Electro Freeze GEN-5099 User Manual

MODEL GEN-5099

This pressurized, 2-avor twist soft serve machine

produces the highest quality, most consistent

and protable product you can serve. Ideal for

operators that want to serve a high-quality product

but don’t require huge volume. This machine is

perfect for co-branding concepts as well as college

cafeterias, buffets and adding additional avors to

any shops.

The Electro Freeze Advantage

• Virtual Quality Management System™

monitors Temperature and Consistency to

provide superior taste and quality.

• Patented Mix Transfer System* simplest and

most reliable pressurized system available.

• Flexible Mix Holding System Pumps directly

from bags or from mix containers

• Innovative Solutions providing the Best

product quality in the industry.

• Meets ADA Specications for self service

applications

• Multi-function LED display with manager

smart tools.

• The Finest Frozen Product, consistently the

best frozen product available. Smooth, creamy

and protable.

• Self Closing Spigots prevents the mess and

eliminates waste

• Exclusive Auger Design Superior low

temperature refrigeration system provides the

best in class production and product quality.

• Energy Conservation Mode reduces energy

cost and holds product safely during nonbusiness hours

• Superior Low Temperature Refrigeration

System provides the best in class production

and product quality

• Scroll Compressor Technology provides

increased capacity, reliability and efciency.

PRESSURIZED SOFT

SERVE FREEZER

GENESIS SERIES™

2 Flavor Twist featuring

VQM™

Virtual Quality

Management System™

Let VQM help manage your frozen

dessert business more effectively.

electrofreeze.com

GEN-5099 Soft Serve Freezer

MODEL GEN-5099 SPECIFICATIONS

Due to continual product improvements all specications are subject to change without notice.

Weights lbs. kgs.

Net 653 296

Crated 709 321

cu.ft. cu.m.

Volume 58.42 1.65

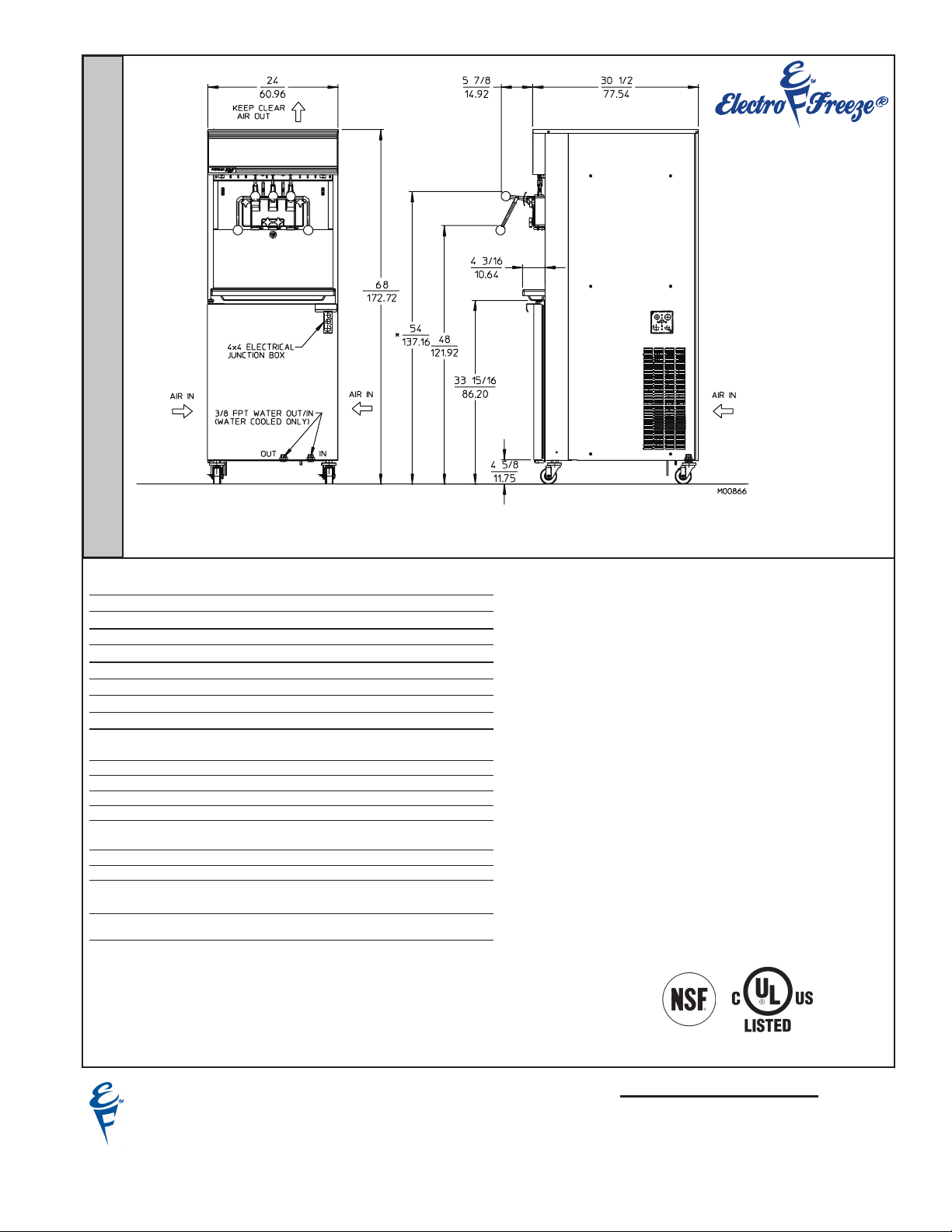

Dimensions in. cm

Width 24 60.96

Depth 30-1/2 77.54

Height 68 172.72

Electrical Maximum Minimum Circuit NEMA

Fuse Size Ampacity (Qty) Plug Type

208-230/60/1 Air 45 38.0 2P, 2W

208-230/60/1 Water 45 36.5 2P, 2W

208-230/60/3 Air 30 28 3P, 3W

208-230/60/3 Water 30 26.5 3P, 3W

Total Poles (P)

Amps (Qty) kW Wires (W)

400/50/3 Air 14.7 6.1 3P 4W

400/50/3 Water 13.3 5.8 3P 4W

Electrical characteristics other than above available on request from

factory or local distributor. Check nameplate for exact electrical data.

Bidding Spec

Electrical: Volt___________________ Hz_______ Ph

Cooling: ______________________ Neutral _____Yes_____No

Options: ____________________________________________

___________________________________________________

_________

Electrical

A dedicated electrical connection is required. Manufactured

to be permanently connected. See electrical chart for the

proper requirement. Consult your local electrical codes for

cord and receptacle specications.

Beater Motor

Two, 2hp.

Refrigeration Systems

One, 12,000 Btuh. R404a.

Separate Cabinet Refrigeration, One, 1000 Btuh, R134a.

Btuh may vary depending on compressor used.

Air Cooled

6” (15.2 cm) air space required on both sides for proper air

circulation and be open on the top.

Mix Hopper Capacity:

Freezing Cylinder Capacity: two - 3.7 quarts (3.5

liters) each

Certied and/or listed by:

*UL listed and listed by Underwriters Laboratories under

Canadian National Standard C22.2 No. 120-13

two - 22 quarts (20.8 liters) each

*

Electro Freeze div. of H.C. Duke & Son, LLC

2116-8th Avenue, East Moline, Illinois 61244 USA

Phone (309) 755-4553 • (800) 755-4545

FAX (309) 755-9858

E-mail: sales@electrofreeze.com • www.electrofreeze.com

HC185247 Printed in U.S.A. 2/16

Authorized Distributor

Loading...

Loading...