ELECTRO FREEZE CS700-FG Operator's Manual

OPERATOR’S MANUAL

with Illustrated Parts List

COMPACT SERIES

SHAKE FREEZER

Model CS700-FG

185231 - 2/14

H. C. Duke & Son, LLC P/N 185231 - November 2015 Printed in U.S.A.

Operator’s Manual

for the

Electro Freeze Model CS700-FG

Compact Series

Shake Freezer

All contents © Copyright 2015 H.C. Duke & Son, LLC, 2116 Eighth Avenue, East Moline, Illinois 61244

i

ELECTRO FREEZE Shake Model CS700-FG

SAFETY FIRST!

Follow these four steps to safety ....

1. Recognize Safety Information ....Look for this

safety alert symbol throughout this manual.

When you see this symbol on your freezer or in

this manual, be alert to the potential for personal

injury. Follow recommended precautions and safe

operating practices.

2. Understand Signal Words ....

The signal words — DANGER, WARNING

DANGER

WARNING

CAUTION

and CAUTION — are used with the safety alert

symbol (DANGER decals on the freezer may or

may not have the safety alert symbol, but the

message is the same). Decals with the words

DANGER, WARNING or CAUTION appear on

the freezer. DANGER identies the most serious

hazard. Decals with the words DANGER or

WARNING are typically near specic hazards

on the freezer. General precautions are listed on

CAUTION safety decals.

In this manual, CAUTION messages with the

safety alert symbol call attention to safety

messages.

ii

ELECTRO FREEZE Shake Model CS700-FG

SAFETY FIRST!

3. Follow Safety Instructions ....

Read and understand all safety messages in

this manual. Read and understand the decal

safety messages on your freezer. Take notice

of the location of all decals on the freezer and

keep the safety decals in good condition. Check

them periodically and replace missing, damaged

or illegible safety decals. The safety decals

must remain in place and legible for the life of

the freezer. If you need new decals, use the

information and illustrations on pages iv and v

of this manual to identify the decal and order

replacement parts.

DO NOT attempt to operate the CS700 freezer

until you read and understand all safety messages

and the operating instructions in this manual.

4. Operate Safely ....

DO NOT allow untrained personnel to maintain

or service this machine. Failure to follow this

instruction may result in severe personal injury. DO

NOT operate the freezer unless all service panels

and access doors are secured with screws. DO

NOT attempt to maintain or repair the freezer until

the main power supply has been disconnected.

Contact your local Electro Freeze Distributor for

authorized service.

iii

ELECTRO FREEZE Shake Model CS700-FG

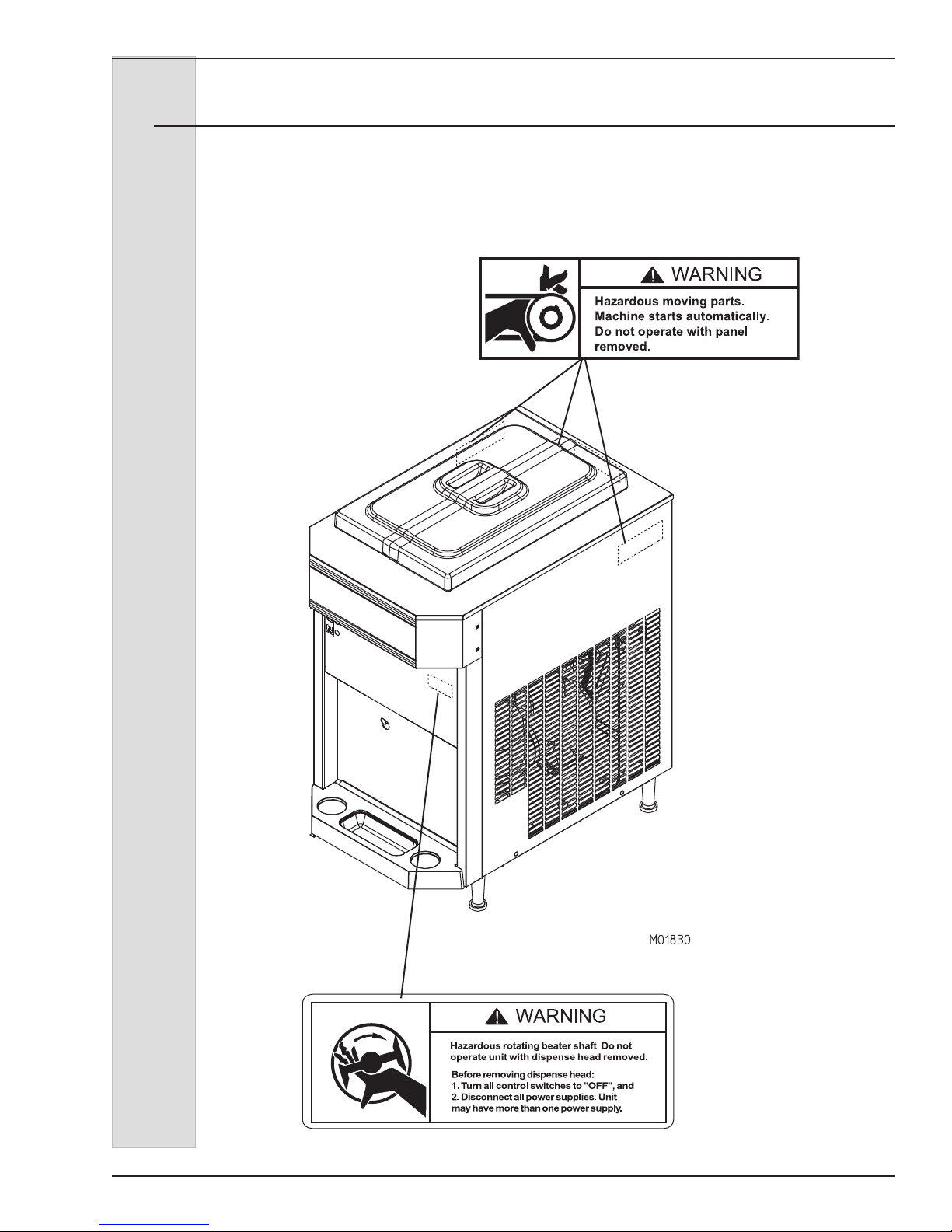

Safety Decal Locations

Do not attempt to operate the freezer

until all safety precautions and operating

instructions in this manual are read and

understood.

Take notice of all warning, caution,

instruction and information decals (or

labels) on the freezer as shown in the

gure on the following page. The labels

have been put there to help maintain a

safe working environment.

The labels have been designed to

withstand washing and cleaning. All

labels must remain legible for the life of

the freezer. Check labels periodically

to be sure they can be recognized as

warning labels.

If it is necessary to replace any label,

please contact your local authorized

Electro Freeze Distributor or H. C. Duke &

Son. When ready to order you will need to

determine the (1) part number, (2) type of

label, (3) location of label, and (4) quantity

required, and include a return shipping

address.

You may contact your local authorized

Electro Freeze Distributor, as follows:

Name:

Address:

Phone:

or — for factory service assistance —

contact H. C. Duke & Son, LLC. Electro

Freeze Service Department by phone or

FAX:

Phone: 309-755-4553

800-755-4545

FAX: 309-755-9858

E-mail: service@electrofreeze.com

(The decals on the next page are

numbered 1 and 2. Those numbers

correspond to the numbers in the table

below. The table provides the part

number, description, and quantity for each

decal.)

No. Part No. Description (Qty)

1 HC165126 Decal — Panel Removal Warning (3)

2 HC165025 Decal — Beater Warning (1)

iv

ELECTRO FREEZE Shake Model CS700-FG

Safety Decal Locations

1 P/N HC165126

2 P/N HC165025

v

ELECTRO FREEZE Shake Model CS700-FG

Table of Contents

SECTION DESCRIPTION PAGE

SAFETY ...........................................................................................ii

SAFETY DECALS LOCATIONS ............................................ iv

PART I

1. INTRODUCTION .............................................................................1

2. NOTE TO INSTALLER ...................................................................1

2.1. Electrical Requirements .................................................................2

3. SPECIFICATIONS ...........................................................................2

3.1 Particulars. ......................................................................................2

3.2 ...................................................................................Data Plate

3

3.3 Reference Information .....................................................................3

3.4 Installation Date ..............................................................................4

3.5 Dimensions. .....................................................................................5

4. PART NAMES AND FUNCTIONS .............................................6

5. OPERATOR CONTROLS & INDICATORS .................. 10

5.1 Selector Switch .............................................................................11

5.2 Reset -Circuit Breaker ...................................................................11

5.3 Indicator Light “ADD MIX” .............................................................11

5.4 Indicator Light “MIX OUT” ..............................................................11

5.5 Mix Float ........................................................................................11

6. DISASSEMBLY AND CLEANING ...........................................12

6.1 Accessories ..................................................................................12

6.2 Disassembly Instructions ...............................................................13

6.3 Cleaning Instructions ....................................................................15

7. ASSEMBLY .......................................................................................17

8. START-UP INSTRUCTIONS .....................................................20

8.1 Sanitizing ......................................................................................20

8.2 Priming .........................................................................................21

vi

ELECTRO FREEZE Shake Model CS700-FG

Table of Contents - continued

SECTION DESCRIPTION PAGE

9. CLOSING PROCEDURES ........................................................ 22

9.1 End of Day Operation ....................................................................... 22

9.2 Draining Product From Freezer ........................................................ 23

10. PRODUCT INFORMATION ............................... 24

10.1 Overrun ........................................................................................ 24

10.2 Rerun ............................................................................................24

11. SPINDLE MIXER (OPTIONAL) .......................... 25

11.1 Preparation .................................................................................. 25

11.2 Cleaning and Sanitizing - Spindle Mixer ........................................ 25

11.2.1 Daily Cleaning ...................................................................25

11.2.2 Daily Sanitizing ..................................................................26

11.3 Operation-Spindle Motor ...............................................................26

12. ROUTINE MAINTENANCE ............................................ 27

13. TROUBLESHOOTING TABLE .......................... 31

PART II

MODEL CS700 REPLACEMENT PARTS WITH ILLUSTRATIONS *

* Refer to Part II Table of Contents for help with locating part numbers and illustrations.

vii

ELECTRO FREEZE Shake Model CS700-FG

1 Introduction

This freezer is designed to produce

milkshakes with a temperature range of

24° to 30°F (-4° to -1°C). If such products

are prepared from powdered concentrate,

they should be precooled to 38°F (3°C)

prior to introduction to the freezer. Use

of other products in this machine is

considered misuse (see Warranty).

This manual has been prepared to assist

you in the proper operation and general

maintenance of the H.C. Duke & Son,

LLC. Model CS700 Freezer.

Your freezer will not compensate for or

correct any assembly or priming errors

made during the initial start-up. Therefore,

it is important to follow the assembly

and priming procedures detailed in this

manual.

Make sure all personnel responsible for

equipment operation completely read and

understand this manual before operating

the freezer. When properly operated and

maintained, the freezer will produce a

consistent quality product.

If you require technical assistance, please

contact the factory service department at

H.C. Duke & Son, LLC. as follows:

Name _________________________

Address________________________

_______________________________

Phone__________________________

Phone: (309) 755-4553

(800) 755-4545

Fax: (309) 755-9858

E-mail: service@hcduke.com

2 Note to Installer

This freezer must be installed and

serviced by an Electro Freeze Distributor

or authorized service technician

in accordance with the installation

instructions in this manual.

Verify the weight of the freezer. Ensure

a counter or table of sufcient strength

is used to hold this weight and prevent

excessive vibration.

Air cooled models require a minimum of

3-inches (7.6 cm) air space on both sides

and back of the freezer for adequate

ventilation.

Freezer is equipped with a deector plate

that will need to be mounted. Facing

the front of the freezer the plate will

be mounted on the screws on the left

side panel. The deector is required to

prevent air from recirculating back to the

freezer. Failure to install deector will void

warranty.

If this freezer is to be used in a selfservice application, it is recommended

that the machine be tted with a self-

service kit. Contact your Electro Freeze

Distributor or H. C. Duke & Son, LLC. for

this kit.

Test the operation of the head switch

prior to placing the freezer in service.

See Section 11, Routine Maintenance,

Monthly.

After installation the warranty registration

card must be completed and returned to

validate the warranty.

185231-17

1

ELECTRO FREEZE Shake Model CS700-FG

2.1 Electrical Requirements

CAUTION

All materials and

connections must conform

to local requirements and

be in compliance with the

National Electric Code (NEC).

CAUTION

To prevent accidental

electrical shock, a receptacle

with a positive earth ground

is required.

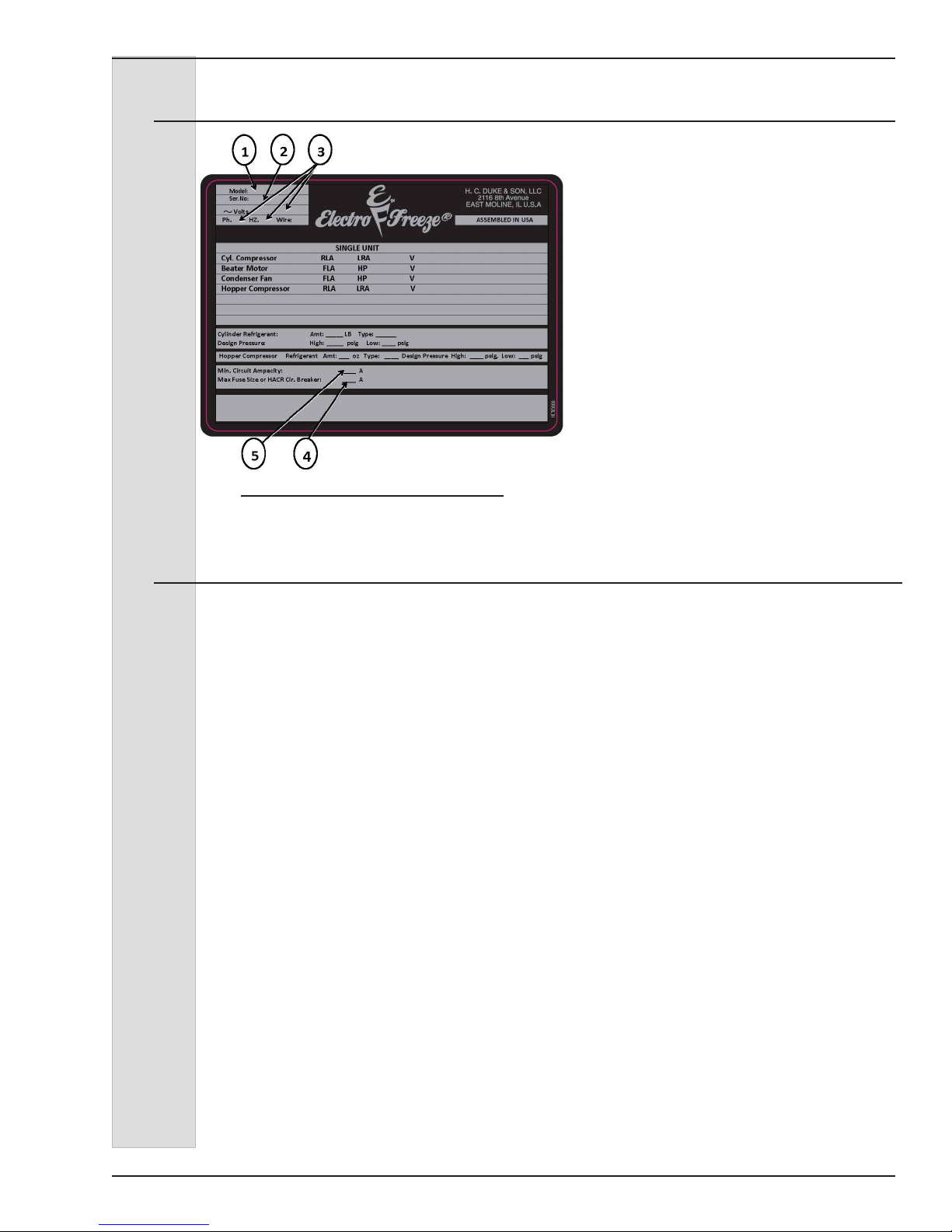

1. Always verify electrical

specications on the data plate (gure

3-2) of each individual freezer. Data plate

specications will always supersede the

information in this manual.

2. This freezer requires a protected

20 amp 230 volt circuit. Connect the

freezer to a circuit separate from any

other electrical equipment. The power

cord on this freezer connects to a NEMA

6-20R receptacle. See Figure 2-1.

3. Supply voltage must be within

±10% of voltage indicated on the

nameplate. Request your local power

company to correct any voltage problem.

4. The transformer in the electrical

box is factory wired for 240 volts. This

connection maybe used for all voltages

above 200 volts. If the power supply

is less than 200 volts, move the L2

transformer wire connector to the 208 volt

connector.

Figure 2-1

3 Specifications

3.1 Particulars

Width (in/cm) 18.4/46.7

Height (in/cm) 35.2/89.4

Depth (in/cm) 28.1/71.4

Weight (lbs/kg) 220/99.8

Voltage* 208-230/60/1

Min.Circuit Ampacity 20.0

Compressor 1 HP/8000 (BTUH)

.75 kw (Motor)

2.3 kw (Cooling)

Beater Motor 1/2 HP/.37 kw

Refrigerant R-404a

2

Charge 32.0 oz/.91 kg

Cooling Air

Hopper 20 qts/18.8 liters

Cylinder 7 qts/7.1 liters

*Contact factory for other voltages.

185231-17

ELECTRO FREEZE Shake Model CS700-FG

3.2 Data Plate

Figure 3-1

The data plate provides important

information that the operator should

record and have available for parts

ordering, warranty inquiries and service

requests.

3.3 Reference Information

Write in Reference

Information HERE!

Fill in the following information as soon as

you receive the Electro Freeze CS700-FG.

(The item numbers — encircled, below —

correspond with the callout numbers in

gure 4-1.)

1.) Model Number: _________________

2.) Serial Number:__________________

3.) Electrical Spec: Voltage ________

4.) Phase _______ Hertz _________

5.) Maximum Fuse Size: ____________

6.) Minimum Circuit Ampacity: _______

185231-17

3

ELECTRO FREEZE Shake Model CS700-FG

3.4 Installation Date

Fill in the date of installation, and the name, address, and phone number of the

installer in the space provided below. This information will be needed when ordering

parts or service for the CS700-FG Freezer.

Date of installation: _____________________________________

Installed by: _____________________________________

Address: _____________________________________

_____________________________________

Phone: _____________________________________

4

185231-17

ELECTRO FREEZE Shake Model CS700-FG

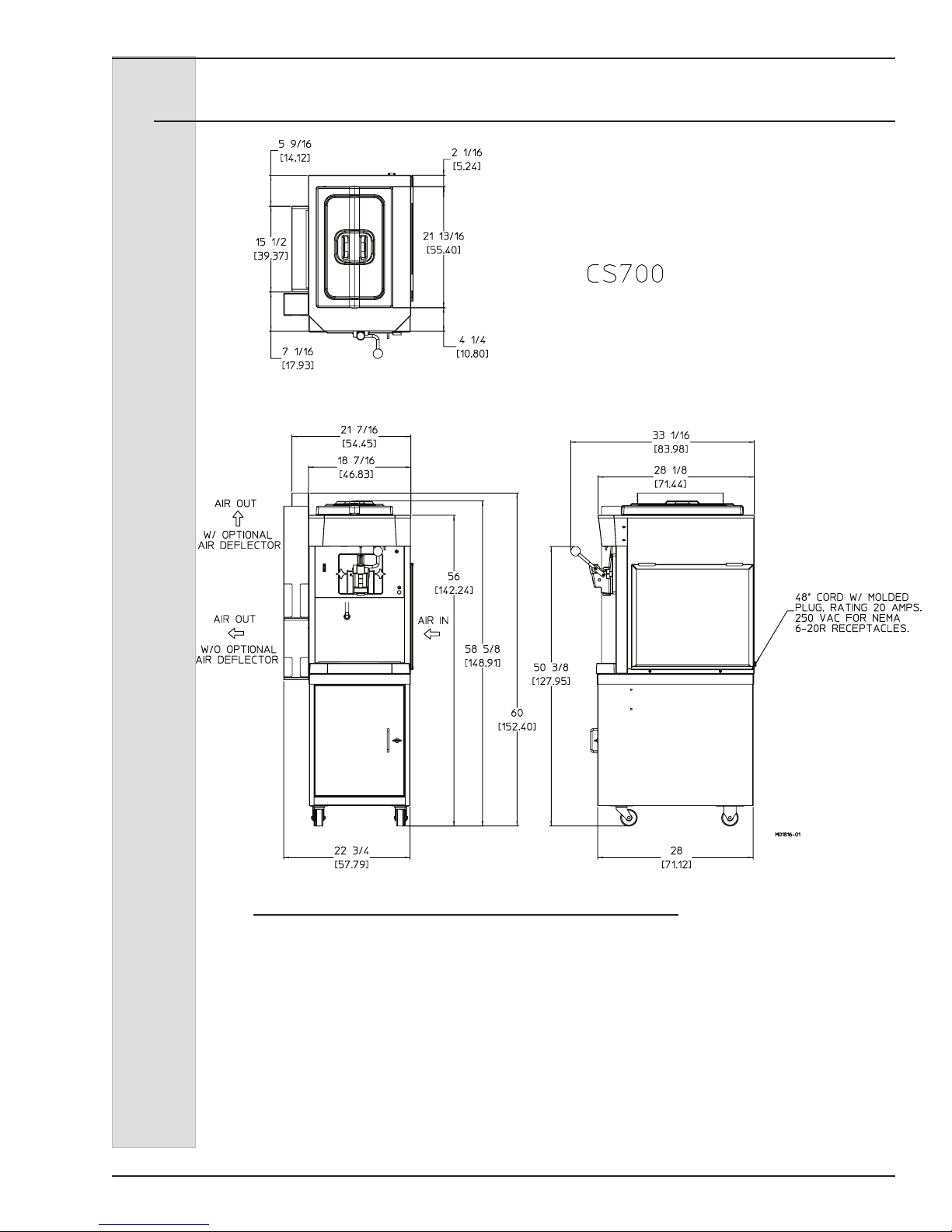

3.5 Dimensions

Figure 3-2 Electro Freeze Model CS700 Dimensions

185231-17

5

ELECTRO FREEZE Shake Model CS700-FG

4 Part Names and Functions

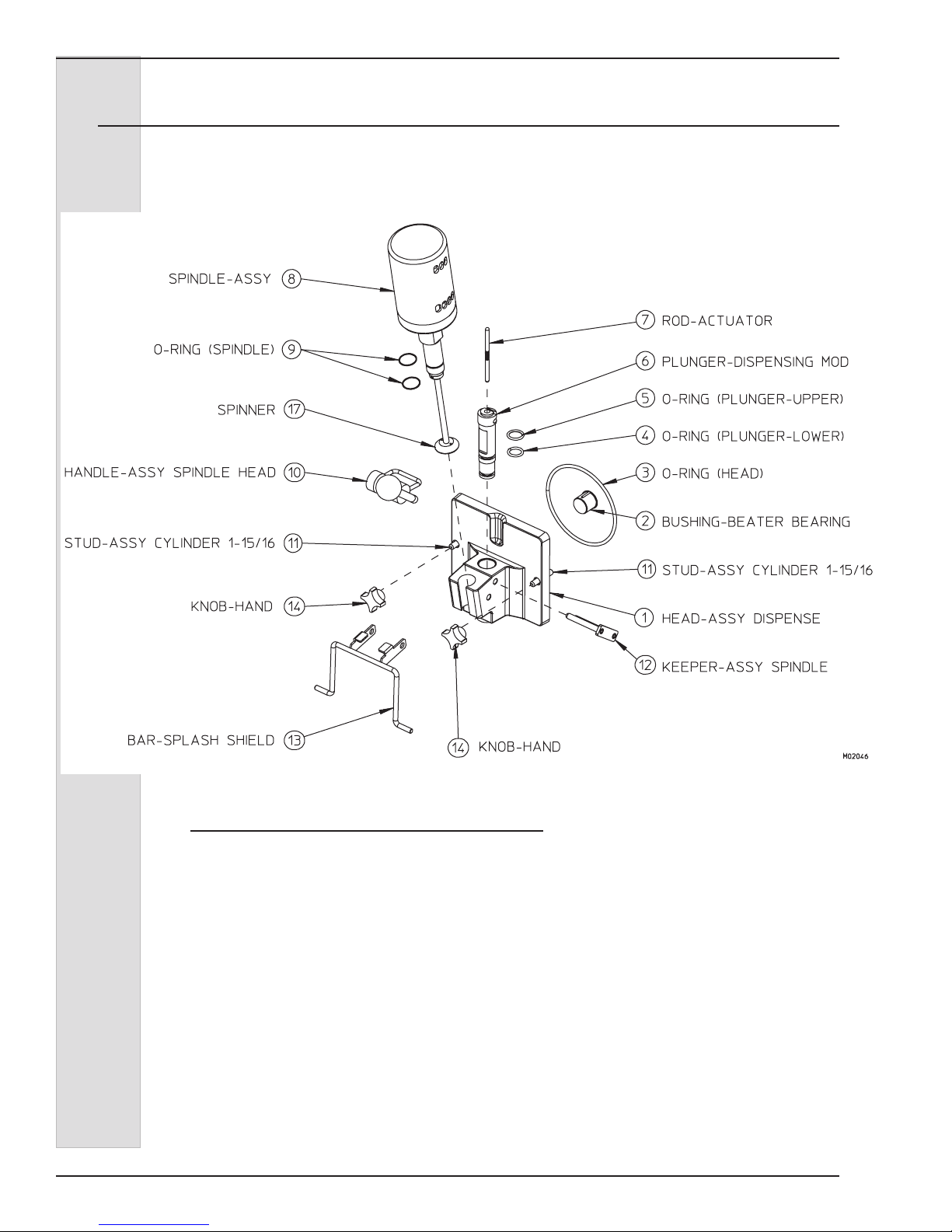

Figure 4-1 Head Assembly

6

185231-17

ELECTRO FREEZE Shake Model CS700-FG

4 Part Names and Functions — continued

The following part names and descriptions refer to gure 4-1.

1.) HEAD - ASSY. DISPENSE: Encloses

the freezing cylinder and provides an

opening for product to be dispensed.

2.) BUSHING - BEATER BEARING:

Holds the beater in place at the front of

the cylinder. Must be inserted into the

head and lubricated before assembly.

3.) O-RING - HEAD: Seals the head

to the freezing cylinder. Must be

lubricated.

4.) O-RING - PLUNGER LOWER: Seals

the plunger in the head. Must be

lubricated to seal and slide properly.

5.) O-RING - PLUNGER UPPER: Seals

the plunger in the head. Must be

lubricated to seal and slide properly.

6.) PLUNGER: Seals the product opening

in the head when closed. Allows product

to ow when open.

7.) ROD - ACTUATOR: Starts the freezer

when dispensing. Must be in place

before freezer will operate.

8.) SPINDLE - ASSY.: Mixes the shake

as it is dispensed.

9.) O-RING - SPINDLE: Holds the spindle

or pivot post in place.

10.) HANDLE - DISPENSE: Opens and

closes the plunger to start and stop the

ow of product from the freezer.

11.) STUD - ASSY.: Hand knobs screw on

studs to hold head assembly in place.

12.) KEEPER: Secures the handle to the

head.

13.) BAR-SLASH SHIELD:

splash shield to the dispense head.

14.) KNOB - HAND: Secures the head to

the freezing cylinder.

185231-17

Attaches the

7

ELECTRO FREEZE Shake Model CS700-FG

T

4. Part Names and Functions — continued

4

WASHER - BEATER SHAFT

3

SEAL CUP- BEATER SHAFT

BEATER - ASSY.

1

SHAKE SHORT

2

BLADE - SHAKE SCRAPER

SEAL CUP- BEATER SHAF

3

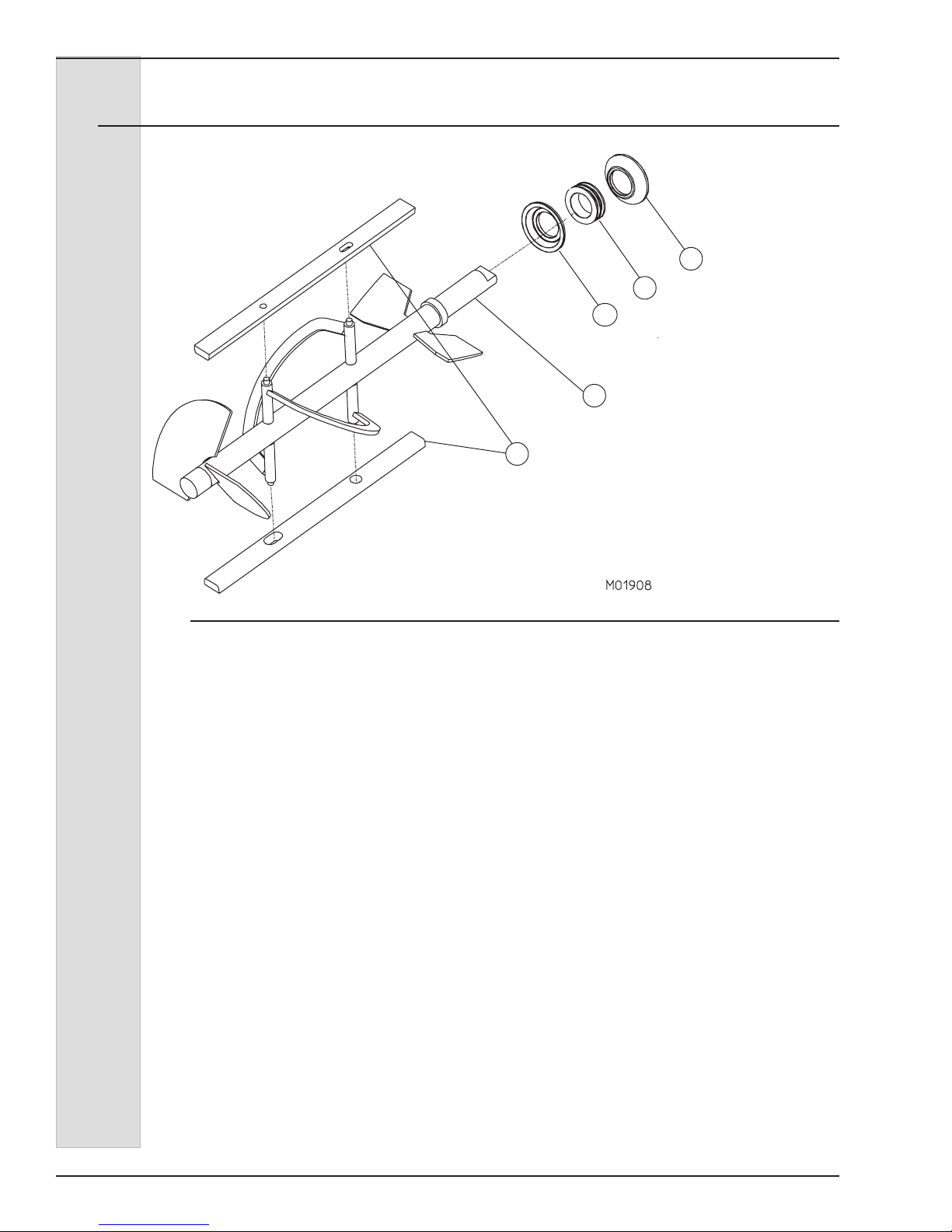

Figure 4-2 Beater Shaft

The following part names and descriptions refer to gure 4-2.

1.) SHAFT-BEATER:

Rotates in the

freezing cylinder, blending air and

mix and ejecting product.

2.) BLADE-SCRAPER:

Scrapes the

frozen product from the freezing

cylinder wall.

3.) SEAL (CUP) - BEATER SHAFT:

Seals the opening between the

freezing cylinder and the beater. DO

NOT LUBRICATE.

4.) WASHER - SHAFT SEAL:

Holds

the shaft seals together. Must be

lubricated.

8

185231-17

ELECTRO FREEZE Shake Model CS700-FG

4. Part Names and Functions — continued

O-Ring

Tube-Mix Feed

Insert-Assy. Mix

Feed

O-Ring

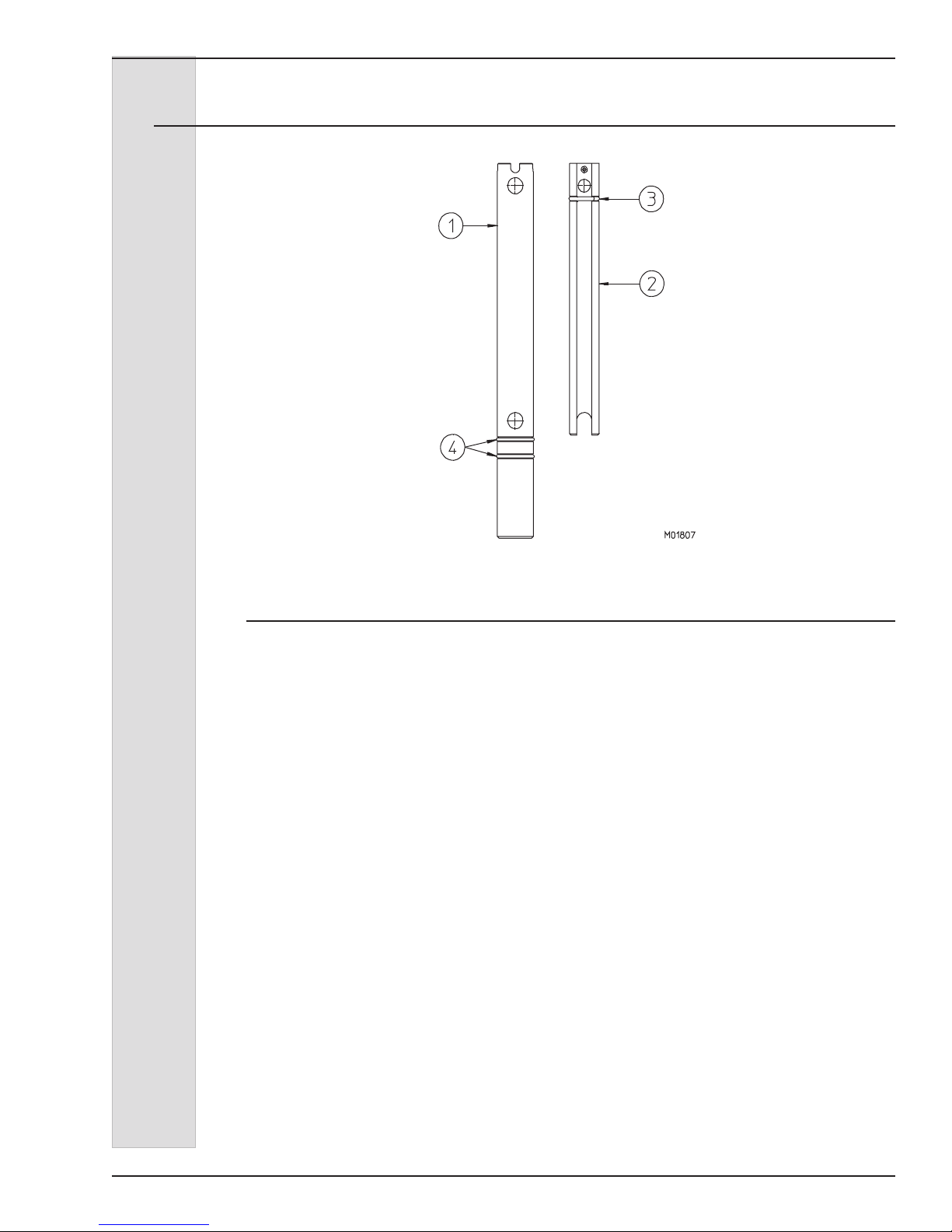

Figure 4-3 Mix Feed Tube

The following part names and descriptions refer to gure 4-3.

1.) TUBE-MIX FEED: Meters the correct

amount of mix and air into the freezing

cylinder from the hopper.

2.) INSERT- MIX FEED: Meters the correct

amount of mix and air into the freezing

cylinder from the hopper.

3.) O-RING - MIX FEED TUBE: Seals the

opening between the mix feed tube and

mix feed tube insert.

4.) O-RING-MIX FEED TUBE: Seals

the opening between the hopper and

mix feed tube. O-rings do not need

lubrication.

185231-17

9

ELECTRO FREEZE Shake Model CS700-FG

5 Operator Controls

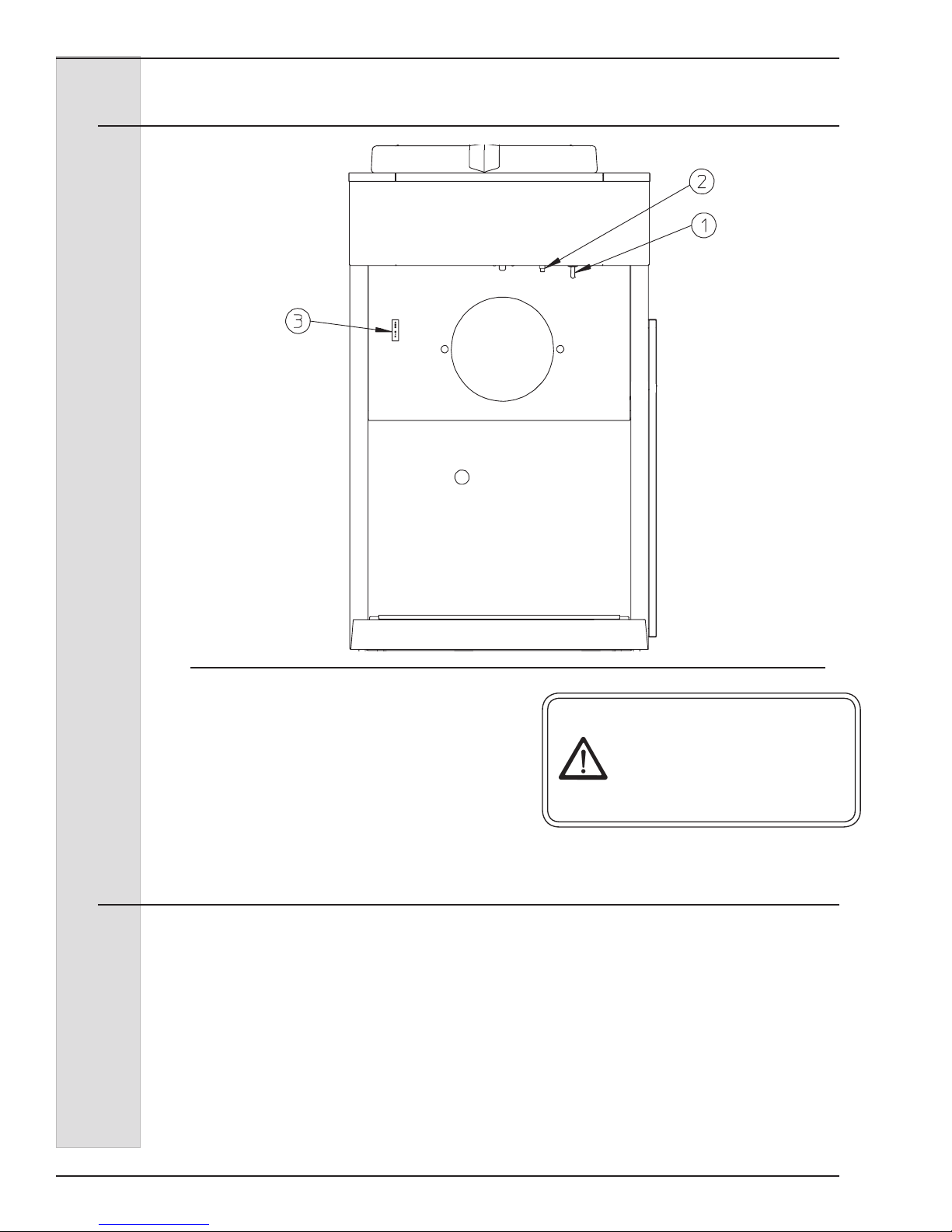

Figure 5-1

The following paragraphs describe the

operator controls and indicators. Refer to

gure 5-1 for location of these controls

and indicators on the freezer.

NOTE: The head and actuator rod must

be in place before the beater will operate.

5.1 Selector Switch (1)

This three-position switch controls the

operating mode of your freezer.

a. “CLEAN” (left) — This

position operates the beater only (no

refrigeration). Always use this mode

when performing cleaning and sanitizing

operations.

b. “OFF” (center) — In this

position the beater motor and refrigeration

system will not operate.

CAUTION

Test operation of the head

switch prior to placing

the freezer in service.

See Section 11, Routine

Maintenance, Monthly.

Important:

Do not use the “AUTO” position with

water or sanitizer in the cylinder — the

freezer will be damaged.

c. “AUTO” (right) — This

position activates both the beater motor

and refrigeration unit. This is the normal

operating position which will maintain a

cylinder temperature of 26° to 28°F (-3° to

-2°C).

—continued

10

185231-17

ELECTRO FREEZE Shake Model CS700-FG

5 Operator Controls — continued

5.2 Reset — Circuit Breaker (2)

This control protects the beater motor

against failure from an overload condition

by automatically shutting down the

freezer. To restart properly, turn the

SELECTOR switch to “OFF”, wait 2-3

minutes, then depress the reset button

and turn the SELECTOR switch back to

the “AUTO” or “CLEAN” position.

Important:

If the circuit breaker trips frequently,

your freezer should be checked for

proper product temperature, overrun

and voltage. Contact your Electro

Freeze Distributor.

5.3 Outlet Spindle (3)

This 220v receptacle provided in the

electrical box accepts the spindle cord.

5.4 Indicator- Light — “ADD MIX” (4)

This light indicates the mix in the mix

hopper is at a low level and should be

relled as soon as possible. Always

maintain at least 2 inches (5.1 cm) of mix

in the hopper. For best operating results

keep hopper full.

5.5 Spindle Auxiliary Switch (5)

This push-button, when depressed, will

activate the spindle motor for additional

mixing of shake or during cleaning.

5.6 Mix Float (not shown)

When this oat is mounted on the

oat stem inside the mix hopper it

automatically senses the mix level. It

activates the “Add Mix” light.

185231-17

11

Loading...

Loading...