Page 1

GE Infrastructure

Sensing

Druck RTX 1000H series

HART® Pressure transmitter

User manual - KA297

Page 2

Page 3

Customer service

Visit our web site: www.gesensing.com

Publication: KA297 Issue 2

© 2004 General Electric Company. All rights reserved.

Page 4

Page 5

RTX 1000H series user manual

Safety

To use this equipment safely, you must use the data and procedures in these

publications:

• The “Calibration data and instructions” for the equipment

• The applicable CSA or FM Approvals 'Control Drawing'

(Hazardous or Classified areas only)

• This user manual

These publications contain instructions to operate the equipment and maintain

it in a safe condition. To prevent damage or injury:

• Obey all warnings and cautions.

• Use the equipment only for the specified applications.

• Operate the equipment only in the specified limits.

To install and use the equipment, use only approved engineers who have the

necessary skills and qualifications.

Hazardous (Classified) areas

Some versions of this equipment are certified for use in hazardous (classified)

areas. For these versions, GE supplies 'Control Drawings' with additional

installation data. The 'Control Drawings' are:

• CSA 'Control Drawing' - KA337

• FM Approvals 'Control Drawing' - KA253

Trademarks

All product names are trademarks of their respective companies.

i KA297 Issue 2

Page 6

RTX 1000H series user manual

Abbreviations

The abbreviations in this publication are as follows:

Note: Abbreviations are the same in the singular and plural.

a absolute pressure

A/D analog to digital

AWG American wire gage

CSA Canadian Standards Association

D/A digital to analog

DAC digital to analog convertor

DIN Deutsche Industrie Norm

DIP dual inline package

DPM digital pressure module

°C degrees Celsius

°F degrees Fahrenheit

EEPROM electrically erasable programmable read-only memory

EMC electromagnetic compatibility

FM Factory Mutual Approvals

FS full-scale

g gage pressure

®

HART

HHC hand held communicator

in inch (")

O inches of water

inH

2

IS intrinsically safe

kg kilogram

lb pound

LCD liquid crystal display

LRL lower range limit

LRV lower range value

m meter

mA milliampere

highway addressable remote transducer

KA297 Issue 2 ii

Page 7

RTX 1000H series user manual

max maximum

mbar millibar

µF microfarads

mH millihenry

min minimum/minute

mm millimeter

MWP maximum working pressure

MSDS materials specification data sheet

NAMUR Normenarbeitsgemeinschaft für Mess- und Regeltechnik

(An association of users of process control technology)

PCB printed circuit board

psi pound-force per square inch

PTFE polytetrafluoroethylene

PV primary variable

RH relative humidity

RTX Rangeable Transmitter

s seconds

sg specific gravity

TSL terminal straight line

URL upper range limit

URV upper range value

Vvolt

V d.c. volts direct current

Ω ohm

iii KA297 Issue 2

Page 8

RTX 1000H series user manual

Table of Contents

Page

Safety ......................................................................................................... i

Abbreviations ........................................................................................... ii

Table of Contents ..................................................................................... iv

1 DESCRIPTION ...................................................................................... 1-1

1.1 Introduction .................................................................................. 1-1

1.2 About the Electronics Housing ..................................................... 1-1

1.3 Identification Codes ..................................................................... 1-3

2 TECHNICAL DATA .............................................................................. 2-1

2.1 Pressure Ranges ......................................................................... 2-1

2.2 Environment Data ........................................................................ 2-1

2.3 Performance Data ........................................................................ 2-1

2.4 Physical Data ............................................................................... 2-5

3 INSTALLATION .................................................................................... 3-1

3.1 Introduction .................................................................................. 3-1

3.2 Special Tools and Equipment ...................................................... 3-1

3.3 Location and Mounting ................................................................. 3-2

3.4 To Rotate the LCD Module Thru 90° ........................................... 3-2

3.5 To Rotate the Housing ................................................................. 3-3

3.6 Impulse Piping ............................................................................. 3-3

3.7 The Transmitter Pressure Connections ....................................... 3-4

3.8 Liquid Level Measurement ........................................................... 3-6

3.9 Electrical Data .............................................................................. 3-7

3.10 System Checks ............................................................................ 3-10

KA297 Issue 2 iv

Page 9

RTX 1000H series user manual

Page

4 OPERATION ......................................................................................... 4-1

4.1 General ........................................................................................ 4-1

4.2 Manual Configuration Facilities .................................................... 4-2

4.3 Manual Configuration - Calibration .............................................. 4-3

4.4 Manual Configuration - LCD ........................................................ 4-6

5 MAINTENANCE .................................................................................... 5-1

5.1 General ........................................................................................ 5-1

5.2 Fault Finding ................................................................................ 5-2

5.3 Returned Goods Procedure ......................................................... 5-4

Safety Precautions ....................................................................... 5-4

Important Notice ........................................................................... 5-4

Customer service ......................................................................... Back cover

v KA297 Issue 2

Page 10

RTX 1000H series user manual

Illustrations

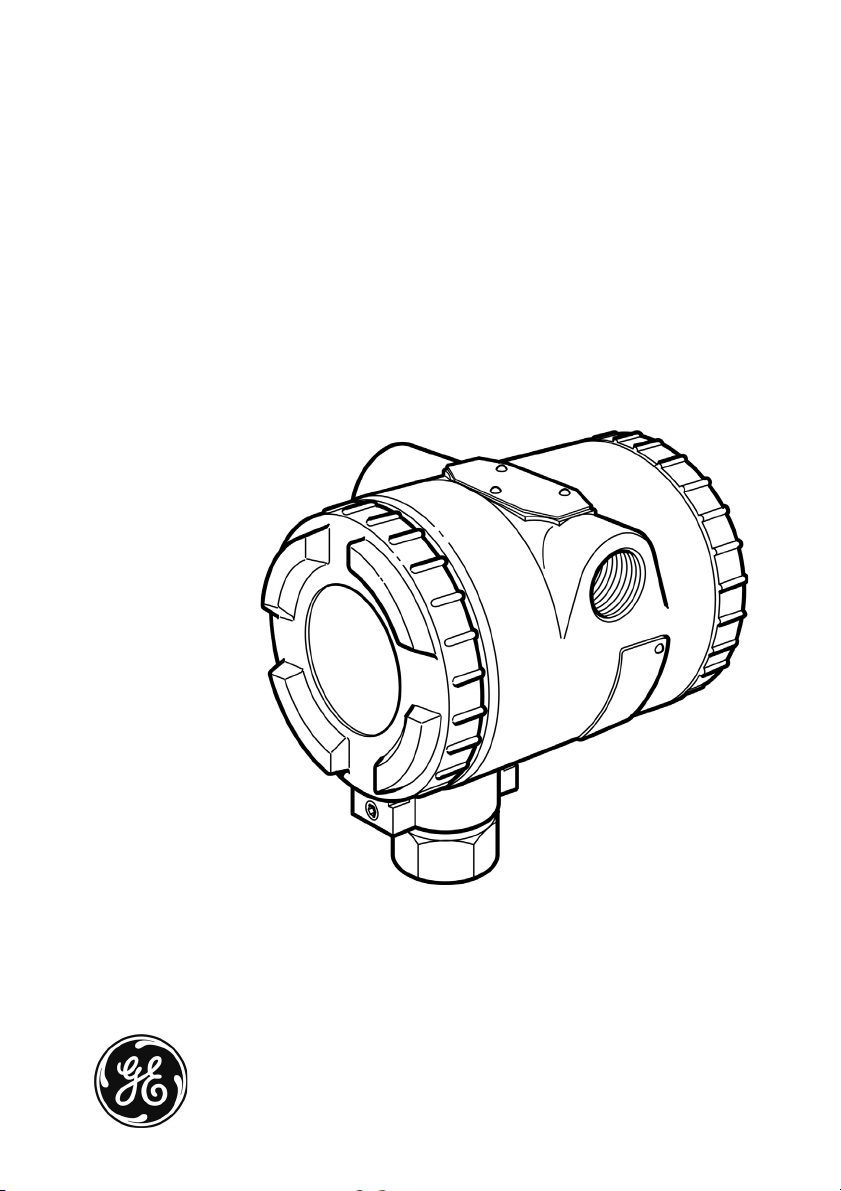

1-1 General view ................................................................................ 1-1

1-2 Transmitter schematic diagram .................................................... 1-2

2-1 Range limits ................................................................................. 2-1

2-2 Dimensions (Transmitter) ............................................................. 2-5

2-3 Dimensions (Optional mounting bracket) ..................................... 2-6

3-1 LCD module - Turn thru 90° ......................................................... 3-2

3-2 Housing locking screws ............................................................... 3-3

3-3 Piping arrangements .................................................................... 3-5

3-4 Open tank level measurement ..................................................... 3-6

3-5 Power and load requirements ...................................................... 3-7

3-6 Electrical conduit configuration .................................................... 3-9

3-7 Transmitter connections ............................................................... 3-9

4-1 Display - Normal operation .......................................................... 4-1

4-2 Location of DIP switches and push buttons ................................. 4-2

4-3 Calibration set-up for safe areas .................................................. 4-3

4-4 LCD - Range selection ................................................................. 4-5

4-5 Selection sequence - LCD configuration ...................................... 4-6

Page

5-1 Fault finding from the output signal .............................................. 5-2

Tables

1-1 Identification codes ...................................................................... 1-4

3-1 Wire resistance ............................................................................ 3-8

4-1 DIP switch operation .................................................................... 4-2

5-1 LCD alarm/error codes ................................................................. 5-3

KA297 Issue 2 vi

Page 11

RTX 1000H series user manual

1 DESCRIPTION

1.1 Introduction

The Druck RTX 1000H series is a process pressure transmitter that measures

the pressure of liquid, gas or vapor and gives an analog output proportional to

the applied pressure. The transmitter is available in a compact and lightweight

metal housing with facilities for direct mounting to pipeline installations. The

type of housing is specified in the order.

The transmitter uses the HART

®

communication. The HART

protocol gives easy access to the process data

and makes it possible to adjust the transmitter operation. For example: to make

accurate adjustments to the zero and span. There are also push-buttons and

switches on the electronics module to adjust the transmitter operation.

1.2 About the Electronics Housing (Figure 1-1)

The electronics housing contains a digital pressure module (DPM), electronics

module, connecting cables and the terminal block.

®

protocol to give digital two-way

end-cap (with

access to the

terminal block)

electronics

housing

electrical

conduit entry

certification

label (If fitted)

process pressure

connection

Figure 1-1: General view

1-1 KA297 Issue 2

name

plate

end-cap

(with access to the

electronics module)

housing locking

screw

Page 12

RTX 1000H series user manual

KA297 Issue 2 1-2

Figure 1-2: Transmitter schematic diagram

Page 13

RTX 1000H series user manual

Digital Pressure Module (DPM) - (Figure 1-2)

The sensing element in the DPM is constructed from a micro-machined silicon

diaphragm assembly bonded to a stainless steel or Hastelloy body. A Hastelloy

isolation diaphragm and silicone fluid isolates the sensing element from the

process media.

The sensor piezo-resistors, diffused into the surface of the silicon diaphragm,

produce a signal in response to applied pressure. The accuracy of the sensor

element is enhanced by measuring the residual errors over its operating

temperature and pressure range and applying digital compensation in the

transmitter electronics.

Electronics Module (Figure 1-2)

The electronics module uses microprocessor technology to give a compact

circuit with the minimum of components. The module produces an extremely

stable signal unaffected by changes in ambient temperature.

The HART

HART

®

communication module gives digital two-way communications. The

®

protocol gives easy access to the process data and makes it possible

to adjust the transmitter configuration from any point in the loop.

An optional LCD module shows the applied pressure value in two ways:

• as a % of calibrated span represented by a bar graph

• as a value in the applicable engineering units.

The LCD shows the Primary Variable (PV) value for the applied pressure. The

LCD value is not affected by the re-range facilities.

1.3 Identification Codes (Table 1-1)

Table 1-1 shows the identification codes for the transmitter. Before you install

the transmitter, use this table to make sure that the data on the transmitter is

correct.

1-3 KA297 Issue 2

Page 14

RTX 1000H series user manual

Table 1-1: Identification codes

RTX 10 Base Model Number

Code Diaphragm Process Wetted Body Fill Fluid

00 Hastelloy C 316 stainless steel Silicone oil

10 Hastelloy C Hastelloy C Silicone oil

20 Inconel 625 * Inconel 625 * Silicone oil

Code Output

H 4 - 20 mA + HART®

Code Max Span Min Span Notes

07 0 - 30 psi 0 - 0.3 psi Gage or absolute

10 0 - 100 psi 0 - 1 psi Gage or absolute

13 0 - 300 psi 0 - 3 psi Gage or absolute

16 0 - 1,000 psi 0 - 10 psi Gage or absolute

18 0 - 3,000 psi 0 - 30 psi Sealed gage or absolute

22 0 - 10,000 psi 0 - 100 psi Sealed gage or absolute

24 0 - 20,000 psi ** 0 - 200 psi Sealed gage or absolute

Code Type

A Absolute

G Gage (sealed gage for ranges above 1,000 psi)

Code Process Connection

1G½ female

2 ½-14 NPT female

3 G½ male to BS EN 837-1 (DIN 16288)

4 ½ NPT male

5 9/16" tube Autoclave Engineers medium pressure,

SF562CX20 female ***

Code Electrical Entry

N ½-14 NPT female (via adaptor)

Example identification code

Code Electronics Housing End-caps

0 Aluminum Alloy Aluminum Alloy

S Stainless Steel Nickel plated

Code Approvals

0 Safe area

F FM & CSA IS / Explosionproof

/ Division 2

Code Options

0None

LH Digital indicator

B Bracket mounting

T DIN 3.1B material certificate

aluminum bronze

RTX10 00 H 07 G 2 N 0 0 0

* Only available with range code 24, process connection code 5. Not available with CSA

or FM approval.

** Range code 24 (0-20,000 psi) only applies to RTX 1020 models.

*** Process connection code 5 (autoclave fitting) only applies to range code 24.

KA297 Issue 2 1-4

Page 15

RTX 1000H series user manual

2 TECHNICAL DATA

2.1 Pressure Ranges

The transmitter is supplied in one of the standard (zero based) ranges or it can

be calibrated to any acceptable intermediate span. Refer to Table 1-1.

The transmitter label shows the factory calibrated range and the maximum

working pressure (MWP). The upper range limit (URL) = MWP.

2.2 Environment Data

Service .............................................................................. Liquid, gas or vapor

Pollution Degree.............................................................................................. 2

Installation (over-voltage) Category ....................................................................... II

Temperature

ambient (Not CSA or FM approved)........... -40°F to +185°F (- 40°C to +85°C)

(LCD Option) ........................................ -4°F to +158°F (- 20°C to +70°C)

ambient (CSA or FM approved) ................................. minimum: - 40°F (-40°C)

.........................................maximum: Refer to the product approval label.

process...................................................... -40°F to +248°F (- 40°C to +120°C)

compensated.............................................. -40°F to +185°F (- 40°C to +85°C)

Humidity limit

......................................................................................................0 - 100% RH

2.3 Performance Data

Range adjustment

0

(psi a)

Minimum span

(URV - LRV): ≥ 1% URL URL

LRV (or URV) URV (or LRV)

-15

(psi g)

Lower range value (LRV) = 4 mA pressure value

Upper range value (URV) = 20 mA pressure value

Figure 2-1: Range limits

Figure 2-1 shows the limits for range adjustment. For example:

Span: The minimum span available for a 30 psi device is 0.3 psi (100:1

down-ranging).

2-1 KA297 Issue 2

Page 16

RTX 1000H series user manual

Zero offset: A 30 psi (MWP) gage device can give 4 to 20 mA in the range

-15 psi to 30 psi. For example: If the span is 0.3 psi, 4 to 20 mA is available

anywhere in the range up to a maximum zero offset of 29.7 psi (calibrated

range = 29.7 to 30 psi).

Accuracy

For a calibrated span ≥ 10% of URL: 0.075% Terminal Straight Line (TSL).

For a calibrated span < 10% of URL: (0.025% + 0.005 [URL/Span] %TSL.

These values include non-linearity, hysteresis and repeatability.

Long term stability

At standard reference conditions, the maximum change in calibration is not

more than 0.2% URL in a five year period.

Time response

Update rate (Compensated pressure reading)....................................... 100ms

Damping (DIP switch selection) ..............0.1 or 1 s to reach 63% of final value

Damping (HART

Temperature effects

For the compensated temperature range, the maximum output deviation from

the room temperature calibration at 73.4°F (23°C):

0.1% configured span + 0.2% reading + 0.1% URL

(where the reading is expressed as % of the configured span)

Mounting position effect

Negligible effect.

Alarm/Error conditions (NAMUR NE 43 compliant)

Alarm output (< 3.6 or > 21 mA).......... DIP Switch selected option (Table 4-1)

Under range ......................................................................... 3.8 mA minimum

Over range ......................................................................... 20.5 mA maximum

An optional LCD module shows the applicable alarm/error data (Table 5-1). If

the pressure is not between the upper or lower range limits, the pressure value

on the display will flash.

®

adjusted) .................. 0.1 to 30 s to reach 63% of final value

(This function is always in operation)

KA297 Issue 2 2-2

Page 17

RTX 1000H series user manual

Turn-on time

......................................................................................................... 2 seconds

Electronics housing

Material .................................... Aluminum alloy with polyester powder coating

or ...................... Stainless steel with nickel plated aluminum bronze end-caps

Environmental protection ........................................................................... IP67

CSA/FM approved units ............................................................ NEMA 4X

Overpressure

These pressure values will not degrade performance:

.................................. 4 x URL (2,000 psi max) for ranges: 30 psi to 1,000 psi

...................... 2 x URL (13,000 psi max) for ranges: 3,000 psi to 10,000 psi

........................................................................ 30,000 psi for 20,000 psi range

Pressure containment

These pressures may damage the sensor but there is no leakage of the

process media.

......................... 6 x URL (3,000 psi max) for ranges: 30 psi to 1,000 psi gage

................................................... 3,000 psi for ranges up to 1,000 psi absolute

....... 20,000 psi for ranges: 3,000 psi to 10,000 psi sealed gage and absolute

........................................................................ 30,500 psi for 20,000 psi range

Process media

A liquid, gas or vapor compatible with a fully welded assembly that includes:

• A Hastelloy C276 diaphragm, and a body that is made of either

316 stainless steel or Hastelloy C276. Complies with NACE MR-01-75.

• Inconel 625 (20,000 psi range, range code 24 only).

Sensor fill fluid

........................................................................................................ Silicone oil

2-3 KA297 Issue 2

Page 18

RTX 1000H series user manual

Output current

(two wire configuration) ..................................................................... 4 - 20 mA

®

The output is proportional to the calibrated pressure range. The HART

signal is superimposed on the output.

Supply voltage (at the terminals)

Safe area................................................................................... 12 to 35 V d.c.

Hazardous (Classified) area............................................... minimum: 12 V d.c.

..................................... maximum: Refer to Control Drawing KA253 or KA337

for the applicable conditions

®

HART

receive impedance data

Transmitter equivalent resistance (Rx) ................................................... 40 KΩ

Transmitter equivalent capacitance (Cx).................................................. 13 nF

digital

KA297 Issue 2 2-4

Page 19

RTX 1000H series user manual

2.4 Physical Data

Electrical/Process connections

............................................................................................. Refer to Table 1-1

Dimensions

.................................................................................... Refer to Figure 2-2, 2-3

Weight (without options)

Aluminum housing............................................................... ≈ 2.51 lb (1.14 kg)

Stainless steel housing ................................................................. ≈ 5.95 lb (2.7 kg)

Options

• Digital indicator: polarity sign + 5 digits, bar graph, and units

- Aluminum option ................................................. Add ≈ 0.35 lb (0.16 kg)

- Stainless steel option............................................ Add ≈ 0.66 lb (0.3 kg)

• Mounting bracket/bolts (stainless steel)

• Material traceability for pressure containment parts to EN10204 3.1B

≈ 4.61"

(117* mm)

3.19"

(81 mm)

≈ 4.21"

(107 mm)

*LCD indicator option: 5.43" (138 mm)

Dimensions in inches (millimeters) - illustrations not to scale

Figure 2-2: Dimensions (Transmitter)

2-5 KA297 Issue 2

≈ 3.62"

(92 mm)

Page 20

RTX 1000H series user manual

(a) Example -

Panel mounting

6.5"

(165 mm)

(b) Examples -

Horizontal pipe

mounting

2.8"

(70 mm)

4.4"

(113 mm)

Dimensions in inches (millimeters)

- illustrations not to scale

3.2"

(82 mm)

4.4"

(113 mm)

(c) Example -

Vertical pipe

mounting

Figure 2-3: Dimensions (Optional mounting bracket)

KA297 Issue 2 2-6

0.8"

(20 mm)

2.8"

(70 mm)

Page 21

RTX 1000H series user manual

3 INSTALLATION

Note: If the equipment is certified for use in a hazardous (classified)

area, refer to the applicable “Control Drawing” for additional data.

3.1 Introduction

The following procedures detail the correct installation of the unit.

Use qualified plant installation personnel and follow good engineering practice

at all times.

WARNINGS:

1. Observe appropriate local safety instructions.

2. Before installation, examine all fittings and equipment for damage

and make sure that all equipment is to the correct pressure rating.

3. Use the identification code on the transmitter to make sure that it

has the correct specification for the installation (refer to Table 1-1).

3.2 Special Tools and Equipment

The following special tools and equipment are required.

Note: Equivalent substitutes can be used.

Special tools

• Applicable torque wrench

• Druck UPS-II [to measure current output]

• Multimeter [to measure loop resistance]

Materials

• Piping - the necessary length and rating depends on the distances

• Fittings to connect the above items including (but not limited to):

- Pipe tee (steam or high temperature liquid)

- Pipe fittings

• Pipe compound or Teflon tape (where local piping codes allow)

• Loctite PST sealant

3-1 KA297 Issue 2

Page 22

RTX 1000H series user manual

3.3 Location and Mounting (Figure 3-3)

Although designed to withstand harsh industrial environments, the transmitter

should be located to minimize the following:

• Vibration

• Ambient temperature fluctuations

• Physical impact or shock

3.4 To Rotate the LCD Module Thru 90° (Figure 3-1)

If applicable, use the following procedure to turn the optional LCD module in the

electronics housing.

LCD cable

spacer (x4)

Power

cables

DPM

cables

screw/washer (x4)

connector

LCD

cable

access hole to release

the LCD module

end-cap

LCD module

Figure 3-1: LCD module - Turn thru 90°

1. Isolate the power supply to the transmitter.

2. Remove the end-cap.

3. Insert an applicable tool into the access hole and release the first leg of

the LCD module. Then carefully release the module.

4. To disconnect the LCD cable, release the clamp on the LCD cable

connector and carefully remove the cable.

5. Remove each screw/washer (x4).

6. Turn the PCB thru 90° until the screw holes align with the spacers again.

7. Tighten each screw/washer (x4) back in position, but make sure that

there is not too much force on the cables, and that they are not caught.

KA297 Issue 2 3-2

Page 23

RTX 1000H series user manual

8. Reconnect the LCD cable.

9. With the LCD module at the correct angle, push the module into the new

position until the legs are fully engaged.

10. Attach the end-cap.

3.5 To Rotate the Housing (Figure 3-2)

CAUTION: Do not rotate the electronics housing on the transmitter more

than 180 degrees relative to the pressure connection.

Two locking screws (hexagon socket screws) lock the electronics housing to

the sensor body. To rotate the housing, loosen both of the screws and rotate

the housing. When the angle is correct, tighten the screws.

Note: Do not remove the locking screws.

locking screws

(hexagon socket screws)

Figure 3-2: Housing locking screws

3.6 Impulse Piping (Figure 3-3)

The purpose of arranging impulse piping for the specific application is to

maintain a single phase of fluid in the piping and transmitter. Liquid applications

should maintain a liquid state and allow any air or gas formation to travel up

and away from the transmitter. Gas applications should allow the formation of

liquids to drain down and away from the transmitter.

The pipe or tubing used for connection must be rated for continuous operation

at the pipeline designed pressure and temperature. Threaded pipe fittings

create voids (where air can be trapped) and increase the possibility of leaks.

When installing the connecting tubing or impulse piping, the following apply:

• Horizontally installed impulse piping must slope at least 1" per foot

(approximately 75 mm per meter). For liquid and steam applications the

piping must slope down towards the transmitter. For gas applications the

piping must slope down away from the transmitter.

• Impulse piping should be kept as short as possible and maintained at

ambient temperature avoiding fluctuations and gradients.

3-3 KA297 Issue 2

Page 24

RTX 1000H series user manual

• Installations outdoors for liquid or saturated gas service may require

insulation and heat tracing to prevent freezing.

• For installations where the transmitter is more than 6 feet (1.8 m) from

the tapping, the impulse piping must be supported to prevent sagging

and vibration.

• Impulse piping must be located in protected areas or against walls or

ceilings. If routed across a floor, protective coverings or kick plates must

be used. High temperature piping or equipment should be avoided.

• Appropriate pipe sealing compound rated at the design piping

temperature must be used on all threaded connections. When making

threaded connections between stainless steel fittings, Loctite PST

Sealant is recommended.

3.7 The Transmitter Pressure Connections

The recommended connection uses a two-valve manifold connected between

the transmitter and the process pressure. Before connecting the transmitter

remove the protection caps and carefully inspect the sealing face and threaded

bore of the connection for damage.

Liquid service connections (Figure 3-3a)

Liquid measurement connections should be made to the side of the process

line to avoid deposits of sediment. The transmitter should be mounted beside

or below the connection so that gases vent into the process line.

Gas service connections (Figure 3-3b)

Gas measurement connections should be made to the top or side of the

process line. The transmitter should be mounted beside or above the

connection allowing any liquid to drain into the process line.

Steam service connections (Figure 3-3c)

Steam measurement connections should be made to the side of the process

line. The transmitter should be mounted below the connection so that the piping

remains filled with condensate. Live steam must not come into contact with the

transmitter; to prevent this the lines should be filled with water or condensate.

KA297 Issue 2 3-4

Page 25

RTX 1000H series user manual

two-valve

manifold

two-valve

manifold

(a) Liquid service (b) Gas service

two-valve

manifold

set length for

cooling

(c) Steam service

Figure 3-3: Piping arrangements

3-5 KA297 Issue 2

plugged tee-piece

for sealing fluid

(water, condensate)

Page 26

RTX 1000H series user manual

3.8 Liquid Level Measurement

Gage pressure transmitters can be used to measure liquid level in an open or

vented tank by measuring the hydrostatic pressure head. The head pressure

can be calculated by multiplying the liquid height above the transmitter

diaphragm by the specific gravity of the liquid.

The tank's volume and shape does not affect the head pressure. If the

transmitter is mounted below the zero point (minimum level) of the measured

range, zero suppression will be required.

maximum level

sg = 1.1

20

zero

suppression

200"

minimum level

40"

Figure 3-4: Open tank level measurement

Calculations

Min. level = (40" x 1.1) inH2O

=44" inH

Max level = ([40 + 200] x 1.1) inH

= (240 x 1.1) inH

=264 inH

Range = 44 to 264 inH

(Span = 220 inH

O

2

O

2

O

2

O

2

O)

2

mA

4

44

O

2

inH

O

2

2640

KA297 Issue 2 3-6

Page 27

RTX 1000H series user manual

3.9 Electrical Data

Note: If the equipment is certified for use in a hazardous (classified)

area, refer to the applicable “Control Drawing” for additional data.

WARNING: Switch off and isolate the power supply before connecting or

disconnecting the transmitter.

CAUTIONS:

1. The transmitter uses DC power in a 2-wire system to control current

through a resistive load.

2. Do not apply more than 35 Volts to the loop circuit. The transmitter

may be damaged.

General

The electrical installation must comply with local wiring codes and standards.

To get the full performance from the transmitter, carefully choose the wiring

scheme to be used and take care connecting the transmitter.

Power and maximum load (Figure 3-5)

The total loop resistance must include the connection wire resistance.

e

M

i

x

a

r

m

u

m

c

n

a

t

s

i

s

e

Operating

region

Note:

For HART® operation,

the minimum loop

resistance is 250 Ω.

No HART®

Resistive Loop Load - Ohms

Loop DC Power - Volts

Operation

Figure 3-5: Power and load requirements

3-7 KA297 Issue 2

Page 28

RTX 1000H series user manual

Wire selection (Table 3-1)

To get the best EMC performance, use shielded twisted pair cable for the field

wiring.

• Select a wire gage for the required total length so the transmitter

operates within the load requirements.

• When using external power supplies, make sure the connection polarity

allows current to flow into the +ve terminal and out of the -ve terminal.

Refer to Figure 3-7.

Table 3-1: Wire resistance

AWG Wire Diameter Loop Resistance

Inches mm Ohms/Foot Ohms/Meter

16 0.0508 1.291 0.0082 0.0264

18 0.0403 1.024 0.0128 0.0418

20 0.0320 0.812 0.0204 0.0666

22 0.0254 0.644 0.0322 0.1060

24 0.0201 0.511 0.0514 0.1680

Note: The typical values for resistance per length are doubled as the

circuit is a direct current loop.

Electrical conduit (Figure 3-6)

Use electrical conduit in accordance with local wiring codes. The electronics

housing has two threaded holes for electrical conduit connections. The

configuration in Figure 3-6 prevents moisture getting into the housing. If conduit

is not used, use the correct cable gland/plugs to seal the housing.

KA297 Issue 2 3-8

Page 29

RTX 1000H series user manual

Plug

min: 2"

(50 mm)

Flex Conduit

Conduit

Tee

Figure 3-6: Electrical conduit configuration

Electrical connections (Figure 3-7)

The transmitter is a 2-wire loop powered device. The marks +ve and -ve

identify the polarity of the connection terminals.

A label in the transmitter shows how to use the third terminal to measure the

output current from the transmitter. In hazardous (classified) areas, do not use

this third terminal.

To Drain

250 Ω

Note:

For HART® operation,

the minimum loop

HART® - HHC

Power

supply

resistance is 250 Ω.

Figure 3-7: Transmitter connections

Because the transmitter circuit is isolated from the housing, one of the signal

wires (+ve or -ve) can be earthed (grounded) if necessary.

3-9 KA297 Issue 2

Page 30

RTX 1000H series user manual

3.10 System Checks

Leak test

Before the system is filled and/or commissioned, do a leak test with

compressed air (or other inert compressed gas) or water. The minimum test

pressure must be equal to the normal operating pressure. The maximum

pressure is the MWP.

• Apply pressure at a convenient point on the system.

• Apply an applicable leak test solution to the impulse piping, valves,

transmitter connections and joints.

• Look for a continuous stream of bubbles.

• Bleed the system.

• Do all the necessary repairs, and test the system again.

• Return the system to the original configuration.

Transmitter test

Connect the necessary instruments to monitor the pressure signal. If

necessary, connect a milliammeter to measure the output from the transmitter.

• Apply power to the transmitter.

• Apply the applicable pressure.

• Monitor the pressure signal.

Refer to the 'Operation' section for the procedures to set up and operate the

transmitter.

KA297 Issue 2 3-10

Page 31

RTX 1000H series user manual

4 OPERATION

Note: If the equipment is certified for use in a hazardous (classified)

area, refer to the applicable “Control Drawing” for additional data.

4.1 General

CAUTION: DO NOT over-pressurize the system.

Pressure ranges

The transmitter label shows the factory calibrated range and the maximum

working pressure (MWP).

Start up procedure

When power is supplied to the transmitter, the output is set to the applicable

alarm level (Refer to Table 4-1). When the start up sequence is complete, the

output changes to give the applicable process value.

During start up, the display (if applicable) shows the parameter data for the

transmitter. This includes:

1. SOFTWARE: Software version

2. UNITS: Pressure units

3. URV: Upper Range Value + applicable units

4. LRV: Lower Range Value + applicable units

5. TRANSFER: Shows that the transmitter uses a linear transfer function

6. DAMPING: Damping value in seconds

7. EE PROTECT: Write protect status (on/off)

8. ALARM: Specified alarm level (high: > 21 mA, low: < 3.6 mA)

When the start up sequence is complete, the display shows the PV value for

the applied pressure and the applicable units (Figure 4-1).

PV value

Figure 4-1: Display - Normal operation

Alarm/Error conditions

Refer to the 'Maintenance' section.

Bar graph

(0%: 4 mA, 100%: 20 mA)

Applicable units

4-1 KA297 Issue 2

Page 32

RTX 1000H series user manual

4.2 Manual Configuration Facilities (Figure 4-2)

The manual configuration facilities (DIP switches and push buttons) are in the

electronics module. To get access to the electronics module:

1. Remove the end-cap (with access to the electronics module).

2. If applicable, release the LCD module to get access to the DIP switches.

- Insert an applicable tool into the access hole, and release the first leg

of the LCD module. Then carefully release the module.

DIP switches

1 to 4

Access hole to release

Push buttons:

- span (S)

- zero (Z)

Optional LCD module

with push buttons span

(S) and zero (Z)

the LCD module

Figure 4-2: Location of DIP switches and push buttons

Table 4-1: DIP switch operation

DIP

Switch

1 Write Protection To prevent accidental

2 Alarm level To use the high NAMUR

3 Damping To use the ON_Damping

4 Not used - -

Function Set ON Set OFF

changes to the EEPROM

values.

alarm (> 21 mA) when there

is a transmitter fault.

factor. Default = 1 s

KA297 Issue 2 4-2

1) To change values for

span and zero.

2) To set up the display - if

applicable.

To use the low NAMUR

alarm (< 3.6 mA) when there

is a transmitter fault.

To use the OFF_Damping

factor. Default = 0.1 s

Page 33

RTX 1000H series user manual

4.3 Manual Configuration - Calibration

To get accurate results, do the calibration in conditions where the pressure and

temperature are stable.

Equipment

• A precision pressure calibrator such as the Druck DPI 605 or

DPI 610/615. The accuracy of the supplied pressure must be better than

±0.075%.

• In safe areas, a 12 to 35 Volt DC power supply (separate or part of

another system)

• Fittings and tubing as required

Excitation voltage and

4 mA to 20 mA signal

Transmitter

Precision Pressure

Calibrator

Figure 4-3: Calibration set-up for safe areas

Calibration ranges

Set any span value from 1 - 100% of the URL. Refer to the 'Technical Data'

section.

4-3 KA297 Issue 2

Page 34

RTX 1000H series user manual

Procedure to adjust the range (No LCD)

1. Set DIP switch 1 to OFF (write protect - OFF).

2. To set the pressure for the lower range value (LRV):

a. Press the S and Z buttons together, and supply the LRV pressure.

b. To set the LRV, press the Z button.

3. To set the pressure for the upper range value (URV):

a. Press the S and Z buttons together, and supply URV pressure.

b. To set the URV, press the S button.

4. To prevent accidental changes to the new values, set DIP switch 1 to

ON.

To leave the set up procedure without saving a value:

• Press the S and Z buttons together OR

• Do not press the buttons for 25 seconds.

If a value is not in the applicable range, the value is ignored.

KA297 Issue 2 4-4

Page 35

RTX 1000H series user manual

Procedure to adjust the range (LCD option) - (Figure 4-4)

Note: The push buttons on the LCD module only work when it is

attached to the PCB.

1. Set DIP switch 1 to OFF (write protect - OFF).

2. Press S and Z together: 3. Press Z:

Figure 4-4: LCD - Range selection

4. To set the pressure for the lower range value (LRV):

a. Supply the applicable LRV pressure.

b. Press the Z button.

5. To set the pressure for the upper range value (URV):

a. Supply the applicable URV pressure.

b. Press the S button.

6. To prevent accidental changes to the new values, set DIP switch 1 to

ON.

Note: The LCD shows the PV value for the applied pressure. The LCD

value is not affected by the re-range facilities. Refer to the

'Description' section.

To leave the set up procedure without saving a value:

• Press the S and Z buttons together OR

• Do not press the buttons for 25 seconds.

If a value is not in the applicable range, the display shows error code 00. The

specified value is ignored.

4-5 KA297 Issue 2

Page 36

RTX 1000H series user manual

4.4 Manual Configuration - LCD (Figure 4-5)

There are three items to set up for the optional LCD: the pressure units, the

decimal point position, and the display contrast.

Note: The push buttons on the LCD module only work when it is

attached to the PCB.

1. Set DIP switch 1 to OFF (write protect - OFF).

2. Press S and Z together: 3. Press S:

Figure 4-5: Selection sequence - LCD configuration

4. UNITS: Use the S and Z buttons to step through the available units.

Wait 5 seconds or press S and Z together to go to the DECIMAL display.

5. DECIMAL: Use the S and Z buttons to move the decimal position. There

is a maximum number of decimal places for each unit.

Wait 5 seconds or press S and Z together to go to the CONTRAST

display.

6. CONTRAST: Use the S and Z buttons to adjust the contrast.

Wait 5 seconds or press S and Z together to return to normal operation.

7. To prevent accidental changes to the new values, set DIP switch 1 to

ON.

KA297 Issue 2 4-6

Page 37

RTX 1000H series user manual

5 MAINTENANCE

Note: If the equipment is certified for use in a hazardous (classified)

area, refer to the applicable “Control Drawing” for additional data.

5.1 General

The transmitter contains no moving parts and requires a minimum of

maintenance.

Visual inspection

• Inspect the transmitter for damage and corrosion. Any damage to the

transmitter must be assessed. If the housing is no longer sealed against

water and/or dust, the transmitter must be replaced.

Cleaning

• Clean the transmitter case with a damp lint-free cloth and mild detergent.

• Corrosion must be removed and the area of corrosion cleaned and, if

necessary, neutralized.

• If the product has been in contact with hazardous or toxic materials, obey

all the applicable MSDS references and precautions when handling.

5-1 KA297 Issue 2

Page 38

RTX 1000H series user manual

5.2 Fault Finding

If the measured pressure goes above URV or goes below LRV, the output

signal will saturate at the following values:

LRV - - URV

fault

indication

← →

2 mA

3.6 mA

-2.5%

Fault indications

If there is a specified fault condition, the transmitter output changes to the

specified NAMUR alarm level. The alarm level is set by the position of

DIP switch 2 (refer to Table 4-1).

If applicable, the optional display shows an alarm code to help identify the fault.

Table 5-1 shows some of the codes. If there are several fault conditions, the

alarm code is the sum of all the applicable codes.

not

allowed

3.8 mA

-1.25%

under

range

4 mA

0.00%

normal signal range over

20 mA

100%

range

20.5 mA

103.15%

not

allowed

21 mA

106.25%

Figure 5-1: Fault finding from the output signal

fault

indication

22 mA

KA297 Issue 2 5-2

Page 39

RTX 1000H series user manual

Table 5-1: LCD alarm/error codes

Code Possible cause To correct the error

Too much positive or negative pressure. Supply pressure in the specified limits

02

ALARM

ALARM

ALARM

ERROR

DPM error Power off, wait 25 seconds, then power

DPM data not received Power off, wait 25 seconds, then power

04

LCD adjustment has loosened the DPM

cable connection on the PCB.

LCD adjustment has loosened the DPM

08

cable connection on the PCB.

Configuration error. The range is not in

the specified limits for the device.

00

Configuration error. DIP switch 1 set to

ON (Write protect).

If you cannot identify the code or the fault condition does not change, contact

an approved service agent.

Over/under range

If the measured pressure goes above or below the set range of the transmitter,

the electronics module causes the transmitter output to change.

When the measured pressure is under range, the transmitter output continues

below the 4.0 mA level until it reaches 3.8 mA (Figure 5-1). When the

measured pressure is over range, the transmitter output continues above the

20.0 mA level until it reaches 20.5 mA (Figure 5-1).

If applicable, the optional display will also show a flashing pressure value.

for the device.

on again.

on again.

Examine the DPM cable connection

(Figure 3-1).

Examine the DPM cable connection

(Figure 3-1).

Refer to section 2 for the specified

range limits.

Set DIP switch 1 to OFF, then follow the

procedures in Section 4.

5-3 KA297 Issue 2

Page 40

RTX 1000H series user manual

5.3 Returned Goods Procedure

To repair or calibrate the transmitter, return it to the applicable GE Service

Department.

To contact our Service Department, select “Contact Us’” on the web site:

www.gesensing.com, and get a Returned Material Authorization (RMA)

number.

Please supply these details:

Product (i.e. RTX 1000H)

Pressure range

Serial number

Details of defect/work to be undertaken

Calibration traceability requirements

Operating conditions

Safety Precautions

To prevent possible injury when we receive the product, you must also tell us if

the product has been in contact with hazardous or toxic materials. Please

supply the applicable MSDS references and precautions.

Important Notice

Service or calibration by unauthorized sources will affect the warranty and may

not guarantee further performance. If the equipment has “Hazardous

(Classified) area” approval, the approval will also be invalid.

KA297 Issue 2 5-4

Loading...

Loading...