Page 1

T-34 Mentor 25 ePTS

Assembly Manual

Specifications

Wingspan: 55 in (1575mm)

Length: 44 in (1110mm)

Wing Area: 545 sq in 34.9 sq dm)

Weight w/ Battery: 4.4–4.5 lb (1.9–2.0 kg)

Weight w/o Battery: 5.0–5.2 oz (2.2–2.3 kg)

Page 2

Table of Contents

Introduction

Specifications ...................................................................... 1

Introduction ......................................................................... 2

Using the Manual ................................................................ 2

Contents of Kit/Parts Layout ................................................. 3

Required Tools and Adhesives .............................................. 3

Optional Accessories ........................................................... 3

Warranty Information .......................................................... 4

Note on Lithium Polymer Batteries ........................................ 6

Warning ............................................................................. 6

Safety, Precautions, and Warnings ....................................... 6

Wing and Landing Gear Assembly ...................................... 7

Tail Installation ..................................................................10

Battery and Wing Installation ............................................. 13

Centering the Control Surfaces and

Checking Control Direction ...................................... 15

Setting the Control Throws ................................................. 22

General Maintenance ........................................................ 25

Positioning the Flaps .......................................................... 27

Removing the NACA Wing Droops .................................... 28

Operational Flap Installation (Optional) .............................. 29

Center of Gravity .............................................................. 34

Range Test Your Radio ....................................................... 34

Instructions for Disposal of WEEE by

Users in the European Union ................................... 34

Preflight ............................................................................ 35

Li-Po Battery Pack Information ............................................ 35

2008 Official AMA National Model Aircraft Safety Code ... 38

Optional Items for Your T-34 Mentor ................................... 39

For decades, the T-34 has been the airplane in which nearly all

U.S. Navy, Marine, and Coast Guard aviators have earned their

wings of gold. Based upon the civilian Model 35 Bonanza, the

all-metal T-34 has been rugged and reliable, enduring countless

loops, rolls, stalls and hard landings at the hands of student pilots

throughout the years.

And now, E-flite provides you with the most advanced electric

training aircraft in the RC world. ePTS™ stands for Electric

Progressive Trainer System—an airplane that will allow you to go

from training to aerobatics without upgrading or purchasing a

new plane.

This warbird comes ready-to-fly—no building is required and

everything needed to fly is included. The T-34 Mentor sports

removable NACA droops and a progressive 3-position flap

system to provide extra stability and slow flying. Master the

basics, remove the droops, and change flap position to move up

to great sport performance and mild aerobatics.

Progress from student pilot to aerobatic performer with E-flite’s

T-34 Mentor 25 ePTS RTF.

Using the Manual

This manual is divided into sections to help make assembly

easier to understand, and to provide breaks between each major

section. In addition, check boxes have been placed next to each

step to keep track of each step completed. Steps with a single

circle () are performed once, while steps with two circles ( )

indicate that the step will require repeating, such as for a right or

left wing panel, two servos, etc.

Remember to take your time and follow the directions.

2 E-flite T-34 Mentor ARF Assembly Manual

Page 3

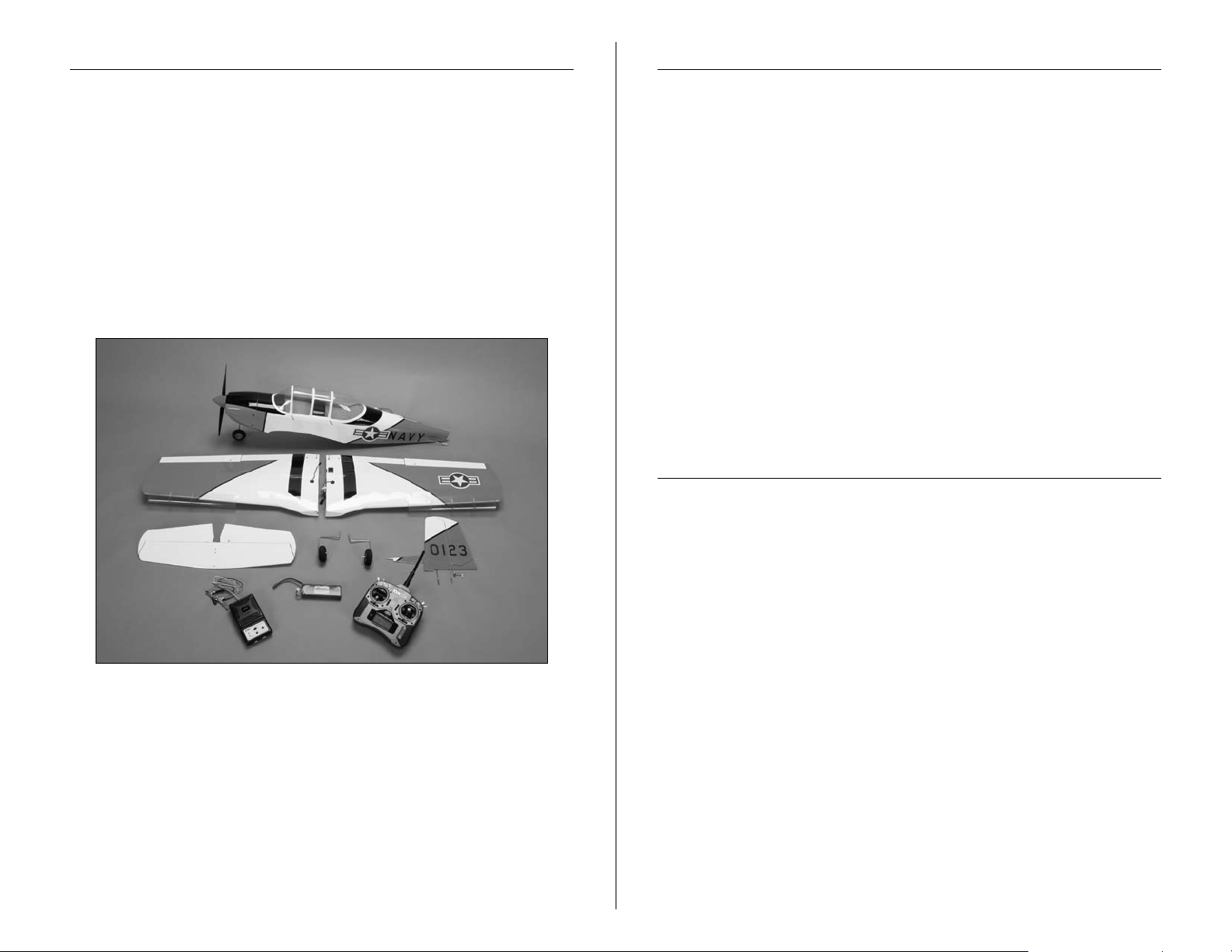

Contents of Kit/Parts Layout

Required Tools and Adhesives

Large Parts:

EFL4801 Wing Set w/Ailerons

EFL4802 Fuselage

EFL4803 Tail Set

EFL4804 Cowling

EFL4805 Fuselage Hatch

EFL4806 Pushrod Set

EFL4807 Landing Gear

EFL4808 Spinner

EFL4809 Tail Cone

EFLP12080E 12x8 Electric Propeller

Tools & Equipment

EFLA250 Park Flyer Tool Assortment, 5-piece

Or Purchase Separately

EFLA257 Screwdriver, #1 and #2 Phillips

(or included with EFLA250)

Covering iron

Adjustable wrench

Pin drill

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

Flat blade screwdriver

Phillips screwdriver: #1, #2

Medium CA

Threadlock

Hex wrench: 2.5mm

Ruler

Optional Accessories

EFLA110 Power Meter

EFLC3005 Celectra

EFLC505 Intelligent 1- to 5-Cell Balancing Charger

EFLB32003S 3200mAh 3S 11.1V 20C Li-Po Battery

APC12080E 12x8 Elecrtic Prop

JSP20050 ST47 Standard Servo

SPM6805 Trainer Cord

DYN4055 12-Volt, 10-Amp Power Supply

™

1- to 3-Cell Li-Po Charger

3E-flite T-34 Mentor ARF Assembly Manual

Page 4

Warranty Information

Warranty Period

Horizon Hobby, Inc., (Horizon) warranties that the Products purchased

(the “Product”) will be free from defects in materials and workmanship

at the date of purchase by the Purchaser.

Limited Warranty

(a) This warranty is limited to the original Purchaser ("Purchaser") and

is not transferable. REPAIR OR REPLACEMENT AS PROVIDED UNDER

THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER.

This warranty covers only those Products purchased from an

authorized Horizon dealer. Third party transactions are not covered

by this warranty. Proof of purchase is required for warranty claims.

Further, Horizon reserves the right to change or modify this warranty

without notice and disclaims all other warranties, express or implied.

(b) Limitations- HORIZON MAKES NO WARRANTY OR

REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT

THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE

PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon's sole obligation hereunder

shall be that Horizon will, at its option, (i) repair or (ii) replace, any

Product determined by Horizon to be defective. In the event of a

defect, these are the Purchaser's exclusive remedies. Horizon reserves

the right to inspect any and all equipment involved in a warranty

claim. Repair or replacement decisions are at the sole discretion of

Horizon. This warranty does not cover cosmetic damage or damage

due to acts of God, accident, misuse, abuse, negligence, commercial

use, or modification of or to any part of the Product. This warranty

does not cover damage due to improper installation, operation,

maintenance, or attempted repair by anyone other than Horizon.

Return of any goods by Purchaser must be approved in writing by

Horizon before shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCT, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE, OR STRICT LIABILITY. Further, in no

event shall the liability of Horizon exceed the individual price of the

Product on which liability is asserted. As Horizon has no control over

use, setup, final assembly, modification or misuse, no liability shall be

assumed nor accepted for any resulting damage or injury. By the act

of use, setup or assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept the liability

associated with the use of this Product, you are advised to return this

Product immediately in new and unused condition to the place of

purchase.

Law: These Terms are governed by Illinois law (without regard to

conflict of law principals).

Safety Precautions

This is a sophisticated hobby Product and not a toy. It must be

operated with caution and common sense and requires some basic

mechanical ability. Failure to operate this Product in a safe and

responsible manner could result in injury or damage to the Product or

other property. This Product is not intended for use by children without

direct adult supervision. The Product manual contains instructions for

safety, operation and maintenance. It is essential to read and follow

all the instructions and warnings in the manual, prior to assembly,

setup or use, in order to operate correctly and avoid damage or

injury.

4 E-flite T-34 Mentor ARF Assembly Manual

Page 5

Questions, Assistance, and Repairs

Non-Warranty Repairs

Your local hobby store and/or place of purchase cannot provide

warranty support or repair. Once assembly, setup or use of the

Product has been started, you must contact Horizon directly. This will

enable Horizon to better answer your questions and service you in the

event that you may need any assistance. For questions or assistance,

please direct your email to productsupport@horizonhobby.com, or call

877.504.0233 toll free to speak to a service technician.

Inspection or Repairs

If this Product needs to be inspected or repaired, please call for a

Return Merchandise Authorization (RMA). Pack the Product securely

using a shipping carton. Please note that original boxes may be

included, but are not designed to withstand the rigors of shipping

without additional protection. Ship via a carrier that provides tracking

and insurance for lost or damaged parcels, as Horizon is not

responsible for merchandise until it arrives and is accepted

at our facility. A Service Repair Request is available at www.

horizonhobby.com on the “Support” tab. If you do not have internet

access, please include a letter with your complete name, street

address, email address and phone number where you can be reached

during business days, your RMA number, a list of the included items,

method of payment for any non-warranty expenses and a brief

summary of the problem. Your original sales receipt must also be

included for warranty consideration. Be sure your name, address, and

RMA number are clearly written on the outside of the shipping carton.

Should your repair not be covered by warranty the repair

will be completed and payment will be required without

notification or estimate of the expense unless the expense

exceeds 50% of the retail purchase cost.

item for repair you are agreeing to payment of the repair without

notification. Repair estimates are available upon request. You must

include this request with your repair. Non-warranty repair estimates

will be billed a minimum of ½ hour of labor. In addition you will be

billed for return freight. Please advise us of your preferred method

of payment. Horizon accepts money orders and cashiers checks, as

well as Visa, MasterCard, American Express, and Discover cards.

If you choose to pay by credit card, please include your credit card

number and expiration date. Any repair left unpaid or unclaimed

after 90 days will be considered abandoned and will be disposed of

accordingly.

Please note: non-warranty repair is only available

By submitting the

on electronics and model engines.

Electronics and engines requiring inspection or repair should be

shipped to the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

All other Products requiring warranty inspection or repair should be

shipped to the following address:

Warranty Inspection and Repairs

To receive warranty service, you must include your original

sales receipt verifying the proof-of-purchase date. Provided warranty

conditions have been met, your Product will be repaired or replaced

free of charge. Repair or replacement decisions are at the sole

discretion of Horizon Hobby.

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

Please call 877-504-0233 with any questions or concerns

regarding this product or warranty.

5E-flite T-34 Mentor ARF Assembly Manual

Page 6

Note on Lithium Polymer Batteries

Safety, Precautions, and Warnings

Lithium Polymer batteries are significantly more

volatile than alkaline or Ni-Cd/Ni-MH batteries used

in RC applications. All manufacturer’s instructions

and warnings must be followed closely. Mishandling

of Li-Po batteries can result in fire. Always follow the

manufacturer’s instructions when disposing of Lithium

Polymer batteries.

Warning

An RC aircraft is not a toy! If misused, it can cause serious bodily

harm and damage to property. Fly only in open areas, preferably

at AMA (Academy of Model Aeronautics) approved flying sites,

following all instructions included with your radio.

Keep loose items that can get entangled in the propeller away

from the prop, including loose clothing, or other objects such as

pencils and screwdrivers. Especially keep your hands away from

the propeller.

As the user of this product, you are solely responsible for

operating it in a manner that does not endanger yourself

and others or result in damage to the product or the property

of others.

Carefully follow the directions and warnings for this and any

optional support equipment (chargers, rechargeable battery

packs, etc.) that you use.

This model is controlled by a radio signal that is subject to

interference from many sources outside your control. This

interference can cause momentary loss of control so it is

necessary to always keep a safe distance in all directions around

your model, as this margin will help to avoid collisions or injury.

• Always operate your model in an open area away from cars,

traffic, or people.

• Avoid operating your model in the street where injury or

damage can occur.

• Never operate the model out into the street or populated areas

for any reason.

• Never operate your model with low transmitter batteries.

• Carefully follow the directions and warnings for this and any

optional support equipment (chargers, rechargeable battery

packs, etc.) that you use.

• Keep all chemicals, small parts and anything electrical out of

the reach of children.

• Moisture causes damage to electronics. Avoid water exposure

to all equipment not specifically designed and protected for this

purpose.

6 E-flite T-34 Mentor ARF Assembly Manual

Page 7

Wing and Landing Gear Assembly

Required Parts

Wing panel (left and right) Landing gear strap (5)

Flap linkage (fixed flap) Wing tube

Aluminum anti-rotation pin

3mm x 10mm sheet metal screw (10)

Required Tools and Adhesives

Medium CA Phillips screwdriver: #2

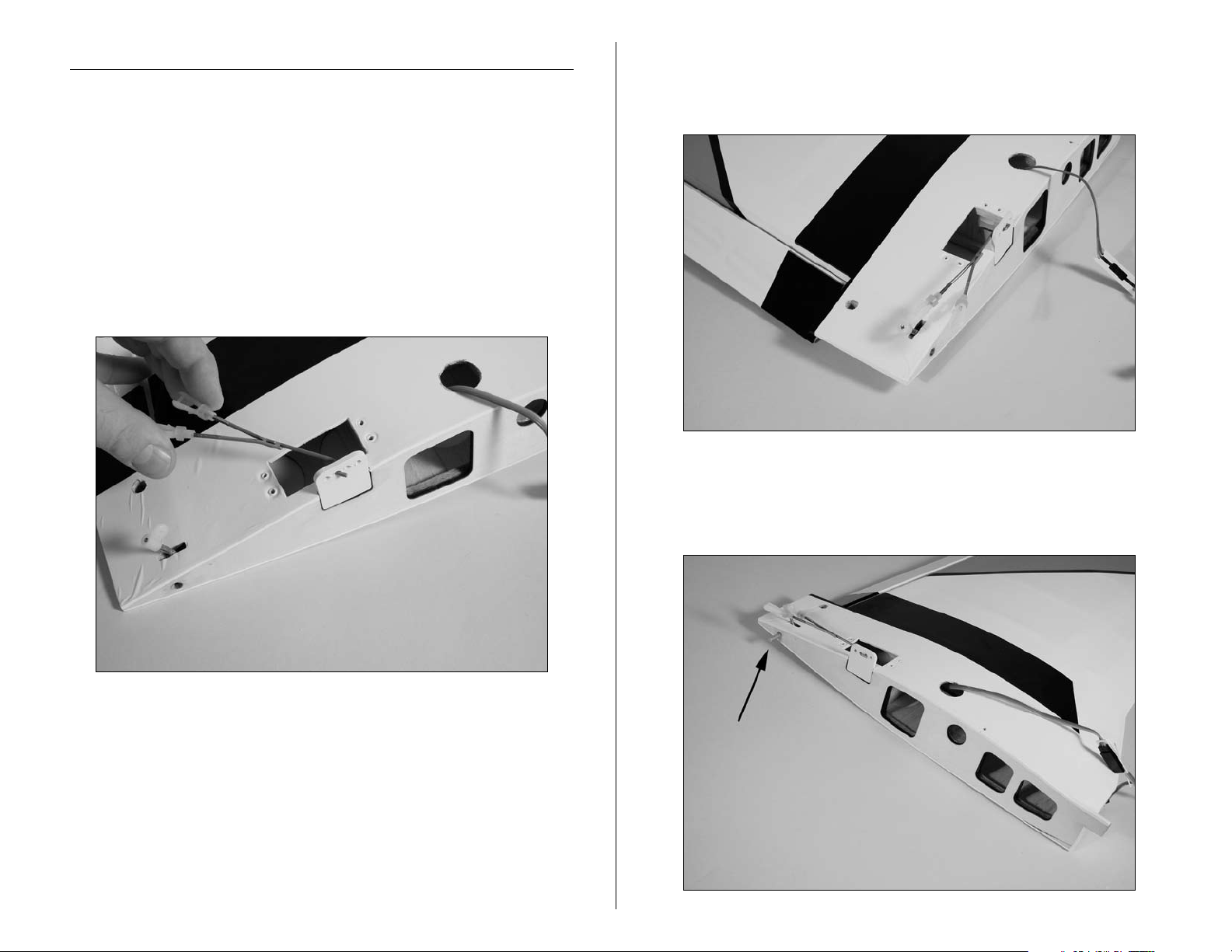

1. Attach the flap linkage to the flap linkage stay. The

linkage will attach to the third hole.

2. Connect the clevis to the flap control horn. You will

note the flap is driven down when you connect the clevis.

We will adjust this position in a few steps.

3. Slice the aluminum anti-rotation pin into the wing. It is

suggested to use medium CA to glue the pin in place to

prevent it from falling out and getting lost.

Note: The flap will be set to the training position in this

section. Setting the flap position for your particular level

of flight skills will be covered later in the manual.

Hint: You can skip steps 1 and 2 if you plan on installing

a servo for the operational flaps. Follow the steps in the

section "Operational Flap Installation (Optional)" instead.

7E-flite T-34 Mentor ARF Assembly Manual

Page 8

4. Slide the wing tube into the wing panel at this time.

5. Attach the landing gear to the bottom of the wing

using two landing gear straps, four 3mm x 10mm sheet

metal screws and a #2 Phillips screwdriver. Attach both

main gears at this time.

6. Slide the two wing panels tightly together. Once

together install the wing securing strap with two screws

using a #2 Phillips screwdriver.

8 E-flite T-34 Mentor ARF Assembly Manual

Page 9

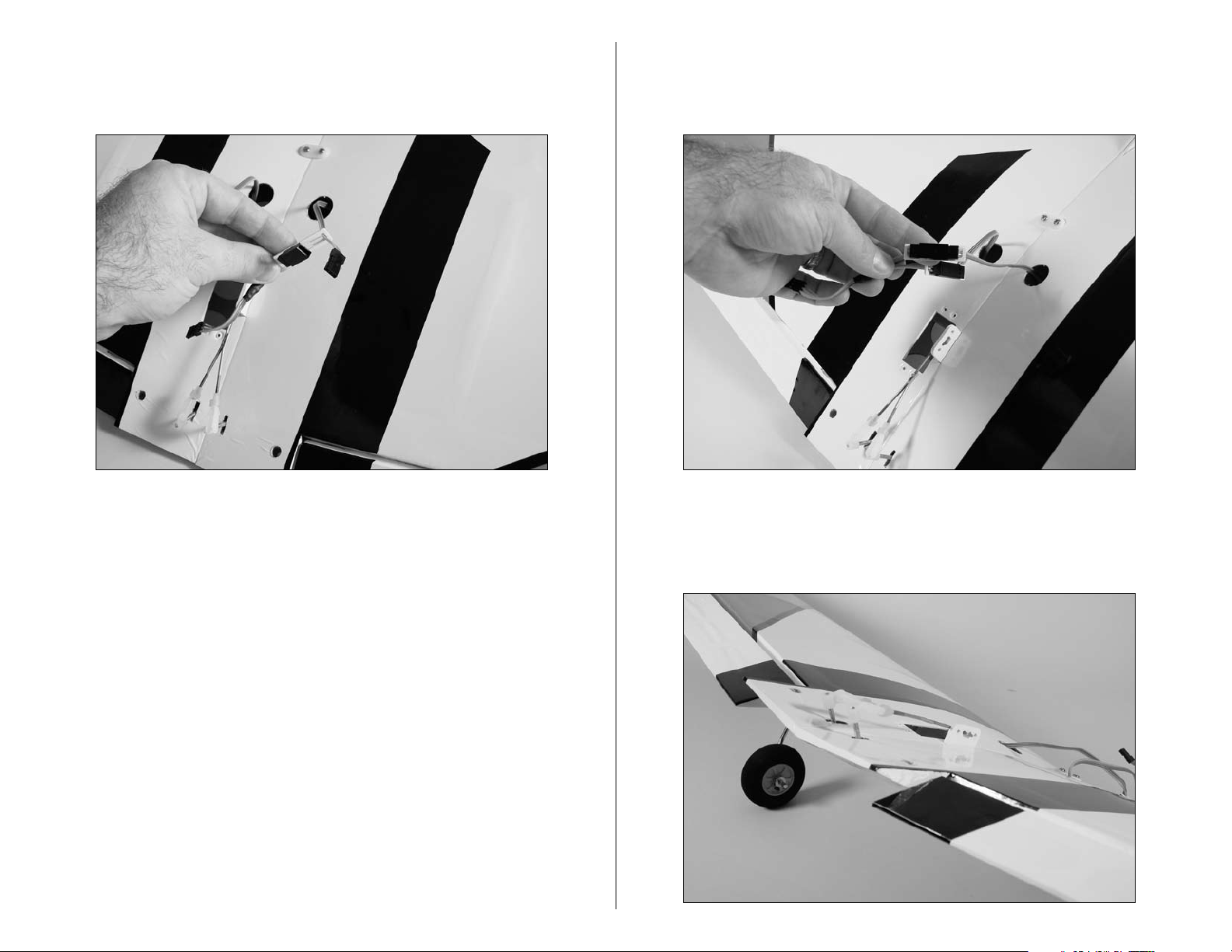

7. Slide the lead from the wing panel through the

connector stay as shown. The stay will prevent the lead

from being unplugged accidentally.

8. Rotate the lead in the stay so the colors align

with those of the lead already installed. Plug the two

connectors together and slide them tight against the stay.

9. Connect the flap linkage to the flap control horn. We

will adjust the flaps to their correct setting later on in the

manual in the "Positioning the Flaps" section on page 27.

9E-flite T-34 Mentor ARF Assembly Manual

Page 10

Tail Installation

Required Parts

Fuselage assembly Stabilizer/elevator

Fin/rudder 3mm washer (2)

3mm locknut (2) 2mm x 8mm sheet metal screw (2)

Tail cone

Required Tools and Adhesives

Phillips screwdriver: #1, #2 Adjustable wrench

Threadlock

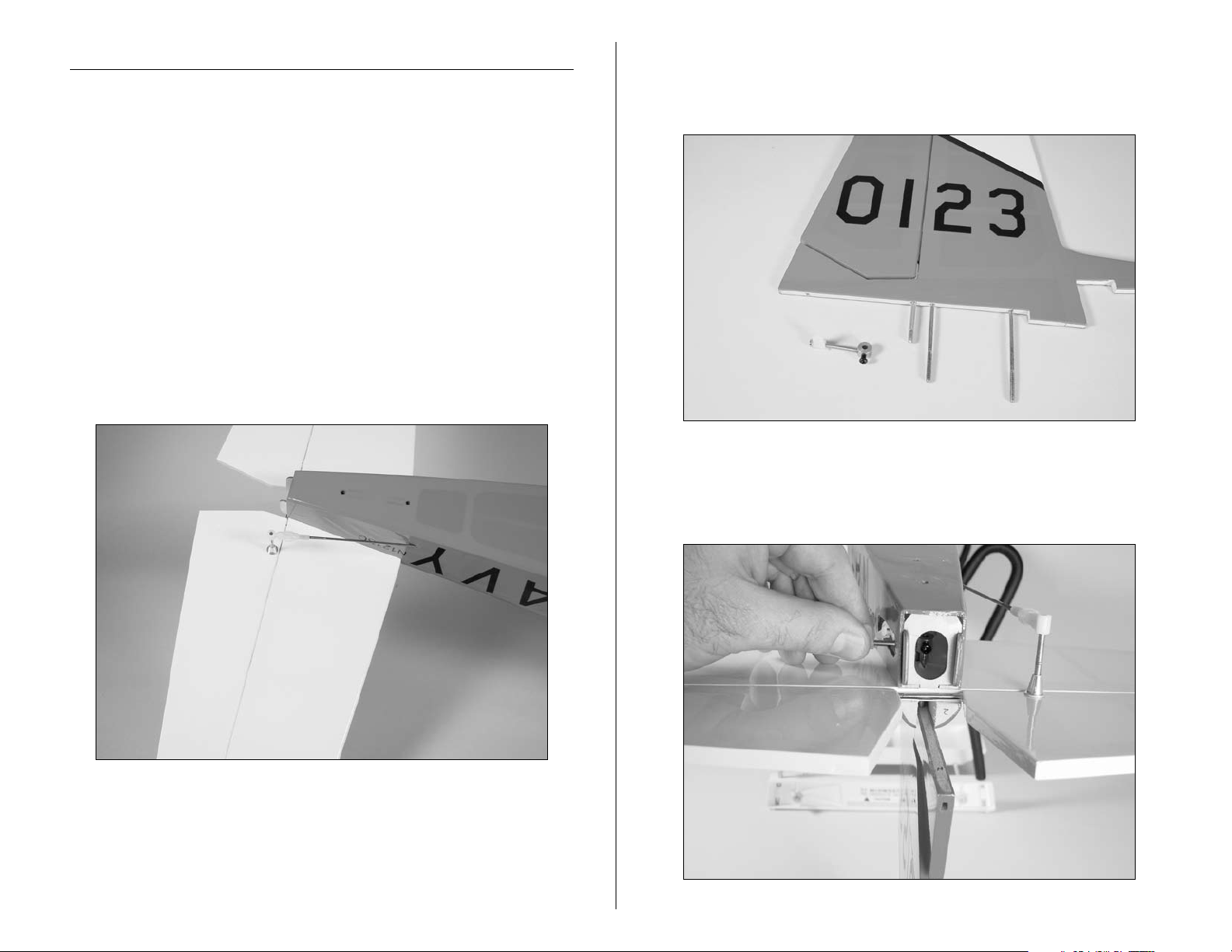

1. Slide the stabilizer/elevator into the slot at the rear of

the fuselage. Make sure the control horn faces the bottom

of the fuselage. Align the holes in the stabilizer with the

holes in the fuselage. Connect the elevator pushrod to the

elevator control horn.

2. Use a #2 Phillips screwdriver to remove the rudder

control horn. You will need to loosen both the short black

screw and control horn screw to remove the control horn.

3. Slide the rudder partially into the fuselage. Install the

control horn so the black screw faces the rear of the

fuselage.

10 E-flite T-34 Mentor ARF Assembly Manual

Page 11

4. Slide the fin fully into position. Use two 3mm washers

and two 3mm locknuts to secure the fin. Tighten these

nuts down using an adjustable wrench.

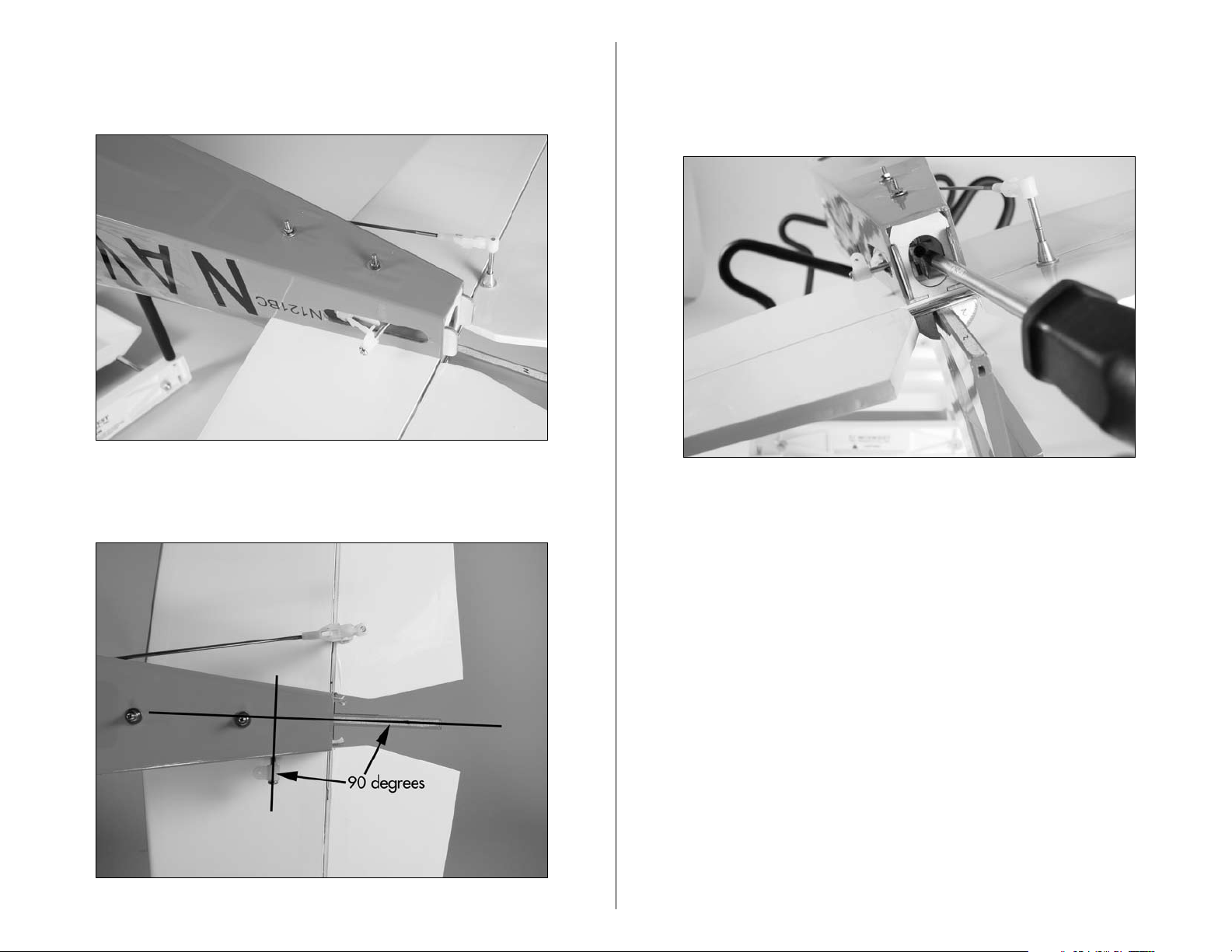

5. Align the control horn so it is 90 degrees to the rudder

as shown.

6. Center the control horn vertically in the slot on the side

of the fuselage. Use a #2 Phillips screwdriver to tighten

the black screw against the rudder control rod. Use

threadlock on the screw to prevent it from vibrating loose.

11E-flite T-34 Mentor ARF Assembly Manual

Page 12

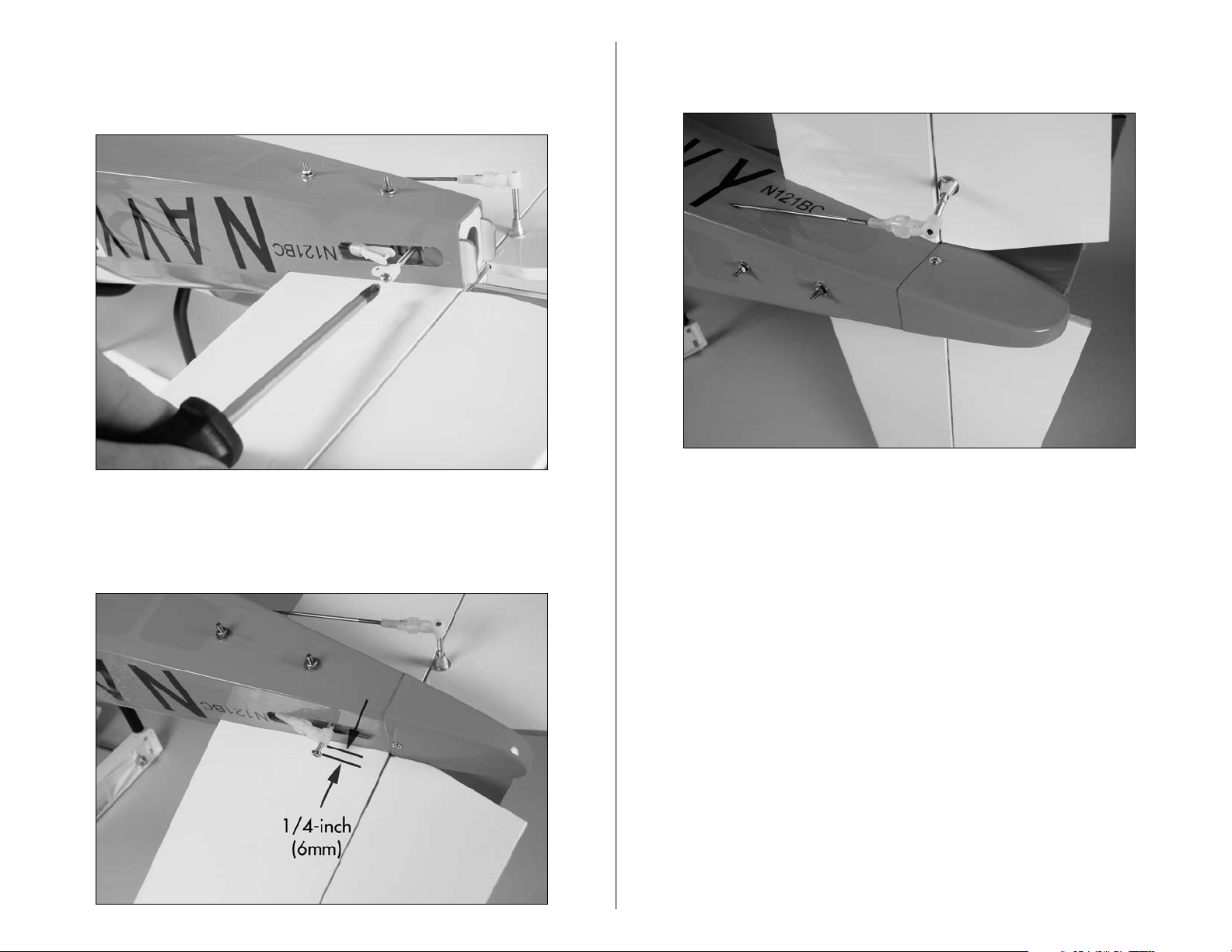

7. Use a #2 Phillips screwdriver to tighten the control

horn screw. Again, the use of threadlock is necessary to

prevent the screw from vibrating loose.

9. Attach the tail cone to the fuselage using two 2mm x

8mm sheet metal screws and a #1 Phillips screwdriver.

8. Screw the nylon control horn in 1/4-inch (6mm).

Connect the clevis from the rudder pushrod to the rudder

control horn.

12 E-flite T-34 Mentor ARF Assembly Manual

Page 13

Battery and Wing Installation

Required Parts

Fuselage assembly Wing assembly

Motor battery Nylon wing bolt (2)

Required Tools and Adhesives

Flat screwdriver: 1/4-inch

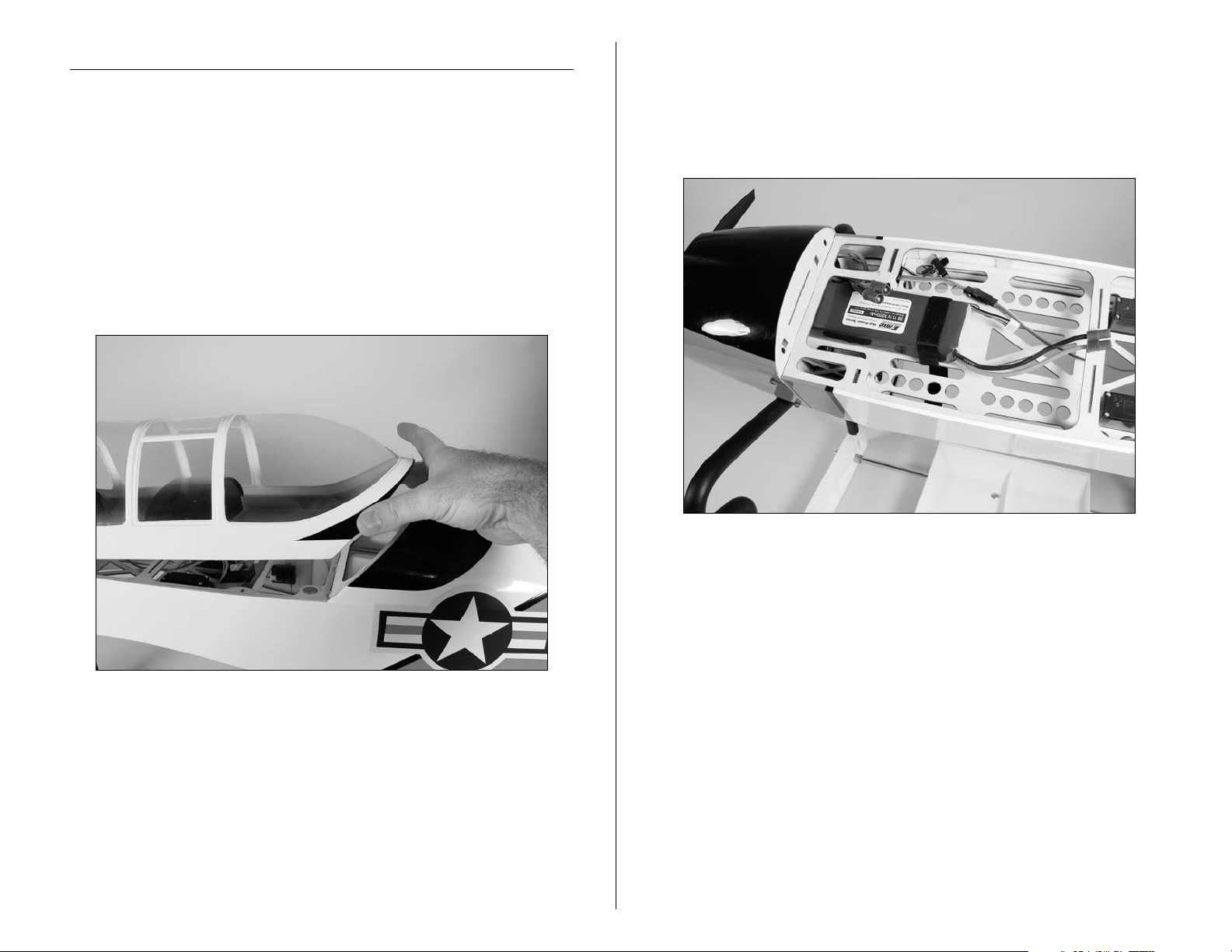

1. Remove the canopy from the fuselage by grasping the

canopy at the aft edge and rocking it left to right. This

will disengage the magnets that hold it in place. The front

has two pins that key into the fuselage.

2. Use the hook and loop straps to secure the motor

battery in the fuselage. The position of the battery

can be adjusted inside the fuselage to correctly balance

the aircraft. For your initial flights, position the battery as

far forward in the fuselage as possible.

13E-flite T-34 Mentor ARF Assembly Manual

Page 14

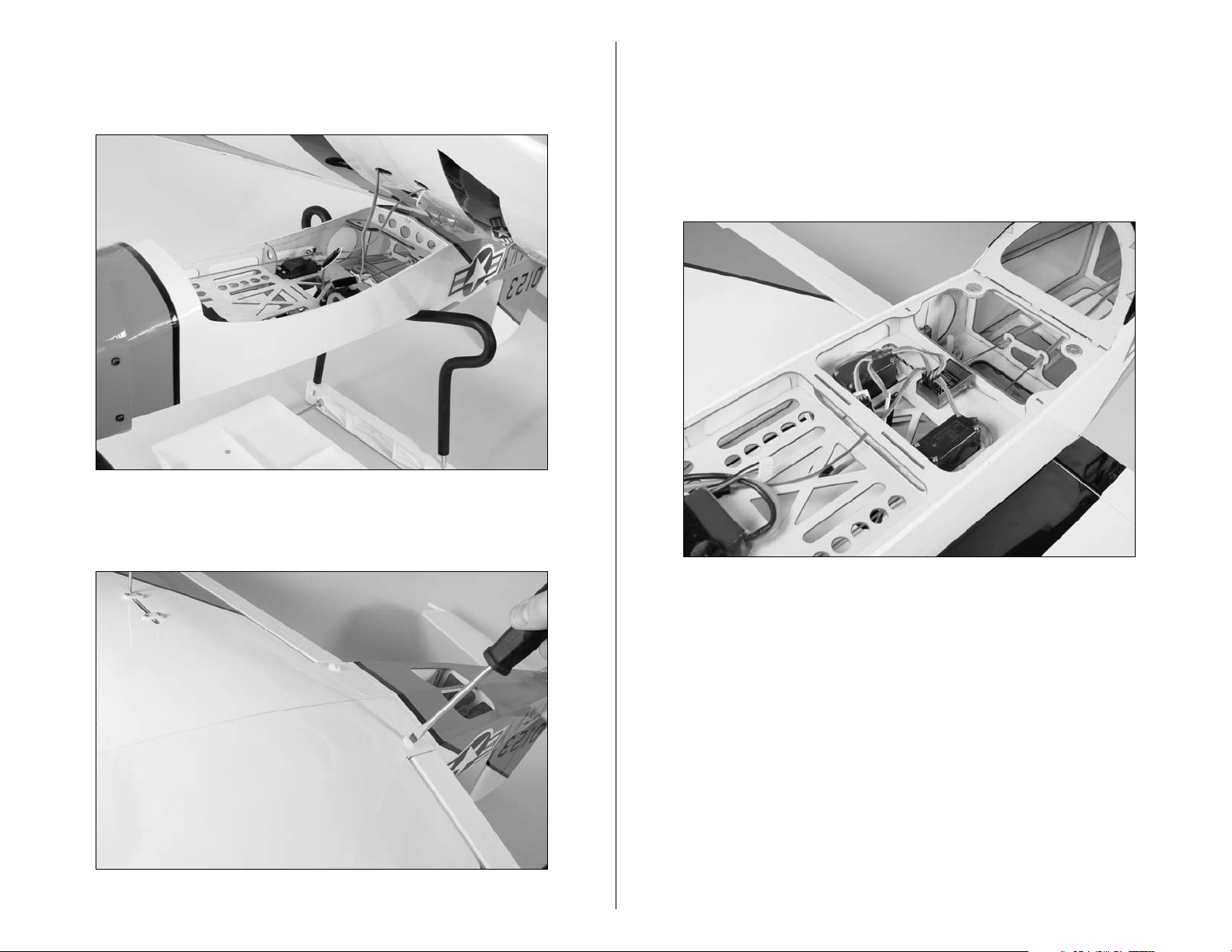

3. Pass the leads for the ailerons (and flap) through the

cross bracing in the fuselage. Guide the tab at the front

of the wing into the slot in the fuselage.

5. Plug the aileron lead into the receiver in the slot

marked AILE. (The flap servo is plugged into the AUX1

slot of the receiver when the optional flaps have been

installed.) Replace the canopy back onto the fuselage.

You will want to make sure you have the wires pressed

down flat and to the side of the receiver before installing

the top hatch.

4. Use two nylon wing bolts and a flat screwdriver to

secure the wing to the fuselage.

14 E-flite T-34 Mentor ARF Assembly Manual

Page 15

Centering the Control Surfaces and

Checking Control Direction

Required Parts

Assembled airframe Motor battery

Radio system

Required Tools and Adhesives

AA battery (4)

Note: This section is designed to help you become

acquainted with the operation of the radio in correlation

to the model. If a flight control moves in the incorrect

direction we will instruct you how to change it in the next

section. ,

1. Follow the radio instructions to install the four AA

batteries.

2. Turn the radio on and check that the sticks and trims

have been centered. The transmitter should display

"T-34EPTS" on the screen.

15E-flite T-34 Mentor ARF Assembly Manual

Page 16

3. Plug the motor battery into the speed control.

Set the throttle stick to low throttle and turn on the

speed control. You will hear a series of beeps or tones

when you plug the battery in. During this process it is

normal for the prop to pulse slightly as the ESC powers

up. Please ensure you are not in line with the prop or in

front of it during power up.

4. Your transmitter should still be on and the battery

plugged in. Now turn the switch on inside the model. The

radio in the model should link up within 10 seconds. If it

does not, turn the switch off and the transmitter off. Then

turn the transmitter on and the switch inside the model on

again and see if the radio links up. If the radio does not

link up at this time, you will need to rebind the system.

This is accomplished in the radio manual that is included

with your system.

Important: Always use extreme caution around the

propeller when the motor battery is plugged in. A

spinning propeller can cause serious damage or injury.

It is always best to stay behind the propeller and keep

it away from loose objects when the battery and speed

control are connected.

16 E-flite T-34 Mentor ARF Assembly Manual

Page 17

Note: The following steps will ensure your flight

controls are centered for the first flight. In the

instructional DVD included with your T-34, we have

shown you how to adjust the clevises and also servo

arms if necessary. Use both of these instructions to

accomplish the following steps.

Checking the Elevator

5. Center the elevator stick and trim. Thread the clevis

in or out on the elevator pushrod until the elevator is

aligned with the stabilizer as shown.

6. Check the movement of the elevator with the radio

system. Pulling the elevator/aileron stick (right stick on

the transmitter) back will make the airplane elevator

move up.

17E-flite T-34 Mentor ARF Assembly Manual

Page 18

7. Check the movement of the elevator with the radio

system. Pushing the elevator/aileron stick forward will

make the airplane elevator move down.

Checking the Rudder

8. Center the rudder stick and trim. Thread the clevis in

or out on the rudder pushrod until the rudder is aligned

with the fin as shown.

18 E-flite T-34 Mentor ARF Assembly Manual

Page 19

9. Check the movement of the rudder using the

transmitter. When the rudder/throttle stick (left side of the

transmitter) is moved right, the rudder should also move

right.

10. Check the movement of the rudder using the

transmitter. When the left stick is moved left, the

rudder should also move left.

19E-flite T-34 Mentor ARF Assembly Manual

Page 20

Checking the Ailerons

11. Center the aileron stick and trim. Thread the clevis

in or out on the aileron pushrod until the ailerons are

aligned with the wing as shown.

12. Check the movement of the aileron using the

transmitter. When the elevator/aileron stick is moved

right, the right aileron will move up and the left aileron

will move down.

20 E-flite T-34 Mentor ARF Assembly Manual

Page 21

13. Check the movement of the aileron using the

transmitter. When the aileron/elevator stick is moved left,

the left aileron will move up and the right aileron will

move down.

Reversing Direction of Flight Controls

If you find any of the control surfaces moving in the opposite

direction (example shown below), you will need to use the Servo

Reversing feature of your radio system. Follow the instructions

for the radio to enter the programming and change the servo

reversing of the offending control surface.

21E-flite T-34 Mentor ARF Assembly Manual

Page 22

Setting the Control Throws

Required Parts

Assembled airframe Motor battery

Radio system

Required Tools and Adhesives

Ruler

Your transmitter and model come out of the box set up and ready

to fly. Should you need to replace your fuselage or wing due to

a mishap or such, this section will help you reset your control

throws to the factory settings.

Note: Measurements are taken at the widest point on

the surface.

These are general guidelines measured from our own flight tests.

You can experiment with different rates to match your preferred

style of flying.

1. Turn the radio on and check that the sticks and trims

have been centered.

2. Plug the motor battery into the speed control.

Set the throttle stick to low throttle and turn on the

speed control.

Important: Always use extreme caution around the

propeller when the motor battery is plugged in. A

spinning propeller can cause serious damage or injury.

It is always best to stay behind the propeller and keep

it away from loose objects when the battery and speed

control are connected.

22 E-flite T-34 Mentor ARF Assembly Manual

Page 23

Elevator Throw

3/8-inch (9.5mm)

Low Rate

3/8-inch (9.5mm)

Low Rate

3/4-inch (19mm)

High Rate

3/4-inch (19mm)

High Rate

3/4-inch (19mm)

High and Low Rate

3/4-inch (19mm)

High and Low Rate

Rudder Throw

3. Use a ruler to check the amount of throw for the

elevator. Move the elevator stick fully and check the

measurements. Adjust the radio as necessary following

the instructions provided with the radio to achieve the

following measurements.

Low Rate: 3/8-inch (9.5mm) (Up/Down)

High Rate: 3/4-inch (19mm) (Up/Down)

4. Use a ruler to check the amount of throw for the

rudder. Move the rudder stick fully and check the

measurements. Adjust the radio as necessary following

the instructions provided with the radio to achieve the

following measurements.

Low Rate: 3/4-inch (19mm) (Right/Left)

High Rate: 3/4-inch (19mm) (Right/Left)

23E-flite T-34 Mentor ARF Assembly Manual

Page 24

Aileron Throw

1/4-inch (6mm)

Low Rate

1/4-inch (6mm)

Low Rate

1/2-inch (13mm)

High Rate

1/2-inch (13mm)

High Rate

5. Use a ruler to check the amount of throw for the

ailerons. Move the aileron stick fully and check the

measurements. Adjust the radio as necessary following

the instructions provided with the radio to achieve the

following measurements.

Low Rate: 1/4-inch (6mm) (Up/Down)

6. Once all the control throws have been set, make sure

to slide the clevis retainers over the clevises to prevent

them from opening accidentally.

High Rate: 1/2-inch (13mm) (Up/Down)

24 E-flite T-34 Mentor ARF Assembly Manual

Page 25

General Maintenance

Required Parts

Fuselage

Required Tools and Adhesives

Phillips screwdriver: #1 Hex wrench: 2.5mm

1. Use a #1 Phillips screwdriver to remove the two screws

that secure the spinner cone to the spinner backplate.

2. Check that the propeller adapter is tight using

a hex wrench or screwdriver that fits into the hole

in the adapter. You will turn this nut counterclockwise to

loosen or clockwise to tighten.

3. To check that the motor is secure to the firewall, you

will first need to remove the spinner. Use a 2.5mm hex

wrench to remove the four screws that secure the cowling

to the fuselage.

25E-flite T-34 Mentor ARF Assembly Manual

Page 26

4. Use the same 2.5mm hex wrench to check the four

screws that secure the motor to the firewall. Once the

motor screws are tight, reverse the previous steps to

install the cowling, propeller and spinner.

5. If your aircraft does not track straight during taxi,

use the screw at the rudder servo and a #1 Phillips

screwdriver to correct the trim. Do not use the radio trim

for ground tracking. The rudder trim at the radio is only

used to trim the rudder in flight.

26 E-flite T-34 Mentor ARF Assembly Manual

Page 27

Positioning the Flaps

Intermediate Setting

Required Parts

Wing assembly

Initial Training Flap Settings

1. Setting the linkage to the third hole back from the

front of the stay sets the flaps to the position for initial

flight training. This will allow the plane to fly at its slowest

speed and will be slowest during landing as well. The

setting for the flaps in this position is 1/2-inch (13mm)

when measured from the trailing edge of the wing to the

trailing edge of the flap.

2. As you continue to advance, the flap linkage can

again be moved forward one hole. The measurement

for the flaps in this setting is 1/4-inch (6mm) from the

trailing edge of the wing to the trailing edge of the flaps.

As described in Step 1, this will allow the aircraft to

fly slightly faster, but will also require a slightly faster

landing speed.

27E-flite T-34 Mentor ARF Assembly Manual

Page 28

Advanced Setting

Removing the NACA Wing Droops

3. Setting the linkage in the forward hole will place the

flap in the full "UP" position. This is the preferred position

for those with flight experience, as the plane will fly more

like a sport aircraft and will require the greatest amount

of skill (for this type of aircraft) during landing.

Required Parts

Wing panel (left and right)

1. Carefully remove the tape from the wing on both the

top and bottom of the wing droop.

28 E-flite T-34 Mentor ARF Assembly Manual

Page 29

2. Once the wing droop has been removed, use a

cleaner to remove the tape residue from the wing.

Note: Check your particular cleaner in an inconspicuous

place before applying it to the wing. If your cleaner is

not compatible with the covering of your aircraft and

damages the covering, it will be in a place that cannot

be seen.

Operational Flap Installation (Optional)

Required Parts

Wing panel (left and right) Flap servo w/hardware

Flap linkage (operational flap)

Required Tools and Adhesives

Phillips screwdriver: #1 Pin drill

Thin CA

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

1. Carefully remove the flap stay from the wing panel

as shown.

29E-flite T-34 Mentor ARF Assembly Manual

Page 30

2. Position the flap servo in the wing. Use a felt-tipped

pen to mark the locations for the four servo mounting

screws.

4. Apply a few drops of thin CA into each hole. This will

harden the surrounding wood, making the screws more

secure when they are installed.

3. Use a pin drill and 1/16-inch (1.5mm) drill bit to drill

the four holes in the wing to mount the flap servo.

30 E-flite T-34 Mentor ARF Assembly Manual

Page 31

5. Install the flap servo in the wing using hardware

provided with the servo. The lead from the servo will

pass through the wing and out of the same hole the

aileron lead exits.

6. Use the radio system to center the flap servo. Install

the servo arm so it is perpendicular to the servo. You will

want equal throw in both directions from this position to

operate the flaps.

7. Use a pin drill and 5/64-inch (2mm) drill bit to

enlarge the outer hole of the servo arm.

8. Slide the flap linkage into the hole as shown.

31E-flite T-34 Mentor ARF Assembly Manual

Page 32

9. Slide the linkage connector on the wire, then rotate it

so it snaps on the wire.

10. Use the radio to move the flap servo to the "UP"

position. The servo arm will face toward the leading edge

of the wing. Connect the clevis to the flap control horn.

Check that the flap is aligned with the wing. If not, thread

the clevis in or out until the flap is aligned with the wing.

32 E-flite T-34 Mentor ARF Assembly Manual

Page 33

11. Slide the wing panels together. Connect the linkage

to the remaining flap control horn and adjust the linkage

to set the neutral position for the remaining flap. Secure

the wing panels together as outlined in the first section

of the manual; Wing and Landing Gear Installation

beginning on page 7.

12. Use the radio system to set the position for the flap.

It may be necessary to use the radio system to change

the amount of throw electronically to match those in the

following images. Your goal here is to mimic the flap

settings from the previous section.

33E-flite T-34 Mentor ARF Assembly Manual

Page 34

Center of Gravity

Range Test Your Radio

An important part of preparing the aircraft for flight is properly

balancing the model.

Caution: Do not inadvertently skip this step!

The recommended Center of Gravity (CG) location for the

T-34 Mentor ARF is 4

3

/

– 4

4

7

/

-inch (120–124mm) back from

8

the leading edge of the wing. Mark the location of the CG on

the top of the wing.

Please balance your model while it is inverted with the

battery installed. With the model inverted, lift the model at

the marks using your fingertips, or use a commercially available

balancing stand. The model will rest level or slightly nose down

when balanced correctly. Adjust the position of the motor battery,

or add weight to the nose or tail if necessary to achieve the

correct CG. Please understand that if you use a different Li-Po

battery than the one included, you need to rebalance the model

to verify the Center of Gravity.

1. Please consult your radio instructions for complete

range testing instructions.

2. Double-check that all controls (aileron, elevator, rudder

and throttle) move in the correct direction.

3. Be sure that your transmitter batteries are fully

charged, per the instructions included with your radio.

Instructions for Disposal of WEEE by

Users in the European Union

This product must not be disposed of with other waste. Instead, it

is the user’s responsibility to dispose of their waste equipment by

handing it over to a designated collection point for the recycling

of waste electrical and electronic equipment. The separate

collection and recycling of your waste equipment at the time of

disposal will help to conserve natural resources and ensure that

it is recycled in a manner that protects human health and the

environment. For more information about where you can drop

off your waste equipment for recycling, please contact your local

city office, your household waste disposal service or where you

purchased the product.

After the first flights, the CG position can be adjusted for your

personal preference.

34 E-flite T-34 Mentor ARF Assembly Manual

Page 35

Preflight

Flying the T-34 Mentor

Check Your Radio

Before going to the field, be sure that your batteries are fully

charged per the instructions included with your radio. Charge

both the transmitter and receiver pack for your airplane. Use the

recommended charger supplied with your particular radio system,

following the instructions provided with the radio. In most cases,

the radio should be charged the night before going out flying.

Before each flying session, be sure to range check your radio.

See your radio manual for the recommended range and

instructions for your radio system. Each radio manufacturer

specifies different procedures for their radio systems. Next, start

the motor. With the model securely anchored, check the range

again. The range test should not be significantly affected. If it is,

don’t attempt to fly! Have your radio equipment checked out by

the manufacturer.

Note: Keep loose items that can get entangled in

the propeller away from the prop. These include

loose clothing, or other objects such as pencils and

screwdrivers. Especially keep your hands away from the

propeller.

It is recommended for your first flights to search out the assistance

of a qualified instructor, who will help you through your first

flights and assist you in the basics of Radio Controlled flight. You

can find this guidance at your local hobby dealer’s store. Your

T-34 is capable of flying in winds up to 20 mph but, for flight

training, it is recommended to fly in the lightest wind possible.

You will need to ensure your battery is fully charged and the

model is set up accordingly for your first flight. Do not attempt to

fly the model on a partially charged battery.

The Initial Training Flap Setting is set up for slow gentle flight

with very easy landing characteristics. This setting uses the flaps

in their full down position (as shown on page 27 of the manual)

with the NACA droops installed on the wings. The NACA droops

come pre-installed for you out of the box. This setting is used

for initial flight training as well as initial landing training. In

this configuration, the model will not drop a wing during flight

or landing approach. You will notice a slight amount of down

elevator trim required for level flight due to the flap position. Use

this setting for your first flights and first landing approaches.

Double-check that all controls (aileron, elevator, rudder and

throttle) move in the correct direction.

Check the radio installation and make sure all the control

surfaces are moving correctly (i.e. the correct direction and with

the recommended throws). Test run the motor and make sure

it transitions smoothly from off to full throttle and back. Also

ensure the engine is installed according to the manufacturer’s

instructions, and it will operate consistently.

Check all the control horns, servo horns, and clevises to make

sure they are secure and in good condition. Replace any items

that would be considered questionable. Failure of any of these

components in flight would mean the loss of your aircraft.

35E-flite T-34 Mentor ARF Assembly Manual

Page 36

The Intermediate Flap Setting is set up for gentle flight with easy

landing characteristics. This setting uses the flaps in their half

down position and the NACA droops installed. In this setting,

you will notice a slightly faster landing speed and still very gentle

flight characteristics. A very slight amount of down elevator trim

is required for level flight due to the flap position. Use this setting

for flight once you have mastered the basic flight parameters. For

some, it may be possible to use this setting for your first landing

approaches.

The Advanced Flap Setting is set up for your final training flights.

With the flaps all the way up and the NACA droops still installed,

you will find the stall characteristics of the model continue to

be very benign, but the model will be faster in flight and more

maneuverable. Landings will be a bit faster but still very easily

accomplished with the stability of the T-34. You will find the basic

flight maneuvers of loops and rolls are easily accomplished with

the model in the Advanced Flap Setting mode.

36 E-flite T-34 Mentor ARF Assembly Manual

Page 37

The final setting is to remove the NACA droops. With these

removed, you will find the T-34 very lively in its flight abilities

while maintaining a very docile flight profile. Stalls in this

configuration will routinely fall straight ahead and recover

almost instantly. Inverted flight, loops, and rolls all are easily

accomplished while maintaining the model’s quality scale

appearance.

Li-Po Battery Pack Information

Warning!

Lithium Polymer (Li-Po) batteries are significantly more volatile

than other rechargeable batteries used in RC applications. Failure

to read and follow these instructions and safety precautions may

result in fire, personal injury and damage to property. E-flite,

Horizon Hobby, Inc., its retailers, and any other representatives,

assume absolutely no liability for use of this product or failure to

comply with these instructions and precautions.

If you are not prepared to accept complete liability for the

purchase and/or use of this product, you are advised to return

it new and unused to the place of purchase immediately.

Never ship batteries without the expressed permission of the

recipient. Batteries carrying 25% or more charge cannot be

shipped safely. Batteries which are damaged cannot be shipped

safely. Damage or loss due to unsafe shipping is the legal

responsibility of the person who shipped the product.

We hope you enjoy the T-34 as much as we have. We are

confident you will enjoy many flights with your T-34. Happy

landings.

CAUTION: This product may ignite under certain

conditions. Please read all safety precautions before use.

Please call 877-504-0233 with any questions or concerns

regarding this product or warranty.

37E-flite T-34 Mentor ARF Assembly Manual

Page 38

Usage Guidelines, Warnings and Safety Precautions

• Li-Pobatteriesmayexplodeifdamagedorifdisposed

of improperly.

• Lithium batteries can still ignite after at least 45 minutes

due to a delayed chemical reaction. If battery is damaged or

overheats, observe the battery in a safe area outside of any

building or vehicle and away from combustible material.

• Alwaysinspectbatteriesbeforecharging.

• Never charge or use a Li-Po battery or pack that shows

any damage or disfigurement of any kind. Swelling is a

sign of internal damage. Any breach of protective cover,

wiring or plugs is also reason to discontinue use (See

Disposal Instructions).

• Use specific Lithium Polymer charger only. Do not use a Ni-Cd

or Ni-MH charger – failure to do so may cause a fire, which

may result in personal injury and/or property damage.

• Never charge around or in the area of any flammable or

combustible materials.

• Always charge Li-Po batteries in or on fire resistant materials

or containers.

• Never leave battery and charger unattended while in use.

Improper charging or discharging of Li-Po batteries could

result in fire.

• Constantly monitor the temperature of the battery pack while

charging. If the battery becomes hot to the touch discontinue

charging immediately. Disconnect the battery from the charger

and observe it in a safe place for at least 15 minutes.

• If at any time you see a battery starting to balloon or swell up,

discontinue charging or using immediately.

• DonotallowchildrentochargeLi-Pobatterypacks.

• DonotallowchildrentouseLi-Pobatterieswithout

adult supervision.

• Shorting the wire leads can cause fire. If you accidentally

short the wires, the battery must be placed in a safe area for

observation for at least 15 minutes.

• Never store or charge a battery pack where the temperature

will go below 32 degrees Fahrenheit or above 130 degrees

Fahrenheit. Extreme temperatures will damage the battery pack

and may cause a fire. Battery performance may be diminished

by less extreme temperatures.

• Any of the following may cause the battery to be damaged

resulting in battery swelling, leaking, or fire:

• Bending, folding or dropping of the battery

• Damaging the edge seal of the battery

• Taking apart the battery

• Mixing cells of differing chemistry, or types, or sizes

• Mixing cells of different ages

Crash Damage

If there are signs of smoke or overheating, DO NOT go

near the battery or equipment until it has been observed from

a safe distance for at least 15 minutes. Once it is safe, remove

the battery and check for damage. Dispose of damaged

batteries appropriately.

38 E-flite T-34 Mentor ARF Assembly Manual

Page 39

Swollen Batteries

Basic Disposal Instructions

Immediately stop using or charging. If the battery is not warm

to the touch, move it to an open safe area and observe it for at

least 15 minutes. Be VERY CAREFUL when moving the batteries.

Do NOT put ANY pressure on the batteries or covering as this

may cause fire.

Additional Information & Guidelines

1. Battery temperature the best indicator for safety. The E-flite Li-Po

Battery’s temperature should never drop below 32 degrees

Fahrenheit or go above 130 degrees Fahrenheit while charging

or discharging.

2. Changing plugs is NOT recommended as the process is

dangerous and any error can cause immediate fire. Improperly

installed plugs can also cause fire due to shorts, reverse polarity

or other improper handling which can cause battery damage.

3. Batteries should be stored in a vented, fire resistant container.

Each pack should be stored in its own locked plastic bag within

the container. The number of battery packs per container

should be extremely limited to avoid chain reactions. Storage

temperatures should not fall below 32 degrees F or above

130 degrees F. Damaged batteries must be kept at even more

ambient temperatures. High temperatures may cause fire even

with undamaged batteries.

Battery Disposal

Li-Po batteries require special handling for safe disposal. The

following are basic instructions for safe disposal. For more

detailed safety, disposal and recycling information please go to:

www.rbrc.org or www.earth911.org.

Before discarding any Li-Po battery it must be rendered safe.

The following steps must be taken to avoid damage or injury to

yourself, your property and anyone who comes in contact with

the battery.

If the battery is undamaged but no longer useful:

1. Discharge the battery to a maximum of 2.5V using a slow, safe

discharge method.

2. Leave battery uncharged and retest after at least 24 hours.

Many batteries experience “rebound” and may have more

than 2.5V after 24 hours. If the battery is over 2.5V, repeat the

procedure until the battery is 2.5V or less.

3. Insulate each wire lead with electrical tape or other

appropriate material.

4. Assure that wire leads cannot touch each other by taping them

to opposite sides of the battery.

5. Place battery in a sealed plastic bag and place plastic bag in a

vented, fire-safe container.

6. Use fire-safe container to deliver battery to a recycling center

authorized for Lithium Polymer batteries. Please note that not all

battery-recycling services include Li-Po’s. If no Li-Po recycling

facility is available in your area, contact your state or local

Hazmat agencies for instructions.

7. If the battery or wiring is damaged please contact your

state or local Hazmat facilities for instructions. Batteries must

be rendered safe before being transported or recycled. Do

NOT transport or ship batteries which have more than 2.5V

charge OR that show signs of damage without following the

instructions given by authorities. Damaged batteries should be

rendered as safe as possible and stored in a vented fireproof

container until recycled.

39E-flite T-34 Mentor ARF Assembly Manual

Page 40

Optional Items for Your T-34 Mentor

As you have selected the world of electric power to begin your

RC experience, we thought it would be good to show you some

optional equipment that will help you grow and enjoy the world

of electric flight. The equipment included with your T-34 ePTS

works very well and will serve your needs without hesitation. All

of the items shown in this section are available from your local

hobby dealer.

The chargers listed in this section will help you achieve a more

versatile charging network for you to operate your electric

powered models.

E-flite 1-5 cell Li-Po charger

Thunder Power 610 Charger

The Thunder Power charger is a charger than can charge any

battery currently in use the RC industry. It has software for

charging Ni-cd, NiMh, Li-Ion, Li-Po, and A123 cells. Ask for part

number #THP610 at your local hobby dealer.

The E-flite Li-po balancing charger is capable of charging up to

5 cell Li-Po packs. Ask for part number #EFLC505 at your local

hobby dealer.

40 E-flite T-34 Mentor ARF Assembly Manual

Page 41

Thunder Power 33003S battery

E-flite 32003S battery

The Thunder Power Extreme V2 battery is the highest quality,

strongest power density battery in its class. This battery requires

the Thunder Power 610 Charger listed in this section. Ask for part

number #THP33003SXV2 at your local hobby dealer.

The E-flite battery is a high quality replacement battery that

can use either of the chargers listed in this section. Ask for part

number EFLB32003S at your local hobby dealer.

41E-flite T-34 Mentor ARF Assembly Manual

Page 42

2008 Official AMA National

Model Aircraft Safety Code

GENERAL

1) I will not fly my model aircraft in sanctioned events, air shows

or model flying demonstrations until it has been proven to be

airworthy by having been previously, successfully flight tested.

2) I will not fly my model higher than approximately 400 feet within 3

miles of an airport without notifying the airport operator. I will give

right-of-way and avoid flying in the proximity of full-scale aircraft.

Where necessary, an observer shall be utilized to supervise flying

to avoid having models fly in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the flying

site I use, and I will not willfully or deliberately fly my models in a

careless, reckless and/or dangerous manner.

4) The maximum takeoff weight of a model is 55 pounds, except

models flown under Experimental Aircraft rules.

5) I will not fly my model unless it is identified with my name and

address or AMA number on or in the model. (This does not apply

to models while being flown indoors.)

6) I will not operate models with metal-bladed propellers or with

gaseous boosts, in which gases other than air enter their internal

combustion engine(s); nor will I operate models with extremely

hazardous fuels such as those containing tetranitromethane or

hydrazine.

RADIO CONTROL

1) I will have completed a successful radio equipment ground range

check before the first flight of a new or repaired model.

2) I will not fly my model aircraft in the presence of spectators until I

become a qualified flier, unless assisted by an experienced helper.

3) At all flying sites a straight or curved line(s) must be established

in front of which all flying takes place with the other side for

spectators. Only personnel involved with flying the aircraft are

allowed at or in front of the flight line. Intentional flying behind the

flight line is prohibited.

4) I will operate my model using only radio control frequencies

currently allowed by the Federal Communications Commission.

(Only properly licensed Amateurs are authorized to operate

equipment on Amateur Band frequencies.)

5) Flying sites separated by three miles or more are considered safe

from site-to-site interference, even when both sites use the same

frequencies. Any circumstances under three miles separation

require a frequency management arrangement, which may be

either an allocation of specific frequencies for each site or testing

to determine that freedom from interference exists. Allocation plans

or interference test reports shall be signed by the parties involved

and provided to AMA Headquarters.

Documents of agreement and reports may exist between (1) two

or more AMA Chartered Clubs, (2) AMA clubs and individual

AMA members not associated with AMA Clubs, or (3) two or

more individual AMA members.

6) For Combat, distance between combat engagement line

and spectator line will be 500 feet per cubic inch of engine

displacement. (Example: .40 engine = 200 feet.); electric motors

will be based on equivalent combustion engine size. Additional

safety requirements will be per the RC Combat section of the

current Competition Regulations.

7) At air shows or model flying demonstrations, a single straight line

must be established, one side of which is for flying, with the other

side for spectators.

8) With the exception of events flown under AMA Competition rules,

after launch, except for pilots or helpers being used, no powered

model may be flown closer than 25 feet to any person.

9) Under no circumstances may a pilot or other person touch a

powered model in flight.

42 E-flite T-34 Mentor ARF Assembly Manual

Page 43

Building and Flying Notes

43E-flite T-34 Mentor ARF Assembly Manual

Page 44

12845

© 2008 Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, Illinois 61822

(877) 504-0233

horizonhobby.com

E-fliteRC.com

Loading...

Loading...