Page 1

SimplIQ for Steppers

SimplIQ for Steppers

SimplIQ for SteppersSimplIQ for Steppers

Getting Started &

Tuning and Commissioning

Guide

Ver 1.1 - June 2009

Page 2

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Notice

This guide is delivered subject to the following conditions and restrictions:

This guide contains proprietary information belonging to Elmo Motion

Control Ltd. Such information is supplied solely for the purpose of assisting

users of the Bell servo drive in its installation.

The text and graphics included in this manual are for the purpose of

illustration and reference only. The specifications on which they are based

are subject to change without notice.

Elmo Motion Control and the Elmo Motion Control logo are trademarks of

Elmo Motion Control Ltd.

Information in this document is subject to change without notice.

Document No. MAN-BELGS

Copyright 2009

Elmo Motion Control Ltd.

All rights reserved

2

Revision History:

Ver. 1.0 January 2008 (MAN-BELIG.PDF)

Ver 1.1 June 2009

Elmo Motion Control Ltd.

64 Gisin St., P.O. Box 463

Petach Tikva 49103

Israel

Tel: +972 (3) 929-2300

Fax: +972 (3) 929-2322

info-il@elmomc.com

Elmo Motion Control Inc.

42 Technology Way

Nashua, NH 03060

USA

Tel: +1 (603) 821-9979

Fax: +1 (603) 821-9943

info-us@elmomc.com

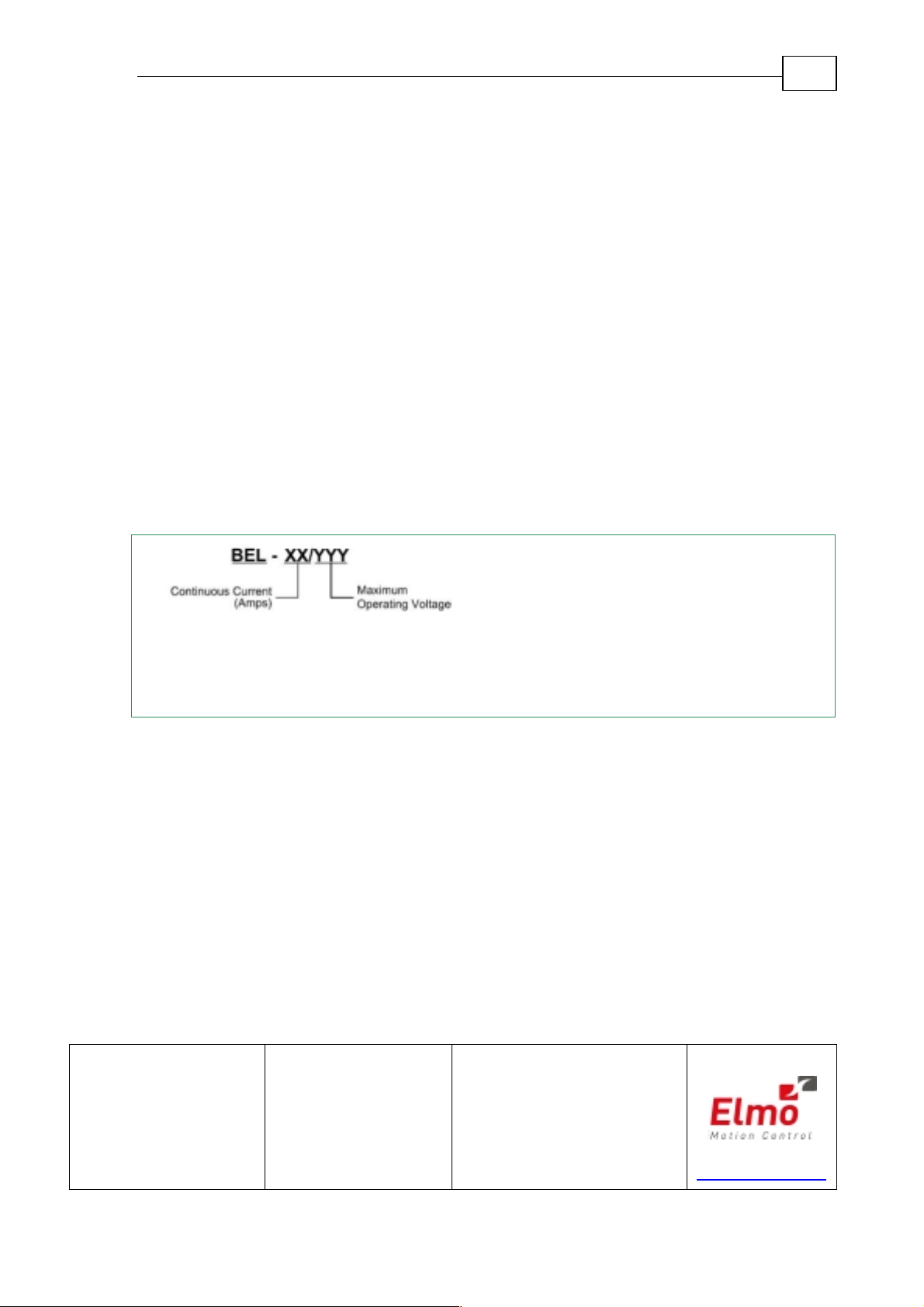

The model that is currently available is the

BEL-5/100.

Elmo Motion Control GmbH

Steinkirchring 1

D-78056, Villingen-Schwenningen

Germany

Tel: +49 (0) 7720-85 77 60

Fax: +49 (0) 7720-85 77 70

info-de@elmomc.com

www.elmomc.com

Page 3

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Contents

Chapter 1:Introduction...............................................................................................................5

1.1 Qualified Personnel....................................................................................................7

1.2 Working with this Document....................................................................................7

Chapter 2:Elements ...................................................................................................................8

2.1 Establishing Communication with a Drive..............................................................8

2.1.1 Changing the Communication Parameters.......................................................................11

2.2 Application Parameters and Programming...........................................................13

2.2.1 Flash, RAM and Tables.........................................................................................................13

2.2.2 Creating an Application File................................................................................................14

2.2.3 Downloading an Application File.......................................................................................14

2.2.4 Observing the Contents and Editing an Application File................................................15

2.3 Firmware....................................................................................................................15

2.3.1 Version Verification..............................................................................................................15

2.3.2 Normal Firmware Download..............................................................................................16

2.3.3 Abnormal (from Boot) Firmware Download.................................................................... 16

3

2.4 The Conductor Wizard.............................................................................................17

2.4.1 The Conductor Tabs..............................................................................................................17

2.4.2 The Expert List.......................................................................................................................18

2.4.3 Accepting a Change of Parameters..................................................................................... 20

Chapter 3:Getting Started with Sensors and Motion Control Setup................................21

3.1 Introduction...............................................................................................................21

3.1.1 Tune the Drive to the Motor................................................................................................21

3.1.2 Tune the Motion Controller.................................................................................................21

3.1.3 Database Maintenance..........................................................................................................21

3.2 Abort and Enable Switches......................................................................................21

3.2.1 Brakes......................................................................................................................................22

3.2.2 Application Limits ................................................................................................................23

3.3 Set up the Sensors.....................................................................................................25

3.3.1 Setting up Sensor #1............................................................................................................. 26

3.4 Tuning the Drive to the Motor.................................................................................27

3.4.1 Selecting the Motor Type..................................................................................................... 28

3.4.2 Tuning or Checking the Current Control.......................................................................... 29

3.5 Commutation.............................................................................................................30

3.6 Motion Tuning...........................................................................................................32

3.6.1 Torque Drive..........................................................................................................................32

3.6.2 Stepper Drives with no Commutation Sensor...................................................................33

3.6.3 Speed and Position Control.................................................................................................35

3.7 Fine Tuning................................................................................................................45

3.7.1 Cogging Compensation........................................................................................................45

3.7.2 Fine Tuning an Analog Encoder.........................................................................................49

3.8 Database Maintenance..............................................................................................51

Page 4

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Chapter 4:Advanced Control Tuning.....................................................................................52

4.1 Start Step Control......................................................................................................52

4.2 Identification.............................................................................................................52

4.2.1 Identification and Uncertainty............................................................................................53

4.2.2 Identification Results Management....................................................................................53

4.2.3 Identification Work Point.....................................................................................................54

4.2.4 Selecting the Identification Frequencies.............................................................................55

Appendix A: Manual Tuning of Speed and Position Control....................................60

A.1 Scope...........................................................................................................................60

A.2 Safety..........................................................................................................................60

A.3 Make it Simple...........................................................................................................61

A.4 Keep Margins............................................................................................................62

A.5 The Basic Concepts...................................................................................................62

A.5.1 Fixed- vs. Gain-scheduled Controllers...............................................................................62

A.5.2 Resonance and Notch Filters...............................................................................................63

A.5.3 High Frequency Noise and Low-pass Filters....................................................................63

A.5.4 Evaluating a Step Response – Rise Time, Settling Time, and Overshoot...................... 64

4

A.6 The Example System.................................................................................................65

A.7 Testing the Response of a Controller......................................................................66

A.7.1 Current Limits .......................................................................................................................66

A.7.2 Recording the Experiment Results......................................................................................66

A.8 Fixed Gain Manual Tuning for a Speed Loop........................................................67

A.8.1 Manual Tuning of a PI Controller....................................................................................... 67

A.8.2 Manual Tuning of a PI Controller and a Low Pass Filte r ................................................72

A.8.3 Manual Tuning of a PI Controller and a Notch Filter......................................................74

A.9 Executing Manual Tuning for a Cascaded Position Controller............................78

A.10 Manual Tuning of Gain Scheduling........................................................................79

A.10.1 Manual Gain Scheduling......................................................................................................79

A.10.2 Automatic Gain Scheduling................................................................................................. 80

Appendix B: A Short Course in Linear Control............................................................82

B.1 Linear Systems and Transfer Functions..................................................................82

B.2 Mathematical Models for LTI Systems...................................................................83

B.3 Motor Systems Models.............................................................................................85

B.3.1 A Simple Model ..................................................................................................................... 85

B.3.2 Model with Flexible Transmission (resonance) ................................................................86

B.4 Feedback Control......................................................................................................90

B.4.1 Why Feedback is Required ..................................................................................................90

B.4.2 Open Loop, Gain Margin and Phase Mar gin, Bandwidth and Stability .......................91

B.4.3 P, PD, PI and PID Controllers..............................................................................................92

Page 5

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Chapter 1: Introduction

The SimplIQ documentation and support software is divided into the following

areas:

Usage Phase Document Tool

Exploratory Sales documents for SimplIQ and Bell

Planning/configuration SimplIQ for Steppers Sizer configurat ion

tool

Decision/ordering Elmo Catalog and website

Installation/assembly Device specific installation guide, e.g.

Bell Installation Guide

Commissioning and Getting Started This guide

Composer Guide

5

Usage/operation SimplIQ for Steppers Command Reference

Manual

SimplIQ Programming and Language Guide

SimplIQ for Steppers Application Note

DS301 document

DS402 document

The diagram below shows the SimplIQ for Steppers documentation set:

As depicted in the previous figure, this Getting Started & Tuning guide is an

integral part of the Bell documentation set, comprising:

Page 6

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

The SimplIQ for Steppers Command Reference and the SimplIQ for Steppers

Application Note, which describe in detail each software command used to

manipulate the Bell motion controller.

The SimplIQ Programmin g and Lang uag e Manua l, which includes explanations of

all the software tools that are part of Elmo’s Composer software environment.

The Bell Stepper Drive Installation Guide, which describes, in detail, th e dif fe ren ces

that have been introduced by the Bell to SimplIQ to cover 2-phase motors and

steppers.

The SimplIQ for Steppers Getting Started Guide, which describes how to set up and

tune the stepper drive.

Note that this documentation does not contain all the information for all product

types and cannot take into account every possible aspect of installation, operation,

or maintenance.

Support Software

This Getting Started manual relies heavily on the Composer and Conductor tools.

The Composer is a support program by Elmo for SimplIQ.

6

The Composer supplies the basic services for communicating wi th driv es and

collecting data from them.

The Conductor is a tuning tool developed by Digi tal Feedback Technol ogies. The

Conductor enables the SimplIQ parameters to be tuned.

The Conductor is normally called from the Composer environment.

Audience and Objective

This document is intended for machine manufacturers, commissioning engineers,

and service personnel who use the SimplIQ drive system.

It is intended to make you familiar with the software environment provided for

SimplIQ. With this environment, you will be able to set up your drive with relative

ease.

This manual is intended to give you a solid starting point. Once you understand the

environment's core logic, you can work efficiently by referring to the online help. In

addition, there is a lot of relevant information in other the manuals of the

documentation set.

Prerequisite

This manual assumes that you installed the drive correctly according to the Bell

Stepper Drive Installation Guide.

Danger and Warning Symbols

The following danger and warning notices are used in this document:

Danger:

This symbol indicates that death, severe personal injury, or

substantial property damage may result if proper precau tions are not

taken.

Page 7

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Caution (With or without a warning triangle, according to severity):

This symbol indicates that minor personal injury or property damage

may result if proper precautions are not taken.

Note:

This symbol highlights supplementary information

This symbol indicates that the topic is normally handled

automatically by support software, and the material is only given for

enhanced understanding.

1.1 Qualified Personnel

For this document, Qualified Personnel means:

For devices that are 60 V or less: someone familiar with the drive, following a

training course, after reading material, and with adequate technical education.

For higher voltage drives it has the additional meaning of someone licensed to

deal with electricity of the relevant voltage and power, according to local

regulations.

Up-to-date information about our products can be found on the Internet at the

following address:

www.elmomc.com

7

ESD Notices

Caution:

The SimplIQ drives are Electrostatic-Sensi ti ve Devices (ESD). Thi s

means that handling them incorrectly may damage them. Please

carefully read the ESD precautions in the Installation Guide.

Danger:

All the devices must be installed according to the device-specific

Installation Guide. Special attention must be given to earth

grounding and for high voltage connections and insulations.

Before dealing with a device, verify it is in the proper condition, and

that it is not damaged mechanically or electrically.

1.2 Working with this Document

We recommend new users to:

Thoroughly read Chapter 2: Elements

Go through Chapter 3: Getting Started

Chapter 4: Advanced Control Tuning

can exploit the extra flexibility of the SimplIQ environment beyond the "Getting

Started" level.

.

.

is for experienced control practitioners, who

The appendices give more general data on the linear system and on manual tuning.

Page 8

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Chapter 2: Elements

This section deals with the most basi c concepts of dr iv e commi ssi oning:

Communication

Application programming

Firmware

The Conductor Wizard

2.1 Establishing Communication with a Drive

When you open the Composer it tries to communicate wit h the driv e. The

communication may be one of the following:

RS-232

CANopen

The Composer application can be connected simultaneously to more than one

drive. In this manual we focus on single drive connections.

8

The Composer can communicate with multiple drives and define a network

setup. For further details, refer to the Composer online help.

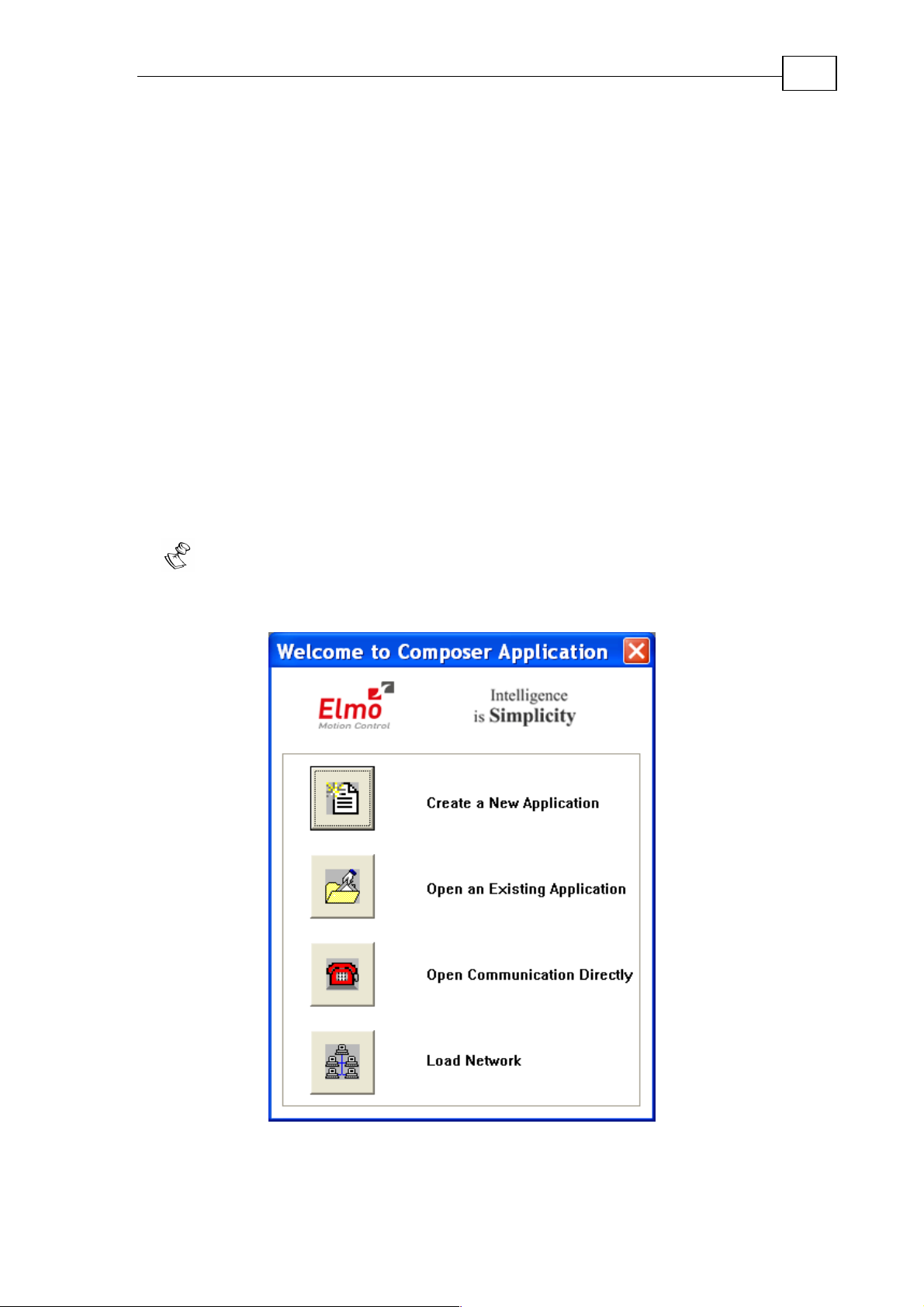

When you open the Composer, the following window opens:

Figure 1: Starting the Composer

Click Open Communication Directly. The following window opens:

Page 9

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

9

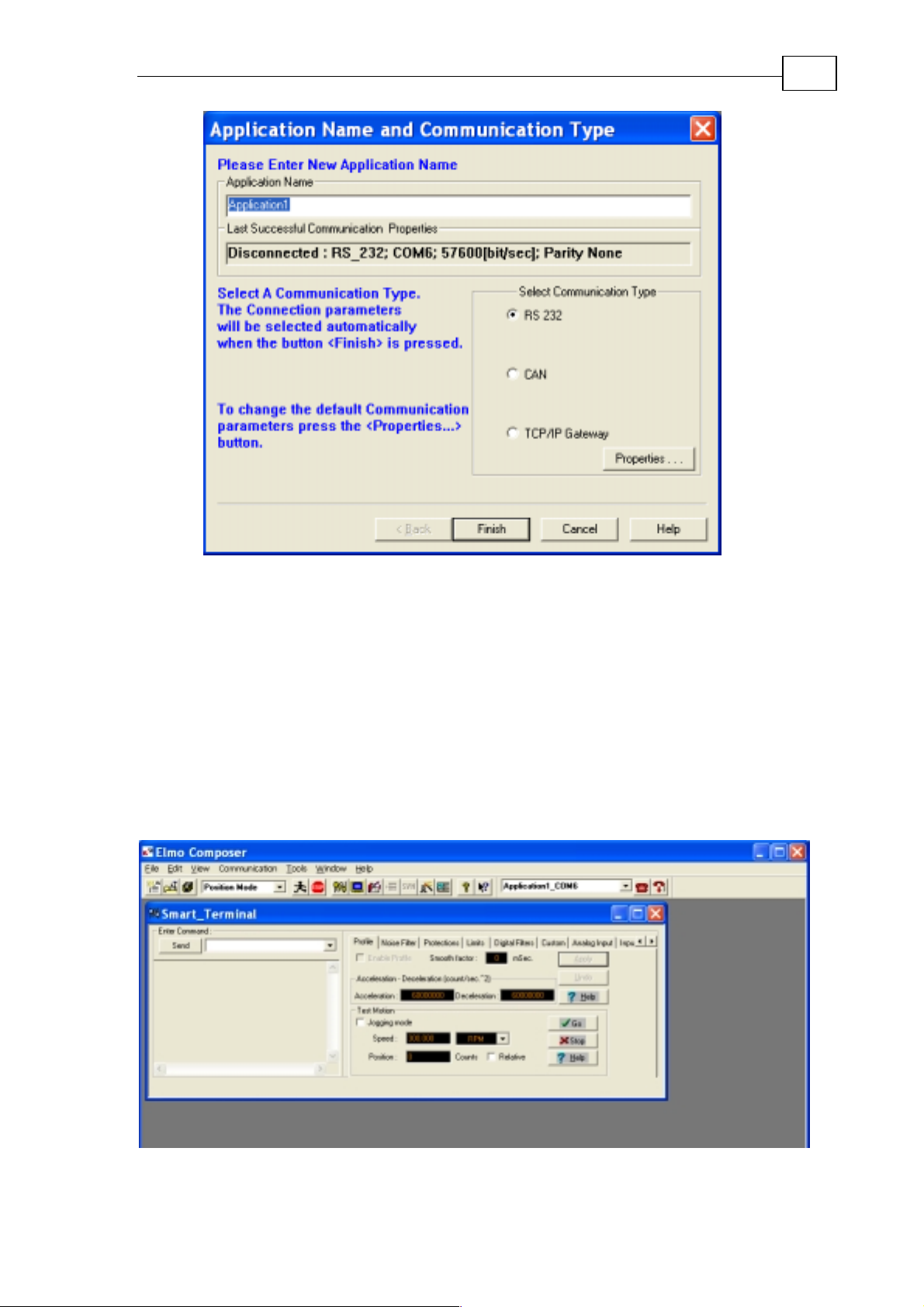

Figure 2: Composer connecting window

Ignore the Application Name field.

Look at Last Successful Communication Properties. If the properties listed there

are as required, click Finish. Otherwise, click Properties:

For RS-232 you need to set the number of the COM port in use, the baud rate

and the parity. The communication is always 8 bits in a byte, and it has one stop

bit.

For CAN you need to set the ID and the baud rate. In addition, you will have to

select the CAN adapter from the supported types.

Then click Finish. The Composer opens to the main window:

Figure 3: The main Composer window

Page 10

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

The Smart Terminal lets you enter commands manually – please refer to the

SimplIQ for Steppers Command Reference Manual. To send a command, type it

in the Enter Command field and click Send.

Notes:

At the connection step you need to know the drive communication param eters.

It is possible to change the drive communication parameters only later, after

communication is established.

If you do not know the CAN ID, you may either:

o Connect first with RS-232, then ask for PP[13] (can ID) and PP[14] (CAN

baud rate).

o Use the DSP 305 protocol to find out the drive parameters (you will need

your own CAN application for that).

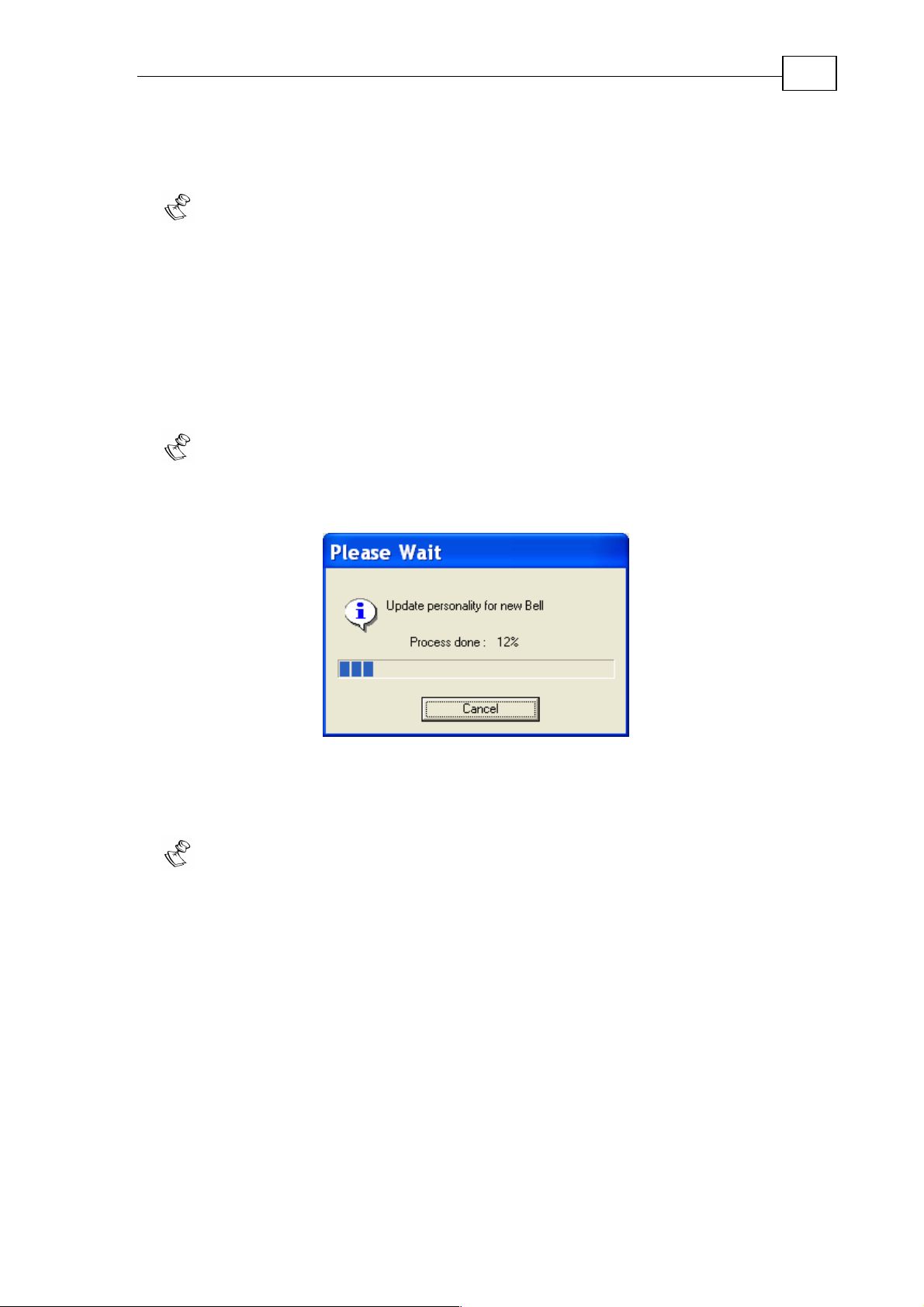

The drive stores a lot of information about itself internally and this enables

the Composer to interact with a multitude of drive types. When a Composer first

meets a drive version it uploads this internal information. You will see the

following window:

10

Figure 4: Uploading personality data

The next time you contact the same drive version, the Composer already has all

its personality data stored and will not ask you to wait again.

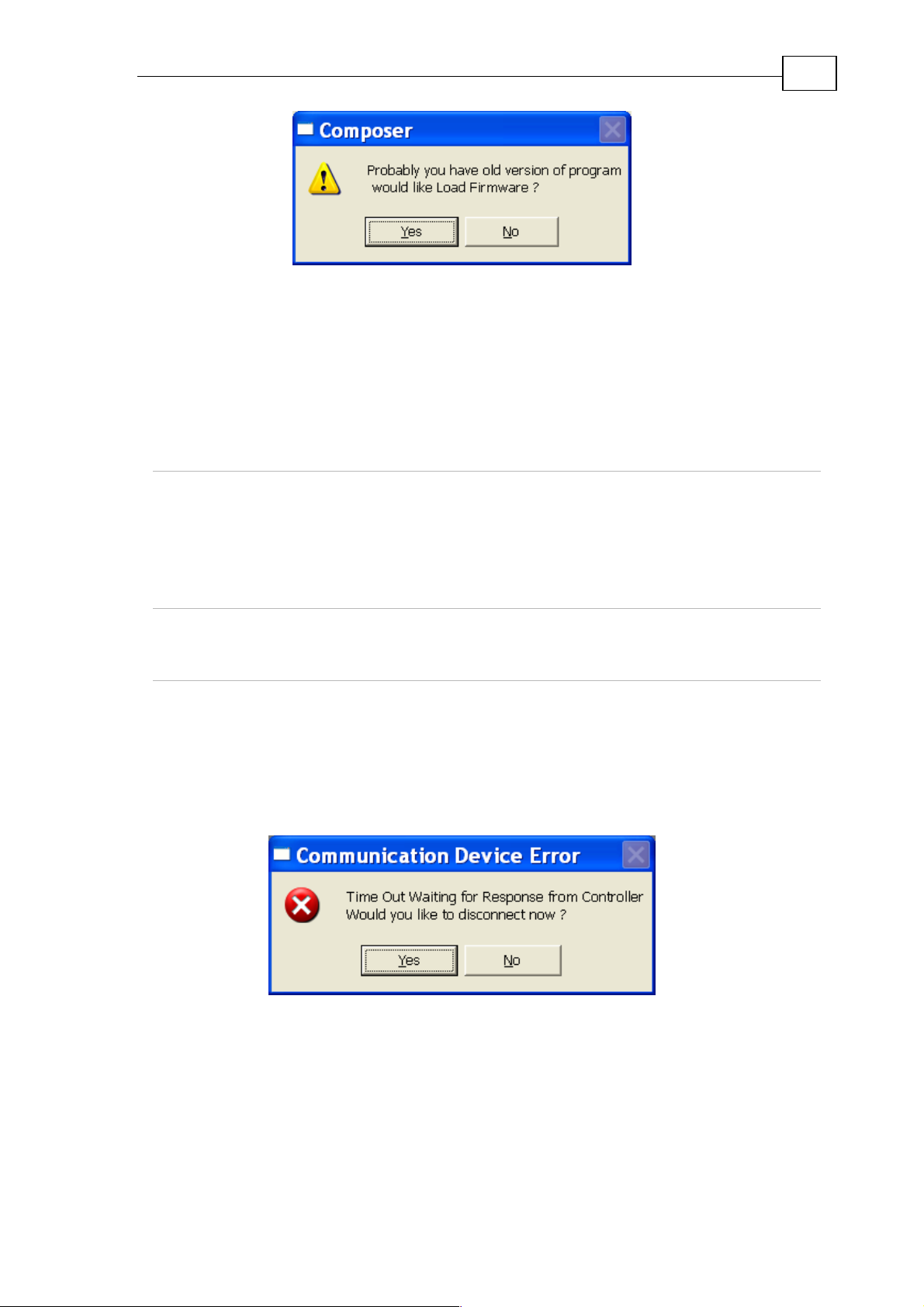

If the drive lost its software, for example by a power-down during firmware

downloading, it will withdraw to a very limited default, or "boot" software. With

this boot, it is only possible to download the new firmware version. The

communication parameters in the "boot" state are fixed (not affected by any user

setting):

Baud rate of 57600 and no parity for RS-232.

Baud rate of 500000 and CAN ID of 127 for CAN.

After you set the correct communication parameters, you will see the following

message:

Page 11

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Figure 5: Boot software message

Click Yes to open the windows related to downloading the firmware.

2.1.1 Changing the Communication Parameters

2.1.1.1 Changing the RS-232 Communication Rate and

Parity

First set the desired parameters in the Composer smart terminal:

11

PP[2] RS-232 baud rate.

5: 115,200;

4: 57,600

3: 38,400

2: 19,200

1: 9,600

0: 4,800

PP[4] RS-232 parity. 0: None

1: Even

2: Odd

Setting PP[2] and PP[4] alone does not change the communication setting, so the

Composer can continue communication with the drive.

Write, for example, PP[2]=5. This is a requirement for a baud rate of 115200/sec.

Next write PP[2]=1. This is a command to accept the new setting. Almost

immediately, you will see:

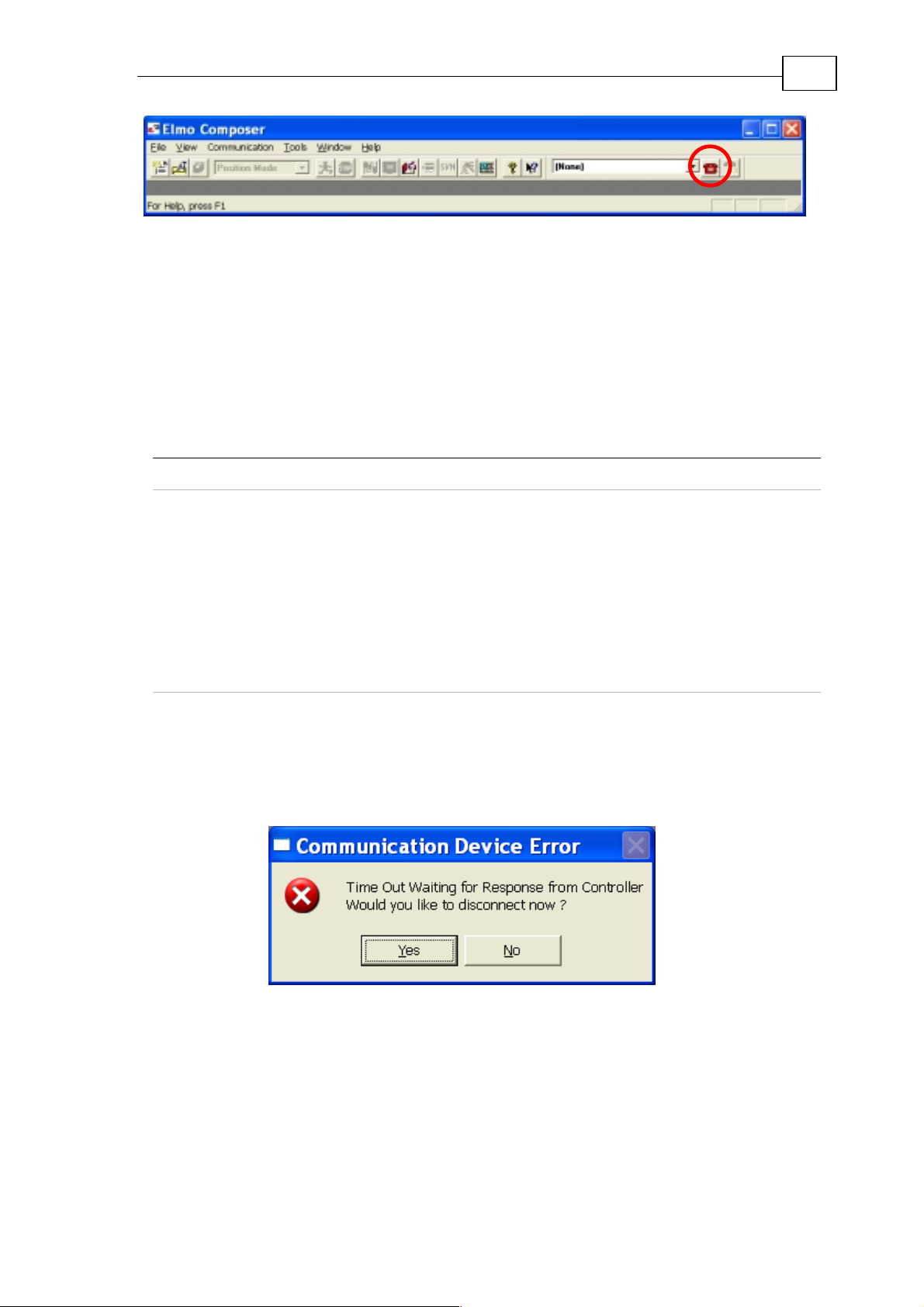

Figure 6: Communication disconnect message

This is because you changed the baud rate so the communications from the

Composer fail. Click Yes to disconnect, than re-open communication by clicking

Connect.

Page 12

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

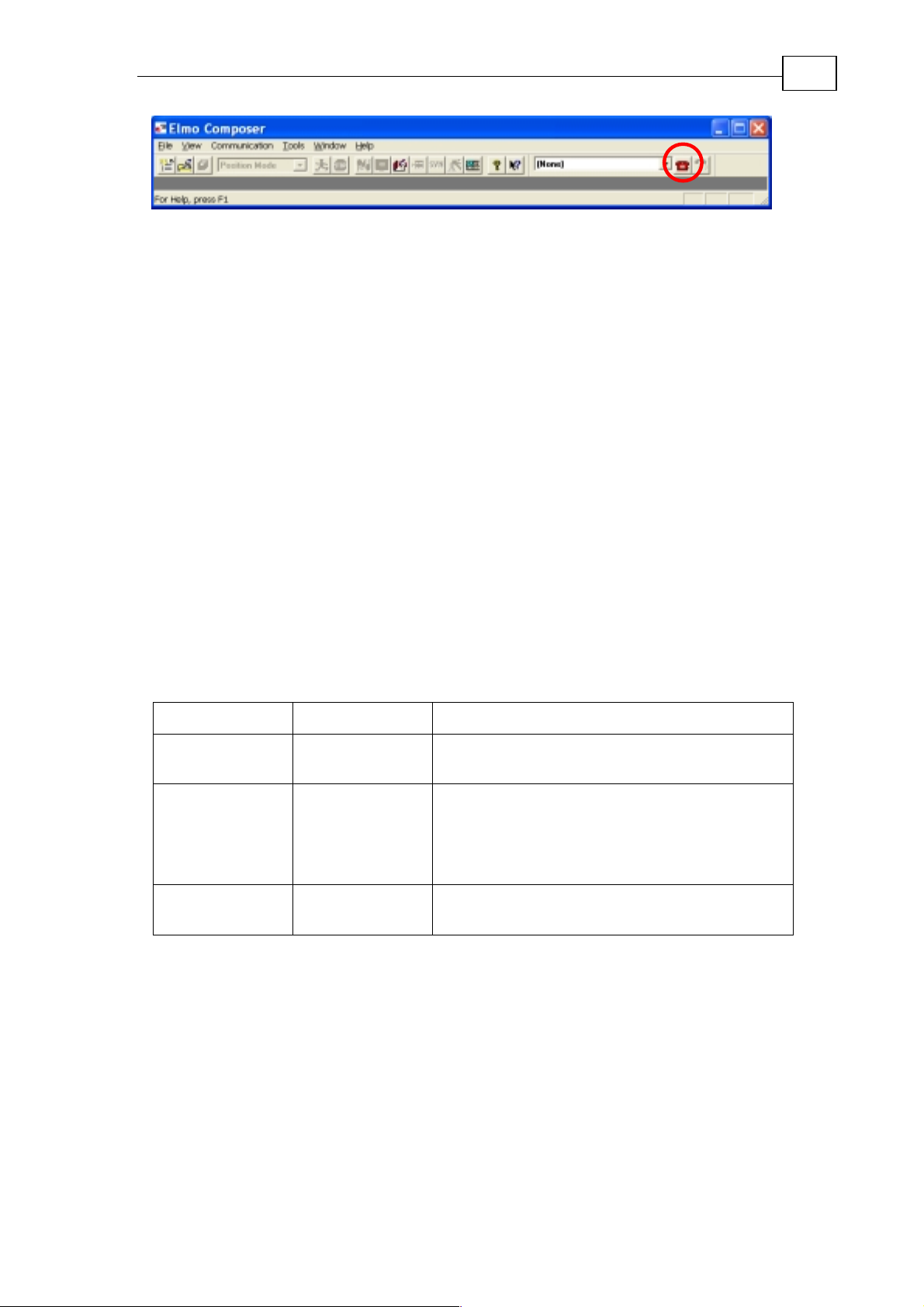

Figure 7: The Connect button, circled in red

Next select the new baud rate using the Properties button (See Figure 2).

When the Composer Smart Terminal re-opens, you may use the SV command to

make the new baud setting permanent.

2.1.1.2 Changing the CAN Communication Rate and ID

First set the desired parameters in the Composer smart terminal:

Parameter Description Range

PP[13] CANopen device ID. 1 – 127

12

PP[14] CAN baud rate. 0: 1,000,000

1: 500,000

2: 250,000

3: 125,000

4: 100,000

5: 50,000

6: 50,000

7: 50,000

8: 800,000

Setting PP[13] and PP[14] alone does not change the communication setting, so

the Composer can continue communication with the drive.

Write, for example, PP[13]=5. This is a requirement for the node ID of 5. Next write

PP[2]=1. This is a command to accept the new setting. Almost immediately, you will

see:

Figure 8: Communication disconnect message

This is because you changed the baud rate so the communications from the

Composer fail. Click Yes to disconnect, than re-open communication by clicking

Connect.

Page 13

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Figure 9: The Connect button, circled in red

Next select the new baud-rate using the Properties button (see Fi gure 2).

When the Composer Smart Terminal re-opens, you may use the SV command to

make the new baud setting permanent.

2.2 Application Parameters and Programming

When you commission a drive, you create an Application. An Application refers

to the entire data set you download and store into the drive. The application

includes:

Parameters to store permanently in the drive, such as controller coefficient s.

User programs: please refer to the SimplIQ Programming and Language Guide.

13

The Composer packs all the non-volatile parameters and the User Program in a

single file, with the .dat extension.

The Composer can later use this .dat file to program many amplifiers to the same

parameters and User Program.

2.2.1 Flash, RAM and Tables

The drive contains the following memory types:

Memory Type Used for

Serial Flash Non-volatile This flash stores all the non-volatile

parameters, as well as the User Program

Table Flash Non-Volatile This high speed flash stores the motion

correction tables for real-time use.

The data in the Table Flash must be an

identical copy of the data in the serial flash.

RAM Volatile Stores a volatile copy of the serial-flash

parameters for real-time high-speed use.

When the drive powers-on, it loads the RAM as a copy of the table flash.

It also compares the Table Flash with the Serial Flash. If the contents are not-

equal, you will not be able to start the motor until the situation is corrected.

When you communicate with the drive the parameters you modify are in the

RAM. When you write, for example, KI[1]=1, you update the copy of KI[1] in the

RAM. The parameter KI[1] has a copy in the serial flash which remains as is.

When you want to synchronize the RAM and the serial flash, you can:

Use the SV command to copy the entire RAM contents into the serial flash (for

example, after you tuned some parameters).

Page 14

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Use the LD command to copy the entire Serial Flash contents into the RAM.

When you want to synchronize the Table Flash and the Serial Flash, use the SI=1

command.

Notes:

The SV, LD, and SI commands work on an entire data set. There is no way to

save some of the parameters and not save others.

SV does not automatically synchronize the Tabl e Flash because Tab le Fl ash

synchronizations take a long time. Table Flash synchronizations are carried out

very rarely.

2.2.2 Creating an Application File

In this Section we will create an application file in the PC computer.

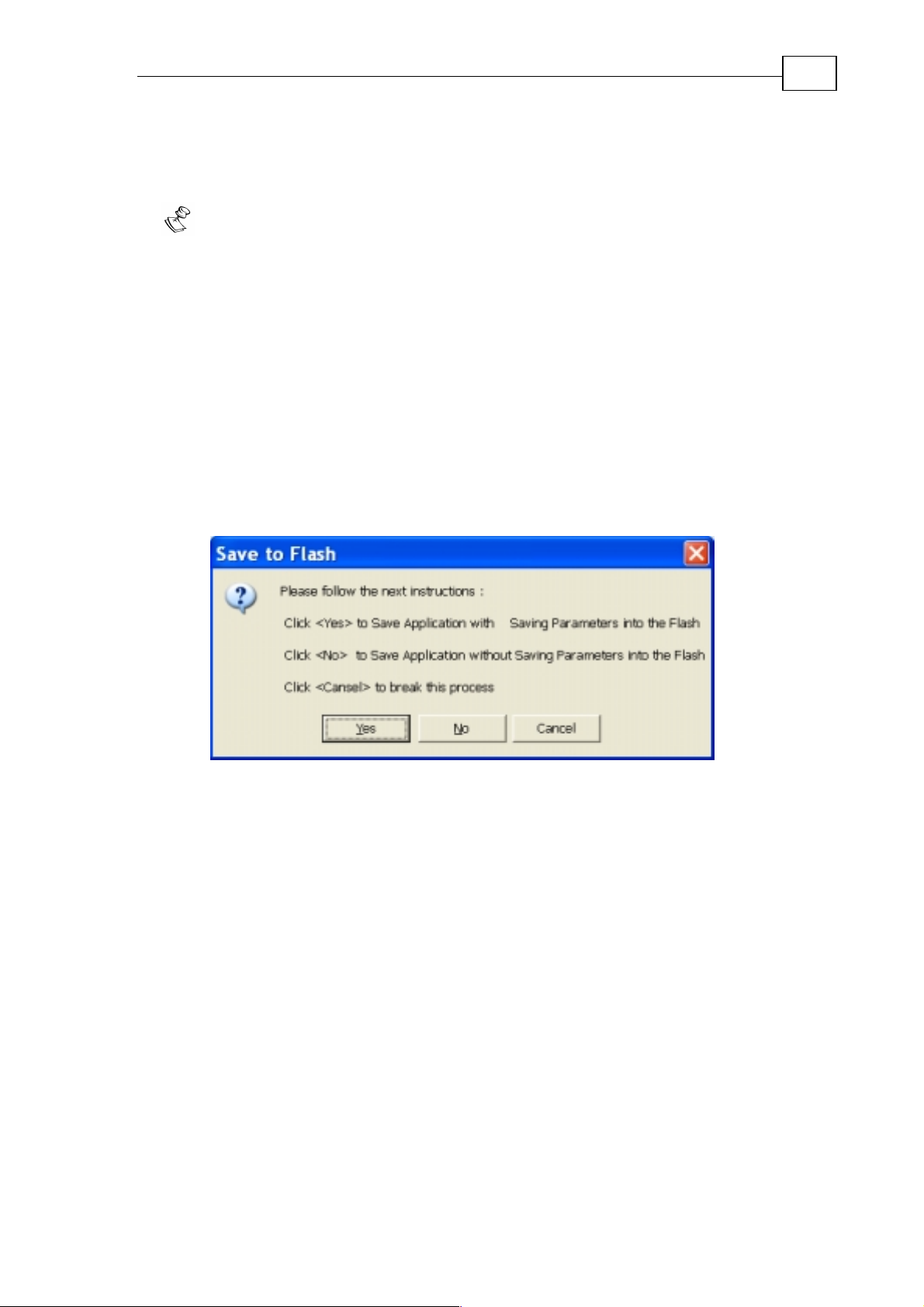

From the menu select File>Save Application.

The Composer will prepare to pack all the parameters and the User Program into

an application file. It displays the following message:

14

Figure 10: Save application message

The Composer uploads the parameters directly from the serial flash. It enables

you to synchronize the parameters in the Serial Flash to the copy in the RAM

<Yes>, or to skip synchronization <No>.

After this enter a file name.

2.2.3 Downloading an Application File

In order to distribute an application from a data file to a driver, do the following:

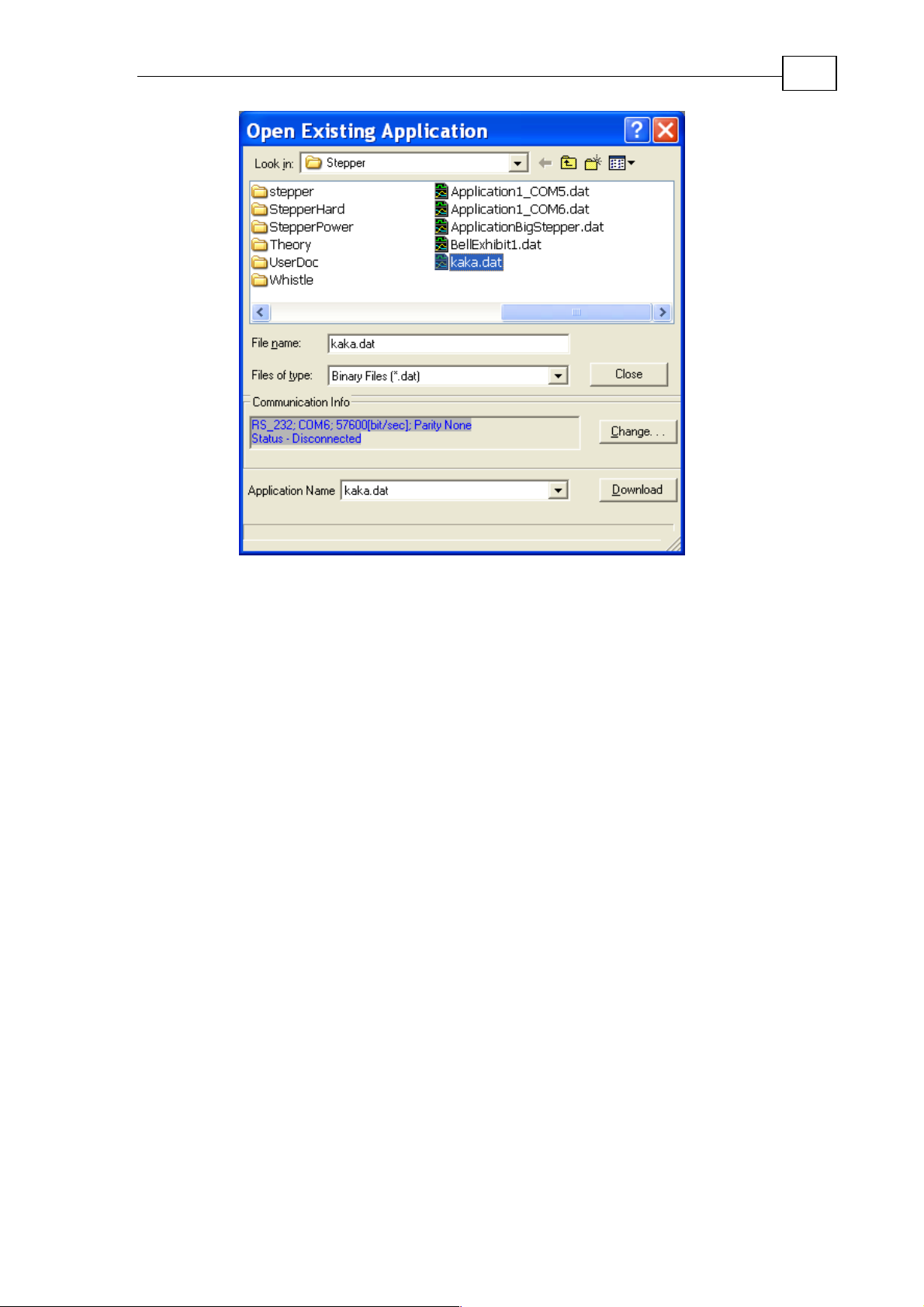

From the menu select File>Open Application. The following wind ow opens:

Page 15

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

15

Figure 11: Open Application window

Upon selection, look at the Communication Info data box. Verify that the

communication parameters there are correct, or click Change to edit them.

Then click Download to complete the downloading.

After downloading, the Serial Flash and the Table Flash may become non-

synchronized, and in this case you need to enter SI=1 at the smart terminal in

order to complete the synchronization.

2.2.4 Observing the Contents and Editing an Application

File

The Composer has a tool called the Application Editor.

2.3 Firmware

This section deals with keeping the drive software version up-to-date.

The drive must be loaded with the correct software to operate. You will normally

receive the drive loaded with the correct software from the dealer. Firmware

upgrades are, however, available from time to time. You can download the latest

firmware from the Elmo web site. It is a text file with the .abs extension.

2.3.1 Version Verification

For version verification, use the VR command. It should return something like

Bell 2.02.07.21 10Dec2007. You can compare this string with the latest available

firmware at the Elmo web site.

Page 16

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

2.3.2 Normal Firmware Download

In the Composer Smart Terminal, select Tools>Firmware Download. The

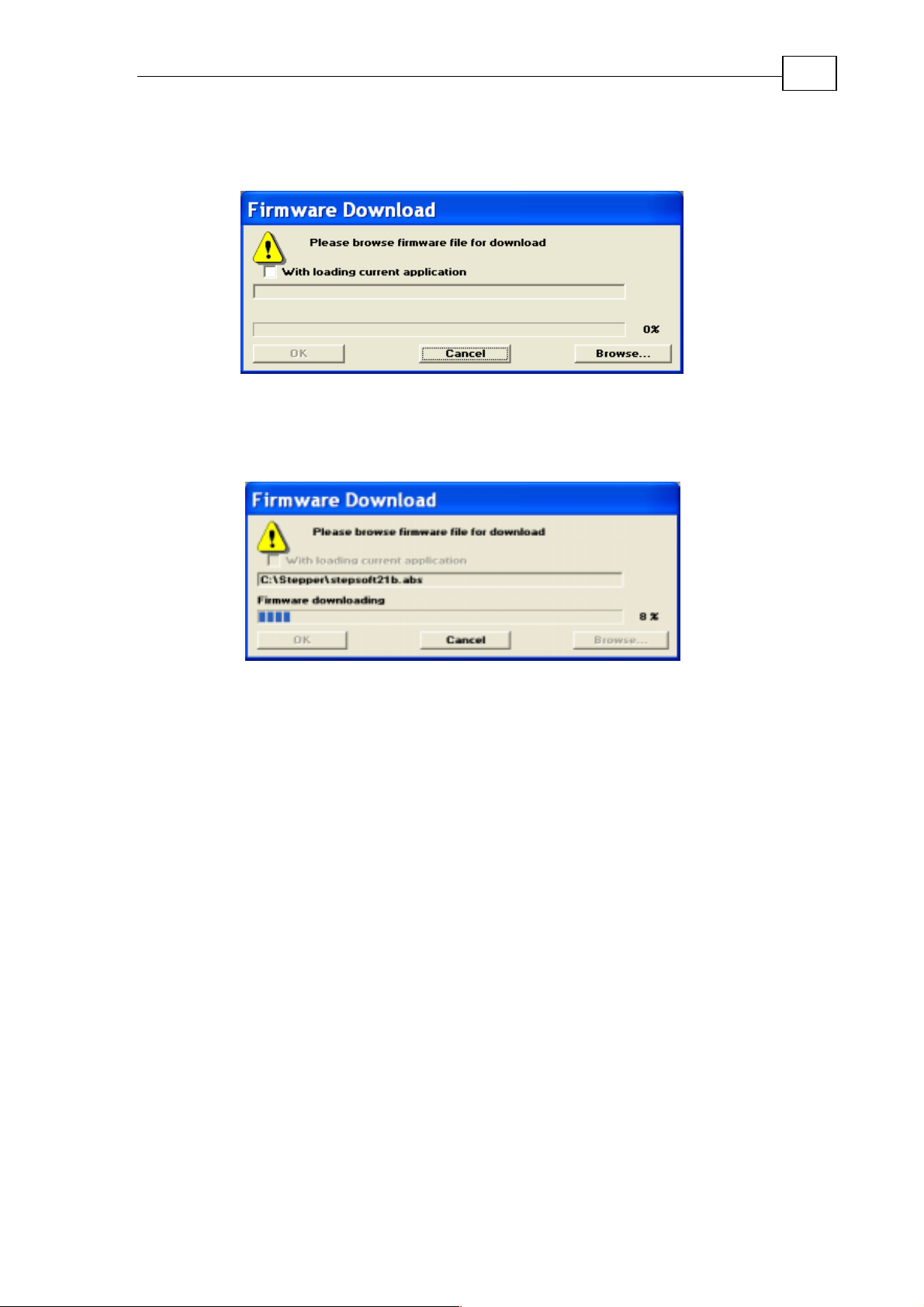

following window opens:

Figure 12: Download firmware window

Use the Browse button to select the firmware .abs file, and then click OK.

The firmware starts to load, and you can watch the progress bar:

16

Figure 13: The Firmware progress bar

The firmware is internally divided into a few sections, and you can observe the

part that is currently being loaded. The first part is "Firmware downloading" and

the last part is "Extended firmware downloading".

When it has finished loading, a message asks you to reboot the drive by

disconnecting it from the electricity.

2.3.3 Abnormal (from Boot) Firmware Download

If the drive lost its software, for example by a power-down during firmware

downloading, it will withdraw to a very limited default, or "boot" software. With

this boot, it is only possible to download the new firmware version. The

communication parameters in the "boot" state are fixed (not affected by any user

setting):

Baud rate of 57600 and no parity for RS-232.

Baud rate of 500000 and CAN ID of 127 for CAN.

After you set the correct communication parameters, you will see the following

message:

Page 17

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Figure 14: Firmware message

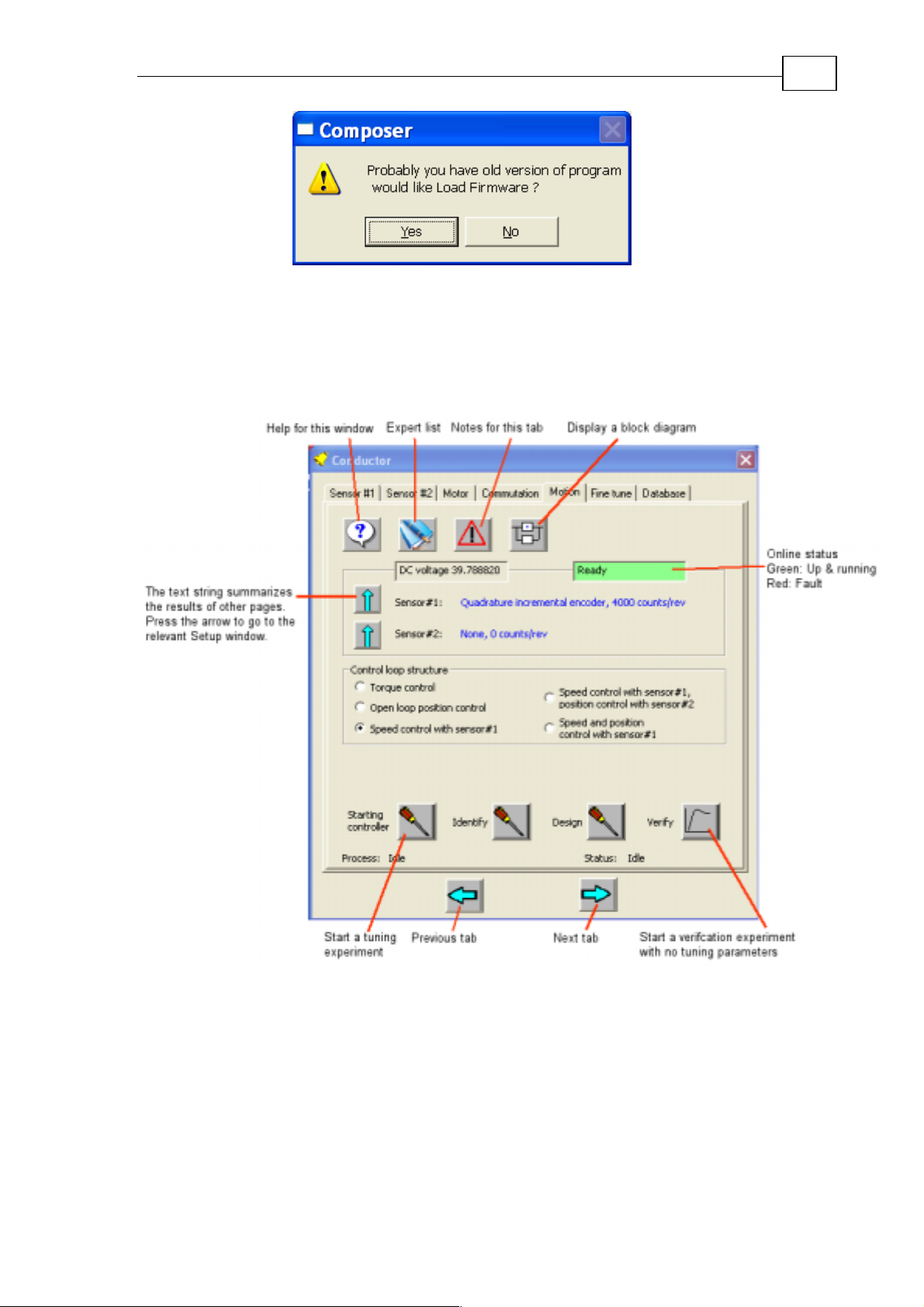

2.4 The Conductor Wizard

2.4.1 The Conductor Tabs

The Conductor is the main tool for tuning the SimplIQ control functions.

17

Figure 15: The Conductor window

The Conductor manages some experiments for the tuni ng curr ent and mot ion

controls. You have a lot of flexibility in managing the experiment, but you do not

need to be an expert.

A color code defines which parameter fields you may leave as is, and which require

your attention and understanding – refer to the figure below.

Page 18

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

18

Figure 16: User editable fields in a tuning experiment

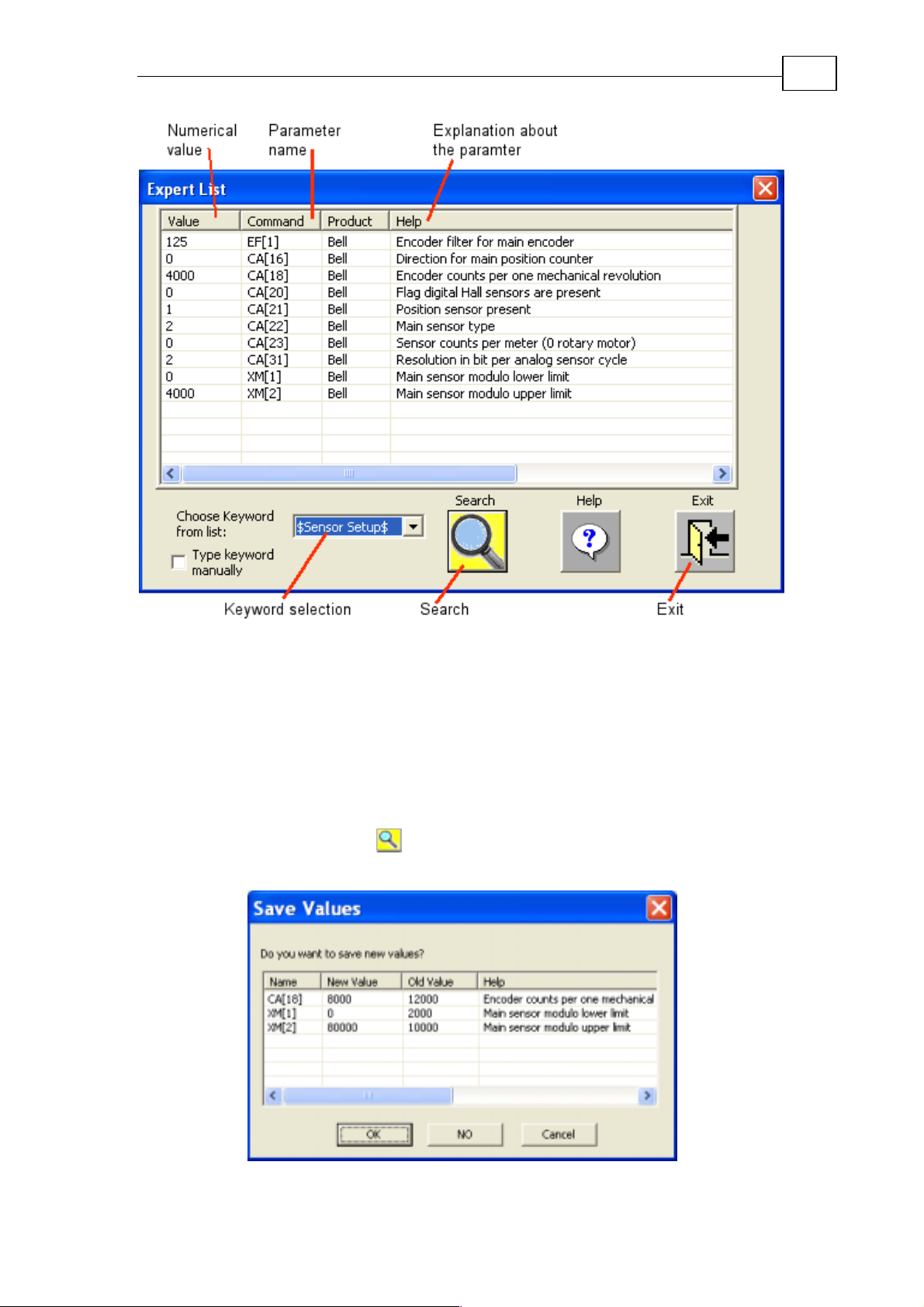

2.4.2 The Expert List

The Expert list is a tool for observing and editing the drive parameters. It gives

extra flexibility for the experienced user, and it lets you track which drive

parameters you changed and how.

Expert lists and the Conductor wizards work with the parameters in RAM

only. Your work is volatile (will disappear at the next power-on or LD

command), until you click Save in Flash in the Database tab.

When you open the Expert List using the Expert list button

following:

, you see the

Page 19

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

19

Figure 17: Expert list window

Here you see, and may edit (simply by clicking the value), each of the parameters

that this wizard pad controls.

The Expert List finds which parameters relate to a given Conductor tab using a

keyword; Conductor tabs use keywords that are delimited by $ signs at both

ends.

You can, however, select another keyword from the list, or type a keyword

manually. Then click Search

.

If the Expert List detects a change when you exit, it will display:

Figure 18: Expert List exit comparison

Page 20

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

2.4.3 Accepting a Change of Parameters

When you change drive parameters with the Conductor, and you exit a tab, the

conductor displays an exit comparison, as in Figure 18.

After confirmation, the parameters are accepted and cannot be restored by the

Conductor.

Expert lists and the Conductor wizards work with the parameters in RAM only.

Your work is volatile (will disappear at the next power-on or LD command),

until you click Save in Flash in the Database tab.

20

Page 21

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Chapter 3: Getting Started with

Sensors and Motion Control Setup

3.1 Introduction

Tuning a SimplIQ drive to a motor is an ordered, step-by-step process. In this

"Getting Started" chapter, we go through the setup process step by step.

Note that this chapter does not contain all the detailed information for all product

types and cannot take into account every possible aspect of the drive setup.

3.1.1 Tune the Drive to the Motor

All motor and application types:

Set the switch functions for limits; enable functions, brakes, etc. This will create

the initial conditions for the motor to work.

Set the application limits for current, speed, and position. This will prevent

system constraints being violated later on.

21

Defining the sensors.

Selecting the motor type (DC, Stepper, Brushless).

Tuning the current controller.

Brushless motors only:

Commutation tuning (finding how to power the stator so that the motor will

develop maximum torque in the desired direction).

3.1.2 Tune the M otion Control l er

For open loop stepping applications, you only need to set few parameters.

If you have a motion sensor, you may want the following:

Tune speed and position controls.

Set corrections for motor cogging and define the speed-dependent corrections

to the current loop.

3.1.3 Database Maintenance

All the steps until now have manipulated variables in the drive's database. The

last step is to check database validity, and to save the outcome in a permanent

(flash) memory.

3.2 Abort and Enable Switches

First, set the enabling switches.

The drive has several digital inputs (depending on the drive type). There are

several automatic functions that may be assigned to drive digital inputs.

It is important that at this stage you define which switches are used to abort or to

stop motion, as well as limit switches when applicable.

Page 22

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

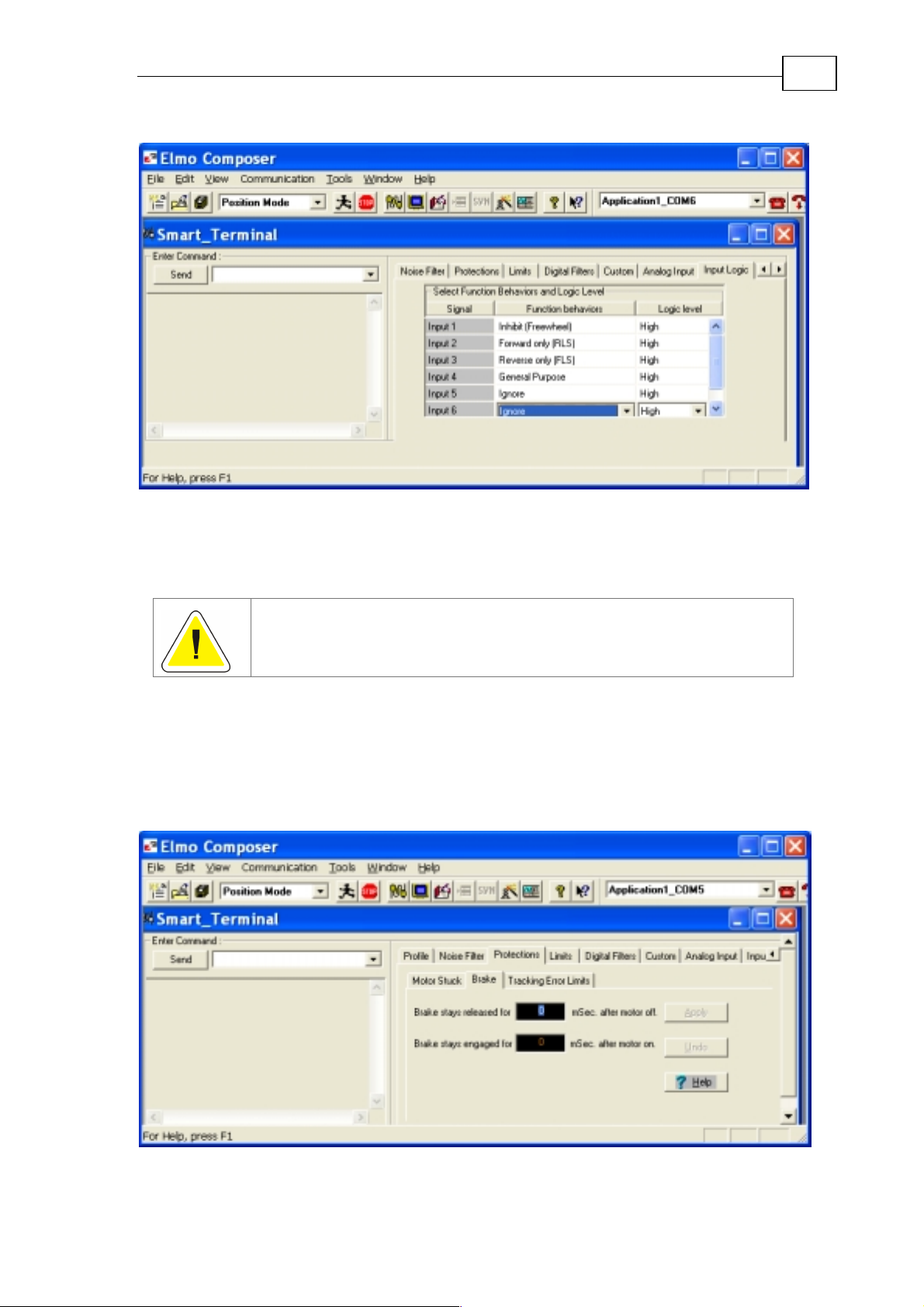

For this purpose, use the Input Logic tab in the Smart Terminal.

22

Figure 19: Defining input logic

For a detailed description of the functions that may be assigned to digital inputs,

refer to the IL[N] command in the Sim pl IQ for St eppers Com mand Reference

Manual.

Correct digital input definitions help to guarantee that the drive

generates only safe motions in the course of the tuning pr ocess.

Incorrect digital input settings may prevent drive motion or tuning.

3.2.1 Brakes

If a brake is installed and you want to operate it automatically when the motor

starts, set it up now.

First select the brake engage and release delays. For this purpose select the

Protections>Brake tab in the Composer’s Smart Terminal:

Figure 20: The Brake tab

Page 23

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Do not specify brake delays greater than you actually need.

Next, define the digital output for use as brake control; use the Output Logic tab

of the Composer's Smart Terminal.

For a detailed description of the functions that may be assigned to digital

outputs, refer to the OL[N] command in the SimplIQ for Steppers Command

Reference Manual.

You can test brake operation by programming the brake control temporarily

as a general purpose output, and manipulate it using the OB[N] command.

23

Figure 21: The Output Logic tab

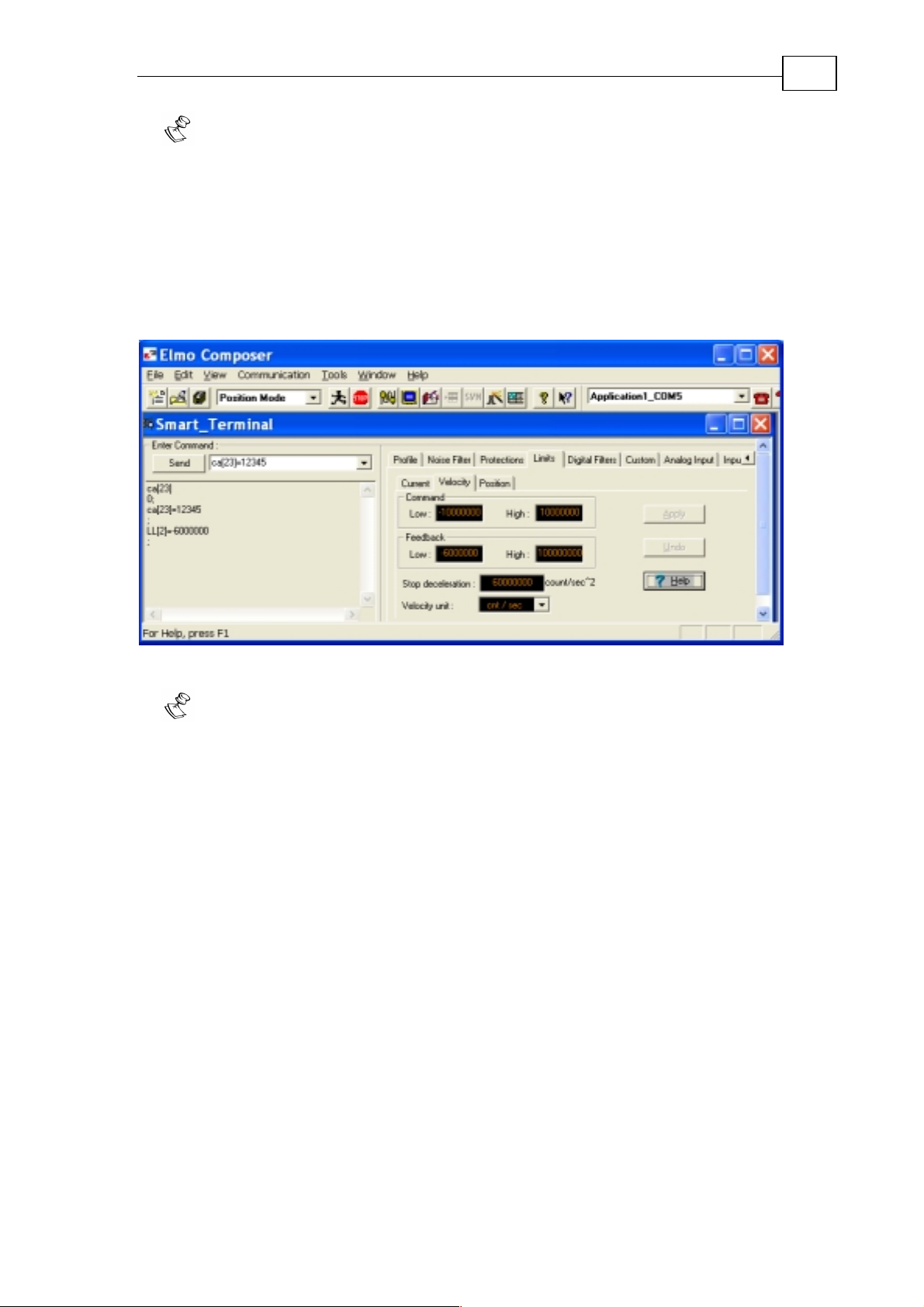

3.2.2 Application Limits

Next, set the application current, speed and position limits. This will h elp to ke ep

the motor within its safe operation range.

Current Limits

Use the Limits>Current tab in the smart terminal:

Figure 22: The Current tab

Page 24

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Notes:

The MC command returns the current limit of the drive peak.

You may set the current limits in the Conductor wizard as well.

Refer to the CL[1],PL[1], and PL[2] commands in t he Sim plI Q for St eppers

Command Reference Manual.

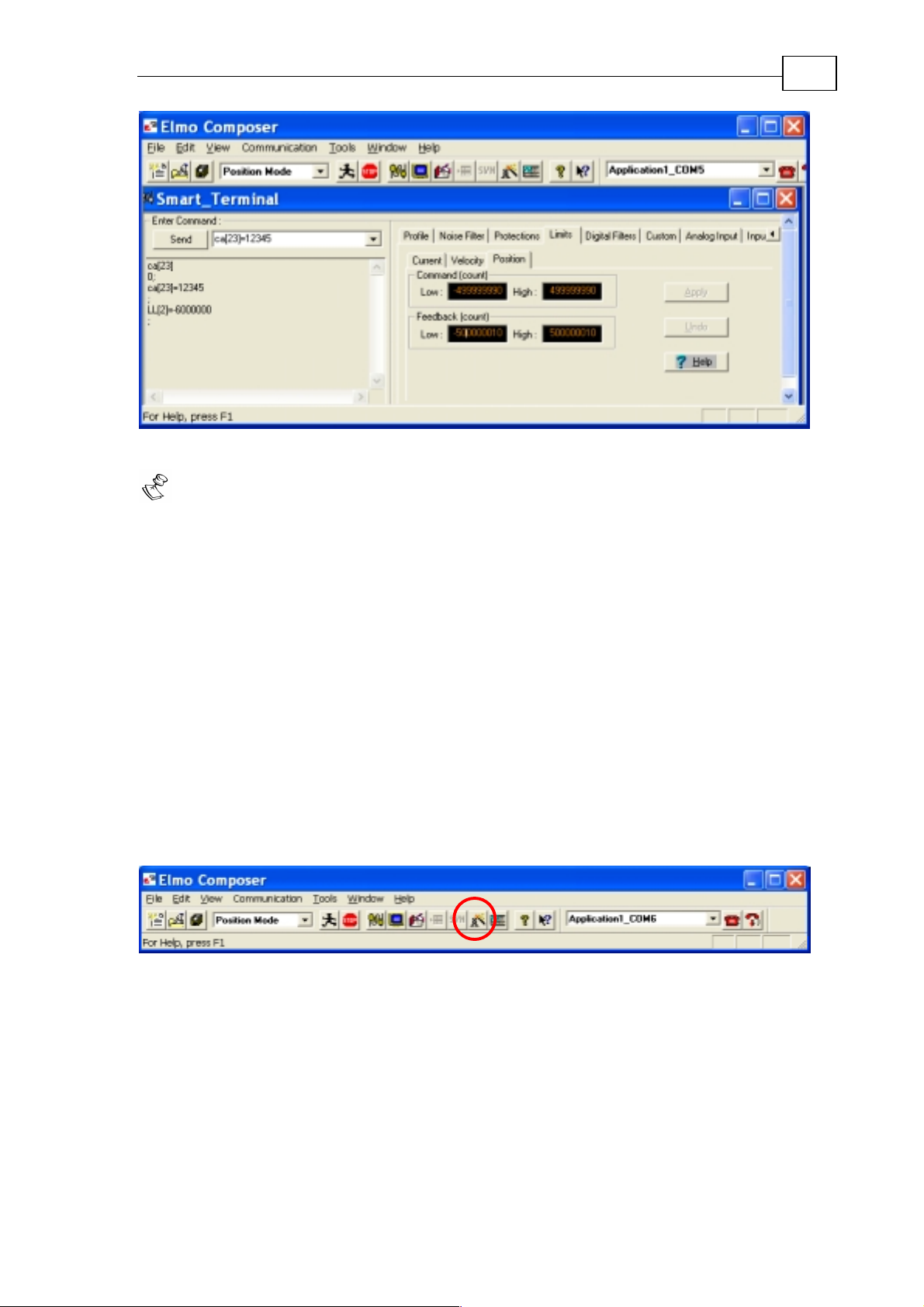

3.2.2.1 Speed Limits

Use the Limits>Velocity tab in the smart terminal:

24

Figure 23: Setting the speed limits

In the Speed Limits tab, you can select RPM as the speed units. For correct

translation between RPM and sensor counts, you need to set the CA[18]

parameter (sensor counts per motor revolution) properly. Take care before you

change CA[18] because if you enter an incorrect value, brushless and stepper

motors cannot work.

3.2.2.2 Position Limits

Open the Protections>Position tab in the smart terminal:

The position command limits apply for open loop stepper applications as well as

for position feedback applications. They do not apply to speed-only or currentonly applications.

Page 25

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Figure 24: Position command limits

Notes:

25

This tab does not set the counting range (modulo limits). You can define the

modulo limits in the setup window of the feedback sensor in the Conductor

Wizard. In an open loop stepping application the relevant modulo limits are

XM[1],XM[2].

The command limits must always be stricter than the feedback limit.

If the command limits are beyond the modulo limits they will be ignored.

3.3 Set up the Sensors

The drive may accept two sensors. Sensor #1 is for speed feedback and possibly

position feedback. The second feedback serves for position feedback, or as a

source for ECAM.

To set up the sensor, open the Conductor tool:

From the Composer, select the Wizard from the tools menu, or use the Wizard

button:

Figure 25: The Wizard button, encircled in red

This will open the Conductor window.

Page 26

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

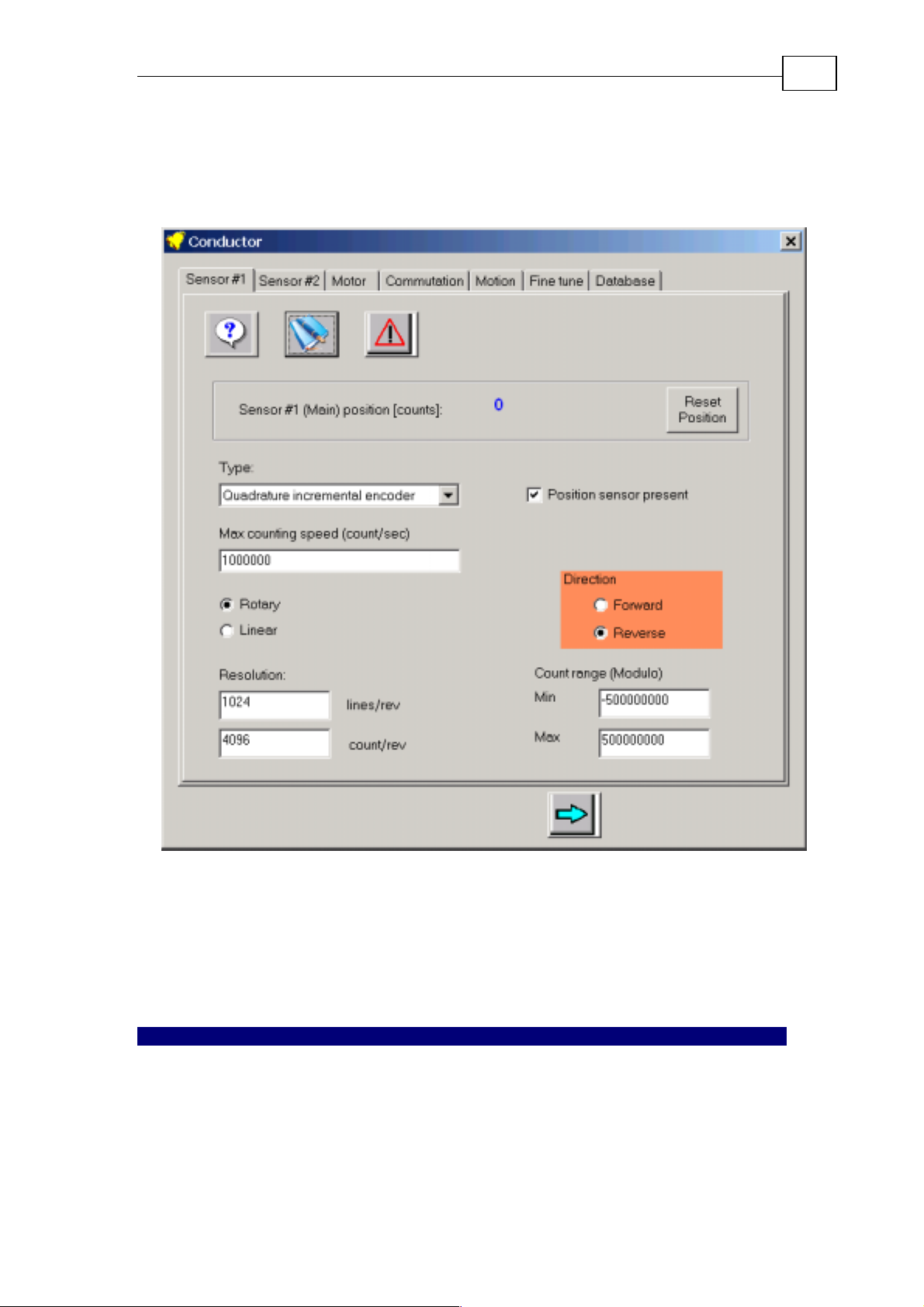

3.3.1 Setting up Sensor #1

Skip this section for open loop stepper applications.

26

Figure 26: Sensor #1 tuning window

Select the type of motion sensor #1.

For a detailed explanation of each of the fields in the tab, click the Help button.

If the motor is small and you can move it by hand, you can observe that the

position readout behaves correctly – either by observing the online position

display, or by taking a record.

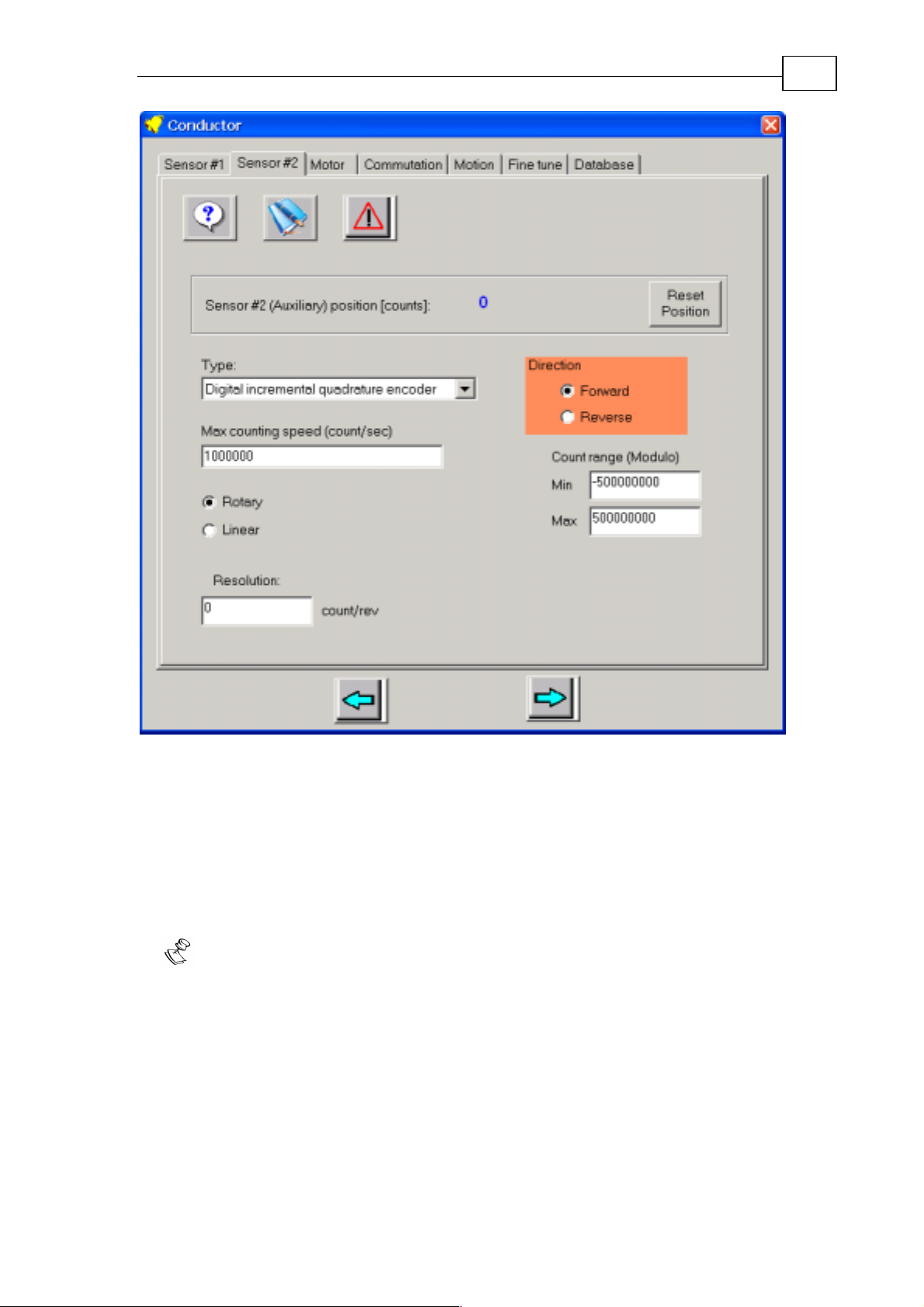

Setting up Sensor #2

You need to set up sensor #2 if you are going to use it for load feedback, ECAM,

or as PWM input.

Page 27

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

27

Figure 27: Sensor #2 setup

Sensor #2 can also be configured as a PWM input, or as a PWM output – refer to

the online help.

3.4 Tuning the Drive to the Motor

The next step is to define the motor type. After this step, the digital current

control of the motor will work, at least at the basic level.

The motor tuning will not be complete after this stage. Additional stages are

required, as will be explained, before going to the final fine tuning.

Page 28

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

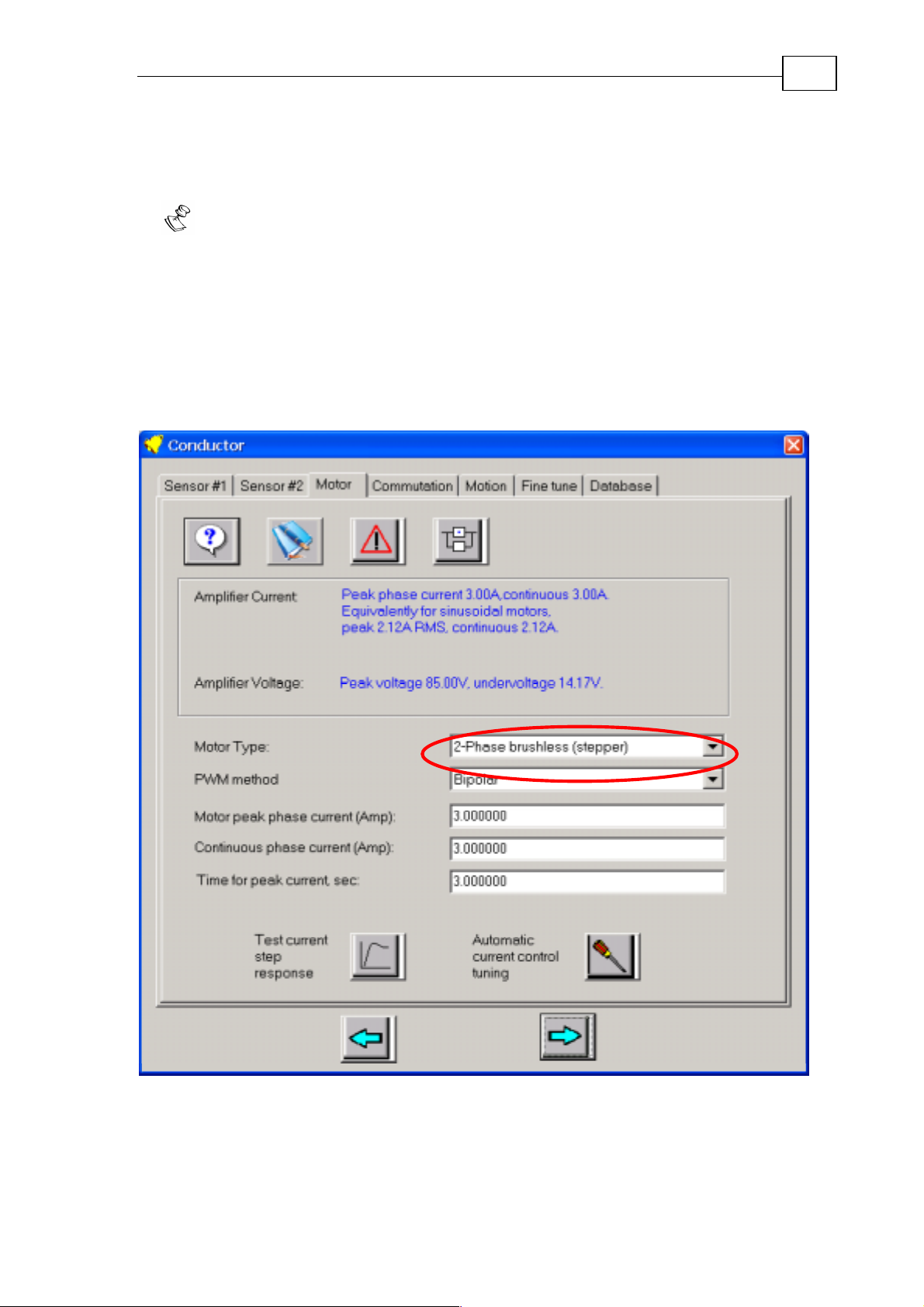

3.4.1 Selecting the Motor Type

The SimplIQ drive can drive DC, 2-phase steppers, or brushless motors.

Notes:

Check that the motor leads are connected correctly. DC motors connect between

M1 and M2. Brushless 3-phase motors connect between M1, M2, and M3, the

phase order does not matter. Steppers connect one phase between M1 and M2,

and the other phase between M3 and M4.

You do not need to know any of the motor parameters (resistance, inductance,

torque sensitivity, etc.) in advance.

You probably do not need to edit the current limiting values, as this was done

at the protections stage.

28

Figure 28: Selecting the motor type

Page 29

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

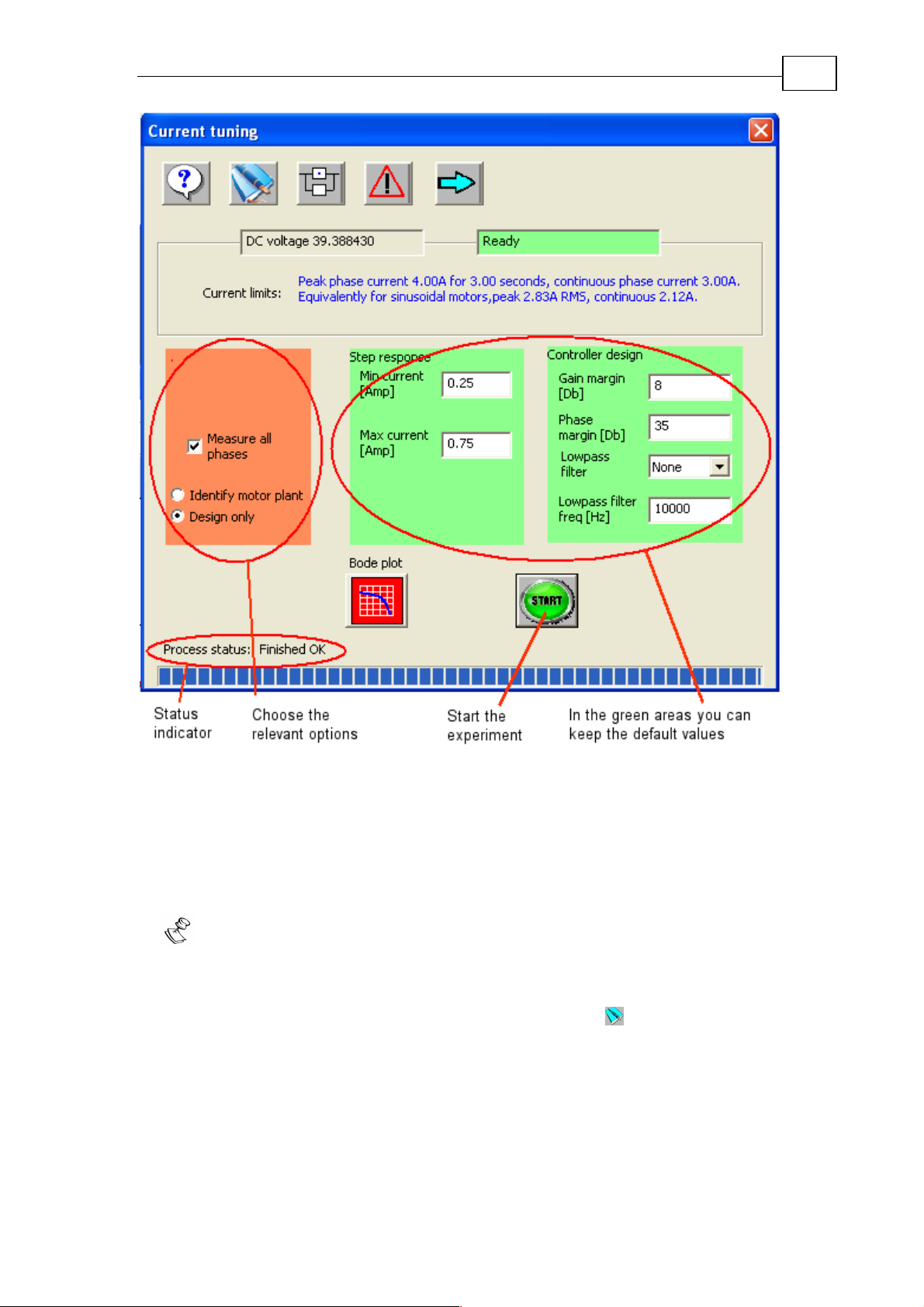

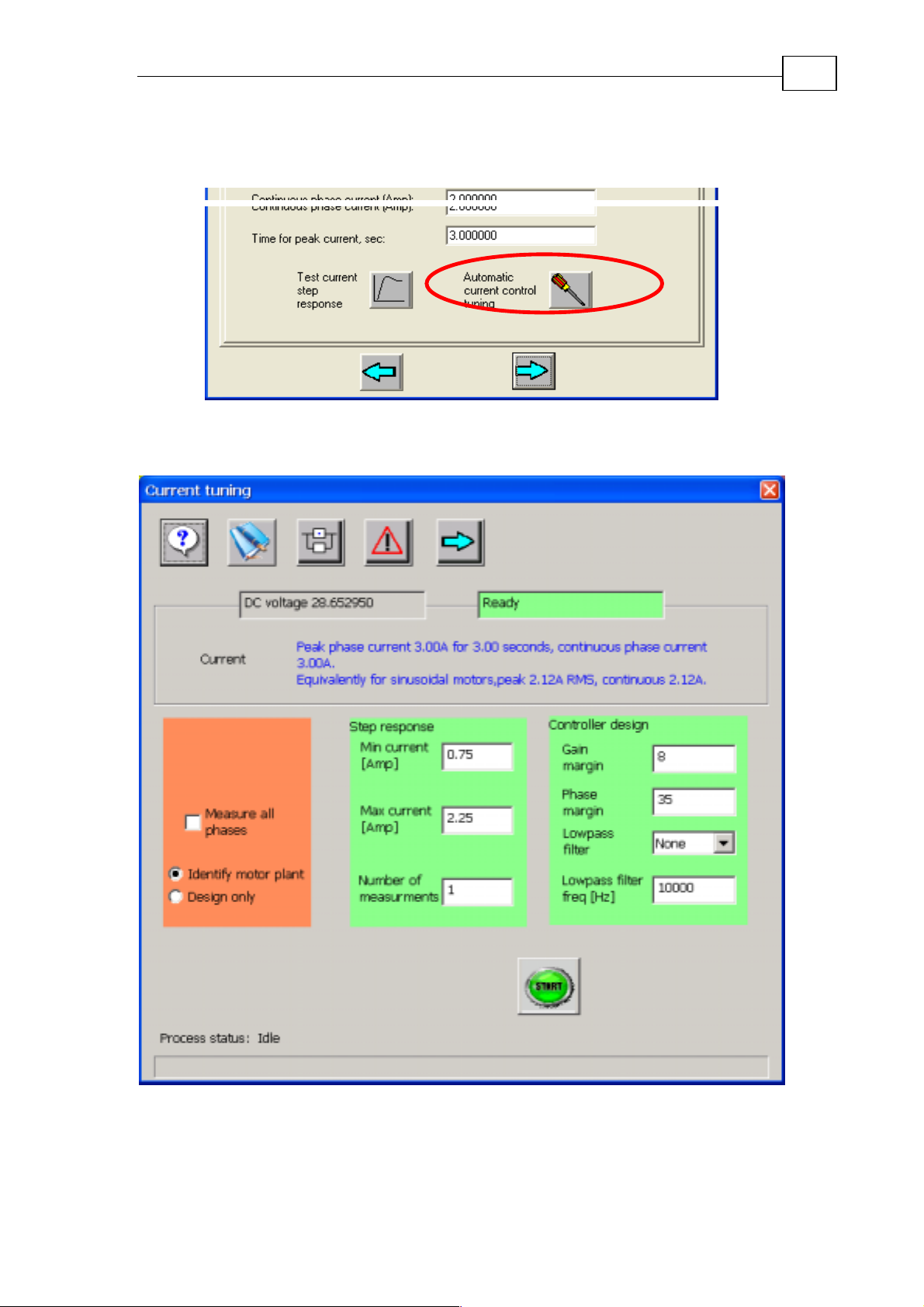

3.4.2 Tuni ng or Checki ng the Current Control

In the same window, select the automatic current control tool.

Figure 29: Entering the current control tuner

The following window opens:

29

Figure 30: Current tuning window

In general, you do not have to change anything in this window, just click Start.

When tuning is over, you will see a graph of the resulting current controller

response.

Page 30

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

By clicking the frequency graph button, you can also see the frequency r esponse

of both the open and closed current controller.

Notes:

Setting greater phase margins reduces overshoot , but it also r educes the

bandwidth of the resulting current l oop.

Apply the low-pass filter only if the current control is very noisy (this is very

rare).

Use greater current levels if you suspect the motor is working near magnetic

saturation.

Un-checking Measure all phases will result in shorter, but less accurate current

control tuning.

3.5 Commutation

Commutation tuning means the process of:

Defining which rotation directi on i s positi ve (t his i s a subj ecti ve user decisi on).

30

Learning the order and the polarity at which the motor phases were connected.

Learning the order and the polarity of the Hall sensors (if present).

Adjusting the parameters of the initial rotor position finding – this is essential

for a brushless motor to rotate.

Click the Commutation tab:

Page 31

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

31

Figure 31: The Commutation tab

After checking if Digital Hall sensors are installed, go to the tuning process.

The Conductor is responsible to make the motor rotate, so that when the

direction is positive:

The position sensor reading will increase.

The consumed current will be positive.

The problem is that the positive direction is subjective; unless you forced the

sensor direction (to remain as is), the Cond uctor does not know which d ir ecti on

your application calls positive.

To solve this, the Conductor will rotate the motor, and ask you to look at the

motor while it rotates. The following window will open:

Figure 32: Motor direction decision message

Page 32

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Check Reset Commutation Every Hall Edge if your position sensor is not

mounted directly on the motor, but through a gear train or a backlash.

3.6 Motion Tuning

This step depends upon the drive method you choose.

3.6.1 Torque Drive

If you want to enhance the torque control smoothness and performance, you may

want cogging and speed corrections. For that you will need to tune a speed

controller (even though you will disable it later). After tuning the speed

controller, go to the Fine Tune tab, finish the fine tuning, and then back to the

Motion tab to select Torque control.

If you do not need to enhance the torque control, go to the Database tab and save

your work. Then exit the Conductor.

32

Figure 33: Motion tab for torque drives

Page 33

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

3.6.2 Stepper Drives with no Commutation Sensor

For stepper drives, click the Motion tab and select either Open loop stepper or

Closed loop stepper with sensor #1.

33

Figure 34: Motion tab

Here you need to enter the holding torque component (static torque, speed

dependent torque, and accelerating torque).

The Motor Calculator button helps you to find the required parameters.

Page 34

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Motor calculator tool

34

Figure 35: Motion tab for stepper

After opening the Motor Calculator tool the following window appears:

Page 35

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

35

Figure 36: Motor calculation window

Complete the Inputs section of the form from the motor datasheet; then click

Calculate. This will give the holding torque fixed, speed dependent, and

acceleration dependent components, and also the maximum deceleration SD – f or

further explanations click the Help butt on.

For closed loop position control, this calculator also obtains the dynamic torque

limit PF[29].

You can download the calculated parameters to the drive by clicking Download.

3.6.3 Speed and Position Control

This section describes the speed and position control loop closure wide vi ew. The

details are also described.

There are three options that lead to approximately the same setup actions:

Speed control with sensor #1.

Position and speed control with sensor #1.

Speed control on sensor #1 and position control with sensor #2.

Select one and the Motion tab appears as follows:

Page 36

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

36

Figure 37: Motion tab for closed loop control

The Conductor presents an advanced set of motion tuning tools.

The usage level for the tools can be anything from novice to control expert.

Before using the Motion tab read the following sections.

The process is divided into several st eps:

Prepare for identification.

Identification.

Design.

Verification.

This division is because the process may be iterative in which case you may need

to repeat some of the steps.

Page 37

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Notes:

This step assumes that you have properly set the current control and the

commutation in advance. If the current control or commutation are not

optimum, the controller tuning will yield poor results.

If you use analog sensors (Analog encoder, Resolver, Potentiometer, LVDT, etc.)

take extra care to ensure your position signals are clean be fore you s tart motion.

The sensor quality must be tested with the motor fully powered, since RFI from

the motor occasionally disturbs the sensor quality. To find the sensor quality,

open the Composer, set UM=3 (Open loop), set HT[1]=CL[1] (maximum

holding torque), and record the motion sensor Position and Speed. (The

disturbance display on the speed record is much clearer than on the position

record).

3.6.3.1 Prepare for Identification

The control tuning environment needs a working closed loop to start from. The

initial closed loop does not need high performance.

37

Allow the Conductor to find a controller automatically. The Conductor tries to

follow the guidelines of the Appendix on manual tuning automatically. It concludes

with a controller that has quite low performance – only enough to continue

automatic tuning from here.

On starting the Controller tool, the following window opens:

Page 38

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

38

Figure 38: Start step designer window

Click Start and wait for the Conductor. Usually it succeeds and you have

completed the process.

If it failed, use the controls and read the online help in order to obtain a working

starting controller.

The starting controller replaces the motion controller with a lowperformance fixed controller. If you had a good controller in the drive before

starting the process of finding a controller, save your work (using the Database

tab) before opening this window.

3.6.3.2 Identification

Identification is the process of finding the transfer function of the controlled

plant. The transfer function will serve you later when you design a controller to

match it.

Page 39

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

The method for finding the transfer function is simple: inject sine signals of

varying frequency to the plant and measure the resulting motion. The

implementation of this method by the Conductor, however, is quite complex.

The transfer function of motion systems depends on the signal amplitude and the

working conditions. You can log differi ng tr ansfer funct ions, i denti fied wit h

different working conditions, an d then us e the m all in a co mbine d design proces s

to generate a controller that fits them all.

For quick identification, select the Identify tool.

The following window opens:

39

Figure 39: Identification window

Click Run, answer Yes to confirm the change of control parameters, and wait

until completion. The noises you hear are the frequencies that run through your

plant.

You will receive an identification result with a frequency response plot:

Page 40

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

40

Figure 40: Example of a frequency response

Click OK to return to the main identification screen, then save your work using

the File>Save menu. Name it MyFirstIden.idn.

3.6.3.3 Design

With the identification results you can design a controller. The controller has to

meet the following goals:

The robustness figures of merit: acceptable gain and phase margins.

Maximize crossover frequency and low frequency gain for agile and accurate

control.

Minimize high frequency response, in order to attenuate noises and in order to

de-sensitize the controller to the large uncertainti es of high frequency

identification.

These is a conflict between these goals so there is a trade off.

environment of the conductor is built to optimize this trade off.

Example: a completely automatic design: Select the Design tool.

The design

Select the Plant tab and click Add. Select MyFirstIden.idn as the identification

file. The following window opens:

Page 41

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

41

Figure 41: Add identified plant to the designer

Select Tools>Automatic design.

The following window opens:

Page 42

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

42

Figure 42: Automatic design window

Click Run. The results appear in the following window:

Figure 43: Complete design

Page 43

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

You have now completed your first successful design. You can save it to a file.

Select Tools>Download Design, and in the following window:

select the “Position” unit mode.

3.6.3.4 Verification

43

In the verification stage simpl y run st ep responses and j udge t hem accor di ng to

your needs.

Click the Verification tool.

The following window opens:

Page 44

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

44

Figure 44: Verification window

Click Start, and the results appear in the following window:

Page 45

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

45

Figure 45: Controller verification results

3.7 Fine Tuning

The Fine Tuning tab enables special enhancements to be t uned. Thi s is not

required for all applications.

The following fine tunings are availab le:

Cogging compensation Analog encoder index tuning

3.7.1 Cogging Compensation

The first compensation is for cogging. It becomes availab le when you check

Enable Cogging Compensation.

The cogging compensation adds a compensation torque

motor’s electrical angle; The aim of this window is to map

This mapping can be saved in the drive, saved to a file, or retrieved from a file.

)(T θ where θ is the

)(T θ .

Page 46

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

46

Figure 46: The Fine Tuning Tab

On opening the cogging compensation tool, the following window opens:

Page 47

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

47

Figure 47: Cogging compensation tuner window

The following options are available:

Set the cogging compensation to default, i.e., there will be no cogging

compensation.

Load a cogging table from a file, without measuring anything.

Measure the actual motor cogging by clicking Start.

When starting a cogging measurement, the following window opens:

When you click Yes, the experiment starts and the progress is displayed at the

bottom of the window.

Page 48

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

48

Page 49

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

3.7.2 Fine Tuni ng an Anal og Encoder

If sensor #1 is set to "Analog incremental encoder" in the "Sensor #1" window,

then the "Analog index tuning" button i s vi sib le. Thi s tuni ng defi nes the si gnal

level and position where analog index capture occurs.

Please note that for analog encoder, the index appears at different positions for

forward travel and for reverse travel; both cases are measured.

49

Figure 48: The Fine Tuning window whem sensor #1 is an analog encoder

When you click Analog Index Tuning, you need to define the experiment motion

in the following window. The motion has to traverse the analog encoder index.

Page 50

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

50

Figure 49: Analog index tuning

After you set the parameters for the experiment, click Start to begin; progress is

displayed in the progress bar at the bottom of the window.

Page 51

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

3.8 Database Maintenance

Finally, save the results. Click the Database tab:

51

Figure 50: Database maintenance tab

Check the database integrity. This checks for certain conflicts that can prevent

the motor from starting. For example, if you selected a commutation finding

method by CA[17] that does not match the installed sensors, the motor will not

start and it will report "Bad Database". Checking the database here will prevent

this error.

Save your parameters in flash memory.

Restore your previously stored parameters from flash memory if you want to

purge your Conductor session.

The Expert List of this window brings up the entire SimplIQ database.

Page 52

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Chapter 4: Advanced Control Tuning

This chapter is intended for users wishing to use the extra flexibility of the

motion control tuning system beyond the "getting started" level.

52

This chapter assumes you are familiar with Section

Feedback design is a four-step procedure.

The first step is to generate a low performance controller that is called the

"starting step controller".

This minimal controller only has to stabilize the motor while the plant dynamics

are identified. The Getting Started

Appendix, covers this step.

The second step is to identify the plant model, that is, to find its transfer

function; amplitude-phase versus frequency. Several frequency response

measurements can describe the same plant in order to reflect plant uncertainty.

The third step is to design a controller to match the plant's frequency response.

The user orients the design optimization by emphasizing design margins,

bandwidth, or noise attenuation.

The fourth step is verification – running a 'field' evaluation test.

Notes:

The "Getting Started" chapter has taken you through all these stages, choosing

full automation. This chapter goes over the tuner options in greater detail.

chapter, together with the Manual Tuning

3.6.3.

The feedback design process may be iterative – you can return to the design

stage to improve on the test results, or you can return to the identification stage

to add the results of new working points.

The auto-tuner is very flexible regarding these steps, as explained in the

following sections.

4.1 Start Step Control

4.2 Identification

This chapter deals with identifying the plant including, its uncertainty.

Notes:

This Chapter focuses on understanding what you do rather than on detailed

explanations of the window controls.

Detailed explanations of the window controls are in the online help.

The window controls may differ between Conductor versions, so the

explanations given here may also vary slightly.

Page 53

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

4.2.1 Identification and Uncertainty

The identification produces a frequency response. A frequency response is a

characteristic of a linear, time invariant plant. We take frequency response not

because the plant is really linear and time invariant; but because all the

established control design theory d eals wi th pl ants havi ng frequency r esponses.

Knowing very well the limitations of frequency responses, the DFT tuner

identifies many frequency responses instead of one. Each frequency response

describes the plant linearized about a different working point.

After this process, you will have many measured values for th e amplitu de/ph ase

of the plant at any given frequency. This set of values forms an "uncertainty set"

for the frequency.

Later, the Conductor will design a controller that optimizes the response to the

entire uncertainty set. This is much better than traditional methods that can only

consider one plant model at a time.

53

When the Conductor presents the identification result it normally shows one

nominal transfer function. This is because handling a multitude of transfer

functions is very complex.

Identification is an involved process, as it is nonlinear and noisy.

The Conductor is based on many years of trials and collecting data from actual

motion systems.

4.2.2 Identification Results Management

The Conductor stores the identification results in files with the .idn extension.

An identification file stores a list of frequencies and th e as soc iated amplitude an d

phase values of the plant transfer function.

You can keep several .idn files, each describing the plant with different working

conditions.

Identification file maintenance is from the window that opens by clicking

Identify in the Motion tab of the Conductor.

Page 54

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

n

MAN-BELGS (Ver. 1.1)

Ope

Sav e

New

Cleanu p

54

Figure 51: Identification file maintenance options

You can reset the identification pr ocess (New) and stor e resul ts (Sav e).

You can also edit existing identification results.

You can add frequency points to an existing identification. Open an existing

file, then add the frequencies you want (further details appear later in this

manual). This means that if you want to add data in a certain frequency region

you do not need to go through the entire identification process.

You can clean outliers from frequency responses (Cleanup) – deleti ng an

identified frequency which you consider unreliabl e

4.2.3 Identification Work Point

Identification is the art of exciting the plant with signals, so that its response will

reveal the most about its nature.

The Conductor identifies frequency responses, thus it naturally selects sinusoidal

excitation. Applying pure sinusoidal excitation in an open loop may not be such

a good idea – the motor may drift away and high frequency data may be

completely obscured by frictions.

The Conductor uses the "Starting Step" controller to set the plant working point;

at this working point it applies the sinusoidal exciting signals.

You need to help the Conductor in selecting the identification work-point, from

the following options:

Stay in place: The start step controllers hold the motor more or less in a fixed

position. The motor will hardly drift; the identification will suffer from

frictions.

Page 55

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Free: For non-restricted displacement around the initial position. The starting

step controller will keep the motor w ith con stan t sp eed, s o th at the friction s w ill

minimally affect identification. This mode gives the best linear identification.

Bounded: For restricted displacement around the initial position with given

position limits around the initial position. This mode gives most of the Free

mode advantages when you cannot allow free rotation of the motor.

You can identify in each of the "Stay in place", "Free" or "B ounded" modes.

The comparison will inform you how frictions affect your system; and the later

control design may consider all the cases.

The following figure shows your selection. The window opens by clicking

Identify in the Motion tab of the Conductor.

55

Figure 52: Selecting the identification method

Check Identify Aux. Sensor if you intend to use sensor #2 for position control.

4.2.4 Selecting the Identification Frequencies

The Conductor applies sine signals to the plant . Each si ne signal must be

maintained long enough for the transients to disappear, then the Conductor can

extract the frequency response for that single frequency.

Putting so much energy in a single frequency gives the best results which are also

the most noise immune. However, the identifi cation i s slow.

The Conductor must select the identification frequency with care, so that:

It will find all the critical plant data, without missing important points.

It can complete the identification in a reasonable time.

The Conductor applies an iterative search which first spans a broad set of

frequencies.

Where it finds large amplitude or phase gradients, it applies denser frequencies.

Where the frequency response looks locally smooth, it accept s it .

Page 56

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Although the automated frequency search works well in m ost cases, t he

Conductor may miss very narrow resonance/anti-resonance pairs.

We recommend that you first let the Conductor identify with automated

frequency search.

Check Automatic Refinement to allow intensified resolution where the

frequency response changes rapidly, e.g. near resonant modes.

Make manual adjustments when:

The identification results do not look continuous and smooth enough.

You suspect, based on the evaluation results, t hat the Cond uctor m issed a

resonance.

For this purpose, use the Frequency Editor.

56

Figure 53: Selecting the frequency editor

If you open the Frequency Editor before you have an identification result, the

window looks like this:

Page 57

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

57

Figure 54: Frequency Editor, when no identification is available

The red points, and the list in the Frequency area, show the frequencies for plant

excitation. For every frequency there is also an associated excitement current

amplitude.

Before the identification you can see the default set of frequencies that the

Conductor sets before learning the plant.

Bigger current amplitudes generate a better signal to noise ratio, and are thus

better for identification. There are other considerations, however:

o Large currents at high frequencies tend to saturate the amplifier voltage

due to motor inductance. This saturation is reflected in the identified

transfer function by decreased amplitude and increased delay.

o Large current near resonant modes lead to unpleasant noises, or even

mechanical damage.

After clicking Run Identification the window appears as follows:

Page 58

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

58

Figure 55: Frequency editor window after identification

The blue points show identification results.

There are no red points and no point listing in the selection box since all the

frequency points have been run and there has not yet been a new request.

You can add and edit new frequency points and run them; their identification

result will be appended to the existing frequency response results.

For the above identification, the resolution seems poor near t he anti resonance

and near the 2-3-4 resonances. We would like to increase the resolution there, and

use the Add>Graphics tool.

Add the red frequency points to the graph; on the next "Run Identification" only

the frequencies you added will be identified, and appended to the existing

identification record.

Notes:

Poor resolution usually reflects in the phase window being clearer than in the

amplitude window.

Do not confuse 360

°

phase jumps with phase resolution problems. Phase jumps

of 360° (see the right end of the above phase plot) come from angle display

folding.

Page 59

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

59

Figure 56: The Frequency Editor

Page 60

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Appendix A: Manual Tuning of Speed

and Position Control

A.1 Scope

This Appendix explains how to manually tune control ler s of the foll owi ng types:

1. A PI speed controller.

2. Cascaded position controller: The inner loop is a PI speed controller and the outer

loop is a position simple gain controller.

3. A PI speed controller with a single notch filter, a low-pass filter or both.

4. Cascaded position: The inner loop is a PI speed controller with a single notch filter,

a low-pass filter or both; and the outer loop is a simple gain.

The notch filter and/or low-pass filter are termed in this document as "High

order filters".

if the sensors are noisy with systems that exhibi t r esonance, and when i t i s

essential to decrease high frequency motor curr ents. The Hi gh order fil ter can

improve the controller performance dramatically when used correctly. Incorrect

usage of the High order filter can lead to a poor or even unstable controller.

High order filters are expected to improve closed loop performance

60

Use the manual tuning as a starting point for automatic tun ing: Au tomatic tuning

brings better results than human t uning i n most cases.

Notes:

This appendix concentrates on manual tuning tips and theory, and it does not

provide an accurate description of controller parameterization. For that, refer to

the KP[N], KI[N] commands etc in the SimplI Q for Stepper s Comm and

Reference Manual. All the relevant commands have links to the full control

structure description.

This appendix does not describe the tuning interfaces – see the sections on

motion tuning for that.

We strongly recommend familiarizing yourself with the controller structure and

parameterization before attempting to tune it.

A.2 Safety

Servo systems must be treated with car e. In the t uning pr ocess, they must be

treated with extreme care. Although we have made our best efforts to generate

safe tuning conditions:

In the tuning process, the motion controller may become unstable, leading to an

abrupt, unexpected response.

In the tuning process, the motion controller may become very weak, letting

disturbances and external loads drive the shaft.

Read this appendix carefully before launching an experiment, and evaluate the

experiment parameters carefully before launching it. The Conductor suggests

some experiment parameters, but it may mislead you, being unaware of your

specific limitations.

Page 61

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Treat unbalanced1 systems with extreme care.

A.3 Make it Simple

This Appendix gives some simple guidelines for manual controller tuning. In

order to simplify the tuning process we di vi de i t int o a seri es of steps.

The rules of simplification are:

Never tune your controller to perform better than you need. A controller of

lower bandwidth decreases stresses and is m ore ro bust to changes and ageing.

In this Appendix you will learn how the High order filter may decrease control

stresses.

Tuning a speed controller is simpler than tuning a position controller. If you

need to tune a position controller, try to tune first its embedded speed

controller. The Conductor program lets you tune a speed controller without the

risk that the motor will drift away from its starting shaft position.

If your mechanics are simple and good enough to avoid the High order filter,

adhere to the simple PI speed controller. The High order filter requir es more

skill to use. The High order filter always introduces a filtering delay, which

usually limits the achievable bandwidth compared to a simple PI.

61

Use the High order filter when encountering oscillations and high frequency

noise. The small extra effort of tuning the High order filter can b e very

beneficial.

If your encoder has good enough resolution and the friction is low enough, use

a fixed controller.

Use controller scheduling (dynamic adaptation of the controller parameters to

the situation) if you have a low-resolution encoder or high friction. The extra

effort of tuning the High order filter can be very beneficial.

Work linearly. With high controller gains the current command saturates for

very small tracking errors. The saturation makes the evaluation of control

quality very difficult. Keep the motions small enough and verify by the current

waveforms that the current command does not saturate2. Verify how the

controller works with large signals only after it is satisfactory with small

signals.

Work with steps. When you test a controller with limited acceleration or even

smoothed reference waveforms, don't excite high frequencies. The results will

not reveal oscillations and high frequency problems that may exist.

Do not fear overshoots. Overshoots are necessary if the controller is to track

without a time delay. Reducing the height of the overshoots lengthens their

duration. Evaluate the overshoot that you can tolerate by experimenting with

acceleration limited test waveforms, without exceeding the acceleration you

actually use.

1

Systems that do not stay in place when the motor is shut down.

2

Note that the rate of change of the current command is also limited. This is because

dI

max

inductance.

V

B

= where I is the motor current,

dt

L

V is the supply voltage and L is the motor

B

Page 62

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

A.4 Keep Margins

It is very tempting to increase the controller gains and enjoy the maximal

performance of your system. You must bear in mind that the price of maximum

performance is decreased robustness to system variations. The higher the gains, the

greater the chance that the system will become noisy or even unstable due to

changing work conditions, or due to ageing. The following tips will help you create

a stable, long-lasting motion system:

Tune for minimum inertia. If the inertia of the system varies, e.g. for a rot ary

robot arm, tune for minimal inertia

higher inertia will have a slower response time, but are likely to remain stable.

The controller must remain stable (it does not have to maintain an optimum

response) when you double the selected gains, and also when the selected gains

are reduced by half4.

Acceleration limits. For a position controller, the maximum motor acceleration

(parameter GS[9]) must be set high enough so that it does not disturb normal

operation, but also low enough so that it prevents position disturbances from

creating large overshoots.

3

. Positions or loading conditions with

62

A.5 The Basic Concepts

This section concisely and informally explains the entities you will come across

when tuning.

A.5.1 Fixed- vs. Gain-scheduled Controllers

The drive can run either a fixed- or a gain-scheduled controller. A fixed controller

runs a fixed set of control parameters

Gain scheduling is the process of adapting the controller parameters "on the fly"

to a given situation. The Drive stores 16 sets of controller parameter sets. The

active controller parameters set is chosen by the gain scheduling process.

The drive supports two types of gain scheduling.

Automatic gain scheduling: the Drive adapts the controller to the speed

controller command, in real-time. The reasons for automatic gain scheduling

are:

o When the speed becomes low, there is a large delay between consecutive

encoder position updates. This delay requires a decreased controller

bandwidth.

o At low speeds friction becomes a dominant control problem. Increasing

the integrator gain at low speeds may improve low speed behavior.

5

.

3

Tuning for the least inertia may have a high price with high inertia postures or load conditions. You

can tune instead for several postures or loads and apply manual gain scheduling.

4

If you tune a speed controller you don't have to test with halved gains. Position controllers are,

however, conditionally stable. This means that a position controller will loose stability with gains that

are small enough.

5

The fixed/scheduled option refers to the proportional and the integral speed gains, position gain, and

some parameters of the Advanced filter.

Page 63

The SimplIQ for Steppers Getting Started & Tuning and Commissi oning Guide

MAN-BELGS (Ver. 1.1)

Manual gain scheduling: The controller parameters may adapt due to a user

program or an external command. For example, the controller gains of a winder

may be increased as it rolls and gains weight.