Duke AHPO Installation Manual

OWNER’S MANUAL

AHPO/EPO

PROOFER OVEN

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

502821F

CONTENTS

Manufacturing Introduction 2

Safety Instruction 3

Spec Sheets 4

Main Features 5

Installation Instructions 6-9

Oven Start-Up 10

Proofer Operating Instructions 10-11

Oven Operating Instructions 12- 13

Care and Cleaning 14

Troubleshooting 15-16

Door Adjustments and Gasket Maintenance 17 -2 2

Air-wash door Information and Cleaning Instructions 23

Bulb Mounting Details 24

Parts List and Illustrations 25 -27

Wiring Diagrams 28

Customer Assistance 29

Manufacturers Introduction

The Duke AHPO or EPO Proofer Oven were developed

in response to Customer’s need for uniform baking

capabilities to provide consistently high, “just baked”

bread quality .

The Duke Proofer Oven utilizes Duke’s unique directional

convection airflow technology that provides even heat

distribution and a uniform bake without the need for

turning pans during the bake cycle. This enhances the

quality and consistency of the baked products while

reducing food scrap/waste and simplifying operating

procedures.

The low profile oven won’t block the view of menu boards

and will easily roll through a standard height door . The

oven and proofer doors are field reversible with a drip

channel on the proofer door to prevent water from

dripping on the floor.

Full width doors on the oven and proofer help to display

and merchandise fresh baked bread to the customer.

The controls are simple to operate, there are two timers

for independent timing of the proofer and oven.

The full width oven and proofer cavity will accept

standard ½ size or full size sheet pans.

Supplier Name: Duke Manufacturing Co.

Address: 2305 N. Broadway

St. Louis, MO 63102

Model #:

AHPO-6/18-208

AHPO-6/18-230

Note:“230V” can be used

for 220-240V

1Ph or 3Ph

AHPO-6/18-400

EPO-3/9-208

EPO-3/9-230

3N (3Ph w/neutral)

Note:“230V” can be used

for 220-240V

1Ph or 3Ph

EPO-3/9-400

3N (3 Ph w/neutral)

Serial #:

Date

Received:

Date

Installed:

T elephone: (800) 735-DUKE (3853)

(314) 231-1 130

Fax: (314) 231-5074

Service

Referral #:

Local

Service

Name:

Local

Service #:

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

2 of 29

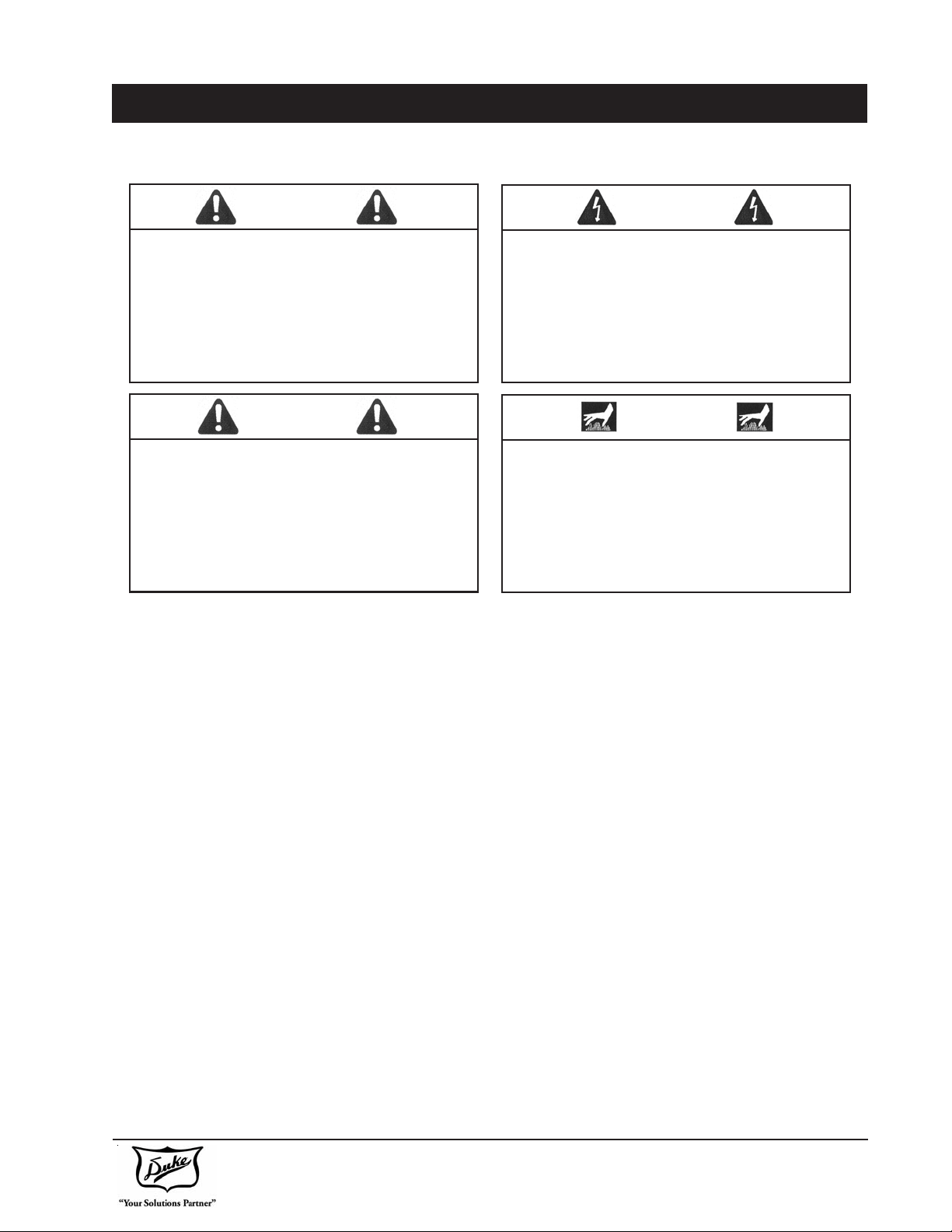

IMPORTANT SAFETY INSTRUCTIONS

Throughout this manual, you will find the following safety words and symbols that signify important safety issues

with regards to operating or maintaining the equipment.

W ARNING

GENERAL WARNING. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment and/

or severe bodily injury or death.

CAUTION

GENERAL CAUTION. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment.

In addition to the warnings and cautions in this manual,

use the following guidelines for safe operation of the unit.

• Read all instructions before using equipment.

• For your safety, the equipment must be furnished

with a properly grounded cord connector. Do not

attempt to defeat the grounded connector.

• Install or locate the equipment only for its intended

use as described in this manual.

• Do not use corrosive chemicals in this equipment.

• Do not operate this equipment if it has a damaged

cord or plug, if it is not working properly, or if it has

been damaged or dropped.

• This equipment should be serviced by qualified personnel only. Contact the nearest Duke authorized

service facility for adjustment or repair .

• Do not block any openings on the unit.

• A minimum clearance of 6” (152,4 mm) from the top

of the unit to the ceiling must be provided.

• This appliance must be secured to building structure

(Restraining Device Kit).

• Keep cord away from heated surfaces.

• To prevent tipping, securely attach unit to the wall

using brackets provided.

W ARNING

ELECTRICAL WARNING. Indicates information relating to possible shock hazard.

Failure to observe may result in damage

to the equipment and/or severe bodily

injury or death.

W ARNING

HOT SURFACE WARNING. Indicates information important to the handling of

equipment and parts. Failure to observe

caution could result in personal injury.

The following warnings and cautions appear throughout

this manual and should be carefully observed.

• Turn the unit off, disconnect the power source and

allow unit to cool down before performing any service

or maintenance on the unit.

• The procedures in this manual may include the use

of chemical products. You must read the Material

Safety Data Sheets before using any of these products.

• The unit should be grounded according to local electrical codes to prevent the possibility of electrical

shock. It requires a grounded receptacle with separate electrical lines, protected by fuses or circuit

breaker of the proper rating.

• All electrical connections must be in accordance with

local electrical codes and / or any other applicable

codes.

• Disposal of the unit must be in accordance with local environmental codes and/or any other applicable

codes.

SAVE THESE INSTRUCTIONS

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

3 of 29

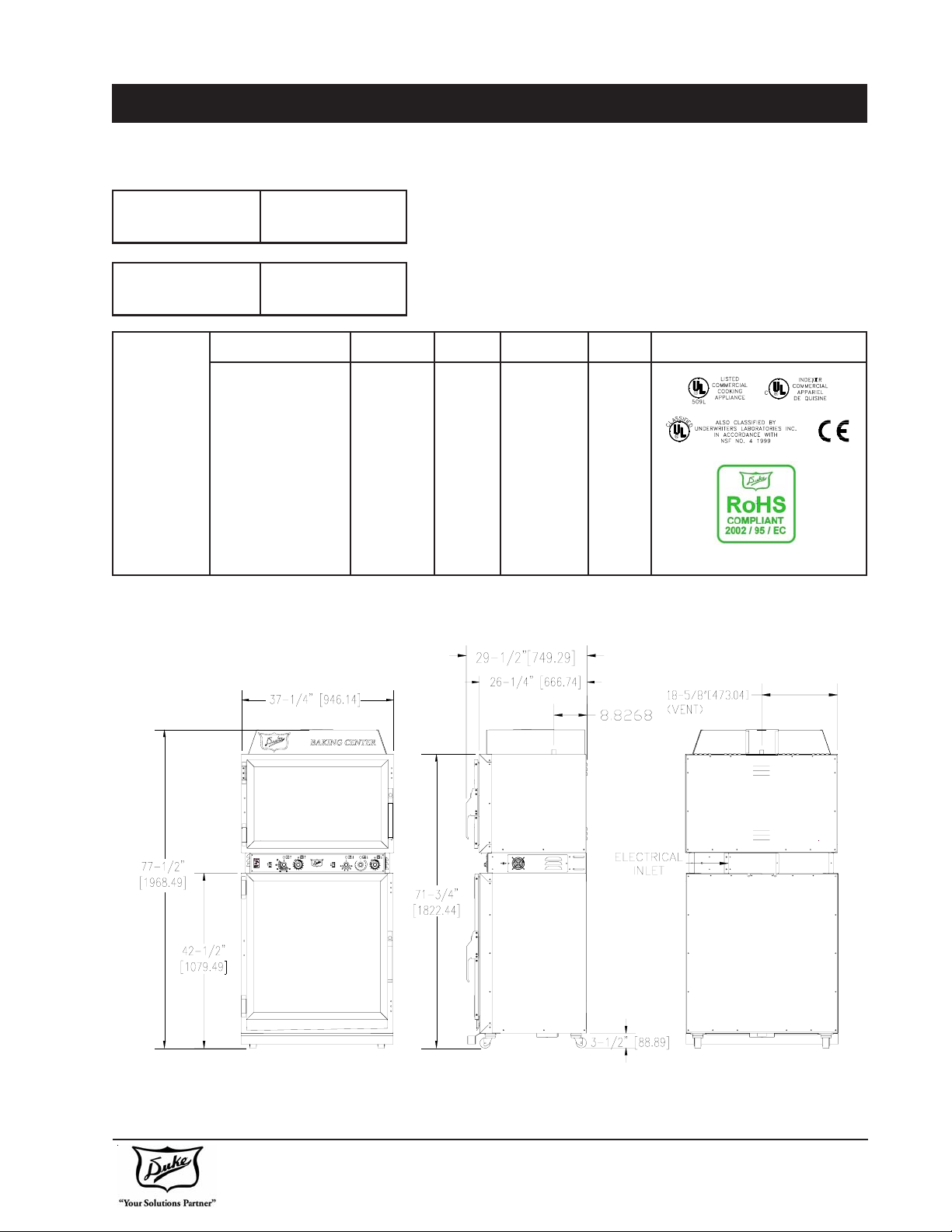

SPEC SHEET

U.S. Patent. Other US and Foreign Patents Pending

Model AHPO or EPO

Shipping Weight:

Carton Box

Shipping Weight:

Wooden Crate

208 1 60 6650 32.0

208 1 50 6650 32.0

230 (220-240) 1 6 0 6650 32.0

AHPO /

EPO

230 (220-240) 1 5 0 6650 32.0

230 (220-240) 3 6 0 6650 16.7

230 (220-240) 3 5 0 6650 16.7

400 (380-415) 3N 60 6650 16.7

400 (380-415) 3N 50 6650 16.7

625lbs/284 Kg

760lbs/345 Kg

Volts Phase Hz Watts Amps

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

4 of 29

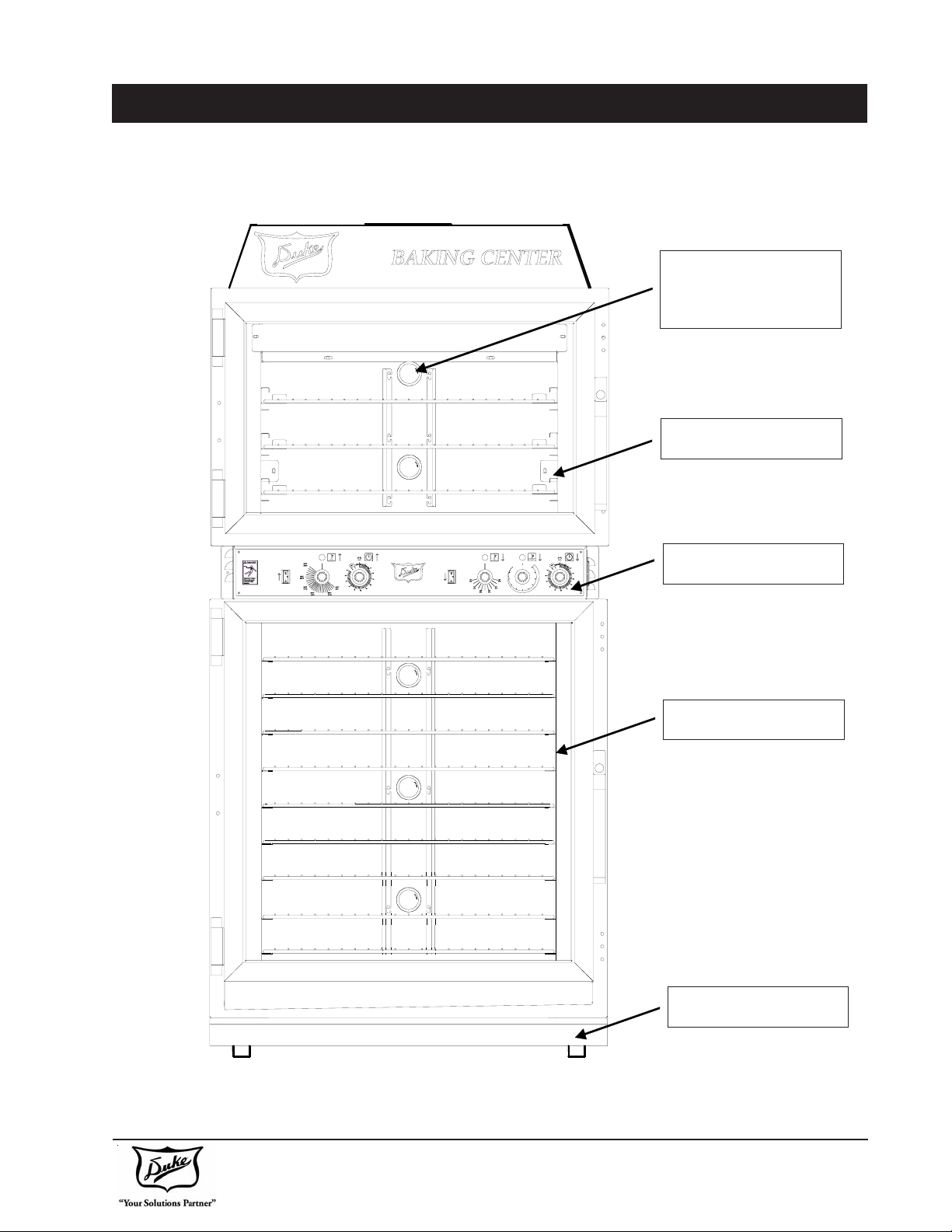

MAIN FEATURES

LOW VOL T AGE

LIGHTING SYSTEM

12V HALOGEN LAMP

CONVECTION OVEN

CONTROL P ANEL

PROOFER

DRIP P AN

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, MO 63102

www.dukemfg.com

5 of 29

INSTALLATION

Unpacking Unit

• Inspect the shipping carton and/or container, carefully noting any exterior damage on the delivery receipt, which was not evident on the outside of the

shipping container (concealed damage). Contact the

carrier immediately and file a damage claim with them.

Save all packing materials when filing a claim. Freight

damage claims are the responsibility of the purchaser

and are not covered by the warranty .

• Follow the instructions on the Carton Box for unpacking the unit.

• Inspect unit for damage such as, broken glass, etc.

• Report any dents or breakage to source of purchase

immediately .

• Do not attempt to use unit if damaged.

• Remove all materials from unit interior.

• If unit has been stored in extremely cold area, wait a

few hours before connecting power.

Unit Placement

• Do not install unit next to source of heat, such as

deep fat fryer, etc.

• Install unit on level surface floor.

• A Minimum Clearance of:

Unit Clearance

Right Side 0 ”

W ARNING

T o avoid risk of electrical shock or death,

this unit must be grounded or field connection must not be altered.

Earthing Instructions

Unit MUST be grounded.

Grounding reduces risk of

electric shock by providing an

escape wire for the electric

current if an electrical short

occurs. When using an ap-

propriate plug it must be

plugged into an outlet that is properly installed and

grounded.

Consult a qualified electrician or servicer if grounding

instructions are not completely understood, or if doubt

exists as to whether the oven is properly grounded.

Do not use an extension cord. This unit should be

plugged or field connected into a separate circuit with

the electrical rating as provided in product specifications.

All electrical connections must be in accordance with

local electrical codes and/or any other applicable codes.

Left Side 0”

External Equipotential

Rear 0”

Ceiling 6”

Must be maintained between the unit and any

combustible or non-combustible substance.

Proper airflow around unit cools electrical components.

With restricted airflow, unit may not operate properly

and life of electrical parts is reduced.

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

Earthing Terminal

Equipment has secondary earthing terminal.

Terminal provides external earthing connection

used in addition to earthing prong on plug. Located

on outside of oven back, terminal is marked with

this symbol.

6 of 29

INSTALLATION

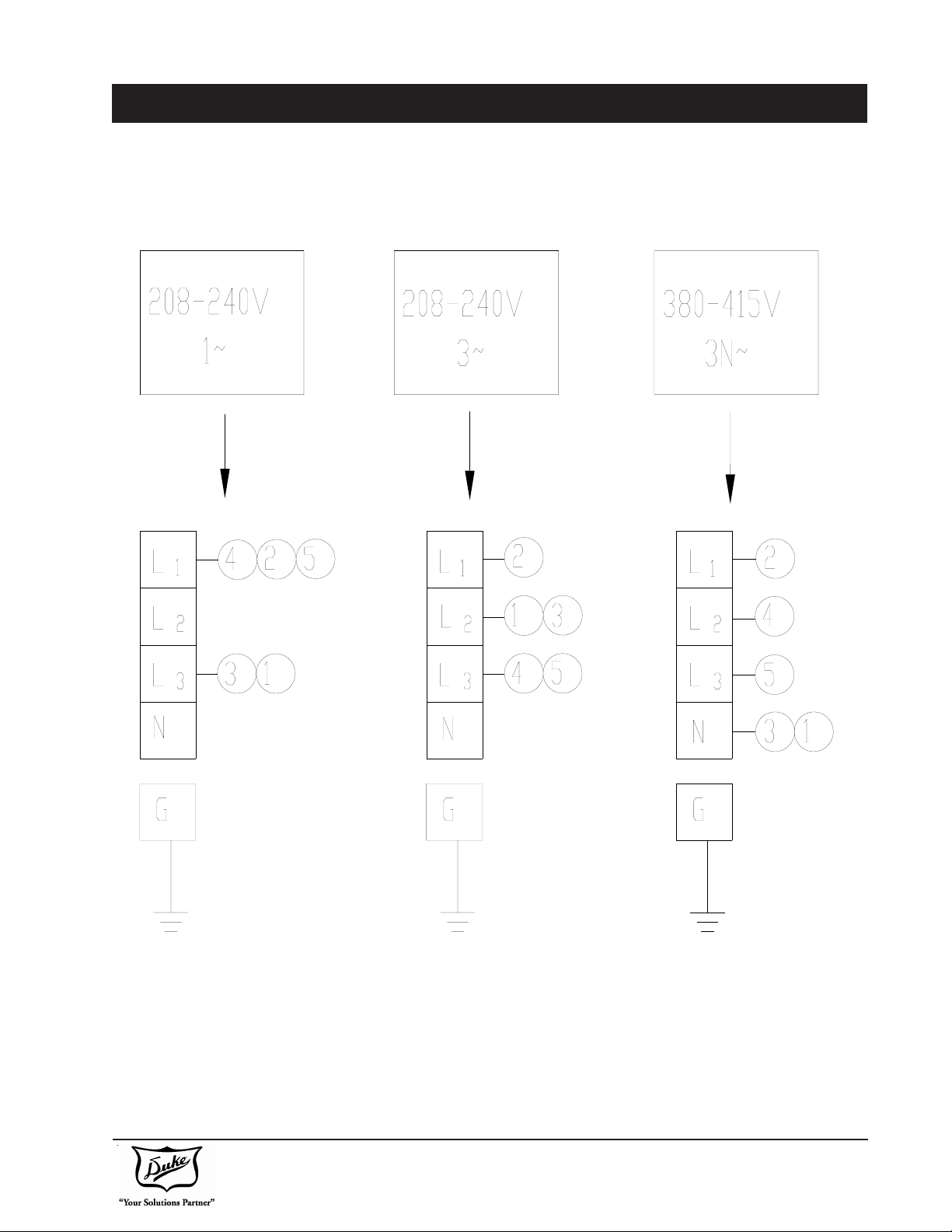

1. Compare the voltage and phase from the oven specification label to the power supply for the oven and call Duke

if there is a difference. If the phase is wrong, a qualified service technician can change the wire connections

inside the oven to correct the problem. See the illustration on page 4 for phase conversions. If the voltage is

wrong, the heat elements must be changed. Call Duke to get new elements.

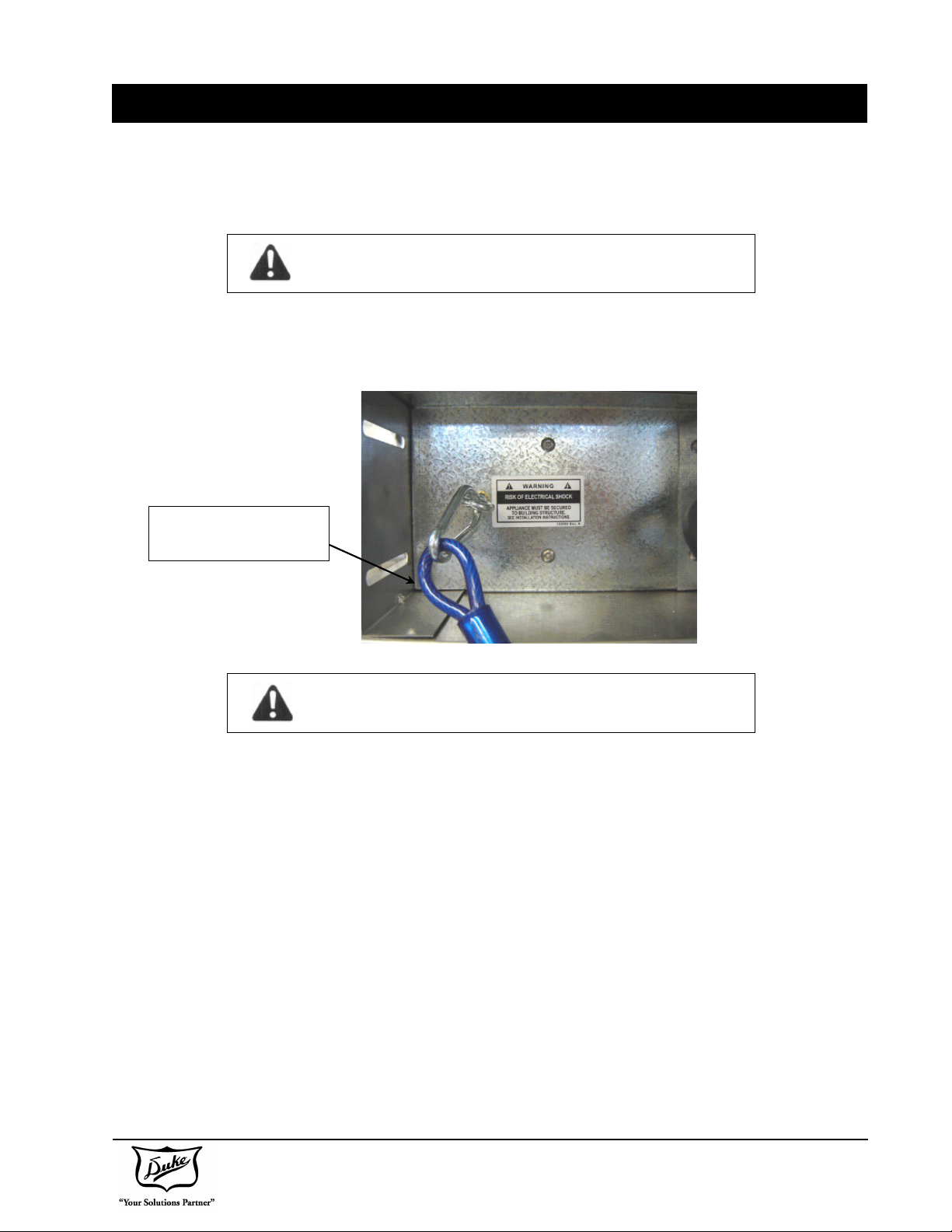

WARNING Risk of Injury

2. This appliance must be secured to building structure. A restraining device kit (#153586) was provided with the

unit to limit the movement of the appliance without depending on or transmitting stress to the electrical conduit.

Installation instruction is in the kit. Permanent installation of the unit requires that the utility connection be of

sufficient length to allow the equipment to be moved for cleaning.

RESTRAINING DEVICE

KIT (PART # 153586)

WARNING Risk of Electric Shock

This Restraining Device MUST always be connected when the Appliance is in Service. Disconnect for movement,

servicing and or cleaning, then reconnect when the appliance has been returned to its normal position.

The appliance shall be installed using flexible conduit or equivalent to meet the local electrical codes and shall be

of sufficient length to allow the equipment to be moved for cleaning.

3. IMPORTANT: A minimum clearance of 6” from the top of unit to the ceiling must be provided.

4. TO PREVENT FROM TIPPING: Unit must be permanently attached to wall using wall-mounting brackets. Refer

page 9 for the instructions on Installation of Wall Brackets to the wall.

5. Check the swing of the door. The hinge side can be changed by following the instructions on the following pages.

The door swing direction can be changed in the field after you have a new drip channel for the proofer door. Call

Duke to get the new drip channel for the proofer door.

6. Check the door seal and make sure both doors close completely. If they do not close and seal properly, call

Duke for assistance.

7. Place the wire racks in the oven and proofer.

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

7 of 29

INSTALLATION

Illustration of the Wiring connection for single phase and three phase connections.

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

8 of 29

INSTALLATION

Instruction for the installation of W all Brackets to the wall for tipping!

1. Mount the Wall Mounting Bracket with screws provided to the Proofer Oven & extend the Wall Mounting Bracket

towards the wall by sliding it thru the slot provided. Do not tighten the screws.

2. Mark on the Wall & Drill in the Wall for fixing anchors for screws.

3. Insert the wall anchors into the already drilled holes on the wall.

4. Butt the Wall Mounting Bracket against the wall.

5. Insert the screws provided into the Wall Mounting Bracket to firmly secure it against the wall.

6. Please re-ensure that the Bracket is firmly secured to the wall. Tighten the screws into the unit.

HOLE DRILLED IN

WALL

WALL FOR FIXING

BRKT

WALL

WALL MOUNTING BRACKET

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

Duke Manufacturing Co.

9 of 29

Loading...

Loading...