Page 1

Gold Maestro

Network Motion Controller

Installation Guide

January 2013 (Ver. 1.301)

www.elmomc.com

Page 2

GOLD-MAESTRO01

13 to 96 VDC power supply

Notice

This guide is delivered subject to the following conditions and restrictions:

• This guide contains proprietary information belonging to Elmo Motion Control Ltd.

Such information is supplied solely for the purpose of assisting users of the Gold

Maestro servo drive in its installation.

• The text and graphics included in this manual are for the purpose of illustration and

reference only. The specifications on which they are based are subject to change

without notice.

• Information in this document is subject to change without notice.

Elmo Motion Control and the Elmo Motion Control logo are

registered trademarks of Elmo Motion Control Ltd.

EtherCAT Conformance Tested. EtherCAT® is a registered

trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

Document no. MAN-GOLD-MAESTRO-IG (Ver. 1.301)

Copyright 2013

Elmo Motion Control Ltd.

All rights reserved.

Catalog Number

GOLD-MAESTRO02 20 to 196 VDC power supply

Revision History

Version Date Details

Ver. 1.0 6th May 2010 Initial Release

Ver. 1.1 13th May 2010 Minor updates

Ver. 1.2 July 2010 Updates to Chapter 3 and Chapter 4 (Appendix)

Ver. 1.300 Oct. 2012 Updates to Chapter 3 and minor updates in other

Ver. 1.301 January 2013 Added a caution and recommendation on the

chapters.

type of cleaning solution to use for the Elmo unit.

Page 3

Elmo Worldwide

Head Office

Elmo Motion Control Ltd.

60 Amal St., P.O. Box 3078, Petach Tikva 49516

Israel

Tel: +972 (3) 929-2300 • Fax: +972 (3) 929-2322 • info-il@elmomc.com

North America

Elmo Motion Control Inc.

42 Technology Way, Nashua, NH 03060

USA

Tel: +1 (603) 821-9979 • Fax: +1 (603) 821-9943 • info-us@elmomc.com

Europe

Elmo Motion Control GmbH

Hermann-Schwer-Strasse 3, 78048 VS-Villingen

Germany

Tel: +49 (0) 7721-944 7120 • Fax: +49 (0) 7721-944 7130 • info-de@elmomc.com

China

Elmo Motion Control Technology (Shanghai) Co. Ltd.

Room 1414, Huawen Plaza, No. 999 Zhongshan West Road, Shanghai (200051)

China

Tel: +86-21-32516651 • Fax: +86-21-32516652 • info-asia@elmomc.com

Asia Pacific

Elmo Motion Control APAC Ltd.

B-601 Pangyo Innovalley, 621 Sampyeong-dong, Bundang-gu, Seongnam-si, Gyeonggi-do,

South Korea (463-400)

Tel: +82-31-698-2010 • Fax: +82-31-801-8078 • info-asia@elmomc.com

Page 4

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Table of Contents

Gold Maestro Installation Guide

Chapter 1: Safety Information ...................................................................................... 6

1.1. Cautions ......................................................................................................................6

1.2. Directives and Standards ............................................................................................7

1.3. Warranty Information ................................................................................................7

Chapter 2: Product Description .................................................................................... 8

2.1. Description .................................................................................................................8

2.2. Specifications ..............................................................................................................9

2.2.1. Gold Maestro Hardware ..............................................................................9

2.2.2. Gold Maestro Software ............................................................................ 10

2.3. Communication Options .......................................................................................... 12

2.4. How to Use this Guide ............................................................................................. 12

Chapter 3: Installation ............................................................................................... 13

4

3.1. Before You Begin ..................................................................................................... 13

3.1.1. Site Requirements .................................................................................... 13

3.1.2. Working Environment ............................................................................... 13

3.2. Unpacking the Components .................................................................................... 13

3.3. Connectors............................................................................................................... 14

3.3.1. Connector Types ....................................................................................... 14

3.3.2. Pinouts ...................................................................................................... 15

3.3.2.1. Power Connector ..................................................................... 15

3.3.2.2. EtherCAT In Connector ............................................................ 16

3.3.2.3. EtherCAT Out Connector ......................................................... 16

3.3.2.4. CAN Connectors ....................................................................... 17

3.3.2.5. Ethernet Connector ................................................................. 17

3.3.2.6. USB 2.0 Connector ................................................................... 18

3.4. Mounting the Gold Maestro .................................................................................... 18

3.4.1. Wall Mount ............................................................................................... 18

3.4.2. Surface Mount .......................................................................................... 20

3.4.3. Installation on a DIN Rail .......................................................................... 20

3.5. Connecting the Cables ............................................................................................. 21

3.5.1. Wiring the Gold Maestro .......................................................................... 21

3.5.2. Connecting the DC Power Supply ............................................................. 22

3.5.3. Ethernet .................................................................................................... 23

3.5.4. USB 2.0 Communication ........................................................................... 24

3.5.5. CAN Communication ................................................................................ 25

3.5.6. EtherCAT Communication ........................................................................ 27

3.6. Powering Up ............................................................................................................ 28

3.7. Initializing the System .............................................................................................. 28

Chapter 4: Technical Specifications ............................................................................ 29

Page 5

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Table of Contents

4.1. Gold Maestro Dimensions ....................................................................................... 29

4.2. General Specifications ............................................................................................. 29

4.3. Environmental Conditions ....................................................................................... 29

4.4. Power Supply ........................................................................................................... 30

4.5. Communications ...................................................................................................... 30

4.6. Compliance with Standards ..................................................................................... 31

5

Page 6

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Chapter 1: Safety Information

Warning:

Caution:

Gold Maestro Installation Guide

In order to achieve the optimum, safe operation of the Gold Maestro Multi-Axis Controller, it is

imperative that you implement the safety procedures included in this installation guide. This

information is provided to protect you and to keep your work area safe when operating the

Gold Maestro and accompanying equipment.

Please read this chapter carefully before you begin the installation process.

Before you start, ensure that all system components are connected to earth ground. Electrical

safety is provided through a low-resistance earth connection.

To avoid any potential hazards that may cause severe personal injury or damage to the product

during operation, keep all covers and cabinet doors shut.

The following safety symbols are used in this manual:

This information is needed to avoid a safety hazard, which might cause

bodily injury.

6

This information is necessary for preventing damage to the product or

to other equipment.

1.1. Cautions

• The Gold Maestro must be connected to an approved 24 VDC power supply through a

line that is separated from hazardous line voltages using reinforced or double

insulation in accordance with approved safety standards.

• Before switching on the Gold Maestro, verify that all safety precautions have been

observed and that the installation procedures in this manual have been followed.

• Do not clean any of the Gold Maestro drive's soldering with solvent cleaning fluids of

pH greater than 7 (8 to 14). The solvent corrodes the plastic cover causing cracks and

eventual damage to the drive's PCBs.

Elmo recommends using the cleaning fluid Vigon-EFM which is pH Neutral (7).

For further technical information on this recommended cleaning fluid, select the link:

http://www.zestron.com/fileadmin/zestron.comusa/daten/electronics/Product_TI1s/TI1-VIGON_EFM-US.pdf

www.elmomc.com

Page 7

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Safety Information

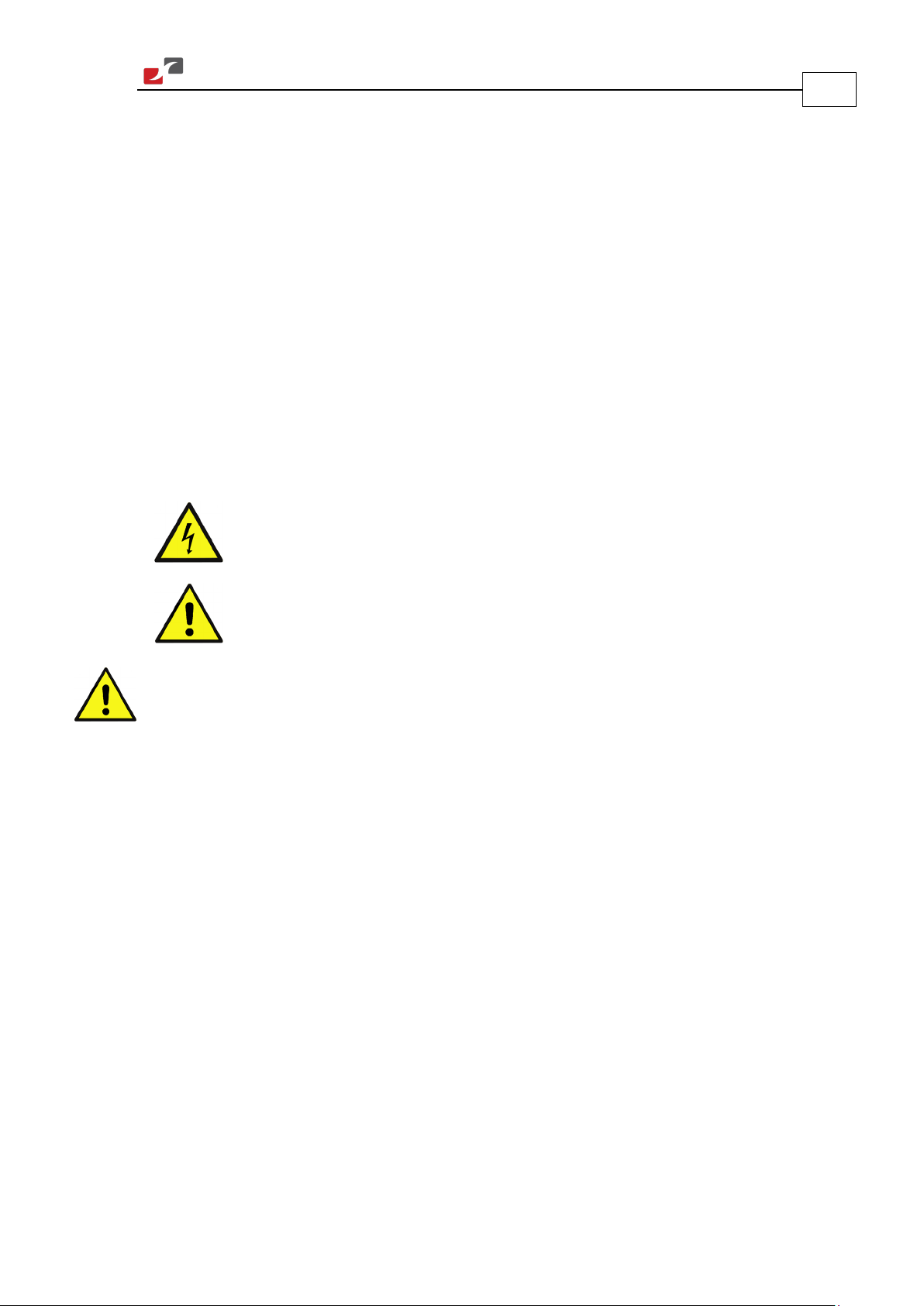

1.2. Directives and Standards

The Gold Maestro conforms to the following industry safety standards:

Safety Standard Item

Approved IEC/EN 61800-5-1, Safety Adjustable speed electrical power drive systems

Recognized UL 508C Power Conversion Equipment

In compliance with UL 840 Insulation Coordination Including Clearances and

Creepage Distances for Electrical Equipment

7

In compliance with UL 60950-1

(formerly UL 1950)

Safety of Information Technology Equipment

Including Electrical Business Equipment

In compliance with EN 60204-1 Low Voltage Directive 73/23/EEC

The Gold Maestro has been developed, produced, tested and documented in accordance with

the relevant standards. Elmo Motion Control is not responsible for any deviation from the

configuration and installation described in this documentation. Furthermore, Elmo is not

responsible for the performance of new measurements or ensuring that regulatory

requirements are met.

1.3. Warranty Information

The products covered in this manual are warranted to be free of defects in material and

workmanship and conform to the specifications stated either within this document or in the

product catalog description. The Gold Maestro is warranted for a period of 12 months from the

time of installation, or 18 months from time of shipment, whichever comes first. No other

warranties, expressed or implied – and including a warranty of merchantability and fitness for a

particular purpose – extend beyond this warranty.

www.elmomc.com

Page 8

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Chapter 2: Product Description

Gold Maestro Installation Guide

This installation guide describes the Gold Maestro Network Motion Controller and the steps for

its wiring, installation and power up. Following these guidelines ensures maximum functionality

of the system to which it is connected.

2.1. Description

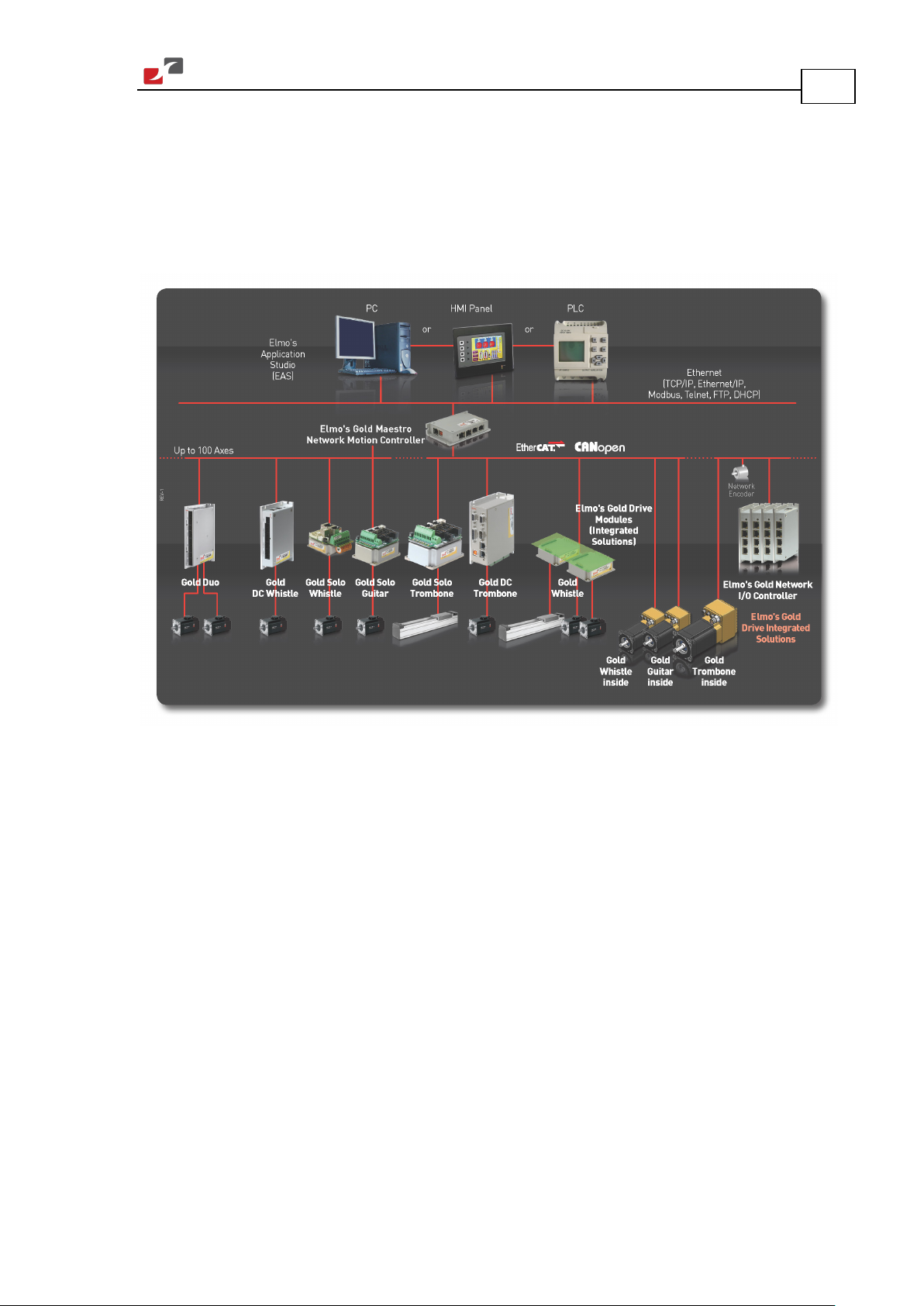

The Gold Maestro is Elmo’s network motion controller. It works in a network based system in

conjunction with Elmo’s intelligent servo drives to provide a total multi-axis motion control

system solution.

The Gold Maestro is designed to support both the existing SimplIQ drives, based on standard

CAN network architecture, as well as the new Gold Line, adding EtherCAT networking.

While being a true network controller, the Gold Maestro shares the motion processing

workload with Elmo’s SimplIQ and Gold Line drives, forming a distributed motion control

system. The best servo and system performance is achieved combining the Gold Family drives,

and the new real-time motion control capabilities of the Gold Maestro controller.

8

The Gold Maestro provides:

• Full, real-time, multi-axis motion synchronization

• Advanced user programming capabilities based on the leading standards

• Time deterministic control over motion, I/Os and processes in the system

The Gold Maestro offers real-time motion control support for full multi-axis system

synchronization, using the well known industry interface PLCopen for Motion Control standard.

Various programming capabilities, such as the IEC-61131-3 standard languages, as well as

native C programming support, dramatically accelerate user level program execution. Standard

solutions were selected for ease of use.

Low level communication with drives and I/O devices over the device network uses the CAN

industry standard (DS 301, DS 401 for I/O devices, and DS 402 for drives and motion device

profiles). These are used over standard CAN networks, as well as with the new EtherCAT CoE

(CAN over EtherCAT) protocols.

Host interfaces are implemented using industry standard communications protocols, such as

Ethernet TCP/IP and higher level protocols such as Ethernet/IP and Modbus.

Standardization in protocols, definitions and APIs allows users rapid system level integration

and opens the system to third party devices on the device network.

www.elmomc.com

Page 9

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Product Description

2.2. Specifications

2.2.1. Gold Maestro Hardware

• Hardware: Standalone

• Power Supply: Single DC supply, with two product options available:

13 VDC to 96 VDC

20 VDC to 196 VDC

• Processor: PowerPC, 333 MHz, with double precision floating point support by

hardware.

• Memory

Flash: 32 MB

RAM: 64 MB (DDR2, 333 MHz)

• Communication Hardware

Host:

• Ethernet: 1 port, Standard Ethernet, 10/100 Mbps, automatically detected

• USB: 1 port, USB2.0, 12 Mbps

Device Networks:

9

• EtherCAT: 2 x EtherCAT master ports, with redundancy support (optional)

• CAN: CANopen master port

• I/O System: All I/O interfaces are handled via the device network.

• Internal System BIT: The Gold Maestro supports internal hardware BIT (Built-in-tests)

procedures to check the system integrity level on each power up.

• Diagnostic LEDs: EtherCAT and Ethernet activity

• Dimensions: 115 mm x 75 mm x 25.4 mm (4.53" x 2.95" x 1")

• Weight: 250 g ( 8.75 oz)

• Operational Temperature: 0 °C to 40 °C

www.elmomc.com

Page 10

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Product Description

2.2.2. Gold Maestro Software

• Operating System: Linux Operating System, with Elmo’s RT extension for real-time

motion control support

• Motion Programming and Debugging

Native C Programming, running on the target CPU. Compiling and debugging via the

Eclipse IDE using GCC under Cygwin

IEC 61131-3 with PLCopen Motion Library extension, using Elmo IDE. The following

languages are supported:

• Structured text (ST), textual

• Function block diagram (FBD), graphical

• Ladder diagram (LD), graphical

• Sequential function chart (SFC), has elements to organize programs for sequential

and parallel control processing.

• Number of Axes: Up to 96 axes, allowing mixed single axis, multiple axis and

coordinated axes motions

• Axis Types

10

Intelligent Servo Drives (Elmo), supporting both the SimplIQ and Gold lines

Operation in Numeric Control – NC - (real-time master synchronization) as well as

non-NC modes

DS 402 CoE for EtherCAT and standard DS 402 drives for CANopen

• Control System Update Rate

EtherCAT

• Cycle Update Rate: ≥ 500 µs (up to 16 axes can be updated simultaneously at a rate

of 500 µs)

• Cycle Jitter: < 1 µs, based on Master DC (Distributed Clock) support, for the full

network

CAN

• Cycle Update Rate ≥ 1 ms (CAN physical network limitations only)

• Cycle Jitter: < 100 µs for CAN Sync message initiation (actual jitter dependant on the

CAN network’s physical limitations)

• Motion Modes and Interfaces: The Gold Maestro motion interfaces use the PLCopen

Standard.

64 bit, real-time, double precision profile calculations, allowing full on-the-fly control

over speed, acceleration, deceleration and jerk

Complex motion schemes, including look-ahead optimizing of trajectory speed

calculations, for complex vector motions

Cyclic buffer for 1,000 function blocks (a buffer for 1,000 motion segments). The cyclical

buffer removes any practical limit on the number of function blocks.

• Communication Protocols

Host

• Ethernet TCP-IP/UDP for operational modes

www.elmomc.com

Page 11

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Product Description

• Telnet communication for setup and configuration

• USB: Using binary protocol (maintenance)

• Application level: Ethernet-IP/Modbus

Device Network

• EtherCAT: CoE/EoE/FoE, supports distributed clock master

• CAN: CANopen device profiles, e.g., DS 301, DS 305, DS 402, DS 401 (I/O device

profile)

• Host and Internal Software Interface

TCP/IP interface from Host Computer. Software Library is provided for easy TCP/IP

communication interface.

Future version will also support Ethernet-IP and Modbus over the TCP-IP.

Internal Software libraries, for "C" user programs are provided, to write user code

running on the Gold Maestro target processor (native mode).

• Data Recording

4 MB data recording

Up to 32 vectors can be recorded simultaneously.

Supports more than 10 advanced triggering options and real-time scope capabilities

Very fast data upload using Ethernet

11

• Upload/Download Support

Firmware update support (Gold Maestro and drives)

System resource files

Axis parameter files

• Drive Communication Bridge Support: The Gold Maestro supports full communication

with any specific drive (EtherCAT and CAN), for the purpose of simple tuning or

configuration at the drive level, i.e. there is no need for direct communication with the

drive.

• Spatial Position-Based Pulse Generation

The Gold Maestro supports spatial (along the path) position-based pulse generation.

This is a unique feature, required for the generation of position-based events in 3D

scanning systems.

The Gold Maestro system, with Elmo’s intelligent Gold servo drives, can support single

axis and spatial enhanced position-based compare functions, resulting in trigger output

signals accurate to 1 encoder count along the trajectory path.

• Network Encoders: Supports master based motion on network encoders

• Position Error Mapping: Supports 1-D and 2-D position-based error mapping

compensation

• System Boot up Time: < 30 sec

www.elmomc.com

Page 12

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Product Description

2.3. Communication Options

The Gold Maestro can communicate with a host PC through either a standard Ethernet port or

through USB using a binary protocol for maintenance.

The Gold Maestro communicates with its network devices using either EtherCAT or CAN

networks.

12

Figure 1: The Gold Maestro Network Connections

2.4. How to Use this Guide

This manual is part of a documentation set that can be used to set up and program the motion

of any machine whose motors are controlled by Elmo’s SimplIQ or Gold Line servo drives.

When used in conjunction with the Gold Maestro Software Manual it describes everything

needed to get the Gold Maestro up and running. Please read the safety instructions in the first

chapter before starting.

After you have successfully mounted and installed the Gold Maestro we suggest that you read

the Gold Maestro Software Manual. If you have not already done so, follow the instructions in

the Installation Guide that arrived with your servo drive, and install a drive. At least one drive

needs to be connected to the Gold Maestro in order for it to function as a motion controller.

www.elmomc.com

Page 13

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Chapter 3: Installation

Gold Maestro Installation Guide

3.1. Before You Begin

3.1.1. Site Requirements

For safe operation of the Gold Maestro make sure it is installed in an appropriate environment.

Feature Value

13

Ambient operating temperature

Maximum non-condensing humidity 90%

Operating area atmosphere No flammable gases or vapors permitted in area

0 °C to 40 °C (32 °F to 104 °F)

3.1.2. Working Environment

Warning: During operation the Gold Maestro becomes hot to the touch (the

case can heat up to 50 °C). Care should be taken when handling it.

Caution: The Gold Maestro dissipates its heat by natural convection. The

maximum ambient operating temperature must not be exceeded.

3.2. Unpacking the Components

Before you begin working with the Gold Maestro system, verify that you have all of its

components, as follows:

• The Gold Maestro multi-axis controller

• Gold Maestro software which may be downloaded from www.elmomc.com

The Gold Maestro is shipped in a cardboard box with Styrofoam protection.

To unpack the Gold Maestro:

1. Carefully remove the Gold Maestro from the box.

2. Check the Gold Maestro to ensure that there is no visible damage to the instrument. If any

damage has occurred, report it immediately to the carrier that delivered your controller.

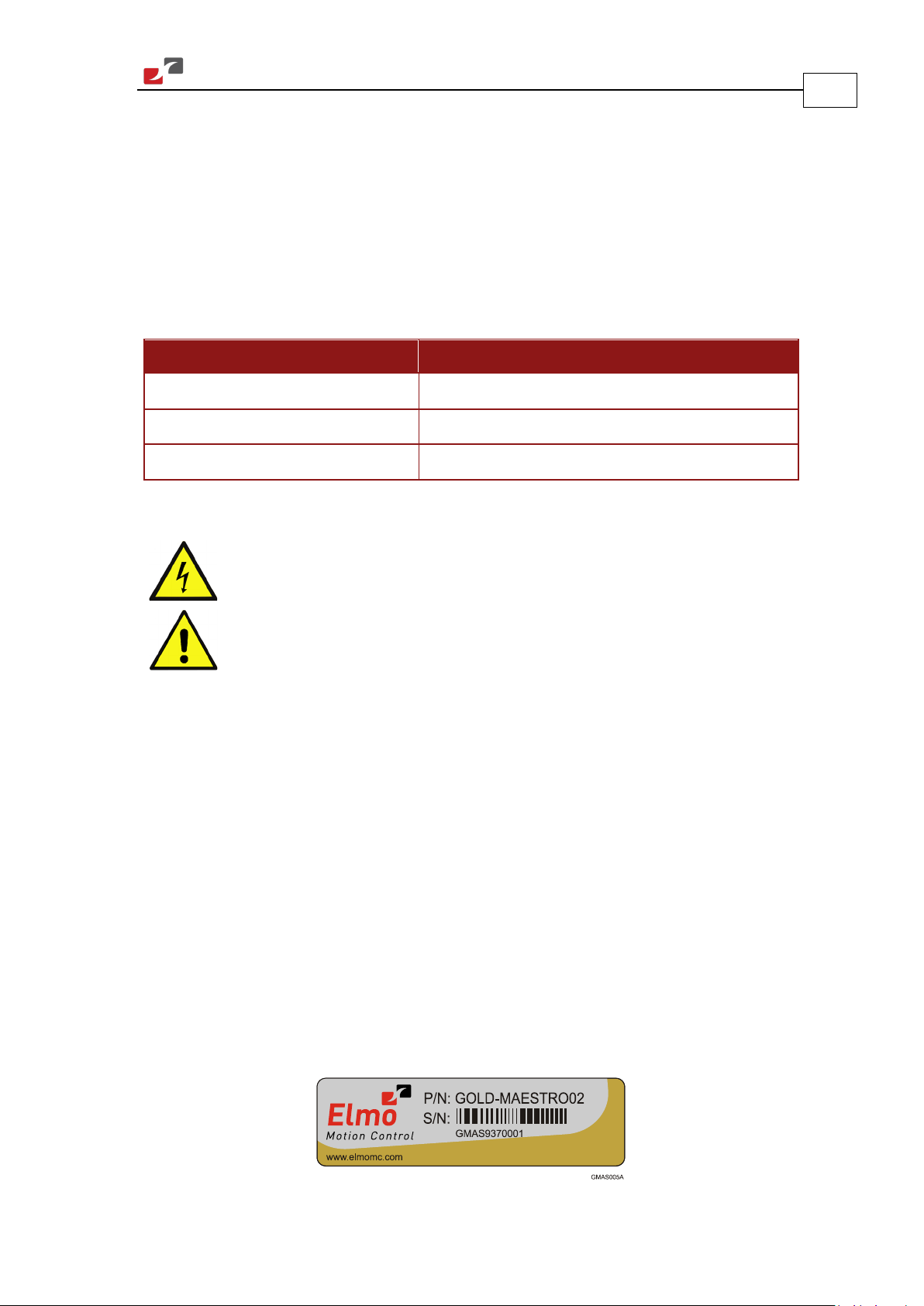

3. To ensure that the Gold Maestro you have unpacked is the appropriate type for your

requirements, locate the part number sticker on the side of the Gold Maestro as shown

below.

www.elmomc.com

Page 14

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

4. The part number at the top gives the type designation as follows:

GOLD-MAESTRO01: 13 to 96 VDC power supply

GOLD-MAESTRO02: 20 to 196 VDC power supply

5. Verify that the Gold Maestro type is the one that you ordered.

6. Verify that you have CAN termination resistors (dongles), illustrated below.

3.3. Connectors

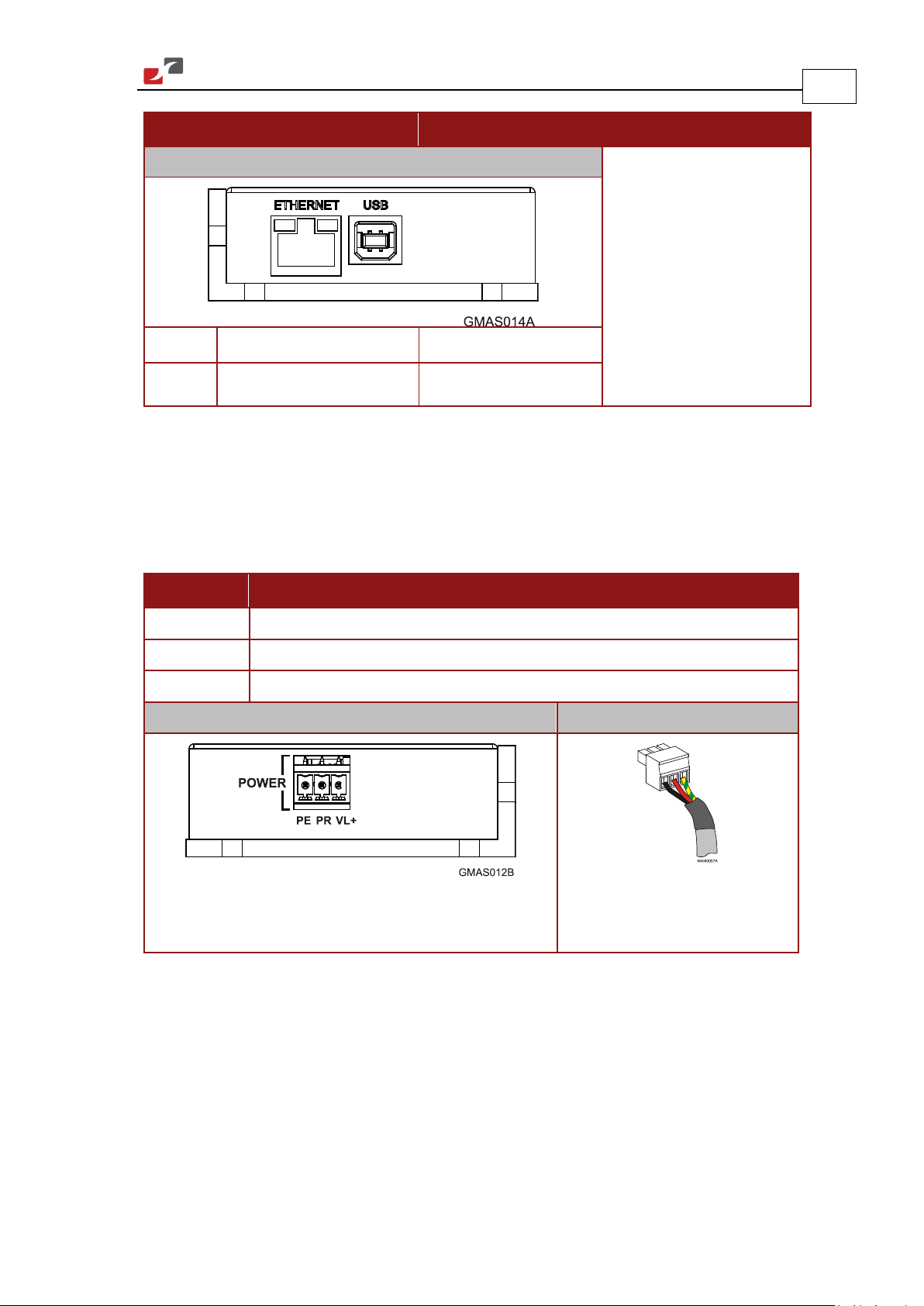

3.3.1. Connector Types

The Gold Maestro has the following connectors:

14

Pins Type Function

Bottom Connector

3 Phoenix 3.81 mm Pitch

Power and ground

Header

Front Connectors

8 RJ-45 EtherCAT In

8 RJ-45 EtherCAT Out

8 RJ-45 CAN1

8 RJ-45 CAN2

www.elmomc.com

Page 15

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

Pins Type Function

Bottom Connectors

8 RJ-45 Ethernet

4 USB USB

Table 1: Connector Types

3.3.2. Pinouts

3.3.2.1. Power Connector

15

See Section 3.5.2 for full details.

Pin Function

PE Protective Earth

PR Power Return

VL+ Positive Power Input

Connector Location Cable Connector

3-Pin 3.81 mm Pitch Phoenix Header

3-Pin Phoenix Plug

(MC 1.5/3-ST-3.81)

(MC 1.5/3-G-3.81)

Table 2: Gold Maestro Power and Ground Connectors

www.elmomc.com

Page 16

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

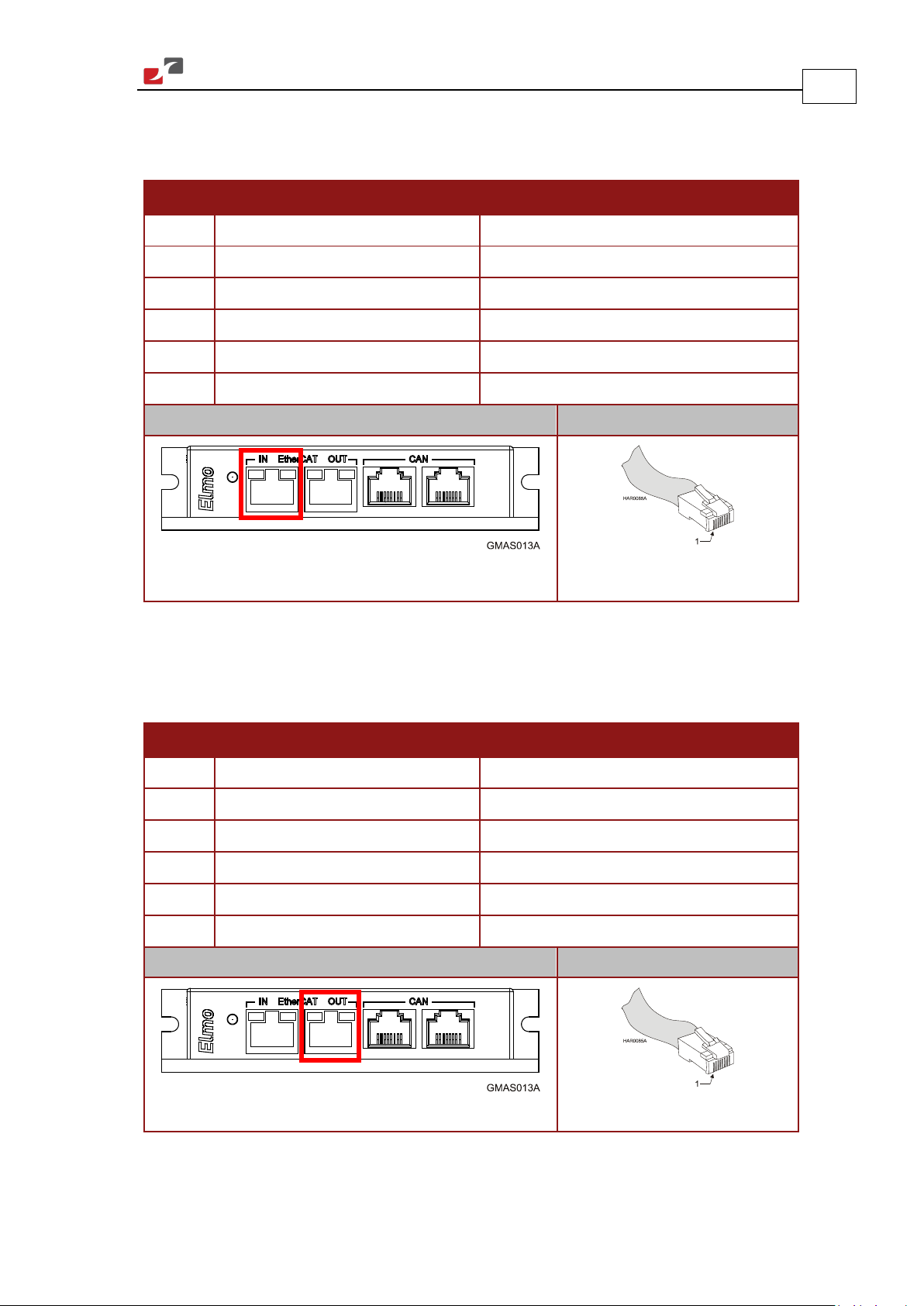

3.3.2.2. EtherCAT In Connector

See Section 3.5.6 for full details.

Pin Signal Function

1 EtherCAT_IN/Ethernet_TX+ EtherCAT in/Ethernet transmit +

2 EtherCAT_IN/Ethernet_TX- EtherCAT in/Ethernet transmit -

3 EtherCAT_IN/Ethernet_RX+ EtherCAT in/Ethernet receive +

4,5 N/A

6 EtherCAT_IN/Ethernet_RX- EtherCAT in/Ethernet receive -

7, 8 N/A

Connector Location Cable Connector

16

8-Pin RJ-45 Connector

Standard CAT5e Ethernet Cable

Table 3: EtherCAT In Pin Assignments

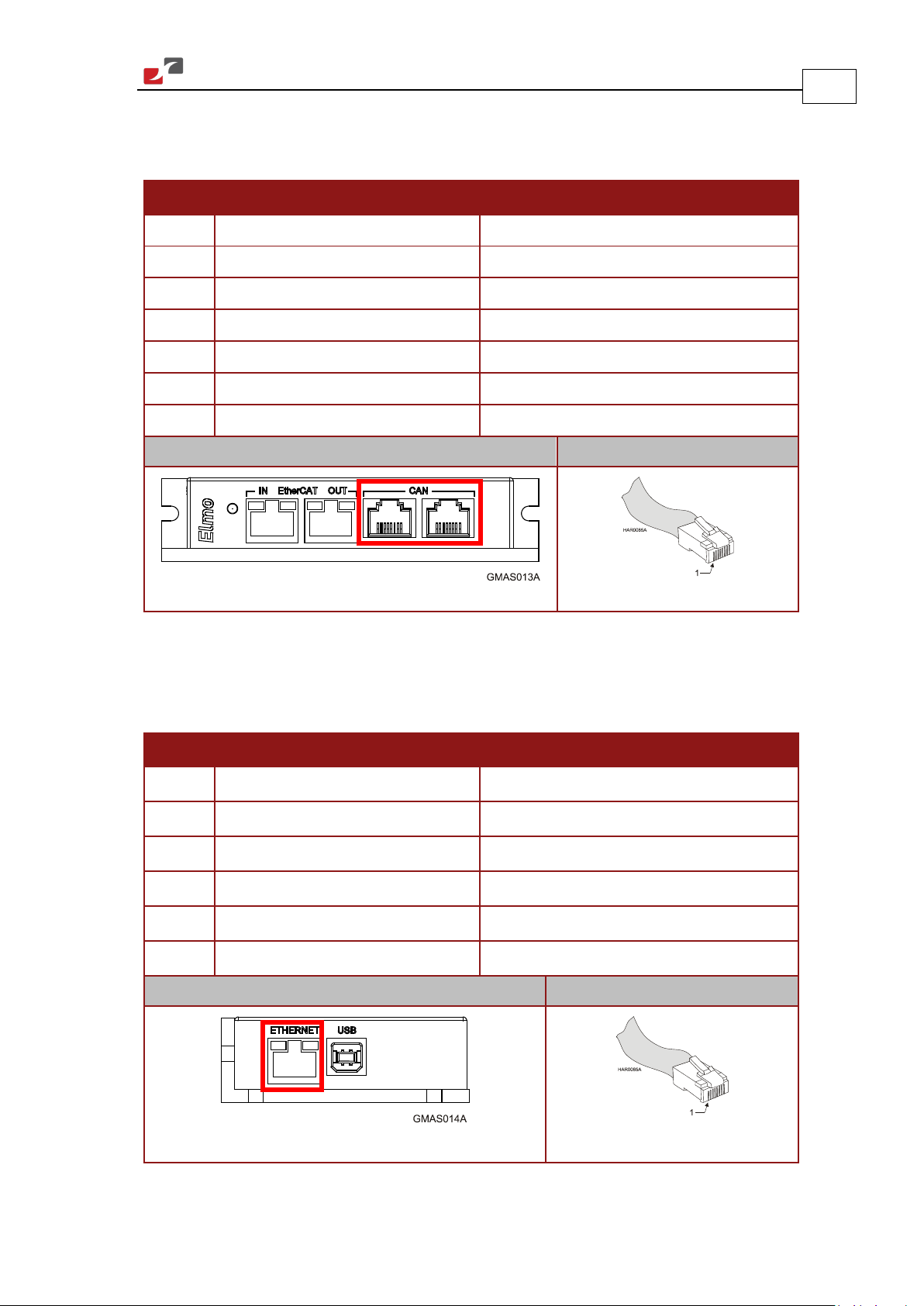

3.3.2.3. EtherCAT Out Connector

See Section 3.5.6 for full details.

Pin Signal Function

1 EtherCAT_OUT_TX+ EtherCAT in transmit +

2 EtherCAT_OUT_TX- EtherCAT in transmit -

3 EtherCAT_OUT_RX+ EtherCAT in receive +

4,5 N/A

6 EtherCAT_OUT_RX- EtherCAT in receive -

7, 8 N/A

Connector Location Cable Connector

8-Pin RJ-45 Connector

Table 4: EtherCAT Out Pin Assignments

Standard CAT5e Ethernet Cable

www.elmomc.com

Page 17

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

8-Pin RJ-45 Connector

Gold Maestro Installation Guide Installation

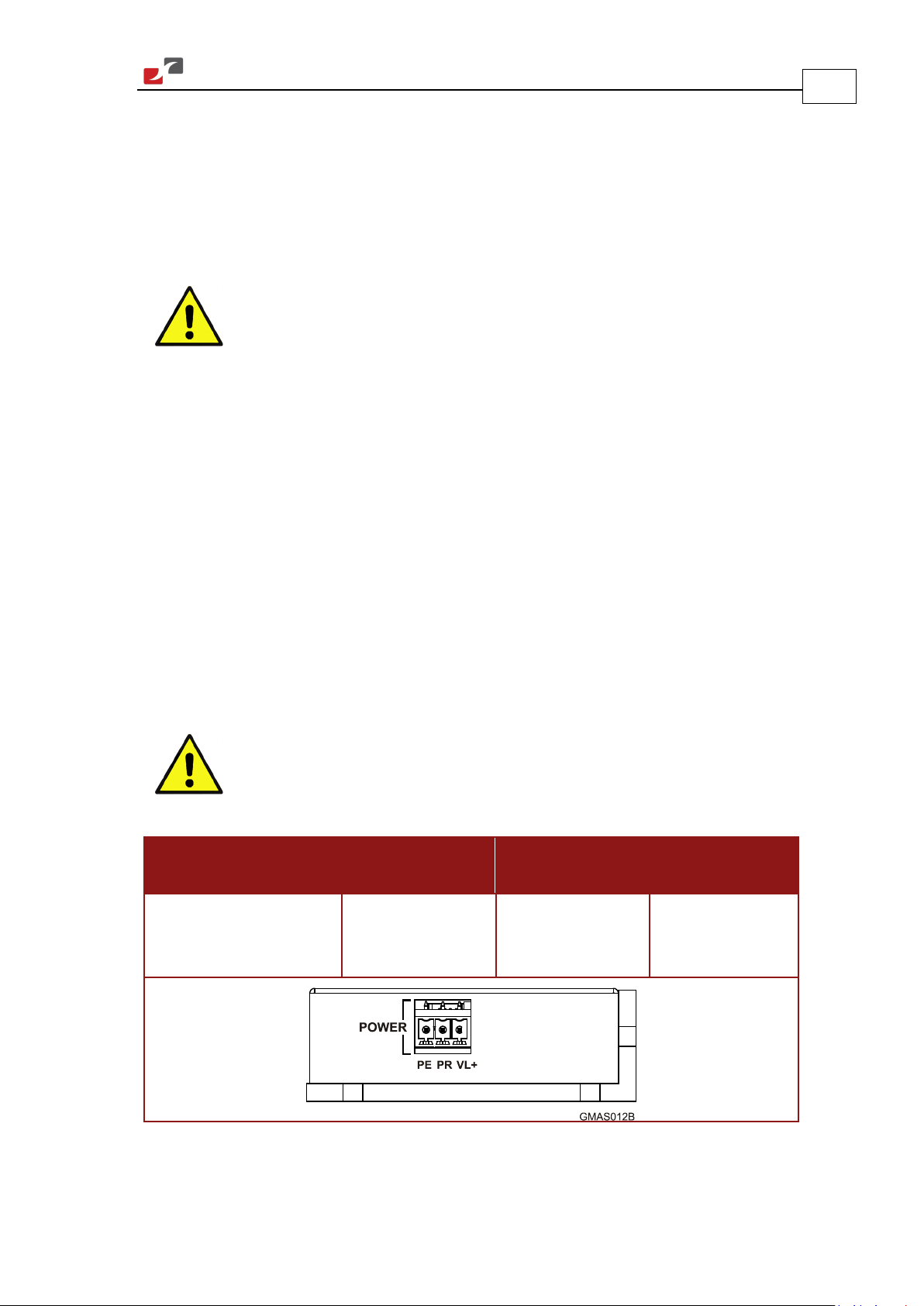

3.3.2.4. CAN Connectors

See Section 3.5.5 for full details.

Pin Signal Function

1 CAN_H CAN_H bus line (dominant high)

2 CAN_L CAN_L bus line (dominant low)

3 CAN_COMRET CAN Communication Return

4,5 N/A —

6 CAN_SHLD Shield, connected to the RJ-45 plug cover

7 CAN_COMRET CAN Communication Return

8 N/A —

Connector Location Cable Connector

17

Standard CAT5e Ethernet Cable

Table 5: CAN Pin Assignments

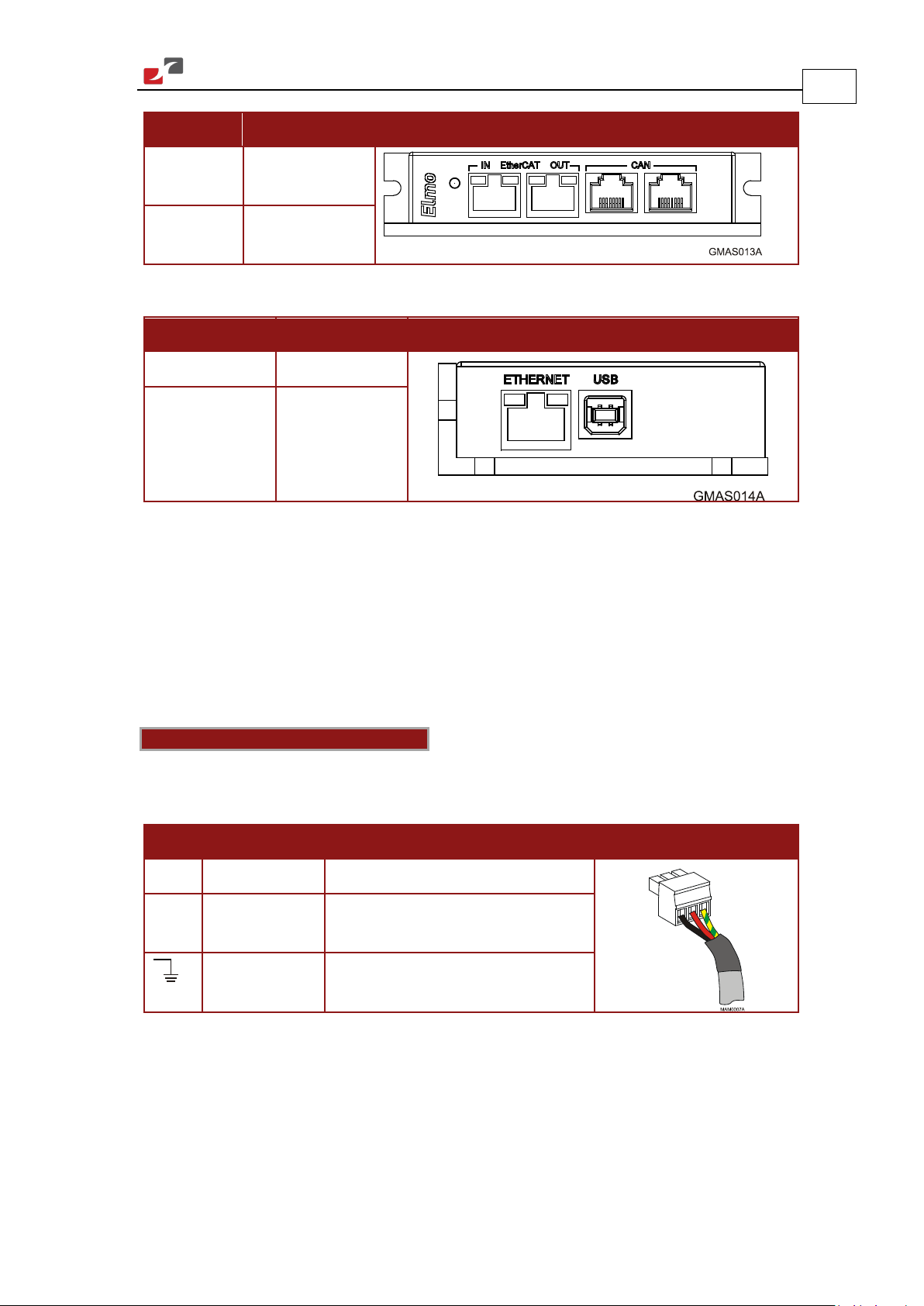

3.3.2.5. Ethernet Connector

See Section 3.5.3 for full details.

Pin Signal Function

1 TX+ Ethernet transmit +

2 TX- Ethernet transmit -

3 RX+ Ethernet receive +

4,5 N/A

6 RX- Ethernet receive -

7, 8 N/A

Connector Location Cable Connector

8-Pin RJ-45 Connector

Standard CAT5e Ethernet Cable

Table 6: Ethernet Pin Assignments

www.elmomc.com

Page 18

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

3.3.2.6. USB 2.0 Connector

See Section 3.5.4 for full details.

Pin Signal Function

1 USB VBUS USB VBUS from host

2 USBD- USB _N line

3 USBD+ USB _P line

4 USB COMRET USB communication return

Connector Location Cable Connector

USB 2.0 Connector

USB Device Type B Plug

18

Table 7: USB Pin Assignments

3.4. Mounting the Gold Maestro

The Gold Maestro has three mounting options:

1. Wall mount

2. Surface mount

3. Mounting on a DIN rail

3.4.1. Wall Mount

Two M4 round head screws, one through each opening in the heat sink, are used to mount the

Gold Maestro (see the diagram below) on a wall.

www.elmomc.com

Page 19

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

19

Figure 2: Wall Mounting the Gold Maestro

www.elmomc.com

Page 20

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

3.4.2. Surface Mount

Use four M4 round head screws, one through each opening in the heat sink to connect the

Gold Maestro to a surface.

20

Figure 3: Surface Mounting the Gold Maestro

3.4.3. Installation on a DIN Rail

Use one M3x5 round head screw to connect the DIN rail mounting clip to the back of the Gold

Maestro.

Figure 4: Mounting the Gold Maestro on a DIN Rail

www.elmomc.com

Page 21

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

3.5. Connecting the Cables

3.5.1. Wiring the Gold Maestro

Once the Gold Maestro is mounted, you are ready to wire the device. Proper wiring, grounding

and shielding are essential for ensuring safe, immune and optimal performance of the Gold

Maestro.

Caution: Follow these instructions to ensure safe and proper wiring.

• Use twisted pair shielded cables for communication connections. For best results, the

cable should have an aluminum foil shield covered by copper braid, and should contain

a drain wire.

The drain wire is a non-insulated wire that is in contact with parts of the cable, usually the

shield. It is used to terminate the shield and act as a grounding connection.

• Use CAT5e cables for Ethernet and EtherCAT communication.

• Keep all wires and cables as short as possible.

21

• Ensure that in normal operating conditions, the shielded wires and drain carry no

current. The only time these conductors carry current is under abnormal conditions,

when electrical equipment has become a potential shock or fire hazard while

conducting external EMI interferences directly to ground. This is in order to prevent

them from affecting the controller. Failing to meet this requirement can result in drive,

controller or host failure.

• After completing the wiring, carefully inspect all wires to ensure tightness, good solder

joints and general safety.

Caution: When the EtherCAT is connected, and FoE in operation, the USB

cable connection must be disconnected.

The following connectors are used for wiring the Gold Maestro:

Type Manufacturer &

Part No.

3.81 mm pitch

Header and Plug

Phoenix Header

MC 1.5/3-G-3.81

Mating

Connector

Phoenix Plug

(supplied)

Port

Power

PE, PR, VL+

MC 1.5/3-ST-3.81

Table 8: Gold Maestro Power and Ground Connectors

www.elmomc.com

Page 22

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

Type Port Connector Location

RJ-45 EtherCAT In/

EtherCAT Out

RJ-45 CAN x 2

Table 9: Connectors on the Front of the Gold Maestro

Type Port Connector Location

USB USB

RJ-45 Ethernet

Table 10: Connectors on the Top of the Gold Maestro

22

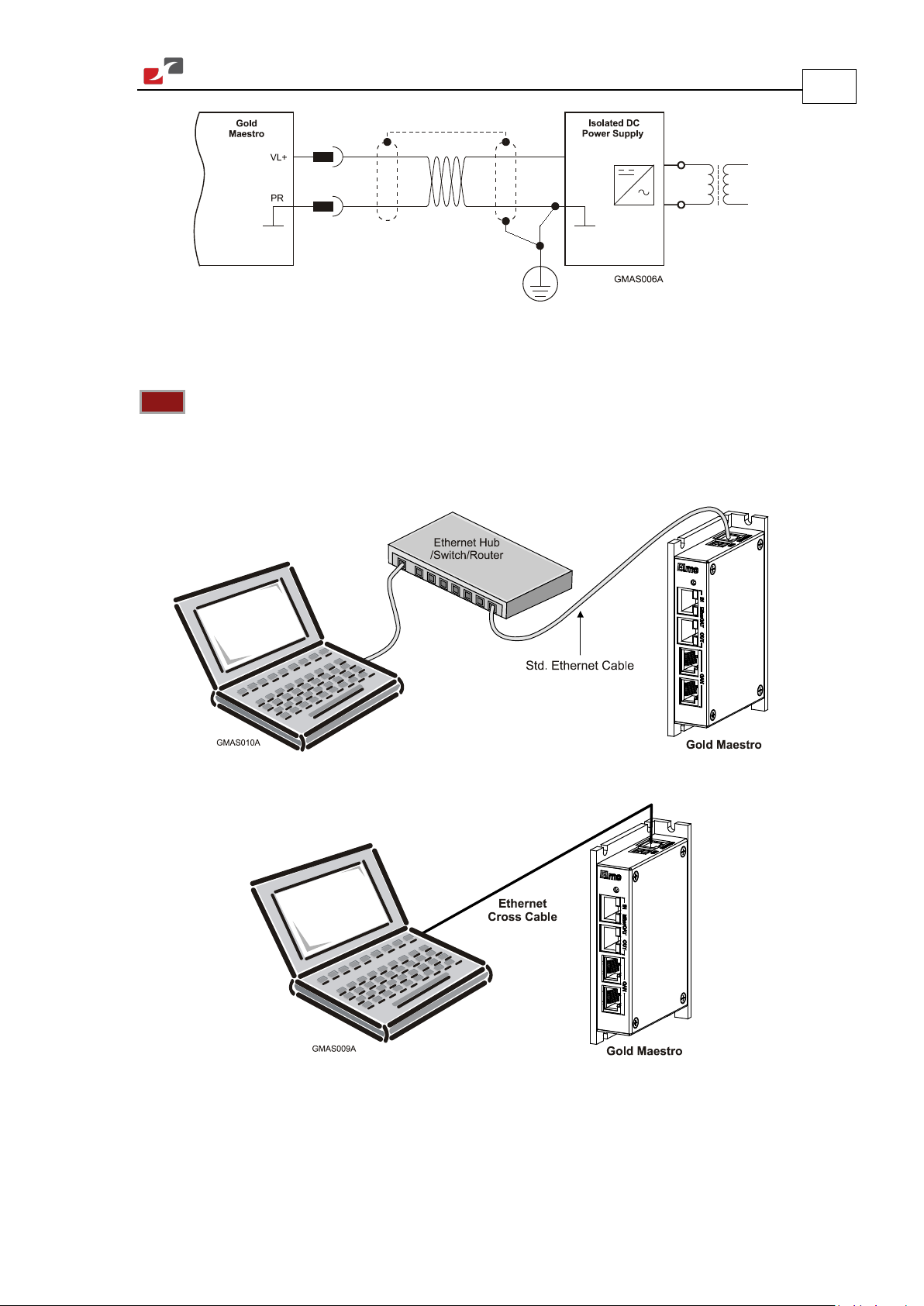

3.5.2. Connecting the DC Power Supply

The Gold Maestro requires 4.5 W when turned on. Any isolated power supply that can supply

that power is acceptable. The supplied power must be within the rated voltage range according

to the model: 13 V to 96 V or 20 V to 196 V.

Connect the DC output from the power supply to the power input port on the Gold Maestro

using the 3-pin power plug provided.

Notes for power supply connections:

Use a 24 AWG twisted pair shielded cable. The shield should have copper braid.

Before applying power, first verify the polarity of the connection (protected).

Pin Signal Function Pin Position

[+] VL+ DC power supply

[-] PR Power Return

PE Protective Earth

Table 11: Power Plug

www.elmomc.com

Page 23

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

Figure 5: Power Supply Connection Diagram

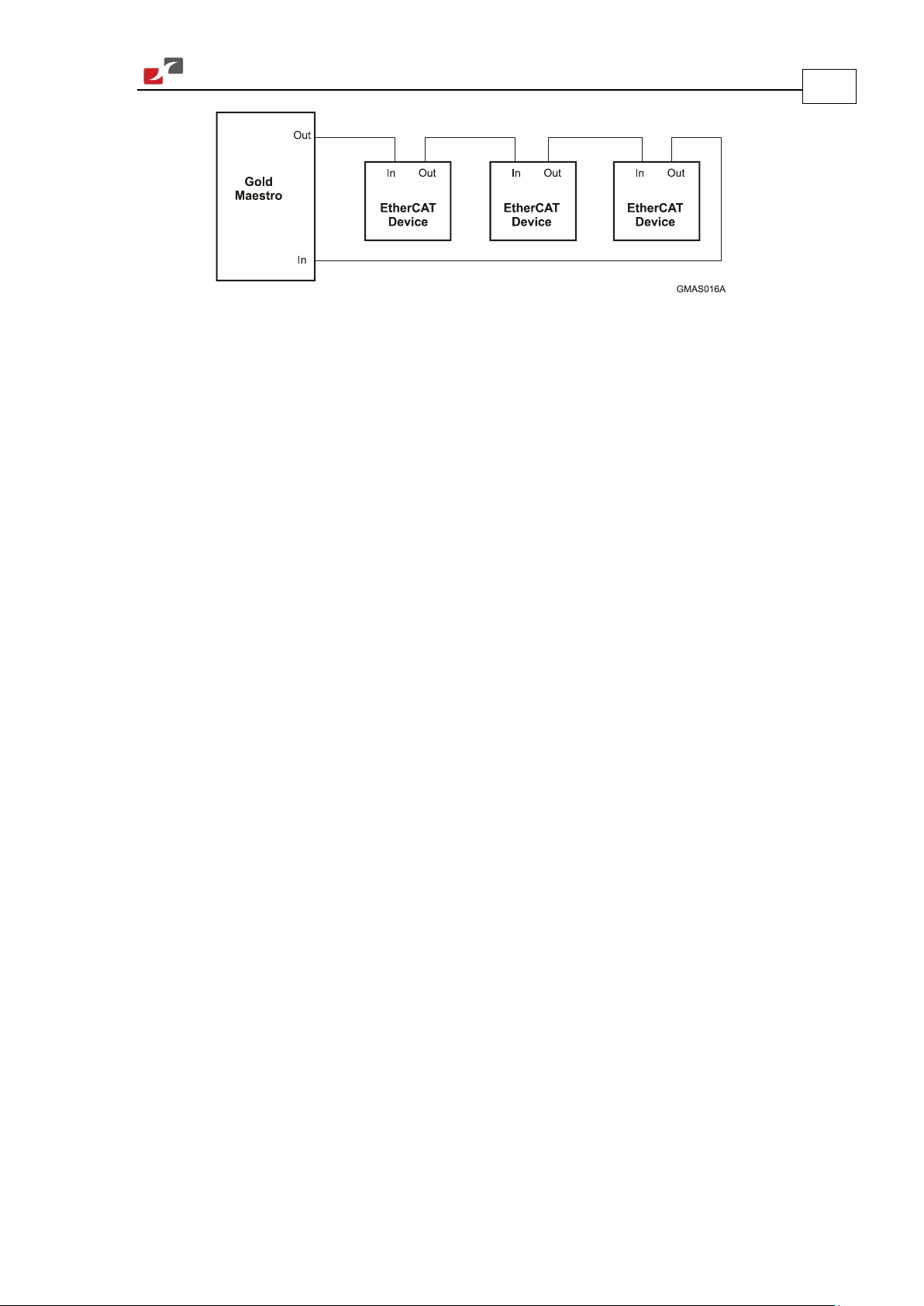

3.5.3. Ethernet

Note: When connecting the Ethernet communication cable use a shielded CAT5e Ethernet

cable.

The Gold Maestro connects to a PC either directly or through a hub, switch or router. Use a

standard or cross CAT5e Ethernet cable.

23

Figure 6: Gold Maestro Connected to a Network

Figure 7: Gold Maestro Connected Peer-to-Peer to a PC

www.elmomc.com

Page 24

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

3.5.4. USB 2.0 Communication

The USB Network consists of Host controller and multiple devices. The GMAS is a USB Device.

Notes for connecting the USB communication cable:

Connect the shield to the ground of the host (PC). Usually, this connection is soldered internally

inside the connector at the PC end. You can use the drain wire to facilitate connection.

Ensure that the shield of the cable is connected to the shield of the connector used for

communications. The drain wire can be used to facilitate the connection.

Pin Signal Function

1 USB VBUS USB VBUS From Host

2 USBD- USB _N line

3 USBD+ USB _P line

4 USB COMRET USB Communication Return

24

Table 12: USB 2.0 Pin Assignments

Figure 8: USB Network Diagram

www.elmomc.com

Page 25

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

3.5.5. CAN Communication

Notes for connecting the CAN communication cable:

Use 26 or 28 AWG twisted pair shielded cables. For best results, the shield should have

aluminum foil and be covered by copper braid with a drain wire (CAT5e FTP applicable).

Connect the shield to the ground of the host (PC). Usually, this connection is soldered internally

inside the connector at the PC end. You can use the drain wire to facilitate connection.

The male RJ plug must have a shield cover.

Ensure that the shield of the cable is connected to the shield of the RJ plug. The drain wire can

be used to facilitate the connection.

Connect a 120 Ω termination resistor to each end of the network cable.

(The Gold Maestro does not have an internal terminal.)

Termination resistors should be installed in all the unused CAN ports on the Gold Maestro.

Use the CAN termination dongle supplied as a second “device end”. Simply insert the

termination resistor into the CAN connector of the second end device on the bus. This is only

possible if there are two CAN connectors.

25

Figure 9: Connecting a 120 Ω Termination Resistor to Each End of the Network Cable

www.elmomc.com

Page 26

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

Pin Signal Function Pin Position

1 CAN_H CAN_H bus line (dominant high)

2 CAN_L CAN_L bus line (dominant low)

3 CAN_COMRET CAN Communication Return

4, 5 N/A —

6 CAN_SHLD Shield, connected to the RJ plug

cover

26

7 CAN_COMRET CAN Communication Return

8 N/A —

Table 13: CAN Cable Pin Assignments

www.elmomc.com

Page 27

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

3.5.6. EtherCAT Communication

The Gold Maestro is the master of the EtherCAT network and must always be the first device in

the line.

The EtherCAT Out port of the Gold Maestro should be connected to the EtherCAT In port of the

next device down the line. The Out port of the last device in line can be left open. If

redundancy is required, the Out port of the last device should be connected to the In port of

the Gold Maestro.

Note: When connecting the EtherCAT communication cable it is recommended to use CAT5e

cable.

27

Figure 10: EtherCAT Network Example

Figure 11: EtherCAT Network with no Redundancy

www.elmomc.com

Page 28

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Installation

Figure 12: EtherCAT Network with Redundancy

EtherCAT with redundancy is an optional method of connection.

3.6. Powering Up

After the Gold Maestro has been mounted, check that the cables are intact. The Gold Maestro

is then ready to be powered up.

3.7. Initializing the System

28

After the Gold Maestro has been connected and mounted, the system must be set up and

initialized. The minimum system requirements for a setup are:

• Gold Maestro (and power supply)

• PC with the required Elmo software

• At least one servo drive and motor

• EtherCAT cables or a terminated CAN network

• A servo drive connected through an EtherCAT cable or a CAN cable (the terminated

CAN network)

Users of SimplIQ servo drives:

Setting up the drives and motors is described in the Installation Guide for each servo drive and

in the Elmo Application Studio User Guide. Advanced features are described in the SimplIQ

Software Manual, Interlude API User Guide, SimplIQ Command Reference and CAN

Implementation Guide.

Users of Gold Line servo drives:

Setting up the drives and motors is described in the Gold Line Servo Drive Installation Guide

and Elmo Application Studio Users Guide. Advanced features are described in the Gold Line

Software Manual, Gold Line Command Reference and CAN Implementation Guide.

www.elmomc.com

Page 29

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Chapter 4: Technical Specifications

Gold Maestro Installation Guide

4.1. Gold Maestro Dimensions

29

All measurements are in mm.

4.2. General Specifications

Feature Details

Weight 250 g (8.75 ounces)

Dimensions 115 mm x 75 mm x 25.4 mm (4.53" x 2.95" x 1")

Mounting Method (with adapter) Wall Mount (“Bookshelf”)

4.3. Environmental Conditions

Feature Details

Ambient operating temperature

Storage temperature -20 °C to +85 °C ( -4 °F to +185 °F)

Maximum non-condensing humidity 90%

Protection level IP32

0 °C to 40 °C (32 °F – 104 °F)

www.elmomc.com

Page 30

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Used only for setup and determining IP address.

Gold Maestro Installation Guide Technical Specifications

4.4. Power Supply

Feature Details

Auxiliary power supply DC source only

Auxiliary supply input voltage 13 V to 96 V or

20 V to 196 V depending on the model

Auxiliary supply input power 4.5 W

4.5. Communications

Specification Details

Ethernet 100 base-T

Baud Rate: 10/100 Mbit/sec, automatically detected

CAT5e Cable

UDP, Telnet, TCP

30

USB

One port, USB 2.0, 12 Mbps

EtherCAT 100 base-T

Baud Rate: 100 Mbit/sec

CAT5e Cable

CoE, EoE, FoE

CAN CAN bus Signals:

CAN_H, CAN_L, CAN_GND

Maximum Baud Rate of 1 Mbits/sec.

CAN Profile:

DS 301

Device Profile (drive and motion control):

CAN device profiles, e.g., DS301, DS505, DS402, DS401

(for I/O)

www.elmomc.com

Page 31

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Technical Specifications

4.6. Compliance with Standards

Specification Details

Quality Assurance

ISO 9001:2008 Quality Management

Design

Approved IEC/EN 61800-5-1, Safety Printed wiring for electronic equipment

(clearance, creepage, spacing, conductors

sizing, etc.)

MIL-HDBK- 217F Reliability prediction of electronic equipment

(rating, de-rating, stress, etc.)

31

• UL 60950

• IPC-D-275

• IPC-SM-782

Printed wiring for electronic equipment

(clearance, creepage, spacing, conductors

sizing, etc.)

• IPC-CM-770

• UL 508C

• UL 840

In compliance with VDE0160-7 (IEC 68) Type testing

Safety

Recognized UL 508C Power Conversion Equipment

In compliance with UL 840 Insulation Coordination Including Clearances

and Creepage Distances for Electrical

Equipment

In compliance with UL 60950 Safety of Information Technology Equipment

Including Electrical Business Equipment

Approved IEC/EN 61800-5-1, Safety Adjustable speed electrical power drive

systems

In compliance with EN 60204-1 Low Voltage Directive 73/23/EEC

www.elmomc.com

Page 32

MAN-GOLD-MAESTRO-IG (Ver . 1.301)

Gold Maestro Installation Guide Technical Specifications

Specification Details

EMC

Approved IEC/EN 61800-3, EMC Adjustable speed electrical power drive

systems

32

In compliance with EN 55011 Class A with

Electromagnetic compatibility (EMC)

EN 61000-6-2: Immunity for industrial

environment, according to:

IEC 61000-4-2 / criteria B

IEC 61000-4-3 / criteria A

IEC 61000-4-4 / criteria B

IEC 61000-4-5 / criteria B

IEC 61000-4-6 / criteria A

IEC 61000-4-8 / criteria A

IEC 61000-4-11 / criteria B/C

Workmanship

In compliance with IPC-A-610, level 3 Acceptability of electronic assemblies

PCB

In compliance with IPC-A-600, level 2 Acceptability of printed circuit boards

Packing

In compliance with EN 100015 Protection of electrostatic sensitive devices

Environmental

In compliance with 2002/96/EC Waste Electrical and Electronic Equipment

regulations (WEEE)

Note: Out-of-service Elmo drives should be

sent to the nearest Elmo sales office.

In compliance with 2002/95/EC

(effective July 2006)

Restrictions on Application of Hazardous

Substances in Electric and Electronic

Equipment (RoHS)

www.elmomc.com

Loading...

Loading...