Page 1

Page 2

Index

Typical installations 2

Components of system 3

Seven Step Installation

Step #1: Choose your system 3

Step #2: Plan number of inlets 4

Step #3: Plan placement of inlets 4

Step #4: Plan tubing installation 5

Step #5: Install inlet valves

Existing home 5

New construction 8

Step #6: Install tubing 9

Step #7: Install power unit 10

Safety warnings 12

Page 3

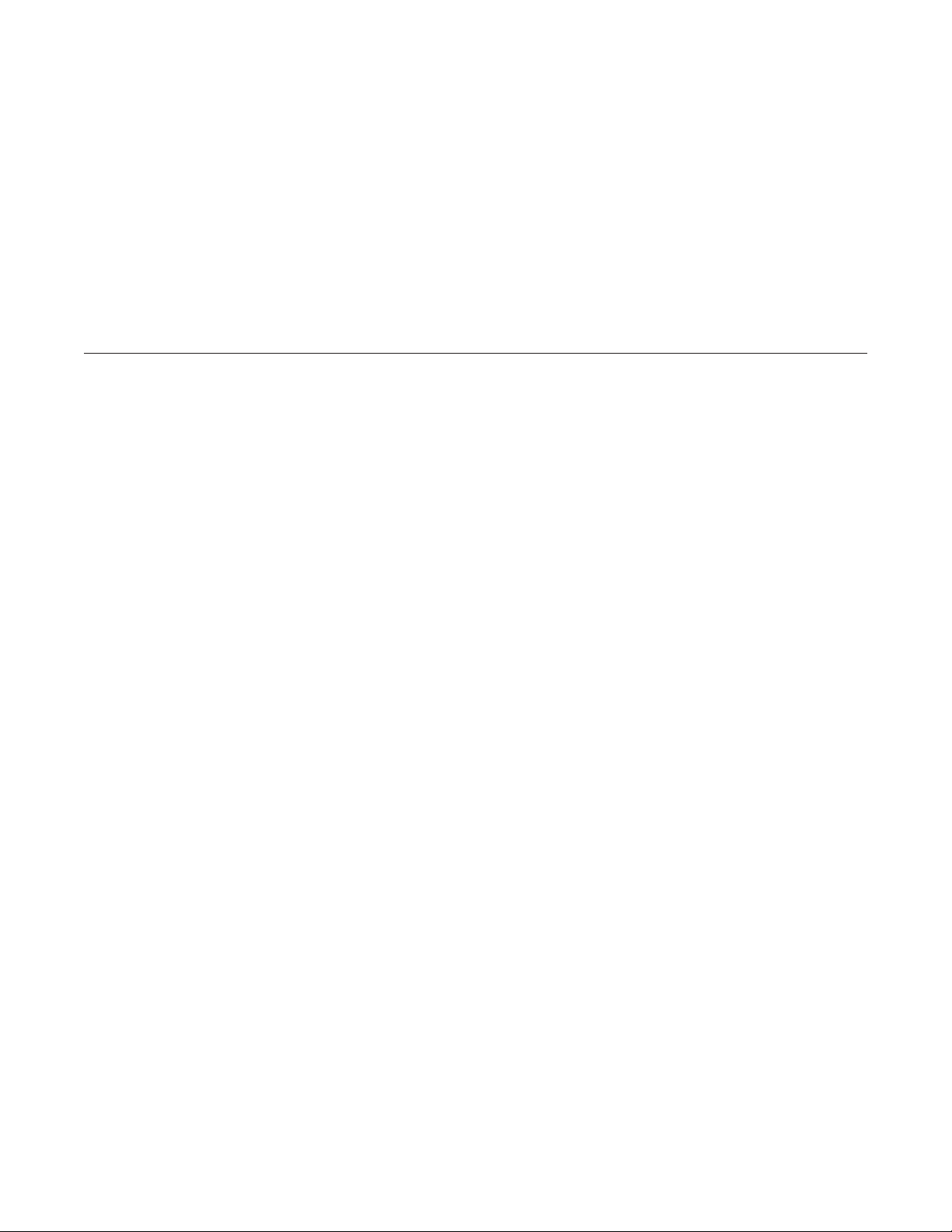

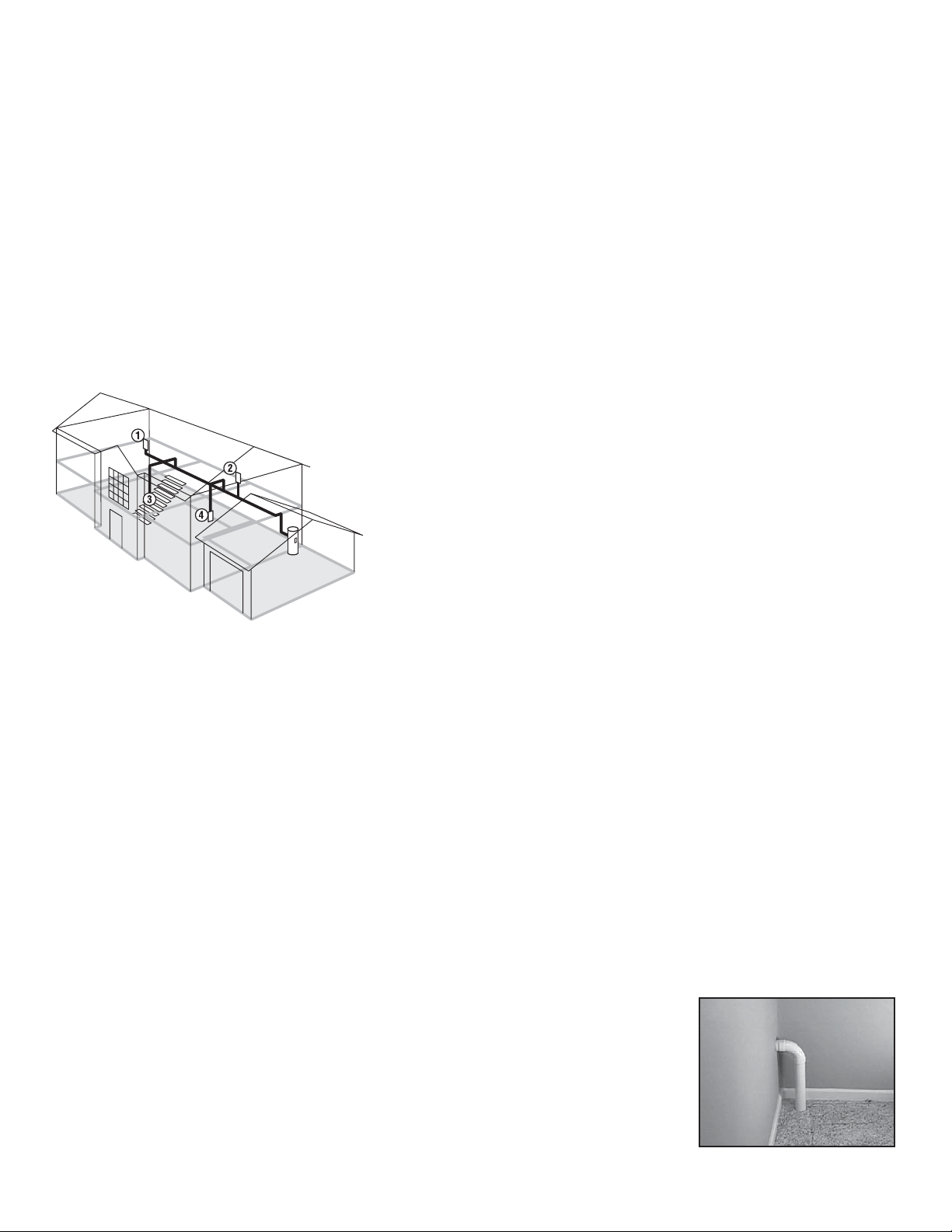

Typical Central Vacuum System Installations

Ranch-style bungalow

MAIN FLOOR

BASEMENT

2

GARAGE1

3

3

4-level split Large 4-level split

UPPER LEVEL

LOWER LEVEL GARAGE

MAIN FLOOR

1

3

Single story on slab/crawlspace

MAIN FLOOR GARAGE

1

CRAWLSPACE

UPPER LEVEL

1

LOWER LEVEL

2

MAIN FLOOR

33

3

5

GARAGE

CRAWLSPACE

UPPER LEVEL

MAIN FLOOR

BASEMENT

BASEMENT

Two-story

1

2

3

2

CRAWLSPACE BASEMENT

2

4

Large 3-level split

1

4

GARAGE

4

UPPER LEVEL

LOWER LEVEL

1

2

MAIN FLOOR

CRAWLSPACE

3

4

GARAGE

2

Page 4

Seven Step Installation

Installation Step 1: Choose

Congratulations on the purchase of your new

central vacuum system. It will make cleaning your

home easier and improve indoor air quality. The

system typically can be installed in virtually any home

with no costly alterations and very little mess. This

guide will show how to install your central vacuum

system in your home in just seven steps.

Before you begin installation, read this guide. Also

review local building codes so your installation

complies with them.

Components of a central vacuum system

installation.

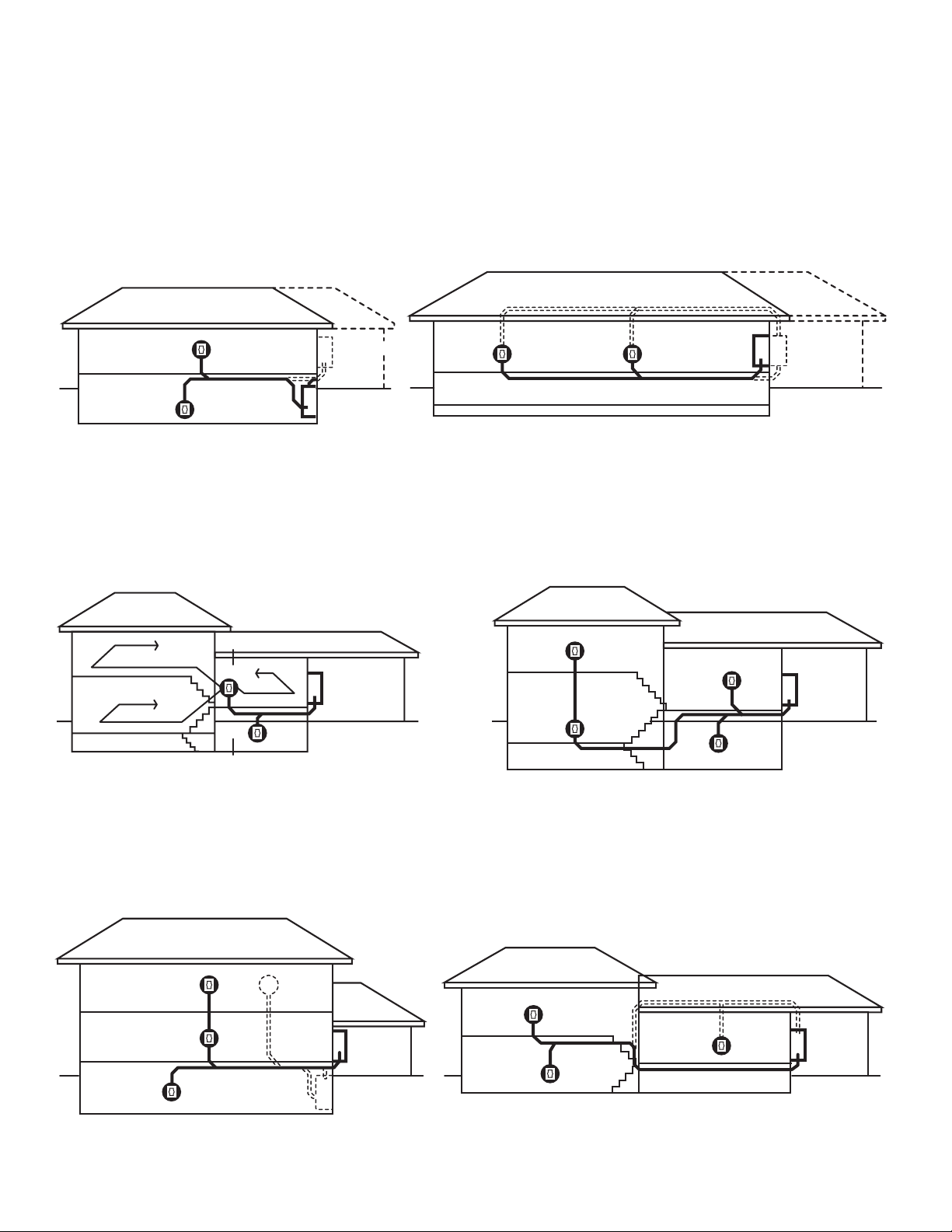

The Power Unit/Dust Collection

Receptacle is usually mounted in

the garage, basement, utility or

storage room to remove dust and

allergens from living areas.

Tubing & Fittings: Dust and dirt are

carried through tubing from “inlet

valves” to the power unit. Note:

ASTM tubing and fi ttings are

specifi cally designed for your

central vacuum system. Other

types of tubing, like plumbing pipe,

are different sizes and will not fi t.

your system.

You’ve already completed step number one...you’ve

purchased your powerful new system. Next, inventory

the component parts that arrived with your central

vacuum system kit and assemble the tools you will need.

(See front cover.)

Inventory all the parts.

Lay out the parts so you know you have them all

and what each is called. A three-inlet valve system

typically includes:

80' low-voltage wire

3 mounting brackets

6 nail guards

3 plaster guards

1-1/4 pint solvent sealer

6 45 degree elbows

9 90 degree sweep elbows

2 90 degree sweep tees

6 stop couplers

3 90 degree dual elbows

6 hanger clamps

6 wire nuts

3 fl oor mounting adapters

*Inlet covers sold separately

Inlet valves: Installed in the wall or

fl oor, each inlet valve connects the

powerhead and fl exible cleaning

hose to the tubing in your home.

3

Page 5

Installation Step 2: Decide

how many inlets you will need.

To make sure your central vacuum system reaches

every room throughout the house, you must fi rst

determine the number of inlets you will need and

where to place them. One inlet valve can serve

700-800 square feet (63-72 sq m). Use only interior

walls if possible, so you won’t have to deal with

insulation typically found in exterior walls.

Choosing the right spot for the

inlet valve.

Use a stud fi nder, or sound out the wall, to make sure

the site for the inlet valve is between the studs and

that the space is open behind the wall board. Also

check the other side of the wall to make sure it’s clear

of obstructions such as utilities and outlets. Caution:

Do not install an inlet behind a door or in a wall

that has a pocket door. Then have a helper hold the

end of the hose at the proposed site for the inlet valve

and take the other end and walk around the room(s).

If you have no helper, use a piece of cord or string

that is 30 feet (9.15m) long—the length of the hose.

You want to be able to reach everywhere from fl oor to

ceiling even with furniture in the way. You may have

to choose a different location or add another inlet to

cover the entire fl oor. Remember, one inlet usually lets

you cover about 700-800 square feet (63-72 sq m).

Repeat this on each fl oor of your home.

Installation Step 3: Decide

where to place inlets.

Good locations are centrally located in hallways or

closet walls and/or doorways. Do not place inlets

behind doors or furniture.

Existing home: The inlet valve must be within 6 feet

(1.83m) of an electrical outlet to provide power to the

powerhead. A switch on the handle sends a signal

through “low-voltage” (24 volt) wiring to turn the power

unit on and off.

New construction: If your home is under construction,

you should consider using “electrifi ed” inlet valves.

Electrifi ed valves have low-voltage and household

wiring connections built in, so there’s no need for

a nearby electrical outlet. Inlet valves should be

installed before drywall is hung. Installation must

be coordinated with an electrician to hook up the

electrical line after the tubing has been installed

(electrifi ed valves sold separately).

What about installing inlet valves

upstairs?

Because there are fi nished walls above and below the

second-fl oor sole plate, installing inlet valves upstairs

can take a little more ingenuity. There are several

options: Place an inlet outside a closet wall and then

run the tubing through the wall and through the inside

of the closet and down (see Fig. 03, Page 07).

Another option is to run the tubing up into the attic

then across and down to the inlet. Yet another

solution is to install the upstairs inlet valve directly

into the fl oor. Note: Although plastic inlet valves

are acceptable as long as they’re installed next

to the wall where no one will step on them, metal

fl oor inlets provide added durability. Hint: Do not

install fl oor inlets where furniture will be.

To run tubing through a

closet, mount the inlet

outside the closet and

run tubing into the closet

and down through the

closet fl oor.

4

Page 6

Deciding where to mount the power unit.

To be sure that dust and dirt are effectively removed

from living areas in your home, mount the power unit

in your attached garage. If you do not have an

attached garage, the basement, utility room, storage

room or mud room is the best alternative location.

Find a spot that is close to an electrical source, yet

with plenty of room for air to circulate on either side of

the unit. You’ll need a dedicated 15- or 20-amp circuit.

Check the owner’s manual.

Installation Step 4:

Plan the tubing installation.

Before you install tubing to carry dust and dirt to the

power unit, plan your route. Run the tubing beneath

the sub-fl oor whenever possible because it makes

tubing easier to work with and creates the shortest

path between the inlet valves and the power unit.

If the tubing has to run next to a water heater or

chimney fl ue—for your safety and to comply with

building codes—use metal central vacuum system

tubing for that section. Hint: A local central vacuum

system dealer may provide metal tubing. If the

tubing runs through an unheated attic or other

unprotected environment, wrap it with insulation to

prevent condensation and the possibility of clogging.

Installation Step 5:

Install the inlet valves.

Existing home inlet valve installation.

Directly beneath the proposed inlet site, use a fl at-

bladed screwdriver to wedge the molding aside. Then,

take a wire coat hanger and snip a long straight piece

from it. Insert the wire into the chuck of your drill and

then holding the drill vertically beneath the intended

inlet site, slowly drill down into the fl oor alongside the

baseboard or where the wall and fl oor intersect.

Release the wire from the drill chuck and leave it in

the pilot hole to serve as a locator. Then go to the

basement and look for the wire protruding from the

ceiling.

Now you can see where the inlet valve is going to be

above you. Measure from the wire to fi nd the center

of the sole plate and wall cavity. Note: You may want

to drill a 3/4" (1.9cm) diameter inspection hole to

avoid cutting into the bottom of a stud or other

inner-wall obstructions. Then using a fl ashlight

and/or probe, inspect the interior of the wall to be sure

there are no obstructions. If there are obstructions,

you may have to move the inlet site. If there are no

obstructions, drill a 2-1/4" diameter hole (5.7cm) in

the bottom of the hollow wall through the sole plate.

Make sure to cut in between the walls. The tubing is 2"

(5.08cm) in diameter, so the hole will give you room

to manipulate the tubing. Again, check for obstructions

using a fl ashlight and a length of tubing. If there are

no obstructions, go back upstairs and mark the inlet

location on the wall. To do that, at the electrical outlet

adjacent to the inlet site, measure up from the fl oor

to the center of the outlet. At the proposed inlet site

measure up from the fl oor the same distance. This will

be the center of your inlet valve. If you prefer, you may

locate the inlet at a more convenient height. Some

homeowners prefer the inlet at fi ngertip height, about

30" (76.2cm) above the fl oor.

5

Page 7

Installing an inlet valve.

Take a wall mounting bracket, cut or snap off the new

construction fl ange and dispose of it. In new construction,

nail the tab to the stud. (See New Construction inlet

valve installation.) Use a level to make sure the

mounting bracket is level. Then trace the outline of the

mounting bracket onto the wall. Take a utility knife and

score the lines. Then use the utility knife or a drywall

saw to cut a hole though the drywall. Hint: A drywall

saw makes the job easier.

Attach a 90 degree dual elbow fi tting to the fl ange on

the back of the mounting bracket. Note: The ends of

the fi tting are different depths to accommodate

walls of different widths. Apply glue around the outside

of the mounting bracket fl ange and twist the 90 degree

elbow fi tting into place. Make sure the open end faces

the direction it will meet the tubing—usually straight

down. Note: If tubing has to run from the attic, the

opening of the 90 degree fi tting will face upward.

Caution: Never apply glue to the inside of fi ttings

or tubing. Apply glue only to the outside of the tubing.

This will prevent glue from creating obstructions which

could clog your system.

Run about 6" (15.24cm) of low-volt wire through the

guide hole in the mounting bracket. Split the wire into

two strands and strip 1" of insulation from each strand.

Wrap the strands in a clockwise direction around the

screws on the back of the inlet valve. Tighten the screws.

Now attach a weight to the end of the low-voltage wire

and drop it down to the basement or crawlspace.

Have a length of wire coat hanger ready with one end

bent into a hook. Insert the mounting bracket into the

wall hole...fi rst down...then up...centering it. Take

the hanger and insert the hooked end of the hanger

into the 90 degree elbow to hold the bracket in place.

Then, slide the inlet valve along the wire hanger into

the mounting bracket. Screw the valve into place.

Remove the wire hook. Caution: Inlet kits come with

a long and a short screw, so be sure to use the

short screw in the hole facing the elbow since the

long screw could puncture it. Be sure to mount

the inlet valve so the lid pulls down to open. Then

apply glue to an adequate length of tubing and aim it

upward through the hole in the sole plate and into the

90 degree fi tting on the back of the mounting bracket.

(See Installation Step #6 for information on installing

tubing.)

Need more space?

If you cannot locate a hollow wall, or the space

between your walls isn’t wide enough, there are

two alternatives: One is to run the tubing through a

concealed area such as the inside of a closet; then

run the tubing downward. Another alternative is to use

a fl oor mounted inlet.

Closet wall installation.

Often the only practical

solution is to install your

system with the tubing

going through a wall

into a closet, then down

through the closet fl oor.

To use this method,

select a suitable inlet

valve location outside a

closet—exercising the

same precautions as for

normal wall installation.

Then, using a length of coat hanger, drill a hole

through both walls (Fig. 01). Hold the wire perfectly

horizontal so the interior and exterior holes line up

with one another. Check for inner wall obstructions by

bending a short length of coat hanger wire at a right

angle and twirl the right angle piece inside the wall. If

there are no obstructions, drill a 2-1/4" (5.7cm) hole

horizontally through both walls.

Fig. 01

Closet Wall Installation In

An Existing Structure

6

Page 8

Enlarge the hole in the exterior wall to accommodate

the inlet valve assembly (valve and mounting bracket).

(As described above in “Installing an inlet valve.”)

Inside the closet, drill a pilot hole through the fl oor

beneath the opening in the wall or at a convenient

spot nearby to check for obstructions. If there are no

obstructions, cut a 2-1/4" (5.7cm) hole through the

fl oor. Run low-voltage wire through the hole in fl oor,

and through the wall to exterior of closet.

Fig. 02

Inner-Wall Closet Assembly

Floor valve installation.

To install a fl oor inlet valve, drill a pilot hole with a

wire coat hanger and check the location as previously

described. When you are sure that the proposed location

will not be blocked by a joist or other obstruction, cut

a hole in the carpet slightly larger than your 2-1/4"

(5.7cm) drill bit. Drill a 2-1/4" (5.7cm) hole in the fl oor.

Enlarge the opening to accommodate the low-volt

connections. Assemble an adapter reducer bushing

and attach the low-volt wire to the inlet valve. Drop the

low-volt wire to the basement. Screw the valve to the

fl oor. Repeat until all inlets are installed.

Multi-story homes.

Multi-story homes usually require one or more inlets

on each level. Instead of trying to line up inlet valves

from one level to the next, run a separate line of

tubing from the upstairs inlet valve to a branch line

or to the main trunk line (Fig. 04).

Pass low-voltage wire through the wire guide hole in

the inner wall closet assembly (Fig. 02) and tape or

cable tie low-voltage wire to this assembly immediately

behind the bracket. Attach wires to low-voltage terminals

on the back of the inlet valve. Place the inner wall

assembly lengthwise through the wall opening and

arrange the assembly so the bracket is fl ush with the

inside surface of the wall. Screw the inlet valve to the

wall (Fig. 03).

Fig. 03

Inner-Wall Closet Assembly – Installed

Fig. 04

In a two-story home, upstairs beneath the site you’ve

selected for the inlet valve cut a hole just large

enough to allow you to reach the second-fl oor sole

plate. Hint: Cut the hole low in the wall for easier

drilling through the sole plate. Cut a 2-1/4" (5.7cm)

hole in the sole plate. Install the inlet valve just as

before. Then, from the basement, insert a length of

tubing long enough to reach through the hole in the

second fl oor sole plate to the site for the inlet valve.

You may have to join several lengths of tubing.

Measure and pre-cut these pieces and test-fi t them

before gluing. When you do apply glue, work quickly

to prevent the glue at the top end of the tubing from

drying out before it reaches the fi tting at the inlet valve.

7

Page 9

Remember: Apply glue only to the outside of the tubing.

Hint: When upstairs, remember to aim the elbow

downward. Other ways to reach the upstairs in your

home are through the interiors of closets or pantries,

beneath a staircase, or with fl oor inlets. If the inlet

valve will be serviced from the attic, shorter pieces of

tubing joined by couplings may be required because of

overhead space restrictions. Again, measure and test

fi t. When gluing, work quickly to prevent the glue from

drying before the tubing reaches the inlet valve.

Installing an automatic sweep inlet.

An automatic sweep inlet — an automatic dustpan —

a very popular option for the kitchen, mudroom and

bath. Here are some pointers for installation. First,

determine the best place to install the sweep inlet —

usually beneath a cabinet — and remove any shoe

molding. Drill a pilot hole

using a length of wire coat hanger

and fi nd the wire in the ceiling

below. Drill up through the fl oor

beneath the cabinet to check

for obstructions and make sure

you can connect the tubing to the main line. If there

are no obstructions, enlarge the hole in the fl oor

beneath the cabinet and check the clearances.

New construction inlet valve installation.

Select a site for the inlet valve and drill a pilot hole

through the fl oor. Go below to check that the tubing

path is clear of present, or future, obstructions such as

fl oor joists, heating ducts, plumbing, wires, etc. At the

inlet valve location, drill a 2-1/4" (5.7cm) diameter hole

through the sole plate. The hole should be 2" (5.1cm)

from the side of the stud and centered between the

front and back edges of the sole plate (Fig. 05).

Fig. 05

Glue a length of tubing into a stud-mounting bracket

assembly. Cut a length of low-voltage wiring, bring

approximately 6" (15.24cm) through top wire guide

hole in stud bracket assembly and double it back into

elbow hole. Tape wire to tubing at assembly elbow

and again close to end, and tuck remaining wire into

bottom of tubing. Screw plaster guard onto face of

assembly (Fig. 06).

VacPan VacuSweep

Cut hole 6-3/4" x 1-3/4"

(17.15cm x 4.45cm)

Now, return to the kitchen/mudroom/bath to measure

and saw the rectangular hole for the sweep inlet and

fasten the inlet into place. In the basement, attach

the tubing and string the low-voltage wire just as you

would for any inlet. Hint: See sweep inlet manual for

details.

Cut hole 6-5/8" x 2-3/8"

(16.83cm x 6.04cm )

Fig. 06

Stud-Mounting Bracket Assembly (New Construction)

8

Page 10

Drop bottom of tubing through 2-1/4" (5.7cm) hole and

nail stud-mounting bracket assembly to stud. Make

sure the center of the inlet hole is at the correct height

above fl oor level and the tubing extends below the

sub-fl ooring. To prevent a nail or screw from

penetrating the vacuum tubing, install nail guards

on the sole or top plates adjacent to the tubing. See

“Installation Step Six: Install the tubing” and complete

tubing installation as much as possible. After the

walls are fi nished and painted, plaster guards can be

removed and inlet valves installed. The tubing system

may be completed at that time and the power unit

installed.

Installation Step 6:

Install the tubing.

(Existing Home or New Construction)

Beginning at the inlet farthest from the power unit,

temporarily fasten tubing for the main trunk line into

position. Hint: Loop string or low-voltage wire to

create a hanger strap from a nail or overhead pipe,

etc., to cradle the tubing — holding it in position

while you work.

Push a length of tubing up into bottom of the elbow

on the inlet valve assembly. Piece together sections

of tubing without glue at fi rst to make sure things

fi t properly. Mark the connections so you can

re-assemble them the same way. Remember, the

tubing enters the fi tting approximately 3/4" (1.9cm).

Measure, cut, and de-burr tubing, and, using a 90

degree sweep elbow, slip-fi t the vertical tubing line to

the main horizontal line. To avoid potential clogging

problems when installing tubing and fi ttings:

• Make straight cuts on tubing (pipe/tubing

cutter works well).

• Remove burrs from ends of tubing.

• Be sure tubing fi ts against the shoulder of the

fi tting with no gaps.

• Glue only the outside edge of the tubing before

assembly into fi ttings.

9

Page 11

Connect tubing from additional inlet valves to the main

trunk line using 90 degree sweep tee elbow fi ttings.

(Fig. 07) and use clamps to hold the sections in place.

Be sure to install the sweep tee fi ttings so the sweep

is toward the power unit (Fig. 08). Always run branch

lines from the sides or top of the main trunk line, never

out of the bottom because this will create a trap for dirt

to fall into.

Fig. 07

Typical Under-Floor Installation

Fig. 08

Hint: Create clamps from extra tubing to hold low-

voltage wire in place.

Masonry or concrete walls.

If you have to run tubing through masonry or concrete

walls, rent a hammer drill and/or masonry hole saw.

Run the tubing through and patch the hole once you’re

up and running. Before drilling, check local building

codes for special fi rewall penetration regulations. The

code also should tell you if steel tubing is required.

Installation Step 7:

Install the power unit.

Attach the power unit to the wall with the bottom

screws of the mounting bracket located 48" (1.2m)

above the fl oor to allow easy removal of the dirt

canister. For proper motor cooling, there must be at

least 12" (30.48cm) between the unit and the ceiling.

Do not install the power unit where the ambient

temperature regularly exceeds 120 degrees

Fahrenheit (48.9 degrees C).

90 Degree Sweep Tee

String the low-voltage wire along as you assemble

the tubing. Join or splice low-volt wires with wire

connectors at each junction or branch in the tubing.

To make sure the polarity is right, always attach wires

of the same color to each other — typically copper-

to-copper and silver-to-silver. Proceed until the tubing

system is complete.

If mounting on plaster, wall board or panel walls,

be sure mounting bolts enter studs. If mounting on a

block or concrete wall, drill the holes with a masonry

bit and insert plastic or lead anchors. As an alternative

to mounting on concrete walls, suspend 2" x 4" (5.1cm

x 10.16cm) studs or plywood from overhead.

10

Page 12

To attach the low-voltage wires, strip the wire and

crimp the strands into the two “slip-on” terminals

provided. Attach the terminals and plug the power

unit into the dedicated electrical outlet. The sentry

light should come on. Flip the switch and the power

unit should come to life. Attach the remaining

section of tubing to the power unit with connector/s

and clamp/s provided. Caution: Do not glue the

connection because you may need to disconnect

the system at a future date. For added installation

convenience, some power units may have inlet

connections on either side. If your system came

with a muffl er, clamp it to the exhaust port.

NOTE: Unit may be exhausted to exterior. Use

the same tubing and fi ttings. If vented, the exhaust

air should not be vented into a wall, ceiling or

concealed space of a building. Venting over

10 feet (3m) is not recommended.

Power unit electrical wiring.

Check local codes but use not less than #14-3 wire.

Plug power unit cord into appropriate 120/220/230/240V

— 50/60 cycle electrical outlet. Be sure line voltage

is suffi cient to handle a 15- or 20-amp load. See your

owner’s guide.

Check your installation to make sure

it works properly.

All that’s left to do is check the quality of your

installation. First, check to see if you have a closed

system; with no hose or handle attached, and all

inlet valves closed, there should be little or no air

coming through the exhaust on the power unit when

it is turned on. Second, with the system still running,

walk through your home. If you hear whistling or

hissing, you may have forgotten to glue a connection.

Check basement and attic areas, too. Third, have a

helper plug the hose into each of the inlet valves to

be sure you can turn the power on. Turn off the switch

on the hose handle and the unit should turn off.

That’s it! You’ve just installed your own

central vacuum system.

You’ve just made cleaning easier... while

improving the air quality in your home.

Congratulations!

11

Page 13

WARNING: ELECTRIC SHOCK COULD OCCUR IF USED ON WET SURFACES.

'2/5.$%$

/54,%4

'2/5.$%$0).

'2/5.$%$

/54,%4

"/8

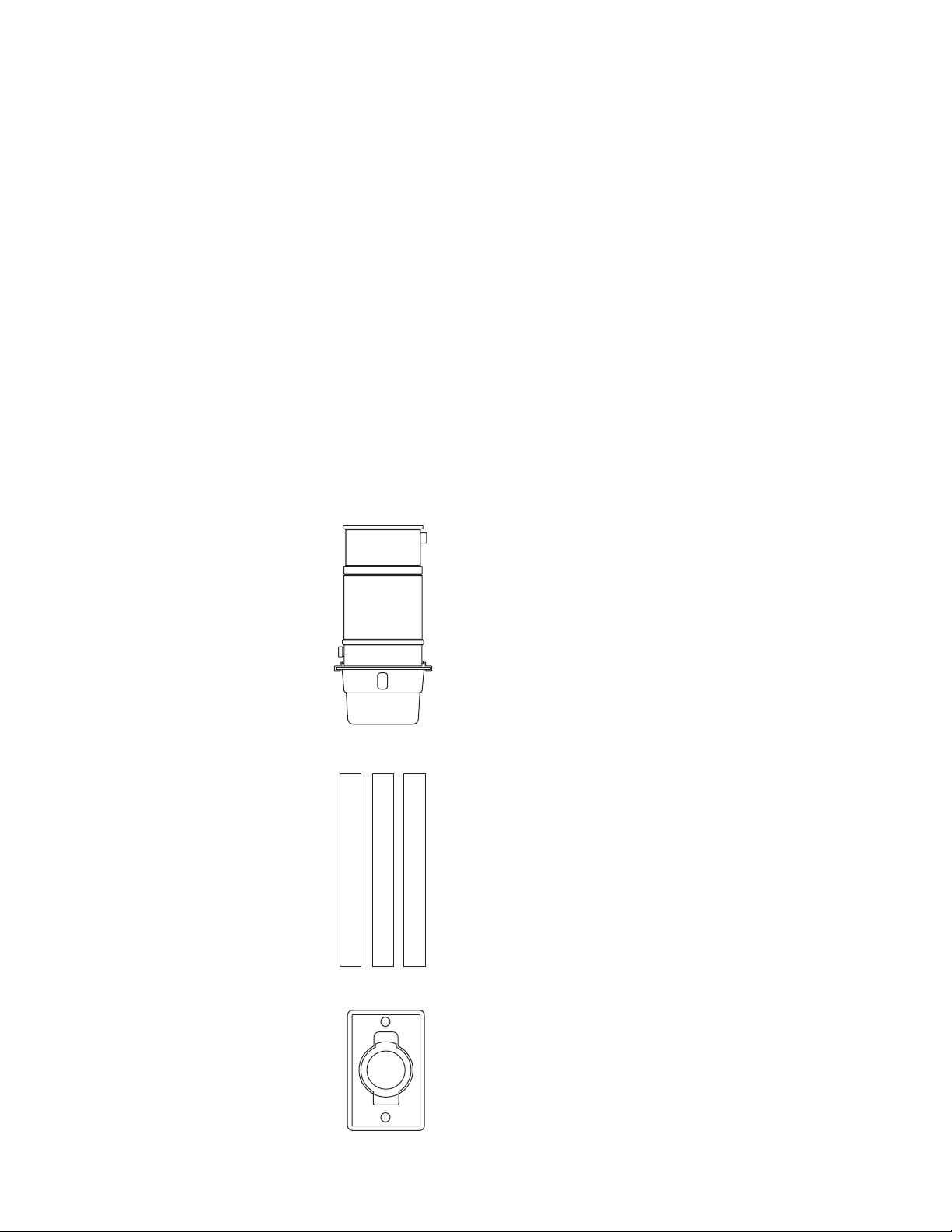

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should malfunction or break down, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. This appliance is equipped with a cord that has an

equipment-grounding conductor and grounding plug. The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WARNING

Improper connection of the equipment-grounding conductor can result in a risk

of electric shock. Check with a qualifi ed electrician or service person if you are

in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the appliance—if it will not fi t the outlet, have a proper outlet

installed by a qualifi ed electrician. This appliance is for use on a nominal

120-volt circuit and has a ground plug that looks like the plug illustrated in

(Fig. 09) for North American units. For 220/230/240 volt units, consult your local

building code/electrician. Make sure that the appliance is connected to an outlet

that has the same confi guration as the plug. No adapter should be used with

this appliance. Check power unit On/Off switch and all inlet valves for operation.

This power unit is intended for household and commercial use.

Fig. 09

Read all instructions before using this vacuum.

NOTE: Your central vacuum system is listed and approved by the appropriate agencies for dry pick-up only.

Please see your rating plate for details. To reduce the risk of electric shock, DO NOT USE outdoors or on

wet surfaces.

12

Page 14

IMPORTANT SAFETY INSTRUCTIONS

When using electrical appliances, basic safety precautions should always be

followed, including the following:

DANGER: Always unplug power unit from the electrical outlet before servicing and

cleaning.

WARNING: To reduce the risk of burns, fire, electric shock or injury to persons:

1. Keep cord away from heated surfaces.

2. Do not allow to be used as a toy. Close supervision is necessary when this vacuum is used by or near children.

3. Use this vacuum only for its intended use as described in the operating and maintenance manual. (Use of

attachments not recommended by the manufacturer may cause fi re, electric shock or injury.)

4. Never operate this vacuum if it has a damaged cord or plug, if it is not working properly or if it has been dropped

or damaged. Return to service center or have service person examine and repair.

5. Do not pull or carry this power unit by supply cord, use cord as a handle, close a door on cord or pull cord around

sharp edges or corners.

6. Never disconnect plug by pulling on cord. To disconnect from outlet, grasp the plug, not the cord.

7. Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair and

anything that may reduce air fl ow.

8. Keep hair, face, fi ngers and loose clothing away from any openings.

9. Do not pick up cigarettes, live hot ashes, matches or similar materials.

10. Never operate vacuum without dust bag and/or fi lter in place.

11. To disconnect, turn all controls to the OFF position; then remove plug from outlet.

12. Never handle plug, cord or power unit with wet hands.

13. Electric shock could occur if used on wet surfaces.

14. Use extra care when cleaning on stairs.

15. Do not use to pick up fl ammable or combustible liquids such as gasoline or use in areas where they may be present.

16. For a grounded appliance: Connect to a properly grounded outlet only. See grounding instructions.

SAVE THESE INSTRUCTIONS

Technical support is available at 1-866-831-2303 Monday - Friday 8:00 am - 4:30 pm CST

Loading...

Loading...