90 Oil seal axis 4 right 1 1 1 1 252 Bore plug axis 3 left 1 1 1 1

91 Oil seal axis 4 left 1 1 1 1 253 Bore plug axis 3 right 1 1 1 1

93 Ring seal axis 4 (option) 1 1 1 1 254 Plain plugs 2 3 3 2

99 Top cover gasket 1 1 1 1 255 Breather plug 1 1 1 1

103 Oil deector 1 1 1 1 257 Magnetic Pipe Plug 1 1 1 1

111 Bearing spacer axis 2 1 1 1 1 261 Breather plug with dipstick 0 0 0 0

112 Bearing spacer axis 3 right 1 1 1 1 264 Bore plug axis 4 1 1 1 1

114 Bearing spacer axis 3 left 1 1 1 1 282 nameplate 1 1 1 1

115 Bearing spacer axis 2 front 1 1 1 1 284 nameplate rivets 2 2 2 2

117 Shim axis 2 rear 1 to 3 3 3 3 501 Nilos deector axis 4 (left) 0 0 0 0

118 Shim axis 2 front 1 to 3 3 3 3 502 Nilos deector axis 4 (right) 0 0 0 0

Shims axis 3 1 to 4 4 2 or 3 3

119

120 Bearing shim (SCD) 1 1 1 1

121 Bearing shim (SCD) 1 1 1 1

122 End cap 1 1 1 1

123 Snap ring 1 1 1 1

124 Extraction washer 1 1 1 1

125 Snap ring 1 1 1 1

126 Bushing capscrews 3 3 3 3

127 tapered bushing 1 1 1 1

128 Bushing collar 1 1 1 1

+ not illustrated in exploded view drawing

** there are (2) used on C, B shafts

*** not used on C, B shafts

Qty Per Frame

32 33 34 35 32 33 34 35

Item # Description

Qty Per Frame

Common Replacement Parts

Frame Size Shaft

G-D 6208 ZZ C3 6208 ZZ C3 40 x 80 x 10 *

32

C-B 6010 ZZ C3 6010 ZZ C3 50 x 80 x 8 50 x 80 x 8

G-D 6309 ZZ C3 6309 ZZ C3 45 x 100 x 8 *

33

C-B 6211 ZZ C3 6211 ZZ C3 55 x 100 x 10 55 x 100 x 10

33A C-B 6013 ZZ C3 6013 ZZ C3 65 X 100 X 10 65 x 100 x 10 JOI208JN002

G-D 6213 ZZ C3 6213 ZZ C3 65 x 120 x 10 *

34

C-B 6213 ZZ C3 6213 ZZ C3 65 x 120 x 10 65 x 120 x 10

G-D 6313 ZZ C3 6313 ZZ C3 65 x 140 x 12 *

35

C-B 6018 ZZ C3 6018 ZZ C3 90 x 140 x 11 90 x 140 x 11

* Bore plug utilized

Bearings Oil Seals

61 62 90 (mm) 91 (mm)

Top Cover Gasket

JOI161JN002X 6208 ZZ C3 6208 ZZ C3 40 x 80 x 10 40 x 80 x 10

JOI208JN002X 6309 ZZ C3 6309 ZZ C3 45 x 100 x 8 45 x 100 x 8

JOI247JN001X 6213 ZZ C3 6213 ZZ C3 65 x 120 x 10 65 x 120 x 10

JOI295JN002X 6313 ZZ C3 6313 ZZ C3 65 x 140 x 12 65 x 140 x 12

15

Page 16

THREE STAGE OtN SERIES 3000

OtN 36-38 Three Stages (Quantity Per Unit)

115

282

193

99

118

9

1

1

257

63

43

148

93

Ring sealed

reinforced option

166

165

80

64

155

117

154

111

153

138

139

2

52

284

255

2

264

130

113

120

61

501

76

31

77

51

502

62

121

151

131

91

4

133

112

3

53

66

152

114

134

253

51

62

131

91

126

127

81

41

128

119

65

122

129

76

31

252

254

187

90

130

61

132

213

16

4

125

124

123

76

31

Page 17

Parts List - Three Stage Frame 36 through 38

Item # Description

1 Main housing 1 1 1 128 Bushing collar 1 1 1

2 Top cover 1 1 1 129 Dust cover 1 1 1

9 Output ange (primary) 1 1 0 130 Bearing snap ring axis #4 1 1 1

10 Output ange (secondary) + 1 1 n/a 131 Bearing snap ring axis #4 1 1 1

15 Output shaft cover (hollow design) 1 1 1 132 Bearing snap ring axis 2 1 1 1

31 Output shaft 1 1 1 133 Bearing snap ring axis 3 1 1 1

41 Pinion axis 3 1 1 1 134 Snap ring axis #4 1 1 1

43 Bevel pinion axis 2 1 1 1 136 Snap ring MD axis 4 2 2 0

51 Gear axis 4 1 1 1 138 Bearing snap ring axis 2 1 1 1

52 Gear axis 2 1 1 1 139 Primary gear xing snap ring 1 0 1

53 Bevel gear axis 3 1 1 1 142 Primary Gear xing screw 0 1 0

61 Bearing axis 4 left 1 1 1 148 Spacer axis 2 1 1 1

62 Bearing axis 4 right 1 1 1 152 Shims axis 3 1 to 3 1 to 3 1 to 3

63 Bearing axis 2 front 1 1 1 153 Snap ring axis 2 0 0 0

64 Bearing axis 2 rear 1 1 1 154 Washer axis 2 0 0 0

65 Bearing axis 3 right 1 1 1 155 Shim axis 2 0 0 0

66 Bearing axis 3 left 1 1 1 165 Nut (rep 64) 1 1 1

76 Key for axis 4 gear (rep 51) 1 1 1 ** 166 Lock washer (rep 165) 1 1 1

77 Output shaft key D or G 1 1 1 187 Flange screws 7 9 11

80 Key (prim. gear) 1 1 1 193 Top cover screws 10 11 11

81 Key (rep. 53) 1 1 1 213 Roll pin (ange) 1 1 1

90 Oil seal axis 4 right 1 1 1 251 Bore Plug 0 0 0

91 Oil seal axis 4 left 1 1 1 252 Bore plug axis 3 left 1 1 1

93 Ring seal axis 4 (option) 1 1 0 253 Bore plug axis 3 right 1 1 1

94 O-ring seal axis 4 + 0 0 2*** 254 Plain plugs 5 5 4

95 Bearing carrier axis 4 + 0 0 2*** 255 Breather plug 0 0 0

99 Top cover gasket 1 1 1 257 Magnetic Pipe Plug 1 1 1

103 Oil deector 1 1 1 261 Breather plug with dipstick 1 1 1

111 Bearing spacer axis 2 1 1 1 264 Bore plug axis 4 1 1 1

112 Bearing spacer axis 3 right 1 1 1 282 nameplate 1 1 1

114 Bearing spacer axis 3 left 1 1 1 284 nameplate rivets 2 2 2

115 Bearing spacer axis 2 front 1 1 1 501 Nilos deector axis 4 (left) 1 1 1

117 Shim axis 2 rear 1 to 3 1 to 3 1 to 3 502 Nilos deector axis 4 (right) 1 1 1

118 Shim axis 2 front 1 to 3 1 to 3 1 to 3

119 Shims axis 3 1 to 3 1 to 3 1 to 3

120 Bearing shim (SCD) 1 1 0

121 Bearing shim (SCD) 1 1 0

122 End cap 1 1 1

123 Snap ring 1 1 1

124 Extraction washer 1 1 1

125 Snap ring 1 1 1

126 Bushing capscrews 3 3 1

127 Tapered bushing 1 1 1

+ not illustrated in exploded view drawing

** there are (2) used on C,B shafts

*** not used on C,B shafts

Qty Per Frame

36 37 38 36 37 38

Item # Description

Qty Per Frame

Common Replacement Parts

Frame Size Shaft

G-D 32020 32020 85 x 150 x 12 *

36

37

38

* Bore plug utilized

X 32020 32020 85 x 150 x 12 85 x 150 x 12

C-B 6020 ZZ 6020 ZZ 100 X 150 X 13 100 X 150 X 13

G-D 32024 32024 120 X 180 X 15 *

X 32024 32024 120 X 180 X 15 120 X 180 X 15

C-B 6024 ZZ 6024 ZZ 120 X 180 X 15 120 X 180 X 15

G-D 30220 30220 120 X 180 X 15 *

C-B 30228 30228 140 x 250 x 15 140 x 250 x 15

Bearings Oil Seals

61 62 90 91

Top Cover gasket

JOI414JN001

JOI475JN001

JOI475J N001X 30224 30224 120 X 180 X 15 120 X 180 X 15

17

Page 18

C - Face Input Parts List

OtN 31 - 38 Two and Three Stage (Quantity Per Unit)

12

8

18

6

5

4

3

17

2

7

1

16

15

14

9

10

11

19

13

No. Description 56C 140TC 180TC 210TC 250TC 280TC

1 Non-metallic Liner 1 1 1 1 1 1

2 Seal 1 1 1 1 1 1

3 Motor Adapter 1 1 1 1 1 1

4 Cap screw 6 6 6 6 6 6

5 Bearing 1 1 1 1 1 1

6 Spacer 1 1 1 1 1 1

7 Input Shaft 1 1 1 1 1 1

8 Bearing 1 1 1 1 1 1

9 Internal Snap Ring 1 1 1 1 1 1

10 Key* 1 1 1 1 1 1

11 Pinion 1 1 1 1 1 1

12 Nuts Q ** ** ** ** ** **

13 Studs Q ** ** ** ** ** **

14 Adapter Flange 1 1 1 1 1 1

15 Gasket 1 1 1 1 1 1

16 Plug *** 1 1 1 1 1 1

17 Motor Adapter Flange N/A N/A N/A N/A N/A 1

18 Backstop Kit (optional) 1 1 1 1 1 1

19 Nilos Seal 0 0 0 0 1 1

* Pin used with 9mm, 12mm, 15mm, and 18mm pinions

** Depending on gear frame and red.stages:Two stages 31=4, 32=5; Three stages 32,35=4 ,33=5,34=6, 36,37=8

*** For frames 31 through 35 these are 1/4” BSP, and 3/4” BSP on frames 36 and larger

Gear

Frame

31 to 35 56C , 140TC 6007 ZZ C3 6207 ZZ C3 2 x 1.375 x .312

32 to 37 180TC 6012 ZZ C3 6210 ZZ C3 4 x 2.250 x .468

33 to 38 210TC 6012 ZZ C3 6210 ZZ C3 4 x 2.250 x .468

35 to 38 250TC, 280TC 6014 ZZ C3 NJ210 4.438 x 2.625 x .437

18

Motor

Frame

5 8 2

Bearings Seal (inches)

Page 19

C-Face Coupling Input Parts List

OtN 36 - 38 Three Stage (Quantity Per Unit)

20

17

18

19

16

15

14

13

12

11

10

9

8

7

6

3

5

4

2

1

No. Description Of Part 320TC/360TC

1 Setscrew 1

2 Motor Coupling 1

3 Motor Adapter 1

4 Coupling Sleeve 1

5 Seal 1

6 Internal Snap Ring 1

7 Bearing 1

8 External Snap Ring 1

9 Adapter Flange 1

10 Capscrew 8

11 Backstop 1

12 Capscrew 12

13 Spacer 1

14 Bearing 1

15 Internal Snap Ring 1

16 Bearing Seal 1

17 Pinion 1

18 Key 1

19 External Snap Ring 1

20 Input Shaft 1

Gear

Frame

36 to 38 6216 ZZ C3 NJ310 140x110x12 (mm) nitrile

7 14 1

Bearings Seal

19

Page 20

AP Input Shaft Parts List

9

15

12

OtN 31 - 35 Two and Three Stage (Quantity Per Unit)

2

3

8

10

12

11

13

7

6

4

5

1

9

OtN 36 - 38 Three Stage

8

10

16

5

11

17

14

13

7

6

4

1

No. Description of Part

1 Seal 1 1 1 1 1 1 1

2 Nuts 4 5 4 5 6 4 0

3 Studs 4 5 4 5 6 4 0

4 Housing 1 1 1 1 1 1 1

5 External Snap Ring 1 1 1 1 1 1 1

6 Bearing 1 1 1 1 1 1 1

7 Spacer 1 1 1 1 1 1 1

8 Bearing 1 1 1 1 1 1 1

9 Input Shaft 1 1 1 1 1 1 1

10 Internal Snap Ring 1 1 1 1 1 1 1

11 Pinion 1 1 1 1 1 1 1

12 Key* 1 1 1 1 1 1

13 Backstop Kit (optional) 1 1 1 1 1 1 1

14 Spacer - - - - - - 1

15 Bolt - - - - - - 8

16 Bearing Seal - - - - - - 1

17 External Snap Ring - - - - - - 1

* Pin used with 9mm, 12mm, 15mm, and 18mm pinion

Double Reduction Triple Reduction

31 32 32 33 34 35 36, 37, 38

Gear

Frame

31, 32, 33 6206 ZZ C3 6207 ZZ C3 1.875 x 1.125 x 0.25 DL, nitrile

34 6308 ZZ C3 6309 ZZ C3 2.5 x 1.50 x 0.312 DL, nitrile

35 NJ209 6311 ZZ C3 2.5 x 1.50 x 0.312 DL, nitrile

36, 37, 38 22310 NJ2210 3.1878 x 1.938 x 0.438 DL, nitrile

DL - double lipped seal designs

6 8 1

Bearings Seal (inches)

20

Page 21

1

3

2

4

5

7

6

8

9

10

11

184

183

254

Gear Motor Input Parts List

OtN 31 - 38 Two and Three Stage (Quantity Per Unit)

No. Description Of Part

Double Reduction Triple Reduction

31 32 32 33 34 35 36, 37, 38

1 Motor Adapter 1 1 1 1 1 1 1

2 Input Shaft 1 1 1 1 1 1 1

3 Pinion 1 1 1 1 1 1 1

4 Internal Snap Ring 1 1 1 1 1 1 1

5 Bearing Cap** 1 1 1 1 1 1 1

6 Bearing Cap** 1 1 1 1 1 1 1

7 Adapter Flange 1 1 1 1 1 1 1

8 External Snap Ring 1 1 1 1 1 1 1

9 Seal 1 1 1 1 1 1 1

10 Pinion Pin 1 1* 1 1* 1* 1* N/A

11 Cap screw** 2 2 2 2 2 2 2

183 Stud 4 5 4 5 6 4 8

184 Nut 4 5 4 5 6 4 8

254 Plug (or Breather) 1 1 1 1 1 1 1

* key used with 23mm and 32mm pinions.

** Explosion proof motor only

Bearings and Seals

Reduction

Stages

2

Gear

Frame

Motor

Frame

Bearing Seal (inches)

6 9

31 48 6005 ZZ C3 1.50 x .937 x .250

31,32 56, 140T 6007 ZZ C3 2.25 x 1.375 x .312

32 180T 6207 ZZ C3 2.25 x 1.375 x .312

32 48 6005 ZZ C3 1.50 x .937 x .250

32,33,34,35 56, 140T 6007 ZZ C3 2.25 x 1.375 x .312

3 or more

32,33,34,35, 36, 37, 38 180T, 210T 6207 ZZ C3 2.25 x 1.375 x .312

34 250T 6209 ZZ C3 2.875 x 1.750 x .375

35, 36, 37, 38 250T, 280T 6310 ZZ C3 3.500 x 2.250 x .375

36, 37, 38 320T 6311 ZZ C3 3.875 x 2.5 x .470

21

Page 22

Integral Motor Parts List

Frames 180T, 210T, 250T, A280T

Frames 56, 140T

Part # Description Qty. Part # Description Qty.

1 Fan Cover 1 1 Fan Cover 1

2 Self Tapping Screw 3 2 Self Tapping Screw 4

3 Hex Nut 1 3 Hex Nut 1

4 Stud 1 4 Stud 1

5 Retaining Snap Ring 1 5 Fan 1

6 Fan 1 6 Bracket 1

7 Bracket 1 7 Hex Head Bolt 4

8 Screw 4 8 Lifting Lug 1

9 Bushing 4 9 Hex Countersunk Pipe Plug 2

10 Plastic Plug 4 10 Ball Bearing 1

11 Ball Bearing 1 11 Rotor Assembly (includes items 12 & 13) 1

12 Rotor Assembly (includes items 13 & 14) 1 12 Shaft 1

13 Shaft 1 13 Rotor Core 1

14 Rotor Core 1 14 Wound Stator Assembly 1

15 Wound Stator Assembly 1 15 Gasket 1

16 Gasket 1 16 Outlet Box Base 1

17 Outlet Box Base 1 17 Self Tapping Screw 2

18 Self Tapping Screw 2 18 Outlet Box Cover 1

19 Outlet Box Cover 1 19 Self Tapping Screw 2

20 Self Tapping Screw 2

When ordering replacement motor parts, the following motor nameplate information is required:

• Model #

• Frame Size

• Type

• Horsepower

Browning, Emerson and Emerson Industrial Automation are trademarks of Emerson

Electric Co. or one of its affiliated companies.

©2007, 2009, 2010, 2011, 2012, 2014 Emerson Power Transmission, All Rights Reserved.

MCIM14001E • Form 9020E • Printed in USA

22

Loading...

Loading...