EATON MVX9000 Service Manual

MVX9000 Adjustable Frequency Drives

Technical Data

MVX9000 Drives

Prices effective December 2004

Model MVX9000

Product Description

Cutler-Hammer

vector adjustable frequency AC Drives

from Eaton’s electrical business are

designed to provide adjustable speed

control of three-phase motors. These

microprocessor-based, sensorless

vector drives have standard features

that can be programmed to tailor the

drive’s performance to suit a wide

variety of application requirements.

The MVX9000 sensorless vector product line utilizes a 32-bit microprocessor

and insulated gate bipolar transistors

(IGBTs) which provide quiet motor

operation, high motor efficiency and

smooth low speed performance. The

size and simplicity of the MVX9000

make it ideal for hassle free installation

where size is a primary concern.

Models rated at 480 volts, three-phase,

50/60 Hz are available in sizes ranging

from 1 to 10 hp. Models rated at 240

volts, single- or three-phase, 50/60 Hz

are available in sizes ranging from 1/2

to 7-1/2 hp. Models rated at 115 volts,

single-phase, 50/60 Hz are available in

the 1/4 to 1 hp size range.

®

MVX9000 sensorless

Contents

Description Page

Product Description . . . . . . . . . . . . 1

Features and Benefits

Technical Data and

Specifications

Wiring Diagrams

Dimensions

. . . . . . . . . . . . . . . . . . 5

Catalog Number Selection

Product Selection

Options

. . . . . . . . . . . . . . . . . . . . . . 8

The standard drive includes a digital

display, operating and programming

keys on a removable keypad.

The display provides drive monitoring

as well as adjustment and diagnostic

information. The keys are utilized for

digital adjustment and programming

of the drive as well as for operator

control. Separate terminal blocks for

control and power wiring are provided

for customer connections. Other features

provided as standard include built-in

DC braking, RS-485 serial communications and PID control.

. . . . . . . . . . 1

. . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . 3

. . . . . . 6

. . . . . . . . . . . . . 8

Features and Benefits

Table 1. Features and Benefits

Feature Customer Benefit

Sensorless Vector Control with auto tuning. Provides 200% starting torque and advanced low

Clearly laid out and easy to understand keypad

with 4-character LED display, 7 status indicating

LEDs, speed potentiometer, and 6 function keys.

2 analog inputs

6 programmable, intelligent digital inputs

1 programmable digital output

1 programmable relay

PID control of a process variable such as pressure,

flow, temperature, liquid level, etc.

Built-in dynamic braking chopper. Superior deceleration performance.

Serial communication port (RS-485). Direct connection to serial communications

Single-phase or three-phase input capability on

240V AC rated units, 3 hp and below.

TD04002001E For more information visit: www.EatonElectrical.com

speed torque control.

Most informative operator’s interface in this

class of VFD, provided as standard. All parameters,

diagnostic information and metering values are

displayed with a bright 4-character LED display.

Provide enhanced application flexibility.

Eliminates requirement for separate setpoint

controller.

networks.

Operate three-phase motor with single-phase

supply.

Technical Data

Page 2

Technical Data and Specifications

Output Ratings

■

Horsepower;

❑

90V – 132V, 1/4 – 1 hp

❑

200 – 240V: 1/2 – 7-1/2 hp

❑

380 – 480V: 1 – 10 hp

Frequency Range: 0.1 – 400 Hz

■

■

Overload Rating: 150% for 60 seconds

Frequency Resolution:

■

❑

Digital: 0.1 Hz

Analog: Max. (Set Frequency/1000) Hz

❑

■

Frequency Accuracy

Digital: ± 0.01% of max. frequency

❑

Analog: ± 0.2% of max. frequency

❑

Undervoltage Carryover Limit:

■

0.3 to 25 seconds

Motor Performance

Motor Control:

■

■

Constant and Variable Torque:

Standard

■

Speed Regulation:

Input Power

■

Voltage at 50/60 Hz ± 3 Hz

100V – 120V, -10% +10% / 1-phase

❑

200V – 240V, -10% +5% / 1-phase

❑

200V – 240V, -10% +5% / 3-phase

❑

❑

380V – 480V, -10% +10% / 3-phase

Displacement Power Factor:

■

Better than 0.95

Efficiency: Typically greater than 95%

■

Design Type

■

Microprocessor: 32-Bit

■

Converter Type: Diode

Inverter Type: Insulated Gate Bipolar

■

Transistor

Waveform: Sensorless Vector

■

Environment

■

Operating Temperature:

-10°C to +50°C

❑

-10°C to +40°C (above 7-1/2 hp)

❑

Humidity: 20 to 90% non-condensing

■

■

Maximum Elevation: 1000 meters

(3300 ft.)

Codes and Standards

■

NEMA, IEEE, NEC: Design Standards

UL Listed

■

■

cUL Listed

■

CE Marked (Requires EMI filter)

Effective: December 2004

Sensorless Vector

0.5% of base speed

MVX9000 Adjustable

Frequency Drives

Enclosure

■

Standard: Protected Chassis (IP20)

Protective Features

■

Ground Fault: Standard

Overload Protection: Standard

■

■

Overcurrent: Standard

Overvoltage: Standard

■

■

Undervoltage: Standard

■

Overtemperature: Standard

■

Overload Limit: Standard

Set Up Adjustments, Performance

Features, Operator Control and

External Interface

Keypad

Alphanumeric Display:

■

Standard, 1 x 4 character

Digital Indications:

■

Frequency (Hz), Motor Current

(amps), User-Defined RUN/STOP,

FORWARD/REVERSE and Parameters

■

Diagnostics: Last 3 trips with cause

■

LED Status Indicators: 8

(RUN/STOP, FORWARD/REVERSE,

Hz, Amps, User Defined, and Input

Speed)

Operator Functions:

■

START/STOP, Speed control (digital

or potentiometer), RESET, SETUP

Keys and ENTER.

I/O Terminal Block

Analog Inputs:

■

❑

2 Inputs: 0 – 10V DC, 4 – 20 mA

Potentiometer: 1K ohm to 2K ohm

❑

Analog Voltage: Nominal 10V DC

❑

(10K ohm input impedance)

❑

Analog Current: Nominal 4 – 20

mA (250 ohm)

■

Digital Inputs: 6 Programmable

Inputs

■

Digital Outputs: 1 Programmable

Open collector and 1 Form C Relay

contact

■

Analog Monitor Output:

❑

Analog meter – frequency or

output current

■

Dynamic Brake Chopper

Programmable Parameters

Out of the Box: Factory settings

■

loaded for quick start-up.

Accel. and Decel.: 2 separately

■

adjustable Linear or S Curve times:

0.1 – 3000 seconds

Auto Restart:

■

Overcurrent, overvoltage and

undervoltage with 4 selectable retry

restart modes

DC Injection Braking

■

■

External Fault: Terminal input

Jog: Terminal input

■

Fault Reset: STOP/RESET or terminal

■

input

■

I/O: NO/NC Selectable

Jump Frequencies: 3 (with adjustable

■

width)

Parameter Security: Programmable

■

software lock

Preset Speeds: 7 preset speeds

■

■

PID Controller: PID process control

Reversing: Keypad or terminal

■

■

Speed Setting: Keypad, terminal

or pot

■

START/STOP Control: Keypad or

terminal

■

Stop Modes: Decel, coast or DC

injection

Reliability

■

Pretested Components: Standard

■

Surface Mount Technology:

Standard (PCBs)

■

Computerized Testing: Standard

Final Test with Full Load: Standard

■

■

Eaton’s Cutler-Hammer Engineering

Systems and Service: National network of AF drive specialists

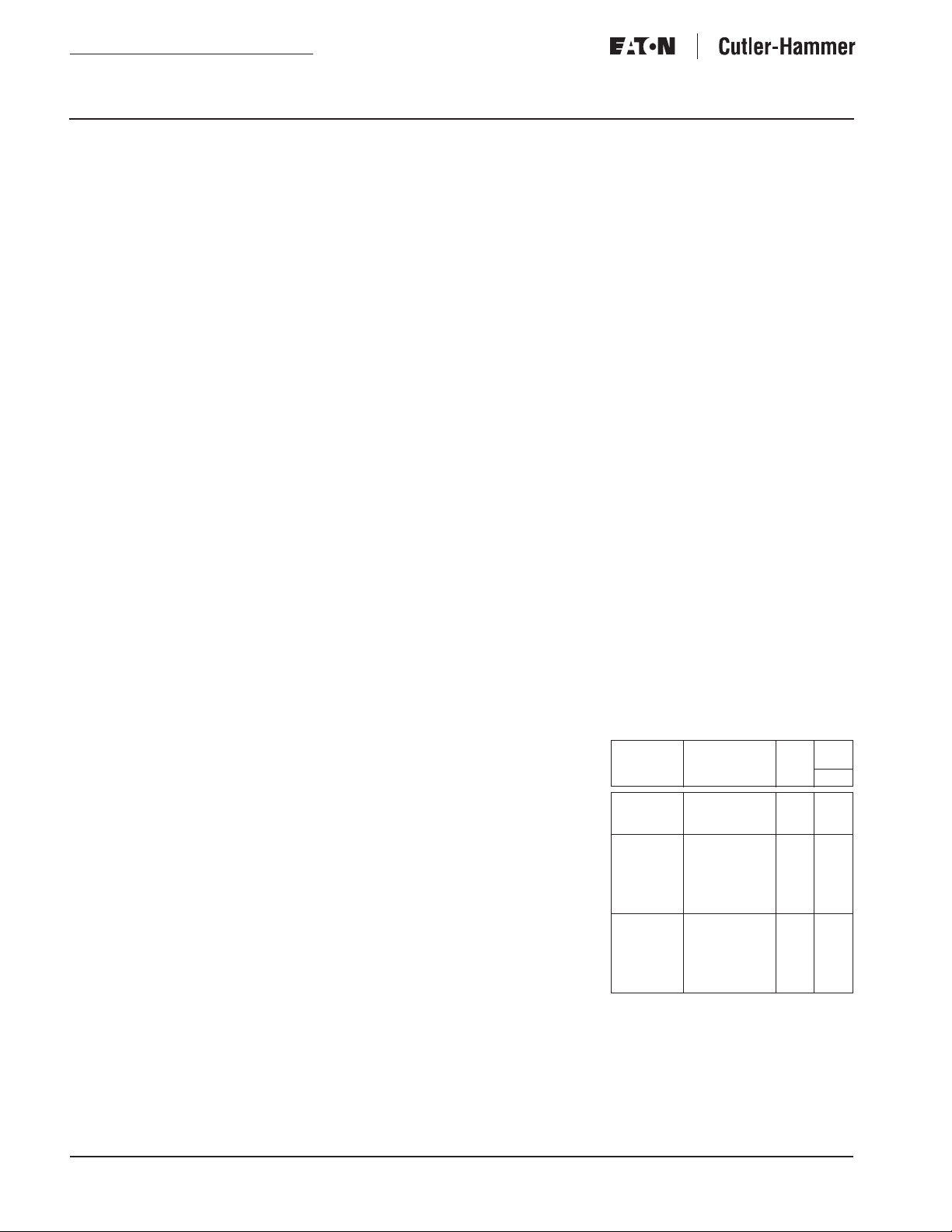

Table 2. Watts Loss

Horsepower Catalog

1/4

1/2

1

1/2

1

2

3

5

7-1/2

1

2

3

5

7-1/2

10

Number

MVXF25A0-1

MVXF50A0-1

MVX001A0-1

MVXF50A0-2

MVX001A0-2

MVX002A0-2

MVX003A0-2

MVX005A0-2

MVX007A0-2

MVX001A0-4

MVX002A0-4

MVX003A0-4

MVX005A0-4

MVX007A0-4

MVX010A0-4

Volts Watts

115VAC20W

240V AC20W

480V AC38W

Loss

9 kHz

20W

38W

38W

75W

110W

185W

275W

75W

110W

185W

275W

375W

For more information visit: www.EatonElectrical.com

TD04002001E

MVX9000 Adjustable

Frequency Drives

Table 3. Dynamic Breaking Resistor Sizing

Dynamic Braking Resistors, Open Units Catalog Number Resistor

Horsepower Volts

1/4

1/2

1

1/2

1

2

3

5

7-1/2

1

2

3

5

7-1/2

10

Braking resister kit includes two resistors to be connected in parallel.

Braking resister kit includes three resistors to be connected in parallel.

115V

Series

230V

Series

460V

Series

K13-000034-0821

K13-000034-0821

K13-000034-0821

K13-000034-0821

K13-000034-0821

K13-000034-0824

K13-000034-0824

K13-000034-0825

K13-000034-0826

K13-000034-0841

K13-000034-0843

K13-000034-0843

K13-000034-0844

K13-000034-0845

K13-000034-0846

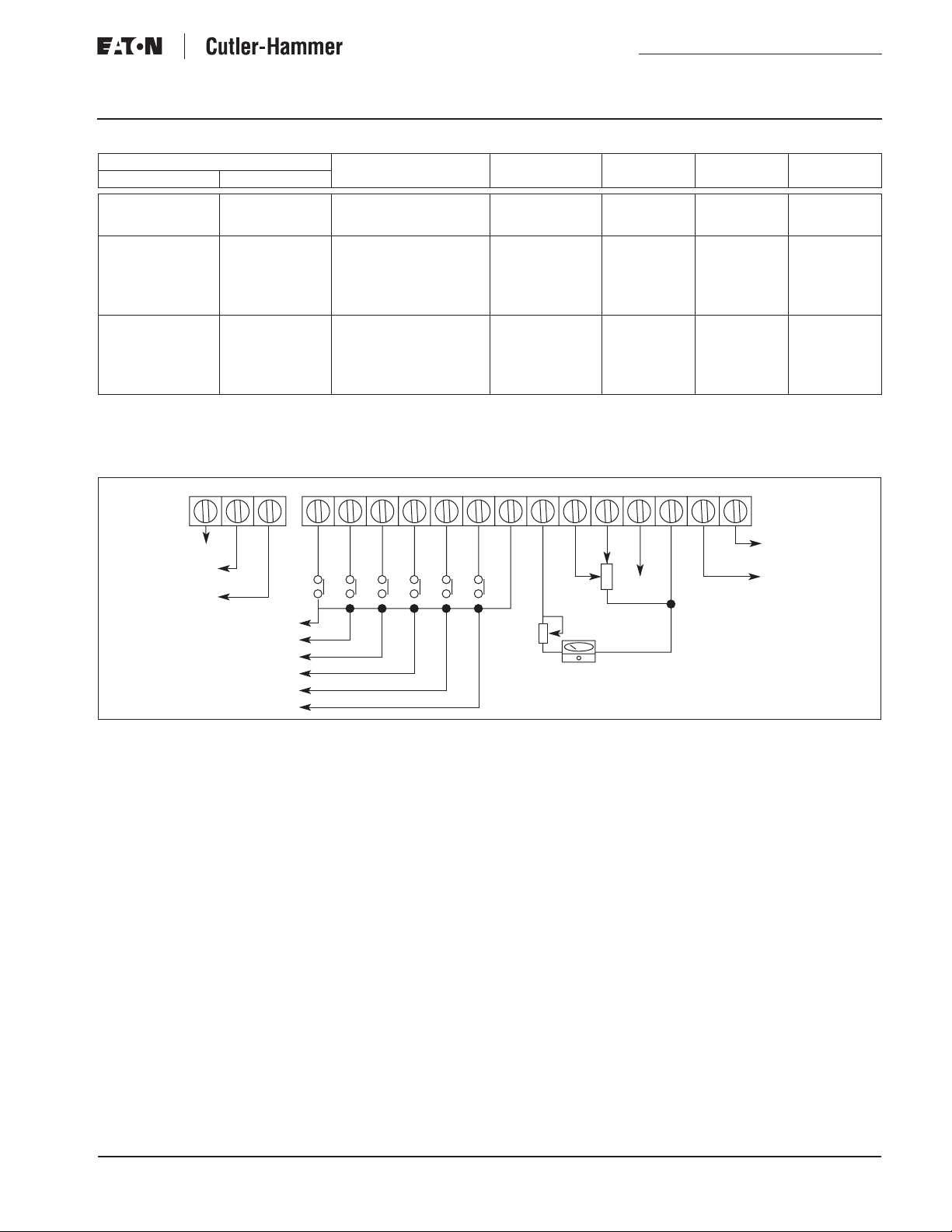

Wiring Diagrams

RO3

RO1 DI1 DI2 DI3 DI4 DI5 DI6 COM AO+ AI1 +10V AI2 COM DO1 DOC

RO2

(Min. Ohms)

100

100

80

100

80

55

35

25

16

260

190

145

95

60

45

Technical Data

Effective: December 2004 Page 3

Watts Braking

80W

80W

80W

80W

80W

300W

300W

400W

500W

80W

300W

300W

400W

500W

700W

Torque

220%

220%

125%

220%

125%

125%

125%

125%

125%

125%

125%

125%

125%

125%

125%

Duty

Cycle

10%

10%

10%

10%

10%

10%

10%

10%

10%

10%

10%

10%

10%

10%

10%

NC Relay Output

Factory Setting:

Inverter Fault

NO Relay Output

Forward/ Stop

Reverse/ Stop

Preset Speed 1

Preset Speed 2

Preset Speed 3

Reset

Figure 1. Control Terminal Wiring (Factory Settings)

4 – 20 mA

Bias

Potentiometer

Full Scale Voltmeter:

0 to 10V DC

Factory Setting:

Output Frequency

Factory Setting:

Inverter Running

Digital Output

TD04002001E For more information visit: www.EatonElectrical.com

Loading...

Loading...