Electrolux AOS061GAPQ Installation Manual

air-o-steam® ELECTRIC COMBI OVENS

6 GN 1/1

260450 260462 260456

260451 260463 260457

°

**

°

**

°

**

400 230 200

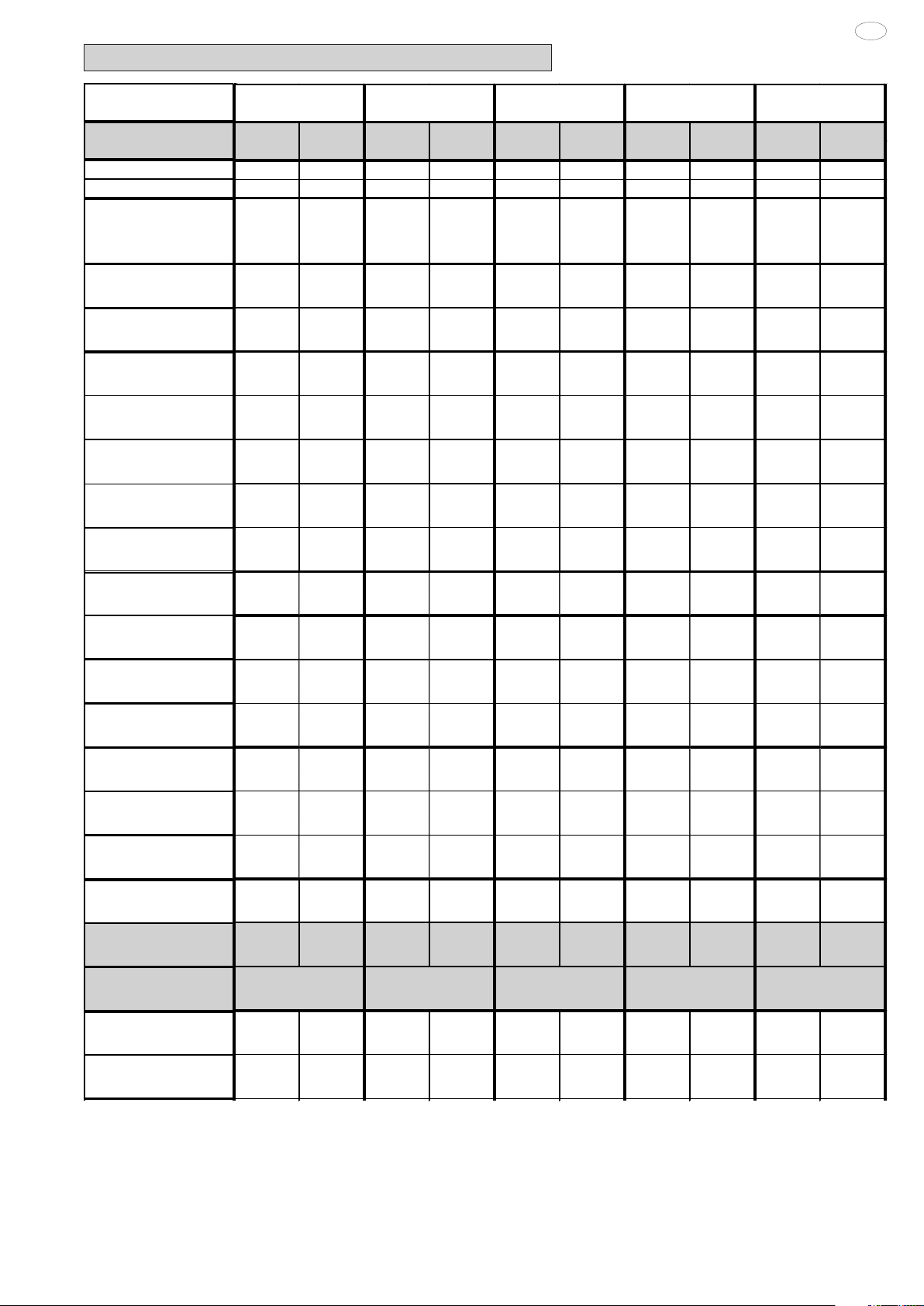

2. TABLE 1: TECHNICAL DATA

INSTRUCTIONS FOR INSTALLATION AND USE

Table of contents Page

- Installation diagram .......................................................... 2

- Appliance identification ................................................... 9

I. MAIN FEATURES ............................................................. 10

1. Description of appliance ............................................ 10

2. Table 1: Technical data ................................................. 11

3. Precautions .................................................................. 12

4. Safeguarding the environment ................................... 13

4.1 Packaging .............................................................. 13

4.2 Use ......................................................................... 13

4.3 Cleaning ................................................................. 13

4.4 Disposal ................................................................. 13

II. INSTRUCTIONS FOR INSTALLATION ........................... 14

1. Place of Installation .................................................... 14

1.1 Ventilation ................................................................. 14

1.2 Reference standards................................................ 14

1.3 Unpackaging ............................................................ 14

1.4 Immediately inspect for shipping damage ............... 14

2. Positioning .................................................................... 14

3. Combusted gas discharge .......................................... 14

3.1 Foreword .................................................................. 14

Installation of accessories ............................... 15

3.2

3.3 Warnings regarding the fluimg system .................. 15

4. Electrical connection .................................................. 15

4.1 Installing the power supply cable ........................... 16

5. Water mains connection ............................................. 16

5.1 Water supply characteristics .................................. 16

5.2 Water drain system ................................................ 16

6. Gas connection ........................................................... 17

6.1 Warning .................................................................. 17

6.2 Nominal heat output ............................................... 17

6.2 Checking the supply pressure ............................... 17

7. Safety devices ............................................................. 17

8. Operation check .......................................................... 17

9. Servicing ....................................................................... 17

10. Troubleshooting ........................................................... 18

11. Layout of main components ..................................... 18

III. INSTRUCTIONS FOR USE ............................................ 19

1. Opening the oven door ............................................... 19

1.1 6- and 10-grid models ............................................ 19

1.2 20-GRID models .................................................... 19

2. Closing the oven door ................................................ 19

2.1 6- and 10-GRID models ......................................... 19

2.2 20-GRID models .................................................... 19

3. Description of the control panel ................................ 20

3.1 Introduction ............................................................ 20

3.2 Main controls .......................................................... 20

3.3 Main cooking modes .............................................. 20

3.4 Special cooking modes .......................................... 20

3.5 Additional functions ................................................ 21

USING THE OVEN ................................................................. 22

4. Introduction ................................................................. 22

4.1 Switching the oven on ............................................ 22

4.2 Selecting the controls ............................................ 22

4.3 Manual controls ...................................................... 22

4.4 Automatic controls ................................................. 26

5. Information and error codes ...................................... 29

6. SWITCHING off in the event of a fault ....................... 30

7. Care and maintenance ................................................ 30

7.1 Periodical maintenance of the BOILER ................. 31

7.2 Replacing CONSUMABLE components ................ 32

7.3 Special cleaning instructions ................................. 32

- CONTROL PANEL FIGURES .......................................... 105

USA

- APPLIANCE IDENTIFICATION

5938 026 00

Rating plate

PNC 9PDX 260462 05

260462

9

USA

I. MAIN FEATURES

1. DESCRIPTION OF APPLIANCE

This booklet describes a number of appliance models.

For more detailed information about the model in your possession,

refer to "Technical Data" table 1.

The appliance has the following features:

• Digital temperature controlle.

• Thermostatic probe for measuring the core temperature of products (core temperature probe).

• Automatic flush to drain every two hour to prevent the build-up of

lime-scale in the boiler.

• Periodic draining and automatic washing of the boiler to prevent

the build-up of lime-scale.

• Boiler lime-scale level indicator (see corresponding paragraph).

• Oven chamber automatic fast steam drain device for gratins.

• Air-break (anti-backup drain) device to prevent backflows from

the drain system from entering the oven.

• Halogen lighting in the cooking chamber.

• Double-action door opening safety mechanism designed to

protect the user from scalding steam.

• Double-glazed oven door for reduced heat dispersion into the

kitchen and low temperatures on the exterior of the oven.

• Self-diagnostics system indicating oven faults using error codes

(see "Information and error codes ").

10

5938 026 00

2. TABLE 1: TECHNICAL DATA

Boil

Boil

USA

GRID S

P NC *

CONVECTOR °

BOILER **

SUPPLY VOLTAGE

Total W atts

Maximum load capacities

(food)

Net w eight

Shipping we ight

Shipping width

Shipping height

Shipping depth

6 GN 1/1 10 GN 1/1 10 GN 2/1 20 GN 1/1 20 GN 2/1

260860 260870 260862 260872 260864 260874 260866 260876 260868 260878

° ° ° ° ° ° ° ° ° °

** ** ** ** ** ** ** ** ** **

208V 2ph

60Hz

6amps

120V 1ph

60Hz

10amp

208V 2ph

60Hz

6amps

120V 1ph

60Hz

10amps

208V 2ph

60Hz

6amps

120V 1ph

60Hz

10amps

208V 2ph

60Hz

10amps

120V 1ph

60Hz

16amps

208V 2ph

60Hz

15amps

0,25 kW 0,25 kW 0,3 kW 0,3 kW 1 k W 1 kW 0,5 kW 0,5 kW 2 kW 2 kW

66 lbs.

(30 kg)

253.53 lbs.

(115 kg)

295.42 lbs.

(134 kg)

37 1/64"inch

(940 mm)

40 15/16" inch

(1040 mm )

38 9/16"inch

(980 mm)

66 lbs.

(30 kg)

253.53 lbs.

(115 kg)

295.42 lbs.

(134 kg)

37 1/64"inch

(940 mm)

40 15/16" inch

(1040 mm )

38 9/16"inch

(980 mm)

110 lbs.

(50 kg)

319.67 lbs

(145 kg)

363.76 lbs.

(165 kg)

37 1/64"inch

(940 mm)

49 5/8"inch

(1260 mm)

38 9/16"inch

(980 mm)

110 lbs.

(50 kg)

319.67 lbs

(145 kg)

363.76 lbs.

(165 kg)

37 1/64"inch

(940 mm)

49 5/8"inch

(1260 mm)

38 9/16"inch

(980 mm)

220 lbs.

(100 kg)

504.86 lbs

(229 kg)

538 lbs

(244 kg)

50"inch

(1270 mm)

52 3/8"inch

(1330 mm)

44 7/8"inch

(1140 mm)

220 lbs.

(100 kg)

504.86 lbs

(229 kg)

538 lbs

(244 kg)

50"inch

(1270 mm)

52 3/8"inch

(1330 mm)

44 7/8"inch

(1140 mm)

220 lbs.

(100 kg)

533.52 lbs.

(242 kg)

639.34 lbs.

(290 kg)

37 1/64"inch

( 94 0 mm)

79 1/2"inch

(2020 mm)

42 1/2"inch

(1080 mm)

220 lbs.

(100 kg)

533.52 lbs.

(242 kg)

639.34 lbs.

(290 kg)

37 1/64"inch

(94 0 mm)

79 1/2"inch

(2020 mm)

42 1/2"inch

(1080 mm)

440 lbs.

(200 kg)

551.16 lbs

(250 kg)

573 lbs

(260 kg)

47 5/8"inch

(1210 mm)

70 7/8"inch

(1800 mm)

41 3/4"inch

(1060 mm)

120V 1ph

60Hz

20amps

440 lbs.

(200 kg)

551.16 lbs

(250 kg)

573 lbs

(260 kg)

47 5/8"inch

(1210 mm)

70 7/8"inch

(1800 mm)

41 3/4"inch

(1060 mm)

ISO 7/1 ga s

connectionDiameter

Nominal hea t output

NATURAL

er unit nominal

hea t output

NATURAL

Convector unit nominal

heat output

NATURAL

Nominal hea t output

PROPANE

er unit nominal

hea t output

PROPANE

Convector unit nominal

heat output

PROPANE

Gas type

Construction type

Diagram of fume s

discharge system

NATURAL pre ssure

1/2 " M 1/2" M 1/2" M 1/2" M 1/2 " M 1/2" M 1" M 1" M 1" M 1" M

68303.6

btu/h

(20 kW)

40982.1

btu/h

(12 kW)

40982.1

btu/h

(12 kW)

61473.2

btu/h

(18 kW)

35859.4

btu/h

(10.5 kW)

35859.4

btu/h

(10.5 kW)

NA TURA L

PROPA NE

A3

B13

68303.6

btu/h

(20 kW)

40982.1

btu/h

(12 kW)

40982.1

btu/h

(12 kW)

61473.2

btu/h

(18 kW)

35859.4

btu/h

(10.5 kW)

35859.4

btu/h

(10.5 kW)

NATURAL

PROPANE

A3

B13

136607.2

btu/h

(40 kW)

78549.1

btu/h

(23 kW)

78549.1

btu/h

(23 kW)

126361.6

btu/h

(37 kW)

71718.8

btu/h

(21 kW)

71718.8

btu/h

(21 kW)

NATURAL

PROPANE

A3

B13

136607.2

btu/h

(40 kW)

78549.1

btu/h

(23 kW)

78549.1

btu/h

(23 kW)

126361.6

btu/h

(37 kW)

71718.8

btu/h

(21 kW)

71718.8

btu/h

(21 kW)

NATURAL

PROPANE

A3

B13

177589.3

btu/h

(52 kW)

102455.4

btu/h

(30 kW)

105870.5

btu/h

(31 kW)

160513.4

btu/h

(47 kW)

88794.7

btu/h

(26 kW)

95625.0

btu/h

(28 kW)

NATURAL

PROPANE

A3

B13

177589.3

btu/h

(52 kW)

102455.4

btu/h

(30 kW)

105870.5

btu/h

(31 kW)

160513.4

btu/h

(47 kW)

88794.7

btu/h

(26 kW)

95625.0

btu/h

(28 kW)

NATURAL

PROPANE

A3

B13

232232.2

btu/h

(68 kW)

102455.4

btu/h

(30 kW)

160513.4

btu/h

(47 kW)

208325.9

btu/h

(61 kW)

88794.7

btu/h

(26 kW)

143437.5

btu/h

(42 kW)

NATURAL

PROPANE

A3

B13

232232.2

btu/h

(68 kW)

102455.4

btu/h

(30 kW)

160513.4

btu/h

(47 kW)

208325.9

btu/h

(61 kW)

88794.7

btu/h

(26 kW)

143437.5

btu/h

(42 kW)

NATURAL

PROPANE

A3

B13

379084.9

btu/h

(111 kW)

218571.5

btu/h

(64 kW)

218571.5

btu/h

(64 kW)

334687.5

btu/h

(98 kW)

191250.0

btu/h

(56 kW)

191250.0

btu/h

(56 kW)

NATURAL

PROPANE

A3

B13

379084.9

btu/h

(111 kW)

218571.5

btu/h

(64 kW)

218571.5

btu/h

(64 kW)

334687.5

btu/h

(98 kW)

191250.0

btu/h

(56 kW)

191250.0

btu/h

(56 kW)

NATURAL

PROPANE

A3

B13

1a-1b-1c 1a-1b-1c 1a-1b-1c 1a-1b-1c1a-1b-1c

7"w c

(17,4mbar)

7"w c

(17,4mbar)

7"w c

(17,4mbar)

7"w c

(17,4mbar)

7"w c

(17,4mbar)

7"w c

(17,4mbar)

7"w c

(17,4mbar)

7"w c

(17,4mbar)

7"w c

(17,4mbar)

7"w c

(17,4mbar)

PROPANE pressure

11"w c

(27,4mbar)

11"w c

(27,4mbar)

11"w c

(27,4mbar)

Noise emission data: Noise emissions generated by the appliances described in this booklet do not exceed 70 dB (A).

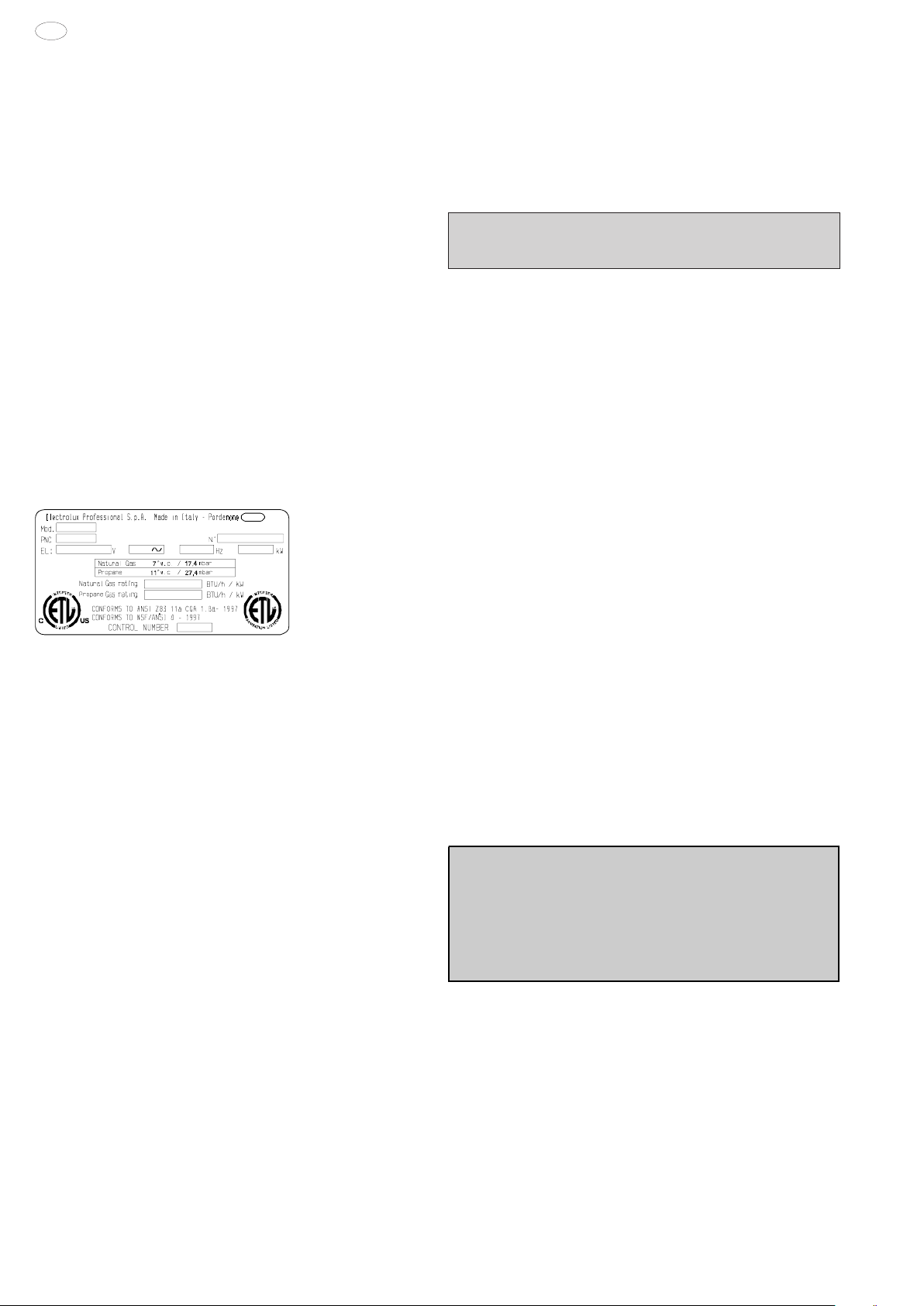

Your appliance model is indicated in the box marked PNC on

*

the Identification dataplate affixed to the bottom left hand side of

5938 026 00

the oven.

11"w c

(27,4mbar)

11

11"w c

(27,4mbar)

11"w c

(27,4mbar)

11"w c

(27,4mbar)

11"w c

(27,4mbar)

11"w c

(27,4mbar)

11"w c

(27,4mbar)

USA

3. PRECAUTIONS

• The following terms alert you to potentially dangerous conditions

to the operator, service personnel or to the equipment.

• Danger! This term warns of immediate hazards which will result in

severe injury or death.

• Warning! This term refers to a potential hazard or unsafe

practice which could result in injury or death.

• Notice. This term refers to information that needs special

attention or must be fully understood, even though not dangerous.

• Keep the appliance area free and clear from combustibles.

Warning

For your safety, do not store or use gasoline or other

flammable, vapors and liquids in the vicinity of this or any other

appliance.

Keep area around appliances free and clear of combustibles

Warning!

Failure to properly vent the oven can be hazardous to the

health of the operator; and will result in operational problems,

unsatisfactory baking, and possible damage to the equipment.

Damage sustained as a direct result of improper ventilation will

not be covered by the Manufacturer's warranty.

NOTICE: INTENDED FOR COMMERCIAL USE ONLY. NOT

FOR HOUSEHOLD USE.

Fire hazard.

CAUTION HOT SURFACES

CAUTION RISK ELECTRIC SHOCK

Important: The installation instructions contained herein

are for the use of qualified installation and service

personnel only. Installation or service by other than

qualified personnel may result in damage to the appliance

and/or injury to the operator. FAILURE TO COMPLY

WITH INSTALLATION INSTRUCTION OR IMPROPER

INSTALLATION WILL VOID WARRANTY AND

RESPONSIBLITIES OF THE MANUFACTURE.

• Our appliances have been studied and optimized to give the

highest performance. This appliance is intended for industrial use

only and is specifically designed to cook food. Any other use will be

considered “improper use” and will void the warranty and

manufacturer liability.

WARNING: ANY POTENTIAL USER OF THE EQUIPMENT

SHOULD BE TRAINED IN SAFE AND CORRECT OPERATIONG

PROCEDURES.

WARNING: BEFORE SERVICING, DISCONNET THE

ELECTRICAL SERVICE AND PLACE A RED TAG AT THE

DISCONNECT SWITCH TO INDICATED WORK IS BEING DONE

ON THAT CIRCUIT.

NOTICE: Using any parts other than OEM original spare parts

relieves the manufacturer of all warranty and liability.

NOTICE: Manufacturer reserves the right to change specifications

at any time without notice.

Failure to comply with the above requirement may jeopardise

the safety of the appliance and invalidate the guarantee.

WARNING: DO NOT SPRAY THE OUTSIDE OF THE

APPLIANCE WITH WATER OR CLEAN WITH A WATER JET.

CLEANING WITH A WATER JET CAN IMPREGNAT

CHLORIDES INTO THE STAINLESS STEEL, CAUSING THE

ONSET OF CORROSION.

CAUTION: Do not locate unit adjacent to any high heat or

grease producing piece of equipment, such as a range top,

griddle, fryer, etc., that could allow radiant heat to raise the

exterior temperature of the Air-O-Steam Oven.

• Carefully read this instruction booklet, as it contains important

advice for safe installation, operation and maintenance.

• Keep this instruction booklet in a safe place for future reference.

• The installation of this unit must conform to local codes or, in the

absence of local codes, to all National Codes governing plumbing,

sanitation, safety and good trade practices.

WARNING: The equipment warranty is not valid unless the

appliance is installed, started and demonstrated under the

supervision of a factory trained installer.

WARNING: The unit must be installed by Personnel who are

qualified to work with electricity and plumbing. Improper installation

can cause injury to personnel and/or damage to the equipment.

The unit must be installed in accordance with applicable codes.

WARNING: DO NOT USE PRODUCTS CONTAINING

CHLORINE (BLEACH, HYDROCHLORIC ACID ETC.) EVEN

DILUTED, TO CLEAN STEEL SURFACES.

WARNING: DO NOT USE CORROSIVE SUBSTANCES (E.G.

MURIATIC ACID) TO CLEAN THE FLOOR UNDER THE

APPLIANCE.

12

5938 026 00

4. SAFEGUARDING THE ENVIRONMENT

4.1 PACKAGING

• All the packaging materials used are environmentally safe and

friendly. They may be stored without fear or danger. They may be

recycled or burned in a special waste incineration plant. Recyclable

plastic components are marked as follows:

polyethylene : external wrapping film, instructions

PE booklet bag and gas injectors bag

polypropylene: top packaging panels and straps

pp

expanded polystyrene: protective surround elements

PS

4.2 USE

• The appliance has been designed and perfected under laboratory

testing conditions to offer exceptional levels of performance.

However, to minimise energy consumption (electricity, gas and

water), do not leave the appliance in operation for long periods

without food in the oven chamber and avoid conditions that

reduce efficiency (e.g. door open). We also recommend preheating

the appliance immediately prior to use.

USA

4.3 CLEANING

• To minimise the emission of pollutants into the environment,

clean the appliance (externally and, where necessary, internally)

with products that are at least 90% biodegradable.

4.4 DISPOSAL

• Appliances that have reached the end of their service life should

be suitably disposed of.

• The appliance is made from more than 90% recyclable materials

(stainless steel, iron, aluminium, galvanised sheet steel, etc.).

These materials may therefore be scrapped in accordance with

local waste disposal regulations at a conventional recycling plant.

• Make the appliance unusable by cutting off the power cord. Also

remove any compartment or interior closure device fitted on the

appliance to prevent persons from becoming trapped inside.

5938 026 00

13

USA

II. INSTRUCTIONS FOR INSTALLATION

Important

perform the operations described in this chapter. Since the

appliance must be switched on to make certain

adjustments, exercise the utmost care when working in the

vicinity of live electrical parts.

: The oven outer panels must be removed to

1. PLACE OF INSTALLATION

1.1 VENTILATION

The necessity for a properly designed and installed ventilation

system cannot be over emphasized. The ventilation system will

allow the unit to function properly while removing unwanted vapors

and products of combustion from the operating area.

The appliance must be vented with a properly designed mechanically

driven exhaust hood. The hood should be sized to completely

cover the equipment plus an overhang of a least 6"/15.3cm on all

sides not adjacent to a wall. The capacity of the should be sized

appropriately and provisions for adequate makeup air.

Refer to your local ventilation codes. In the absence of local codes,

refer to the National ventilation code titled, “Standard for the

Installation of Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equipment”, NFPA-96Latest Edition.

It is recommended that the ventilation system and duct work be

checked at prevailing intervals as specified by the hood manufactured

• The appliance must only be installed in adequately ventilated

premises.

NOTICE: Proper ventilation is the owner's is responsibility. Any

problem due to improper ventilation will not be covered by the

warranty.

1.2 REFERENCE STANDARDS

Note: The electric supply installation must satisfy the requirements

of the appropriate statutory authority, such as the National

Electrical Code (NEC) ANSI/NFPA70, (U.S.A..): the Canadian

Electrical Code, CSA C22.2; or other applicable regulations.

Note: The electric supply connection must meet all national and

local electrical code requirements.

Note: The installation of this unit must conform to local codes or,

in the absence of local codes, to all National Codes governing

plumbing, sanitation, safety and good trade practices, and to the

National Gas Code ANSI Z223.1.

• Local codes regarding installation vary greatle from one area to

another. This equipment is to be installed to comply with the

applicable federal, state or local codes.

The installation instructions contained herein are for the use of

qualified installation and service personnel only. Installation or

service by other than qualified personnel may result in damage to

the appliance and/or injury to the operator.

FAILURE TO COMPLY WITH INSTALLATION INSTRUCTION

OR IMPROPER INSTALLATION WILL VOID WARRANTY AND

RESPONSIBLITIES OF THE MANUFACTURE.

The National Fire Protection Association, Inc states in its NFPA

96 latest edition that local codes are the "authority having

jurisdiction" when it comes to installation requirements for

equipment. Therefore, installations should comply with all local

codes.

1.3 UNPACKAGING

• Remove the appliance from the packaging and take away the

protective film that covers the appliance's external panels carefully to avoid leaving any trace of glue. If necessary remove the

glue using an a non-corrosive solvent, rinsing it off and drying

carefully.

• Dispose of packaging material in compliance with the regulations

in force in the country where the product is to be used.

1.4 IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

The container should be examined for damage before and during

unloading. The freight carrier has assumed responsibility for its

safe transit and delivery. If damaged equipment is received,

either apparent or concealed, a claim must be made with the

delivering carrier. Apparent damage or loss must be noted on the

freight bill at the time of delivery. The freight bill must then be

signed by the carrier representative (Driver). If the bill is not

signed, the carrier may refuse the claim. The supply can supply

the necessary forms. A request for inspection must be made to

the carrier within 15 days if there is concealed damage or loss that

is not apparent until after the equipment is uncrated. The carrier

should arrange an inspection. Be certain to hold all contents plus

all packing material. Under no circumstances should a damaged

appliance be returned to the manufacturer without prior notice

and written authorization.

2. POSITIONING

• Refer to the installation diagrams at the beginning of this

booklet for the space requirements and connection dimensions of

the appliance.

• Clearance of approximately 23.62" (50cm) must be left between

the appliance’s left side panel and adjacent structures in order to

provide space for maintenance operations when needed; the

right side panel and the rear panel of the appliance must be at

least 1.97" (5cm) from adjacent structures.

• Place the appliance in the required position and level the oven

with a slight pitch toward the rear to help drain water from

chamber using the appropriate bullet feet.

• The appliance is not suitable for built-in installation.

Warning: The oven must be installed on an even (level) nonflammable flooring and any adjacent walls must be non-flammable.

Recommended minimum clearance are specified in this manaul.

Important

Make sure steam from the oven’s drain or adjacent

appliances does not enter the aeration vents under the

appliance, designed to cool internal components

located at the bottom of the appliance.

:

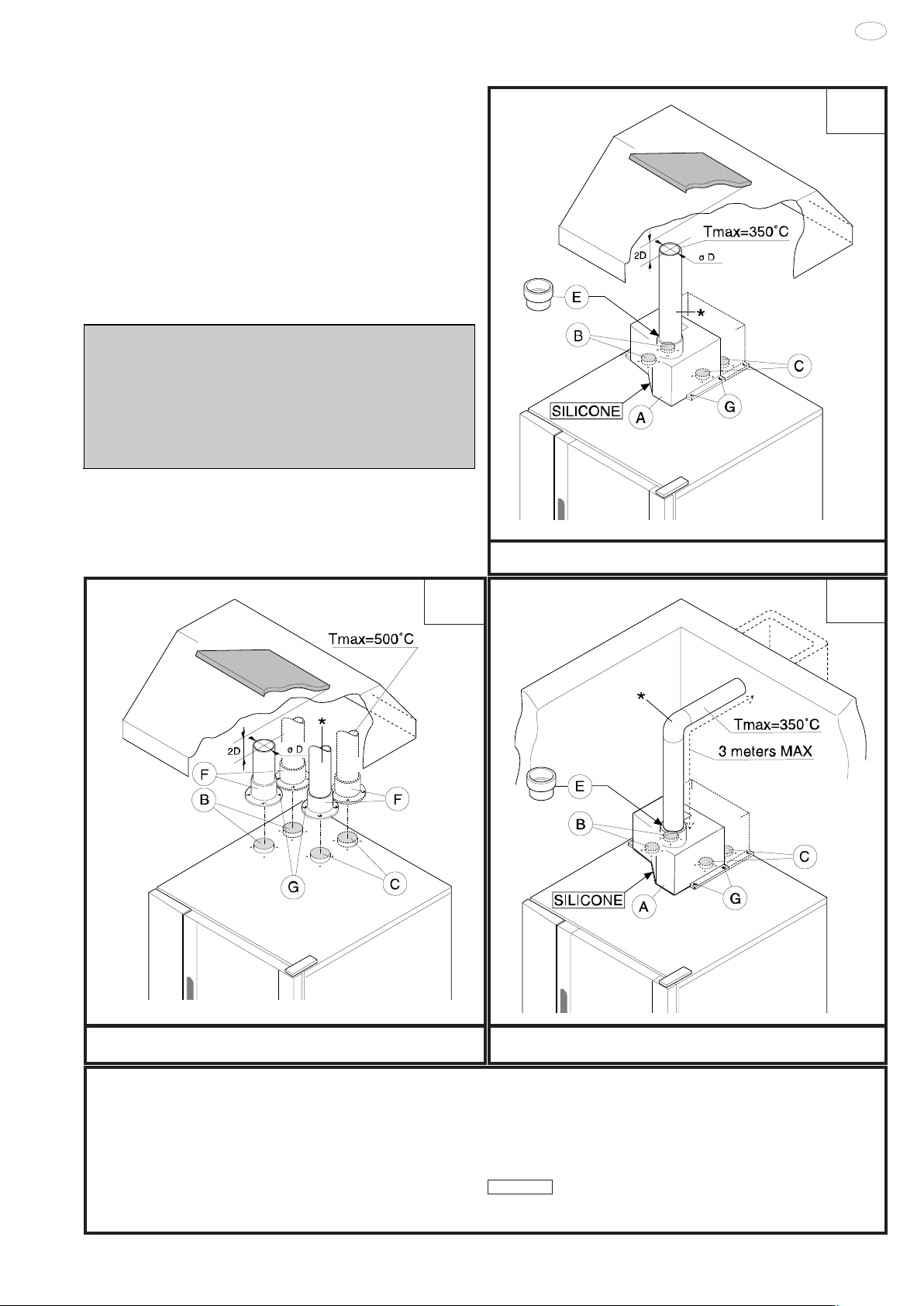

3. COMBUSTED GAS DISCHARGE

3.1 FOREWORD

In relation to the combustion technology utilised, gas fired steam/

convection ovens are classified in accordance with their

"Construction Type". For each of these types of appliances

applicable regulations stipulate a specific type of combusted gas

discharge system.

Consequently, before installing the discharge system:

a) identify the "Construction type" of your model in Table 1

(technical data) or by checking the appliance identification

dataplate;

b) choose the diagram with the type of construction among

those shown as follows (fig. 1a-1b-1c), depending on how you

intend to exhaust the appliance fumes from the place of installation

(e.g. discharge under extraction hood, direct to the outside, or in

a central flue).

5938 026 00

14

USA

3.2 WARNINGS REGARDING THE FLUING SYSTEM

Before installation check, on the basis of the contents of the

reference standard, to ensure that the volume aspirated by the

fumes exhausting system is greater than the volume of combusted

gas produced by the appliance (see point 1.1).

If the solution of combusted gas discharge under an extractor

hood is chosen, observe the distance (shown in the figure)

between the top of the discharge pipe and the lowest point of the

hood filters. This distance is defined on the basis of discharge

pipe diameter "D".

In the case of discharge direction to the outside or into a central

flue (Fig. "1c"), the discharge ducts must NOT present an overall

length in excess of 762"(3 metres), must NOT have any reductions

in diameter, and must be subjected to periodic inspection and,

when necessary, cleaning.

Warning:

high temperatures, check the heat resistant properties of

extension ducts if fitted and the filters in the extractor hood

to ensure the materials are compatible with the temperature

conditions. In addition, periodically check the condition of

the filters which, if excessively fouled with fat and dirt, will

reduce the efficiency of the suction system and may catch

fire.

Since combusted gas (see figure) can reach very

3.3 INSTALLATION OF ACCESSORIES

Accessories can be easily installed by following the figures below

together with the relative key.

The screw holes for fixing accessories "A" and "F" are 0.14"(3.5

mm) in diameter and they must be drilled in-situ on the oven cover

in correspondence with the punch marks.

CONSTRUCTION TYPE

B13

DISCHARGE WITH SHROUD UNDER EXTRACTOR HOOD

1b

CONSTRUCTION TYPE

A3

1a

CONSTRUCTION TYPE

B13

1c

DIRECT UNDUCTED DISCHARGE UNDER EXTRACTOR HOOD

LEGENDA:

A: Cam / draught damper accessory

(to be ordered from manufacturer)

B: Boiler combusted gas discharge

C: Oven chamber convector combusted gas discharge

E: Adapter ring for commercial ducts

(to be ordered from manufacturer)

5938 026 00

DISCHARGE TO THE OUTSIDE OR CENTRAL FLUE WITH SHROUD

F: Conical connections for single outlet (supplied)

(always install)

G: Fixing screws (supplied);

*: Commercial extension pipes (not supplied)

SILICONE :

Apply silicone sealant between contact surfaces

15

USA

4. ELECTRICAL CONNECTION

• A fused disconnect switch or main circuit breaker (customer

furnished) MUST be installed in the electric supply line for the

appliance. It is recommended that this switch/circuit breaker

have lockout/tagout capability. Before making any electrical

connections to this appliance, check that the power supply is

adequate for the voltage, amperage, and phase requirements

on the rating plate.

• A safety cutout switch of suitable capacity with a contact

breaking distance of at least 3 mm must be fitted upstream of

the appliance.

The cutout switch must be installed near the appliance in the

permanent electrical system of the premises.

• The appliance must be electrically grounded in accordance

with local codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.2, as applicable.

The grounding conductor must therefore be connected to the

terminal marked Gon the connection terminal board. The

appliance must also be connected to an earth grounding

system.

This connection is made using the stop screw marked E

located on the outside of the appliance near the power cable

inlet.

The grounding wire must have a minimum cross-section of

8 AWG (10 mm

4.1 INSTALLING THE POWER SUPPLY CABLE

To access the power supply cable connection terminal board,

proceed as follows:

Model 6 - 10 - 20 GN

• Remove the left side panel.

• Connect the power supply cable to the terminal board accord-

ing to the instructions given in the wiring diagram and fasten the

power supply cable by means of strain-relief fitting (not furnished

with the oven).

Failure to comply with safety rules and regulations relieves

the manufacturer of all liability.

The manufacturer requires when stacking units each appliance

have its own branch circuit protection. An air-o-steam® unit

stacked with an air-o-chill® unit should have a separate protection

for the upper and lower units.

2

).

RATING PLATE

Before fitting the filters allow the water to flow out for sufficient

time to flush any solid particles from the piping.

5.1 WATER SUPPLY CONNECTIONS

5.1.1 WATER INLET "N".

Attention

The water supply pipe (not supplied) must have a 3/4" dia (20

mm) pipe and must be without elbow fittings.

The steam condensation system must be connected to a cold

quality water supply in keeping with local plumbing codes, with

the following characteristics:

- total hardness: up to 400ppm (40°fH) .

- pressure: 22 to 36 psi (150-250 kPa); higher pressure

values result in increased water consumption.

Note:

To check correct water installation, make sure the rotating wash

arm (CLEANING SYSTEM) does not turn below 100 rpm (120

max).

5.1.2 WATER INLET "B".

(water pipe supplied)

The steam production system must be connected to a quality

water supply in keeping with local plumbing codes, with the

following characteristics:

- total hardness:

build-up of lime-scale inside the boiler.

On request the oven is supplied with an optional water softener

with automatic regeneration which must be installed on inlet line

"B". This device can also be fitted with an optional resin sanitizer

kit.

- pressure: 22 to 36 psi (150-250 kPa); higher pressure

values result in increased water consumption.

- chlorine ion concentration (Cl -): not more than ~10 ppm

(acceptable value) to avoid damaging the oven's internal steel

parts.

- pH: over 7.

The oven can be equipped with an optional special filtration unit

which is installed on inlet line "B". This unit also acts as a water

softener, reducing water hardness to less than

(optimum value).

- electrical conductivity: 50 to 2000 µS/cm (68°F)(20°C).

Important: The use of water treatment systems featuring

technology that differs from that of the systems supplied by the

manufacturer is prohibited and will automatically invalidate the

warranty.

The use of dosing systems designed to prevent the buildup of lime-scale in pipes (i.e. polyphosphate dosing

systems) is also prohibited since such systems may impair

the performance of the appliance.

5 - 50ppm (0.5 - 5 °fH) to reduce the

50ppm (5 °fH)

5. WATER MAINS CONNECTION

(Refer to the installation diagrams at the beginning of this booklet).

This equipment is to be installed to comply with the applicable

Federal, State, Local plumbing codes, or the Basic Plumbing

Code of the Building Officials and Code Administrators

International Inc. (BOCA) and Food Service Sanitation Manual

of the Food and Drug Administration (FDA).

The appliance is fitted with two separate water inlets ("B" and "N").

The water lines supplying both inlets must be fitted with a

mechanical filter and shut-off valve (keeping with local plumbing

codes).

5.2 WATER DRAIN SYSTEM

The oven is supplied with an air-break system to prevent any

backflow from the drainage system from reaching the oven’s internal circuits and the cooking chamber. The presence of this

system means that the drain pipe can be connected directly to

the mains drainage system or routed to a floor gulley with grating.

The flexible drainage hose or rigid pipe can be directed to the

side or rear of the appliance if the oven is not positioned against

a wall; this line must not be directed towards the front of the

appliance to prevent interference with roll-in grid racks. The drainage pipe internal diameter must be no smaller than the oven

16

5938 026 00

Loading...

Loading...