Page 1

Owner's manual

848

DUCATI SUPERBIKE

Page 2

Use and maintenance manual

848

E

1

Page 3

E

2

Page 4

Welcome to the world of Ducati enthusiasts! We

congratulate you on your excellent choice of motorcycle.

We are sure that you will use your Ducati for longer journeys

as well as short daily trips, but however you use your

motorcycle, Ducati Motor Holding S.p.A wishes you an

enjoyable ride.

Ducati Motor Holding S.p.A. recommends that you adhere

strictly to the instructions in this manual, especially those

regarding the running-in period. This will ensure that your

Ducati motorcycle will continue to be a pleasure to ride.

For repairs or advice, please contact one of our authorized

service centres.

We also provide an information service for all Ducati owners

and enthusiasts for any advice and suggestions you might

need.

Enjoy the ride!

Notes

Ducati Motor Holding S.p.A. cannot accept any liability

for errors that may have occurred in the preparation of this

manual. All information in this manual is valid at the time of

going to print. Ducati Motor Holding S.p.A. reserves the right

to make any modifications required due to the ongoing

development of their products.

For safety and reliability, to avoid invalidating the warranty

and to maintain the value of your motorcycle, use only

original Ducati spare parts.

Warning

This manual is an integral part of the motorcycle and,

if ownership of the motorcycle is transferred to a third party,

the manual must be handed over to the new owner.

E

3

Page 5

Table of contents

E

General indications 6

Warranty 6

Symbols 6

Useful road safety information 7

Riding with a full load 8

Identification data 9

Controls 10

Position of the motorcycle controls 10

Instrument panel

LCD – Main functions 13

LCD – How to set/display parameters 15

The immobilizer system 38

Code card 39

Immobilizer override procedure 40

Duplicate keys 42

Ignition switch and steering lock

Left-hand handlebar switch

Clutch lever 45

Right-hand handlebar switch

Throttle twistgrip

Front brake lever

Rear brake pedal

Gearchange pedal

Adjusting the position of the gearchange and rear brake pedals

4

11

46

47

48

48

44

46

43

Main components and devices 51

Position on motorcycle 51

Fuel tank filler cap

Seat lock 53

Sidestand

Front fork adjusters 55

Rear shock absorber adjusters

52

54

57

Riding the motorcycle 59

Running-in precautions 59

Pre-ride checks 61

Starting the engine 62

Moving off 64

Braking 64

Stopping the motorcycle 65

Parking 65

Refuelling

Toolkit and accessories

66

67

Main Maintenance Operations 68

Removal of the fairings 68

Checking and topping up the coolant

Checking the brake and clutch fluid level 73

Checking the brake pads for wear

Lubricating cables and linkages 76

Adjustment of the throttle cable free play 77

Charging the battery

Checking the chain tension

Lubricating the drive chain 79

49

78

72

75

79

Page 6

Changing the high and low beam bulbs 80

Changing the sidelight bulb 82

Rear turn indicators

Number plate light

Headlight aim

Rearview mirror adjustment

Tubeless tyres 86

Checking the engine oil level

Cleaning and renewing the spark plugs

General cleaning 90

Storing the motorcycle 91

Important notes 91

84

83

83

85

88

89

Maintenance 92

Programmed maintenance plan: operations to be carried out

by the dealer 92

Programmed maintenance plan: operations to be carried out

by the dealer 95

Technical data 96

Overall dimensions (mm) 96

Weights 96

Engine 98

Timing system 98

Performance data 98

Spark plugs 99

Fuel system 99

Brakes 99

Transmission 100

Frame 101

Wheels 101

Tyres 101

Suspension 102

Exhaust system 102

Colour schemes 102

Electrical system 103

Routine maintenance record 107

For United States of America version

Only 109

Reporting of safety defects 109

Safety warnings 109

Noise emission warranty 109

Noise and exhaust emission control system information 109

Tampering warning 110

Riding safety 111

Protective apparel 112

Vehicle identification number (VIN) 112

Label location

California evaporation emission system 115

Ducati limited warranty on emission control system 115

113

Routine maintenance record 118

E

5

Page 7

General indications

E

Symbols

Ducati Motor Holding S.p.A. advises you to read this manual

carefully in order to familiarise yourself with your motorcycle.

If in doubt, please contact a Ducati Dealer or Authorized

Service Centre. You will find the information in the manual

useful on trips (which Ducati Motor Holding S.p.A. hopes will

be smooth and enjoyable), and it will help you obtain top

performance from your motorcycle for a long time.

This booklet uses a set of symbols with special meanings:

Warranty

In your own interest, and in order to ensure the reliability

of the motorcycle, you are strongly advised to contact a

Ducati Dealer or Authorized Service Centre for any

servicing that requires particular technical expertise.

Our highly qualified staff have access to the specialised

tools required to perform any servicing job to the highest

professional standards, using only Ducati original spare

parts as the best guarantee for perfect interchangeability,

smooth running and long service life.

All Ducati motorcycles come with a Warranty Booklet.

However, the warranty does not apply to motorcycles used

in competitions. If any motorcycle part is tampered with,

modified, or replaced with parts other than original Ducati

spare parts during the warranty period, the warranty is

automatically invalidated.

6

Warning

Failure to comply with these instructions may put you

at risk, and could lead to severe injury or even death.

Important

Risk of damage to the motorcycle and/or its

components.

Notes

Additional information about the current operation.

References to the right or left side of the motorcycle

assume you are sitting on the seat, facing forward.

Page 8

Useful road safety information

Warning

Read this section before riding your motorcycle.

Many accidents are the result of the inexperience of the

rider. Always make sure you have your licence with you; you

need a valid licence that entitles you to ride a motorcycle.

Do not lend your motorcycle to persons who are

inexperienced or do not hold a valid licence.

Riders and passengers must always wear appropriate

clothing and a safety helmet.

Do not wear loose clothes or accessories that could become

tangled in the controls or limit your field of vision.

Never start or run the engine in enclosed space. Exhaust

gases are toxic and may lead to loss of consciousness or

even death within a short time.

The rider should keep his/her feet on the footrests when the

motorcycle is in motion.

Always hold the handlebars firmly with both hands so you

will be ready for sudden changes in direction or in the road

surface. The pillion passenger should always hold on to

the strap on the pillion seat with both hands.

Obey the legal requirements and observe national and local

regulations.

Always respect speed limits where these apply, and never

exceed the speed allowed by the parti cular visibility, road and

traffic conditions.

Always signal your intention to turn or change lane in good

time, using the appropriate turn signals.

Be sure you are clearly visible and avoid riding within the

blind spot of a vehicle in front of you.

Be very careful at road junctions, or when riding in areas near

exits from private land or car parks, or on the slip roads to

motorways.

Always turn off the engine when refuelling. Be extremely

careful not to spill fuel on the engine or on the exhaust pipe

when refuelling.

Do not smoke when refuelling.

While refuelling, it is possible to inhale noxious fuel vapours.

Should any fuel drops be spilled on your skin or clothing,

immediately wash with soap and water and change your

clothing.

Always remove the key if leaving your motorcycle unattended.

The engine, exhaust pipes and silencers remain hot for a long

time.

Warning

The exhaust system might be hot even after engine is

switched off; take special care not to touch the exhaust

system with any part of your body and do not park the

motorcycle next to inflammable material (wood, leaves, etc.).

Park your motorcycle where no one is likely to knock against

it, and use the sidestand.

Never park on uneven or soft ground, or your motorcycle

may fall over.

E

7

Page 9

Riding with a full load

Your motorcycle is designed for travelling over long

E

distances with a full load in complete safety.

Even weight distribution is critical for maintaining safety

standards, and to avoid getting into difficulties when

making sudden manoeuvres or riding on bumpy roads.

Information on load capacity

The total weight of the motorcycle in running order with

rider, luggage and additional accessories should not exceed

390 kg.

8

Arrange your luggage or heavy accessories in the lowest

possible position and as close to centre of the motorcycle

as possible.

Secure the luggage firmly to the motorcycle structure.

Luggage incorrectly secured may cause the motorcycle to

become unstable.

Never attach bulky or heavy objects to the top yoke or front

mudguard, as this would cause dangerous instability.

Do not insert objects into gaps in the frame, where they

could interfere with moving parts.

Check that the tyres are inflated to the pressure indicated

on page 86 and that they are in good condition.

Page 10

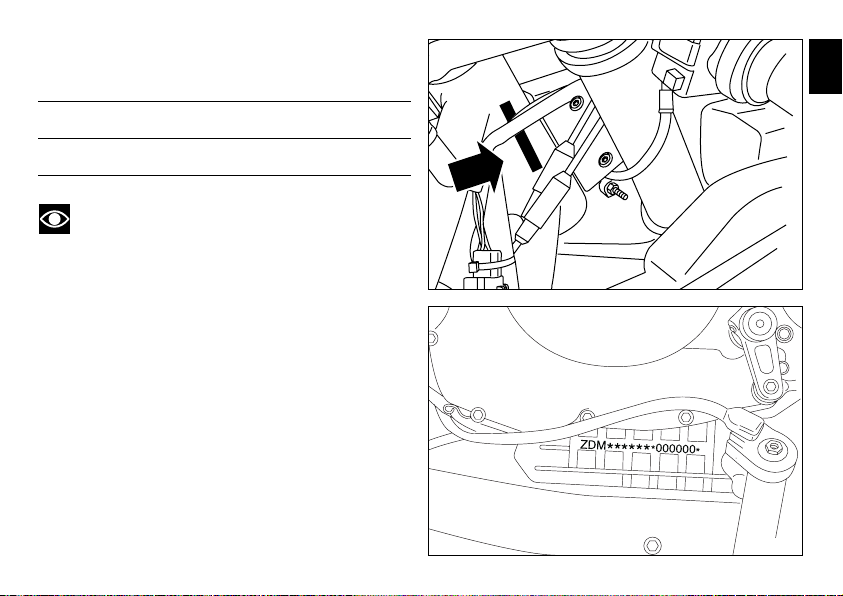

Identification data

All Ducati motorcycles have two identification numbers,

one for the frame (fig. 1) and one for the engine (fig. 2).

Frame number

Engine number

Notes

These numbers indicate the motorcycle model and

should be quoted when ordering spare parts.

E

fig. 1

fig. 2

9

Page 11

Controls

E

1

Warning

This section shows the position and function of the

controls used to drive the motorcycle. Be sure to read this

information carefully before you use the controls.

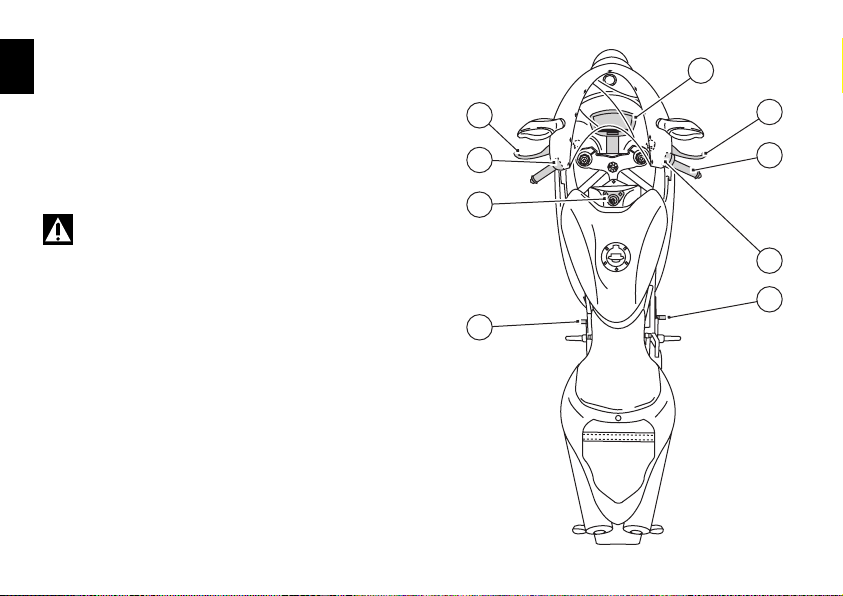

Position of the motorcycle controls (fig. 3)

1) Instrument panel.

2) Key-operated ignition switch and steering lock.

3) Left-hand handlebar switch.

4) Clutch lever.

5) Rear brake pedal.

6) Right-hand handlebar switch.

7) Throttle twistgrip.

8) Front brake lever.

9) Gearchange pedal.

10

4

3

2

9

8

7

6

5

fig. 3

Page 12

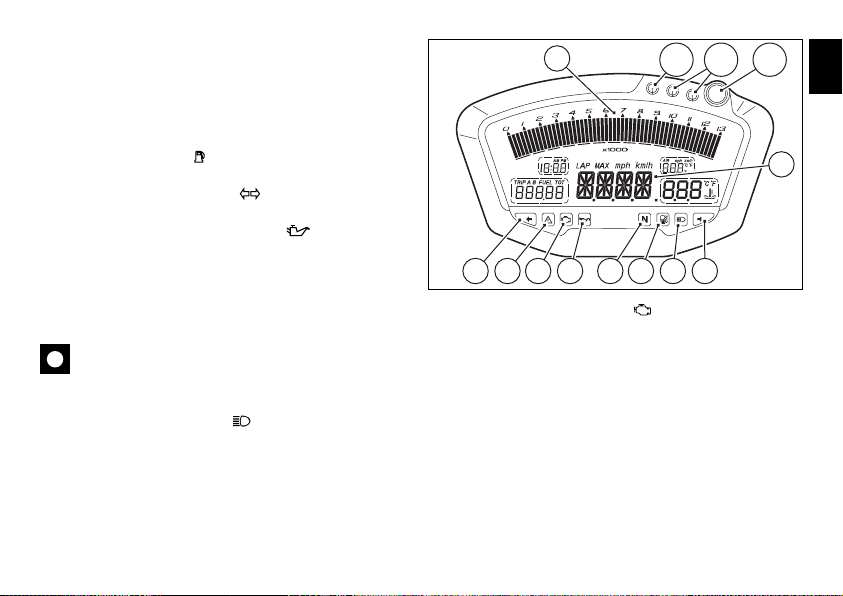

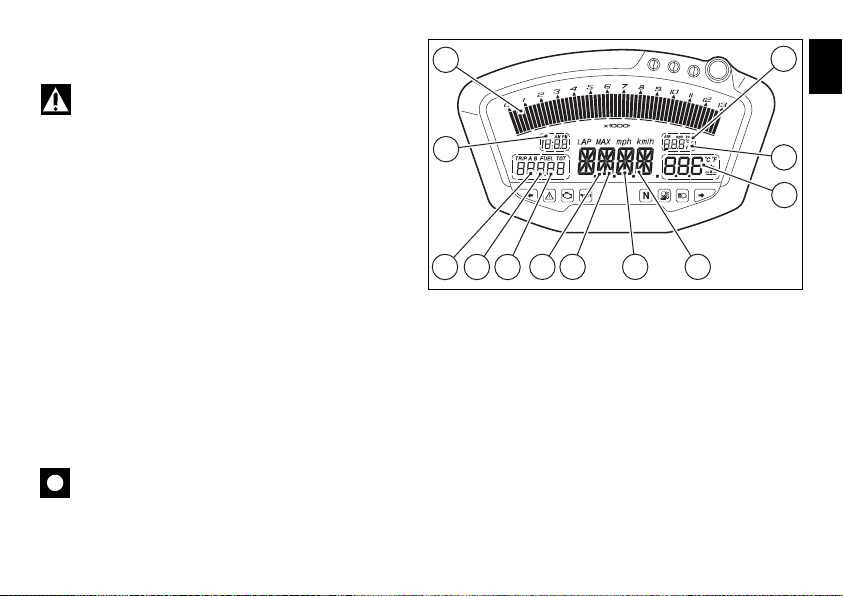

Instrument panel (fig. 4)

1) LCD (see page 13).

2) Tachometer (rpm).

Indicates engine revs per minute.

3) Neutral (N) indicator (green).

Illuminates when the gearbox is in neutral.

4) Fuel warning light (yellow).

Illuminates when there are about 3 litres of fuel left in the tank.

5) Turn signal indicator light (green).

Illuminates and flashes when the turn signal is in operation.

6) Engine oil pressure warning light (red).

Illuminates when engine oil pressure is too low. This light

should illuminate when the ignition is switched to ON and

should go out a few seconds after the engine starts.

It may come on briefly if the engine is very hot, but should

go out again as engine speed increases.

Important

If this light (6) stays on, stop the engine to avoid

serious damage.

7) High beam warning light (blue).

Illuminates when the high beam headlight is on.

2

10B 10C10A

1

5 9 8 6 3 4 57

8) “Engine diagnostics light” (amber).

The engine ECU illuminates this light steadily to indicate the

presence of errors leading to engine lock.

9) ”Motorcycle diagnostics” light.

Illuminates when the motorcycle diagnostics detects a problem.

10) Rev limiter indicator lights.

Indicator light 10A: illuminates steadily at 800 rpm before

intervention of the rev limiter.

Indicator lights 10A + 10B: illuminate st eadily 400 rpm before

intervention of the rev limiter.

Indicator lights 10A + 10B + 10C: start flashing when the rev

limiter is reached.

fig. 4

E

11

Page 13

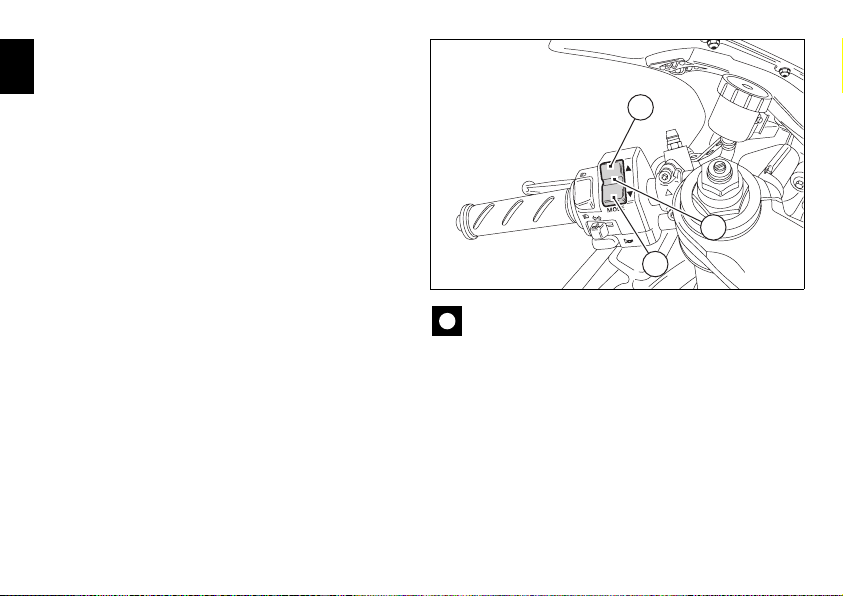

11) 2-position switch A and B.

Switch used for displaying and setting instrument panel

E

parameters. It has two positions, A “▲” and B “▼”.

12) High beam headlight flasher switch (fig. 5).

The high beam headlight flasher switch is also used for

the LAP and USB data aquisition functions.

12

A

11

12

B

fig. 5

Page 14

LCD – Main functions

Warning

Any adjustments to the instrument panel must only be

carried out when the motorcycle is stationary. Never operate

the instrument panel controls while riding the motorcycle.

1) Speedometer.

Indicates road speed.

2) Odometer.

Shows total distance travelled.

3) Trip meter.

Shows the distance travelled since the last reset (TRIP A and

TRIP B).

4) Fuel reserve trip counter.

Shows distance travelled on reserve fuel.

5) Clock.

6) Lap time.

7) Rev counter (RPM).

8) Recording of lap time, maximum speed and

maximum rpm.

9) Battery voltage indicator (BATT).

10) Air temperature indicator.

11) Coolant temperature indicator.

Indicates engine coolant temperature.

Important

Stop riding if the temperature reaches the maximum

value, otherwise the engine might be damaged.

7

5

2 3 4

1 6

8 12

fig. 6

10

11

9

E

13

Page 15

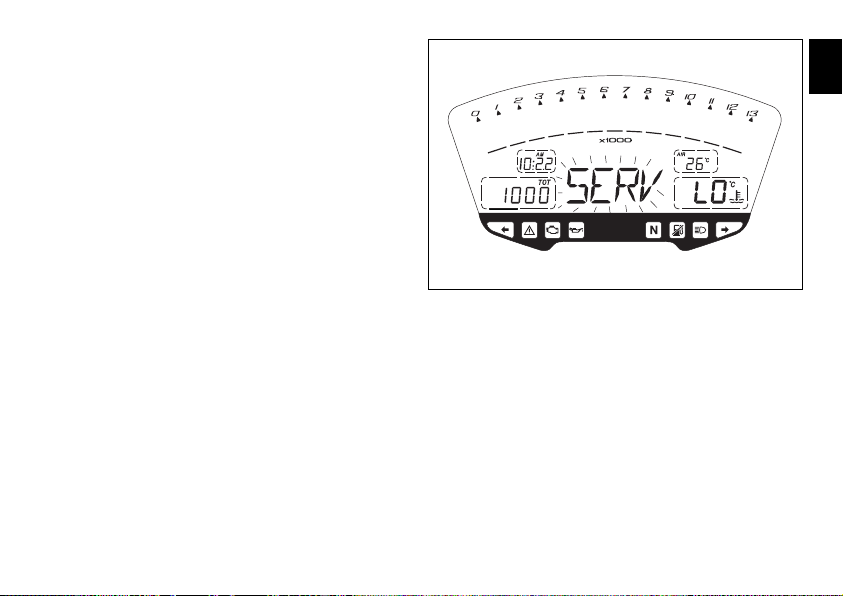

12) Servicing indicator (SERV) (fig. 6).

The message “SERV” indicates that the service interval

E

has been reached. The message is displayed only at Key-On

for 5 seconds. The service indicator will be reset at an

authorized Ducati Service Centre during the service.

Important

The instrument panel incorporates diagnostic functions

for the electronic injection/ignition system. The relative

menus are for use by trained personnel only. If you

accidentally access this function, turn the key to OFF

and have the motorcycle checked at an authorised

Ducati Service Centre.

14

Page 16

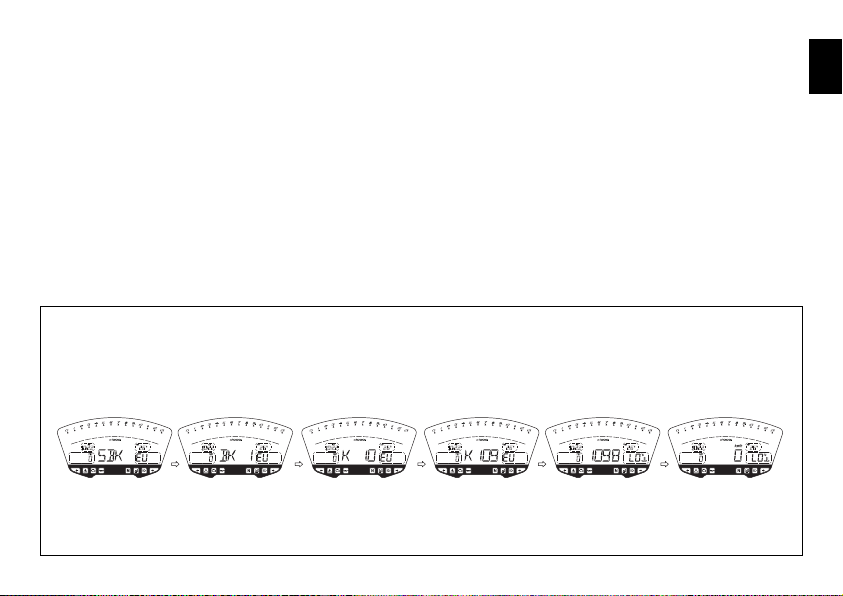

LCD – How to set/display parameters

At key-on (key turned from OFF to ON) the instrument

panel activates all the digits of the LCD for 1 second and

switches on the indicator lights in sequence.

It then reverts to “normal” display mode and, in place of

motorcycle speed, shows the model and, for 2 seconds,

also the version (EU, UK, USA, CND, FRA, JAP).

The model is displayed cyclically until the engine is started.

ENGINE OFF ENGINE OFF ENGINE OFF ENGINE OFFENGINE OFF ENGINE RUNNING

E

fig. 7

15

Page 17

At Key-On, the instrument panel always shows the following

information (de-activating any previously activated functions):

E

Odometer

Air temperature

Clock

Speed

Coolant temperature

Engine rpm

At this point, with button (1, fig. 8) in position B “▼” it is

possible to switch from the odometer display function to

the following functions:

TRIP A

TRIP B

TRIP FUEL (only if active)

before returning to TOT (odometer function).

If, however, you press switch (1, fig. 8) in position A “▲”,

the system enters MENU mode and displays the following

functions in sequence:

Error (only if active)

BATT

RPM

LAP (OFF or ON)

LAP MEM

USB (OFF or ON)

Erase USB

TIME Set

CODE (only if active)

16

A

1

B

fig. 8

Important

This menu is active only if the speed of the motorcycle

is less than 20 km/h. If this menu is on the display and the

speed of the motorcycle exceeds 20 km/h, the instrument

panel automatically exits the menu and returns to the initial

display. It is possible to exit the menu at any time, however,

by pressing switch (1, fig. 8) in position A “▲” for 3 seconds.

Page 18

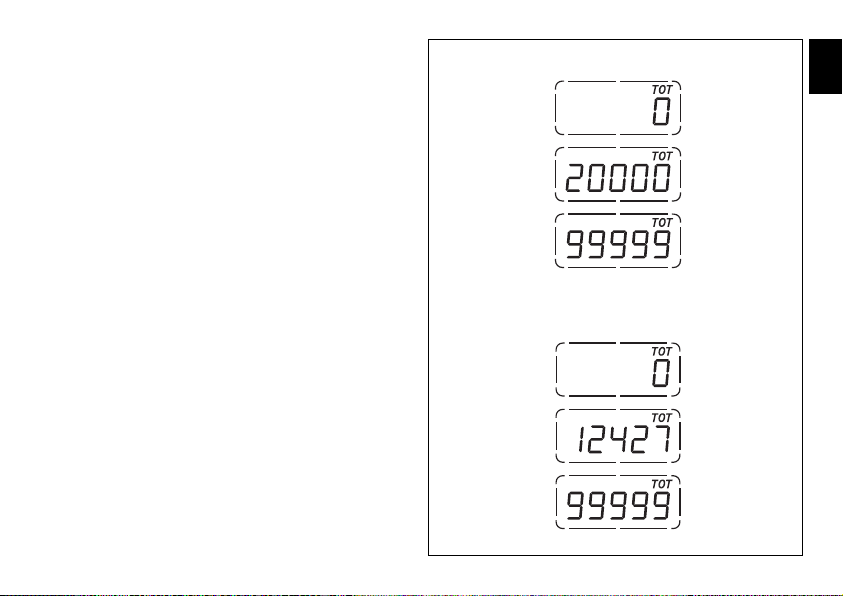

Total distance travelled indicator (odometer)

At Key-On the system automatically enters this function.

The reading is saved permanently and cannot be reset.

If it exceeds 99999 km (or 99999 miles), the reading

“99999” remains displayed permanently.

vs. EU

vs. UK

v.s. USA

E

fig. 9

17

Page 19

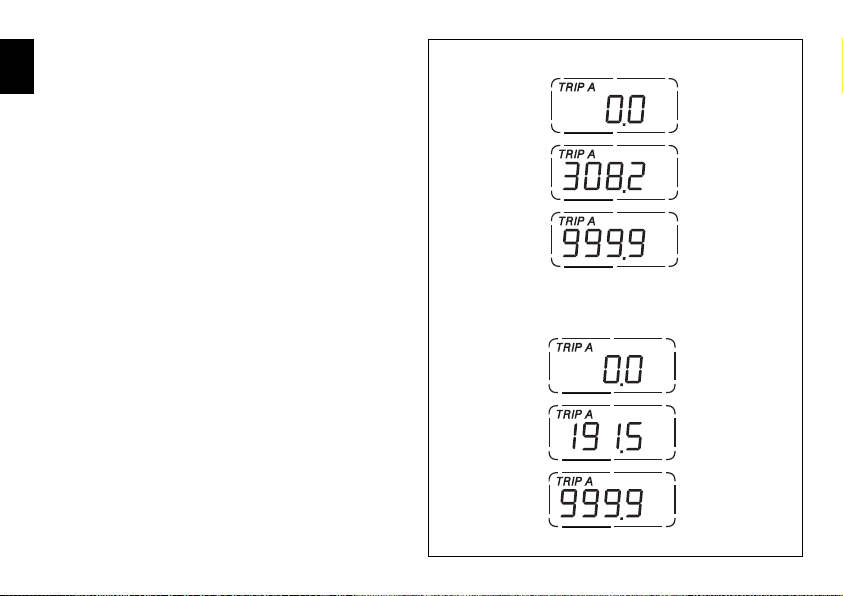

Trip meter “TRIP A”

While in this function, if you press switch (1, fig. 8) in

E

position B “▼“ for 3 seconds, the reading is reset.

If the reading exceeds 999.9, it is reset to zero and the

count restarts automatically.

If the units of measurement set by the dealer are changed,

the distance travelled is reset to zero and the count is

restarted in the new units.

18

vs. EU

vs. UK

v.s. USA

fig. 10

Page 20

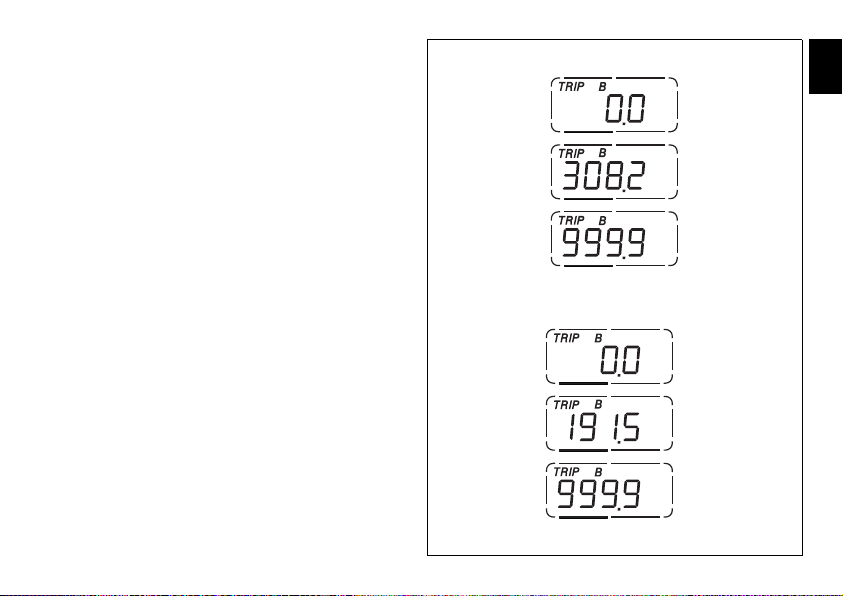

Trip meter “TRIP B”

While in this function, if you press switch (1, fig. 8) in

position B “▼“ for 3 seconds, the reading is reset.

If the reading exceeds 999.9, it is reset to zero and the

count restarts automatically.

If the units of measurement set by the dealer are changed,

the distance travelled is reset to zero and the count is

restarted in the new units.

vs. EU

vs. UK

v.s. USA

E

fig. 11

19

Page 21

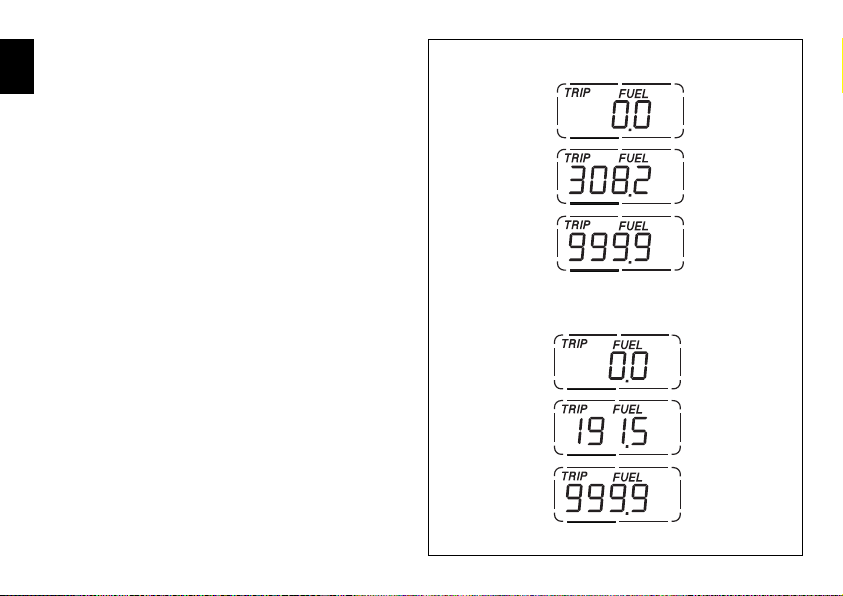

“TRIP FUEL” (distance travelled on reserve fuel)

indicator

E

When the fuel warning light comes on, the TRIP FUEL meter

is activated automatically, regardless of the function

displayed. If the fuel level remains in reserve, the reading is

saved even after Key-Off.

The count stops automatically when the fuel level rises

above reserve.

If the reading exceeds 999.9, it is reset and the count

restarts automatically.

20

vs. EU

vs. UK

v.s. USA

fig. 12

Page 22

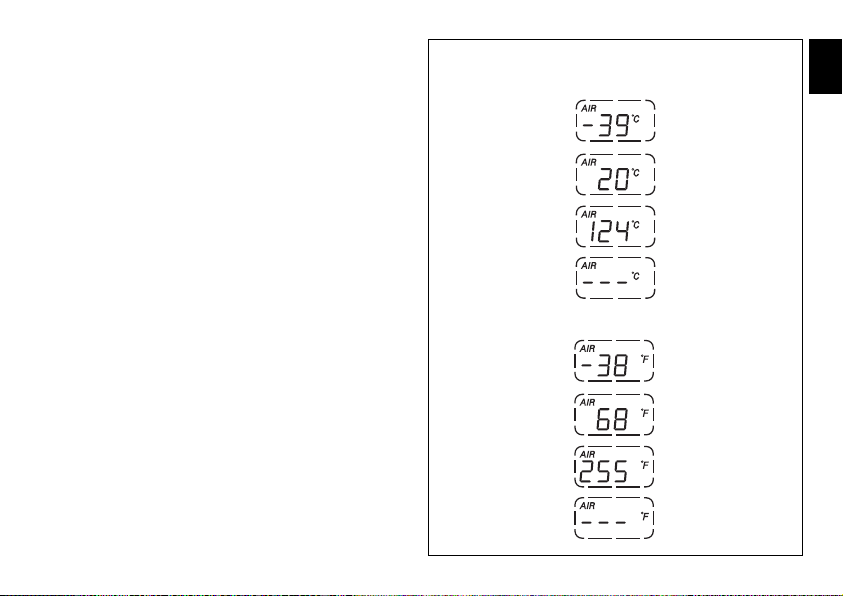

Air temperature indicator

Shows the outside air temperature.

Display limits: -39 °C÷+124 °C.

In the event of a sensor FAULT (-40 °C, +125 °C or

disconnected) a series of dashes “- - -” is displayed steadily

and the Engine Diagnostics warning light (8, fig. 4) comes on.

vs. EU

v.s. USA

vs. USA

E

fig. 13

21

Page 23

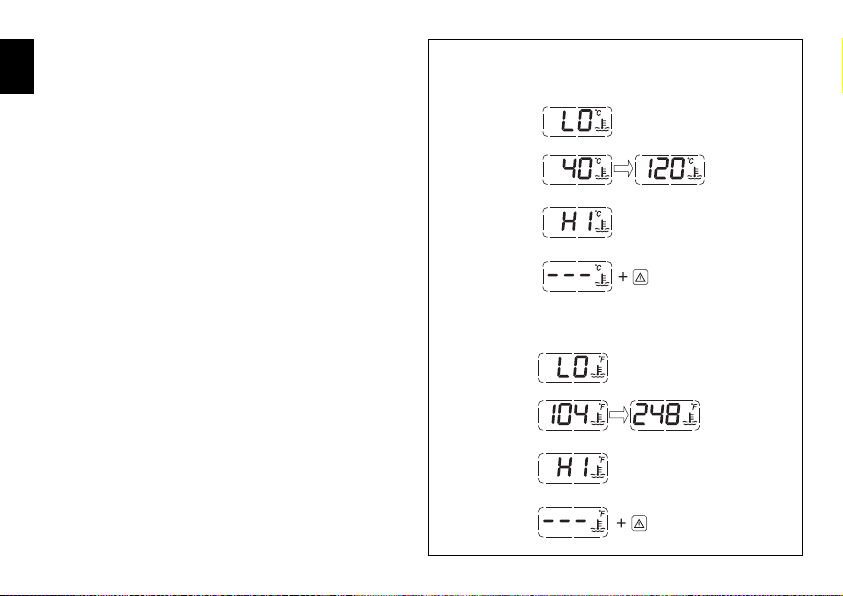

Coolant temperature indicator

Displays the engine coolant temperature:

E

if the reading is less than or equal to -40 °C (-40 °F), the

display shows a series of flashing dashes (“- - -”) and the

Engine Diagnostics warning light comes on (8, fig. 4);

if the reading is between -39 °C (-38 °F) and +39 °C

(+102 °F), the message “LO” is displayed steadily;

if the reading is between +40 °C (+104 °F) and +120 °C

(+248 °F), it is displayed steadily;

if the reading is between +121 °C (+250 °F) and +124 °C

(+255 °F), the message “HI” flashes on the display;

if the reading is greater than or equal to +125 °C (+257 °F),

the display shows a series of flashing dashes (“- - -”) and

the Engine Diagnostics warning light (9, fig. 4) comes on.

In the event of a sensor FAULT, a series of dashes (“- - -”)

will flash on the display and the Engine Diagnostics

warning light (8, fig. 4) will illuminate.

vs. EU - vs. UK

FIXED DATUM

FIXED DATUM FIXED DATUM

FLASHING DATUM

FLASHING DATUM

VEHICLE

DIAGNOSTICS

v.s. USA

FIXED DATUM

FIXED DATUM FIXED DATUM

FLASHING DATUM

22

FLASHING DATUM

VEHICLE

DIAGNOSTICS

fig. 14

Page 24

Service indicator (SERV)

Indicates that the next service is due.

The message “SERV” appears on the display at the following

intervals:

after the first 1000 km on the odometer;

every 12000 km on the odometer.

The message is displayed only at Key-On for 5 seconds.

When the indicator appears, contact your Ducati dealer or

Authorized Service Centre.

E

fig. 15

23

Page 25

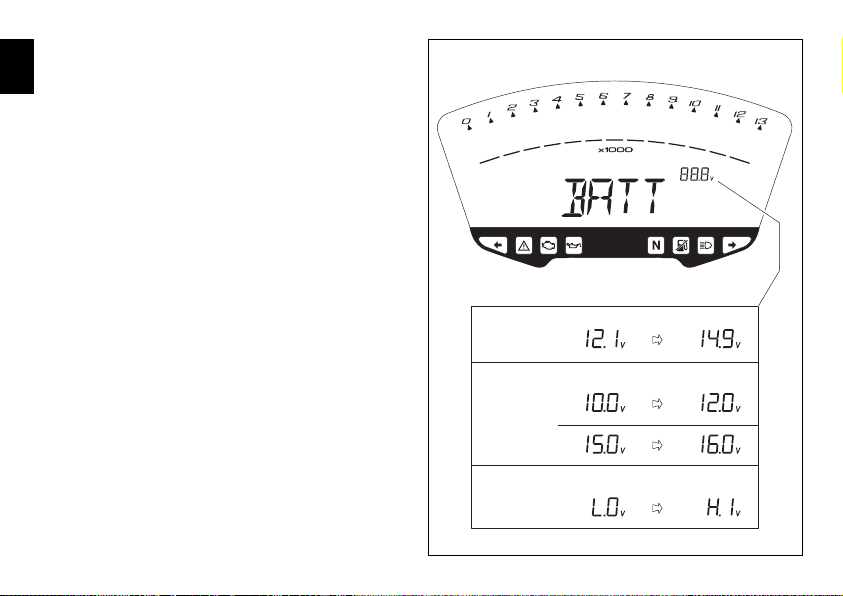

Battery voltage indicator (BATT)

To display this function, go into the menu and select the

E

“BATT” page.

The battery voltage reading is displayed as follows:

if the reading is between 12.1 and 14.9 Volts, it is steadily

illuminated on the display;

if the reading is between 10.0 and 12.0 Volts or between

15.0 and 16.0 Volts, it flashes on the display;

if the reading is less than or equal to 9.9 Volts, the

message “LO” flashes on the display and the Motorcycle

Diagnostics warning light (9, fig. 4) comes on;

if the reading is greater than or equal to 16.1 Volts, the

message “HI” flashes on the display and the Motorcycle

Diagnostics warning light (9, fig. 4) comes on;

24

FIXED FIXED

STATUS 1

FLASHING FLASHING

STATUS 2

FLASHING FLASHING

STATUS 3

fig. 16

Page 26

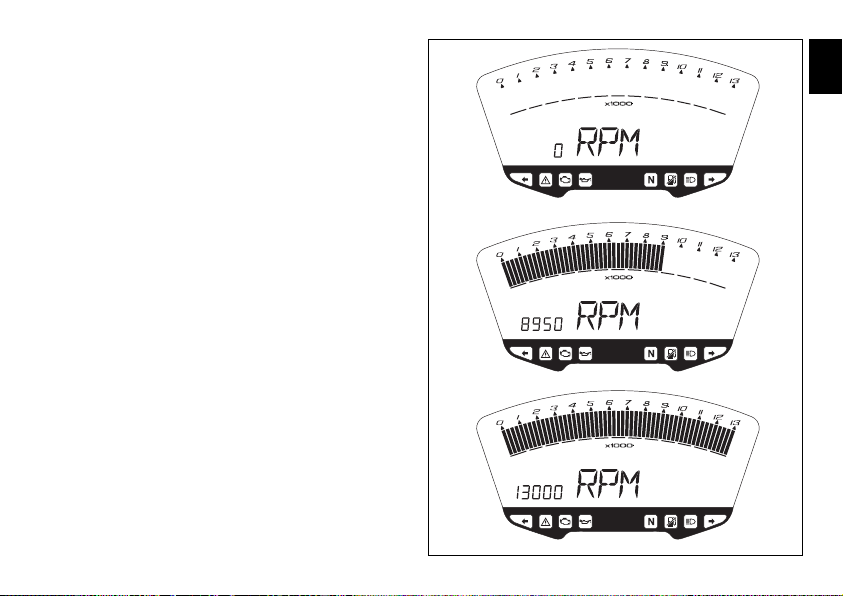

Adjusting the engine idle speed (rpm)

To display the function, access the menu and select the

“RPM” page.

In addition to the upper rev counter scale, the display also

shows engine rpm numerically so that you can adjust the

idle speed more precisely.

E

fig. 17

25

Page 27

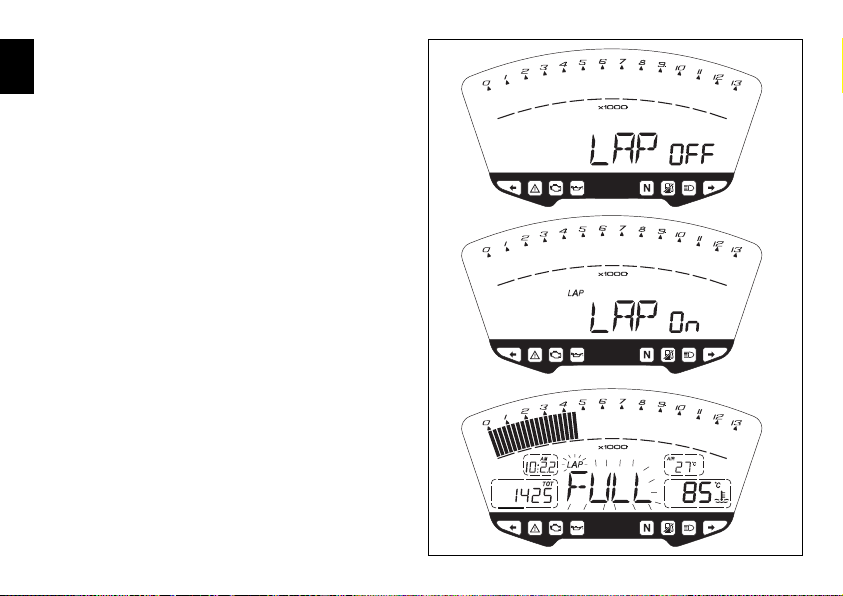

LAP time display function

To activate this function, go into the menu and set the “LAP”

E

function to “On” by pressing switch (1, fig. 8) in position B

“▼“ for 3 seconds.

START and STOP the timer by pressing the high beam

flasher switch (12, fig. 5) on the left-hand handlebar switch.

When the LAP function is active, each time you press the

flasher switch, the display will show the lap time for

10 seconds, before reverting to normal mode.

You can save a maximum of 30 laps in the memory.

If the memory is full, each time you press the flasher switch,

the display will not save any more lap times and will display

the flashing message “FULL” for 3 seconds until the

memory is reset.

26

fig. 18

Page 28

When you switch the LAP function off from the menu, the

lap in progress will not be saved.

If the LAP function is active and the display is suddenly

switched off (Key-Off), the LAP function is switched off

automatically (even if the timer was ON, the lap in

progress is not saved).

If the timer is not stopped, when it reaches 99 minutes,

59 seconds and 99 hundredths of a second, it restarts from

0 (zero) and continues until the function is switched off.

If, however, the LAP function is switched on and the

memory has not been cleared, but fewer than 30 laps

have been saved (e.g. 18 laps), the display will save any

remaining laps until the memory is saturated (in this case,

it will save a further 12 laps).

In this function, lap time only is displayed, but other data are

also saved (MAX speed, MAX rpm, rev limiter if reached)

for viewing at a later date in the Lap Memory function.

E

press C

after 10 sec.

press C

after 10 sec.

fig. 19

27

Page 29

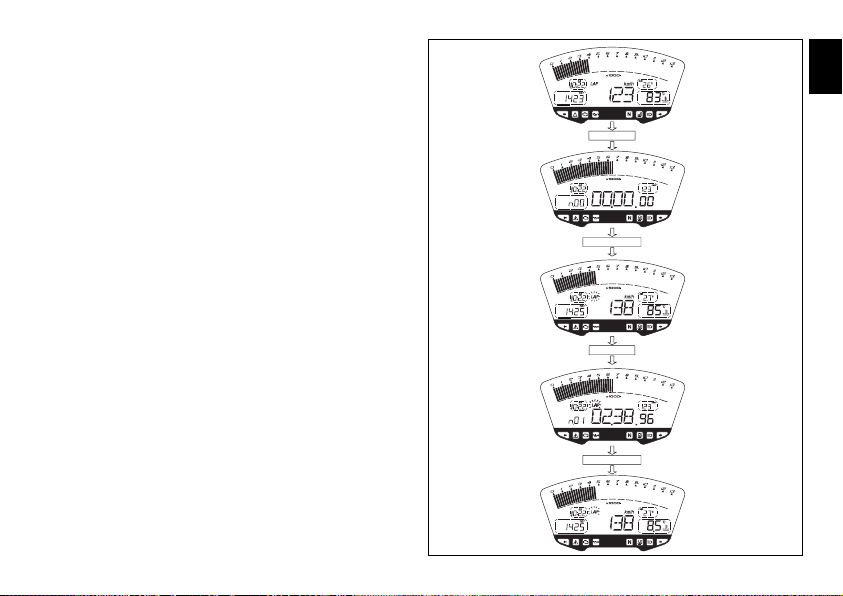

LAP Memory display

Displays the data saved with the LAP function: lap time,

E

MAX speed and MAX rpm.

To display the saved lap times, enter the menu and select

the “LAP MEM” page.

From this menu page, if you hold pressed switch (1, fig. 8)

in position B “▼“ for 3 seconds, the data for the first lap will

appear. The display will show the lap number, lap time, MAX

speed and the MAX rpm reached for the lap in question.

If you press switch (1, fig. 8) in position B “▼“, the display

scrolls through the 30 saved times, before returning to the

st

1

lap.

If you press switch (1, fig. 8) in position B “▼“ for 3 seconds

while the saved times are displayed, the display immediately

resets all the saved times. In this case, if the LAP function

was active, it is switched off automatically.

The MAX speed saved is the maximum speed indicated on

the display in Lap function.

During saving, if the MAX speed shown exceeds 299 km/h

(186 mph), the speed reached is displayed (e.g. 316 km/h).

If there is no reading in the memory, the 30 times are shown,

with the lap timer showing “00.00.00”, MAX rpm = 0 and

MAX speed = 0.

During the lap, if the engine reaches one of the two

thresholds before the rev limiter or the rev limiter itself,

the respective warning lights (10, fig. 4) come on during

the display of the saved times.

28

press A

press A

Reset of all times in memor

press A

press A

press B

press B. . x 19

press Bpress B

B= On 3 sec.

press B. . x 19

fig. 20

Page 30

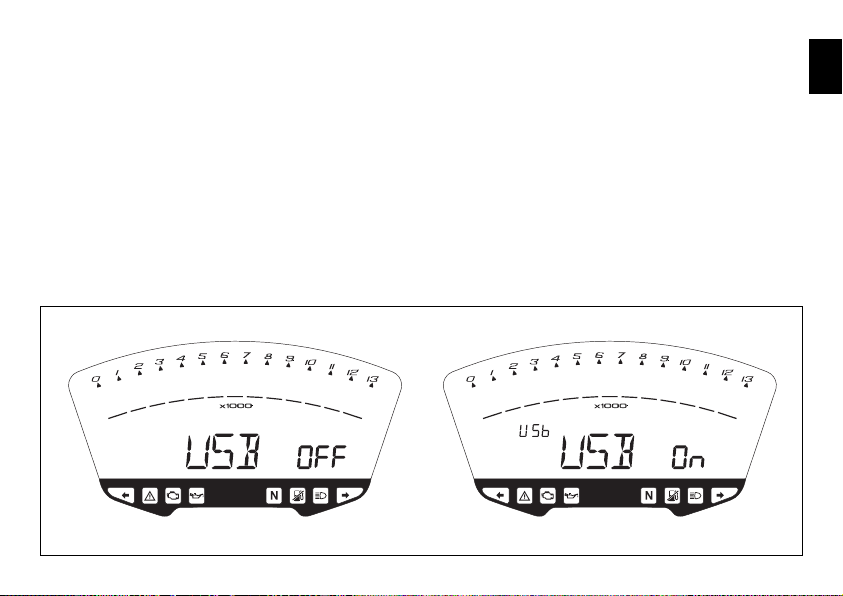

USB DAQ

This function is used to activate the data acquisition USB (not

supplied as standard with this model, but can available for

purchase from the Ducati sales network): the DAQ must be

connected to the motorcycle wiring.

To activate the DAQ, enter the menu and set the USB DAQ

to “On” by holding switch (1, fig. 8) in position B “▼“ for

3 seconds.

START and STOP the lap separator by pressing the high beam

FLASH button (12, fig. 5) on the left-hand handlebar switch.

If the USB function is active and the display is suddenly

switched off (Key-Off), the function is switched off

automatically.

E

fig. 21

29

Page 31

Erase USB

This function is used to erase all the data stored on the data

E

acquisition USB (not supplied as standard with this model,

but available for purchase from the Ducati sales network):

the DAQ must be connected to the motorcycle wiring.

To delete the data, enter the menu and select the “Erase

USB” page.

If you hold the switch (1, fig. 8) in position B “▼“ for

3 seconds and the USB DAQ is not acquiring data, the

message “WAIT…” appears on the display for 10 seconds.

After 10 seconds, the message “OK” appears for 2 seconds,

to confirm that the data has been deleted.

If you hold the switch (1, fig. 8) in position B “▼“ for

3 seconds and the USB DAQ is acquiring data, the DAQ

memory is not cleared and the display shows the message

“ERASE FAIL” for 2 seconds.

30

B = On 3 sec.

USB=ON

NO

WAIT of 4 sec.

display 2 sec.

YES

display 2 sec.

fig. 22

Page 32

Clock setting function

To set the clock, enter the menu and select the “TIME Set”

page.

From this page, if you press switch (1, fig. 8) in position B

“▼” for 3 seconds, you enter clock setting mode.

On entering this function, the message “AM” flashes on the

display; if you press switch (1, fig. 8) in position B “▼”, the

message “PM” flashes on the display; pressing switch

(1, fig. 8) in position B “▼” as second time returns you to

the previous step (if the time is 00:00, when you switch

from AM to PM the time 12:00 will appear);

if you press the switch (1, fig. 8) in position A “▲”, you can

set the hours, which start flashing. Each time you press the

switch in position B “▼”, the count advances cyclically in

steps of 1 hour; if you hold the switch down in position B

“▼”, the count advances cyclically in steps of 1 hour every

second (when the switch is held down continuously, the

hours do not flash);

if you press switch (1, fig. 8) in position A “▲”, you enter

the minutes setting mode and the minute digits will start

flashing. Each time you press the switch in position B “▼”,

the count advances cyclically in steps of 1 minute; if you

hold the switch down in position B “▼”, the count advances

cyclically in steps of 1 minute every second. If the switch is

held pressed in position B “▼” for more than 5 seconds, the

minutes advance by 1 every 100 ms (when the switch is held

in position B “▼” continuously, the seconds do not flash);

if you press the switch in position A “▲”, the system exits

setting mode and displays the newly set time.

B

A

B

A

B

flashing

flashing

setting

flashing

flashing

setting

B

E

B

A

A

A

A

fig. 23

31

Page 33

Instrument panel diagnostics

E

Important

The instrument runs the system diagnostics correctly

60 seconds after the last Key-Off.

Any errors detected in the behaviour of the motorcycle are

displayed.

If there are several errors, they are displayed in rolling mode

every 3 seconds.

The table below shows the errors that can be displayed.

Warning

Whenever an error is displayed, always contact an

authorized Ducati Service Centre.

Warning

32

light

Error message Error

COIL 10.1 Horizontal cylinder coil error

COIL 10.2 Horizontal cylinder coil error

COIL 11.1 Vertical cylinder coil error

COIL 11.2 Vertical cylinder coil error

INJE 12.1 Horizontal cylinder injector error

INJE 12.2 Horizontal cylinder injector error

Page 34

Warning

light

Error message Error

INJE 13.1 Vertical cylinder injector error

INJE 13.2 Vertical cylinder injector error

PUMP 16.0 Fuel pump relay error

FAN 18.1 Fan relay error

FAN 18.2 Fan relay error

STRT 19.1 Starter contactor error

STRT 19.2 Starter contactor error

STEP. 21.1 Stepper motor error

STEP. 21.2 Stepper motor error

STEP. 21.3 Stepper motor error

LAMB. 22.1 Lambda heater error

E

33

Page 35

Warning

E

light

Error message Error

LAMB. 22.2 Lambda heater error

EXVL 23.1 Exhaust valve motor error

EXVL 23.2 Exhaust valve motor error

EXVL 23.3 Exhaust valve motor error

EXVL 23.4 Exhaust valve motor error

EXVL 23.5 Exhaust valve motor error

TPS 1.1 Throttle position sensor error

TPS 1.2 Throttle position sensor error

PRESS 2.1 Pressure sensor error

PRESS 2.2 Pressure sensor error

T.WAT 3.1 Engine coolant temperature sensor error

34

Page 36

Warning

light

Error message Error

T.WAT 3.2 Engine coolant temperature sensor error

AIR 4.1 Air temperature sensor error

AIR 4.2 Air temperature sensor error

BATT 5.1 Battery voltage error

BATT 5.2 Battery voltage error

LAMB 6.1 Lambda sensor error

TILT 6.2 Lambda 2 sensor error

E

DTC 8.0

ECU 30.0 Engine ECU error

PK.UP 34.0 Pick-up sensor error

SPEE. 36.0 Speed sensor error

Traction control unit error (this error can only occur if the bike has been

fitted with the traction control kit available from Ducati performance)

35

Page 37

Warning

E

light

Error message Error

IMMO 37.0 Immobilizer error

IMMO 37.1 Immobilizer error

IMMO 37.3 Immobilizer error

IMMO 37.4 Immobilizer error

IMMO 37.5 Immobilizer error

CAN 38.0 CAN line error

36

Page 38

Display backlight

The instrument panel backlight is switched on only if the side

lights or low/high beam is on.

The instrument panel has sensors that measure ambient

temperature and light intensity, and automatically turns the

backlighting on or off accordingly.

Intelligent headlight switch-off

This function helps reduce battery use by automatically

switching off the headlight. The device is triggered in

3 cases:

- in the first case, if you turn the key from OFF to ON and

do not start the engine within 60 seconds, the headlight

is turned off and will be turned on again only when the

engine is next switched on;

- in the second case, after the normal use of the

motorcycle with the lights on, if the engine is stopped

using the RUN-STOP on the right-hand handlebar switch.

In this case, the headlamp is switched off 60 seconds

after the engine is switched off, and only switched on

again the next time the engine is started;

- in the third case, the headlight is switched off while the

engine is being started and switched back on again

when the engine is running.

Intelligent headlight switch-on

This function allows programmed activation of the headlight

even with the motorcycle off (Key-Off).

Immediately after key-off, the instrument panel remains

active for 60 seconds, thus allowing the headlight to be

switched on if the button (1, fig. 8) is switched to position B

“▼”.

During these 60 seconds, each time switch (1, fig. 8) is

pressed in position B “▼”, the instrument panel will activate

the headlight for 30 seconds; each press of switch (1, fig. 8)

in position B “▼” will add to the headlight activation time,

up to a maximum of 6 presses (equivalent to a maximum

activation time of 180 seconds).

The first time you press the button (1, fig. 8) in position B

“▼”, the 30 second period starts, thus switching on the

headlight. Further switch-on time can be added only if you

press the button again within these 30 seconds. If the

30 second period has elapsed, no further multiples of

30 seconds can be added, and the instrument panel will

switch off the headlight.

To reset this function, you must perform at least one Key-On/

Key-Off.

If the battery power is interrupted at any time while this

function is active, when power is restored, the instrument

panel will de-activate the function (the instrument panel

does not remain active for 60 seconds).

E

37

Page 39

The immobilizer system

For additional anti-theft protection, the motorcycle is

E

equipped with an IMMOBILIZER, an electronic system

that locks the engine automatically whenever the ignition

switch is turned off.

The grip of each ignition key contains an electronic device

that modulates the output signal from a special antenna in

the switch when the ignition is switched On. The modulated

signal represents the “password” (which is changed at each

start-up) by which the ECU recognizes the ignition key.

The ECU will only allow the engine to start if it recognises

this password.

Keys

(fig. 24)

The owner receives a set of keys, comprising:

- 2 black keys (B).

These contain the “code” of the immobilizer system.

Notes

The two keys have a small tag (1) attached, which

shows their identification number.

Notes

Your Ducati dealer may ask you to produce your Code

Card in order to carry out certain servicing operations.

The black keys (B) are the keys for normal use, and are

used to:

- start the engine;

- open the lock on the fuel tank filler cap;

- open the seat lock.

38

B

1

fig. 24

Page 40

Warning

Keep the keys separate, and store the tags (1) in a safe

place.

It is also advisable to use only one of the black keys to start

the motorcycle.

Code card

A CODE CARD (fig. 25) is supplied with the keys. This shows

the electronic code (A, fig. 26) that must be used if the

engine is locked by the immobilizer and consequently

does not start when the key is turned to ON.

E

Warning

Keep the CODE CARD in a safe place. We advise the

user to keep the code printed on the CODE CARD on his/her

person at all times in order to be able to override the engine

lock using the procedure described below, in the event of a

malfunction of the immobilizer system, signalled by

illumination of the amber diagnostic light (9, fig. 4).

This operation is only possible if the electronic code

indicated on the code card is known.

Warning

Your dealer will ask you to produce the Code Card in

order to re-program or replace a key.

fig. 25

A

fig. 26

39

Page 41

Immobilizer override procedure

Should the immobilizer become locked, you can perform

E

the “Immobilizer Override” procedure from the instrument

panel by entering the respective function as follows:

select the “CODE” page from the menu.

Notes

This menu should be active only if there is at least one

immobilizer error.

With this page selected, the initial code is always displayed

as “00000”. If you hold the button (1, fig. 8) in position B

“▼” for 3 seconds, you will access the procedure for

entering the electronic code given on the Code Card.

40

B= ON 3 sec.

lamp.

B

sell.

A

lamp.

B

sell.

A

lamp.

B

sell.

A

lamp.

B

sell.

A

lamp.

B

sell.

A

A

A

A

A

A

NO

Insert CODE

OK?

SI

fig. 27

Page 42

Entering the code:

on entering this function, the first digit on the left starts flashing.

Switch (1, fig. 8):

each time you press the switch in position B “▼”, the number

increases cyclically in steps of one digit every second;

if you press the switch in position A “▲”, you can set the

second digit, which will start flashing. Each time you press

the switch in position B “▼”, the number increases

cyclically in steps of one digit every second;

if you press the switch in position A “▲”, you can set the

third digit, which will start flashing. Each time you press

the switch in position B “▼”, the number increases

cyclically in steps of one digit every second;

if you press the switch in position A “▲”, you can set the

fourth digit, which will start flashing. Each time you press

the switch in position B “▼”, the number increases

cyclically in steps of one digit every second;

if you press the switch in position A “▲”, you can set the

fifth digit, which will start flashing. Each time you press

the switch in position B “▼”, the number increases

cyclically in steps of one digit every second;

press in position A “▲” to confirm the code.

If the code has been entered correctly, the message CODE

and the code itself will flash simultaneously for 4 seconds.

The motorcycle diagnostics warning light (9, fig. 4) will go

off. The instrument panel then automatically exits the menu,

thus allowing “temporary” starting of the motorcycle.

If the error persists, at the next key-on, the instrument panel

will return to an error state and immobilize the engine.

If instead the code has been entered incorrectly, the

instrument panel will automatically return to the “CODE”

menu and display the code “00000”.

E

41

Page 43

Operation

When the ignition key is turned from ON to OFF, the

E

immobilizer system activates the engine lock. When the

ignition key is turned from OFF to ON to start the engine:

1) if the code is recognised, the protection system releases

the engine lock. When you press the START (2, fig. 31)

switch, the engine will start up.

2) if the motorcycle diagnostics warning light (9, fig. 4)

comes on and if, when you press the button (1, fig. 8) in the

“▼” position, the “Error IMMO” message appears on the

display, indicating that the code has not been recognised.

In this case, turn the ignition key back to OFF and then to

ON again. If the engine still does not start, try again with the

other black key. If the engine still does not start, contact

the DUCATI Service network.

Warning

Sharp knocks can damage the electronic components

inside the key.

Always use the same key throughout the procedure. Using

different keys could prevent the system from recognising

the code in the key.

42

Duplicate keys

If you need additional keys, contact your DUCATI Service

Centre with all the keys you have in your possession and

your CODE CARD.

The Ducati Service Centre will program all the new keys as

well as any keys you already have.

You may be asked to provide proof that you are the

legitimate owner of the motorcycle.

The codes for any keys not present during the memory

programming procedure are cancelled, to ensure that any

keys that may have been lost can no longer be used to

start the engine.

Notes

If you sell your motorcycle, do not forget to pass on all

the keys and the CODE CARD to the new owner.

Page 44

Ignition switch and steering lock (fig. 28)

This is located in front of the fuel tank and has four positions:

A) ON: enables lights and engine operation;

B) OFF: disables lights and engine operation;

C) LOCK: the steering is locked;

D) P: parking light on and steering locked.

Notes

To move the key to the latter two positions, push it in

before turning. The key can be removed in positions (B), (C)

and (D).

A

B

C

D

fig. 28

E

43

Page 45

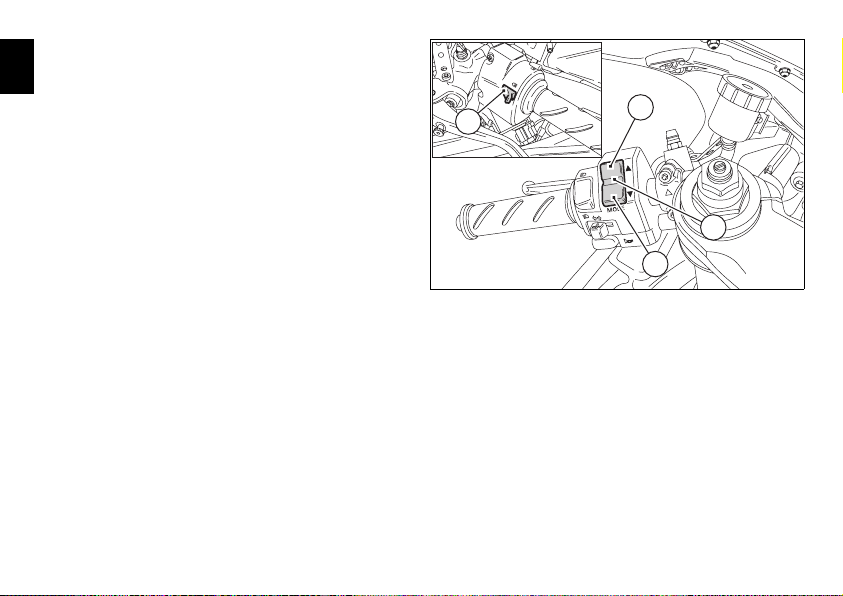

Left-hand handlebar switch (fig. 29)

1) Dip switch, two-position light selector switch:

E

position = low beam headlight on;

position = high beam headlight on.

2) Switch = three-position turn signal:

centre position = off;

position = left turn;

position = right turn.

To cancel the indicator, press the lever once it has returned

to the central position.

3) Button = horn.

4) Switch = high beam flasher and instrument panel

control.

5) Two-position instrument panel control switch:

position “▲”;

position “▼”.

44

4

1 2

3 5

fig. 29

Page 46

Clutch lever

The lever (1) disengages the clutch. The span adjuster (2)

serves to alter the distance of the lever from the handlebar.

Lever distance is adjusted by 10 clicks of the knob (2).

Turn the knob clockwise to move the lever away from

twistgrip, or anti-clockwise to move it closer.

When the clutch lever (1) is operated, drive from the

engine to the gearbox and the rear wheel is disengaged.

Correct use of the clutch lever is very important in all

riding situations, especially when moving off.

Warning

Any adjustment of clutch lever must be carried out

when motorcycle is stationary.

Important

Using the clutch properly will prolong the life of the

engine and prevent any damage to components in the

transmission.

Notes

The engine can be started with the sidestand down

and the gearbox in neutral. When starting the engine with

a gear engaged, pull in the clutch lever (in this case the

sidestand must be in the raised position).

E

2 1

fig. 30

45

Page 47

Right-hand handlebar switch (fig. 31)

1) Two-position ENGINE STOP switch:

E

position (RUN) = run;

position (OFF) = stop engine.

Warning

This switch is mainly intended for use in emergencies

when you need to stop the engine quickly. After stopping

the engine, return the switch to the position to start

the engine.

Important

After travelling with the lights on, if the engine is

switched off using switch (1) and the ignition key is left in

the ON position, the battery can be drained since the

headlamp remains on.

2) Button = engine start.

Throttle twistgrip (fig. 31)

The twistgrip (3) on the right handlebar opens the butterfly

valves in the throttle body. When released, the twistgrip

returns automatically to the initial position (idling speed).

46

3

1

2

fig. 31

Page 48

Front brake lever (fig. 32)

Pull the lever (1) towards the twistgrip to operate the front

brake. The system is hydraulically assisted and you only

need to pull the lever gently.

The brake lever has a knob (2) for adjusting the distance

between lever and twistgrip on the handlebar.

Lever distance is adjusted by 10 clicks of the knob (2).

Turn the knob clockwise to move the lever away from

twistgrip, or anti-clockwise to move it closer.

E

21

fig. 32

47

Page 49

Rear brake pedal (fig. 33)

Push down on the pedal (1) with your foot to operate the rear

E

brake.

The system is controlled hydraulically.

1

fig. 33

Gearchange pedal (fig. 34)

The gearchange pedal is at rest when in centre position N,

and automatically returns to the centre position. When in this

position, light N (3, fig. 4) on instrument panel comes on.

The pedal can be moved:

downwards = push down on the pedal to engage 1

and to shift down. At this point the N light on the instrument

panel will go off;

upwards= lift the pedal to engage 2

th

5

and 6th gears.

Each time you move the pedal you engage the next gear, one

gear at a time.

nd

gear and then 3rd, 4th,

48

st

gear

6

5

4

3

2

N

1

fig. 34

Page 50

Adjusting the position of the gearchange

and rear brake pedals (fig. 35 and fig. 36)

The position of the gearchange and rear brake pedals in

relation to the footrests can be adjusted to suit the

requirements of the rider.

To adjust the position, proceed as follows:

restrain the tie-rod (1) and slacken the locknuts (2) and (3).

Notes

The locknut (2) has a left-hand thread.

Turn the tie-rod (1) using an open-ended wrench on the flats

to move the gearchange pedal to the required position.

Tighten the two lock nuts (2) and (3) onto the rod.

E

2 1 3

fig. 35

49

Page 51

To adjust the position of the rear brake pedal, proceed as

follows.

E

Loosen the locknut (4).

Turn the pedal travel adjustment bolt (5) until the pedal is in

the desired position.

Tighten the locknut (4) to a torque of 2.3 Nm.

Operate the pedal by hand to check that there is 1.5 to 2 mm

of freeplay before the brake bites.

If not, adjust the length of the master cylinder pushrod as

follows.

Slacken off the locknut (6) on the pushrod.

Screw the rod into the clevis (7) to increase play, or unscrew

it to reduce play.

Tighten the lock nut (6) to a torque of 7.5 Nm and re-check

the free play.

50

7

6

4

5

fig. 36

Page 52

Main components and

devices

Position on motorcycle (fig. 37)

1) Fuel tank filler cap.

2) Seat lock.

3) Sidestand.

4) Rearview mirrors.

5) Front fork adjusters.

6) Rear shock absorber adjusters.

7) Suspension tie-rod for adjustment of rear ride height.

8) Exhaust silencer (see note on page 65).

9) Catalytic converter.

5

4 2

6

5

89

E

7

3

14

fig. 37

51

Page 53

Fuel tank filler cap (fig. 38)

E

Opening

Raise the cover (1) and insert the key into the lock.

Give the key a 1/4 turn clockwise to unlock.

Lift the cap.

Closing

Close the cap with the key inserted and push it into its seat.

Turn the key anticlockwise to the initial position and

remove it. Replace the lock cover (1).

Notes

The cap can only be closed with the key inserted.

Warning

Always make sure you have properly closed the fuel

filler cap after refuelling (see page 66).

52

1

fig. 38

Page 54

Seat lock

Opening (fig. 39)

Insert the key into the seat lock (1) and turn it clockwise

until the seat catch disengages with an audible click.

Raise the rear of the seat (2) until it can be extracted.

0

0

E

1

1

Closing

Fit the hooks on the base of the seat under the rear subframe.

Press down on the pillion seat until you hear the catch

engage with an audible click.

Make sure that the pillion seat is properly secured by gently

pulling it upwards.

(fig. 40)

1

2

fig. 39

fig. 40

53

Page 55

Sidestand (fig. 41)

E

Important

Before lowering the sidestand, check that the ground

is sufficiently even and firm.

Do not park on soft ground, gravel or on asphalt softened by

the sun etc. or the motorcycle may fall over.

When parking on a slope, always park with the rear wheel

on the downhill side.

To lower the sidestand, hold the motorcycle handlebars

with both hands and, with your foot, push down the stand (1)

until fully extended. Tilt the motorcycle until the sidestand

is resting on the ground.

Warning

Do not sit on the motorcycle when it is supported on

the sidestand.

To raise the sidestand to rest position (horizontal), tilt the

motorcycle to the right and, at the same time, lift the

stand (1) with your foot.

54

Notes

It is advisable to check periodically that the stand

mechanism (consisting of two springs, one inside the other)

and safety sensor (2) are working properly.

Notes

The engine can be started with the sidestand down

and the gearbox in neutral. If starting with a gear engaged,

pull in the clutch lever (in this case the sidestand must be up).

2

1

fig. 41

Page 56

Front fork adjusters

The front fork can be adjusted for rebound, compression and

spring preload.

The settings are adjusted by way of external adjuster screws:

1) to adjust rebound damping (fig. 42);

2) to adjust inner spring preload (fig. 42);

3) to adjust compression damping (fig. 43).

Park the motorcycle in a stable position on its sidestand.

To adjust the rebound damping setting, turn the adjuster (1)

on the top of each fork leg using the special wrench.

As you turn the adjusters (1 and 3), you will hear them click.

Each click corresponds to different damping setting. The

stiffest damping setting is obtained with the adjuster turned

fully clockwise to the “0” position. Start with this position

and turn counterclockwise. Count the clicks, which

correspond to position 1, 2 and so forth.

E

1

2

A

fig. 42

55

Page 57

The STANDARD factory settings are as follows:

compression:

E

3/4 turns;

rebound:

12 clicks.

Spring preload (A, fig. 42): 18 mm.

To change the spring preload for each fork leg, turn the

adjuster (2, fig. 42) with a 22 mm hex wrench.

Important

Adjust both fork legs to the same setting.

56

3

fig. 43

Page 58

Rear shock absorber adjusters (fig. 44)

The shock absorber has external adjusters that enable you to

adjust the suspension to suit the load on the motorcycle.

Adjuster (1), located on the left-hand side at the point at

which the shock absorber is fixed to the swingarm, controls

rebound damping.

The adjuster (2) on the shock absorber reservoir controls

compression damping.

Turn the adjusters (1 and 2) clockwise to stiffen the damping

or anti-clockwise to soften it.

STANDARD setting:

from the fully closed position (turned fully clockwise), unscrew:

adjuster (1) by 2 turns;

adjuster (2) by 2 turns.

Spring preload: 20 mm.

The two nuts (3) on the upper part of the shock absorber

serve to adjust the preload on the external spring. To

change spring preload, slacken off the upper lock nut.

Then tighten or loosen the lower nut to increase or

decrease spring preload as required.

2

E

1

3

fig. 44

57

Page 59

Once the desired spring preload has been set, re-tighten the

upper lock nut.

E

Warning

Use a pin wrench to turn the preload adjusting nut.

Take special care when turning the nut, to avoid injuring

your hand by striking it violently against other parts of the

motorcycle if the wrench suddenly slips off the nut while

turning.

Warning

The shock absorber is filled with gas under pressure

and may cause severe damage if taken apart by unskilled

persons.

If you plan to carry a passenger and luggage, adjust the rear

shock absorber spring load to the maximum setting to

improve the handling characteristics of the motorcycle and

to avoid the possibility of ground contact. It may also be

necessary to adjust the rebound damping accordingly.

58

Page 60

Riding the motorcycle

Running-in precautions

Max. rpm (fig. 45)

Rpm limits to be observed during the running-in period and in

normal use:

1) up to 1000 km;

2) from 1000 to 2500 km.

Up to 1000 km

During the first 1000 km keep an eye on the rev counter.

The indicator must not exceed 5500-6000 rpm.

During the first hours of riding, it is advisable to continuously

vary the load on the engine and the rpm, though still keeping

within the above limits.

For this reason, roads with numerous bends and hilly areas

are ideal for running in the engine, brakes and suspension.

For the first 100 km, use the brakes gently. Do not brake

violently or keep brake applied for too long. This will enable

a correct break-in of friction material on brake pads against

brake discs.

To allow all the mechanical moving parts in the motorcycle to

adapt to one another, and to avoid shortening the life of the

main engine components, it is advisable to avoid sudden

acceleration and running the engine at high rpm for too long,

especially uphill.

It is also advisable to check the drive chain frequently and

ensure that it is lubricated as required.

E

59

Page 61

From 1000 to 2500 km

At this point, you can ask for more power from the engine,

E

being careful, however, never to exceed 7000 rpm.

Important

Throughout the running-in period, be careful to stick

to the recommended maintenance schedule and periodic

service intervals indicated in the warranty booklet.

Failure to follow these instructions releases Ducati Motor

Holding S.p.A. from any liability whatsoever for any

engine damage or shorter engine life.

Keeping to the running-in recommendations will ensure

longer engine life and reduce the need for overhauls and

re-tuning.

60

0 ÷ 1000 Km

1000 ÷ 2500 Km

fig. 45

Page 62

Pre-ride checks

Warning

Failure to carry out these checks before starting may

result in damage to the motorcycle and injury to rider.

Before starting, check the following points:

Fuel level in the tank

Check the fuel level in the tank. Re-fuel if necessary (page 66).

Engine oil level

Check the oil level in the sump through the sight glass.

Top up if necessary (page 88).

Brake and clutch fluid

Check the fluid levels in the respective reservoirs (page 73).

Coolant

Check coolant level in the expansion reservoir. Top up if

necessary (page 72).

Tyre condition

Check the pressure and condition of the tyres (page 86).

Controls

Operate the brake, clutch, throttle and gear change controls

(levers, pedals and twistgrip) to check that they function

correctly.

Lights and indicators

Make sure the lights, indicators and horn work properly.

Replace any burnt-out bulbs (page 80).

Key locks

Check that the fuel filler cap (page 52) and the seat are

locked (page 53).

Sidestand

Make sure the sidestand operates smoothly and is in the

correct position (page 54).

Warning

If there are any faults or malfunctions, do not start

the motorcycle and contact your DUCATI Dealer or

Authorized Service Centre.

E

61

Page 63

Starting the engine

E

Warning

Before starting the engine, familiarise yourself with

the controls that you will use when riding (page 10).

Warning

Never start or run the engine in enclosed space.

Exhaust gases are toxic and may lead to loss of

consciousness or even death within a short time.

1) Turn the ignition key to ON (fig. 46). Check that both

the green light N and the red light on the instrument

panel come on.

A

B

C

D

fig. 46

Important

The oil pressure warning light should go out a few

seconds after the engine has started (page 11).

Warning

The sidestand should be in rest position (horizontal),

otherwise the safety sensor prevents the engine starting.

62

Notes

The engine can be started with the sidestand down

and the gearbox in neutral. If starting with a gear engaged,

pull in the clutch lever (in this case the sidestand must be up).

Page 64

2) Check that the stop switch (2, fig. 47) is positioned to

(RUN), then press the starter button (3, fig. 47).

Important

Do not rev the engine when cold. Allow some time for

the oil to warm up and reach all points that need lubricating.

E

2

3

fig. 47

63

Page 65

Moving off

1) Disengage the clutch by squeezing the clutch lever.

E

2) Push down the gearchange lever firmly with the tip of your

foot to engage first gear.

3) Raise the engine revs by turning the throttle twistgrip

while gradually releasing the clutch lever. The motorcycle

will start moving.

4) Release the clutch lever completely and accelerate.

5) To change up to the next gear, close the throttle to

reduce the engine revs, disengage the clutch, lift the

gearchange lever and release the clutch lever.

To change down, proceed as follows: release the twistgrip,

disengage the clutch, briefly rev the engine to allow the

gears to synchronize, shift down and release the clutch lever.

Use the controls intelligently and opportunely: when riding

uphill, do not hesitate to shift down as soon as the

motorcycle starts to slow down, so you will avoid

overloading the engine and putting too much strain on the

the motorcycle generally.

Important

Avoid sudden acceleration, as this may lead to

misfiring and transmission snat ching. The clutch lever should

not be held in longer than necessary after a gear is engaged,

otherwise friction parts may overheat and wear out.

64

Braking

Slow down in time, change down to use the engine brake,

then apply both brakes. Pull in the clutch lever before the

motorcycle comes to a stop to prevent the engine stalling.

Warning

Use both the brake lever and the brake pedal for

effective braking. Using only one of the brakes will give

you less braking power.

Never use the brake controls harshly or suddenly as you

may lock the wheels and lose control of the motorcycle.

When riding in the rain or on slippery surfaces, braking

capacity is significantly reduced. Always use the brakes

very gently and carefully when riding under these conditions.

Any sudden manoeuvres may lead to loss of control.

When riding down long, steep downhill slopes, change

down to use engine braking. Apply the brakes intermittently

for brief periods only. Keeping the brakes applied

continuously causes the friction material to overheat and

dangerously reduces braking effectiveness. Under-inflated

or over-inflated tyres reduce braking efficiency and may

adversely affect safe riding and road-holding on bends.

Page 66

Stopping the motorcycle

Reduce speed, change down and release the throttle twistgrip.

Change down to engage first gear and then neutral. Apply the

brakes and bring the motorcycle to a complete stop. Switch

the engine off by turning the key to OFF (page 43).

Parking

Stop and park the motorcycle on the sidestand

(see page 54).

To prevent theft, turn the handlebar fully left and turn the

ignition key to the LOCK position.

If you park in a garage or other indoor area, make sure that

there is proper ventilation and that the motorcycle is not

near a source of heat.

If necessary, you can leave the sidelights on by turning the

key to position P.

Important

Do not leave the key at P for long periods or the

battery will run down. Never leave the motorcycle

unattended with the ignition key inserted.

Warning

The exhaust system might be hot even after engine

is switched off; take special care not to touch the exhaust

system with any part of your body and do not park the

motorcycle next to inflammable material (wood, leaves, etc.).

Warning

Using padlocks or other locks designed to prevent

movement of the motorcycle (such as brake disc locks, rear

sprocket locks, and so on) is very dangerous, and may impair

motorcycle operation and the safety of rider and passenger.

E

65

Page 67

Refuelling (fig. 48)

Do not overfill the tank when refuelling. The fuel level should

E

always be below the rim of the filler recess.

Warning

Use fuel with low lead content and an original octane

number of 95 minimum (see table “Fluids and lubricants”

on page 97).

Check that no fuel is trapped in the filler cap recess.

66

Max level

fig. 48

Page 68

Toolkit and accessories (fig. 49)

The compartment under the pillion seat contains:

use and maintenance manual;

toolkit consisting of:

- spark plug wrench;

- tommy bar for spark plug wrench;

- double-ended screwdriver;

- Allen key for fairing panels.

E

fig. 49

67

Page 69

Main Maintenance Operations

E

Removal of the fairings

Some parts of the motorcycle fairing have to be removed

for certain maintenance or repair operations.

Warning

If parts that have been removed are not refitted

correctly they may become loose suddenly while riding

and cause you to lose control of your motorcycle.

Important

On refitting the headlight fairing, always refit the nylon

washers in correspondence with the retaining screws to

avoid damaging the painted parts and the Plexiglas

windshield.

Side fairings

Remove the side fairings using the Allen key located in the

underseat compartment; unscrew:

the two bolts (1) securing the fairing panels to the brackets;

the six bolts (2) securing the fairing panels to the headlight

fairing;

the four bolts (3) securing the fairing panels to the frame;

the two bolts (4) located under the fairing that join the right

fairing panel to the left fairing panel;

the two bolts (5) securing the fairing panels to the oil cooler;

the two bolts (6, fig. 51) securing the front of the fairing to

the headlight fairing.

2

3

1

68

5

4

fig. 50

Page 70

Notes

Be careful of the splashguard, which is released by the

fairing panel fastening.

E

Notes

To refit the left fairing panel, lower the sidestand and

pass it through the aperture in the panel.

6

fig. 51

69

Page 71

Rearview mirrors

Unscrew the bolts (1) securing the rearview mirror.

E

Release the pins (2) from the retaining clips (3) attached to

the headlight fairing bracket (4). Slip off the rubber covers (5)

and disconnect the turn indicator wiring connectors (6).

Repeat the procedure to remove the other rearview mirror.

Important

On refitting, apply medium-strength threadlocker to

the threads of the bolts (1).

70

3

4

2

1

3

fig. 52

556

fig. 53

Page 72

Headlight fairing

Notes

To remove the headlight fairing, first remove the rear-

view mirrors and side fairing panels as described above.

Unscrew the two rear bolts (1) securing the headlight fairing

to the headlight support.

Notes

After refitting the headlight fairing, refit the side body

panels and rear-view mirrors.

1

fig. 54

E

71

Page 73

Checking and topping up the coolant

E

(fig. 55)

Check the coolant level in the expansion reservoir on the

right side of the motorcycle. It should be between the two

marks (1) and (2). Mark (2) indicates MAX level, and mark (1)

indicates MIN level.

Top up if below the MIN level.

Remove the right-hand fairing (page 68).

Unscrew the filler cap (3, fig. 55) and add a mixture

consisting of water and antifreeze SHELL Advance Coolant

or Glycoshell (35-40% of the volume) up to the MAX mark.

Refit the cap (3) and replace all removed parts.

This type of mixture gives the best operating conditions

(the coolant starts to freeze at -20 °C/-4 °F).

Cooling circuit capacity: 2,3 dm

3

(litres).

Warning

This operation must be carried out with the engine

cold and with the motorcycle vertical and level.

72

3

2

1

MAX

MIN

fig. 55

Page 74

Checking the brake and clutch fluid level

The level must not fall below the MIN mark on the

corresponding reservoir (fig. 56) (the figure shows the front

and rear brake fluid reservoirs).

If the level is too low, air can get into the circuit, thus

impairing the efficiency of the system.

Brake and clutch fluid must be topped up and changed at

the intervals specified in the routine maintenance table

(see Warranty Booklet) by a Ducati Dealer or Authorized

Service Centre.

Important

It is recommended that all brake and clutch hoses be

renewed every four years.

Brake system

If there is excessive play at the brake lever or pedal even

though the brake pads are still in good condition, contact a

Ducati Dealer or Authorized Service Centre to have the

system inspected and any air expelled from the circuit.

Warning

Brake and clutch fluid can damage paintwork and

plastic parts, so avoid contact. Hydraulic fluid is corrosive

and can cause damage and injuries. Never mix fluids of

different qualities.

Check that the seals are in good condition.

E

fig. 56

73

Page 75

Clutch system

If there is too much play at the clutch lever and the

E

motorcycle jumps or stops when a gear is engaged, this

indicates air in the system. Contact a Ducati Dealer or

Authorized Service Centre to have the system inspected

and the air bled from the system.

Warning

The clutch fluid level in the reservoir tends to rise as

the friction material on the clutch plates wears out. Do not

exceed the specified level (3 mm above the minimum level).

74

fig. 57

Page 76

Checking the brake pads for wear (fig. 58)

The brake pads are marked with wear indicators so that they

can be checked without removing them from the calipers.

If the grooves in the pad friction material are still visible,

the pad is still in good condition.

Important

Have the brake pads replaced by a Ducati Dealer or

Authorized Service Centre.

MIN

1 mm

E

fig. 58

75

Page 77

Lubricating cables and linkages

The condition of the outer throttle and choke cables should

E

be checked at regular intervals. The outer cables should

show no signs of kinking or cracking. Operate the controls to

make sure the inner cables slide smoothly inside the outer

cables: if you feel any friction or catching, have the cable

replaced by a Ducati Dealer or Authorized Service Centre.

To prevent problems, periodically open the twistgrip

housing by unscrewing the two bolts (1, fig. 59) and

lubricate the ends of each control cable and the races

with SHELL Advance Grease or Retinax LX2.

Warning

Close the twistgrip housing carefully, inserting the

cable in the race.

Refit the housing and tighten the bolts (1) to 10 Nm.

To ensure smooth operation of the sidestand pivot, remove

dirt and apply SHELL Alvania R3 grease to all friction points.

76

1

fig. 59

Page 78

Adjustment of the throttle cable free play

In all handlebar positions, the throttle twistgrip should have

free play of 1.5 to 2.0 mm measured at the edge of the

twistgrip. If necessary, adjust using the adjusters (1 and 2,

fig. 61) located on the steering tube on the right-hand side

of the motorcycle.

Adjuster (1) is for throttle opening, and adjuster (2) is for

throttle closing.

Peel back the sleeves to access the adjusters and slacken

the locknuts. Adjust both adjusters by the same amount:

turn clockwise to increase free play and anti-clockwise to

reduce free play. When finished, tighten the locknuts and

replace the sleeves.

1

1,5÷2 mm

1,5÷2 mm

2

➤

fig. 60

fig. 61

➤

E

77

Page 79

Charging the battery (fig. 62)

Before charging the battery, it is best to remove it from the

E

motorcycle.

Remove the left-hand side fairing (page 68), unscrew the

bolt (1) and remove the mounting bracket (2). Always

disconnect the black negative terminal (-) first, and then

the red positive terminal (+).

Warning

The battery produces explosive gases: keep it away

from heat sources and flames.

Charge the battery in a well-ventilated area.

Connect the battery charger leads to the battery terminals:

red to the positive terminal (+), black to the negative

terminal (-).

Important

Connect the battery to the charger before switching

on: failure to do so can result in sparking at the battery

terminals, which could ignite the gases inside the cells.

Always connect the red positive terminal (+) first.

Replace the battery in its support (3), then connect the

terminals. Apply some grease to the bolts to improve

conductivity and fasten the bracket (2) with the bolt (1).

78

Warning

Keep the battery out of the reach of children.

Charge the battery at 0.9 A for 5 to 10 hours.

3

+

1

-

2

fig. 62

Page 80

Checking the chain tension (fig. 63)

Important

Have the chain tensioned at a Ducati Dealer or

Authorized Workshop.

Chain tensioning (on sidestand): hold a rule half way along the

bottom run of the chain, push down on the chain and adjust

the tension until the distance between the aluminium of the

swingarm and the centre of the chain pin is 31 to 33 mm.

Warning

The tensioner lock nuts (1) must be tightened correctly

to ensure rider safety.

Important

An incorrectly tensioned chain will cause the rapid

wear of transmission parts.

Lubricating the drive chain

The chain fitted on your motorcycle has O-rings that keep

dirt out of and lubricant inside the sliding parts.

So as not to damage these seals when cleaning the chain,

use special solvents and avoid aggressive washing with

high-pressure steam cleaners.

After cleaning, blow the chain dry with compressed air or

wipe with an absorbent material, then lubricate each link

with SHELL Advance Chain or Advance Teflon Chain.

Important

Using non-specific lubricants may cause severe

damage to the chain and the front and rear sprocket.

.

31 to 33 mm

E

fig. 63

79

Page 81

Changing the high and low beam bulbs

Before replacing a burnt-out bulb, make sure that the new

E

one matches the voltage and wattage specifications in the

“Electrical System” paragraph on page 103. Always check

that the new bulb works before refitting removed parts;

fig. 64 shows the position of the low beam (LO), high beam (HI)

and side light (1) bulbs.

Headlight

To gain access to the left-hand bulb, remove the cover (2)

by pressing the lever (A).

Rotate the locking ring nut (3) of the upper bulb body

anti-clockwise and extract the burnt-out bulb. Replace with

a bulb of equal rating.

On refitting, rotate the locking ring nut (3) clockwise to

secure the bulb in place.

The right-hand bulb is replaced in the same way.

80

LO

1

HI

fig. 64

A

3

2

fig. 65

Page 82

Notes

It is not necessary to disconnect the main wiring loom

cable in order to replace the headlight bulbs.

Notes

Be careful to hold the new bulb at the base only.

Never touch the transparent body with your fingers or it

will blacken resulting in reduced bulb brilliancy.

Refitting

After changing the burnt-out bulb, replace the cover and

close it by pressing it against the lever.

E

81

Page 83

Changing the sidelight bulb

To access the sidelights (1), reach your hand inside the

E

headlight support and take the bulb-holders out of their

seats. Turn the bulb retaining ring (1) anti-clockwise and

remove the burnt-out bulb.

Renew the burnt-out bulb.

On refitting, turn the bulbs (1) clockwise to secure.

82

1

fig. 66

Page 84

Rear turn indicators (fig. 67)

To change the rear turn indicator bulbs, rotate the indicator

body (1) by a quarter of a turn so that the lens is facing

upwards, and withdraw it from indicator support.

The bulb has a bayonet-type end fitting: to remove it, push it

in and turn it counter-clockwise. Push in the new bulb and

turn it clockwise until it clicks into place. Refit the indicator

body (2) to its support and rotate it by a quarter of a turn.

Number plate light (fig. 68)

To access the number plate light bulb, unscrew the bolt (3)

securing the cover (4). Remove the bulb and replace it.

E

1

2

fig. 67

4

3

fig. 68

83

Page 85

Headlight aim (fig. 69)

To check the headlight aim, place the motorcycle upright

E

with the tyres inflated to the correct pressure and one person

sitting astride the motorcycle. The motorcycle should be

perfectly vertical, with its longitudinal axis at right angles to a

wall or screen at a distance of 10 metres. Draw a horizontal

line on the wall at the height of the centre of the headlight

and a vertical one in line with the longitudinal axis of the

motorcycle.

If possible, perform this check in conditions of low ambient

light.

Switch on the low beam headlight:

the height of the upper limit between the dark area and the

lit area must not be more than nine tenths of the height of

the centre of the headlamp from the ground.

Notes