Page 1

ValveMate

™

7040 Controller

Operating Manual

Electronic pdf files of EFD®manuals are also available at www.efd-inc.com/manuals.html

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com

VALVEMATE

7040

A NORDSON COMPANY

Page 2

EFD ONE YEAR LIMITED WARRANTY

All components of the EFD ValveMate 7040 are warranted for one year from

date of purchase to be free from defects in material and workmanship (but not

against damage caused by misuse, abrasion, corrosion, negligence, accident,

faulty installation or by dispensing material incompatible with equipment) when

the equipment is installed and operated in accordance with factory recommendations and instructions. EFD will repair or replace free of charge any part

of the equipment thus found to be defective, on authorized return of the part

prepaid to our factory during the warranty period.

In no event shall any liability or obligation of EFD arising from this warranty

exceed the purchase price of the equipment. This warranty is valid only when

oil-free, clean, dry, filtered air is used.

EFD makes no warranty of merchantability or fitness for a particular purpose.

In no event shall EFD be liable for incidental or consequential damages.

Page 3

Warranty ....................................................inside cover

Introduction and Specifications ..................................2

Operating Features ......................................................3

Typical Setup................................................................4

Setup ........................................................................5-6

Adjusting the Spray......................................................7

Programming Nozzle Air Delay ....................................8

Schematic and Replacement Parts ............................9

Troubleshooting Guide ..............................................10

Input / Output Connections..................................11-12

Connecting More than One 7040 Controller..............13

Contents

Page 4

2 / Introduction and Specifications

The ValveMate 7040 provides easy adjustment of valve output for maximum

end-user convenience and efficiency. Designed for use with the 781S

Series spray valves, the ValveMate 7040 features an adjustable nozzle airflow regulator and a microprocessor-based timed air-pressure output for

controlling valve ON time. The ValveMate 7040 is simple to use and will

operate many millions of cycles without maintenance.

Introduction

Note: Specifications and technical

details are subject to engineering

changes without prior notification.

Size: 19 cm W x 14 cm D x 7 cm H (7.5”W x 5.6”D x 2.7” H)

Weight: 1.4 kg (3.1 lb)

Cabinet: Aluminum

Input Voltage: Selectable 100/120/220 VAC

Internal Voltage: 24 VDC

Feedback Circuits: 5 to 24 VDC NC solid-state switch 250mA maximum

Initiate Circuit: 5 to 24 VDC signal or contact closure

Air Input: 70 psi (4.8 bar)

Cycle Rate: Exceeds 600 per minute

Time Range: .001 to 99.9 seconds

Meets CSA and CE standards.

Specifications

The small size and adjustable mounting bracket allow for positioning of the

ValveMate close to the point of valve operation and provide convenient

access to setup and dispensing adjustment controls.

“On the fly” time adjustment allows adjustment of valve output while the

equipment is running. This feature eliminates the need to shut down parent

machinery to change or adjust dispense time settings.

Other features and explanations of controls are detailed in the diagrams on

pages 4 and 5.

Page 5

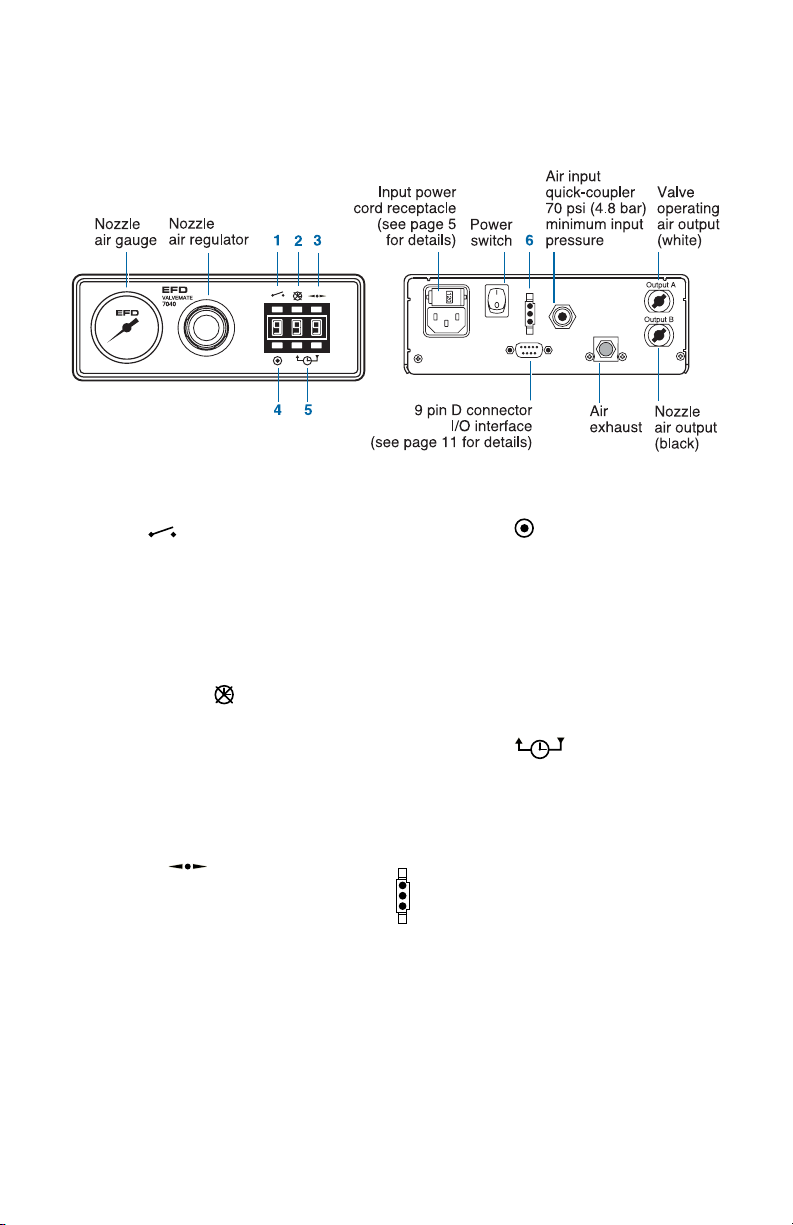

3 / Operating Features

1. Cycle

Press to initiate one complete

dispense cycle. Press again to

interrupt a timed cycle. Press

and hold while in the time override mode for continuous cycle.

Release to stop.

2. Time override

Press to override time control.

Display will show (---). While in this

mode, dispensing is manual using

the cycle button, voltage initiate

source or foot pedal (optional,

#2015A).

3. Decimal

Press to move decimal and change

time range maximums from .999

to 9.99 or 99.9. Decimal does not

appear in the display while in the

.999 second range.

Operating Features

4. Program

Press to clear display to zeros.

Display flashes bright/dim while in

program mode.

Press cycle button and hold until

proper amount is sprayed. Total

spray time will be displayed. Press

program button again to lock in

spray time.

5. Time set

Press to change time setting up or

down. Press and release to advance

one digit at a time, or press and

hold to scroll quickly.

6. Foot pedal connector

If using the optional foot pedal, press

the pedal momentarily to initiate the

controller. To interrupt a timed dispense cycle, press the pedal again.

Page 6

4 / Typical Setup

Caution: Always depressurize the reservoir

before opening. To do this, slide the shutoff valve

on the air line away from the reservoir. If using

an EFD tank, open the pressure relief valve as

well. Before opening the reservoir, check the

pressure gauge to verify that pressure is zero (0).

On all EFD cartridge reservoirs, the unique

threaded design provides fail-safe air pressure

release during cap removal.

Typical Setup

Five micron filter regulator

Plant air

70 psi (4.8 bar)

minimum

White quick-connect

Air tee #1116

To exhaust

To pressurize

Shut-off valve

Flexible air line

#2310S

Note: Use only oil-free,

clean, dry, filtered air

Controller

VALVEMATE

7040

ValveMate

7040 Controller

Material

Constant air

Pulsed air for valve operation

Pulsed nozzle air

Black quick-connect

Fluid feed hose

Pressurized

reservoir with

5

0

LVL P

spray valve

20

air regulator

Fluid inlet

fitting

#7543BP

for 1/4" OD tube

#7610BP

for 3/8" OD tube

Page 7

5 / Setup

VALVEMATE

70

40

➀ Mounting

Use the universal mounting bracket

(included) to mount the controller

either over or under the cabinet. The

bracket allows the controller to pivot

30º from a horizontal position. For

panel mounting, a panel mount

bracket kit is available (#7000PMK).

➁ Input Power

1. View cartridge window in power

cord receptacle to ensure that the

voltage is set properly. Selections

are 100, 120 or 220 VAC.

2. If it does not match, remove the

fuse cartridge. Then remove the

fuse holder from the cartridge,

rotate the holder and position the

correct voltage to show through

the cartridge window.

Reassemble in reverse order.

3. Connect the power cord.

Setup

Voltage value

Spare fuse

Cartridge window

(check voltage indicated)

➀

2

2

0

120

0

0

1

Page 8

➂

Initiate Connection

The 7040 can be operated by

applying a 5 to 24 VDC pulse to

terminal pins 1 and 2, or providing

contact closure across pins 5 and

7. Alternatively, a foot pedal may

be ordered (#2015A) and plugged

into the connector located on the

rear panel.

➃

Air Input Connection

1. Connect the controller to plant air

by first installing the five micron

filter regulator (#2000F755) to

the plant air supply.

2. Install the air tee with barb fitting (#1116 supplied with EFD

tank reservoirs) in the output of

the filter regulator, and install the

black hose with coupling to the

barb fitting. The quick-connect

on the air tee is used to provide

air pressure to the air pressure

regulator on EFD tank reservoirs. This connection will be

made during valve installation.

3. Remove the cap plug from the air

input of the controller and attach

the input air hose coupling onto

the controller air-input fitting.

4. Set the pressure at the filter

regulator to 70 psi (4.8 bar).

➄ Control Air Output

The 781S is equipped with nozzle

and control air hoses with male

quick-connects that plug into the

ValveMate7040.

a) Plug the control air hose

labeled “A” into output “A”

(white) of the 7040.

b) Plug the nozzle air hose

labeled “B” into output “B”

(black).

➅ Power

1. Turn the power switch on.

2. Press the time override button

to place the controller in manual

mode (---).

6 / Setup

➂

➅

➄

a

➄

b

➃

Setup

120

Output A

Output B

Page 9

7 / Adjusting the Spray

Adjusting the Spray

1. Turn the nozzle air pressure on the

controller to zero. Using the needle stroke control knob ➀ on the

781S valve, set the fluid flow rate

to one or two drops per second.

Check flow rate by actuating the

controller in the time override

mode. Make valve stroke adjustments when the controller is off.

2. Set the nozzle air pressure on the

controller to 10 psi (0.7 bar) and

actuate the controller. The valve

will produce a fine spray.

3. To change fluid flow, use the

needle stroke control knob ➀,

and/or tank air pressure.

Note: Avoid tight stroke settings with high

tank pressure.

4. To change nozzle air, use the nozzle

air pressure regulator ➁. Higher

pressures will provide finer spray.

To Make Timed Deposits

1. Return to the time control by pressing the time override button ➂. The

display should show the time setting.

2. Adjust the deposit time to 0.5 seconds by using the time set ➃ and

decimal ➄ buttons.

3. Press the cycle button ➅. The controller will open the valve for 0.5 seconds. Adjust time and test deposits

until desired output is obtained.

➀

VALVEMATE

7040

➁

➂➃➄

➅

Note: Optimal results will be obtained

with the proper combination of time

setting, needle stroke control knob,

and reservoir and nozzle air pressure.

Page 10

8 / Programming Nozzle Air Delay

Nozzle air delay is the time the nozzle air continues to

spray after the fluid is turned off. When spot marking

with low viscosity fluids, the delay can be reduced to

prevent blowing out the center of the mark. The delay

can be increased with high viscosity fluids and greases

to provide a spreading out effect.

1. Turn the power switch off.

2. Press and hold the time override button while

turning power switch on.

3. The display will read “SEL” (select). Release the

time override button.

4. Press either the up or down time set buttons once

and release. The current nozzle air-delay setting will

be displayed. (The delay is preset to 0.24 seconds

for all new controllers.)

5. Press the up or down time set button again to program the new nozzle air delay. (Available range is

0.00 to 2.50 seconds.)

6. To exit the nozzle air-delay program mode, momentarily press the time override button. The spray time

setting will be displayed.

Note: The controller will not operate while in the nozzle air

delay program mode.

Programming Nozzle Air Delay

Page 11

9 / Schematic and Replacement Parts List

Schematic and Replacement Parts List

1. 2-2002-7040 Regulator assembly

0 to 30 psi, 0 to 2.07 bar

2. 2-2003-7040A Control solenoid assembly

3. 2-2003-7040B Nozzle air solenoid assembly

4. 2-2006DB-VC Display PCB assembly

5. 2-2006PS-VC Power supply PCB assembly

6. 2-2017-1500 Foot pedal

receptacle assembly

7. 2001A Gauge 0 to 30 psi,

0 to 2.07 bar

8. 2004B Female quick-connect – black

(hidden from view

- below item #9)

9. 2004B-W Female quick-connect – white

10. 2024-160 1/4” OD x .160” ID tubing

11. 2081A Air input quick-connect

12. 2085 1/8 NPT x 1/4 barb – low profile

13. 2086 1/8 NPT x 1/4 barb 90° – brass

14. 2087 1/8 NPT x 1/4 barb elbow – brass

15. 2088 Fitting

1/8 NPT x 1/4 barb – brass

16. 7108 Exhaust muffler

17. 7109 Power switch

18. 7111 Fuse – .125A

19. 7143-01 Output circuit fuse

16

9

14

3

11

2

12

14

18

6

17

19

5

10

15

7

14

13

4

1

Input Air

Regulated Air

Page 12

Timer seems inoperative.

Troubleshooting Guide

End-of-cycle feedback circuit

is not functioning

No power

Valve does not spray below

.015 second time setting

If trouble cannot be corrected, or if you need further assistance,

please call us

.

In the US, call 800-556-3484. In the UK, phone 0800 585733.

In Asia, +86 (21) 5854 2345.

Trouble Possible cause and correction

Be sure that there is power at the wall

receptacle. Check the input power fuse.

If the fuse has blown, check the voltage

value in the fuse cartridge window. Be

sure that it matches the input voltage.

Ensure that the external voltage to the

circuit is between 5 and 24 VDC and that

the load does not exceed 250mA. If the

circuit has been overloaded, the fuse may

have blown. Replace fuse, if necessary.

Response delay in pneumatic circuit does

not allow the valve to open when time is

at or below 0.015 seconds. Increase time.

Valve operating pressure lower than 60 psi

(4.1 bar) can cause inconsistent output.

Make sure pressure is set at 70 psi (4.8 bar).

Check controller and reservoir air pressure readings to be sure air pressure is

not varying.

Air bubbles in the material can cause

inconsistency. For best results, remove all

air bubbles.

Check to be sure time override mode is off.

Inconsistent deposits

10 / Troubleshooting Guide

Page 13

11 / Input / Output Connections

Note: 9-pin male connector assembly is

included (replacement part # 7154).

]

]

5-24 VDC

250mA Max

5-24 VDC

Pin Function

1. Initiate +

2. Initiate -

3. Output +

4. Output -

5. Contact Closure

6. Chassis Ground

7. Contact Closure

8. Not Used

9. Not Used

I/O Connection

The 9-pin D connector

and internal circuitry provide external initiate and

end-of-cycle feedback

signal. The pin connections are shown below.

Input/Output Connections

1. Voltage Initiate Circuit

The controller may be initiated with

a 5 to 24 VDC signal across pins

1 and 2. The signal can be momentary (no less than 0.02 seconds) or

maintained. A new cycle will begin

once power is removed and then

applied again.

2. End-of-Cycle Feedback Circuit

Upon completion of a dispense

cycle, an open collector circuit

closes and remains closed until the

next dispense cycle. This circuit

can be utilized to signal back to a

host computer, start another device

in sequence or other operations

that need to be tied into completion of the dispense cycle.

Upon closure, power from an external 5 to 24 VDC source is allowed

to pass through the circuit to operate a load. The load illustrated is a

relay, but this could be any device

that will operate within the 5 to 24

volt range. Power consumption of

the load must not exceed 250mA.

3. Mechanical Contact Initiate

The controller can be initiated via

the closure of mechanical contacts such as a relay or switch

using pins 5 and 7. Closure of

the contacts can be momentary

(no less than 0.02 seconds) or

maintained. A new cycle will

begin once the contacts are

opened and then closed again.

Note: For applications using more than

one 7040, see page 15 for connection

instructions.

6789

12345

Page 14

Micro-

controller

Opto

coupler

Fuse

Voltage Initiate Circuit

5 to 24 VDC power source

power consumption

2.2mA at 5 VDC

15.0mA at 24 VDC

End-of-Cycle

Feedback Circuit

5 to 24 VDC power

source maximum

load 250mA

1

00/120/220 VAC

50/60 Hz 14/12 VA

+ 5 VDC

Solenoid 1

7815

control

Protector

Solenoid 2

atomizer

control

Power

supply

Nonvolatile

memory

Programmable

display

Opto

coupler

+ 24 VDC

Mechanical Contact Initiate

Mechanical contact power

consumption contact load

= 5.5 VDC / 100uA

Foot Pedal

+

+

_

_

2

3

4

5

7

1

A relay is

illustrated

as one example

for utilizing the

feedback circuit.

NOTE: DO NOT APPLY

VOLTAGE across pins

5 and 7.

12 / Input / Output Connections

Input/Output Connections

Page 15

13 / Connecting More Than One 7040 Controller

Connecting more than one 7040 Controller

2. Series circuit for End-of-Cycle Feedback

feature. A relay is illustrated as one

example for utilizing the feedback circuit.

1. Parallel circuit diagram for Voltage Initiate.

1. Voltage Initiate Circuit

To start the dispense cycle for multiple 7040 controllers at the same time,

connect the voltage initiate circuit in

parallel as illustrated.

Note: The amperage consumption for the

voltage initiate circuit will increase

with each controller that is connected.

The initiate power supply should be

sized accordingly.

2. End-of-Cycle Feedback Circuit

This circuit will ensure that the endof-cycle signal will come from the last

7040 to complete a dispense cycle.

Connect in series as illustrated.

Note: There will be a maximum voltage

drop of 2.0 VDC through the feedback circuit with each 7040 that is

added to the series. The input power

should be adjusted for this drop to

ensure that the required voltage is

available to operate the load.

Maximum input voltage to terminals

3 and 4 must not exceed 30.0 VDC.

12345

6789

12345

6789

12345

6789

5-24 VDC

-

_

+

Source

6789

6789

6789

+

12345

12345

12345

Page 16

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

EFD, Inc.

East Providence, RI USA

800-556-3484; +1-401-434-1680 (outside the USA)

info@efd-inc.com www.efd-inc.com

EFD International Inc.

Dunstable, Bedfordshire, UK

0800 585733 or +44 (0) 1582 666334

Ireland 00800 8272 9444

europe@efd-inc.com www.efd-inc.com

EFD, Inc., Asia

China: +86 (21) 5854 2345

china@efd-inc.com www.efd-inc.com/cn

Singapore: +65 6896 9630 sin-mal@efd-inc.com

©2006 Nordson Corporation 7040-MAN-01 v062606

®

A NORDSON COMPANY

This equipment is regulated by the European Union under WEEE

Directive (2002/96/EC). See www.efd-inc.com for information about

how to properly dispose of this equipment.

Loading...

Loading...