Page 1

Installation Guide Smart Control Modules

QC01 24VDC

QC03 Intrinsically safe

QC04 Intrinsically safe with NAMUR feedback

English = En

Deutsch = D

Français = F

Español = Es

TM

DOC.IG.QC01.1 Rev.: B

Page 2

En

OK

OK

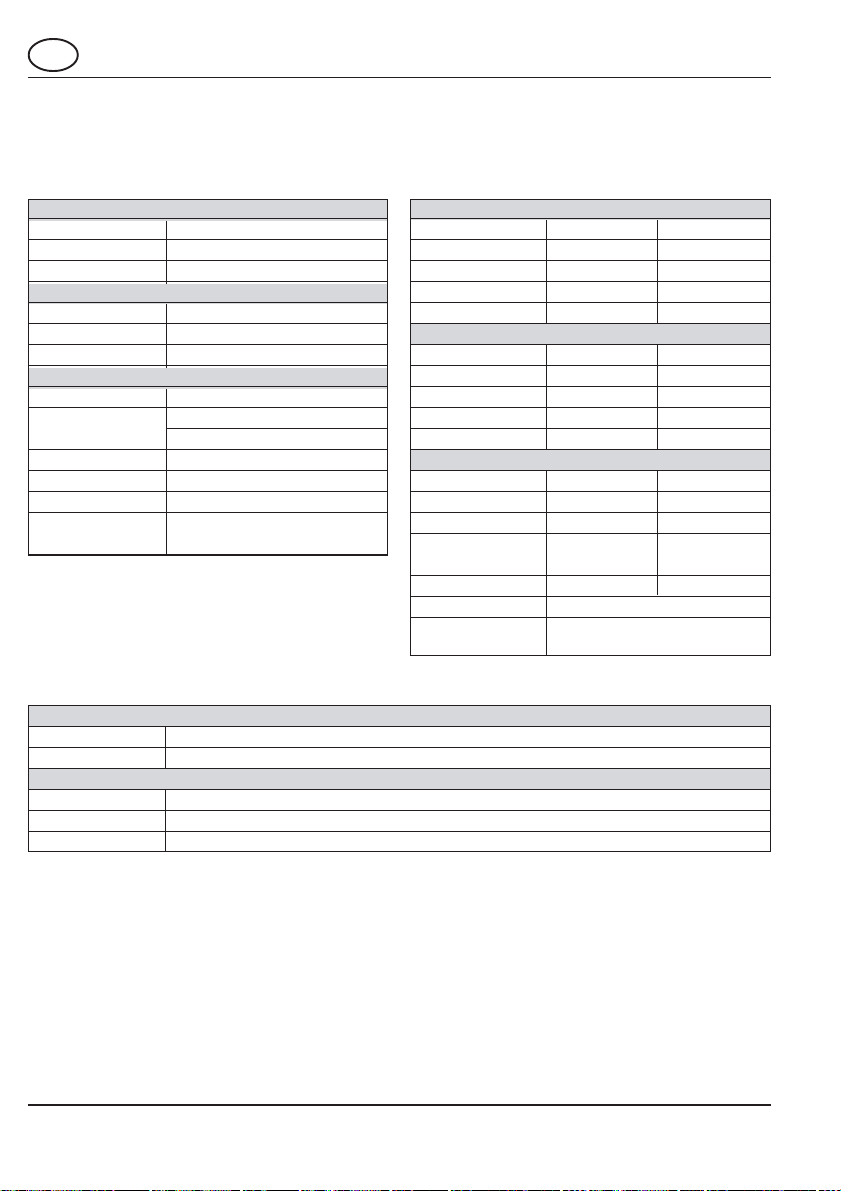

1 Applicable Control Modules

QC01 - 24 VDC

QC01 - 24 VDC Non-Incendive or

Non Sparking

QC03 - IS Intrinsically safe

QC04 - IS-NAMUR Intrinsically safe with NAMUR

position feedback

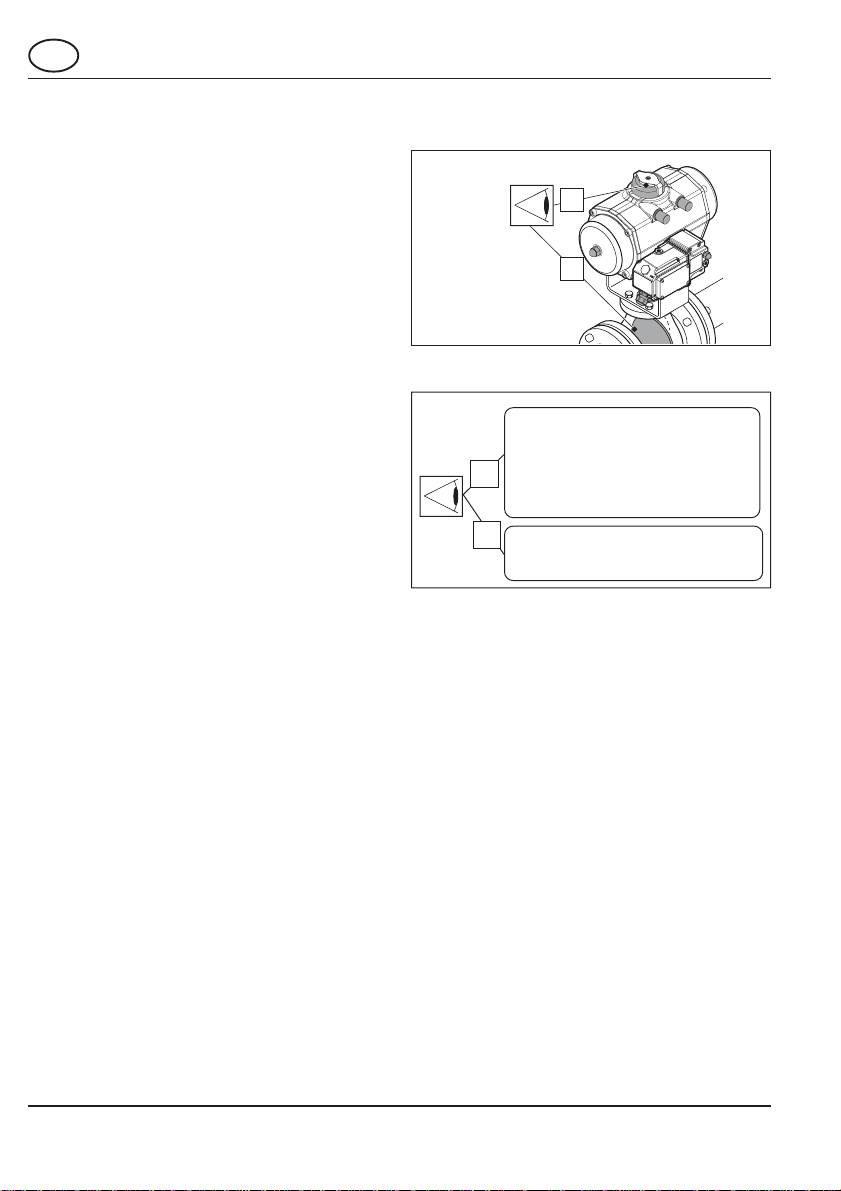

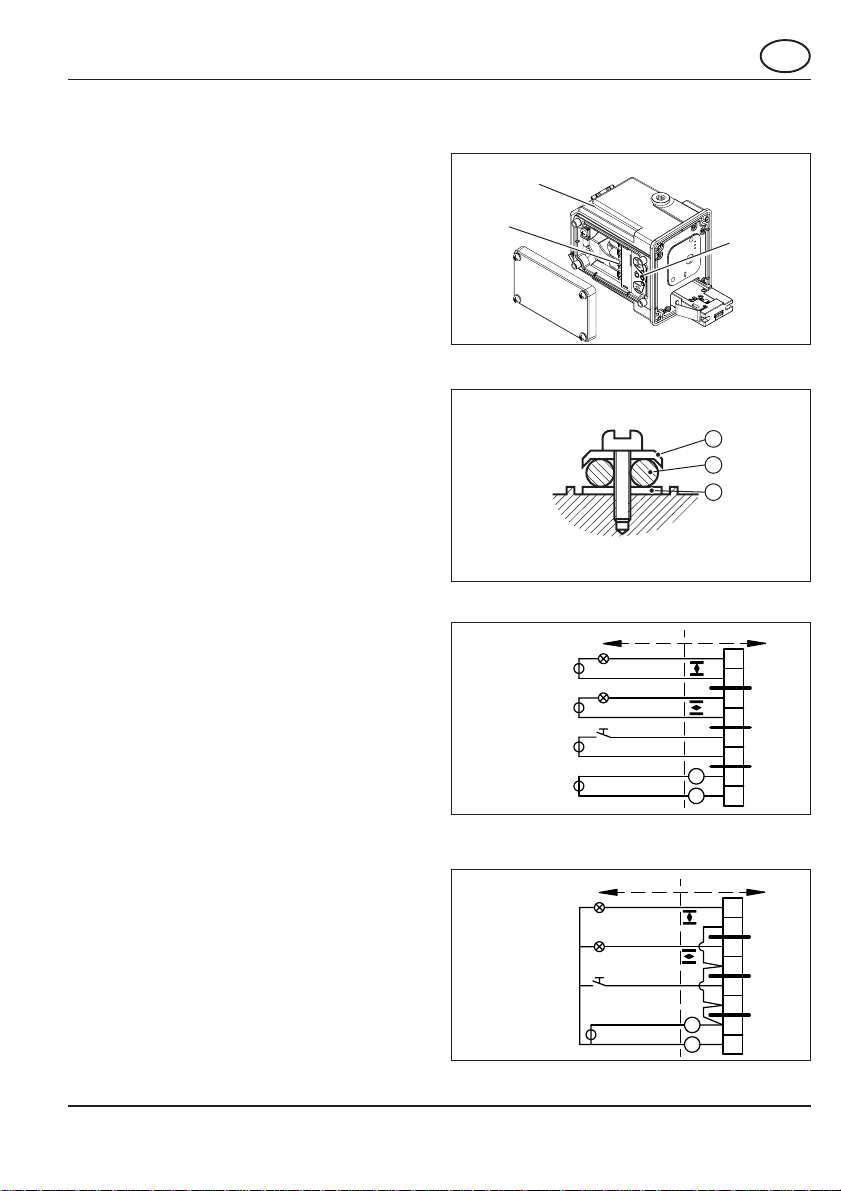

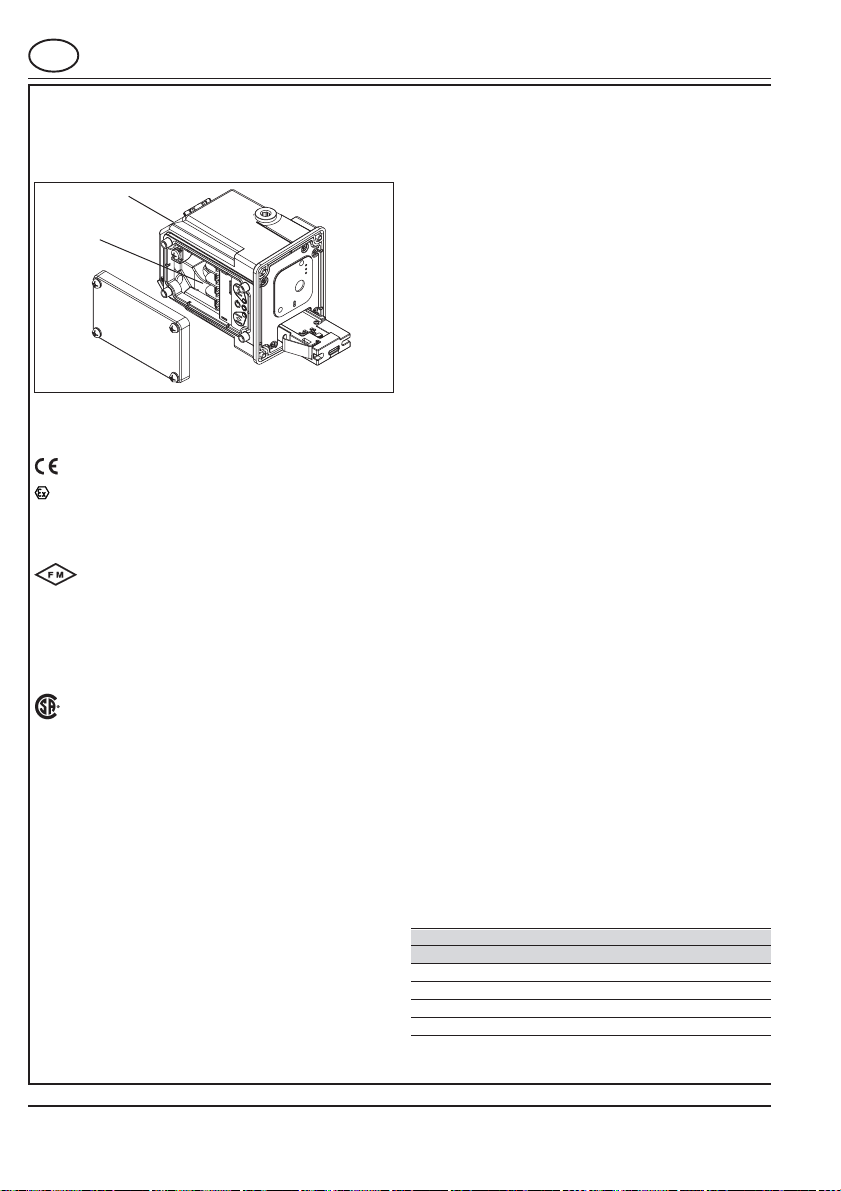

2 Before starting

* Be sure that the actuator is correctly mounted

on the valve before connecting air supply and

electrical wiring (see Installation & Operation

Manual FieldQ Valve Actuator, DOC.IOM.Q.E)

* Check the Module label for the right execution

(see figure 2)

* Check the type of actuator: single or double

acting (see figure 2)

Fig. 1: Check proper mounting before connecting

air supply and electrical wiring.

Control Module Type Label =

QC01..WP.. = 24VDC

QC01..P4.. = 24VDC Non incendive /

OK

QC03..P1.. = Intrinsically safe

QC04..P1.. = Intrinsically safe with NAMUR

OK

Actuator Type Label =

QS xxxx = Single acting (Spring Return)

QD xxxx = Double acting

Non Sparking

position feedback

Fig. 2 Identification

2DOC.IG.QC01.1 Rev.: B December ‘06

Page 3

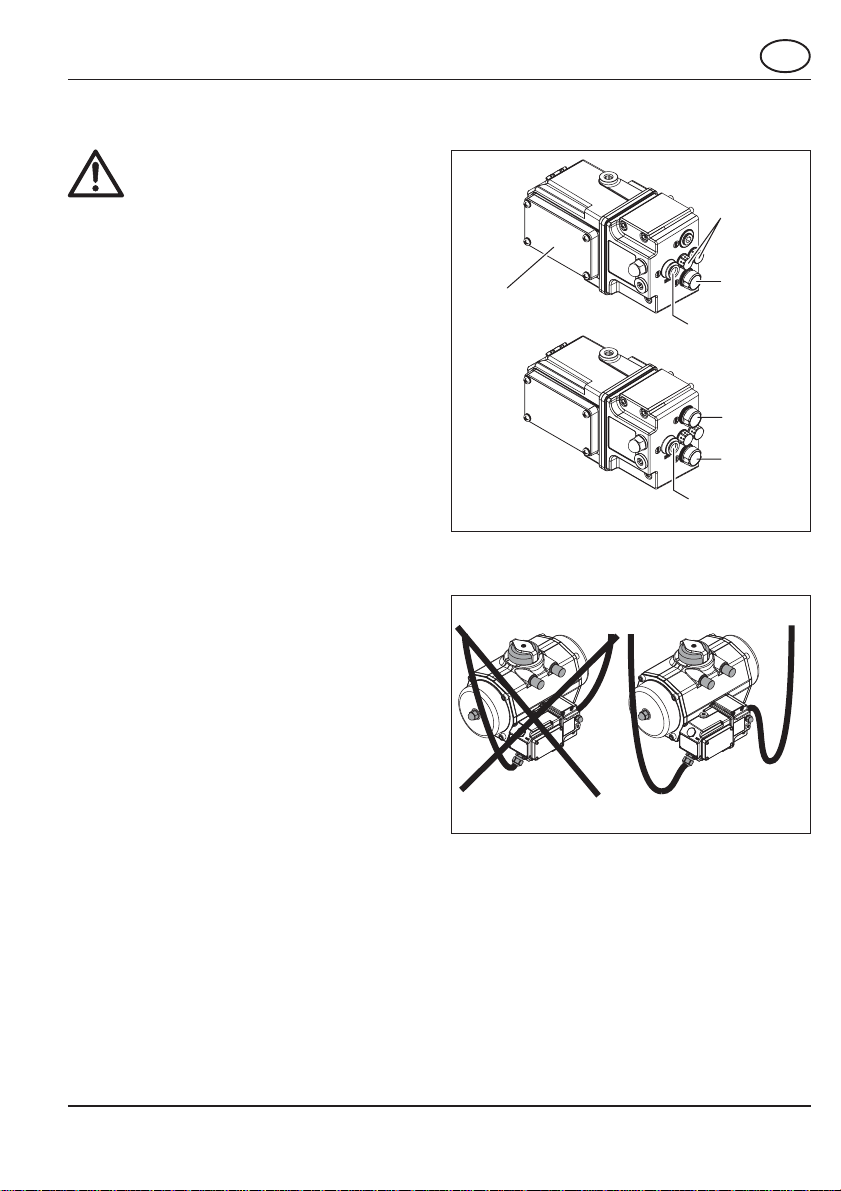

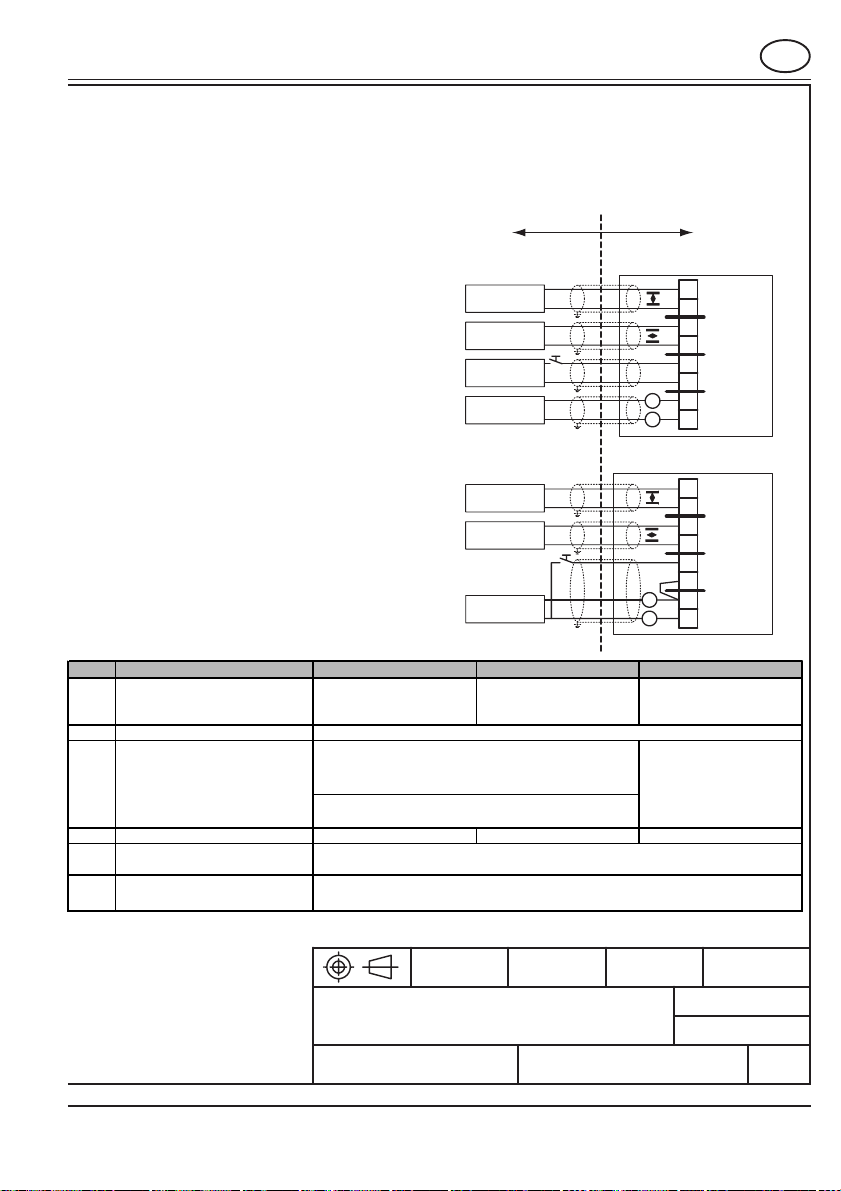

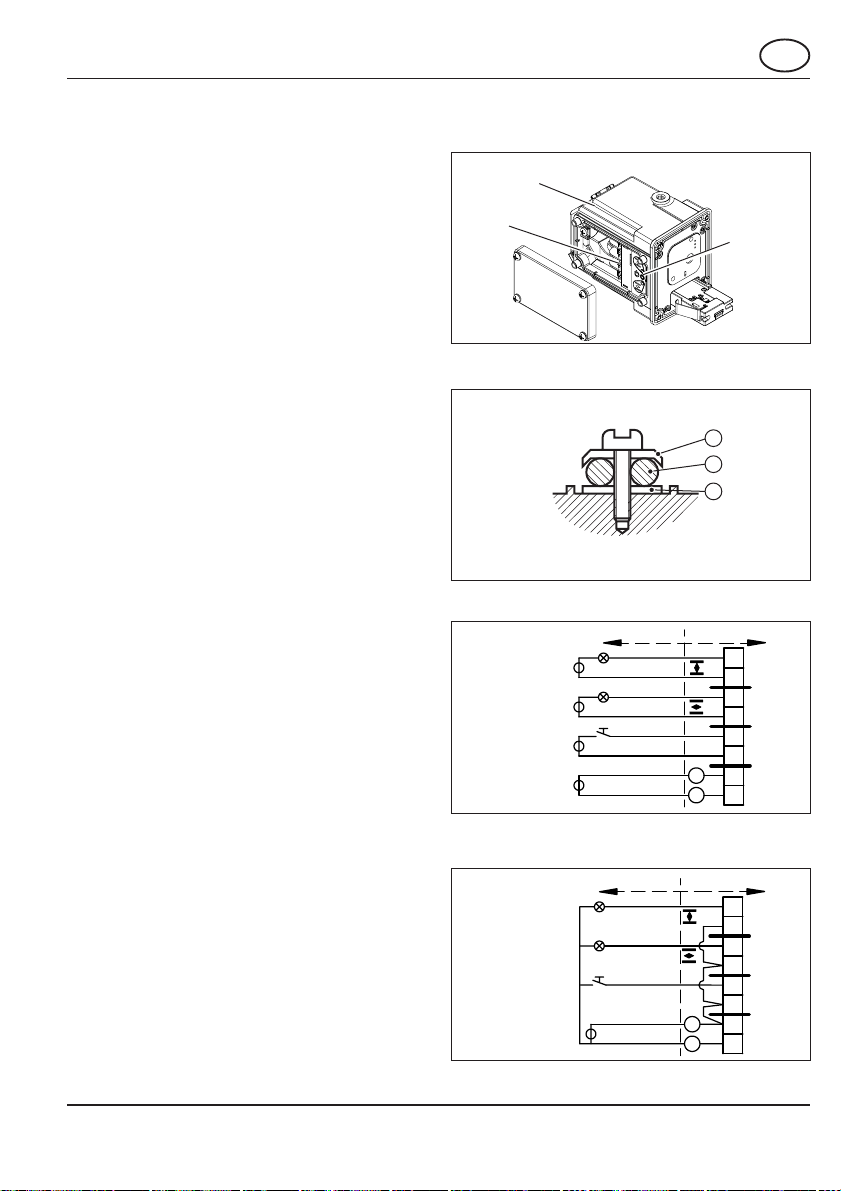

3 Pneumatic connections

En

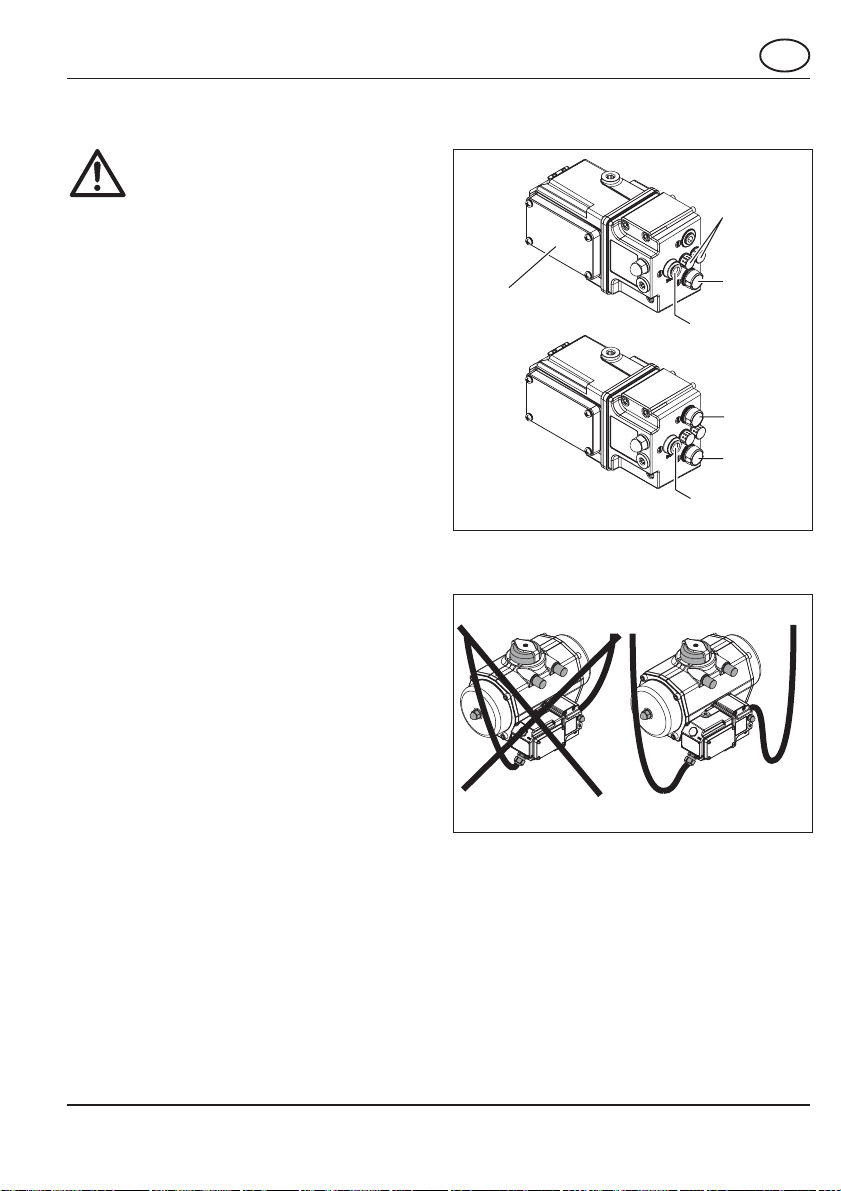

IMPORTANT

* The actuator/valve combination can move after

connecting the air supply.

* Ensure that the pneumatic Module and the Control

Module are mounted properly to the actuator to

achieve a degree of ingress protection rated IP65 /

NEMA4X before connecting the air supply.

* Check the maximum pressure P

* Be sure that the minimum required supply

pressure for the application is available at the

actuator.

* Condensation or moisture that enters the actuator,

the pneumatic Module or the Control Module can

damage these components and can result in

failures. We strongly recommend to install drip

loops in cables in pipes (see figure. 4).

* The venting ports on the pneumatic Module (see

figure 3) are equipped as standard with silencers/

filters rated IP65 / NEMA4X.

* In case IP65 / NEMA4X ingress protection is

required, the exhaust ports Ra and Rb and the

electrical entries must be fitted with devices rated

IP65 / NEMA4X or higher.

= 8bar/116Psi

max

3.1 Operating media :

* Air or inert gasses.

* QC01, air filtered at 50 micron.

QC03 and QC04, air filtered at 25 micron.

* Dew point 10 K below oper ating temperature.

* For subzero applications tak e appropriate

measures.

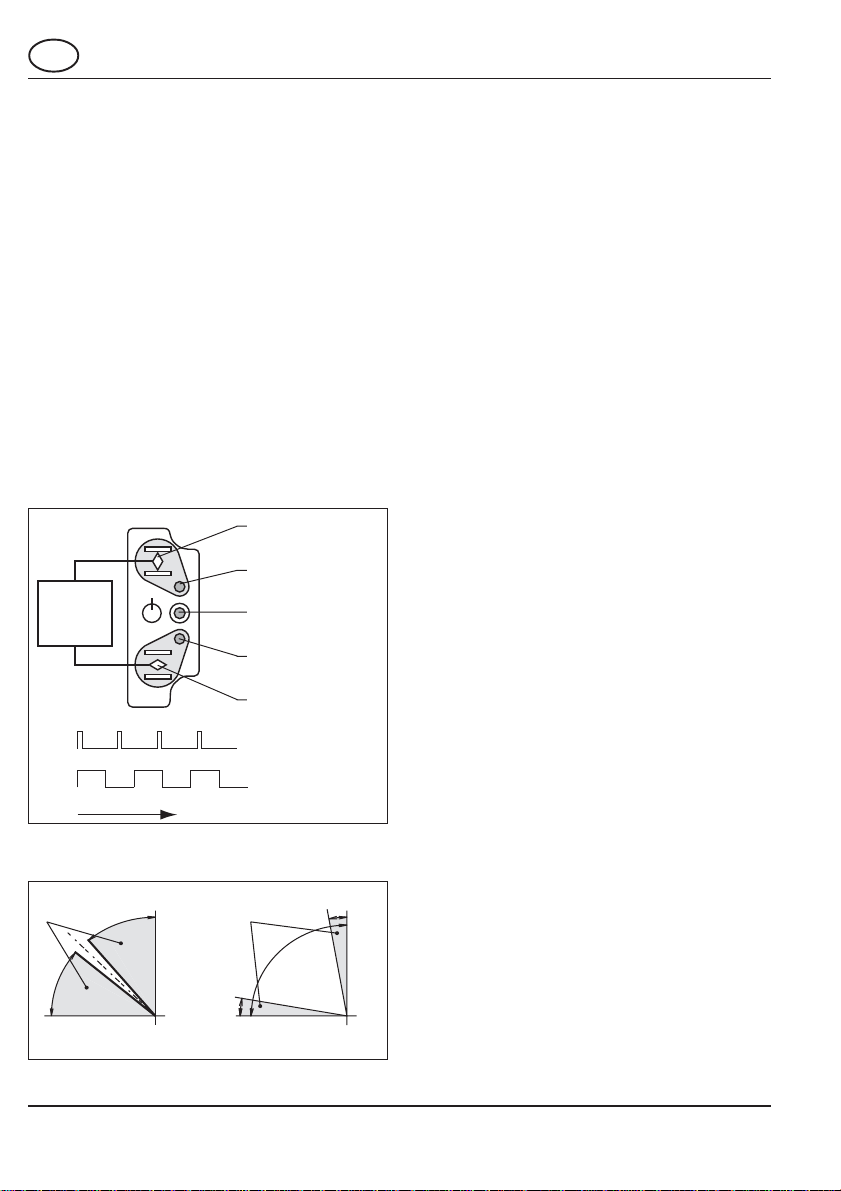

3.2 Single acting (spring return) or

Double acting actuator :

1 Remove the plug from the air supply (Ps).

2 Connect air supply to port (Ps).

Single

acting

Control

Module cover

Double

acting

Fig. 3: Pneumatic connections

Fig 4 Install drip loops

Venting

ports

Rb

Ps

1/4”BSP or 1/4”NPT

Ra

Rb

Ps

1/4”BSP or 1/4”NPT

OK

3DOC.IG.QC01.1 Rev.: B December ‘06

Page 4

En

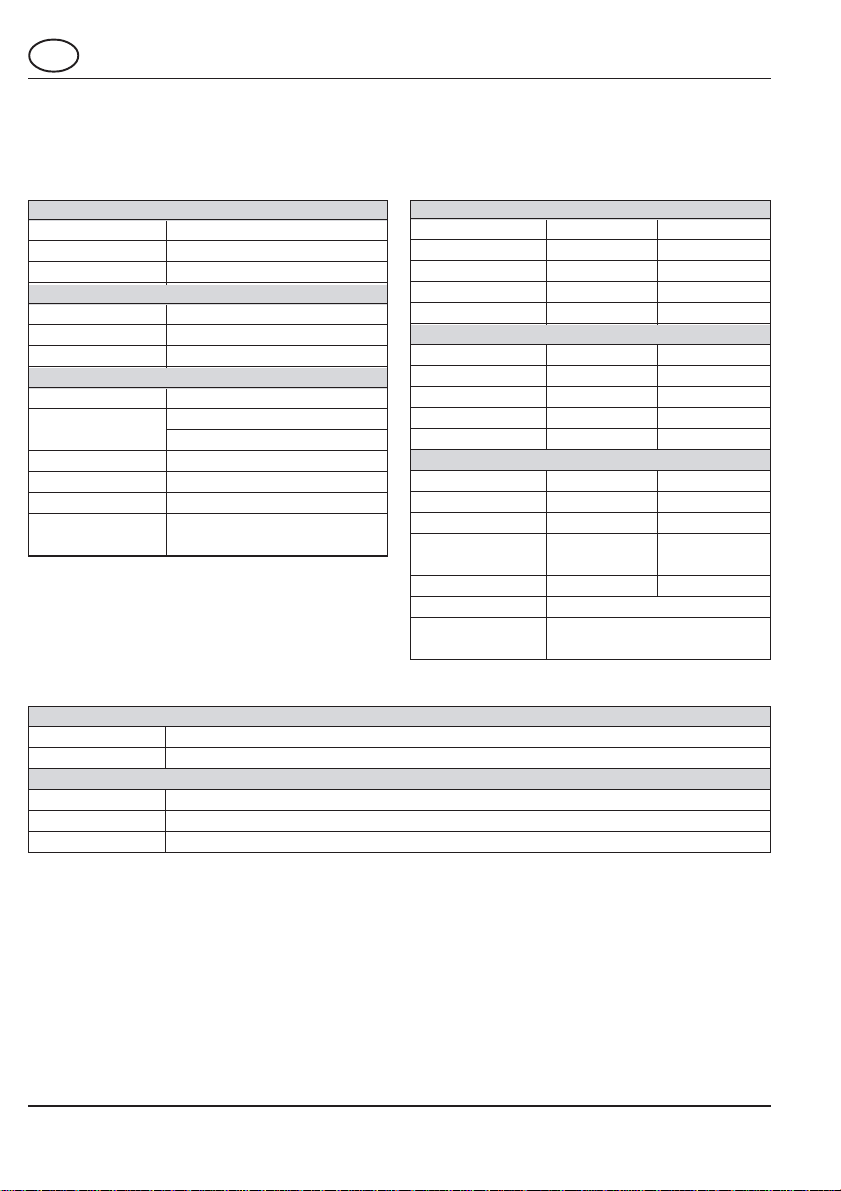

4 Electric Connections

4.1 Electrical data Control Modules

QC01 - 24VDC

Power supply input:

Voltage 24VDC (±15%)

Maximum current 125 mA

Power (nominal) 2.5 W

Control signal input:

Voltage 24VDC (±15%)

Maximum current 5mA max.

Contacts Potential free

Feedback outputs:

Voltage 0-30 VDC

Current DC 500mA (maximum)

1 mA (advised minimum)

Resistance (nom.) 0.5 Ohm (On state)

Maximum power 15W

Electric contacts Potential free

Temperature * -20°C to +80°C

(-4°F to +176°F)

* In case the Control Modules are used in

Hazardous locations, check the Control

Drawings as per chapter 4.2 for the applicable

temperature range.

QC03 - IS QC04 - IS-N

Power supply input:

Voltage 13.5 - 27.6 V 13.5 - 27.6 V

Maximum current 68 mA 68 mA

Maximum Power 1.2 W 1.2 W

Capacity Ci (max.) 15 nF 15 nF

Inductivity Li 0 mH 0 mH

Control signal input:

Voltage 6 - 30 V 6 - 30 V

Maximum current 5 mA 5 mA

Capacity Ci (max.) 3.2 nF 3.2 nF

Inductivity Li 0 mH 0 mH

Contacts Potential free Potential free

Feedback outputs:

Maximum voltage 30 VDC IEC 60947-5-6

Maximum current 32 mA IEC 60947-5-6

Resistance (nom.) 440 Ohm 440 Ohm

Switch resistance 300kOhm 10440 Ohm

(off-state)

Maximum power 1.2 W IEC 60947-5-6

Electric contacts Potential free IEC 60947-5-6

Temperature * -20°C to +50°C

(-4°F to +122°F)

Polarity:

Dependent Power supply

Independent Control signal + f eedback switches

Environmental conditions :

Humidity 0 to 85% at 25°C(+77°F) derate to 50% above 40°C(104°F) (non-condensing).

Altitude Operating full power available up to 2000 meter (6000 feet).

Use In- and outdoor.

4.2 Electrical data of the hazardous

area executions

Please check the following chapters for electrical

data and instructions in case an approved Control

Module is used in a hazardous location:

Non Incendive/Non Sparking

- QC01 24VDC Chapter 10

Intrinsically safe

- QC03 IS Chapter 11

- QC04 IS-NAMUR Chapter 12

4DOC.IG.QC01.1 Rev.: B December ‘06

Page 5

2

1

3

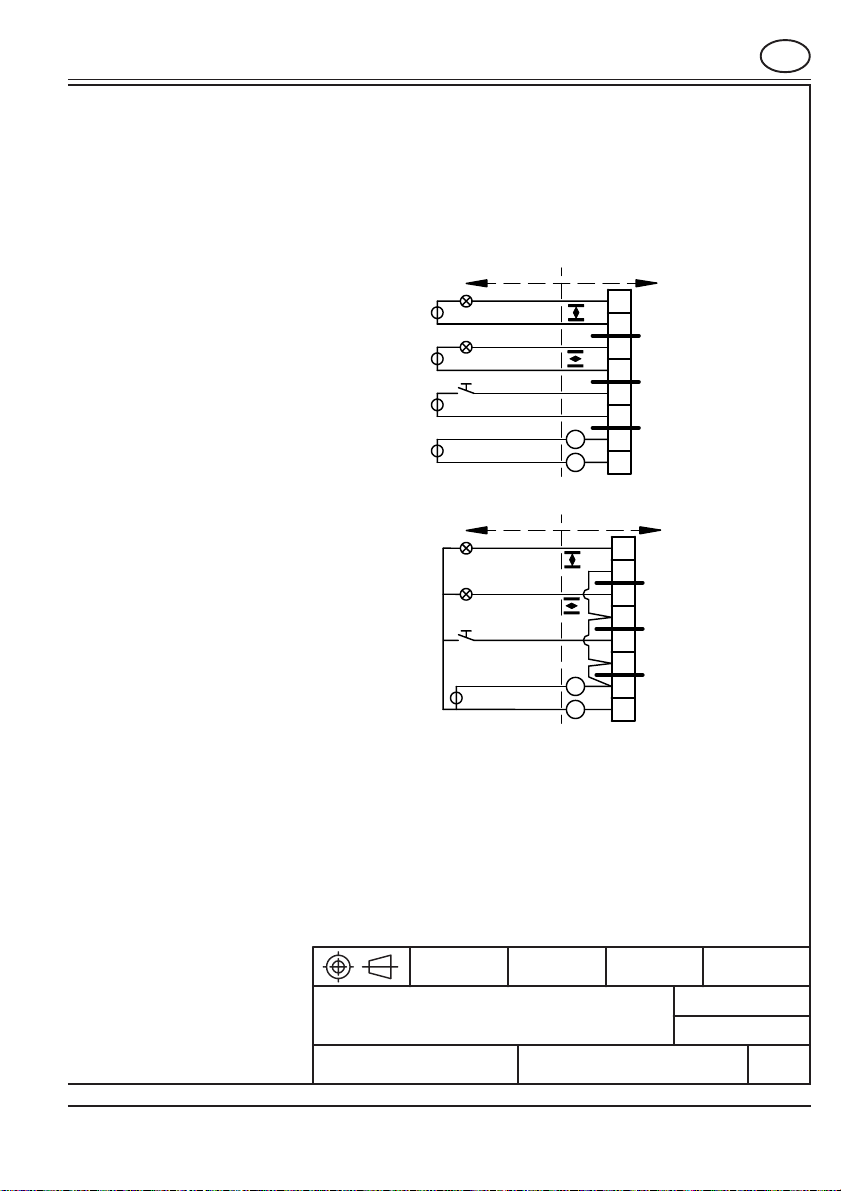

4.3 Wiring dimensions

Solid wire : 2.5mm2 max.

Stranded wire : 0.2-3.3mm2 or 24-12 AWG

4.4 Tools

Tool for terminals : Screw driver 0.6 x 3.5

Tool for cover screws : Screw driver for cross

slotted Phillips screws nr. 2

WARNING:

* Do not put the Control Module and the Pneumatic

Module in direct contact with magnetic material.

This can cause damage or malfunction of the

position feedback.

* If the Control Module is used in a manner not

specified by the manufacturer, the protection

provided by the equipment may be impaired.

* If required, mount earth wire (1) between top (2)

and bottom (3) ring of earth wire connection (see

figure 6).

4.5 Procedure

1 Remove Control Module cov er (see figure 5).

2 Guide the cable(s) through the electrical

entry(ies).

- Use and mount cable glands as required by

national or local legislation.

- When IP65 / NEMA4X ingress protection is

required, the electrical entries must be fitted

with glands rated IP65 / NEMA4X or higher.

3 Make the electrical connections as shown in

figure 7 or 8.

- For hazardous area connections, see the

instructions in chapter 10 or 11.

4 Mount the Control Module cover to the housing

(see figure 5) or continue with chapter 5. Take

care that the cover seal is in place to comply to

dust and water tightness according to

IP65 / NEMA4X.

En

Control Module

Type Label

Terminals

Fig.5: Terminal connections behind cover.

Fig.6 Earth wire connection

Field wiring Unit wiring

1-2 Feedback 2

3-4 Feedback 1

5-6 Control supply

voltage

7-8 Power supply

voltage

0-30 VDC/VAC

15VA

0.5 A

max.

0-30 VDC/VAC

0.5 A

15VA

max.

24 VDC +/- 15%

24 VDC +/- 15%

max.

max.

Fig.7: QC01 electric connections, seperate

circuits

Field wiring

1-2 Feedback 2,

3-4 Feedback 1

5-6 Control

7-8 Power supply

voltage

0.5 A

15VA

max.

0.5 A

15VA

max.

24 VDC +/- 15%

max.

max.

Fig.8: QC01 electric connections, common “-”

5DOC.IG.QC01.1 Rev.: B December ‘06

-

+

Unit wiring

-

+

Status LED

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Page 6

En

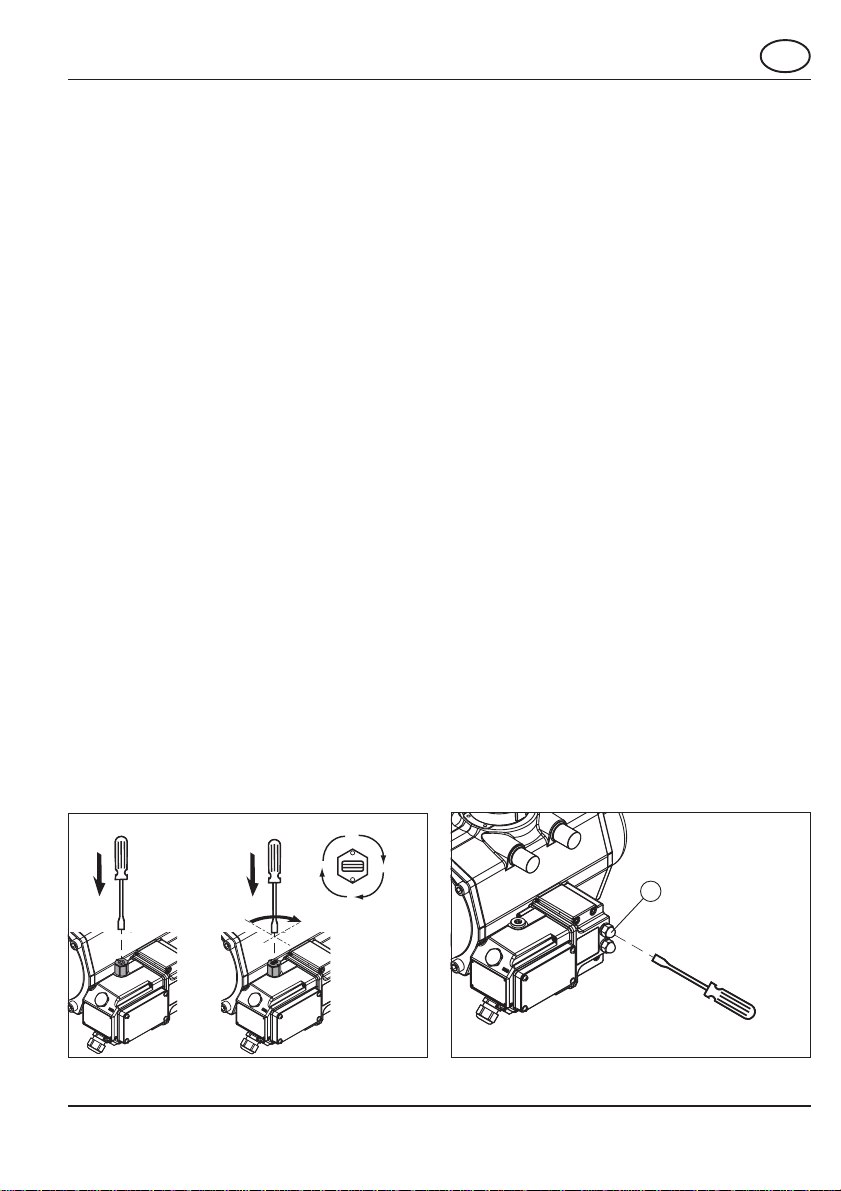

5 Initialization

5.1 Initialization procedure

Initialization sets the limit stop points for the

position feedback of the actuator. This process is

done automatically, by the Module, however, the

user must start it and the unit must be wired

according chapter 4.

WARNING:

* During the initialization routine the actuator /valve

combination will cycle several times.

* Before initialization check whether the actuator

and valve have the same “Open” and “Closed”

positions (see Chapter 4 of Installation & Operation

Manuals FieldQ-series Pneumatic Actuators,

DOC.IOM.Q.E)

* Ensure that the valve stroke is not obstructed

before the initialization routine is started.

Closed reassignment button

Closed LED

Push

4 sec.

Status LED

Open LED

Open reassign-

on

off

on

off

Time

Fig. 9: Reassignment b uttons (located behind

front cover of Module).

Switch

points

Closed

±40˚

ment button

LED = Flashing

LED = Blinking

Switch

points

10˚

max

Closed

5.2 Start initialization procedure (see

figure 9)

1 Push "Open" and "Closed" reassignment

buttons at the same time for 4 seconds.

2 Status LED will blink.

3 Actuator will cycle 2 or 3 times.

4 At the end of the routine the Status LED

switches to constant on, meaning the initializa-

tion was successful.

5 Check that the actual valve position (open or

closed), is indicated on the button board.

5.3 Troubleshooting

5.3.1 If auto initialization procedure has failed

(Status LED is flashing):

1 Check supply pressure

2 Check Actuator assembly code (see Installa-

tion & Operation Manual FieldQ Valve

Actuator DOC.IOM.Q.E)

3 Repeat auto initialization routine

4 When the actuator does not move within 10

seconds, the auto initialization will fail.

5 To solve this either;

- perform the “default setting” procedure (see

§5.3.5) and repeat the initialization procedure (see §5.2), or

- set manually the limit switch points (see

§5.3.4).

5.3.2 If the position feedback on the button board

is reversed:

1 Check if the actuator is correctly mounted to the

valve, if yes:

2 Push the button, corresponding with the actual

position of the actuator, for 3 seconds (“Open”

or “Closed”).

3 The corresponding LED starts flashing.

4 Release the button and push again until LED

burns constantly , Status LED indicates “init

successful”.

5 The feedback of the opposite position changes

automatically.

±40˚

Open

Factory settings Setting after initialization

10˚

max

Fig. 10:Feedback characteristic

Open

6DOC.IG.QC01.1 Rev.: B December ‘06

Page 7

En

5.3.3 If readjustment of the positions is needed

without cycling the actuator:

After adjusting the mechanical limit stops on the

actuator, in such a way that the switch points are

not reached (i.e. reducing the stroke), the Module

will not give proper position feedback.

The easiest way of readjustment of the exact

positions is performing the initialization procedure

(see §5.2).

1 Check if the actuator is correctly mounted to the

valve, if yes:

2 Push the button, corresponding with the actual

position of the actuator, f or 3 seconds (“Open”

or “Closed”).

3 The corresponding LED starts flashing.

4 Release the button and push again until LED

burns constantly , Status LED indicates “init

successful”.

During initialization the actuator will cycle 2 or 3

times. When it is not allowed that the actuator/

valve unit cycles, the new s witch point can be set

with the following procedure:

T able 1. LED indications

Status Status LED action Open/Close LED action

OK (Init successful) Constant on Normal operation (position indicated by LED which is constant on)

Initializing Blinking (see fig. 9) Normal operation

Init error Flashing (see fig. 9) Normal operation

Init default Flashing (see fig. 9) Activated LED (depending on position) blinking

Waiting for Constant on Activated by push button LED Flashing, other LED is off

reassignment confirm

Identification Flashing for 300 sec Normal operation

T able 2 Button board functionality

Action Reassignment buttons

Set to factory default Push both buttons before power up, and than hold until Status LED is constant

on. Release and observe LEDs to indicate default

Initialize While powered up push both buttons until Status LED starts blinking

Reassignment “Open” end position Push “Open” button until “Open” LED starts flashing, release button and push

again until LED is constant on, Status LED indicates “init successful”.

Reassignment “Close” end position Push “Close” button until “Close” LED starts flashing, release button and push

again until LED is constant on, Status LED indicates “init successful”.

7DOC.IG.QC01.1 Rev.: B December ‘06

Page 8

En

5.3.4 Manual setting of limit switch points

When the auto initialization procedure has failed,

the switch points can be set manually with the

following procedure:

1 Move the actuator to the closed position (see

chapter 6 or 8)

2 Push the “closed” button on the board for 3

seconds.

3 The corresponding LED starts flashing.

4 Release the button and push again until LED

burns constantly (Status LED indicates “OK”).

5 Move the actuator to the open position (see

chapter 6)

6 Push the “open” button on the board for 3

seconds.

7 The corresponding LED starts flashing.

8 Release the button and push again until LED

burns constantly (Status LED indicates “OK”).

5.3.5 “Factory default settings”, using the button

board.

To set the Control Module to its factory default

settings, do the following;

1 Pow er must be connected according chapter 4

and the Status LED is either “on” or “flashing.”

2 Disconnect the power.

3 Press both reassignment buttons.

4 Keep the buttons pressed and reconnect

power.

5 Status LED goes on.

6 Release the reassignment buttons.

7 Observe that the Status LED indicates that the

unit is in its “Init Default” state (flashing). The

unit can now be initialized (see §5.2)

6 Check functioning

1 Connect power supply to terminals 7 and 8.

2 Connect control signal to terminals 5 and 6.

3 Actuator moves to "Open" position.

4 Remove control signal from terminals 5 and 6.

5 Actuator moves to "Closed" position.

6 Mount the Control Module cover to the housing

(see figure 5).

8DOC.IG.QC01.1 Rev.: B December ‘06

Page 9

7 Maintenance

The FieldQ Control Modules are designed to

operate without maintenance. For any further

maintenance to the actuator see Installation &

Operation Manual FieldQ Valve Actuator,

DOC.IOM.Q.E or contact your local FieldQ

representative.

Installation, adjustment, putting into service, use,

assembly, disassembly, maintenance and repair of

the Control Module must be done by qualified

personnel.

8 Optional Controls

8.1 Manual Control options

(see figure 11)

For commissioning, emergency or maintenance

purposes, the FieldQ can be supplied with Manual

Control options. These options can operate the

actuator when there is air pressure available, b u t

no control signal or power supply.

1 “Push” version. Pressing the spring return

button will operate the actuator. Releasing the

button will bring back the actuator to its original

position.

2 “Push & Lock” ver sion. T o oper ate this

version, use a screw driver . Push and turn it

90°, to lock it in position and keep the actuator

in its operated state.

It is possible to rotate the screw multiple cycles.

The unit will toggle every 90° between “locked”

(1) and “unlocked” (0).

En

8.2 Speed control option

(see figure 12).

The FieldQ can be supplied with Speed Control

options. There are two versions of this option:

- One Way.

-Two Way

For more detailed information on these two speed

control version see data sheet 1.605.01 or manual

DOC.IOM.Q.E

To adjust the Speed Control options:

1 Remove the nut cap (1).

2 Clockwise rotation of the adjustment screw

reduces the speed.

3 Counter clockwise rotation of the adjustment

screw increases the speed.

4 Replace the nut cap.

9 Related Information

Other documents containing information related to

the FieldQ Module include:

- 1.604.01 FieldQ Smart Control Module

data sheets

- DOC.IOM.Q.E Installation Operation &

Maintenance Manual.

These documents are available, in multiple

languages, for download from www.FieldQ.com

“Push” “Push & “Lock

1

1

Fig. 11 Manual Control options

2 (90˚)

0

1

0

1

1 = “locked”

0 = “unlocked”

1

Fig. 12 Speed control operation

9DOC.IG.QC01.1 Rev.: B December ‘06

Page 10

En

10 QC01 Smart Modules Non Incendive / Non sparking

10.1 Product marking

Type plate

Terminals

Do not open

when energized

Fig 13. Product marking

A TEX Hazardous or Classified Location

II 3 GD EEx nA II T4 T90°C IP65

KEMA 02ATEX1258X

Ta = -20°C…+75°C (-4°F…167°F)

APPROVED

Non-Incendive, Class I, II, III, Div.2,

Group ABCDFG T4, T ype 4X/IP65

Class I, Zone 2, IIC T4

Ta = -20°C…+75°C (-4°F…167°F)

Non Incendive: Class I, II, III, Div.2,

Groups ABCDFG, T4

Ex nA II T4 (Class I, Zone 2)

Ta = -20°C…+75°C (-4°F…167°F)

Hazardous or Classified Location

Hazardous or Classified Location

10.2 ATEX Intended use

• The Control Module QC01..P4.. of the FieldQ

pneumatic actuator is a Group II category 3

equipment.

• The pneumatic actuator part, together with the

pneumatic Module part of the FieldQ pneumatic

actuators is a Group II category 2 equipment.

• Both are intended for use in areas in which

explosive atmospheres caused by mixtures of

air and gases, vapours, mists or by air/dusts

are likely to occur.

• Therefore the assembly may be used in (ATEX)

classified Zones 2 (Gasses) and/or 22 (Dust).

10.3 Safety instructions

• Do not open when Module is energized.

• Prevent any kind ignition during installation,

adjustment, putting into service and use.

• Assembly, disassembly and maintenance must

be done in safe area’s without a potential

explosion hazard.

• Installation, adjustment, putting into service,

use, assembly, disassembly and maintenance

of the pneumatic actuator must be done by

qualified personnel.

10DOC.IG.QC01.1 Rev.: B December ‘06

Page 11

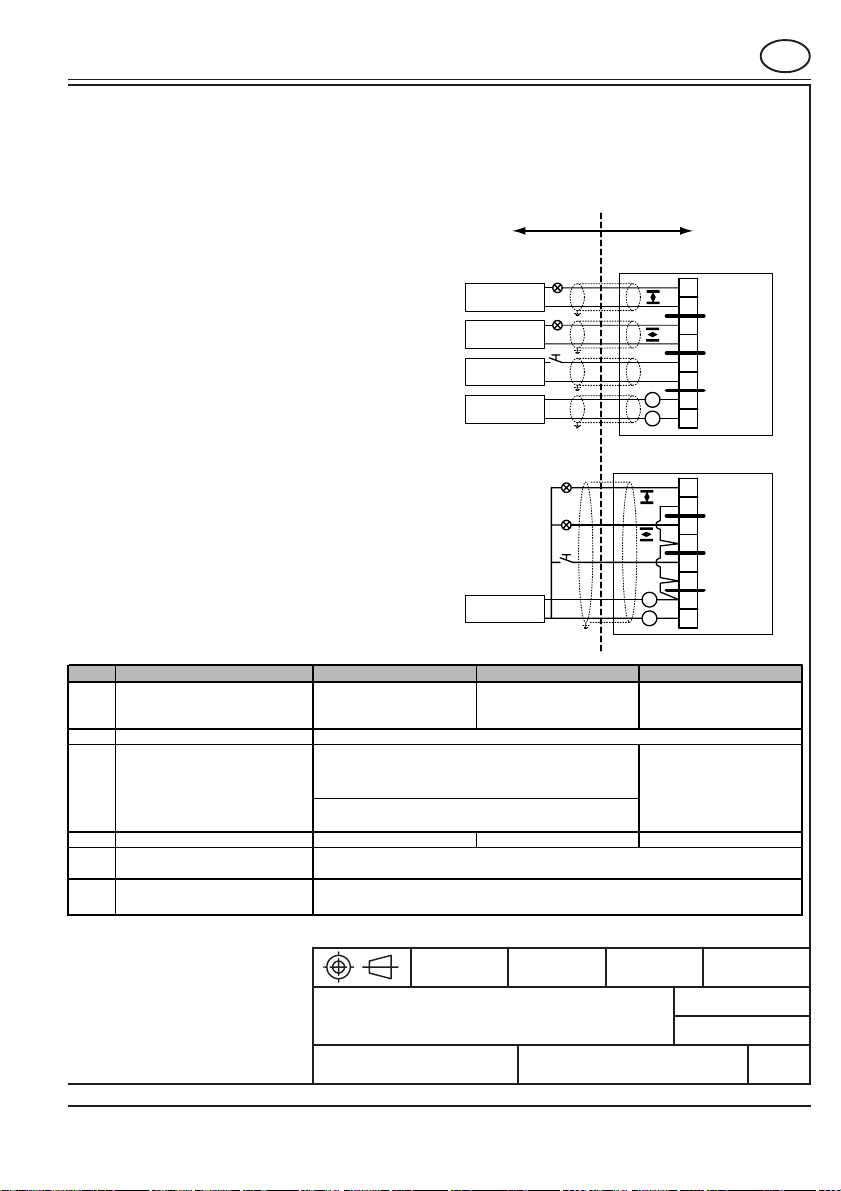

10.4 Wiring instructions QC01 Non Incendive / Non Sparking Control Modules

En

Terminal connections,

with seperate circuits

1-2 Feedback 2

3-4 Feedback 1

5-6 Control supply

voltage

7-8 Power supply

voltage

Terminal connections,

with common “-”

1-2 Feedback 2,

3-4 Feedback 1

5-6 Control

7-8 Power supply

voltage

Unclassified or Non

Hazardous Location

0-30 VDC/VAC

0.5 A

max.

0-30 VDC/VAC

0.5 A

max.

24 VDC +/- 15%

24 VDC +/- 15%

0.5 A

max.

0.5 A

max.

24 VDC +/- 15%

Hazardous or

Classified Location

15VA

max.

15VA

max.

-

+

15VA

max.

15VA

max.

-

+

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Certified Document:

No modification permitted without reference to the certifying authority.

Format :

Drn.:

Scale :

A4

Title :

Control Drawing FieldQ

QC01 Smart Modules Non Incendive /

Non sparking

Home page:

www.FieldQ.com

11DOC.IG.QC01.1 Rev.: B December ‘06

Drw nr.

C0542-01 A

Date :

ENOC nr.:

State :

Par. :Date :

Rev. :

Page 12

En

11 QC03 Smart Module Intinsically safe

11.1 Product marking

Control Module

Type Label

Terminals

Fig 14. Product marking

A TEX Hazardous or Classified Location

0344

II 1 GD Ex ia IIC T4 T80°C IP65

KEMA 02ATEX1242X

Ta = -20°C…+50°C (-4°F…122°F)

APPROVED

Intrinsically safe, Class I, II, III Div.1,

Groups ABCDEFG, T4, T ype 4X/IP65

Class I, Zone 0, AEx ia IIC T4, IP65,

Ta = -20°C…+50°C (-4°F…122°F)

Intrinsically safe, Class I, II, III Div.1,

Groups ABCDEFG, T4

Ex ia IIC T4, IP65, (Class I, Zone 0/1)

Ta = -20°C…+50°C (-4°F…122°F)

Hazardous or Classified Location

Hazardous or Classified Location

11.2 ATEX Intended use

The Control Module QC03..P1.. of the FieldQ

pneumatic actuator are Group II category 1

equipment and intended for use in areas in which

explosive atmospheres caused by mixtures of air

and gases, vapours, mists or by air/dusts are lik ely

to occur.

The pneumatic actuator part, together with the

pneumatic Module part of the FieldQ pneumatic

actuators is a Group II category 2 equipment and

intended for use in areas in which explosiv e

atmospheres caused by mixtures of air and gases,

vapours, mists or by air/dusts are likely to occur.

Therefore it may be used in (ATEX) classified

Zones 1, 2 (Gasses) and/or 21, 22 (Dust).

11.3 Special conditions for safe use

(ATEX).

The material for the Control Module housing is an

aluminum alloy. When the unit is used in a

potentionally explosive atmosphere, requiring

ATEX equipment category 1 G, the unit must be

installed in such a way, that even in the event of

rare incidents, an ignition source due to impact or

friction between the enclosure and iron/steel is

prevented.

For applications in explosiv e atmospheres caused

by air/dust mixtures and where category 1D

apparatus is required, the surface temperature has

been determined for a dust layer with a thickness

of 5 mm maximum.

11.4 Dielectric strength

Control Module QC03 complies to the dielectric

strength requirement according IEC- 60079-11

QC03 Intrinsically Safe Entity Parameters

Circuit Terminal Ui Ii Pi Ci Li

Power Supply 7-8 30VDC 300mA 1.2W 15 nF 0

Control input 5-6 30VDC 300mA 1.2W 15 nF 0

Feedback 1 3-4 30VDC 300mA 1.2W 18 nF 0

Feedback 2 1-2 30VDC 300mA 1.2W 18 nF 0

12DOC.IG.QC01.1 Rev.: B December ‘06

Page 13

11.5 Wiring instructions QC03

Intrinsically safe Control Module

Minimum operating values:

- Control supply:

Umin = 6 VDC

Imin = 1 mA

- Power supply:

Umin = 13.5 VDC

Imin = 33 mA

Cable range:

Wire range: 2.5mm2 max.

Solid / Stranded wire: 0.2-3.3mm2 or

24-12 AWG

Unclassified or Non

Hazardous Location

Terminal connections, with

seperate circuits

1-2 Feedback 2

3-4 Feedback 1

5-6 Control supply

voltage

7-8 Power supply

voltage

Terminal connections,

with common “-”

1-2 Feedback 2

3-4 Feedback 1

5-6 Control

7-8 Power supply

voltage

IS Approved

Barrier

IS Approved

Barrier

IS Approved

Barrier

IS Approved

Barrier

IS Approved

Barrier

Hazardous or

Classified Location

1

2

3

Control

4

Module

5

6

-

7

+

8

1

2

3

4

Control

Module

5

6

-

7

+

8

En

FieldQ

QC03

FieldQ

QC03

Notes: CSA FM ATEX

1 Installation must be inaccordance

with:

2 Before operation:

3

Barriers: Must be FM/CSA Approved and installed in an enclosure

4 Intrinsically safe equipement Must be CSA Approved Must be FM Approved Must be ATEX Approved

5

Barrier I.S. Entity Parameters must

meet the following conditions:

6 When multiple barriers are used:

Canadian Electrical Code,

Part1

The control module in combination with the pneumatic module must be mounted properly.

that meets the requirements of ANSI/ ISA S82.01/CEC

part1.

Control equipment connected to the barrier must not use

or generate more than 250Vrms or Vdc.

Uo =< Ui Io =< Ii Po =< P i

Co >= Ci + Cable Lo >= Li + Cable

* Each I.S. Circuit must use shielded, twisted pairs

* Cable insulation and shielding must extend to within paritioned area of terminals

Certified Document:

No modification permitted without reference to the certifying authority.

Title :

Control Drawing FieldQ

Format :

QC03 Smart Modules Intinsically safe

Home page:

www.FieldQ.com

National Electrical Code

(ANSI/NFPA 70) and

ANSI/ISA RP12.06.01

Drn.:

A4

Drw nr.

The national wiring practices

of the country of use

Must be certified by an

European Notified body and

installed per manufacturer’s

installation instructions

Scale :

ENOC nr.:

State :

C0542-06

Date :

27/06/2006

13DOC.IG.QC01.1 Rev.: B December ‘06

Date :

Rev. :

Par. :

A

Page 14

En

12 QC04 Smart Module Intinsically safe

12.1 Product marking

Control Module

Type Label

Terminals

Fig 14. Product marking

A TEX Hazardous or Classified Location

0344

II 1 GD Ex ia IIC T4 T80°C IP65

KEMA 02ATEX1242X

Ta = -20°C…+50°C (-4°F…122°F)

APPROVED

Intrinsically safe, Class I, II, III Div.1,

Groups ABCDEFG, T4, T ype 4X/IP65

Class I, Zone 0, AEx ia IIC T4, IP65,

Ta = -20°C…+50°C (-4°F…122°F)

Intrinsically safe, Class I, II, III Div.1,

Groups ABCDEFG, T4

Ex ia IIC T4, IP65, (Class I, Zone 0/1)

Ta = -20°C…+50°C (-4°F…122°F)

Hazardous or Classified Location

Hazardous or Classified Location

12.2 ATEX Intended use

The Control Module QC04..P1.. of the FieldQ

pneumatic actuator are Group II category 1

equipment and intended for use in areas in which

explosive atmospheres caused by mixtures of air

and gases, vapours, mists or by air/dusts are lik ely

to occur.

The pneumatic actuator part, together with the

pneumatic Module part of the FieldQ pneumatic

actuators is a Group II category 2 equipment and

intended for use in areas in which explosiv e

atmospheres caused by mixtures of air and gases,

vapours, mists or by air/dusts are likely to occur.

Therefore it may be used in (ATEX) classified

Zones 1, 2 (Gasses) and/or 21, 22 (Dust).

12.3 Special conditions for safe use

(ATEX).

The material for the Control Module housing is an

aluminum alloy. When the unit is used in a

potentionally explosive atmosphere, requiring

ATEX equipment category 1 G, the unit must be

installed in such a way, that even in the event of

rare incidents, an ignition source due to impact or

friction between the enclosure and iron/steel.

For applications in explosiv e atmospheres caused

by air/dust mixtures and where category 1D

apparatus is required, the surface temperature has

been determined for a dust layer with a thickness

of 5 mm maximum.

12.4 Dielectric strength

Control Module QC04 complies to the dielectric

strength requirement according IEC- 60079-11

QC03 Intrinsically Safe Entity Parameters

Circuit Terminal Ui Ii Pi Ci Li

Power Supply 7-8 30VDC 300mA 1.2W 15 nF 0

Control input 5-6 30VDC 300mA 1.2W 15 nF 0

Feedback 1 3-4 30VDC 300mA 1.2W 18 nF 0

Feedback 2 1-2 30VDC 300mA 1.2W 18 nF 0

14DOC.IG.QC01.1 Rev.: B December ‘06

Page 15

12.5 Wiring instructions QC04

Intrinsically safe Control Module

Minimum operating values:

- Control supply:

Umin = 6 VDC

Imin = 1 mA

- Power supply:

Umin = 13.5 VDC

Imin = 33 mA

Cable range:

Wire range: 2.5mm2 max.

Solid / Stranded wire: 0.2-3.3mm2 or

Note:

* Use approved barrier according

EN60947-5-6 (NAMUR) for appropriate

signal level. Un = 8.2VDC

24-12 AWG

Unclassified or Non

Hazardous Location

Terminal connections, with

seperate circuits

1-2 Feedback 2*

(EN60947-5-6)

3-4 Feedback 1*

(EN60947-5-6)

5-6 Control supply

voltage

7-8 Power supply

voltage

Terminal connections,

with common “-”

1-2 Feedback 2*

3-4 Feedback 1*

5-6 Control

7-8 Power supply

voltage

IS Approved

Barrier

IS Approved

Barrier

IS Approved

Barrier

IS Approved

Barrier

IS Approved

Barrier

IS Approved

Barrier

IS Approved

Barrier

Hazardous or

Classified Location

1

FieldQ

2

Control

Module

3

QC04

4

5

6

-

7

+

8

1

FieldQ

2

Control

3

Module

QC04

4

5

6

-

7

+

8

En

Notes: CSA FM ATEX

1 Installation must be inaccordance

with:

2 Before operation:

3

Barriers: Must be FM/CSA Approved and installed in an enclosure

4 Intrinsically safe equipement Must be CSA Approved Must be FM Approved Must be ATEX Approved

5

Barrier I.S. Entity Parameters must

meet the following conditions:

6 When multiple barriers are used:

Canadian Electrical Code,

Part1

The control module in combination with the pneumatic module must be mounted properly.

that meets the requirements of ANSI/ ISA S82.01/CEC

part1.

Control equipment connected to the barrier must not use

or generate more than 250Vrms or Vdc.

Uo =< Ui Io =< Ii Po =< P i

Co >= Ci + Cable Lo >= Li + Cable

* Each I.S. Circuit must use shielded, twisted pairs

* Cable insulation and shielding must extend to within paritioned area of terminals

Certified Document:

No modification permitted without reference to the certifying authority.

Title :

Control Drawing FieldQ

Format :

QC 04 Smart Modules Intinsically safe

Home page:

www.FieldQ.com

National Electrical Code

(ANSI/NFPA 70) and

ANSI/ISA RP12.06.01

Drn.:

A4

Drw nr.

The national wiring practices

of the country of use

Must be certified by an

European Notified body and

installed per manufacturer’s

installation instructions

Scale :

ENOC nr.:

State :

C0542-07

Date :

27/06/2006

15DOC.IG.QC01.1 Rev.: B December ‘06

Date :

Rev. :

Par. :

A

Page 16

En

13 EC Declaration of Conformity

Asveldweg 11

7556 BR, HENGELO

The Netherlands

EC DECLARATION OF CONFORMITY

- Machinery Directive 98/37/EC, Appendix IIb - Low Voltage Directive 73/23 EC

- EMC Directive 89/336/EC, Appendix 1 - ATEX Directive 94/9/EC

We hereby declare, that the products specified below meet the basic health and safety requirements of

the above mentioned European Directives.

Before the Control Module is put into operation, the machine into or onto which the Control Module will

be installed, must comply with the stipulations of the machinery directive.

Product description : FieldQ Control module

Serial number : Each Control module has an identifiable serial number

Year of Construction : Each Control module has an identifiable Year of Construction

A TEX DIRECTIVE

Types : QC01...P4... , QC02...P4... , QC30...P4... and QC34...P4...

A TEX Certificate No. : KEMA 02ATEX1258X,

Marking QC01 & QC30 :

QC02 :

QC34 :

QC34 :

Applicable standards : EN 60079-0 : 2004 EN 60079-15 : 2003

Types : QC03...P1..., QC04...P1... and QC34...P1...

A TEX Certificate No. : KEMA 02ATEX1242X,

Marking :

Applicable standards : EN 60079-0 : 2004 EN 60079-11 : 1999 EN 60079-26 : 2004

Notified body : KEMA Quality B.V., Notified body no : 0344

EMC, LVD and Machinery Directive

Types : QC01..., QC02..., QC03..., QC04..., QC30..., QC34...,

Applicable standards : IEC61326-1 :1998 NAMUR Recommendations : NE21

Types : QC02...WP...

Applicable standards : IEC61010-1 : 2004

Note : The above listed ATEX certified products are excluded from the Low

Issued in accordance with the

II 3 GD EEx nA II T4 T90°C, IP65 Ta = -20°C ... +75°C

II 3 GD EEx nA II T4 T90°C, IP65 Ta = -20°C ... +73°C

II 3 GD EEx nA II T4 T90°C, IP65 Ta = -20°C ... +50°C

II 3 GD EEx nL IIC T4 T80°C, IP65 Ta = -20°C ... +50°C

IEC 61241-0 : 2004 EN 61241-1 : 2004

II 1 GD EEx ia IIC T4 T80°C

EN 60079-27 : 2005 EN 50020 : 2002 IEC 61241-0 : 2004

EN 61241-1 : 2004 EN 50014 : 1997 EN50284 : 1999

Utrechtseweg 310, 6812 AR Arnhem, The Netherlands

Voltage Directive

TM

Signed : _____________________________

Name : D.L.Farr

Function : Vice President Operations - Emerson Valve Automation

Date : October 4, 2006

16DOC.IG.QC01.1 Rev.: B December ‘06

Page 17

En

17DOC.IG.QC01.1 Rev.: B December ‘06

Page 18

D

1 Anwendbare Steuermodule

QC01- 24 V D C

QC01- 24 V D C Nicht zündgefährlich oder

nicht funkenbildend

QC03 - IS Eigensicher

QC04 - IS-NAMUR Eigensicher mit NAMUR-

Stellungsrückmeldung

2 Vor dem Start

* Stellen Sie sicher, dass der Stellantrieb

ordnungsgemäß an der Armatur montiert ist,

bevor die Luftversorgung und die Verdrahtung

angeschlossen werden (siehe die Installa-

tions- und Betriebsanleitung des FieldQVentilstellantriebs, DOC.IOM.Q.D).

* Kontrollieren Sie das Schild am Modul auf die

richtige Ausführung (siehe Abb. 2)

* Überprüfen Sie den Stellantriebstyp: einfach-

oder doppeltwirkend (siehe Abb. 2)

OK

OK

Abb. 1: Auf ordnungsgemäße Montage prüfen,

bevor die Luftversorgung und die

Verdrahtung angeschlossen werden.

Steuermodul-Typenschild =

QC01..WP .. = 24VDC

QC01..P4.. = 24VDC Nicht zündgefährlich/

OK

QC03..P1.. = Eigensicher

QC04..P1.. = Eigensicher mit NAMUR-

OK

Antriebs-T ypenschild =

QS xxxx = einfachwirkend (mit Federrückstellung)

QD xxxx = doppeltwirkend

nicht funkenbildend

Stellungsrückmeldung

Abb. 2 Identifizierung

18DOC.IG.QC01.1 Rev.: B December ‘06

Page 19

3 Druckluftanschlüsse

D

WICHTIG

* Der FieldQ kann sich nach dem Anschluss der

Luftversorgung bewegen.

* Stellen Sie vor Anschluss der Luftversorgung sicher,

dass das pneumatische Modul und das Steuermodul

ordnungsgemäß am Antrieb montiert sind, um einen

Einlassschutz gemäß IP65/NEMA4X zu erzielen.

* Kontrollieren Sie den höchstzulässigen Druck:

P

= 8 bar/116 Psi

max

* Stellen Sie sicher, dass der minimale V er sorgungs-

druck für die Anwendung am Antrieb verfügbar ist.

* Das Eindringen von Kondensat oder Feuchtigkeit in

den Antrieb, das pneumatische Modul oder das

Steuermodul kann zur Beschädigung dieser

Komponenten und zu Funktionsstörungen führen.

Wir empfehlen Ihnen dringend, T r opfschleifen in

Kabeln in Rohren zu installieren (siehe Abb. 4).

* Die Lüftungsanschlüsse des pneumatischen Moduls

(siehe Abb. 3) sind standardmäßig mit Schalldämpfern/Filtern gemäß IP65/NEMA4X ausgestattet.

* Falls Einlassschutz gemäß IP65/NEMA4X

erforderlich ist, müssen die Abluftöffnungen Ra und

Rb sowie die elektrischen Eingänge mit Geräten

gemäß IP65/NEMA4X oder höher ausgestattet

werden.

3.1 Betriebsmedien:

* Luft oder Inertgase.

* QC01, mit 50 Mikron gefilterte.

QC03 und QC04, mit 25 Mikron gefilterte Luft.

* Druck-Taupunkt 10 °K unter der

Betriebstemperatur

* Für Anwendungen unter Null sind die

erforderlichen Maßnahmen zu ergreifen.

3.2 Einfachwirkender (mit

Federrückstellung) oder

doppeltwirkender Antrieb:

1 Den Stopfen aus dem Luftzufuhranschluss

(Ps) entfernen.

2 Die Luftversorgung mit dem Anschluss (Ps)

verbinden.

Einfachwirkend

Steuermodulabdeckung

Doppeltwirkend

Abb. 3: Druckluftanschlüsse

Abb. 4 Tropfschleifen installieren

Lüftungsanschlüsse

Rb

Ps

1/4”BSP oder 1/4”NPT

Ra

Rb

Ps

1/4”BSP oder 1/4”NPT

OK

19DOC.IG.QC01.1 Rev.: B December ‘06

Page 20

D

4 Elektrische Anschlüsse

4.1 Elektrische Daten Steuermodule

QC01 - 24 VDC

Stromversorgung:

Spannung 24 VDC (±15%)

Max. Strom 125 mA

Nennleistung 2,5 W

Steuersignal Eingang:

Spannung 24 VDC (±15%)

Max. Strom 5 mA max.

Kontakte Potentialfrei

Ausgänge:

Spannung 0-30 VDC

Strom DC 500 mA (maximal)

1 mA (empfohlenes Minimum)

Widerstand (nom.) 0,5 Ohm (Ein-Zustand)

Max. Leistung 15 W

Elektr. Kontakte Potentialfrei

Temperatur * -20°C bis +80°C

(-4°F bis +176°F)

* Falls das Steuermodul an explosionsgefähr-

deten Orten eingesetzt wird, entnehmen Sie

den gültigen Temperaturbereich der

Installationsanleitung in Kapitel 4.2.

QC03 - IS QC04 - IS-N

Stromversorgung:

Spannung 13,5 - 27,6 V 13,5 - 27,6 V

Max. Strom 68 mA 68 mA

Max. Leistung 1,2 W 1,2 W

Kapazität Ci (max.) 15 nF 15 n F

Induktivität Li 0 mH 0 mH

Steuersignal Eingang:

Spannung 6 -30 V 6 - 30 V

Max. Strom 5 mA 5 mA

Kapazität Ci (max.) 3,2 nF 3,2 nF

Induktivität Li 0 mH 0 mH

Kontakte Potentialfrei Potentialfrei

Ausgänge:

Max. Spannung 30 VDC IEC 60947-5-6

Max. Strom 32 mA IEC 60947-5-6

Widerstand (nom.) 440 Ohm 440 Ohm

Schalterwiderstand 300 kOhm 10,44 kOhm

(Aus-Zustand)

Max. Leistung 1,2 W IEC 60947-5-6

Elektr. Kontakte Potentialfrei IEC 60947-5-6

Temperatur * -20°C bis +122,00°F

(-4°F bis +122°F)

Polarität:

Abhängig Stromversorgung

Unabhängig Steuersignal +Rückmeldung

Umgebungsbedingungen:

Feuchtigkeit 0 bis 85% bei 25°C herabgesetzt auf 50% bei über 40°C (nichtkondensierend).

Höhe Voll funktionsfähig bis zu 2000 Meter.

Einsatzgebie t Innen und im Freien.

4.2 Elektrische Daten für den Einsatz

an explosionsgefährdeten Orten

Bitte prüfen Sie in den folgenden Kapiteln, welche

elektrischen Daten und Anleitungen gelten, falls

ein zugelassenes Steuermodul an einem

explosionsgefährdeten Ort eingesetzt wird:

Nicht zündgefährlich/nicht funkenbildend

- QC01 24VDC Kapitel 10

Eigensicher

- QC03 IS Kapitel 11

- QC04 IS-NAMUR Kapitel 12

20DOC.IG.QC01.1 Rev.: B December ‘06

Page 21

D

2

1

3

4.3 Drahtmaße

Massivdraht : 2,5mm2 max.

Litze : 0,2-3,3 mm2 oder 24-12

AWG

4.4 Werkzeuge

Werkzeug für Klemmen : Schraubendreher 0,6 x 3,5

Deckelschrauben : Schraubendreher für

Kreuzschlitzschrauben

Nr. 2

WARNUNG:

* Achten Sie darauf, dass Steuermodul und pneu-

matisches Modul nicht direkt mit magnetischem

Material in Kontakt kommen. Dies kann die

Stellungsrückmeldung beeinträchtigen oder

beschädigen.

* Falls das Steuermodul in einer vom Hersteller nicht

angegebenen Weise eingesetzt wird, kann der von

der Ausrüstung gebotene Schutz beeinträchtigt

werden.

* Erden Sie das Steuermodul gemäß Abb. 6.

4.5 Anschluss

1 Entfernen Sie den Deckel des Steuermoduls

(siehe Abb. 5).

2 Führen Sie das/die Kabel durch den/die

elektrischen Eingänge.

- Verwenden und montieren Sie Kabelverschraubungen entsprechend den nationalen

oder örtlichen Vorschriften.

- Für IP65 nutzen Sie die zugelassenen

Kabelverschraubungen.

3 Stellen Sie die elektrischen Anschlüsse

gemäß Abb. 7 oder 8 her.

- Beachten Sie bei Anschlüssen an

explosionsgefährdeten Orten die

Anweisungen in Kapitel 10 oder 11.

4 Schließen Sie den Deckel wieder (siehe

Abb. 5), oder fahren Sie fort mit Kapitel 5.

Achten Sie darauf, dass die Deckeldichtung

angebracht ist, um die Staub- und

Wasserdichtheit gemäß IP65/NEMA4X zu

gewährleisten.

SteuermodulT ypenschild

Klemmen

Status-LED

Abb. 5: Elektrischer Anschluss

Abb. 6 Erdung

Feldverdrahtung Geräteverdrahtung

1-2 Schalter 2

3-4 Schalter 1

5-6 Steuer-

spannung

7-8 Stromversor-

gungsspannung

0-30 VDC/VAC

15VA

0.5 A

max.

0-30 VDC/VAC

0.5 A

15VA

max.

24 VDC +/- 15%

24 VDC +/- 15%

max.

max.

1

2

3

4

5

6

-

7

+

8

Abb. 7: QC01 Elektrische Anschlüsse,

potenzialgetrennt

1-2 Schalter 2,

3-4 Schalter 1

5-6 Steuerung

7-8 Stromversor-

gungsspannung

Feldverdrahtung

0.5 A

max.

0.5 A

max.

24 VDC +/- 15%

15VA

15VA

max.

max.

Geräteverdrahtung

1

2

3

4

5

6

-

7

+

8

Abb. 8: QC01 Elektrische Anschlüsse,

gemeinsames Potenzial

21DOC.IG.QC01.1 Rev.: B December ‘06

Page 22

D

5 Initialisierung

5.1 Initialisierung

Bei der Initialisierung werden die Schaltpunkte für

die Stellungsrückmeldung des Stellantriebs

festgelegt. Dieser Vorgang wird automatisch vom

Modul ausgeführt, der Benutzer muss ihn jedoch

starten, und das Gerät muss wie in Kapitel 4

beschrieben verdrahtet sein.

WARNUNG:

* Während des Initialisierungsvorgangs führt der FieldQ

mehrere Zyklen durch.

* Prüfen Sie vor der Initialisierung, ob die „Auf“- und

„Zu“-Stellungen des FieldQ und der Armatur miteinander

übereinstimmen (siehe Kapitel 4 der Installations- und

Betriebsanleitungen des FieldQ, DOC.IOM.Q.E)

* Stellen Sie sicher, dass die Armatur nicht blockiert ist,

bevor die Initialisierungsroutine gestartet wird.

Taste „Geschlossen“

LED „Geschlos-

4 s

sen“

Status-LED

drücken

LED „Offen“

Taste „Offen“

ein

aus

ein

aus

Zeit

Abb. 9: Tasten (hinter dem Deckel).

Typisch

bei ca. 35°

Offen

Werkseitige Einstellungen Einstellung nach Initialisierung

Geschlossen

±40˚

±40˚

Abb. 10: Lage der Schaltpunkte

10˚

Schaltpunkte

max

LED = Blitzen

LED = Blinken

Offen

10˚

max

Geschlossen

5.2 Start der Initialisierung (siehe Abb. 9)

1 Die „Auf“- und „Zu“-Tasten gleichzeitig

4 Sekunden lang drücken.

2 Die Status-LED blinkt.

3 Der Stellantrieb öffnet und schließt zwei- oder

dreimal.

4 Am Ende der Routine leuchtet die Status-LED

konstant und bestätigt so den erfolgreichen

Verlauf der Initialisier ung.

5 Prüfen Sie, ob die aktuelle Armaturenposition

(offen oder geschlossen) auf dem Tastenfeld

angezeigt wird.

5.3 Fehlerbehebung

5.3.1 Wenn der automatische Initialisierungs-

vorgang nicht erfolgreich abgeschlossen

wurde (die Status-LED blitzt):

1 Den Versorgungsdruck prüfen.

2 Überprüfen Sie die Bauform des Stellantriebs

(siehe die Installations- und Betriebs-

anleitung des FieldQ DOC.IOM.Q.D)

3 Wiederholen Sie den automatischen

Initialisierungsvorgang.

4 Wenn innerhalb von 10 Sekunden keine

Bewegung stattfindet, wird der automatische

Initialisierungsvorgang nicht erfolgreich

abgeschlossen.

5 Um dieses Problem zu lösen,

- führen Sie das Verfahren zur „Standardeinstellung“ durch (siehe §5.3.5) und

wiederholen Sie den Initialisierungsprozess

(siehe §5.2), oder

- stellen Sie die Endschalterpunkte manuell

ein (siehe §5.3.4).

5.3.2 Wenn die Stellungsrückmeldung am

Tastenfeld umgekehrt ist:

1 Prüfen, ob der Stellantrieb ordnungsgemäß

auf der Armatur montiert ist. Wenn ja:

2 Die Taste, die der aktuellen Position des

Stellantriebs entspricht („Offen“ oder „Zu“)

3 Sekunden lang drücken.

3 Die entsprechende LED blitzt auf.

4 Taste freigeben und erneut drücken, bis die

LED konstant leuchtet, Status-LED zeigt an

„Init. erfolgreich“.

5 Der andere Schalter wird automatisch

geändert.

22DOC.IG.QC01.1 Rev.: B December ‘06

Page 23

D

5.3.3 Manuelle Schaltereinstellung:

Nach einer Veränderung der mechanischen

Anschläge entweder des Antriebs oder der

Armatur stimmen die Schaltpunkte nicht mehr.

Am einfachsten erfolgt die Neueinstellung der

Schaltpunkte mit der automatischen Initialisierung

(siehe §5.2).

Während der Initialisierung bewegt sich der

Stellantrieb zwei- oder dreimal. Wenn dies nicht

1 Prüfen, ob der Stellantrieb ordnungsgemäß

auf der Armatur montiert ist. Wenn ja:

2 Die Taste, die der aktuellen Position des

Stellantriebs entspricht („Offen“ oder „Zu“)

3 Sekunden lang drücken.

3 Die entsprechende LED blitzt auf.

4 Taste freigeben und erneut drücken, bis die

LED konstant leuchtet, Status-LED zeigt an

„Init. erfolgreich“.

zulässig ist, kann der neue Schaltpunkt mit

folgendem Verfahren eingestellt werden:

Tabelle 1: LED-Anzeigen

Status Status-LED-Aktion Öffnen/Schließen LED-Aktion

OK (Init. erfolgreich) Konstant ein Normaler Betrieb (Position wird von konstant leuchtender LED angezeigt)

Initialisierung Blinken (siehe Abb. 9) Normaler Betrieb

Init.-Fehler Blitzen (siehe Abb. 9) Normaler Betrieb

Init. Standard Blitzen (siehe Abb. 9) Aktivierte LED (abhängig von Position) blinkt

Warten auf Bestätigung Konstant ein Aktiviert durch blitzende Druckknopf-LED, andere LED ist aus

der Neuzuweisung

Identifizierung Blitzen für 300 Sek. Normaler Betrieb

Tabelle 2: Tastenfeldfunktionen

Aktion Tasten

Auf werkseitige Einstellung setzen Vor dem Einschalten beide Tasten drücken und halten, bis Status-LED konstant

leuchtet. Freigeben und beobachten, ob LEDs Standard anzeigen.

Initialisieren Während des Einschaltens beide Tasten drücken, bis Status-LED zu blinken

beginnt.

Neuzuweisung Endstellung „Offen“ Drücken Sie den „Auf“-Taste, bis die „Offen“-LED zu blitzen beginnt, geben Sie

die Taste frei und drücken sie erneut, bis die LED konstant leuchtet, Status-LED

zeigt an „Init. erfolgreich“.

Neuzuweisung Endstellung „Zu“ Drücken Sie die „Zu“-Taste, bis die „Schließen“-LED zu blitzen beginnt, geben

Sie die Taste frei und drücken Sie erneut, bis die LED konstant leuchtet, StatusLED zeigt an „Init. erfolgreich“.

23DOC.IG.QC01.1 Rev.: B December ‘06

Page 24

D

5.3.4 Manuelle Einstellung von

Endschalterpunkten

Wenn die automatische Initialisierung misslingt,

können die Schaltpunkte mit folgendem Verfahren

manuell eingestellt werden:

1 Den Stellantr ieb in die Position „Zu“ bringen

(siehe Kapitel 6 oder 8).

2 Drücken Sie die „Zu“-Taste auf dem Tasten-

feld für 3 Sekunden.

3 Die entsprechende LED blitzt auf.

4 Taste freigeben und erneut drücken, bis die

LED konstant leuchtet (Status-LED zeigt „OK“

an).

5 Bringen Sie den Stellantrieb in die „Offen“-

Stellung (siehe Kapitel 6).

6 Drücken Sie die „Auf“-Taste auf dem

Tastenfeld für 3 Sekunden.

7 Die entsprechende LED blitzt auf.

8 Taste freigeben und erneut drücken, bis die

LED konstant leuchtet (Status-LED zeigt „OK“

an).

5.3.5 „Werkseitige Standardeinstellungen“

mithilfe des Tastenfelds

So setzen Sie das Steuermodul auf die

werkseitigen Standardeinstellungen:

1 Die Stromversorgung muss gemäß Kapitel 4

angeschlossen sein und die Status-LED

leuchtet oder blitzt.

2 Unterbrechen Sie die Stromversorgung.

3 Drücken Sie beide Tasten.

4 Halten Sie die Tasten gedrückt und schließen

Sie die Stromversorgung wieder an.

5 Die Status-LED leuchtet.

6 Geben Sie beide Tasten frei.

7 Beobachten Sie, ob die Status-LED anzeigt,

dass die Einheit sich im Status „Init. Standard“

befindet (Blitzen). Die Einheit kann jetzt

initialisiert werden (siehe §5.2)

6 Funktionsprüfung

1 Schließen Sie die Stromversorgung an die

Klemmen 7 und 8 an.

2 Aktivieren Sie das Steuersignal mit den

Klemmen 5 und 6.

3 Der Stellantrieb geht in die „Offen“-Stellung.

4 Deaktivieren Sie das Steuersignal von den

Klemmen 5 und 6.

5 Der Stellantrieb geht in die „Zu“-Stellung.

6 Den Deckel des Steuermoduls am Gehäuse

anbringen (siehe Abb. 5).

24DOC.IG.QC01.1 Rev.: B December ‘06

Page 25

7 Wartung

Die FieldQ-Steuermodule sind für den

wartungsfreien Betrieb konzipiert. Weitergehende

Informationen finden Sie in der Installations- und

Betriebsanleitung des FieldQ, DOC.IOM.Q.E,

oder wenden Sie sich an Ihren FieldQ-Vertreter.

Installation, Justierung, Inbetriebnahme, Betrieb,

Montage, Demontage, Wartung und Reparatur

des Steuermoduls dürfen nur von entsprechend

qualifizierten Personen durchgeführt werden.

8 Optionale Steuerungen

8.1 Manuelle Steuerungsoptionen

(siehe Abb. 11)

Bei Inbetriebnahme, Notfällen oder zur Wartung

können manuelle Steuerungsoptionen auf den

FieldQ angewandt werden. Diese Optionen

können den Antrieb betreiben, wenn Luftdruck

verfügbar ist, aber kein Steuersignal oder keine

Stromversorgung.

1 „Push“-Version. Durch Drücken des

Federrückstellungsknopfes wird der Antrieb

betrieben. Bei Freigabe des Knopfes geht der

Antrieb in seine Ausgangsposition zurück.

2 „Push & Lock“-Version. Verwenden Sie zur

Anwendung dieser Version einen Schraubendreher. Drücken und drehen Sie ihn um 90°,

um ihn in der Position zu sperren, und halten

Sie den Antrieb in seinem Betriebszustand.

Mehrere Umdrehungen der Schraube sind

möglich. Das Gerät schaltet alle 90° um

zwischen „Offen“ (1) und „Geschlossen“ (0).

D

8.2 Geschwindigkeitssteuerungsoption

(siehe Abbildung 12).

Der FieldQ kann mit Geschwindigkeitssteuerungsoptionen geliefert werden. Es gibt zwei

Versionen dieser Option:

- Ein Weg

- Zwei Wege

Ausführliche Informationen zu diesen beiden

Geschwindigkeitssteuerungsversionen finden Sie

im Datenblatt 1.605.01 oder in der Anleitung

DOC.IOM.Q.E.

So stellen Sie die Geschwindigkeitssteuerungsoptionen ein:

1 Entfernen Sie die Abdeckkappe (1).

2 Durch Drehen der Einstellschraube im

Uhrzeigersinn wird die Geschwindigkeit

verringert.

3 Durch Drehen der Einstellschraube gegen

den Uhrzeigersinn wird die Geschwindigkeit

gesteigert.

4 Bringen Sie die Abdeckkappe wieder an.

9 Zugehörige Informationen

Zu den sonstigen Dokumenten mit Informationen

über das FieldQ-Modul gehören:

- 1.604.011 FieldQ Smart

Steuermodul-Datenblätter

- DOC.IOM.Q.D Installations-, Betriebs- und

Wartungsanleitung

Diese Dokumente stehen unter

www.FieldQ.com in verschiedenen Sprachen

zum Herunterladen zur Verfügung.

„Push“ „Push & Lock“

1

1

0

2 (90˚)

Abb. 11 Manuelle Steuerungsoptionen

1

0

1

1 = „gesperrt“

0 = „entsperrt“

1

Abb. 12 Einsatz der Geschwindigkeitssteuerung

25DOC.IG.QC01.1 Rev.: B December ‘06

Page 26

D

10 QC01 Intelligente Module – nicht zündgefährlich/nicht funkenbildend

10.1 Produktkennzeichnung

Typenschild

Klemmen

Im stromführenden Zustand

nicht öffnen

Abb. 13. Produktkennzeichnung

ATEX Gefährdeter oder klassifizierter

KEMA 02ATEX1258X

Ta = -20°C…+75°C (-4°F…167°F)

APPROVED

Nicht zündgefährlich, Class I, II, III, Div.2,

Gruppe ABCDFG T4, Typ 4X/IP65

Klasse I, Zone 2, IIC T4

Ta = -20°C…+75°C (-4°F…167°F)

Bereich

II 3 GD EEx nA II T4 T90°C IP65

Gefährdeter oder klassifizierter

Bereich

10.2 ATEX – Vorgesehener

Verwendungszweck

• Der FieldQ gehört zu Gruppe II Kategorie 3.

• Er ist zur Verwendung in Bereichen

vorgesehen, in denen durch Gemische von

Luft und Gasen, Dämpfen, Dünsten oder Luft/

Stäuben hervorgerufene explosionsgefährdete Atmosphären auftreten können.

• Dieser Antr ieb kann daher in den (ATEX)

klassifizierten Zonen 2 (Gase) und/oder 22

(Staub) verwendet werden.

10.3 Sicherheitshinweise

• Modul im stromführenden Zustand nicht

öffnen.

• Verhindern Sie während der Installation, der

Justierung, der Inbetriebnahme und des

Betriebs jegliche Art von Funkenbildung.

• Montage, Demontage und Wartung müssen in

sicheren, nicht explosionsgefährdeten

Bereichen durchgeführt werden.

• Installation, Justierung, Inbetriebnahme,

Betrieb, Montage, Demontage und Wartung

des pneumatischen Antriebs dürfen nur von

entsprechend qualifizierten Personen

durchgeführt werden.

Gefährdeter oder klassifizierter

Bereich

Nicht zündgefährlich: Klasse I, II, III, Div.2,

Gruppen ABCDFG, T4

Ex nA II T4 (Klasse I, Zone 2)

Ta = -20°C…+75°C (-4°F…167°F)

26DOC.IG.QC01.1 Rev.: B December ‘06

Page 27

10.4 Verdrahtungsanleitung QC01 –

nicht zündgefährliche/nicht funkenbildende Steuermodule

D

Klemmenanschlüsse, mit

separaten Schaltkreisen

1-2 Schalter 2

3-4 Schalter 1

5-6 Steuer-

spannung

7-8 Stromversorgungs-

spannung

Klemmenanschlüsse,

mit allgemeinen „-“

1-2 Schalter 2

3-4 Schalter 1

5-6 Steuerung

7-8 Stromversorgungs-

spannung

Nicht klassifizierter oder

nicht gefährdeter Bereich

0-30 VDC/VAC

15VA

0.5 A

max.

0-30 VDC/VAC

0.5 A

15VA

max.

24 VDC +/- 15%

24 VDC +/- 15%

0.5 A

15VA

max.

0.5 A

15VA

max.

24 VDC +/- 15%

Gefährdeter oder

klassifizierter Bereich

max.

max.

1

2

3

4

5

6

-

7

+

8

max.

1

2

max.

3

4

5

6

-

7

+

8

Zertifiziertes Dokument:

Ohne Erlaubnis der zertifizierenden Behörde sind keine Änderungen zulässig.

Format :

Drn.:

Scale :

A4

Title :

Control Drawing FieldQ

QC01 Intelligente Module – nicht

zündgefährlich/nicht funkenbildend

Home page:

Drw nr.

www.FieldQ.com

27DOC.IG.QC01.1 Rev.: B December ‘06

C0542-01 A

ENOC nr.:

State :

Date :

Date :

Rev. :

Par. :

Page 28

D

11 QC03 eigensicher

11.1 Produktkennzeichnung

SteuermodulT ypenschild

Klemmen

Abb. 14. Produktkennzeichnung

ATEX Gefährdeter oder klassifizierter

KEMA 02ATEX1242X

Ta = -20°C…+122,00°F (-4°F…122°F)

APPROVED

Eigensicher, Klasse I, II, III, Div.1,

Gruppen ABCDEFG T4, Typ 4X/IP65

Klasse I, Zone 0, AEx ia IIC T4, IP65,

Ta = -20°C…+122,00°F (-4°F…122°F)

Eigensicher, Klasse I, II, III, Div.1,

Gruppen ABCDEFG, T4

Ex ia IIC T4, IP65, (Klasse I, Zone 0/1)

Ta = -20°C…+122,00°F (-4°F…122°F)

Bereich

0344

II 1 GD Ex ia IIC T4 T80°C IP65

Gefährdeter oder klassifizierter Bereich

Gefährdeter oder klassifizierter Bereich

11.2 ATEX – Vorgesehener

Verwendungszweck

Der FieldQ ist ein Gerät der Gruppe II, Kategorie 3

und konzipiert für den Einsatz in Gebieten, in denen

explosionsgefährdete Atmosphären durch Mischungen von Luft und Gasen, Dämpfen oder Nebeln oder

Luft-/Staubmischungen wahrscheinlich sind.

Dieser Antrieb kann daher in den (ATEX) klassifizierten Zonen 1, 2 (Gase) und/oder 21, 22

(Staub) verwendet werden.

11.3 Spezielle Bedingungen für sicheren

Einsatz (A TEX)

Das Material für das Steuermodulgehäuse ist eine

Aluminiumlegierung. Wird die Einheit in potenziell explosionsgefährdeten Bereichen verwendet, in denen

ATEX-Ausrüstung der Kategorie 1 G erforderlich ist,

muss die Einheit so installiert werden, dass auch bei

seltenen Zwischenfällen das Entstehen von Funkenquellen aufgrund von Schlägen oder Reibung zwischen dem Gehäuse und Eisen/Stahl verhindert wird.

Für Anwendungen in durch Luft-/Staubmischungen

verursachten explosionsgefährdeten Atmosphären,

wo Geräte der Kategorie 1D erforderlich sind, wurde

die Oberflächentemperatur für eine maximal 5 mm

dicke Staubschicht bestimmt.

11.4 Dielektrische Durchschlagsfestigkeit

Das Steuermodul QC03 erfüllt die Anforderungen

für dielektrische Durchschlagsfestigkeit gemäß

IEC- 60079-11.

QC03 Eigensichere Einheit Parameter

Schaltkreis Klemme Ui Ii Pi Ci Li

Stromversorgung 7-8 30 VDC 300 mA 1,2 W 15 nF 0

Steuerung Eingang 5-6 30 VDC 300 mA 1,2 W 15 nF 0

Schalter 1 3- 4 30 VDC 300 mA 1,2 W 18 nF 0

Schalter 2 1- 2 30 VDC 300 mA 1,2 W 18 nF 0

28DOC.IG.QC01.1 Rev.: B December ‘06

Page 29

11.5 Verdrahtungsanleitung QC03

eigensicher

Klemmenanschlüsse, mit

separaten Schaltkreisen

1-2 Schalter 2

3-4 Schalter 1

5-6 Steuer-

spannung

7-8 Stromversorgungs-

spannung

Klemmenanschlüsse,

Minimale Betriebswerte:

- Steuerung:

Umin = 6 VDC

Imin = 1 mA

- Stromversorgung:

Umin = 13,5 VDC

Imin = 33 mA

Kabelbereich:

Drahtbereich: 2,5mm2 max.

Massiv-/Litzendraht: 0,2-3,3 mm2 oder

24-12 AWG

mit allgemeinen „-“

1-2 Schalter 2

3-4 Schalter 1

5-6 Steuerung

7-8 Stromversorgungs-

spannung

Nicht klassifizierter oder

nicht gefährdeter Bereich

IS-Barriere

IS-Barriere

IS-Barriere

IS-Barriere

IS-Barriere

Gefährdeter oder

klassifizierter Bereich

1

2

3

FieldQ-

4

Elektronik-

modul

5

QC03

6

-

7

+

8

1

2

3

FieldQ-

4

Elektronik-

modul

5

QC03

6

-

7

+

8

D

Hinweise: CSA FM ATEX

1 Installation muss

übereinstimmen mit:

2 Vor dem Betrieb:

Barriere: Benötigt FM/CSA-Zulassung und mus s in einem Gehäuse

3

4 Eigensicheres Gerät: Benötigt CSA-Zulassung Benötigt FM-Zulassung Benötigt ATEX-Zulassung

Bedingungen für Barriere:

5

6 Bei Verwendung mehrerer

Barrieren:

Canadian Electrical Code,

Part1

Das Elektronikmodul muss in Kombination mit dem pneumatischen Modul richtig montiert sein.

gemäß ANSI/ ISA S82.01/CEC Part1 installiert sein.

Das an den Begrenz er angeschlossene Steuergerät darf nicht

mehr als 250 Vrms oder Vdc verwenden oder erzeugen.

Uo =< U i Io =< Ii Po =< Pi

Co >= Ci + Kabel Lo >= Li + Kabel

* Jeder I.S.-Schaltkreis kann mit abgeschirmtem und/oder Twisted Pair-Kabel angeschlossen

werden

* Kabelisolierung/-abschirmung muss in geteilte Bereiche von Anschlüssen hineinreichen

Zertifiziertes Dokument:

Ohne Erlaubnis der zertifizierenden Behörde sind keine Änderungen zulässig.

National Electrical Code

(ANSI/NFPA 70) und ANSI/ISA

RP12.06.01

Format :

Drn.:

A4

Title :

Control Drawing FieldQ

QC03 Intelligente Module eigensicher

Home page:

www.FieldQ.com

Drw nr.

Die im Anwendungsland

übliche Verdrahtung

Muss von einer benannten

europäischen Institution

zertifiziert und nach Anleitung

des Herstellers installiert sein.

Scale :

ENOC nr.:

State :

C0542-06

Date :

27/06/2006

29DOC.IG.QC01.1 Rev.: B December ‘06

Date :

Rev. :

Par. :

A

Page 30

D

12 QC04 eigensicher Namur

12.1 Produktkennzeichnung

SteuermodulT ypenschild

Klemmen

Abb. 14. Produktkennzeichnung

ATEX Gefährdeter oder klassifizierter Bereich

0344

II 1 GD Ex ia IIC T4 T80°C IP65

KEMA 02ATEX1242X

Ta = -20°C…+122,00°F (-4°F…122°F)

APPROVED

Eigensicher, Klasse I, II, III, Div.1,

Gruppen ABCDEFG T4, Typ 4X/IP65

Klasse I, Zone 0, AEx ia IIC T4, IP65,

Ta = -20°C…+122,00°F (-4°F…122°F)

Eigensicher, Klasse I, II, III, Div.1,

Gruppen ABCDEFG, T4

Ex ia IIC T4, IP65, (Klasse I, Zone 0/1)

Ta = -20°C…+122,00°F (-4°F…122°F)

12.2 ATEX – Vorgesehener

Das Steuermodul QC04..P1.. des pneumatischen

Stellantriebs FieldQ ist ein Gerät der Gruppe II,

Kategorie 1 und konzipiert für den Einsatz in

Gebieten, in denen explosionsgefährdete Atmosphären durch Mischungen von Luft und Gasen,

Dämpfen oder Nebeln oder Luft-/Staubmischungen wahrscheinlich sind.

Gefährdeter oder klassifizierter Bereich

Gefährdeter oder klassifizierter Bereich

Verwendungszweck

Das pneumatische Antriebsteil ist zusammen mit

dem pneumatischen Modulteil des pneumatischen Antriebs FieldQ ein Gerät der Gruppe II,

Kategorie 2 und konzipiert für den Einsatz in

Gebieten, in denen explosionsgefährdete Atmosphären durch Mischungen von Luft und Gasen,

Dämpfen oder Nebeln oder Luft-/Staubmischungen wahrscheinlich sind.

Dieser Antrieb kann daher in den (ATEX) klassifizierten Zonen 1, 2 (Gase) und/oder 21, 22

(Staub) verwendet werden.

12.3 Spezielle Bedingungen für sicheren

Einsatz (A TEX)

Das Material für das Steuermodulgehäuse ist

eine Aluminiumlegierung. Wird die Einheit in potenziell explosionsgefährdeten Bereichen verwendet,

in denen ATEX-Ausrüstung der Kategorie 1 G

erforderlich ist, muss die Einheit so installiert

werden, dass auch bei seltenen Zwischenfällen

verhindert wird, dass Funkenquellen aufgrund

von Schlägen oder Reibung zwischen dem

Gehäuse und Eisen/Stahl entstehen.

Für Anwendungen in durch Luft-/Staubmischungen verursachten explosionsgefährdeten

Atmosphären, wo Geräte der Kategorie 1D

erforderlich sind, wurde die Oberflächentemperatur für eine maximal 5 mm dicke Staubschicht

bestimmt.

12.4 Dielektrische

Durchschlagsfestigkeit

Steuermodul QC04 erfüllt die Anforderungen für

dielektrische Durchschlagsfestigkeit gemäß IEC60079-11

QC03 Eigensichere Einheit Parameter

Schaltkreis Klemme Ui Ii Pi Ci Li

Stromversorgung 7-8 30 VDC 300 mA 1,2 W 15 nF 0

Steuerung Eingang 5-6 30 VDC 300 mA 1,2 W 15 nF 0

Schalter 1 3- 4 30 VDC 300 mA 1,2 W 18 nF 0

Schalter 2 1- 2 30 VDC 300 mA 1,2 W 18 nF 0

30DOC.IG.QC01.1 Rev.: B December ‘06

Page 31

12.5 Verdrahtungsanleitung QC04

eigensicher Namur

Minimale Betriebswerte:

- Steuerung:

Umin = 6 VDC

Imin = 1 mA

- Stromversorgung:

Umin = 13,5 VDC

Imin = 33 mA

Kabelbereich:

Drahtbereich: 2,5mm2 max.

Litze: 0,2-3,3 mm2 oder

Hinweis:

24-12 AWG

* Verwenden Sie zugelassene

Barrieren gemäß

EN60947-5-6 (NAMUR) für

einen angemessenen

Signalpegel. Un = 8,2 VDC

Klemmenanschlüsse, mit

separaten Schaltkreisen

1-2 -Schalter 2*

(EN60947-5-6)

3-4 Schalter 1*

(EN60947-5-6)

5-6 Steuer-

spannung

7-8 Stromversorgungs-

spannung

Klemmenanschlüsse,

mit allgemeinen „-“

1-2 Schalter 2*

3-4 Schalter 1*

5-6 Steuerung

7-8 Stromversorgungs-

spannung

Nicht klassifizierter oder nicht

gefährdeter Bereich

IS-Barriere

IS-Barriere

IS-Barriere

IS-Barriere

IS-Barriere

IS-Barriere

IS-Barriere

Gefährdeter oder

klassifizierter Bereich

1

FieldQ-

2

Steuermodul

3

QC04

4

5

6

-

7

+

8

1

FieldQ-

2

Steuer-

3

modul

QC04

4

5

6

-

7

+

8

D

Hinweise: CSA FM ATEX

1 Installation muss

übereinstimmen mit:

2 Vor dem Betrieb:

3

Barriere: Benötigt FM/CSA-Zulassung und mus s in einem Gehäuse

4 Eigensicheres Gerät: Benötigt CSA-Zulassung Benötigt FM-Zulassung Benötigt ATEX-Zulassung

5

Bedingungen für Barriere:

6 Bei Verwendung mehrerer

Barrieren:

Canadian Electrical Code,

Part1

Das Elektronikmodul muss in Kombination mit dem pneumatischen Modul richtig montiert sein.

gemäß ANSI/ ISA S82.01/CEC Part1 installiert sein.

Das an den Begrenz er angeschlossene Steuergerät darf nicht

mehr als 250 Vrms oder Vdc verwenden oder erzeugen.

Uo =< U i Io =< Ii Po =< Pi

Co >= Ci + Kabel Lo >= Li + Kabel

* Jeder I.S.-Schaltkreis kann mit abgeschirmtem und/oder Twisted Pair-Kabel angeschlossen

werden

* Kabelisolierung/-abschirmung muss in geteilte Bereiche von Anschlüssen hineinreichen

Zertifiziertes Dokument:

Ohne Erlaubnis der zertifizierenden Behörde sind keine Änderungen zulässig.

National Electrical Code

(ANSI/NFPA 70) und ANSI/ISA

RP12.06.01

Format :

Drn.:

A4

Title :

Control Drawing FieldQ

QC 04 Intelligente Module eigensicher

Home page:

www.FieldQ.com

Drw nr.

Die im Anwendungsland

übliche Verdrahtung

Muss von einer benannten

europäischen Institution

zertifiziert und nach Anleitung

des Herstellers installiert sein.

Scale :

ENOC nr.:

State :

C0542-07

Date :

27/06/2006

31DOC.IG.QC01.1 Rev.: B December ‘06

Date :

Rev. :

Par. :

A

Page 32

D

13 EC Konformitätserklärung

Asveldweg 11

7556 BR, HENGELO

Niederlande

KONFORMITÄTSERKLÄRUNG DER EG (EC DECLARATION OF CONFORMITY)

- MASCHINENRICHTLINIE 98/37/EC, Anhang IIb - Richtlinie Niederspannung 73/23/EC

- EMC Richtlinie 89/336/EC, Anhang 1 - ATEX Richtlinie 94/9/EC

Hiermit erklären wir, dass die unten spezifizierten Produkte den grundlegenden Gesundheitsund Sicherheitsbestimmungen der oben erwähnten europäischen Richtlinien entsprechen.

Bevor das Steuermodul in Betrieb genommen wird, muss die Maschine, in oder auf der das

Steuermodul installiert wird, den Anforderungen der Maschinenrichtlinie entsprechen.

Produktbeschreibung : FieldQ-Steuermodul

Seriennummer : Jedes Steuermodul verfügt über eine identifizierbare Seriennummer.

Konstruktionsjahr : Jedes Steuermodul besitzt eine identifizierbare Angabe des Konstruktionsjahrs.

ATEX-RICHTLINIE

Typen : QC01...P4... , QC02...P4... , QC30...P4... und QC34...P4...

ATEX-Zertifikatsnr. : KEMA 02ATEX1258X

Bezeichnung QC01 & QC30 :

QC02 :

QC34 :

QC34 :

Anwendbare Standards : EN 60079-0 : 2004 EN 60079-15 : 2003

Typen : QC03...P1..., QC04...P1... und QC34...P1...

ATEX-Zertifikatsnr. : KEMA 02ATEX1242X,

Bezeichnung :

Anwendbare Standards : EN 60079-0 : 2004 EN 60079-11 : 1999 EN 60079-26: 2004

Gemeldetes Gehäuse : KEMA Quality B.V., Gemeldetes Gehäuse Nr.: 0344

EMC-, LVD- und Maschinenrichtlinie

Typen : QC01..., QC02..., QC03..., QC04..., QC30..., QC34...,

Anwendbare Standards : IEC61326-1 :1998 NAMUR-Empfehlungen: NE21

Typen : QC02...WP...

Anwendbare Standards : IEC61010-1 : 2004

Hinweis : Die oben aufgelisteten ATEX-zertifizierten Produkte sind von der

Herausgegeben in Übereinstimmung mit der

II 3 GD EEx nA II T4 T90°C, IP65 Ta = -20°C ... +75°C

II 3 GD EEx nA II T4 T90°C, IP65 Ta = -20°C ... +73°C

II 3 GD EEx nA II T4 T90°C, IP65 Ta = -20°C ... +50°C

II 3 GD EEx nL IIC T4 T80°C, IP65 Ta = -20°C ... +50°C

IEC 61241-0 : 2004 EN 61241-1 : 2004

II 1 GD EEx ia IIC T4 T80°C

EN 60079-27 : 2005 EN 50020 : 2002 IEC 61241-0 : 2004

EN 61241-1 : 2004 EN 50014 : 1997 EN50284 : 1999

Utrechtseweg 310, 6812 AR Arnheim, Niederlande

Niederspannungsrichtlinie ausgenommen.

TM

Unterzeichnet : _____________________________

Name : D.L.Farr

Funktion : Vice President Operations - Emerson Valve Automation

Datum : 4. Oktober 2006

32DOC.IG.QC01.1 Rev.: B December ‘06

Page 33

D

33DOC.IG.QC01.1 Rev.: B December ‘06

Page 34

F

1 Modules de contrôle applicables

QC01 - 24 V CC

QC01 - 24 V CC non incendiaire ou

anti-étincelant

QC03 - IS Sécurité intrinsèque

QC04 - IS-NAMUR Sécurité intrinsèque avec

feedback de positionnement

NAMUR

2 Considérations préalables

* Avant de connecter l’alimentation d’air et le

circuit électrique, vérifiez que l’actionneur est

monté correctement sur la soupape

(consultez Actionneur de soupape FieldQ :

manuel d’installation et de

fonctionnement, DOC.IOM.Q.F).

* Vérifiez la procédure sur l’étiquette du module

(voir la figure 2)

* Vérifiez le type d’actionneur : simple effet ou

double effet (voir la figure 2).

OK

OK

Fig. 1 : Vérifiez le montage avant de connecter

l’alimentation d’air et le circuit électrique.

Étiquette du type de module de contrôle =

QC01..WP .. = 24V CC

QC01..P4.. = 24V CC non incendiaire /

OK

QC03..P1.. = Sécurité intrinsèque

QC04..P1.. = Sécurité intrinsèque avec feed-

OK

Étiquette du type d’actionneur =

QS xxxx = simple effet (à rappel ressort)

QD xxxx = double effet

anti-étincelant

back de positionnement NAMUR

Fig. 2 Identification

34DOC.IG.QC01.1 Rev.: B December ‘06

Page 35

3 Raccordements pneumatiques

F

IMPORTANT

* L’assemblage actionneur/v anne peut se déplacer une

fois alimenté en air.

* Vérifiez que le module pneumatique et le module de

contrôle sont correctement montés sur l’actionneur

pour atteindre un niveau de protection en entrée IP65

/ NEMA4X avant de connecter l’alimentation d’air .

* Vérifiez la pression maximale P

116 psi.

* Assurez-vous que la pression d’alimentation

minimale requise pour l’application est disponible

au niveau de l’actionneur.

* La condensation ou l’humidité qui pénètre dans

l’actionneur, le module pneumatique ou le module de

contrôle peut endommager certains composants et

entraîner des erreurs. Nous vous recommandons

vivement d’installer des anneaux d’écoulement dans

les câbles des tuyaux (voir la figure 4).

* Les orifices de ventilation du module pneumatique

(voir la figure 3) sont équipés, en standard, de

silencieux/filtres IP65 / NEMA4X.

* Si une protection en entrée IP65 / NEMA4X est

requise, les orifices d’échappement Ra et Rb et les

entrées électriques doivent être équipés de

dispositifs IP65 / NEMA4X ou supérieurs.

= 8 bars /

max.

3.1 Milieu d’exploitation :

* Air ou gaz inertes.

* QC01, air filtré à 50 microns.

QC03 et QC04, air filtré à 25 microns.

* Point de rosée : 10 K sous la température

d’exploitation.

* Prenez les mesures qui s’imposent pour les

applications destinées à des températures

inférieures à 0 °C.

3.2 Actionneur simple effet (à rappel

ressort) ou double effet :

1 Enlevez le bouchon de l’alimentation d’air (Ps).

2 Connectez l’alimentation d’air à l’orifice (Ps).

Simple

effet

Orifices de

ventilation

Couvercle du

module de

contrôle

Rb

Ps

1/4”BSP ou 1/4”NPT

Double

effet

Ra

Rb

Ps

1/4”BSP ou 1/4”NPT

Fig. 3 : Raccordements pneumatiques

OK

Fig. 4 Installer des anneaux d’écoulement

35DOC.IG.QC01.1 Rev.: B December ‘06

Page 36

F

4 Connexions électriques

4.1 Données électriques des modules de contrôle

QC01 - 24V CC

Entrée d’alimentation :

Tension 24V CC (±15 %)

Courant maximal 125 mA

Alimentation (nom.) 2,5 W

Entrée du signal de commande :

Tension 24V CC (±15 %)

Courant maximal 5 mA max.

Contacts Exempts de potentiel

Sorties de feedback :

Tension 0-30 V CC

CC 500 mA (maximum)

1 mA (min. recommandé)

Résistance (nom.) 0,5 Ohm (état passant)

Alimentation max. 15 W

Contacts électriques Exempts de potentiel

Température * de -20 °C à +80 °C

(-4 °F à +176 °F)

* Si les modules de contrôle sont utilisés dans

des lieux à risque, consultez les schémas de

contrôle du chapitre 4.2 pour connaître la

plage de températures applicable.

Entrée d’alimentation :

Tension 13.5 - 27,6 V 13.5 - 27,6 V

Courant maximal 68 mA 68 mA

Alimentation max. 1,2 W 1,2 W

Capacité Ci (max.) 15 nF 15 nF

Inductance Li 0 mH 0 mH

Entrée du signal de commande :

Tension 6 - 30 V 6 - 30 V

Courant maximal 5 mA 5 mA

Capacité Ci (max.) 3,2 nF 3,2 nF

Inductance Li 0 mH 0 mH

Contacts Exempts de potentiel Exempts de potentiel

Sorties de feedback :

Tension maximale 30 V CC IEC 60947-5-6

Courant maximal 32 mA IEC 60947-5-6

Résistance (nom.) 440 Ohms 440 Ohms

Résistance à 300 KOhms 10440 Ohms

commutateur (état bloqué)

Alimentation max. 1,2 W IEC 60947-5-6

Contacts électriques Exempts de potentiel IEC 60947-5-6

Température * de -20 °C à +50 °C

QC03 - IS QC04 - IS-N

(-4 °F à +122 °F)

Polarité :

Dépendante Alimentation

Indépendante Signal de commande + commutateurs de réaction

Conditions d’environnement :

Humidité 0 à 85 % à 25 °C (+77 °F) passe à 50 % au-dessus de 40 °C (104 °F) (sans condensation).

Altitude Pleine puissance de fonctionnement disponible jusqu’à 2 000 mètres (6 000 pieds).

Utilisation Intérieur et extérieur.

4.2 Données électriques pour les exécutions

dans des zones dangereuses

Consultez les chapitres suivants pour connaître les données

électriques et instructions à suivre lorsqu’un module de

contrôle approuvé est utilisé dans un lieu à risque :

non incendiaire / anti-étincelant

- QC01 24V CC Chapitre 10

Sécurité intrinsèque

- QC03 IS Chapitre 11

- QC04 IS-NAMUR Chapitre 12

36DOC.IG.QC01.1 Rev.: B December ‘06

Page 37

2

1

3

4.3 Dimensions du câblage

Câble solide : 2,5 mm2 max.

Câble toronné : 0,2-3,3 mm2 ou 24-12

AWG (calibre américain

des fils)

4.4 Outils

Outil pour les bornes : Tournevis 0,6 x 3,5

Outil pour les vis du : Tournevis pour vis

couvercle à tête cruciforme de type

Philips n° 2

ATTENTION :

* Ne placez pas le module de contrôle et le module

pneumatique en contact direct avec du matériel

magnétique. Le feedback de positionnement pourrait

s’en trouver endommagé ou déréglé.

* Si le module de contrôle est utilisé d’une façon qui

n’a pas été indiquée par le fabricant, la protection

fournie par l’équipement peut être affectée.

* Si nécessaire, montez un fil de mise à la terre (1)

entre la bague supérieure (2) et la bague inférieure