Page 1

libri

7320

und

7520

Page 2

From

Drager:

incubators

important

For

correct

apparatus,

wish

to

point

1

Any

use

precise

hese

The

apparatus

purposes

manual

writing

The

regular

nel

actual

inspections

Drágerwerk

monthly

=

applicable,

qualified

tenance

by

apparatus

(inspection = determination

condition).

inspection

Notice

and

effective

and

to

out

the

of

the

knowledge

operating

is

specified

or

for

purposes

Dragerwerk

must

intervais

must

AG

maintenance

and

repair)

personnel.

record

use

avoid

hazards,

following:

apparatus

and

observation

instructions.

intended

in

only

the

specified

AG.

be

inspected

by

qualified

An

official

be

kept.

stipulates

(maintenance

servicing

to

be

performed

An

official

must

be

of

the

we

requires

for

the

operating

person-

record

six-

and,

main-

kept.

Only

in

at

of

of

if

by

7320

genuine

used

5

We

servicing

out

inspections

ensured

Contract

or

6

For

reducers

least

7

Inthe

and

in

equipped

0107.

8

The

in

9

Responsibility

of

Drager

when

carrying

recommend

and

by

Drägerwerk

by

with

distributor.

reasons

should

every 6 years.

interests

staff

apparatus

rooms

which

in

apparatus

areas

of

explosive

the

apparatus

and

spare

out

that

repair

work

and

servicing

parts

repairs.

inspections,

AG.

7520

may

be

carried

Regular

are

best

concluding a Service

your

Drager

of

safety,

be

of

the

accordance

is

not

for

reliable

is

transferred

subsidiary

overhauled

safety

may

only

are

wired

approved

risks.

functioning

pressure

of

patient

be

used

with

for

to

and

VDE

use

the

be

at

owner

or

the

apparatus

maintained

not

employed

iary

or

distributor

has

been

does

not

conditions

Dragerwerk

distributors

which

arises

tion

of

this

and

liability

and

delivery

AG,

its

subsidiaries

not

extended

Notice.

We

also

wish

national

and

equipment

recommendations,

laws

governing

operator

has

or

repaired

by

the

in

used

in a

conform

of

use.

AG,

its

are

not

as a result

Important

stated

or

implied

conditions

or

by

the

to

point

the

should

be

DRAGERWERK

in ali

cases

not

been

properly

by

persons

Dräger

question

subsid-

manner

to

the

specified

subsidiaries

liable

for

damage

on

non-observa-

Notice.

above

observed.

Warranty

in

the

of

Drágerwerk

distributors

important

out

that

regulations

use

of

technical

AG

LUBECK

where

or

if

which

and

sales

are

the

it

Contents

Important

1

Intended

2

TechnicalData........................

3

Design

3.1—3.7

3.BAccessories.........................

Notice

Use.

and

Mode

Standard

..

of

Operation

Equipment

4-11

3

4

5

6

7

8

9

Initial

Preparation

Operational

Trouble

Care

Order

Shooting.

and

Servicing

List

Dimensional

Use

Drawings.............

15

18

20

Page 3

1

Intended

1.1

Incubator

The

for

Warmth,

centration

against

environment

development

Various

tus

secretion

and

Its

makes

able

therapy

sive-care

7320

Incubator

premature

humidified

infections

items

can

be

aspiration,

for

infusions.

large

front-opening

the

for

the

and

treatment.

Use

7320

(Fig.

and

ill

of

oxygen

which

ideally

of

the

of

supplementary

connected,

~

Incubator

performance

for

certain

1a)

is

designed

newborn

air, a higher

and

protection

all

add

up

promotes

baby.

for

instance,

for

aerosol

hinged

particularly

of

types

babies.

con-

to

appara-

therapy

window

suit-

photo-

of

inten-

an

the

for

1.2

Intensive-care

The

Intensive-care

(Fig.

1b)

to 6 months

following

ing

features

model

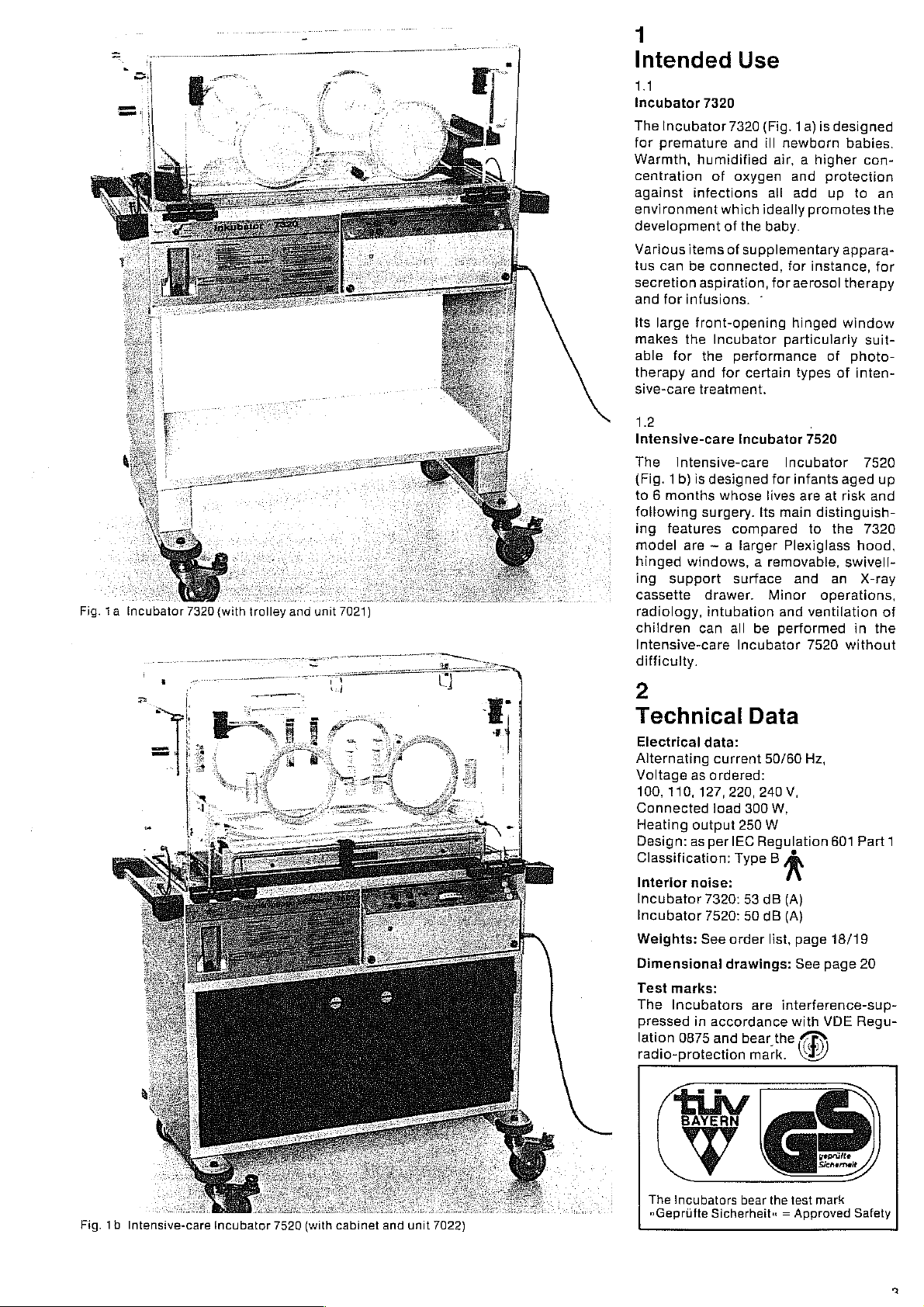

Fig.

1a

Incubator

7320

(with

trolley

and

unit

7021)

hinged

ing

cassette

radiology,

children

Intensive-care

difficulty.

are ~ a

windows, a removable,

support

Incubator

is

designed

whose

surgery.

compared

larger

surface

drawer.

intubation

can

all

Incubator

İts

be

,

7520

Incubator

for

infants

lives

are

main

to

Plexiglass

and

Minor

and

ventilation

performed

7520

7520

aged

up

at

risk

and

distinguish-

the

7320

hood,

swivell-

an

X-ray

operations,

of

in

the

without

2

Technical

Electrical

Alternating

Voltage

100, 110,

Connected

Heating

Design:

Classification:

Interior

Incubator

Incubator

Weights:

Dimensional

Test

The

pressed

lation

radio-protection

as

127,

output

as

noise:

See

marks:

Incubators

in

0875

Data

data:

current

ordered:

220,

load

300

250

perlEC

Type B ň

7320:

53

7520:

50

order

drawings:

are

accordance

and

bear

mark.

50/60

Hz,

240

V,

W,

W

Regulation

dB

dB

list,

interference-sup-

the

(A)

(A)

page

See

with

РУ

601

18/19

page

VDE

Part

20

Regu-

1

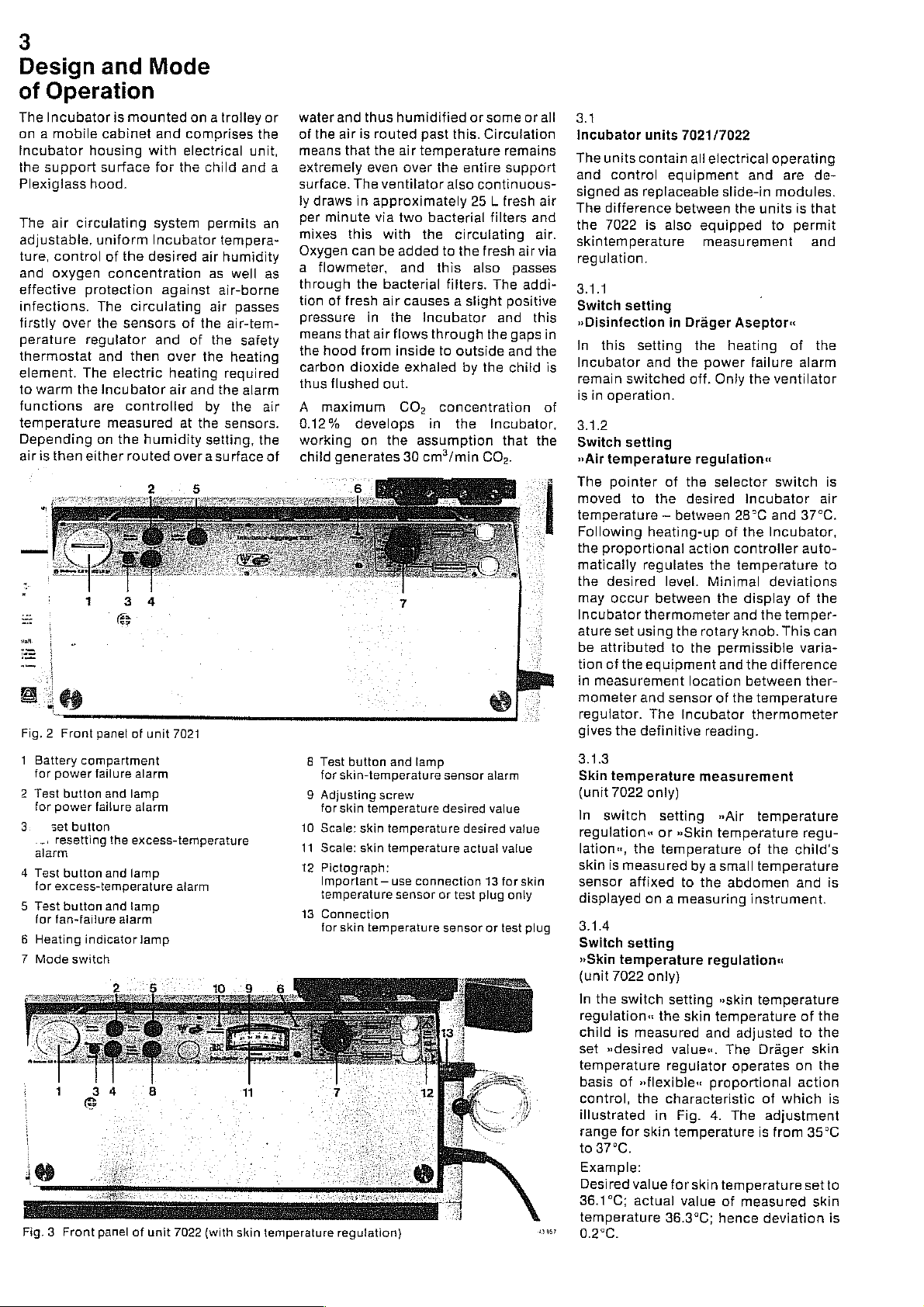

Fig.

1b

Intensive-care

Incubator

7520

(with

cabinet

and

unit

7022)

The

incubators

»Gepriifte

bear

the

test

Sicherheit« = Approved

mark

Safety

Page 4

3

Design

of

Operation

The

Incubator

on a mobile

Incubator

the

support

Plexiglass

The

air

circulating

adjustable,

ture,

control

and

oxygen

effective

infections.

firstly

perature

thermostat

element.

to

warm

functions

temperature

Depending

air

Fig. 2 Front

1

Battery

for

2

Test

for

3

..:

alarm

4

Test

for

5

Test

for

6

Heating

7

Mode

Fig.3 Front

protection

over

regulator

The

the

is

then

either

compartment

power

button

power

set

button

resetting

button

excess-temperature

button

fan-failure

indicator

switch

and

cabinet and

housing

surface

hood.

is

mounted

Mode

with

for

system

uniform

of

the

desired

Incubator

concentration

The

circulating

the

sensors

and

and

then

electric

Incubator

are

controlled

measured

on

the

humidity

routed

panel

of

unit

failure

alarm

and

lamp

failure

alarm

the

excess-temperature

and

lamp

and

lamp

alarm

lamp

panel

of

unit

on a trolley

comprises

electrical

the

child

permits

tempera-

air

humidity

as

well

against

over

heating

air

of

of

and

at

air-borne

air

the

the

the

required

the

by

the

sensors.

air-tem-

heating

the

setting,

over a surface

7021

alarm

7022

(with skin

or

the

unit,

and

an

as

passes

safety

alarm

air

the

of

temperature

a

water

and

of

the

air

means

that

extremely

surface.

ly

per

mixes

Oxygen

a

The

draws

minute

this

can

flowmeter,

through

tion

of

fresh

pressure

means

that

the

hood

carbon

thus

A

dioxide

flushed

maximum

0.12%

working

child

generates

8

Test

button

for

skin-temperature

9

Adjusting

for

skin

10

Scale:

11

Scale:

12

Pictograph:

Important — use

temperature

13

Connection

for

skin

regulation)

thus

humidified

is

routed

past

the

air

temperature

even

over

ventilator

in

approximately

via

two

with

the

be

added

and

the

bacterial

air

causes a slight

in

the

Incubator

air

flows

from

inside

exhaled

out.

CO,

develops

on

the

assumption

30

cm?/min

and

lamp

screw

temperature

skin

temperature

skin

temperature

connection

sensor

temperature

or

some

this.

Circulation

the

entire

also

continuous-

25 L fresh

bacterial

filters

circulating

to

the

fresh

this

also

filters.

The

and

through

to

the

outside

by

the

concentration

in

the

Incubator,

that

CO».

sensor

alarm

desired

value

desired

actual

vatue

13

or

test

sensor

for

plug

or test

or

alt

remains

support

air

and

air.

air

via

passes

addi-

positive

this

gaps

in

and

the

child

is

of

the

value

skin

only

plug

13957

3.1

Incubator

The

units

and

signed

The

the

skintemperature

units

contain

control

equipment

as

replaceable

difference

7022

is

also

7021/7022

all

electrical

between

equipped

measurement

regulation.

3.1.1

Switch

»Disinfection

In

Incubator

remain

is

setting

this

switched

in

operation.

in

setting

and

Drager

the

the

power

off.

Only

3.1.2

Switch

»Air

The

moved

setting

temperature

pointer

to

of

the

regulation«

the

selector

desired

temperature ~ between

Following

the

matically

the

may

Incubator

ature

be

attributed

tion

in

measurement

mometer

regulator.

gives

heating-up

proportional

regulates

desired

occur

set

of

the

level.

between

thermometer

using

the

equipment

and

sensor

The

definitive

action

the

Minimal

the

rotary

to

the

location

Incubator

reading.

the

permissible

and

of

3.1.3

Skin

temperature

(unit

7022

only)

In

switch

regulation«

lation,

skin

sensor

displayed

the

is

measured

affixed

on a measuring

measurement

setting

or

»Skin

»Air

temperature

temperature

by a small

to

the

3.1.4

Switch

»Skin

(unit

In

regulation«

child

set

temperature

basis

control,

illustrated

range

to

36.1°C;

temperature

temperature

7022

the

switch

is

»desired

of

for

37°C.

Example:

Desired

setting

only)

setting

the skin

measured

value«.

regulator

»flexible«

the

characteristic

in

Fig.

skin

temperature

value

for

actual

36.3°C;

regulation«

»skin

temperature

and

proportional

4.

skin

value

hence

0.2°C.

operating

and

are

slide-in

the

modules.

units

to

Aseptor«

heating

failure

the

ventilator

of

switch

Incubator

28°C

and

of

the

Incubator,

controller

temperature

deviations

display

and

the

temper-

knob.

This

the

difference

between

the

temperature

thermometer

temperature

of

the

temperature

abdomen

instrument.

temperature

adjusted

The

Drager

operates

of

which

The

adjustment

is

from

temperature

of

measured

deviation

de-

is

that

permit

and

the

alarm

is

air

37°C.

auto-

to

of

the

can

varia-

ther-

regu-

child's

and

is

of

the

to

the

skin

on

the

action

is

35°C

set

to

skin

is

Page 5

‘Incubator

37

36

35

34

33

32

air

— — — =

temperature

Example

(°C}

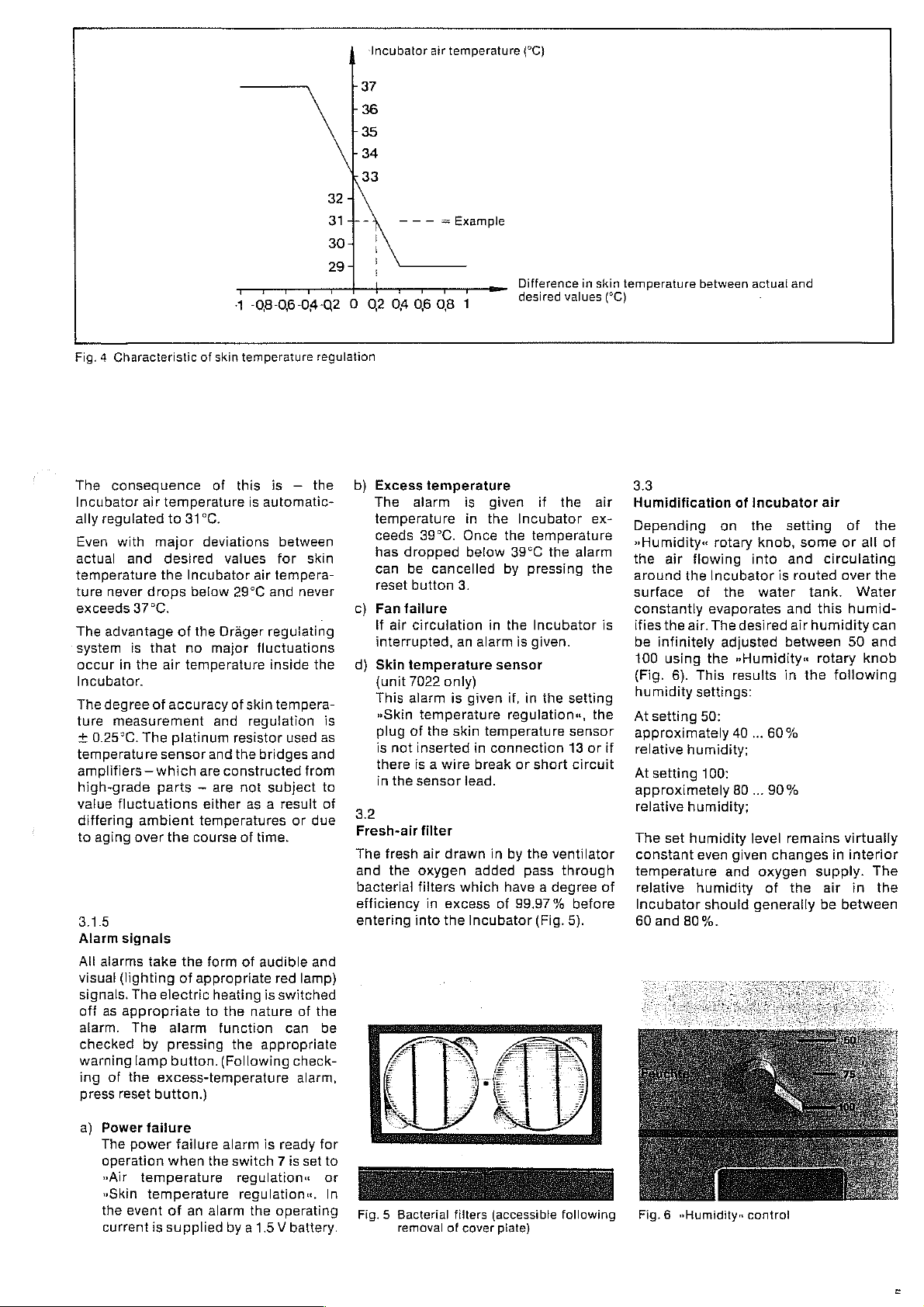

Fig. 4 Characteristic

The

consequence

Incubator

ally

Even

actual

temperature

ture

exceeds

The

system

occur

Incubator.

The

ture

+

0.25°C.

temperature

amplifiers — which

high-grade

value

differing

to

aging

3.1.5

Alarm

Alt

visual

signals.

off

alarm.

checked

warning

ing

press

air

regulated

with

and

never

drops below

37°C.

advantage

is

that no

in

the

degree

alarms

as

of

measurement

The

fluctuations

ambient

over

signals

take

(lighting

The

appropriate

The

by

lamp

of

the

reset

temperature

to

31°C.

major

desired

the

Incubator

of

air

temperature

accuracy

platinum

sensor

parts — are

the

the

of

electric

alarm

pressing

button.

excess-temperature

button.)

4

-08-06-04-02 O 02 04 06

of

skin

temperature

of

this

is

deviations

vaiues

air

29°C

the

Drager

major

fluctuations

of

skin

and

regulation

resistor

and

the

bridges

are

constructed

not

either

as a result

temperatures

course

of

time.

form

of

audible

appropriate

heating

to

the

nature

function

the

appropriate

(Following

regulation

is — the

automatic-

between

for

skin

tempera-

and

never

regulating

inside

the

tempera-

is

used

as

and

from

subject

red

is

to

of

or

due

and

lamp)

switched

of

the

can

be

check-

alarm,

b)

Excess

The

alarm

temperature

ceeds

has

dropped

can

be

reset

button

Fan

failure

if

air

circulation

interrupted,

d)

Skin

temperature

{unit

7022

This

alarm

»Skin

plug

of

is

not

there

in

the

3.2

Fresh-air

The

fresh

and

the

bacterial

efficiency

entering

08

1

temperature

is

in

39°C.

Once

below

cancelled

3.

an

only)

is

given

temperature

the

skin

inserted

is a wire

sensor

oxygen

filters

into

filter

air

drawn

in

excess

the

lead.

which

Incubator

Difference

desired

given

the

Incubator

the

39°C

by

pressing

in

the

alarm

is

sensor

if,

in

regulation«,

temperature

in

connection

break

or

in

by

the

added

pass

have a degree

of

99.97%

in

skin

values

if

the

air

ex-

temperature

the

alarm

the

Incubator

given.

the

short

ventilator

(Fig.

setting

the

sensor

13

or

circuit

through

before

5).

is

of

temperature

(°C)

3.3

Humidification

Depending

»Humidity«

the

air

around

surface

constantly

ifies

the

be

infinitely

100

using

(Fig.

humidity

At

setting

approximately

if

relative

At

setting

approximeiely

relative

The

set

constant

temperature

relative

Incubator

60

and

between

rotary

flowing

the

Incubator

of

evaporates

air.

The

the

6).

This

settings:

50:

humidity;

100:

humidity;

humidity

even

humidity

should

80%.

actual

of

Incubator

on

the

knob,

into

the

water

desired

adjusted

»Humidity«

results

40

...

60%

80

...

90%

level

given

and

oxygen

of

generally

and

setting

some

and

is

routed

tank.

and

air

humidity

between

in

the

remains

changes

the

air

of

the

or

all

circulating

over

the

Water

this

humid-

can

50

and

rotary

supply.

following

virtually

in

interior

air

in

be

between

knob

The

the

of

a)

Power

The

operation

»Air

»Skin

the

current

failure

power

failure

when

temperature

temperature

event

of

is

supplied

an

the

alarm

alarm

is

ready

switch 7 is

regulation«

regulation«.

the

operating

by a 1.5 V

for

setto

or

In

battery.

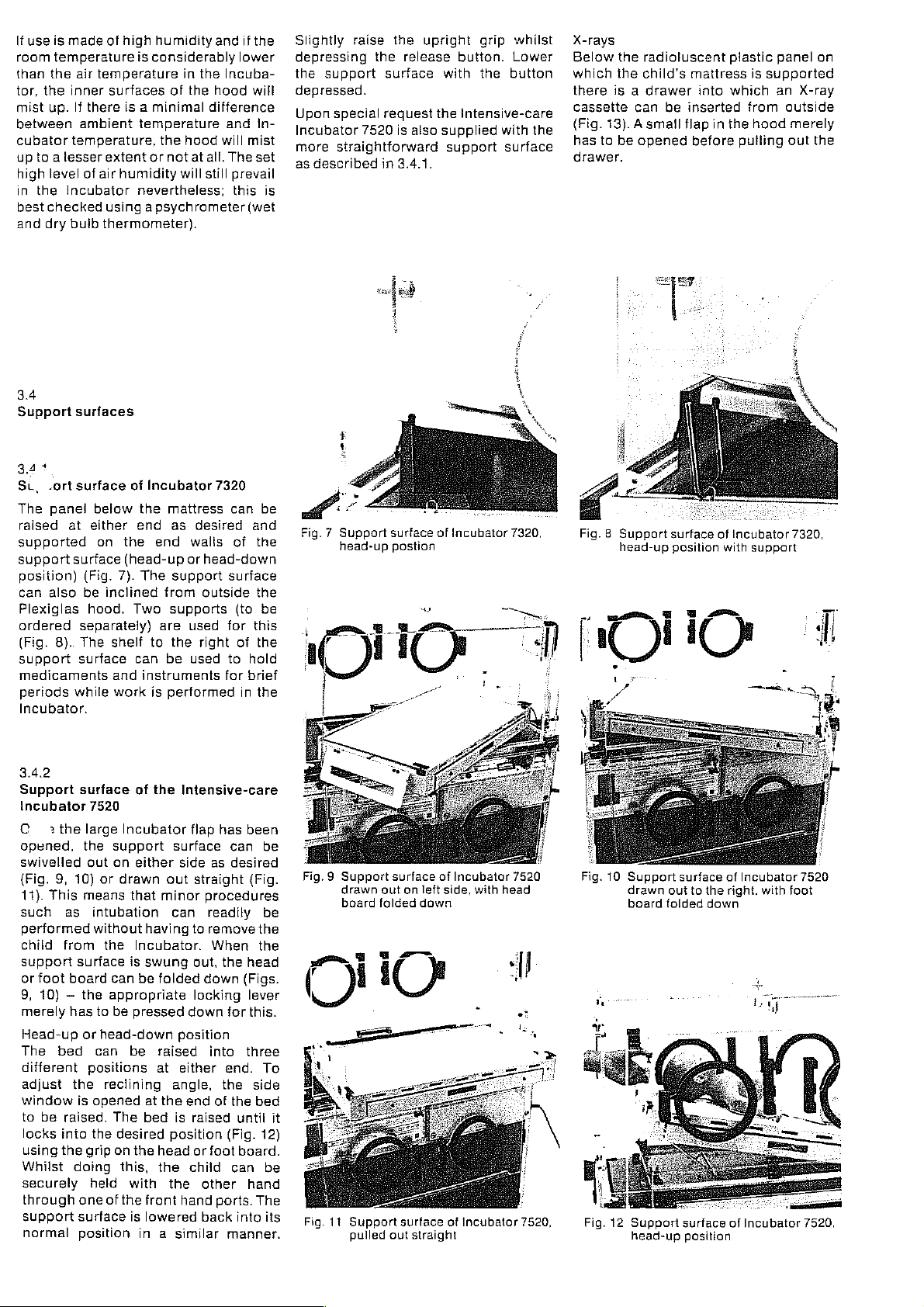

Fig. 5 Bacterial

removal

filters

(accessible following

of

cover

plate)

Fig. 6 »Humidity«

control

Page 6

lf

use

is

made

of

room

temperature

than

the

air

temperature

tor,

the

inner

surfaces

mist

up.

If

there

between

cubator

up

high

in

best

and

34

Support

3.4

SL,

The panel

raised

supported

support

position)

can

Plexiglas hood.

ordered

(Fig.

support

medicaments

periods

Incubator.

ambient

temperature,

to à lesser

level

of air

the

Incubator

checked

dry

buib

surfaces

+

.ort

surface

below

at

either

surface

(Fig.

also

be

separately)

8).

The

surface

while

extent

using a psychrometer

thermometer).

on

inclined

high

humidity

is

considerably

of

is a minimal

temperature

the

or

not

humidity

nevertheless;

of

Incubator

the

mattress

end

as

the

end

(head-up

7).

The

from

Two

supports

are

shelf

to

the

can

be

and

instruments

work

is

performed

and

in

the

the

hood

difference

hood

at

all.

will

still

7320

desired and

walis

or

head-down

support

outside

used

right

used

if

the

lower

Incuba-

will

and

In-

will

mist

The

set

prevail

this

(wet

can

of

the

surface

the

(to

for

this

of

the

to

hold

for

brief

in

the

Slightly

depressing

the

depressed.

Upon

Incubator

more

as

is

be

be

raise

the

support

special

7520

straightforward

described

Fig. 7 Support

head-up

the

release

surface

request

is

also

in

3.4.1.

surface

postion

upright

button.

with

the

intensive-care

supplied

support

of

Incubator

grip

the

with

whilst

Lower

button

the

surface

7320,

X-rays

Below

the

radioluscent

which

the

child's

there

is a drawer

cassette

(Fig.

has

drawer.

é

Fig. 8 Support

can

13). A small

to

be

opened

head-up

be

surface

position

mattress

into

inserted

flap

in

before

of

with

plastic

is

supported

which

from

the

hood

pulling

Incubator

support

panel

an

X-ray

outside

merely

out

7320,

on

the

3.4.2

Support

Incubator

C > the

opened,

swivelled

{Fig.

9,

10)

11).

This

such

as

performed

child

from

support

or

foot

board

9,

10) — the

merely

Head-up

The

different

adjust

window

to

Whilst

securely

bed

be

raised.

locks

into

using

the

through

support

normal

has

the

doing

surface

7520

large

Incubator

the

support

out

on

or

drawn

means

intubation

without

the

surface

can

appropriate

to

be

or

head-down

can

positions

reclining

is

opened

The

the

desired

grip

on

this,

held

one

of

the

surface

position

of

the

Intensive-care

surface

either

side

out

that

minor

can

having

Incubator.

is

swung

be

folded

pressed

position

be

raised

at

either

angle,

at

the

end

bed

is

position

the

head

or

the

with

the

front

hand

is

lowered

in a

similar

flap

has

as

straight

procedures

readily

to

remove

When

out,

the

down

locking

down

into

end.

the

of

raised

foot

child

other

ports.

back

been

can

be

desired

(Fig.

be

the

the

head

(Figs.

lever

for

this.

three

To

side

the

bed

until

(Fig.

12)

board.

can

be

hand

The

into

its

manner.

Fig.9

Support

drawn

board

surface

out

on

folded

left

down

of

Incubator

side,

with

7520

head

Fig.

10

Support

drawn

board

surface

out

to

folded

the

down

of

Incubator

right.

with

7520

foot

it

e

E

nl

Fig.

11

Support

pulled

surface

out

straight

of

Incubator

7520,

Fig.

12

Support

head-up

surface

position

of

Incubator

7520.

Page 7

3.5

Plexiglas

3.5.1

Plexigias

(Fig.

1a)

In

the

front

hinged

This

therapeutic

the

Incubator

hood.

and

hinged

it

therapy

phototherapy

moved

opened.

Four

access

nursing.

ing

of

Two

Incubator

removal

openings

designed

such

are

and

panel

facilitates

young

The

removed

flap.

is

even

aside

iris

for

windows

the

iris

sliding

as

used

cables.

without

diaphragm

Upon

of

ventilation

hoods

hood

of

Incubator

of

the

hood

which

can

performance

procedures

patient

under

child

possible

routine

diaphragms

windows

permit simple

dirty

of

to

accommodate

to

pass

can

the

can

also

from

the

to

interruption

unit

does

when

the

hand

manipulations

special

can

also

linen.

the

sliding

hoses.

through

7320

there

is a large

be

opened

of

during

remain

protection

be

placed

unit

through

perform

not

have

hinged

parts

request

be

(see

at

the

Recesses

swivell-

fitted

Fig. 14).

ends

and

hygienic

windows

wide

Other

small

up.

many

which

in

the

of

the

into

the

photo-

as

the

to

be

flap

is

provide

and

instead

of

the

in

the

are

hoses,

holes

hoses

Fig.

14

Fig.

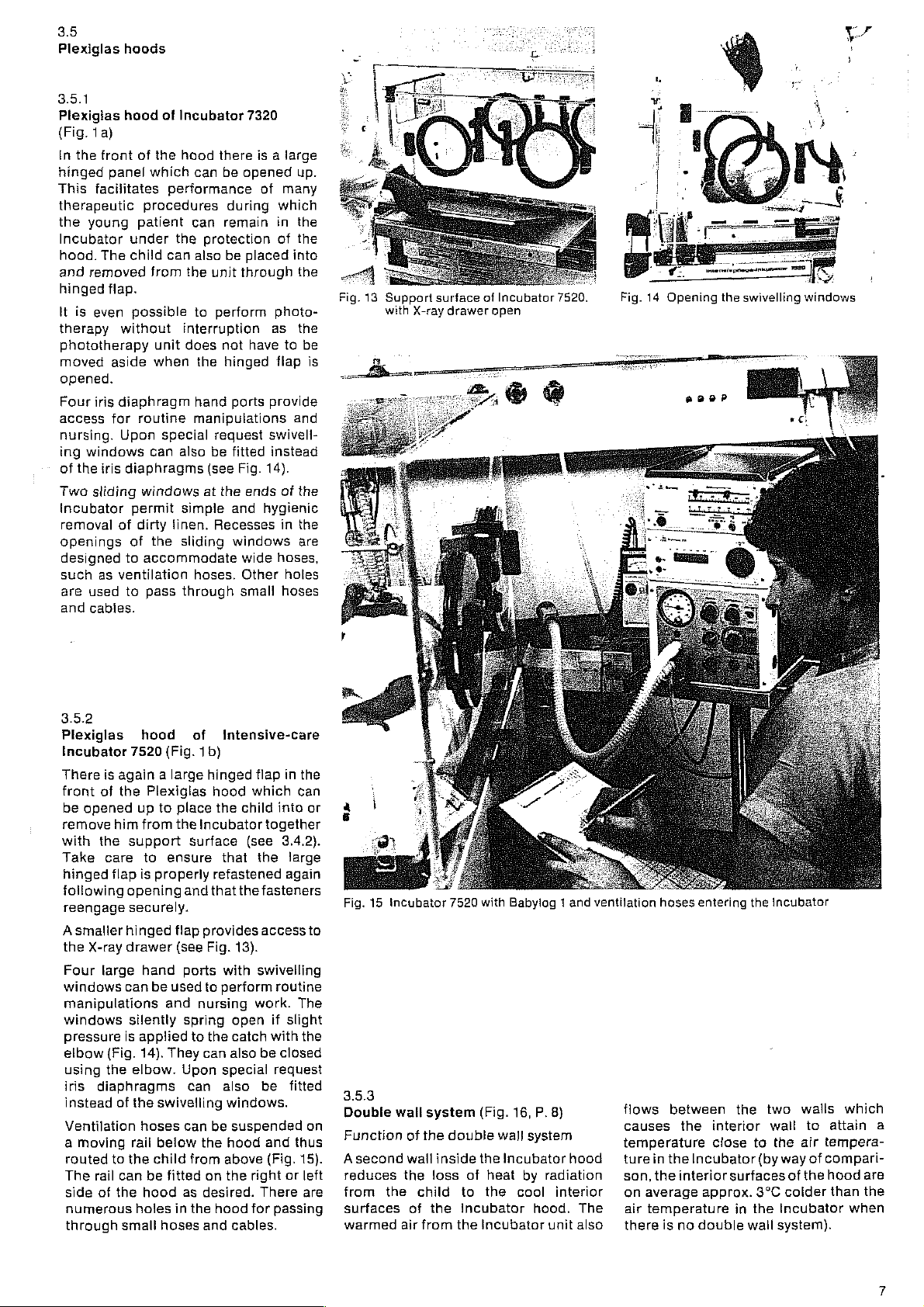

13

Support

with

X-ray

surface

drawer

of

Incubator

open

7520,

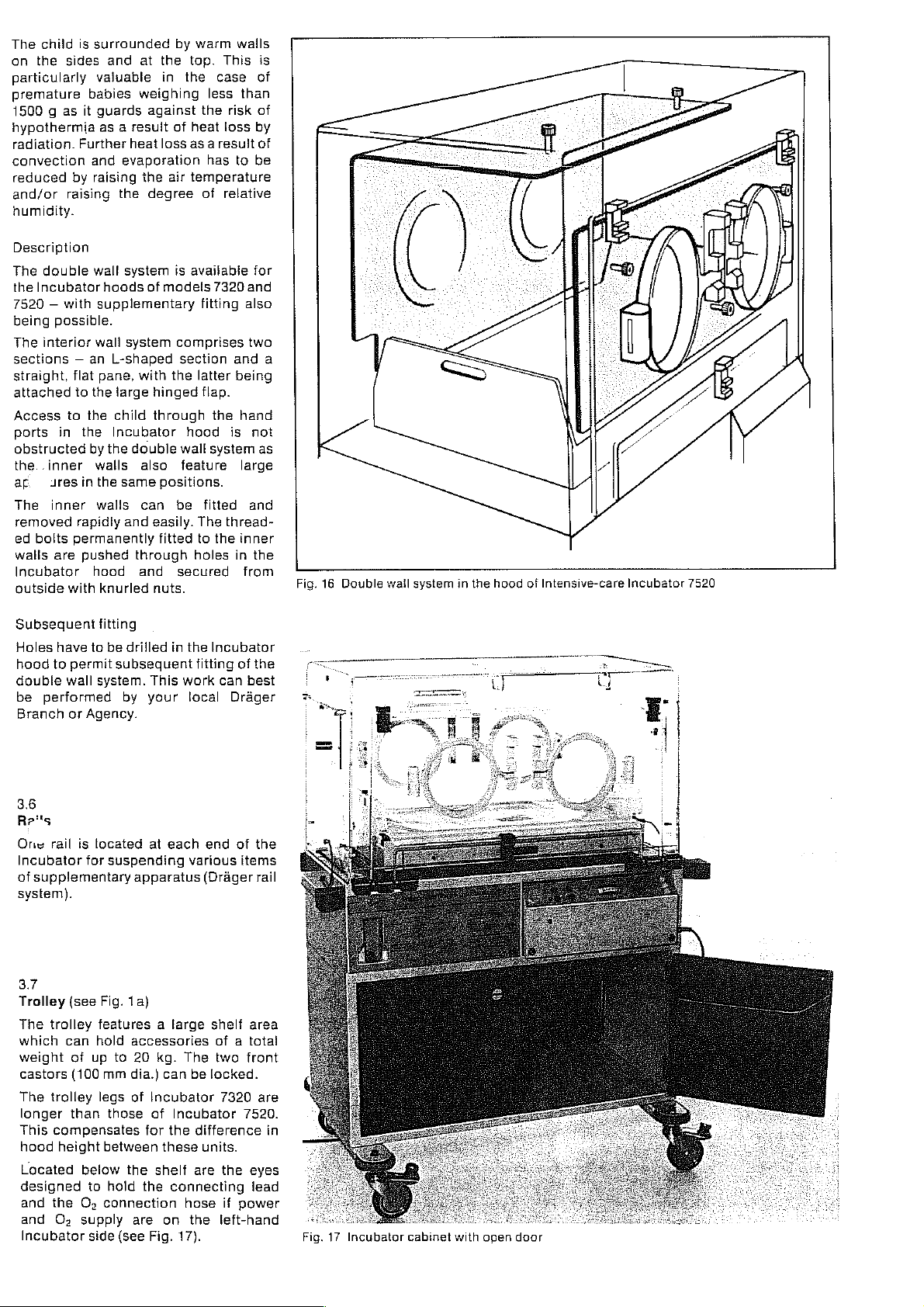

Opening

the

swivelling

windows

3.5.2

Plexiglas

Incubator

There

front

be

opened

remove

with

Take

hinged

following

reengage

A

smaller

the

X-ray

Four

windows

Manipulations

windows

pressure

elbow

using

iris

instead

Ventilation

a

moving

routed

The

side

numerous

through

hood

7520

is

again a large

of

the

up

him

from

the

support

care

to

flap

is

opening

securely.

hinged

drawer

large

hand

can

silently

is

applied

(Fig.

14).

the

elbow.

diaphragms

of

the

hoses

rail

to

the

rail

can

of

the

hood

holes

small

of

(Fig.

1b)

Plexiglas

to

place

the

Incubator

surface

ensure

properly

and

flap

(see

ports

be

used

and

nursing

spring

to

They

Upon

can

swivelling

can

below

child

from

be

fitted

as

in

the

hoses

intensive-care

hinged

that

provides

Fig.

to

the

can

the

on

desired.

and

flap

hood

which

the

child

together

(see

that

the

refastened

the

fasteners

access

13).

with

swivelling

perform

work. The

open

catch

also be

special

also

be

windows.

be

suspended

hood

and

above

(Fig.

the

right

There

hood

for

cables.

in

the

can

into

or

3.4.2).

large

again

to

routine

if

slight

with

the

closed

request

fitted

on

thus

15).

or

left

are

passing

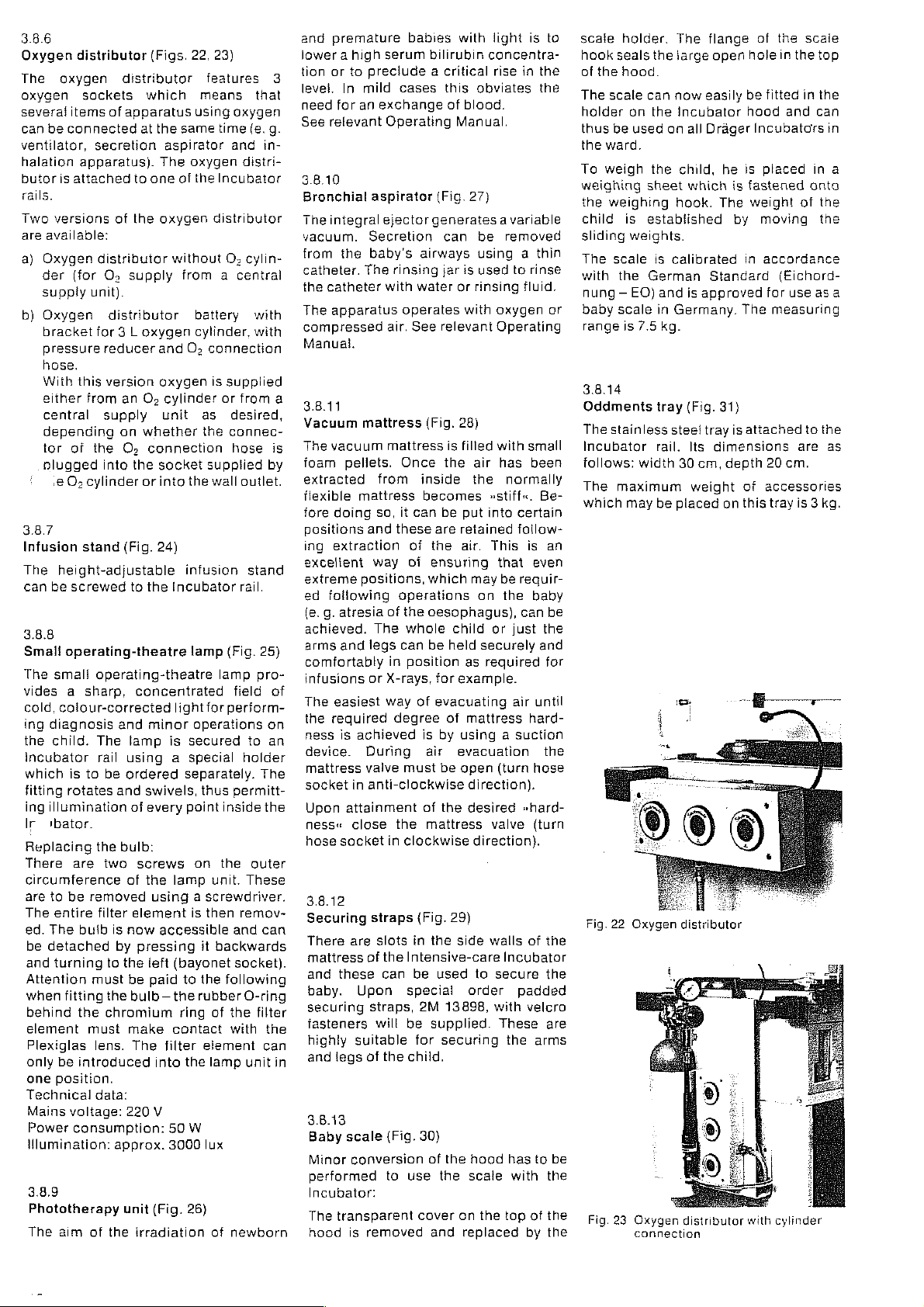

Fig.

15

incubator

3.5.3

Double

Function

Asecond

reduces

from

the

surfaces

warmed

wall

air

of

the

wail

the

child

of

from

7520

system

double

inside

!oss

the

the

with

Babylag 1 and

(Fig.

16,

wall

the

Incubator

of

heat

to

the

cool

incubator

Incubator

P.

system

by

radiation

hood.

unit

ventilation

8)

hood

interior

The

also

hoses

flows

between

causes

temperature

turein

son,

on

air

there

the

the

Incubator

the

interior

average

temperature

is

no

entering

the

interior

close

surfaces

approx.

in

double

the

incubator

two

wall

to

(by

3°C

the

wail

walls

to

the

air

way

of

of

the

colder

Incubator

system).

which

attain

tempera-

compari-

hood

are

than

the

when

a

Page 8

The

child

is

on

the

sides

particularly

premature

1500 g as

hypothermia

radiation.

convection

reduced

and/or

humidity.

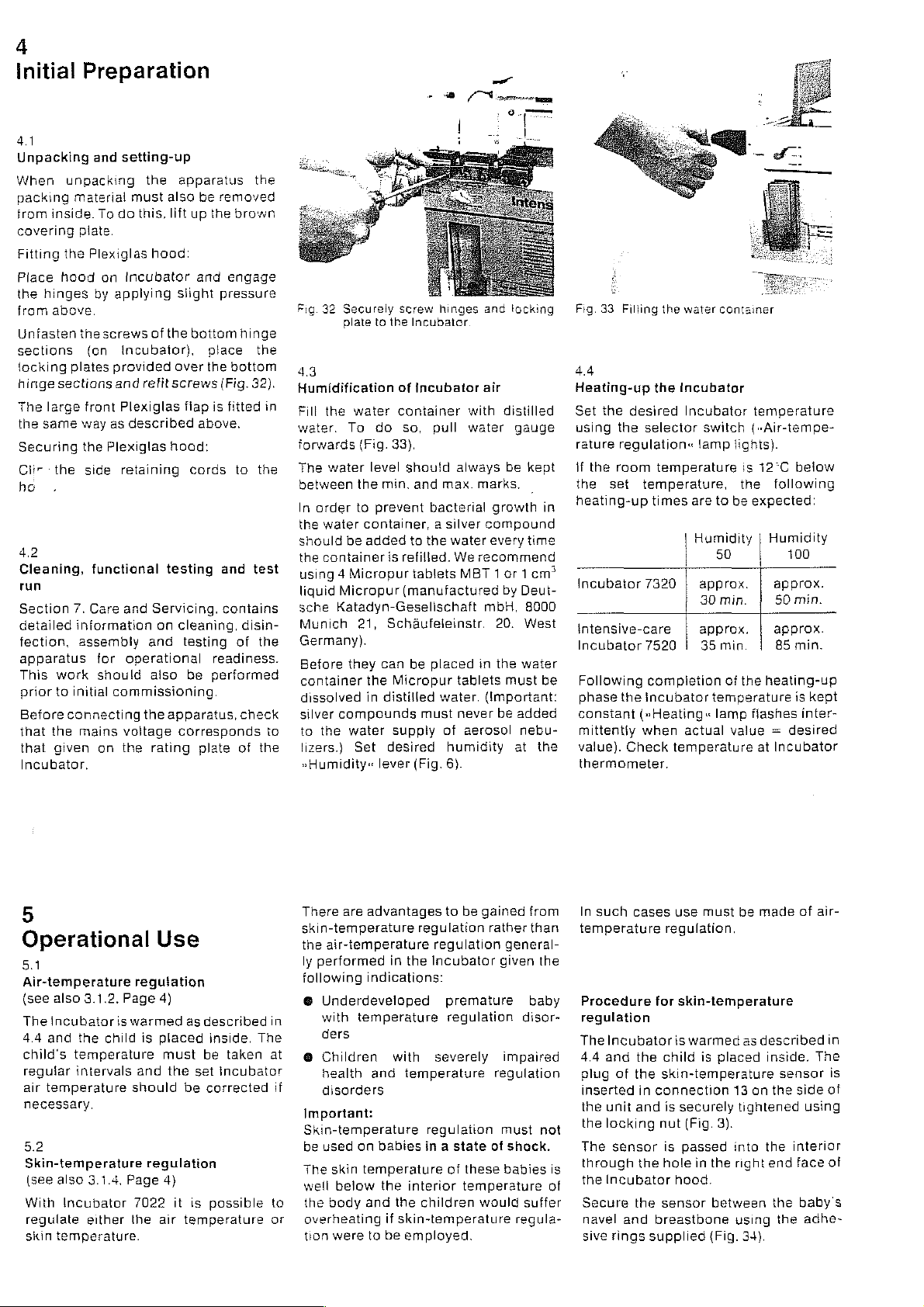

Description

The

the

Incubator

7520 — with

being

The

sections — an

straight,

attached

Access

ports

obstructed

the..inner

ap

The

removed

ed

bolts

walls

Incubator

outside

babies

it

Further

by

raising

double

possible.

interior

flat

to

to

the

in

the

by

uresin

inner

rapidly

permanently

are

pushed

with

surrounded

and

at

the

valuable

weighing

guards

as a result

and

raising

wall

supplementary

wall

pane,

the

walls

the

walls

hood

knurled

against

heat

evaporation

the

the

degree

system

hoods

of

system

L-shaped

with

large

hinged

child

through

Incubator

the

double

also

same

can

and

easily.

through

and

nuts.

loss

positions.

fitted

by

warm

top.

in

the

less

the

of

heat

as a result

has

air

temperature

of

is

available

modets

fitting

comprises

section and

the

latter

flap.

hood

wall

system

feature

be

fitted

The thread-

to

holes

secured

wails

This

case

than

risk

loss

to

relative

7320

being

the

hand

is

large

the

inner

in

is

of

of

by

of

be

for

and

also

two

not

as

and

the

from

a

Fig.

16

Double

wail

system

in

the

|

|

/

hood

of

Intensive-care

|

Incubator

7520

Subsequent

Holes

have

hood

to

permit

double

be

Branch

3.6

Ars

One

Incubator

of

system).

3.7

Trolley

The

which

weight

The

This

wall

performed

or

rail

supplementary

(see

trolley

can

of

castors

longer

hood

Located

designed

and

and

Incubator

(100

trolley

than

compensates

height

the

O,

fitting

to

be

drilled

subsequent

system.

Agency.

is

located

for

Fig.

features a large

hold

up

legs

below

to

O;

supply

side

This

by

your

at

suspending

apparatus

1a)

accessories

to

20

kg.

mm

dia.)

of

Incubator

those

of

for

between

the

shelf

hold

the

connection

are

(see

Fig.

in

the

Incubator

fitting

work

local

each

end

various

(Dräger

shelf

of a total

The

two

can

be

locked.

Incubator

the

difference

these

units.

are the

connecting

hose

on

the

17).

of

the

can

best

Drager

of

the

items

rail

area

front

7320

are

7520.

in

eyes

lead

if

power

left-hand

Fig.

17

Incubator

cabinet

with

open

door

Page 9

3.8

Accessories

{on

special

3.8.4

Cabinet

The

trolley

The

doors

applying

All

doors

which

weighing

Larger

be

stored

The

longer

This

hood

3.8.2

O,

metering

The

incubator

tor

via a metering

a

connection

The

attached

means

humidify

achieved

order)

(Figs.

cabinet

with

doors

can

pressure

are

can hold

up

items

on

the

cabinet

compensates

oxygen

metering

than

height

air

to

of

aclamp.

the

inside

legs

between

(Fig.

the

1b

and

can

be

on

be

opened

(e.

fitted

to

max. 1 kg

weighing

bottom

of

those

for

18)

required

is

routed

vaive

socket

valve

incubator

It

oxygen

the

17)

described

the

front

and

and

closed

g.

with

the

with

18796

medicaments

(Fig.

up

to

20

of

fhe

cabinet.

Incubator

of

Incubator

the

these

into

and a rubber

and

is

not

as this

Incubator.

difference

units.

to

enrich

the

with

flowmeter.

flowmeter

rail

(Fig.

necessary

7320

is

as

back.

by

knee).

pockets

etc.

17).

kg

can

are

7520.

the

incuba-

hose.

are

18) by

ideally

3.8.5

Water

See

The

tion

spontaneously

aerosols

a

micron).

When

tion

infinitely

100%.

breathing

operates

Nebulizer

the

breathing

point

in

temperature.

nebulizer

increases

original

Nebulizer

to

nebulizer

relevant

water

of

using

af

the

If

with

correct

of

level.

(Fig.

21)

Operating

nebulizer

the

breathing

{average

oxygen

Manual.

permits

breathing

particle

the

breathing

adjusted

no O;

gas

heating

conditions

gas

view,

performance

to

operation

between

enrichment

is

desired

compressed

is

available

in

from a physiological

including

If

the

heating

two

or

three

causes

humidifica-

air

of

the

child

with

size

0.65

O;

concentra-

gas

can

40

and

of

the

the

nebulizer

air.

to

create

the

humidified

the

correct

is

used

simultaneously

times

the

modifica-

be

tion

of

the

the

Table

in

The

O,

concentration

Incubator

O,

meter

(see

Section

Nebulization

in

These

applied

nebulizer

the

5.3).

form

substances

in

advantages

backs

and

remembered

be

deposited

apparatus

strong

tendency

Regular

Incubator

order

to

reduce

the

child.

Please

the

observe

substances

O,

concentrations

Section

must

be

determined

also

of

expectorant

of

aqueous

the

Incubator

in

cases

clearly

hazards

that

these

on

and

that

thorough

is

absolutely

the

instructions

employed.

5.3.

prevailing

the

relevant

solutions.

should

with

where

the

outweigh

involved.

substances

ali

surfaces

the

residue

to

develop

cleaning

imperative

risk

of

shown

in

using

notes

substances

only

the

water

expected

the

draw-

It

must

of

has

fungus.

of

infection

for

use

in

the

an

in

be

be

wil!

the

a

the

in

for

of

3.8.3

Oxygen

An

the

screwed

meter

limiter

oxygen

Incubator.

onto

(3.8.2)

limiter

the

in

socket.

Two

switch

handwheel

a)

White

QO,

for

into

to

approx.

if a lower

supply

at

b)

Red

supply.

3.8.4

Oxygen

A

Plexiglas

ter

high

child

of

acute

into

the

(setting

nebulizer

If

an

desired a nappy

around

settings

of

the

setting:

metering

more

than 6 L/min

the

Incubator.

an

oxygen

40%.

O,

rate

of

the

metering

setting:

helmet

helmet

concentrations

as

quickly

asphyxia.

helmet

approx.

and a corrugated

extremely

the

child's

(Fig.

19)

can

be

connected

The

bottom

piace

limiter:

even

valve

oxygen

of

can

it

limiter

of

the

the

connection

be

fixed

with a fuliy-open

is

not

oxygen

This

corresponds

concentration

content

fess

no

(Fig.

as

The

via

the

10

high

neck

is

required,

than 6 L/min

valve.

restriction

20}

is

used

to

of

oxygen

possible

L/min), a humidifier/

O;

must

in

oxygen

O2

metering

hase.

concentration

be

to

create a seal.

to

is

O:

flow-

at

the

possible

to

flow

of

is

set

of

O;

adminis-

to

the

the

case

is

routed

valve

is

wrapped

a

Fig.

20

Oxygen

helmet

Fig.

21

Water

nebulizer

with

heater

Page 10

3.8.6

Oxygen

The

oxygen

several

can

ventilator,

halation

butor

rails.

Two

are

a)

b)

3.8.7

Infusion

The

can

distributor

oxygen

sockets

items

of

be

connected

secretion

apparatus).

is

attached

versions

available:

Oxygen

der

suppiy

Oxygen

bracket

pressure

hose.

With

either

central

depending

tor

plugged

.e

(for

this

of

O,

distributor

O,

unit).

distributor

for

reducer

version

from

supply

the

into

cylinder

stand

height-adjustable

be

screwed

3.8.8

Smali

operating-theatre

The

smal!

operating-theatre

vides a sharp,

cold,

colour-corrected

ing

diagnosis

the

child.

The

incubator

which

fitting

ing

illumination

Ir

tbator.

Replacing

There

circumference

are

to

The

ed.

The

be

detached

and

Attention

when

behind

element

Plexiglas

only

one

Technical

Mains

Power

illumination:

3.8.9

Phototherapy

The

rail

is

to

rotates

the

are

be

removed

entire

filter

buib

turning

must

fitting

the

must

lens.

be

intreduced

position.

data:

voltage:

consumption:

aim

of

be

two

to

the

chromium

the

(Figs.

22,

distributor

which

apparatus

at

the

using

same

aspirator

The

oxygen

to

one

of

the

of

the

oxygen

without

supply

from a central

battery

3 L

öxygen

an

Os

on

whether

O:

connection

the

or

(Fig.

and

O,

oxygen

cylinder

unit

socket

into

the

24)

cylinder.

infusion

to

the

Incubator

lamp

concentrated

light

and

minor

operations

lamp

is

secured

using a special

ordered

and

of

bulb:

screws

of

element

is

now

by

pressing

the

be

separately.

swivels,

every

point

on

the

lamp

using a screwdriver.

is

accessible

teft

(bayonet

paid

to

bulb — the

ring

make

contact

The

filter

into

the

220

V

50

W

approx.

3000

unit

(Fig.

irradiation

26)

23)

features

means

time

Incubator

that

oxygen

(e.

and

distri-

3

g.

in-

distributor

O;

cylin-

with

with

connection

is

supplied

or

from

a

as

desired,

the

connec-

hose

is

supplied

wall

by

outlet.

stand

rail.

(Fig.

25)

lamp

pro-

field

of

for

perform-

on

to

an

holder

The

thus

permitt-

inside

the

the

outer

unit.

These

then

remov-

and can

it

backwards

socket).

the

following

rubber O-ring

of

the

filter

with

the

element

lamp

lux

of

can

unit

newborn

in

and

premature

lower a high

tion

or

to

preciude a critical

level.

In

mild

need

for

an

See

relevant

3.8.10

Bronchial

The

integral

vacuum.

from

catheter.

the

The

compressed

Manual.

Secretion

the

baby's

The

catheter

apparatus

3.8.11

Vacuum

The

foam

extracted

flexible

fore

positions

ing

exceltent

extreme

ed

(e.g.

mattress

vacuum

pellets.

mattress

doing

and

extraction

positions,

following

atresia

achieved.

arms

and

legs

comfortably

infusions

The

the

ness

device.

mattress

socket

Upon

ness«

hose

or

easiest

required

is

achieved

During

valve

in

anti-clockwise

attainment

close

socket

3.8.12

Securing

There

are

mattress

and

baby.

securing

fasteners

highly

and

these

Upon

suitable

legs

of

straps,

of

3.B.13

Baby

scale

Minor

conversion

performed

Incubator:

The

transparent

hood

is

removed

babies

serum

cases

exchange

Operating

aspirator

ejector

rinsing

with

water

operates

air.

See

mattress

Once

from

so,

it

can

these

of

way

of

operations

of

the

The

whole

can

in

position

X-rays,

way

of

degree

must

the

in

clockwise

straps

(Fig.

slots

in

the

Intensive-care

can

be

special

will

be

for

the

child.

(Fig.

to

use

cover

with

light

bilirubin

(Fig.

generates a variable

airways

relevant

(Fig. 28)

inside

becomes

be

are

the

ensuring

which

oesophagus),

be

for

evacuating

is

by

air

be

of

the

mattress

concentra-

rise

this

obviates

of

blood.

Manual.

27)

can

be

removed

using a thin

jar

is

used

to

or

rinsing

with

oxygen

Operating

is

filled

with

the

air

has

the

normally

»stiff«.

put

into

retained

air.

This

that

may

be

on

the

child

or

just

held

securely

as

required

example.

air

of

mattress

using a suction

evacuation

open

(turn

direction}.

desired

valve

in

fluid.

small

certain

follow-

is

requir-

can

»hard-

direction).

29)

the

side

walls

of

Incubator

used

to

secure

2M

13898,

supplied.

securing

30)

of

the

the

and

order

hood

scale

on

replaced

the

with

These

the

has

with

top

padded

velcro

by

is

to

the

the

rinse

or

been

Be-

an

even

baby

be

the

and

for

until

hard-

the

hose

(turn

the

the

are

arms

to

be

the

of

the

the

scale

holder.

hook

seals

of

the

hood.

The

scale

holder

thus

be

the

ward.

To

weigh

weighing

the

weighing

child

is

sliding

The

scale

with

the

nung — EO)

baby

scale

range

is

the

can

now

on

the

used

on

the

sheet

established

weights.

is

calibrated

German

and

in

Germany.

7.5

kg.

The

flange

large

open

easily

Incubator

all

Drager

child,

he

which

hook.

The

Standard

is

approved

of

hole

be

fitted

hood

Incubators

is

placed

is

fastened

weight

by

moving

in

accordance

for

The

measuring

the

scale

in

the

top

in

the

and

can

in

onto

of

the

the

(Eichord-

use

as

in

a

a

3.8.14

Oddments

The

Incubator

follows:

The

which

tray

stainless

rail.

width

maximum

may

be

(Fig.

steel

tray

Its

30

cm,

weight

placed

31}

is

attached

dimensions

depth

20

of

accessories

on

this

cm.

tray

to

the

are

as

is 3 kg.

Fig. 23

Oxygen

connection

distributor

with

cylinder

Page 11

Fig.

27

Fig.

30

Bronchial

Sliding-weight

aspirator

baby

scale

Fig.

31

Oddments

tray

Fig.

29

Fastening

the

securing

straps

11

Page 12

4

initial

4.1

Unpacking

When

packing

from

covering

Fitting

Place

the

from

Unfasten

sections

locking

hinge

The

the

Securing

Clir

ho

4.2

Cleaning,

Preparation

unpacking

material

inside.

plate.

the

Plexiglas

hood

hinges

above.

thescrews

(on

plates

sections

large

front

same

way

the

the

side

functional

run

Section

detailed

fection,

apparatus

This

prior

Before

that

that

7.

Care

information

assembly

work

to

initial

connecting

the

mains

given

Incubator,

and

setting-up

the

must

To

do

this,

hood:

on

Incubator

by

applying

of

the

incubator),

provided

and

refit

Plexiglas

as

described

Plexiglas

retaining

testing

and

Servicing.

on

and

for

operational

should

aiso

commissioning.

the

apparatus,

voltage

on

the

rating

apparatus

also

be

removed

lift

up

the

and

slight

pressure

bottom

place

over

the

screws

(Fig.

fiap

is

above.

hoad:

cords

cleaning,

testing

readiness.

be

performed

corresponds

plate

the

brown

engage

hinge

the

bottom

32).

fitted

in

to

the

and

test

contains

disin-

of

the

check

to

of

the

Fig.

32

Securely

plate

43

Humidification

Fill

the

water.

forwards

The

To

water

between

In

order

the

water

should

the

sche

be

container

using 4 Micropur

liquid

Micropur

Katadyn-Geselischaft

Munich

Germany).

Before

they

container

dissolved

silver

compounds

to

the

water

lizers.)

»Humidity«

screw

to

the

water

do

(Fig.

33).

level

the

min.

to

prevent

container, a silver

added

is

21,

Scháufeleinstr.

can

the

in

distilled

Supply

Set

desired

lever

hinges

Incubator

of

incubator

container

so,

pull

should

refilled.

tablets

(manufactured

and

bacterial

to

the

be

placed

always

max.

water

We

Micropur

water.

must

of

humidity

(Fig.

6).

and

locking

air

with

distilled

water

gauge

be

kept

marks.

growth

compound

every

time

recommend

MBT 1 or 1 em?

by

Deut-

mbH,

8000

20.

West

in

the

water

tablets

never

must

(Important:

be

aerosol

added

nebu-

at

the

Fig.

4.4

Heating-up

Set the

using

rature

if

the

heating-up

in

Incubator

intensive-care

Incubator

Following

be

phase

consiant

mittentiy

value).

thermometer.

33

Filling

the

regulation«

the

room

set

the

the

the

desired

selector

temperature

temperature,

times

7320 | approx.

7520 | 35

compietion

Incubator

(»Heating«

when

Check

water

container

Incubator

Incubator

switch

lamp

are

Humidity | Humidity

30

approx.

actual

temperature

temperature

(«Air-tempe-

lights).

is

12°C

the

to

be

expected:

50

min.

min.

of

the

heating-up

temperature

lamp

flashes

value = desired

at

below

following

100

approx.

50

min.

approx.

85

min.

is

kept

inter-

Incubator

5

Operational

5.1

Air-temperature

(see also

The

4.4

child's

regular

air

3.1.2,

incubatoris

and

the

temperature

intervals

temperature

necessary.

5.2

Skin-temperature

(see also

With

regulate

skin

3.1.4,

Incubator

either

temperature.

regulation

Page

warmed

child

and

should

Page

7022

the

Use

4)

as

is

placed

must

the

be

regulation

4)

it

is

air

temperature

described

inside.

be

taken

set

incubator

corrected

possible

There

skin-temperature

the

ly

following

@

in

The

at

e

if

Important:

Skin-temperature

be

The

well

to

the

or

overheating

tion

are

advantages

air-temperature

performed

Underdeveloped

with

ders

Children

health

disorders

used

skin

below

body

were

in

indications:

temperature

with

and

on

babies

temperature

the

and

if

to

be

to

be

gained

regulation

regulation

the

Incubator

premature

regulation

severely

temperature

regulation

in a state

of

these

interior

the

skin-temperature

employed.

temperature

children

would

from

rather

than

general-

given

baby

disor-

impaired

regulation

must

of

shock.

babies

suffer

regula-

the

not

is

of

In

such

cases

temperature

Procedure

regulation

The

Incubator

4.4

and

the

plug

of

the

inserted

the

the

The

through

the

Secure

navel

sive

in

unit

and

locking

sensor

the

Incubator

the

and

rings

supplied

use

must

be

regulation.

for

skin-temperature

is

warmed

child

is

placed

skin-temperature

connection

is

securely

nut

(Fig.

is

passed

hole

3).

in

the right

13

tightened

into

hood.

sensor

breastbone

between

using

(Fig.

made

as

described

inside.

on

the

the

end

the

34).

of

sensor

side

using

interior

face

baby's

the

adhe-

air-

in

The

is

of

of

Page 13

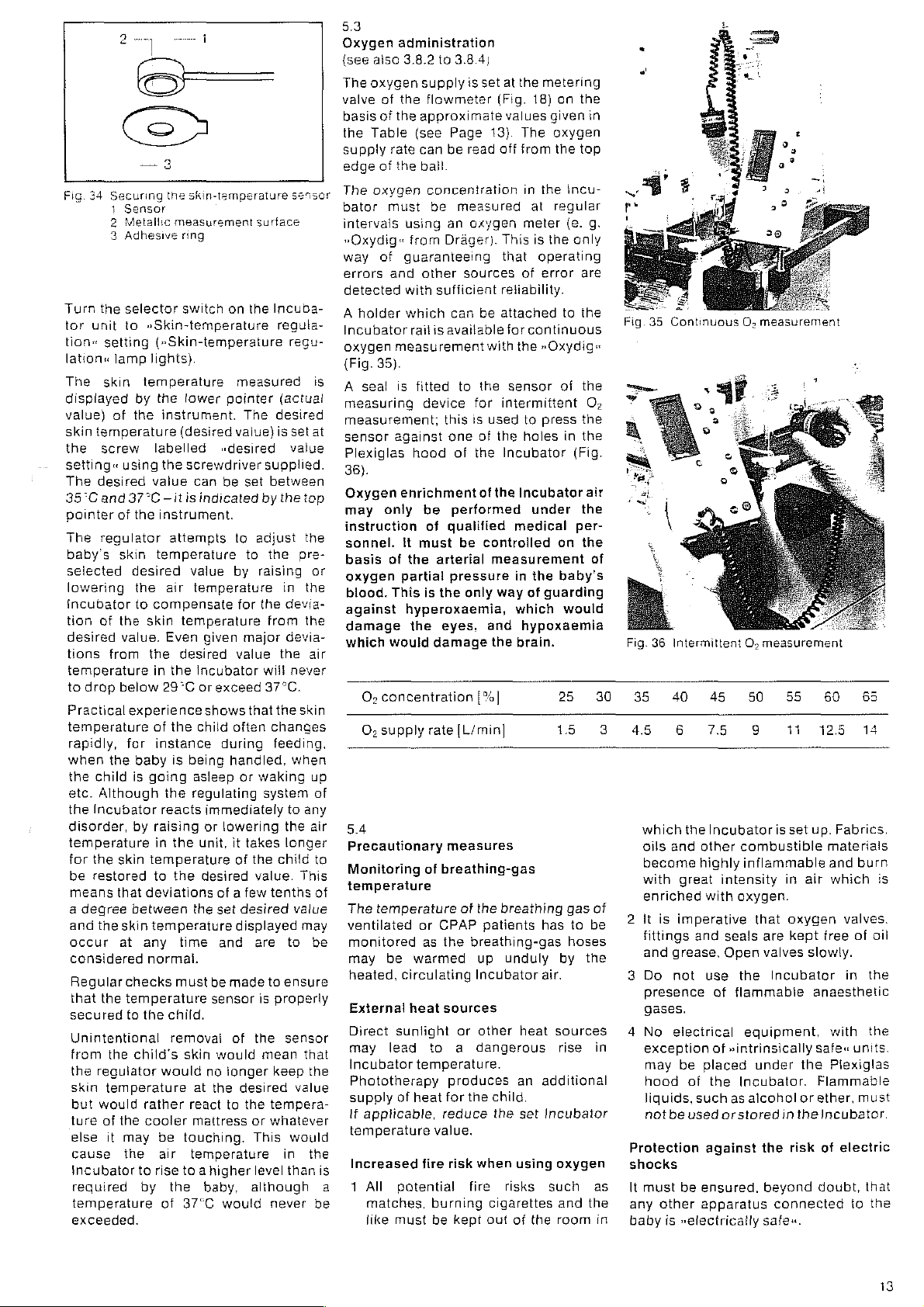

Fig.

34

Securing

1

Sensor

2

Metallic

3

Adhesive

Turn

the

selector

tor

unit

to

tion«

setting

lation«

The

displayed

value)

skin

the

setting«

The

35°C

pointer

The

baby's

selected

incubator

tion

desired

tions

Practical

lamp

skin

of

temperature

screw

using

desired

and

37°C — itis

of

regulator

skin

lowering

of

the

value.

from

temperature

to

drop

below

experience

temperature

rapidly,

when

the

etc.

the

disorder,

temperature

for

be

means

a

and

occur

considered

Regular

that

secured

the

child

Although

Incubator

the

skin

restored

that

degree

the

skin

at

the

for

checks

temperature

to

by

the

the

desired

the

to

baby

is

by

between

Unintentional

from

the

child’s

the

reguiator

skin

temperature

but

would

ture

of

the

else

it

may

cause

Incubator

required

temperature

exceeded.

the

to

the

skin-temperature

measurement

ring

switch

on

»Skin-temperature

(»Skin-temperature

lights}.

temperature

the

lower

instrument.

(desired

labelled

the

screwdriver

value

instrument.

attempts

temperature

air

compensate

skin

temperature

Even

the

desired

in

the

29°C

of

the

instance

is

being

going

the

reacts

raising

in

the

temperature

to

the

deviations

temperature

any

time

normal.

must

the child.

removai

skin

would

rather

cooler

be

touching.

air

rise

to a higher

by

the

of

37°C

measured

pointer

The

vaiue)

«desired

can

be

set

indicated

to

to

value

by

temperature

for

given

major

value

Incubator

or

exceed

shows

that

child

often

during

handled,

asleep

or

regulating

immediately

or

lowering

unit,

it

takes

of

desired

of a few

the

set

desired

displayed

and

be

made

sensor

of

would

no

ionger

at

the

desired

react

to

the

mattress

temperature

baby,

would

surface

the

Incuba-

regula-

(actual

desired

is

supplied.

between

by

the

adjust

the

raising

in

the

devia-

from

devia-

the

will

37°C.

the

changes

feeding.

waking

system

the

longer

the

child

value.

tenths

are

to

ensure

is

properly

the

sensor

mean

keep

tempera-

or

whatever

This

in

level

than

although

never

sensor

regu-

is

set

at

value

top

the

pre-

or

the

the

air

never

skin

when

up

of

to

any

air

to

This

of

value

may

to

be

that

the

value

would

the

is

be

5.3

Oxygen

(see

The

valve

basis

the

supply

edge

The

bator

intervals

»Oxydig«

way

errors

detected

A

holder

Incubator

oxygen

(Fig.

A

seal

measuring

measurement;

sensor

Plexiglas

36).

Oxygen

may

instruction

sonnel.

basis

oxygen

blood.

against

damage

which

O;

O;

5.4

Precautionary

Monitoring

temperature

The

ventilated

monitored

may

heated,

External

Direct

may

Incubator

Phototherapy

supply

lf

applicable,

temperature

Increased

1

All

a

matches,

like

administration

also

3.8.2

to

oxygen

Table

oxygen

supply

of

the

of

the

approximate

(see

rate

can

of

the

ball.

must

using

from

of

guaranteeing

and

other

with

which

rail

measurement

flowmeter

concentration

be

sufficient

is

35).

is

fitted

device

against

hood

enrichment

only

be

of

it

must

of

the

arterial

partial

This

is

the

hyperoxaemia,

the

eyes,

would

damage

concentration

supply

temperature

be

rate

of

breathing-gas

or

CPAP

as

the

warmed

circulating

heat

sunlight

lead

to a dangerous

temperature.

of

heat

reduce

value.

fire

potential

burning

must

be

3.8.4)

is

set

(Fig.

Page

18).

be

read

off

measured

an

oxygen

Drager).

can

available

this

one

of

performed

qualified

pressure

sources

be

with

to

the

for

is

used

of

the

of

the

be

controlled

measurement

only

This

that

reliability.

attached

intermittent

the

way

and

the

[%]

[L/min]

measures

of

the

breathing

patients

breathing-gas

up

Incubator

sources

or

other

produces

for

the

child.

the

risk

when

fire

cigarettes

kept

out

at

the

metering

18)

values

given

The

from

in

the

at

meter

is

the

operating

of

error

for

continuous

the

»Oxydig«

sensor

to

press

holes

Incubator

Incubator

under

medical

in

the

of

guarding

which

hypoxaemia

brain.

has

unduly

air.

heat

an

additional

set

Incubator

using

risks

such

of

the

on

the

in

oxygen

the

top

incu-

regular

(e.

g.

only

are

to

the

of

the

O:

the

in

the

(Fig.

air

the

per-

on the

of

baby’s

would

Fig.

25 30 35

15

3

45

gas

of

be

the

in

as

the

in

2

3

4

Protection

shocks

lt

any

baby

to

hoses

by

sources

rise

oxygen

and

room

36

Intermittent

40 45

6

which

oils

and

become

with

enriched

it

is

imperative

fittings

and

grease.

Do

not

presence

gases.

No

electrical

exception

may

hood

liquids,

not

be

must

other

is

O,

50 55

75

the

Incubator

other

combustible

highly

inflammable

great

intensity

with

oxygen.

and

seals

Open

use

the

of

flammabie

equipment,

of

»intrinsically

be

placed

of

the

Incubator.

such

as

alcohol

used

orstored

against

be

ensured,

apparatus

»electricatly

measurement

9

11

is

set up.

in

that

oxygen

are

kept

valves

Incubator

under

the

or

in

the

the

risk

beyond

connected

safe«.

60

Fabrics,

materials

and

burn

air

which

valves.

free

of

slowly.

in

anaesthetic

with

safe«

units.

Plexiglas

Flammable

ether,

must

Incubator.

of

electric

doubt,

to

65

is

ail

the

the

that

the

13

Page 14

6

Trouble

Fault

»Power

depressed — buzzer

Power

sounds. warning

button

Buzzer

does

Red

lamp

buzzer

failure»

Warning

»Excess

»Fan

lamp

liyats,

Incubator

preset

For

Water

marker

not visible:

Oxygen

when

Table

using

Oxygen

when

No

lamp does

failure

temperatures

depressed

does

not

light

»excess

lights.

failures

does

does

»fan

fallure«

buzzer

does

temperature

skin-temperature

»Skin-temperature

button

depressed:

Buzzer

does

does

not

Red

»skin-temperature

warning

Skin-temperature

wkin-temperature

No

regulation

level

of

concentration

adjusted

on

P.

oxygen

concentration

set

according

oxygen

Shooting

test

does

not

alarm:

lamp

not

sound,

temperature“

buzzer

sounds

test

button

not

sound,

not

light

warning

sounds

not

attain

not

sound,

light

lamp

lights.

of

skin

is

below

the

sight

glass

in

accordance

13

{can

be

meter}

flow

button

not

light

buzzer

lights

test

lamp

depressed:

lamp

regulation

sensors

lamp

sensor«

buzzer

display

display

temperature

the

bottom

or

too

determined

tao

to

Table

sound

warning

only:

test

sounds

shows

too

tow

is

high

with

low

minimum

Possible

Battery

Battery

Battery

Selector

»Disinfection

Alarm

Bulb

Mains

Power

Selector

Bulb

defective

Previously

alarm

Heating

sunlight.

Defective

the

above

Selector

Bulb

Fan

correctly

Motor

Excessive

Incubator

Room

Hand

Brown

incorrectly

Selector

or

Bulb

Skin-temperature

properly

Sensor

short

Sensor

Sensor

Selector

temperature

Too