Electrofreeze GEN-101 User Manual

H. C. DUKE & SON, LLC

2116 - 8th Avenue • East Moline, Illinois 61244

OPERATOR’S MANUAL

with Illustrated Parts List

High Capacity

Soft Serve Freezer

Model

GEN-101

185239— 3/19

H.C. Duke & Son, LLC. P/N 185239 March 2019 Printed In U.S.A.

Operator’s Manual

for

H.C. Duke & Son

Soft Serve Freezer

Model GEN-101

All contents © Copyright 2019 H.C. Duke & Son, LLC., 2116 Eighth Avenue, East Moline, Illinois 61244

184297 iii

Soft Serve Model GEN-101

SAFETY FIRST!

Follow these four steps to safety ....

1. Recognize Safety Information ....Look for this

safety alert symbol throughout this manual.

When you see this symbol on your freezer or in this manual, be

alert to the potential for personal injury. Follow recommended

precautions and safe operating practices.

2. Understand Signal Words ....

The signal words — DANGER, WARNING and

DANGER

WARNING

CAUTION

CAUTION — are used with the safety alert symbol

(DANGER decals on the freezer may or may not have the

safety alert symbol, but the message is the same). Decals

with the words DANGER, WARNING or CAUTION appear

on the freezer. DANGER identies the most serious

hazard. Decals with the words DANGER or WARNING

are typically near specic hazards on the freezer. General

precautions are listed on CAUTION safety decals. In this

manual, CAUTION messages with the safety alert symbol

call attention to safety messages.

3. Follow Safety Instructions ....

Read and understand all safety messages in this manual.

Read and understand the decal safety messages on your

freezer. Take notice of the location of all decals on the freezer

and keep the safety decals in good condition. Check them

periodically and replace missing, damaged or illegible safety

decals. The safety decals must remain in place and legible

for the life of the freezer. If you need new decals, use the

information and illustrations on pages vi and vii of this manual

to identify the decal and call or write to H.C. Duke & Son, LLC.

DO NOT attempt to operate the soft serve freezer until you

read and understand all safety messages and the operating

instructions in this manual.

iv 185239

SAFETY FIRST!

4. Definitions ....

Trained person (or Operator): A person who has been trained in the basic operation of

the freezer. This person is knowledgeable in the operation of machine startup, stopping,

lling, and basic cleaning, disassembly, washing, and sanitation of the freezer.

Freezer Technician: A person who has been trained by a factory representative, or

an experienced and qualied service person, to perform more complicated operations

such as freezer installation, maintenance repairs, component replacement , is aware of

hazards associated with electricity, moving parts, and takes necessary steps to protect

against injury to themselves and other people.

Soft Serve Model GEN-101

5. Operate Safely ....

IMPORTANT: Store Managers,owners, and supervisors must be aware of staff

capabilities and that they do not perform freezer operations outside their level of

knowledge or responsibility.

6. Caution ....

• This Freezer is to be operated by trained persons. The Dispense

feature, if used by public in self-serve applications, shall be monitored

by trained persons able to assist people with physical, sensory or mental

impaired capabilities.

• Children should not be allowed to play around this equipment.

• Do not store explosive substances such as aerosol cans with a ammable

propellant in freezer.

• This appliance is not designed for outdoor weather conditions and shall not be

exposed to rain.

• Do not wash machine with power sprayer. Do not install machine next to a power

sprayer where splash of freezer can occur.

• Machine is designed for use in areas of normal atmosphere. It is not to be used in

areas subject to explosion-proof standards.

DO NOT allow untrained personnel to maintain or

service this freezer. Failure to follow this instruction

may result in severe personal injury. DO NOT operate

the freezer until all service and access covers are

secured with screws. DO NOT attempt to repair

the freezer until the main power supply has been

disconnected. Some freezers have more than one

disconnect switch. Contact your IDQ authorized

service representative or H.C. Duke & Son, LLC

Service Department for original equipment parts.

185239 v

Soft Serve Model GEN-101

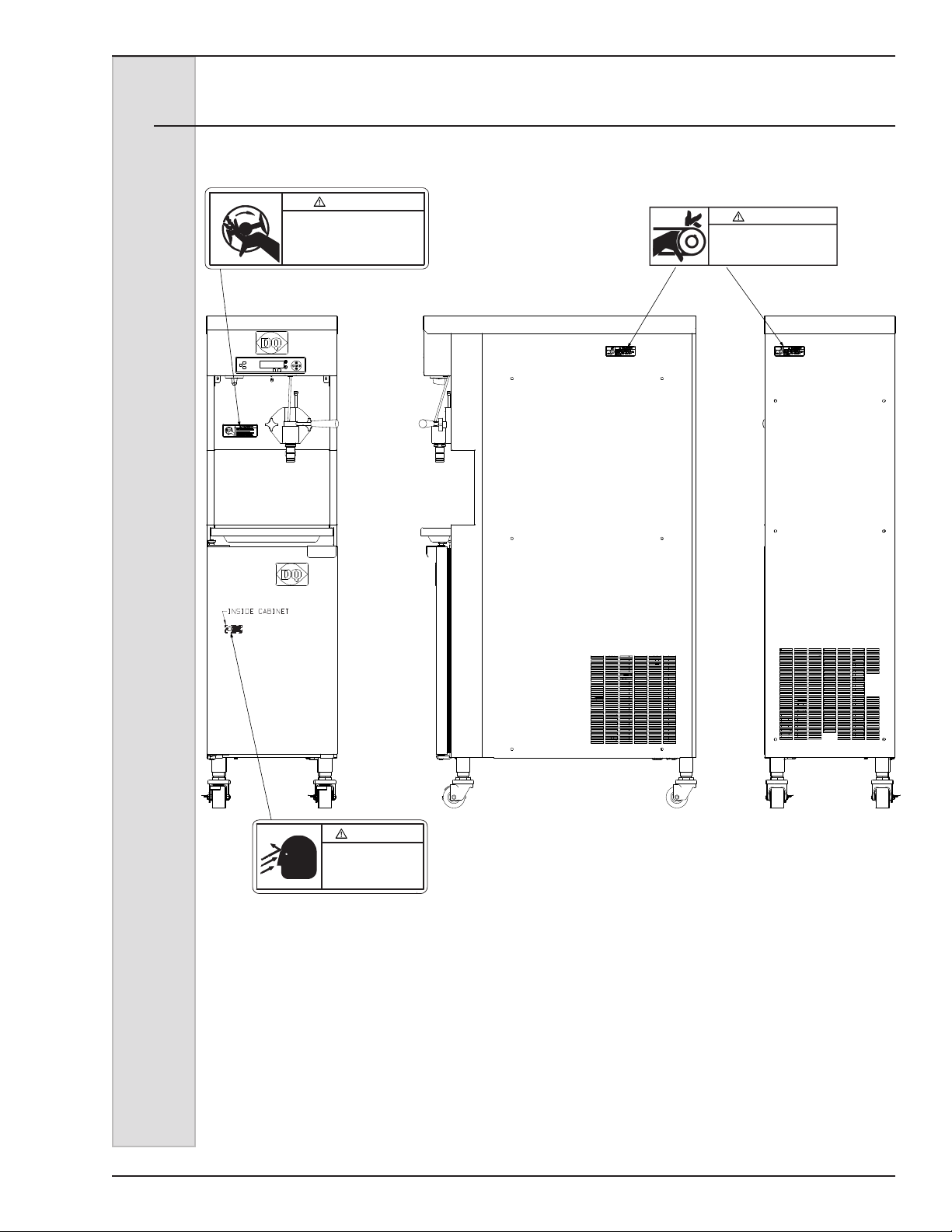

Safety Decal Locations

Do not attempt to operate the freezer

until all safety precautions and operating

instructions in this manual are read and

understood.

Take notice of all warning, caution,

instruction and information decals (or

labels) on the freezer as shown in the

gure on the next page. The labels have

been put there to help maintain a safe

working environment.

The labels have been designed to

withstand washing and cleaning. All labels

must remain legible for the life of the

freezer. Check labels periodically to be

sure they can be recognized as warning

labels.

If it is necessary to replace any label,

please contact H.C. Duke & Son, LCC

When ready to order you will need to

determine the (1) part number, (2) type of

label, (3) location of label, and (4) quantity

required, and include a return shipping

address.

For factory service assistance, contact H.

C. Duke & Son, LLC, Service Department

by phone or FAX:

Phone: (309) 755-4553

(800) 755-4545

FAX: (309) 755-9858

E-mail: service@hcduke.com

(The decals on the next page are

numbered 1, 2, 3, and 4. Those numbers

correspond to the numbers in the table

below. The table provides the part

number, description, and quantity for each

decal.)

No. Part No. Description (Qty)

1 HC165025 Decal — Beater Warning (1)

2 HC165126 Decal — Panel Removal (3)

3 HC165048 Decal — Rotating Parts (1)

4 HC165246 Decal — Pressurized System (1)

vi 185239

Safety Decal Locations

1

P/N HC165025

WARNING

WARNING

Hazardous rotating beater shaft. Do not

Hazardous rotating beater shaft. Do not

operate unit with dispense head removed.

operate unit with dispense head removed.

Before removing dispense head,

Before removing dispense head:

1. Turn all control switches to "OFF", and

1. Turn all control switches to “OFF”, and

2. Disconnect all power supplies. Unit

2. Disconnect all power supplies. Unit may

may have more than one power supply.

have more than one power supply.

Soft Serve Model GEN-101

P/N HC165126

2

!

WARNING

Hazardous moving parts.

Hazardous moving parts.

Machine starts automatically.

Machine starts automatically.

Do not operate with panel

Do not operate with panel

removed.

removed.

WARNING

Pressurized system.

Pressurized system.

Depressurized unit

Depressurize unit

before dismantling mix

before dismantling

mix transfer system.

transfer system.

P/N HC165246

3

185239 vii

Soft Serve Model GEN-101

Safety Decal Locations .................................................. vi

1 Introduction ..............................................................1

2 Note to Installer ......................................................... 1

2.1 Uncrating and Inspection ............................................2

2.2 Installation ..................................................................3

2.3 Electrical Requirements ...........................................3

2.4 Electrical Connections ................................................4

3 Specifications ........................................................... 5

3.1 Particulars ..................................................................5

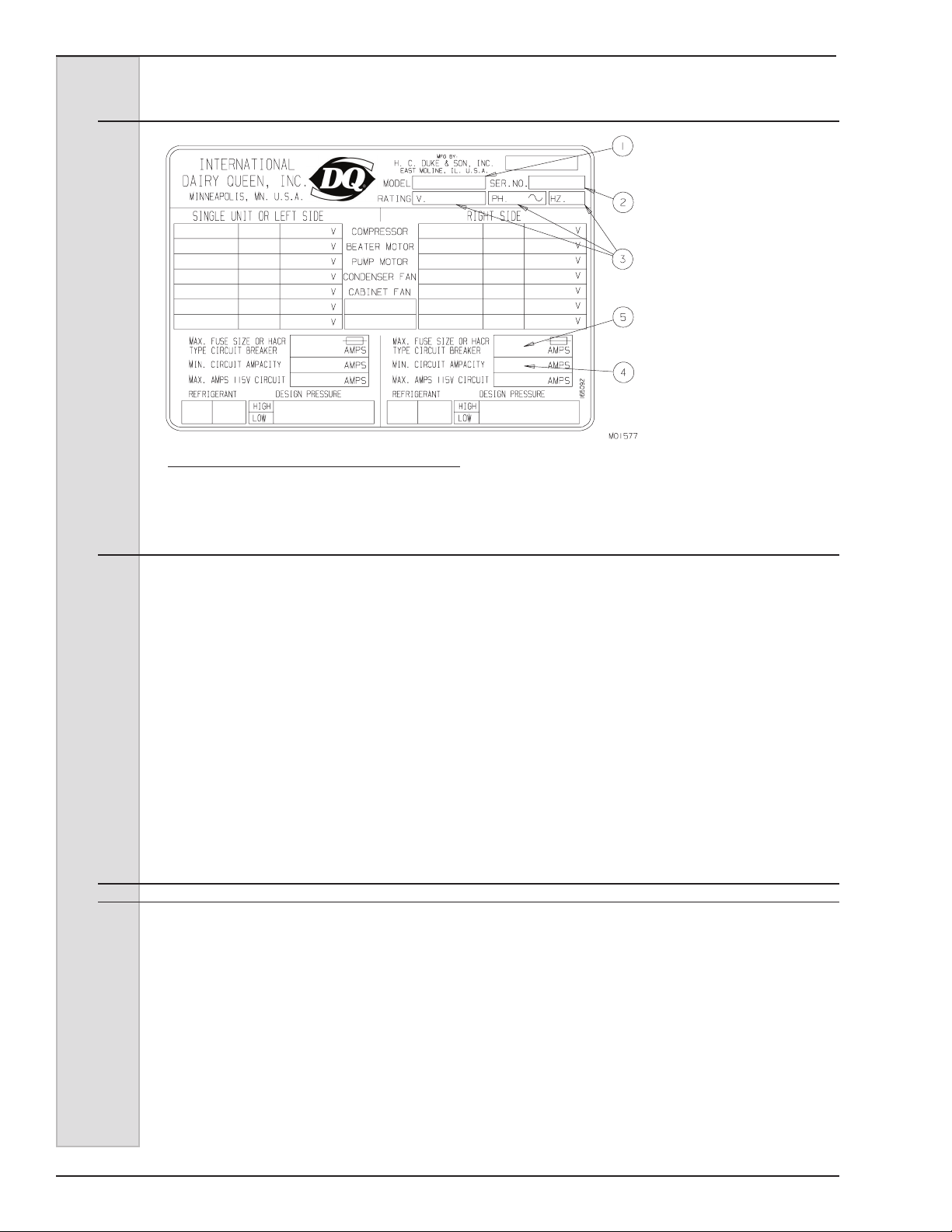

3.2 Data Plate ...................................................................6

3.3 Reference Information ................................................6

3.4 Installation Date ..........................................................6

3.5 Dimensions .................................................................7

3.6 WEEE (Waste Electrical and Electronic Equipment) ....7

4 (VQM) Terminology .................................................... 8

Table of Contents

5 Part Names and Functions ....................................... 10

6 Operator Controls ................................................... 16

7 Operator Display Menus .......................................... 18

8 Disassembly and Cleaning ....................................... 22

8.1 Cleaning Accessories ....................................................23

8.2 ...................................................................................Disas-

sembly Instructions .............................................................24

8.3 ...................................................................................Clean-

ing Instructions ...................................................................26

8.3.1 ...................................................................... Clean-

ing and Lubricating - MTS Assembly ...................... 28

9 Assembly ................................................................ 29

10 Start-up Instructions ............................................... 34

10.1 Sanitizing ..................................................................34

9.2 ...................................................................................Prim-

ing .................................................................................35

11 Closing Procedures ................................................. 36

10.1 Draining Product ........................................................36

12 Soft Serve Information ............................................. 38

12.1 Overrun .......................................................................38

12.2 Overrun Adjustment .....................................................39

12.3 Rerun ...........................................................................39

13 Routine Maintenance ............................................... 40

14 Troubleshooting Tables ........................................... 42

14.1 MTS Troubleshooting Tables ......................................47

15 VQM Error Codes .................................................... 49

viii 185239

1 Introduction

Soft Serve Model GEN-101

The GEN Series Freezer is designed

to produce DQ frozen soft serve ice

cream or DQ yogurt, with a product

serving temperature of 18 to 19ºF (-8

to -7ºC). If such products are prepared

from powdered concentrate, they should

be precooled to 40°F (4°C) prior to

introduction to the freezer. Use of other

products in this machine is considered

misuse (see Warranty.)

This manual has been prepared to assist

in the training of personnel on the proper

operation and general maintenance of

your Duke freezer.

Your freezer will not compensate for or

correct any assembly or priming errors

made during the initial start-up. Therefore

it is extremely important to follow the

assembly and priming procedures

detailed in this manual.

Be sure all personnel responsible for

equipment operation completely read and

understand this manual before operating

the freezer. When properly operated and

maintained, your freezer will produce a

consistent quality product.

If you require technical assistance, please

contact your local authorized H.C. Duke &

Son, LLC service company:

Name __________________________

Address _________________________

____________________________

Phone __________________________

or H.C. Duke & Son, LLC Service Dept.

for factory service assistance.

Phone: (309) 755-4553

(800) 755-4545

Fax: (309) 755-9858

E-mail: service@hcduke.com

2 Note to Installer

This freezer must be installed and serviced by a service technician in

accordance with the installation instructions.

After installation the warranty registration card must be completed and

returned to validate warranty.

IMPORTANT

DISPENSING HEAD MUST BE

INSTALLED FOR BEATER

MOTOR(S) TO OPERATE.

DO NOT INTERCHANGE HEADS

FROM OTHER FREEZERS.

CAUTION

THE DISPENSING HANDLE

MUST BE COMPLETELY

CLOSED AFTER EACH DRAW.

FAILURE TO CLOSE THIS

HANDLE WILL ENGAGE THE

REFRIGERATION SYSTEM

CAUSING A FREEZE UP AND

DAMAGE TO BELTS, GEAR

REDUCER, AND MOTORS

COULD OCCUR.

185239 1

Soft Serve Model GEN-101

2.1 Uncrating and Inspection

CAUTION

Be sure to properly support

the machine when removing

bolts and installing legs or

casters.

When the unit is received and while

the carrier is still present, inspect the

shipping carton for any damage that

may have occurred in transit. If the

SHOCKWATCH® label indicates red and/

or the carton is broken, torn, or punctured,

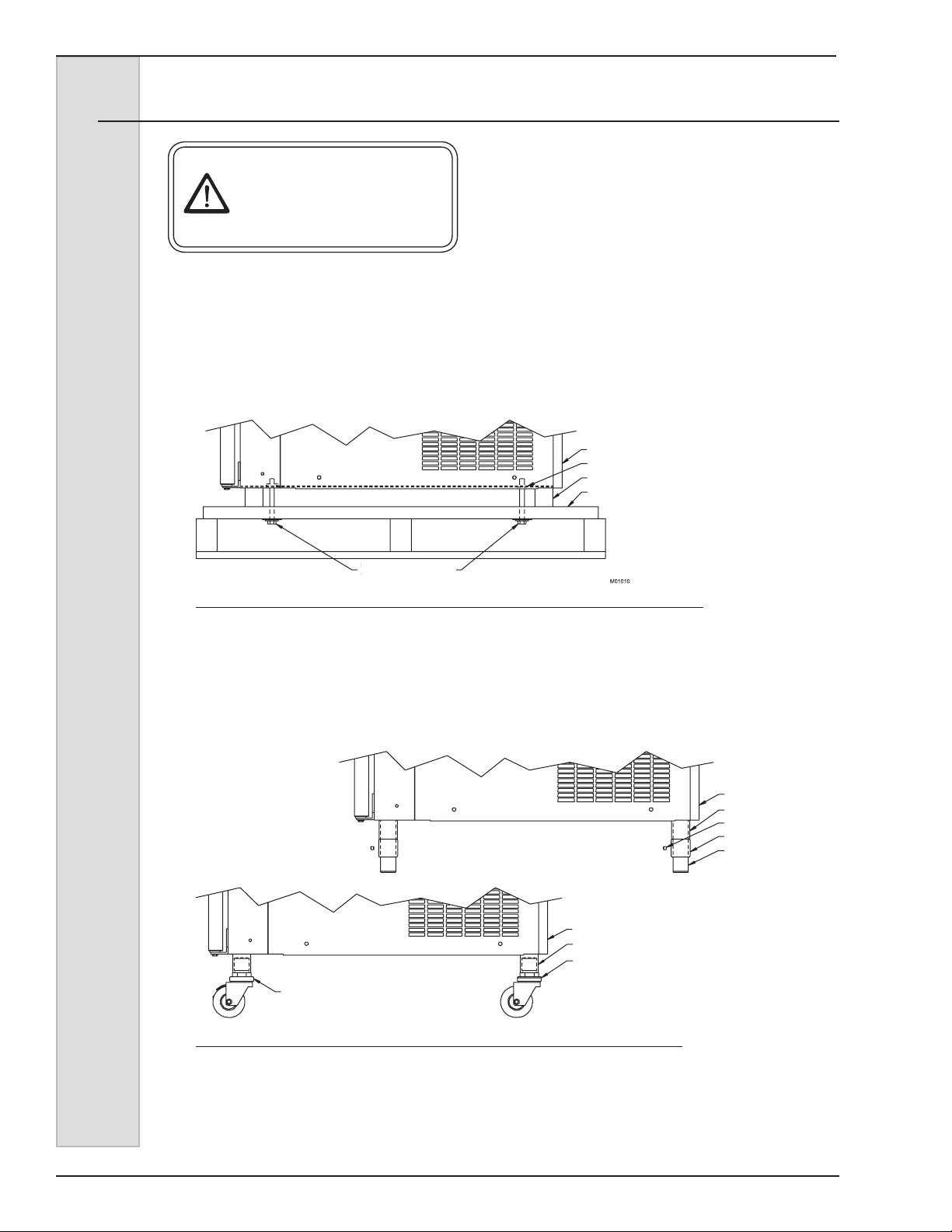

REMOVE HEX HEAD BOLTS

(4) AND FLAT WASHERS

Figure 2-1 Machine Bolted to Shipping Base

note the damage on the carrier’s freight

bill and notify the carrier’s local agent

immediately.

1. Remove the carton from the pallet,

and move the machine as close as

possible to the permanent location.

2. Remove the shipping bolts on the

bottom of the freezer (gure 2-1) and

install either the legs or casters (gure

2-2).

REAR OF UNIT

FRAME WELDNUT

LEG SUPPORT

PALLET

REAR OF UNIT

LEG SUPPORT

SET SCREW

LEG COVER

LEG

NOTE: Screw casters

or legs all the way in

coupling, then adjust

out to level with 1/4

inch slope to front.

CASTER WITH BRAKE

REAR OF UNIT

LEG SUPPORT

CASTER WITHOUT

BRAKE

Figure 2-2 Installing Mounting Legs or Casters

2 185239

2.2 Installation

Soft Serve Model GEN-101

CAUTION

All materials and

connections must conform

to local requirements and

be in compliance with the

National Electrical Code.

1. This freezer is designed for indoor use

and must be protected from outdoor

weather conditions.

2. Where codes permit, we recommend

that the freezer be installed on casters

and have exible water and electrical

connections for service and cleaning

ability.

3. All models require a minimum 6 inch

(15cm) clearance on either the side

panels and 0 inch in the rear or 6 inch

(15cm) in the rear and 0 inch on the

side panels for adequate ventilation.

Freezers require a least 24 inches

(61cm) clearance above the top panel

and be free of obstructions. Anything

blocking ventilation of the freezer

(including cone dispensers) will

reduce the efciency of the freezer.

4. Water cooled double models will

require a 1/2” MPT water inlet and

water waste connection. Both water

condensers are tied together so that

one water inlet and one water waste

is all that is required. The connections

are found on the bottom under the

compressor mounting area and are

clearly tagged - “Water Inlet” and

“Water Waste”. A manual shut-off

valve should be installed in the water

inlet line at the time of installation.

The water pressure must be between

35-140 psig (241-965kPa) for proper

operation.

5. Place the freezer in the nal location

and level the machine by adjusting

the legs or casters so that the unit

is level side-to-side, and the front

is approximately ¼” lower than the

rear, to allow proper drainage of the

freezing cylinder.

6. Water Cooled Do not allow freezer to

be in ambient where air temperature

goes below 0°C (32°F),the freezing

temperature of water.

7. Water consumption increases

if temperature of entering water is

above 20°C (65°F)

2.3 Electrical Requirements

1. Supply voltage must be within + 10%

CAUTION

To prevent accidental electrical

shock, a positive earth ground

is required.

1. Always verify electrical specications

on the data plate of each freezer.

Data plate specications will always

supersede the information in this

manual.

185239 3

of voltage indicated on the nameplate.

Also, on three-phase systems,

voltage between phases must be

balanced within 2%. (More than a

6 volt difference between any two

voltage measurements at 208-230

volts indicates a possible imbalance.)

Request your local power company to

correct any voltage problem.

2. An easily accessible main power

disconnect must be provided for all

poles of the wiring to the freezer.

Soft Serve Model GEN-101

2.4 Electrical Connections

CAUTION

To prevent accidental

electrical shock, a positive

earth ground is required.

Important!

A positive earth ground is required for

electronic VQM system

to operate correctly.

1. Double freezers with two compressors

require one power supply for each

side of the freezer. Each side of the

freezer operates independently.

2. Check the data plate for fuse

size, wire ampacity, and electrical

specications. (See Figure 3-2)

3. Refer to the wiring diagram provided

for proper power connections.

4. Electrical connections are made in

the junction boxes located mid-level

behind the left side panel.

WARNING

Warning: When installing the machine,

insert an all pole disconnect, adequately

sized according to freezer nameplate

marking with electrical contact spacing

of 3mm minimum. This should be within

sight of the freezer.

Important

Set switch next to the connection

box “UP” for 220-230v or “DOWN”

for 208-219V. Failure to set switch to

proper voltage will cause damage to

the electrical components and will void

all warranties.

5. Use a exible connection when

permissible.

6. For 3 phase freezers, beater shaft

rotation must be clockwise as viewed

from the front of the freezer.

4 185239

3 Specifications

3.1 Particulars

Always check and verify voltage and amperage on the data

plate located on the back panel of each freezer.

GEN-101

Width (in/cm) ......................... 18/46

Height (in/cm)(WC) ............... 67.5/171

Height (in/cm)(AC) ................ 68/173

Depth (in/cm) ......................... 36/91

Weight (lbs/kg) ...................... 847/385

Compressor-Cylinder * ........ 2 HP/19000 BTUH

2.2 kw (Motor)

3.2 kw (Cooling)

Refrigerant ............................ 404a

Charge** ................................ 3.75 lb/1.7 kg

Compressor-Cabinet (1)* ..... 1/6 HP/650 BTUH

125w (Motor)

190kw (Cooling)

Refrigerant ............................ 134a

Charge ................................... 6 oz/0.37 lb/.17 kg

Beater Motor ......................... 2 HP/1.5 kw

Mix Container***.................... 24 Qts/22.7 Liters

Cylinder ................................. 4 Qts/3.8 Liters

ACR

Soft Serve Model GEN-101

Noise: The Steady acoustic pressure level, for both air cooled and water cooled freezers, is less

than 70dB(A).

Water Cooled units: Water consumption increases if temperature of entering water is above 20°C

(65°F)

*Contact factory for other voltages.

**Approximate for each side. See nameplate for actual charge.

*** Do not add mix above line marked on side of mix tank wall.

185239 5

Soft Serve Model GEN-101

3.2 Data Plate

Figure 3-1

The data plate provides

important information that

the operator should record

and have available for

parts ordering, warranty

inquiries, and service

requests.

3.3 Reference Information

Write in

Reference

Information HERE!

3.4 Installation Date

Fill in the date of installation, and the name, address, and phone number of the

installer in the space provided below. This information will be needed when ordering

parts or service for the GEN-101 freezer.

Date of installation: _____________________________________________

Fill in the following information below

as soon as you receive the GEN-101.

(The item numbers—encircled, below—

correspond with the callout numbers

above.)

IMPORTANT: Complete for reference:

1.) Model Number: _________________

2.) Serial Number: _________________

3.) Electrical Spec: Voltage ___________

Phase _______ Hertz ___________

4.) Minimum Circuit Ampacity: ________

5.) Maximum Fuse Size: ____________

Installed by: ___________________________________________________

Address: _____________________________________________________

____________________________________________________________

Phone: _______________________________________________________

6 185239

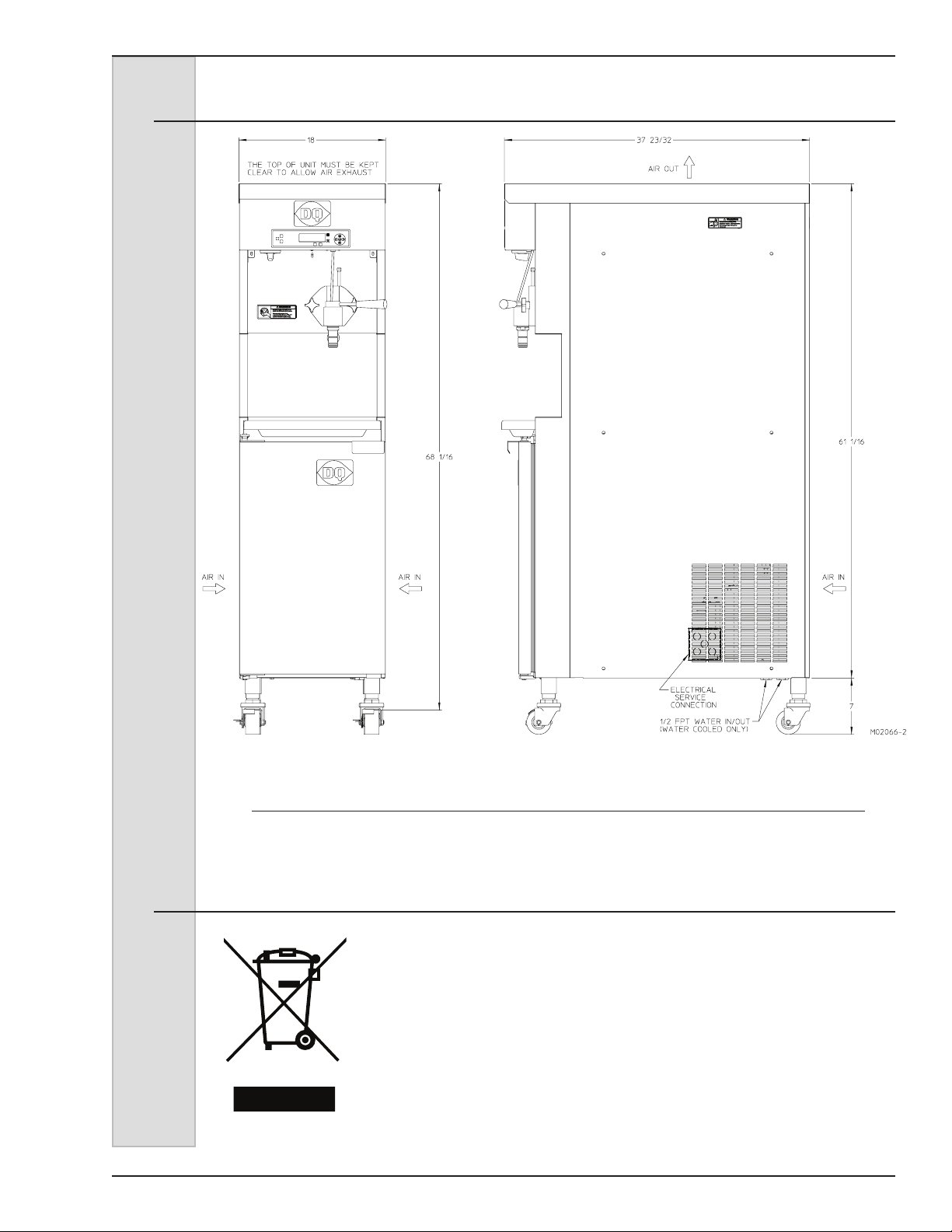

3.5 Dimensions

Soft Serve Model GEN-101

* NOTE: Electrical service box is located behind left side panel.

Figure 3-2 Dimensions

3.6 WEEE (Waste Electrical and Electronic Equipment)

In conformity with EU 2002/96/EC,

this freezer, at the end of life cycle,

is not to be discarded with normal

urban waste. Instead, it is the user’s

responsibility to dispose of this product

by returning it to a collection point

designated for the recycling of electrical,

electronic components and separation

of reclaimable, recyclable materials.

Contact your local distributor or authority

for correct disposal.

185239 7

Soft Serve Model GEN-101

4 Virtual Quality Management System

(VQM) Terminology

Beater Run: ...................... This D.O.B. timer used to delay the beater motor after

the refrigeration shuts down. Beater Run Range: 0 to 10

seconds

Demand Run Comp: ......... The D.O.B. timer used to delay the compressor when

product is being drawn. Demand Run Comp. Range: 0 to

12 seconds

Differential/ Hyst: .............. Symbolizes the differential setting. Differential range: 7 to

20°F i.e. if your cut in is at 18°F and your Differential is

at 10°F your unit will cut out at 8°F

Dual Diff: ........................... The differential used when product is being drawn out of

the center spigot. Dual Differential range: 7 to 20°F

Idle: ................................... When the unit is cycling on temperature and no product

is being dispensed

Idle Run Comp:................. Delay on break (D.O.B.) timer used for the compressor

when the unit is in idle mode/no product being drawn.

Idle Run Comp. Range: 0 to 20 seconds

Lock outs: ......................... Allows the function of a specic feature/button to be

temporarily disabled to deter un-necessary usage of that

feature.

Main P.C. Board: ............... Main Control board for the unit, housed behind the trim

strip panel. This board has many connectors on it and is

responsible for the main operations of the unit.

Membrane Switch: ............ The black H.C. Duke & Son, LLC. decal visible on the

front of the unit, which houses the hidden operator,

technician, soft, and hard keys used to navigate the

menus.

Relay Board ...................... A control board located in the main electrical control box.

This Board contains no software, only solid state control

relays to operate system components.

Single Diff: ....................... The differential used when product is being drawn out of

one barrel. Single Hysteresis range: 7 to 20°F

Slope/Demand Slope: ...... Utilizes a function within the system to watch the

temperature change as the unit freezes a barrel. If

utilizing the slope feature and the unit sees a lack of

temperature change during freeze down, the unit will

cycle off. This will prevent a freeze up condition due to a

long run time. Demand Slope range: 0 to -0.2

8 185239

Soft Serve Model GEN-101

4 VQM System Terminology (continued)

Temp. Comp.: ................... Temperature compensation, utilized when the slope feature

is turned on. It prevents the system from seeing the

slope temperature curve until a determined temperature

is reached. Once that temperature has been reached

then the system will examine the curve and shut down if

necessary. Temp. Comp. Range: -10 to 22°F

Temperature Offset: .......... A function that allows temperature adjustment to the

operator. Adjustable from 1-9 and 5 being neutral/no

change, Lower than 5= colder and greater than 5=warmer

Transducer: ...................... An electronic control used to measure the cylinder

pressure for mix pump operation.

U.I./ User Interface: .......... The board that lies directly behind the membrane switch

on the front panel. This board houses the LED screen that

displays the menus and operations. The membrane switch

is connected to this board via a ribbon cable. This board

also has its own software.

185239 9

Soft Serve Model GEN-101

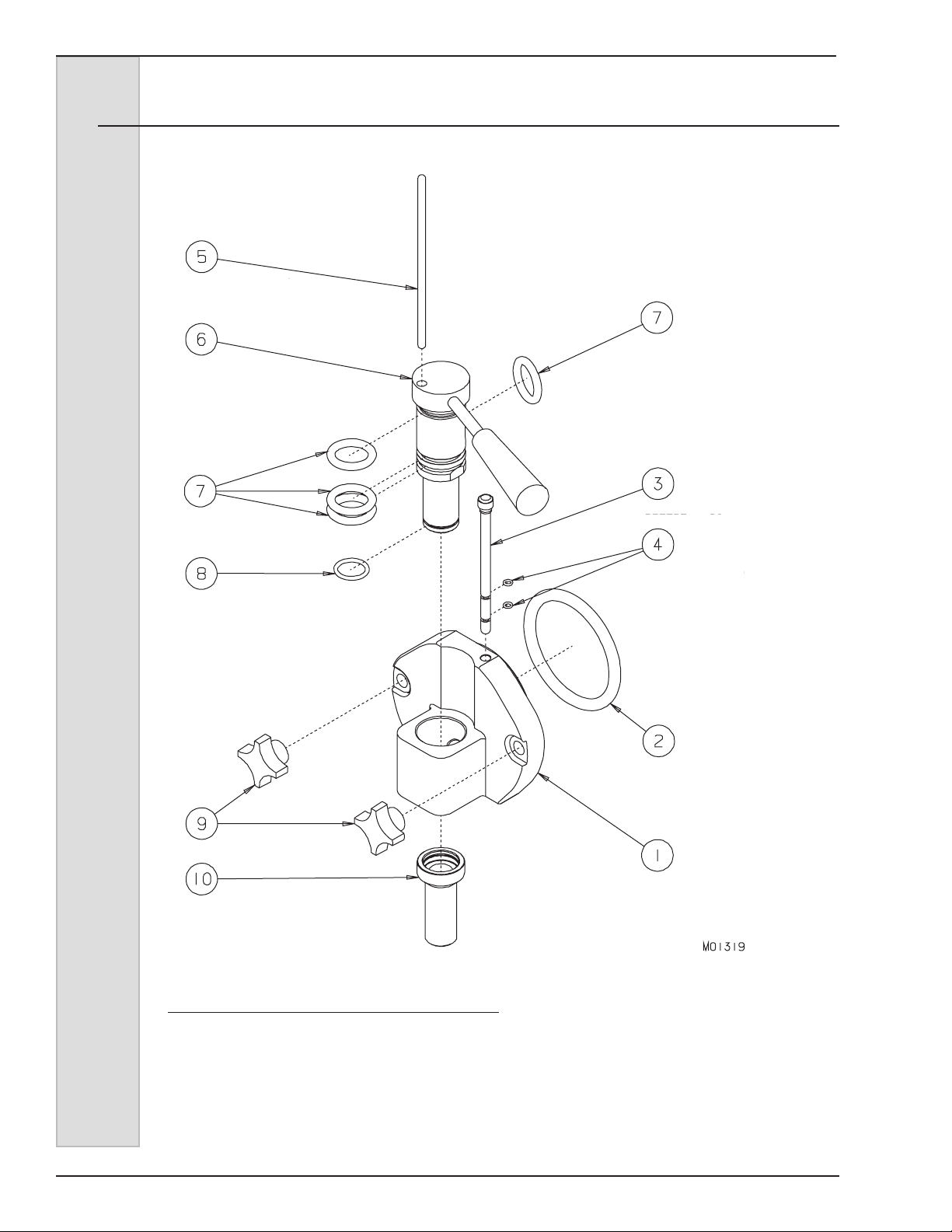

5 Part Names and Functions

ROD - SPIGOT SWITCH

SPIGOT - LONG HANDLE

O-RING - SPIGOT

O-RING - SPIGOT

O-RING - EXTENSION

KNOB - HAND

EXTENSION - SPIGOT

BLEEDER - ASSY

O-RING - BLEEDER

O-RING - HEAD

HEAD - ASSY

Figure 5-1 Head Assembly

10 185239

Soft Serve Model GEN-101

5 Part Names and Functions (continued)

The following descriptions apply to gure 5-1. The number preceding the part

name corresponds to the number in the gure.

1.) HEAD:

Encloses the freezing cylinder and

provides an opening for product to be

dispensed. NOTE: Beater motors will not

operate with the head removed from the

freezer.

2.) O-RING - HEAD:

Seals the head to the freezing cylinder.

Must be lubricated.

3.) PLUG-AIR BLEED (BLEEDER ASSY.):

Seals the air bleed opening in the head

when closed. Allows excess air to be

removed from the cylinder when priming.

4.) O-RING-AIR BLEED PLUG:

Seals the air bleed plug in the head.

5.) ROD - SPIGOT:

Starts the freezer when dispensing.

6.) SPIGOT - ASSEMBLY SIDE WITH

HANDLE (STAINLESS STEEL):

Seals the product opening in the head

when closed. Allows product to ow

when open.

7.) O-RING - SPIGOT:

Seals the spigot in the head. Must be

lubricated to seal and slide properly.

8.) O-RING - SPIGOT EXTENSION:

Holds the extension on to the spigot.

9.) KNOB-HAND:

Secures the head to the freezing

cylinder.

10.) EXTENSION - SPIGOT (ACCESSORY):

Extends the product opening down to

shape the product as it is dispensed.

185239 11

Soft Serve Model GEN-101

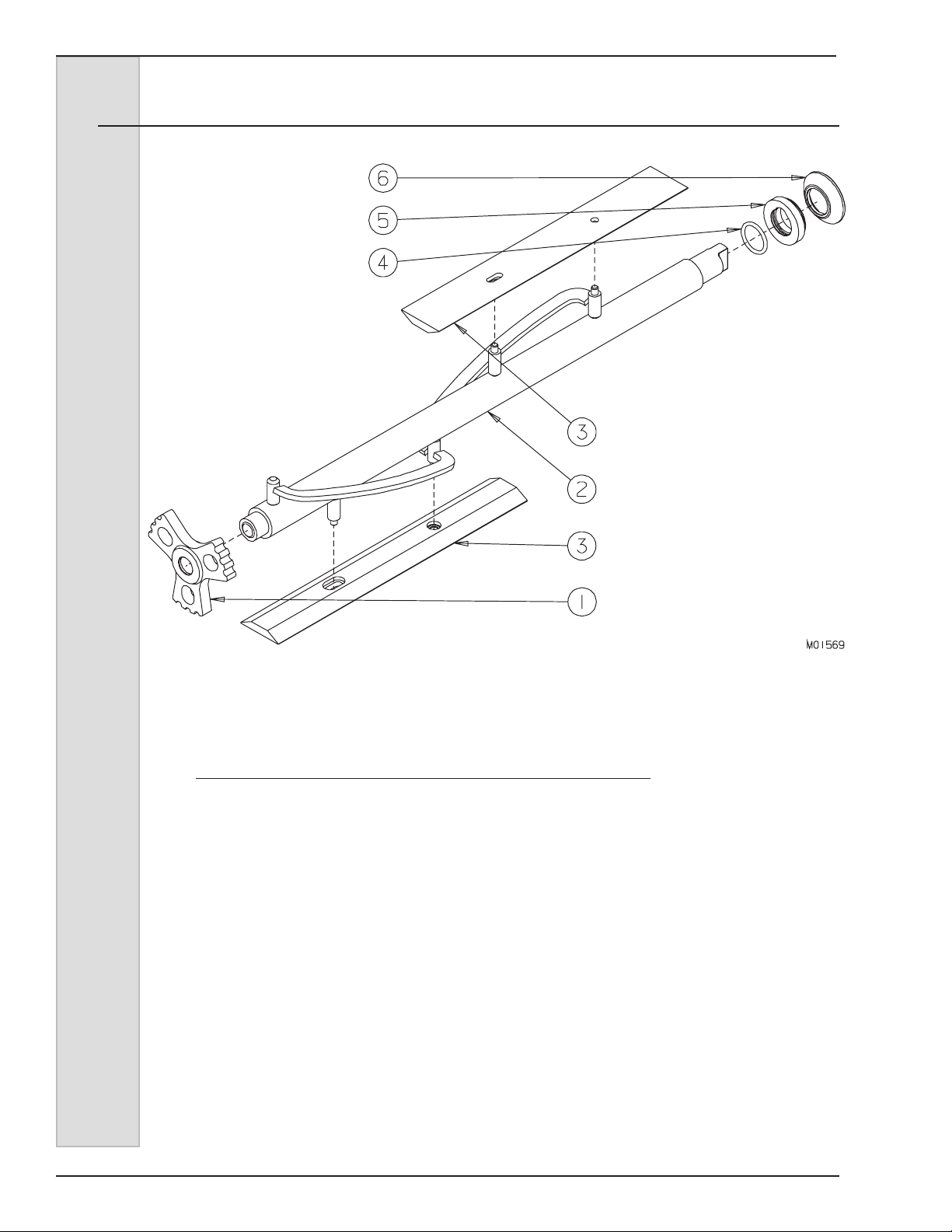

5 Part Names and Functions (continued)

SEAL - BEATER SHAFT

WASHER - SHAFT SEAL

O-RING SHAFT SEAL

BLADE - SCRAPER SOFT SERVE

SHAFT - ASSY BEATER

Figure 5-2 Beater Shaft Assembly

BLADE - SCRAPER SOFT SERVE

BUSHING - CYLINDER

12 185239

Soft Serve Model GEN-101

5 Part Names and Functions (continued)

The following descriptions apply to gure 5-2. The number preceding the part

name corresponds to the number in the gure.

1.) BUSHING - CYLINDER:

Holds the beater in place at the front

of the cylinder.

2.) SHAFT - BEATER:

Rotates in the freezing cylinder,

blending air and mix as it ejects

product.

3.) BLADE - SCRAPER:

Scrapes the frozen product from the

freezing cylinder wall

4.) O-RING-SHAFT SEAL:

Seals the beater shaft to the shaft

seal. Is inserted into the shaft seal

washer. Must be lubricated.

5.) WASHER-SHAFT SEAL:

Holds the shaft seal o-ring. Lightly

lubricate the side opposite the cup

seal.

6.) SEAL(CUP)-BEATER SHAFT:

Seals the opening between the

freezing cylinder and the beater

shaft. Do not lubricate rubber cup

portion.

185239 13

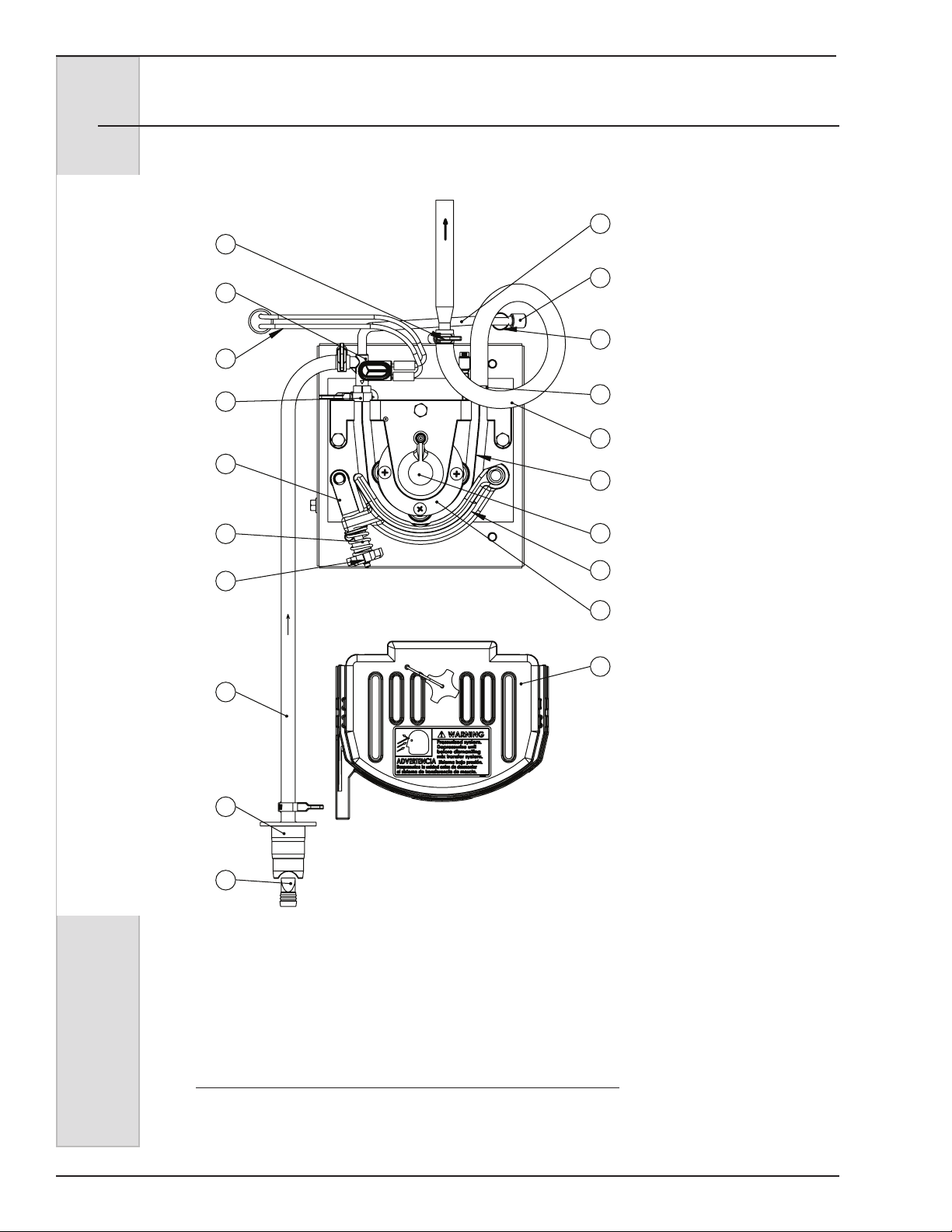

Soft Serve Model GEN-101

TO CYLINDER

5 Part Names and Functions (continued)

11

TUBE-AIR

CLAMP-SOFT TUBE

PORT-AIR/MIX

CORDSET-MIX OUT

CLAMP-SOFT TUBE

ARM-SWING CLAMP

10

12

9

MIX FLOW

AIR METER

13

AIR METER RETAINER

8

14

7

CLAMP SOFT HOSE

15

HOSE-MIX BRAIDED

6

16

HOSE-TRANSFER

RED LINE

SHOE SPRING

KNOB-HAND

TUBING-MIX PICKUP

BAG ADAPTOR

DUCKBILL-INLET

5

4

17

SUPPORT-ROLLER BEARING

18

SHOE-ROLLER

19

ROLLER-ASSY

COMPLETE

COVER-MTS

20

3

MIX FLOW

2

1

Figure 5-3 Mix Transfer System (MTS)

14 185239

Soft Serve Model GEN-101

5 Part Names and Functions (continued)

The following descriptions apply to gure 5-3. The number preceding the part

name corresponds to the number in the gure.

1.) DUCKBILL:

A rubber check valve that prevents

mix from falling back into the mix

container.

2.) ADAPTER - MIX BAG:

Connects the mix inlet tube to the

mix bag.

3.) TUBE - ASSEMBLY MIX INLET:

Carries mix from mix container to

MTS.

4.) KNOB - HAND:

Locks roller shoe in position.

5.) SHOE - spring:

Holds clamp in place.

6.) ARM - SWING CLAMP:

Swings hand knob into position over

roller shoe.

7.) CLAMP - ASSY. SOFT HOSE 5/8”:

Prevents mating parts from leaking.

8.) CORDSET - SOFT TUBE:

9.) PORT - AIR/MIX:

Blends air and mix as it ows into the

transfer hose.

14.) CLAMP - ASSY. SOFT HOSE 5/8”:

Prevents mating parts from leaking.

15.) HOSE - ASSY. MIX BRAIDED:

Connecting tube between the Mix

Transfer System and the cylinder

inlet.

16.) HOSE - TRANSFER RED:

Special “red-lined” hose that is

squeezed by rollers to transfer mix to

freezer.

17.) SUPPORT - ROLLER BEARING:

Holds roller assembly in place.

18.) SHOE - ROLLER:

Provides an opening to insert the

mix transfer hose. Squeezes transfer

hose against rollers.

19.) ROLLER ASSEMBLY COMPLETE:

Squeezes mix/air through tubing to

freezing cylinder.

20.) COVER - MTS:

Protection against moving parts.

Cover must be in place for the MTS

to operate.

10.) CLAMP - ASSY. SOFT HOSE 5/8”:

Prevents mating parts from leaking.

11.) TUBE - AIR:

Provides connection for the air

meter.

12.) AIR METER:

Regulates the amount of air being

drawn into the system.

13.) RETAINER - AIR TUBE:

Holds air meter tube in the “up”

position.

185239 15

Soft Serve Model GEN-101

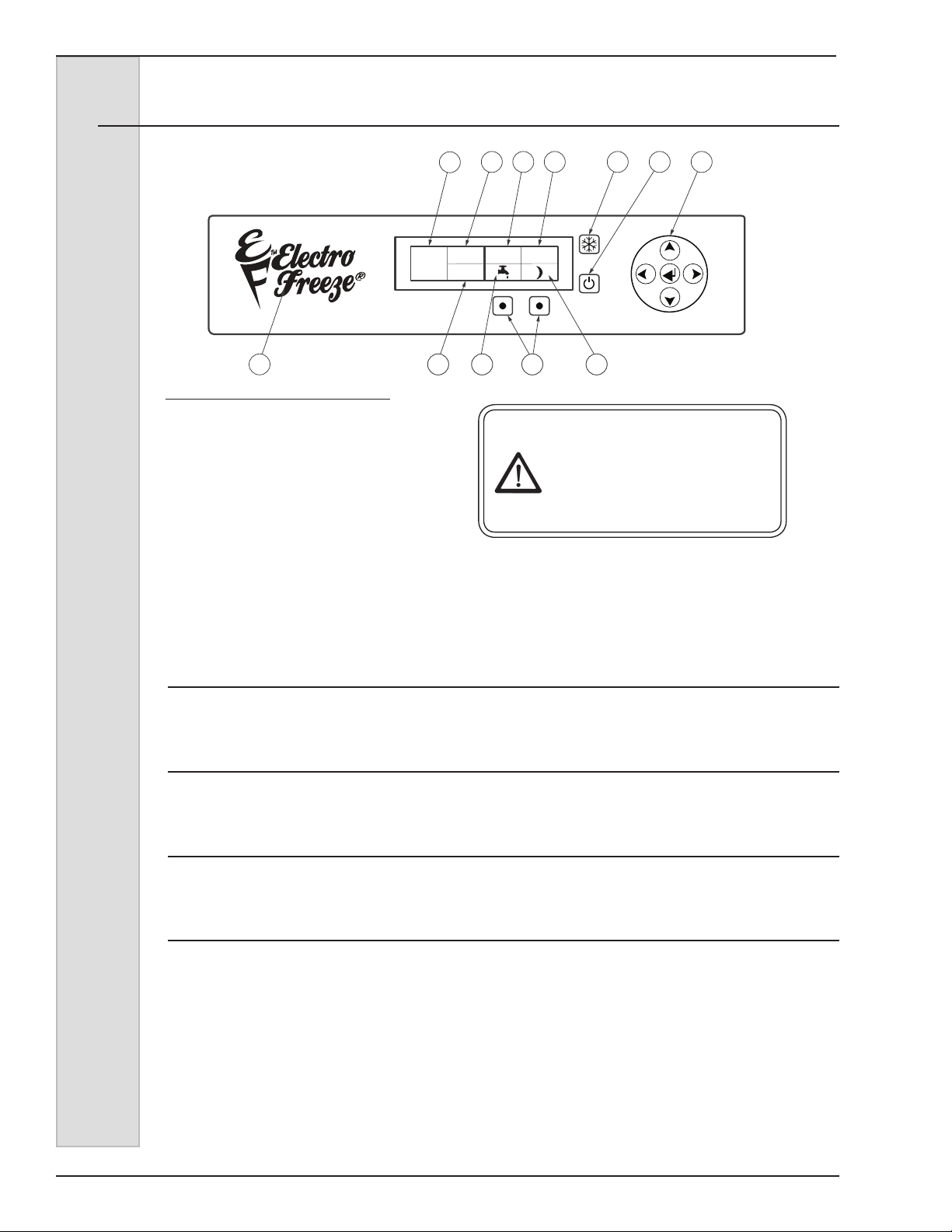

6 Operator Controls

2 4 75 6

1

3

CYL

CAB

OFF

37ºF

8

9 10 11 12

OFF

CAB ON

CAB OFF

Figure 6-1

The following paragraphs describe the

operator controls. Refer to Fig. 6-1 for

numbered items in description. The

display window has three levels of

display: Operators Menu, Technician

Menu. The last two menus are

CAUTION

Test operation of the head

switch prior to placing the

freezer in service. See Section

11, Routine Maintenance,

Monthly.

restricted and reserved for use by

qualied personnel.

NOTE: The dispense head must be in

place before the freezer will operate.

1. Cabinet Error Window

This window displays warnings and errors pertaining to the freezers’ cabinet.

2. Cabinet Status Indicator

This window displays the current cabinet status (ON/OFF).

3. Cylinder Error Window

This window displays messages and errors pertaining to cylinder.

4. Cabinet Status Indicator

This window displays the current cylinder status (OFF, Clean, Stby, FRZ).

16 185239

Soft Serve Model GEN-101

6 Operator Controls (continued)

5. Freeze Key

There are three primary modes of operation:

a. OFF –This is the indicator when power is applied to freezer and when

(OFF) button is pressed. In this mode, the refrigeration and beater motor

will not operate.

b. FRZ – This is the indicator when Freeze button is pressed. In this

mode, the freezer is in automatic freeze mode and both the beater motor

and refrigeration will activate as needed. Use this position for dispensing

product from freezer. Cabinet will also be refrigerated as needed to

maintain product below 41°F.

Important:Do not use the freeze position with water or sanitizer

in the cylinder or pump. The freezer will be damaged.

c. Night – This is the indicator when Night button is pressed. In this

mode, an energy-saving feature will activate and reduce product

refrigeration. The freezer will automatically cycle to maintain temperatures

in the cylinder and cabinet below 41°F and keep product from deteriorating.

Use this position when the freezer will not be in use for periods of more

than one hour.

6. OFF Key

When this symbol is pressed, the left side of unit will shut off. The beater motor and

compressor will not operate.

7. Navigation Pad (Up/Down = Cabinet ON/OFF)

Used to navigate the menu structure. Up/Down arrows are used to turn the cabinet

on/off when the cylinder is off. Used by technicians for programming and setting

changes. See Troubleshooting section for Operator accessible controls.

8. Hidden Operator Menu Key

Press this key to enter the operator menu to adjust the freezers settings.

9. Cabinet Temperature

This window displays the current cabinet temperature. Can be set to display either

Fahrenheit or Celsius.

10. Wash or Clean Mode

Press the function button directly below icon to activate clean mode.

11. Function Buttons (Two)

Pressing either of these buttons will activate the icon directly above it in the display

screen.

185239 17

Soft Serve Model GEN-101

6 Operator Controls (continued)

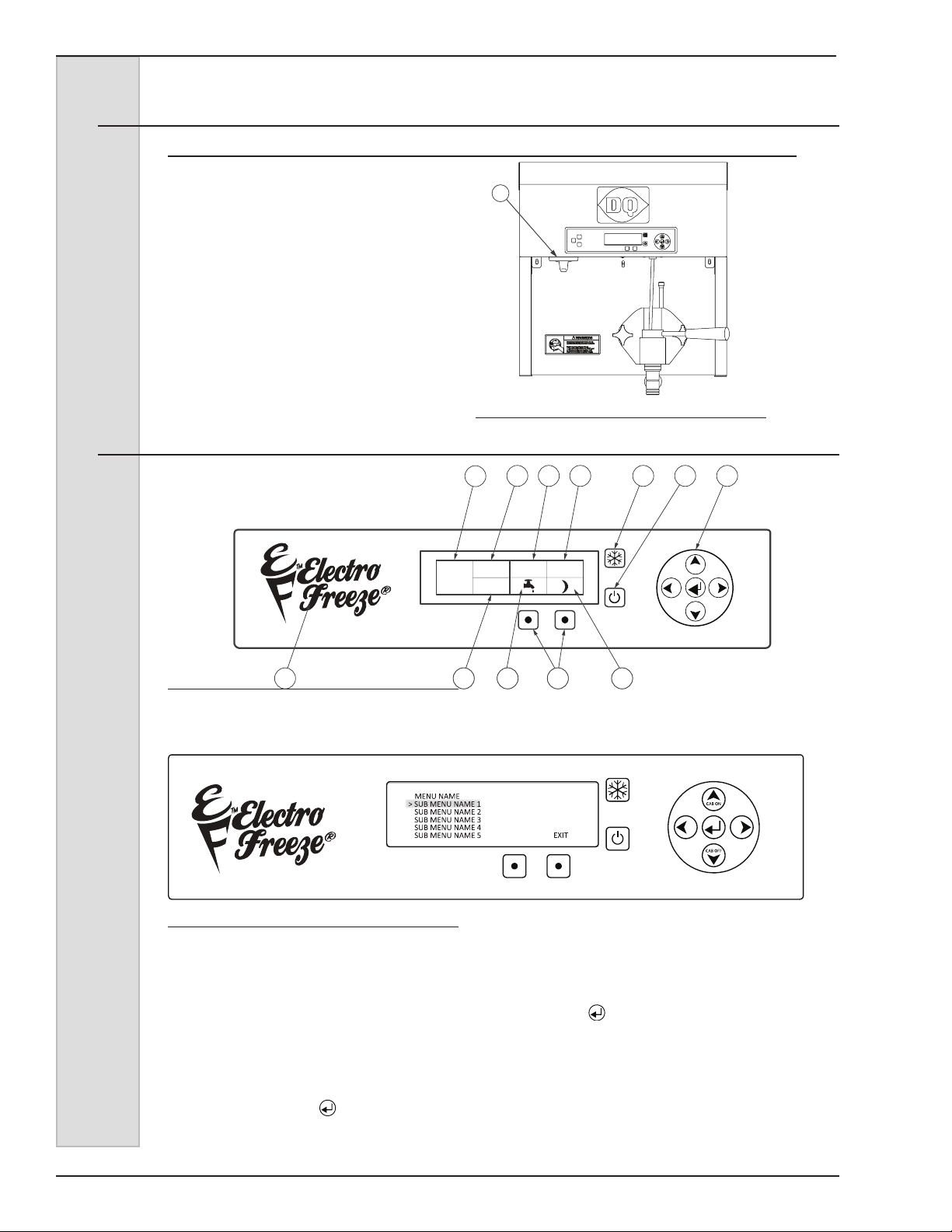

13 Power Switch See Figure 6-3

In the “ON” position, power is supplied

to the beater motors. Use this position

to operate the freezer. Select the ”OFF”

position for disassembly and cleaning.

See Operators Display Menu for use of

this switch in recording cleaning cycles.

13

Figure 6-3

7 Operator Display Menus

1

2 4 75 6

3

CAB ON

CAB OFF

Figure 7-1

CYL

CAB

OFF

37ºF

8

9 10 11 12

OFF

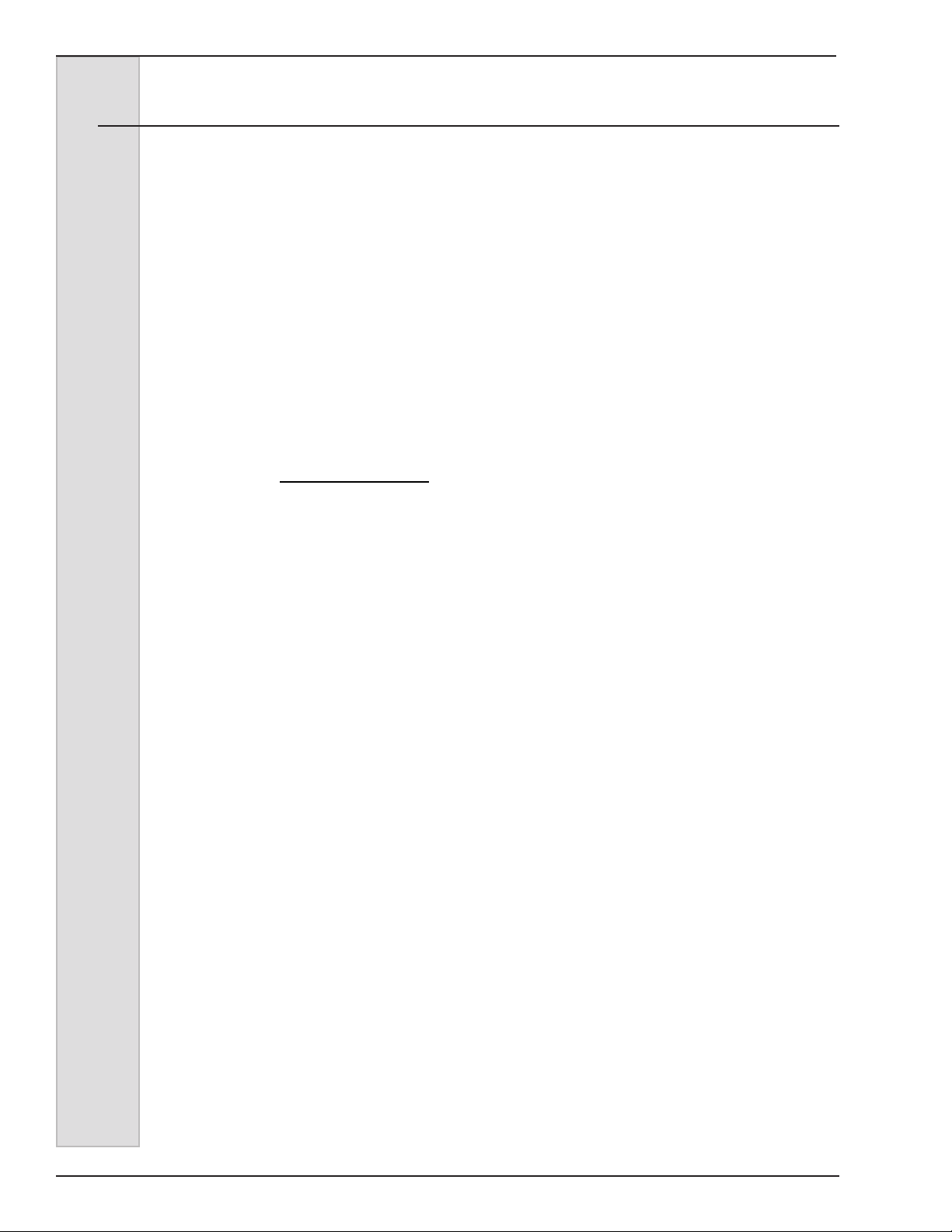

To Enter the Operator Menu, push and hold the hidden key (8) under the F for 3 seconds

(gure 7-1).

Figure 7-2

The operator menu will show up on the screen (gure 7-2). The cursor will highlight the

selected sub-menu (i.e. Basic Setting, Actual Temps, etc.), use the Arrow Buttons to move

the cursor up or down to the desired sub-menu. Once the desired menu is highlighted, in

this example we will use Basic Settings, press the select ( ) button to enter the sub-menu.

Product Type and Temperature Offset will be shown for left and right barrel. Use the Arrow

Buttons to move the cursor to highlight the value to be changed, once highlighted press the

select button and the cursor will now be blinking. While the cursor is blinking the value may

now be changed using the left or right Arrow Buttons, once you have reached the desired

setting press select ( ) one more time, the cursor will now stop blinking, this indicates that

the value change has been stored. Follow these steps to change any other desired settings,

once complete you may use the far right Function button to exit the operator menu or just wait

and the menu will time out and return to the Home screen.

18 185239

Soft Serve Model GEN-101

7 Operator Display Menus

Below is a list of the menu categories that are displayed upon entering the

Operator’s menu.

Operator’s Menu Options

• Basic Settings

• Actual Temps

• Event Log

• Error Log

• Lockouts

• Screen Settings

• Date/Time

• Last Clean

• Software Version

The following information explains more about each of the menu options.

Basic Settings: Information Shown

Product Type: Alt 1 (Preset for DQ Product)

Temperature Offset 1-9 5 is Neutral

Cabinet Temp. 6 is Default setting

Actual Temps: Information Shown

Cabinet Temperature

Cylinder Temperature: Left or Right Cylinder

Event Log: Allows the operator to look at logged events i.e. power switch cycle, low

mix, etc. The log will display the last 50 events with the newest event at

the top.

Error Log: Allows the operator to look at logged errors i.e. Barrel refrigeration

timeout, low/high refrigeration pressure, etc. The log will display the last

50 events with the newest event at the top.

Statistics: Shows the number of starts that the compressor/compressors,

switches and beater motors have seen. Also displays the cumulative

run time in hours for compressors and beater motors.

Information Shown

On Time Left & Right Barrel

Freeze Mode Left & Right Barrel

Standby Mode Left & Right Barrel

Off Left & Right Barrel

Last PWR Fail

All PWR Fail Time

All PWR Fails

Spigot Left & Right Barrel

185239 19

Soft Serve Model GEN-101

7 Operator Display Menus (continued)

Statistics Cont.

Center Spigot

Spigot Hours Left & Right Barrel

C Spigot Hours

Comp. Starts Left & Right Barrel

Comp. Hours Left & Right Barrel

Beater Starts Left & Right Barrel

Beater Hours Left & Right Barrel

Cab Comp. Starts

Cab Comp. Hours

Pump Starts Left & Right Barrel

Pump Hours Left & Right Barrel

Lockouts: Allows the operator to lock out the clean, freeze, and night function

so that on the home screen when the button is pressed the unit will not react.

Information Shown

Freeze Mode Y or N

Clean Mode Y or N

Cab Only Mode Y or N

Cones Left 5

Screen Settings: Operator can turn on or off the following functions:

Display Cabinet Temperature Y or N

(Will or will not display Cabinet temp. on home screen)

Alternate Moon Y or N

Beep Function Y or N

(unit will or will not beep when a button is pressed)

Hide Clock Error Y or N

Date/Time: Allows user to set the Real Time Clock and current date in the unit.

Last Clean: Displays the Last time the unit has been cleaned

Software Versions: Has current software version numbers for both the U.I. and

Main board

Main ———

U.I. ————

Model GEN

Cyl Count 2

Compressors 2

Hopper Y or N

Cabinet Y or N

Product Table GEN or SLX

Cabinet Temperature Map for user adjustment. User will only see 1 through 9 but the

table below shows the differences with each number change. 6 is default setting

20 185239

Soft Serve Model GEN-101

7 Operator Display Menus (continued)

CAB

OFF

CYL

OFF

CAB ON

37ºF

CAB OFF

Press to start

PRESS TO START

CLEAN MODE

clean mode

CAB

OFF

37

º

F

CYL

BEATER

ON OFF

Press to

turn

beater on

PRESS

TO TURN

BEATER ON

Clean

PUMP

ON OFF

Press to

turn

pump on

PRESS TO

TURN

PUMP ON

CAB ON

CAB OFF

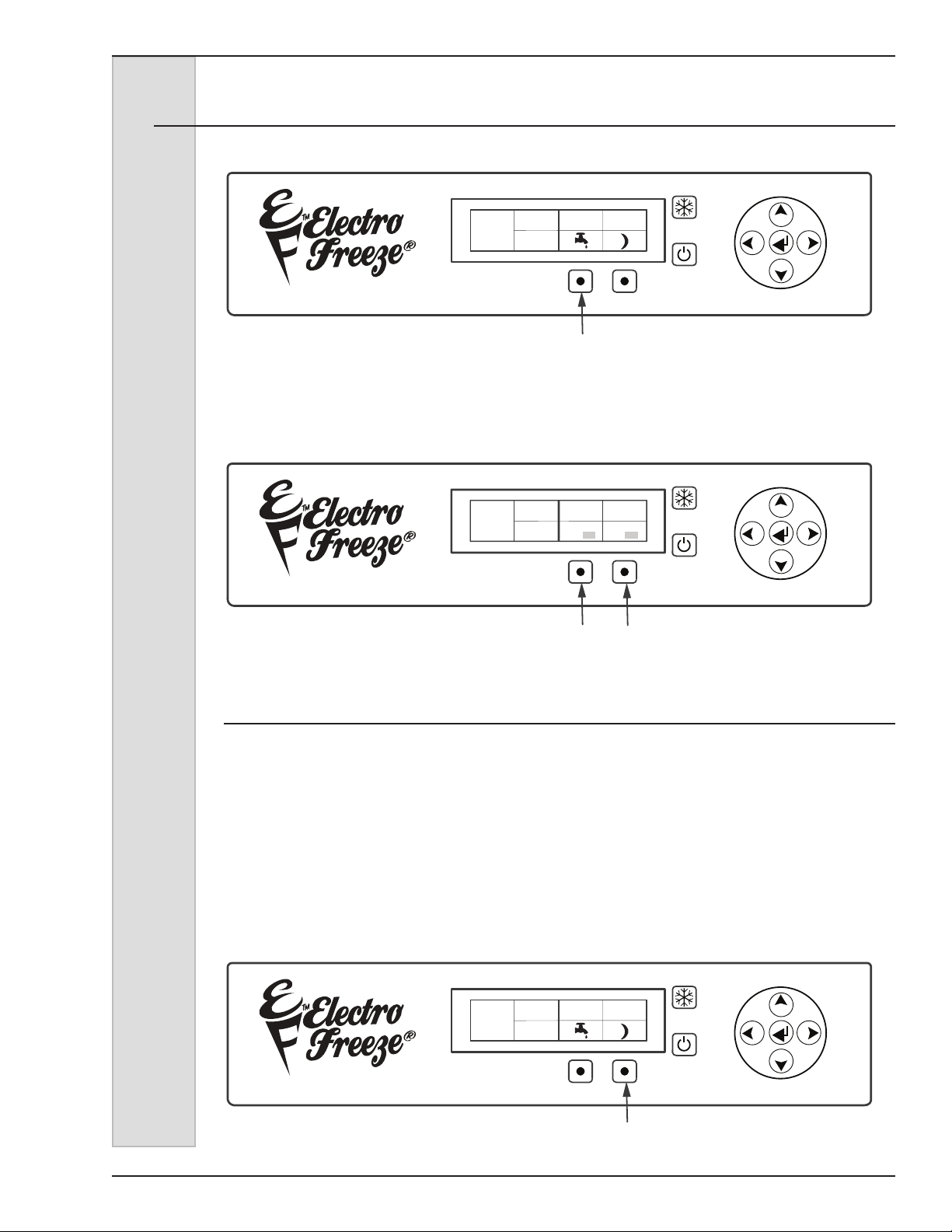

Night Mode Operation

As pictured below, the Soft Key located below the image of the Moon will allow the machine

to be switched into NIGHT refrigeration mode. This feature is used at the closing of the

day’s business to hold the product at safe storage temperatures but not in a frozen state.

PLEASE NOTE: Dairy Queen allows the Night mode to be used for 72 Hours before

the machine MUST be disassembled and cleaned per instructions in this manual.

During the use of the NIGHT mode, the computer will monitor the system and maintain

a mix holding temperature of 36°F (2.2°C) or below. The beater will cycle throughout this

mode to maintain product circulation through the dispensing head.

CYL

CAB

OFF

OFF

37ºF

Press to start

PRESS TO START

NIGHT MODE

night mode

185239 21

CAB ON

CAB OFF

Loading...

Loading...