Duke AHPO-6-18 Service Manual

AHPO / EPO

B

AKIN

G CENTER

PROOFER OVEN

MODELS

AHPO-6/18

EPO-3/9

Service Manual

Please read this manual completely before attempting to install,

operate or service this equipment

This document is prepared for trained Duke service technicians. It is not to be used by anyone not properly qualied

to perform these procedures.

This Service Manual is not all encompassing. If you have not been trained on servicing this product, be sure to

read the manual completely before attempting servicing. Be sure all necessary tools, test equipment, and skills are

available. Those procedures for which you do not have the proper skills and test equipment must be performed only

by a qualied Duke trained service technician.

This manual is Copyright © 2009 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Co.

Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N 512981B

Service Manual for AHPO / EPO Proofer Oven

IMPORTANT WARNING AND SAFETY INFORMATION

IMPORTANT FOR YOUR SAFETY

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING

MAINTENANCE ON THE EQUIPMENT.

Failure to follow instructions in this manual can cause property

damage, injury or death.

Do not store or use gasoline or other ammable vapors or liquids

in the vicinity of this or any other appliance.

This unit is designed for a xed, permanent (hard) wired connection

to an appropriate AC power source as stated on the model label. The external

wiring interface must be installed as per the local AC wiring codes.

Always lockout / tagout the unit from the main AC power source

before removing any sheet metal panels or attempting to service this unit. Failure

to comply to this procedure may cause property damage, injury or death.

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this equipment.

Do not operate this equipment without properly placing and

securing all cover and access panels.

In the event of a power failure, do not attempt to operate this

device.

2

Service Manual for AHPO / EPO Proofer Oven

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................... 4

INSTALLATION ..................................................................................................................................... 4

OPERATION ........................................................................................................................................... 4

CLEANING ............................................................................................................................................ 4

TOOLS ........................................................................................................................................................ 4

STANDARD ........................................................................................................................................... 4

SPECIFICATIONS .......................................................................................................................................... 5

REMOVAL AND REPLACEMENT OF COMPONENTS ............................................................................. 6

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE ........................................................................... 6

COVERS AND PANELS ........................................................................................................................ 6

General Service Notes .................................................................................................................... 6

Proofer Rear Panel .......................................................................................................................... 6

Oven Rear Panels ............................................................................................................................ 6

Oven Fan Cage and Wire Harness Cover ....................................................................................... 7

Proofer Floor Panel ......................................................................................................................... 7

Oven Ceiling Panel ......................................................................................................................... 8

Control Panel .................................................................................................................................. 8

AC Power Access Panel ................................................................................................................. 9

AC INPUT VOLTAGE WIRING CONNECTIONS .............................................................................. 9

INTERNAL LAMP REPLACEMENT ................................................................................................... 9

CONTROL PANEL COOLING FAN ................................................................................................... 10

PROOFER LIGHTS CIRCUIT BREAKER ......................................................................................... 10

BUZZER ............................................................................................................................................... 11

OVEN POWER SWITCH .................................................................................................................... 12

OVEN THERMOSTAT ......................................................................................................................... 12

OVEN TIMER ...................................................................................................................................... 12

PROOFER POWER SWITCH .............................................................................................................. 13

PROOFER THERMOSTAT .................................................................................................................. 13

PROOFER HUMIDITY CONTROL .................................................................................................... 14

PROOFER TIMER................................................................................................................................ 14

PROOFER HEAT ELEMENTS ............................................................................................................ 15

PROOFER HUMIDITY ELEMENT .................................................................................................... 15

PROOFER CIRCULATION FAN......................................................................................................... 16

OVEN HEAT ELEMENTS ................................................................................................................... 17

OVEN CIRCULATION FAN ............................................................................................................... 17

OVEN HI-LIMIT THERMOSTAT ....................................................................................................... 18

DOOR GASKET REPLACEMENT ..................................................................................................... 18

OVEN SAFETY SWITCH ................................................................................................................... 18

ADJUSTMENTS ........................................................................................................................................... 19

DOOR GASKET COMPRESSION CHECK ....................................................................................... 19

DOOR GASKET ADJUSTMENTS ...................................................................................................... 19

AIR WASH DOOR ADJUSTMENT .................................................................................................... 20

Air Wash Door Adjustment – Hinge Side ..................................................................................... 20

Air Wash Door Adjustment – Handle Side............................................................................................ 20

MAINTENANCE .......................................................................................................................................... 21

STAINLESS STEEL CARE .................................................................................................................. 21

GENERAL CLEANING ....................................................................................................................... 21

TROUBLESHOOTING ................................................................................................................................. 22

ELECTRICAL SCHEMATIC ........................................................................................................................ 23

3

Service Manual for AHPO / EPO Proofer Oven

INTRODUCTION

INSTALLATION

For detailed installation instructions, refer to the Owner’s

Manual (502821A).

OPERATION

For specic operating instructions, refer to the Owner’s

Manual (502821A).

CLEANING

For specic instructions, refer to the Owner’s Manual

(502821A).

TOOLS

STANDARD

• Standard set of hand tools.

• VOM with AC current tester. (Any quality VOM or

DVM with a sensitivity of at least 20,000 Ohms per

Volt can be used.)

• A ladder or other appropriate item to stand on, if servicing

the top of the unit.

4

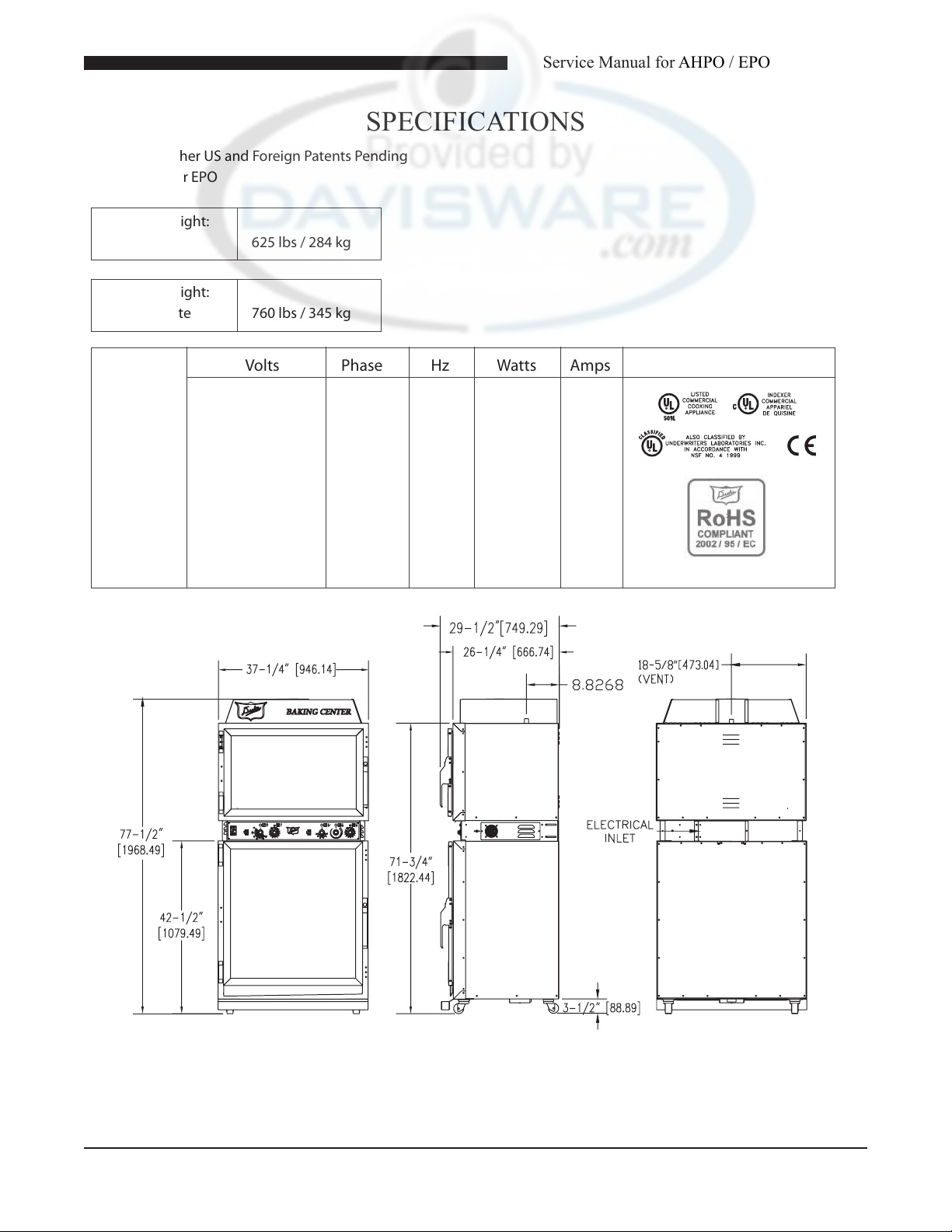

Volts Phase Hz Watts Amps

208 1 60 6650 32.0

208 1 50 6650 32.0

230 (220-240) 1 60 6650 32.0

230 (220-240) 1 50 6650 32.0

230 (220-240) 3 60 6650 16.7

230 (220-240) 3 50 6650 16.7

400 (380-415) 3N 60 6650 16.7

400 (380-415) 3N 50 6650 16.7

U.S. Patent. Other US and Foreign Patents Pending

Model AHPO or EPO

Shipping Weight:

Carton Box 625 lbs / 284 kg

Shipping Weight:

Wooden Crate 760 lbs / 345 kg

AHPO /

EPO

Service Manual for AHPO / EPO Proofer Oven

SPECIFICATIONS

5

Service Manual for AHPO / EPO Proofer Oven

REMOVAL AND REPLACEMENT OF COMPONENTS

ELECTRICAL LOCKOUT/TAGOUT

PROCEDURE

Before performing any service that

involves electrical connection or disconnection and/or

exposure to electrical components, always follow the

Electrical LOCKOUT/TAGOUT Procedure. Disconnect

all circuits. Failure to comply can cause property

damage, injury or death.

The Electrical LOCKOUT/TAGOUT Procedure is used to

protect personnel working on an electrical appliance. Before

performing any maintenance or service that requires exposure

to electrical components, follow these steps:

1. In electrical box, place appliance circuit breaker into

OFF position.

2. Place a lock or other device on electrical box cover to

prevent someone from placing circuit breaker ON.

3. Place a tag on electrical box cover to indicate that

appliance has been disconnected for service and

power should not be restored until tag is removed by

maintenance personnel.

Most service can be accomplished without moving the

unit from its mounted position. However, if the unit is

moved during service, then these securing devices must

be reinstalled for continued protection against tip-over

and to meet other compliance regulations.

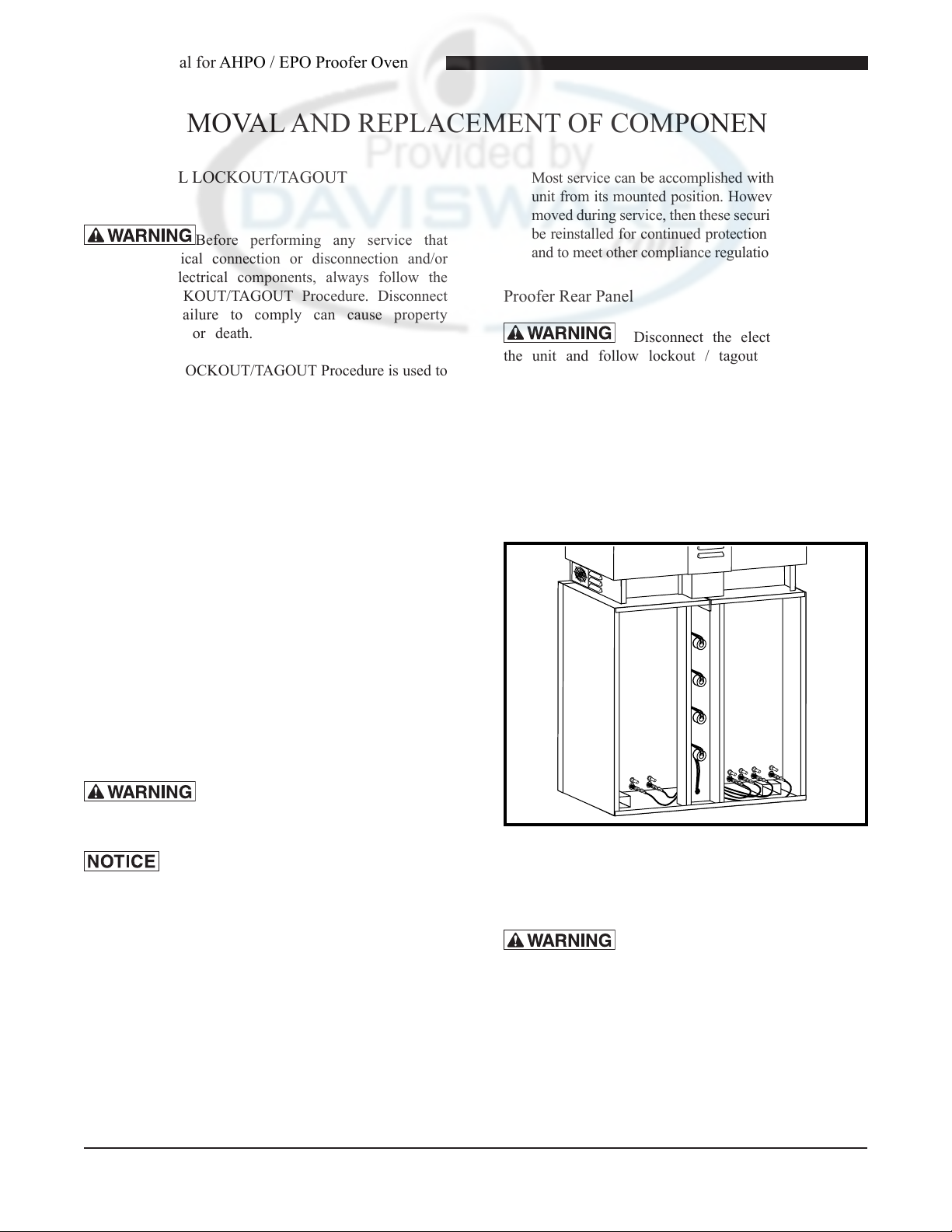

Proofer Rear Panel

Disconnect the electrical power to

the unit and follow lockout / tagout procedures.

Removing the Proofer Rear Panel, gains access to the Proofer

Light Fixtures, Proofer Burners connections, and Proofer

Wiring Harnesses.

1. Remove all of the self-tapping sheet metal screws that

secure the Rear Panel to the Proofer. Set aside for reuse.

2. Remove the Rear Panel to gain access to the components

located at the rear of the Proofer.

4. Disconnect appliance power cord from electrical outlet.

5. Place a tag on the cord to indicate that unit has been

disconnected for service and power should not be restored

until tag is removed by maintenance personnel.

COVERS AND PANELS

Disconnect the electrical power to

the unit and follow lockout / tagout procedures.

Interior components and surfaces may be hot

if the unit has been in recent use.

General Service Notes

• This unit uses water trays for humidity control. Remove

any water that might be present in the trays before

attempting service of any kind.

• During its installation, this unit is required to be secured to

the building structure. There is also a Restraining Device

(a heavy, exible metal cable) that was installed to prevent

the unit from moving beyond a certain distance in order

to prevent damage to the electrical conduit feeding it.

Figure 1. Proofer – Rear Panel Removed

Oven Rear Panels

Disconnect the electrical power to

the unit and follow lockout / tagout procedures.

The Oven section of the unit has three rear panels. The Center

Panel provides access to the Oven Light Fixtures and Oven

Light Fixture wiring harness. Right and Left Panels provide

access to the Oven Burner Element connections and Element

wiring harnesses.

1. Remove the screws securing the Center Panel. Retain

for reuse.

6

Service Manual for AHPO / EPO Proofer Oven

2. Remove the Center Panel to gain access to Light Fixtures

and wiring harness.

The Center Panel side screws must be removed

when removing either of the side panels.

3. Remove the screws securing the Side Panels. Retain for

reuse.

4. Carefully remove the insulation to gain access to the

Oven Burner Element connections and Oven Burner

Element wiring harness. Retain the insulation for reuse.

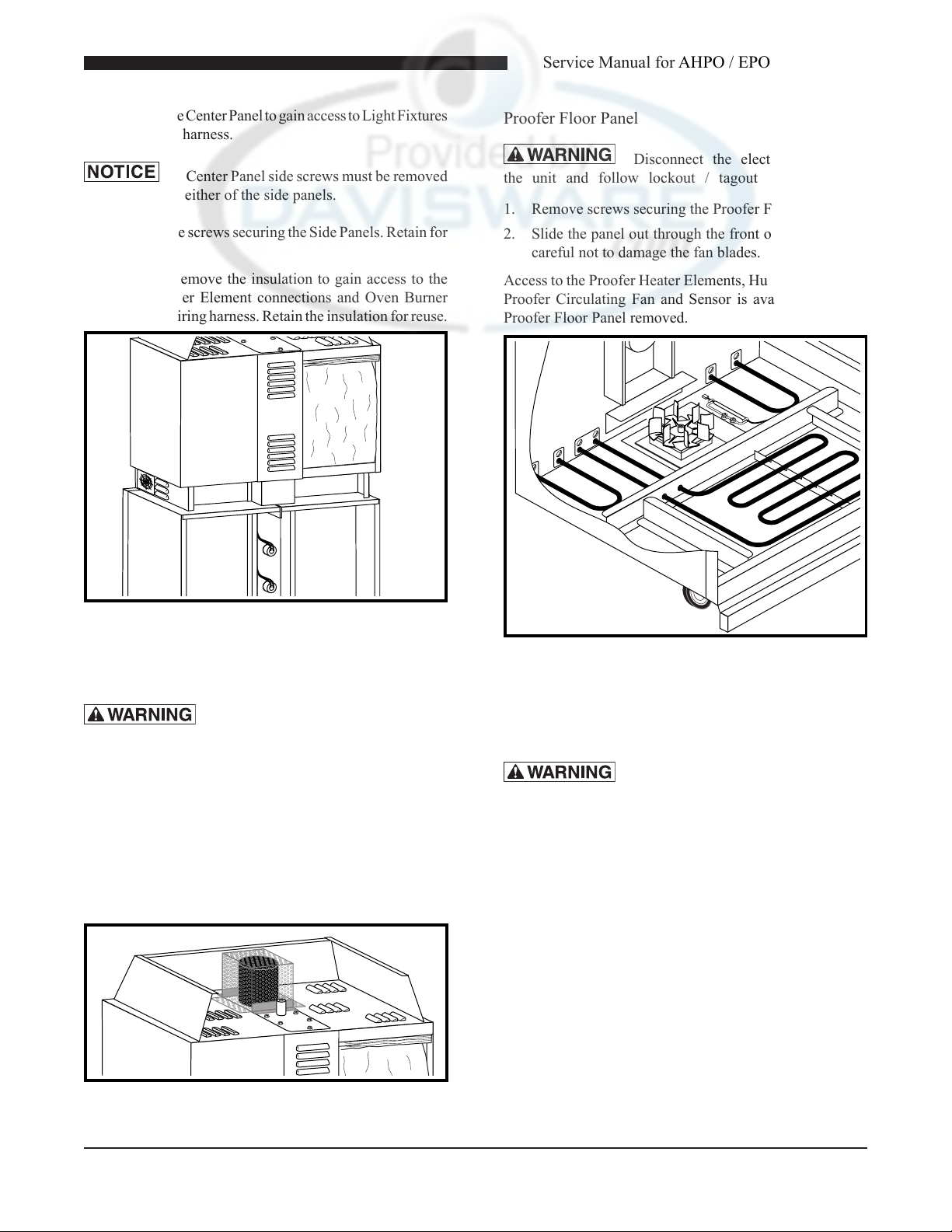

Proofer Floor Panel

Disconnect the electrical power to

the unit and follow lockout / tagout procedures.

1. Remove screws securing the Proofer Floor Panel.

2. Slide the panel out through the front of the unit being

careful not to damage the fan blades.

Access to the Proofer Heater Elements, Humidity Element,

Proofer Circulating Fan and Sensor is available with the

Proofer Floor Panel removed.

Figure 2. Oven – Right Side Panel Removed

Oven Fan Cage and Wire Harness Cover

Disconnect the electrical power to

the unit and follow lockout / tagout procedures.

1. Remove the four screws securing the Oven Fan Cage

to the top of the unit. Retain for reuse.

2. Remove the Cage to gain access to the Oven Fan Motor.

3. Remove the screws securing the Oven Fan Wire Harness

Cover to top of unit. Retain for reuse.

4. Remove the Oven Fan Wire Harness Cover to gain

access to the wiring harness and connections.

Figure 4. Proofer Components with

Floor Panel Removed

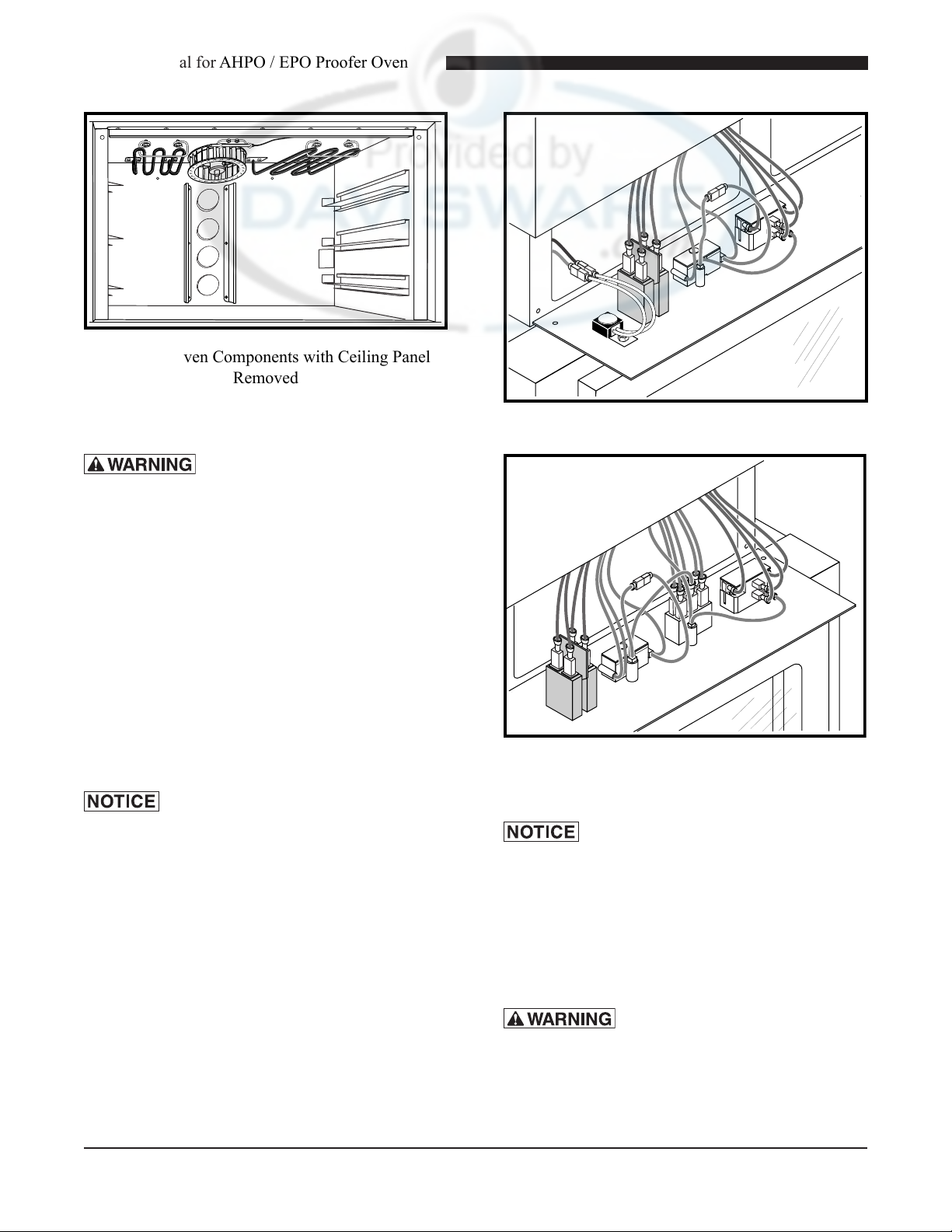

Oven Ceiling Panel

Disconnect the electrical power to

the unit and follow lockout / tagout procedures.

1. Remove the Humidity Pan.

2. Remove the screws securing the panel. Retain screws

for reuse.

3. It may be necessary to pry the panel forward from the

front of the unit. Be careful not to damage the fan blade

when removing the panel.

Access to Oven Heating Elements, Fan Blade and Sensors

is available with the Oven Ceiling Panel removed.

Figure 3. Oven Fan Cage and

Wire Harness Cover

7

Service Manual for AHPO / EPO Proofer Oven

Figure 5. Oven Components with Ceiling Panel

Removed

Control Panel

Disconnect the electrical power to

the unit and follow lockout / tagout procedures.

It is not necessary to move the unit to gain access to the

Control Panel. It might become necessary to remove the

unit from the wall if troubleshooting leads into other areas.

Refer to the specic component section of this manual when

replacing a component on the Control Panel.

1. Remove the four screws retaining the Control Panel to

the cabinet.

2. Carefully pull the front panel assembly away from the

cabinet while observing clearances of the wiring around

the controls.

All of the Operator Controls and related wiring are now

accessible.

DO NOT power on the unit while the Control

Panel is removed from the cabinet.

3. To troubleshoot for problems, use visual checks, an

Ohmmeter, the proper Schematic and Illustrations pages

for the version of the unit being serviced.

Figure 6. Components on Left Side of Control Panel

Figure 7. Components on Right Side of Control

Panel

When reassembling, make sure that wires do

not become pinched between the Control Panel and the

cabinet surfaces.

4. Replace all securing screws to the Control Panel before

re-powering the unit.

AC POWER ACCESS PANEL

Disconnect the electrical power to

the unit and follow lockout / tagout procedures.

8

Loading...

Loading...