Page 1

VIO-VELOCITY

OPERATING MANUAL

Rev 5/00

Elmo Motion Control

Page 2

Page 3

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

TABLE OF CONTENTS

Safety Information ...........................................................................................................................1

Introduction ......................................................................................................................................3

Servo Amplifier Description............................................................................................................5

2.1 STANDARD FEATURES .......................................................................................................................5

2.2 FAULT PROTECTION ...........................................................................................................................5

2.3 TYPE DESIGNATION ...........................................................................................................................6

2.4 TERMINAL DESCRIPTION....................................................................................................................6

2.4.1 Power connections......................................................................................................................6

2.4.2 Control connections....................................................................................................................6

2.5 DIP SWITCHES ...................................................................................................................................8

2.6 TEST POINTS ......................................................................................................................................9

2.7 ADJUSTABLE COMPONENTS...............................................................................................................9

Operation of the Servo Control.....................................................................................................13

3.1 COMMAND .......................................................................................................................................13

3.2 CFM.................................................................................................................................................13

3.3 CURRENT GAIN CONTROL (CGC)....................................................................................................14

3.4 EXTERNAL CURRENT LIMIT - CONTINUOUS (ECLC).......................................................................14

3.4.1 ECLC external voltage .............................................................................................................14

3.4.2 Continuous current limit resistor .............................................................................................14

3.5 EXTERNAL CURRENT LIMIT - PEAK (ECLP)....................................................................................14

3.5.1 ECLP external voltage..............................................................................................................15

3.5.2 Peak current limit resistor........................................................................................................15

3.6 LATCH MODE ...................................................................................................................................15

3.7 ENABLE ............................................................................................................................................15

3.8 LIMIT SWITCHES...............................................................................................................................16

3.8.1 FLS ...........................................................................................................................................16

3.8.2 RLS ...........................................................................................................................................16

3.9 VELOCITY MODE .............................................................................................................................16

3.9.1 Tachometer feedback................................................................................................................17

3.9.2 Armature Feedback ..................................................................................................................17

3.9.3 I*R Compensation ....................................................................................................................17

3.10 RESPONSE ADJUSTMENT (VELOCITY MODE ONLY) ....................................................................18

3.11 CURRENT MODE ...........................................................................................................................20

Mounting and wiring instructions ................................................................................................21

4.1 HEAT SINK MOUNTING ....................................................................................................................21

4.2 WIRING.............................................................................................................................................21

4.3 DC POWER SUPPLY...........................................................................................................................22

Status Indicators.............................................................................................................................23

Technical Specifications.................................................................................................................25

Dimensional Drawing.....................................................................................................................27

Accessories ......................................................................................................................................29

8.1 INTERFACE & EVALUATIONS BOARDS ............................................................................................29

Service Centers and Warranty......................................................................................................31

Page I

Page 4

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

9.1 WARRANTY PERFORMANCE ............................................................................................................ 31

List of Figures

FIGURE 1: TYPE DESIGNATION..................................................................................................................6

FIGURE 2: COMPONENT LAYOUT ...........................................................................................................11

FIGURE 3: TYPICAL VELOCITY RESPONSE WAVEFORMS ................................................................19

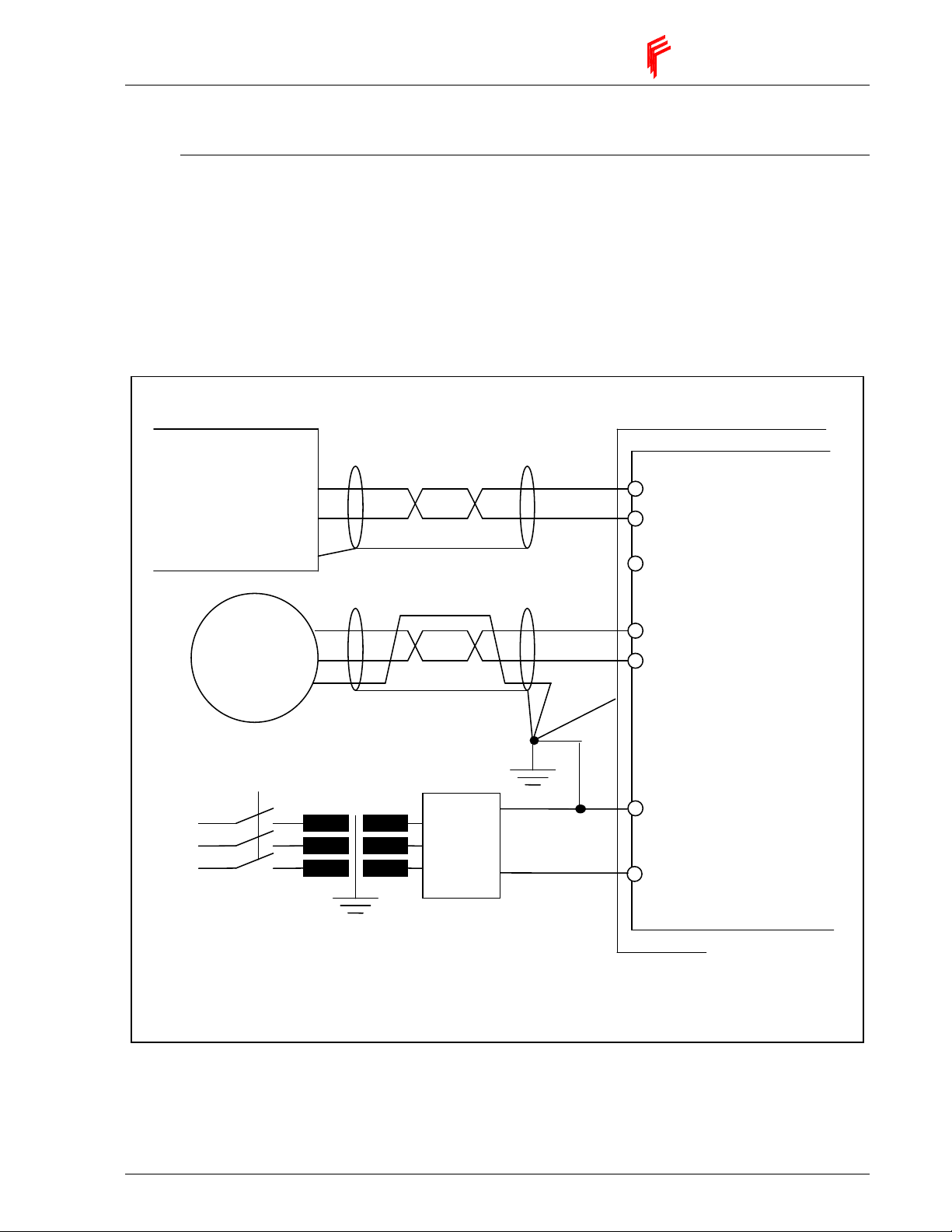

FIGURE 4: MOTOR WIRING .......................................................................................................................21

FIGURE 5: DIMENSIONAL DRAWING......................................................................................................27

FIGURE 6: SIB-SSA.......................................................................................................................................29

List of Tables

TABLE 1: POWER CONNECTIONS ..............................................................................................................6

TABLE 2: CONTROL CONNECTIONS .........................................................................................................7

TABLE 3: DIP SWITCH SETTINGS...............................................................................................................8

TABLE 4: TEST POINTS.................................................................................................................................9

TABLE 5: POTENTIOMETERS......................................................................................................................9

TABLE 6: REMOVABLE COMPONENTS ..................................................................................................10

TABLE 7: CFM EFFECTS.............................................................................................................................13

TABLE 8: MINIMUM INDUCTANCE VALUES ........................................................................................14

TABLE 9: RECOMENDED CAPACITANCE...............................................................................................22

TABLE 10: DIAGNOSTIC LED’S ................................................................................................................23

TABLE 11: RATING SPECIFICATION........................................................................................................25

TABLE 12: ELECTRICAL SPECIFICATION ..............................................................................................25

TABLE 13: ENVIRONMENTAL SPECIFICATION ....................................................................................26

TABLE 14: MECHANICAL SPECIFICATION ............................................................................................26

Page II

Page 5

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Safety Information

Read this page carefully before installation and use of the instrument, and follow all instructions in

this for safe installation of this product.

INTRODUCTION

The following clauses contain information, cautions and warnings that must be followed to ensure

safe operation and to retain the instrument in a safe condition.

This product is intended for incorporation into a machine or end product. The end product must

comply with all safety aspects of the relevant requirements of the European Safety of Machinery

Directive 89/392/EEC as amended, and with those of the most recent versions of standards

EN60204-1 and EN292-2 at least.

Only qualified personnel shall carry out installation, adjustment, maintenance and repair of the

instrument.

WARNINGS

Any removal from the structure or removal of parts, except those to which access is permitted, is

likely to expose live parts and accessible terminals, which can be dangerous to life. Only a

qualified person who is aware of the hazard involved shall perform any adjustment, maintenance or

repair, of the opened instrument under voltage.

The instrument shall be disconnected from all voltage sources before it is opened (for service).

Any interruption of the protective earth conductors inside the instrument is likely to make

the instrument dangerous.

Components, which are important for the safety of the instrument, may only be renewed by

components obtained through the Elmo service organization.

Before switching on, ensure that the instrument has been installed in accordance with the

Installation Instructions.

Maximum AC & DC supplies must be according to the types described in the operating manual.

The VIO-Velocity conforms to the following industry safety standards:

Power Conversion Equipment Recognized UL508c.

Insulation Coordination Including Clearance

and Creepage Distances Of Electrical

Equipment

Dielectric Voltage Withstand (Between the

base plate to any other part of the product).

Safety of Information Technology

Equipment, Including Electrical Business

Equipment

Low Voltage Directive, 73/23/EEC. In compliance with EN60204-1.

Page 1

In compliance with UL840.

In compliance with UL1557

Conditions 12.3- 12.5, 3000VAC or

4300 VDC.

In compliance with UL1950.

Page 6

Page 7

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Introduction

This manual is intended for the use of the design engineer who is implementing the VIO-Velocity

servo amplifier into a machine. It covers the various aspects of the implementation process from

basic understanding of the product concept and features, through a detailed explanation of the user

accessible functions, down to mounting guidelines and requirements from peripheral devices.

Chapter 2, “Servo Amplifier Description”, includes a description of the various features of the VIO-

Velocity, a list of all the pins and their functions and a block diagram of the product.

Chapter 3, “Operation of the Servo Control”, describes all the user accessible functions and gives

the design engineer the guideline as for how to design the peripheral circuits.

Chapter 4, “Mounting and Wiring Instructions”, covers the requirements from peripheral equipment

like motors, cables, and the power supply in order to achieve successful operation of

the VIO-Velocity.

Chapter 5, “Status Indications” summarizes all the indication outputs that are available to the user

in order to determine the amplifier status.

Page 3

Page 8

Page 9

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Servo Amplifier Description

The VIO-Velocity extends the VIO line by adding a velocity loop daughter board. This series of miniature

servo amplifiers for DC brush motors incorporate custom mixed analog/digital ICs and hybridized power

stage.

The product meets UL508c and the suitable CE regulations.

The power stage is implemented on a single ceramic substrate. This design enables very high thermal

conductivity, high current carrying capacity, better EMC and good mechanical strength. The control section

is implemented by dedicated custom ICs that contribute to higher and improved performance.

2.1 Standard Features

Operation in current mode or velocity mode

Armature feedback with I*R compensation,

Tachometer feedback

Internal DC to DC converter allows for operation from a single supply

Zero dead band

Excellent linearity

Motor current monitor

Current gain change for low inductance motors

Current feedback multiplier for low current motors

External continuous and peak current limits adjustments

Latch mode for the protective features

Forward and Reverse limit switches

Socketed components for adjusting:

• Continuous current limit

• Peak current limit

• Command scaling

• Tachometer scaling

• Velocity loop tuning

Full array of diagnostic LED’s

Additional capacitance on the DC bus

DIP switches for selecting functions such as CGC, CFM, Latch mode, Directional limits, and

Enable

An encoder feedback option card can be installed on the basic velocity board when required.

2.2 Fault Protection

• Short between the outputs or between each output and the Power Return.

• Over temperature

• Under/over voltage

Page 5

Page 10

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

Maximum voltage

Velocity version

2.3 Type Designation

VIO

15

55

////

V

VIO amplifier

Rated current

Figure 1: Type Designation

2.4 Terminal Description

2.4.1 Power connections.

Pin Function Remarks

VP+ Positive power Input Voltage determined by VIO model

PR Power input Return

M1 Motor power output 1

M2 Motor power output 2

This output will be positive when pin CREF (+) is

positive relatively to pin CREF (-).

Table 1: Power Connections

2.4.2 Control connections.

Pin # Short form Function Remarks

1 TAC+ Tach positive input.

2

TAC- Tach negative input.

Positive input of a differential amplifier with two

adjustable resistors R1 and R2.

Negative input of a differential amplifier.

Specification as for pin 1.

3 REF-

4 REF+ Command positive input

5 ECLC

Page 6

Command negative

input

External current limit –

continuous

Negative input of a differential amplifier.

Specification as for pin 4.

Positive input of a differential amplifier with two

adjustable resistors R5 and R6.

External voltage reduces the Ic limit.

For more details see "current limit paragraph".

Page 11

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Pin # Short form Function Remarks

6 ECLP

External current limit –

peak

External voltage reduces the Ip limit.

For more details see "current limit paragraph".

7 ECLRET Current limits return Return for the current limit signals.

8 FLS Forward limit switch

9 RLS Reverse limit switch

Positive input of the opto isolated forward limit

switch

Positive input of the opto isolated reverse limit

switch

10 LSRET "FLS", "RLS" – Return Return for limit switch signals.

Analog output with a scale of ± 5V for ± Ip.

11 CM Current monitor

Output resistance: 11Kohm

12 CMRET Current monitor return Return for the current monitor (CM) signal.

13 EN+ Enable (+) Positive input of the opto isolated enable input

14 EN- Enable (-) Negative input of the opto isolated enable input

“Amplifier OK” indication output pin.

When the amplifier is at normal operating

conditions this output is in “active Low “ state.

When a failure occurs this output is changed to

15 AOK Amplifier OK

“open” state.

Opt isolated, open collector NPN type. Max.

Voltage = 30V.

16 AOKRET Amplifier OK return

Table 2: Control Connections

Max. Current = 8 ma.

“On” voltage: V

OUT (On)

< 0.8V

Status Outputs Common for AOK.

Isolated from the circuit common.

Page 7

Page 12

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

2.5 DIP Switches

Switch Function ON OFF

S1

S2 CFM

S3 CGC

Armature

Feedback signal.

Armature Feedback is

connected.

Changing S2 to ON

position multiplies the

current feedback

signal by 2.

Changing S3 to ON

position reduces the

proportional gain (P)

of the current loop by

70%.

Armature Feedback is

disconnected.

CFM – OFF

CGC – OFF

S4 LM Latch mode. Non-Latch mode.

S5 "FLS" and "RLS"

S6 EN+

Directional inhibits

are bypassed

Amplifier is Enabled

when S6 is in the ON

position and EN-

(pin 14) is connected

to ECLRET (pin 7)

Directional inhibits are

active.

" Amplifier Disable ".

Table 3: DIP Switch Settings

Page 8

Page 13

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

2.6 Test Points

Test point

VM Velocity Feedback signal

CC Current Command to the VIO

G GND Ground

G

GND Ground

Function Description

2.7 Adjustable Components.

Potentiometer Function Description

P1 Velocity Feedback gain.

P2 Offset trimmer.

±4V

±3.75V = nominal Ip of the VIO

Table 4: Test Points

Adjust for 4V on VM at max

velocity.

With command at 0V adjust to

cancel drift.

P3

Compensation, AC gain

compensation of velocity loop.

Table 5: Potentiometers

Adjust CW until a buzz is heard

then CCW until quiet again.

Page 9

Page 14

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

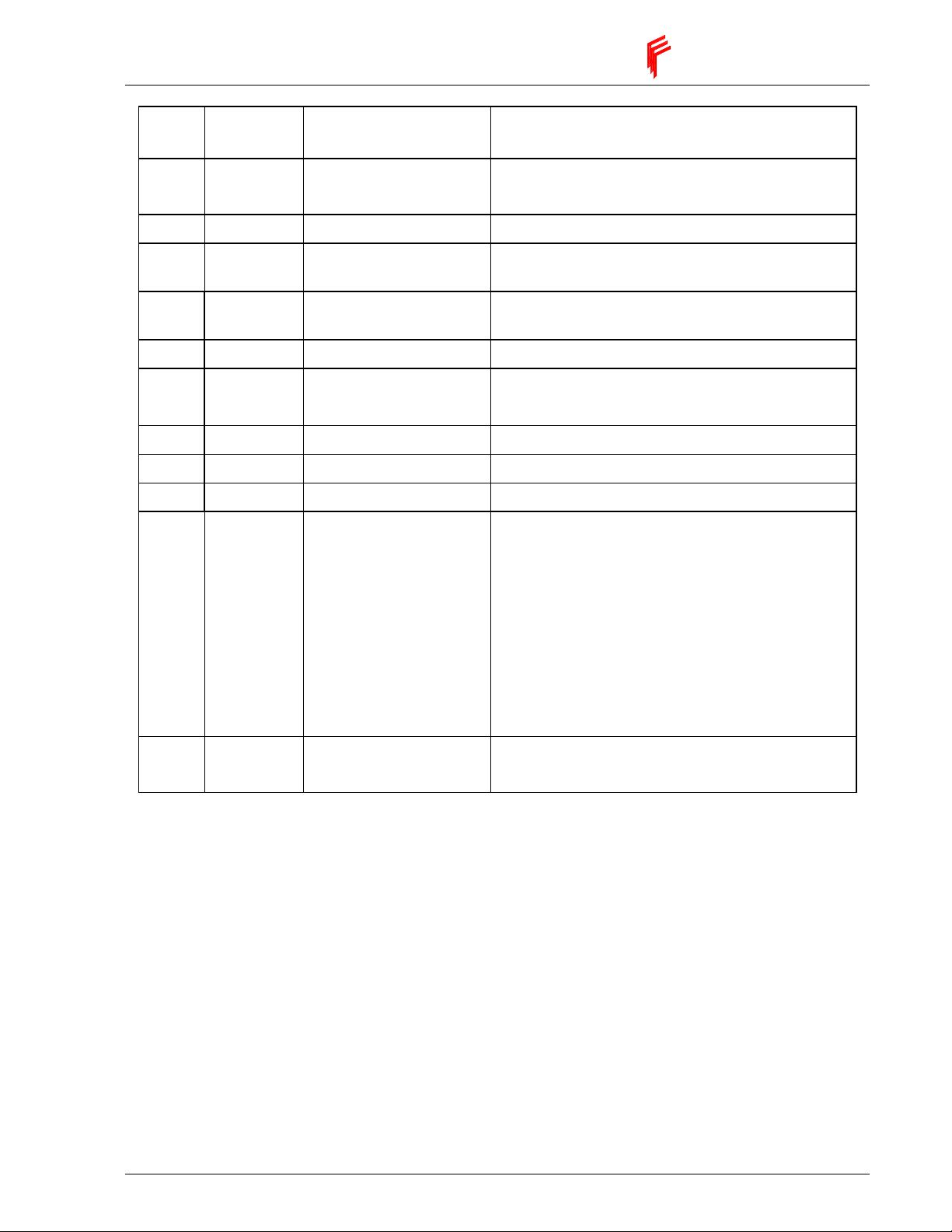

Component Stock Value Function

R1 Not installed Tachometer feedback resistor. (See 3.4 below)

R2 Not installed Tachometer feedback resistor. (See 3.4 below)

R3 Not installed Tachometer feedback resistor. (See 3.4 below)

R4 Not installed I x R compensation resistor. (See 3.9.2 below)

R5

R6

R7

R8

R9 Not installed Continuous current limit resistor. (See 3.4.2 below).

R10 Not installed Peak current limit resistor. (See 3.5.2 below)

C1

24.3KΩ

24.3KΩ

30Ω

475KΩ

0.022µf

Input scaling resistor. (See 3.1 below)

Input scaling resistor. (See 3.1 below)

DC gain adjustable resistor of the error amplifier.

(See 3.9 below).

AC gain adjustable resistor of the error amplifier.

(See 3.10 below).

Adjustable capacitor for the AC gain of the error amplifier.

(See 3.10 below)

Table 6: Removable Components

Page 10

Page 15

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Test

Points

Figure 2: Component Layout

Page 11

Page 16

Page 17

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

===

=

Operation of the Servo Control

3.1 Command

The user can change the default scale of the differential input (±10.0V) by calculating and inserting R5 &

R6 into the designated solderless terminals. The value of theses resistors is given by:

KohmsVRR MAXIN

)(*5.265

The factory default values of R5 and R6 are 25Kohms. This value is for ±10V command input.

Care must be taken not to apply input voltage above the maximum input voltage as this will cause the input

op amp to operate beyond its limits and in extreme cases may even damage the op amp. The maximium

voltage is calculated by:

8.0*)(5)( KohmsRV MAXIN

3.2 CFM

The amplifier is equipped with Current Feedback Multiplier (CFM). By switching S2 to the ON position the

signal of the current feedback is multiplied by 2 and consequently the following changes occur:

• Current gains are divided by 2.

• Current monitor is multiplied by 2.

• Current limits are divided by 2.

This function should be activated whenever the rated current AND the peak current of the motor are less

than 50% of the amplifier rated continuous and peak limits respectively.

Cont.

Current limit

With no CFM Ic Ip Ip/4 5/Ip

With CFM Ic/2 Ip/2 Ip/8 10/Ip

Peak Current

limit

Current

Gain (A/V)

Current

monitor

(V/A)

Table 7: CFM effects

The default (S2 Off) is normal current feedback.

Page 13

Page 18

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

75.3

V

3.3 Current Gain Control (CGC)

The amplifier is equipped with Current Gain Control (CGC) for improved performance of low induction

motors. By switching S3 to the ON position the gain of the current loop is reduced, thus enabling the use of

low inductance motors without the insertion of an additional inductor. The default (S3 OFF) is high gain.

Switching S3 to the ON position reduces the proportional gain (P) of the current loop by approx. 70%. In

the following table, minimum inductance values can be calculated.

25/50 L

15/55 L

10/100 L

15/100 L

6/200 L

15/200 L

Minimum inductance for High Gain Minimum inductance for Low Gain

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

> 2.4*10

> 4*10

> 9*10 -3 * V

> 6*10 -3 * V

> 16.5*10 -3 *V

> 6.6*10 -3 *V

-3

-3

* V

* V

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

L

L

L

L

L

L

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

Load (millihenry)

> 0.9*10 -3 * V

> 1.6*10 -3 * V

> 2.2*10 -3 * V

> 1.5*10 -3 * V

> 4*10 -3 * V

supply (Volt)

> 1.6*10 -3 * V

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

supply (Volt)

Table 8: Minimum inductance values

3.4 External Current Limit - Continuous (ECLC)

The amplifiers' continuous current limit can be reduced by an external voltage or by a fixed resistor R9. .

For most applications using a fixed resistor will be the preferred method.

3.4.1 ECLC external voltage

An external positive voltage (0 to 3.75V) to terminal ECLC in reference to terminal ECLRET will control

continuous current limit from zero to Ic (nom).

V

ECLC

)( nomI

newI C

C =

)(*

Remarks:

The voltage will be internally clamped to 3.75V whenever the external V

will be higher

ECLC

than 3.75V.

The external voltage source must be capable to source/ sink at least ±0.2 ma.

The max absolute V

ECLC

is 12V.

3.4.2 Continuous current limit resistor

The user can change the continuous current limit by calculating and inserting R9. The value is given by:

)(

KohmR

*4.37)(9 −=

nomIc

Remarks:

• 0 < R9 < 36.4K (1/8 Watt)

• If R9 is larger than 36.4K the current limit will be internally clamped to the nominal value.

newIc

• I

is the nominal continuous current limit of the amplifier.

C (nom)

1

)(

3.5 External Current Limit - Peak (ECLP)

The amplifiers' peak current limit can be reduced by an external voltage or by a fixed resistor R10. . For

most applications using a fixed resistor will be the preferred method.

Page 14

Page 19

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

75.3

V

3.5.1 ECLP external voltage

An external positive voltage (0 to 3.75V) to terminal ECLP in reference to terminal ECLRET will control

peak current limit from zero to Ip (nom).

V

ECLP

)( nomI

newI P

P =

Remarks:

The voltage will be internally clamped to 3.75V whenever the external V

than 3.75V.

The external voltage source must be capable to source/ sink at least ±0.2 ma.

The max absolute V

ECLP

is 12V.

)(*

will be higher

ECLP

3.5.2 Peak current limit resistor

The user can change the continuous current limit by calculating and inserting R10. The value is given by:

)(

KohmR

*4.37)(10 −=

nomIp

Remarks:

• 0 < R10 < 36.4K (1/8 Watt)

• If R10 is larger than 36.4K the current limit will be internally clamped to the nominal

value.

newIp

• I

is the nominal peak current limit of the amplifier.

P (nom)

1

)(

3.6 Latch Mode

By setting S4 to the ON position, whenever one of the following failures: Short, and Over Temperature

occur the amplifier will be latched in Disable mode.

Disabling the amplifier (removing the power from the Enable pins J4/13 and J4/14) resets the latch. If the

amplifier is enabled by S6, switch S6 off then back on.

3.7 Enable

Pins J4/13 and J4/14 are the inputs of an opto-coupler. The opto-coupler must be energized to enable the

operation of the amplifier. If the Enable input is kept High before powering the amplifier, the amplifier

power output will be active immediately upon power on.

To enable the operation of the amplifier the opto must be “on”. This can be done in two ways:

1. Apply voltage between this J4 pin 13(+) and J4 pin 14 (-).

Minimum “ON” voltage: 5V, current consumption 1.2 ma.

Maximum “ON” voltage: 15V, current consumption 5 ma.

When operating in this mode Dipswitch 6 must be in the OFF position.

2. Set Dip switch 6 to the ON position and connect "EN-" (pin 14) to ECLRET (pin 7).

Page 15

Page 20

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

7

R

3.8 Limit switches

When one direction of rotation is disabled, the reference input is clamped to 0V in this direction. Please be

aware that the unit can still drift due to offset. If an absolute stop is critical to the application the controller

of the machine should also handle the switch.

3.8.1 FLS

To enable the operation of the amplifier in the forward direction the FLS opto must be “on”. This can be

done by either of two methods:

1. Applying voltage between this J4 pin 8(+) and J4 pin 10 (-).

Minimum “ON” voltage: 5V, current consumption 1.6 ma.

Maximum “ON” voltage: 15V, current consumption 5.6 ma.

When using with this mode Dipswitch 5 must be in OFF position.

2. Changing Dipswitch 5 to ON position.

3.8.2 RLS

To enable the operation of the amplifier in the reverse direction the RLS opto must be “on”. This can be

done by either of two methods:

1. Applying voltage between this J4 pin 9(+) and J4 pin 10 (-).

Minimum “ON” voltage: 5V, current consumption 1.6 ma.

Maximum “ON” voltage: 15V, current consumption 5.6 ma.

When using with this mode Dipswitch 5 must be in OFF position.

2. Changing Dipswitch 5 to ON position.

Note: Changing dipswitch 5 to the ON position bypasses both directional limit switches

3.9 Velocity Mode

In the velocity mode, op amps U1/2 are employed as a high gain error amplifier. The

amplifier sums velocity command and the velocity feedback signal, and provides the

necessary servo compensation and gain adjustments, resulting in stable, optimum servo

operation.

This op amp is configured with two feedback paths:

One, in the form of a resistive T network, controls the DC gain of this amplifier. The

equivalent value of a T network is given by:

10

Rf

10

Ω=

Resistor R7 is mounted in solderless terminals so it can be changed easily whenever the

DC gain of the error amplifier is to be changed. The AC gain is controlled by C1, R8 and

P3. Maximum AC gain is obtained with P3 set fully CCW. Setting P3 fully CW removes

AC gain and no lag in response occurs. R8 and C1 are mounted in soldering terminals and

can be easily replaced in cases when P3 range is not enough to get optimum response.

Page 16

Page 21

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

===

=

3.9.1 Tachometer feedback

When using Tachometer feedback the user must select the scale for the differential input by calculating and

inserting R1 & R2 into the designated solderless terminals. The value of theses resistors is given by:

*5.221

VTM = maximum Tachometer voltage at the differential Input.

Care must be taken not to apply input voltage above the maximum input voltage as this will cause the input

op amp to operate beyond its limits and in extreme cases may even damage the op amp. The maximium

voltage is calculated by:

8.0*)(1)( KohmsRV MAXIN

Note: 1) * When using Tachometer feedback R3 must be Inserted (R3 value is 0 to 100 ohm).

* Dipswitch 1 must be in OFF position.

2) When using Armature feedback R3 must be removed.

KohmsVRR TM

3.9.2 Armature Feedback

An internal differential amplifier with fixed gain is used for armature feedback. The gain of this circuit is

set for the maximum voltage of the VIO. If the adjustment range of the potentiometer P1 does not provide

enough gain, the armature signal can be externally connected like a tachometer. When this is done,

calculate R1&2 using the DC bus voltage for VTM. This should only be required when the bus voltage is

near the minimum operating voltage of the VIO.

To activate Armature feedback change S1 to the ON position and remove resistor R3.

3.9.3 I*R Compensation

In order to improve the speed stability in various load conditions, I*R compensation is required.

This is achieved by inserting R4. The value of R4 can be achieved empirically.

The following procedure should be performed to determine R4 empirically:

a) Connect a decade resistor box in the terminals of R4 - start with 3Mohm

b) Run the motor at 2/3 of nominal speed.

c) Apply nominal load.

d) Decrease resistance value until motor speed reaches the no load speed.

e) Install R4 as close as possible to the decade box value. R4 should be between 500K and

3Mohms.

Note: A high compensation may result in unstable operation of the amplifier.

Page 17

Page 22

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

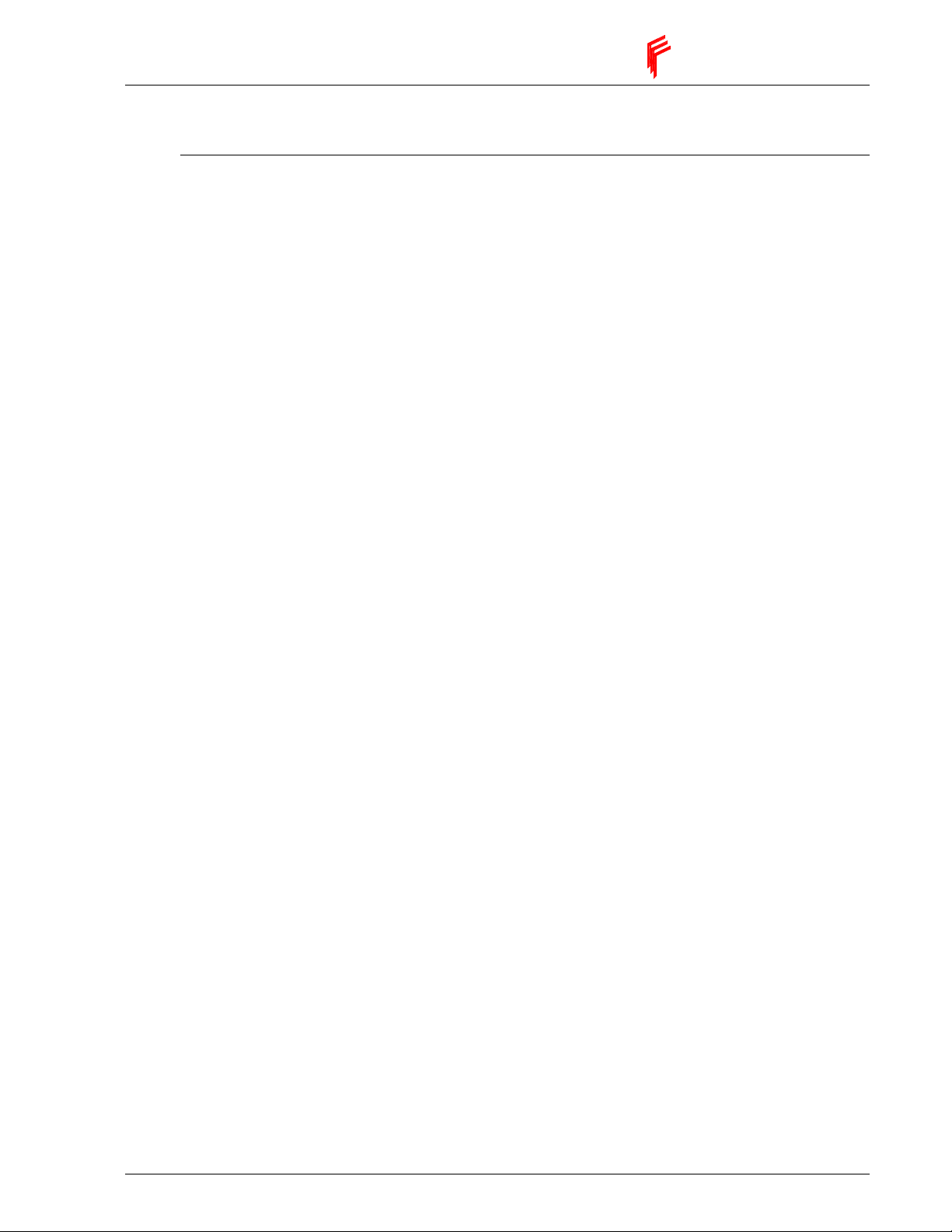

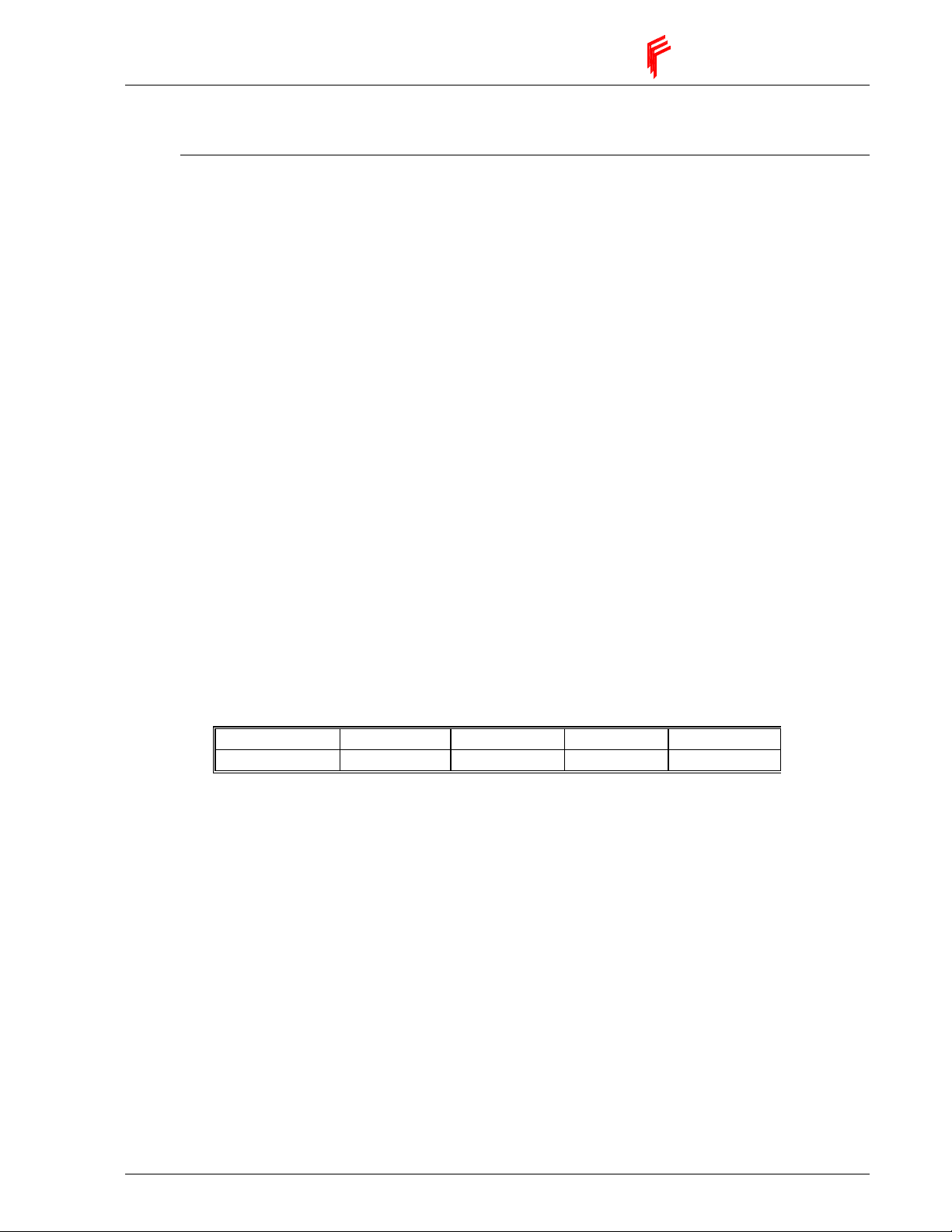

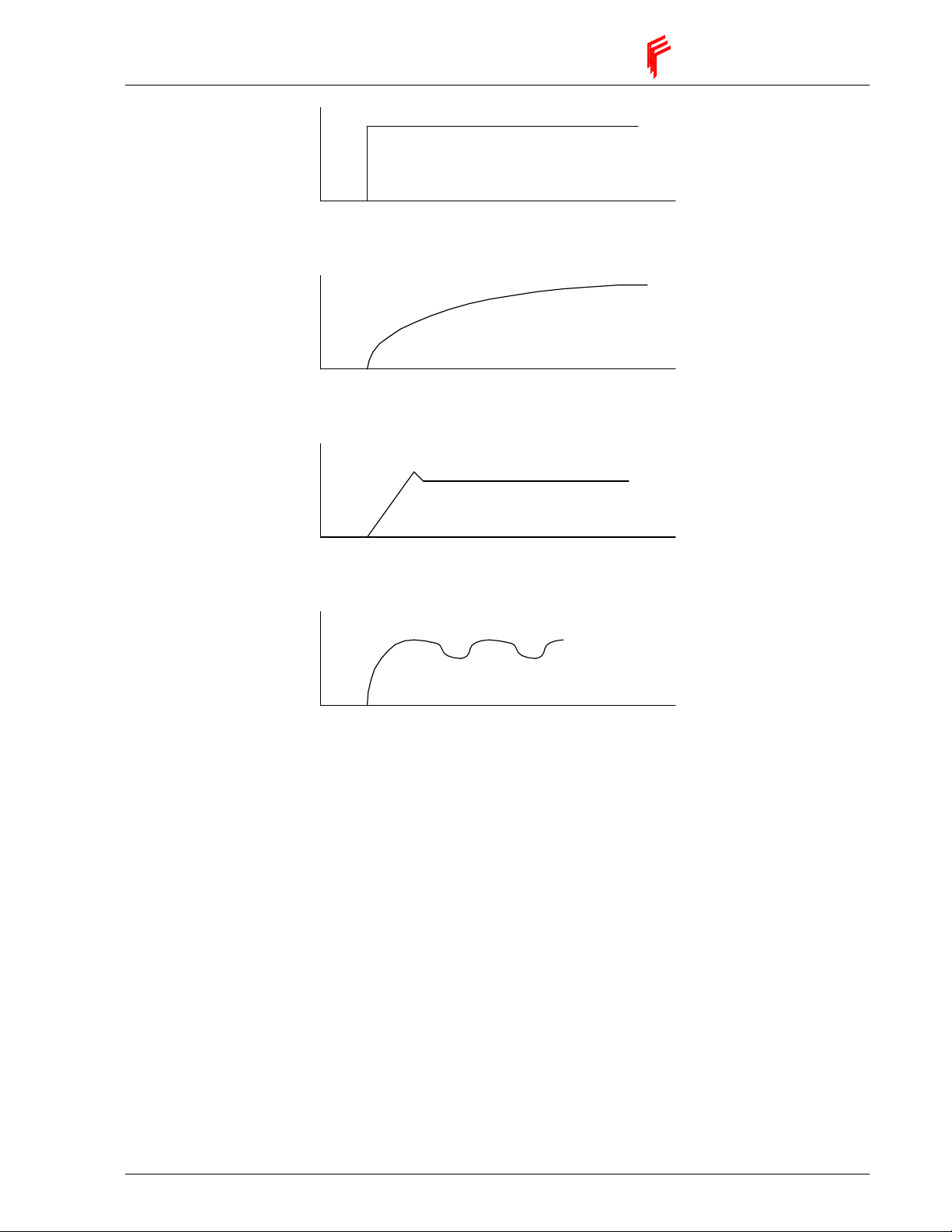

3.10 Response Adjustment (Velocity Mode Only)

In most applications optimum response is achieved by adjusting the compensation (COMP)

trimmer. Adjustment procedure is as follows:

- Provide the amplifier with a low frequency, bi-directional square wave velocity command (A 0.5Hz,

±2V waveform is often employed).

- Apply power to the amplifier, and while monitoring the tachometer signal, gradually adjust the

COMP trimmer from the CCW toward the CW position. Optimum response (critically-damped)

should be achieved at some position before reaching full CW on P3. Fig 8.1 illustrates the types

of waveforms observed for various setting of P3.

In some applications, especially those where the load inertia is much smaller or larger than

normally encountered, the standard compensation components values of 0.022µF for C1 and

475Kohm for R8 may not allow an optimum setting of the COMP trimmer P3. In fact, the velocity

loop may be unstable for any setting of P3.

In these cases different values for C1 and R8 must be chosen. The following procedure can be used

to select these values:

a) - Replace C1 with a short jumper wire.

b) - Replace R8 with a decade resistance box. Initially set the box resistance at 20Kohm.

c) - Set P3, the COMP trimmer to approximately midrange.

d) - Input a 0.5Hz, 2V bi-directional square wave velocity command signal to the amplifier.

e) - Apply power, and while monitoring the tachometer signal, gradually increase the value of

the box resistance until optimum response as depicted in Fig 8.1 is achieved.

f) - Substitute the closest standard value discrete resistor for R8 and remove the decade

resistance box.

g) Remove the shorting jumper, install C1, and again check the response using the square wave

test signal. If near optimum results are obtained, trim the response using the COMP trimmer

P3 for the optimum.

h) - If the previous step does not yield satisfactory results, if unacceptable overshooting has been

noted, substitute a larger value than 0.022µµµµF; or, if the response is over damped substitute a

smaller value than 0.022µµµµF. Repetition of this procedure should yield an optimum choice for

C1.

Page 18

Page 23

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Underdamped: P3 too far CCW

Reference input signal

Overdamped: P3 too far CW

Critically damped: P3 optimum

Figure 3: Typical velocity response waveforms

Page 19

Page 24

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

3.11 Current Mode

In order to operate the servo amplifier as a current amplifier, the velocity loop should be disabled. This is

done by converting the error amplifier into a low gain DC amplifier that has a flat response beyond the

desired current bandwidth. To run the VIO-V in current mode:

Set S1 to OFF

Remove R3 (in solderless terminals)

Remove R4 (in solderless terminals)

Remove R7 (in solderless terminals)

Remove C1 (in solderless terminals)

When operating in current mode the user adjustments are command scaling, CFM, CGC, and offset.

Page 20

Page 25

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

A

Vp+

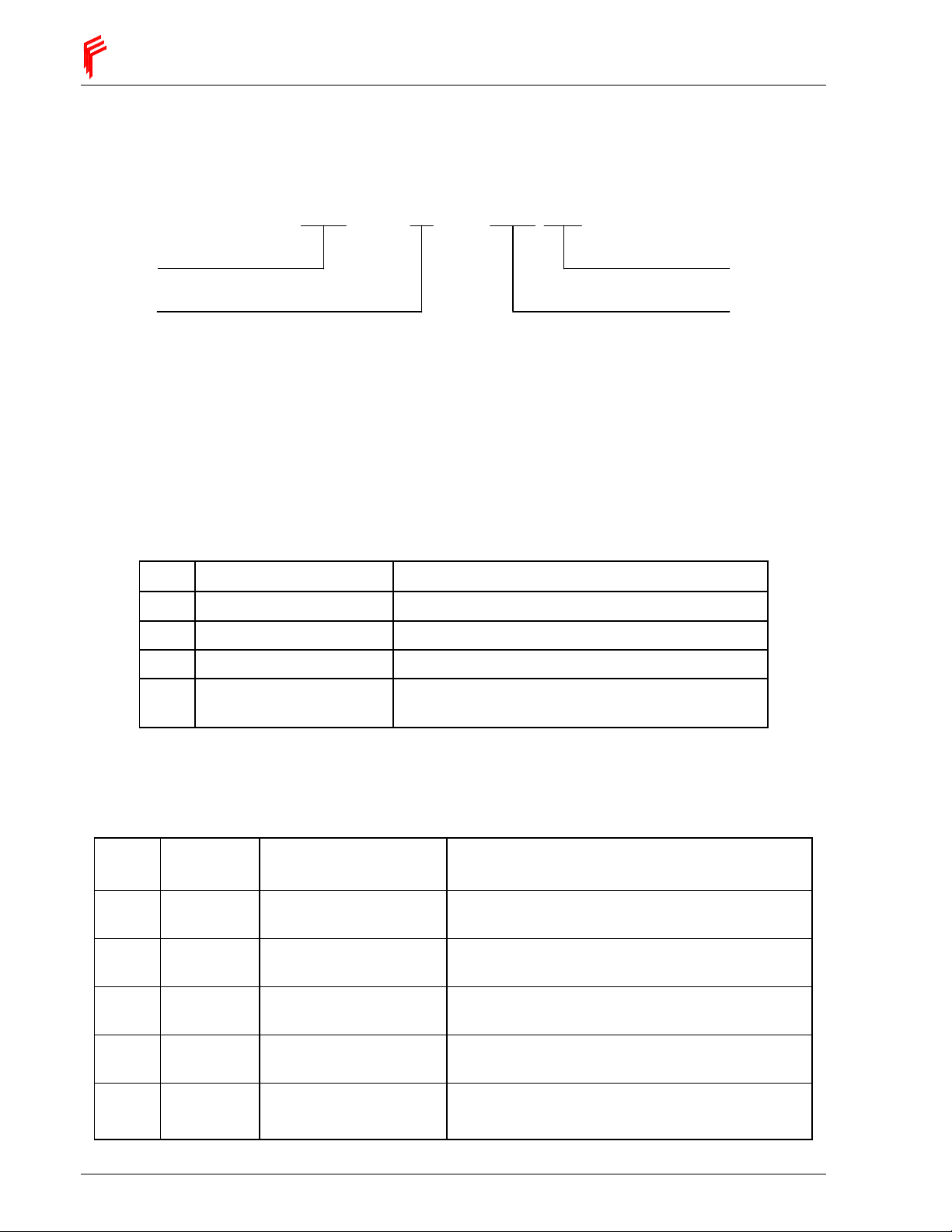

Mounting and wiring instructions

4.1 Heat Sink Mounting

The VIO series dissipates its heat by natural convection for loads up to 500W. For higher output loads the

amplifier should be mounted on an additional heat sink or cooled by fan. Care should be taken that the

motor leads are as short as possible. The capacitance of long shielded motor leads can cause the amplifier

to generate a significant amount of heat. There are two 4.5mm holes in the base plate for mounting to an

additional heat sink (see Figure 5).

4.2 Wiring

Motion Controller

Controller's common

Motor

Chassis

Isolating transformer

See remark below

Power wires twisted and shielded

B

(-)

(+)

Power

Supply

REF+

REF-

CMRET

M1

M2

VIO-V

PR,

Power Return (-)

Heatsink

Figure 4: Motor wiring

Page 21

Page 26

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

Guidelines for connecting a non isolated amplifier with an isolating power transformer

Ground:

DC power common

Motor chassis

Amplifier's heat sink

4.3 DC power supply

DC power supply can be at any voltage in the range defined within the technical specifications. The supply

source must comply with the safety aspects of the relevant requirements in accordance with the most recent

version of the standard EN60950 or equivalent Low Voltage Directive Standard, all according to the

applicable over voltage Category. If the power source to the power supply is the AC line (through a

transformer), safety margins have to be considered to avoid activating the under/over voltage protection due

to line variations and/or voltage drop under load.

In addition to the above, the transformer must comply with the safety aspects of the relevant requirements

in accordance with the most recent version of the standard EN60742 (Isolating and Safety Isolating

Transformers). The nominal DC bus voltage should be in the following range:

1.2VDC

VDC

VDC

Recommended minimum power supply capacitance for single phase connection:

- Minimum DC bus

min

- Maximum DC bus

max

< VDC < 0.9VDC

min

max

Type of amplifier VIO-

25/50V

Recommended

5600µF 5600µF 3300µF 5600µF 1500µF 5600µF

VIO-

15/55V

VIO-

10/100V

VIO-

15/100V

VIO-

6/200V

VIO-

15/200V

capacitance

Table 9: Recomended Capacitance

The transformer power should be calculated to have the capability to deliver power to the amplifier

(including peak power), without significant voltage drops.

The power supply should be located as close as possible to the amplifier. Maximum distance is 30cm (1

foot).

While driving high inertia loads, the power supply must be equipped with a shunt regulator, otherwise, the

amplifier will be disabled whenever the capacitors are charged above the maximum voltage.

Page 22

Page 27

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Status Indicators

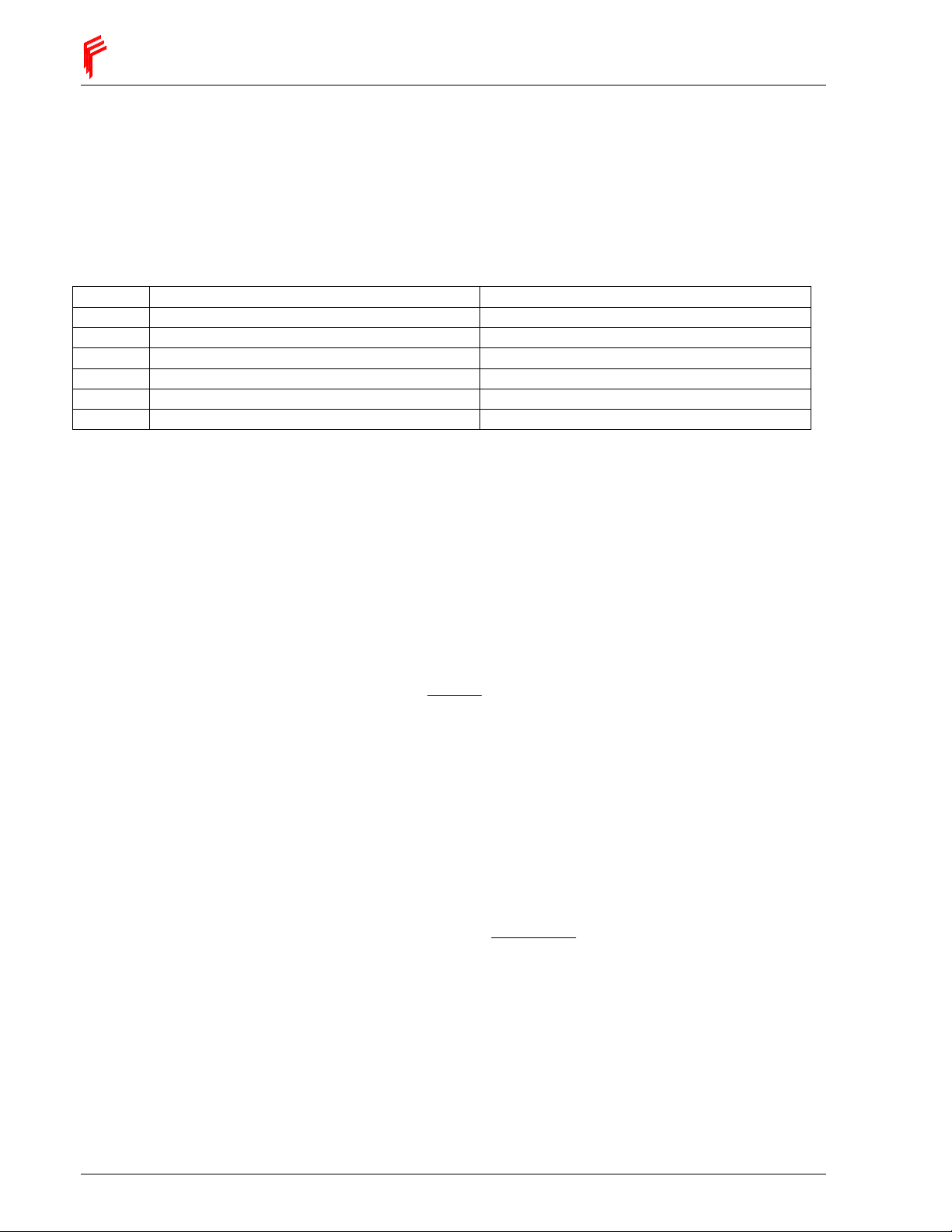

LD1

Latch

Function

Amplifier

OK (AOK)

External

disable

Current limit No ON OFF OFF ON

Short Yes OFF ON OFF ON

Over

temperature

Internal

supplies

protection

Under

voltage

Over voltage No OFF OFF ON OFF

Power Up

Reset

option

N/A ON OFF OFF OFF

No ON ON OFF ON

Yes OFF OFF ON ON

No OFF ON ON OFF

No OFF ON OFF OFF

No OFF OFF OFF OFF

AOK

Yellow

LD2

SO1

Red

LD3

SO2

Red

LD4

SO3

Red

Table 10: Diagnostic LED’s

Note:

Latch mode OFF: The LED indications are present only while the fault is active.

Latch mode ON: The LED's indications (temperature and short) are reset when the enable

signal is removed from the enable input.

Multiple Faults: Only the reading of the first fault is reliable. Additional faults add to the

status and the indication will be meaningless

Page 23

Page 28

Page 29

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Technical Specifications

Table 11: Rating specification

Type DC Supply

Min-Max (V)

*

*

*

Current limits

Cont/Peak (A)

VIO-25/50V 10-49 25/50

VIO-15/55V 10-56 15/30

VIO-10/100V 20-96 10/20

VIO-15/100V 20-96 15/30

VIO-6/200V 40-196 6/12

VIO-15/200V 40-196 15/30

Table 12: Electrical specification

Parameter Value

DC output voltage >93% of DC input voltage

Switching frequency on the load

Current loop response 3kHz minimum

Current step response

Efficiency at rated current 97%

Peak current duration (full rated peak current)

Continuous current limit tolerance -1% +5%

Peak current limit tolerance -1% +5%

Current gain linearity

Current gain accuracy

Current monitor accuracy

32kHz (±5%)

<150µs

2.7seconds ±15%

Better than ±1% of rated continuous current

Better than ±5% for 0.05Ic<Imotor>Ip

Better than ±5% for 0.05Ic<Imotor>Ip

*

*

*

These are the absolute minimum-maximum DC supply voltages under any condition.

Page 25

Page 30

Elmo Motion Control Rev 09/09 VIO-Velocity - Operating Manual

Table 13: Environmental specification

Parameter Value

Operating ambient temperature

Max. Case temperature

Storage temperature

Operating humidity 90% non condensing

Max. Operating altitude 2000m (6,500 feet)

Storage humidity 98% non condensing

Protective coating Applied to all the circuits

0-60°C (32-140°F)

87°C (-2°C/+7°C) (188.6°F (-3.6°F/+12.6°F))

-40 - +100°C (-40 - +212°F)

Table 14: Mechanical specification

Parameter Value

Size 105x60.5x42 mm (4.1”x2.4”x1.7”)

Weight 0.25 Kg (8oz)

Power connector

Power connector wire capacity 0.14-1.5 mm2 (26-14AWG)

Signal connector Molex, 90709-1601

Phoenix Contact MKDS1,5-5,08

Page 26

Page 31

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Dimensional Drawing

Figure 5: Dimensional Drawing

Page 27

Page 32

Page 33

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Accessories

8.1 Interface & Evaluations Boards

Elmo offers an interface connection board, the SIB-SSA, to simplify the connection of the VIO-Velocity for

prototyping and evaluation. The SIB-SSA connects with a ribbon cable to signal connector J4 and provides

those signals to the user on a convenient terminal strip.

Figure 6: SIB-SSA

Page 29

Page 34

Page 35

VIO-Velocity - Operating Manual Rev 09/09. Elmo Motion Control

Service Centers and Warranty

ISRAEL

Elmo Motion Control LTD

64 Gisin ST.

Petah-Tikva 49103

Tel: (03)922-0864

Fax: (03)922-6949

EUROPE

Switzerland

Elmo Motion Control

7 Stanserstrasse

CH-6362 Stansstad

Tel: +41 41 6100775

Fax: +41 41 6100778

Germany

Elmo Motion Control GmbH

Steinbeisstrasse 41

D-78056 Villingen-Schwenningen

Tel: +49 7720 857760

Fax: +49 7720 857770

U.S.A

Elmo Motion Control Inc.

900H River Street

Windsor, CT 06095-1330

Tel: (860) 683-0095

Fax: (864) 683-0336

9.1 Warranty performance

The warranty performance covers only Elmo’s products and only the elimination of problems that are due

to manufacturing defects resulting in impaired function, deficient workmanship or defective material.

Specifically excluded from warranty is the elimination of problems that are caused by abuse, damage,

neglect, overloading, wrong operation, unauthorized manipulations etc.

The following maximum warranty period applies:

12 months from the time of operational startup but not later than 18 months from shipment by the

manufacturing plant.

Damage claims, including consequential damages, which exceed the warranty obligation will be rejected in

all cases.

If any term or condition in this warranty performance shall be at variance or inconsistent with any provision

or condition (whether special or general) contained or referred to in the Terms and Conditions of Sales set

out at the back of Elmo's Standard Acknowledge Form, than the later shall prevail and be effective.

Page 31

Loading...

Loading...