Page 1

9

5141.0

BA

'

Incubators

7010,

7310

OPERATING MANUAL

and 7510

Page 2

From

Drger:

Incubators

OPERATING INSTRUCTIONS

Important

For correct and

paratus,

point

1

2

4

and to avoid

out the

of the

use

Any

cise

knowledge

these

operating

The

apparatus

purposes

Manual or for

writing by Dragerwerk

The

apparatus

experts

cial

drawn

Only

at‘regular

report

up.

original Drager spare parts

Notice

effective

following:

apparatus requires pre-'

is intended

specified

purposes

should

of the

_

use of the

hazards,

and

observation

instructions.

in the

AG.

be

time intervals.

inspections

ap—

we would

the

for

only

Operating

confirmed

inspected by

An offi-

be

should

should

of

in

7010,

be used for maintenance and

Repairs

placement

carried out

We

repair

Customer Service

Branch or

Regular inspection

entering

Contract with the Technical Customer

Service of

Responsibility

the

operator

and

of

by experts.

recommend

work carried out

Agent.

into an

your

apparatus

in all

7310

maintenance,

spare

having inspections

Dr'ager

forthe reliable function

passes

cases

should

parts

the Technical

by

of

your

is best ensured

Inspection

Branch or

to the owner

where the

repairs.

and the

only

Drager

'

Service

and

Agent.

ap-

and

re-

be

by

of

or

paratus

or

the

been used

conform

7 For reasons of

ers

6

8 The

We would also

recommendations,

governing

should

7510

has been

repaired by

Drager Organisation

should be overhauled

years.

apparatus

in areas of

be observed.

persons

in

a

to the normal

explosive

point

the use of technical

DRAGERWERK

inexpertly

manner which

safety,

is not

out that the national

maintained

not

employed by

or where it has

conditions

pressure

at least

approved

risks.

regulations

equipment

AG LUBECK

does not

of use.

reduc—

every

use

for

and laws

Contents

Important

1

2

3 Construction ..................

3.1 to3.7 Standard

4

5

6

7 Care and Maintenance

8 OrderList

9 Scale

N

Notice .

........................

Duty

Technical Data

'

3.8

PreparatoryWork

Operation

Trouble

Shooting

Drawings

. . .' .............

................ 3

Accessory

. .« ..................

...r ................. 19

................

_

Equipment

Devices

..............

...............

.......... 16

Page

. . .

.,

...... 9

21

2

3

4

4

12

13

14

Fig.

Incubator 7010

1a

(with trolley

with base-unit

and

7011)

32(81b

Page 3

Fig.

.

1

Duty

1.1

Incubator 7010

The

Incubator

for

premature

Warmth,

concentration

provide

tory development.

Various

can

be added: for

for

aerosol

cation

of GNP

1.2

Incubator

The Incubator

construction as

its

large hinged

suited for

care

measures.

13

Intensive-care

'

The

Intensive-care

(Fig. Ic)

months old

lowing

surgery.

compared

larger

Plexiglass

removeable and

flaps)

surface,

surgical

1b

Incubator

is

lowered

7310

to

place

(with

trolley

the

baby

and with

inside

base—unit

(of. 3.5.2).

7011).

The

large

hinged

front

panel

38665»

intubation and

in

the

ple

7010

and

humidified

and

favourable

of

types

therapy,

and CPAP

7310

7310

the model

front

phototherapy

Incubator

is

designed

whose

Its

with

models

and

X-ray

procedures

ventilation

Intensive-care

(Fig. 1a)

sick

air,

protection

conditions for

is

raised

from

designed

oxygen

infection

satisfac-

newborn babies.

supplementary apparatus

of

ventilation.

7010.

it

is

7510

Incubator

secretions,

for

appli-

is of

similar

Owing

particularly

as intensive

7510

up

and fol—

aspiration

for

infusions,

(Fig. 1b)

panel

as well

for babies of

lives are at risk

mostimportantfeatures,

hood,

cassette

on

7010 and 731

hinged

swivelable

drawer.

children,

are all

Incubator

flaps

reclining

radiology,

quite

O,

(spring

Minor

sim-

7510.

to

to 6

are:

2

Technical

Scale

drawings:

Weights: (see

Noise level

Electrical

Alternating

Voltage:

100,

Current

Heat

Certifications

The

free in

Regulation

radio-protection

VDE: Verband

*)

(German

data

current

according

110, 127, 220,

consumption:

output:

apparatus

accordance with

0875,

Association of

Order

(inside):

250 W

marks

are

mark.

Deutscher

Data

see

page

List,

i

50/60 Hz

to order

240 V

300

interference

and

carry

21

page 19)

50

dB(A)

W

—

—

VDE*)

the

Elektrotechniker

Electricians)

f"

6”

Fig.

1 c

Intensive-care

Incubator

7510

cabinet and with

(with

base-unit

7011)

38816

Incubators with mark of

«Geprtifte

by

Technical

Sicherheit»

Inspection

conformity

(checked

Board Bavaria

safety)

Page 4

Construction

The

incubator mounted on

mobile

cabinet consists of the

housing

clining

glass

The air

ble to

cubator

and

tection from infection.

flows

ture

(and

electrical

air and the

by

sensors.

the

to

or

temperature

even. The ventilator also

with its electrical

surface for the

cover.

circulating

provide

temperature,

oxygen

then

concentration,

over the sensors of

regulator

and the

over the

heating forwarming

warning

the air

temperature

According

is

air

then

be

humidified,

wholly.

passed

The air

overthe

system

an

heating

devices are controlled

to the

or this is

circulation

base-unit,

baby,

makes it

adjustable,

the

desired

and

circulating

The

the

safety

element. The

measured

humidity setting,

over a

water surface

bypassed partly

reclining

continously

a

trolley

incubator

the re-

and a

Plexi-

possi-

even in—

humidity

good pro-

air fist

air-tempera-

thermostat

the incubator

by

the air

keeps

surface

draws

in ca. 25 l/min of fresh air from outside

through

with the

ded to the fresh air via a

or

is also

The

the

fect of

around the

carbon

3.1

Incubator base-units 7011/7012

These base-units contain all the electrical

operating

designed

They

tional

surement and

the

3.1.1

Switch

tor’

In

current-failure

very

switched off.

two bacterial filters and mixes this

circulating

air.

passed through

slight

positive

incubator

causing

dioxide

and control

as

differinthat base-unit 7012 has addi-

provision

pressure

by adding

air to flow out

and the

hood,

is thus

replaceable

for

skin-temperature

regulation.

’Disinfection in

the incubator

this

position:

position,

warning signal

the ventilator runs.

Only

Oxygen

flowmeter,

the bacterial filters.

fresh

flushed out.

equipment

can be ad-

and this

created inside

the ef-

air has

through

expired

baby’s

and are

plug-in

units.

mea-

leaks

Asep-

heating

remains

3.1.2 ,

Switch

ulation’

The

the desired incubator

between 28°C and

cubator

position: ’Air-temperature reg-

pointer

has warmed

regulator

temperature

deviations

of the incubator

ing

temperature

due to the tolerances

different

the

mometer and

ture

regulator.

the

gives

3.1.3

Skin-temperature

with

(only

The

baby‘s

means of a small

and

by

affixing

In

to

the switch

regulation’

tion’ the

on

played

atUre).

on the selector switch is set to

air

370. After the in-

automatically

at the desired

develop

may

set

thermometer and the

on the control knob. This is

of the

measuring

the sensor of the

incubator thermometer

The

definitive

base

skin

reading.

measurement

unit

7012)

temperature

temperature

the abdomen.

temperature

the

up,

proportional

maintains the

value.

between the reac-

apparatus

sites of the

tempera—

is measured

sensorfor

positions ’Air-temperature

and

’Skin—temperature regula-

gauge

skin

8

in

temperature

3

Fig.

(actual temper-

baby’s

Slight

and

ther-

is dis-

Fig.2Front panel

1

Battery

_

ure

2

3 Test button

warning

Test button

failure

of base-unit

compartment (forcurrent-fail-

signal)

and lamp for current-

warning signal

and

temperature/ventilator-failure

ing signal

Heating pilot lamp

Selector switch for

01-h

Fig.

Front

3

of base-unit 7012

panel

lamp

type

7011

'

for excessive-

warn-

of

operation

:

6

Connecting

system

7

Adjustingscrewforsettingthedesired

skin-temperature

8 Skin

value

Skin

9

ing

10 Connector for

socket

~

temperature

temperature

for house

value

scale. Desired

scale. Actual read-

skin-temp.

sensor

alarm

3.1.4

Switch

pasition: ’Skin-temperature

regulation’

with

(only

In the

base-unit

switch

regulation’,rthe baby's

measured

sired value’

and

(setpoint).

temperature regulator operates

ble’

proportional

teristics

are illustrated in

temperature adjustment range

to 37°C.

Example:

Desired

actual

Deviation: 02°C.

air

Even

and

incubator

low 29°C or rise above 37°C.

The DRAGER

advantage

place

when

the environment.

Simpler

feedback’

stable.

sist of a

not thermo-isolated

air. This is the case when

attached to the child’s

ter.

This has the

”true” skin

and

the skin and

Without

cuit of a

38 825

start to

skin-temperature setting

skin-temperature

temperature

with

large

desired

skin

air

temperature

that no

in the incubator air

a sensorthermo—isolated

using

control

in

order

Such ’thermal feedback’

skin-temperature

disadvantage

temperature

regulated

incubator-air

’thermal

simple

’oscillate’,

\

7012)

position

brought

’Skin—temperature

skin

to the

The

control,

whose

temperature

preset

Drager

with ’flexi-

charac-

4.

Fig.

from 36°C

skin-

Skin-

361°C;

reading

Consequence:

to 31°C.

falls

deviations between actual

temperature

does not fall be—

regulating system

great

temperature

systems require

to

the

keep

sensor

from the

the sensor is

body

that is measured

but a mixed value between

363°C.

incubator

values,

has the

variations

even

’thermal

control

circuit

can con-

poorly

surrounding

with a thin

that it is not the

plas-

temperatures.

control cir-

i.

system

e.

the

large

can

variations

easily

feedback‘,

control

is

’De-

the

take

from

or

only

4

Page 5

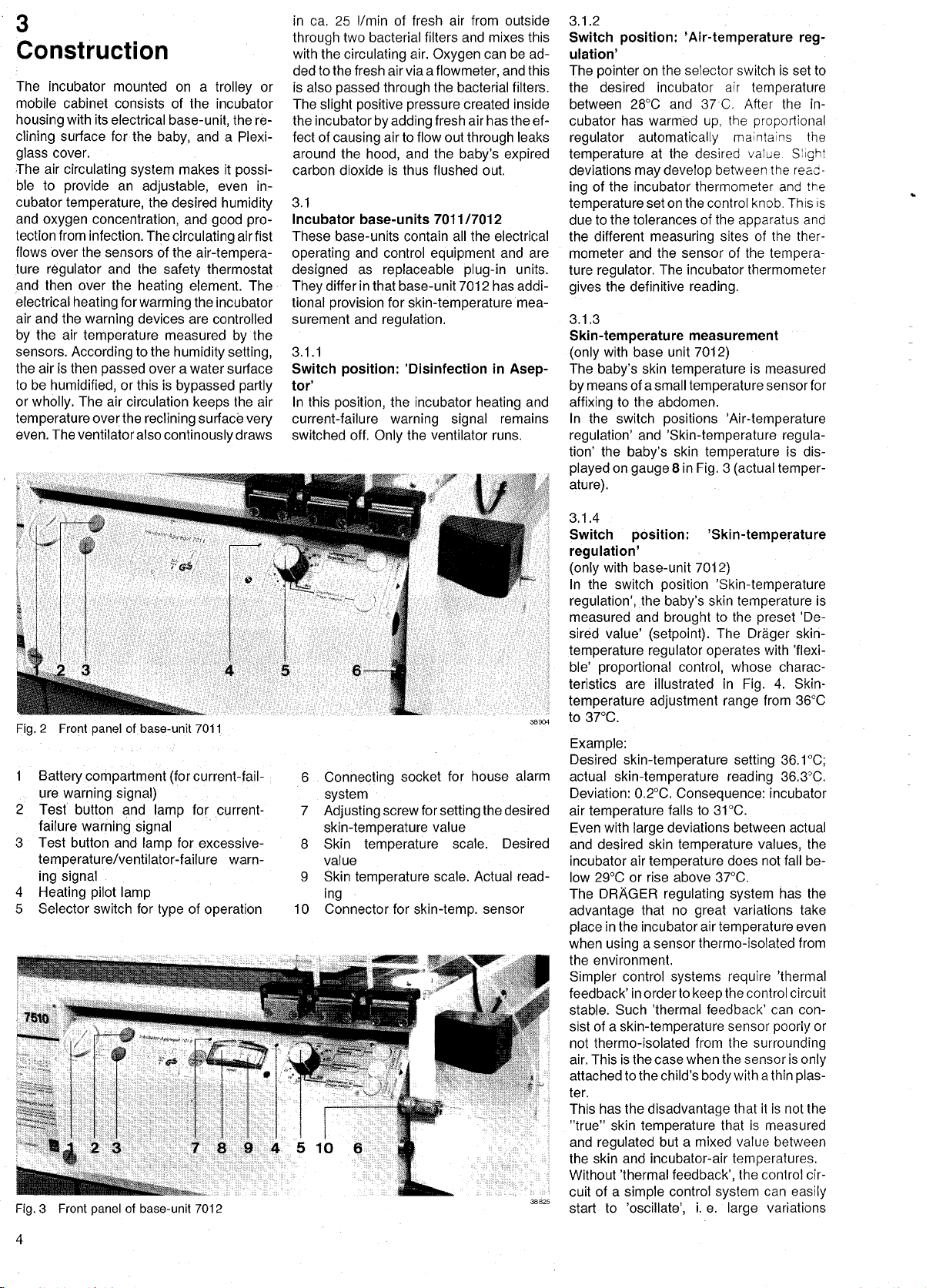

Fig.

4

— —

—

2

Example

Characteristics of

skin-temperature

-1

-0,8-0,6—0,4-QZ

regulation

37

36

35

34

33

0

Incubator-air

0,4

0,2

0,6

temperature (°C)

1

0,8

Skin

actual

temperature

reading

and

difference

desired

between

value

(°C)

would

develop

ature. This

the

ployed

skin

for children

would

temperature

well-developed

regulation.

The

accuracy

measurement

02°C.

The

platinum

temperature

bridges

precision

values either

and

components

temperatures

through

are

3.1.5

ageing.

therefore not

Warning signals

Current

When

temperature

failure

the

apparatus

regulation‘

tureregulation’,

warning

for

from a

signal

operation.

1.5 V

battery.

in

the

occur,

who

capacity

of the

and

regulation

sensor

amplifiers

at

different

or in

Constant

necessary.

the

for

current failure

It

is

supplied

incubator—air

for

example,

regulation

already possess

for

temperature

skin-temperature

amount

resistor

the

and

do

employed

the

made

not alter

environmental

course

readJUStments

is

switched to ’Air-

or

”Skin-tempera-

optical

and

with

temper—

when

is

em-

to i

measuring

from

high-

their

of

time,

acoustic

is

ready

current

The

ets1

and

a

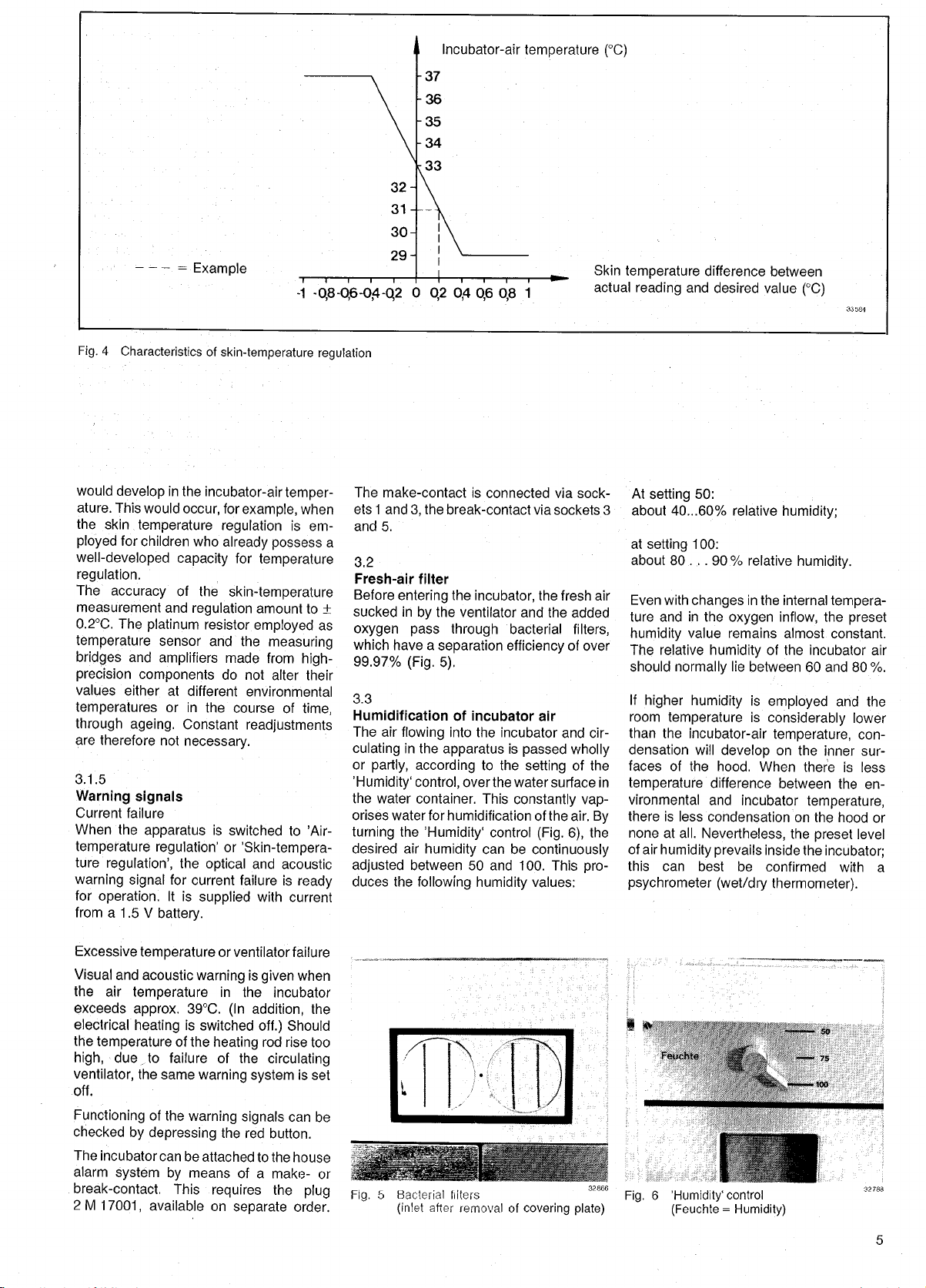

3.2

Fresh-air

Before

sucked

as

oxygen pass

which have a

99.97%

3.3

Humidification

The air

culating

or

’Humidity‘

the

orises water for

turning

desired air

adjusted

duces

make-contact is

and3,the

5.

filter

entering

in

the

by

separation

(Fig. 5).

flowing

in the

apparatus

partly,

according

control,

water container.

the

’Humidity‘

humidity

between

the

following

connected via sock-

break—contact via

the

incubator,

ventilator and

through

bacterial

efficiency

of

incubator air

into

the

incubator and cir-

is

passed

to the

the water

This

constantly vap-

control

can be

setting

continuously

values:

over

humidification

50 and 100. This

humidity

sockets

the

fresh

the added

of over

wholly

surface

of the air.

(Fig. 6),

filters,

of the

the

pro-

3

air

in

By

this

At

about

at

setting

about

Even with

ture and

humidity

The relative

should

If

higher

room

than the

densation will

faces of

50:

setting

40...60%

100:

. .

80.

changes

in

value remains almost

normally

humidity

temperature

incubator-air

the

temperature

vironmental

there is less

none at all.

of

air

humidity prevails

can best

psychrometer

relative

90% relative

in the

the

oxygen

humidity

of the

lie between

is

employed

is

considerably

temperature,

develop

hood. When

difference

and

condensation on

on

incubator

Nevertheless,

inside the

be

confirmed with

(wet/dry

thermometer).

humidity;

humidity.

internal

inflow,

incubator air

60 and 80

the

there is

between

temperature,

the hood

the

preset

tempera—

the

preset

constant.

and the

lower

con-

sur-

inner

less

the en-

level

incubator;

%.

or

a

Excessive

Visual and

the air

exceeds

electrical

the

high,

ventilator,

off.

Functioning

checked

The

alarm

temperature

acoustic

temperature

approx.

heating

temperature

due

,to

the

by

incubator

system

same

of

the

depressing

can

break-contact.

2

M

17001,

available on

or

warningisgiven

in

39°C.

is

switched

of

the

heating

failure of

warning system

warning

the red

be

attached to

means of a

by

This

requires

ventilator failure

when

the

incubator

addition,

(In

the

separate

off.)

rod

signals

Should

rise too

circulating

is set

can be

button.

the

house

make-

the

order.

the

plug

or

5

Fig.

Bacterial filters

(inlet

.

after

F

.

removal of

32866

covering plate)

Fig.

6

’Humidity‘

control

(Feuchte=Humidity)

Page 6

3.4

Reclining

3.4.1

Reclining

7010 and 7310'

‘The

either

at

the

(head-up

Raising

position

side the

means of two metal

special request,

right

place

surfaces

surfaces of Incubators

under the

panel

end,

end-boards of the

or head—down

the

reclining

can also be undertaken

Plexiglass

mattress

as

desired,

hood. This is done

Fig.

of

the

reclining

for

down treatment and nurs-

laying

surface to the

supporting

8).

surface serves as a

ing equipment temporarily

the incubator.

can be raised

and

supported

reclining

surface

position) (Fig. 7).

sloping

from out-

levers

The shelf to

when

(on

the

working‘in

on

by

Fig.7Reclining

7310,

surface of

head-up

Incubator 701 0 and

position

82800

L

Fig.

:

8

Reclining

7310,

head-up position

porting

lever

surface

Incubator 7010

of

with metal

'

32808

and

sup—

9

Fig.

3.4.2

Reclining

swung

down

Reclining

cubator 7510

After

opening

reclining

either side as desired

drawn

minor

readily

move

head-

when the

(Fig.

lever

[surface

out

procedures

be

the child from the incubator. The

or foot-board can be folded down

or

9

has been

Head—up

The

reclining

separate

the

slope,

which the bed

lifted out

foot-board

position

child can

through

the

is done

grip

(Fig. 12).

one of the hand

reclining

in much

is

slightly

releasing

surface.

The Intensive-care

available on

reclining

surface described

surfaCe‘of Incubator 7510

out on

left,

surface of Intensive-care

the

large

can be

incubator

(Figs.

parallel

performed

reclining

10)

or

steps

window is

by

until it

be

button,

(Fig.

such as intubation

without

surface is

the relevant

after

pressed

head-down

bed can be raised

at each end. To

downwards.

position

opened

is to be raised. The bed is

the

hand-grip

engages

At

the same

held with the

firmly

surface to the normal

the same

while

raised

lowers the

which

Incubator 7510 is also

order with the

special

head-board folded

flap,

9 and

In this

having

out on

10)

way,

to re-

swung

11).

hinged

supporting

in

three

adjust

at that end at

of the head- or

in

the desired

time,

free

hand,

ports. Lowering

position

The

way.

upright

depressing

reclining

simpler

3.4.1.

in

32304::

In-

the

or

can

out

the

the

the

Fig.

Fig.

10

12

Reclining

swung

down

Reclining

out on

“wan

surface

right,

surface

of Incubator 7510

foot-board

of Incubator

turned

“'

L

lmensivpagoxkubmor

7510

m;

Fig.

i

X

head-up position

11

7510

Reclining

drawn out

’

£

surface

parallel

‘

Incubator 7510

of

32796

WWI

32 787 a

6

Page 7

X-rays

Beneath

on

which

drawer in

from

placed

Before

necessary

3.5

Plexiglass

the

X-ray permeable

the

baby’s

which

outside

to

hoods

out

open

pulling

an

mattress

X-ray

the

the

a small

incubator

drawer,

plastic

panel

there

lies,

cassette can be

is a

(Fig. 13).

it

is

only

in

the hood.

flap

Fig.

13

Reclining

X-ray

surface of lncubator

drawer

7510

3.5.2

Plexiglass

hood of

(Fig. 1b)

to

Contrary

sion is fitted with

which can

facilitates a

sures

remain within

tective

can also be

taken out

the model

be

during

hood need

through

opened

number of

which

the

placed

Even‘photo-therapy'

since

pushed

the

asidewhenthe

rupted

not

is

opened.

be

Incubator:

7010 the

a

large hinged

(cf.

Fig. 1b).

therapeutic

the little

incubator and the

not be lifted.

into the

this

incubator and

hinged panel.

must not be

photo-therapy

hinged panel

'

7310

7310 ver—

front

patient

The child

unit

panel

This

mea-

may

pro-

inter—

must

3.5.1

Plexiglass

(Fig.

1a)

Four

iris-diaphragm

the

usual

Hinged

ted to

special

phragms

Used

washing

removed

caily

at

each end.

of

each of

windows

ing

hoses,

large

apertures

smaller

hood

access

flaps

(see

A

the

provide

hoses

of

Incubator 7010

hand

and

nursing

(spring flaps)

order in

place

Fig. 14).

can

be

simply

through

largish

openings

permits

e.g.

and

the

aperture

covered

the

ventilator

for.

cables.

ports

can also

of

and

sliding

suspension

hoses.

the

provide

measures.

be fit-

the iris dia-

hygieni-

windows

to one

the

by

Further

passage

side

slid-

for

3.5.3

Plexiglass

cubator 7510

In

the front of the

also a

large hinged panel

lowered to

out of

the incubator

(see

3.4.2).

should be

panel

opening

and its

hood of

(Fig.

the

lay

It

is vital

Intensive-care In-

1C)

Plexiglass

which can

inside or

baby

on the

reclining

that the

properly

fastenings

hood

there is

to

pull

surface

large

hinged

closed after

securely

be

it

en—

gaged.

of

of

t

A smaller

the

Four

hinged flaps

32806a

Fig.

14

Opening

the

hinged flaps

(spring flaps)

and

open silently

the

can

lris-diaphragms

cial

Ventilation hoses can

sliding

thus led to

The rod can be

of

the

tures in the

small

hinged

drawer

X-ray

large

hand

provide

nursing

measures. The

with

releasing

also be closed

in

order,

rod

beneath the

the

as

hood,

hood

hoses and

place

panel provides

(see Fig. 13).

ports

for the

light

mechanism

again

can

also be fitted to

of

be

from above

baby

fitted on

desired.

provide

of cables.

equipped

usual

elbow

(Fig.

with

the

spring flaps.

suspended

of the hood and

top

the

right

Numerous

for the

flaps spring

pressure

14). They

the elbow.

or left

passage

entry

with

access

on

spe-

from a

(Fig. 15).

side

aper—

to

of

Fig.

3.5.4

Double wall

Function of the

A

second wall inside the incubator

possible

radiation

incubator. The air which

heating system

between outer and

inner wall

which

erature within the

ble walls the

surfaces of the hood

than the air

The child

side

walls and

radiation

15

incubator

7510 with

ventilator

Babylog

1 and ventilator

hoses

entering

incubator

41 354

particularly important

system

to reduce the

heat to

is warmed

almost

corresponds

average temperature

(Fig.

double wall

the inner surface of the

of the incubator also

innerwalls

up

incubator. Without dou-

is

temperature

is surrounded with warm

undercooling

heat is thus

for

15a)

system

child’s loss

is warmed

whereby

to a

temperature

to the air

roughly

in

the incubator.

due to loss of

prevented.

premature

makes it

by

flows

temp-

at inner

3°C cooler

top

This is

infants

of

the

the

and

7

Page 8

of less than 1500

losses of heat

tion have to be

the air

temperature

relative

humidity

g body weight.

convection and

by

compensated

and/or

in

the

incubator.

Description

The

all incubator hoods of

and 751

tion.

The

model

glas

walls

hood.

with

wall

shaped

which

AcCess't'o

of the incubator

double wall

also

place.

Assembly

walls can

rapidly.

mounted to the

through

are secured from

nuts.

wall

double

0,

additional inner wall for the incubator

7010

pane,

and

In

the

even

which

the

case

large

syStem

for

consists

upper part

of

hinged

system comprises

and

one

‘is‘attached

the

child

hood is

system,

have

large

and

be carried out both

Threaded

bores in the incubator hood and

‘

can be

models

supplementary

of a

U-shaped

in

runs

parallel

of

models

7310

front

two

plane pane,

the

to

large

thrbugh

not

since the inner walls

openings

disassembly

which are

pins

inner walls

outside

by way

Further

evapora-

by increasing

increasing

supplied

7010,

installa-

to the

the incubator

and

the inner

panel

—

parts

the latter

hinged flap.

the

handports

impairedby

at the same

of the inner

easily

are

pushed

of knurled

7310

Plexi-

side

7510

one

and

firmly

the

for

L-

of

the

[supplementary

The

incubator hood must be

bores for

double wall

performed

Agency.

-

3.6

Rails

For

supporting

plementary

each end of the

System”).

3.7

Trolley

The

place

The

mm

The

7310 are

7510;

of these

sated for.

(see

great

accessories

two self-

diam.)

trolley legs

in this

installation

supplementary

system.

by

your

various

apparatus

incubator

_

Figs.

floor of the

-steering

can be

of Incubators 7010

than those

longer

the different

way

of

types

apparatus

provided

installation

This Work is best

Drager

Branch or

types

there is a rail et

(“Drager

1a and

locked.

1b)

trolley

'

front wheels

can be used

of Incubator

hood

are

of the

of

heights

compen-

with

sup-

Rail

(100

and

to

16 incubator cabinet

Fig.

with

open

door

Page 9

3.8

Accessory

(on

special

3.8.1

Cabinet

The

with

The

means of

Each door

treatment

paratus

cabinet.

The

7310-are

7510;

of

sated for.

(see

mobile cabinet

doors on

doors can

can be

cabinet

in

this

these

types

Devices

order)

Figs.

the front

be

pressure

contains a

material

placed

legs

than

longer

the

way

of

_

1c and

opened

16)

is a

trolley equipped

and

and

with

(e.g.

large storage

(Fig. 16).

on

the floor of the

of

Incubators 7010

those of

different hood

apparatus

back.

closed

the

Larger ap-

incubator

are

compen-

knee).

tray

and

heights

by

for

3.8.2

02-dosage

The

ment

(Fig. 17)

oxygen required

of the

incubator

incubator via a

a

ter,

connecting

The

tached

clamp

oxygen

dosage

valve

to

the

(Fig. 17).

is

not

humidification takes

3.8.3

Oxygen

An

cubator. The

below

necting

.Two

the

a)

b)

3.8.4

Oxygen

So

high

.

acute

ployed.

via a

meter

hose.

If

the

limiter

oxygen

even with

open,

can flow

ponds

40%.

if

the

of

no

as to

limiter

flowmeter in

O2

the

nozzle

switch

a lower

positions

position:

more than

no

into the

to an

manual control of

White

dosage

less

than 6 l/min.

Red

position:

limitation of

helmet

administer

concentration

asphyxia,

The

oxygen

humidification

(setting

a

very

high

neck

baby’s

nappy-

,

for

air is

nozzle

with

valve with

and a

flowmeter are

rail

dosage

incubator

Humidifications of

necessary,

in

place

(Fig. 18)

can be

attached to the

oxygen

limiter

place

(3.8.2).

can be

the limiter:

the

02-dosage

6 l/min of

incubator. This

oxygen

concentration of

Oz-conCentration

valve is

O2

adjusted

‘

inflow.

(Fig. 19)

oxygen

as

rapidly

a

Plexiglass

is fed into

nebuliser with

10

02

should be

and a

l/min)

concentration is

sealed off with

oxygen-enrich-

passed

into

glowme-

rubber

hose.

means of

by

as

optimal

the

incubator.

is screwed on

of

the con-

engaged

valve

oxygen

corres—

_

is

desired,

to an

inflow

to the

baby

as

possible

helmet is em-

the helmet

Oz-tlow

corrugated

desired,

the

at-

the

in-

on

fully

ca.

in

in

M

17

flowmeter on

Fig.

a

O2

incubator rail

270

.3

208

18

Fig.

a

Fig.

Ozflowmeterwit

19

Oz

helmet

h

limiter

02

39

39 209

t

20 Water nebuliser

Fig.

3.8.5

Water

nebuliser

it is

possible

the incubator. With

water nebuliser is

cubator at one

surface

clining

led in

through

nebuliser with the outlet

compressed-air supply.

tioned

parts

The water nebuliser is

Prospectus

In

the

incubator,

powered onlybycompressed

ing oxygen

high oxygen

When the water

compressed

the

oxygen

cannot be utilised.

output (aerosol

varied with the

the

purpose (setting

aerosol;

The

nebuliser is also

setting

quantity

ing pressure.

constantly

compressed

ter nebuliser will

mixing

given

tion in the

no

oxygen

more

in

oxygen

necessary,

is

ratio between

in the table

longer

concentration

oxygen

the table. Should

be

attached,

(Fig. 20)

to

carry

out

the aid of

suspended

of the

end-boards of the re—

(Fig. 20).

an

opening

are available

described

6224e

(older

the nebuliser

to

concentration in

air,

concentration on

power

nebuliser is

the

provision

it would

However,

quantity per hour)

control knob

40%

02:

of

aerosol

dependent

in

addition to

drawn in

air

by

required

enter the

’Oxygen

incubator‘

applies.

must

required

if

an

to set it to the

(page 13)

To obtain a

be fed in than

more than

for

oxygen

aerosol

valve of the central

the

for

in

this

limiter

therapy

a

holder,

in

A

pressure

in the

hood,

The aforemen-

on

special

in

no.

8424e).

should be

since us—

air,

produce

the incubator.

powered by

for

adjusting

the nebuliser

the nebuliser

designed

100%

02:

much

aerosol).

delivered

on

the

the fresh air

ventilator,

driving

incubator. The

air

and

oxygen

concentra-

therefore

the

incubator,

is shown

6 l/min of

purpose,

(see

red

position.

32 811

in-

the

hose,

links

order.

detail in

can be

for

little

the

by

operat-

the

the wa-

desired

it

3.8.3)

in

a

a

is

Page 10

Nebulisation of

These substances should be

in the incubator with

when

only

clearly

dangers

_

taken into account that

stances

es of the

override the

predispose

reduce the

thorough

is

absolutely

3.8.6

Medication

Medicaments

incubator.

medication

holder

special

front of

the

large part

be

directly

purpose

that

will

be

apparatus,

strongly

risk of

routine

essential.

nebuliser

instead

nebuliser

baby’s

ofthe

inhaled.

are

available on

expectorants

the water nebuliser

the

anticipated

disadvantages

be involved. it must be

may

deposited

and the residues

to

fungal growth.

infecting

cleaning

of

(Fig.

can also be

of the

(Fig. 21),

face in such

nebulised

All

nebulised in

water

is

employed.

it can

medicament

parts

required

special

applied

benefits

these sub-

on all

surfac-

the

the incubator

21)

nebuliser,

With a

be

placed

a

way

forthe

order.

and

baby,

the

that

can

To

a

in

a

3.8.8

Infusion

The

infusion stand is

and can be

screw

clamp.

22

Fig.

Oxygen

.

stand

fixed to the

(Fig. 24)

adjustable

incubator rail with a

distributor

in

height

3.8.9

Small

operating-theatre

For

diagnosis

the

baby,

offers

a well-defined

colour-corrected

cold,

secured to

be ordered

and

swivelled so as to

the incubator.

Replacement

cated on the external

lamp

body.

screwdriver. The

withdrawn. The bulb is

be taken out

may

and

turning

reassembling

to the

paid

behind the chrome

lying

element must lie

disc. The filter

into the

Technical data:

Mains

Current

illumination

and for

the

small

operating-theatre

an incubator rail with a

separately.

of bulbs:

These are

complete

by

to the left

the

lamp,

following:

up against

element can be

lamp body

supply:

in

220 V

consumption:

intensity:

lamp (Fig. 25)

minor

procedures

lamp

concentrated field of

The

light.

lamp

clamp

it can be

illuminate

two screws are lo-

circumference

unscrewed with a

filter

now accessible

pressing

rotated

any part

of the

element is

and

backwards

(bayonet fitting).

attention

the round rUbber

only

50 W

ca.

of the filter

ring

the

introduced

one

3000 Lux

should be

ring

Plexiglass

position.

on

is

to

of

in

21

Fig.

3.8.7

Oxygen

The

plug-in

Medication nebuliser

distributor

oxygen

distributor contains

sockets,

utilising pieces

tached

apparatus,

inhalation

tributor is

Two different

able for selection:

at

the same time

secretion

apparatus).

suspended

a) Oxygen

connector

valve ofacentral

b) Oxygen

nector,

gauge

gen

ment to a

sible.

distributor with

pressure

(for

cylinder

central

so that several

of

apparatus

oxygen

distributor

(for

supply

connection

B

2533).

22,

(Figs.

aspiration

on an

distributors are avail-

(e.g.

The

oxygen

incubator rail.

23)

3

oxygen

oxygen-

can

be

ventilation

apparatus,

without cylinder

the wall

from

Oz

installation).

cylinder

reducer

02installation

to a

Here

and

3-litre

too,

pressure

attach-

is

dis-

con-

oxy-

pos—

at—

Fig.

Fig.

23

Oxygen

nector

24 infusion

distributor

stand

with

cylinder

con-

35494

Fig.

Fig.

25 Small

26

Distribution

operating-theatre

box

lamp

32 818 a

35

496

10

Page 11

3.8.10

Distribution box

A

distribution

sockets can

cubator

taneously

apparatus

sion

surplus

cables can

distribution

pump,

rail. It

with

(e.g.

monitoring

length

be

box.

box

be

can

various

incubator

of

placed

26)

(Fig.

equipped

suspended

be

types

apparatus

the

various

in

with

6

safety

from

the in-

connected simul-

of

electrical

etc.).

infu-

The

base-unit,

connecting

the

pocket

of

the

_

-

_

“

;

9heto»Tnerame

3.8.11

Phototherapy

(Prospectus

irradiation of

The

babies with

the aim

serum

bilirubin

a

critical rise. in

ing

transfusion

3.8.12

Bronchial

(Fig.

28)

The

apparatus

mounted

ejector

produces

pressure.

the

baby's

catheter.

sucking

rinsing

The

the

fluid.

apparatus

compressed

Cf.

appropriate

‘

apparatus

6141

.31e)

newborn

from

mild

thus

be

suspended

incubator.

an

this

the

equipment

adjustable

light

of

lowering

concentration

can

aspiration

on

the

is

Secretions can be

airways

The

catheter

by

rinsing glass provides

through

is

powered

air.

Operating

(Fig. 27)

and

premature

apparatus

already-raised

orof

prevent-

cases,

avoided.

exchange

from

The

negative

removed from

means of a

with

water

with

oxygen

Manual.

has

the rail

integral

thin

for

if

“ImenwvnW-amkumtor

5

i

or

or

15w

.

.1

3a8cuim

The

foam

inside,

comes

put

fixed

tions of

after

resia),

entire

be

instance,

Evacuation

degree

out with

the

tion

After

been

hose

mattress

vacuum

balls.

into

after

After

the

normally

’stiff‘. It

particular

evacuation.

the

baby,

mattress is

operations

can

be

attained in

baby,

orjust

comfortably positioned

for

infusions

of the

of

hardness is

suction

mattress

(turn

the

hose

desired

obtained,

coupling

has to

coupling

to

(Fig. 29)

extraction of

flexible

can

previously

positions,

Thus

such

for

(e.g.

the

arms and

or

mattress to

most

equipment.

be

opened

degree

the

valve is

the

right).

filled

with

the air

mattress

have

which

extreme

as

those

oesophageal

ideal

fashion.

legs,

as

desired,

taking

X-rays.

the

simply

The

for

to

the

left).

of

”hardness” has

closed

small

from

be—

been

remain

posi-

required

The

can

desired

carried

valve of

evacua-

(turn

at-

for

E

27

'23

incubator

Bronchial

Fig.

’

7

Fig.

with

phototherapy

aspiration equipment

apparatus

32819;!»

Fig.

29 Vacuum

~-

mattress

11

Page 12

Fig.

31

Baby

scale

32 8l5

33 Instrument

Fig.

tray

336073

3.8.14

Securing straps (Fig. 30)

The side walls of

sive-care

can be used to secure

securing straps

which are well suited

sures,

arms and

baby's

separate

order.

incubator

the mattress of

possess

the

2

M

13898

can be

legs,

4

Preparatory

4.1

Unpacking

When the

packing

from inside the

tates removal of the brown

and

apparatus

material

Work

setting up

is

must also be removed

apparatus.

the inten-

slots which

Padded

baby.

with

velcro clo-

to

securing

supplied

unpacked,

This necessi~

covering plate.

3.8.15

scale

Baby

The scales are

are

the

on

They

fore be used

cubators in the

baby

suspended

The

the

The scales are

with the

EO)

easily

is

laid

baby‘s weight

sliding weights.

German standard

and

approved

Germany.

amounts to 7.5

4.2

Cleaning,

Cleaning,

ing

in section 7 Care and Maintenance.

tasks should also be carried out before

the

tial

.

Before

that the mains

the indicator

disinfection,

readiness for use

commissioning.

connecting

31)

(Fig.

placed

removable and can there—

in

turn for all the DRAGER in-

ward. For

in

a

weighing

from the hook on the scales.

is determined

calibrated

for use as

The measurement

kg.

functional

are

the

voltage corresponds

on the incubator.

plate

on

top

weighing,

sheet which is

in

(Eichordnung

baby

testing

assembly

described

apparatus,

of the hood.

by moving

accordance

scales in

range

test run

and

and

in

detail

These

check

the

test-

ini-

with

—

3.8.16

Instrument

The

stainless

cubator

cm.

20

rail,

tray (Fig.

steel

measures:

tray,

33)

secured to

width

30

cm,

the

depth

in-

”my.

in)

llillll

1

Mounting

Place hood onto incubator and

pins (at

incubator

Now unscrew the screws of the lower-

the

the

housing).

Plexiglass

hood)

hood:

into the lower

press hinge

hinges (at

hinge parts, place securing plates (which

are

comprised separately)

hinge parts,

34).

Fig.

Mounting

panel (at

hinges

described above.

Securing

cords at each end are to be

ing

the hood.

12

and attach screws

the

large hinged Plexiglass

Incubators 7310 and

are mounted in the same manner as

the

Plexiglass

over the

hood: The retain-

again

7510):

clipped

lower

(of.

front

The

onto

4.3

Humidification

Fill

the water container with distilled

the water indicator

pulling

the

purpose (Fig. 35).

The water

tained

between the two lines marked max

and min.

To

prevent

silver

compound

water at each

use

4

of

Micropurtablets

quid

Micropur

Katadyn-Gesellschaft

straBe

20,

Micropurtablets

led water before

of incubator

level should

bacterial

growth

should be added

refilling.

We recommend

(manufacted

D—8000 Mtinchen

mbH,

must be dissolved

beingvadded

MBT 1 orl cm3

glass

always

in

air

water,

forward for

be main-

the

water,

to the

Deutsche'

by

Schaufelen—

12).

in

distil-

to the water.

The

the

34 Screw

Fig.

a

li-

35

Fig.

hinges including

plates firmly

the water container

Filling

to

incubator

the

‘m

securing

32794

Page 13

(Note:

Silver

added to

nebulisers.)

Set

the

control

4.4

desired

lever

,

Heating-up

Set the

desired

the

selector switch

ation’

lamp

The incubator

after

a heating-up period

This

level is

blinks

lamp

=

desired

Check

value).

the

temperature

compounds

the

water

humidity

(Fig. 6).

the

Incubator

incubator

(’air~temperature

comes

on).

temperature

then held

periodocally

temperature

gange.

may

supply

on

the

temperature

set is

of

ca.

constant

when

on

theincubator

not be

of aerosol

’Humidity‘

with

regul-

reached

30...60 min.

(‘heating’

actual value

After

the other end

been introduced

its

hood,

contains the

be

and

tant to see that

wet,

otherwise

ing).

slightly

temperature

secured between

sternum with

the

as false

This

skin-temperature reading

result

danger

ings by evaporation

if

one of the

over the

with

securely

a further

isolating

plaster (3)

l

of the

sensor

cable

thickened

an

aperture

tip

(1),

through

element,

the

plaster

plaster

to

(due

of

evaporation

falsification of the read—

cooling

caps (2)

fixed

temperature

umbilicus

baby’s

It is

(3).

has

not become

can be averted

is stuck down

(Fig. 36).

has

in the

which

should

impor-

cool-

sensor

value,

cubator

tion of

sired

value. In

incubator-air

29°C or

deviations

will

Experience

baby’s

rapidly,

handled,

ing

Although

cubator

bance

cubator-airtemperature,

for the

brought

Deviations of

between the

actual skin

therefore

regarded

in that

air

temperature

the skin

doing

temperature

rise

above

from

in

skin

temperature

e.

when

g.

going

the

regulation

reponds

by raising

baby‘s

back

to the

about

preset

temperature

develop

as

normal.

it

raises or

temperature

so,

37°C even

the

desired value.

practice

the

babyisfeeding,

to

sleep

immediately

or

skin

temperature

desired value

one-tenth of a

desired

at

any

lowers

to

counter

from the

it will

not

to fall

shows that

often

and

waking

system

to

any

lowering

it takes

value

indicated can

time and

the in-

devia-

allow the

below

with

large

changes

of the in-

distur-

the in-

sometime

to be

again.

degree

and the

are to be

de-

the

be-

etc.

5

Operation

5.1

Incubator

(see

the

Lay

ed-up

baby’s

periodically;

air-temperature

5.2

Skin-temperature

(see

With

temperature

regulated,

Skin-temperature

vantageous

ulation

particularly

—

immature

temperature

—

severely

temperature

Notice:

Skin-temperature

employed

When their

children can

over

tion

they

case,

employed.

Procedure

regulation

The

incubator is

with

4.4

of

plug

into

the

screwed

(Fig. 3).

air-temperature

also

3.1.2,

in

baby

the

apparatus

temperature

the

.

also

3.1.4,

the

incubator

or the

as

desired.

than

usually

for the

premature

regulation

disabled child

regulation

for

babies in a

skin

have

with

37°C);

would

become

air—temperature

for

skin-temperature

_

and

the

the

temperature

socket

home

page 4)

the

incubator after

according

is to

be

of

set-point

is to

set

regulation

page 4)

base-unit

skin

regulation

the

employed

following

regulation

temperature

fever

skin-temperature

warmed in

baby placed

10 of

with

the

right

temperature

air-temperature

in

indications:

birth with

with

should not

state of

(rectal

overheated. in

regulation

-

sensor

the

base-unit and

the

securing

regulation

heat

to

4.4. The

measured

Incubator

if

necessary.

7

the air

7012,

can

is

more ad-

incubators,

disturbed

disordered

shock.

is

these

low,

temperature

regula—

must

accordance

inside. The

is inserted

36

Fig.

The

.

mo—isolation of the

ing

that the ’true‘ skin

measured. With

ture of

erature sensor

whereas a

Securing

isolating cap provides

which has

air,

37°C,

temperature

a

plaster,

~

The selector switch

be

base-unit

regulation‘ (the

tion‘

reg-

lamp lights up).

The skin

on the lower indicator

played

of the

ing)

temperature

screwdriver

’Desired value

be

value can

is

displayed

instrument.

The desired

this

be

normally

thermo—isolated

When the

secured

and

vironmental

set at

to the child with an

thus

skin-temperature

36.8

C.

nut

Theregu‘atcrseeksto‘oringthebaby‘sskin

temperature

the

skin-temperature

sensor from

the further

temperature

an internal

a

thermo-isolated

measures

non-thermo-isolated skin-

sensor,

measures ca.

is

turned to

i.e. secured

’Skin-temperature regula-

temperature

instrument. The desired skin

(desired

supplied

value)

on the screw

adjustment‘.

be

set between 36°C and

on

the

upper

skin-temperature

361°C

skin-temperature

skin—temperature

thermo—isolated

temperature,

value should

to

the

preselected

1

sensor

very good

surround—

advantage

is

actually

body

tempera-

skin-temp-

ca.

368°C,

only

361°C.

on the incubator

’Skin-temperature

measured is dis-

read-

(actual

is set

with the

marked

The desired

37°C;

indicator of the

value is

when

using

sensor is

a

sensor.

isolating cap,

from the

the

desired

be set at

desired

27522

ther—

with

non-

en—

Please watch

be ensured

remains

advertent

skin would result in

baby’s

longer

maintaining

ature

at the desired

the

ple,

on which

As a

would climb to a

by

never be exceeded.

A

sor could also lead to

the incubator—air

could never

29°C.

in

result,

the

possible

order to

temperature

baby,

securing

temperature

observed.

fully

The

skin-temperature

stand at

skin-temperature

it

5.3

administration

02

also 3.8.2 to

(see

The

inflow is set on

02

the

flowmeter

the

approximate guidance

the Table

be

read

ball.

The

should be

against

oxygen

gen-measuring

DRAGER

can

recognition

sources of

most

certainty.

the sensor!

that the

properly

separation

the sensor

the

temperature

secured

ofthe sensor

the

value

of the cooler

might

incubator—air

higher

but the value

defect of the

undesired

temperature,

exceed 37°C or fall

avoid the

of

indicator

maximum

forementioned

the

sensor and the skin-

must both be care-

indicator should not

or minimum

regulation.

3.8.4)

the

(Fig. 17)

(see page 14).

the

upper

concentration in

measured

Oxycom

failure be

instrument

of

servicing

100

regularly

assured with

it should

to the

the

regulator

skin

baby’s

—

for exam-

but,

chance to rest.

temperature

level than

of 37°C could

temperature

changes

but

metering

in

accordance with

values

The flow

surface of the

the

incubator

with an

(e. g.

Only

faults or

in

D).

always

sensor

baby.

from the

temper—

mattress

required

sen-

these

below

faults,

during

valve of

given

should

oxy-

this

way

other

the ut-

In-

no

in

in

the

13

Page 14

For

continuous

above-mentioned

able

forfixing

For

periodic

is

ring

measuring

screwed onto

device;

pressed against

Plexiglas

hood of

measurement

02

device,

tothe incubator rail.

a holder is

O2 measurement,

the sensor

the sensor is

this,

with

one of the

the

apertures

incubator

with the

avail-

(Fig. 37).

a

sealing

of the

in

(Fig. 38).

the

Oxygen

should

dance with

gen partial

baby’s

it

enrichment of the

only

arterial

possible

endangering

damaging

be controlled in

determinations

blood.

eyes and

brain.

carried out on

Only

pressure

to

avoid both

the

the

incubator air

accor-

of the

in this

way

hyperoxaemia

hypoxaemia

oxy-

5.4

Precautionary

the

Warming-up

is

the Incubator

It is

the

ation or CPAP

gas

ing

important

to monitor the

breathing gas

hoses

may

to the warm

measures

of

breathing gas

in

case of

method,

be warmed

circulating

temperature

artificial

since the

up

incubator air.

hoses

breathing

unduly,

in

of

respir-

ow-

concentration

02

inflow

o2

Fig.

37

(l/min)

Continuous

(%)

Oz

measurement

'

25 3O

1.5 3

35497

35 40 45

4.5

6 7.5 9 11

38 Periodic

Fig.

50 55 60 65

12.5 14

measurement

O2

No direct

The incubator should not be

_

rect

being

sunlight,

switched

exposure

because,

temperatures may

Increased fire risk when

All

1

sources of fire such as

lighted cigarettes,

from

away

cubator

air, textiles,

materials are

stands.

to

off,

otherwise

etc. should be

the room

With

oils and other flammable

easily ignited

great intensity.

2

Oxygen fittings

kept

absolutely

valves

Open

Do not use the

of flammable

Electrical

’built-in

under the

cubator! Flammable

cohol

stored

safety’,

orethershould be neither

in

and

free from oil and

slowly.

incubator in the

anaesthetic

apparatus,

should

Plexiglass

the

incubator.

sunlight

placed

despite

severely

the

excessive

heating

develop.

using oxygen

matches,

in

which the in—

oxygen-enriched

and burn

washers must be

grease.

presence

gases.

except

liquids

that with

not be

employed

hood of the in-

such as at-

used nor

in di-

kept

with

6

Trouble

Fault

Pressing

buzzer

does not

the

’Current failure‘

sound

Shooting

test

button:

Possible

cause

Battery incorrectly

Battery

Battery

Selector switch

infection

Warning

flat

contact corroded

in

Drager Aseptor’

device

inserted

in

“off"

defective

position,

or to ’Dis-

Remedy

Positive

poleofbattery

Change battery (use

teries)

Clean contacts

Set

selector switch to

regulation’

tion’

Call nearest

or

’Skin-tempmperature

Drager

to

top

only leak-proof

’Air-temperature

representative

bat-

regula-

I ll

ll

.

llllw

lllll

ill

wivllllillllllll

it

..ml.l.l...l.r

r

ll

will

.m

Warning lamp'does

Power

failure alarm:

ing lamp

14

lights

not

buzzer

light

sounds,

warn-

Bulb

Mains

Current

defective

plug pulled

supply

failure

out

Change

Insert mains

Check fuses

bulb

plug

Page 15

Trouble

RE

Fault

a

Oxygen

according

concentration

to

Table on

Shooting

too

low for

13

page

(continued)

setting,

Possible

’Unwanted‘

Hand-port

Seals

between

tor

chamber

cause

open,

air

not in

flows

into

incubator:

flap open

base-unit and

order

incuba-

Remedy

Close

openings

According

Refix seal or

tative

to

construction of

call

nearest

Drager

base-unit:

represen-

No

oxygen

M

Pressing

ventilator

buzzer

or

Red

ture or

sounds

Incubator does

ture

the

failure’

does

does

lamp

warning lamp

ventilator

flow

’Excessive

not

not

test

sound

light

for’

failure’

not reach

button:

Excessive

lights

preset

temperature

tempera-

up,

tempera—

buzzer

Base-unit

Dosage

not

opened

Oxygen cylinder,

lation

empty

Oxygen

or

Selector switch in

Warning

Bulb

defective

External

Sunshine,

Defective

Incubator

—

value

Ventilator wheel not

Motor

defective

Excessive

standing

not

fully

valve

connecting

device

heating-up

near

temperature

temperature

ventilator

external

in

draught.

screwed

or

oxygen cylinder

oxygen

hose not

“off”

position

defective

of

incubator:

radiator

regulator:

rises above

failure

correctly

cooling:

Room

home

supply

too cool

instal—

attached

attached

Incubator

valve

preset

Retighten

valves

Open

.

Obtain new

Connect

Set

selector

regulation’

Call

nearest

Change

Site

incubator

Take

apparatus

Drager representative

Put

ventilator

ure

Take

apparatus

Drager representative

Stop

draught

Raise room

securing

hoses

or

screws of

oxygen

supply

switch

’Skin-temperature

Drager representative

bulb

elsewhere

out

of use

wheel on

out

of use

temperature

base-unit

to

’Air-temperature

regulation’

and call

correctly

and call

nearest

and sec-

nearest

For

skin-temperature

Skin-temperature

Skin-temperature

Skin-temperature

No

regulation

Water

level

below the

on

the

sight-glass

Oxygen

according

sured'with

mm

concentration

to

Table

oxygen-measuring

indicator at

indicator at

too

of

skin

low

temperature

lower

or

not

too

page

regulation

maximum

minimum

line

visible

high

13

(can

only:

marked

for

setting,

be

mea-

apparatus)

Hand-ports

Brown

covering plate

round

end of

Upper

not

tilator)

plate

Lateral

laid—down

Thermometer

Sensor

Sensor

Sensor

Sensor still

Sensor not

Selector switch

slots for

nappies

defect

plug

defect

temperature

Too

little

water in

Interrupted

Ventilator

Motor

Bacterial filters

wheel

detective

open

air-channel

lying

air

indicates

inserted

not

too cool

correctly

regulation’

or

impaired

not

blocked

is

on

put

(leading

exactly

not

against

circulation covered

or

other items

wrong

secured to

positioned

water

container

fresh-air

correctly

wrong way

to

covering

baby

to

supply:

secured

ven-

’Skin—

by

Close

hand-ports

Insert

plate

Bend

the

downwards

Remove

Insert a new

Replace

Insert

Replace

Wait

Secure sensor

Set

spring

nappies

sensor

sensor

sensor

for sensor

selector

regulation’

Refill with

Put

ure

Take

Drager

Replace

distilled

ventilator wheel on

apparatus

representative

bacterial filters

Correctly

etc.

one

plug

to warm

correctly

switch to

water

out of

supporting—rod

correctly

up

’Skin-temperature

correctly

use and

call

slightly

and sec—

nearest

15

Page 16

7

Care,

7.1

Care

after use

At least

change

of

dismantled,

sembled

readiness for

in

Dragerwerk

nance

centre’

Maintenance

once

weekly

the

baby,

cleaned,

a

’clean

room’,

operation.

offers its

(Prospectus

and with

incubator must be

disinfected

’Apparatus

and tested

For

this

and reas—

purpose

mainte-

5029.0e).

every

for its

7.1.1.

Dismantling

Switch off

supply plug.

secretion

moved and laid to

tainers should be

Water-absorbent

cellular material

incubator.

Mattress,

are taken

plate

‘

apparatus

Acessory

aspiration equipment

one side. All

emptied.

parts

etc. are removed

_

reclining

out of the

39).