Electrolux AOS061ECR2 Instructions For Installation And Use Manual

27

GB

5938 033 01

INSTRUCTIONS FOR INSTALLATION AND USE (for the United Kingdom)

Contents Page

- APPLIANCE IDENTIFICATION

ELECTRIC STEAM/CONVECTION AND CONVECTION OVENS

- CONTROL PANEL FIGURES .......................................... 247

260450-260510 260462 260456

26045

260451-260511 260463 260457

2604

°

**

°

**

°

**

400

230

200

6GN1/1

(AOS061E)

Made in E E C.

IP25

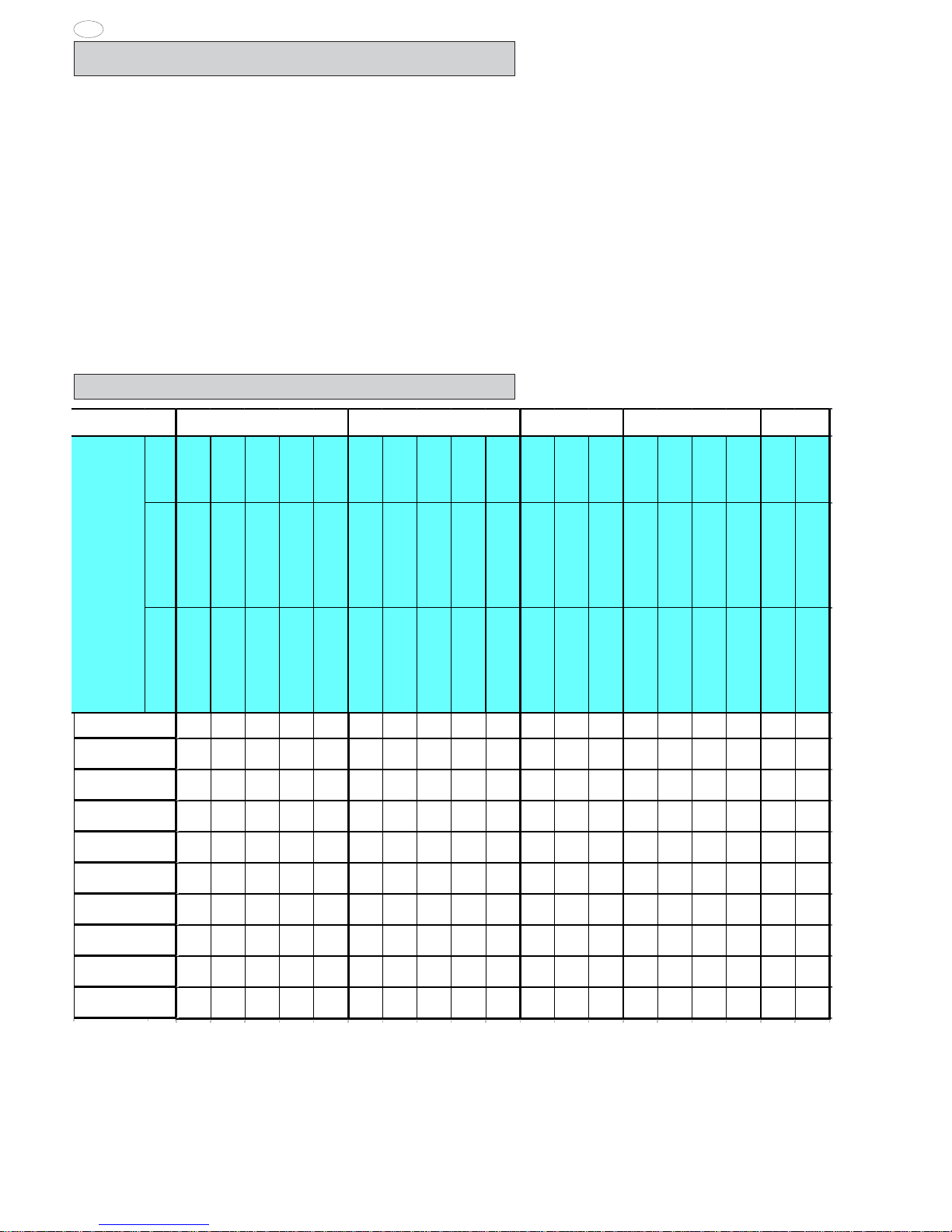

2. TABLE 1: TECHNICAL DATA

PNC 9PDX 260462 05

260462

Identification dataplate

- Installation diagrams ........................................................ 4

- Appliance identification .................................................. 27

I. MAIN FEATURES ............................................................. 28

1. Description of appliance ............................................. 28

2. Table 1: Technical data ................................................. 28

3. Precautions .................................................................. 29

4. Safeguarding the environment ................................... 29

4.1 Packaging ..............................................................29

4.2 Use ......................................................................... 29

4.3 Cleaning ................................................................ 2 9

4.4 Disposal ................................................................. 29

II. INSTRUCTIONS FOR INSTALLATION ............................ 30

1. Place of installation ..................................................... 30

1.1 Reference standards ............................................... 30

2. Positioning ..................................................................... 30

3. Electrical connection ................................................... 30

3.1 Installing the power supply cable .......................... 30

4. Water mains connection ............................................. 30

4.1 Water supply characteristics .................................. 30

4.2 Water drain system ................................................ 31

5. Safety devices ............................................................. 31

6. Operation check .......................................................... 31

7. Servicing ....................................................................... 32

8. Troubleshooting ............................................................ 32

9. Layout of main components ........................................ 32

III. INSTRUCTIONS FOR USE ............................................. 33

1. Opening the oven door ................................................ 33

1.1 6- and 10-grid models ........................................... 33

1.2 20-grid models ....................................................... 33

2. Closing the oven door ................................................. 33

2.1 6- and 10-grid models ........................................... 33

2.2 20-grid models ....................................................... 33

3. Description of the control panel ................................. 34

3.1 Introduction ............................................................ 3 4

3.2 Main controls ......................................................... 34

3.3 Main cooking modes ............................................. 34

3.4 Special cooking modes ......................................... 34

3.5 Additional functions ............................................... 35

USING THE OVEN ................................................................. 36

4. Operating level A, B and C ...................................... 36

4.1 Switching the oven on ........................................... 36

4.2 Selecting the controls ............................................ 3 6

4.3 Manual controls ..................................................... 36

4.4 Automatic controls ................................................. 40

5. Information and error codes ....................................... 43

6. Switching off in the event of a fault ............................ 44

7. Care and maintenance ................................................ 44

7.1 Periodic maintenance of the boiler ........................ 45

7.2 Replacing consumable components ..................... 4 6

7.3 Special cleaning instructions ................................. 4 6

28

GB

5938 033 01

Noise emission data: Noise emissions generated by the appliances described in this booklet do not exceed 70 dB (A).

*

Your appliance model is indicated in the box marked PNC on

the Identification dataplate affixed to the bottom left hand side of

the oven.

^ FUNCTIONAL LEVEL (C = Convect, Convection).

I. MAIN FEATURES

2. TABLE 1: TECHNICAL DATA

1. DESCRIPTION OF APPLIANCE

This booklet describes a number of appliance models.

For more detailed information about the model in your possession,

refer to "Technical Data" table 1.

The appliance has the following features:

• Digital temperature indicator.

• Thermostatic probe for measuring the core temperature of products (core temperature probe).

• Continuous monitoring of cooking parameters throughout the

entire cooking cycle.

• Periodic draining and automatic washing of the boiler to prevent

the build-up of lime-scale (only available on certain models).

• Boiler lime-scale level indicator (see corresponding

paragraph)(only available on certain models).

• Oven chamber automatic fast steam drain device for gratins.

• Air-break anti-backup drain device to prevent backflows from the

drainage system from entering the oven (only available on certain

models).

• Oven chamber lighting.

• Double-action door opening safety mechanism designed to

protect the user from scalding steam (only available on certain

models).

• Double-glazed oven door for reduced heat dispersion into the

kitchen and low temperatures on the exterior of the oven.

• Daily oven chamber cleaning cycle (CLEANING SYSTEM)(only

available on certain models).

• Self-diagnostics system indicating oven faults using error codes

(see "Information and error codes ").

267000

267010

237000

237010

647000

647070

267020

237020

267030

267002

267012

237002

237012

647002

647072

267022

237022

267032

267003

237003

647003

267063

267033

237033

267004

267014

237004

237014

647004

647074

267024

237024

267005

237005

647005

268000

268010

238000

238010

648000

648070

268020

238020

268030

268002

268012

238002

238012

648002

648072

268022

238022

268032

268003

238003

648003

268033

238003

268004

268014

238004

238014

648004

648074

268024

238024

268005

238005

648005

269000

269010

239000

239010

649000

649070

269020

239020

269002

269012

239002

239012

649002

649072

269022

239022

269003

239003

649003

269004

269014

239004

239014

649004

649074

269024

239024

269005

239005

649005

°

**

°

°

**

°

° **°

**

°

°

**

°

° **°

**

°

° **°

**

°

°

**

°

°

**

°

400

3 N~

400

3 N~

230

3 ~

230

3 ~

200

3 ~

400

3 N~

400

3 N~

230

3 ~

230

3 ~

200

3 ~

400

3 N~

400

3 N~

200

3 ~

400

3 N~

400

3 N~

230

3 ~

230

3 ~

400

3 N~

400

3 N~

50/60 50/60 50 /60 50/61 50/60 50/60 50/60 50/60 50/60 50/60 50/60 50/60 50/60 50/6050/60 50/60 50/60 50/60 50/60

10,1 10,1 10,1 10,1 10,1 17,5 17,5 17,5 17,5 17,5 25 25 25 34,5 34,5 34,5 34,5 50 50

25 25 32 32 40 32 32 50 50 63 63 63 100 63 63 125 125 100 100

5x2,5 5x2,5 4x4 4x4 4x4 5x4 5x4 4x10 4x10 4x10 5x10 5x10 5x16 5x10 5x10 4x25 4x25 5x16 5x16

0,19 0,19 0,19 0,19 0,19 0,19 0,19 0,19 0,19 0,19 0,75 0,75 0,75 0,38 0,38 0,38 0 ,38 1,5 1,5

9 9 9 17 17 17 24 24 24 20 48

9,69,69,69,69,61717171717242424343434344848

30 30 30 30 30 50 50 50 50 50 100 100 100 100 100 10 0 100 200 200

20 GN 2/1 6G N 1/1 10GN1/1 20 GN1/110 GN 2/1

A ^

B ^

C ^

PNC *

G RID S

CONVECTOR °

BOILE R **

POWER SUPPLY

VOLTAGE (VOLT)

FREQUENCY (Hz)

Max. elect ri cal p ower

input (Kw)

Main s fuses

(3 x 500V)

Power supply cable

cross-section (mm

2

)

Fan motor power rating

(Kw)

Steam unit power rating

(Kw)

Convection unit power

rating (Kw)

Max. food load (kg)

A ^

267000

267010

237000

237010

647000

647070

267020

237020

267030

267072

237002

237012

647002

647072

267022

237022

267032

267003

237003

647003

267063

267033

237033

267004

267014

237004

237014

647004

647074

267024

237024

267005

237005

647005

B ^

238000

238010

268200

268210

268300

238200

238210

648000

648070

268020

238020

268220

238220

268030

268230

238002

238012

268202

268212

268302

238202

238212

648002

648072

268022

238022

268222

238222

268032

268232

268003

238003

268203

238203

268303

648003

268033

268233

238003

238004

238014

268204

268214

268304

238204

238214

648004

648074

268024

238024

268224

238224

268005

238005

268205

268305

238205

648005

C ^

239000

239010

269200

269210

269300

269330

239200

239210

649000

649070

269020

239020

269220

239220

239002

239012

269202

269212

269302

269332

239202

239212

649002

649072

269022

239022

269222

239222

269003

239003

269203

269303

239203

649003

269204

269214

269304

239204

239214

649004

649074

269024

239024

269224

239224

269005

239005

269205

269305

239205

649005

20 GN 2/1 n° GRIGLIE 6GN 1/1 10 GN1/1 20GN1/110 GN 2/1

PNC *

29

GB

5938 033 01

3. PRECAUTIONS

• Before installing or using the appliance read this instruction

booklet carefully because it contains important information

concerning safety, operation and maintenance.

• Keep this instruction booklet in a safe place for future

consultation by other users or purchasers in the event that the

appliance is resold.

Important: Installation and maintenance of the appliance

and its conversion to a different gas supply must only be

performed by a qualified installer authorised by the

manufacturer.

• This appliance is intended for collective use and is expressly

designed for cooking food. Any other use is deemed improper.

The appliance must only be used by trained staff.

• This appliance is not intended for use by people (including

children) with limited physical, sensory or mental abilities or

without experience and knowledge of it, unless they are

supervised or instructed in its use by a person responsible for

their safety.

• Switch off the appliance if it breaks down or malfunctions.

• Only contact the technical service centre authorised by the

manufacturer for repairs and only use original spare parts.

Failure to comply with the above requirement may jeopardise

the safety of the appliance and invalidate the guarantee.

• Do not wash the appliance with water jets.

• Do not use products containing chlorine (bleach, hydrochloric

acid etc.) even diluted, to clean steel surfaces.

• Do not use corrosive substances (e.g. muriatic acid) to clean the

floor under the appliance.

• For more information, refer to the section on "Care and

maintenance".

4. SAFEGUARDING THE ENVIRONMENT

4.1 PACKAGING

• All the packaging materials used are environmentally friendly.

They may be stored at no risk or burnt at an authorised incineration

plant. Plastic materials suitable for recycling are marked with the

following symbols:

polyethylene : external wrapping film, instructions

PE booklet bag and gas injectors bag

polypropylene: top packaging panels and straps

pp

expanded polystyrene: protective surround elements

PS

4.2 USE

• The appliance has been designed and perfected under laboratory

testing conditions to offer exceptional levels of performance.

However, to minimise energy consumption (electricity, gas and

water), do not leave the appliance in operation for long periods

without food in the oven chamber and avoid conditions that

reduce efficiency (e.g. door open). We also recommend

preheating the appliance immediately prior to use.

4.3 CLEANING

• To minimise the emission of pollutants into the environment,

clean the appliance (externally and, where necessary, internally)

with products that are at least 90% biodegradable.

4.4 DISPOSAL

• The appliance must be disposed of properly at the end of its

service life.

• The appliance is made from more than 90% recyclable materials

(stainless steel, iron, aluminium, galvanised sheet steel, etc.).

These materials may therefore be scrapped in accordance with

local waste disposal regulations at a conventional recycling

plant.

• Make the appliance unusable by cutting off the power cord. Also

remove any compartment or interior closure device fitted on the

appliance to prevent persons from becoming trapped inside.

The symbol L on the product indicates that this product

should not be treated as domestic waste, but must be correctly

disposed of in order to prevent possible negative consequences

for the environment and the human health.

Regarding the recycling of this product, please contact the sales

agent or dealer of your product, your after-sales service or the

appropriate waste disposal service.

30

GB

5938 033 01

3.1 INSTALLING THE POWER SUPPLY CABLE

To access the power supply cable connection terminal board,

proceed as follows:

Model 6 - 10 - 20 GN

• Remove the left side panel.

• Connect the power supply cable to the terminal board according to the instructions given in the wiring diagram and fasten the

power supply cable by means of the cable clamp.

The manufacturer declines all responsibility if the applicable

safety regulations are disregarded.

4. WATER MAINS CONNECTION

(Refer to the installation diagrams at the beginning of this booklet).

When connecting the appliance to the water system with

flexible tubes they must be new and not used.

The appliance is fitted with two separate water inlets ("B" and "N").

The water lines supplying both inlets must be fitted with a

mechanical filter and shut-off cock.

Before fitting the filters allow the water to flow out for sufficient time

to flush any solid particles from the piping.

Pressure between 150 and 450 kPa (1.5-4.5 bar).

WATER INLET “N”

Attention (water inlet N)

If the supply pipes provided with the appliance are not long

enough for installation, use longer ones with int. diameter at

least ø 20 mm and free of elbow unions.

Note:

To check correct water installation, make sure the rotating wash

arm (CLEANING SYSTEM) does not turn below 100 rpm (120

max).

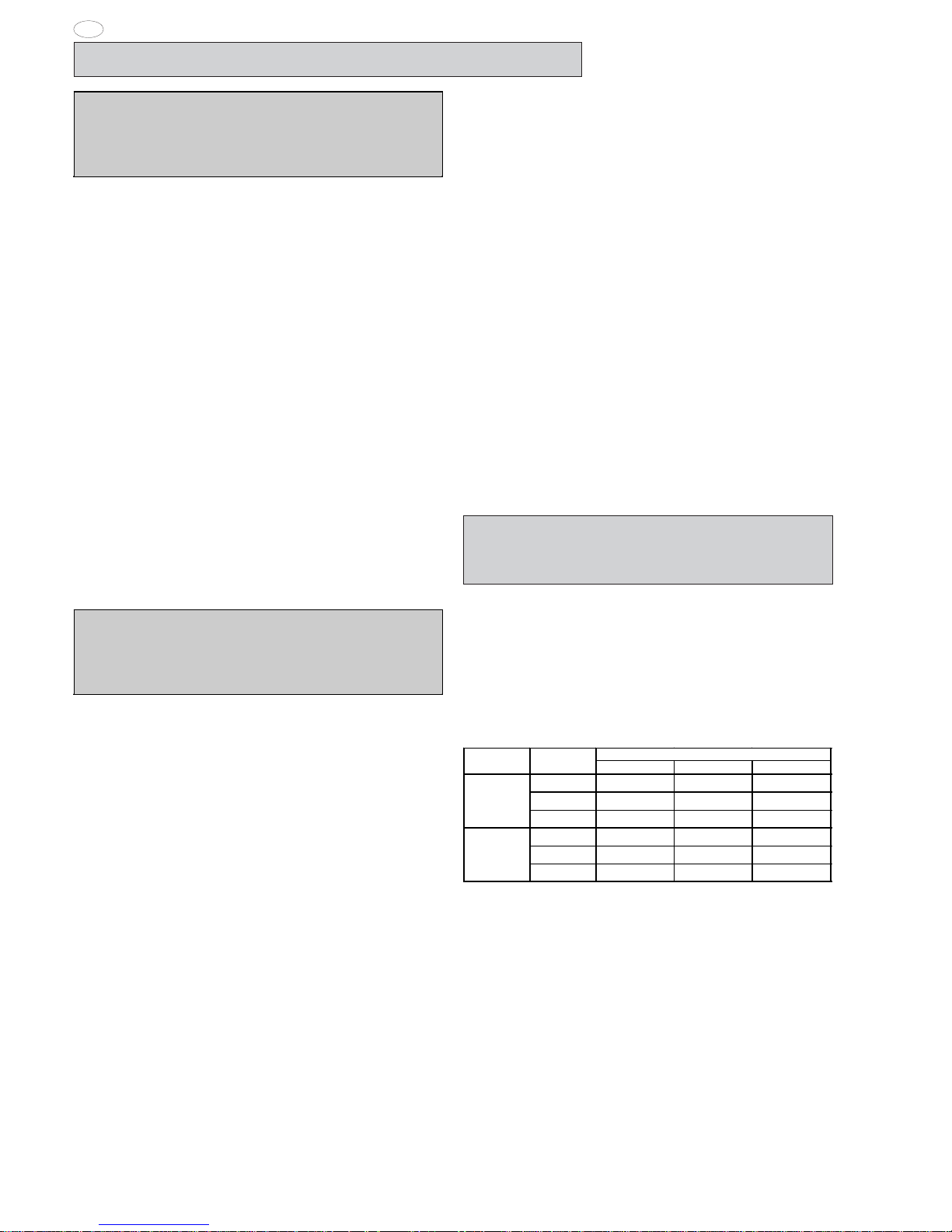

4.1 WATER SUPPLY CHARACTERISTICS

The appliance must be supplied with drinking water having

specific characteristics given in this section.

HARDNESS FILTER

°f pp m °dH

Water

in le t

Appl. Hardness

A ^ 0,5 - 5 5 - 50 0,28 - 2,8

B ^ 0,5 - 5 5 - 50 0,28 - 2,8

C ^ m ax 5 m ax 50 m ax 2,8

A ^ m ax 5 m ax 50 m ax 2,8

B ^ m ax 40 m ax 400 m ax 22

C ^ m ax 5 m ax 50 m ax 2,8

N

B

^ OPERATING LEVEL (C = Convect, Convection).

The hardness values given in the table are for reducing scaling

inside the steam generator and possible cooking compartment

washing system.

If the available water does not have these hardness characteristics

a water softener must be installed.

Therefore the Automatic Water Softener with automatic

regeneration for installing on the inlet line, can be requested as

an accessory; it has a Resin Sterilizer kit (also by request).

HARDNESS AND CHLORIDE FILTERS

The chloride concentration (Cl-) (ppm - mg/l) values with pH

(>7) and Conductivity (µS/cm) (measured at 20°C) must be

such as to not damage the steel structures inside the oven (only

water inlet B).

Therefore the characteristics of the available water must be

identified in the graph given at the end of this handbook (page

251), if necessary installing at the inlet the type of filter indicated

in the relevant area of the values.

II. INSTRUCTIONS FOR INSTALLATION

Important: The oven outer panels must be removed to

perform the operations described in this chapter. Since the

appliance must be switched on to make certain

adjustments, exercise the utmost care when working in the

vicinity of live electrical parts.

1. PLACE OF INSTALLATION

• The appliance must only be installed in adequately ventilated

premises.

1.1 REFERENCE STANDARDS

• Install the appliance according to the prescriptions of current

safety standards.

2. POSITIONING

• Unpack the appliance and carefully remove the protective film

from the outer panels to avoid leaving any trace of adhesive. Use

a suitable solvent to remove any adhesive residues.

• Dispose of the packaging as instructed in the chapter on

"Safeguarding the environment"

• Refer to the installation diagrams at the beginning of this

booklet for the space requirements and connection dimensions

of the appliance.

• Clearance of approximately 50 cm must be left between the

appliance’s left side panel and adjacent structures in order to

provide space for maintenance operations when needed; the

right side panel and the rear panel of the appliance must be at

least 10 cm from adjacent structures.

• Place the appliance in the required position and adjust the

height of the work surface using the adjustable feet.

• The appliance is not suitable for built-in installation.

Important:

Make sure steam from the oven’s drain or adjacent

appliances does not enter the aeration vents under the

appliance, designed to cool internal components

located at the bottom of the appliance.

3. ELECTRICAL CONNECTION

The appliance must be connected to the mains power supply

in compliance with current regulations.

• Before connecting the appliance to the mains supply, make

sure that the voltage and frequency shown on the appliance

identification dataplate correspond with those of the power

supply.

• The appliance must be permanently connected to the mains

power supply with an H05 RN-F type cable. The power supply

cable must be protected by a metal or rigid plastic conduit. If the

appliance is connected by way of an existing lead, do not insert

the cable conduit into the appliance and make particularly sure

that the conduit has no sharp edges.

• A safety cutout switch of suitable capacity with a contact

breaking distance of at least 3 mm must be fitted upstream of

the appliance.

The cutout switch must be installed near the appliance in the

permanent electrical system of the premises.

• Appliance maximum leakage current is 1 mA/kW

• The appliance must be suitably earthed. The earthing conductor

must therefore be connected to the terminal marked Gon the

connection terminal board. The appliance must also be

connected to an earth bonding system.

This connection is made using the stop screw marked E

located on the outside of the appliance near the power cable

inlet.

The bonding wire must have a minimum cross-section of

10 mm

2

.

31

GB

5938 033 01

The filters indicated are:

- No filter for chloride (Cl-) in the conforming area (Normal)

- Nanofilter

as an accessory on request, called Water Filter.

- Osmotizer.

Make sure the water coming out the filter is inside the optimum

area (Normal).

These filters also have the function of reducing the water

hardness to optimum values (below 5°f), and therefore also act

as a water softener.

ATTENTION: Periodical checking according to the filter

manufacturer’s instructions is important to maintain its efficiency

and avoid the risk of corrosion in the appliance.

Level C ovens are convection ovens. If water having

characteristics outside those specified is used to create humidity

inside the oven, there will be the risk corrosion of the compartment

and that present inside it.

Carry out regular maintenance of the water softeners and filters

to ensure their optimum efficiency.

To avoid damage to the appliance, after every periodical

regeneration do a filter cleaning cycle without introducing water

in the oven.

The manufacturer declines any liability in case of incorrect

maintenance.

Important:

The use of dosing systems designed to prevent the buildup of lime-scale in pipes (i.e. polyphosphate dosing

systems) is prohibited since such systems may impair the

performance of the appliance.

For UK and COMMONWEALTH only:

In accordance with "the water supply (Water Fittings)

Regulations 1999", it is mandatory that this appliance when

installed to the mains water supply has fitted an approved

"double check valve" connected upstream of the appliance.

Failure to comply with these regulations may lead to the

appliance being disconnected.

4.2 WATER DRAIN SYSTEM

- OVEN level A -

The oven is supplied with an air-break system to prevent any

backflow from the drainage system from reaching the oven’s

internal circuits and the cooking chamber. The presence of this

system means that the drain pipe can be connected directly to

the mains drainage system or routed to a floor gulley with grating.

The flexible drainage hose or rigid pipe can be directed to the

side or rear of the appliance if the oven is not positioned against

a wall; this line must not be directed towards the front of the

appliance to prevent interference with roll-in grid racks. The drainage pipe internal diameter must be no smaller than the oven

drain outlet (1” 1/4), no longer than 1 metre and must resist

temperatures of up to at least 100°C. Avoid restrictions in the

case of flexible hose pipes, do not fit elbows on metal pipes

anywhere along the drainage line. Also avoid horizontal sections in which water might collect (minimum gradient 5%).

C - Oven drain

C1 - Safety outlet

Important:

- Do not obstruct the safety outlet C1.

- Do not connect the safety outlet C1 to the drainage system.

Note:

If water comes out of the AIR-BREAK (safety outlet C1) this means

the drain C is blocked. Any elimination of the obstruction must

be carried out by specialised technical personnel.

- OVEN level B and C -

Connect drain fitting “C” to a drain pipe of the same diameter

which is between 0.5 and 3 metres in length and is resistant to

temperatures of at least 100°C. The drain pipe must be siphoned

(height 80 mm) to an open drain “O” (“Air-Break”) or floor grating

(see Fig. 12b) in order to prevent any back-flow from the sewage

system from reaching the piping inside the oven or oven chamber.

Check the hoses and elbows on metal pipes for kinks or pinching

along the entire drain line and make sure the drain line has a

minimum gradient of 5° to prevent water from collecting inside

the

system.

Important: The drain system must be installed so that any

vapours from the open drain do not enter the aeration vents

under the appliance.

OK

min 5°

C

AIR-BREAK

T max = 100°C

max 3m

0,08 m

min 0,5m

O

C

AIR-BREAK

O

KO

5. SAFETY DEVICES

The appliance is fitted with the following safety devices:

- Fuses (see electrical circuit diagram) located behind the control

panel.

To change a fuse unscrew and remove the retainer cap and

replace the blown fuse with an identically rated component; the

fuse rating value is specified on the relative dataplate.

min 0,04m

32

GB

5938 033 01

- Oven chamber safety thermostat with manual reset, located

behind the control panel; when this device trips, convection

heating power is disconnected.

The thermostat must be reset exclusively by specialised technical personnel after the cause of the trip has been eliminated.

- Automatic reset thermal protection inside the fan unit: this

device trips in the event of overheating of the fan motor; this cutout protects the appliance by disconnecting the power supply.

6. OPERATION CHECK

- Switch on the appliance in accordance with the following

section "Instructions for use".

- With the aid of the Instruction Booklet, explain operation,

routine maintenance, and cleaning to the user.

Important:

- Exercise due care since certain areas of the oven exterior

become hot during use.

- Do not cover the exhaust outlets on top of the appliance.

- With oven hot, check the correct working of the door closing

mechanism. If necessary, adjust closing by adjusting the position

of the catch.

7. SERVICING

All components requiring routine maintenance may be easily

reached by opening the control panel, removing the left side

panel, or removing the rear panel.

8. TROUBLESHOOTING

Faults may occur even during normal use of the appliance.

Oven chamber heating not started or inefficient. Possible

causes:

- Oven chamber temperature limit switch tripped

- Damaged heating elements

- Damaged heating element contactor coil

- Damaged thermostat probe showing error “EPt1”.

- Damaged controller

- Fuse “F2” blown, see circuit diagram.

Steam production not started or inefficient.

Possible causes:

- Damaged heating elements

- Damaged heating element contactor coil

- Damaged controller

- Fuse “F2” blown

- No mains water supply

- Faulty boiler drainage outlet closing device

- Damaged water inlet solenoid valves (do not open)

Oven chamber temperature reading incorrect

Possible causes:

- Damaged electronic controller

- Thermostat probe damaged, dirty or interrupted, see error

“EPt1”.

Oven switches off

Possible cause:

- Fuse “F2” has blown due to damage of control circuit

components.

Oven chamber lamp fault

WARNING: Switch off the appliance before changing oven

chamber lamps.

9. LAYOUT OF MAIN COMPONENTS

(All work inside the appliance must be carried out exclusively

by a trained installer authorised by the manufacturer)

Removing the control panel provides access to the following

components:

- Electronic circuit boards

- Oven chamber temperature limit thermostat

- Fuses

- Door microswitch

- Oven chamber lamp transformer

- Geared motor for the oven chamber pressure relief butterfly

valve.

To gain access to all other components remove the appliance’s

left and rear side panels.

Loading...

Loading...