Page 1

25M01A-100 to 25M01A-19925M01A-100 to 25M01A-199

25M01A-100 to 25M01A-199

25M01A-100 to 25M01A-19925M01A-100 to 25M01A-199

HSI Single Stage Combination Gas Valve

INSTALLATION INSTRUCTIONSINSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONSINSTALLATION INSTRUCTIONS

Operator: Save these instructions for future use!Operator: Save these instructions for future use!

Operator: Save these instructions for future use!

Operator: Save these instructions for future use!Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFOREFAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFOREFAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURYINSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURYINSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY

AND/OR PROPERTY DAMAGE.AND/OR PROPERTY DAMAGE.

AND/OR PROPERTY DAMAGE.

AND/OR PROPERTY DAMAGE.AND/OR PROPERTY DAMAGE.

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

The 25M01A series valve is a combination gas pressure

regulator and dual automatic gas valve. These valves are

designed for gas clothes dryers with Hot Surface Ignition

(HSI) systems. These valves are equipped with redundant

and main solenoid valves that control the gas flow to the

burner, and a direct acting pressure regulator.

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

Type of Gas:Type of Gas:

Type of Gas: Natural gas

Type of Gas:Type of Gas:

LP gas (use conversion kit)

Pressure Regulator Setting:Pressure Regulator Setting:

Pressure Regulator Setting:

Pressure Regulator Setting:Pressure Regulator Setting:

Nat. GasNat. Gas

Nat. Gas – 2.5" to 5.4" W.C.

Nat. GasNat. Gas

LP GasLP Gas

LP Gas – 7.0 to 12.0"W.C.

LP GasLP Gas

Ambient Temperature:Ambient Temperature:

Ambient Temperature:

Ambient Temperature:Ambient Temperature:

Pressure Rating:Pressure Rating:

Pressure Rating: 14" W.C. (1/2 PSI) max.

Pressure Rating:Pressure Rating:

Voltage:Voltage:

Voltage: 120 VAC

Voltage:Voltage:

Frequency:Frequency:

Frequency: 60 Hz

Frequency:Frequency:

Current:Current:

Current: .06 amps

Current:Current:

Description......................................................... 1

Specifications .................................................... 1

Precautions ....................................................... 2

Installation ......................................................... 2

Adjustment ........................................................ 4

Pressure Regulator Adjustment

Lighting Instructions ........................................... 5

32° to 155°F

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

Mounting Positions:Mounting Positions:

Mounting Positions:

Mounting Positions:Mounting Positions:

Control may be mounted in the following positions: horizontal, vertical or 90° of horizontal. NOT UPSIDE DOWN.

Capacity (BTU/hr) at

1” pressure drop across valve

White-Rodgers is a division

of Emerson Electric Co.

www.white-rodgers.com

PART NO. 37-6643A

0530

Page 2

PRECAUTIONSPRECAUTIONS

PRECAUTIONS

PRECAUTIONSPRECAUTIONS

DO NOT BEGIN INSTALLATION UNTIL YOU READDO NOT BEGIN INSTALLATION UNTIL YOU READ

DO NOT BEGIN INSTALLATION UNTIL YOU READ

DO NOT BEGIN INSTALLATION UNTIL YOU READDO NOT BEGIN INSTALLATION UNTIL YOU READ

THE FOLLOWING PRECAUTIONS.THE FOLLOWING PRECAUTIONS.

THE FOLLOWING PRECAUTIONS.

THE FOLLOWING PRECAUTIONS.THE FOLLOWING PRECAUTIONS.

!

WARNING

1.1.

Failure to turn off electric or main gas supply toFailure to turn off electric or main gas supply to

1.

Failure to turn off electric or main gas supply to

1.1.

Failure to turn off electric or main gas supply toFailure to turn off electric or main gas supply to

clothes dryer could cause personal injury and/orclothes dryer could cause personal injury and/or

clothes dryer could cause personal injury and/or

clothes dryer could cause personal injury and/orclothes dryer could cause personal injury and/or

property damage by shock, gas suffocation, fire,property damage by shock, gas suffocation, fire,

property damage by shock, gas suffocation, fire,

property damage by shock, gas suffocation, fire,property damage by shock, gas suffocation, fire,

and/or explosion.and/or explosion.

and/or explosion.

and/or explosion.and/or explosion.

2.2.

Do not use this control on circuits exceeding speci-Do not use this control on circuits exceeding speci-

2.

Do not use this control on circuits exceeding speci-

2.2.

Do not use this control on circuits exceeding speci-Do not use this control on circuits exceeding speci-

fied voltage. Higher voltage will damage the controlfied voltage. Higher voltage will damage the control

fied voltage. Higher voltage will damage the control

fied voltage. Higher voltage will damage the controlfied voltage. Higher voltage will damage the control

and may cause shock or fire hazard.and may cause shock or fire hazard.

and may cause shock or fire hazard.

and may cause shock or fire hazard.and may cause shock or fire hazard.

!

CAUTION

1.1.

Do not short out terminals on gas valve or primaryDo not short out terminals on gas valve or primary

1.

Do not short out terminals on gas valve or primary

1.1.

Do not short out terminals on gas valve or primaryDo not short out terminals on gas valve or primary

control to test. Short or incorrect wiring can causecontrol to test. Short or incorrect wiring can cause

control to test. Short or incorrect wiring can cause

control to test. Short or incorrect wiring can causecontrol to test. Short or incorrect wiring can cause

equipment damage, property damage, and/or per-equipment damage, property damage, and/or per-

equipment damage, property damage, and/or per-

equipment damage, property damage, and/or per-equipment damage, property damage, and/or personal injury.sonal injury.

sonal injury.

sonal injury.sonal injury.

If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

3.3.

NEVER USE FLAME OR ANY KIND OF SPARK TONEVER USE FLAME OR ANY KIND OF SPARK TO

3.

NEVER USE FLAME OR ANY KIND OF SPARK TO

3.3.

NEVER USE FLAME OR ANY KIND OF SPARK TONEVER USE FLAME OR ANY KIND OF SPARK TO

CHECK FOR GAS LEAKS–COULD CAUSE FIRECHECK FOR GAS LEAKS–COULD CAUSE FIRE

CHECK FOR GAS LEAKS–COULD CAUSE FIRE

CHECK FOR GAS LEAKS–COULD CAUSE FIRECHECK FOR GAS LEAKS–COULD CAUSE FIRE

AND/OR EXPLOSION.AND/OR EXPLOSION.

AND/OR EXPLOSION.

AND/OR EXPLOSION.AND/OR EXPLOSION.

4.4.

Do not use a control set for natural gas with LP gas,Do not use a control set for natural gas with LP gas,

4.

Do not use a control set for natural gas with LP gas,

4.4.

Do not use a control set for natural gas with LP gas,Do not use a control set for natural gas with LP gas,

or a control set for LP gas with natural gas. Personalor a control set for LP gas with natural gas. Personal

or a control set for LP gas with natural gas. Personal

or a control set for LP gas with natural gas. Personalor a control set for LP gas with natural gas. Personal

injury and/or property damage, gas suffocation, fire,injury and/or property damage, gas suffocation, fire,

injury and/or property damage, gas suffocation, fire,

injury and/or property damage, gas suffocation, fire,injury and/or property damage, gas suffocation, fire,

and/or explosion may result.and/or explosion may result.

and/or explosion may result.

and/or explosion may result.and/or explosion may result.

2.2.

This control is not intended for use in locationsThis control is not intended for use in locations

2.

This control is not intended for use in locations

2.2.

This control is not intended for use in locationsThis control is not intended for use in locations

where it may come in direct contact with water.where it may come in direct contact with water.

where it may come in direct contact with water.

where it may come in direct contact with water.where it may come in direct contact with water.

Suitable protection must be provided to shield theSuitable protection must be provided to shield the

Suitable protection must be provided to shield the

Suitable protection must be provided to shield theSuitable protection must be provided to shield the

control from exposure to water (dripping, spraying,control from exposure to water (dripping, spraying,

control from exposure to water (dripping, spraying,

control from exposure to water (dripping, spraying,control from exposure to water (dripping, spraying,

rain, etc.).rain, etc.).

rain, etc.).

rain, etc.).rain, etc.).

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

1. Before attempting to service dryer, unplug power cord,

turn off main gas supply and consult dryer manufacturer's instructions for accessing gas valve.

2. Disconnect exhaust vent duct.

3. Disconnect gas line from rear of dryer.

4. Remove access panel from dryer. On some models this

involves removing the entire front panel.

5. The gas valve/burner assembly should now be visible.

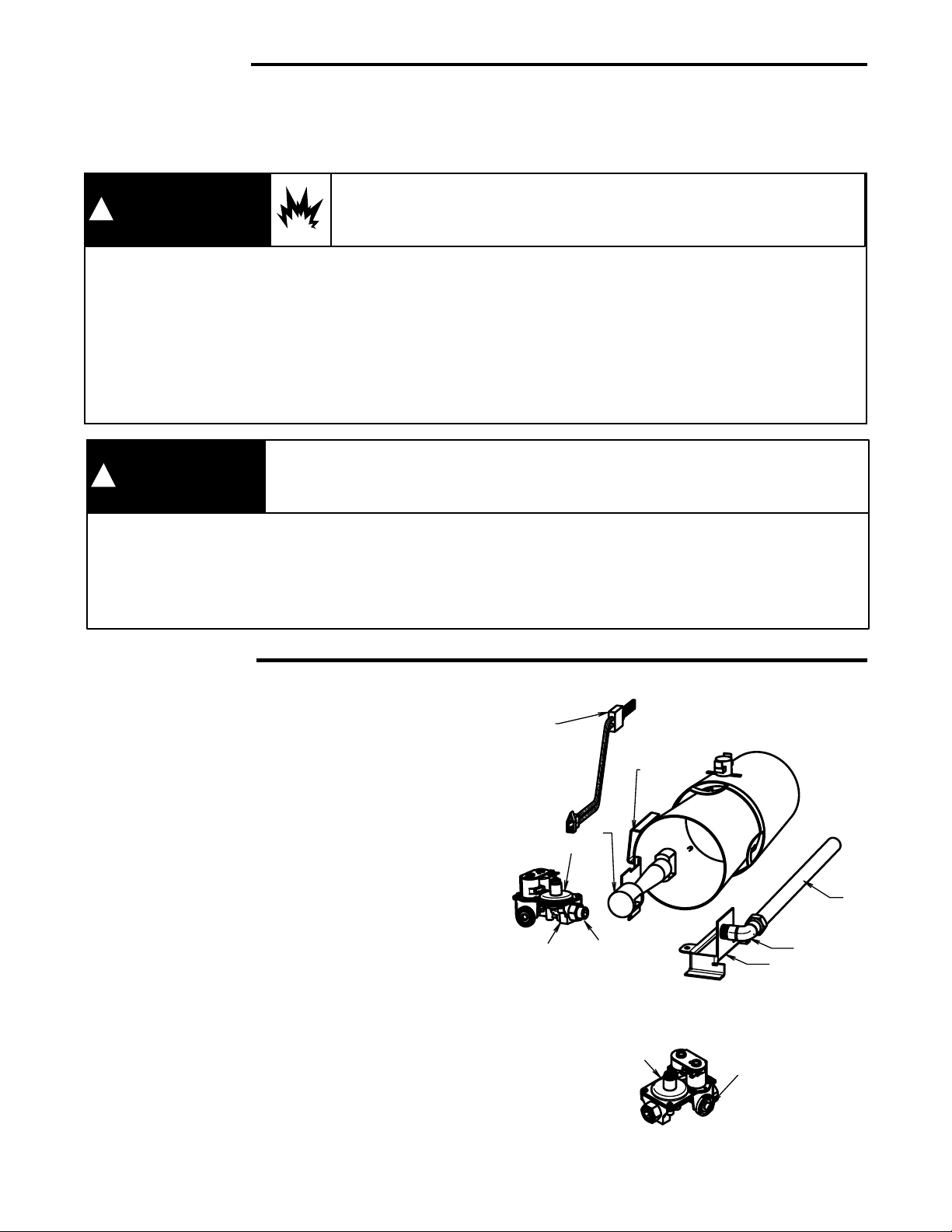

6. The burner assembly consists of (see figure 1 & 2):

a. Gas inlet pipe.

b. Brass inlet fitting with union – some models may also

have a manual shut-off valve.

c. Gas valve.

d. Mounting bracket.

e. Burner orifice.

f. Burner assembly with air shutter.

g. Igniter.

h. Radiant sensor – located on heat exchanger on

some models.

7. Disconnect the wiring harness from gas valve and

igniter.

8. Remove screw(s) fastening the mounting bracket to the

bottom of dryer.

9. Burner assembly should now be free to slide out of the

front of dryer. Take care not to bump or jar igniter. It is

very fragile.

10. Remove the gas inlet pipe by unscrewing the union.

11. Remove screw(s) fastening the gas valve to the mounting bracket and set them aside. They will be reused.

E (not shown)

2

G

H

F

A

C

B

Figure 1Figure 1

Figure 1

Figure 1Figure 1

C

Figure 2Figure 2

Figure 2

Figure 2Figure 2

E

B

D

Page 3

INSTALLATION (cont.)INSTALLATION (cont.)

INSTALLATION (cont.)

INSTALLATION (cont.)INSTALLATION (cont.)

12. The gas valve should now be free to slide out of burner

and off of mounting bracket. Take care not to disturb the

air shutter.

13. Remove inlet fitting from old gas valve and set it aside.

Take care not to damage the sealing surfaces. This part

will be reused.

14. Clean the threads of the inlet fitting. Apply pipe sealant

(approved for all gases) to the threads. Install the fitting

into the inlet of the new valve and tighten to 200 lbf-in

(16.6 lbf-ft) using a 3/8 inch hex head wrench.

15. Remove orifice screw from old gas valve and set it

aside. Take care not to damage the sealing surfaces.

This part will be reused.

16. Inspect the threads of the orifice screw and clean if

necessary.

17. Inspect the orifice hole and remove any foreign material.

18. Install orifice screw into new valve and tighten to 40 lbfin. Do not use any pipe sealant.

19. Slide the outlet boss of the new valve into the burner.

Take care not to disturb the air shutter.

20. Fasten the gas valve to the mounting bracket using the

screw(s) removed earlier.

21. Connect the gas inlet pipe to the inlet fitting by threading

the union together and tightening to 150 lbf-in (12.5 lbfft).

22. Insert the burner assembly back into the dryer so that

the gas inlet pipe exits through the square hole in the

back of the dryer cabinet, and the burner fits inside the

heat exchanger. Take care not to bump or jar igniter. It is

very fragile.

23. Fasten the mounting bracket to the bottom of the dryer

cabinet using the screw removed earlier.

24. Reconnect the wiring harness to the igniter and the gas

valve.

25. Reconnect the exhaust vent duct to the back of the

dryer.

26. Apply pipe sealant to the threads of the inlet gas pipe

and reconnect the gas line to the back of the dryer and

tighten.

ChecChec

k fk f

27. Turn on gas supply and

28. Remove the outlet pressure tap from the gas valve (see

figure 3). Apply pipe sealant to the 1/8-inch NPT threads

of a hose barb. Install the hose barb into the outlet

pressure tap and tighten to 40 lbf-in (see figure 4).

29. Connect a manometer to the hose barb. Manometer

should be capable of measuring pressure from 2.5" WC

up to 14.0" WC.

30. If entire front cover was removed, the connector for the

door switch must be temporarily jumpered. Otherwise

the dryer will not function.

NONO

TETE

NO

TE: On some dryers, the front cover supports the

NONO

TETE

drum. On these models, the drum must be removed in

order to energize the system and adjust the regulator.

Chec

ChecChec

or leaksor leaks

k f

or leaks.

k fk f

or leaksor leaks

Outlet Pressure

Tap (Plugged)

Figure 3Figure 3

Figure 3

Figure 3Figure 3

Hose Barb Installed

in Outlet Pressure Tap

Figure 4Figure 4

Figure 4

Figure 4Figure 4

31. Plug dryer power cord into electrical socket.

3232

32. Energize dryer and verify ignition. Also observe the

3232

reading on the manometer. It should read the same

outlet pressure as stated on the rating plate on the old

gas valve. If it does not, see section on

Regulator AdjustmentRegulator Adjustment

Regulator Adjustment.

Regulator AdjustmentRegulator Adjustment

33. De-energize the dryer.

34. Remove the hose barb.

35. Apply pipe sealant to the 1/8 inch NPT plug screw. Install

the 1/8 inch NPT plug screw into the outlet pressure tap

and tighten 40 lbf-in.

Check for leaksCheck for leaks

36.

Check for leaks.

Check for leaksCheck for leaks

37. Remove temporary jumper from door switch connector

and reconnect to door switch.

38. Reinstall the access panel/front cover.

PressurePressure

Pressure

PressurePressure

3

Page 4

ADJUSTMENTADJUSTMENT

ADJUSTMENT

ADJUSTMENTADJUSTMENT

PRESSURE REGULAPRESSURE REGULA

PRESSURE REGULA

PRESSURE REGULAPRESSURE REGULA

ADJUSTMENTADJUSTMENT

ADJUSTMENT

ADJUSTMENTADJUSTMENT

This control was shipped from the factory with the regulator

set as specified on the control label. Consult the appliance

rating plate to ensure burner manifold pressure is as

specified. If outlet pressure adjustment is required, follow

these steps.

TT

T

TT

OROR

OR

OROR

NOTE

If a valve has been factory-adjusted for the 2.5 to 5 inches

W.C. range, it cannot be field-adjusted outside that range.

This is also true for valves adjusted to the 7.0 to 12 inches

W.C. range for LP gas.

1. Unlplug dryer power cord.

2. Attach a hose and manometer to the hose barb in the

tap of the valve (see figure 5).

3. Turn on system power and energize valve.

4. Remove regulator cover screw and turn regulator adjust

clockwiseclockwise

screw

clockwise (

clockwiseclockwise

counterclockwisecounterclockwise

counterclockwise (

counterclockwisecounterclockwise

figure 6). Always adjust regulator to provide the correct

pressure according to the original equipment

manufacturer’s specifications listed on the appliance

rating plate.

Replace regulator cover screw and tighten securely.

5. Turn off all electrical power to the system.

6. Remove manometer hose from outlet pressure hose

barb.

7. Remove hose barb and replace plug. Use pipe sealant.

8. Plug in power cord.

9. Using a leak detection solution, check for leaks at

pressure boss screw. Bubbles forming indicate a leak.

SHUT OFF GAS AND FIX ALL LEAKS IMMEDIATELY.

to increase pressureto increase pressure

)

to increase pressure, or

to increase pressureto increase pressure

to decrease pressureto decrease pressure

)

to decrease pressure (see

to decrease pressureto decrease pressure

REGULATOR

ADJUSTMENT

TOWER

HOSE BARB

INSTALLED

Figure 5Figure 5

Figure 5

Figure 5Figure 5

REGULATOR COVER

SCREW

PLASTIC ADJUST SCREW

REGULATOR SPRING

Figure 6Figure 6

Figure 6

Figure 6Figure 6

4

Page 5

LIGHTING INSTRUCTIONSLIGHTING INSTRUCTIONS

LIGHTING INSTRUCTIONS

LIGHTING INSTRUCTIONSLIGHTING INSTRUCTIONS

!

WARNING

A. This appliance does not have a pilot. It is equipped with an

ignition device which automatically lights the burner. Do not

try to light the burner by hand.

B. BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

FOR YOUR SAFETY

“WHAT TO DO IF YOU SMELL GAS”

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

1. Unplug power cord to the appliance.

2. Slide dryer away from wall.

3. Close manual shut-off valve for dryer, if none present, shut off gas supply line where it enters the building.

If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

C. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

For additional product information, please visit our web site.

www.white-rodgers.comwww.white-rodgers.com

www.white-rodgers.com

www.white-rodgers.comwww.white-rodgers.com

5

Page 6

Loading...

Loading...