Duke FBB-1C-230-AU Installation Manual

Installation & Operation Manual

BURGER KING

FLEXIBLE BATCH

BROILER

Australia Version

Please read this manual completely before attempting

to install, operate or service this equipment

This manual is Copyright © 2011 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Co.

Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-2460

www.dukemfg.com

P/N 175187J

Installation & Operation Manual for Flexible Batch Broiler

Australian Units

2

Installation & Operation Manual for Flexible Batch Broiler

Australian Units

TABLE OF CONTENTS

PAGE

I. General Information ......................................................................................................5

A. Batch Broiler Specications ......................................................................................5

A-1.0 Model Number Key ......................................................................................5

A-2.0 Broiler Dimensions ......................................................................................6

II. Installation Instructions ................................................................................................7

A. Qualied Personnel ..................................................................................................7

B. Delivery and Inspection ............................................................................................7-8

C. Broiler Assembly ......................................................................................................9

D. Adjustments at Installation .......................................................................................11

E. Location of the Broiler ..............................................................................................12

F. Gas Piping ................................................................................................................12

G. Electrical Connections .............................................................................................12

H Ventilation ................................................................................................................12

III. Operation Instructions .................................................................................................13

A. Broiler Controls .........................................................................................................13

B. Cooking Product .......................................................................................................13

B-1.0 Lighting the Broiler.......................................................................................13

B-2.0 Cook Product ...............................................................................................14

B-3.0 Cook Cycle Complete ..................................................................................15

B-4.0 Fine Cooking Adjustment.............................................................................15

B-5.0 Cancel a Cook Cycle ...................................................................................15

B-6.0 Checking the Broiler Temperature ...............................................................15

B-7.0 Checking the Set Point Temperature ...........................................................15

B-8.0 Shutdown the Broiler ...................................................................................15

C. Cleaning....................................................................................................................15-16

C-1.0 Four (4) Hour Cleaning ...............................................................................17

C-2.0 Daily Cleaning .............................................................................................18-19

C-3.0 Weekly Cleaning .........................................................................................20-22

C-4.0 Monthly Cleaning.........................................................................................23

D. Troubleshooting ........................................................................................................24-26

IV. Service and Repair .......................................................................................................27

V. Replacement Parts List ................................................................................................28-29

VI. Wiring diagram .............................................................................................................30

VII. Customer Assistance .................................................................................................31

3

Installation & Operation Manual for Flexible Batch Broiler

Australian Units

IMPORTANT WARNING AND SAFETY INFORMATION

Post In A Prominent Location Instructions To Be Followed In The Event The

User Smells Gas. This Information Shall Be Obtained By Consulting The Local

Gas Supplier.

FOR YOUR SAFETY:

• Do not store or use gasoline or other ammable vapors or liquids in the

vicinity of this or any other appliance.

• Do not spray aerosols in the vicinity of this appliance while it is in

operation.

: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before installing or

servicing this equipment.

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

4

Installation & Operation Manual for Flexible Batch Broiler

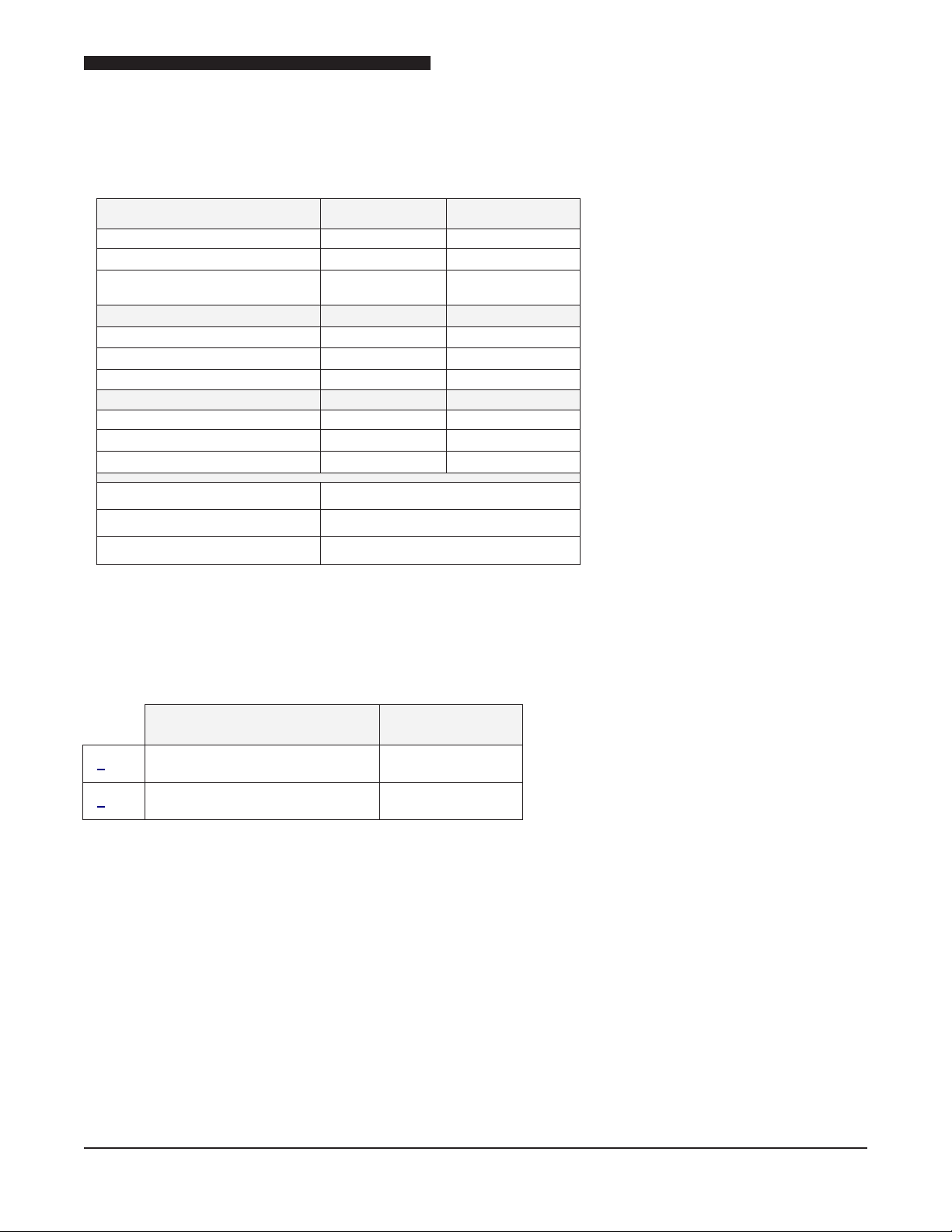

I. GENERAL INFORMATION

A. Batch Broiler Specications

NATURAL GAS PROPANE GAS

ALTITUDE (MAXIMUM) 607 m 607 m

GAS PIPE CONNECTION 12.7mm BSPT 12.7mm BSPT

BURNER AERATION

SHUTTER SETTING

Supply Pressure (KPa) 1.13 2.75

IR Burner Pressure (KPa) 0.93 1.99

Lower Burner Pressure (KPa) 0.93 1.99

ORIFICE – Front IR Burner (mm) 2.35 1.55

ORIFICE – Rear IR Burner (mm) 2.50 1.61

ORIFICE – Lower Burner (mm) 3.05 1.85

SHIPPING WEIGHT 204 Kg (450 lbs)

SHIPPING DIMENSIONS

ELECTRICAL RATING

OPEN

9.55 mm

121.9 cm x 99.1 cm x 172.7 cm (48” x

39” x 68”)

230V~ 50Hz 1.1A 250W

OPEN

8.00 mm

Australian Units

A-1. Model Number Key

FBB-XY-230

X identies Gas Conguration Y = C with Catalyst

DESCRIPTION MODEL

X = 1 Propane Gas with Catalyst FBB-1C-230-AU

X = 2 Natural Gas with Catalyst FBB-2C-230-AU

5

Installation & Operation Manual for Flexible Batch Broiler

Australian Units

A-2. Broiler Dimensions

Note: Dimension shown in centimeters, bracketed [ ]are in inches

44"

111.9

20 3/4"

52.9

8 1/2"

21.6

50 3/8"

128

39 1/2"

100.3

34 3/4"

88.4

GAS CONNECTION*

3/4" BSPT FEMALE

3 7/8"

9.7

36 1/4"

92.2

HIGH POSITION

53 5/8"

136.1

31 1/2"

80

HIGH POSITION

ELECTRICAL CONNECTION*

FOR 250cm [98"] LONG

INTERNATIONAL

ELECTRICAL CORDSET

28 1/4"

71.9

LOW POSITION

63 5/8"

161.7

45 5/8"

115.8

55 5/8"

141.4

23 1/2"

59.8

LOW POSITION

Note: Refer to Australian Service Agent, as per clause 2.10.2.4(c) of AS4563.

6

Installation & Operation Manual for Flexible Batch Broiler

II. INSTALLATION INSTRUCTIONS

Australian Units

A. QUALIFIED PERSONNEL

These installation instructions are for the use of

qualied installation and service personnel only.

Installation or service by other than qualied personnel

may result in damage to the broiler and/or injury to the

operator.

Qualied installation personnel are those individuals,

rms, companies or corporations which either in person

or through an agent is engaged in and responsible

for:

• Compliance with the installation in force

in the country in which the appliance is to

be installed.

• This appliance shall be installed with sufcient

ventilation to prevent the occurrence of unacceptable

concentrations of substances harmful to health in

the room in which the appliance is installed.

• Caution - the appliance is mounted on 4

wheels. Care must be taken not to hit kitchen walls

or similar hard objects while moving or installing

the appliance.

• Parts protected by the manufacturer, agent, or

assignee shall not be adjusted by the installer.

B. DELIVERY AND INSPECTION

Duke Manufacturing Co. does everything within its power

to insure you received your broiler in good condition.

They are strapped down on heavy wooden skids and

packed to prevent shipping damage. They have all been

carefully inspected before they were packaged and

consigned to the carrier.

Upon delivery of your Duke broiler:

• Look over the shipping container, carefully noting

any exterior damage on the delivery receipt,

which must also be signed by the driver/ delivery

person.

• Unpack and check for any damage, which

was not evident on the outside of the shipping

container.

Caution: The Broiler is very heavy!

Use adequate help for lifting.

• This appliance shall be installed in accordance

with the requirements of AS5601, local authorities,

gas, electricity and any other relevant statutory

regulations.

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

7

Installation & Operation Manual for Flexible Batch Broiler

Australian Units

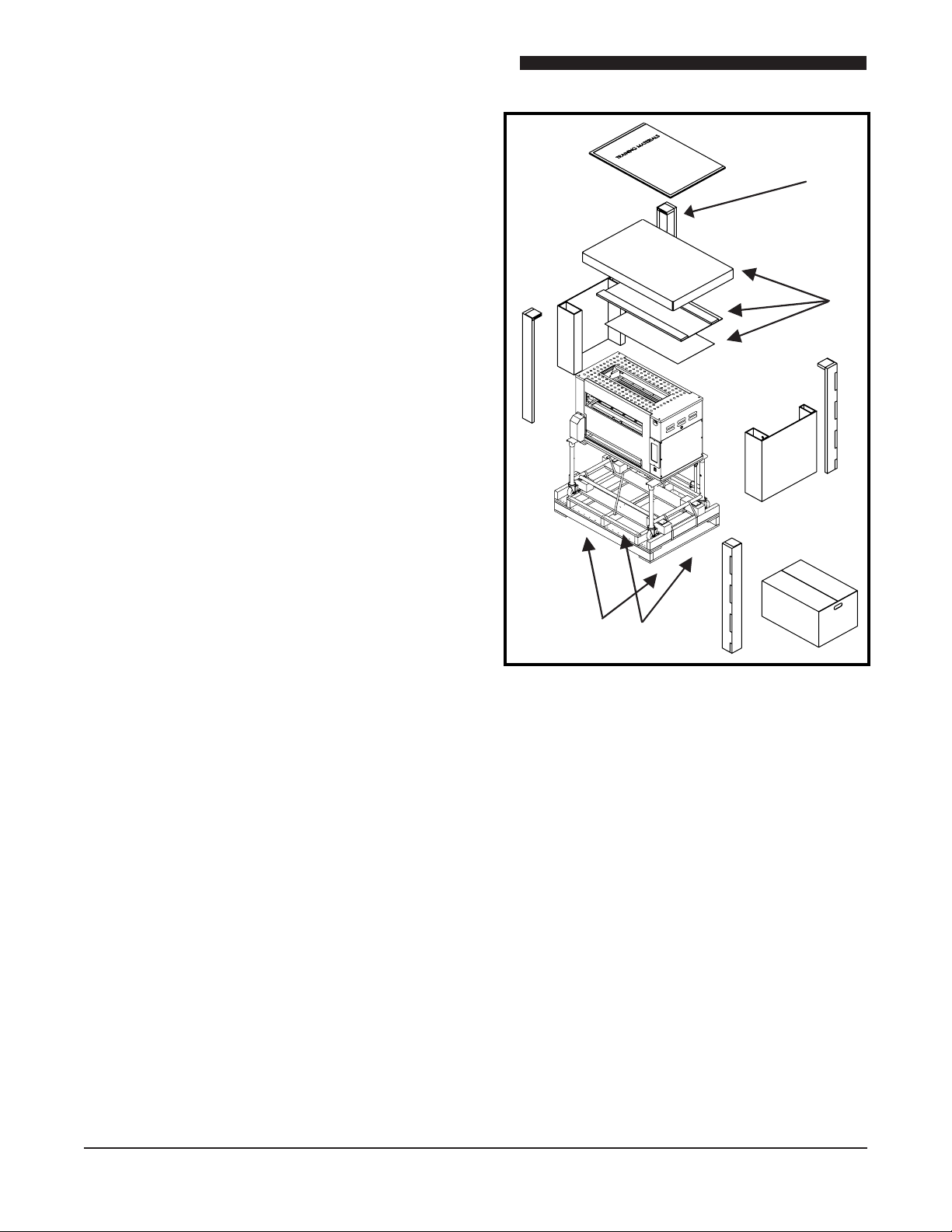

1. Using a utility knife, cut away plastic wrap

(Not shown).

2. Remove Training Material Box.

3. Remove the top cardboard and inner cap

4. Re mo ve ca rd bo ar d f ro m t he co rn er s

(4 places).

5. Remove cardboard on the ends (2 places).

6. Remove banding straps (Cut with utility knife or

scissors: 5 places).

7. Remove box of attachable parts & accessories

from the front.

8. Safely lift one end of broiler and tap block towards

center and then sideways to remove. Repeat for

remaining blocks. This allows casters to touch the

pallet.

9. While carefully supporting broiler, slowly

roll it off the pallet taking care not to damage the

casters.

10. Remove blue tape from broiler panels.

• Check for concealed damage. The carrier must be

notied within fteen (15) days of the delivery of

the broiler and the carton, skid and all packaging

materials must be retained for inspection.

• Duke Manufacturing Co. cannot assume liability

for loss or damage suffered in transit. The carrier

assumes full responsibility for delivery in good order

when the shipment was accepted. However, we

are prepared to assist you with ling your claim.

4

5

8

6

2

4

3

5

4

7

4

8

Installation & Operation Manual for Flexible Batch Broiler

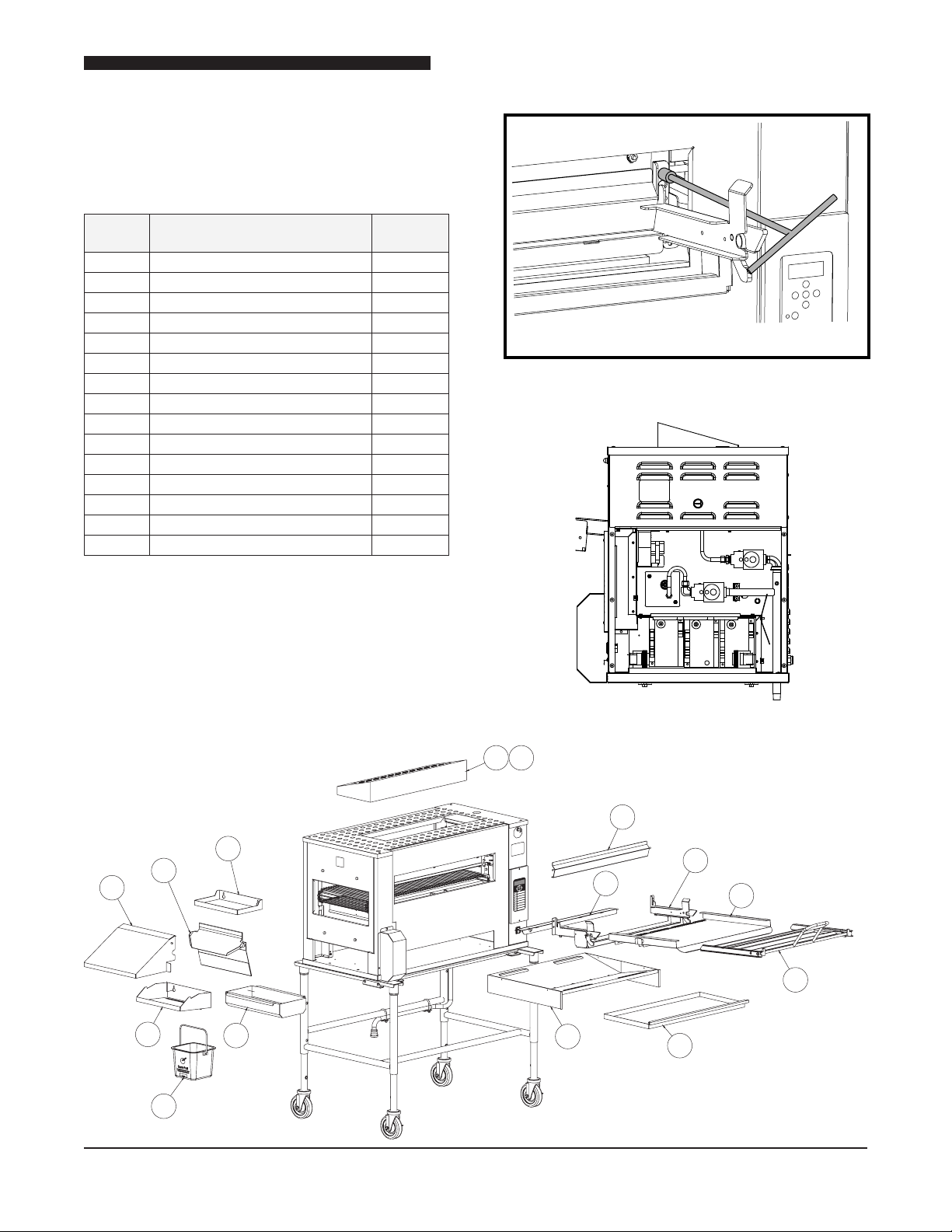

C. BROILER ASSEMBLY

Before assembling and installing the broiler,

please check to make sure that all necessary

parts are present.

Australian Units

ITEM

#

1 PRODUCT PAN SHELF 175353

2 DISCHARGE CHUTE 175340

3 DISCHARGE HOOD 175362

4 DISCHARGE PAN HOLDER 175358

5 DISCHARGE GREASE PAN 175357

6 “V” GREASE PAN 175325

7 MAIN GREASE PAN 175329

8 LOADER 175444

9 LOADER TRAY 175430

10 LOADER BRACKET 175438

11 DOOR 175429

12 LOADER RAMP 175741

13 CATALYST 175480

14 CATALYST GUARD 175482

15 SANITATION PAIL 175842

PART NAME

Setup: Install all items as shown below.

Note: Install loader bracket with (4) ¼-20 nuts. Use

supplied extension tool to remove and reinstall nuts.

(Nuts are shipped installed on loader mounting

studs.)

PART

#

Loader Install Tool

(Included with Broiler Tools Kit)

I.R. BURNER VALVE

BOTTOM

BURNER

MODULE

BOTTOM BURNER VALVE

TOP

TOP

FRONT I.R.

REAR I.R.

BURNER

BURNER

MODULE

MODULE

CONTROLLER

Control Panel

(For Reference Only)

13 14

11

1

2

3

12

10

9

8

4

5

6

7

15

9

Installation & Operation Manual for Flexible Batch Broiler

Australian Units

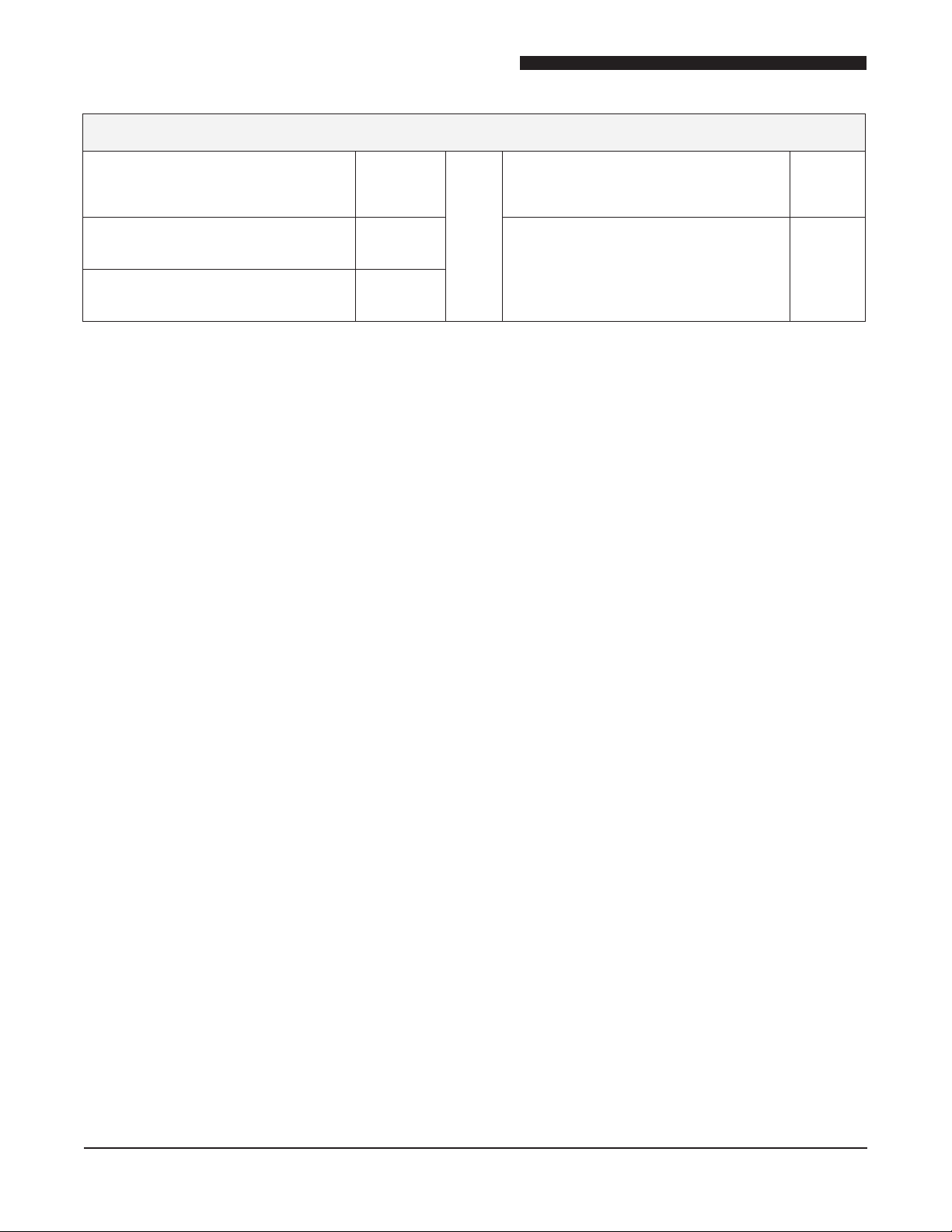

OPTIMAL SERVICE PARTS & ACCESSORIES

PARTS KIT – NATURAL GAS (w/

Controller & Cook Chain)

PARTS KIT – PROPANE GAS (w/

Controller & Cook Chain)

PARTS KIT - NATURAL AND PROPANE

GAS (Burner & Flame Arrestor)

175850

175852

175520

PARTS KIT - NATURAL AND PROPANE

GAS (Burner, Arrestor, Loader, & Burner

Shield)

KIT – CE GAS HOSE CONNECTOR

175526

175831

10

Loading...

Loading...