Duke 613-G1-G4 NAT-LP User Manual

613 & E SERIES GAS-FIRED

CONVECTION OVEN

Installation and

Operation Manual

POWER

OVEN OFF

COOL

COOK

DOWN

LIGHT OFF

OVEN READY

TEMPERATURE

TIME

Qualied Energy Star Models:

613-G1V 613-G2V

613-G1XX 613-G2XX

613Q-G1V 613Q-G2V

613Q-G1XX 613Q-G2XX

E101-G E102-G

CAUTION:

Please read this manual completely before attempting

to install, operate or service this equipment

GAS SHUTOFF

ON

OFF

This manual is Copyright © 2018 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Co.

Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N: 153810

REV AD 4/5/2018

Installation and Operation of 613 & E Series Gas Fired Convection Oven

CAUTION

CAUTION

IMPORTANT WARNING AND SAFETY INFORMATION

POST IN A PROMINENT LOCATION instructions to be followed in the event the

user smells gas. This information shall be obtained by consulting the local gas

supplier.

FOR YOUR SAFETY:

Do not store or use gasoline or other ammable vapors or liquids in the vicinity

of this or any other appliance.

: Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this equipment.

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

IMPORTANT SAFETY INSTRUCTIONS

Throughout this manual, you will nd the following safety words and symbols that signify

important safety issues with regards to operating or maintaining the equipment.

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

Indicates electrical shock hazard which, if not avoided, could

Indicates hot surface which, if not avoided, could result in

Indicates Important Information

result in death or serious injury and/or equipment damage.

minor or moderate injury.

2

Installation and Operation of 613 & E Series Gas Fired Convection Oven

In addition to the warnings and cautions in this manual, use the following guidelines for

safe operation of the unit.

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with a properly grounded cord connector. Do

not attempt to remove or disconnect the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual.

• Do not use corrosive chemicals on this equipment.

• Do not operate this equipment if it has a damaged cord or plug, if it is not working

properly, or if it has been damaged or dropped.

• This equipment should be serviced by qualied personnel only. Contact the nearest

Duke authorized service facility for adjustment or repair.

• Do not block or cover any openings on the unit.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or counter.

The following warnings and cautions appear throughout this manual and should be

carefully observed.

• Turn the unit o, disconnect the power source and allow unit to cool down before

performing any service or maintenance on the unit.

• The procedures in this manual may include the use of chemical products. You must read

the Material Safety Data Sheets before using any of these products.

• The unit should be grounded according to local electrical codes to prevent the

possibility of electrical shock. It requires a grounded receptacle with dedicated electrical

lines, protected by fuses or circuit breaker of the proper rating, in accordance with all

applicable regulations.

• Disposal of the unit must be in accordance with local environmental codes and/or any

other applicable codes.

• This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

3

Installation and Operation of 613 & E Series Gas Fired Convection Oven

TABLE OF CONTENTS

IMPORTANT WARNING AND SAFETY INFORMATION ......................................................................... 23

SPECIFICATIONS

............................................................................................................................................................................... 5

INSTALLATION INSTRUCTIONS ...................................................................................................................................................... 6

A. QUALIFIED PERSONNEL .......................................................................................................................................................... 6

B. DELIVERY AND INSPECTION .................................................................................................................................................. 6

C. LOCATION OF THE OVEN ......................................................................................................................................................... 6

D. GAS PIPING ................................................................................................................................................................................... 7

E. ELECTRICAL CONNECTIONS ................................................................................................................................................... 7

F. VENTILATION ................................................................................................................................................................................. 7

G. OVEN ASSEMBLY ........................................................................................................................................................................ 8

H. ADJUSTMENTS ASSOCIATED WITH INSTALLATION ..................................................................................................... 9

I. DOUBLE SECTIONS ..................................................................................................................................................................... 9

OPERATING INSTRUCTIONS ........................................................................................................................................................... 10

A. VCONTROLLER ........................................................................................................................................................................ 12

B. XX CONTROLLER ...................................................................................................................................................................... 13

GENERAL GUIDELINES FOR OPERATION ................................................................................................................................... 14

CLEANING OF THE OVENS ..............................................................................................................................................................15

SUGGESTED COOK TIMES & TEMPERATURES ..........................................................................................................................16

MAINTENANCE INSTRUCTIONS ....................................................................................................................................................17

A. ADJUSTMENTS ...........................................................................................................................................................................17

B. DOOR AJUSTMENT ...................................................................................................................................................................17

C. DOOR SWITCH ADJUSTMENT ............................................................................................................................................... 17

D. THERMOSTAT CALIBRATION .................................................................................................................................................18

E. GAS PRESSURE REGULATION AND ADJUSTMENT .......................................................................................................18

F. VENTILATION SYSTEM .............................................................................................................................................................. 19

ELECTRICAL SCHEMATIC ................................................................................................................................................................. 20

4

Installation and Operation of 613 & E Series Gas Fired Convection Oven

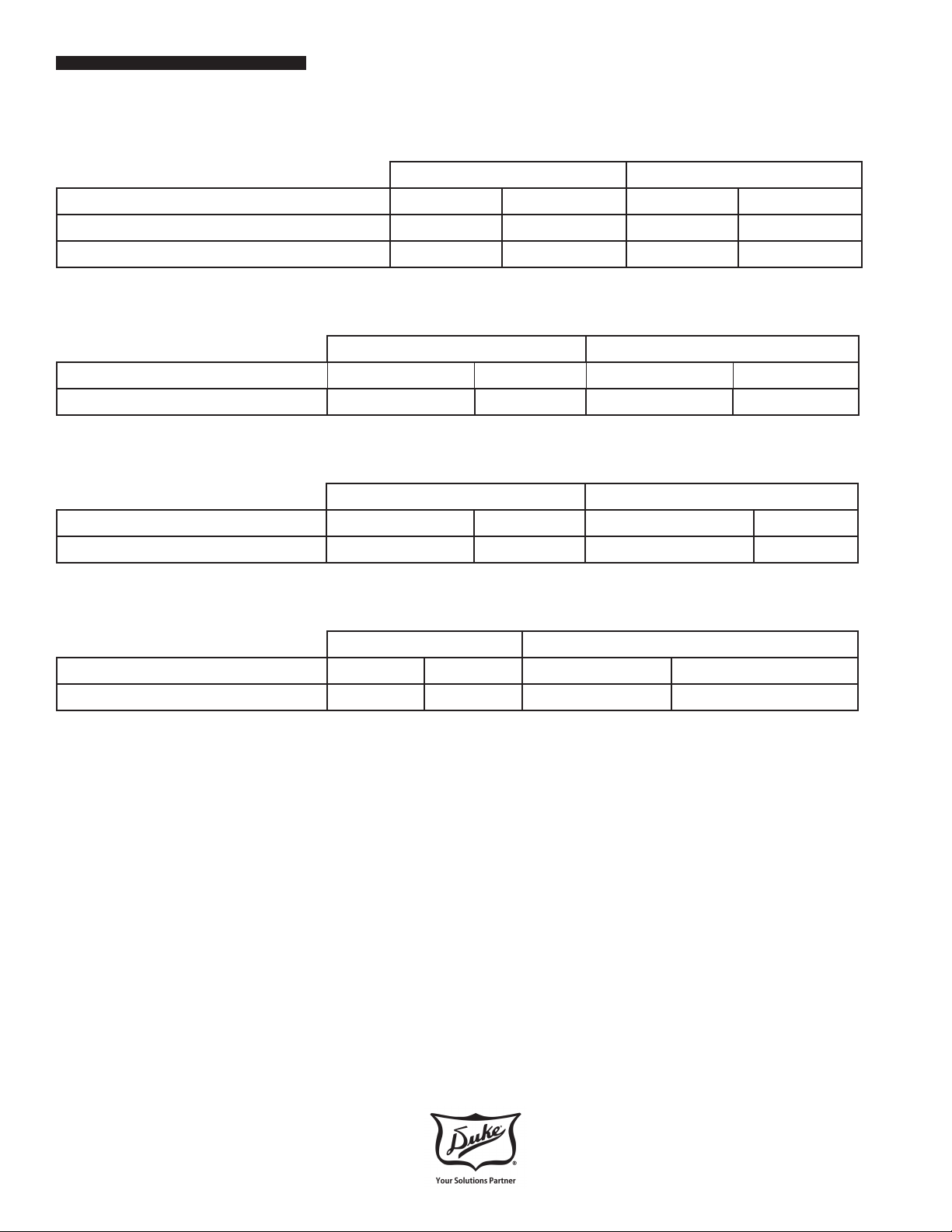

SPECIFICATIONS

NATURAL GAS PROPANE GAS

3

HEATING VALUE 1000 BTU 37.3 MJ/m

SPECIFIC GRAVITY 0.63 0.63 1.53 1.53

GAS PRESSURE AT MANIFOLD 3.5" W.C. 0.87 kPa 10" W.C. 2.49 kPa

OVEN INPUT STANDARD DEPTH

NATURAL GAS PROPANE GAS

PER BURNER 20,000 BTU/HR 5.9 kW 17,500 BTU/HR 5.1 kW

PER OVEN 40,000 BTU/HR 11.8 kW 35,000 BTU/HR 10.3 kW

OVEN INPUT DEEP DEPTH

NATURAL GAS PROPANE GAS

2550 BTU 90.0 MJ/m

3

PER BURNER 23,000 BTU/HR 6.8 kW 23.000 BTU/HR 6.8 kW

PER OVEN 46,000 BTU/HR 13.5 kW 46,000 BTU/HR 13.5 kW

BURNER ORIFICE SIZE

NATURAL GAS PROPANE GAS

STANDARD DEPTH #44 2.18mm (1) #55, (1) #57 (1)1.32mm, (1)1.09mm

DEEP DEPTH #43 2.26mm #54 1.40mm

5

Installation and Operation of 613 & E Series Gas Fired Convection Oven

INSTALLATION INSTRUCTIONS

A. QUALIFIED PERSONNEL

These installation instructions are for the use of qualied

installation and service personnel only. Installation or service

by other than qualied personnel may result in damage to the

oven and/or injury to the operator.

Qualied installation personnel are those individuals, rms,

companies or corporations which either in person or through an

agent is engaged in and responsible for:

• The installation or replacement of gas piping or the

connection, installation, repair or servicing of equipment, who

are experienced in such work, familiar with all precautions

required, and have complied with all requirements of state

and local authorities having jurisdiction. See: National Fuel

Gas Code NFPA 54 (ANSI Z223.1).

• The installation of electrical wiring from the electric

meter, main control box or service outlet to the electrical

appliance. Qualied installation personnel must be familiar

with all precautions required and have complied with

all requirements of state and local authorities having

jurisdiction. See: National Electrical Code, ANSI/NFPA70.

The installation must conform with local codes, or in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA

54, or the Natural Gas and Propane Installation Code, CSA B149.1

as applicable, including:

• The appliance and its individual shuto valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of 1/2 psi (3.5 kPa).

• The appliance must be isolated from the gas supply piping

system by closing its individual manual shuto valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

For an oven equipped with casters, the installation shall be made

with a connector that complies with the Standard for Connectors

for Movable Gas Appliances, ANSI Z21.69/CSA 6.16 and a quickdisconnect device that complies with the Standard for QuickDisconnect Devices for Use with Gas Fuel, ANSI Z21.4/CSA 6.9.

When installing the oven with casters and quick-disconnect

hose, adequate means must be provided to limit the movement

of the oven without depending on the connector and the quick

disconnect device or its associated piping to limit the oven

movement. Restraining means may be attached to the vertical

portion of the base frame in the rear of the oven.

B. DELIVERY AND INSPECTION

Duke Manufacturing Co. does everything within its power

to insure you received your oven in good condition. They

are strapped down on heavy wooden skids and surrounded

by heavy “tri-wall” cartons to prevent shipping damage.

They have all been carefully inspected before they were

packaged and consigned to the carrier.

Upon delivery of your Duke oven:

• Look over the shipping container, carefully noting any

exterior damage on the delivery receipt, which must

also be signed by the driver/ delivery person.

• Uncrate and check for any damage, which was not

evident on the outside of the shipping container.

This is called concealed damage. The carrier must be

notied within fteen (15) days of the delivery of the

oven and the carton, skid and all packaging materials

must be retained for inspection.

Duke Manufacturing Co. cannot assume liability for loss

or damage suered in transit. The carrier assumes full

responsibility for delivery in good order when the shipment

was accepted. However, we are prepared to assist you in

ling your claim.

C. LOCATION OF THE OVEN

Proper planning and placement of the oven will give you

the best results in terms of long-term user convenience and

satisfactory performance. We urge you to give adequate

thought in the placement of your oven prior to its arrival.

• The oven should be placed in an area that is free

from drafts and accessible for proper operation and

servicing.

• The area around the oven must be kept clear of

combustible materials. A minimum clearance must be

maintained between the oven and any combustible

or non-combustible surface.

MINIMUM CLEARANCES

Combustible Non-Combustible

RIGHT SIDE 1" 0"

LEFT SIDE 1" 0"

REAR 3" 3"

FLOOR 8" 8"

6

Loading...

Loading...